1

User Manual

2

一、

1. This product is a Home Use Treadmill. Heart rate sensor does not belong to the

medical equipment, just for your reference.

2. When using this Treadmill, in its rear should be vacated 2m*1m as security zone, and

should not place any stuff within security zone.

3. The Treadmill is suitable to place indoor of avoiding damp, does not allow to splash

water or place any stuff on it.

4. When running the Treadmill, DC Motor may bring spark, should be kept away from

Inflammable and explosive materials.

5. In use, should ensure the Treadmill to put on plat ground, if not, to adjust the mat below

or using carpet、rubber sheet to make it smooth.

6. The voltage is 220V-240V, exceed the range of voltage, may it doesn’t’t work properly.

The power has to match the power line and single-phase, three-hole well-grounded

socket during using, the same power line avoid using other appliance.

7. Before using this Treadmill, please do 10 minutes of warm-up exercises, should wear

sweat suit、sports shoes and socks.

8. Do not stand on running belt when testing, and do not allow two or more than two

person using the Treadmill at the same time.

9. Should be cautious when up and down; before starting, have to hold the handle, put

two feet on both sides of decorative strips; Speed should from low up to high when

running; When leave the Treadmill, first to make the speed to the minimum in order to

avoid hurt that loss balance.

10. Safety Key have to clip cloths when running, if need to stop can pull -off switch, the

Treadmill will stop running to achieve security purposes. After using, unplug the power

plugs that ensure safety.

11. Need to have adult supervision if children use or near the Treadmill. Patients with heart

disease should not use the machine alone. Physical discomfort under the guidance of a

doctor to use.

12. The Treadmill should avoid solar、raining and moist. Should use cleaning rag to clean

machine in order to avoid the accumulation of dust.

13. Do not stand on Treadmill or placing stuff when not using.

14. Should avoid overload operation for a long time, it may cause damage of Motor and

Controller; Accelerated aging bearing and running belt.

15. When moving the Treadmill, first to fold the bottom frame. After locked, to hold the end

of bottom frame, then carefully move.

16. The treadmill designed for Home Use only, please do not used for organization or

commercial.

Attentions

3

17. Store your treadmill in a clean and dry environment, to make sure the power switch is

turned off and unplug it from the outlet.

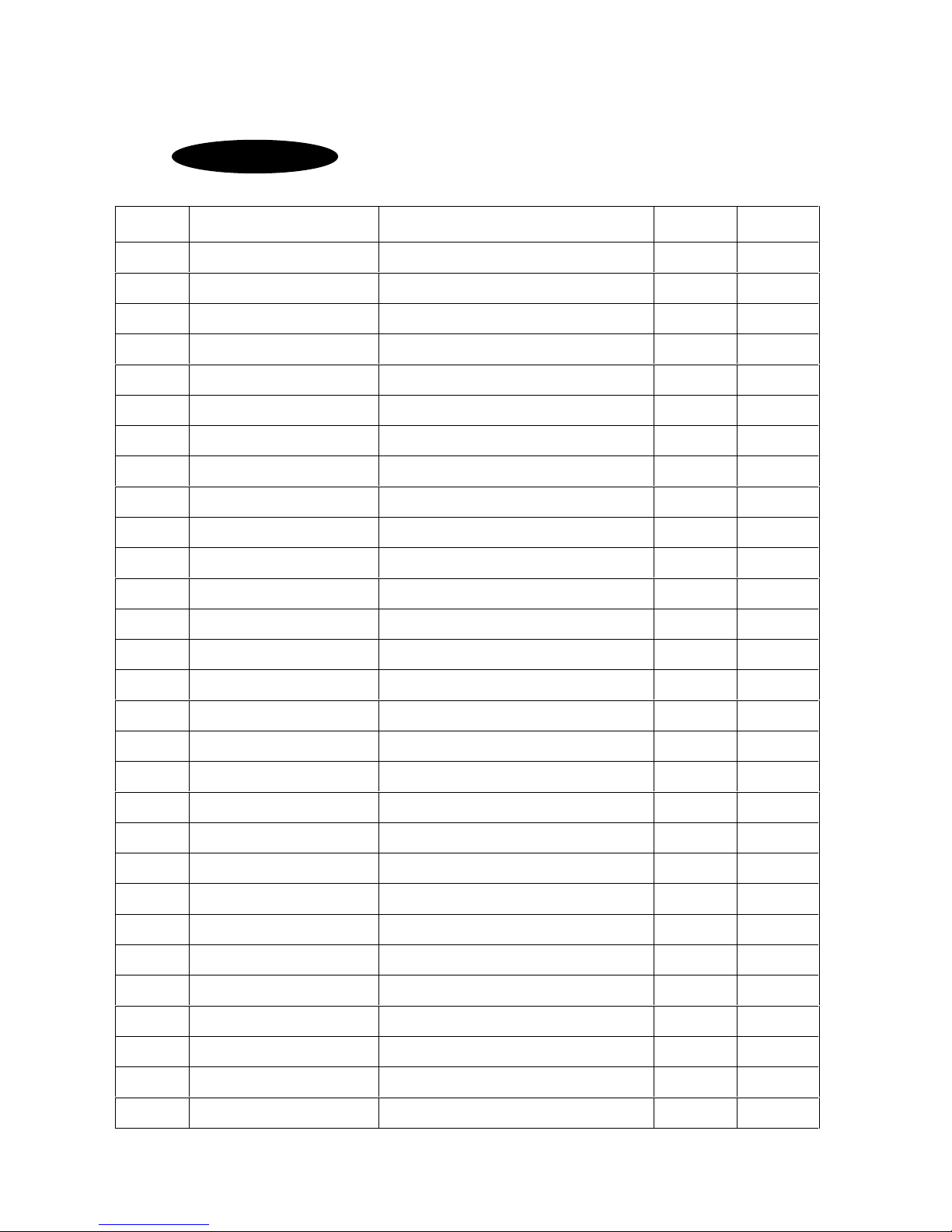

二、

No.

name

specification

unit

QTY

1

Base Frame

SET

1

2

Left Side Post

SET

1

3

Right Side Post

SET

1

4

Incline frame

SET

1

5

Main frame

SET

1

6

Console Frame

SET

1

7

Handle Pipe L

SET

1

8

Handle Pipe R

SET

1

9

side post supporter

SET

1

10

Large flat head screws Hexagon

M8*15 BK

PCS

12

11

Large flat head screws Hexagon

M8*30 BK

PCS

1

12

Large flat head screws Hexagon

M8*35 BK

PCS

2

13

Large flat head screws Hexagon

M8*42 BK

PCS

3

14

Large flat head screws Hexagon

M8*55 BK

PCS

8

15

Large flat head screws Hexagon

M8*100 BK

PCS

1

16

Large flat head screws Hexagon

M10*45 BK

PCS

1

17

Lager flat head socket half toothscrew

∮9.8*M8*21.5 BK

PCS

4

18

Socket head socket screw

M8*60 BK

PCS

1

19

Socket head socket screw

M8*80 BK

PCS

2

20

Hexagon anti-skid screw

M8*20 BK

PCS

4

21

Hexagon anti-skid screw

M10*65 BK

PCS

1

22

Cross countersunk head screw

M6*25 BK

PCS

8

23

Cross countersunk head screw

M6*30 BK

PCS

2

24

Slt + phil flat head screw

M4*10 BK

PCS

3

25

Slt + phil cup head screw

M5*15 BK

PCS

2

26

Cross flat head self tapping screw

∮3*8 BK

PCS

41

27

Cross flat head self tapping screw

∮4*15 BK

PCS

33

28

Cross cup head self tapping screw

∮4*30 BK

PCS

4

29

Cross flat head self tapping screw

∮4*55 BK

PCS

2

Parts List

4

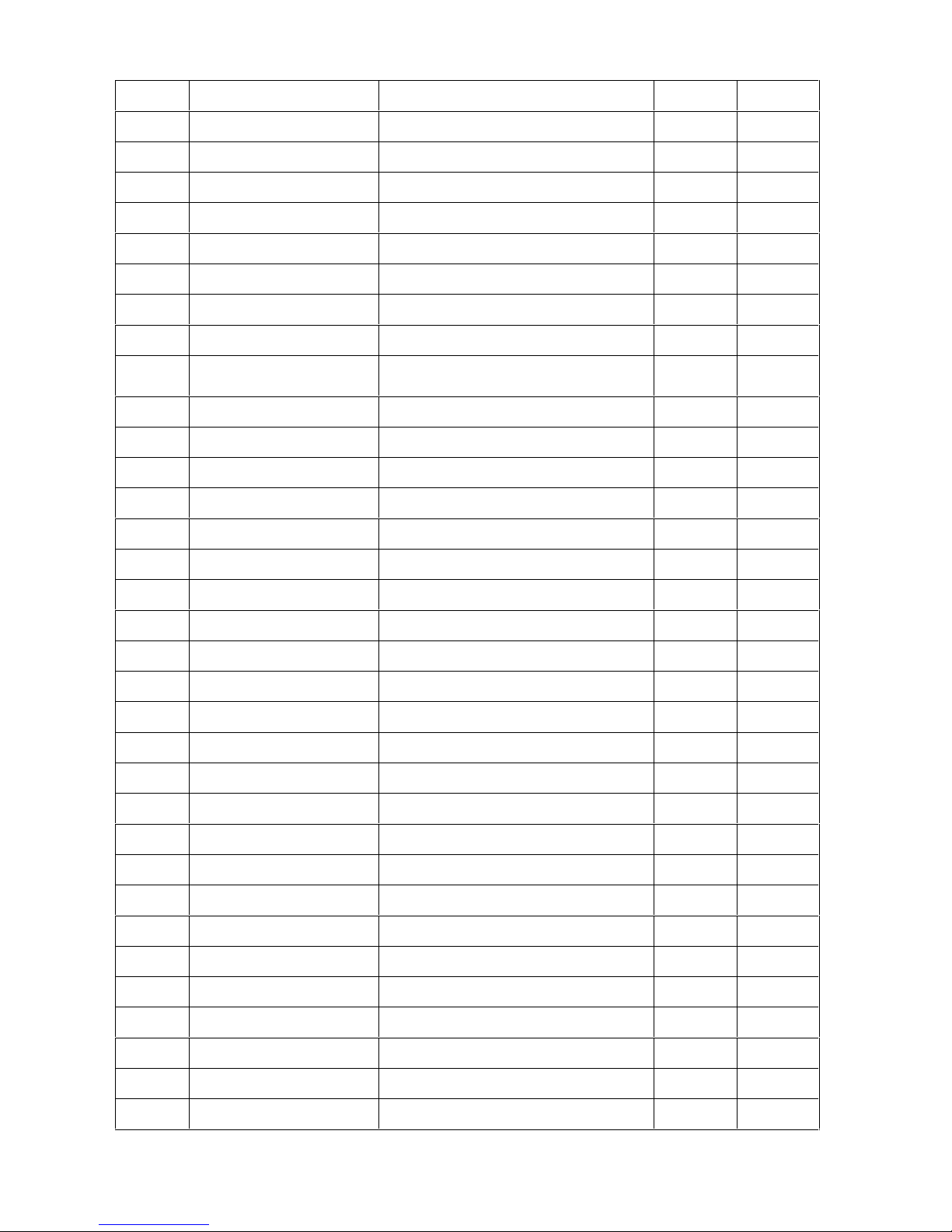

30

Storm screw

∮4*12.7 BK

PCS

14

31

Nut

M4 BK

PCS

3

32

Nut

M6 BK

PCS

2

33

Nut

M8 BK

PCS

14

34

Nut

M10 BK

PCS

2

35

Flat washer

∮ ∮

20* 8.5*T1.5 BK

PCS

38

36

Flat washer

∮ ∮

23* 10.8*T1.6 BK

PCS

2

37

Plastic washer

∮ ∮ ∮23* 12* 5*H5.3 BK

PCS

8

38

Plastic washer sleeve

∮ ∮8.5* 4.5*6 BK

PCS

2

39

Pressure rod

QDY22*10-662-292 40KG

PCS

1

40

Front Roller

∮ ∮ ∮90* 46* 17*525*580

SET

1

41

Rear Roller

∮ ∮

46* 17*495(570

)

SET

1

42

KSS

6P3-4

PCS

1

43

KSS

6N-4

PCS

1

44

left Handle pipe spigot

54*60*30*T3.3

PCS

1

45

Right Handle pipe spigot

54*60*30*T3.3

PCS

1

46

Meter upper cover

505*787*110*T2.7

PCS

1

47

Meter bottom cover

455*380*64*T2.7

PCS

1

48

Loudspeaker cover

112*97*42*T1.8

PCS

2

49

Key board bracket left

102.5*79*13*T2.0

PCS

1

50

Key board bracket right

102.5*79*13*T2.0

PCS

1

51

Keypad left

18*18*12.7*T1.5

SET

1

52

Keypad right

18*18*12.7*T1.5

SET

1

53

Motor cover

638*341*130*T2.6

PCS

1

54

End cover left

152*106*114*T2.6

PCS

1

55

End cover right

152*106*114*T2.6

PCS

1

56

Cushion

∮25*M8*T20

PCS

4

57

Pad

∮ ∮M8*15* 40* 50 BK

PCS

4

58

Pad

∮M8*15* 28 BK

PCS

2

59

wheels

∮ ∮8.2* 52*T20 BK

PCS

4

60

Running belt

2920*460*T1.6

PCS

1

61

Drive Belt

200J

PCS

1

62

Side Rein

85*37*T3.0*1300

PCS

2

63

Electronic board

5" Blue backlit LCD Display

PCS

1

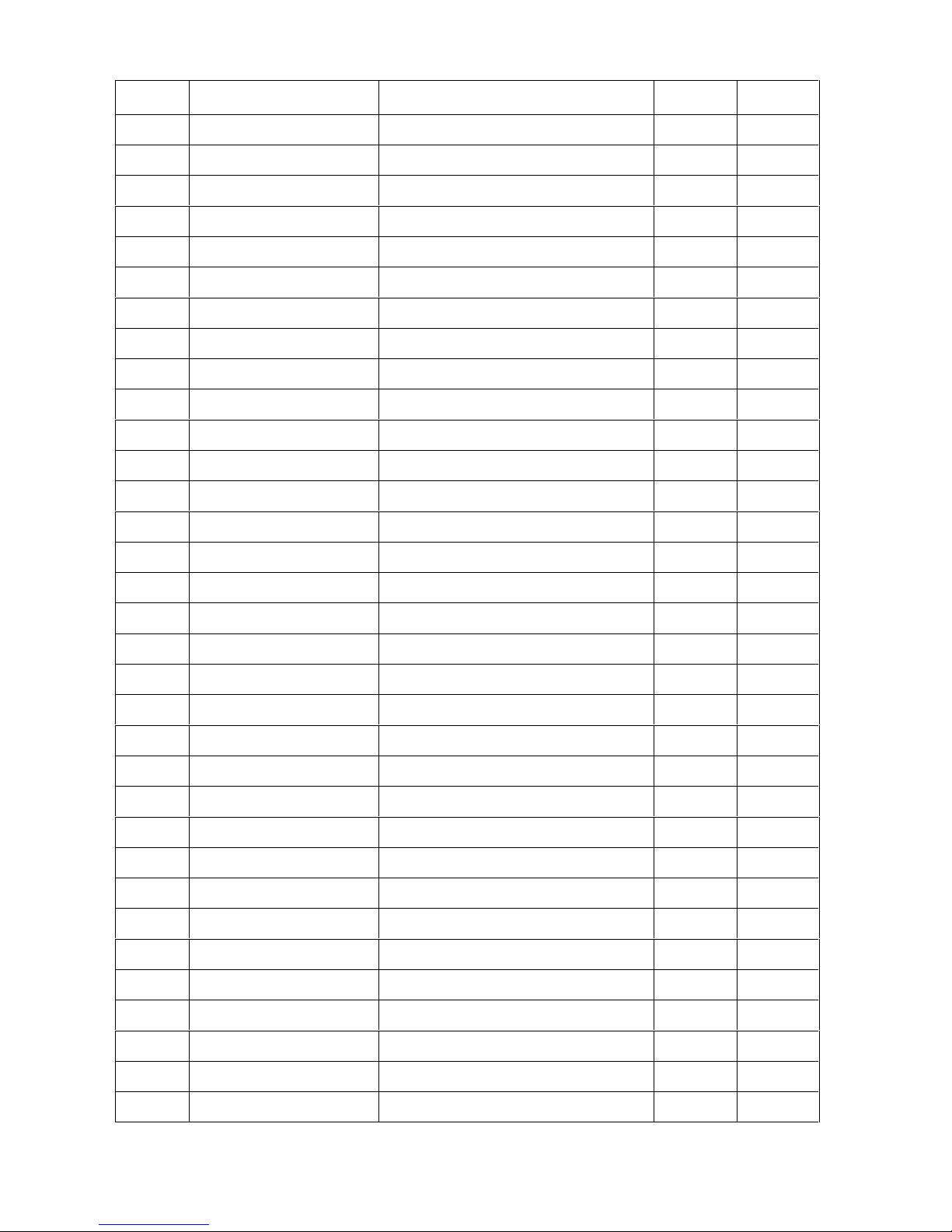

5

64

Keyboard plate

PCS

2

65

Power cord

L1800mm

PCS

1

66

Red connector wire

L150mm*14AWG

PCS

1

67

Green connector wire

L150mm*14AWG

PCS

1

68

White connector wire

L100mm*14AWG

PCS

1

69

Handle swith wire up segment

3P/250MM

PCS

2

70

Handle swith wire down segment

3P/500MM

PCS

2

71

Heart rate connect wire up segment

2P/310MM

PCS

2

72

Heart rate connect wire down segment

2P/800MM

PCS

2

73

Safety switch wire

2P/460MM

PCS

1

74

Power amplifier power cord

2P/250MM

PCS

1

75

MP3 sound source wire

3P/100MM

PCS

1

76

horn wire

2P/270MM

PCS

1

77

horn wire

2P/400MM

PCS

1

78

Speed sensor

2P/980MM

PCS

1

79

Controller wire up segment

L900mm*10pin

PCS

1

80

Controller wire down segment

L1500mm*10pin

PCS

1

81

Audio signal input wire

L350mm

PCS

1

82

Motor

PCS

1

83

Incline motor

JS-09 179+85

PCS

1

84

controller

PCS

1

85

Rocker switch

16A 250V

PCS

1

86

Safety key

33.5*51*8 800mm

PCS

1

87

Safety key plate

T4.6*18*7

PCS

1

88

overload protector

10A

PCS

1

89

toroidal core

∮ ∮

25* 15*H12mm

PCS

1

90

Heart rate handle

130*34*31.5

PCS

2

91

Power amplifiers

AM003-V10

PCS

1

92

Sound source conversion board

GLP3.5JACK

PCS

1

93

Incline

JC 4Ω 3W

PCS

2

94

Sponge sheath

∮46*T3.0*584

PCS

2

95

Running board

1290*630*T18

PCS

1

96

Rectangle pipe plug

25*50

PCS

2

97

Square pipe plug

40*40

PCS

2

6

98

Motor frame

100*160*30

PCS

1

99

Cross large flat head self tapping screw

∮4*10 BK

PCS

12

100

Bottom curtain board

620*147*T1.5

PCS

1

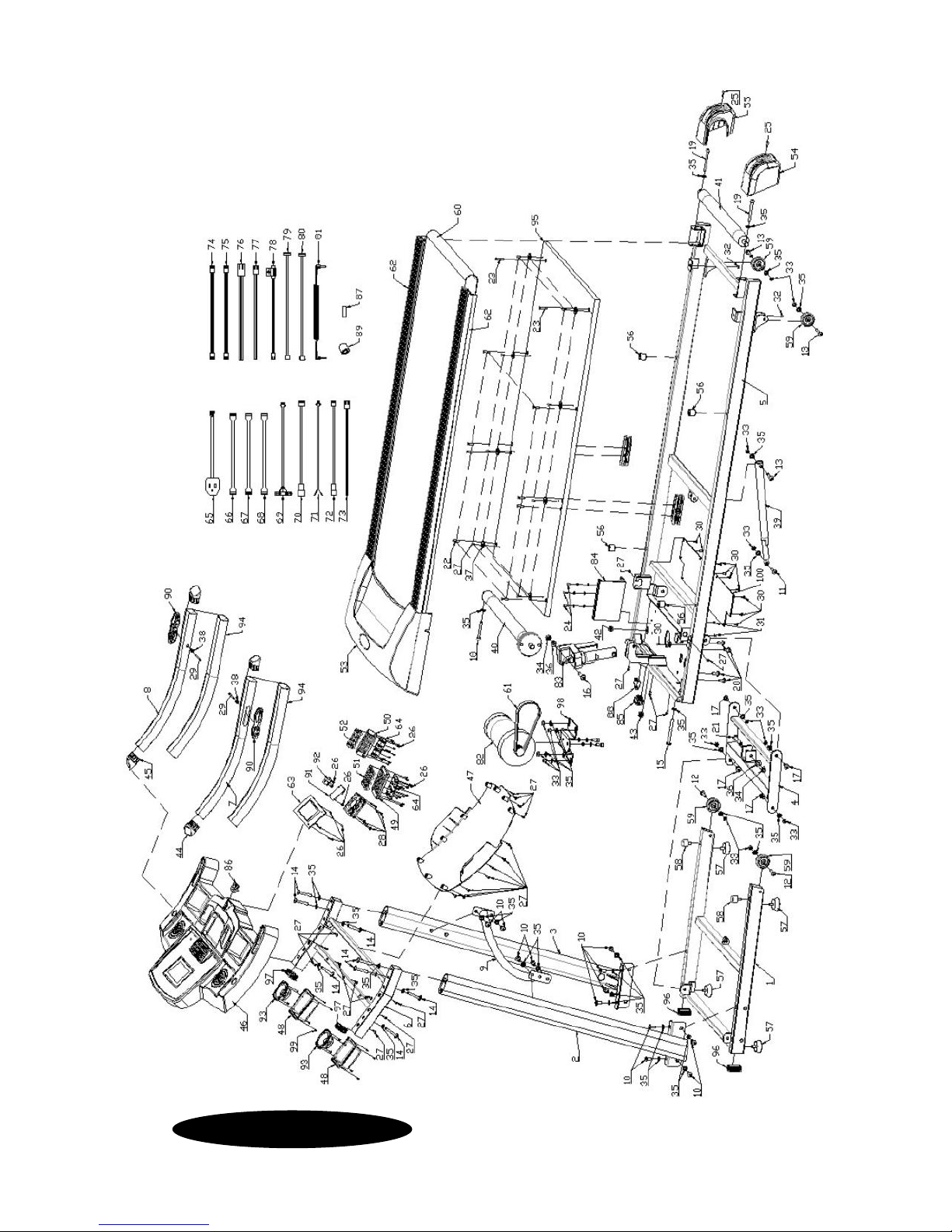

Assembly drawing

7

四、

Assembling Steps

8

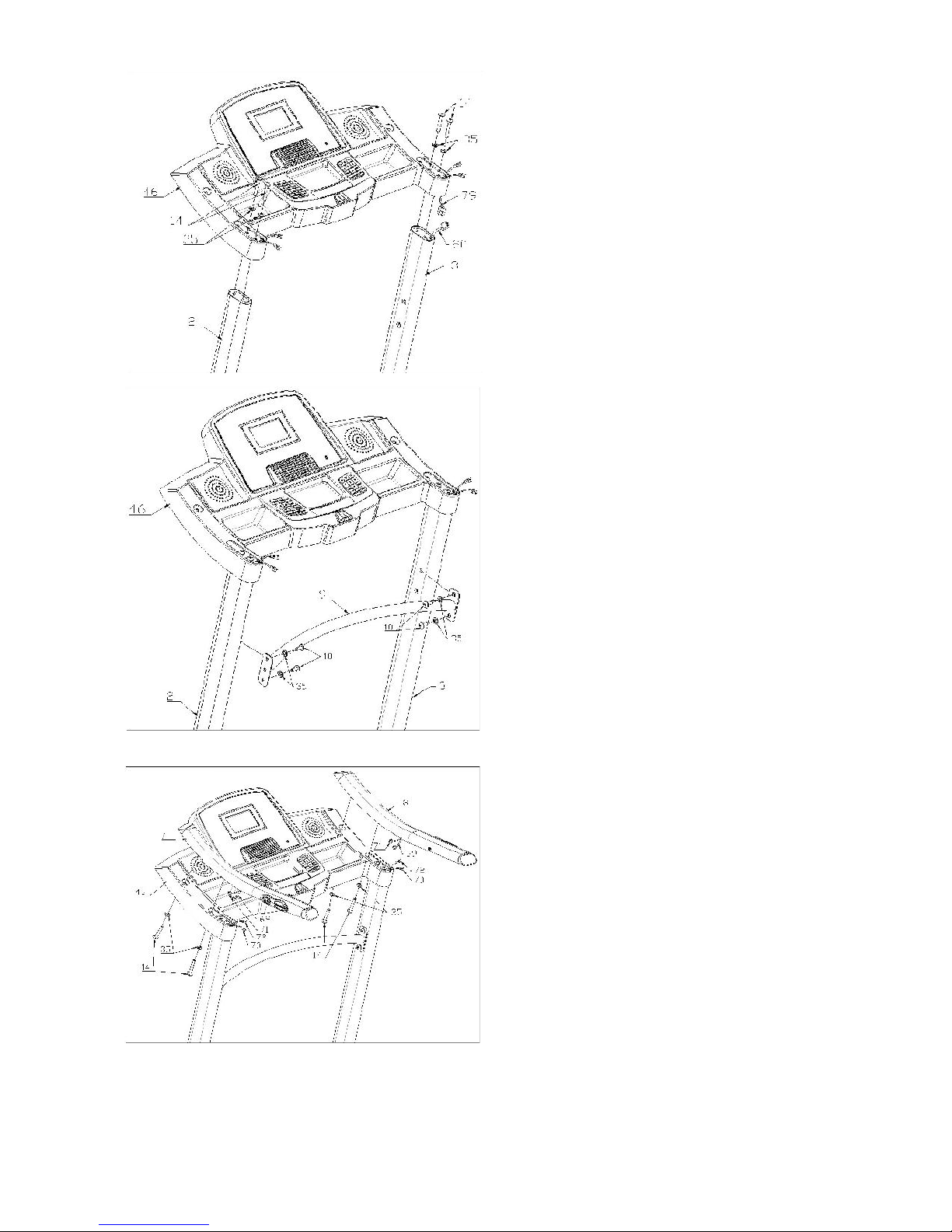

Picture 1

Step1 (as picture 1 show)

1. Unpack the carton and take out all loose parts etc.

and place outside of the carton, take out the treadmill

on the ground and untie it.

2. Fold the treadmill and use the Pressure rod to lock

it.(As picture 1 show)

Step2 (as picture 2 show)

1. Attach Left Side Post (2) into left pipe (1) of base frame, adjust the hole

location aligned. Open hardware bag; take out M8X15L screw (10), flat

washer (35), use correct tools to tight the screw.

2. Across the frame pipe out controller wire (80) through right post (3). Then

insert the right post(3) to the right base pipe(1).Adjust the hole location

aligned ,take out M8X15L screw (10) ,flat washer(35), use correct tools to

tight the screw.

Picture 2

9

Step3 (as picture 3 show)

1. Take out console (46), connect right

controller wire (79) to the wire (80)

from right post (3), and make sure the

connecting is firm.

2. Put the connected wire through the

right post(3)pipe, put the console on

both right post (3)and left

post(2),adjust the hole location

aligned,Open hardware bag, take out

M8X15L screw(14),flat washer(35),

use correct tools to tight the screw.

Step4 (as picture 4 show)

1. take outside post supporter(9), put

it in the middle of two side posts(2)

(3),adjust the hole location aligned,

Open hardware bag, take out

M8X15L screw (10) ,flat washer(35),

use correct tools to tight the screw.

Step5 (as picture 5 show)

1. Takeout right handle(8), connect wire

(69)(71) from right handle with

wires(70)(72)from right post, and keep

firm.

2. Put the connected wires into console

(46), put right handle (8) on right of the

console, take out M8X55L screw (14),

flat washer (35), and use correct tools

to tight the screw through below of the

console.。

3. Left handle (7) assembling the same

way as right handle (8).

Picture 3

Picture 4

Picture 5

10

六、

1、Instruction Of Keyboards

Panel

Design

5" Blue backlit LCD Display,

two sets humanized touch

keyboards,MP3 audio output

Panel

Display

Time, distance ,speed,

incline, calorie, heart

rate

Running

Area

460*1375MM

Belt

Standard

1.6MM

Max Load

110KG

Treadmill Net

Weight

78KG

Treadmill

Dimensions

Unfolded 1785×805×1330 MM

Folded 1065×805×1580 MM

Treadmill

Gross

Weight

88KG

Technical Parameter

Operating Instruction

1) SELECT Key:In standby mode, can set time, distance,

calorie.

2) STOP Key:The key pressed, motor stop working, be in

standby mode.

3) INCLINE UP/DOWN Key: When treadmill running can

adjust inclines by this Key.

4) ON/OFF FAN Key:Open or close Fan.

5) 0%、4%、6%、8%、10%、12%、14% Key:Incline fast key,

when treadmill running, adjust the incline as the key show.

6) MODE Key:In standby mode, this key pressed can choose

procedure P1-P12.

7) START Key: This key pressed, start the treadmill (3

seconds countdown delay start), start at 1KM/H.

8) SPEED FAST SLOW Key:In SELECT mode choices, can

adjust time、distance、calorie or adjust the running speed.

9) ON/OFF MP3 Key:MP3 audio start and stop.

10) 2、4、6、8、10、12、14Km/h Key:Speed fast key. When

treadmill running, the keys pressed, adjust the speed to the

key show

Picture 6

Picture 7

11

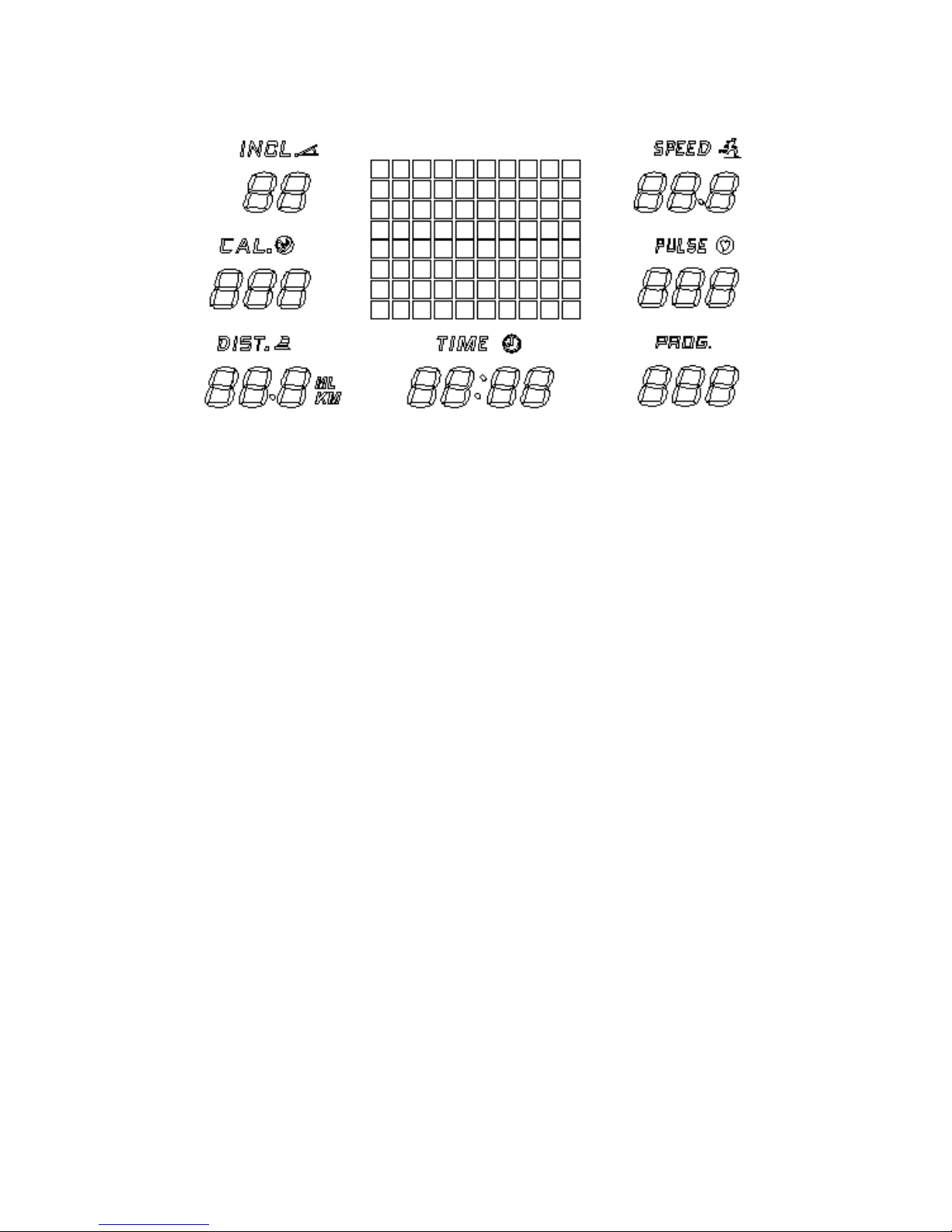

2、Windows display

3、Procedure Instruction

3.1、Normal procedure (P1)

Insert safety key first, turn on power , windows will be in light and with one long

"BEEP", windows display all the numbers is initial value 0, it's the normal mode.

Press START key: after 3 seconds countdown with 3 "BEEP", motor start to work, start

with initial speed 1KM/H.

Press FAST/SLOW key: when treadmill running, it adjust the speed.

Press UP/DOWN key: when treadmills start, adjust the incline.

Press 2、4、6、8、10、12、14KM/H key: when treadmill is working, adjust the speed as

the set value show.

Press 0%、4%、6%、8%、10% 、12%、14% key:when treadmill is working, adjust the

incline as set value show

Press STOP key::motor stop slowly, wait motor to stop(the original value remain)

3.2、Target Mode(In standby mode operate P2-P6)

Only in standby mode can set this mode;

SELECT Key:In regular turn can set time、distance、calorie,the window blink when the

mode set.

1) 、Time Set

Press FAST/SLOW Key:Default time 30 minutes,can adjust time(5:00-99:00);

Press START Key:Work mode start(start after 3 seconds countdown);

2)、Distance Set

SPEED window:display speed;

INCLINE window: display incline

TIME window:display time;

DISTANCE window:display distance;

PULSE window:display heart rate;

CALORIE window:display calorie;

PROGRAM window:display program

12

Press FAST/SLOW Key:Default distance is 1.0KM,can adjust time range

(1.0km-99km);

Press STARTKey:Work mode start(start after 3 seconds countdown);

3) 、Calorie Set

Press FAST/SLOW Key:Default calorie is 500 Kcal,can adjust calorie range

(10Kcal-990Kcal);

Press STARTKey:Work mode start(start after 3 seconds countdown);

3.3、PROGRAM mode

Press MODE Key:Press this key in standby mode to choose P1-P2 program;

Press SELECT Key:Default time is 30 minutes,can adjust time range(5:00-99:

00);

Press STARTKey:Work mode start(start after 3 seconds countdown);

Working mode

According set time change every execute phase, take 90 minutes for example, turn to

next phase in every 3 minutes;

When execute next phase, force back to built-in speed value;

Press STOP Key:Motor stop slowly;

4、Other instructions

When running, press STOP key, speed grind to a halt, incline return to the starting

point ;

Unplug the safety key when running, speed turn to 0, incline return to starting point,

insert the safety key, all data eliminated

5、Daily care and maintenance

5.1、Clean

Keep the appearance clean, make sure the power off before clean the treadmill,

running belt and appearance can be cleansed by soft cloth, attention not leave water on

running belt or display window and the shield;

5.2、Lubrication of Running belt

In using of the treadmill, need to use special lubricant to lubricate the running decking

under the running belt. Suggestion :

Less than 3 hours every week,:lubrication twice a year;

3-6 hours every week:lubrication every 3 months;

More than 6 hours every week:lubrication every month。

Attention:Use the free lubricant with the treadmill in the packing box.Extra silicone you can

buy from your local shop.

Warning:Stop the treadmill and unplug the safety key before lubricate the treadmill

decking.

13

How to lubricate the running decking?

Find the silicone bottle. In the hardware bag come with the treadmill.

Find a straw can put into the silicone bottle, as picture show

Spray silicone evenly on treadmill deck as the drawing shows.

(ATTENTION: The treadmill MUSTBE STOPPED before applying

the silicone lubricant. This is to prevent injury, otherwise the edge

Of the running belt may cut you or your fingers could be crushed

by the rollers. ) Do not put too much silicone on the deck. Excessive

lubricant may cause slippage of the belt on the rollers.

5.3、Belt Adjustment

All running belts are properly set at the factory,if off-center occur, maybe caused by

followed reasons:

Treadmill is not stable;

User's feet are not in the center of the running belt;

User push off harder with one foot than with another.

If the off-center phenomenon caused by user, can return to normal after a few minutes

running with no loading, If the running belt remains consistently off-center, you will need to

center the running belt manually, If toward the left side of the deck, Using wrench, turn the

left adjustment bolt clockwise 1/2 turn and check ,if toward the right side, turn back a little,

till return to center. (As picture followed)

5.4、Running belt "Slipping"

You may need to adjust the running belt during the first few weeks of use... It may

stretch, appearance is normal when no loading, “slipping" or hesitating when runner plant

the foot during a run, when this phenomenon occur, turn both adjustment bolts clockwise

1/2 turn, make sure the turn of both sides is the same, and every time 1/2 turn, till no

"slipping" and no off-center, Be careful not to tighten the running belt tension too much as

you can create excessive pressure on the front and rear roller bearings. An excessively

tightened running belt may damage the roller bearings that would result in bearing noise

from the front and rear rollers.

5.5、Lubricate rollers

Regularly add drops of silicone to the rollers and shafts to keep the good performance.

5.6、Bolts fastening

Regularly check the bolts、screws and nuts, if any loose, please fasten immediately with

tools.

14

6、Trouble shooting

6.1. Speed error:Show“E1”, after 10s speed signal detected, machine stop automatic.

Solution:1) Adjust the position of speed sensor wire

2) Replace the speed sensor wire

6.2. The safety key is not connected: show“E0”, “SAFETY KEY OFF”

Solution:1)Adjust the position of the safety key.

2)Replace the switching line of safety key.

七、

Loading...

Loading...