Page 1

Intra - X

Intra - XE

Automatic X-Ray Film Processor

USER GUIDE

Operation and

Maintenance manual

WARNING:

Do not plug into the electrical mains power supply before

reading this manual – or before filling the machine with

liquids

Register your machine by returning the Warranty Card

to enable full customer support.

Machine serial number to be

quoted on all correspondence:

Page 2

Introduction

Thank you for purchasing your automatic film processor from

Velopex, we certainly appreciate your business.

In order to maintain the quality of our product and your

processing it is important that you pay close attention to the

following instructions contained in this user’s manual. This will

ensure a long life for your processor.

This manual is to be used with the following Velopex processors:

Intra-X, Intra-XE.

Warranty may be voided if the processor is incorrectly installed

or maintained outside the guidelines set forth in this manual.

Caution: Use assistance when unpacking and

positioning the machine.

VELOPEX INTRA-X

User Guide

ii

Contacts

EUROPE

MEDIVANCE INSTRUMENTS LTD.

Barretts Green Road . Harlesden

London . NW10 7AP . UK

Tel.: +44 (0)20 8965 2913

Fax: +44 (0)20 8963 1270

www.velopex.com

USA

VELOPEX INTERNATIONAL INC.

105 East 17th Street . St. Cloud

Florida . 34769 . USA

Tel.: 888 - 835 - 6739

Fax: (407) 957 - 3927

www.velopexusa.com

Page 3

iii

Velopex Processor - Exterior

6

3

2

4

5

7

9

1

1 Velopex X-Ray Film Processor - Left Side

Film Collector

2

Endo Slide

3

On/Off Power Switch

4

‘Run’ Button

5

10

Viewer Cover

6

Daylight Loader viewing Window

7

Hand entry port/Glove

8

Daylight Loader - Left Side

9

Film Entry Guide

10

8

Machine Accessories and Extras Supplied

12

13

14

15

16

Transport Module

11

17

8

11

18

12 Silicone Grease

13 Film Collecting Tray

14 Cleaning Brush

15 Turning Tool

16 UK - Electricity Supply Cord

17 USA - Electricity Supply Cord

18 Continental - Electricity Supply Cord

Page 4

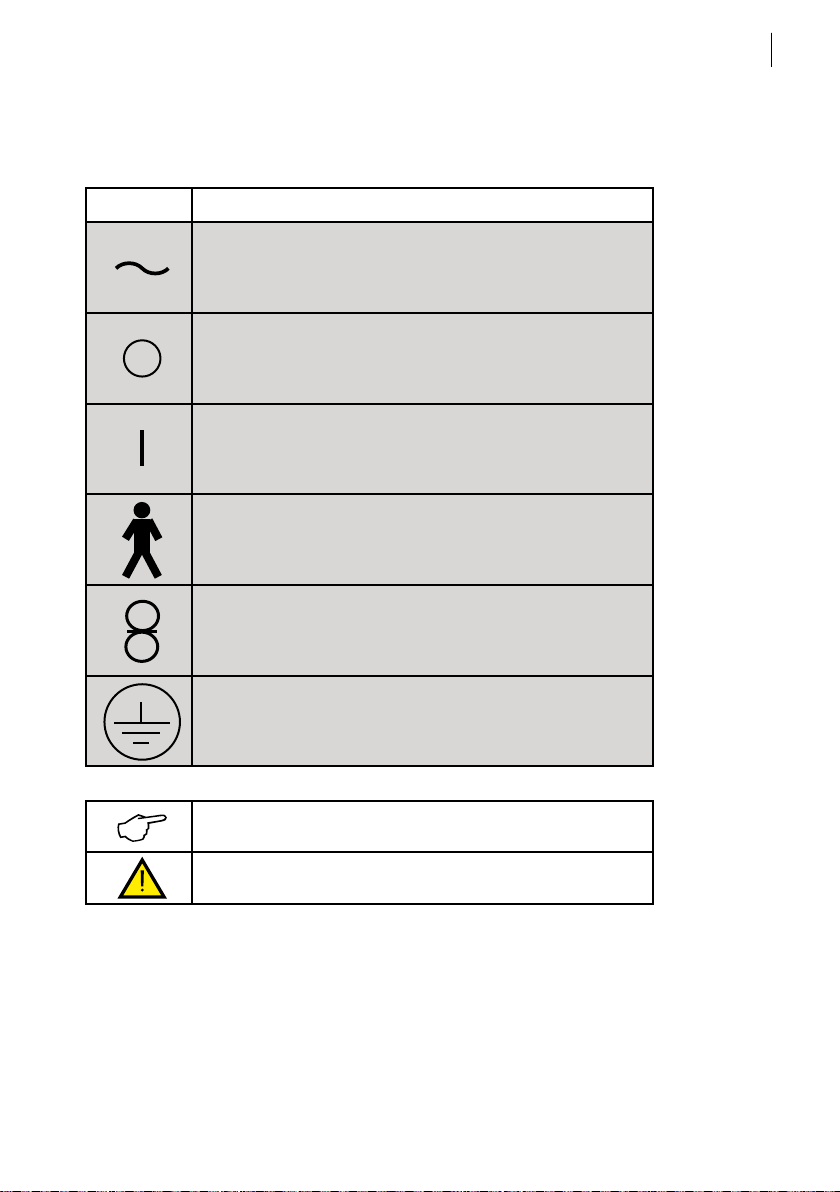

Table of Symbols

Symbol Description

Alternating Current

Off (Power: Disconnect from the mains)

On (Power: Connect to the mains)

Type ‘b’ equipment

VELOPEX INTRA-X

User Guide

iv

‘RUN’ Button / Process switch

Protective Earth (Ground)

Symbols used within Manual

Tip

Attention / Warning

Page 5

Contents

Specification ................................................................. 2

Installation* .................................................................. 3

Pre Installation Instructions .............................................. 3

Daylight Loader Installation (when required) ............... 5

Filling with Chemicals ........................................................ 8

Operation ...................................................................... 11

Maintenance .................................................................. 15

Trouble Shooting .......................................................... 19

1

INSTALLATIONOPERATIONTROUBLE SHOOTING MAINTENANCE

Service Log .................................................................... 24

© June 2005 Medivance Instruments Limited

All rights reserved.

Issue 6 OM13 I/LIT3601M

Page 6

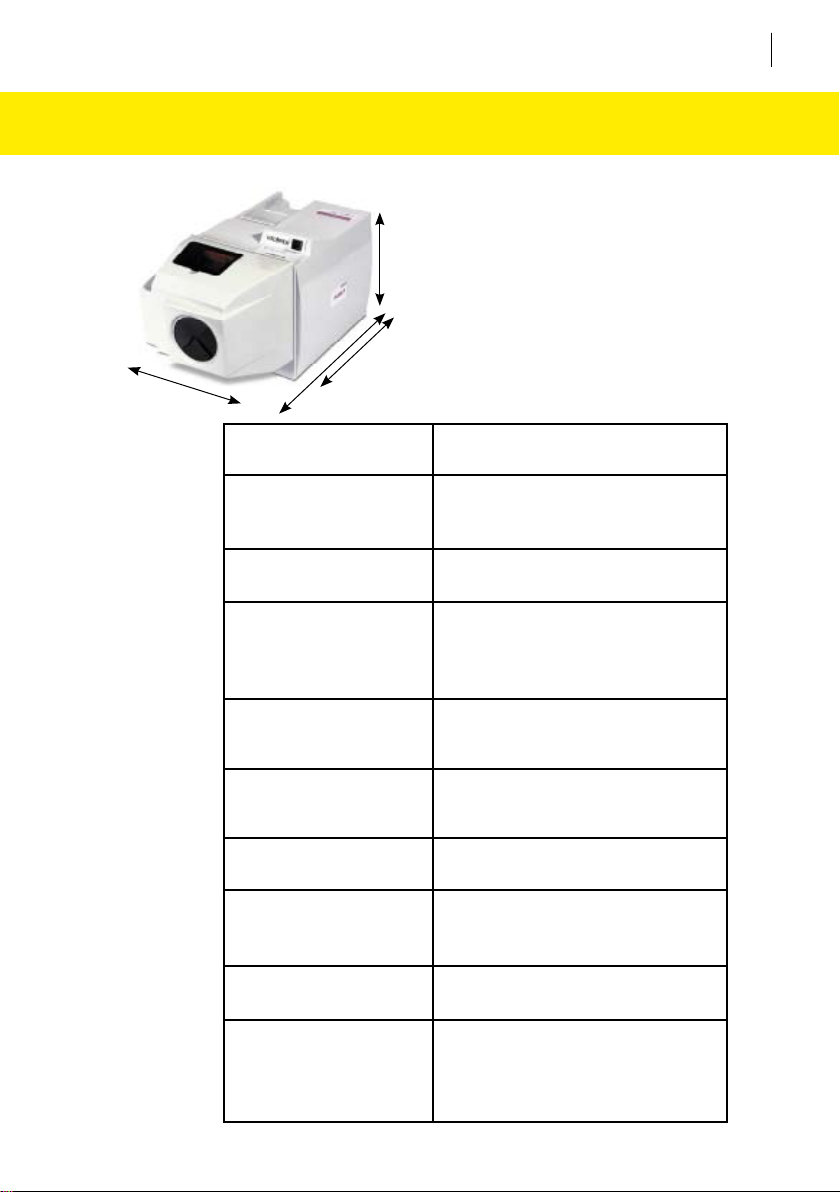

Specification

(W)

Width (W) 290mm / 11½”

(H)

(D)

VELOPEX INTRA-X

User Guide

2

Depth (D)

Inc. Loader

Height (H) 315mm / 12½”

Weight:

Empty

Full Tanks

Tank Capacity 1.4litres / 2½Imp Pints each

Standard Supply

Voltage

Warm-up time 10 min. approx.

Film Feed Speed 470mm / 18½” per min.

Max film width 65mm / 2½”

Processing time:

Dry

Wet-Endodontic

435mm / 17”

635mm / 25”

12.1Kg / 26½lb

13.9Kg / 30½lb

220-240v 50Hz

110-120v 60Hz

4 min. approx.

2 min. approx.

Page 7

Pre Installation Instructions

VELOPEX INTRA-X

User Guide

3

INSTALLATION

• Unpacking the VELOPEX

NOTE: For unpacking and lifting the machine into position it is important to have

assistance.

The machine comes in a single carton containing:

Machine, Operator’s Manual, Silicone Grease, Electrical Cord, Transport Module

Turning Tool, Cleaning Brush, Chemical Change Chart and a box of Cleaning Tablets

(UK only), and Daylight Loader (as required).

1. Familiarise yourself with the layout of the machine by referring to the images

as you progress through the manual.

2. Lift the machine from the carton and position on counter top. Remove outer

and inner packaging. The transport modules are protected by internal

packing pieces: these must be discarded.

Page 8

VELOPEX INTRA-X

User Guide

Pre Installation Instructions (cont.)

• Siting of the VELOPEX

When using the machine in daylight or a darkroom, avoid sources of intense light.

Do not mount the unit under a window, fluorescent light or flood lamp.

4

IMPORTANT NOTE: A well ventilated position is mandatory.

The ambient temperature must be below 80oF (27oC).

Prevent siting the machine above or near other electrical or mechanical equipment.

Surfaces susceptible to water or chemical damage should be avoided, such as

carpeted areas.

1. COUNTER

a. Use a stable and level counter that will support a weight of at least

100 lbs. (50 Kg.).

b. When the machine is filled with chemicals, make sure the stand does not

rock or shake. NEVER move the machine with chemicals in the tanks.

2. ELECTRICAL SUPPLY

a. 115Vac 60Hz, 10A, 1150W (USA)/230Vac 50Hz, 10A, 1150W (World Wide).

b. The power source must be within three (3) feet (1m) of the machine. It

should be easily accessible for operation and maintenance.

WARNING: X-ray radiation can be harmful to patient, technician and dentist.

Inadequate lead shielding of the darkroom or film storage area will also cause

fogging from exposure of films to stray x-ray radiation. Consult your local

codes, Health Department or Dental Equipment Dealer for proper construction

of darkroom or placement of film processing equipment in the vicinity of x-ray

radiation sources.

INSTALLATION

Page 9

Daylight Loader Installation (as required)

Bring the Lid to the upright

position.

1.

TIP: The Lid can be kept in the upright

position while the machine is open, or

lifted away.

Remove Side Panel by Sliding it

Upwards in its Runners.

2.

VELOPEX INTRA-X

User Guide

5

INSTALLATION

3a.

Remove All Packing / Wrapping

Material and Modules.

TIP: Start with the Dryer Module, then

the Water Module followed by the Fixer

and Developer Modules. Those should be

removed by sliding the Tanks out.

Page 10

Daylight Loader Installation (cont.)

3b.

WARNING: When Removing

the Fixer and Developer modules, slide

tanks sideways until completely clear of

the immersion heaters mounted on the

machine internal wall.

Unscrew the Two Retaining

Screws and Remove White

4.

(Retaining

Screw X 2)

protective strip from sealing

material on the back of the

loader.

VELOPEX INTRA-X

User Guide

6

INSTALLATION

(Back of

Loader)

(Front of

Loader)

Remove Protective Film from

Viewing Window Cover.

5.

Page 11

Daylight Loader Installation (cont.)

Slide Loader over Film Entry

Guide and ‘RUN’ Button, Press

6.

the Loader firmly against Machine.

Secure Loader with the Two

Retaining Screws.

7.

VELOPEX INTRA-X

User Guide

7

INSTALLATION

Page 12

Filling with Chemicals

8.

9.

VELOPEX INTRA-X

User Guide

Remove Modules (see Installation

Sections 1-3b).

WARNING: Ensure machine

is disconnected from mains power

supply whilst filling. NEVER turn on the

machine with the tanks empty.

Lift the Transport modules from

their respective tanks

WARNING: BEFORE filling with

chemicals run the machine with clean

water in the Developer, Fixer and

Water tanks with Transport Modules

in position – for a complete running

cycle to remove all packing debris,

dust etc.

8

INSTALLATION

Fill tanks with their respective

chemical solutions or water,

10.

Pouring in 1½ quarts (1400ml)

of fluid.

TIP: Use VELOPEX chemicals designed

for your unit. If unobtainable use ONLY

another proprietary chemical & always

read and follow instructions on bottle.

WARNING: DO NOT use

Chemistry or Film designed for manual

processing.

Page 13

Fill the tanks up to the lowest

Filling with Chemicals (cont.)

edge of the Sight Glass.

11.

Lower Transport Modules carefully

into their respective tanks. Top up

12.

- the correct liquid level will show

half way up the sight glass.

WARNING: This liquid level

should be maintained at all times.

VELOPEX INTRA-X

User Guide

9

INSTALLATION

13.

Grease Immersion Heaters for

Developer and Fixer tanks with the

lubricant provided.

TIP: Spread a thin smear of lubricant

over the two projecting metal heating

elements.

WARNING: Do NOT over

grease.

Page 14

Filling with Chemicals (cont.)

(Drive Pin &

Drive Dog)

14.

15a.

VELOPEX INTRA-X

User Guide

To avoid spillage, carefully

return tanks to the machine.

Start with the Developer tank

followed by the Fixer, Water and

finally the Dryer tanks. Engage

the module drive pins into the

drive dogs, working from right

to left.

TIP: Slide the Developer and Fixer

tanks sideways onto the immersion

heaters till backed up fully against the

machine internal wall.

Return side panel and lid.

10

INSTALLATION

15b.

WARNING:

spilled solution.

The Machine may now be

switched on.

TIP: Check that all modules are

engaged and running smoothly by

passing a ‘clean-up film’ through the

machine. If it fails to exit the machine,

check engagement of modules.

WARNING: The machine will

not operate with the lid open.

Wipe dry any

Page 15

Operating the Processor

1.

2.

VELOPEX INTRA-X

User Guide

Plug in electric cord and switch

on.

TIP: After approx. eight minutes

the processor will go into ‘stand-by’

mode, by which time the chemicals will

have reached their correct temperature.

WARNING: Always turn

mains electricity switch off at night.

Correct temperature is indicated

when the red light is extinguished.

TIP: The time taken to achieve the

correct temperature depends on the

room temperature (usually 10-15 min.).

11

OPERATION

(Image for instruction ONLY,

Viewing Window is closed when

operating machine)

3.

TIP: Intra-XE has no heating and

therefore no temperature indicator. It

relies on ambient room temperature of

20oC - 25oC.

The Velopex is equipped with

automatic stand-by mode. To

initiate processing press the

‘RUN’ Button.

TIP: From time to time the

temperature light will illuminate

for short intervals as the machine

requires heat throughout the day

(Intra-XE excluded).

WARNING:

the machine, intra oral film packets

should be wiped clean of all mouth

contaminants.

Before placing in

Page 16

Operating the Processor (cont.)

4.

(Image for instruction ONLY,

Viewing Window is closed when

operating machine)

5.

(Image for instruction ONLY,

Viewing Window is closed when

operating machine)

VELOPEX INTRA-X

User Guide

Put Hands through Loading

Ports and place Film inside

Daylight Loader.

WARNING: Always remove old

film wrappers from inside the loader.

Press ‘RUN’ button, strip

Wrapping from Film, Insert

Film into Entry Slot.

WARNING: A second film can

be inserted only after the first has fully

entered the machine. Do not remove

hands from loading section until

the film has completely entered the

machine.

12

OPERATION

6.

Each day make sure Chemical

Levels are correct. If necessary,

top up Chemicals (See Installation

sections 10, 11 and 12)

TIP: Before processing run

through “clean-up film” or any spare

strip of extra oral film. This helps to

clean the transport system.

WARNING: The same film may

be used for this purpose for one week,

after which discard the old film and use

a fresh one.

Page 17

Operating the Processor (cont.)

7.

VELOPEX INTRA-X

User Guide

All films are collected in the

Film Catcher at the rear of the

machine.

13

8.

WARNING:

day turn off mains power switch.

For quick viewing of X-Rays

use the Endo Slide, which will

halve the time of processing. To

use: press the Endo Slide FULLY

down, by pressing the latch and

lowering the slide.

TIP: This procedure is only “Dryto-Wet”, which means the film should be

washed with water and hung up to dry

when needed for archiving.

WARNING: The Endo Slide

must be returned to the ‘UP’ position

before further processing.

Remove film from ENDO slot.

At the end of the

OPERATION

9.

TIP: After film exits, you can view

and then wash it with water and hang

it up to dry.

WARNING: Make sure film does

not fall back into the Velopex - remove

it as soon as it emerges.

Page 18

Film Feeding direction.

Operating the Processor (cont.)

10.

TIP: Centre the film on the guide provided to post the film

through the processor.

WARNING: Make sure the film is fed in squarely, and in the

centre of the entry slot, short edge leading.

Film Entry

VELOPEX INTRA-X

User Guide

14

OPERATION

Film

þ ý

Film

Page 19

Velopex Processor Cleaning

1.

2.

VELOPEX INTRA-X

User Guide

Quality Assurance - for

instructions refer to back of

VISCHECK Quality Manager

board supplied with your

machine.

TIP: Regular use of this product

will ensure the quality of the film

processing and reduce the risk of

retakes. Vischeck will also tell you when

to change the chemicals.

Open Lid, remove side

cover, and remove tanks &

modules (see Installation

sections 1-3b & 8-9)

15

3.

WARNING: Carry out the

cleaning routine each chemical

change or approx. once every four

weeks, according to use.

Drain Modules over the tanks

before removing them.

TIP: Tip the Module and lean it

on the edge of the tank letting it drain

before completely removing.

WARNING:

wet with chemicals; handle with care.

May cause staining or corrosion of

surfaces, skin and eye irritation. Wipe

away any spillage immediately and

flush with copious amounts of water.

The Modules are

MAINTENANCE

Page 20

Velopex Processor Cleaning (cont.)

VELOPEX INTRA-X

User Guide

16

Q

4.

5.

Module cleaning - Immerse the

Modules in a tank/sink filled

with hot water and scrub with

the supplied brush around the

gears and roller ends.

TIP: Use the turning tool; turn

the gears and belts by hand to assist in

thorough cleaning.

WARNING: DO NOT use

boiling water; it will damage the

modules. Use ONLY cold water

when cleaning the machine tanks.

Clean the Modules using the

Velopex Cleaning Tablets:

Empty Chemical and Water

tanks. Re-fill with fresh cold

water.

WARNING: Do not empty

cleaning solution into containers

containing processing chemicals

- FOLLOW INSTRUCTIONS SUPPLIED

WITH CLEANING TABLETS.

6.

MAINTENANCE

Replace the modules in their

tanks and run for one cycle.

Empty tanks again, remove

Modules and re-fill with fresh

cold water.

WARNING: Always return a

Module to the tank it was removed

from e.g. Developer-to-Developer.

Page 21

Velopex Processor Cleaning (cont.)

Add Velopex Cleaning Tablets

one per tank..

7.

Replace Modules and run

for TWO cycles at operating

8.

temperature.

VELOPEX INTRA-X

User Guide

17

9.

Dryer Module Cleaning - Place

Dryer Module in container or

sink filled with fresh cold water.

Add one Velopex Cleaning

Tablet and soak for at least 10

minutes. Rinse thoroughly with

water to remove all cleaning

solution.

WARNING: Make sure you

drip-dry the module before replacing

in the dryer compartment.

MAINTENANCE

Page 22

Velopex Processor Cleaning (cont.)

Removal of film debris:

Open Bottom hatch of Loader.

10.

WARNING: Ensure hatch is

securely closed and light - tight.

Remove old film wrappers from

daylight loader. Wipe clean the

11.

interior of loader.

VELOPEX INTRA-X

User Guide

18

12.

TIP: The interior of the daylight

loader should be cleaned with cold

sterilising solution, wipe dry after

appropriate period.

Fill up with Chemicals (See

Installation sections 10-12,

pages 6-7).

For best results, use VELOPEX

chemicals.

TIP: Use the chart provided and

keep a note of the date when chemicals

were changed.

Process a Vischeck strip to produce

the master reference strip and place in

position on the Quality chart (follow

Vischeck instruction for use).

MAINTENANCE

Page 23

VELOPEX INTRA-X

User Guide

19

TROUBLE SHOOTING

Page 24

VELOPEX INTRA-X

User Guide

20

TROUBLE SHOOTING

Page 25

VELOPEX INTRA-X

User Guide

21

TROUBLE SHOOTING

Page 26

VELOPEX INTRA-X

User Guide

22

TROUBLE SHOOTING

Page 27

VELOPEX INTRA-X

User Guide

23

TROUBLE SHOOTING

Page 28

VELOPEX INTRA-X

Service Log:

Date Service Description Serviced By

/ /

/ /

/ /

/ /

/ /

/ /

/ /

/ /

/ /

/ /

/ /

Mac h in e In sta lla t ion

User Guide

24

/ /

/ /

/ /

/ /

/ /

/ /

MC = Monthly Cleaning ; WIA = When In Area ; SC = Service Call

TIP: Service Log Table

Use this table to record any service/maintenance done, including:

Installation, Engineer- Servicing, Parts replaced by user, etc.

Keep this log for reference and use at any time you contact your supplier.

Loading...

Loading...