Velodyne VLP-16 User Manual

VLP-16 User Manual

63-9243 Rev. D

Copyright 2018 Velodyne LiDAR, Inc. All rights reserved.

Trademarks

Velodyne™, HDL-32E™, HDL-64E™, VLP-16™, VLP-32™, Puck™, Puck LITE™, Puck Hi-Res™, and Ultra Puck™ are trademarks of Velodyne LiDAR, Inc. All other trademarks, service marks, and company names in this document or website are

properties of their respective owners.

Disclaimer of Liability

The information contained in this document is subject to change without notice. Velodyne LiDAR, Inc. shall not be liable for

errors contained herein or for incidental or consequential damage in connection with the furnishing, performance, or use

of this document or equipment supplied with it.

The materials and information contained herein are being provided by Velodyne LiDAR, Inc. to its Customer solely for Customer’s use for its internal business purposes. Velodyne LiDAR, Inc. retains all right, title, interest in and copyrights to the

materials and information herein. The materials and information contained herein constitute confidential information of

Velodyne LiDAR, Inc. and Customer shall not disclose or transfer any of these materials or information to any third party.

No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopying and recording, or stored in a database or retrieval system for any purpose without the express written

permission of Velodyne LiDAR, Inc., which reserves the right to make changes to this document at any time without notice

and assumes no responsibility for its use. This document contains the most current information available at the time of publication. When new or revised information becomes available, this entire document will be updated and distributed to all

registered users.

Limited Warranty

Except as specified below, products sold hereunder shall be free from defects in materials and workmanship and shall conform to Velodyne's published specifications or other specifications accepted in writing by Velodyne for a period of one (1)

year from the date of shipment of the products. The foregoing warranty does not apply to any Garmin products, other

products not manufactured by Velodyne or products that have been subject to misuse, neglect, or accident, or have been

opened, dissembled, or altered in any way. Velodyne shall make the final determination as to whether its products are

defective. Velodyne 's sole obligation for products failing to comply with this warranty shall be, at its option, to either repair,

replace or issue credit for the nonconforming product where, within fourteen (14) days of the expiration of the warranty

period, (i) Velodyne has received written notice of any nonconformity; (ii) after Velodyne's written authorization, Buyer has

returned the nonconforming product to Velodyne at Buyer's expense; and (iii) Velodyne has determined that the product is

nonconforming and that such nonconformity is not the result of improper installation, repair or other misuse. Velodyne will

pay for return shipping for all equipment repaired or replaced under warranty and Buyer will pay all duties or taxes, if any,

on all equipment repaired or replaced under warranty. THE FOREGOING WARRANTY AND REMEDIES ARE

EXCLUSIVE AND MADE EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED, IMPLIED OR

OTHERWISE, INCLUDING WARRANTIES OF 65-0003 Rev E Velodyne LiDAR Terms & Conditions Page 3 of 5 201603-31 MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. VELODYNE DOES NOT ASSUME OR

AUTHORIZE ANY OTHER PERSON TO ASSUME FOR IT ANY OTHER LIABILITY IN CONNECTION WITH ITS

PRODUCTS. This warranty is non-transferable.

Velodyne LiDAR, Inc.

5521 Hellyer Ave

San Jose, CA 95138

Phone +1 408-465-2800

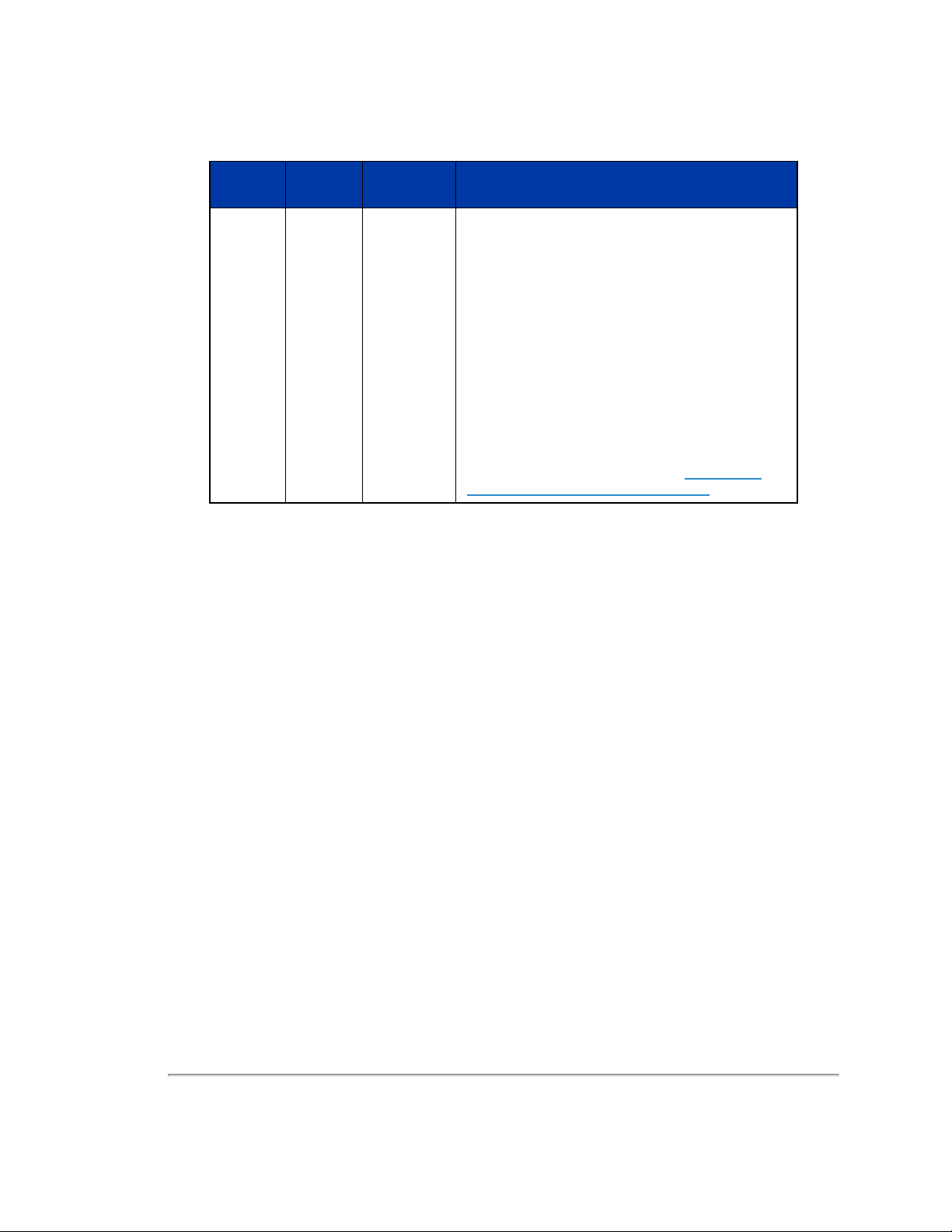

Revision History

Sensor Firmware

VLP-16 3.0.37.0 2017-12-12

Release

Date

Release Notes

• CHANGED: Phase Lock Offset setting now expects

integer degrees instead of hundredths of degrees.

• IMPROVED: Removed 'Update Calibration' from System

tab.

• IMPROVED: Sun Noise Filter.

• ADDED: Ability to change sensor's Ethernet MAC

Address from Web Interface.

• IMPROVED: Low signal cross-talk filtering performance.

• IMPROVED: Firmware update messages during update.

• IMPROVED: Phase Lock rotations error < ±5 degrees.

• FIXED: Intermittent ghost returns at 40, 80 and greater

than 124 meters.

• IMPROVED: Several JSON data additions and changes.

• ADDED: Reverse rotation capability. Specify negative

RPM values to use this capability.

For details, see the full Release Notes at http://www.ve-

lody nelidar.com/downloads.html#firmware.

3

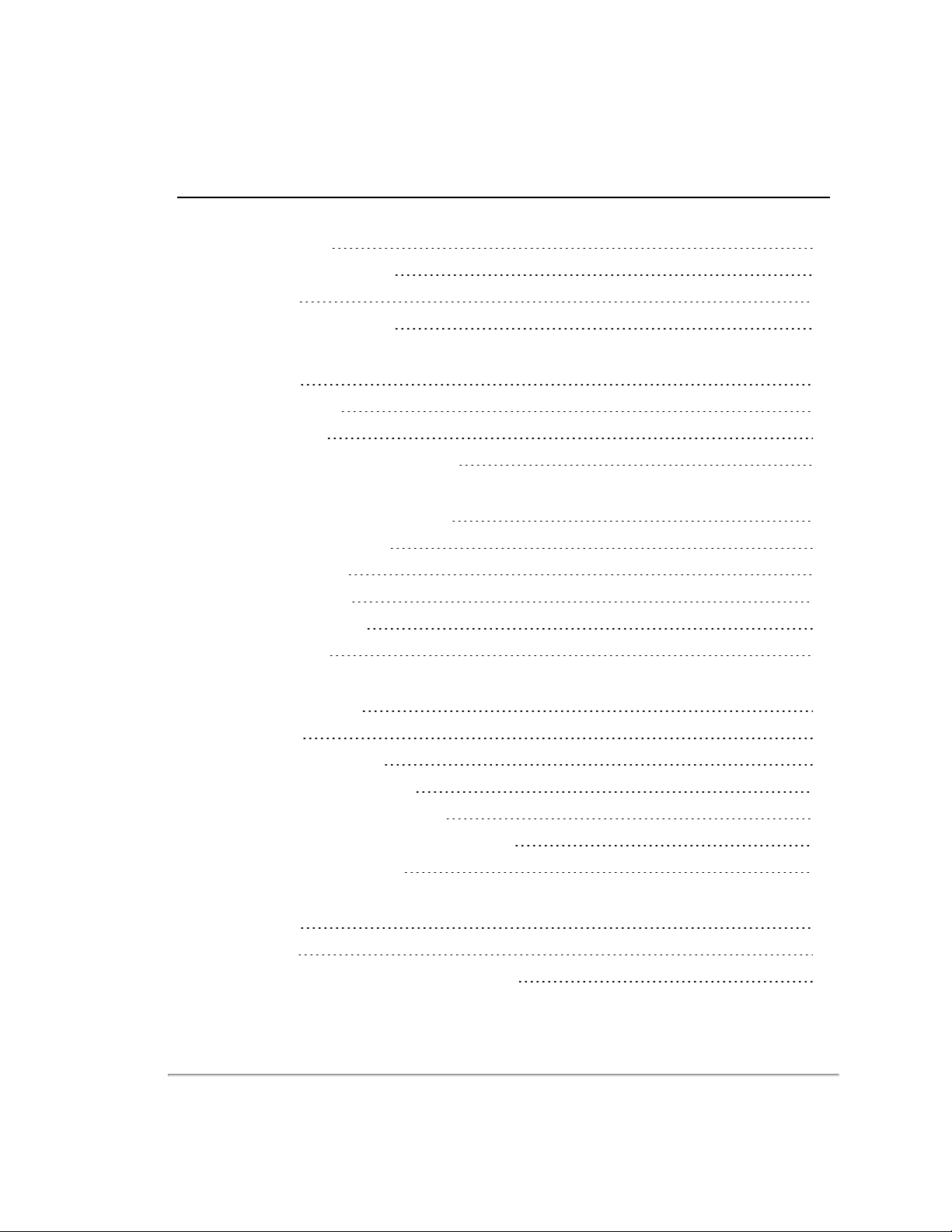

Table of Contents

Chapter 1 • About This Manual

1.1 Manual Scope

1.2 Prerequisite Knowledge

1.3 Audience

1.4 Document Conventions

Chapter 2 • VLP-16 Overview

2.1 Overview

2.2 Product Models

2.3 Time of Flight

2.4 Data Interpretation Requirements

Chapter 3 • Safety Precautions

3.1 Warning and Caution Definitions

3.1.1 Caution Hazard Alerts

3.2 Safety Overview

3.2.1 Electrical Safety

3.2.2 Mechanical Safety

3.2.3 Laser Safety

Chapter 4 • Unboxing & Verification

16

16

16

16

18

19

19

19

20

20

20

20

20

21

4.1 What’s in the Box?

4.1.1 Variants

4.2 Verification Procedure

4.2.1 Network Setup in Isolation

4.2.2 Access Sensor’s Web Interface

4.2.3 Visualize Live Sensor Data with VeloView

4.2.3.1 VeloView Operation

22

22

22

23

24

26

27

Chapter 5 • Installation & Integration

5.1 Overview

5.2 Mounting

5.3 Encapsulation, Solar Hats, and Ventilation

4 VLP-16 User Manual

29

29

30

5.4 Connections

30

5.4.1 Integrated Cable and Interface Box

5.4.2 Operation Without an Interface Box

5.4.3 Power

Chapter 6 • Key Features

6.1 Calibrated Reflectivity

6.2 Laser Return Modes

6.2.1 Single Return Modes: Strongest, Last

6.2.2 Multiple Returns

6.2.3 Dual Return Mode

6.3 Phase Locking Multiple Sensors

Chapter 7 • Sensor Inputs

7.1 Power Requirements

7.2 Interface Box Signals

7.3 Ethernet Interface

7.4 GPS, Pulse Per Second (PPS) and NMEA GPRMC Message

7.4.1 GPS Input Signals

7.4.2 Electrical Requirements

31

31

31

32

32

32

33

33

37

39

40

41

41

41

41

7.4.3 Timing and Polarity Requirements

7.4.4 GPS Connection Scenarios

7.4.4.1 Connecting a Garmin 18x LVC GPS Receiver

7.4.4.2 Connecting to a computer's serial port

7.4.4.3 Connecting to a microcomputer’s UART

7.4.5 NMEA Message Formats

7.4.5.1 Pre-NMEA Version 2.3 Message Format

7.4.5.2 NMEA Version 2.3 Message Format

7.4.6 Accepting NMEA Messages Via Ethernet

Chapter 8 • Sensor Operation

8.1 Firing Sequence

8.2 Throughput Calculations

41

44

44

44

45

46

46

47

48

49

49

5

8.2.1 Data Packet Rate

49

8.2.2 Position Packet Rate

8.2.3 Total Packet Rate

8.2.4 Laser Measurements Per Second

8.2.4.1 Single Return Mode (Strongest, Last)

8.2.4.2 Dual Return Mode

8.3 Rotation Speed (RPM)

8.3.1 Horizontal Angular (Azimuth) Resolution

8.3.2 Rotation Speed Fluctuation and Point Density

Chapter 9 • Sensor Data

9.1 Sensor Origin and Frame of Reference

9.2 Calculating X,Y,Z Coordinates from Collected Spherical Data

9.3 Packet Types and Definitions

9.3.1 Definitions

9.3.1.1 Firing Sequence

9.3.1.2 Laser Channel

9.3.1.3 Data Point

9.3.1.4 Azimuth

50

50

50

50

50

50

50

51

52

52

54

54

55

55

55

55

9.3.1.5 Data Block

9.3.1.6 Time Stamp

9.3.1.7 Factory Bytes

9.3.2 Data Packet Structure

9.3.3 Position Packet Structure

9.4 Discreet Point Timing Calculation

9.5 Precision Azimuth Calculation

9.6 Converting PCAP Files to Point Cloud Formats

55

55

56

56

60

61

65

66

Chapter 10 • Sensor Communication

10.1 Web Interface

10.1.1 Configuration Screen

10.1.1.1 MAC Address

10.1.1.2 Correctly reset MAC Address to Factory MAC Address

6 VLP-16 User Manual

68

69

71

71

10.1.2 System Screen

72

10.1.3 Info Screen

10.1.4 Diagnostics Screen

10.2 Sensor Control with curl

10.2.1 Using curl with Velodyne LiDAR Sensors

10.2.2 curl Command Parameters

10.2.3 Command Line curl Examples

10.2.3.1 Get Diagnostic Data

10.2.3.2 Conversion Formulas

10.2.3.3 Interpret Diagnostic Data

10.2.3.3.1 top:hv

10.2.3.3.2 top:lm20_temp

10.2.3.3.3 top:pwr_5v

10.2.3.3.4 top:pwr_2_5v

10.2.3.3.5 top:pwr_3_3v

10.2.3.3.6 top:pwr_5v_raw

10.2.3.3.7 top:pwr_vccint

10.2.3.3.8 bot:i_out

73

75

76

76

76

77

77

78

78

78

79

79

79

79

79

80

80

10.2.3.3.9 bot:lm20_temp

10.2.3.3.10 bot:pwr_1_2v

10.2.3.3.11 bot:pwr_1_25v

10.2.3.3.12 bot:pwr_2_5v

10.2.3.3.13 bot:pwr_3_3v

10.2.3.3.14 bot:pwr_5v

10.2.3.3.15 bot:pwr_v_in

10.2.3.4 Get Snapshot

10.2.3.5 Get Sensor Status

10.2.3.6 Set Motor RPM

10.2.3.7 Set Field of View

10.2.3.8 Set Return Type (Strongest, Last, Dual)

10.2.3.9 Save Configuration

80

80

81

81

81

81

81

82

82

82

83

83

83

7

10.2.3.10 Reset System

83

10.2.3.11 Network Configuration

10.2.3.12 Set Host (Destination) IP Address

10.2.3.13 Set Data Port

10.2.3.14 Set Telemetry Port

10.2.3.15 Set Network (Sensor) IP Address

10.2.3.16 Set Netmask

10.2.3.17 Set Gateway

10.2.3.18 Set DHCP

10.2.4 curl Example using Python

Chapter 11 • Troubleshooting

11.1 Troubleshooting Process

11.1.1 Turned DHCP On, Lost Contact With Sensor

11.2 Service and Maintenance

11.2.1 Fuse Replacement

11.3 Technical Support

11.3.1 Purchased through a Distributor

11.3.2 Factory Support

83

83

84

84

84

84

84

84

84

87

88

89

89

90

90

90

11.3.3 Support Desk

11.4 Return Merchandise Authorization (RMA)

90

90

Appendix A • Sensor Specifications

Appendix B • Firmware Update

B.1 Firmware Update Procedure

B.1.1 Special Procedure to Update Firmware

B.1.2 If An Error Occurs

92

98

99

Appendix C • Mechanical Diagrams

C.1 Interface Box Mechanical Drawing

C.2 VLP-16 and Puck LITE Mechanical Drawing

C.3 VLP-16 and Puck LITE Optical Drawing

C.4 VLP-16 and Puck LITE Optical Keep Out Zone

8 VLP-16 User Manual

101

102

103

104

C.5 Puck Hi-Res Mechanical Drawing

105

C.6 Puck Hi-Res Optical Drawing

C.7 Puck Hi-Res Optical Keep Out Zone

Appendix D • Wiring Diagrams

D.1 Interface Box Wiring Diagram

D.2 Interface Box Schematic

Appendix E • VeloView

E.1 Features

E.2 Install VeloView

E.3 Visualize Streaming Sensor Data

E.4 Capture Streaming Sensor Data to PCAP File

E.5 Replay Captured Sensor Data from PCAP File

Appendix F • Laser Pulse

F.1 The Semiconductor Laser Diode

F.2 Laser Patterns

F.2.1 Laser Spot Pattern

F.2.2 Laser Scan Pattern

F.2.3 Beam Divergence

106

107

109

110

111

112

112

114

114

119

120

120

120

121

Appendix G • Time Synchronization

G.1 Introduction

G.2 Background

G.3 PPS Qualifier

G.3.1 Require GPS Receiver Valid

G.3.2 Require PPS Lock

G.3.3 Delay

G.4 GPS Qualifier

G.5 Application

G.6 Logic Tables

Appendix H • Phase Lock

H.1 Phase Lock

123

123

124

124

124

125

125

125

125

127

9

H.1.1 Setting the Phase Lock

127

H.1.2 Application Scenarios

H.2 Field of View

Appendix I • Sensor Care

I.1 Cleaning the Sensor

I.1.1 Required Materials

I.1.2 Determine Method of Cleaning

I.1.3 Method One

I.1.4 Method Two

I.1.5 Method Three

I.1.6 Method Four

Appendix J • Network Configuration

J.1 Ethernet and Network Setup

J.1.1 Defaults

J.1.2 Establishing Communication via Ethernet

J.2 Network Considerations

J.2.1 Throughput Requirements

J.2.2 Single Sensor Transmitting to a Broadcast Address

128

130

131

131

132

132

132

132

133

134

134

134

135

135

136

J.2.3 Multiple Sensors in the Same Network

J.2.3.1 Multiple Sensors Transmitting to a Broadcast Address

J.2.3.2 Multiple Sensors Transmitting to a Specific Address

136

136

137

10 VLP-16 User Manual

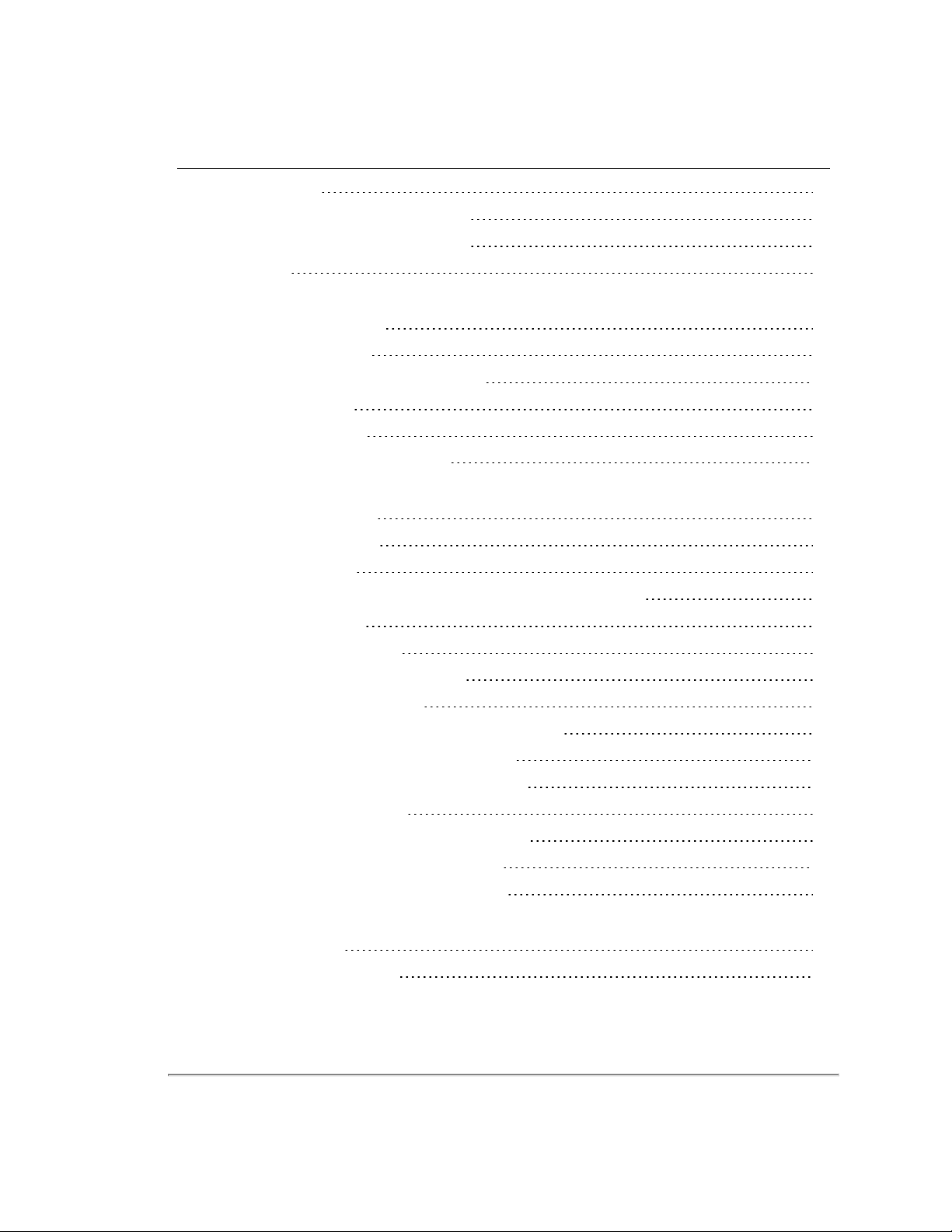

List of Tables

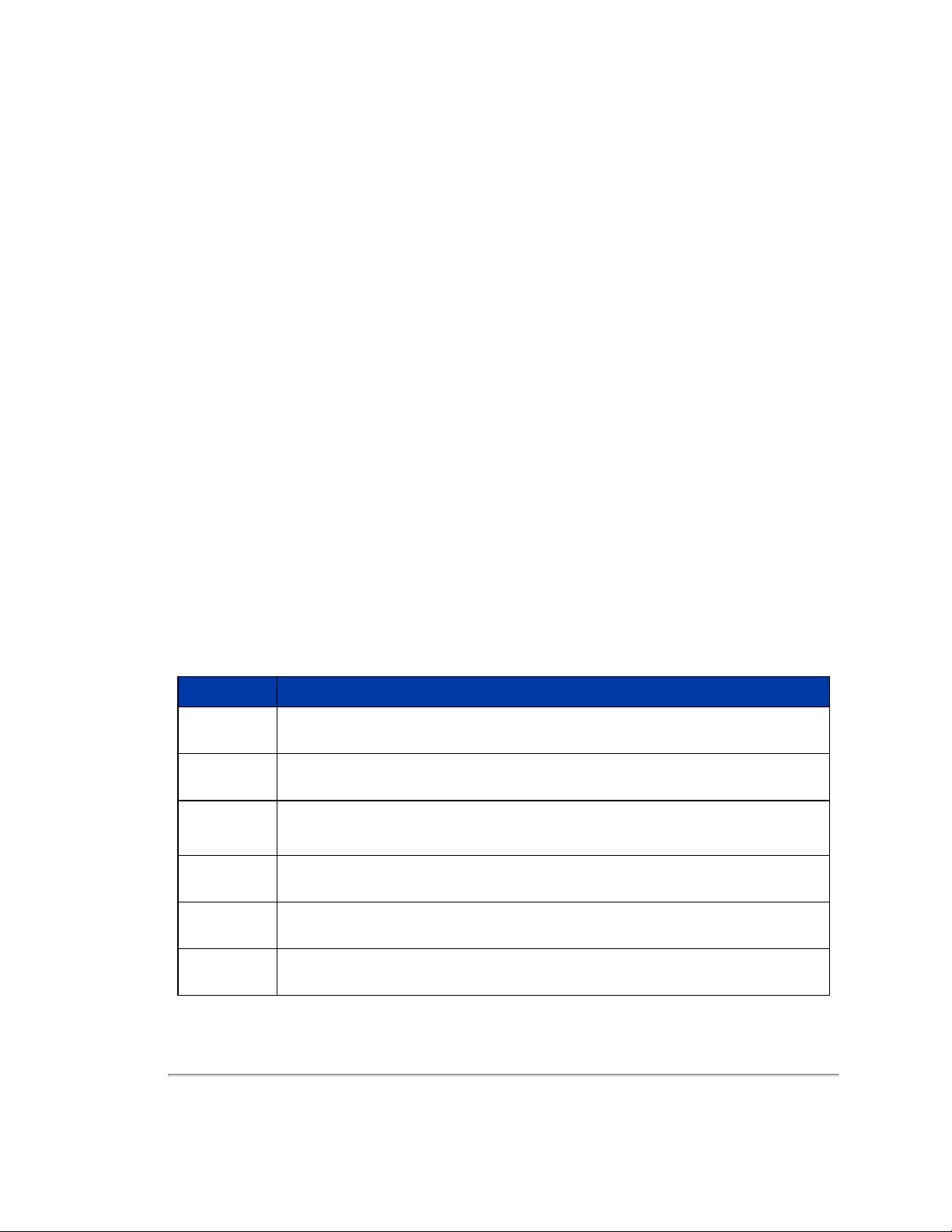

Table 1-1 Doc ument Conventions

Table 2-1 3D Sensing System Components

Table 7-1 Interface Box Signal s

Table 7-2 Pre-NMEA Versi on 2.3 Message Format

Table 7-3 Post-NMEA Version 2.3 Mes sage Format

Table 8-1 Rotation Speed vs Resoluti on

Table 9-1 Verti cal Angles (ω) by Las er ID and Model

Table 9-2 Factory Byte Values

Table 9-3 Position Packet Struc ture Field Offsets

Table 9-4 PPS Status Byte Values

Table 10-1 Configuration Screen Functionality and Features

Table 10-2 System Screen Functionality and Features

Table 10-3 Info Sc reen Functi onality and Features

Table 10-4 System Screen Functionality and Features

Table 11-1 Common Problems and Resolutions

Table F-1 VLP-16 Beam Div ergence

Table F-2 Dimensions of VLP-16 Laser Spots at Distance

16

19

40

47

47

51

53

56

60

60

69

72

73

75

87

122

122

11

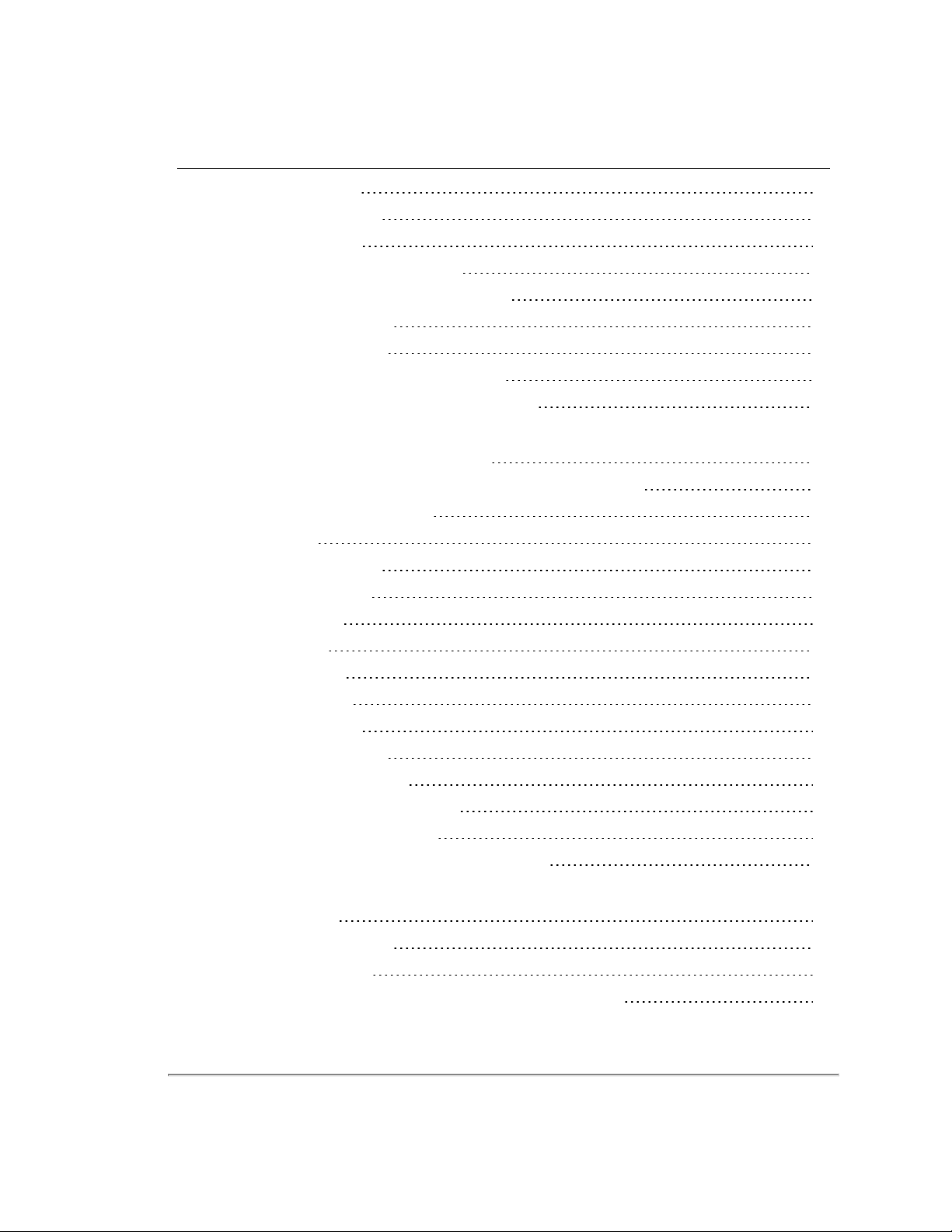

List of Figures

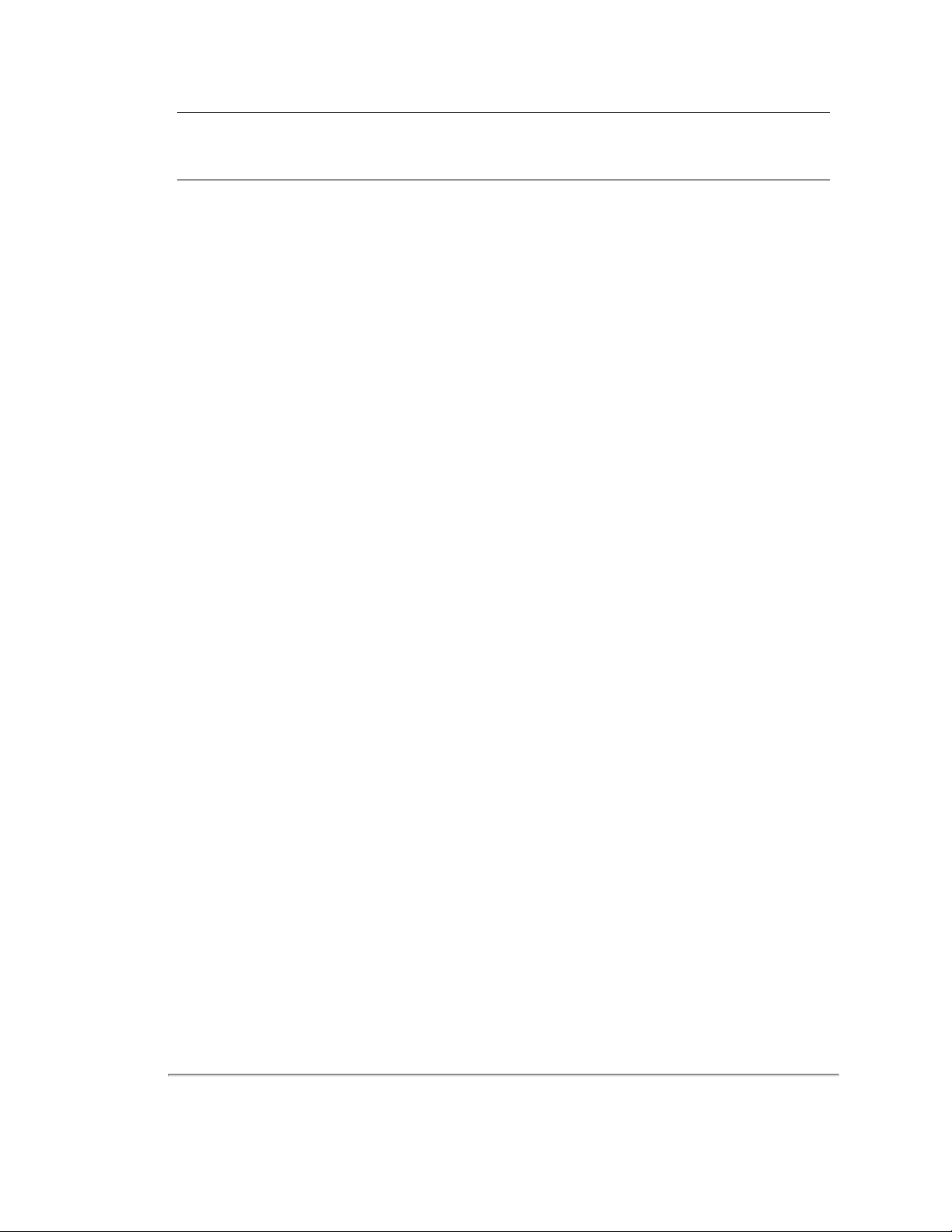

Figure 2-1 Ex ample 3D Sensing Sy stem

Figure 3-1 Clas s 1 Las er

Figure 4-1 Sens or Network Settings

Figure 4-2 Interfac e Box (power and data connections )

Figure 4-3 Sample Web Interface Main Configuration Screen

Figure 4-4 VeloView Open Sens or Stream

Figure 4-5 VeloView Select Sensor Calibration

Figure 4-6 VeloView Sensor Stream Display

Figure 5-1 Mounting Details

Figure 6-1 A Single Return

Figure 6-2 Dual Return with Las t and Stronges t Returns

Figure 6-3 Dual Return with Second Strongest Return

Figure 6-4 Dual Return with Far Retro-Refl ector

Figure 6-5 Forestry Appli cation Multipl e Returns

Figure 6-6 Phas e Lock ing Example

Figure 7-1 Interfac e Box (sensor power and data connections)

Figure 7-2 Sy nchronizing PPS with NMEA G PRMC Message

Figure 7-3 PPS Signal Closely Foll owed by NMEA GPRMC Message

Figure 7-4 PPS Signal Fol lowed 600 ms later by NMEA GPRMC Mess age

Figure 7-5 RS-232 Exampl e Trans missi on

Figure 7-6 G armin GPRMC Mess age

Figure 7-7 DB9 Pin-outs (DTE) and USB-to-Serial Adapter

Figure 7-8 Signal Direc tly from UART (i ncorrect polarity)

Figure 7-9 Inverted Signal from UART (c orrec t pol arity)

Figure 8-1 Firing Sequenc e Timing

Figure 8-2 Point Density Example

Figure 9-1 VLP-16 Sensor Coordinate Sys tem

Figure 9-2 VLP-16 Single Return Mode Data Structure

Figure 9-3 VLP-16 Dual Return Mode Data Struc ture

Figure 9-4 Single Return Mode Pack et Data Trac e (packet start)

Figure 9-5 Single Return Mode Pack et Data Trac e (ending)

Figure 9-6 Wireshark Position Packet Trace

Figure 9-7 Firing Sequenc e Timing

Figure 9-8 Ex ample Data Point Timing Cal culation

18

21

24

25

26

27

27

28

30

33

34

35

36

37

38

40

42

42

43

44

44

45

46

46

49

51

53

57

58

59

59

61

62

63

12 VLP-16 User Manual

Figure 9-9 Single Return Mode Timing Offsets (in µs)

Figure 9-10 Dual Return Mode Timing Offsets (in µs)

Figure 10-1 VLP-16 Configuration Screen

Figure 10-2 VLP-16 System Screen

Figure 10-3 VLP-16 Info Screen

Figure 10-4 VLP-16 Di agnos tics Sc reen

Figure B-1 Velodyne Downloads Page

Figure B-2 Compare Firmware Versions

Figure B-3 Select New Firmware Image

Figure B-4 Upload New Firmware Image

Figure B-5 Firmware Update Complete Page

Figure B-6 Finalize Firmware Update

Figure B-7 Verify Firmware Versions

Figure C-1 Interface Box Mechanical Drawing 50-6001 Rev A

Figure C-2 VLP-16 and Puck LIT E Mec hanical Drawing 86-0101 Rev B1

Figure C-3 VLP-16 and Puck LIT E Optical Drawi ng 86-0101 Rev B1

Figure C-4 VLP-16 and Puck LIT E Optical Keep Out Zone 86-0101 Rev B1

Figure C-5 Puck Hi-Res Mechanical Drawing 86-0129 Rev A

Figure C-6 Puck Hi-Res Optical Drawing 86-0129 Rev A

Figure C-7 Puck Hi-Res Optical Keep O ut Zone 86-0129 Rev A

Figure D-1 Interface Box Wiri ng Diagram 86-0107A

Figure D-2 Interface Box Sc hemati c 69-8230A

Figure E-1 VeloView Open Sensor Stream

Figure E-2 VeloView Select Sensor Calibrati on

Figure E-3 VeloView Sensor Stream Dis play

Figure E-4 VeloView Rec ord Button

Figure E-5 VeloView Open Capture File

Figure E-6 VeloView Play Button

Figure E-7 VeloView Spreadsheet Tool

Figure E-8 VeloView Data Point Table

Figure E-9 VeloView Show Only Selected Elements

Figure E-10 VeloView Select All Points

Figure E-11 VeloView List Selec ted Poi nts

Figure F-1 Laser Diode Conc ept

Figure F-2 Laser Spot Shape

Figure F-3 Laser Spots on a Wall

64

65

69

72

73

75

92

93

94

95

96

97

98

101

102

103

104

105

106

107

109

110

112

113

113

114

115

115

116

116

117

117

118

119

120

121

13

Figure G-1 Web Interface PPS and G PS Qualifi er Option Selec tions

Figure G-2 Top of Hour Counters

Figure G-3 Sub-Second Counter Behavior

Figure G-4 Minutes and Sec onds Counter Behavi or

Figure H-1 Direction of Las er Fi ring

Figure H-2 Configuration Screen - Phase Lock

Figure H-3 Right and Left Sensor Phas e O ffset

Figure H-4 Fore and Aft Sensor Phase Offset

Figure H-5 Sensor Data Shadows

Figure J-1 Sensor Network Settings

Figure J-2 Single Sensor Broadcasting on a Simple Network

Figure J-3 Multiple Sensors - Improper Network Setup

Figure J-4 Multiple Sensors - Proper Network Setup

123

124

125

126

127

128

129

129

130

135

136

137

137

14 VLP-16 User Manual

List of Equations

Equation 8-1 Az imuth Resol ution at 600 RPM

Equation 10-1 Standard Voltage Convers ion

Equation 10-2 Standard Current Conversion

Equation 10-3 Standard Temperature Conv ersion

Equation F-1 Gap Between Scan Lines

Equation H-1 Arc of Shadow

50

78

78

78

121

130

15

Chapter 1 • About This Manual

1.1 Manual Scope

This manual provides descriptions and procedures supporting the installation, verification, operation, and diagnostic evaluation of the VLP-16, Puck LITE and Puck Hi-Res sensors.

For readability, all products in the VLP-16 LiDAR sensor family are referred to as “VLP-16” i n thi s manual , ex cept

where noted.

1.2 Prerequisite Knowledge

This manual is written with the premise that the user has some basic engineering experience and general understanding

of LiDAR technology. In addition, some familiarity with the configuration and operation of networking applications and

equipment is recommended.

It is recommended that prior to installation or other procedures covered in this manual, the user fully reads and comprehends all information within this manual.

1.3 Audience

The user mentioned occasionally in this document is typically an engineer tasked with sensor integration for a project, a

tech tasked with sensor upkeep, or data scientist looking to understand sensor output data.

1.4 Document Conventions

This document uses the following typographic conventions:

Table 1-1 Document Conventions

Convention Description

Bold

Italic

screen/code

[ ] square

brackets

{ } braces

| vertical bar

Indicates text on a window, other than the window title, including menus, menu options, buttons,

fields, and labels. Example: Click OK.

Indicates a variable, which is a placeholder for actual text provided by the user or system. Example:

copy

source-file target-file

Indicates text that is displayed on screen or entered by the user. Example:

# pairdisplay -g oradb

Indicates optional values. Example: [ a | b ] indicates that you can choose a, b, or nothing.

Indicates required or expected values. Example: { a | b } indicates that you must choose either a or

b.

Indicates that you have a choice between two or more options or arguments. Examples: [ a | b ]

indicates that you can choose a, b, or nothing. { a | b } indicates that you must choose either a or b.

Note: Angled brackets (< >) are also used to indicate variables.

16 VLP-16 User Manual

Note: Notes such as this indicate important information. They call attention to an operating procedure or practice which

may enhance user interaction with the product. Notes may also be used to prevent information loss or product damage.

Chapter 1 • About This Manual 17

Chapter 2 • VLP-16 Overview

This chapter provides basic information on the sensor's hardware and software components.

2.1 Overview

2.2 Product Models

2.3 Time of Flight

2.4 Data Interpretation Requirements

18

19

19

19

2.1 Overview

The VLP-16 sensor uses an array of 16 infra-red (IR) lasers paired with IR detectors to measure distances to objects. The

device is mounted securely within a compact, weather-resistant housing. The array of laser/detector pairs spins rapidly

within its fixed housing to scan the surrounding environment, firing each laser approximately 18,000 times per second,

providing, in real-time, a rich set of 3D point data.

Advanced digital signal processing and waveform analysis provide highly accurate long-range sensing, as well as calibrated reflectivity data, enabling easy detection of retro-reflectors like street-signs, license plates, and lane markings.

Combining 16 laser/detector pairs into one VLP-16 sensor and pulsing each at 18.08 kHz enables measurements of up to

300,000 data points per second -- or double that in dual return mode.

Figure 2-1 Example 3D Sensing System

18 VLP-16 User Manual

Table 2-1 3D Sensing System Components

Item Description

1 Desktop/Laptop Computer

2 INS/GPS Antenna/Interface (optional)

3 Velodyne Interface Box

4 Velodyne LiDAR Sensor

5 DC Power Supply

Note: Optional - not included unless ordered: Garmin GPS receiver (P/N: 80-GPS18LVC).

2.2 Product Models

For ordering information, contact Sales at http://www.velodynel idar.c om/c ontac ts.php.

2.3 Time of Flight

Velodyne LiDAR sensors use time-of-flight (ToF) methodology.

When each IR laser emits a laser pulse, its time-of-shooting and direction are registered. The laser pulse travels through

air until it hits an obstacle which reflects some of the energy. A portion of that energy is received by the paired IR detector,

which registers the time-of-acquisition and power received.

2.4 Data Interpretation Requirements

Desktop or Laptop computer

Advanced geo-referencing software application

GPS-Based

SLAM-Based

User Built

Purchased from System Integrator

For more software details, see

Note: Click the following link to view a list of Velodyne system integrators who can sell you imaging software or a complete

system: http://velodyneLiDAR.com/integrators.php.

Converting PCAP Files to Point Cloud Formats on page 66

.

Chapter 2 • VLP-16 Overview 19

Chapter 3 • Safety Precautions

This chapter provides information necessary for the safe operation of Velodyne LiDAR sensors.

Observe the following general safety precautions during all LiDAR sensor phases of operation. Failure to comply with

these precautions or with specific warnings elsewhere in this manual violates safety standards of intended sensor usage

and may impair the protection provided by the equipment. Velodyne LiDAR, Inc. assumes no liability for failure to comply

with these requirements.

3.1 Warning and Caution Definitions

3.1.1 Caution Hazard Alerts

CAUTION

CAUTION indicates a potentially hazardous situation which may result in minor or moderate injury. It may also be used to alert against

unsafe practices. The icon shown in the left column displays the specific concern; in this case, a hot surface.

3.2 Safety Overview

3.2.1 Electrical Safety

Your sensor is powered by a 12 VDC (1.5 A-rated) power supply.

IMPORTANT: Read all installations instructions before powering up the sensor.

Note: The VLP-16 sensor is not field serviceable. For servicing and repair, the equipment must be completely shut off,

removed, packaged carefully, and shipped back to the manufacturer's facility with a completed RMA Form. See

and Maintenance on page 89

3.2.2 Mechanical Safety

for details.

Service

CAUTION

The VLP-16 sensor contains a rapidly spinning assembly. Do not

operate the VLP-16 sensor without its cover firmly installed. The

sensor does not contain user serviceable parts. It should not be

opened in the field.

20 VLP-16 User Manual

3.2.3 Laser Safety

This device complies with FDA performance standards for laser products except for deviations pursuant to Laser Notice

No. 50, dated June 24, 2007.

Figure 3-1 Class 1 Laser

Note: The VLP-16 sensor is a CLASS 1 LASER PRODUCT . The product fulfills the requirements of IEC 60825-1:2014

(Safety of Laser Products).

There are no controls or adjustments on the sensor itself that are user accessible.

Never look directly at the transmitting laser through a magnifying device.

Chapter 3 • Safety Precautions 21

Chapter 4 • Unboxing & Verification

This chapter provides the procedure to test and verify that your sensor is operating properly. Do this to check out a new

sensor before permanently mounting it somewhere.

4.1 What’s in the Box?

4.1.1 Variants

4.2 Verification Procedure

4.2.1 Network Setup in Isolation

4.2.2 Access Sensor’s Web Interface

4.2.3 Visualize Live Sensor Data with VeloView

22

22

22

23

24

26

4.1 What’s in the Box?

A standard Velodyne VLP-16 sensor comes packaged in its own cardboard box.

Ensure all the components are present:

VLP-16 sensor with a fixed 3.0 m data/power cable terminated inside its Interface Box

AC/DC power adapter and 1.8 m AC power cord (once assembled, this is the power cord)

1.0 m Ethernet cable

Velodyne USB memory stick, containing:

User Manual

VeloView application installers for PC, Mac, and linux

Sensor sample data (i.e. pcap files)

Miscellaneous documents

4.1.1 Variants

Variants of the sensor exist, particularly with other connector types and/or cable lengths, and even without an Interface

Box. Your sensor (or the type you are interested in) may vary from the standard configuration above. Contact Velodyne

Sales for details.

4.2 Verification Procedure

The purpose of this procedure is to verify the sensor’s basic functionality and get you started on your way to processing

sensor data in (or from) the field. It involves one computer and one sensor in isolation at a workbench or desk. You’ll need

AC power. You won’t need a GPS receiver.

A video of the VLP-16 installation process is on YouTube at the following location: https://www.y-

outube.com/watc h?v =Pa-q5el S_nE.

22 VLP-16 User Manual

Note: Due to the large volume of data produced by the sensor when scanning, users are cautioned against connecting it

to a corporate network.

1. Unpack the sensor and its accessories, and place them on a workbench or desk. Ensure the sensor is upright with

clear space around it.

2. Create a simple network setup with a test computer and the sensor in isolation. Follow the procedure in

Setup in Isolation below

3. Use the sensor’s Web Interface to perform basic sensor configuration. Follow the procedure in

Web Interface on the next page

4. Use VeloView (or other visualization software of your choice) to view data streaming from your sensor. Follow the

procedure in

When finished, the sensor should be ready for more complicated usage scenarios.

Visualize Live Sensor Data with VeloView on page 26

.

.

.

Network

Access Sensor’s

4.2.1 Network Setup in Isolation

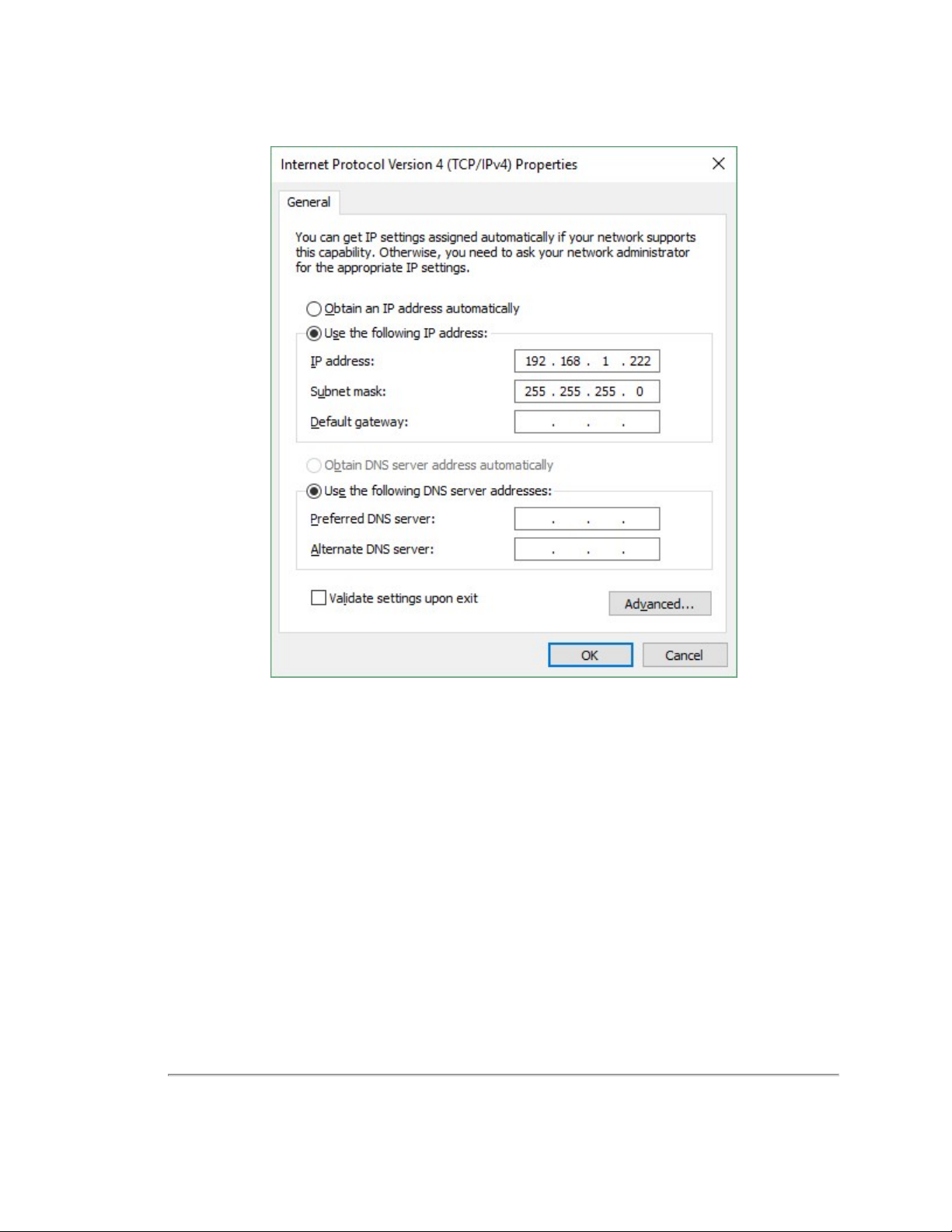

Your sensor’s IP address comes from the factory set to its default value, 192.168.1.201. This procedure prepares a computer to communicate directly with the sensor at that address.

Note: If using the computer’s main Ethernet port, disconnect it from whatever network it’s on. If using a secondary Ethernet interface, the primary network cannot be a 192.168.1 network. If it is, use the primary Ethernet interface instead.

1. Open the computer’s Network Connections page.

2. Open the applicable Ethernet adapter and make sure the interface is enabled.

3. Open Properties > Internet Protocol Version 4 (TCP/IPv4) (

4. Select the Use the following IP address : function.

5. Make up an IP address for the Ethernet port and enter it: 192.168.1.XXX.

“XXX” may be any integer from 2 to 254 except 201.

6. Enter the subnet mask: 255.255.255.0.

When using a Windows-based computer, you can press the TAB key and the subnet mask field will automatically

populate with the default mask for the network class indicated by the IP address entered; which is 255.255.255.0 in

this case.

Figure 4-1 on the next page

).

Chapter 4 • Unboxing & Verification 23

Figure 4-1 Sensor Network Settings

7. Click OK. Gateway and DNS are not necessary when testing in isolation.

In some cases it may be necessary to disable the computer’s firewall or configure it to allow UDP I/O on that Ethernet interface. How to do this is not covered here as the process varies widely.

4.2.2 Access Sensor’s Web Interface

Now the computer is ready to connect to the sensor.

1. Plug the Ethernet cable into the computer and then plug its other end into the Ethernet port on the sensor’s Interface Box.

fuse.

Figure 4-2 on the facing page

shows the Interface Box, its external ports, internal sensor terminal, and

24 VLP-16 User Manual

Figure 4-2 Interface Box (power and data connections)

2. Connect power to the sensor’s Interface Box.

When power is applied, two green LEDs in the Interface Box light up. The sensor begins scanning its environment

and transmitting data approximately 30 seconds after power up.

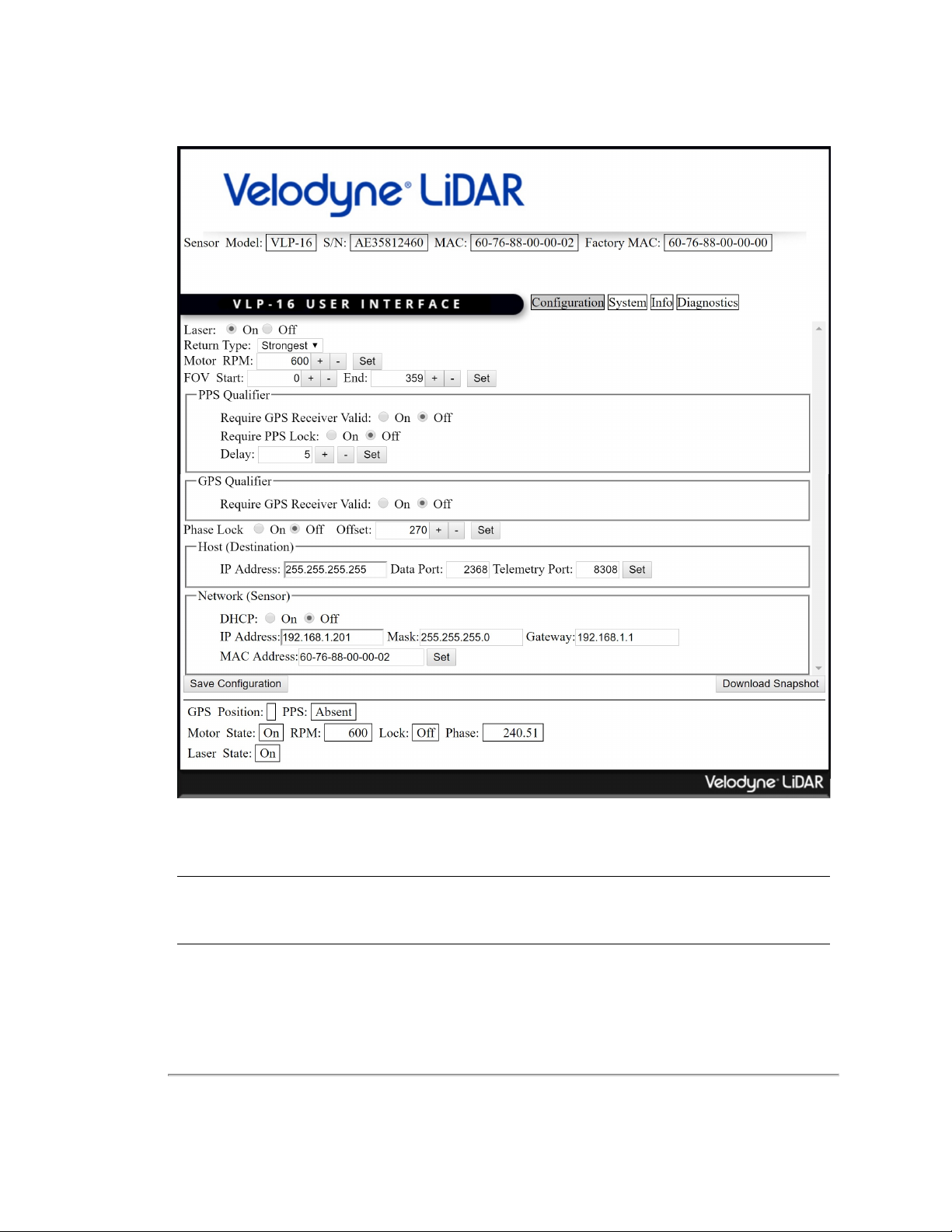

3. On the computer, point a browser to http://192.168.1.201.

4. The sensor’s Web Interface should appear (

The Web Interface provides access to many of the sensor’s control settings. See

details.

Figure 4-3 on the next page

).

Web Interface on page 68

for

Chapter 4 • Unboxing & Verification 25

Figure 4-3 Sample Web Interface Main Configuration Screen

4.2.3 Visualize Live Sensor Data with VeloView

Now that the computer can access the sensor’s Web Interface, it’s time to get a first look at the sensor’s data.

Note: VeloView is an open source visualization and recording application tailored for Velodyne LiDAR sensors. Other

visualization software (e.g. ROS, DSR and PCL) can perform similar functions and may be used instead.

VeloView is documented in more detail in

the procedure detailed in

by following the procedure.

Install VeloView on page 112

VeloView on page 111

. Older versions should be updated to at least the version installed

. If the application isn’t already on the computer, perform

26 VLP-16 User Manual

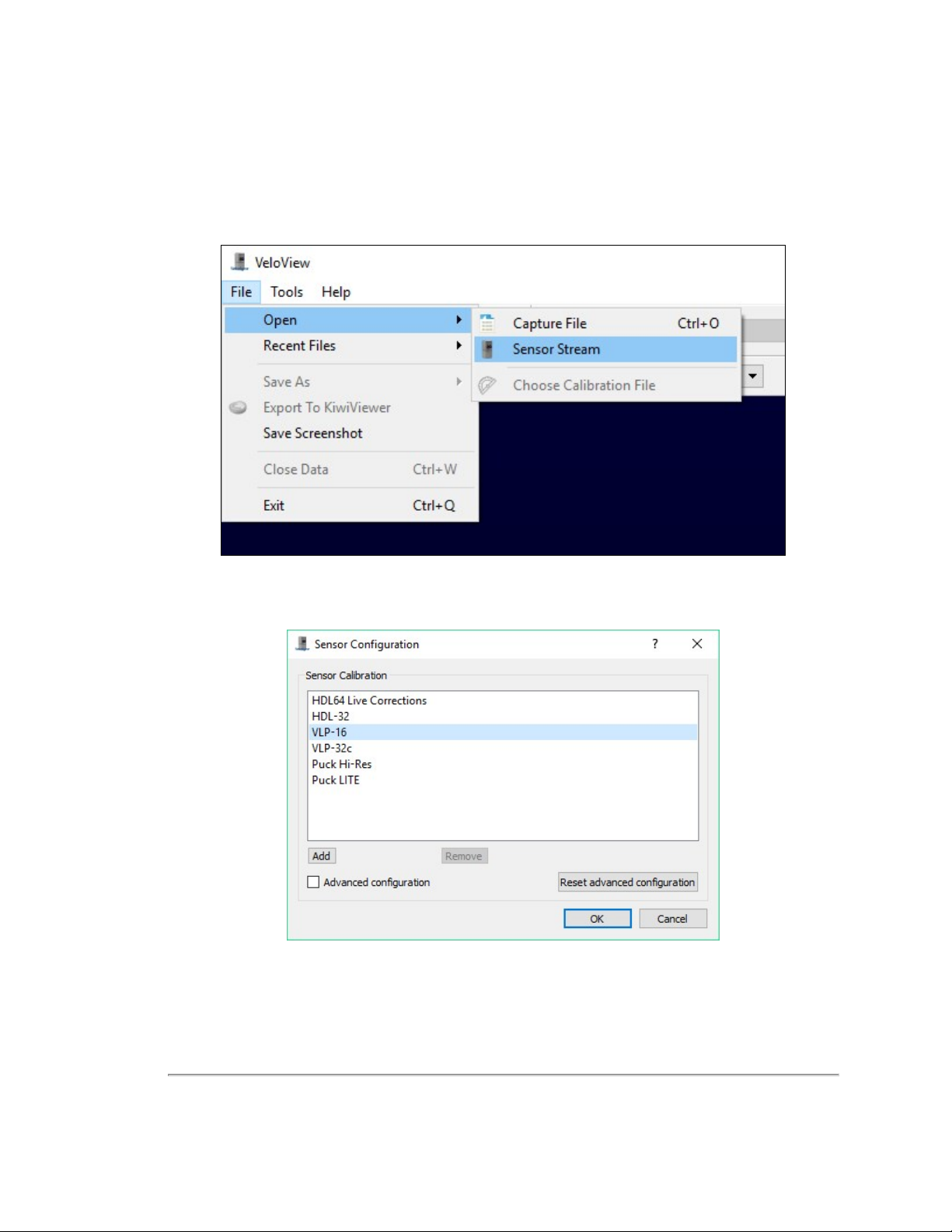

4.2.3.1 VeloView Operation

1. Power-up the sensor.

2. Start the VeloView application.

3. Click on File->Open and select Sensor Stream (

Figure 4-4 VeloView Open Sensor Stream

Figure 4-4 below

).

4. The Sensor Configuration dialog will appear (

Figure 4-5 VeloView Select Sensor Calibration

5. VeloView begins displaying the sensor data stream. See

Figure 4-5 below

). Select the correct sensor type then click OK.

VeloView Sensor Stream Display on the next page

.

Chapter 4 • Unboxing & Verification 27

Figure 4-6 VeloView Sensor Stream Display

Above is an example of a VeloView screen in an office, workbench or lab scenario.

28 VLP-16 User Manual

Chapter 5 • Installation & Integration

This chapter provides important information for integrating the VLP-16 sensor into your application environment.

5.1 Overview

5.2 Mounting

5.3 Encapsulation, Solar Hats, and Ventilation

5.4 Connections

5.4.1 Integrated Cable and Interface Box

5.4.2 Operation Without an Interface Box

5.4.3 Power

29

29

30

30

31

31

31

5.1 Overview

Ensure the sensor is functional first before beginning sensor integration. See

Common steps in installation and integration involve:

Securely mounting the sensor to a vehicle, drone, robot, or other scanning platform

Allowing for proper ventilation, providing thermal protection, and sensor encapsulation

Connecting power to the sensor

Connecting the sensor's Ethernet data output to a computer, switch, or network – see

page 134

Optionally, connecting a GPS receiver or INS (Inertial Navigation System) – see

and NMEA GPRMC Message on page 41

The typical sensor setup uses a standard computer or laptop connected to the sensor. However, it is recommended to use

at least a 100 Mbps Ethernet adapter to accommodate the sensor data rate.

Verification Procedure on page 22

Network Configuration on

GPS, Pulse Per Second (PPS)

.

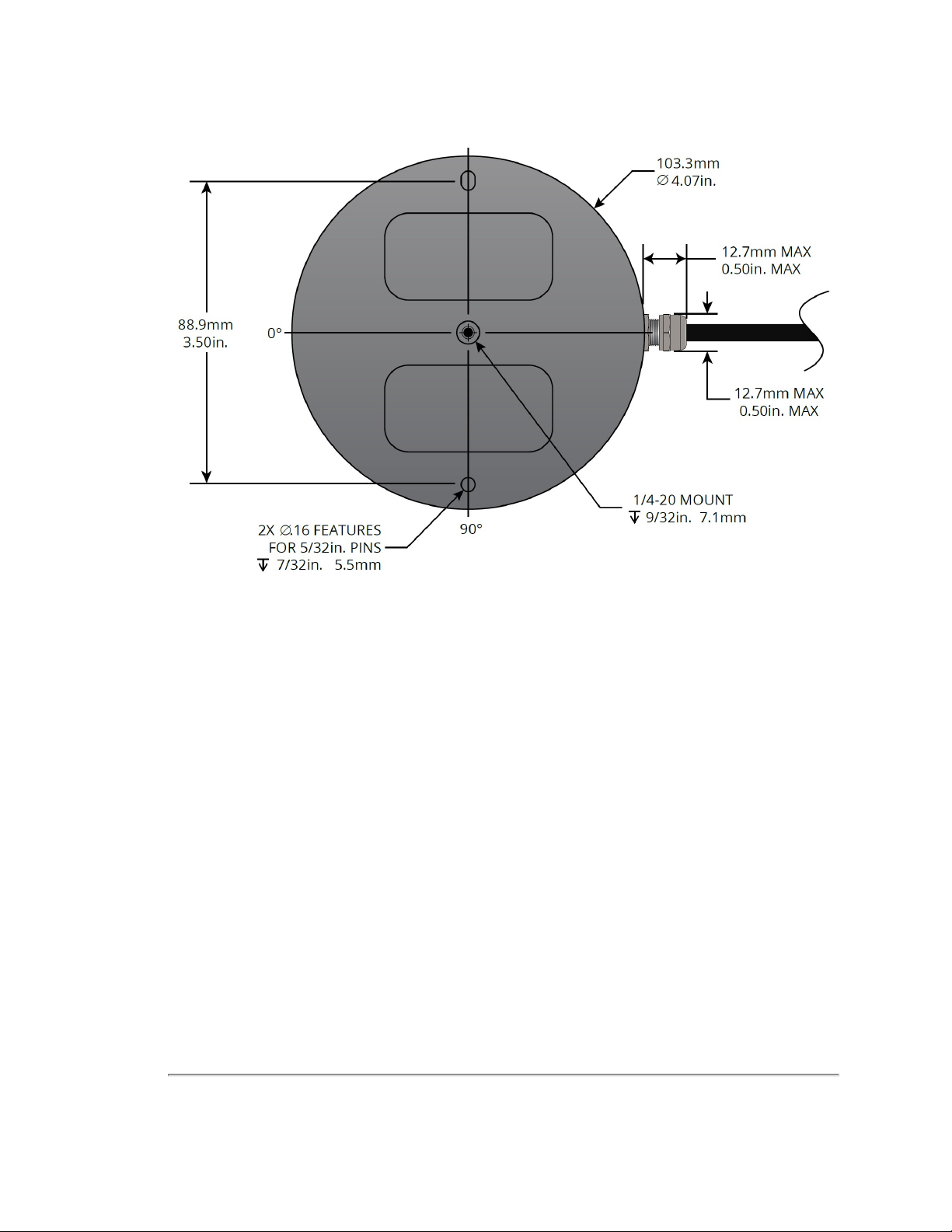

5.2 Mounting

The sensor base provides one ¼”-20-threaded, 9/32"-deep mounting hole, and two precision locating holes for locator

pins (

Figure 5-1 on the next page

best at 0° inclination (i.e. level to ground) as reductions to bearing life may occur at other orientations.

Ensure the sensor is mounted securely to withstand vibration and shock without risk of detachment. The unit does not

need shock proofing. The unit is designed to withstand automotive G-forces (i.e. 500 m/s2 amplitude, 11 ms duration

shock and 3 G

5 Hz to 2,000 Hz vibration).

RMS

Chapter 5 • Installation & Integration 29

). The sensor may be mounted at any angle or orientation, though reliability should be

Figure 5-1 Mounting Details

5.3 Encapsulation, Solar Hats, and Ventilation

For various reasons, you may wish to encapsulate the sensor, either wholly or partially. The working field of view, if

covered with transparent material, should be highly transmissive of near-IR light at and near the 903 nm wavelength. Any

moisture that enters should have a way to drain passively.

The VLP-16 generates a moderate amount of heat during normal operation. Strategies for managing heat in hot weather

include employing a "thermal hat," exposing the sensor to moving air, and drawing heat from the sensor with a heat sink

(e.g. aluminum plate(s)).

The sensor reports internal temperatures passively on its web interface. The same readings may be obtained programmatically via curl commands (i.e. http GET requests). See

sensor's operating temperature range can be found on its data sheet.

Do not operate the sensor without sufficient ambient air flow or cooling.

Sensor Communication on page 68

for details. The

5.4 Connections

This section covers the sensor’s physical connections.

See

Network Considerations on page 135

work. See

nection.

Ethernet and Network Setup on page 134

before connecting one or more Velodyne LiDAR sensors physically to your net-

for instructions on how to configure the sensor's Ethernet con-

30 VLP-16 User Manual

Loading...

Loading...