Page 1

5

0KI10KI10COUSMOGE

A

E

A

-

A

G

A

T

M

R

S

A

E

A

L

R

T

A

G

T

4

4

000

1

-PC G

T DE G

-DELI

T DE G

-TLG.

NJUN

10

RAGE

ARAGE

E GAR

ARAJE

UTOW

O PAR

ET

10 PCS

GESET

10 UDS

RKST

GARA

.

TT-SET

EM 10

PCS

ER MAN

DE D’E

BRUIKE

M

NUAL D

B

DIENUN

M

NUAL D

UAL

PLOI

SHAND

EL USUA

GSANLEI

O UTILIZ

EIDING

IO

UNG

ADOR

11

1

18

21

7

Page 2

5000-10

V. 02 – 08/11/2012 2 ©Velleman nv

Page 3

5000-10

V. 02 – 08/11/2012 3 ©Velleman nv

Page 4

.

t

.3.

o

t

.

w

t

e

e

e

a

m

e

m

d

u

d

r

t

t

e

a

t

d

u

g

s

o

n

s

t

t

h

r

c

o

d

S

o

s

r

f

e

f

k

t

c

k

k

o

a

y

p

e

o

r

n

v

u

e

e

d

i

e

y

e

f

h

a

d

s

v

p

v

u

e

a

s

s

d

v

v

c

n

e

a

n

a

d

s

N

u

e

d

w

t

c

w

t

m

o

k

e

h

r

b

a

e

e

m

t

y

d

e

o

a

t

o

a

l

r

b

c

n

a

s

o

m

h

n

s

p

a

o

n

e

i

c

a

r

r

p

r

p

n

d

u

e

a

e

n

n

c

5000-10

1

Intr

Th

ank you for

An

yone using

de

scribed in it

If

he device

2

Safe

duction

choosing P

his device

as damage

y Instr

Keep the

working a

Only use

weight of

exceed th

Inspect th

cracked p

parts.

When the

dealer for

Only use

frame an

user man

supportin

Incompati

Jack

This devic

must be

Never w

Jack sta

Always u

of gravity

Do not u

building s

rel!

ust fully r

in transit,

ctions

evice out o

ea during u

he jack/jac

he jack/jac

indicated l

e device(s)

rts) is noti

jack or jac

inspection.

he jack/jac

/or underb

al that cam

points.

bility may c

e is for lifti

upported b

rk under or

d

se a single

is in betwe

e the jack

ructure… o

USE

ad and und

do not insta

reach of c

se.

stands on

k stands an

oad limit.

for damage

ed. Contact

stand was

stands on

dy are com

e with the

use struct

ng purpos

a pair of j

near a load

air of jack

n the stand

r jack stan

to move a

R MA

rstand this

ll or use it a

ildren and

flat and st

its load. N

before each

your local

ubjected to

ehicles of

atible with

ehicle to de

ral damage

s only. On

ck stands

that is only

tands with

. Be extre

for continu

ehicle.

UAL

manual and

nd contact

nauthorize

ady surfac

ever use th

use. Do n

ealer for sp

a shock loa

hich the lif

the saddle

ermine loc

to vehicle a

e the vehic

ith the app

supported

he same sp

ely careful

us support

comply wit

our dealer.

users. Do

that is cap

e jack/jack

t use when

re parts. O

d, stop usin

points and

f the jack o

tion and ty

nd/or jack/j

e is lifted t

opriate rati

y this devic

ecifications

when using

e.g. to leve

all safety

ot let them

able of sup

tands on a

damage (b

nly use orig

g it and con

supporting

r jack stand

e of lift poi

ck stand.

the desire

g.

.

and make s

on 3 wheel

l a trailer, c

egulations

enter the

orting the

slope or

oken, bent,

inal spare

tact your lo

oints on

. Check the

ts and

height it

re the cent

d vehicles.

mper,

al

re

Gen

Re

fer to the V

•

Familiaris

•

Only use t

warranty.

Damage c

•

dealer will

•

Keep this

Use the ja

Do not at

supported

Always c

Make su

All modifi

modificati

ral Gui

lleman®

yourself wi

he devices f

used by di

not accept

anual for

ck stands o

empt to mo

by the jack

ock wheels

e the area

ations of th

ns to the d

elines

ervice an

th the funct

r their inte

regard of c

esponsibilit

uture refere

ly if their h

e the vehi

or jack sta

that are in

nder the v

device(s)

vice(s) is

Quality W

ons of the

nded purpo

rtain guidel

for any en

nce.

eight is loc

le and nev

ds.

contact wit

hicle is clea

re forbidde

ot covered

rranty on

evice befor

e. Using th

ines in this

suing defec

ed properly

r enter or

the floor i

before low

n for safety

y the warr

the last pag

actually u

devices in

anual is n

s or proble

by the hold

limb on the

both dire

ering.

reasons. D

nty.

es of this m

ing it.

an unautho

t covered b

s.

ng lever.

vehicle whil

tions.

mage caus

anual.

ised way wi

y the warra

e it is

d by user

ll void the

ty and the

V.

02 – 08/11/2

012

4

©Vellema

nv

Page 5

.

.

ABCDE

1

a

a

.

1Be

a

o

o

o

u

a

h

r

h

t

r

g

l

s

s

e

wFai

h

g

e

h

d

o

e

v

c

a

a

a

p

e

j

h

h

o

e

e

l

s

e

f

t

e

o

f

v

h

d

H

l

s

s

t

t

w

r

a

a

i

r

e

o

d

s

,

s

v

t

c

v

d

r

n

r

n

h

h

o

d

e

o

f

a

t

g

s

r

p

p

n

u

m

b

R

t

a

u

d

a

e

v

g

e

r

e

u

v

2

)

d

e

s

a

a

a

a

s

n

o

e

e

t

t

a

n

h

.

p

s

s

w

t

t

b

p

t

e

t

n

h

y

4

Feat

•

2-tonnes t

•

2 x 2-ton

•

car creepe

•

lug wrenc

•

square oil

•

oil filter w

•

2 wheel c

•

magnetic

5

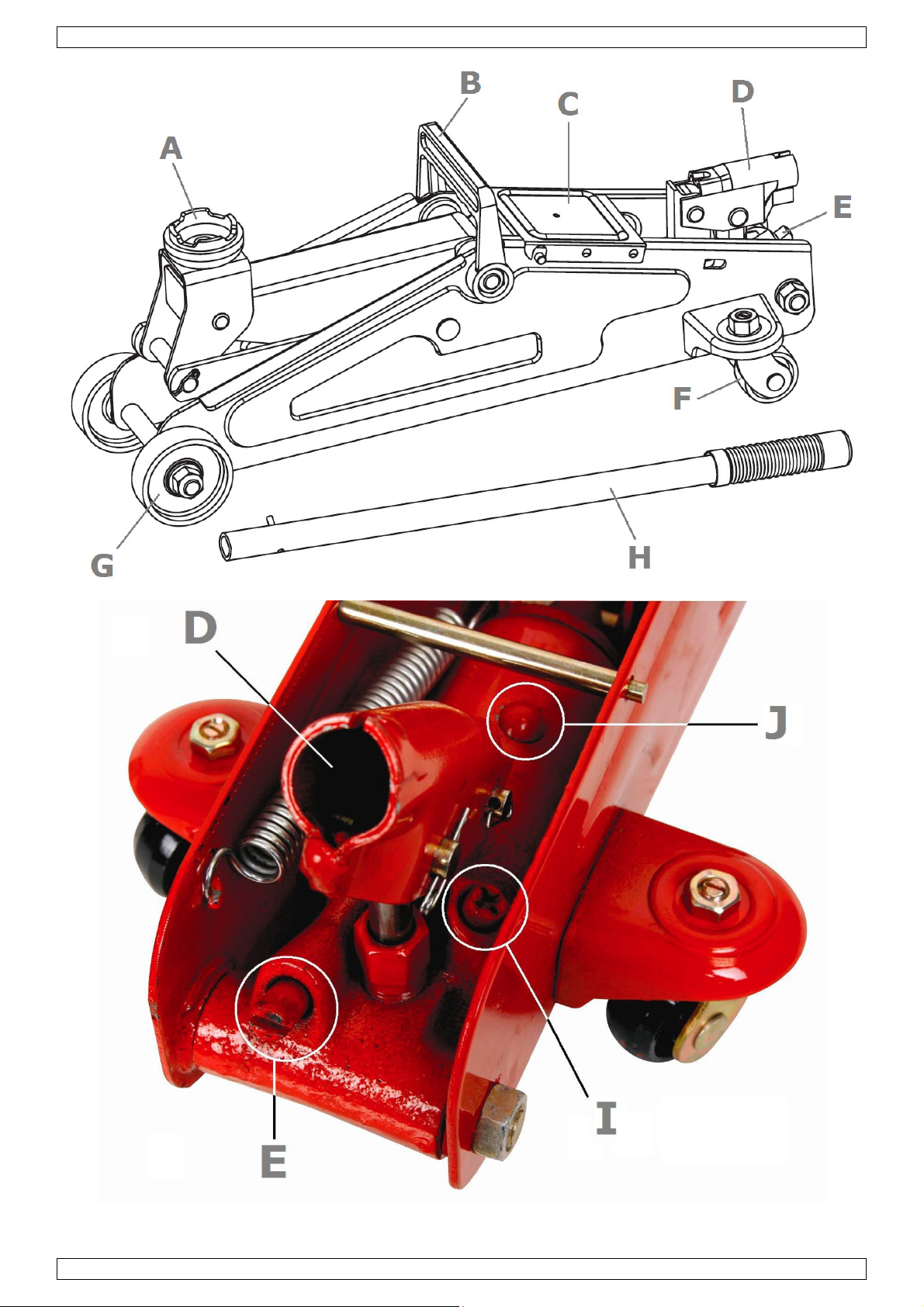

Ove

Re

fer to the ill

Ja

ck

saddle

carryin

cover p

handle

release

Ja

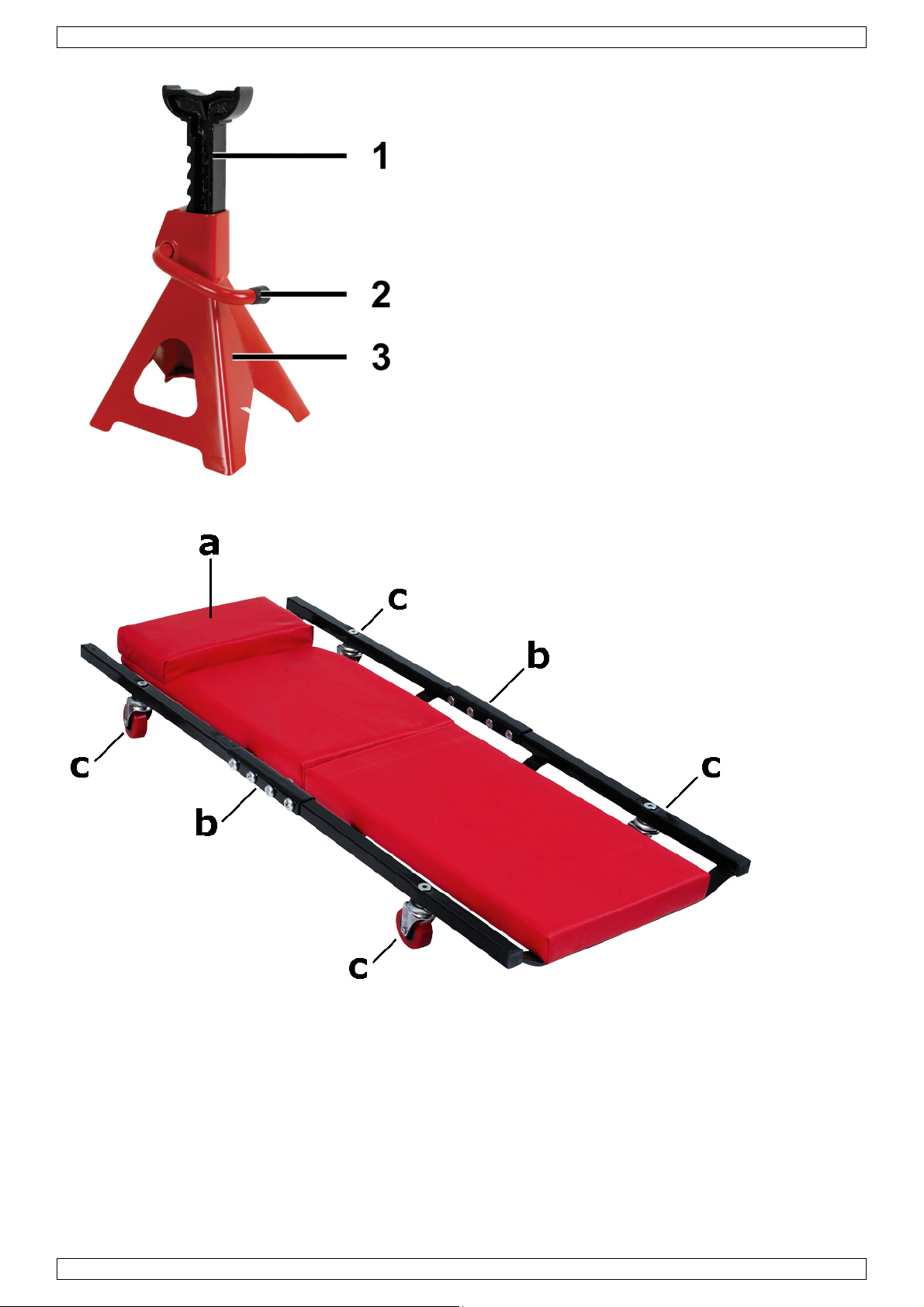

ck stand

post +

C

r creeper

Head r

res

rolley jack

xle stands

r 36"

14"

drip tray

ench

ocks

ray.

view

ustrations o

handle

ate

ocket

valve

addle

st

n pages 2 a

nd 3 of this

5000-10

manual.

F

G

H

I

J

2

3

b

c

rear casto

front whe

handle

overload v

oil filler pl

holding le

base

coupling (

castor (4x

l

alve (do no

g

er

x)

adjust!)

6

Use

6.

Jack

fore use

is possible t

It

m

lfunctionin

1.

Turn the r

Note: the

Remove t

2.

Insert the

3.

socket an

Quickly pu

4.

Close the

5.

te: the ove

N

T

raise a ve

Turn the r

1.

2.

Place the

remain in

Locate the

3.

with the s

structural

Note: alw

Insert the

4.

that the s

Continue

5.

the vehicl

When the

6.

rests on t

T

lower the

1.

Remove t

counter-cl

Note: wh

For storag

2.

Al

rload valve

hicle

damage to

ays comp

lure to do

at during s

.

lease valv

open end o

e cover pla

handle [H]

twist the h

mp 6~8 full

il filler plug

lease valv

ehicle in ge

ontact with

lift points

ddle [A] o

ys centre t

handle [H]

ddle [A] is

umping the

by a pair o

ack stands

e jack stan

vehicle

e handle [

ckwise.

n the vehic

, close the

y with the

o may re

hipment of

[E] 1 turn

the handle

e [C], loca

into the soc

andle clock

strokes to

[J] and pl

[I] is calibr

[E] clockw

ar (or in Pa

the floor in

f the vehicl

the jack. D

ehicle and/

e load on t

into the soc

centred an

handle [H]

f jack stand

are in place

s.

] from the

e is on jack

release val

safety ins

ult in seve

he device a

counter-clo

[H] can be

e and remo

ket [D]; sli

ise to secu

emove air i

ce the cove

ted to 2 to

se until it is

k (P) for ve

both directi

(refer to t

o not use t

r jack.

he saddle t

ket [D] an

good conta

until the v

. Never w

lower the

ocket [D]

stands, firs

e by turnin

ructions a

re injury o

ir gets trap

kwise and

used to tur

e the oil fill

e the protr

e it.

the syste

plate [C]

nes. NEVE

closed tigh

hicles with

ons.

e vehicle’s

e jack if sa

avoid dam

pump until

ct with the l

hicle is rais

rk under a

loor jack sli

nd use the

lift the veh

it complet

describe

death.

ed inside th

ush the sad

the releas

er plug [J].

sion of the

.

ack.

adjust thi

ly.

utomatic tr

ser manual

dle and lift

ge to the j

the jack is

ift point is

d to the de

ehicle that

htly (see i

open end t

icle until th

ly clockwis

in §2.

e hydraulic

dle [A] all

valve.

handle into

overload v

nsmission)

) and make

points are

ck.

lmost touc

ssured.

ired height

is only sup

structions b

turn the re

jack stand

.

system cau

he way do

the slot on

lve [I].

and chock

sure they a

ot compati

ing the lift

Immedia

orted by th

elow) until

lease valve

can easily

ing

n.

op of the

he wheels t

re compatib

le to avoid

oint. Verif

ely support

floor jack!

he vehicle

[E] slowly

be removed

at

le

.

V.

02 – 08/11/2

012

5

©Vellema

nv

Page 6

5000-10

6.2 Jack stand

1. Insert the post [1] into the base [3].

2. Turn the holding lever [2] upwards, set the post at the appropriate height, and turn the holding lever down

again to secure the post. Never use the jack with the holding lever upwards and always set both stands to

the same height!

3. Repeat above procedure for the second stand. The second stand must be set to the same height as the

first.

4. Lift the vehicle by means of a suitable jack.

5. Locate the supporting points of the vehicle (refer to the vehicle’s user manual) and make sure they are

compatible with the saddle of the jack stand. Do not use the jack stand if saddle and supporting points are

not compatible to avoid structural damage to vehicle and/or stand.

6. Position the jack stands under the vehicle, saddles lined up with the supporting points. All supports of the

stand must make full contact with the surface. Make sure the surface is strong enough to carry the weight

of the stand and its load; never use the stands on a slope.

7. Slowly lower the vehicle onto the jack stands. Check again to make sure that they are positioned correctly

before completely lowering the vehicle.

8. Remove the jack.

9. Gently rock the vehicle in all directions to make sure the vehicle is stable and jack stands are applied

correctly.

10. When finished working, clear the area under the vehicle and lift the vehicle with a suitable jack so the jack

stands can be removed.

11. Lower the vehicle onto its wheels.

6.3 Car creeper

1. Slide the couplings [b] over the frame of the car creeper (opposite side of the head rest [a]). Align the

holes in the couplings and the frame and insert the included bolts (2 per coupling). Tighten the nuts.

2. Slide the other part of the car creeper into the couplings, insert the included bolts (2 per coupling) and

tighten the nuts.

3. Mount the 4 castors [c]; refer to the image on page 2 for their location.

7. Care and maintenance

1. When the jack is not in use or for storage, lower the saddle completely to prevent corrosion. Always store

the floor jack in a horizontal position to avoid oil leakage.

2. Keep the jack and jack stands clean and keep all moving parts well lubricated. Remove excessive grease

and dirt from the outside.

3. The jack contains about 7 fl.oz (± 210 ml) oil (SAE5W). To check the oil level, lower the saddle [A]

completely and open the oil filler plug [J] under the cover plate [C]. Add oil when the oil level is

½" (12 mm) under the plug hole.

4. The oil should be replaced once a year. To replace the oil, open the oil filler plug [J] and remove the

release valve [E] completely by turning it counter-clockwise. Be careful not to contaminate the inside of

the hydraulic system! Remove and refill via the oil filler plug hole.

Notes:

o Use of improper oil or other fluids can cause serious damage to the internal parts of the jack!

o Take appropriate safety measurements when handling oil.

o Dispose of used oil in accordance with local regulations.

5. Re-install and close the release valve [E] completely.

6. Pull the saddle [A] all the way up, then open the release valve [E] to lower the saddle. Force the saddle to

lower faster. Close the release valve [E] and repeat this procedure a couple of times to ensure proper oil

distribution.

8. Troubleshooting

Jack will not raise / lift load / lift load to full height

Jack lowers under load

• The weight of the load is higher than 2 tonnes. Use a suitable jack.

• The release valve is open. Close it tightly by turning it clockwise. Check whether dirt prevents the release

valve to be closed completely. Remove the release valve and clean it.

• Check the oil level and add/replace oil when necessary (see §7).

• Remove air from the hydraulic system (see §6.1: Before use).

• If the above steps do not solve the problem, there is something wrong with the hydraulic system itself.

Contact your local dealer for service and support.

Jack will not lower

• When there is a load on the jack and it will not lower, remove the load by carefully lifting it with a second

jack.

• Never apply excessive force (e.g. use a hammer) on the saddle to lower it.

• Check the spring that pulls the lifting arm down. Replace when broken or re-attach when loose.

V. 02 – 08/11/2012 6 ©Velleman nv

Page 7

e

n

.

jac

tcaplenwe

s

h

resor

.

o

.

b

s

r

m

d

o

r

t

t

H

w

o

m

s

o

e

h

d

e

m

h

y

a

e

g

v

–

p

v

e

m

e

h

c

t

s

c

e

e

e

c

,

e

u

n

n

w

R

s

t

l

s

m

o

s

m

t

s

y

d

n

t

t

h

t

m

m

o

l

m

i

p

h

t

d

d

6

h

o

a

6

y

t

l

c

t

E

e

g

v

s

u

e

e

y

e

r

m

e

e

e

t

s

d

e

)

n

n

h

s

s

,

M

i

s

o

n

h

e

d

d

s

a

e

u

e

t± 1

t

F

b

y

c

o

c

N

r

g

e

r

U

e

e

e

n

t

7

t

t

h

e

n

t

t

s

n

e

r

a

o

r

o

n

s

i

n

r

r

u

e

e

m

i

s

n

t

u

p

c

g

n

n

h

m

o

r

s

e

g

t

•

Check the

•

Dirt may

•

Remove ai

•

Make sure

W

ak lifting

•

This is po

•

Close the

closed co

•

Remove ai

U

loaded sa

Re

move air fr

9

Tech

oil level – t

lock the rel

r from the

the system

sibly cause

elease valv

pletely. Re

r from the

dle slowl

m the hydr

nical sp

o much oil

ase valve.

ydraulic sy

is sufficient

by dirty oil

tightly by

ove the re

ydraulic sy

moves up

ulic syste

cificati

ill block th

emove an

tem (see §

ly greased.

– replace t

urning it cl

ease valve

tem (see §

(see §6.1:

ns

5000-10

e hydraulic

clean it an

.1: Before

e oil (see §

ckwise. Ch

nd clean it.

.1: Before

Before use

ystem.

replace th

use).

7).

ck whether

use).

.

oil (see §

dirt preven

).

s the relea

e valve to b

e

k

lif

ing range

acity

gth

ight

U

e this devi

of

damage o

pr

oduct and

T

e informa

©

COPYRIG

erved. No

otherwise

1

Intr

N

us vous re

To

ute personn

da

ns celle-ci.

Si

l’appareil a

2

Con

135 –

2 tonn

54 cm

± 9 k

ce with ori

injury res

he latest

ion in this

T NOTICE

part of this

ithout the

duction

ercions de

e utilisant c

été endom

ignes d

335 mm

es

ginal acce

ulting fro

ersion of

manual is

The copy

manual ma

rior written

otre achat

t appareil

agé penda

sécuri

sories onl

(incorrec

his manua

ubject to

right to thi

be copied,

consent of

MOD

!

oit impérati

t le transpo

é

jack sta

height

capacity

weight

. Vellema

) use of t

, please vi

hange wit

s manual i

reproduced

he copyrigh

D’E

vement lire

rt, ne pas l’

d

11

2

nv canno

is device.

it our we

hout prior

owned b

translated

t holder.

PLOI

cette notice

nstaller et

fixed heigh

onnes

.6 kg (eac

be held r

or more i

site www.

notice.

Velleman

or reduced

au préalabl

onsulter vo

s (± 250 –

)

sponsible

fo concer

perel.eu.

nv. All wo

o any elect

e et suivre l

re revende

410 mm)

n the eve

ing this

ldwide rig

onic mediu

es instructi

r.

t

ts

ns

Garder ho

de travail.

N’utiliser l

cric/des c

le/les sur

Inspecter

présentan

pièces de

chandelle

une inspe

N’utiliser l

compatibl

détermin

le véhicul

Cric

N’utiliser

souhaitée

jamais tra

Chandell

Toujours

que le ce

précautio

Ne pas uti

caravane)

rs de la por

e cric/les ch

andelles et

harger.

le cric/les c

des endo

rechange et

après un i

tion approf

e cric/les ch

avec la se

r l’emplace

et/ou le cr

e cric que

il doit être

vailler sous

s

tiliser les c

tre de gravi

en utilisan

liser le cric/

ou pour le

ée des enfa

andelles qu

de sa char

andelles a

magement

n’utiliser q

pacte trop

ndie.

andelles qu

le du cric/d

ent et le t

c/les chand

our souleve

soutenu pa

ou à proxi

andelles pa

té se situe

des chand

les chandell

éplacemen

nts et des p

sur une su

e. Ne jamai

ant chaque

visibles. C

e des pièce

violent. Co

sur un vé

s chandelle

pe du point

lles.

r le véhicul

deux chan

ité directe

r paire. S’a

xactement

lles sur des

s pour un l

d’un véhic

ersonnes n

rface stable

utiliser le

utilisation.

ntacter vot

s de rechan

tacter votr

icule ayant

s. Se référe

de levage.

. Une fois l

elles pouva

’un véhicul

surer qu’ell

u centre e

véhicules à

vage/main

le.

n autorisée

capable de

ric/les cha

e pas utilis

e revendeu

e d’origine.

revendeur

un point de

à la notice

ne incomp

véhicule s

nt supporte

qui n’est s

s aient les

tre les cha

trois roues.

ien continu

. Interdire l

supporter l

delles sur u

r un cric/d

r pour com

Ne pas util

pour le/les

levage/mai

du véhicule

tibilité peu

ulevé à la h

le poids d

ulevé que

mêmes spé

delles. Proc

(p.ex. leva

’accès à l’ai

poids du

ne pente ni

s chandelle

ander des

ser le cric/l

oumettre à

tien

pour

endomma

auteur

véhicule. N

ar ce cric.

ifications e

der avec

e d’une

e

s

er

e

V.

02 – 08/11/2

012

7

©Vellema

nv

Page 8

.

.

.

ABCDE

h

1

h

a

.

1

v

s

c

a

r

e

e

r

h

d

é

r

m

c

e

u

e

s

s

t

l

,

o

e

c

s

s

c

e

d

é

gé

d

a

q

n

e

q

t

i

s

r

e

n

c

u

n

e

C

h

f

s

m

m

à

e

e

l

2

s

v

u

r

r

e

t

j

d

e

s

t

p

n

é

l

t

é

é

e

[

o

e

j

e

y

i

e

t

n

n

o

h

u

e

u

v

é

t

i

e

e

r

r

l

r

o

u

d

e

j

4

e

t

J

v

c

b

e

q

e

)

e

y

J

é

o

u

g

c

t

î

a

A

n

/

r

5000-10

3

Dire

Se

reporter à l

•

Se familia

•

N’utiliser l

•

La garanti

votre reve

•

Conserver

Utiliser le

de verroui

Ne pas dé

chandelle

Toujours

Veiller à c

Toute mo

occasionn

tives

garantie

iser avec le

cric/les ch

ne s’appli

ndeur décli

cette notic

chandelles

llage.

placer le vé

.

aler l’avant

que la sur

ification de

s par des

nérales

e service

fonctionne

ndelles qu’

ue pas aux

era toute r

pour toute

uniquemen

icule et ne

et l’arrière

ace sous le

appareils

odification

et de quali

ent des ap

sa fonctio

dommages

sponsabilit

référence u

si les haut

amais entr

es roues a

véhicule so

st interdite

aux appar

é Vellema

areils avan

prévue. U

survenus e

pour les pr

térieure.

urs sont co

r dans le v

ant contact

t libre avan

pour des ra

ils par le cli

n® en fin d

de l’utilise

usage imp

négligeant

blèmes et

rrectement

hicule lorsq

avec le sol.

de baisser

sons de sé

nt, ne tom

notice.

.

opre annul

certaines di

es défauts

errouillées

u’il est plac

le véhicule.

urité. Les d

ent pas so

d'office la

rectives de

ui en résul

par la poign

sur le cric

mmages

s la garanti

arantie.

ette notice

ent.

ée

les

e.

et

4

Cara

•

cric de ga

•

paire de c

•

brancard

•

clef en cro

•

bac récup

•

clef de filt

•

2 cales de

•

récipient

5

Des

Se

référer aux

ic

Cr

selle

poigné

couverc

prise d

valve d

C

andelle

tige de

C

ariot de vi

appuie-

6

Emp

ctéristi

age hydraul

andelles 2

e montage

ix ± 35 cm

rateur d'hu

e à huile

roue

agnétique.

ription

illustration

de transpo

le

levier

relâcheme

upport + s

ite

ête

oi

ues

ique 2 tonn

onnes

± 92 cm

le rectangu

en pages

t

nt

lle

s

aire

et 3 de ce

te notice.

F

G

H

I

J

2

3

b

c

roulette a

roulette fr

levier

valve de s

capuchon

poignée d

base

pièces de

roulette (

rière

ntale

rcharge (n

u réservoir

verrouillag

onction (2x

x)

pas modifi

d’huile

e

r !)

Su

ivre les co

Le

non-respe

6.

Cric

A

ant de pro

Il

e peut que

en

travant le b

1.

Tourner la

Remarqu

2.

Retirer le

V.

02 – 08/11/2

céder à to

pendant le

n fonction

valve de re

: Utiliser l

ouvercle [

012

signes de

t des con

te tentati

transport d

ement du c

lâchement [

bout ouve

] et déviss

sécurité d

ignes de s

e de levag

cric, de l’a

ic.

E] 1 tour v

t du levier

r le capuch

crite au c

curité pe

e

ir se soit int

rs la gauch

H] pour to

n du réser

8

apitre §2.

t causer d

roduit à l’in

et enfonce

rner la valv

oir d’huile [

s blessur

érieur du s

r entièreme

e.

].

s ou entra

stème hydr

nt la selle [

ner la mo

ulique

].

©Vellema

t.

nv

Page 9

5000-10

3. Insérer le levier [H] dans sa prise [D] et tourner le levier dans la prise pour le fixer.

4. Actionner le levier rapidement 6 à 8 fois pour faire évacuer l’air du réservoir.

5. Refermer le réservoir avec le capuchon [J] et replacer le couvercle [C].

Remarque : La valve de surcharge [I] peut supporter 2 tonnes. Ne jamais ajuster cette valve [I].

Levage d’un véhicule

1. Tourner la valve de relâchement [E] vers la droite jusqu’à ce qu’il soit bien fermé.

2. Enclencher la première vitesse (ou P pour un véhicule à boîte automatique) et caler l’avant et l’arrière des

roues ayant contact avec le sol dans les deux directions.

3. Placer le cric sous le véhicule de façon à ce que la selle [A] soit en contact solide avec le point de levage

(se référer à la notice d’entretien du véhicule en question). Ne pas utiliser le cric si la selle [A] et le point

de contact ne sont pas compatibles.

Remarque : Veiller à ce que la selle [A] soit bien centrée afin d’éviter d’endommager le cric.

4. Insérer le levier [H] dans la prise [D] et l’actionner jusqu’à ce que la selle [A] se rapproche du point de

levage. Revérifier le bon positionnement du cric.

5. Continuer à actionner le levier [H] jusqu’à ce que le véhicule soit à la hauteur requise. Installer

immédiatement les chandelles de capacité appropriée. NE JAMAIS SE GLISSER SOUS LE VÉHICULE

LORSQUE CELUI-CI N’EST SOUTENU QUE PAR LE CRIC !

6. Une fois les chandelles placées sous le véhicule, abaisser légèrement le cric (voir les instructions ci-

dessous) jusqu’à ce que le véhicule repose sur les chandelles.

Abaissement du véhicule

1. Retirer le levier [H] hors de la prise [D] et tourner la valve de relâchement [E] vers la gauche avec le bout

ouvert du levier.

Remarque : Soulever légèrement le véhicule lorsque celui-ci repose encore sur les chandelles.

2. Refermer la valve de relâchement en le tournant entièrement vers la droite avant de stocker le cric.

6.2 Chandelles

1. Insérer la tige de support [1] dans la base [3].

2. Tourner la poignée de verrouillage [2] vers le haut, régler la tige de support à la hauteur appropriée, et

tourner la poignée de verrouillage de nouveau vers le bas pour sécuriser la tige.

chandelle avec la poignée de verrouillage dirigée vers le haut et toujours régler les deux chandelles à la

même hauteur !

3. Répéter cette procédure pour la deuxième chandelle. Choisir la même hauteur pour les deux chandelles !

4. Soulever le véhicule à l’aide d’un cric adapté.

5. Localiser les points de maintien du véhicule (se référer à la notice du véhicule) et veiller à ce que la selle

des chandelles soit compatible avec le point de maintien. Ne pas utiliser des chandelles non adaptées aux

points de maintien. Une incompatibilité peut endommager le véhicule et/ou les chandelles.

6. Placer les chandelles sous le véhicule, la selle de chaque chandelle alignée avec son point de maintien.

Veiller à ce que la chandelle soit fixement posée sur le sol dur et plat, et à ce que le sol puisse supporter le

poids des chandelles et de la charge.

7. Abaisser légèrement le véhicule tout en vérifiant que les chandelles soient dûment positionnées. Enfin,

abaisser le véhicule jusqu’à ce que repose entièrement sur les chandelles.

8. Retirer le cric.

9. Vérifier que le véhicule soit fixement posé sur les chandelles en le bougeant délicatement.

10. Pour retirer le véhicule des chandelles, libérer la surface sous le véhicule et soulever légèrement le véhicule

avec le cric. Retirer les chandelles.

11. Abaisser entièrement le véhicule et retirer le cric.

6.3 Chariot de visite

1. Faire glisser les pièces de jonction [b] sur le cadre du chariot (du côté opposé de l’appuie-tête [a]). Aligner

les trous des pièces de jonction avec ceux du cadre et insérer les boulons inclus (2x par pièce de jonction).

Serrer les boulons.

2. Insérer l’autre partie du chariot dans les pièces de jonction et insérer les boulons inclus (2x par pièce de

jonction). Serrer les boulons.

3. Monter les quatre roulettes [c] ; se référer à l’illustration en page 2.

Ne jamais utiliser la

7. Entretien

1. Baisser entièrement la selle [A] avant de stocker le cric afin d’éviter tout risque de corrosion. Stocker le

cric dans une position horizontale pour éviter les fuites d’huile.

2. Veiller à maintenir le cric/les chandelles propres et suffisamment lubrifiés. Nettoyer graisse et saleté

excessives.

3. Le réservoir contient environ 210 ml d’huile (SAE5W). Vérifier le niveau en abaissant la selle [A]

entièrement et en dévissant le capuchon [J] sous le couvercle [C]. Rajouter une petite quantité d’huile dès

que le niveau est à 12 mm sous l’ouverture.

V. 02 – 08/11/2012 9 ©Velleman nv

Page 10

5000-10

4. Vidanger l’huile une fois par an : Dévisser le capuchon [J] et retirer la valve de relâchement [E] en veillant

à ne pas contaminer l’intérieur du système hydraulique. Déverser la totalité du réservoir et remplir par

l’orifice de remplissage [J].

Remarque :

o L’utilisation d’une huile non conforme peut endommager le système interne du cric !

o Manipuler l’huile en respectant toute consigne de sécurité.

o Jeter l’huile usagée selon la règlementation relative à la protection de l’environnement.

5. Refermer complètement la valve de relâchement [E].

6. Soulever complètement la selle [A] et ouvrir la valve de relâchement [E] afin que la selle s’abaisse.

Appuyer sur la selle pour qu’elle s’abaisse plus rapidement. Refermer la valve de relâchement [E] et

répéter cette procédure à plusieurs reprises pour assurer une bonne distribution de l’huile.

8. Solution de problèmes

Impossible de remonter le cric/soulever une charge/ soulever une charge à hauteur maximale

Le cric s’abaisse sous le poids de la charge

• Le poids de la charge excède la capacité du cric. Utiliser un cric approprié.

• La valve de relâchement est ouverte. Refermer la valve. S’assurer qu’aucune impureté n’empêche la

fermeture complète de la valve. Le cas échéant, retirer la valve et la nettoyer.

• Inspecter le niveau de l’huile et rajouter une petite quantité si nécessaire (voir §7).

• Retirer l’air du système hydraulique (voir §6.1).

• Contacter votre revendeur si, malgré les solutions proposées, votre cric ne fonctionne pas.

Le cric ne s’abaisse pas

• Soulever la charge posée sur le cric défectueux à l’aide d’un second cric.

• Ne jamais appliquer une force excessive (p.ex. à l’aide d’un marteau) sur la selle.

• Vérifier l’état du ressort maintenant le bras de levage. Remplacer un ressort défectueux ou refixer au cric.

• Vérifier le niveau d’huile. Une quantité excessive d’huile dans le réservoir peut bloquer le système

hydraulique.

• Valve de relâchement bloquée par des impuretés. Nettoyer la valve et remplacer l’huile (voir §7).

• Retirer l’air du système hydraulique (voir §6.1).

• S’assurer d’un bon graissage du cric.

Force de levage insuffisante

• Huile impure. Remplacer l’huile dans le réservoir (voir §7).

• Refermer la valve de relâchement. S’assurer qu’aucune impureté n’empêche la fermeture complète de la

valve. Le cas échéant, retirer la valve et la nettoyer.

• Retirer l’air du système hydraulique (voir §6.1)

La selle déchargée se soulève automatiquement

Retirer l’air du système hydraulique (voir §6.1).

9. Spécifications techniques

cric chandelles

hauteur de levage 135 – 335 mm hauteur 11 hauteurs fixes (± 250 – 410 mm)

capacité 2 tonnes capacité 2 tonnes

longueur 54 cm poids ± 1,6 kg (par unité)

poids ± 9 kg

N’employer cet appareil qu’avec des accessoires d’origine. La SA Velleman ne peut, dans la mesure

conforme au droit applicable être tenue responsable des dommages ou lésions (directs ou indirects)

pouvant résulter de l’utilisation de cet appareil. Pour plus d’information concernant cet article et la

dernière version de cette notice, visiter notre site web www.perel.eu. Toutes les informations

présentées dans cette notice peuvent être modifiées sans notification préalable.

© DROITS D’AUTEUR – SA Velleman est l’ayant droit des droits d’auteur pour cette notice. Tous

droits mondiaux réservés. Toute reproduction, traduction, copie ou diffusion, intégrale ou partielle, du

contenu de cette notice par quelque procédé ou sur tout support électronique que se soit est interdi te sans

l’accord préalable écrit de l’ayant droit.

V. 02 – 08/11/2012 10 ©Velleman nv

Page 11

.

aLee

e

.3.

w

r

t

g

m

V

e

e

g

n

e

s

e

s

l

m

a

e

e

v

t

e

m

e

l

u

e

e

e

n

o

h

o

c

®

e

o

i

R

e

o

s

i

a

e

e

k

h

n

a

.

u

v

n

n

n

s

e

d

d

R

,

r

i

g

l

/

e

e

a

o

w

e

t

e

e

n

n

a

e

e

a

e

o

e

N

e

h

v

f

v

e

s

e

r

s

t

t

d

t

s

t

a

s

o

l

i

a

g

b

D

n

n

e

x

g

o

d

a

n

t

h

n

m

e

t

n

d

o

c

e

e

d

g

o

k

e

t

c

e

e

f

n

s

w

k

.

r

n

t

e

o

g

e

o

w

G

f

p

k

e

e

o

e

e

n

k

o

e

d

n

d

d

e

p

g

e

b

d

e

5000-10

1

Inlei

D

nk u voor u

s deze han

iligheidsvoo

ve

W

rd het toes

2

Veili

ding

aankoop!

dleiding gro

schriften.

el beschadi

heidsi

Houd buit

werkplaat

Gebruik d

krik/asste

krik of as

Ga voor e

assteun

originele

blootgest

Gebruik d

het zadel

hefpunt/s

ernstig be

Krik

Gebruik d

opgetild,

Werk nooi

Assteun

Gebruik a

zwaartep

assteunen

Gebruik d

camper).

GEB

ndig voor u

d tijdens h

structie

n het berei

waar dit t

krik en as

unen en de

teunen noo

k gebruik n

et zichtbar

ccessoires.

ld werd. Co

krik en de

an de krik/

eunpunt en

schadigen.

krik enkel

oet dit vo

t onder of d

n

tijd een en

nt exact in

gebruikt o

ze krik of

UIKE

het toestel i

t transport

s

k van kinde

estel gebru

teunen enk

last kan dra

t op een he

of de krik

schade. Co

Gebruik ge

ntacteer uw

assteunen

assteun. Ra

zadel niet

om een voe

rtuig door t

irect naast

el paar asst

et midden

der een dri

ssteunen ni

SHA

n gebruik n

installeer

en en onbe

kt wordt.

el op een ef

en. Oversc

lend opper

assteun ge

ntacteer uw

n krik of as

verdeler vo

nkel op vo

dpleeg hie

p elkaar pa

rtuig op te

ee geschik

en voertuig

eunen met

ussen de a

wielig voer

t om een l

DLEI

emt. Volg

et dan niet

oegden. O

en en stabi

hrijd de ma

lak.

n beschadi

verdeler v

teun nadat

or een gron

rtuigen wa

voor de ha

sen, kan di

illen. Eens

e stutten o

dat enkel

ezelfde eig

steunen lig

uig.

st te verpla

ING

auwkeurig

en raadplee

tzeg onbev

l oppervla

imaal toeg

ing vertoon

or reservea

deze aan e

ige control

rvan het he

dleiding va

de krik/as

et voertuig

dersteund

et deze kri

nschappen

. Wees voo

atsen of co

e

g uw dealer

egden de t

dat het ge

laten last n

. Gebruik g

cessoires.

n hevige sc

.

punt/steun

uw voertui

teun en oo

tot de gew

orden.

wordt ond

Zorg ervo

zichtig indi

tinu te ond

egang tot

icht van de

ooit. Plaats

een krik of

ebruik enk

hok

unt past o

g. Indien

uw voertui

nste hoogt

rsteund.

r dat het

n u deze

rsteunen (

e

e

l

v.

Alge

Ra

adpleeg de

•

Leer eerst

•

Gebruik d

•

De garanti

dealer zal

houden.

Bewaar d

•

Gebruik d

vergrend

Verplaats

ondersteu

Plaats ee

Maak het

Om veilig

Schade d

de garanti

ene ri

elleman

de functies

toestellen

e geldt niet

de verantw

ze handleid

assteunen

lingshendel

geen voert

nd is.

wielblokje

ppervlak o

eidsredene

or wijziging

e.

htlijne

service- e

van het toe

nkel waarv

voor schad

ordelijkhei

ng voor ver

enkel indie

ig of kruip

ooraan en

deraan het

mag de g

en die de g

n kwaliteit

tel kennen

oor ze gem

door het n

afwijzen v

ere raadpl

de hoogte

iet in het v

chteraan e

voertuig vr

bruiker gee

bruiker hee

sgarantie

voor u het

akt zijn. Bij

geren van

or defecten

ging.

correct zij

ertuig dat

k wiel dat c

j alvorens h

n wijziginge

ft aangebra

chteraan d

aat gebruik

onoordeelk

epaalde ric

of problem

vergrendel

oor deze kr

ntact heeft

et voertuig

n aanbreng

ht aan de t

handleidin

en.

undig gebru

htlijnen in d

n die hier r

d door de

ik of assteu

met de gro

e laten zak

n aan de t

estellen va

.

ik vervalt d

eze handlei

chtstreeks

en

d.

en.

estellen.

llen niet on

garantie.

ing en uw

verband m

er

e

V.

02 – 08/11/2

012

11

©Vellema

nv

Page 12

.

.

rABCD

E

s

1

o

a

.

1VoOn

pEe

e

n

h

e

9

e

g

e

k

h

c

a

t

t

+

e

r

e

s

n

d

e

D

l

k

n

r

d

o

.

n

g

n

o

k

g

k

]

s

k

r

g

r

t

v

o

n

e

[

k

u

e

h

t

e

h

I

a

t

t

g

s

z

k

t

n

s

d

s

]

a

g

s

o

a

k

a

a

v

o

e

e

e

k

H

C

d

m

l

e

m

f

v

t

r

e

n

e

w

e

k

x

r

[

d

e

r

e

e

o

t

o

d

k

i

b

o

a

e

k

t

i

m

o

r

n

n

e

o

e

m

e

m

p

e

t

j

n

d

e

e

t

t

4

Eige

•

hydraulisc

•

2 assteun

•

rolbed ±

•

kruissleut

•

olieopvan

•

oliefiltersl

•

2 wielblok

•

magnetisc

5

Oms

Ra

adpleeg de

K

ik

zadel

handva

plaat

zitting

ontluch

A

steun

kolom

R

lbed

hoofdst

schapp

e garagekr

n 2 ton

2 cm

l ± 35 cm

bak

utel

en

schaaltje.

hrijvin

fbeeldinge

ingsklep

zadel

un

en

ik 2 ton

op pagina’

s 2 en 3 va

5000-10

deze hand

F

G

H

I

J

2

3

b

c

leiding.

achterste

voorste wi

hendel

overbelast

oliedop

handvat

frame

koppelstu

wieltje (4

ieltje

ltje

ingsklep (n

(2x)

)

oit bijregel

n!)

6

Geb

6.

Krik

or het eer

tlucht voor

1.

Draai de o

Opmerki

Verwijder

2.

3.

Plaats het

4.

Pomp me

5.

Draai de o

O

merking:

n last opti

1.

Draai de o

2.

Zet het vo

contact he

3.

Plaats de

de handlei

zijn.

Opmerki

4.

Plaats het

Controlee

5.

Pomp ver

stutten. W

6.

Eens de st

voertuig v

D

last laten

1.

Verwijder

te draaien

Opmerki

Draai de o

2.

Le

He

ntluchtings

liedop [J] o

ntluchtings

ertuig in ee

ding van he

utten onder

het hendel

ntluchtings

uik

f de veilig

t verwaarl

te gebrui

het eerste

g: Gebruik

e plaat [C

hendel [H]

rdere keren

e overbela

len

eft met de

rik zo onde

g: Zorg er

hendel [H]

of het zade

er tot het v

erk nooit o

lledig op d

zakken

Draai de kl

g: Hef een

heidsinstr

zen van d

ebruik het

lep [E] één

het open ui

en draai d

in zijn zittin

om alle luc

pnieuw vast

tingsklep [

lep [E] naa

ste versnell

rond.

het voertu

voertuig).

oor dat de l

in zijn zittin

l [A] nog s

ertuig op d

der of direc

het voertui

stutten ru

H] uit zijn

ep naar lin

voertuig da

lep volledig

cties zoal

veilighei

ydraulisch

draai naar l

einde van h

oliedop [J

g [D] en dr

t uit het sy

en bevesti

] is ingeste

r rechts en

ing (of P vo

ig dat het z

Gebruik de

st centraal

g [D] en dr

eeds centra

e gewenste

naast een

, laat het v

t.

itting [D]

s.

op stutten

naar rechts

beschrev

sinstructi

ysteem om

inks en dru

et hendel [

los.

ai vast.

steem te ha

de plaat [

ld op 2 ton.

chroef goe

r een auto

del [A] vol

rik niet ind

op het zad

ai vast. Po

l op het he

hoogte staa

oertuig da

ertuig voo

n gebruik h

rust enigszi

alvorens d

n in §2 zo

s kan bles

alle lucht ui

het zadel

] om aan

len.

].

U mag dez

dicht.

atische ve

edig met h

en het zad

l [A] staat

p tot het z

punt komt

t. Zet het v

enkel met

zichtig zak

t open uite

s op zodat

krik op te

gvuldig n

sures of d

t de krik te

A] volledig

e klep te dr

klep nooit

snellingsba

t hefpunt in

l [A] en he

m beschad

adel [A] bij

e staan.

ertuig on

eze krik w

en (zie inst

nde om aa

u de stutte

ergen.

.

dood ver

halen.

naar bened

aaien.

zelf instelle

) en blokke

contact ko

hefpunt ni

ging te ver

na tegen he

iddellijk o

rdt onderst

ucties hiero

de ontluch

kunt verwi

orzaken.

n.

n.

er elk wiel

t (raadple

t compatib

ijden.

hefpunt zi

gepaste

und!

nder) tot he

ingsklep [E

deren.

at

g

l

.

t

]

V.

02 – 08/11/2

012

12

©Vellema

nv

Page 13

5000-10

6.2 Assteunen

1. Plaats de kolom [1] in het frame [3].

2. Draai de vergrendelingshendel [2] naar omhoog, stel de kolom in op de geschikte hoogte, en draai de

vergrendelingshendel opnieuw naar omlaag om de kolom vast te zetten. Gebruik de assteun nooit met de

vergrendelingshendel naar omhoog en stel de beide assteunen altijd in op dezelfde hoogte!

3. Herhaal deze procedure voor de tweede assteun. Stel de kolom van beide assteunen op dezelfde hoogte in!

4. Hef het voertuig met de geschikte krik.

5. Zoek de steunpunten van het voertuig (raadpleeg hiervoor de handleiding van het voertuig) en zorg dat ze

op het zadel van de assteunen passen. Gebruik de assteunen niet indien steunpunt en zadel niet op elkaar

passen. Indien steunpunt en zadel niet op elkaar passen, kan dit de assteun en ook uw voertuig ernstig

beschadigen.

6. Plaats de assteunen onder het voertuig, het zadel van elke assteun onmiddellijk onder zijn steunpunt. Zorg

ervoor dat de assteunen op een hard en egaal oppervlak staan, en dat dit oppervlak het gewicht van de

assteunen en de last kan dragen.

7. Laat het voertuig langzaam zakken en ga na of de assteunen nog altijd onmiddellijk onder elk steunpunt

staan. Laat het voertuig volledig op de assteunen zakken.

8. Verwijder de krik.

9. Controleer of het voertuig stevig op de assteunen staat door het voertuig voorzichtig heen en weer te

schommelen.

10. Maak na de werkzaamheden het oppervlak onderaan het voertuig vrij, hef het voertuig lichtjes met de krik

en verwijder de assteunen.

11. Laat het voertuig volledig zakken en verwijder de krik.

6.3 Rolbed

1. Schuif de koppelstukken [b] over het frame van het rolbed (tegenover de hoofdsteun [a]). Plaats de gaten

van de koppelstukken en van het frame op eenzelfde rij, en steek de meegeleverde bouten (2x per

koppelstuk) in de gaten. Draai de bouten vast.

2. Schuif het andere eind van het rolbed in de koppelstukken. Steek de meegeleverde bouten (2x per

koppelstuk) in de gaten en draai ze vast.

3. Monteer de vier wieltjes [c]; raadpleeg de afbeeldingen op pagina 2.

7. Onderhoud

1. Laat het zadel [A] volledig zakken alvorens de krik op te bergen. Zo vermijdt u corrosie. Berg de krik in

een horizontale positie op om olielekken te vermijden.

2. Maak de krik en de assteunen schoon alvorens hem op te bergen en zorg ervoor dat ze voldoende

gesmeerd zijn. Verwijder overtollig vet en vuil.

3. De krik bevat ongeveer 210 ml olie (SAE5W). Controle van het oliepeil: Laat het zadel [A] volledig zakken

en open de oliedop [J] onder de plaat [C]. Voeg olie toe tot het niveau 12 mm onder de vulopening staat.

4. Ververs de olie een keer per jaar. Om de olie te vervangen, open de oliedop [J] en verwijder de

ontluchtingsklep [E] volledig. Zorg ervoor dat er geen vuil binnenin het hydraulisch systeem valt. Giet de

volledige inhoud in een bak en vul met verse olie via de vulopening.

Opmerking:

o Het gebruik van niet-conforme olie of een andere vloeistof kan het hydraulisch systeem beschadigen!

o Ga voorzichtig met olie om en volg de nodige veiligheidsmaatregelen.

o Giet de oude olie weg volgens de plaatselijke milieuwetgeving.

5. Sluit de ontluchti ngsklep [E] volledig.

6. Hef het zadel [A] volledig op en open de ontluchtingsklep [E] zodat het zadel zakt. Duw het zadel naar

beneden en sluit de ontluchtingsklep [E]. Herhaal om de olie goed in het hydraulisch systeem te verdelen.

8. Probleemoplossing

De krik kan de last niet tillen/kan de maximale hoogte niet bereiken

De krik kan de last niet houden

• De last is zwaarder dan 2 ton. Gebruik een zwaardere krik.

• De ontluchtingsklep is geopend. Sluit de klep. Verwijder alle vuil zodat u de ontluchtingsklep volledig kunt

sluiten.

• Controleer het oliepeil en vervang of voeg olie toe (zie §7).

• Ontlucht het hydraulisch systeem (zie §6.1).

• Contacteer uw verdeler indien de oplossingen hierboven niet helpen.

De krik kan niet helemaal zakken

• Hef de last op de defecte krik met een tweede krik.

• Breng nooit een brute kracht op het zadel aan (bv. met een hamer).

• Controleer de staat van de veer die de hefarm vasthoudt. Vervang indien beschadigd of bevestig opnieuw

aan de krik.

• Controleer het oliepeil. Een overtollige hoeveelheid olie kan het hydraulisch systeem blokkeren.

• De ontluchtingsklep is geblokkeerd door vuil. Verwijder alle vuil en vervang de olie (zie §7).

V. 02 – 08/11/2012 13 ©Velleman nv

Page 14

e

eOn

.

n

ekw

a

l

VeHe

c

.

a

.

o

d

o

n

f

o

i

e

o

R

g

o

e

o

a

n

h

r

g

o

s

g

e

d

a

o

n

a

u

g

o

o

o

o

V

a

e

e

m

n

l

e

e

p

t

i

v

e

h

e

r

A

n

g

s

t

e

a

d

u

m

n

n

b

e

o

s

a

t

s

v

w

a

e

d

L

e

t

l

u

a

d

r

c

e

i

a

o

d

p

e

s

a

e

d

l

m

n

i

n

U

e

a

u

t

d

n

q

o

e

n

o

o

o

v

n

s

m

a

e

v

d

R

s

a

e

e

e

d

h

t

n

u

e

p

e

p

k

c

y

e

o

a

t

h

v

p

ó

m

s

u

4

o

t

n

o

m

h

a

u

e

e

s

h

c

.

a

n

e

s

y

i

a

a

s

y

n

•

Ontlucht h

•

Zorg ervo

D

krik kan

•

Vervuilde

•

Sluit de o

•

Ontlucht h

H

t zadel he

tlucht het h

9

Tech

kr

ik

he

fbereik

he

fvermogen

le

gte

ge

wicht

G

bruik dit t

etsuren b

la

tste versi

al

en tijde w

©

AUTEURS

lleman nv

t is niet toe

be

werken en

re

hthebbend

et hydraulis

r dat de kri

e last niet

lie. Vervan

tluchtingskl

et hydraulis

t zich aut

ydraulisch s

nische

135 –

2 ton

54 cm

± 9 k

estel enk

j (verkeer

van deze

rden gewi

ECHT

heeft het

estaan om

p te slaan

.

ch systeem

k voldoende

volledig ti

de olie (zi

ep. Verwijd

ch systeem

matisch o

ysteem (zie

pecifica

335 mm

l met orig

) gebruik

handleidin

jzigd zond

uteursrec

deze handl

p een elekt

(zie §6.1).

gesmeerd i

len

§7).

r eventueel

(zie §6.1).

§6.1).

ies

nele acces

an dit toe

g, zie ww

r voorafg

t voor dez

iding of ge

onisch med

5000-10

s.

alle vuil zo

assteun

hoogte

hefvermo

gewicht

oires. Vel

stel. Voor

.perel.eu.

ande ken

handleid

eelten erva

ium zonder

at u de ont

11

gen 2 to

± 1,

eman nv i

eer infor

De inform

isgeving.

ng. Alle w

over te ne

oorafgaan

luchtingskle

aste hoogte

6 kg (elk)

niet aans

atie over

tie in dez

reldwijde

men, te ko

e schriftelij

p volledig k

s (± 250 –

rakelijk v

dit produc

handleidi

rechten v

iëren, te ve

e toestem

nt sluiten.

10 mm)

or schade

en de

g kan te

orbehoud

talen, te

ing van de

of

n.

1

Intr

¡G

racias por h

Le

atentame

Si

el aparato

2

Inst

ducció

ber compr

te las instr

a sufrido al

uccione

Mantenga

al lugar d

Utilice los

su carga.

Controle l

distribuid

los aparat

hacerlo c

Utilice los

del gato.

del punto

Gato

Utilice el

altura des

trabaje d

gato.

Caballet

Utilice sie

que el ce

cuidadoso

No utilice

caravana)

M

do el 5000

cciones del

ún daño e

s de se

los aparato

nde está u

aparatos só

Nunca sobr

s aparatos

r si necesit

os después

ntrolar min

aparatos só

éase el ma

de levanta

parato sólo

eada, sosté

bajo de o e

pre los ca

tro de grav

al utilizar l

los aparato

o un despl

NUA

-10!

manual ant

el transpor

uridad

lejos del a

ilizando el a

lo en una s

cargue el g

antes de ca

piezas de

e un impa

ciosament

lo para vehí

nual del usu

iento. Una

para levant

galo con d

los alrede

alletes por

dad se sitú

s caballete

para un m

zamiento d

DEL

s de usarlo

e no lo inst

cance de p

parato.

perficie est

to.

a uso. No

ecambio. U

to demasia

.

culos con u

ario del veh

ncompatibil

r el vehícul

s soportes

ores direct

ar. Asegúr

exactame

en vehícul

ntenimient

un vehícul

SUA

.

le y pónga

rsonas no c

ble capaz d

tilice un ap

ilice sólo pi

o violento.

punto de l

ículo para d

idad puede

o. Después

ue pueden

s de un ve

se de que

te en el ce

s con tres r

/levantami

.

IO

e en conta

apacitadas

e soportar

rato dañad

zas de rec

Contacte co

vantamien

terminar el

añar el ve

de haber le

soportar el

ículo que s

engan las

tro entre lo

edas.

nto continu

to con su di

niños. Pro

l peso de lo

. Contacte

mbio origin

n su distrib

o compatibl

emplazami

ículo y/o lo

antado el v

eso del ve

lo esté leva

ismas espe

s caballetes

o (p.ej. par

stribuidor.

íba el acce

s aparatos

con su

les. No util

idor para

con la sell

nto y el tip

aparatos.

ehículo a la

ículo. Nunc

ntado por e

ificaciones

Sea

levantar u

o

ce

o

te

a

V.

02 – 08/11/2

012

14

©Vellema

nv

Page 15

.

.

.

a

A

B

CDE

a

1

a

a

.

1An

d

m

e

o

m

b

m

u

e

n

u

m

c

r

d

a

c

g

imu

o

s

v

a

e

c

i

e

e

e

o

o

u

e

d

9

a

e

á

t

c

u

i

a

e

e

l

a

s

d

o

d

t

d

a

e

s

d

a

a

r

d

c

m

a

d

u

ú

e

o

t

d

d

e

d

h

t

s

t

u

g

a

c

n

a

b

d

o

a

o

a

e

e

d

e

u

)

e

o

e

J

o

e

p

u

c

i

a

o

o

u

á

s

n

s

t

í

5000-10

3

Nor

Vé

ase la Gara

•

Familiaríc

•

Utilice sól

completa

•

Los daños

y su distri

•

Guarde el

Utilice los

palanca d

No despla

caballetes

Bloquee s

Asegúres

Por razon

Los daños

as gen

ntía de ser

se con el fu

los aparat

ente.

causados p

uidor no se

anual del

caballetes s

seguridad.

e el vehicu

.

empre la p

de que la

s de seguri

causados p

rales

vicio y cali

ncionamien

s para las a

r descuido

rá responsa

suario para

ólo si están

e y nunca e

rte delante

uperficie de

ad, las mo

r modifica

ad Velle

o de los ap

plicaciones

e las instr

ble de ning

cuando nec

bloqueados

ntre en el v

a y trasera

bajo del ve

ificaciones

iones no au

an® al fina

ratos antes

escritas en

cciones de

n daño u ot

site consul

correctame

hículo si es

e las rued

ículo esté li

no autoriza

orizadas, n

l de este m

de utilizarl

este manu

eguridad d

ros problem

arlo.

te en la alt

tá levantad

s que están

re antes d

as de los a

están cubi

nual del us

.

l. Su uso in

este manu

as resultant

ura desead

por el gat

en contact

bajar el ve

aratos está

ertos por la

ario.

orrecto an

al invalidar

es.

con la

/los

con el suel

hículo.

n prohibida

garantía.

la la garan

n su garant

o.

.

ía

a

4

Cara

•

gato hidrá

•

2 caballet

•

camilla co

•

llave de cr

•

bandeja c

•

llave para

•

2 tacos pa

•

bandeja

5

Des

Vé

ase las figu

G

to

sella

mango

tapa

entrada

válvula

C

balletes

column

C

milla

Reposa

6

Uso

cterístic

lico, 2 ton

s, 2 tonela

ruedas ±

uz ± 35 cm

adrada par

filtro de ac

ra bloquear

agnética.

ripción

as en las p

e transpor

de la palan

de escape

+ silla

abezas

as

ladas

as

2 cm

la recogid

ite

las ruedas

ginas 2 y 3

e

a

de aceites

de este ma

nual del us

F

G

H

I

J

2

3

b

c

ario.

rueda tras

rueda fron

palanca

válvula de

capuchón

palanca d

base

pieza de j

rueda (4x

ra

tal

sobrecarga

el depósito

seguridad

ntura (2x)

(¡no la mod

de aceite

ifique!)

Si

a las instr

El

ncumplim

erte.

6.

Gato

tes del us

Es

posible que

hi

ráulico cau

1.

Gire la vál

Observac

Saque la t

2.

V.

02 – 08/11/2

, durante el

ando el ma

ula de esc

ión: Utilice

pa [C] y d

012

cciones d

ento de la

transporte

l funcionami

pe [E] haci

l extremo

satornille e

l capítulo

instrucci

el aparato,

ento del ga

la izquier

bierto de la

l capuchón

§2.

nes de se

que se hay

o.

a y apriete

palanca [H

el depósito

15

uridad pu

introducid

ompletam

] para girar

de aceite [

de causar

aire en el

nte la sella

la válvula.

].

lesiones o

nterior del

[A].

incluso la

istema

©Vellema

nv

Page 16

5000-10

3. Introduzca la palanca [H] en la entrada de la palanca [D] y gire la palanca en la entrada para fijarla.

4. Accione la palanca de manera rápida de 6 a 8 veces para hacer evacuar el aire del depósito.

5. Vuelva a cerrar el depósito con el capuchón [J] y vuelva a poner la tapa [C].

Observación: La válvula de sobrecarga [I] puede soportar 2 toneladas. Nunca ajuste esta válvula [I].

Levantar un vehículo

1. Gire la válvula de escape [E] hacia la derecha hasta que esté completamente cerrada.

2. Pace a primera velocidad (o en P para un vehículo con cambio automático) y bloquee la parte trasera y

delantera de las ruedas que están en contacto con el suelo.

3. Ponga el gato por debajo del vehículo de manera a que la sella [A] esté en contacto sólido con el punto de

levantamiento (véase el manual del usuario del vehículo en cuestión). No utilice el gato si la sella [A] y el

punto de contacto no son compatibles.

Observación: Asegúrese de que la sella [A] esté bien centrada para no dañar el gato.

4. Introduzca la palanca [H] en la entrada [D] y acciónela hasta que la sella [A] se acerque del punto de

levantamiento. Vuelva a controlar el buen posicionamiento del gato.

5. Siga accionando la palanca [H] hasta que el vehículo esté a la altura requerida. Instale inmediatamente

los soportes de capacidad adecuada. ¡NUNCA PÓNGASE POR DEBAJO DEL VEHÍCULO SI SÓLO ESTÁ

SOPORTADO POR EL GATO!

6. Después de haber instalado los soportes, baje ligeramente el gato (véase las instrucciones abajo) hasta que

el vehículo estribe en los soportes.

Bajar el vehículo

1. Saque la palanca [H] fuera de la entrada [D] y gire la válvula de escape [E] hacia la izquierda con el

extremo abierto de la palanca.

Observación: Levante ligeramente el vehículo si todavía estriba en los soportes.

2. Vuelva a cerrar la válvula de escape al girarla completamente hacia la derecha antes de almacenar el gato.

6.2 Caballetes

1. Introduzca la columna [1] en la base [3].

2. Gire la palanca de seguridad [2] hacia arriba, ajuste el caballete a la altura deseada y vuelva a girar la

palanca de seguridad hacia abajo para fijar la altura. Nunca

dirigada hacia arriba. ¡Siempre coloque los dos caballetes en la misma altura!

3. Repita este procedimiento para el segundo caballete. ¡Seleccione la misma altura para ambos caballetes!

4. Levante el vehículo con un gato adecuado.

5. Localice los puntos de apoyo del vehículo (véase el manual del usuario del vehículo) y asegúrese de que la

sella de los caballetes sea compatible con el punto de apoyo. No utilice los caballetes no si el punto de

apoyo y la silla no coinciden. Una incompatibilidad puede dañar el vehículo y/o los caballetes.

6. Ponga los caballetes debajo del vehículo, la silla de cada caballete alineado con su punto de soporte.

Asegúrese de que el caballete se encuentre firmemente en una superficie dura y plana, y que la superficie

pueda soportar el peso de los caballetes y la carga.

7. Baje el vehículo ligeramente y controle si los caballetes hayan sido posicionados de manera correcta.

Luego, baje el vehículo hasta que estribe completamente en los caballetes.

8. Saque el gato.

9. Verifique que el vehículo esté firmemente posicionado en los caballetes al moverlo cuidadosamente.

10. Para sacar el vehículo de los caballetes, libere la superficie debajo del vehículo y levante el vehículo

ligeramente con el gato. Saque los caballetes.

11. Baje el vehículo completamente y saque el gato.

Camilla con ruedas

1. Deslice las piezas de juntura [b] en el bastidor de la camilla (del lado opuesto del reposacabezas [a]).

Alinee los agujeros de las piezas de juntura con los del bastidor e introduzca los pernos incluidos (2x por

pieza de juntura). Apriete los pernos.

2. Introduzca la otra parte de la camilla en las piezas de juntura e introduzca los pernos incluidos (2x por

pieza de juntura). Apriete los pernos.

3. Monte las cuatro ruedas [c]; véase la figura en la página 2.

utilice el caballete con la palanca de seguridad

7. Mantenimiento

1. Baje completamente la sella [A] antes de almacenar el gato para evitar cualquier riesgo de corrosión.

Guarde el gato en una posición horizontal para evitar fugas de aceite.

2. Asegúrese de que mantenga limpio y suficientemente lubricado el gato y los caballetes. Quite grasa y

suciedad excesivas.

3. El depósito incluye aproximadamente 210 ml de aceite (SAE5W). Controle el nivel al bajar la sella [A]

completamente y al desatornillar el capuchón [J] debajo de le tapa [C]. Añada una pequeña cantidad de

aceite en cuanto el nivel esté a 12 mm debajo de la abertura.

4. Cambie el aceite una vez al año: Desatornille el capuchón [J] y saque la válvula de escape [E]. Asegúrese

de que no contamine el interior del sistema hidráulico. Vacíe el depósito completo y llénelo por el

hueco [J].

V. 02 – 08/11/2012 16 ©Velleman nv

Page 17

5000-10

Observación:

o ¡El uso de aceite no adecuado puede dañar el sistema interno del gato!

o Maneje el aceite al respectar las instrucciones de seguridad.

o Respete las leyes locales en relación con el medio ambiente al tirar el aceite.

5. Vuelva a cerrar la válvula de escape [E] completamente.

6. Levante completamente la sella [A] y abra la válvula de escape [E] para que la sella se baje. Apriete la

sella para que se baje de manera más rápida. Vuelva a cerrar la válvula de escape [E] y repita este

procedimiento para repartir el aceite en el sistema hidráulica.

8. Solución de problemas

No es posible levantar la carga/ levantar la carga a una altura máx.

El gato no puede mantener el peso de la carga

• El peso de la carga sobrepasa la capacidad del aparato. Utilice un gato adecuado.

• La válvula de escape está abierta. Vuelva a cerrar la válvula. Asegúrese de que ninguna impureza impida

cerrar la válvula de manera correcta. Si es el caso, saque la válvula y límpiela.

• Controle el nivel del aceite y añada una pequeña cantidad si fuera necesario (véase §7).

• Saque el aire del sistema hidráulico (véase §6.1).

• Contacte con su distribuidor si el gato no funcione, a pesar de las soluciones propuestas.

No es posible bajar el gato

• Levante la carga puesta sobre el gato defectuoso con un segundo gato.

• Nunca aplique una fuerza excesiva (p.ej. con un martillo) sobre la sella.

• Controle el estado del resorte que mantiene el brazo de levantamiento. Reemplace un resorte defectuoso o

vuelva a fijarlo al gato.

• Controle el nivel de aceite. Una cantidad excesiva de aceite en el depósito puede bloquear el sistema

hidráulico.

• La válvula de escape está bloqueado por impurezas. Limpie la válvula y reemplace el aceite (véase §7).

• Saque el aire del sistema hidráulico (véase §6.1).

• Asegúrese de que el gato esté suficientemente engrasado.

Fuerza de levantamiento insuficiente

• Aceite impura. Reemplace el aceite del depósito (véase §7).

• Vuelva a cerrar la válvula de escape. Asegúrese de que ninguna impureza impida el cierre completo de la

válvula. Si es el caso, saque la válvula y límpiela.

• Saque el aire del sistema hidráulica (véase §6.1).

La sella descargada se levanta automáticamente

Saque el aire del sistema hidráulica (véase §6.1).

9. Especificaciones

gato caballetes

altura de elevación 135 ~ 335 mm altura 11 alturas regulables (± 250 – 410 mm)

capacidad 2 toneladas capacidad 2 toneladas

longitud 54 cm peso ± 1,6 kg (por unidad)

peso ± 9 kg

Utilice este aparato sólo con los accesorios originales. Velleman NV no será responsable de daños ni

lesiones causados por un uso (indebido) de este aparato. Para más información sobre este producto

y la versión más reciente de este manual del usuario, visite nuestra página www.perel.eu. Se

pueden modificar las especificaciones y el contenido de este manual sin previo aviso.

© DERECHOS DE AUTOR

Velleman NV dispone de los derechos de autor para este manual del usuario. Todos los derechos

mundiales reservados. Está estrictamente prohibido reproducir, traducir, copiar, editar y guardar este

manual del usuario o partes de ello sin previo permiso escrito del derecho habiente.

V. 02 – 08/11/2012 17 ©Velleman nv

Page 18

.

sTraIhr

.3.

e

ü

d

e

ge

a

n

e

n

g

e

e

,

t

e

e

n

b

e

n

b

l

S

e

z

S

e

n

e

h

e

R

e