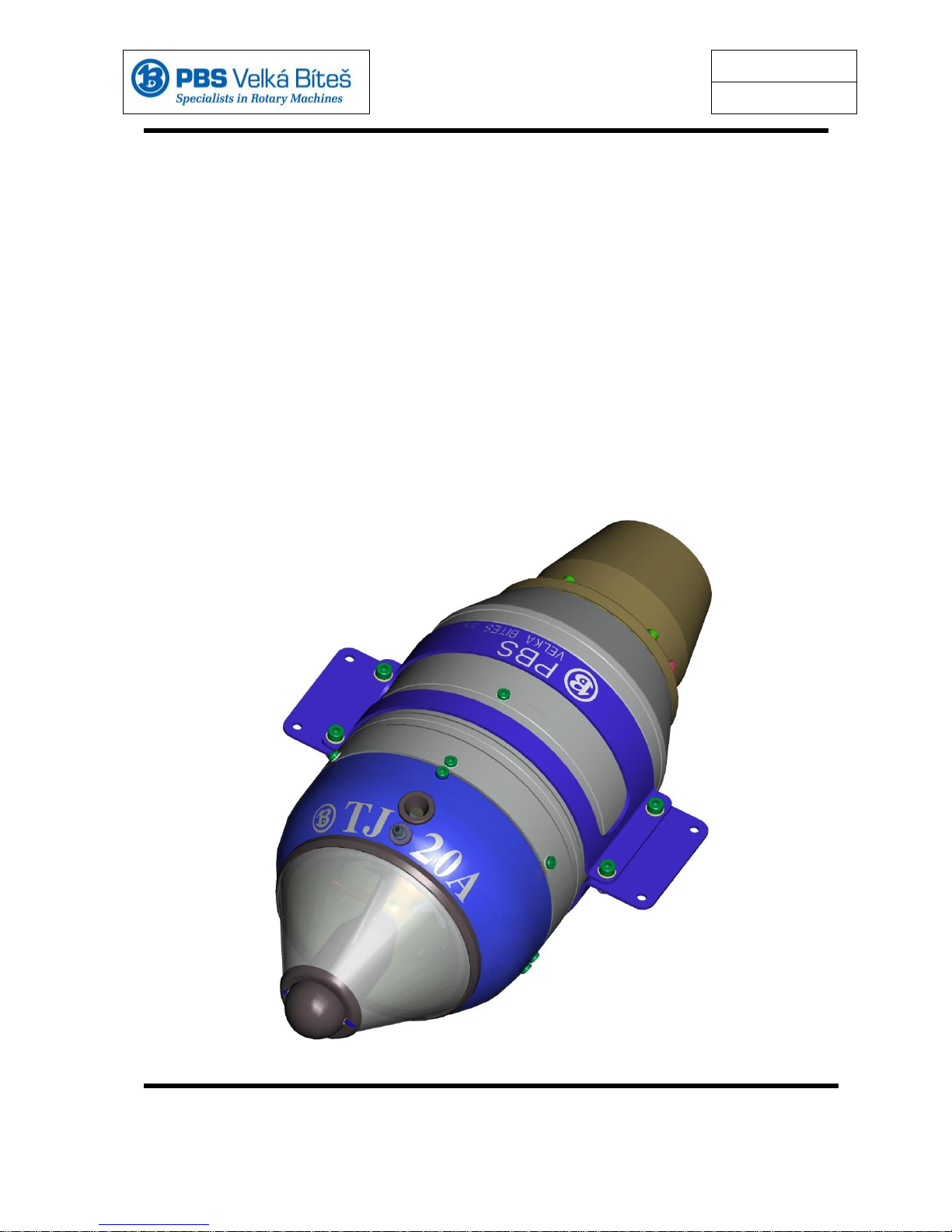

Velká Bíteš Turbojet Engine TJ20A Operation And Maintenance Manual

PP-42A

OPERATION AND MAINTENANCE MANUAL

GUARANTEE CERTIFICATE

TURBOJET ENGINE TJ20A

První brněnská strojírna Velká Bíteš, a.s.

December 2014

PP-42A

2

CONTENTS OF TECHNICAL SPECIFICATION

1. SAFETY INSTRUCTIONS ..................................................................................................... 3

1.1 Definition .................................................................................................................................... 3

1.2 General safety provision ............................................................................................................. 3

1.3 Safety warning ............................................................................................................................ 4

1.4 Warning ...................................................................................................................................... 5

1.5 Guarantee .................................................................................................................................... 6

2. TECHNICAL PARAMETERS ............................................................................................... 7

2.1 Technical parameters .................................................................................................................. 7

3. DESCRIPTION ......................................................................................................................... 9

3.1 Description of engine .................................................................................................................. 9

3.2 Wiring of harness ........................................................................................................................ 9

3.3 Connect of fuel supply ................................................................................................................ 9

3.4 Starting instructions .................................................................................................................. 10

3.5 Connection scheme ................................................................................................................... 11

3.6 Recommended accessories ....................................................................................................... 13

4. EDT STATUS DISPLAY (ENGINE DATA TERMINAL) ................................................ 14

Menu A – Control Unit Modes .......................................................................................................... 15

Menu B - Data .................................................................................................................................... 15

5. MAINTENANCE OF ENGINE ............................................................................................ 28

5.1 Check-up of rotating parts ........................................................................................................ 28

5.2 State of fuel filter pollution ....................................................................................................... 28

5.3 Stocking instructions ................................................................................................................. 28

6. CONTENT OF ENGINE IS PACKAGE .............................................................................. 28

7. EXHAUST PIPE FOR THE TJ20A TURBOJET ENGINE .............................................. 29

8. TURBOJET ENGINE TJ20A DIMENSIONAL DRAWING ............................................ 30

PP-42A

3

1. SAFETY INSTRUCTIONS

1.1 Definition

In this manual relevant steps are preceded by WARNINGS or CAUTIONS. For WARNINGS

and CAUTIONS contained at this manual apply these definitions:

1.1.1 Warning

Caution!

Operating procedures or maintenances jobs, methods, circumstances or

instructions, whose non-observance could cause injury or death of personnel

or can cause long-time health hazard.

Caution!

This symbol warns of hot objects and surfaces.

Any violation of the corresponding restrictions may affect the health of the

user.

Attention!

Fire or explosion hazard!

1.1.2 Caution

Operating procedures or maintenance jobs, methods, circumstances or

instructions, which non-observance could cause damage or destruction of

equipment.

1.2 General safety provision

Following the description of general safety provision, which does not relate to any specific

activity and therefore is not mentioned in other parts of this manual. This is general

recommendation, which should be understand and observed by the maintenance personnel in

course of relevant phases of operation and maintenance.

PP-42A

4

1.3 Safety warning

The operator of turbojet engine TJ20A (below only engine) must during engine testing

and operation take into account the following safety risks:

a) Aspiration of foreign objects

The engine needs a large amount of air for its function, which may result in

suction of foreign objects in the space of the compressor inlet, if are not

fixed sufficiently. You must remove all free objects near of suction chamber

(sweat rag, screws, nut, harness and other materials) before starting of this

engine. Before first starting of model with this engine you must check that

no free object is at suction chamber as chippings, screws or some metal

turnings from production of model. This object can damage the turbine.

b) Single-direction thrust

The engine generates more than tenfold axial thrust in relations to its own

weight, during test it must be fixed sufficiently against movement.

c) Exhaust gas temperature

Never look to the output nozzle and never touch it by hands. Exhaust gases

exit the engine with high speed achieve at nozzle temperature up to 780 °C.

The operator must take necessary precautions against risk of fire.

d) Noise level

Operating of this engine causes high noise level. You must use appropriate

sound protection facilities.

e) Lubrication

This engine has not its lubricating system. Bearings of this engine are

lubricating by fuel where must be add 3 % of turbine oil.

Fully synthetic oils for two-stroke engines are not suitable and must not be

used.

f) Fuel cleanness

The operator must guarantee to be into engine fuel system supply fuel

without any impurities.

g) Law-abidingness

Inquire about law-abidingness concerning operation of this kind of engine.

Please, make sure that you will comply all law of country where will be

operate this engine.

PP-42A

5

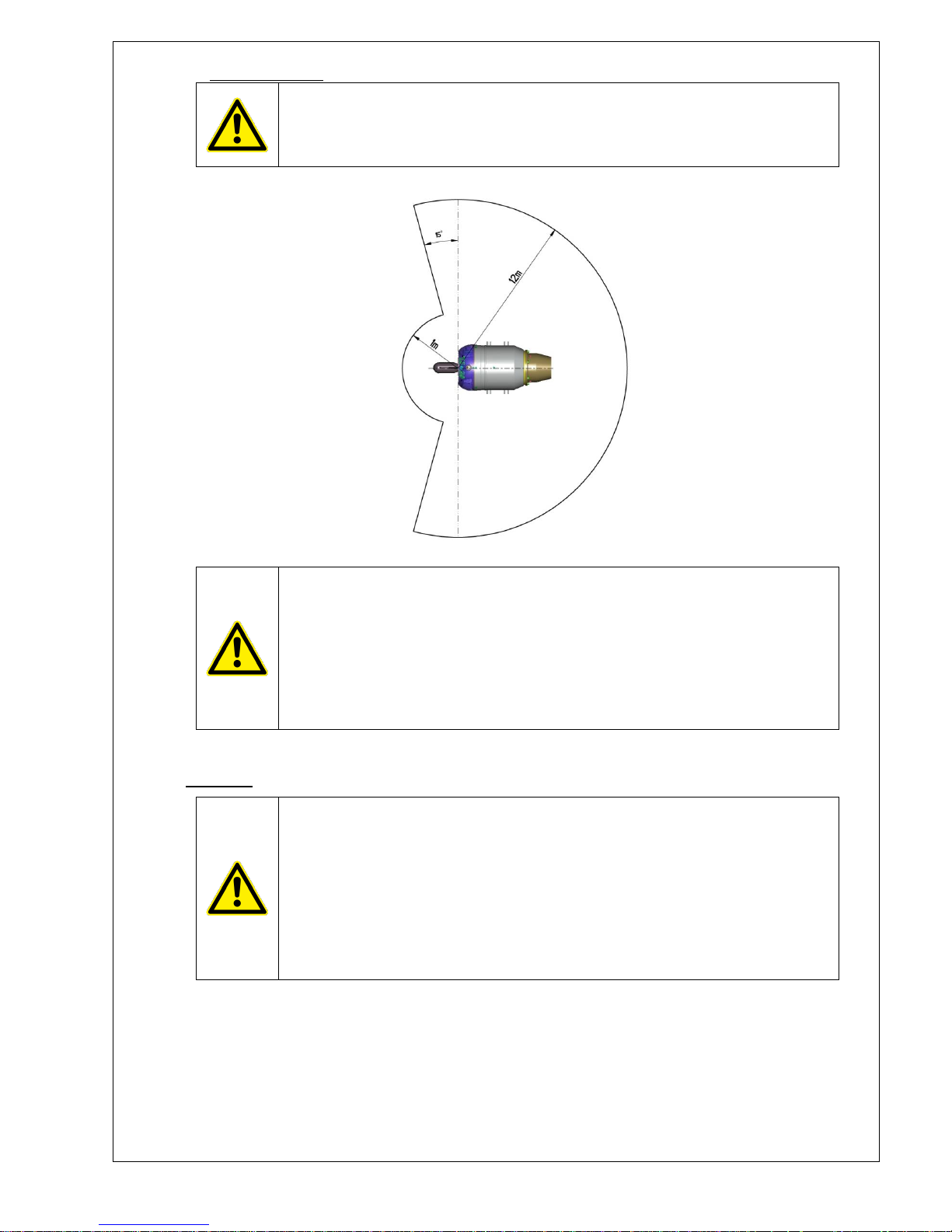

h) Dangerous zone

For safety reason a presence of persons is forbidden in the zone of radius

R1= 12 m on sides and behind the engine in the zone of radius R2=1 m.

Operator can be at these zone only with sound protection facilities.

You are responsible for the protection of people against injury. When

operating the model, maintain safety distance of 1.5 km from populated

areas to protect persons, animals and property. Maintain safe distance from

overhead lines. Don't fly the model in bad weather, especially in case of

low-level clouds and fog. Never fly directly against the sun as you may lose

visual contact with the model. To prevent collision with a real aircraft,

whether manned or unmanned, immediately land the model, if such aircraft

gets near.

1.4 Warning

Turbojet engine TJ20A was designed purely for using inside aircraft model

and it is not suitable for any other purpose. Never use this turbojet engine

for persons, object or vehicles, only for well designed model of aircraft,

every other using can cause hurt or death.

Any deviation from specifications of this manual, using of uncertified parts,

materials, systems design modification or setting can have negative effect for

function and safety of this engine.

You can not operate this engine without presence or assistance of other

person, which can undertake assistance anytime.

PBS Velká Bíteš, a.s. cannot control observation of this manual for operation and

maintenance or installation, operation, using and maintenance of this engine. This is the

reason, why PBS Velká Bíteš, a.s. has not responsibility for losses, claims or costs cause

by wrong using and operation of this engine.

Operation of this engine can be realize purely for own risk of operating person!

PP-42A

6

1.5 Guarantee

The guarantee relating purely to positive manufacturing or material defects arise during the

guarantee period. Any other claims are eliminated. All costs regarding packing and transport

will pay the seller. We will not guarantee waste during the transport. The guarantee is with no

validity when is defect of the product caused by some accident, bad operating or modification

of this product.

Serial number of engine ………………………………………… guarantee 2 years

Date …………………………

PP-42A

7

2. TECHNICAL PARAMETERS

2.1 Technical parameters

* hold for standard conditions t0 = 15°C, p0 = 101,325 kPa, v0 = 0 km/hod

*Max. thrust

[N]

200

55

Max. outsider diameter

[mm]

121

Length including starter

[mm]

315±1

Engine weight

(without battery)

[kg]

< 2,2

Range of operating speed

[RPM]

35 000 ÷ 122 000

Compressor

radial

*compressor compression k

[-]

3,5

*intake air quantity

[kg/sec]

0,4

*SFC at max. trust

[kg/Nh]

0,165

Fuel consumption at idle

ml/min

126,6

Maximal fuel consuption

ml/min

650,0

Fuel

Jet A1 or equivalent + 3 % turbine oil

Cleanness of fuel must match to class

10-11 according GOST 17216-71 or 7-8

according NAS 1638.

Turbine

axial

*Temperature of intake air

[°C]

max. 780

Bearings

hybrid (lubricated by fuel)

Supply voltage rating

[V]

12 V DC (insulated from ground)

Operating range of outdoor

temperature

[°C]

-20 °C ÷ + 50 °C

Flight speed range

[M]

0 ÷ 0,6

Altitude range

[m AMSL]

0 ÷ 6000

2.1.1 Sensor of this engine:

- temperature of intake air t1 1x TC1047A

- temperature of output air t3 1x thermocouple kind K

- engine speed 1x Hall sensor

2.1.2 Inside fittings of this engine:

a). electronic board containing circuits for measure and control function

b). booster with break-in clutch (SE)

c). electro valve for fuel starting circuit (SV)

d). electro valve for operation fuel circuit (FV)

e). heating pencil 11,4 V

f). fuel pump

PP-42A

8

2.1.3 Connection of engine with control electronic

See picture at clause 3.5

2.1.4 Accessories of this engine which is delivery separately:

- Fuel filter fuel input to hose Js 4

fuel output to hose Js 4

- Engine Data Terminal

- Hose D6,5 0,4 m

- Engine clamp optional accessories

- Suction screen optional accessories

2.1.5 Time to overhaul:

- total operation time 50 hours or 500 starts, whichever happens first

2.1.6 Connection dimensions of TJ20A engine

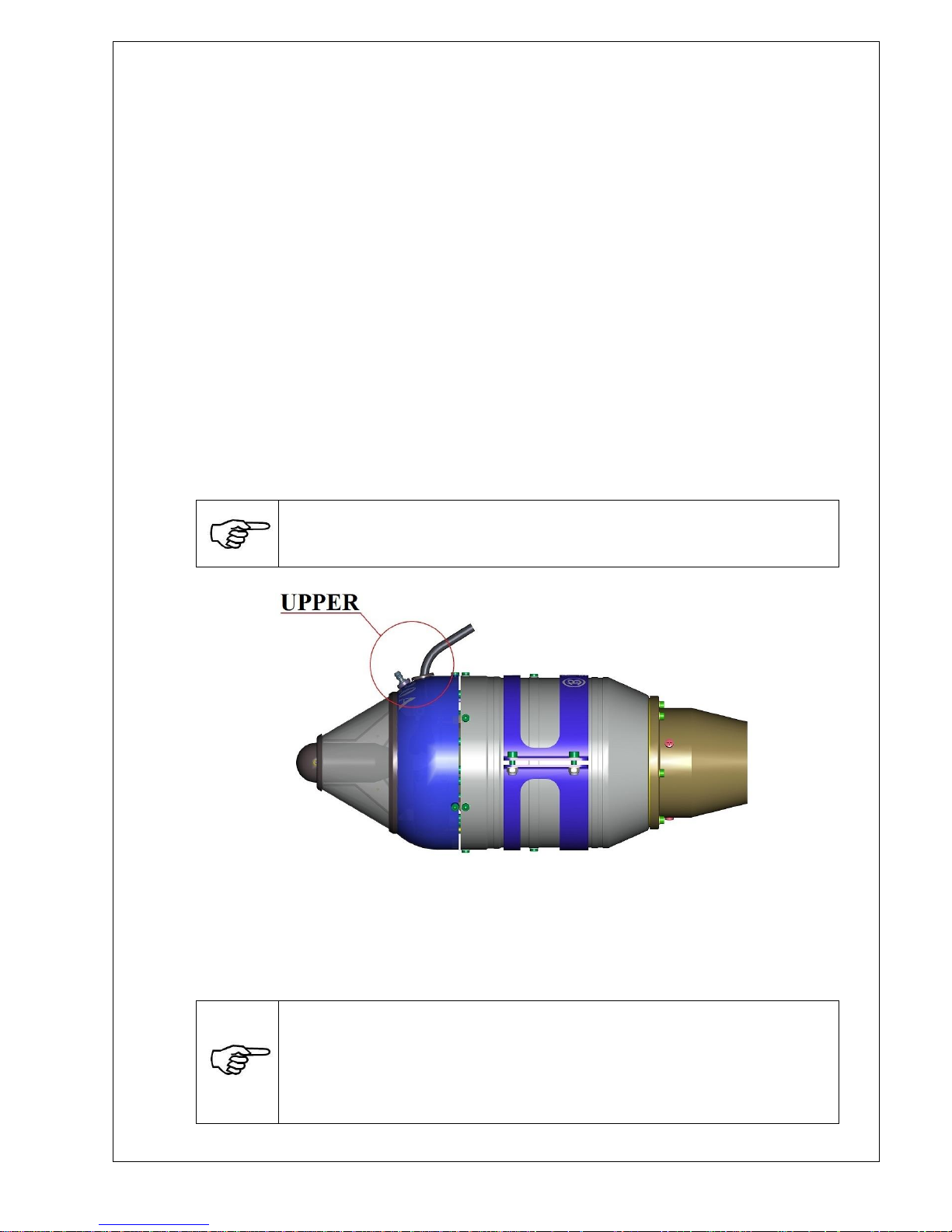

According to customer’s request the TJ 20A engine can be supplied with optional vertical or

horizontal clamp for its fixation.

Connection dimensions of TJ20A engine are mentioned at clause 8.

This engine must be installed in model with fuel supply with up direction,

swing from vertical axe of model can be ±5°.

2.1.7 Required parameters of power supply

Battery 12 V/ 2500 mAh, or 3 Li-Pol battery cell can ensure power supply of this engine.

The battery must be able provide 30A during start of the engine.

The breaker connected downstream the battery must be rated for 30 A.

Ensure the battery is optimally charged to provide enough power for the

start of the turbine, which is very demanding.

Electronic system of engine aborts starting sequence for safety reasons of

engine during flight if voltage drops under 10 V during start.

Also keep in mind that the full battery capacity is not available at low

temperatures, especially when using a LiPol battery.

PP-42A

9

Caution!

The battery must be disconnected from the model during charging.

Attention!

Fire hazard! Li-Pol type batteries can explode if charging parameters are set

incorrectly. Always observe the instructions provided by the manufacturer of

the charger. When charging, the batteries must be under constant

supervision.

CAUTION

Supply voltage of 4,8V from the engine is brought on red wire of RC connector.

For example this supply voltage can be used as power supply of control. Maximal

current drain from the engine is 0,3 A. In case you do not need this additional supply

voltage, don´t wire it!!!!

3. DESCRIPTION

3.1 Description of engine

Turbojet engine TJ20A is single-shaft engine with single-stage radial compressor, annular

combustion chamber, single-stage axial turbine and output nozzle.

At the compressor suction is located booster with break-in clutch enabling starting of this

engine from the cockpit net.

Induced air is compressed at radial compressor wheel, pass through radial and axial diffuser to

the combustion chamber, where is blend with evaporate fuel at evaporating piping. Hot gases

caused by fuel burning at combustion chamber expand through single-stage axial turbine and

exhale by high gear from output nozzle to the atmosphere and cause the thrust of this engine.

Axial turbine provides gear of the compressor. Rotor of this engine placed at 2 axial bearings

lubricated by fuel. Part of this engine is electronic board, this board process data from speed

sensor, exhaust gas temperature sensor and input air temperature sensor. Operation of this

engine is control by control unit. Control unit will check all connected accessories after

receipt of start direction and run starting of this engine automatically. Control unit take control

of starter, fuel sensor, starting and main fuel valve following data from all sensor. After

finishing of engine running will automatically start aftercooling with cyclical switching of

starter as long as temperature of exhaust gases will not drop below stated value.

Control unit works on the principles of model technology (variable width of pulse 1 – 2 ms

with recurrent frequence 50 Hz).

3.2 Wiring of harness

Harness of engine connected according picture at clause No: 3.5.

Attention!

Cable connection to battery must be red wire to +, black wire to -.

Opposite (wrong) connection results in destruction of electronics!!!

3.3 Connect of fuel supply

After installation of engine to the application and harness connection follow fuel insertion.

Connect the fuel pipe from filter to the engine fuel input. See picture at clause No: 3.5.

Loading...

Loading...