VF-61UL

1210 Garden of the Gods Rd., Colorado Springs, CO 80907

INSTRUCTIONS

Phone: (719) 531-5855 FAX: (719) 531-5690

e-mail: vfsales@velcon.com / web site: www.velcon.com

DESCRIPTION

The Velcon VF-61UL filter housing is designed to operate with various Aquacon® or microfilter

elements in diesel fuel applications. The filter housing is shipped with no cartridge installed. Cartridges

must be order ed separately . The VF-61UL vessel only (no cartridges) is Underwriters Laboratory

Approved under Component Listing.

Connections Size: 1-1/2" Female NPT

Housing Pressure Rating: 150 psi

NOTE: FOR LIQUID SER VICE ONLY. Do not use or leak test this filter vessel with compressed

air or other gases.

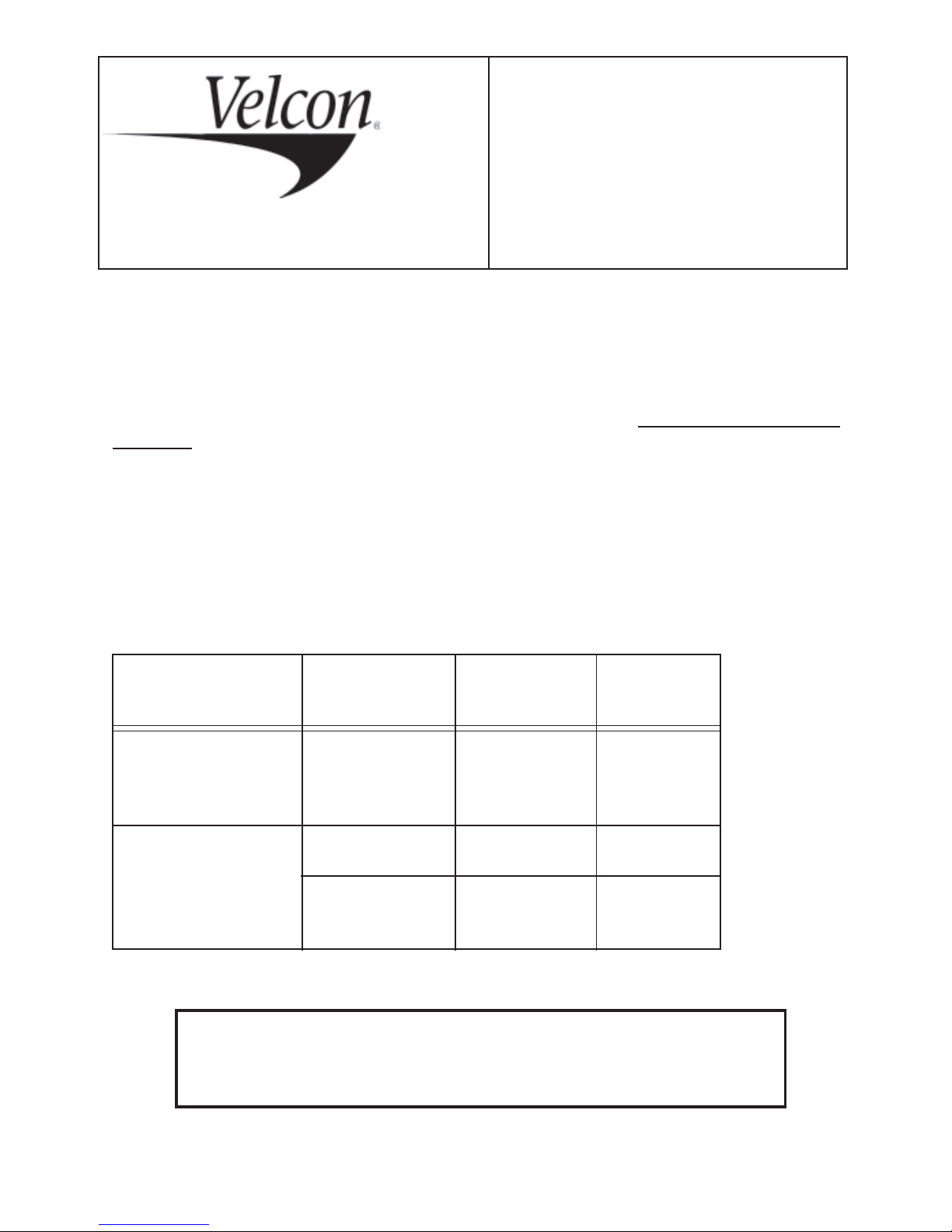

CARTRIDGE SELECTION

MODEL DEGREE OF CO LL AP S E

TYPE NUMBER FILTRATION STRENGTH

PLEATED MEDIA FO-512PL1/2

(Dirt Removal Only) FO-512PL05 5 MICRON 75 psi

FO-512PL25 25 MICRON 75 psi

Aquacon® MEDIA AC-51205 5 MICRON 75 psi

(Dirt and W ater

Removal) AD-51225 25 MICRON 75 psi

1

/2 MICRON 75 psi

*****CAUTION!*****

To protect the fuel system, including the VF-61UL and

other components, be sure to install pressure relief valve(s).

© 2007 Velcon Filters, Inc.

-1-

1981-R2 06/07

P/N 09-1034

INSTALLATION

Install the housing at a convenient point in the line. Note “Inlet” and “Outlet” markings on the cast

head which indicate direction of flow . DO NOT install the housing backwards.

Provide room for the housing shell to clear the cartridge during change-out.

It is good practice to install a differential pressure gauge so that the differential pressure across the

housing can be monitored. This allows accurate determination of when the cartridge should be changed.

Part number 10678, as described on Form 1715 (PN 09-880) is a differential pressure gauge

specifically designed to be used on VF-61. NOTE: PN 09-880 Pressure Gauge is not UL tested or

approved.

FOR Aquacon

DIFFERENTIAL PRESSURE GAUGE OR OTHER MEANS OF DETERMINING THE

DIFFERENTIAL PRESSURE. For diesel fuel service, flow rate should be kept between 15 and 50

gpm. Consult factory for other flow applications.

On systems where pressures can exceed 75 psi, a pressure bypass around the pump should be

installed to protect the cartridge and the system from a high pressure shock or sudden cartridge sealoff due to a slug of water in the product.

Valves ahead of and behind the housing may be required to isolate it during cartridge change-out.

®

CAR TRIDGES USED IN DIESEL FUEL SERVICE, ALWAYS INSTALL A

CARTRIDGE CHANGE-OUT

Replace the cartridge when the differential pressure exceeds 25 psi, after 1 year of service, when the

flow is significantly reduced, or if pressure has been steadily climbing and then begins to decrease –

whichever occurs first.

IMPORT ANT SAFETY PRECAUTION:

MAKE CERT AIN FILTER HOUSING IS COMPLETELY VENTED

BEFORE OPENING HOUSING.

1. Turn off pump.

2. Close isolation valves (if any) and open the valve vent at the top.

3. Place a bucket under the housing to contain any spilled liquid.

4. Drain all liquid from the housing through the bottom plug.

5. Loosen the four bolts and rotate out and down to clear the top clamp. Drop the housing shell.

Remove the spent cartridge.

-2-

6. Wipe the inside of the shell clean of any contaminants.

7. Inspect the O-ring and replace if damaged. Lightly lubricate the O-ring with the fuel or oil in which

it will be used, and position it on the head.

8. Install a new element onto the nozzle of the filter head. T wist and push the cartridge until it bottoms

against the step on the nozzle.

9. Lift shell up to the housing head, making sure the head O-ring is in

place. Align shell bolts so they do not interfere with inlet and outlet

piping. Rotate bolts over clamp top half (see photo). Note: Small Orings on bolts do not seal, but just hold washers next to bolt head.

Tighten all bolts to 33 ft-lbs, alternating in a criss-cross fashion.

10. Open isolation valves and the vent valve so that the vessel slowly

bleeds air from the top vent while filling the housing .

11. Close the vent when the housing has filled. Check all fittings and the

head/shell junction for leaks.

REPLACEMENT PARTS

The VF-61UL is shipped with a Buna-N O-ring installed. When ordering replacement O-rings from

V elcon, specify:

G-0986 for Buna-N (UL Approved)

420X066 for V iton (UL Approved)

Use only UL Approved O-rings listed above to keep UL Component Listing status.

W ARNING: Absorbent-type monitor cartridges will not remove water from

fuel containing alcohol-blending agents (commonly called gasohol). For

removal of solids, please use V elcon particle removal filters specifically

made for gasohol. Consult your V elcon representative.

© 2007 Velcon Filters, Inc.

-3-

1981-R2 06/07

P/N 09-1034

Loading...

Loading...