Velatia Ormazabal cpg.1-c, Ormazabal cpg.1-v2, Ormazabal cpg.1-f1, Ormazabal cpg.1-f2, Ormazabal cpg.1-s1 General Instructions Manual

...

cpg.1

Fully SF6 gas insulated single and

double busbar GIS switchgears up

to 36 kV in accordance with IEC

Standards

General Instructions

IG-137-EN, version 03; 23/06/2016

LIB

Legal Deposit: BI-1548/2015

CAUTION!

When medium voltage equipment is operating, certain components are live, other parts may be in movement and some may reach high

temperatures. Therefore, the use of this equipment poses electrical, mechanical and thermal risks.

In order to ensure an acceptable level of protection for people and property, and in compliance with applicable environmental

recommendations, Ormazabal designs and manufactures its products according to the principle of integrated safety, based on the

following criteria:

• Elimination of hazards wherever possible.

• Where elimination of hazards is neither technically nor economically feasible, appropriate protection functions are

incorporated in the equipment.

• Communication about remaining risks to facilitate the design of operating procedures which prevent such risks, training

for the personnel in charge of the equipment, and the use of suitable personal protective equipment.

• Use of recyclable materials and establishment of procedures for the disposal of equipment and components so that

once the end of their service lives is reached, they are duly processed in accordance, as far as possible, with the

environmental restrictions established by the competent authorities.

Consequently, the equipment to which the present manual refers complies with the requirements of section 11.2 of Standard IEC

62271-1. It must therefore only be operated by appropriately qualified and supervised personnel, in accordance with the requirements

of standard EN 50110-1 on the safety of electrical installations and standard EN 50110-2 on activities in or near electrical installations.

Personnel must be fully familiar with the instructions and warnings contained in this manual and in other recommendations of a more

general nature which are applicable to the situation according to current legislation

1

.

The above must be carefully observed, as the correct and safe operation of this equipment depends not only on its design but also on

general circumstances which are in general beyond the control and responsibility of the manufacturer. More specifically:

• The equipment must be handled and transported appropriately from the factory to the place of installation.

• All intermediate storage should occur in conditions which do not alter or damage the characteristics of the equipment or

its essential components.

• Service conditions must be compatible with the equipment rating.

• The equipment must be operated strictly in accordance with the instructions given in the manual, and the applicable

operating and safety principles must be clearly understood.

• Maintenance should be performed properly, taking into account the actual service and environmental conditions in the

place of installation.

The manufacturer declines all liability for any significant indirect damages resulting from violation of the guarantee, under any jurisdiction,

including loss of income, stoppages and costs resulting from repair or replacement of parts.

Warranty

The manufacturer guarantees this product against any defect in materials and operation during the contractual period. In the event that

defects are detected, the manufacturer may opt either to repair or replace the equipment. Improper handling of this equipment and its

repair by the user shall constitute a violation of the warranty.

Registered Trademarks and Copyrights

All registered trademarks cited in this document are the property of their respective owners. The intellectual property of this manual

belongs to Ormazabal.

1

For example, in Spain the “Regulation on technical conditions and guarantees for safety in high voltage electrical installations” –

Royal Decree 337/2014 is obligatory.

In view of the constant evolution in standards and design, the characteristics of the elements contained in this manual are subject to

change without prior notice. These characteristics, as well as the availability of components, are subject to confirmation by Ormazabal.

General instructions

cpg.1

Fully SF6 gas insulated single and double busbar GIS switchgears up to 36 kV in accordance

with IEC Standards

Contents

1 Description and main characteristics .......................................... 6

1.1 Models .................................................................................6

1.2 Standards applied........................................................................6

1.3 Main components ........................................................................7

1.3.1 Levers for manual operation .........................................................10

1.3.2 Main manual operation panel ........................................................11

1.4 Name plate.............................................................................14

2 Technical characteristics ................................................... 15

3

2.1 Electrical characteristics .................................................................15

2.2 Mechanical characteristics ...............................................................16

2.2.1 Dimensions and weights...........................................................16

2.2.2 Protection grade .................................................................17

3 Service conditions......................................................... 18

4 Handling and transport ..................................................... 19

4.1 Transport conditions ....................................................................19

4.2 Lifting means...........................................................................19

5 Storage conditions ........................................................ 21

6 Installation ............................................................... 22

6.1 Unpacking the equipment ................................................................22

6.2 List of supplied materials.................................................................22

6.3 Minimum installation distances............................................................30

6.4 Cable trench ...........................................................................30

6.5 Fastening to the floor ....................................................................31

6.6 Cubicle joints ..........................................................................32

6.6.1 cpg.1-v ..........................................................................32

6.6.2 cpg.1-s ..........................................................................33

6.6.3 cpg.1-ct / cpg.1-cl ..................................................................33

6.6.4 cpg.1-f ..........................................................................34

IG-137-EN version 03; 23/06/2016

4

General Instructions

cpg.1

Fully SF6 gas insulated single and double busbar GIS switchgears up to 36 kV in accordance

with IEC Standards

6.7 Equipment earthing .....................................................................34

6.7.1 Top section.......................................................................34

6.7.2 Bottom section ....................................................................35

6.7.3 Top and bottom earth side link........................................................35

7 Operations sequence ...................................................... 36

7.1 cpg.1-v1 cubicle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

7.1.1 Commissioning from open position ....................................................37

7.1.1 Medium voltage cable earthing .......................................................38

7.2 cpg.1-v2 cubicle .........................................................................39

7.2.1 Commissioning from open position ....................................................39

7.2.2 Medium voltage cable earthing .......................................................40

7.2.3 Replacing a busbar ................................................................40

7.3 cpg.1-s1 cubicle .........................................................................42

7.3.1 Connection.......................................................................42

7.3.2 Earthing .........................................................................43

7.4 cpg.1-s2 cubicle .........................................................................43

7.4.1 Connection.......................................................................44

7.4.2 Earthing .........................................................................44

7.5 cpg.1-c cubicle ..........................................................................45

7.5.1 Busbar coupling ...................................................................46

7.5.2 Busbar earthing on the right .........................................................47

7.5.3 Busbar earthing on the left...........................................................48

7.6 cpg.1-cl cubicle..........................................................................49

7.6.1 Busbar coupling ...................................................................49

7.6.2 Busbar earthing on the right .........................................................50

7.6.3 Busbar earthing on the left: ..........................................................52

7.7 cpg.1-ct cubicle .........................................................................53

7.7.1 Busbar connection .................................................................54

7.7.2 Main busbar earthing ...............................................................55

7.7.3 Secondary busbar earthing ..........................................................56

7.8 cpg.1-f1 cubicle .........................................................................57

7.8.1 Commissioning the cubicle ..........................................................57

7.8.2 Earthing .........................................................................58

7.9 cpg.1-f2 cubicle .........................................................................58

7.9.1 Commissioning the cubicle ..........................................................59

7.9.2 Earthing .........................................................................59

7.10 Fuse replacement sequence in cpg.1-f .....................................................60

7.10.1 Selection of fuses recommended for cpg.1-f ............................................62

IG-137-EN version 03; 23/06/2016

General instructions

cpg.1

Fully SF6 gas insulated single and double busbar GIS switchgears up to 36 kV in accordance

with IEC Standards

8 Safety elements ........................................................... 63

8.1 Maintenance ...........................................................................63

8.2 Voltage presence detectors ...............................................................63

8.2.1 Locking with a padlock..............................................................64

8.2.1 Locking with lock ..................................................................64

8.3 Interlocks ..............................................................................64

9 Spares and accessories .................................................... 65

9.1 Preventive maintenance for the cpg.1 cubicle ................................................65

10 Environmental information ................................................ 66

10.1 Sulphur Hexafluoride SF6................................................................66

10.2 Recyclability ..........................................................................66

5

IG-137-EN version 03; 23/06/2016

Description and main characteristics

6

Fully SF6 gas insulated single and double busbar GIS switchgears up to 36 kV in accordance

1 Description and main characteristics

General Instructions

cpg.1

with IEC Standards

The cpg.1 family is a series of GIS modular cubicles

with full SF6 gas insulation, for single and double busbar

primary distribution applications in medium voltage

networks up to 36 kV.

1.1 Models

Function Designation

Single busbar Double busbar

Circuit breaker cubicle

Disconnector cubicle

Transversal busbar coupling cubicle

Longitudinal busbar coupling cubicle

Fuse protection cubicle

cpg.1-v1 cpg.1-v2

cpg.1-s1 cpg.1-s2

-- cpg.1-ct

cpg.1-c cpg.1-cl

cpg.1-f1 cpg.1-f2

1.2 Standards applied

Standard Description

IEC 62271-1

IEC 62271-200

IEC 62271-100

IEC 62271-102

IEC 62271-105

IEC 62271-206 / IEC 61243-5

Common specications for high voltage switchgear standards

Metal-enclosed alternating current switchgear for rated voltages

above 1 kV and below or equal to 52 kV

Alternating current circuit breakers

Alternating current disconnectors and earthing switches

Alternating current circuit breaker-fuse combinations for rated voltages

above 1 kV and below or equal to 52 kV

Voltage presence indicating systems

IG-137-EN version 03; 23/06/2016

General instructions

Description and main characteristics

cpg.1

Fully SF6 gas insulated single and double busbar GIS switchgears up to 36 kV in accordance

with IEC Standards

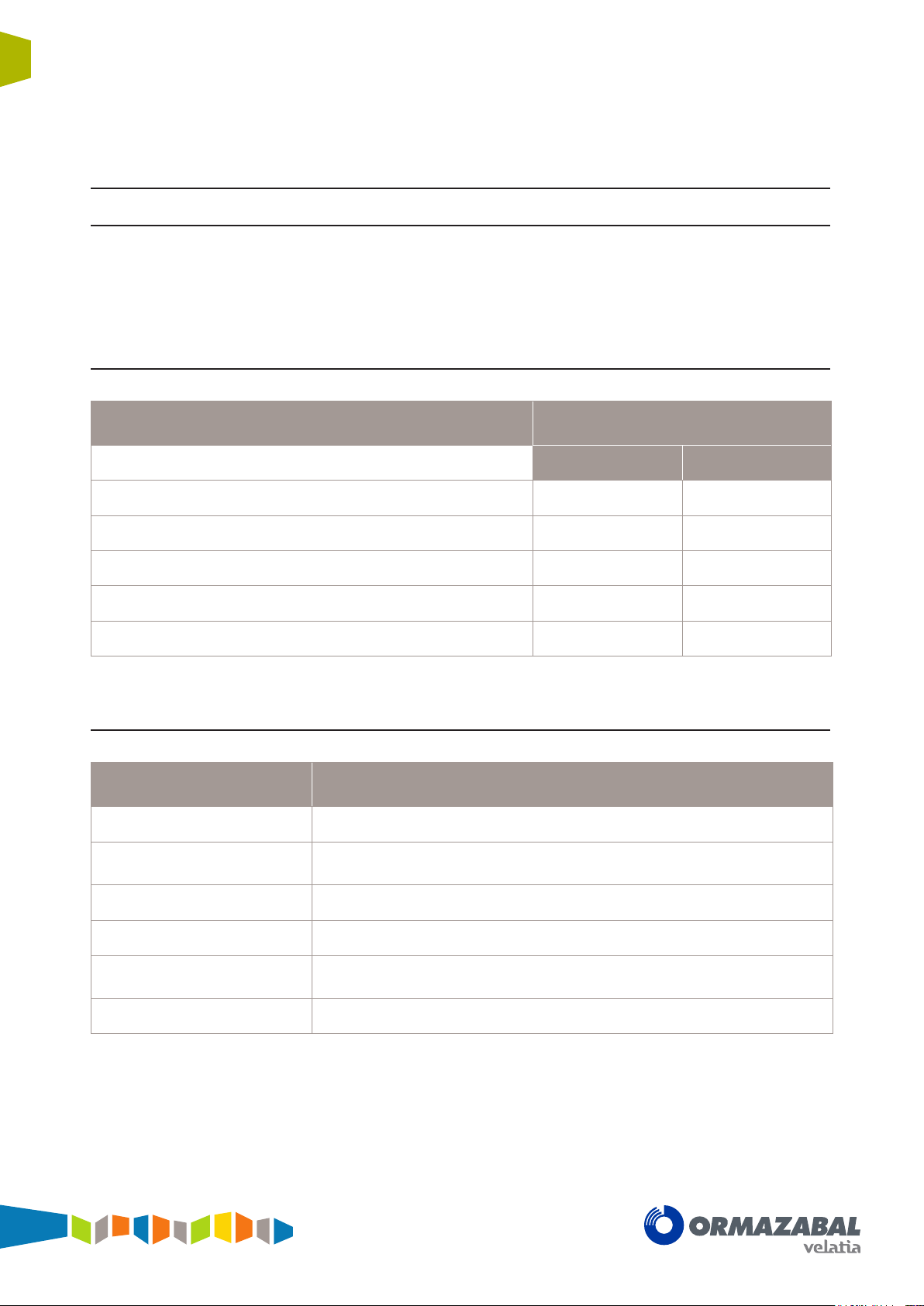

1.3 Main components

Each cubicle is made up of a series of independent

compartments:

1. Gas tanks

2. Busbar compartment

3. Cable compartment

4. Gas pressure relief duct (optional)

5. Control compartment

6. Driving mechanism area

7

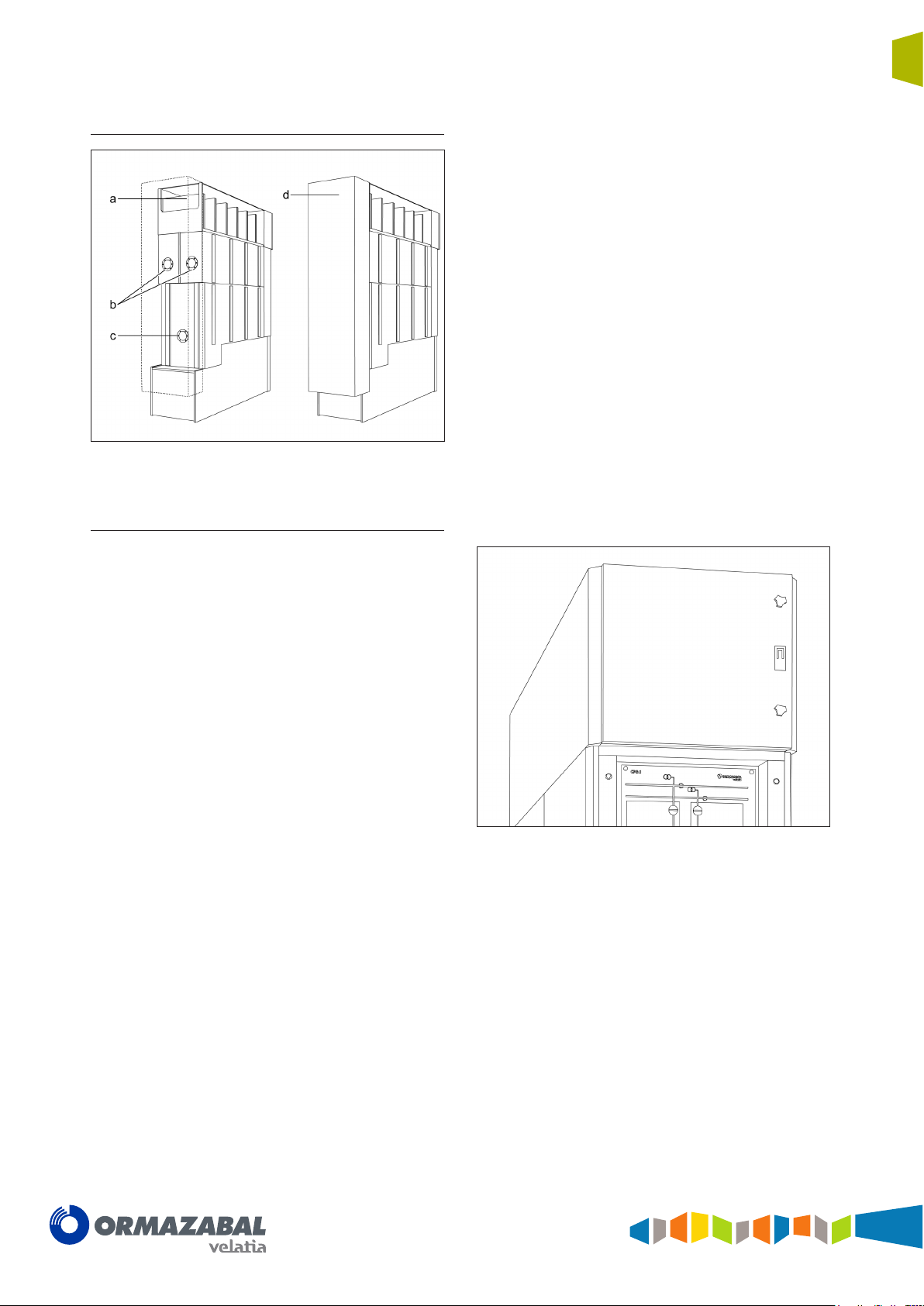

Figure 1.1 Main elements of cpg.1 cubicles

Gas tanks

These are the compartments which house the switching

and breaking switchgear, where the insulating medium is

gas. There are 2 or 3 separate compartments:

SF

6

• 1 for each of the feeder disconnectors

• 1 for the circuit breaker and the earthing switch

These are sealed compartments, made of stainless steel

and sealed for life. They are designed and tested to

withstand an internal arc of up to 31.5 kA - 1 s.

Depending on the function for which the cubicle was

designed, it may contain the following components:

• Feeder disconnectors

• Earthing switch

• Internal busbar and connections

• Vacuum circuit breaker

• Switch - disconnector

• Fuse holders

Figure 1.2 Gas tanks of circuit breaker and disconnectors for

cpg.1-v2 cubicle

There are sets of bushings in the top and bottom of the

compartments for connection of the busbar and the power

cables respectively.

IG-137-EN version 03; 23/06/2016

Description and main characteristics

8

Fully SF6 gas insulated single and double busbar GIS switchgears up to 36 kV in accordance

For testing the gas pressure in each compartment, a

temperature-compensated pressure switch is installed,

Top busbar

General Instructions

cpg.1

with IEC Standards

with a volt-free contact, for possible use as a remote alarm

or blocking/trip for the functional unit.

This is used for connecting cubicles. It has solid and

shielded insulation, earthed by means of the compartment's

specific earthing bar.

Cable compartment

As an option, the busbar is able to segregate the phases

by means of a set of earthed metal plates (metal-clad).

Toroidal current transformers and/or plug-in voltage

transformers can be installed in this compartment, thus

avoiding the need for metering cubicles.

In the most complete case, the base can house the

following components:

• Phase segregation consisting of the main box

and the segregating cover.

• Up to 4 screw-in shielded terminals per phase,

as well as space for the corresponding incoming

power cables.

• Clamp flanges for the medium voltage cables.

• Earthing plates.

• Toroidal current transformers.

• Plug-in voltage transformers.

• Surge arresters.

Figure 1.3 Phase segregation in the cable compartment

(optional)

Located in the bottom part of the cubicle, this has a cover,

interlocked with the earthing circuit, which allows front

access to the medium voltage cables.

All the elements making up the enclosure are earthed by

means of a conductor consisting of a copper bar capable

of withstanding the rated short-time current. It is located

in the base in such a way that it does not need to be

dismantled in order to insert or remove a cable and its

corresponding termination.

IG-137-EN version 03; 23/06/2016

General instructions

Description and main characteristics

cpg.1

Fully SF6 gas insulated single and double busbar GIS switchgears up to 36 kV in accordance

with IEC Standards

Gas pressure relief duct (optional)

This component is used to direct the gases produced by

an internal arc in any of the compartments towards the

top of the cubicle: Disconnector compartment and circuit

breaker compartment, top busbar compartment and cable

compartment.

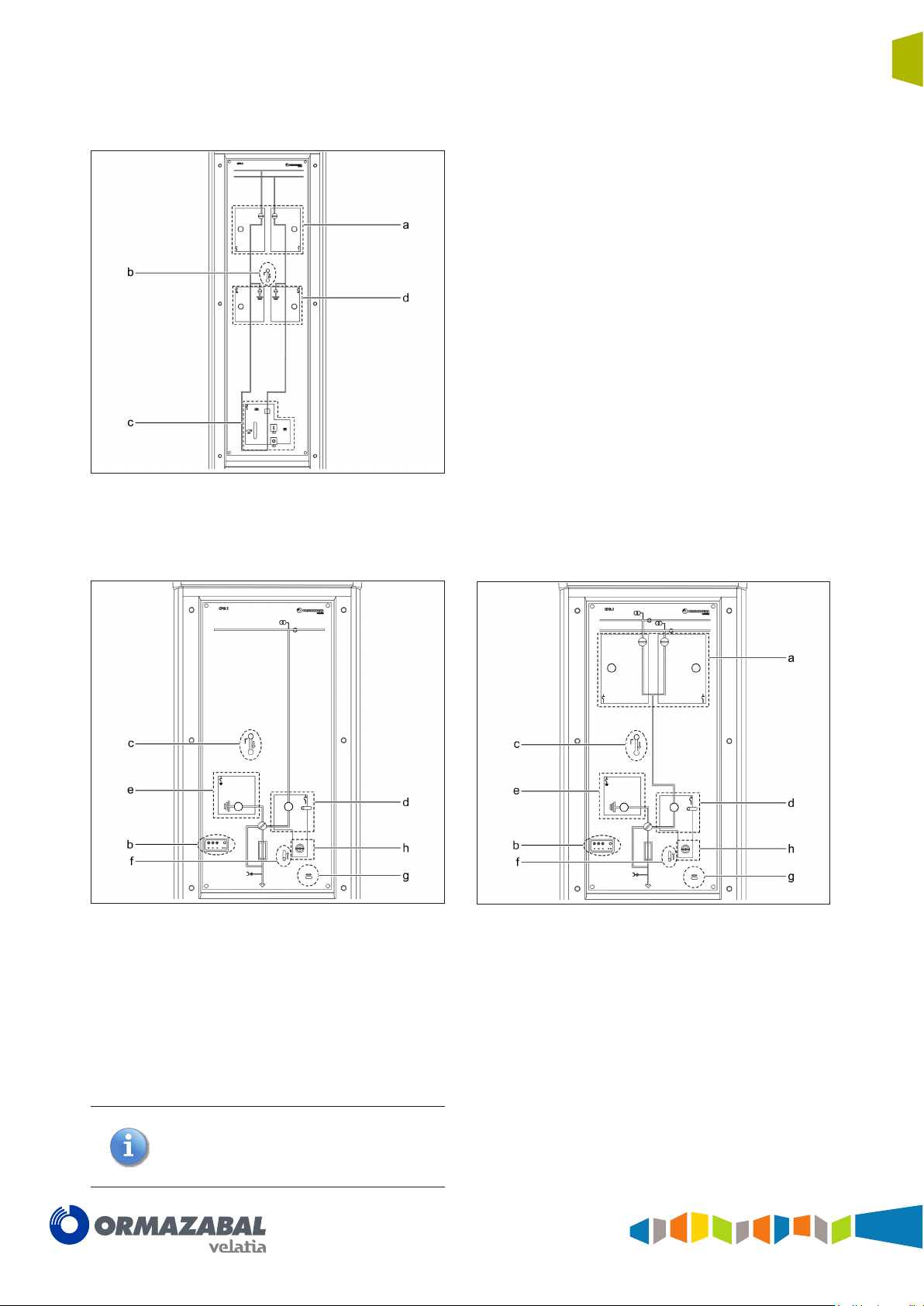

a. Gas vent from busbar compartment

b. Gas vent from disconnector compartments

c. Gas vent from circuit breaker and earthing switch

compartment

d. Internal arc gas directional duct (optional)

Figure 1.4 Internal arc gas pressure relief duct (optional)

9

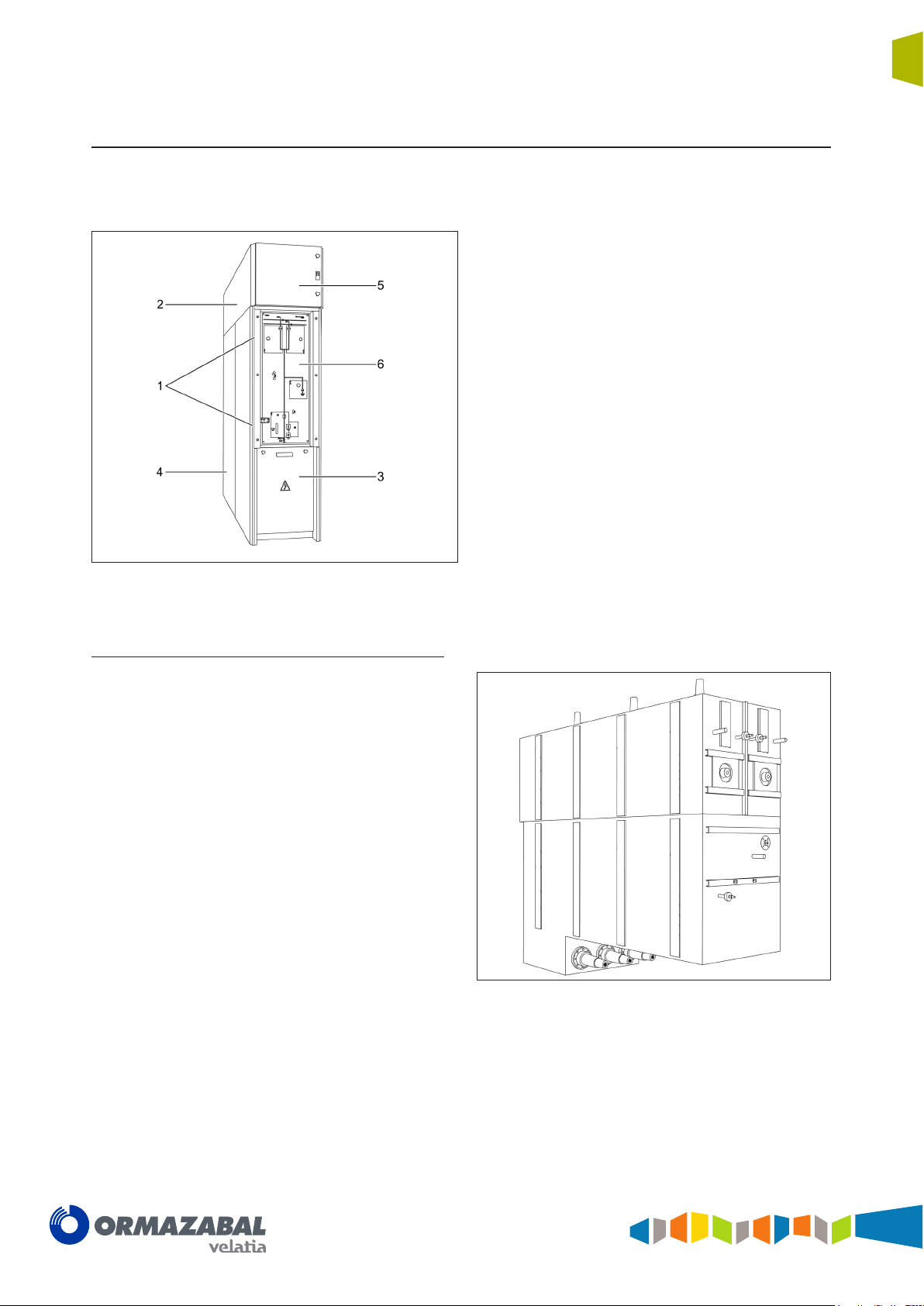

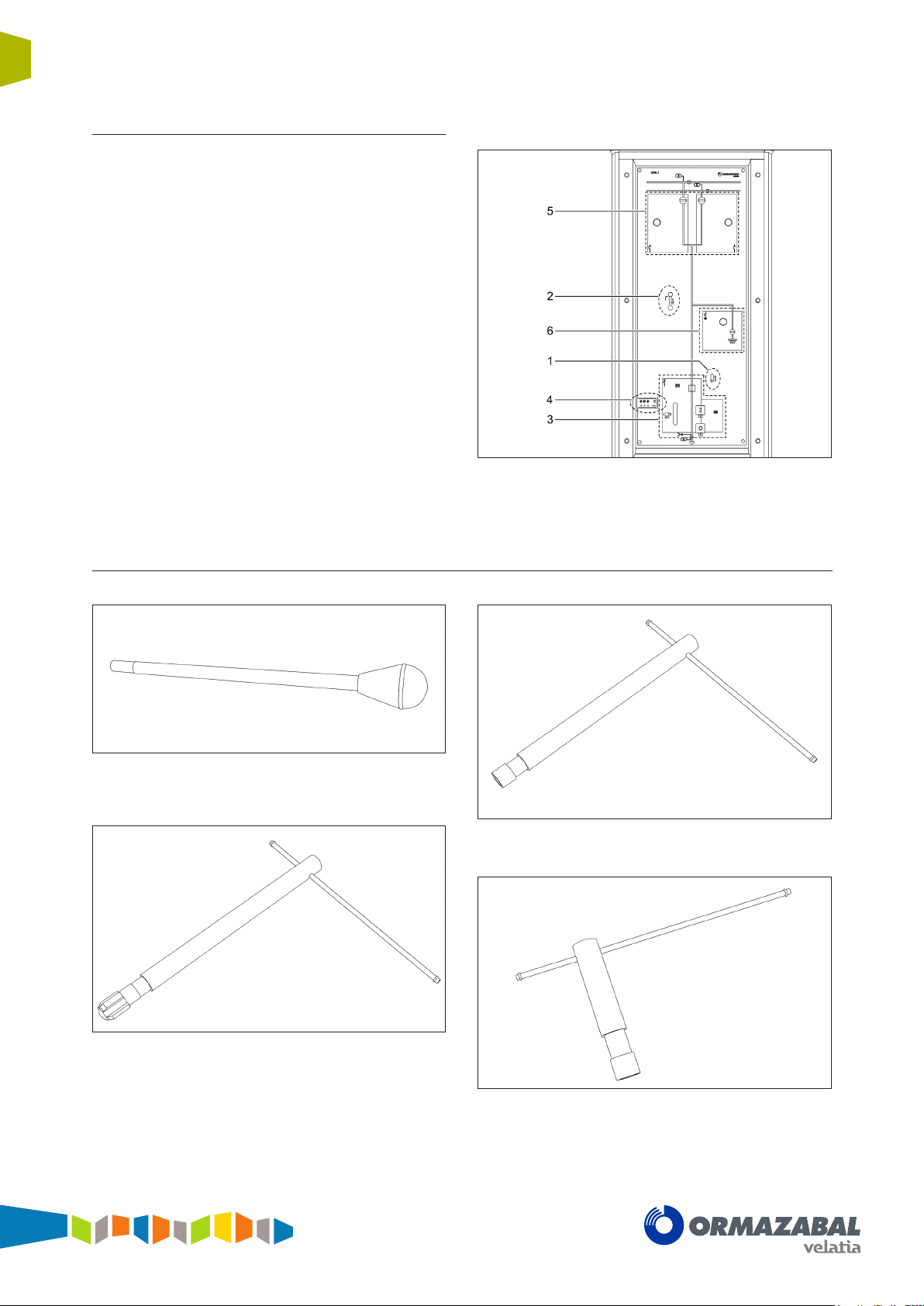

Control compartment

Placed at the top of the cubicle and separate from the

medium voltage area, this is ready for installation of the

metering equipment and protection relays. It contains

the whole terminal block with the control signals already

identified.

Figure 1.5 Control compartment

IG-137-EN version 03; 23/06/2016

10

Description and main characteristics

Fully SF6 gas insulated single and double busbar GIS switchgears up to 36 kV in accordance

Driving mechanism area

In addition to a mimic diagram customised for each type of

cubicle, this has the driving elements in its middle section:

disconnector/earthing switch and circuit breaker driving

mechanisms, circuit breaker opening/closing pushbuttons,

status indicators, groove for access of the spring loading

lever, etc.

1. Cable compartment cover interlocking

2. Driving shaft access interlocking

3. Circuit breaker operation and indication area

4. Voltage presence - absence detector

5. Feeder disconnector operation and indication area

6. Earthing switch operation and indication area

General Instructions

cpg.1

with IEC Standards

Figure 1.6 General manual operation panel detail

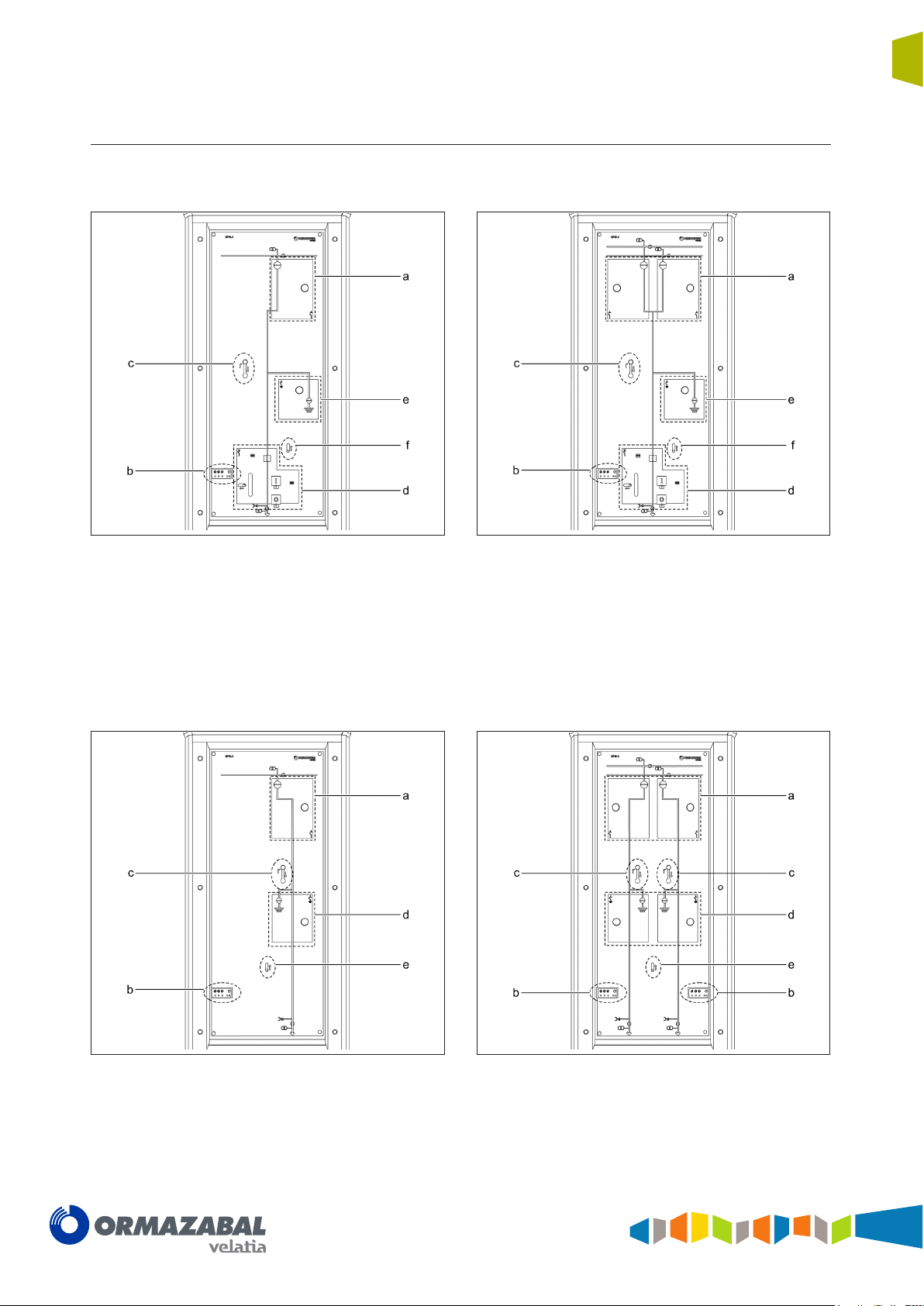

1.3.1 Levers for manual operation

Figure 1.7 Lever for manual loading of the circuit breaker

springs in cpg.1-v cubicle

Figure 1.9 Manual driving lever of the earthing switch

Figure 1.8 Manual operation lever of the feeder disconnectors

IG-137-EN version 03; 23/06/2016

Figure 1.10 Manual operation lever of the cpg.1-f cubicle

General instructions

Description and main characteristics

cpg.1

Fully SF6 gas insulated single and double busbar GIS switchgears up to 36 kV in accordance

with IEC Standards

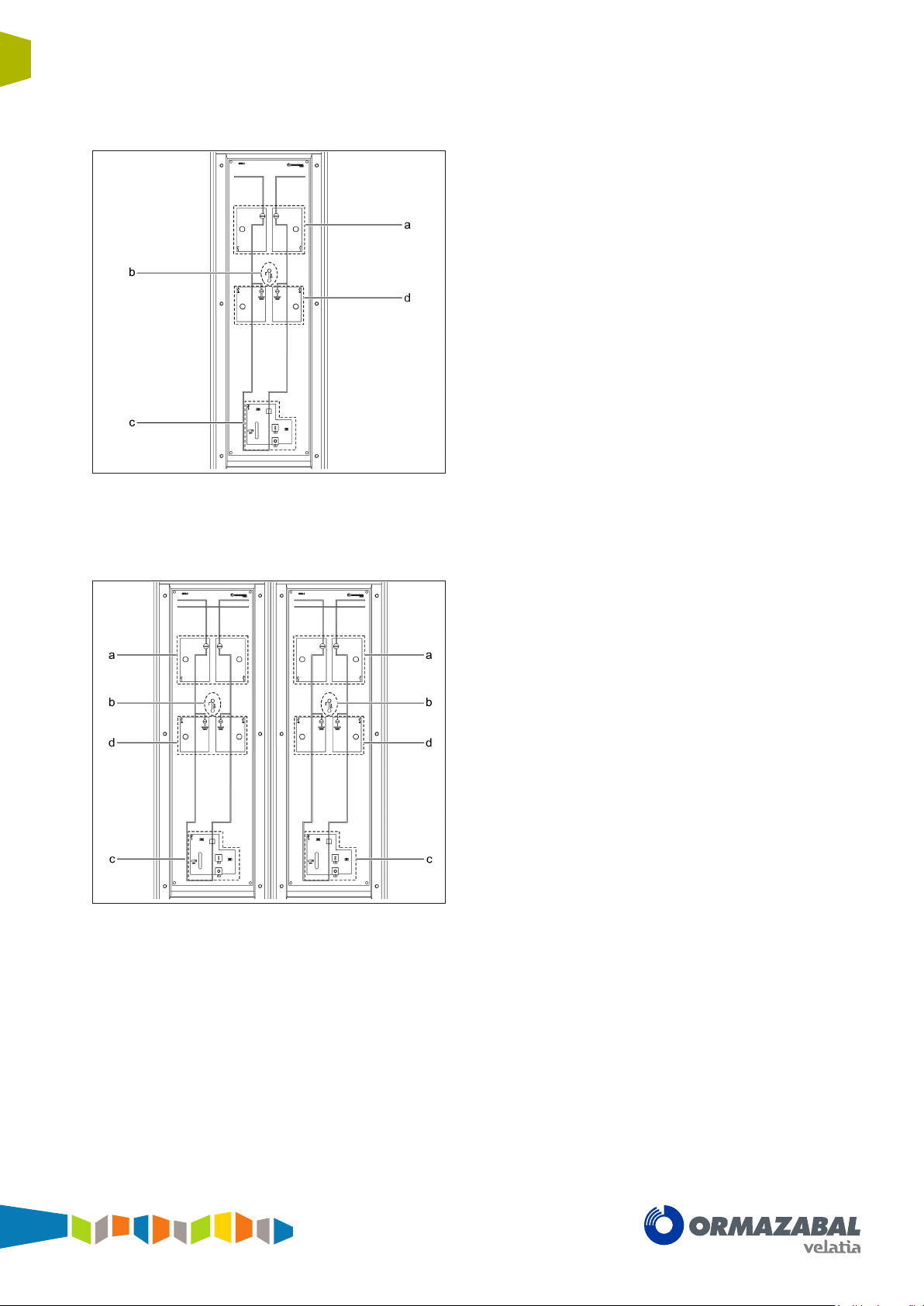

1.3.2 Main manual operation panel

11

cpg.1-v1

Figure 1.11 Manual operation general panel and mimic

diagram for cpg.1-v1

a. Disconnector operation and indication area

b. Voltage presence-absence indicator

c. Driving shaft access handle

d. Circuit breaker operation and indication area

e. Earthing switch operation and indication area

f. Cable compartment cover interlocking

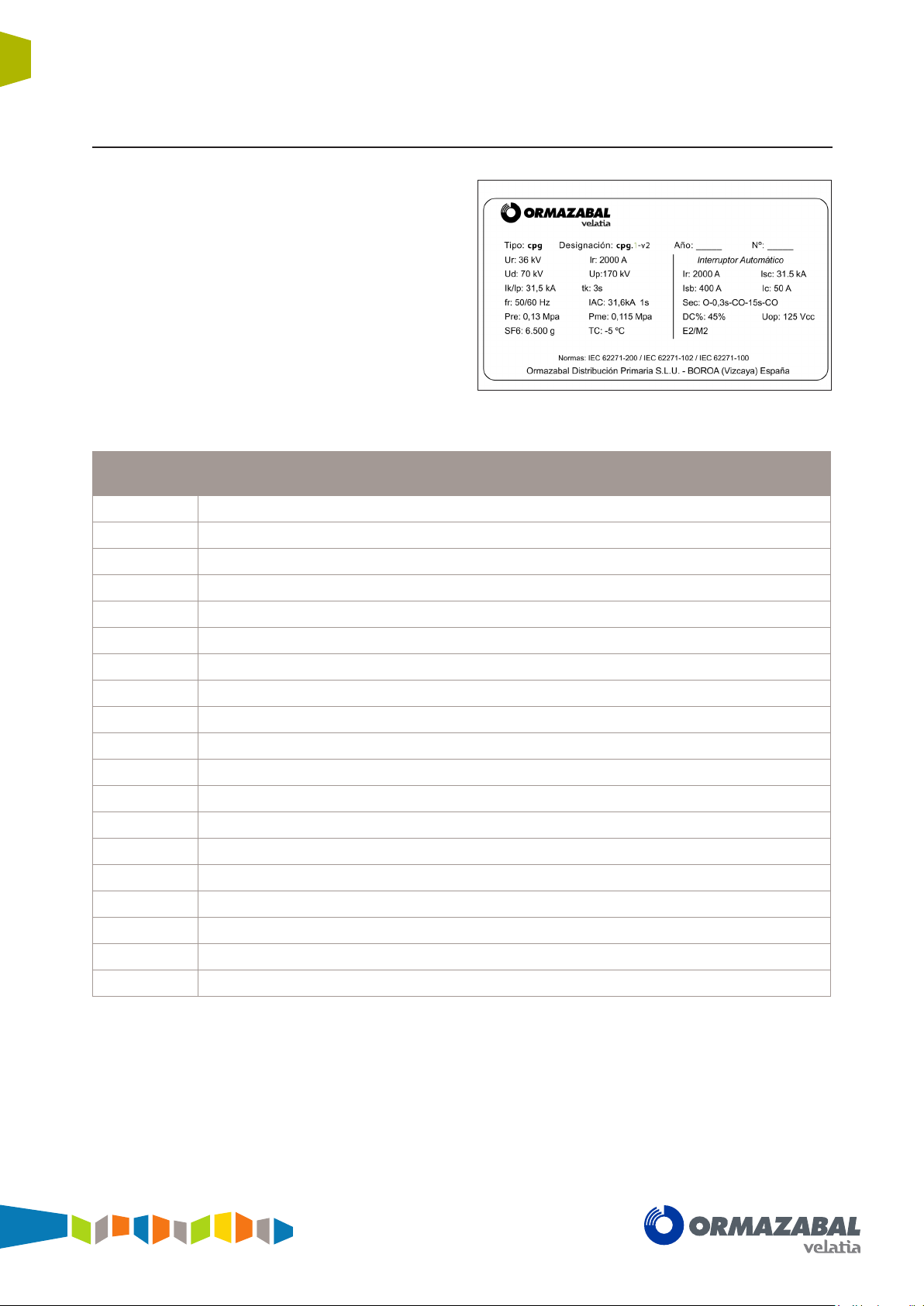

cpg.1-v2

Figure 1.12 Manual operation general panel and diagram for

cpg.1-v2

cpg.1-s1

Figure 1.13 Manual operation general panel and mimic

diagram for cpg.1-s1

a. Disconnector operation and indication area

b. Voltage presence-absence indicator

c. Driving shaft access handle

d. Earthing switch operation and indication area

e. Cable compartment cover interlocking

cpg.1-s2

Figure 1.14 Manual operation general panel and mimic

diagram for cpg.1-s2

IG-137-EN version 03; 23/06/2016

12

Description and main characteristics

Fully SF6 gas insulated single and double busbar GIS switchgears up to 36 kV in accordance

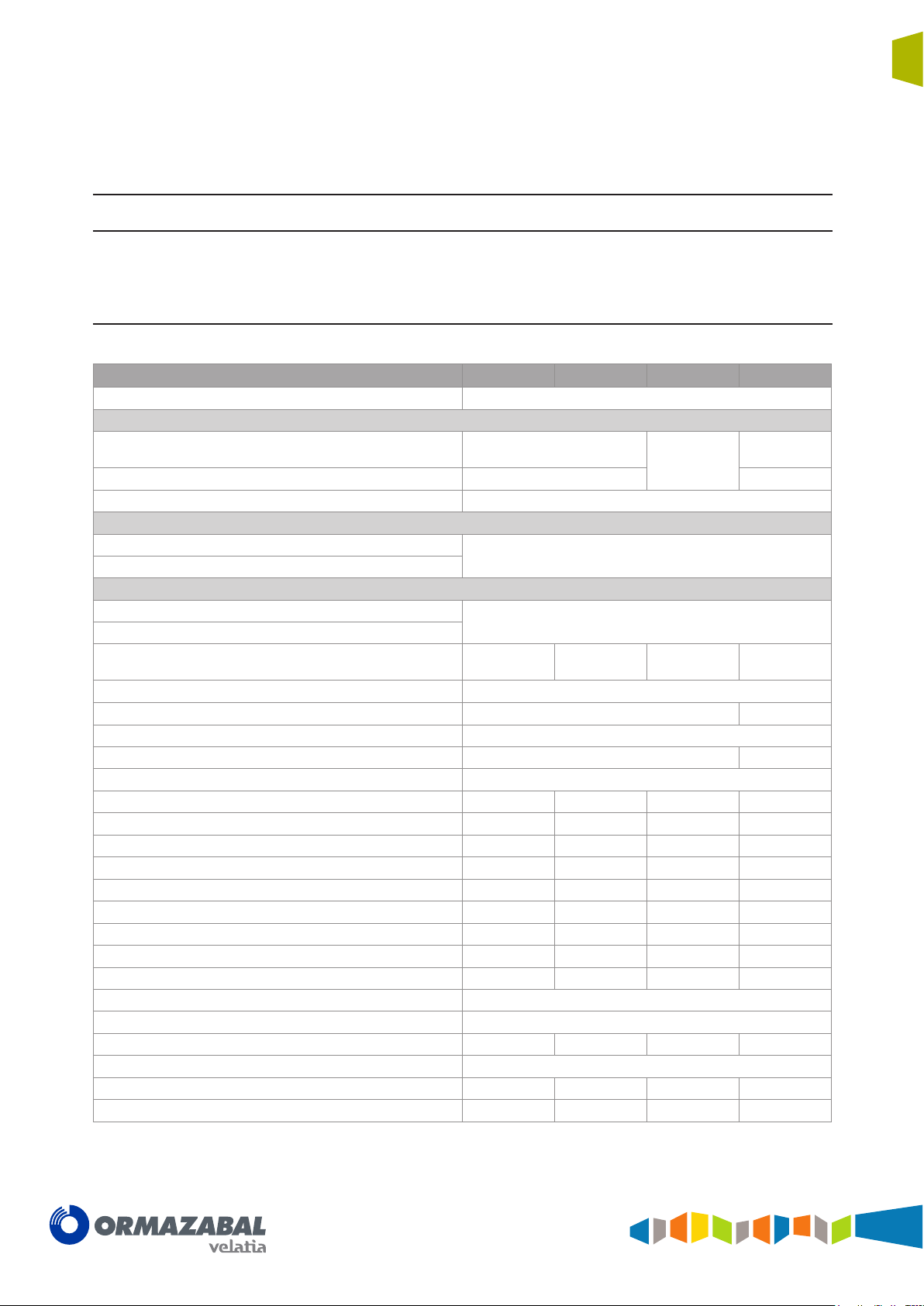

cpg.1-c

General Instructions

cpg.1

with IEC Standards

a. Disconnector operation and indication area

b. Driving shaft access handle

c. Circuit breaker operation and indication area

d. Earthing switch operation and indication area

Figure 1.15 Manual operation general panel and mimic

diagram for cpg.1-c

cpg.1-cl

Figure 1.16 Manual operation general panel and mimic

diagram for cpg.1-cl

a. Disconnector operation and indication area

b. Driving shaft access handle

c. Circuit breaker operation and indication area

d. Earthing switch operation and indication area

IG-137-EN version 03; 23/06/2016

General instructions

Description and main characteristics

cpg.1

Fully SF6 gas insulated single and double busbar GIS switchgears up to 36 kV in accordance

with IEC Standards

cpg.1-ct

a. Disconnector operation and indication area

b. Driving shaft access handle

c. Circuit breaker operation and indication area

d. Earthing switch operation and indication area

13

Figure 1.17 Manual operation general panel and mimic

diagram for cpg.1-ct

cpg.1-f1

Figure 1.18 Manual operation general panel and mimic

diagram for cpg.1-f1

cpg.1-f2

Figure 1.19 Manual operation general panel and mimic

diagram for cpg.1-f2

a. Disconnector operation and indication area

b. Voltage presence-absence indicator

c. Driving shaft access handle

d. Switch - disconnector operation and indication area

e. Earthing switch operation and indication area

f. Cable compartment cover interlocking

g. Blown fuse indicator

h. Switch manual opening handle

Conguration with motorised circuit breaker-

disconnector driving mechanism.

Operation of the earthing switch mechanism

cannot be motorised.

IG-137-EN version 03; 23/06/2016

14

Description and main characteristics

Fully SF6 gas insulated single and double busbar GIS switchgears up to 36 kV in accordance

1.4 Name plate

Every cubicle incorporates a name plate, indicating some

of the following values:

Name plate

General Instructions

cpg.1

with IEC Standards

Figure 1.20 Example of name plate for cpg.1-v2 cubicle

Nº Cubicle serial number

(*)

.

Type Ormazabal cubicle system.

Designation Cubicle model.

Standard Regulations applied to the equipment.

U

U

U

f

r

I

r

I

k

t

k

l

sc

P

P

SF

/ I

r

p

d

p

re

me

6

Equipment rated voltage.

Lightning impulse withstand voltage.

Power frequency withstand voltage.

Equipment rated frequency.

Equipment rated current.

Short-time withstand current/Short-time withstand peak value.

Short-circuit time.

Rated short-circuit breaking capacity.

Gas pressure inside the compartment (MPa).

Minimum operation pressure (MPa).

Weight (g) of insulating fluid.

Year Year of manufacture.

TC Minimum working temperature.

DC% Percentage value of the aperiodic component.

U

op

(*)

In the case of any incidents, note down this number and report it to Ormazabal.

Driving mechanism rated supply voltage for one closing and one opening operation.

IG-137-EN version 03; 23/06/2016

General instructions

Technical characteristics

cpg.1

Fully SF6 gas insulated single and double busbar GIS switchgears up to 36 kV in accordance

with IEC Standards

2 Technical characteristics

2.1 Electrical characteristics

15

Characteristics

Rated voltage kV 24 / 36

Rated current in continuous operation

In main busbar A 1250 / 1600 / 2000

Branching A 630 / 1250 / 1600 / 2000 200

Rated frequency Hz 50 / 60

Lightning impulse voltage

Between phases and phase-to-earth kV

Isolating distance kV

Power frequency voltage

Between phases and phase-to-earth kV

Isolating distance kV

Reclosing sequence

Rated short-time current main circuit kA 25 / 31.5

Rated short-time current earth circuit kA 25 / 31.5 1 / 3

Rated peak current main circuit kA 62.5 / 80

Rated peak current earth circuit kA 62.5 / 80 2.5 / 7.5

Rated short-circuit time s 1 / 3

Short-circuit breaking rated current kA 25 / 31.5 25 / 31.5

Breaking rated current in short-circuit kA 62.5 / 80 62.5 / 80

DC % 45 45

Opening time ms < 45 < 45

Short-circuit breaking time ms < 50 < 50

No-load feeder rated current A 50 50

No-load cable rated current A 31.5 / 50 31.5 / 50

Condenser battery rated current A 400 400

Transfer rated current A 800

Internal fault rated current kA 31.5

Internal fault rated time s 1

Electrical endurance E2/C2 E2/C2 E3 / C2

Auxiliary voltage

Motorised charging time ms < 15 < 15

Mechanical endurance M2 M0 M2 M2

V

cpg.1-v1/v2 cpg.1-s1/s2 cpg.1-c/cl/ct cpg.1-f

1250 / 1600

/ 2000

125 / 170

145 / 195

50 / 70

60 / 80

dc

O-0.3 s-CO-

15 s-CO

NO

O-0.3 s-CO-

15 s-CO

125

1250 / 1600

/ 2000

NO

IG-137-EN version 03; 23/06/2016

16

Technical characteristics

Fully SF6 gas insulated single and double busbar GIS switchgears up to 36 kV in accordance

2.2 Mechanical characteristics

2.2.1 Dimensions and weights

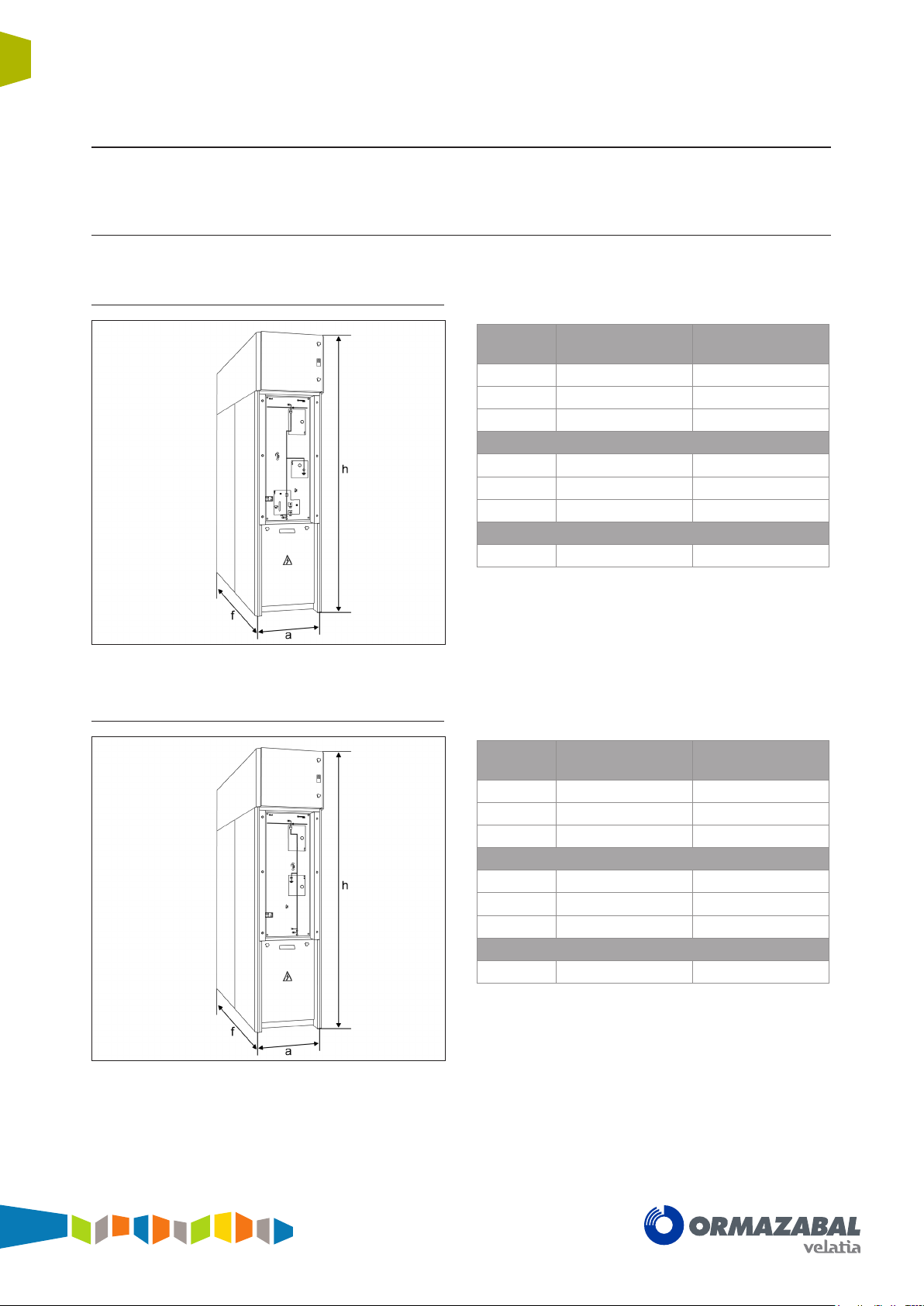

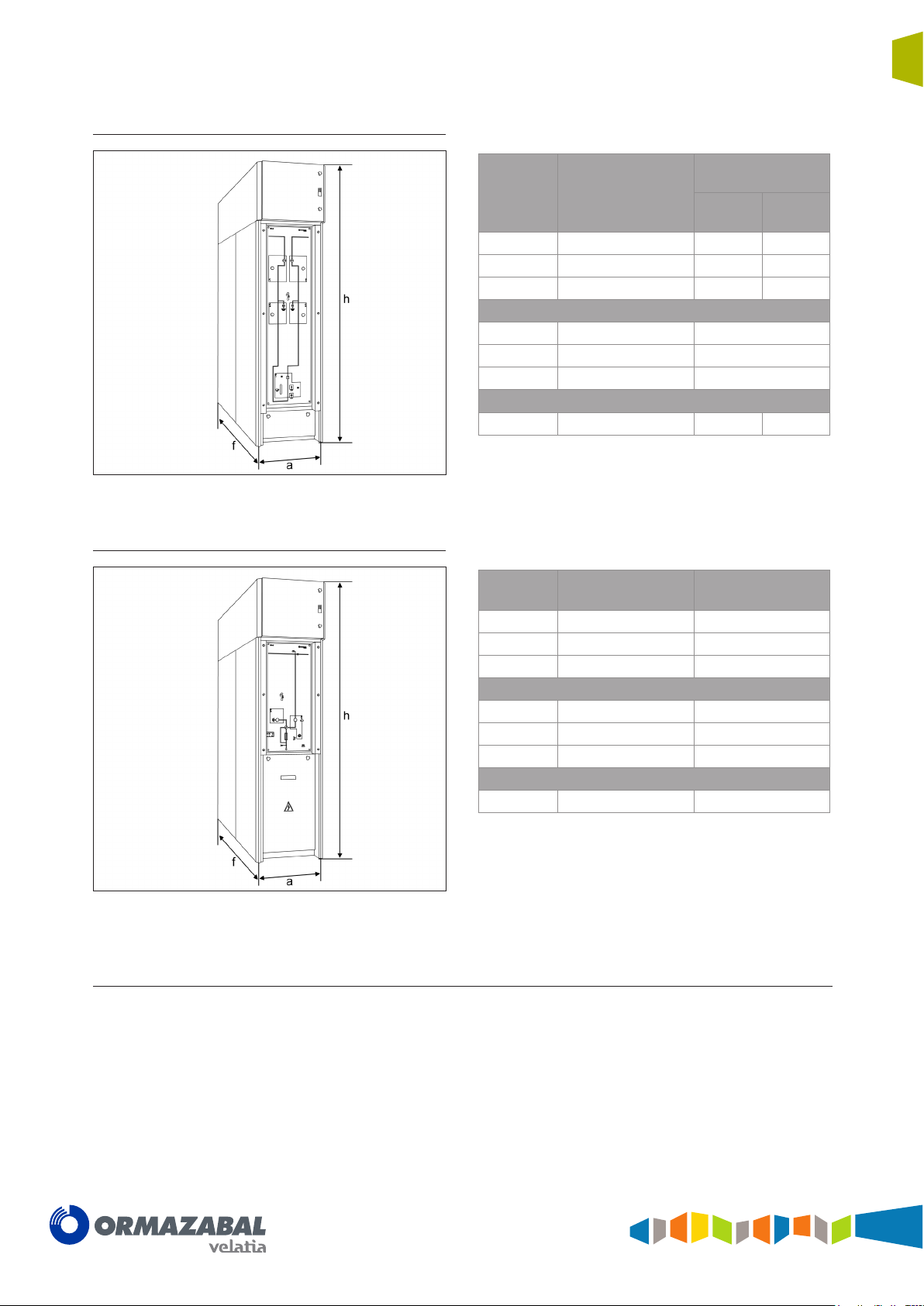

cpg.1-v circuit breaker cubicle

General Instructions

cpg.1

with IEC Standards

Figure 2.1 Dimensions of cpg.1-v cubicle

cpg.1-s disconnector cubicle

Level

a

h

f

Anchors

b

c

d

With single busbar

cpg.1-v1

600 600

2500* 2500*

1900* 1900*

[1]

550 550

500 500

590 590

With double busbar

cpg.1-v2

Weight [kg]

Total

* For control compartment 480 mm high and 561 mm deep. For other

control compartment measurements, check with Ormazabal.

** Cubicles with IAC classification AFLR have an additional 30 kg weight.

[1]

See plan of anchoring points in section 6.5.

Level

a

h

f

Anchors

[2]

b

c

d

1100** 1400**

With single busbar

cpg.1-s1

600 600

2500* 2500*

1900* 1900*

550 550

500 500

590 590

With double busbar

cpg.1-s2

Weight [kg]

Total

1000** 1200**

Figure 2.2 Dimensions of cpg.1-s cubicle

* For control compartment 480 mm high and 561 mm deep. For other

control compartment measurements, check with Ormazabal.

** Cubicles with IAC classification AFLR have an additional 30 kg weight.

[2]

See plan of anchoring points in section 6.5.

IG-137-EN version 03; 23/06/2016

General instructions

Technical characteristics

cpg.1

Fully SF6 gas insulated single and double busbar GIS switchgears up to 36 kV in accordance

with IEC Standards

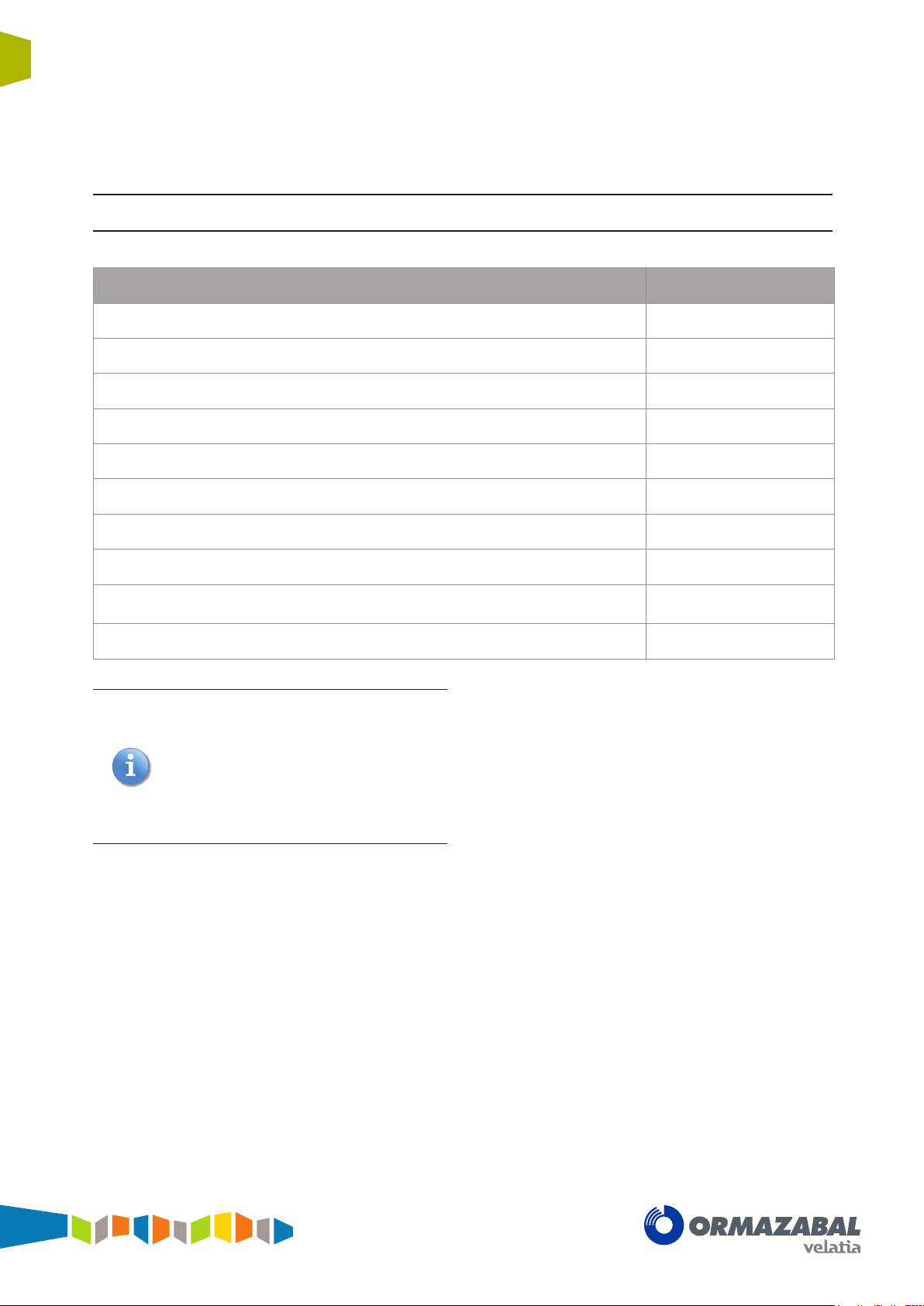

cpg.1-c busbar coupling cubicle

17

Figure 2.3 Dimensions of cpg.1-c cubicle

cpg.1-f fuse protection cubicle

With double busbar

cpg.1-cl cpg.1-ct

Level

a

h

f

Anchors

b

c

d

With single busbar

cpg.1-c

600 1200 600

2500* 2500* 2500*

1900* 1900* 1900*

[3]

550 550

500 500

590 590

Weight [kg]

Total

* For control compartment 480 mm high and 561 mm deep. For other

control compartment measurements, check with Ormazabal.

** Cubicles with IAC classification AFLR have an additional 30 kg weight.

[3]

See plan of anchoring points in section 6.5.

Level

With single busbar

a

h

f

Anchors

[4]

b

c

d

1500* 3000* 1500*

With double busbar

cpg.1-f1

600 600

2500* 2500*

1900* 1900*

550 550

500 500

590 590

cpg.1-f2

Weight [kg]

Total

1000** 1300**

Figure 2.4 Dimensions of cpg.1-f cubicle

2.2.2 Protection grade

All power circuit elements are installed inside a stainless

steel gas tank, providing IP65 degree of protection.

IG-137-EN version 03; 23/06/2016

* For control compartment 480 mm high and 561 mm deep. For other

control compartment measurements, check with Ormazabal.

** Cubicles with IAC classification AFLR have an additional 30 kg weight.

[4]

See plan of anchoring points in section 6.5.

The maximum degree of protection for the cubicle

assembly, in all designations, is IP42.

18

Service conditions

Fully SF6 gas insulated single and double busbar GIS switchgears up to 36 kV in accordance

3 Service conditions

Installation Indoor

Maximum ambient temperature + 40 ºC

Minimum ambient temperature – 5 ºC

Maximum mean ambient temperature, measured over a 24-hour period + 35 ºC

Maximum mean relative humidity, measured over a 24-hour period < 95%

General Instructions

cpg.1

with IEC Standards

Maximum mean relative humidity, measured over a 1-month period < 90%

Maximum height above sea level 1000 m

Solar radiation Negligible

Ambient air pollution (dust, smoke, corrosive and/or flammable gases, vapours or

salt)

Vibrations caused by causes external to the switchgear or by seismic movements Negligible

The specications refer to the section "Normal

service conditions for indoor cubicles" in the

IEC 62271-1 standard 'Common specications

for high voltage cubicle standards”.

For special service conditions: ambient

temperature above + 40 ºC, installation and/

or transport over 1000 m above sea level,

signicant pollution level, or others dierent to

those described, check with Ormazabal.

Insignificant

IG-137-EN version 03; 23/06/2016

General instructions

Handling and transport

cpg.1

Fully SF6 gas insulated single and double busbar GIS switchgears up to 36 kV in accordance

with IEC Standards

4 Handling and transport

4.1 Transport conditions

19

During transport, the switchgear must be perfectly seated

and fixed so that it cannot move about and possibly

damage the equipment. Always in upright position, directly

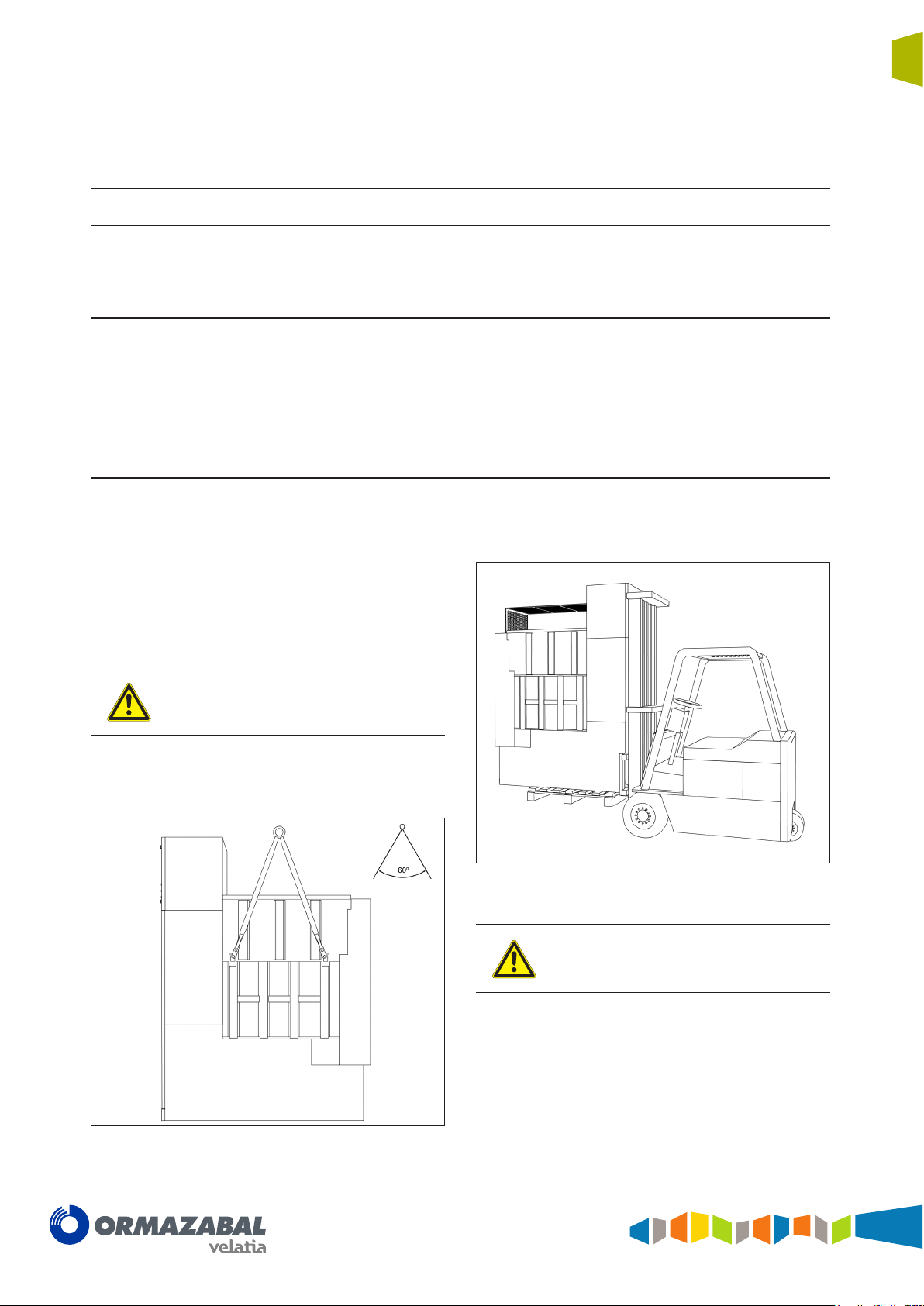

4.2 Lifting means

The cubicles must always be kept upright, directly on the

ground or on a pallet depending on the type of handling

involved.

The cpg.1 cubicles are fitted with four eyebolt-type

suspension points which can be used for handling the

cubicles with a crane; to do this, four slings or cloth straps

are used capable of carrying at least 2500 kg.

Check that the cubicle is perfectly balanced at

all times.

Once the cubicle has been sited as close as possible to

its final installation position, remove all four suspension

points from the cubicle.

on the ground or on a pallet, depending on the type of

handling involved. Check that the switchgear is perfectly

balanced at all times.

If a forklift truck is available, this should have a fork at least

2 m long and be capable of carrying at least 2500 kg.

Figure 4.1 Lifting a cpg.1 cubicle using slings

IG-137-EN version 03; 23/06/2016

Figure 4.2 Lifting a cpg.1 cubicle by forklift truck

The cubicle should always be loaded onto the

forklift truck from the front, as indicated in

gure 4.2.

20

Handling and transport

Fully SF6 gas insulated single and double busbar GIS switchgears up to 36 kV in accordance

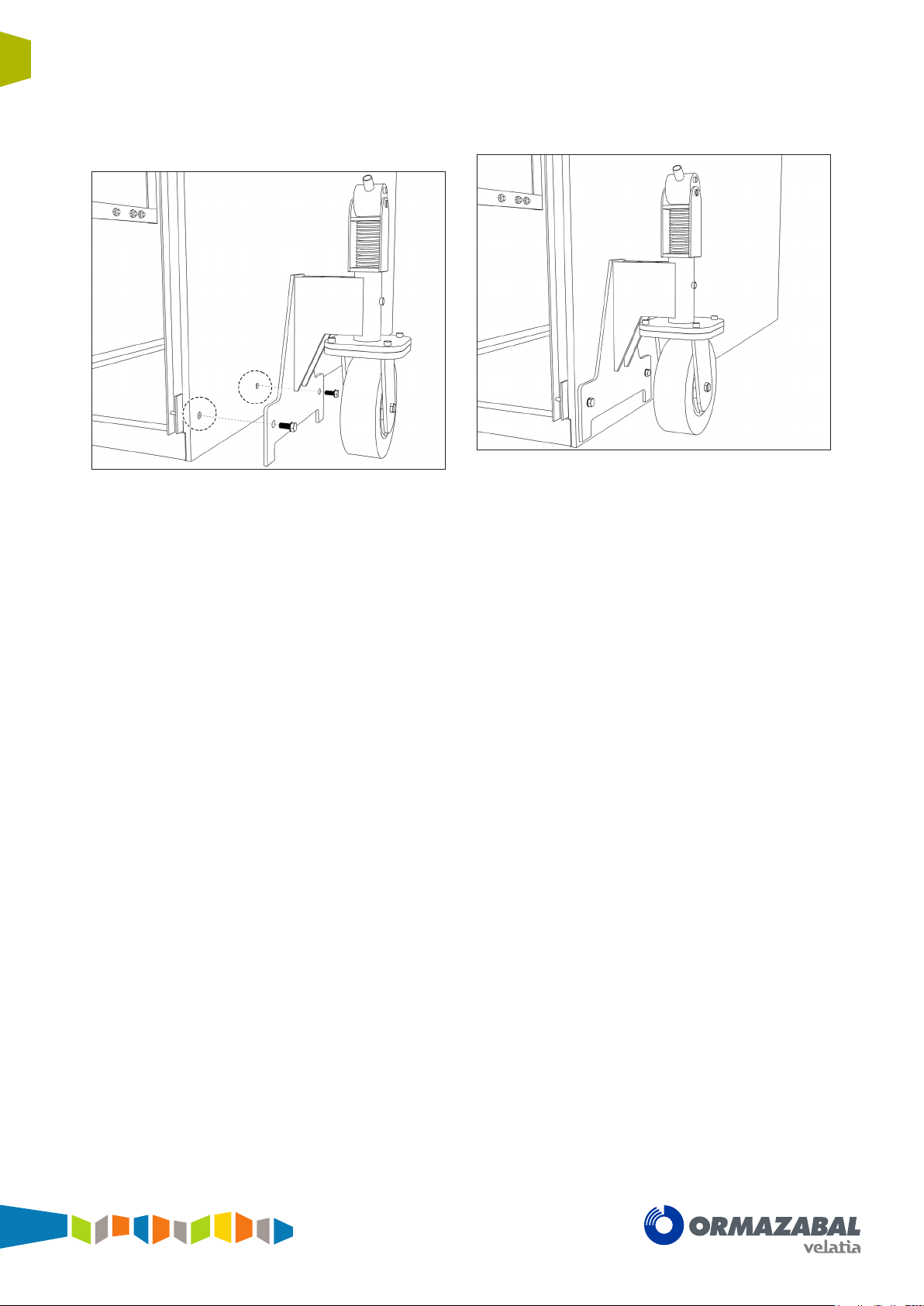

To put the cubicles in their final position, elevating caster

wheels can be used; please check with Ormazabal.

Figure 4.3 Wheel anchors in the cubicle

General Instructions

cpg.1

with IEC Standards

Figure 4.4 Detail of the positioned wheel

IG-137-EN version 03; 23/06/2016

General instructions

cpg.1

Fully SF6 gas insulated single and double busbar GIS switchgears up to 36 kV in accordance

with IEC Standards

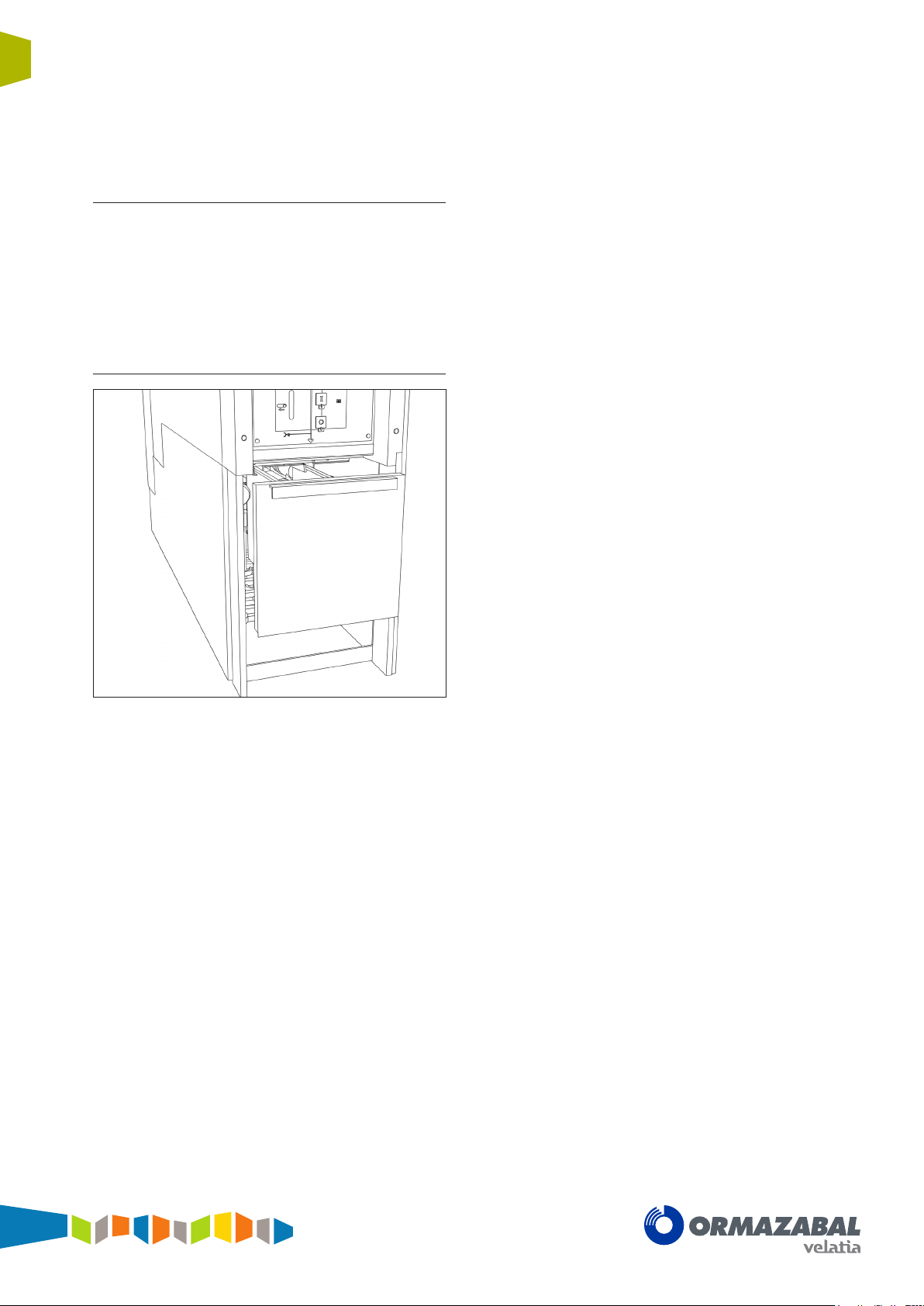

5 Storage conditions

Storage conditions

21

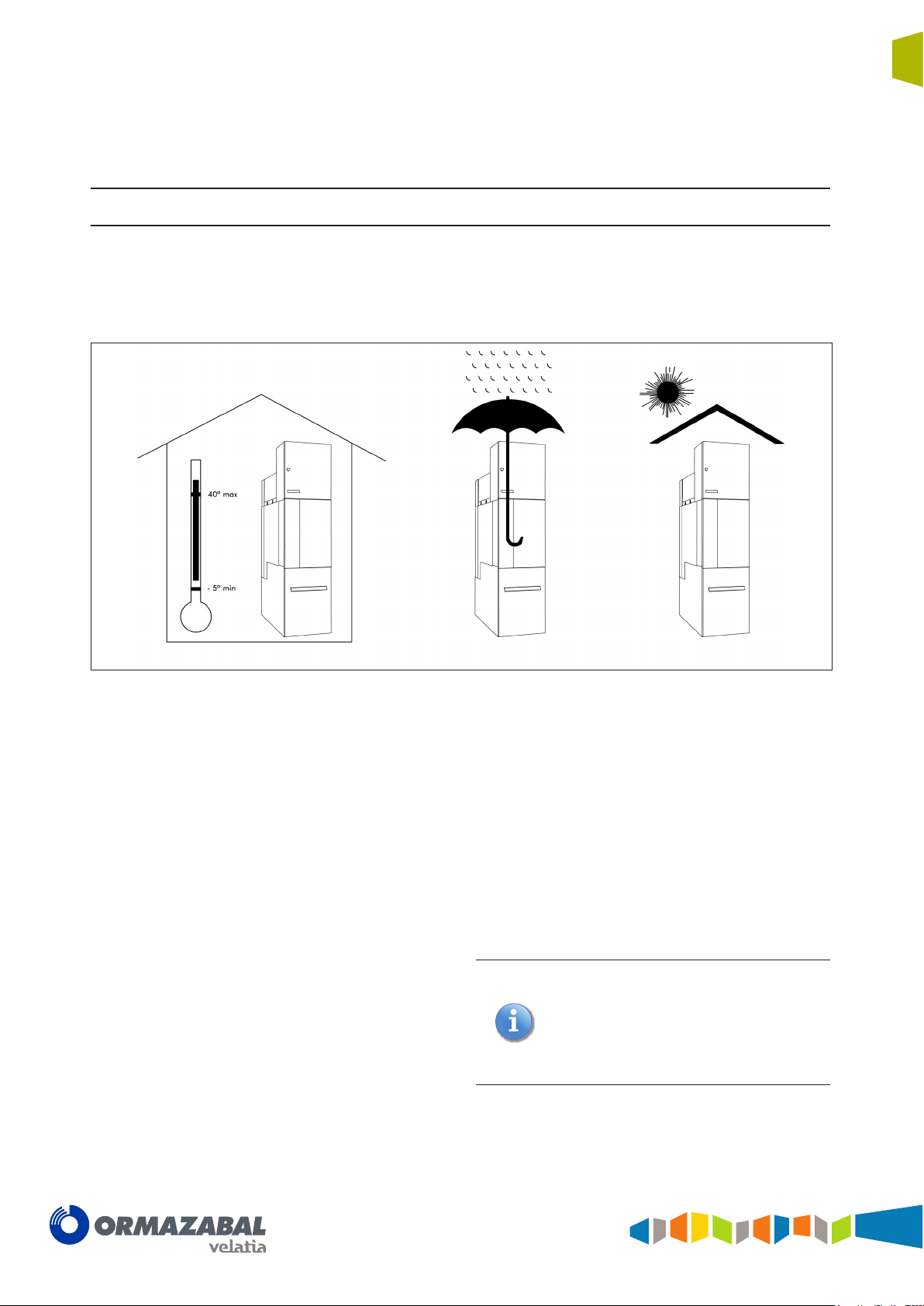

If it needs to be stored, the equipment must be placed on

dry ground or on top of damp-proof insulating material, still

in its original packaging.

Figure 5.1 Storage conditions detail

After prolonged storage, clean all the insulating parts

carefully before commissioning the equipment. The

enclosure should be cleaned with a clean, dry lint-free

cloth.

Storage must always be INDOORS, with the following

conditions recommended:

1. Ambient air temperature should not exceed

40 ºC and its mean value, measured in a period of

24 hours, should not exceed 35 ºC.

2. The ambient air temperature should not drop below

- 5 ºC.

3. The switchgear must be protected from direct solar

radiation.

4. Maximum altitude is 1000 m.

5. The environmental air must not have any significant

contamination from dust, smoke, corrosive and/or

inflammable gases, vapours or salt.

6. The switchgear must be protected from the rain, and

the humidity conditions should be as follows:

a) The mean relative humidity value, measured over

a period of 24 hours, must not exceed 95%.

b) The mean water steam pressure value, measured

in a period of 24 hours, must not exceed 2.2 kPa.

c) The mean relative humidity value, measured over

a period of one month, must not exceed 90%.

d) The mean water steam pressure value, measured

in a period of one month, must not exceed

1.8 kPa.

7. During transport, vibrations caused by external

factors or seismic movements must be insignificant.

Any other conditions must be notied

beforehand, since the equipment must be

factory-adjusted to the atmospheric pressure

at the nal destination or during transport.

Otherwise, the pressure switch may indicate an

incorrect value, even if the equipment's internal

gas pressure is correct.

IG-137-EN version 03; 23/06/2016

Loading...

Loading...