VELAN EE-1000 Maintenance Manual

VEL-BVEE-97

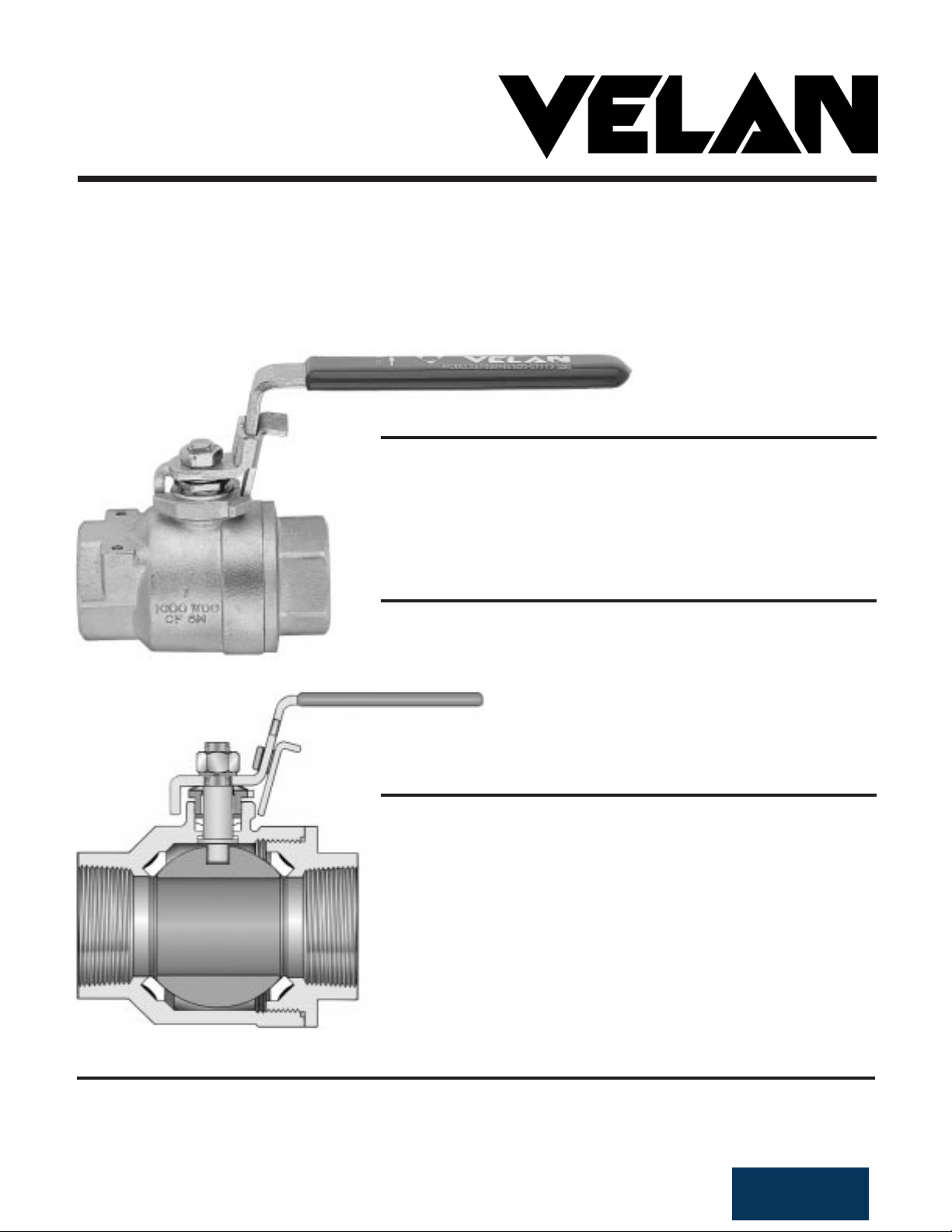

EE-1000 MEMORY SEAL BALL VALVES

MAINTENANCE MANUAL

End-Entry, Threaded, Full Port 1/4–2”, Stainless Steel

I INTRODUCTION

These rugged and universal purpose valves are suited for many

fluids, in industrial, commercial and original equipment applications. Well-suited for steam service to 150 psi. Fire safe, ideal for

fuel lines, LP gas and a variety of petroleum and petrochemical

processes. Also available for oxygen, chlorine, high vacuum and

hydrogen peroxide services.

II PREPARATION AND INSTALLATION

1. Before installing a new valve in the line, make sure the seats and

seals are suited for the intended service.

2. This ball valve is designed for bi-directional flow, unless the ball

is drilled for cavity relief.

3. Valve must be installed with sufficient Teflon tape (or similar

suitable sealant) to ensure proper installation.

III WARNING

For safety reasons, it is important to take these precautions before

you start to work on the valve.

1. Personnel making any adjustments on the valves should wear

equipment normally used to work with the process where the

valve is installed.

2. Line and valve must be depressurized by shutting off the valves

and the bleed line, then cycling the valve once and leaving it half

open to relieve the pressure from the ball cavity.

3. When installing or removing the valve from the piping system,

place a wrench on the body end nearest to the end being worked

on. Make certain body end does not turn out of the valve body.

IV GENERAL MAINTENANCE

Normal maintenance consists of tightening the gland nut as necessary. However, it should not be

tightened excessively because it will result in high torque and high packing wear or packing damage.

It is recommended to relieve the system pressure if possible. Periodically observe the valve to be sure of

proper performance. More frequent observation is recommended under extreme conditions.

Maintenance

Manuals

Valve size Torques

in lbf⋅ft (N⋅m)

1

/2 100 (136)

3

/4 150 (203)

1 175 (237)

11/4 225 (305)

11/2 400 (542)

2 550 (746)

30

33

46

50

1

6

4

59

19

3

13

62

31

V DISASSEMBLY & ASSEMBLY

DISASSEMBLY

NOTE: If complete disassembly becomes necessary,

replacement of all seats and seals is recommended.

a) Follow the instructions in the warning section.

b) Remove valve from line. The valve should be in

the closed position for disassembly.

c) Remove the handle and spring.

d) Remove the packing nut (right hand thread).

e) Remove seat retainer nut with special tool.

(available from Velan).

f) Place the valve on a table in a vertical position

with seat retainer end side down.

g) Push the ball out of the body. If necessary tap the

ball using soft material to remove it.

h) Remove stem by pushing it into the body, then

remove and discard the old packing and the thrust

washer

(see exploded view for details)

.

i) With a screwdriver, carefully push the seats out of

seat area.

NOTE: Do not scratch body in the seat area.

ASSEMBLY

a) Clean and inspect all parts for damage and change

any parts if in doubt. If possible, use a lubricant

which is compatible with fluid in the line for

smoother operation.

b) Insert new seat in body and push it down using

the ball to avoid damage to seat ball contact area.

c) Install thrust washer on stem.

Then install stem in valve.

d) Install new packing rings, tighten packing nut and

reinstall spring & handle.

e) With handle in closed position carefully slide ball

in place with bore in closed position.

f) Install seat in the body end so that the sealing face

of the seat is towards the ball.

g) Apply PTFE paste or a lubricant to the body and

insert threads. Screw the insert into the body until

a metal-to-metal contact is achieved. Tighten the

seat retainer to the required torque as shown in

Table 1.

h) Cycle the valve twice to ensure permanent

position of the ball between the two seats.

PRINTED IN CANADA VEL-BVEE-97

ITEM QTY PART NAME

1 1 Body

4 1 Stem

5 1 Ball

6 1 Thrust washer

9 2 Seat

10 1 Packing washer

13 3 Packing ring

ITEM QTY PART NAME

30 1 Handle nut

31 1 Locking device

33 1 Handle

46 1 Coil spring

50 1 Packing nut sleeve

62 1 Packing nut

71 1 Seat retainer

VELAN, INC

2125 Ward Avenue

Montreal, Quebec

Canada H4M 1T6

Tel: (514) 748-7743

Fax: (514) 748-8635

VELAN VALVE CORPORATION

18 Avenue "C", Griswold Industrial Park

Williston, Vermont USA 05495-9798

TABLE 1 Recommended seat retainer torques

Loading...

Loading...