Veikong VK100 0R2G1, VK100 0R4G1, VK100 0R7G1, VK100 1R1G1, VK100 1R5G1 User Manual

...

VK100 Series Smart Single

Phase Solar inverter

User Manual

2 / 24

1.0 Overview

1.1 Introduction

Thanks for using VK100 solar Solar pump inverter (hereinafter referred to as “this

Inverter"). Please read this operating manual carefully before usage. This operating

manual has specified the basic information regarding the installation, startup,

operation and fault diagnosis of this Inverter. Please keep this operating manual

properly for further maintenance and overhauling.

The solar photovoltaic pump system is mainly composed of solar photovoltaic pump

battery array, solar photovoltaic pump inverter and water pump. Solar photovoltaic

battery array means transmitting the solar radiation energy into DC electric energy,

which is adjusted by the photovoltaic pump inverter. The solar panel nonlinear DC

power is transmitted to the AC power which outputs continuously and complies with

the requirements of water pump motor after inversion and variable frequency

treatment. The maximum power traceability is also made to drive AC water pump

directly. The water pump motor drives impeller to pump up water.

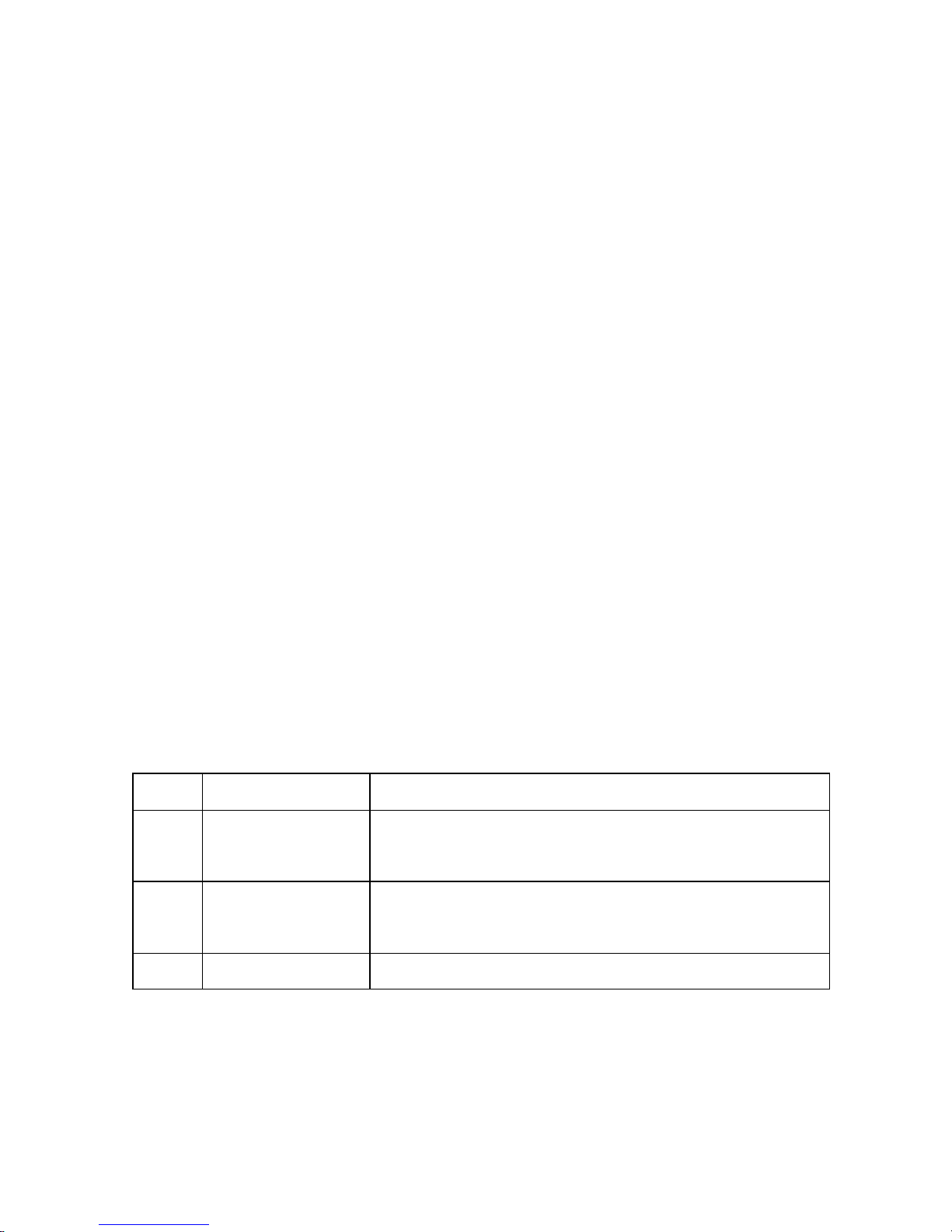

PI150 series solar pumping system

No.

Name

Descriptions

1

Solar panels

Monocrystalline silicon, polycrystalline silicon

2

Solar pump

inverter

VK100 0R2G1, VK100 0R4G1, VK100 0R7G1,

VK100 1R1G1, VK100 1R5G1, VK10 2R2G1

3

AC water pump

Single-phase 230V AC water pump

3 / 24

The photovoltaic pump is widely used in the fields such as farmland irrigation,

irrigation of pasture livestock, ecological management of desert and barren mountain,

supply of clean domestic water for both humans and livestock, municipal sewerage

treatment, landscape fountain of urban square, water conservancy facilities and sea

water desalination, with superior performance price ratio.

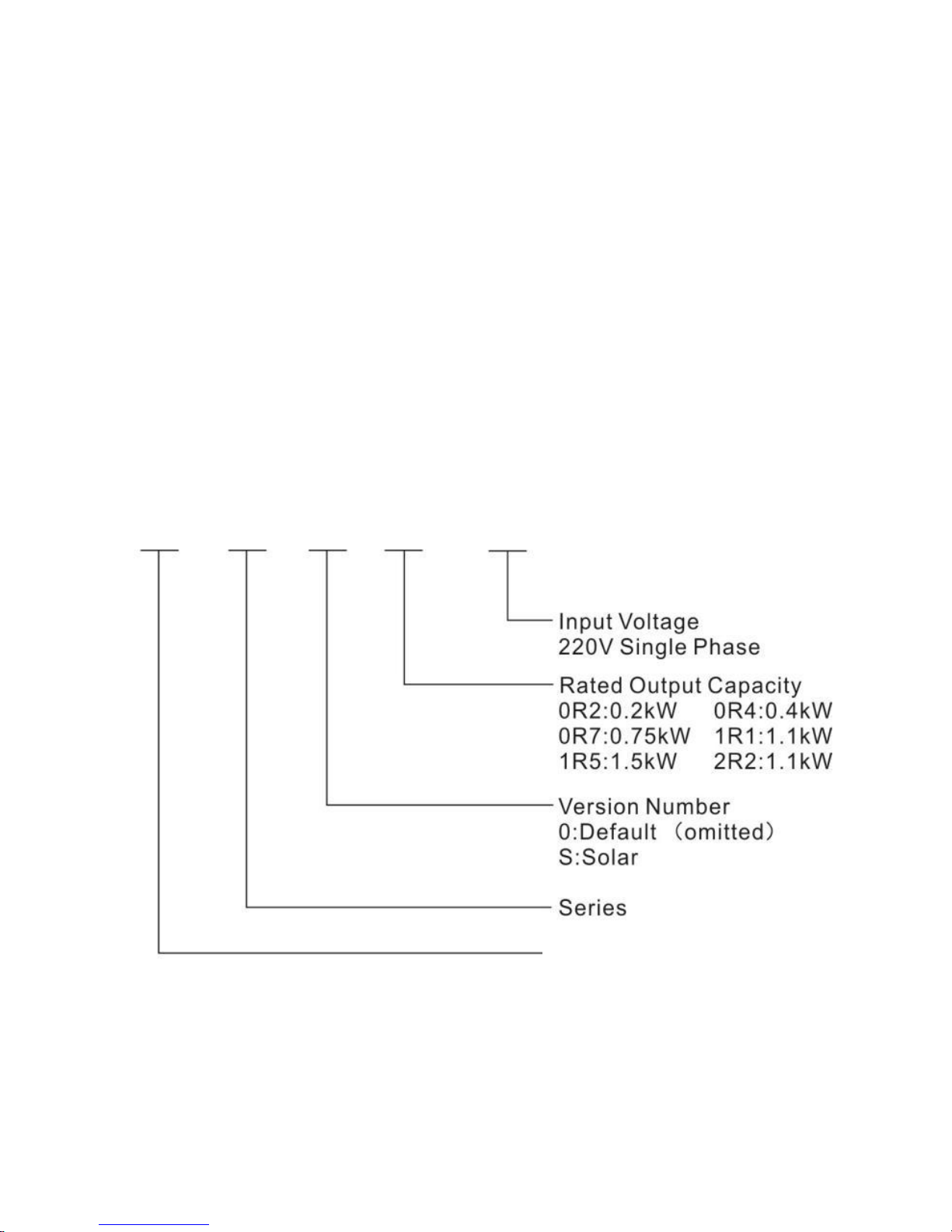

1.2 Model Identification

VK 100 S 1R5 G1

Veikong inverter

4 / 24

Ordering Instruction

1. This inverter is applicable to single phase 200V~240V, 50Hz/60Hz AC motor

water pump. The load is only applicable to motor.

2. Please determine the specific power and model of the water pump according

to the hydraulic head and water yield and by consulting the water pump manufacturer

or referring to the relevant data before purchasing this Inverter.

3. The power as stated in the nameplate of water pump is generally the output

power, instead of the actual input power or motor power, either of which is generally

greater than the nominal power due to the efficiency. The power of this Inverter shall

be larger properly (this Inverter can be configured according to the motor input power

if the power has been noted); otherwise, it easily causes overload.

4. Determination of solar photovoltaic battery array power: configured according

to the requirements for water withdrawal on site; the model and power of the water

pump shall be determined according to the hydraulic head, flow, average sunlight and

wind speed. The total power of photovoltaic array is configured according to 1.5-2

times.

5. This Inverter was provided with two working modes before delivery according

to the client’s actual situations--- automatic mode and manual mode. This Inverter will

start and adjust the output power automatically under automatic mode according to

the input power of solar battery array, that is to realize the traceability of the maximum

power point. It will operate automatically to adjust the output power of this Inverter

according to the sunlight intensity; this Inverter will not drive the water pump until it is

started manually under manual mode.

6. The electric reactor shall be added to remove harmonic wave if this Inverter is

very far away from the water pump.

7.

5 / 24

Product Features

VK100 solar photovoltaic pump inverter is applicable to all industrial and

agricultural water pumps. It can resolve the problem of matching of water

pump and make the costs of system construction and maintenance lower. It is

particularly suitable in the region where electricity can not be supplied

sufficiently.

It is provided with special power tracing algorithm and the output power of the

motor can be adjusted quickly and dynamically according to the change of

sunlight intensity so as to achieve a higher utilization rate of solar energy.

It is provided with soft start function and is free from impact current so that it

can remove water hammer totally. It shall be configured with the battery panel

with small power, which can reduce the costs of solar photovoltaic pump

system dramatically.

It has high transfer efficiency and full automatic frequency conversion with the

unattended control. It is energy saving, green and environmentally friendly.

It can input solar power or power grid AC power and switch both very easily. It

enjoys ultra-wide scope of working voltage and is thus more applicable to the

different application environments of different regions.

It is provided with overvoltage, undervoltage, overload, short circuit and

lightning-proof protection and the system thus becomes safer and more

reliable.

6 / 24

2.0 Installation

2.1 Safety cautions

Safety covers the whole process of installation, trial run, operation and maintenance

of this Inverter. The incorrect use or disoperation may cause damage to the life and

personal safety of the operators and the third party as well as this Inverter. Before

installing and using this Inverter, please read all the safety cautions and warnings

listed below carefully. We bear no liabilities for the warranty of this Inverter damaged

by the failure in installing and operating it according to the contents of this manual.

This Inverter must be used in strict accordance with the statements below in order to

avoid warranty disputes:

1) It is a must to abide by the relevant electrical specifications and this manual

and have excellent electrical operation technology.The professional electrical

technicians who are familiar with the high-voltage line and electrical hazards

shall be liable for the installation and check of this Inverter. The hazards

caused by incorrect operation may cause serious injury or even death or the

hardware damage of this Inverter.

2) Please always make sure that the switch of input power is “OFF” before

connecting and overhauling this Inverter. It is of necessity to check if the

commutating capacitor of DC main bus is totally discharged by DC voltmeter

10min after the input power of this Inverter is cut off before contacting the

internal components. It would be very dangerous since power still remains

within certain period after cutting off the power.

3) It is not allowed to open the enclosure of the inversion part inside this Inverter

by those other than the manufacturer’s professionals since it easily causes

electric shock or equipment damage and m akes the warranty of this Inverter

invalid. Please never open the box when it is electrified or is operated;

Otherwise, electric shock may happen. Never operate this Inverter when the

7 / 24

box is opened since it may cause electric shock by contacting the high-voltage

terminal and other electrified parts. Connection shall be made after installation;

otherwise, it easily causes electric shock or injury. It is also not allowed to

contact the output terminal of this Inverter even if this Inverter is started but

the water pump is not operated. In this circumstance, this Inverter may start

the water pump from time to time due to the change of photovoltaic input

power.

4) The voltage posed on all terminals shall be the one as stipulated in the

manual in order to avoid bursting, damage, etc. Too high voltage may damage

this Inverter very seriously or even makes it no longer available.

5) Never install this Inverter outdoors directly since it shall avoid direct sunshine.

It is not allowed to start/stop the motor with contactor without consulting the

manufacturer. The internal power can not be used for external equipment,

unless otherwise specified.

6) Pay attention to the service environment. The ambient factors such as

humidity, acid and alkaline and too high altitude all can deteriorate the

insulation of the products and easily cause electric shock or damage this

Inverter.

7) This Inverter must be grounded in strict accordance with the national and local

safety regulations and electrical specification. This Inverter can not be

grounded together with large current load such as electric welder and large

power motor but separated. The earthing wire shall be as short as possible. It

is not allowed to form earthing loop if several inverters are grounded at the

same time.

8 / 24

2.2 Mechanical Part

To make this Inverter satisfy the standards and technical specifications, this Inverter

must be installed in strict accordance with the following requirements:

1. This Inverter shall be installed vertically to ensure the cooling fin at the back of

this Inverter can transfer heat in maximum. The gap which is no shorter than

15cm shall be left on the top and at the bottom of this Inverter.

2. Sufficient space shall be left surrounding this Inverter so as to facilitate

maintenance.

3. Please use this Inverter by satisfying the following environmental conditions:

surrounding ambient temperature: -10℃~+50℃ (unfrozen), surrounding

ambient humidity: below 93%RH (non-condensation); storage temperature

-20℃~+70℃ (applicable temperature within short period).

4. The indoor service environment shall be free from corrosive gas, combustible

Loading...

Loading...