Veikong VFD700 Series Operation Manual

Operation manual

VFD700 Series

High Performance Universal Inverter

More options please visit:www.veikong-electric.com

Foreword

Thanks for your choosing VFD700 AC Drive from Veikong company.

This manual introduces installation, setup and commissioning of VFD700 Drive, also

troubleshooting and maintenance. This VFD700 User Manual is for easy and

efficientoperating. For further technical information and guide, you can download the

VFD700 Advanced User Manual from the website:http://www.veikong-electric.com

We will update and improve the manual termly, and this document is subject to change

without notice.

Copyright © 2015 by Shenzhen VEIKONG Electric Co.Ltd

All rights reserved.

Please read the information carefully, and keep the manual, please make sure that the end

customer has the manual.

Contents

Warnings, Cautions and Notes ............................................................................................ I

1 Technical specification .......................................................................................................... 1

1.1 Model reference .......................................................................................................... 1

1.2 Rating Label ............................................................................................................... 1

1.3 Power size ................................................................................................................... 2

1.4 General technical data................................................................................................. 4

2 Installation and cabling .......................................................................................................... 8

2.1 Dimension .................................................................................................................. 8

2.1.1 Parts of drive ................................................................................................... 8

2.1.2Diagram of mounting .......................................................................................... 8

2.1.3Keypad pallet .................................................................................................... 13

2.1.4 Simple keypad pallet ..................................................................................... 15

2.1.5 External DC reactor dimensions ................................................................... 16

2.2 Mechanical installation ............................................................................................. 18

2.2.1Drive installation diagram ................................................................................. 18

2.2.2 How to fit and remove the terminal cover ..................................................... 19

2.2.3How to fit and remove the keypad .................................................................... 20

2.3 Electrical installation ................................................................................................ 20

2.3.1Power terminals ................................................................................................ 20

2.3.2Power connections ............................................................................................ 26

2.3.3 Typical cabling .............................................................................................. 30

2.3.4 Control terminals specification ..................................................................... 31

2.3.5 Brake resistor ................................................................................................ 38

2.3.6 EMC Guide ................................................................................................... 40

2.3.7 EMC Filter .................................................................................................... 40

3 Operation and display .......................................................................................................... 46

3.1 Keypad ..................................................................................................................... 46

3.1.1 LED lights ..................................................................................................... 46

3.1.2 Key function ................................................................................................. 47

3.1.3 Keypad operation .......................................................................................... 48

3.2 Drive control ............................................................................................................. 52

3.2.1 Drive status ................................................................................................... 52

3.2.2 Control modes ............................................................................................... 53

3.2.3 Reference source ........................................................................................... 53

3.2.4 Priority of running mode ............................................................................... 54

3.3 Quick commissioning .............................................................................................. 54

3.3.1 Keypad control .............................................................................................. 54

3.3.2 Terminal control ............................................................................................ 55

4 Parameters .......................................................................................................................... 58

4.1 General description .................................................................................................. 58

4.3 Menu P00 ................................................................................................................. 59

5 Troubleshooting .................................................................................................................. 67

5.1 Faults and corrective actions .................................................................................... 67

5.2 Alarms ..................................................................................................................... 75

5.3 Other issues .............................................................................................................. 76

6 Maintenance ........................................................................................................................ 78

6.1 Routine maintenance ................................................................................................ 78

6.2 Periodic check .......................................................................................................... 78

6.3 Parts replacement ..................................................................................................... 80

6.4 Drive storage ............................................................................................................ 80

6.5 Disposal ................................................................................................................... 80

Appendix .................................................................................................................................. 81

1 Communication ........................................................................................................... 81

2 Parameter list .............................................................................................................. 90

Menu P00: Shortcut menu (quick commissioning) ................................................... 90

Menu P01: Reference ................................................................................................ 94

Menu P02: Ramp ...................................................................................................... 97

Menu P03: Start and stop ........................................................................................ 100

Menu P04: Preset and PLC ..................................................................................... 103

Menu P05: Keypad and display .............................................................................. 108

Menu P06: V/F controls parameters ........................................................................ 111

Menu P07: Vector.................................................................................................... 112

Menu P08: Analogue input and output ................................................................ .... 114

Menu P09: Digital input and output ........................................................................ 118

Menu P10: Comms. and general function ............................................................... 123

Menu P11: Fault Tracking ...................................................................................... 126

Menu P12: Protection ............................................................................................. 127

Menu P13: Motor.................................................................................................... 129

Menu P14: Textile function .................................................................................... 132

Menu P15: PID Controller ................................................................ ...................... 134

Menu P16: Programmable logic and binary sum .................................................... 137

Menu P17: Threshold and variable selector ............................................................ 139

Menu P18: Brake logic control ............................................................................... 144

3 Multistage velocity setup guide .................................................................................... 145

4 User PID controller ....................................................................................................... 147

5 Options ......................................................................................................................... 149

6 Declaration of conformity............................................................................................. 150

Drive Repair Card ..................................................................................................... 152

Service Agreement .................................................................................................................. 153

Warnings, Cautions and Notes

A Warning contains information, which is essential for avoiding a safety hazard.

A Caution contains information, which is necessary for avoiding risk of damage to the

product or other equipment.

A Note contains information, which helps to ensure correct operation of the product.

WARNING

The VFD700 AC drive should ONLY be installed by aqualified electrician.

Install the drive on nonflammable materials like metalsheet in case of fire.

Do not install the drive in environment with explosive gas.

Even when the motor is stopped, dangerous voltage is present at thePower Circuit

terminals L1, L2, L3, U, V, W ,and,depending on the framesize, DC+ and DC−, or

BR.

Dangerous voltage is present when input power supply is connected to the drive.

Afterdisconnecting the supply, wait at least 10 minutes (to let the intermediate

circuitcapacitors discharge) before removing the cover.

PE terminals must be earthed very well.

Caution:

Warning:

CAUTION

The VFD700 is not a field repairable unit. Never attempt to repair a malfunctioning

unit; contact the factory or your local Authorized Service Center forreplacement.

The VFD700 will start up automatically after an input voltage interruption if external

running command is on.

Prior to measurements on the motor or the motor cable, disconnect themotor cable

from the Variable Speed Drive.

Before connecting the Variable Speed Driveto mains, make sure that theVFD700’s

front cover and cable cover are closed.

1 Technical specification

VFD700 AC Drive Getting Started Guide 1

1 Technical specification

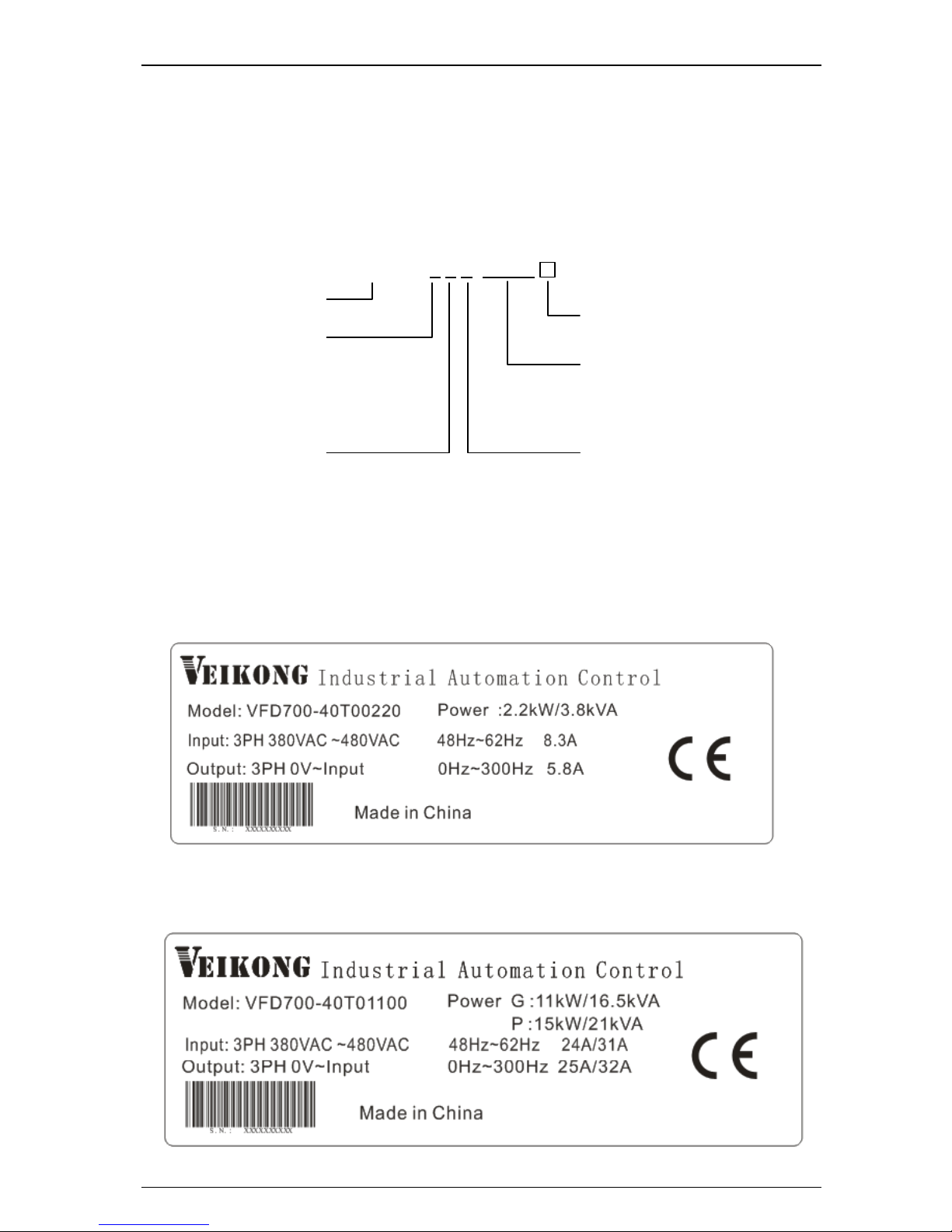

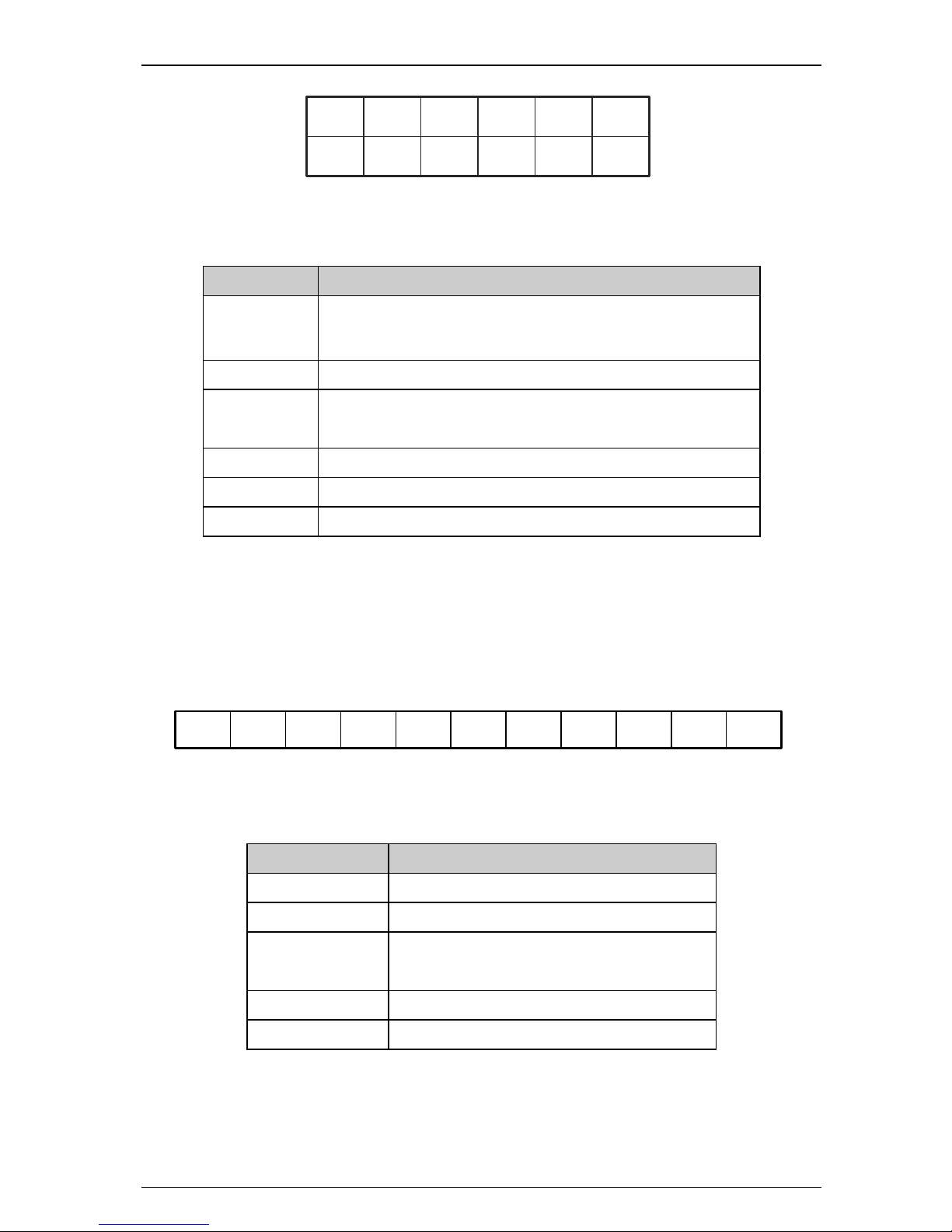

1.1 Model reference

HD700 - 4 0 T 00550

Power size

00040:0.4kW

|

45000:450kW/500kW

Input phase

D:1/3PH

T:3PH

Family

Supply voltage

2:220V

4:380V

6:690V

Brake unit

0:Built-in brake

1:No brake unit

Non: Standard G type

E: small size G type

P: small size P type

Figure1-1 VFD700 model description

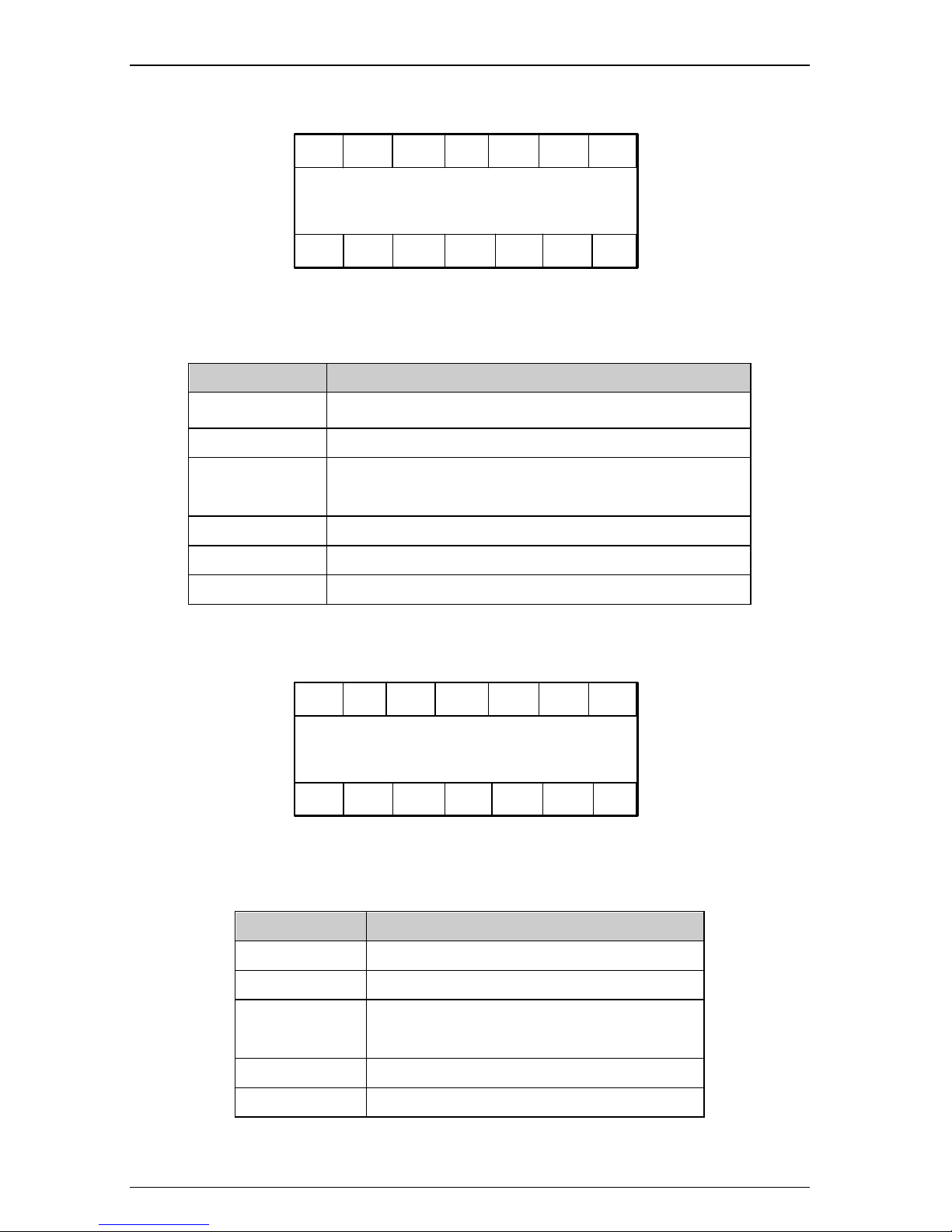

1.2 Rating Label

Figure1-2 VFD700 rating label (Single power type)

VFD700

1 Technical specification

2VFD700 AC Drive Getting Started Guide

Figure1-3 VFD700 rating label (Double power type)

NOTE: Size A, B, C are single types. Size D and above are G/P types.

1.3 Power size

Power size of VFD700 is based on the standard 4 poles inductionmotor at rated voltage.

E, G: Heavy duty

P: Normal duty

Overload of E, G type: 150% rated output current, 1 minute

Overload of Ptype: 110% rated output current, 1 minute

Table 1-1 220V rating data

Power supply: 200VAC~240VAC, 50Hz/60Hz, single/three phase

Model

Default carrier

frequency (kHz)

Drive

Power Size

(kVA)

Rated Input

Current(A)

Rated

Output

Current(A)

MotorP

ower(k

W)

Size

1/3PH

VFD700-20D00040

6

1.1

7.1/4

2.8

0.4

A

VFD700-20D00075

6

1.9

12.8/7.1

5

0.75

A

VFD700-20D00150

6

3.0

20.5/11.3

8

1.5

A

VFD700-20D00220

6

4.2

24/14.5

11

2.2

B

VFD700-20D00400

6

6.7

30.4/16.5

17.6

4

C

Table 1-2380V rating data

Power supply: 380VAC~480VAC, 50Hz, three phase

Model

Default

carrier

freque-

ncy

(kHz)

G

P

Size

Drive

Power

Size

(kVA)

Rated

Input

Current

(A)

Rated

Output

Current

(A)

Motor

Power

(kW)

Drive

Power

Size

(kVA)

Rated

Input

Current

(A)

Rated

Output

Current

(A)

Motor

Power

(kW)

VFD700-40T00075

6

1.7

3.6

2.5

0.75 − − − −

A

VFD700-40T00150

6

2.8

5.7

4.2

1.5 − − − −

A

VFD700-40T00220

6

3.4

6.1

5.2

2.2 A VFD700-40T00220

6

3.8

8.3

5.8

2.2 − − − − B VFD700-40T00400

6

6.3

13.2

9.5

3.7 − − − −

B

VFD700-40T00550

6

8.6

14.3

13

5.5 − − − −

B

VFD700-40T00550P

6 − − − −

8.6

14.3

13

5.5

B

VFD700-40T00550

6

8.6

12.4

13

5.5 − − − − C VFD700-40T00750

6

11

16.1

17

7.5 − − − −

C

VFD700-40T01100P

6 − − − −

15.2

21

23

11

C

VFD700-40T01100

6

16.5

24

25

11

21

31

32

15 D VFD700-40T01500

6

21

31

32

15

25

36

38

18.5

D

1 Technical specification

VFD700 AC Drive Getting Started Guide 3

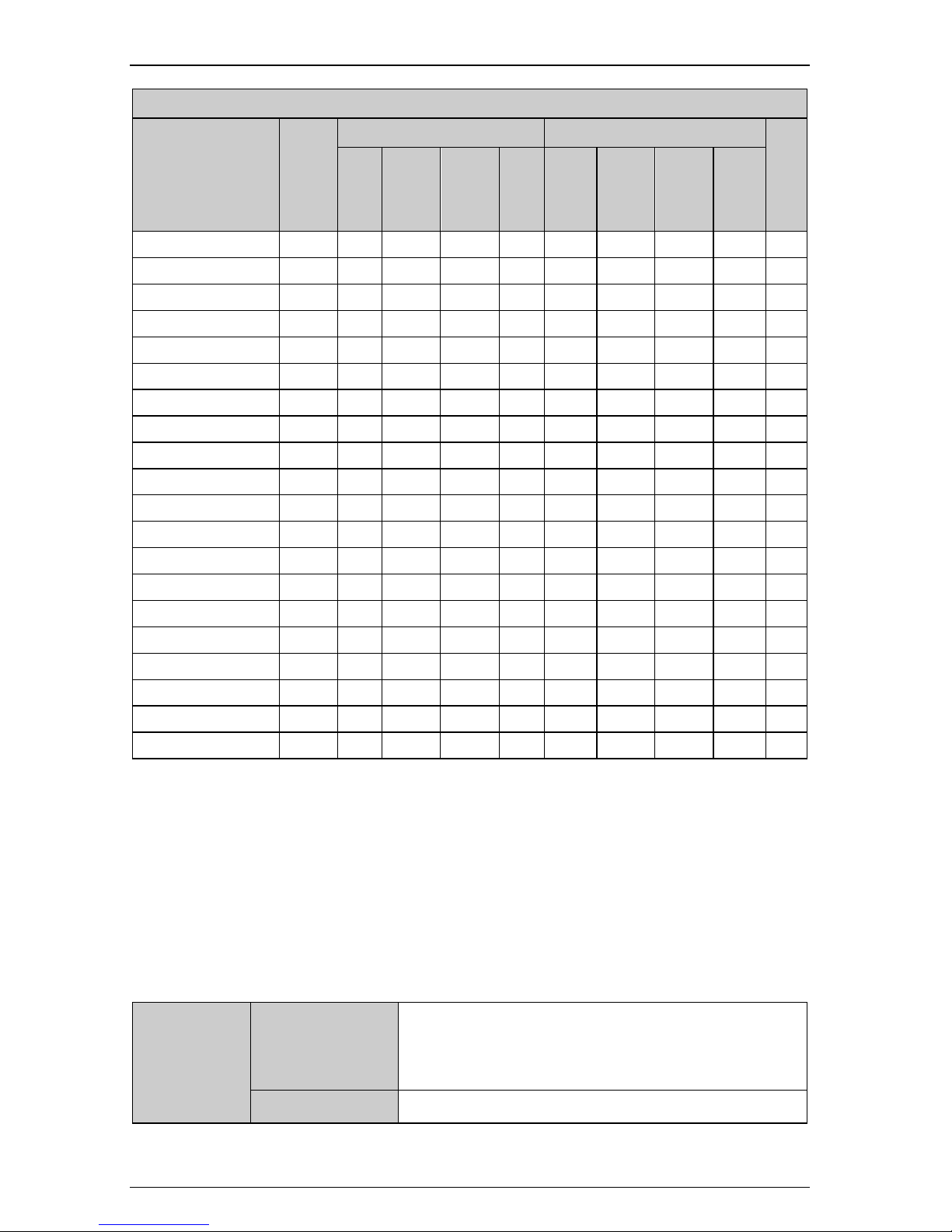

Power supply: 380VAC~480VAC, 50Hz, three phase

Model

Default

carrier

freque-

ncy

(kHz)

G

P

Size

Drive

Power

Size

(kVA)

Rated

Input

Current

(A)

Rated

Output

Current

(A)

Motor

Power

(kW)

Drive

Power

Size

(kVA)

Rated

Input

Current

(A)

Rated

Output

Current

(A)

Motor

Power

(kW)

VFD700-40T01850

6

25

36

38

18.5

30

44

46

22 E VFD700-40T02200

6

30

44

46

22

40

58

60

30 E VFD700-40T03000

3

40

58

60

30

50

72

75

37

E1

VFD700-40T03700

3

50

72

75

37 − − − −

E1

VFD700-40T03000

3

40

58

60

30

50

72

75

37 F VFD700-40T03700

3

50

72

75

37

63

93

96

45 F VFD700-40T04500

3

63

93

96

45

83

121

125

55 F VFD700-40T05500

3

83

121

125

55

103

151

156

75 F VFD700-40T07500

3

103

151

156

75

119

175

180

90 F VFD700-40T09000

3

119

175

180

90

139

204

210

110

G

VFD700-40T11000

3

139

204

210

110

169

248

256

132

G

VFD700-40T13200

3

169

248

256

132

205

301

310注

160

G

VFD700-40T16000

3

205

301

310

160

231

340

350

185

J

VFD700-40T18500

3

231

340

350

185

255

375

387

200

J

VFD700-40T20000

3

255

375

387

200

280

415

427

220

J

VFD700-40T16000

3

205

301

310

160

231

340

350

185

K

VFD700-40T18500

3

231

340

350

185

255

375

387

200

K

VFD700-40T20000

3

255

375

387

200

310

457

471

250

K

VFD700-40T25000

3

310

457

471

250

343

505

520

280

K

VFD700-40T28000

3

343

505

520

280

403

592

610

315

K

VFD700-40T31500

2

403

592

610

315

444

653

673

355

K1

VFD700-40T35500

2

444

653

673

355

495

728

750

400

K1

VFD700-40T31500

2

403

592

610

315

444

653

673

355

L

VFD700-40T35500

2

444

653

673

355

495

728

750

400

L

VFD700-40T40000

2

495

728

750

400

551

810

835

450

L

VFD700-40T45000

2

551

810

835

450

622

915

943

500

L

Table 1-3 690V rating data

Power supply: 500VAC~690VAC, 50Hz, three phase

Model

Default

carrier

freque-

ncy

(kHz)

G

P

Size

Drive

Power

Size

(kVA)

Rated

Input

Current

(A)

Rated

Output

Current

(A)

Motor

Power

(kW)

Drive

Power

Size

(kVA)

Rated

Input

Current

(A)

Rated

Output

Current

(A)

Motor

Power

(kW)

VFD700-60T03000

3

43

36

36

30

51

42

43

37 F VFD700-60T03700

3

51

42

43

37

65

52

54

45

F

1 Technical specification

4VFD700 AC Drive Getting Started Guide

Power supply: 500VAC~690VAC, 50Hz, three phase

Model

Default

carrier

freque-

ncy

(kHz)

G

P

Size

Drive

Power

Size

(kVA)

Rated

Input

Current

(A)

Rated

Output

Current

(A)

Motor

Power

(kW)

Drive

Power

Size

(kVA)

Rated

Input

Current

(A)

Rated

Output

Current

(A)

Motor

Power

(kW)

VFD700-60T04500

3

65

52

54

45

75

61

63

55 F VFD700-60T05500

3

75

61

63

55

103

83

86

75 F VFD700-60T07500

3

103

83

86

75

120

97

100

90 F VFD700-60T09000

3

120

97

100

90

157

127

131

110

G

VFD700-60T11000

3

157

127

131

110

179

145

150

132

G

VFD700-60T13200

3

179

145

150

132

209

170

175注

160

G

VFD700-60T16000

3

209

170

175

160

237

192

198

185

J

VFD700-60T18500

3

237

192

198

185

276

224

231

200

J

VFD700-60T20000

3

276

224

231

200

296

235

248

220

J

VFD700-60T16000

3

209

170

175

160

237

192

198

185

K

VFD700-60T18500

3

237

192

198

185

276

224

231

200

K

VFD700-60T20000

3

276

224

231

200

327

266

274

250

K

VFD700-60T25000

3

327

266

274

250

350

285

293

280

K

VFD700-60T28000

3

350

285

293

280

392

318

328

315

K

VFD700-60T31500

2

392

318

328

315

462

375

387

355

K1

VFD700-60T35500

2

462

375

387

355

509

413

426

400

K1

VFD700-60T31500

2

392

318

328

315

462

375

387

355

L

VFD700-60T35500

2

462

375

387

355

509

413

426

400

L

VFD700-60T40000

2

509

413

426

400

576

468

482

450

L

VFD700-60T45000

2

576

468

482

450

651

529

545

500

L

NOTE:

VFD700-Ч1TЧЧЧЧЧ rating data are the same with VFD700-Ч0TЧЧЧЧЧ.

For 30kW and above models, internal bake unit is optional, please refer to chapter 1.1.

When VFD700-xxT13200 or VFD700-xxT28000 is used as P type, the default carrier

frequency is 1kHz.

1.4 General technical data

Table 1-4 General technical specification

Input Power

Input Voltage U

in

200V (−10%)~240V (+10%) 1/3 PH

380V (−10%)~480V (+10%) 3PH

500V (−10%)~690V (+10%) 3PH

Input Frequency

50/60Hz (±2Hz)

1 Technical specification

VFD700 AC Drive Getting Started Guide 5

Maximum Supply

Imbalance

≤3%

Power Output

Output Voltage

0V~Uin

Output Frequency

0Hz~300Hz

Main

PerformanceF

unction

Voltage Control

V/F, Open loop Vector Control

Switching

Frequency

1kHz~15kHz

SpeedAdjustment

Range

Open loop vector -1:100, V/F mode -1:50

Start Torque

0.5Hz: 100% rated torque, 1Hz: 150% rated torque

Torque Accuracy

7%

Reference

resolution

Digit- 0.01Hz, Analogue- 0.1%×Max. frequency

Acce. & Dece. rate

0.1s~3600min

Voltage Boost

0.1%~30.0%

Overload

E, G type:150% rated output current, 1 minute

P type:110% rated output current, 1 minute

V/F

4 types: V/F(user can program) and ramp (2.0 power, 1.7

power, 1.2 power)

DC Braking

Injection frequency: 0.0%~100.0% Max. frequency

Injection current: 0.0%~300.0% rated current

Injection time: 0.00s~60.00s

Dynamic Brake

Brake rate: 0.0%~100.0%

Jog

Jog frequency: 0.00Hz~maximum frequency

Jog acceleration rate: 0.1s~600.0s

Jog interval time: 0.1s~600.0s

Preset

16 preset speeds (decided by control terminals)

AVR

Maintain the rated output voltage when the input power

supply voltage changed

Special

Function

Textile

For textile machine control

Simple PLC

Onboard PLC

Length Control

Winding control

PID Control

Process control(reference close loop control)

1 Technical specification

6VFD700 AC Drive Getting Started Guide

Advanced

Function Blocks

2 logic control blocks, 1 binary selector, 2 threshold control

blocks, 3 variable selectors

Control

Terminal

Reference Source

Digit: Keypad, motorized pot (E-Pot), preset speed, pulse,

comms.

Analogue: AI1: 0V~10V, 0(4) mA~20mA;

AI2: 0V~10V

Operating Mode

Keypad, Control terminal, Serial comms.

DigitalInput

Terminals

DI1~DI7: Programmable terminals and DI6 can be set as

pulse input, 0Hz~60Hz; DI7 can be high frequency pulse

input(1kHz~50.0kHz)or PTC thermistor input

Digital output

terminals

DO1~DO2: Programmable terminals, Max. output

current:50mA, DO2can be the terminal of output

pulse( 0.1kHz~50.0kHz ), and output PWM

Analogue output

AO1: programmable terminal, 0V~10V

Status relay

2 programmable relays, contactor data:

AC250V/2A(COSφ=1)

AC250V/1A(COSφ=0.4)

DC30V/1A

Comms.

Connector

2 terminals(A&B) and RJ45 Port

Protocol

ModbusRTU

Environment

Altitude

1000m rated

1000m~3000m,1% rated current derating per 100m

Operating

Temperature

−10C~+40C

Max. Humidity

≤90%RH, no-condensing

Vibration

≤5.9m/s

2

(0.6g)

Storage

Temperature

−40C~+70C

Running

Environment

Indoor, no-flammable or corrosive gasses,no contamination

with electrically conductive materials,avoiding dust which

may restrict the fan

1 Technical specification

VFD700 AC Drive Getting Started Guide 7

Optional Module

LCD keypad, HDOM-232, HDOM-USB, Profibusmodule,

keypad pallet, HDSOFT (PCTools), etc.

Protection Function

Output shortage, over current, over load, over voltage,

under Voltage, Phase loss, over heat (heatsink and

junction), external fault, etc.

Efficiency

1.5kW and below: ≥89%

2.2kW~22kW: ≥93%

30kW and above: ≥95%

Installation

can be installed by hanging wall, through holes, or

vertically

Ingress Protection

IP20, IP21 (by adding optional device)

Cooling Method

220V/0.4kWmodel – cools naturally, others cool with

forced air cool

2 Installation and cabling

8VFD700 AC Drive Getting Started Guide

2 Installation and cabling

2.1 Dimension

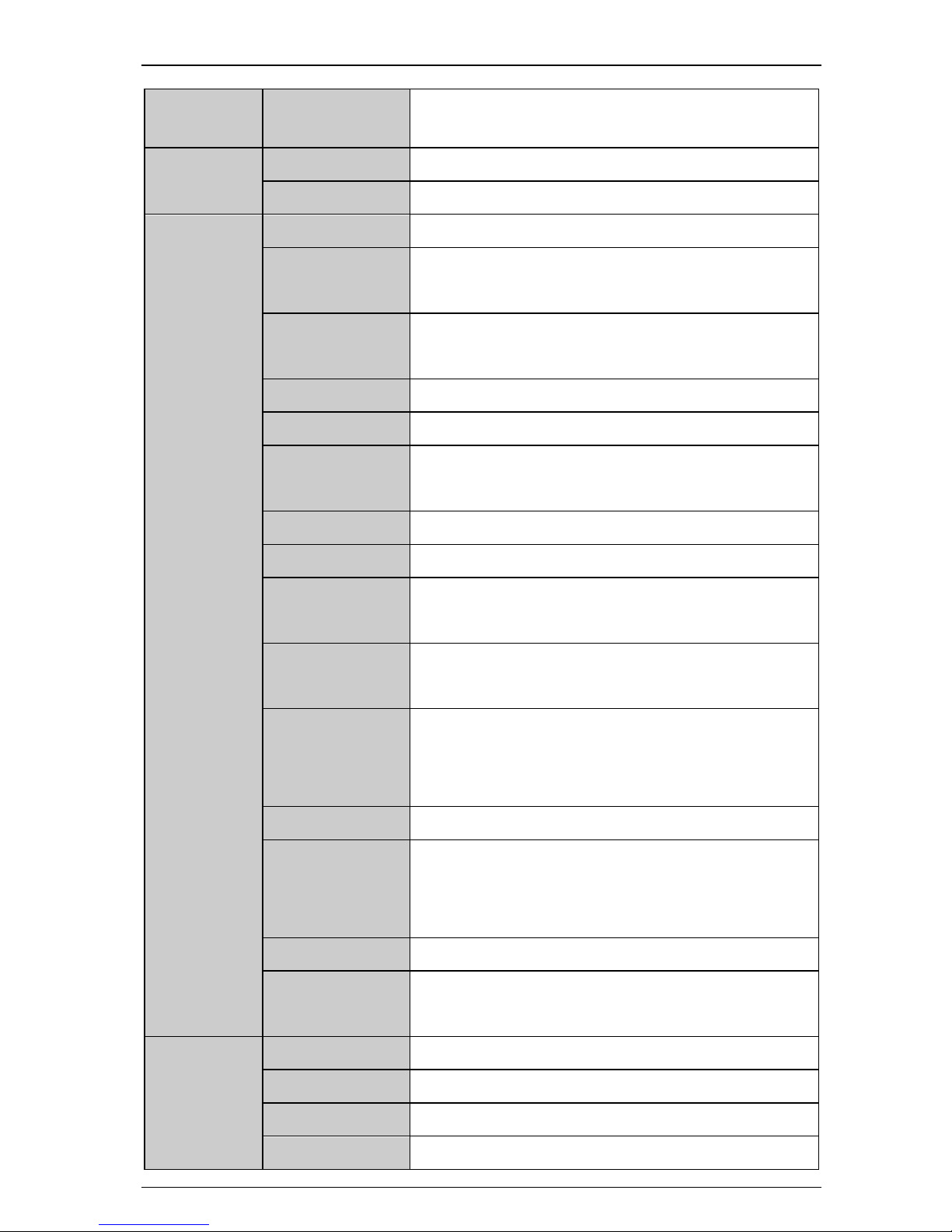

2.1.1 Parts of drive

Figure 2-1 Parts of VFD700 drive

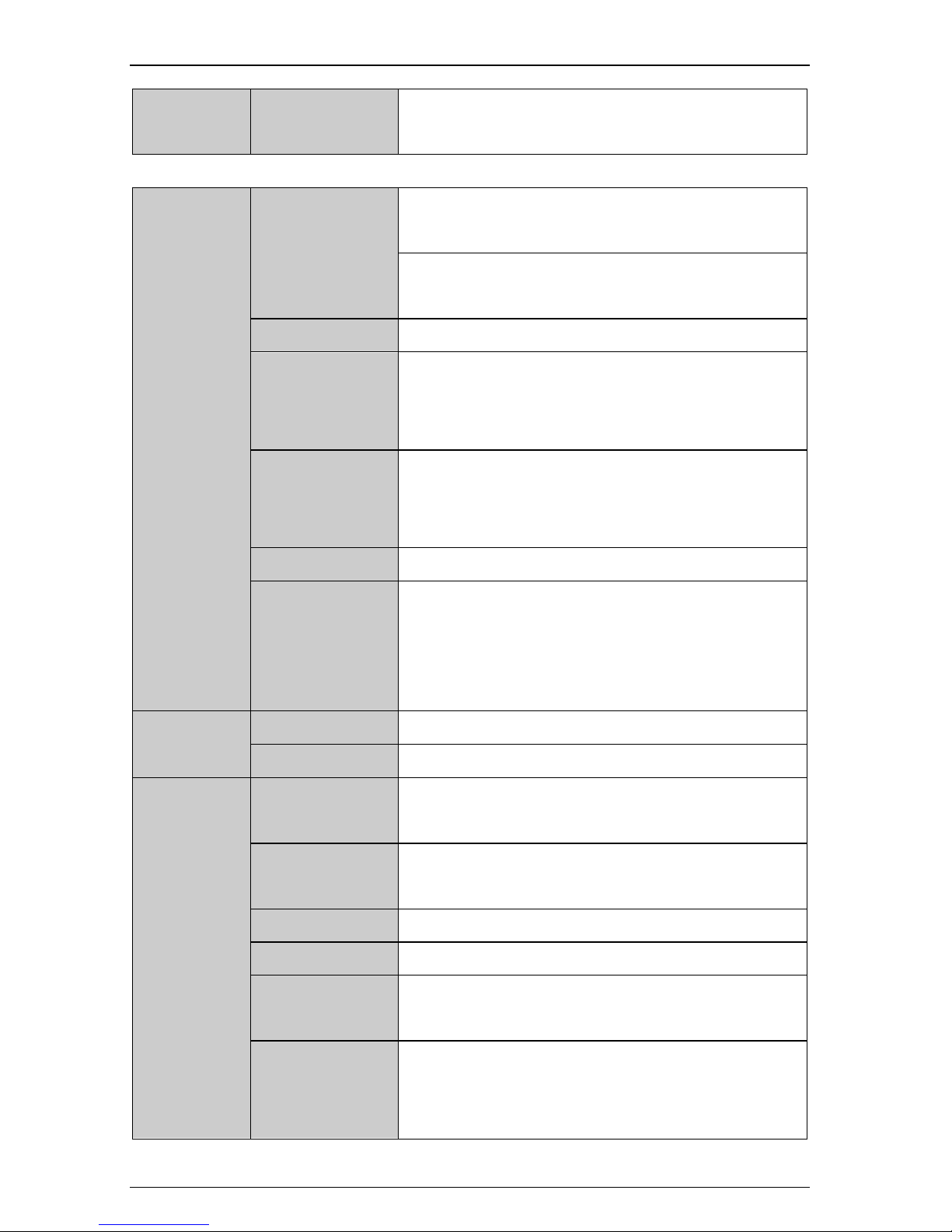

2.1.2Diagram of mounting

Ø

Ø

D

W

W1

H

H1

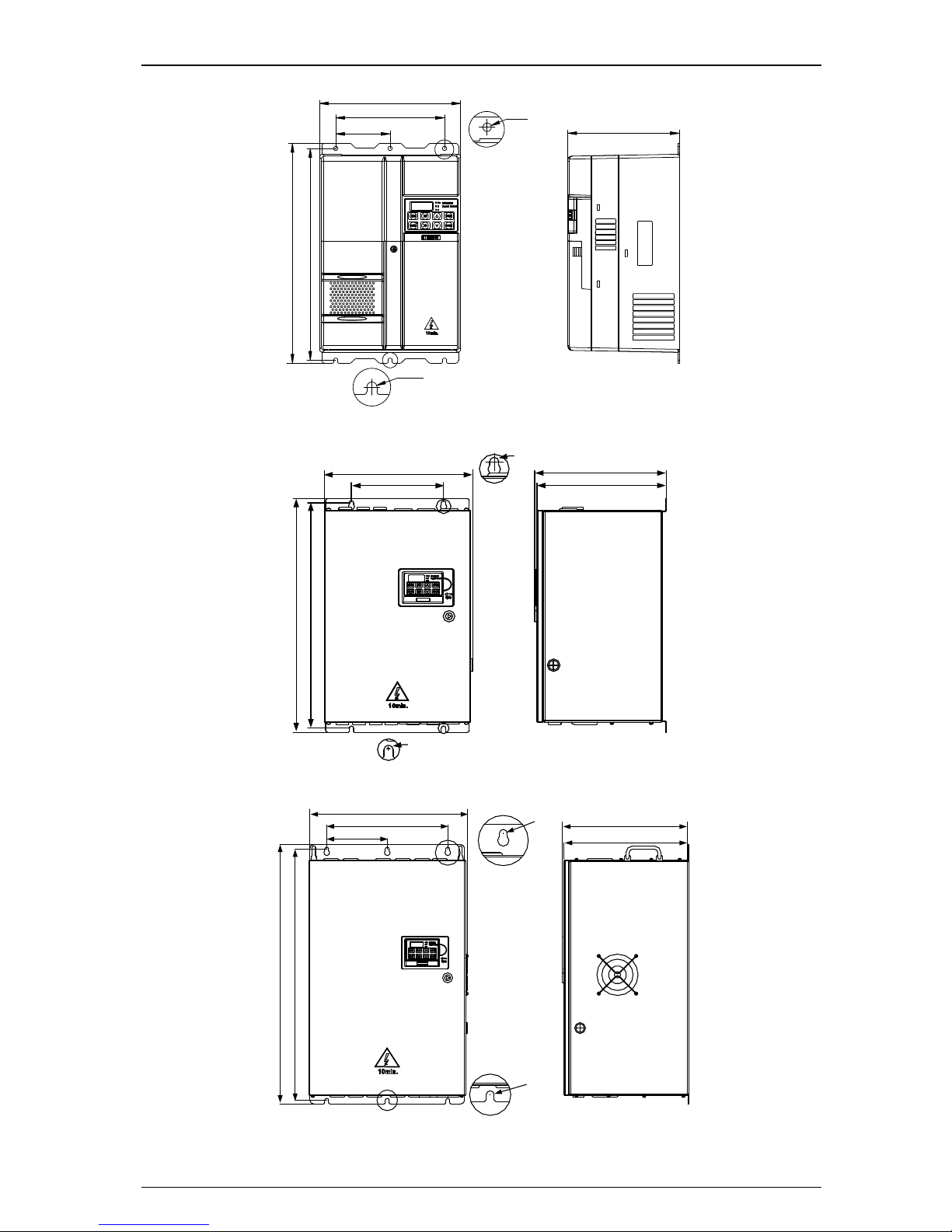

Figure 2-2 Mechanical dimensions and mounting (Size A, B, C)

EMC filter Link

Terminal Cover

Rating Label

Fan

Power Terminals

Option Connector

Control Terminals

RS485 Port

Keypad

Keypad Connector

Barcode

2 Installation and cabling

VFD700 AC Drive Getting Started Guide 9

D

W

W1

W2

Ø

Ø

H1

H

Figure 2-3Mechanical dimensions and mounting (Size D, E)

Ø

W

W1

Ø

D

D1

H

H1

Figure 2-4Mechanical dimensions and mounting (Size E1, F)

W

W1

W2

Ø

Ø

H

H1

D

D1

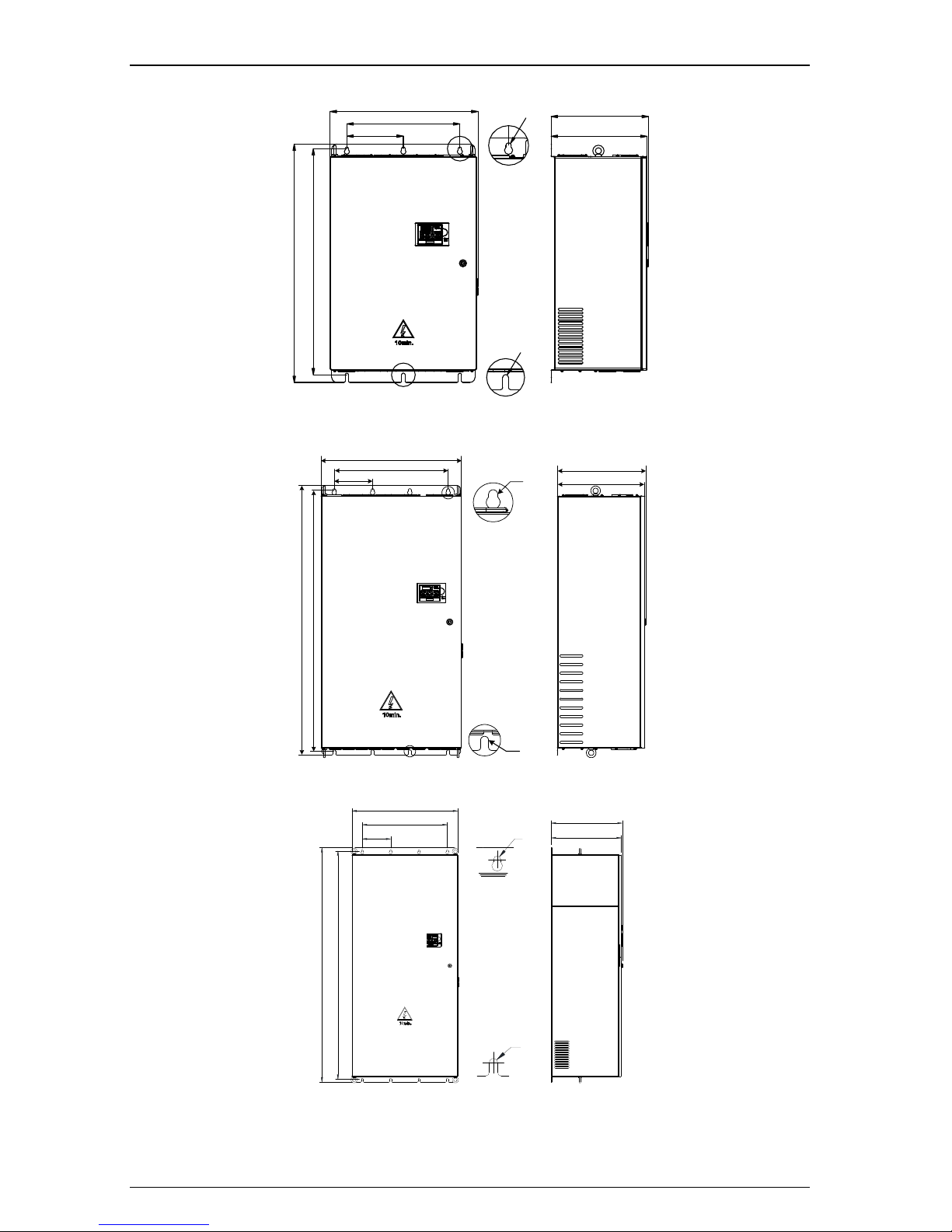

Figure 2-5Mechanical dimensions and mounting (Size G)

VEIKONG

VFD700

VEIKONG

VFD700

2 Installation and cabling

10VFD700 AC Drive Getting Started Guide

W

W1

W2

D

D1

H

H1

Ø

Ø

Figure 2-6Mechanical dimensions and mounting (Size J)

W

W1

W2

H

H1

D

D1

Ø

Ø

Figure 2-7Mechanical dimensions and mounting (Size K)

D1

W2

H1

W

W1

H

D

Ø

Ø

Figure 2-8 Mechanical dimensions and mounting (Size K1)

VFD700

VEIKONG

VEIKONG

VEIKONG

VFD700

VFD700

2 Installation and cabling

VFD700 AC Drive Getting Started Guide 11

H

W

D

Figure 2-9Mechanical dimensions and mounting (Size L)

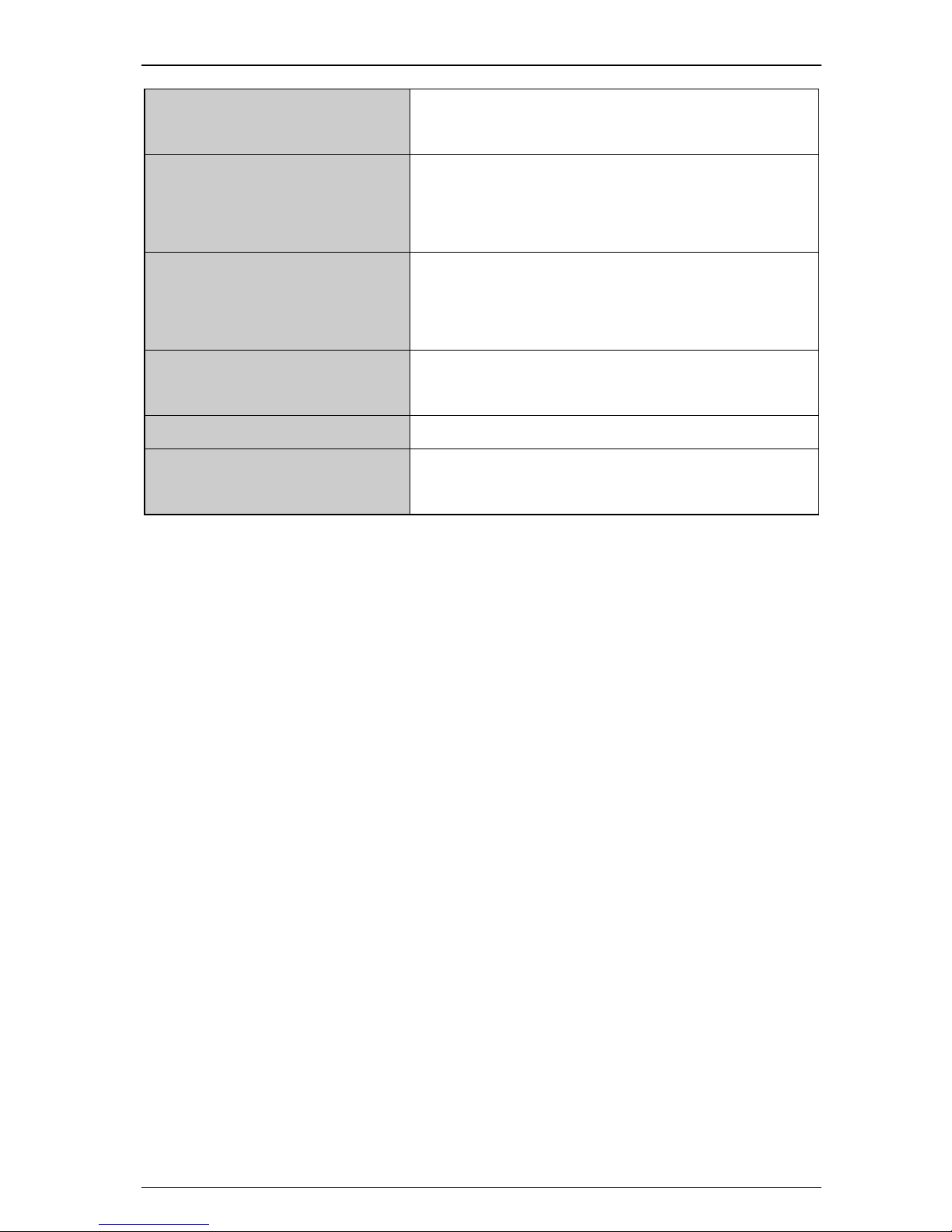

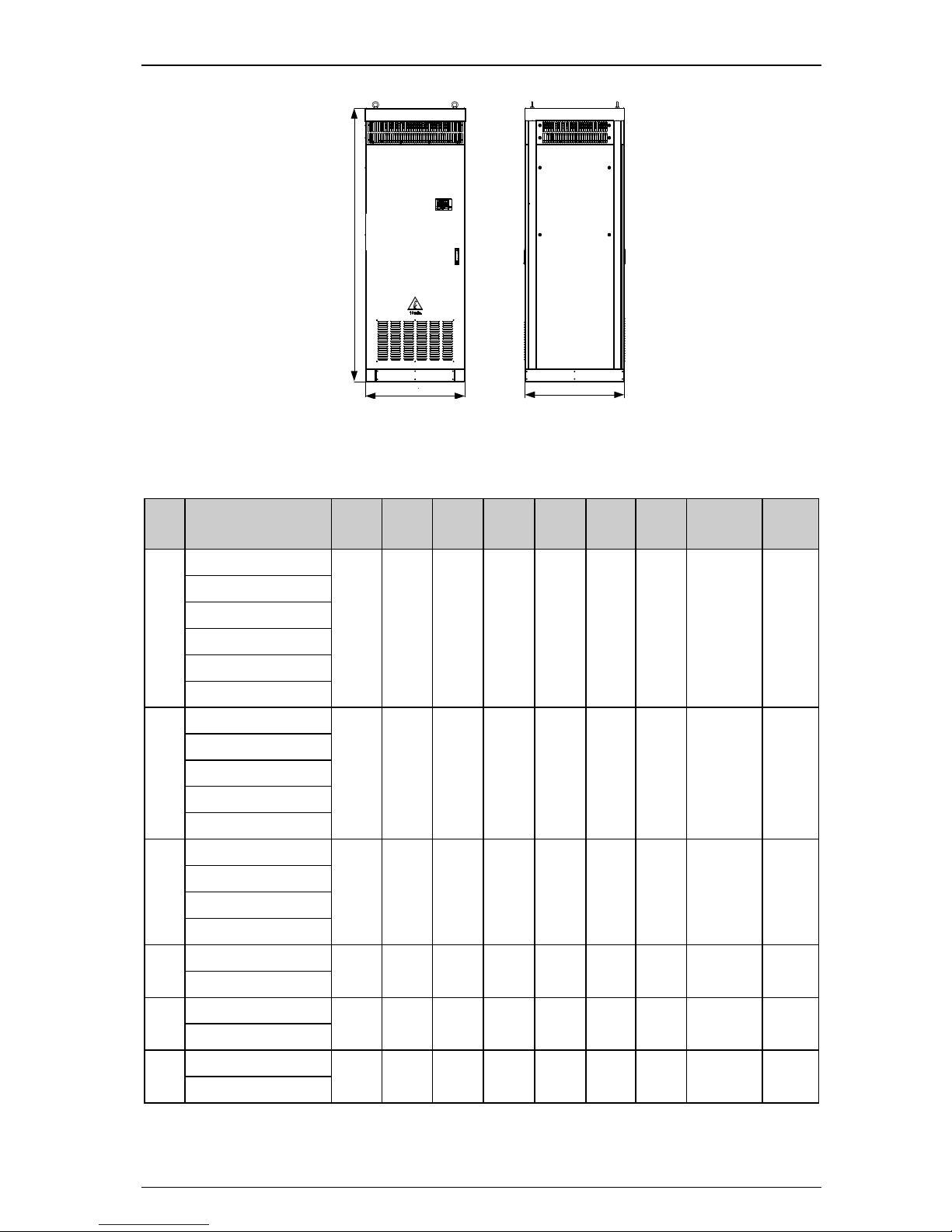

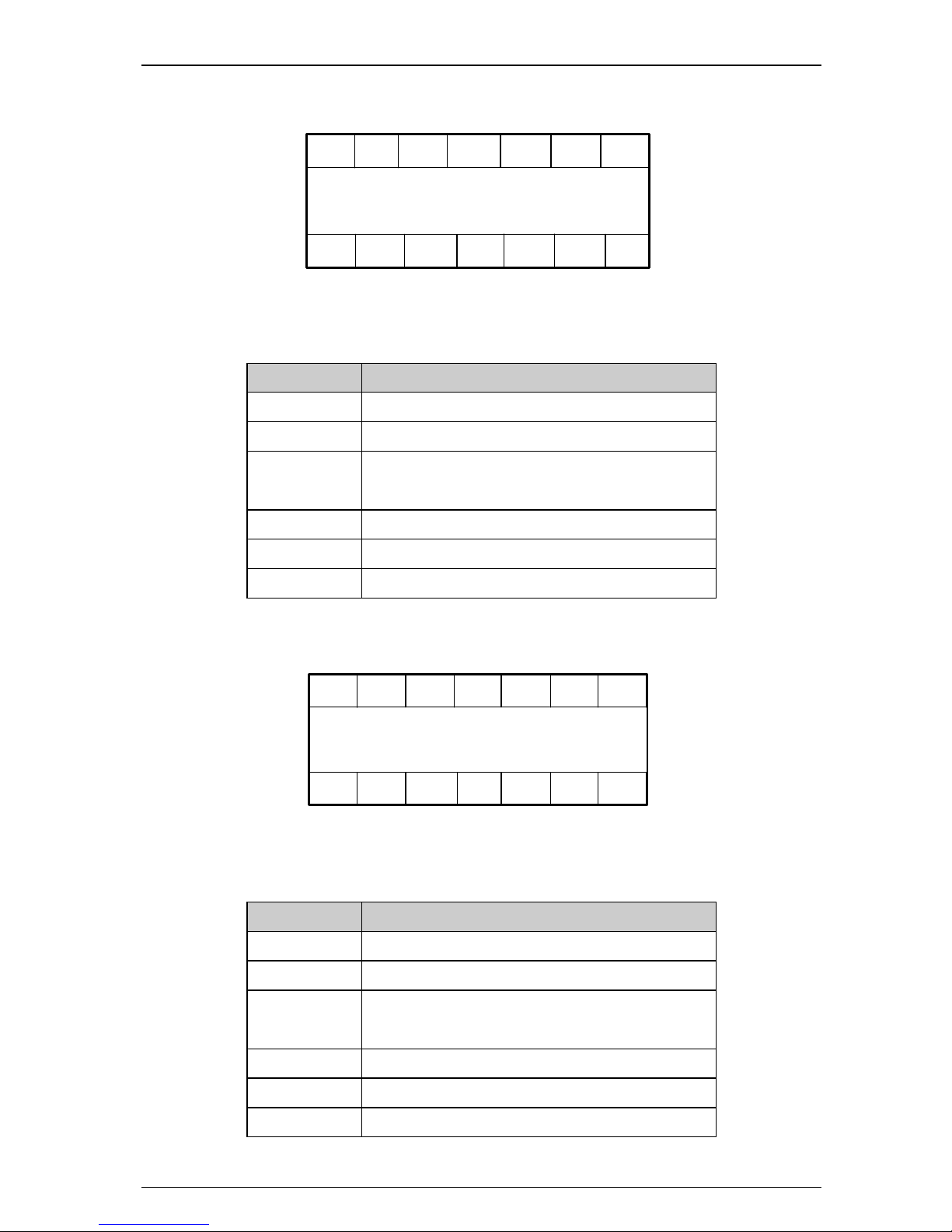

Table 2-1 Mechanical dimensions

Size

Model Name

W

(mm)

W1

(mm)

W2

(mm)

H

(mm)

H1

(mm)

D

(mm)

D1

(mm)

Mounting

Hole Ø

Weight

(kg)

A

VFD700-20D00040

97.4

80 − 202.4

190

148.8 − 5

1.4

VFD700-20D00075

VFD700-20D00150

VFD700-40T00075

VFD700-40T00150

VFD700-40T00220

B

VFD700-20D00220

142.4

123.5

−

220.4

208

155.5 − 5

2.2

VFD700-40T00220

VFD700-40T00400

VFD700-40T00550

VFD700-40T00550

C

VFD700-20D00400

163.1

142 − 300

280

176.8 − 6

4.5

VFD700-40T00550

VFD700-40T00750

VFD700-40T01100P

D

VFD700-40T01100

238.5

184

92

370

356.5

189 − 7

8.8

VFD700-40T01500

E

VFD700-40T01850

238.5

184

92

435.5

422

200.3 − 7

12.1

VFD700-40T02200

E1

VFD700-40T03000

320

210 − 510

490

226

222.5 8 20

VFD700-40T03700

VFD700

VEIKONG

2 Installation and cabling

12VFD700 AC Drive Getting Started Guide

Size

Model Name

W

(mm)

W1

(mm)

W2

(mm)

H

(mm)

H1

(mm)

D

(mm)

D1

(mm)

Mounting

Hole Ø

Weight

(kg)

F

VFD700-40T03000

355.5

221 − 573

552.5

315.5

310

10

40

VFD700-40T03700

VFD700-40T04500

VFD700-40T05500

VFD700-40T07500

VFD700-60T03000

VFD700-60T03700

VFD700-60T04500

VFD700-60T05500

VFD700-60T07500

G

VFD700-40T09000

445.6

340

170

725

701.5

355

349.5

10

63

VFD700-40T11000

VFD700-40T13200

VFD700-60T09000

VFD700-60T11000

VFD700-60T13200

J

VFD700-40T16000

575.5

440

220

937

889

379.3

373.8

13

104

VFD700-40T18500

VFD700-40T20000

VFD700-60T16000

VFD700-60T18500

VFD700-60T20000

K

VFD700-40T16000

640

520

175

1246.5

1207.5

405.5

400

13

150

VFD700-40T18500

VFD700-40T20000

VFD700-40T25000

VFD700-40T28000

VFD700-60T16000

VFD700-60T18500

VFD700-60T20000

VFD700-60T25000

VFD700-60T28000

2 Installation and cabling

VFD700 AC Drive Getting Started Guide 13

Size

Model Name

W

(mm)

W1

(mm)

W2

(mm)

H

(mm)

H1

(mm)

D

(mm)

D1

(mm)

Mounting

Hole Ø

Weight

(kg)

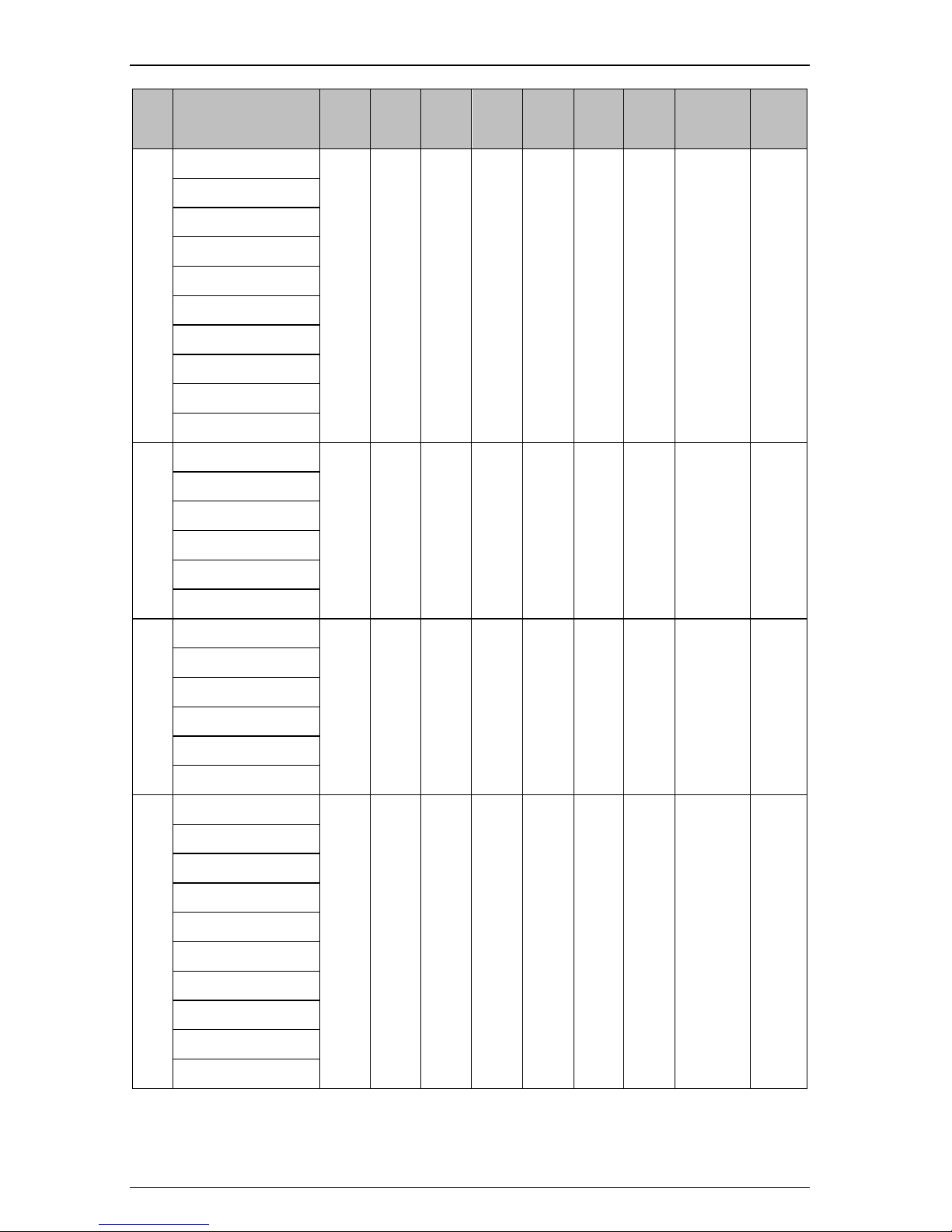

K1

VFD700-40T31500

720

579

194

1595.5

1553.5

483

477.5

13

−

VFD700-40T35500

VFD700-60T31500

VFD700-60T35500

L

VFD700-40T31500

804

−

−

2200

−

804

−

−

350

VFD700-40T35500

VFD700-40T40000

VFD700-40T45000

VFD700-60T31500

VFD700-60T35500

VFD700-60T40000

VFD700-60T45000

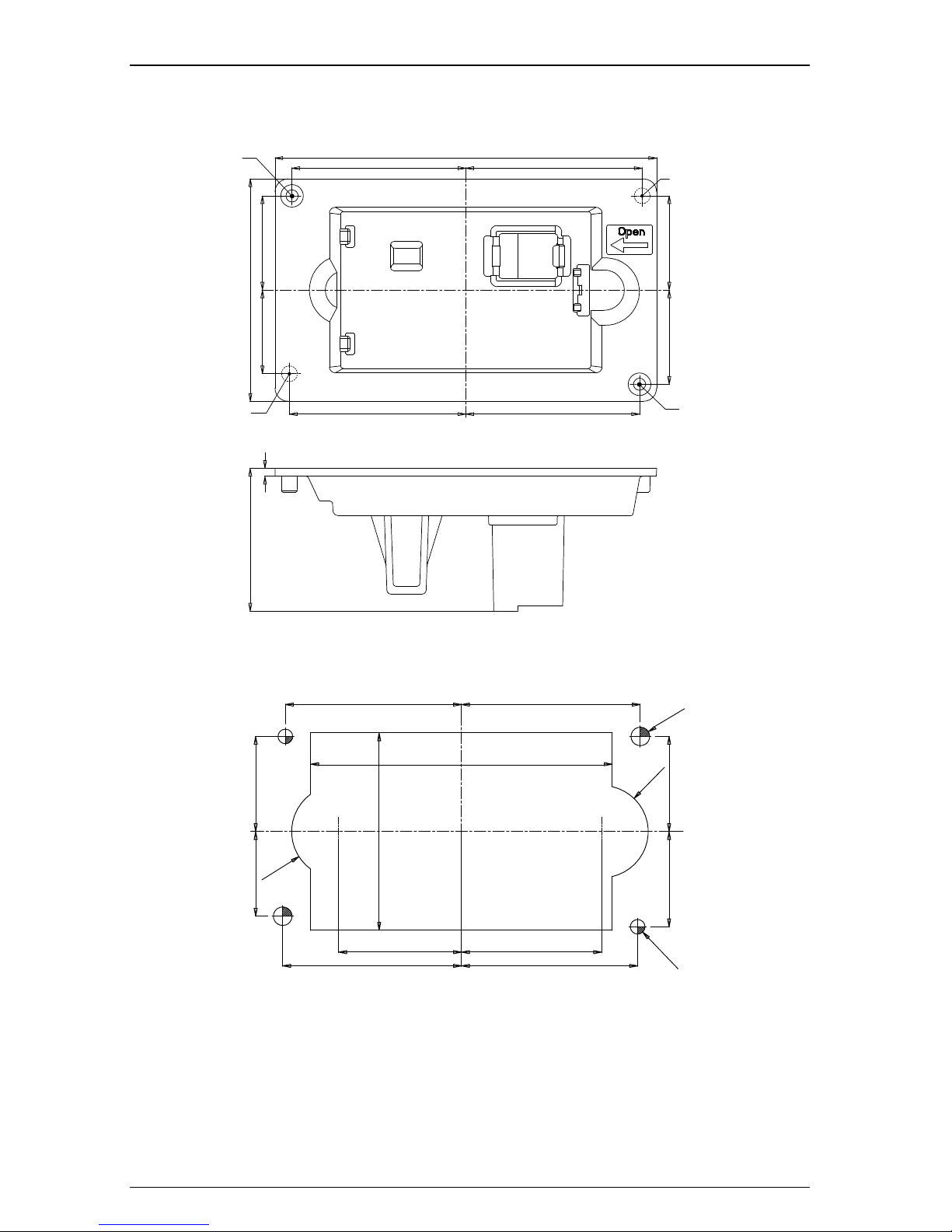

2.1.3Keypad pallet

Figure 2-10Outlook of keypad palle

2 Installation and cabling

14VFD700 AC Drive Getting Started Guide

Diagram of pallet dimensions and mounting

36

6667

36

6766

32

36

145

85

54.5

3

Mounting hole for countersunk

head phillips slot screw

GB/T819.1M4*12

Location pillar Ø 6

Mounting hole for countersunk

head phillips slot screw

GB/T819.1M4*12

Location pillar Ø 6

Figure 2-11Outline dimensions of pallet

32 36

36 36

66 67

46 52.5

R

17.7

R

17

.

5

113

74.7

67 66

2

−

Ø

7

2

−

Ø

5

.

5

Figure 2-12mounting dimensions of pallet

2 Installation and cabling

VFD700 AC Drive Getting Started Guide 15

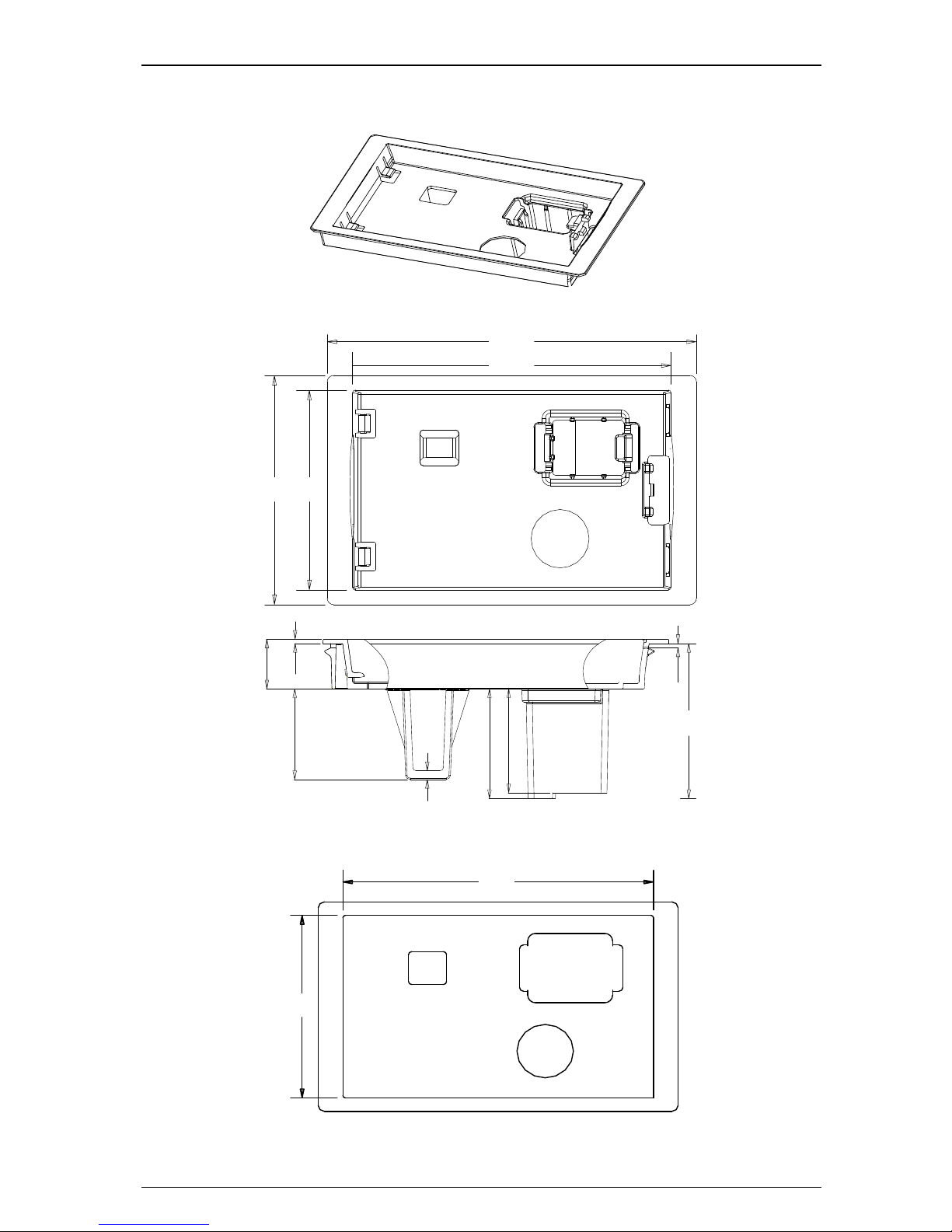

2.1.4 Simple keypad pallet

Figure 2-13Outlook of Simple keypad pallet

114.7

105.6

64.570.6

53.0

31

37.5

35.5

1.5

1.5

17

3

Figure 2-14Outline dimensions of simple keypad pallet

106.6

65.5

Figure 2-15Mounting dimensions of Simple keypad pallet

2 Installation and cabling

16VFD700 AC Drive Getting Started Guide

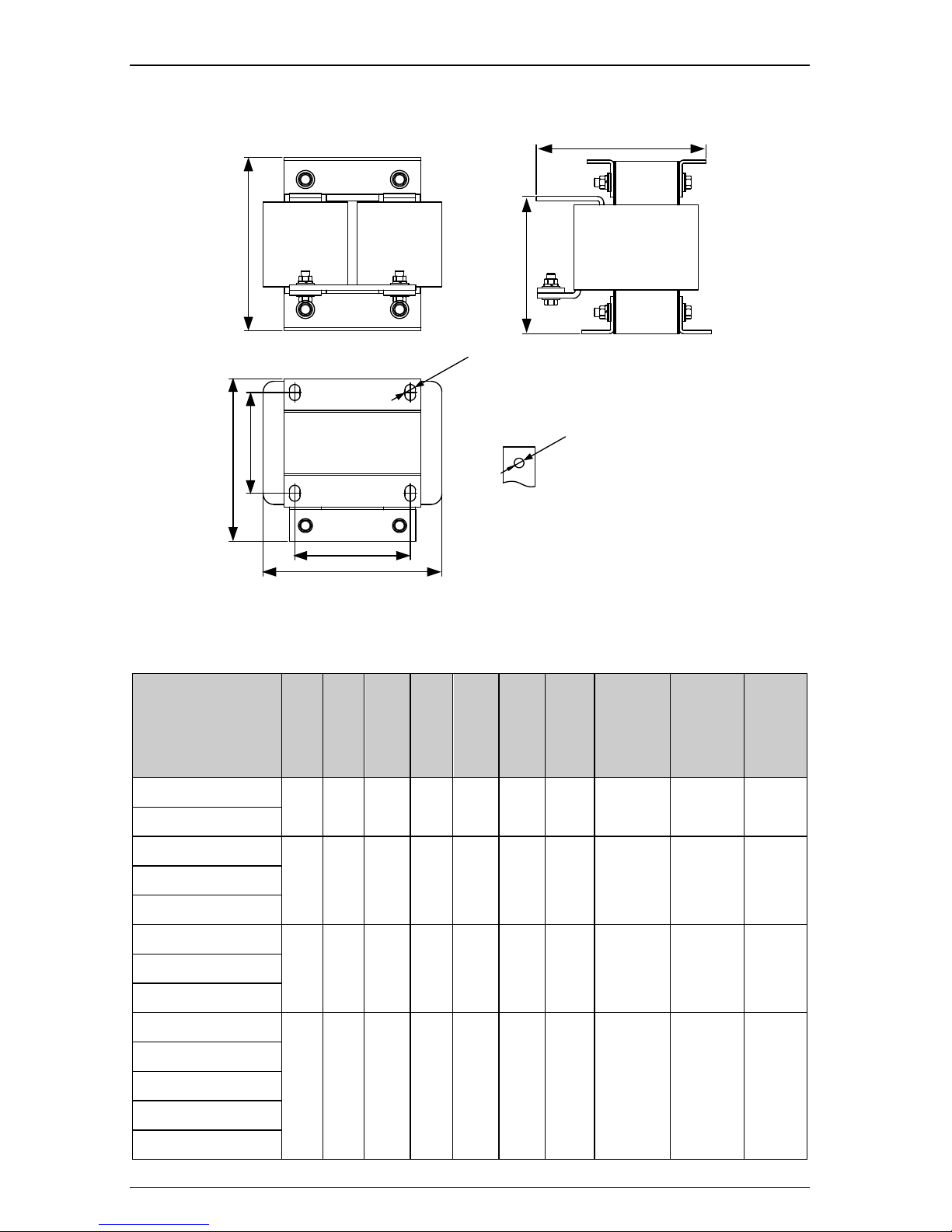

2.1.5 External DC reactor dimensions

Copper bar:30*4.0mm

w1

w

d1

d

h1

f

h

2

-

K

4

-

R

*

L

Figure 2-16 External DC reactor dimensions

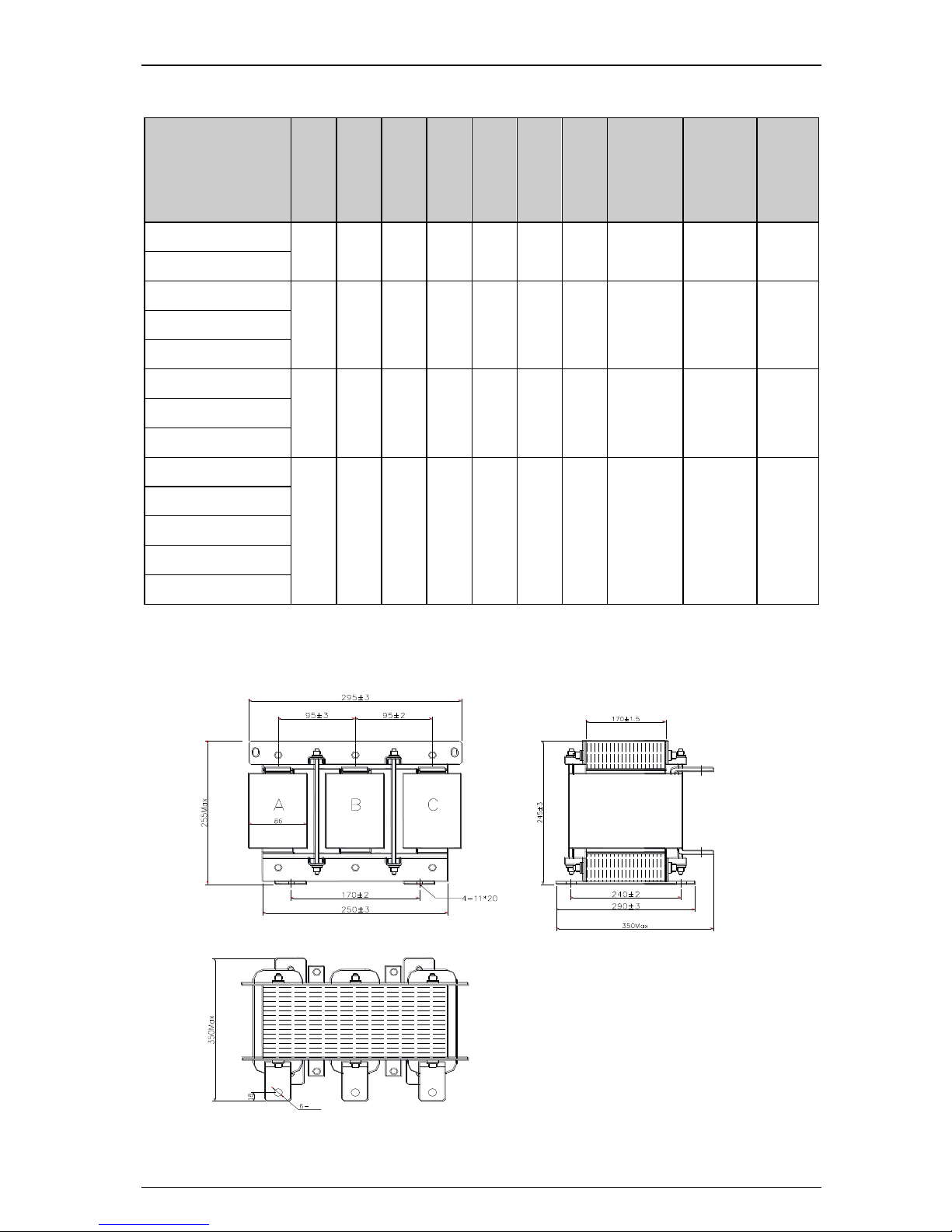

Table 2-2 380V DC reactor dimensions (Unit: mm)

Model

w

w1 d d1 h h1

f

Mounting

hole

R*L

Copper

bar

mounting

hole

K

Reactor

weight

(kg)

VFD700-40T05500

167

108

153.5

95

163.5

131

158.5

10×15

Ø9

10.3

VFD700-40T07500

VFD700-40T09000

190

160

153

117

245

192

180

10×15

Ø12

20

VFD700-40T11000

VFD700-40T13200

VFD700-40T16000E

190

160

148

115

245

192

250

10×20

Ø13

25

VFD700-40T18500E

VFD700-40T20000E

VFD700-40T16000

275

210

240

205

235 − 240

11×18

Ø14

38

VFD700-40T18500

VFD700-40T20000

VFD700-40T25000

VFD700-40T28000

2 Installation and cabling

VFD700 AC Drive Getting Started Guide 17

Table 2-3 690V DC reactor dimensions (Unit: mm)

Model -

w

w1 d d1 h h1

f

Mounting

hole

R*L

Copper

bar

mounting

hole

K

Reactor

weight

(kg)

VFD700-60T05500

128

100

116

90

180

140

175

10×15

Ø9

10

VFD700-60T07500

VFD700-60T09000

190

160

153

117

245

192

180

10×15

Ø12

20

VFD700-60T11000

VFD700-60T13200

VFD700-60T16000

190

160

148

115

245

192

250

10×20

Ø13

25

VFD700-60T18500

VFD700-60T20000

VFD700-60T16000

235

180

230

175

205 − 230

11×18

Ø14

27.5

VFD700-60T18500

VFD700-60T20000

VFD700-60T25000

VFD700-60T28000

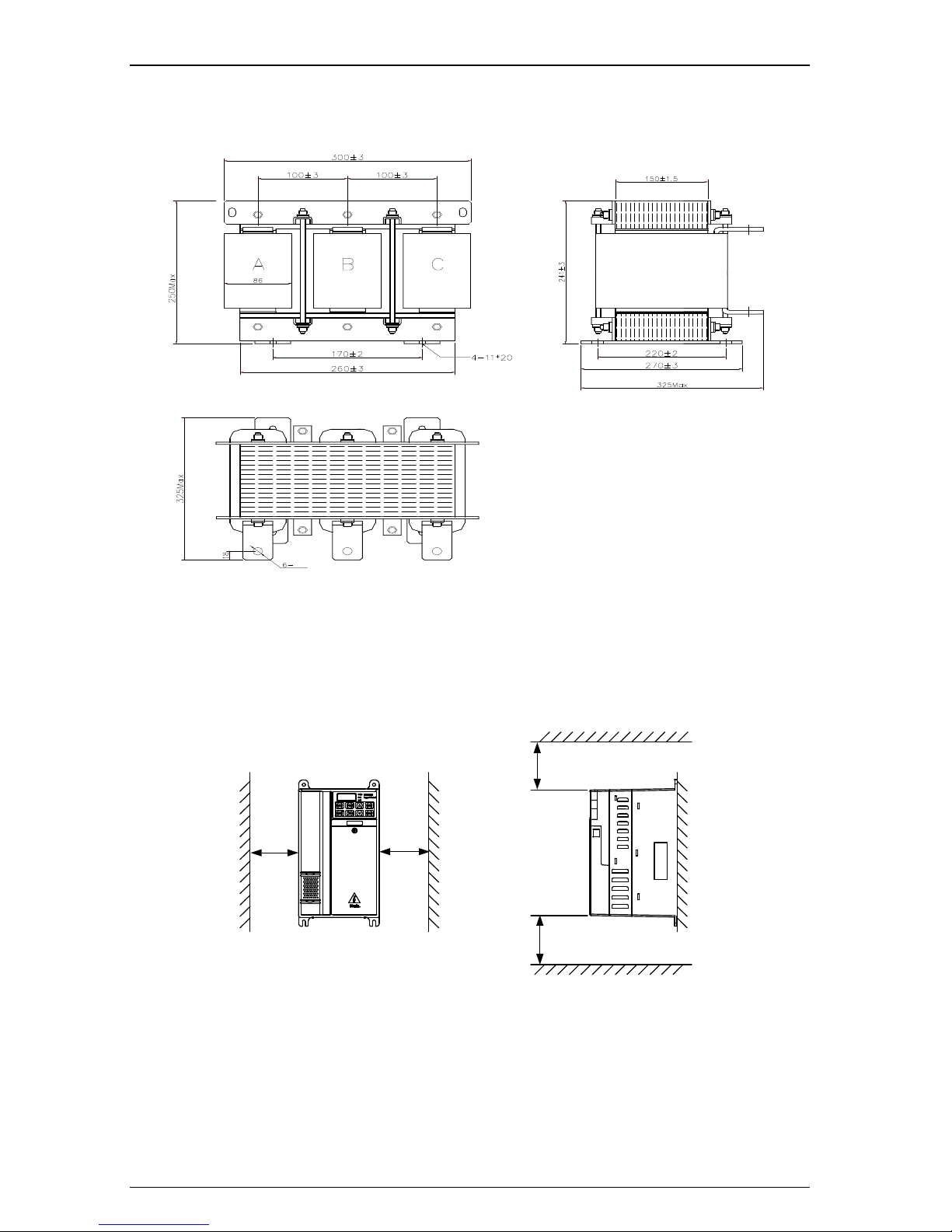

Note: 1.Reactors of VFD700-40T31500E and VFD700-40T35500E are AC Reactor, whose

dimensions are as follows:

Figure 2-17 Dimensions of Externeal AC Reactor (Size K1,380V_)

13

Φ

2 Installation and cabling

18VFD700 AC Drive Getting Started Guide

Note: 2.Reactors of VFD700-60T31500E and VFD700-60T35500E are AC Reactor, whose

dimensions are as follows:

Φ

13

Figure 2-18 Dimensions of Externeal AC Reactor (Size K1,690V_)

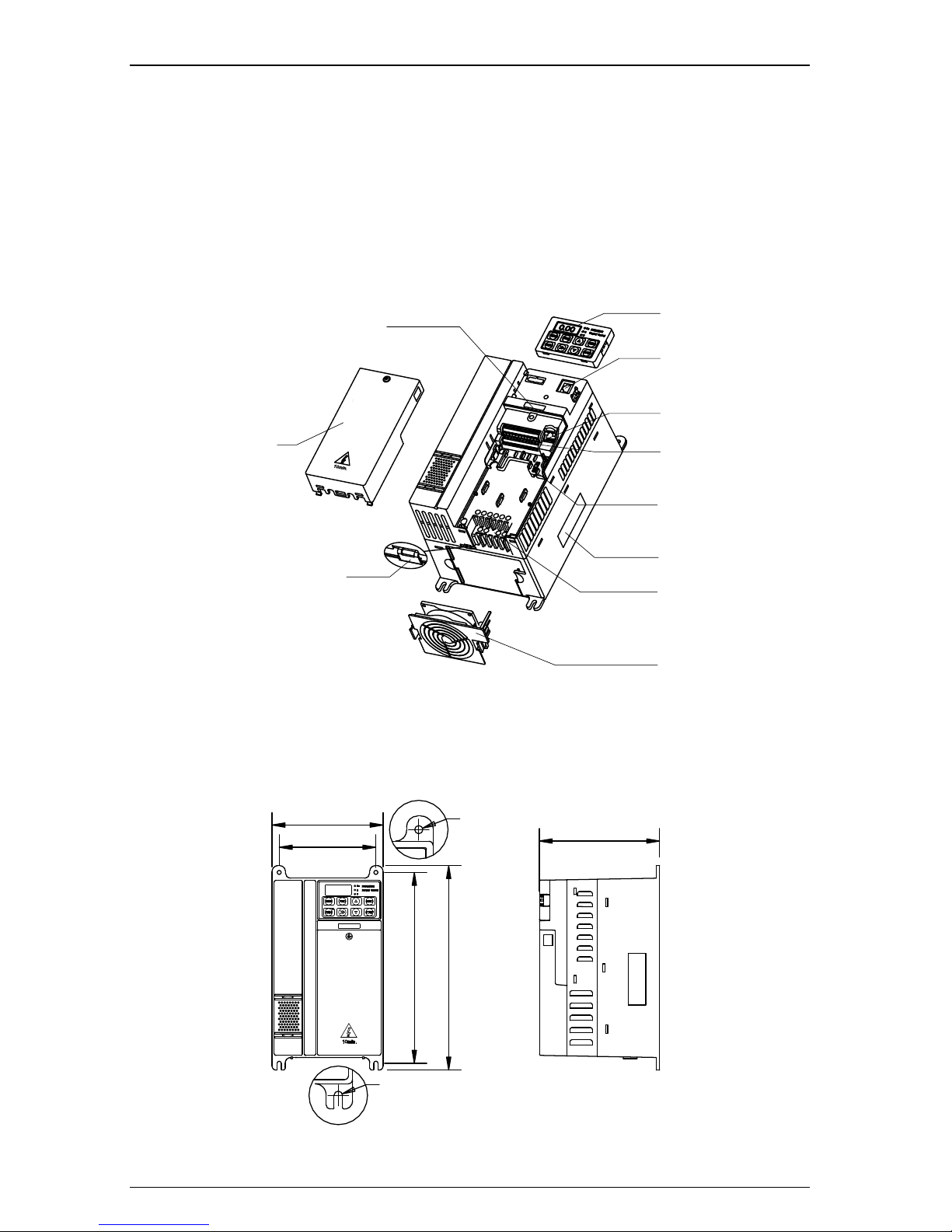

2.2 Mechanical installation

2.2.1Drive installation diagram

L

L

H

H

Figure 2-19Single drive installation

Recommending: L≥50mm, H≥50mm

2 Installation and cabling

VFD700 AC Drive Getting Started Guide 19

L

L

L

Figure 2-20Multi-drives installation

Recommending: L≥50mm

Figure 2-21 Multi drives vertical installation

NOTE:In vertical installations where drives

aremounted above each other, there should

besuitable air flow to keep the drives cool.

Air flowshould be drawn in and expelled as

illustrated inthe left picture.

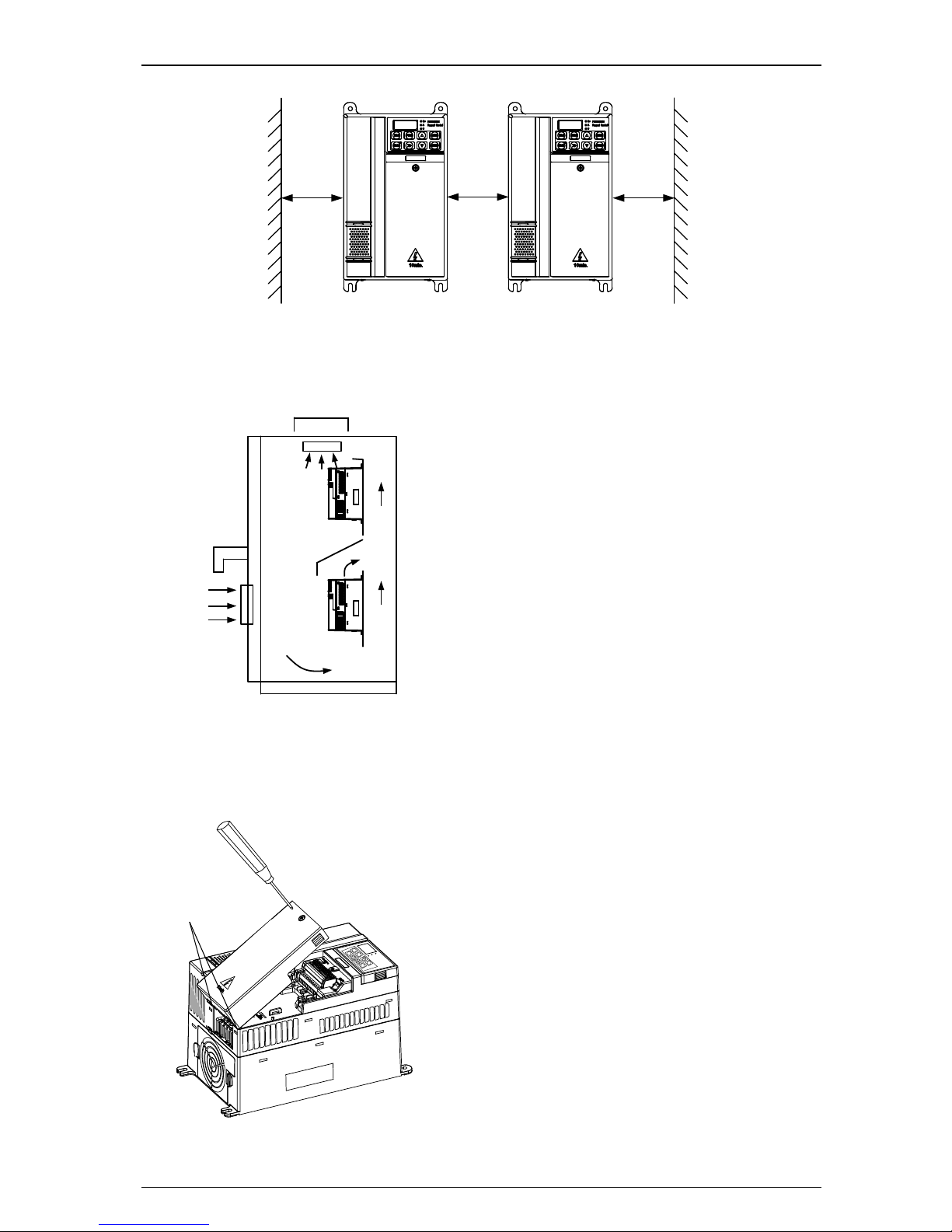

2.2.2 How to fit and remove the terminal cover

Hz

PROGMODE

A Keypad Control

V

ESC

PRO

MOD

RU

N

STO

P

Clips

Remove: Untighten the screw, loose the

clip then take off the cover.

Fit: at a suitable angle, put the clips into

the slots on the middle cover, push the

coveron, tighten the screw M4×10

(Torque 1N·m).

Figure 2-22 Terminal cover fitting and removes

VEIKON

VFD700

VEIKONG

VFD700

VEIKONG

VFD700

2 Installation and cabling

20VFD700 AC Drive Getting Started Guide

2.2.3How to fit and remove the keypad

Figure 2-23 Diagram of the keypad fitting

and removing

Remove: push the spring clip, and then

pull up the keypad.

Fit: fit the left two clips (at correct angle)

into the slots on the control pod, and then

push down the keypad.

VFD700 keypad is removable, and can be linked to the drive with a standard net cable , shown

as below:

port converter

Figure 2-24 Keypad with cable

NOTE: The maximum length of cable is 10m.

2.3 Electrical installation

2.3.1Power terminals

Models of size A, B, C: VFD700-20D00040~VFD700-40T00750

L1 L3/NL2

U

V

W

PE +DC +DC1

−DC

BR PE

Figure 2-25 Size A, B power terminals layout

2 Installation and cabling

VFD700 AC Drive Getting Started Guide 21

L1

L3L2 U

V

W

PE +DC

−DC

BR PE

Figure 2-26 Size C power terminals layout

Table 2-4 Power terminal functions of size A, B, C

Terminals

Functions

L1, L2, L3/N

AC power supply.For single phase supply, L1and L3/N are

suggested

+DC, +DC1

For DC reactor, linked by terminal

BR

Brake resistor, the other side of the resistor is connected to

+DC1

−DC

Negative DC bus

U, V, W

Output terminals(Motor terminals)

PE

Protective earth terminal

NOTE:

Size C has DC reactor inside, +DC1 is not used.

For size C, the brake resistor is connected to BR and +DC.

Models of size D, E: VFD700-40T01100~VFD700-40T02200

L1

L3L2 U V WPE PE+DC

−DC

BR

Figure 2-27 Size D, E power terminals layout

Table 2-5 Power terminal functions of size D, E

Terminals

Functions

L1, L2, L3

AC power supply

+DC, −DC

Positive and negative DC bus

BR

Brake resistor, the other side of the resistor is

connected to +DC

U, V, W

Output terminals (Motor terminals)

PE

Protective earth terminal

2 Installation and cabling

22VFD700 AC Drive Getting Started Guide

Models of size E1: VFD700-××T03000E~VFD700-××T03700E

L1 L2 L3

PE

U V W

+DC

-DC

BR

Size E1

PE

+

DC +DC1

Figure 2-28 Size E1 power terminals layout

Table 2-6 Power terminal functions of size E1

Terminals

Functions

L1, L2, L3

AC power supply

+DC, +DC1

For DC reactor, linked by busbar from factory

BR

Brake resistor, the other side of the resistor is connected to

+DC

−DC

Negative DC bus

U, V, W

Output terminals (Motor terminals)

PE

Protective earth terminal

Models of size F: VFD700-××T03000~VFD700-××T04500

L1 L2 L3

PE U V W+DC

-DC

BR

Size F

PE

Figure 2-29 Power terminal of size F

Table 2-7 Power terminal of size F

Terminals

Function

L1, L2, L3

AC power supply

+DC, −DC

Positive and negative DC bus

BR

Brake resistor, the other side of the resistor is

connected to +DC

U, V, W

Output terminals (Motor terminals)

PE

Protective earth terminal

2 Installation and cabling

VFD700 AC Drive Getting Started Guide 23

Models of size F: VFD700-××T05500~VFD700-××T07500

L1 L2 L3PE

PE U V W+DC

-DC

BR

Size F

+DC +DC1

Figure 2-30 Power terminal of size F

Table 2-8 Power terminal of size F

Terminals

Function

L1, L2, L3

AC power supply

+DC, +DC1

For DC reactor

BR

Brake resistor, the other side of the resistor is

connected to +DC1

−DC

Negative DC bus

U, V, W

Output terminals(Motor terminals)

PE

Protective earth terminal

Models of size G: VFD700-××T09000~VFD700-××T 13200

L1 L2 L3 PE

PEU V W

+DC

-DC

BR

Size G

+DC +DC1

Figure 2-31 Power terminal of size G

Table 2-9 Power terminal functions of size G

Terminals

Function

L1, L2, L3

AC power supply

+DC, +DC1

For DC reactor

BR

Brake resistor, the other side of the resistor is

connected to +DC

−DC

Negative DC bus

U, V, W

Output terminals(Motor terminals)

PE

Protective earth terminal

Loading...

Loading...