Veikong VFD500-PV Series Operation Manual

Operation manual

VFD500-PV Series

Solar pumping Inverter

Solar pumping inverter user manual

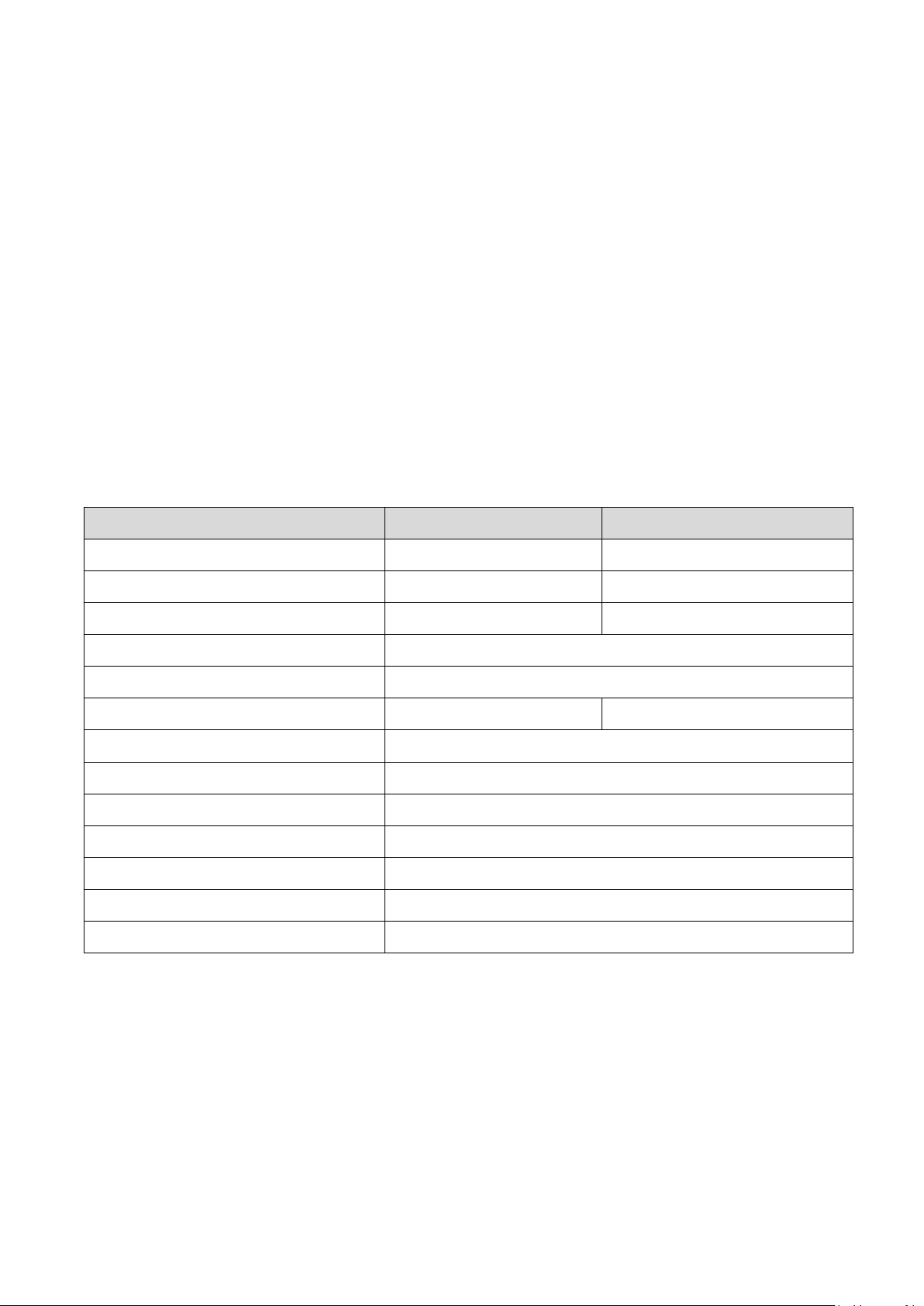

220V

380V

Max input DC voltage

450V

810V

Recommended MPPT voltage range

150~410VDC

250~800VDC

Recommended input voltage

305V

530V

MPPT efficiency

>99%

Input channel

2

Rated output voltage

1/3-phase 220VAC

3-phase 380-480VAC

Output frequency range

0~60Hz

Max efficiency of the machine

99%

Ambient temperature range

-10 °C~50 °C, derating if the temperature is above 40 °C

Cooling method

Air cooling

Protection degree

IP20/IP21

Altitude

Below 1000m; above 1% for every additional 100m.

Standard

CE

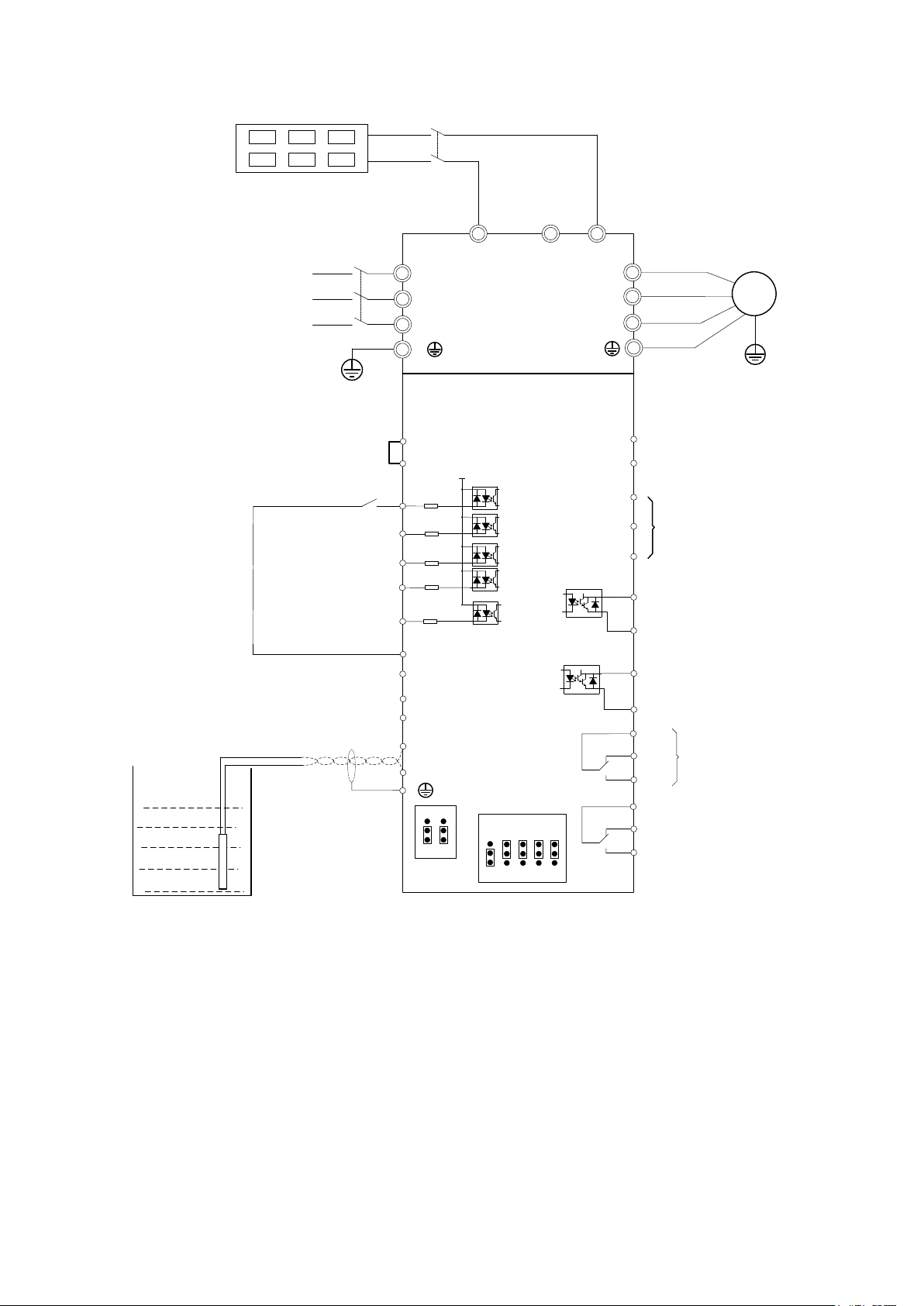

1、Electrical cable Connection

Please follow the diagram below for wiring. And pay attention to the following issues:

The power output of the PV panel is connected to the “+” and “-” terminals. Please note that the

polarity is not reversed.

Make sure that the inverter input AC voltage level is consistent with AC grid voltage before connecting

with Input “R”, “S” and “T” terminals

If Grid is single-phase power supply, you can connect to R T or any two terminals of “R”, “S” and “T”。

DI1 defaults to the running terminal input.

AI2 defaults to the water tank level detection signal input, which is used to control the inverter

sleep and auto start.

Relay 1 output defaults to the fault signal output.

1.1 Electrical Specifications

Table 1-3 Electrical Specifications

Noted: We suggest solar panel power should be 1.2-1.35 times higher than solar pump power ,and solar

pump inverter power should be same or higher level than solar pump. When solar pump distance to

inverter higher than 100m,it should be equipped with Output reactor or higher level power inverter .for

Solar pane,l total VOC less than Maximum DC voltage of inverter and Solar panel vmp is recommend 530V

for 380V pump and 305V for 220V pump

M

U

V

W

R

S

T

3 phase power

input

DI1

DI2

DI3

DI4

COM

AI1

AI2

GND

485+

485-

RS485 port

AO2

GND

AO1、AO2 output:

0~10V/0~20mA

DO1

COM

T1A

T1C

T1B

+10V

PLC

+24V

+24V

-

+

PB

HDI

HDO

COM

AO1

Water tank level

feedback

Relay 1 output,

Default is fault signal

output

485

ON

OFF

AI1VAI2

V

I I I I

AO1VAO2

V

ON ON

OFF OFF

Grounding

Connector slip

GND

Main circuit

Control circuit

Q2

Solar panels

Q1

Start/stop

terminal

Wire Diagram of solar pump inverter

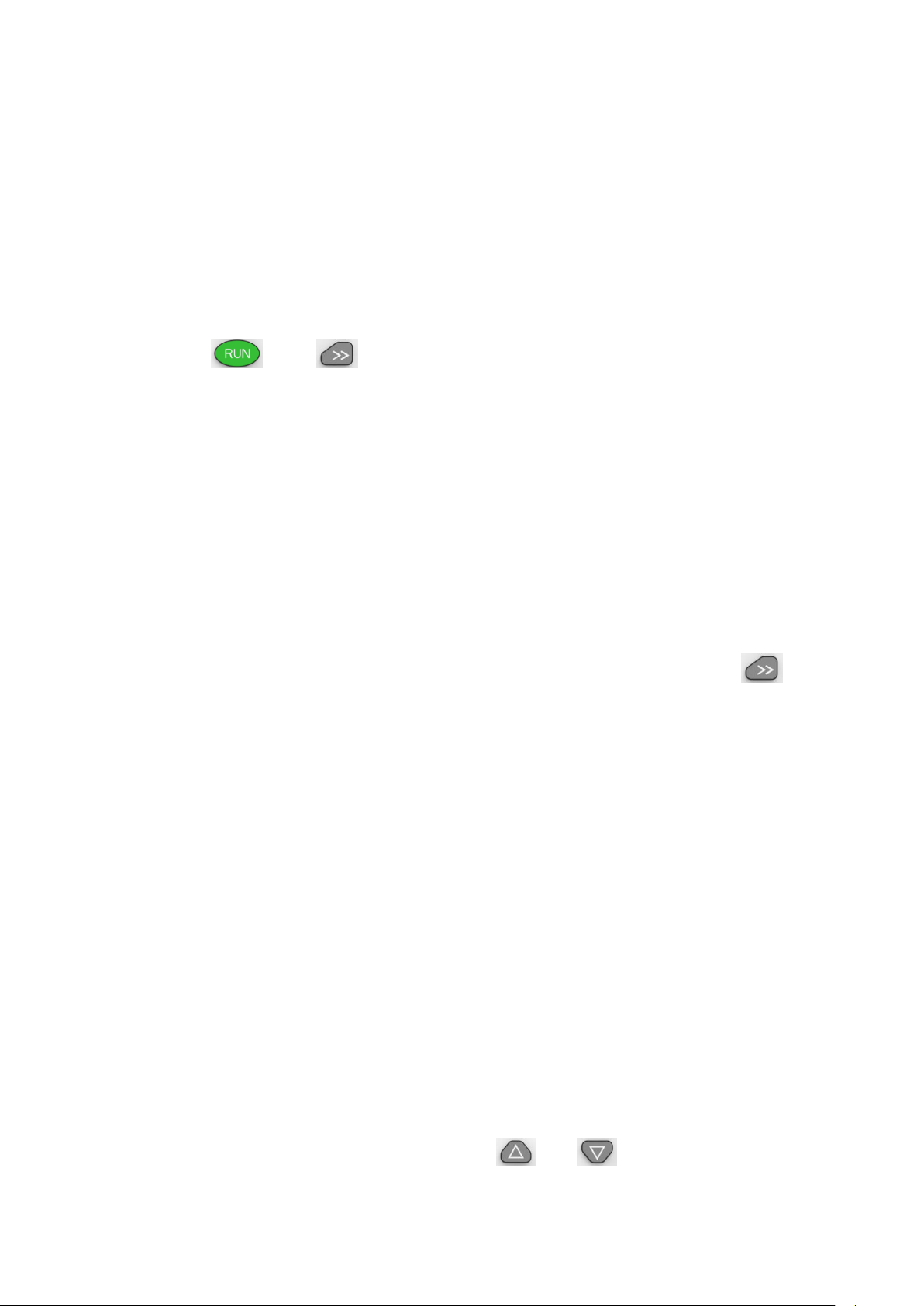

2、Trial run(How to start solar pump inverter)

Make sure all cables connections of solar panel and pump motor correct and no

need to set any parameter,if you want to set parameter ,you can do as follows

Step 1: Keypad control:Set motor parameter P11.02- P11.06 If dry run protection is

required, measure the unload protection current according to the following method. If dry

run protection not required then go to step 2

Notice”Unload detection current self-learning: disable the PV pump function

(P47.00=0), run to 30~40Hz, when the output frequency is stable, enter P24.13, press

the keyboard and simultaneously for more than 2 seconds, then P24.13

value will change automatically. In this process, the pump no need to take out from

water

Step 2: Set other related special solar pump parameters for optimization

Step 3: After trial run finishing, If pump still not pump water when inverter is running

more than 40 Hz.,Please disconnect the power supply and replace any two-phase wiring of

the motor.

3、Keypad display

3.1 Monitor display

According to the running status of the inverter, the digital tube displays different

contents in turn. If the button has no operation, the next monitoring amount is

automatically displayed every few seconds; of course, you can also switch to the

next monitoring indicator

When the inverter is in the stop state, the digital tube is cyclically scrolling to

display:

“00000”DC bus voltage(r27.03)given frequency(r27.01) Distance

remaining time(r47.02)“00000”

When the inverter is in running state, the digital tube is cyclically scrolling to

display.:

“00000”DC bus voltage(r27.03)output frequency(r27.00)output current

(r27.06)output power(r16.02)“00000”

When the inverter is in a fault state, the digital tube is cyclically scrolling to

display.:

Fault code (r25.00) DC bus voltage at fault (r25.03) Output frequency at

fault (r25.01) Output current at fault (r25.02) Output power at fault (r25. 16)

fault code

3.2 Menu mode

After the inverter is power on, the keyboard menu mode is user-defined mode. Most

of users only need to pay attention to the parameters displayed in this mode. To check

the complete inverter parameters, press the and keys while the keyboard is

displayed . When the keyboard is displayed , press the key

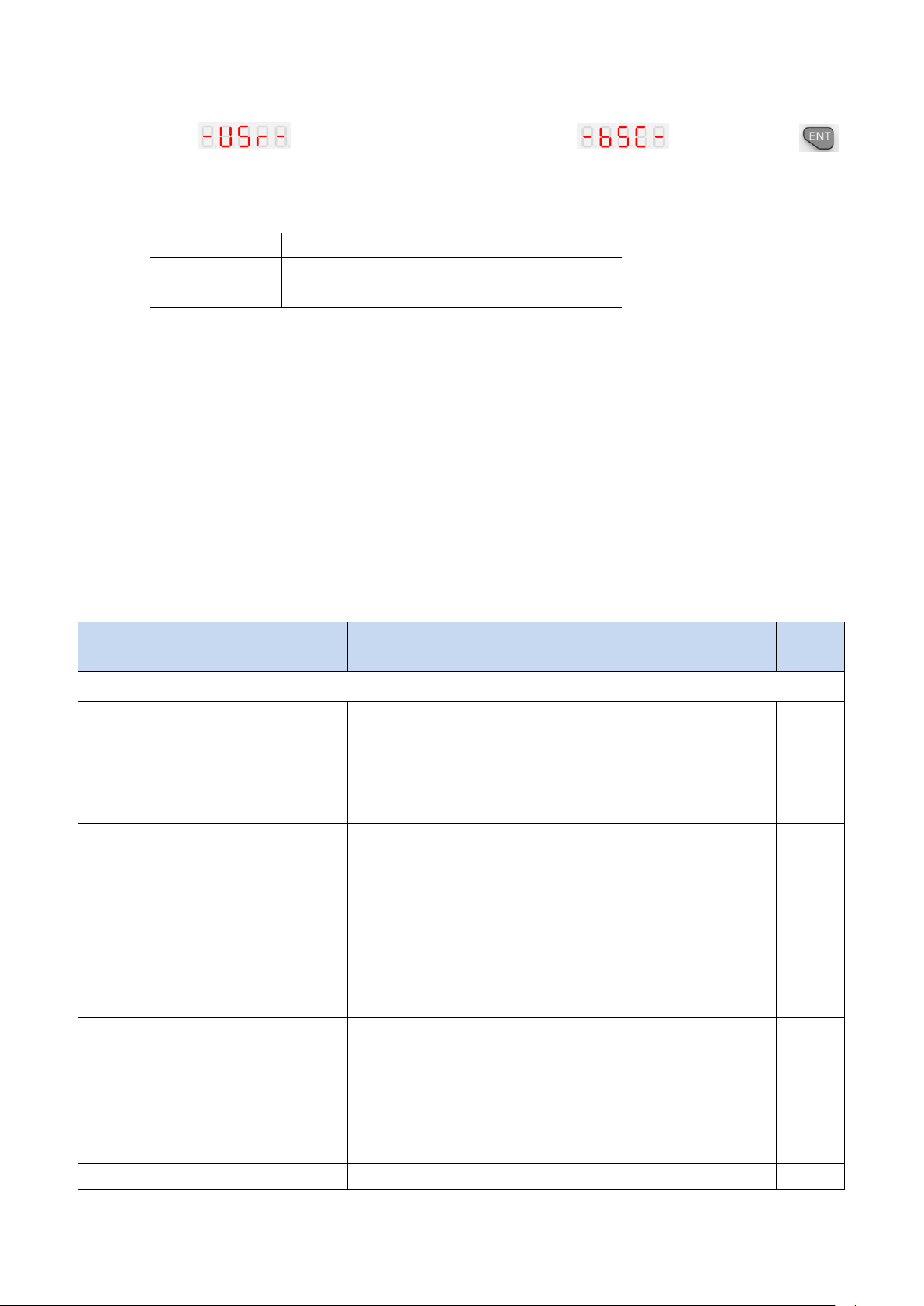

alarm code

meaning

Er.CCC

Light weak fault, please refer to

function code P47.05~P47.07

Function

code

Name

Description

Default

Propert

y

47 Group solar pumping special group

P47.00

Solar pump function

enable

0: invalid

The parameters behind the 47 group cannot

be changed!

1: Enable, to enable the special function of

the PV pump inverter

1

★

P47.01

Solar pump control

mode

Units digit’s: Startup mode

0: Manual start, the start mode is

determined by P00.06;

1: automatic start,

Ten digit’s: MPPT function

0: MPPT is disabled; CVT control is used

(voltage is given as P47.04).

1: Enable MPPT.

11

★

r47.02

Remaining time for

starting

The remaining time of the starting is

displayed In auto start mode,

Unit: second

--

●

P47.03

Automatic start timing

In auto start mode, set the time from power

on to start.

600

★

P47.04

MPPT starting voltage

Set the starting voltage of the MPPT

305V(530V

★

to enter the basic menu mode.

3.3 Error code:For other alarm codes, please refer to Chapter 5 of the manual.

4、Parameter list

Symbol Description:

“☆” means that the set value of this parameter can be changed no matter the inverter is in

the stop state or in running state.

“★” indicates that the set value of this parameter cannot be changed while the inverter is

running.

“●” indicates that the value of this parameter is the actual detected record value and cannot

be changed.

47 Group solar pumping special group

Loading...

Loading...