Veikong VFD500-R75GT4B, VFD500-5R5G/7R5PT4B, VFD500-7R5G/011PT4B, VFD500-011G/015PT4B, VFD500-015G/018PT4B Operation Manual

...

Operation manual

VFD500 Series AC DRIVE

High Performance vector and torque

Preface

Thank you for purchasing the VFD500 series high performance vector and torque control frequency

inverter

VFD500 series Performance higher level than VFD300Afrequency inverterwith advanced functions, such

as high performance vector control of induction motor, user-programmable function and backstage

monitoring software, variable communication and supporting multiple PG cards etc. It is applicable to

textile, papermaking, tension control, wire drawing fans and pumps, machine tools, packaging, food and

all kinds of automatic production equipment.Its excellent performance is equivalent and competitive to

most of international brand AC drives

This manual introduces functional characteristics and usage of VFD500 series inverter, includes product

model selection, parameter settings, running and debugging, maintenance, checking, and so on. Please

be sure to read this manual carefully before operation. For equipment matching manufacturers, please

send this manual to your end user together with your devices, in order to facilitate the usage.

PRECAUTIONS

To describe the product details, the illustrations in the manual sometimes are under the state of

removing the outer housing or security covering. While using the product, please be sure to

mount the housing or covering as required, and operate in accordance with the contents of

manual.

The illustrations in this manual is only for explanation, may be different from the products you

ordered.

committed to constantly improving the products and features will continue to upgrade, the

information provided is subject to change without notice.

Please contact with the regional agent or client service center directly of factory if there is any

questions during usage.

EDIT: V2.1

TIME: 2018-07

Contents

Chapter 1 Safety Information and Precautions ................................................................................................. 1

1.1 Safety Precautions………………………………………………………………………………………………………………………….1

1.2 Precaution………………………………………………………………………………………………………………………………………2

Chapter 2 Product Information ..................................................................................................................... ….4

2.1 Designation Rules……………………………………………………………………………………………………………………………4

2.2product series instruction………………………………………………………………………………………………………………..4

2.3Technical Specifications…………………………………………………………………………………………………………………..5

Chapter 3 Product appearance and Installation Dimension……………………………………………………………….7

3.1 Product appearance and installation……………………………………………………………………………………..….…..7

3.1.1Product appearance .................................................................................................................. 7

3.1.2Appearance and Mounting Hole Dimension ............................................................................. 7

3.1.3Removal and installation of cover and inlet plate ................................................................... 10

3.2Wiring…………………………………………………………………………………………...............................................…..12

3.2.1 Standard wiring diagram ........................................................................................................ 12

3.2.2Main Circuit Terminals ............................................................................................................. 13

3.2.3 Terminal screws and wiring specifications ............................................................................. 14

3.2.4 Cautions for Main Circuit Wiring ............................................................................................ 14

3.2.4Control Circuit Terminal ........................................................................................................... 15

3.3EMCquestion and solution………………………………………………………………………........................................21

Chapter 4 Operation and display ..................................................................................................................... 23

4.1 LED Instruction of operation and display…………………………………………………………………………………...23

4.2 Display hierarchy and menu mode…………………………………………………………………………………………….24

4.3 Digital tube display……………………………………………………………………………………………………………………25

4.4 Test run………………………………………………………………………………………………………………………..………………26

Chapter 5 Function Code Table .................................................................................................................. 27

Chapter6 Fault Diagnosis and Solution .................................................................................................... 90

Chapter7 Selection Guide of inverter Accessory ..................................................................................... 95

7.1 Selection Guide of braking component………………………………………………………….95

7.2 PG card type………………………………………………………………………………………96

7.3 IO Extension card………………………………………………..………………………………...98

Chapter8 Daily maintenance of frequency inverters ............................................................................. 100

8.1 Daily maintenance……………………………………………………………………………….100

8.1.1 Daily maintenance ............................................................................................................ 100

8.1.2 Regular inspection ............................................................................................................ 100

8.2 Wearing parts replacement……………………………………………………………………..100

8.3Warranty Items……………………………………………………………………………………101

Appendix A Modbus communication protocol ..................................................................................... 102

VFD500 high performance vector control frequency inverter user manual Chapter 1 Safety information and precautions

- 1-

Chapter 1 Safety Information and Precautions

Safety Definitions: In this manual, safety precautions are divided into the following two categories:

indicates that failure to comply with the notice will result in serous injury or even death

indicates that failure to comply with the notice will result in moderate or minor injury andequipment

damage

Read this manual carefully so that you have a thorough understanding. Installation, commissioning or

maintenance may be performed in conjunction with this chapter. will assume no liability or responsibility

for any injury or loss caused by improper operation.

1.1 Safety Precautions

Use stage

Security Level

Precautions

Before

Installation

DANGER

packing water, parts missing or damaged parts, please do not install!

Packaging logo and physical name does not match, please do not

install!

WARNING

Handling should be light lift, otherwise there is the danger of damage

to equipment!

Do not use damaged drive or missing drive. Risk of injury!

Do not touch the control system components by hand, or there is the

danger of electrostatic damage!

During

Installation

DANGER

Please install the flame retardant objects such as metal, away from

combustibles, or may cause a fire!

WARNING

Do not allow lead wires or screws to fall into the drive, otherwise the

drive may be damaged!

Install the drive in a place where there is less vibration and direct

sunlight.

Drive placed in airtight cabinet or confined space, please note the

installation of space to ensure the cooling effect.

Wiring

DANGER

You must follow the guidance of this manual and be used by qualified

electrical engineers. Otherwise, unexpected danger may occur!

There must be a circuit breaker between the drive and the power

supply, otherwise a fire may occur!

Make sure the power supply is in zero-energy state before wiring,

otherwise there is danger of electric shock!

Please follow the standard to the drive properly grounded, otherwise

there is the risk of electric shock!

WARNING

Never connect input power to the drive's output terminals (U, V, W).

Note that the terminal markings, do not take the wrong line! Otherwise

it will cause damage to the drive!

Never connect the braking resistor directly to the DC bus +, - terminals.

Otherwise it will cause a fire!

Refer to the manual's recommendations for the wire diameter used.

Otherwise it may happen accident!

Do not disassemble the connecting cable inside the driver. Otherwise,

the internal of the servo driver may be damaged.

Before

Power-on

DANGER

Make sure the voltage level of the input power is the same as the rated

voltage of the driver. Check if the wiring position of the power input

terminals (R, S, T) and output terminals (U, V, W) is correct; Of the

external circuit is short-circuited, the connection is tightened, or cause

Chapter1 Safety information and precaution VFD500 high performance vector control frequency inverter user manual

- 2 -

Use stage

Security Level

Precautions

damage to the drive!

No part of the drive need to withstand voltage test, the product has

been made before the test. Otherwise it may cause accident!

WARNING

The driver must be covered before the cover can be powered,

otherwise it may cause electric shock!

All peripheral accessories must be wired according to the instructions

in this manual, and be properly wired in accordance with this manual.

Otherwise it may cause accident!

After

Power-on

DANGER

Do not open the cover after power on, otherwise there is danger of

electric shock!

If the indicator light does not light after power on, the keyboard does

not display the situation, immediately disconnect the power switch, do

not touch any input and output terminals of the drive, otherwise there is

the risk of electric shock!

WARNING

If parameter identification is required, preclude the possibility of injury

when rotating the motor!

Do not arbitrarily change the drive manufacturer parameters, or it may

cause damage to the device!

During

Operation

DANGER

Do not touch the cooling fan, radiator and discharge resistance to test

the temperature, otherwise it may cause burns!

Non-professional technicians Do not detect the signal during

operation, otherwise it may cause personal injury or equipment

damage!

WARNING

Drive operation, should avoid something falling into the device,

otherwise it will cause damage to the device!

Do not use the contactor on-off method to control the start and stop the

drive, otherwise it will cause damage to the equipment!

Maintenance

DANGER

Do not live on the equipment repair and maintenance, or there is a risk

of electric shock!

Turn off the input power for 10 minutes before performing maintenance

and repair on the drive, otherwise the residual charge on the capacitor

will cause harm to people!

Do not carry out maintenance and repair on the drive without

personnel who have been professionally trained, otherwise personal

injury or equipment damage will occur!

All pluggable plug-ins must be unplugged in the case of power failure!

The parameters must be set and checked after replacing the drive.

WARNING

Before performing maintenance work on the drive, make sure that the

motor is disconnected from the drive to prevent the motor from feeding

back power to the drive due to accidental rotation.

1.2 Precaution

Contactor using

If the contactor is installed on the power input side of the inverter, do not make the contactor frequent on-off

operation. The interval between ON and OFF of the contactor should not be less than one hour. Frequent

charging and discharging will reduce the use of capacitors in the inverter life.

If a contactor is installed between the inverter output terminals (U, V, W) and the motor, make sure that the

inverter is turned on and off when there is no output. Otherwise, the inverter may be damaged.

Lightning impulse protection

Although this series of inverters are equipped with lightning over-current protection device, there is a certain

degree of self-protection for inductive lightning, but for lightning frequent place, customers should also install

lightning protection device in the front of the inverter.

VFD500 high performance vector control frequency inverter user manual Chapter 1 Safety information and precautions

- 3-

Altitude and derating use

In areas above 1000m above sea level, it is necessary to derate the inverter due to poor air quality due to poor

air quality. In this case, please consult our company.

Power input

The inverter power input should not exceed the operating voltage range specified in this manual. If necessary,

use a step-up or step-down device to change the power supply to the specified voltage range.

Do not change the three-phase inverter to two-phase input, otherwise it will cause malfunction or inverter

damage.

Output filtering

When the cable length between the inverter and the motor exceeds 100 meters, it is suggested to use the

output AC reactor to avoid inverter over-current caused by excessive distributed capacitance. Output filter

according to the needs of the field matching.

Inverter output is PWM wave, please do not install the capacitor on the output side to improve the power factor

or lightning varistor, etc., otherwise it may easily lead to inverter instantaneous overcurrent or even damage the

inverter.

About motor heat and noise

Because the inverter output voltage is PWM wave, contains a certain degree of harmonics, so the motor

temperature rise, noise and vibration compared with the same frequency operation will be slightly increased.

Disposal

Electrolytic capacitors on the main circuit and electrolytic capacitors on the printed circuit board may explode

when incinerated, and poisonous gases are generated when plastic parts are burned. Please dispose as

industrial waste.

The scope of application

This product is not designed and manufactured for use on equipment where life is at stake. To use this product

on a mobile, medical, aerospace, nuclear or other special purpose device, please contact our company For more

information.

This product is manufactured under strict quality control and should be equipped with a safety device if it is

used in a device that may cause a serious accident or damage due to inverter failure.

Chapter 2 Product information VFD500 high performance vector control frequency inverter user manual

- 4 -

Chapter 2 Product Information

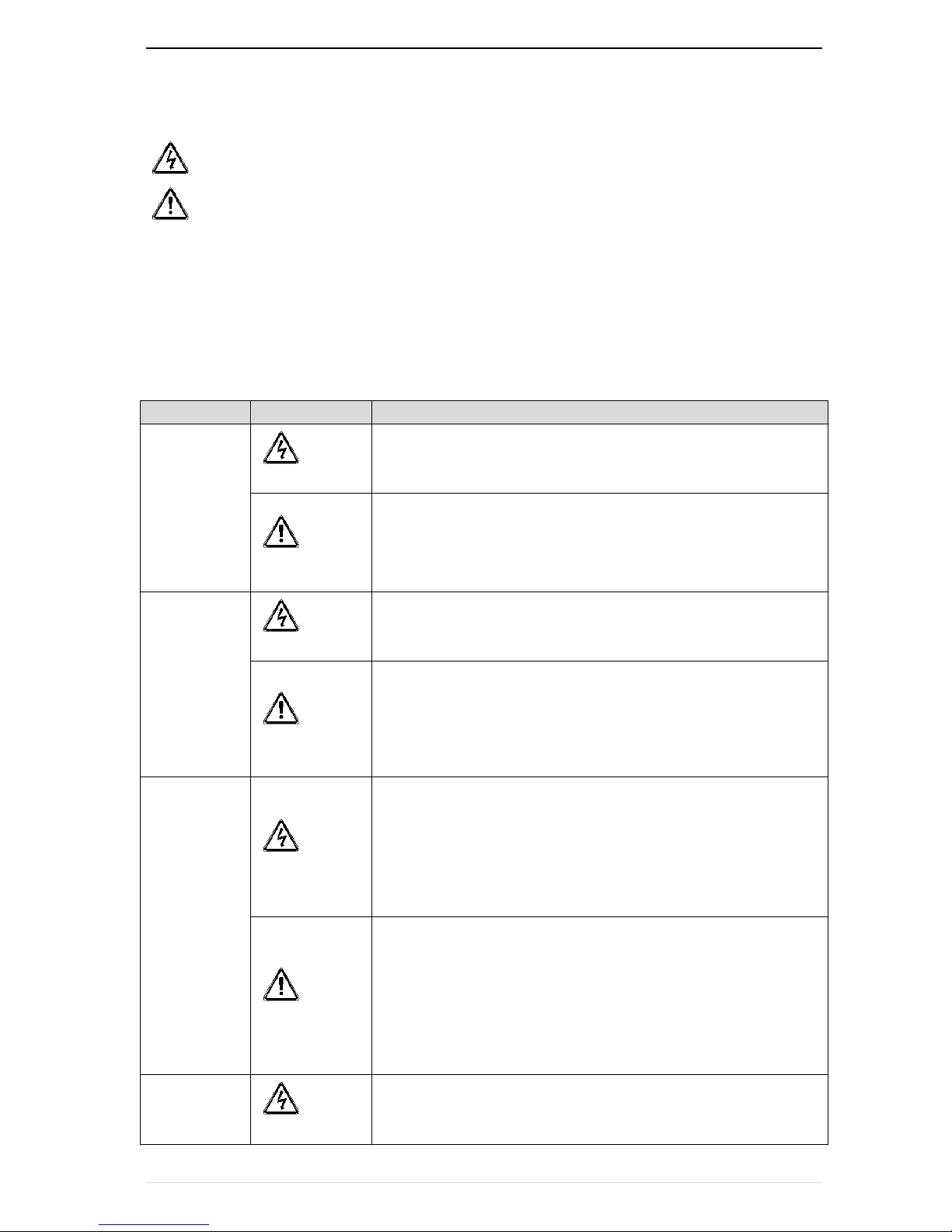

2.1 Designation Rules

Name plate:

MODEL: VFD500-2R2GT4

POWER: 2.2kW/4.0kW

INPUT: 3PH AC380~440V 50Hz/60Hz

OUTPUT: 3PH 0~440V 0~600Hz 5.6A/9.4A

S/N:

TYPE

POWER

INPUT

OUTPUT

CODE

2-1 name plate

Model instruction:

2-2model instruction

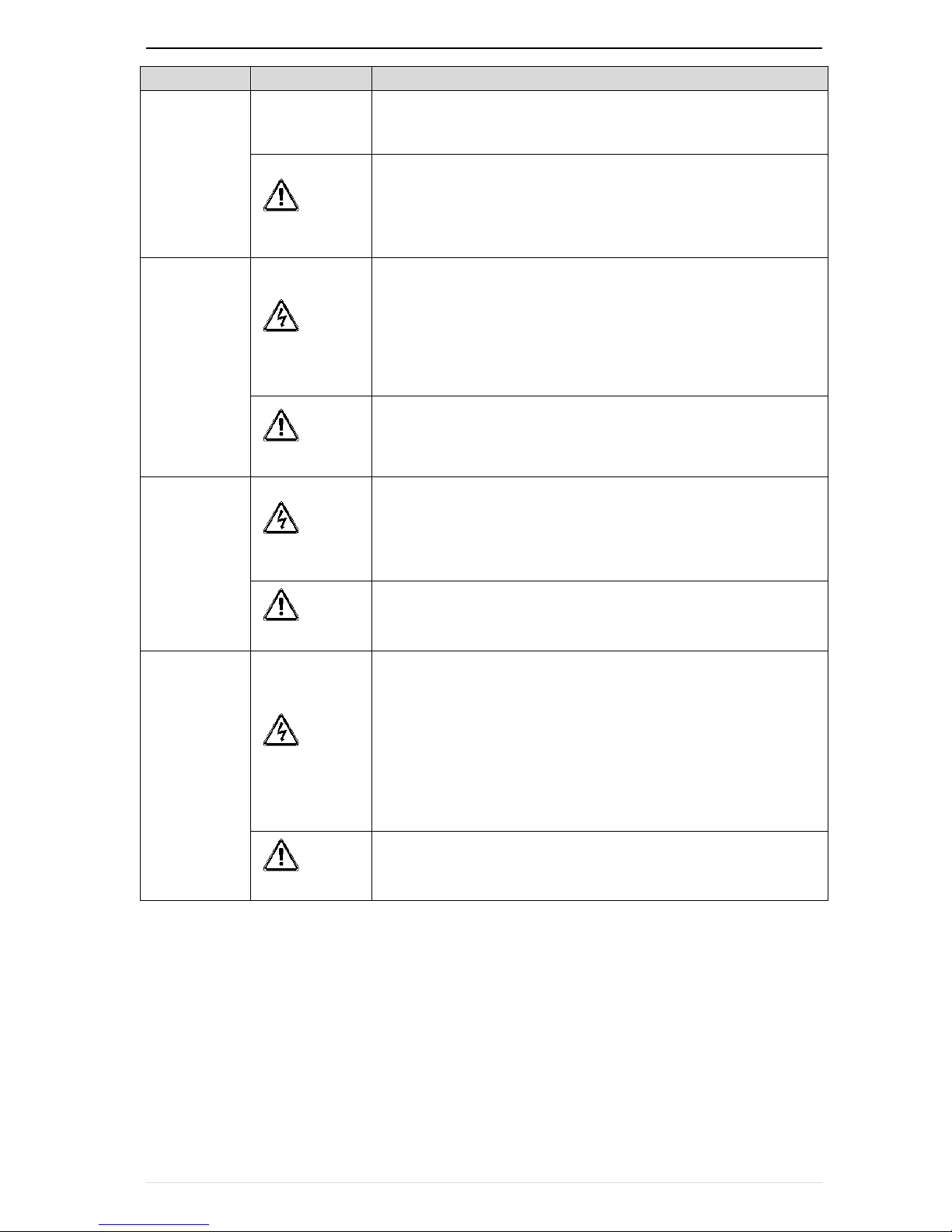

2.2product series instruction

Table 2-1VFD500 inverter models and technical data

Model

Power

capacity

(KVA)

Input

current

(A)

Output current(A)

Adapta

ble

Motor

(KW)

SIZE

Brake

Unit

Heavy

load

Light

load

Three phase: 380-480V,50/60Hz

VFD500-R75GT4B

1.5

3.4

2.5

4.2

0.75

SIZE A

Inter

nal

VFD500-1R5GT4B

3 5 4.2

5.6

1.5

VFD500-2R2GT4B

4

5.8

5.6

9.4

2.2

VFD500-3R7G/5R5PT4B

5.9

10.5

9.4

13.0

3.7

VFD500-5R5G/7R5PT4B

8.9

14.6

13.0

17.0

5.5

SIZE B

VFD500-7R5G/011PT4B

11

20.5

17.0

23.0

7.5

VFD500-011G/015PT4B

17

26.0

25.0

31.0

11

SIZE C

Inter

nal

VFD500-015G/018PT4B

21

35.0

32.0

37.0

15

VFD500-018G/022PT4B

24

38.5

37.0

45.0

18.5

SIZE D

VFD500-022G/030PT4B

30

46.5

45.0

57.0

22

VFD500 -2R2 – G T 4 B

T:three phase

Load type:G normal duty

Power,2R2 means 2.2kW

Product series

B means breaking units

4:380-480v three phase 2: 200-240v

VFD500 high performance vector control frequency inverter user manual Chapter2 production information

- 5-

VFD500-030G/037PT4

40

62.0

60.0

75.0

30

SIZE E

optio

n

VFD500-037G/045PT4

50

76.0

75.0

87.0

37

VFD500-045G/055PT4

60

92.0

90.0

110.0

45

SIZE F

VFD500-055G/075PT4

85

113.0

112.0

135.0

55

VFD500-075G/090PT4

104

157.0

152.0

165.0

75

SIZE G

VFD500-090G/110PT4

112

170.0

176.0

210.0

90

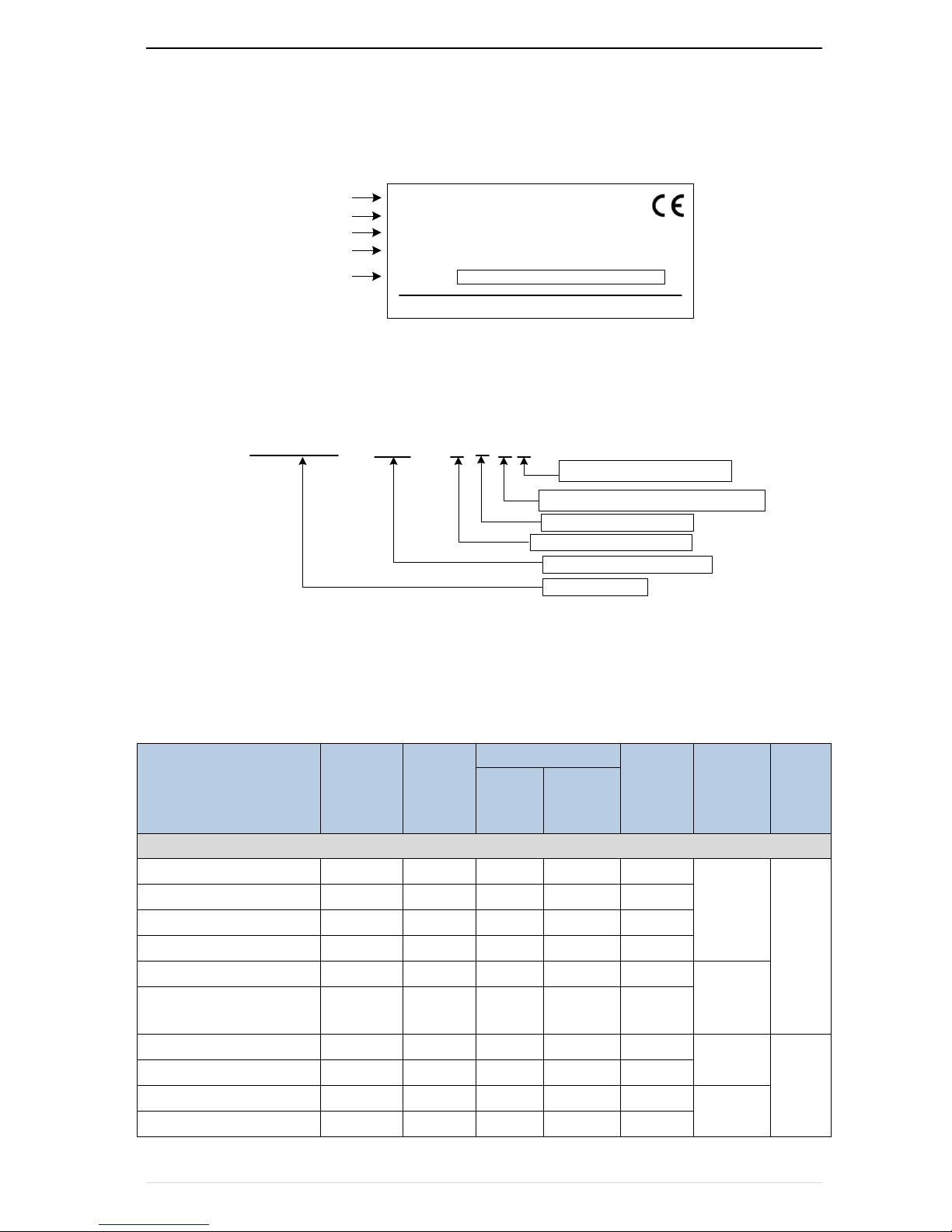

2.3Technical Specifications

Table 2-2 VFD500Technical Specifications

Item

Specifiation

Input

Inuput Voltage

1phase/3phase 220V:200V~240V

3 phase 380V-480V:380V~480V

Allowed Voltage

fluctuation range

-15%~10%

Input frequency

50Hz / 60Hz,fluctuation less than 5%

Output

Output Voltage

3phase:0~input voltage

Overload capacity

General purpose application:60S for 150% of the rated current

Light load application:60S for 120% of the rated current

Control

Control mode

V/f control

Sensorless flux vector control without PG card(SVC)

Sensor speed flux vector control with PG card (VC)

Operating mode

Speed control、Torque control(SVC and VC)

Speed range

1:100 (V/f)

1:200( SVC)

1:1000 (VC)

Speed control

accuracy

±0.5% (V/f)

±0.2% (SVC)

±0.02% (VC)

Speed response

5Hz(V/f)

20Hz(SVC)

50Hz(VC)

frequency range

0.00~600.00Hz(V/f)

0.00~200.00Hz(SVC)

0.00~400.00Hz(VC)

Input frequency

resolution

Digital setting: 0.01 Hz

Analog setting: maximum frequency x 0.1%

Startup torque

150%/0.5Hz(V/f)

180%/0.25Hz(SVC)

200%/0Hz(VC)

Torque control

accuracy

SVC:within 5Hz10%,above 5Hz5%

VC:3.0%

V/f curve

V / f curve type: straight line, multipoint, power function, V / f separation;

Torque boost support: Automatic torque boost (factory setting), manual

torque boost

Frequency giving

ramp

Support linear and S curve acceleration and deceleration;

4 groups of acceleration and deceleration time, setting range 0.00s ~

60000s

DC bus voltage

control

Overvoltage stall control: limit the power generation of the motor by

adjusting the output frequency to avoid skipping the voltage fault;

Chapter 2 Product information VFD500 high performance vector control frequency inverter user manual

- 6 -

Undervoltage stall control: control the power consumption of the motor

by adjusting the output frequency to avoid yaw failure

VdcMax Control: Limit the amount of power generated by the motor by

adjusting the output frequency to avoid over-voltage trip;

VdcMin control: Control the power consumption of the motor by

adjusting the output frequency, to avoid jump undervoltage fault

Carrier frequency

1kHz~12kHz(Varies depending on the type)

Startup method

Direct start (can be superimposed DC brake); speed tracking start

Stop method

Deceleration stop (can be superimposed DC braking); free to stop

Maincontrol

function

Jog control, droop control, up to 16-speed operation, dangerous speed

avoidance, swing frequency operation, acceleration and deceleration

time switching, VF separation, over excitation braking, process PID

control, sleep and wake-up function, built-in simple PLC logic, virtual

Input and output terminals, built-in delay unit, built-in comparison unit

and logic unit, parameter backup and recovery, perfect fault record,fault

reset, two groups of motor parameters free switching, software swap

output wiring, terminals UP / DOWN

function

Keypad

LED Digital keyboard and LCD keypad(option)

communication

Standard:

MODBUS communication

Option:Profibus-DP and CAN OPEN

PG card

Incremental Encoder Interface Card (Differential Output and Open

Collector), Rotary transformer Card

Input terminal

Standard:

5 digital input terminals, one of which supports high-speed pulse input

up to 50kHz;

2 analog input terminals, support 0 ~ 10V voltage input or 0 ~ 20mA

current input;

Option card:

4 digital input terminals

2 analog input terminals.support-10V-+10V voltage input

Output terminal

standard:

1 digital output terminal;

1 high-speed pulse output terminal (open collector type), support 0 ~

50kHz square wave signal output;

1 relay output terminal(second relay is an option )

2 analog output terminals, support 0 ~ 20mA current output or 0 ~ 10V

voltage output;

Option card: 4 digital output terminals

Protection

Refer to Chapter 6 "Troubleshooting and Countermeasures" for the protection function

Environment

Installation

location

Indoor, no direct sunlight, dust, corrosive gas, combustible gas, oil

smoke, vapor, drip or salt.

Altitude

0-3000m.inverter will be derated if altitude higher than1000m and

rated output current will reduce by 1% if altitude increase by 100m

Ambient

temperature

-10°C~ +40°C,maximum 50°C (derated if the ambient temperature is

between 40°C and 50°C)Rated output current decrease by 1.5% if

temperature increase by 1°C

Humidity

Less than 95%RH, without condensing

Vibration

Less than 5.9 m/s2 (0.6 g)

Storage

temperature

-20°C ~ +60°C

others

Installation

Wall-mounted, floor-controlled cabinet, transmural

Protection level

IP20

cooling method

Forced air cooling

VFD500 high performance vector control frequency inverter user manual Chapter3 Product appearance and wiring

- 7-

Chapter 3 Product appearance and Installation Dimension

3.1 Product appearance and installation

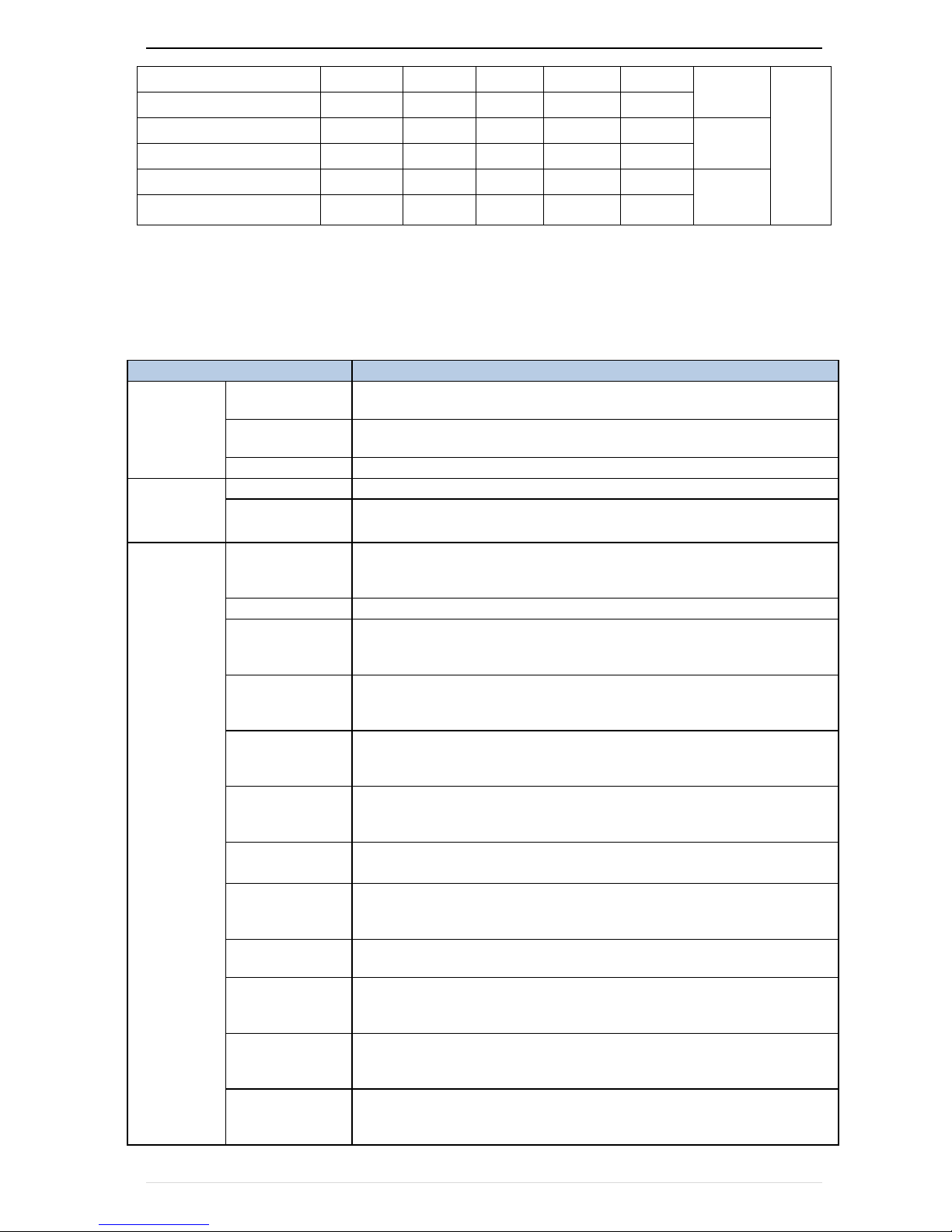

3.1.1Product appearance

fan

Name plate

cover

Line board

Keypad

Fan cover

Back cover

Front cover

Main circuit terminal

Extension card port

Control terminal

3-1:VFD500 series appearance

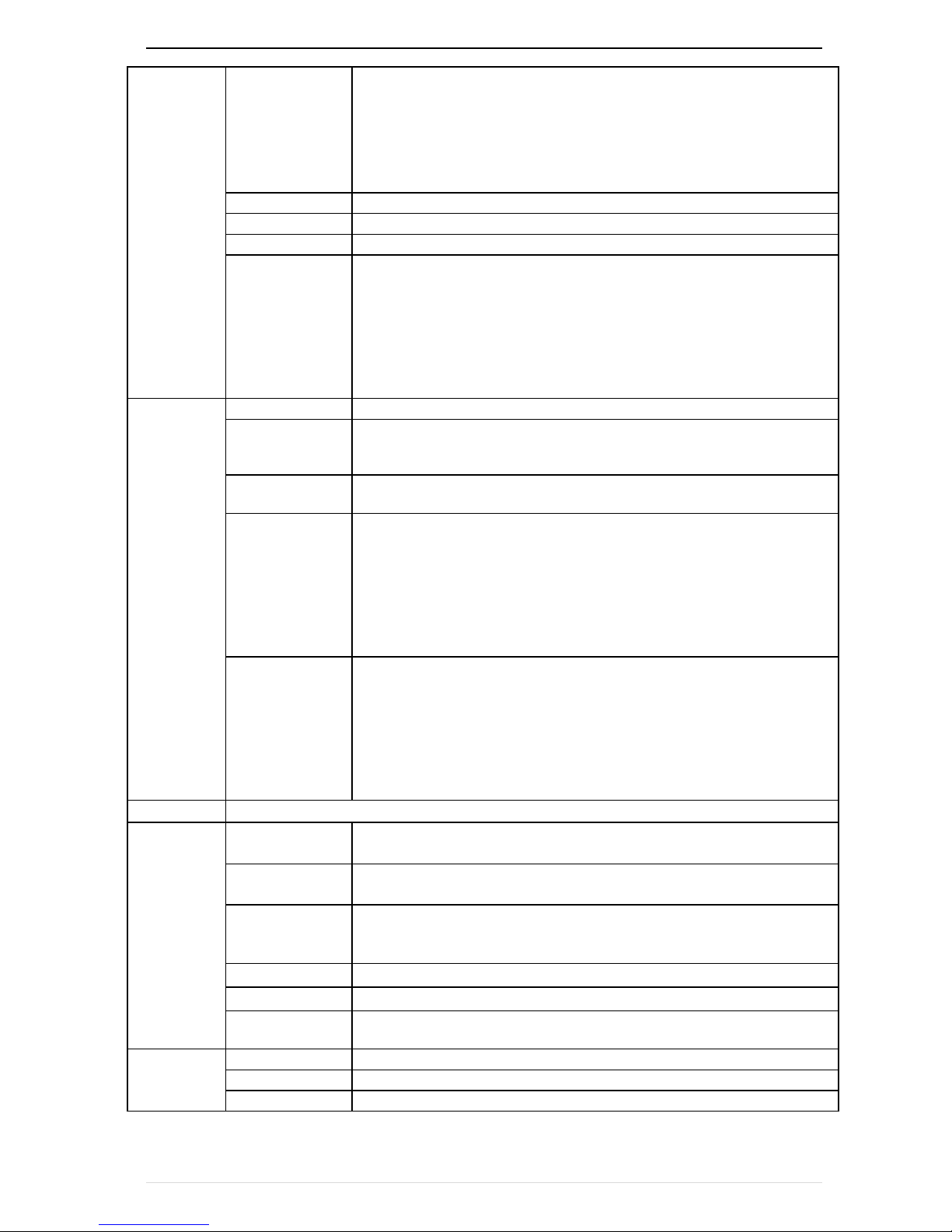

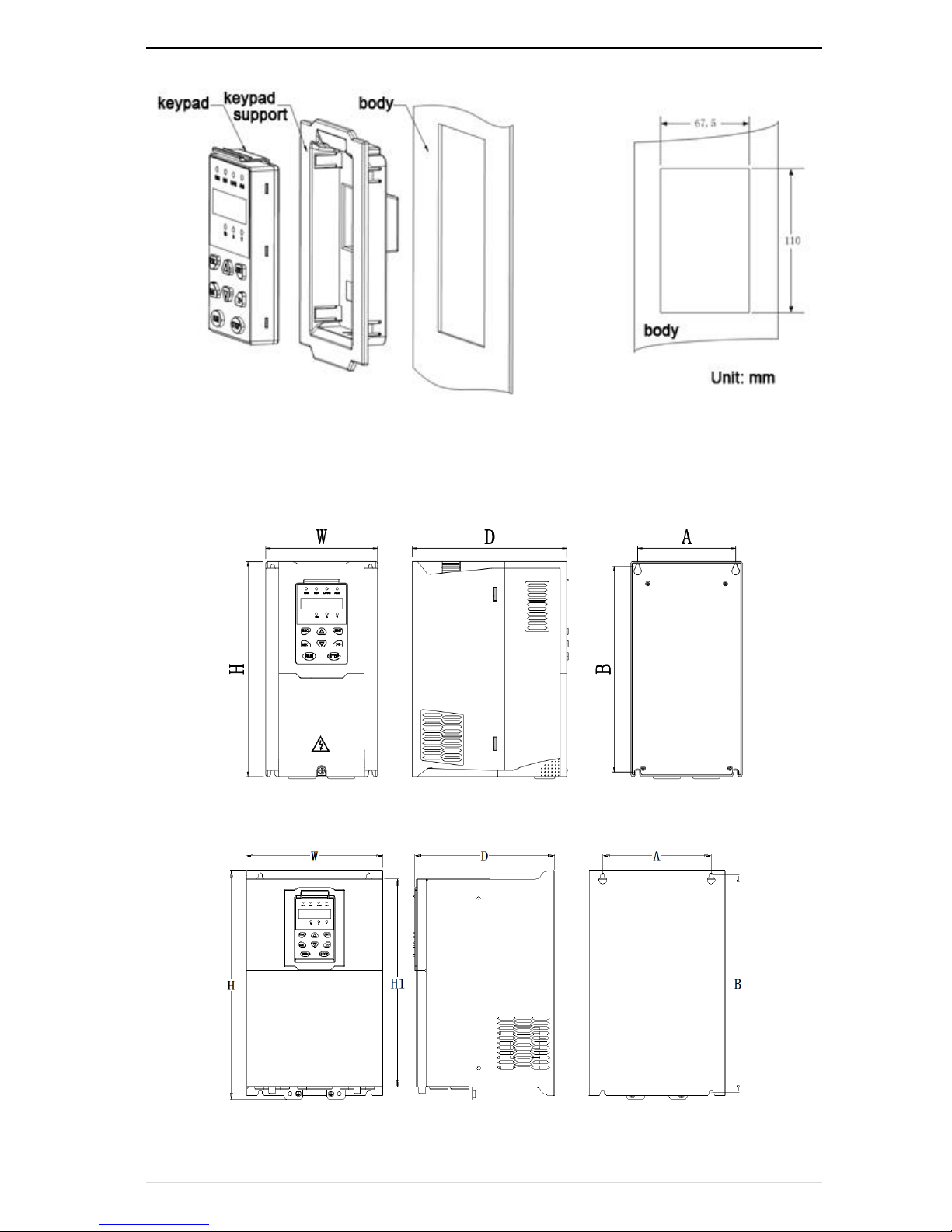

3.1.2Appearance and Mounting Hole Dimension

Keypay and keypad support size

The dimensions of the VFD500 series keypad are shown in Figure 3-1. When installing the keypad on the outside of

the control cabinet, use the two screws on the back of the keypad to fix it (right side of Figure 3-1).

Chapter3 product appearance and wiring VFD500 high performance vector control frequency inverter user manual

- 8 -

diagram 3-2keypad dimension

If you want to install the keypad on the inside of the control cabinet (to prevent the keypad from protruding toward

the outside of the control cabinet), use a keypad Bracket. The dimensions of the keypadbracket are shown in Figure

3-2. The dimensions of the installation diagram and control cabinet are shown in Figure 3-3.

M3 screw X2 depth 8mm (for

mounting to the control cabinet)

Figure 3-3 Keypad Holder Size (Unit: mm)

VFD500 high performance vector control frequency inverter user manual Chapter3 Product appearance and wiring

- 9-

Figure 3-4 Keypad support installation diagram and control cabinet processing dimensions

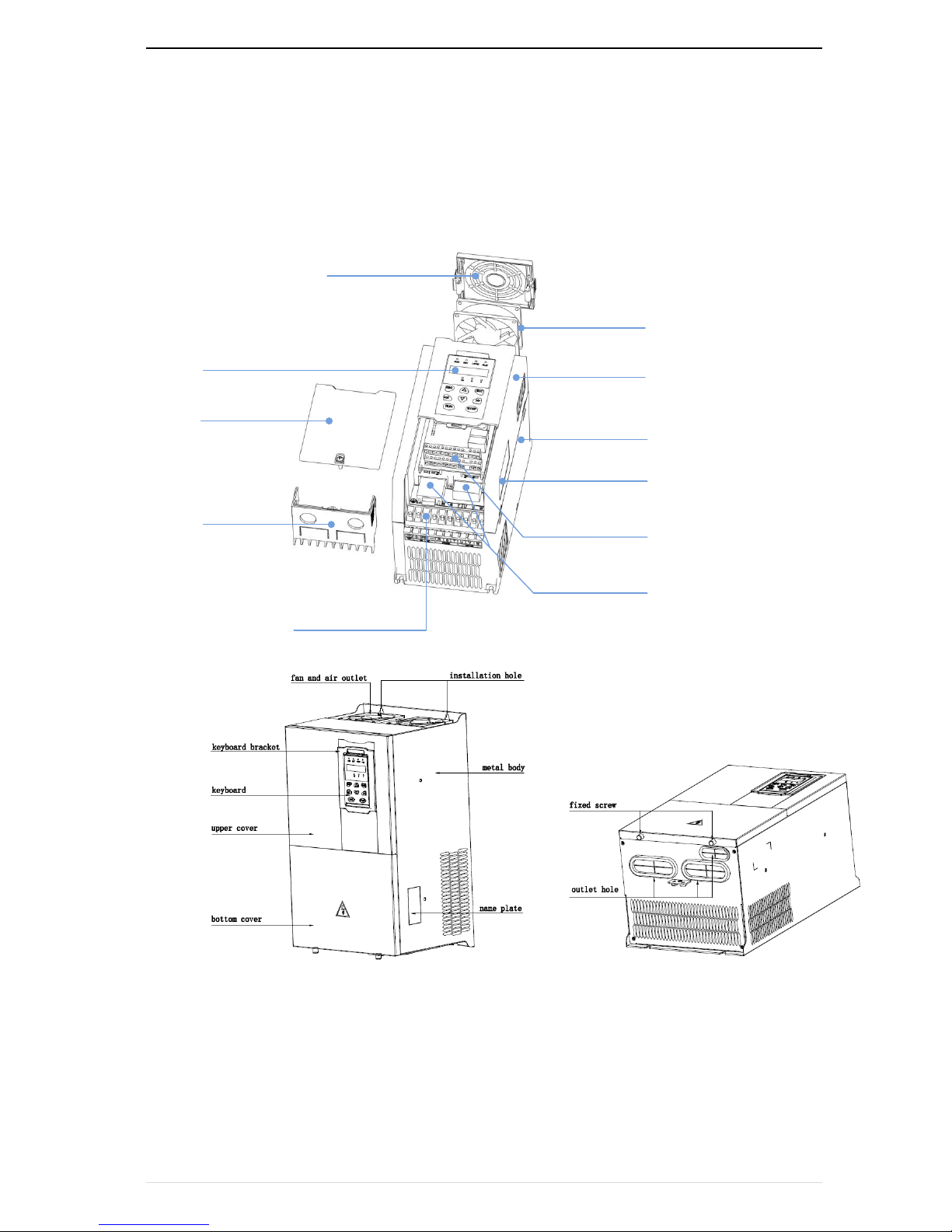

Inverter dimensions and installation dimensions

Figure 3-5 SIZE A to SIZE C Dimensions

Figure 3-6 SIZE D~G Dimensions

Chapter3 product appearance and wiring VFD500 high performance vector control frequency inverter user manual

- 10 -

Table 3-1 VFD500 series appearance and installation dimension

SIZE

Appearance and installation dimension(mm)

A B H

H1 W D

Φd

Mounting

screws

SIZE A

87

206.5

215 / 100

170

ø5.0

M4X16

SIZE B

114

239.5

250 / 130

180

ø5.0

M4X16

SIZE C

159

298

310 / 180

193

Ø6.0

M5X20

SIZE D

165

350

365 210

205

Ø6.0

M5X20

SIZE E

170

437

452.5 260

230

Ø7.0

M6X16

SIZE F

250

535

555 310

275

Ø10.0

M8X20

SIZE G

280

620

640 350

290

Ø10.0

M8X20

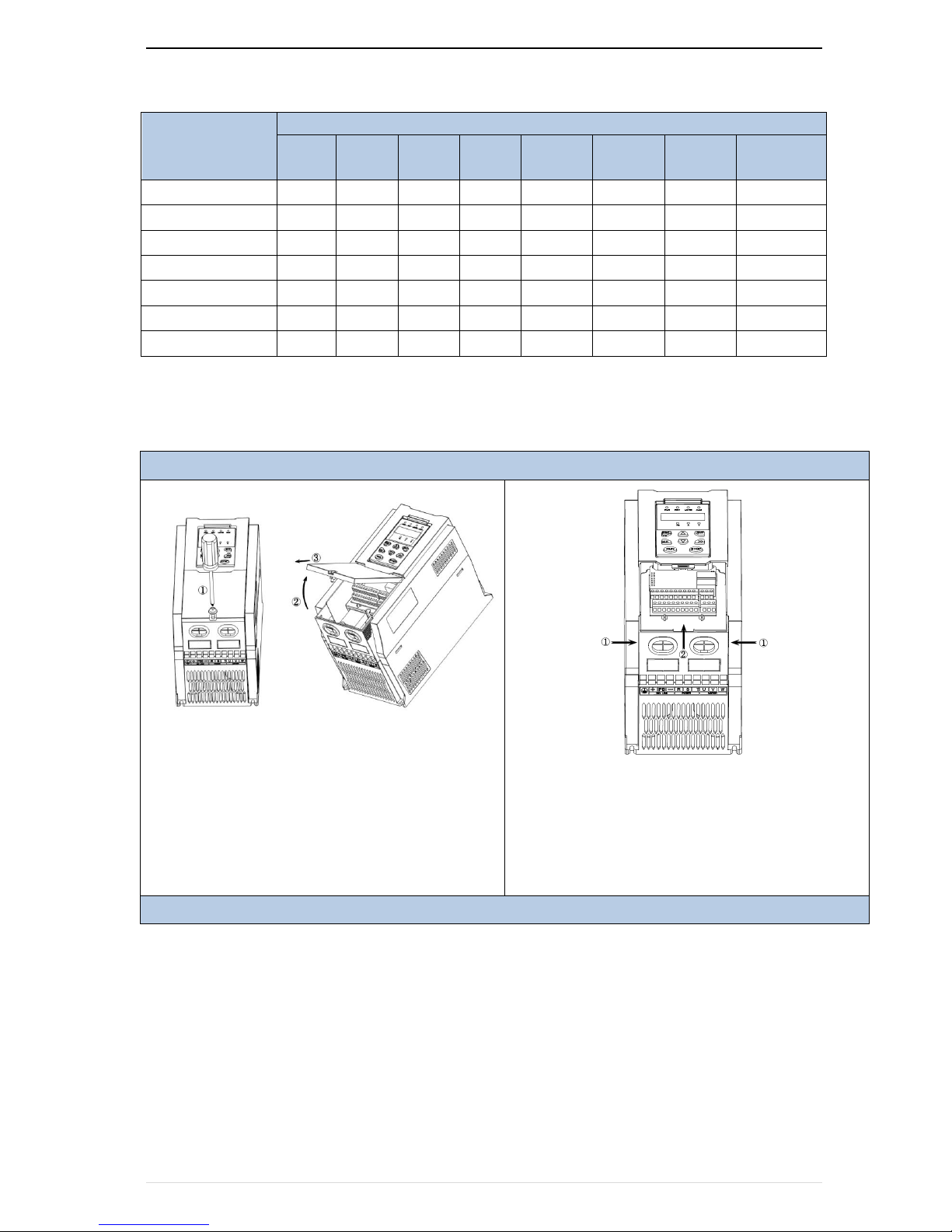

3.1.3Removal and installation of cover and inlet plate

SIZEA~SIZE CRemoval and installation of cover and inlet plate:

Removal steps

Step 1: Open the top cover

① Unscrew the screw on the cover

② Lift up the cover

③ Remove the cover from the front

Step 2: Take out the inlet board

① Hold down the sides of the inlet plate with your

thumb and middle finger

② Press to disengage the buckle and pull it out of the

board

installation steps

VFD500 high performance vector control frequency inverter user manual Chapter3 Product appearance and wiring

- 11-

① Step 1: Install the inlet board

② Put the inlet board from the top down into the

mounting position to ensure that the card buckles

Step 2: Install the upper cover

① Slant the front cover diagonally from the front to

the docking station

② Lower the cover plate toward the inlet board

③ Tighten the screws on the cover

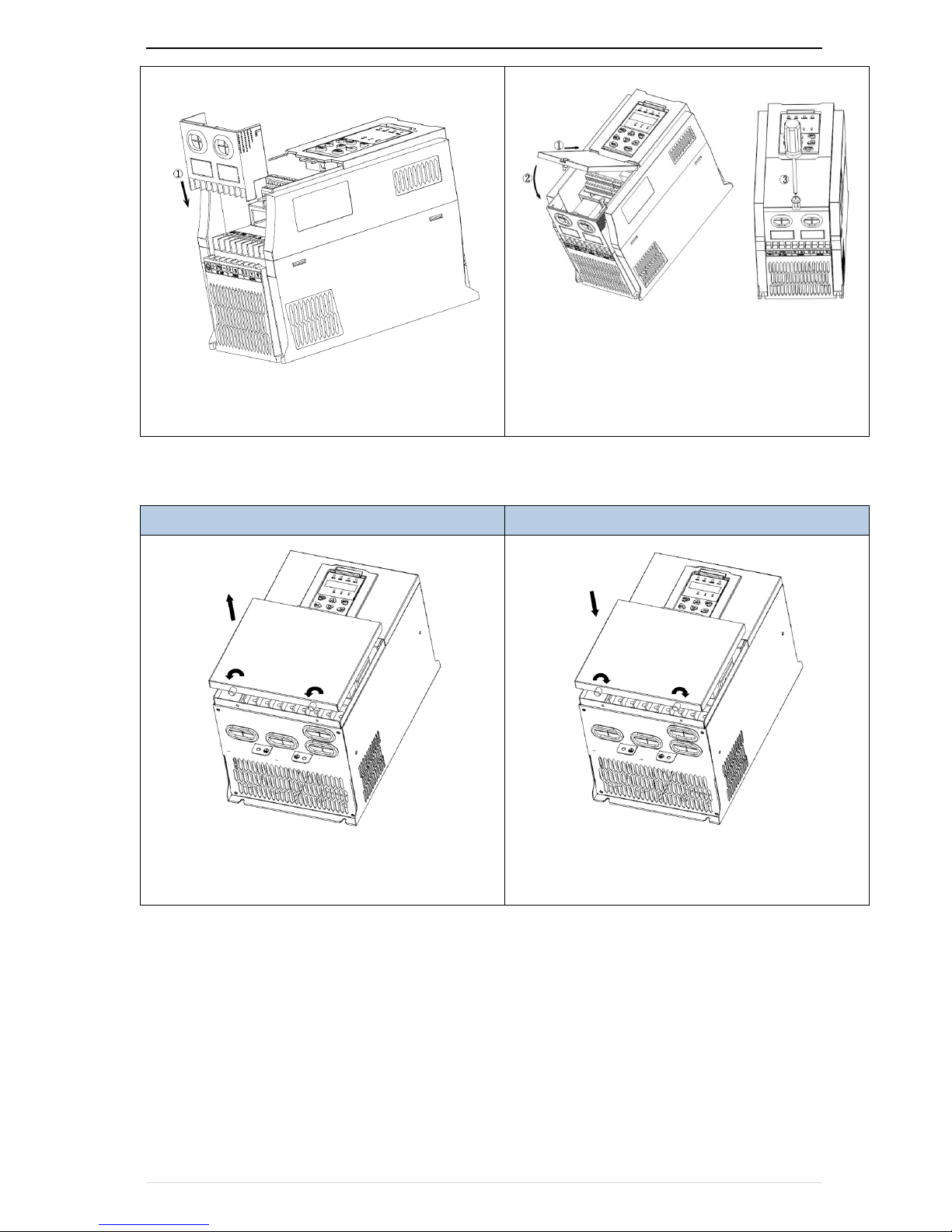

SIZEDRemoval and installation of cover and inlet plate:

Removal steps

installation steps

① Unscrew the two screws at the bottom of the

bottom cover

② Remove the cover vertically

① Close the cover vertically

② Tighten the two screws on the bottom of the cover

○2

○1

○1

○2

○2

○1

Chapter3 product appearance and wiring VFD500 high performance vector control frequency inverter user manual

- 12 -

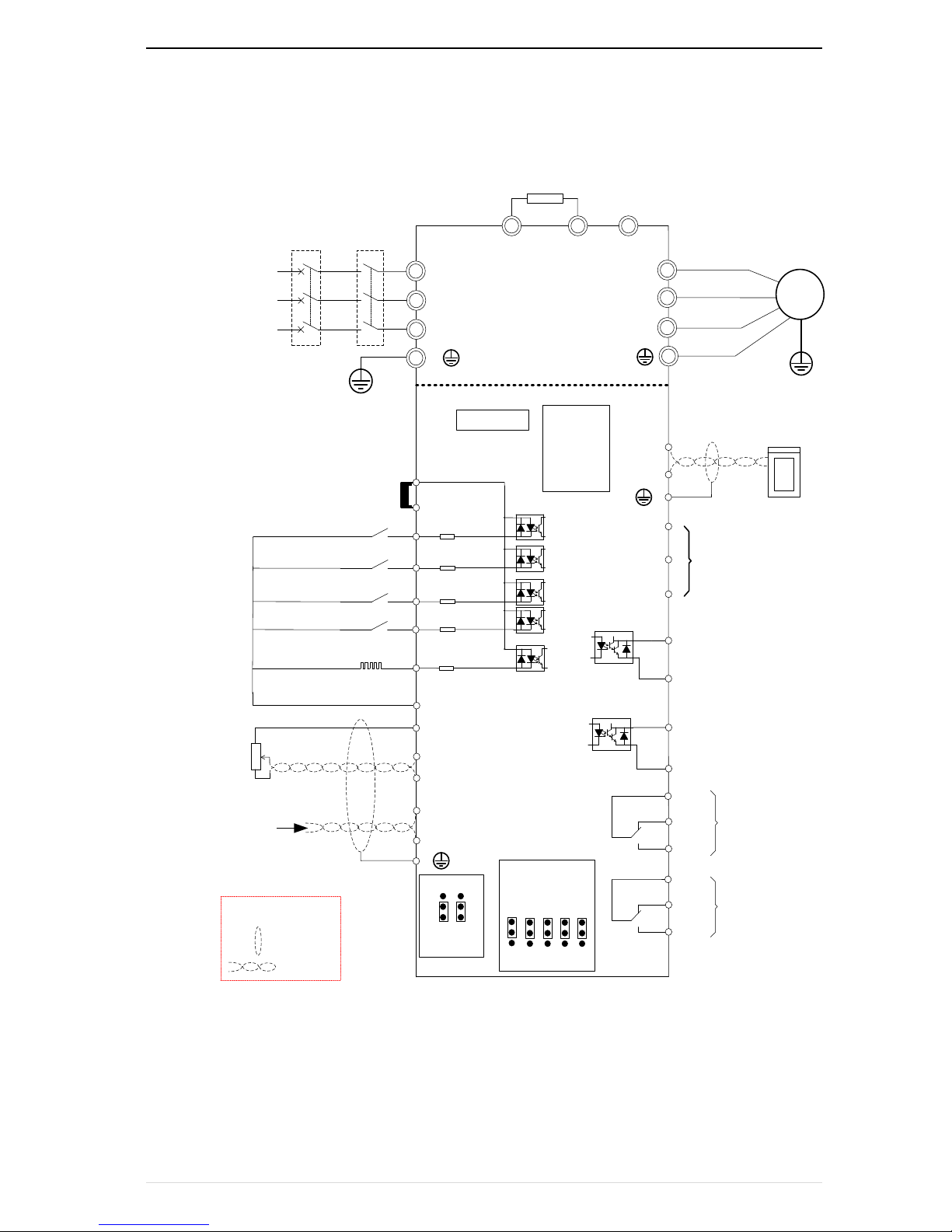

3.2Wiring

3.2.1 Standard wiring diagram

Break resistance

M

U

V

W

R/L1

S/L2

T/L3

3 phase AC input

DI1

DI2

DI3

DI4

COM

AI1

AI2

GND

485+

485-

RS485 port

AO2

GND

AO1、AO2 output:

0~10V/0~20mA

DO

1

CO

M

T1A

T1C

T1B

Relay

output 2

Digital input 1

Digital input 2

Digital input 3

Digital input 4

+10V

Open collector

output1

PLC

+24V

FWD

REV

-

+

PB

HDI

High speed

pluse

terminal

HD

O

COM

Open collector

output2

High speed pluse

output

IO

communi

cation

extension

card

PG card

AO1

380V~ 50/60Hz

Analog input

0~10V/0~20m

A

1~5k

T2A

T2B

T2C

Relay

output 1

485

OFF

ON

AI1VAI2

V

I I I I

AO

1

V

AO

2

V

ON ON

OFF OFF

Ground

Connector slip

GND

Twisted

cable

shield

Note

:

breaker

contactor

Main circuit

Control circuit

PE1

PE2

PC

Diagram 3-7standard wiring

VFD500 high performance vector control frequency inverter user manual Chapter3 Product appearance and wiring

- 13-

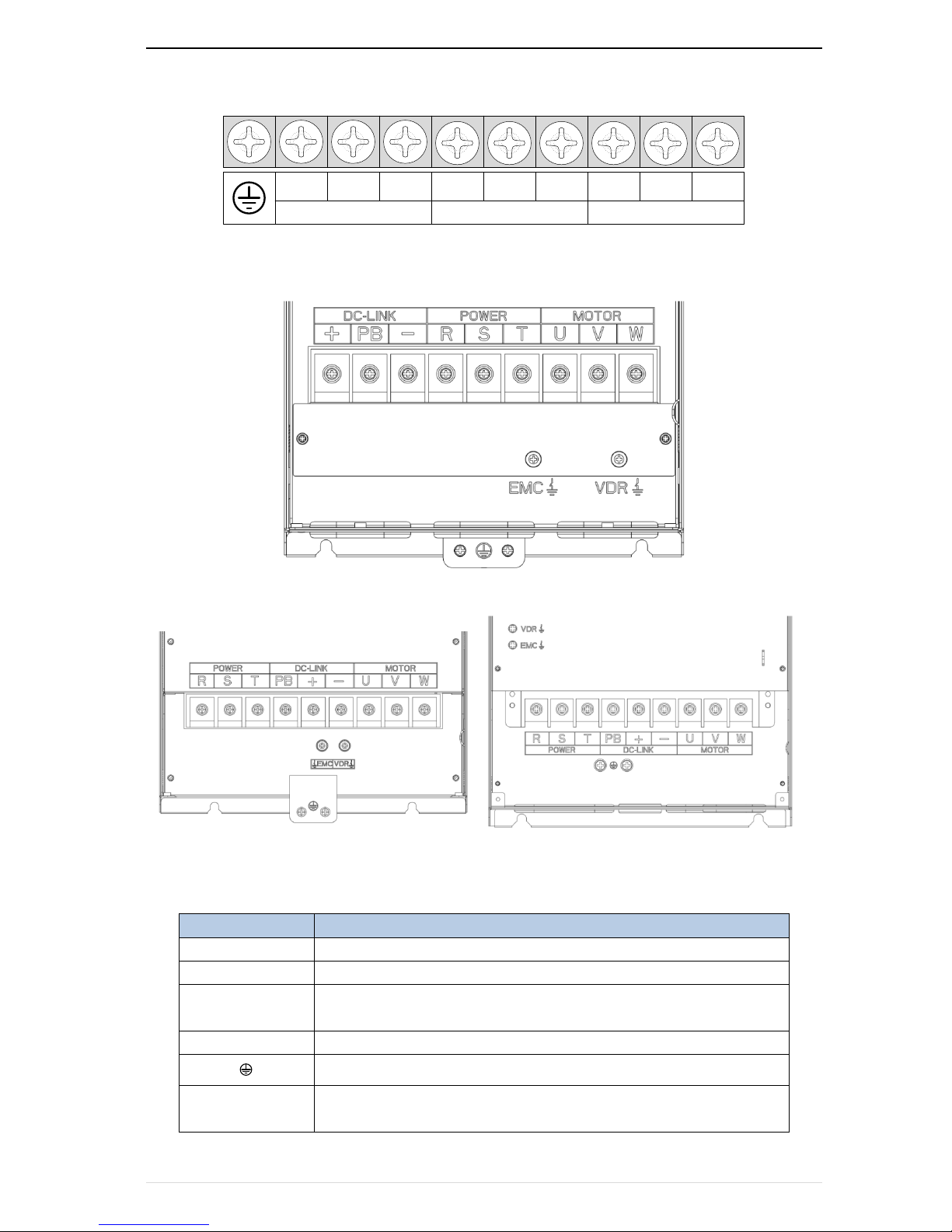

3.2.2Main Circuit Terminals

+ PB -

DC-LINK

R S T

POWER

MOTOR

U V W

Figure 3-8 SIZE A~SIZE C Main Circuit Terminal

Figure 3-9 SIZE D main circuit terminal block diagram

Figure 3-10 SIZE E(LEFT) SIZE F~G(RIGHT) Main Circuit Terminal Blocks

Table 3-2 Function description of the main circuit terminal of the inverter

Terminal

Function instruction

R、S、T

AC power input terminal, connect three-phase AC power

U、V、W

Inverter AC output terminal, connect three-phase AC motor

+、-

The positive and negative terminals of the internal DC bus are connected to the

external brake unit or For common DC bus

+、PB

Braking resistor connection terminal when built-in brake unit

Ground terminal, ground

EMC、VDR

Safety capacitor and varistor grounding selection screw (SIZE A~SIZE C EMC

screw on the left side of the fuselage)

Chapter3 product appearance and wiring VFD500 high performance vector control frequency inverter user manual

- 14 -

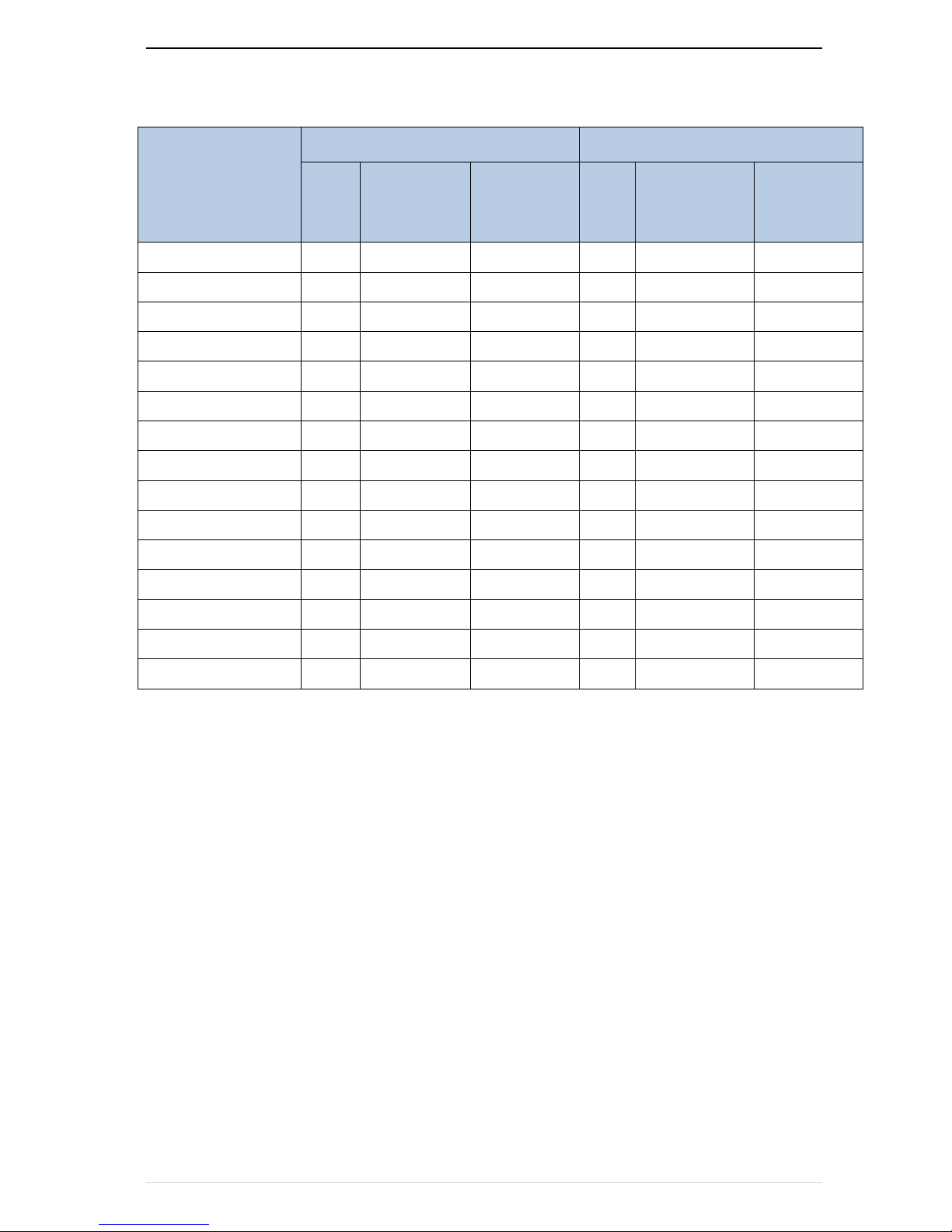

3.2.3 Terminal screws and wiring specifications

Table 3-3 Main circuit cable and screw specifications

Model number

Power terminal

Ground terminal

Screw

Tightening

torque(Nm)

Cable

diameter

(mm2)

screw

Tightening

torque(Nm)

Cable

diameter

(mm2)

VFD500-R75GT4B

M3

1.5

2.5

M3

1.5

2.5

VFD500-1R5GT4B

M3

1.5

2.5

M3

1.5

2.5

VFD500-2R2GT4B

M3

1.5

2.5

M3

1.5

2.5

VFD500-3R7G/5R5PT4B

M3

1.5

4

M3

1.5

4

VFD500-5R5G/7R5PT4B

M4 2 6

M4 2 6

VFD500-7R5G/011PT4B

M4 2 6

M4 2 6

VFD500-011G/015PT4B

M5 4 10

M5 4 10

VFD500-015G/018PT4B

M5 4 10

M5 4 10

VFD500-018G/022PT4B

M6 4 10

M6 4 10

VFD500-022G/030PT4B

M6 4 16

M6 4 16

VFD500-030G/037PT4

M8

10

16

M6 5 10

VFD500-037G/045PT4

M8

10

16

M6 5 10

VFD500-045G/055PT4

M8

10

35

M8 8 16

VFD500-055G/075PT4

M8

10

50

M8 8 25

VFD500-075G/090PT4

M10

20

70

M10

20

35

3.2.4 Cautions for Main Circuit Wiring

(1)Power Supply Wiring

◆ It is forbidden to connect the power cable to the output terminal of the inverter. Otherwise, the internal

components of the inverter will be damaged.

◆ In order to provide input side overcurrent protection and power outage overhaul convenience, the inverter should

be connected to the power supply through circuit breakers and contactors.

◆ Please confirm the power phase, the voltage is consistent with the product nameplate, do not match may result

in damage to the inverter.

(2)DC wiring

◆ Do not connect the braking resistor directly to +, -, which may cause the inverter to be damaged or

even fire.

◆ When using the external brake unit, pay attention to +, - can not be reversed, otherwise it will cause

damage to the inverter and brake unit or even cause a fire.

(3)Motor Wiring

◆It is forbidden to short circuit or ground the inverter output terminal, otherwise the internal components

of the inverter will be damaged.

VFD500 high performance vector control frequency inverter user manual Chapter3 Product appearance and wiring

- 15-

◆Avoid short circuit the output cables or with the inverter enclosure, otherwise there exists the danger of

electric shock.

◆It is forbidden to connect the output terminal of the inverter to the capacitor or LC/RC noise filter with

phase lead, otherwise, the internal components of the inverter may be damaged.

◆When contactor is installed between the inverter and the motor, it is forbidden to switch on/off the

contactor during the running of the inverter, otherwise, there will be large current flowing into the

inverter, triggering the inverter protection action.

◆Length of cable between the inverter and motor

If the cable between the inverter and the motor is too long, the higher harmonic leakage current of the

output end will produce by adverse impact on the inverter and the peripheral devices. It is suggested

that when the motor cable is longer than 100m, output AC reactor be installed. Refer to the following

table for the carrier frequency setting.

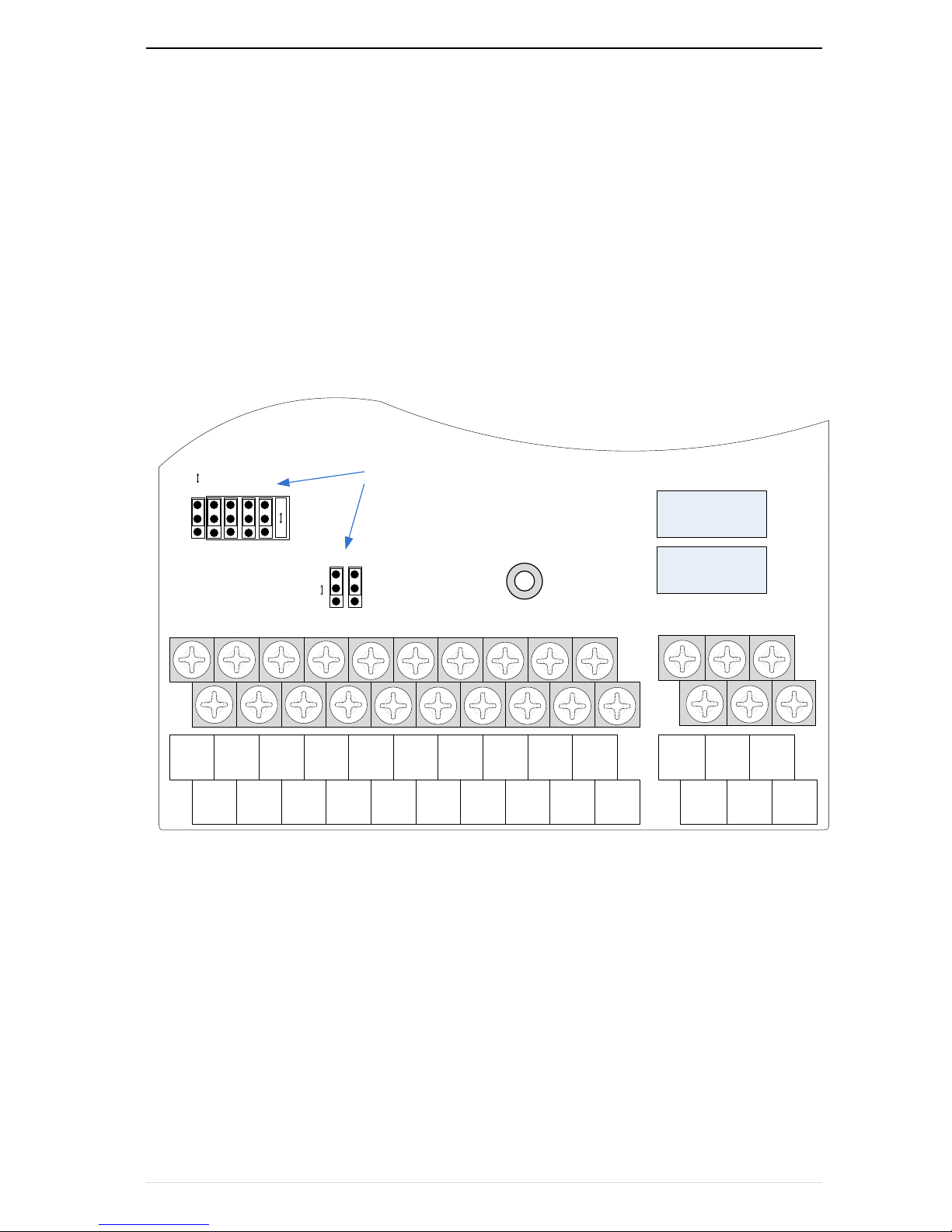

3.2.4Control Circuit Terminal

+10V

AI1

AO1

485+ GND

DI1 DI2

DI3

DI4

HDI

GND

AI2 AO2

485- COM

DO1 HDO

COM PLC +24V

T1/A

T1/B

T1/C

T2/A T2/B T2/C

485

V

I

ON OFF

AI1 AI2 AO1 AO2

ON OFF

PE1 PE2

K2

K1

Jumper switch

Diagram 3-11 VFD500 control circuit terminal

Chapter3 product appearance and wiring VFD500 high performance vector control frequency inverter user manual

- 16 -

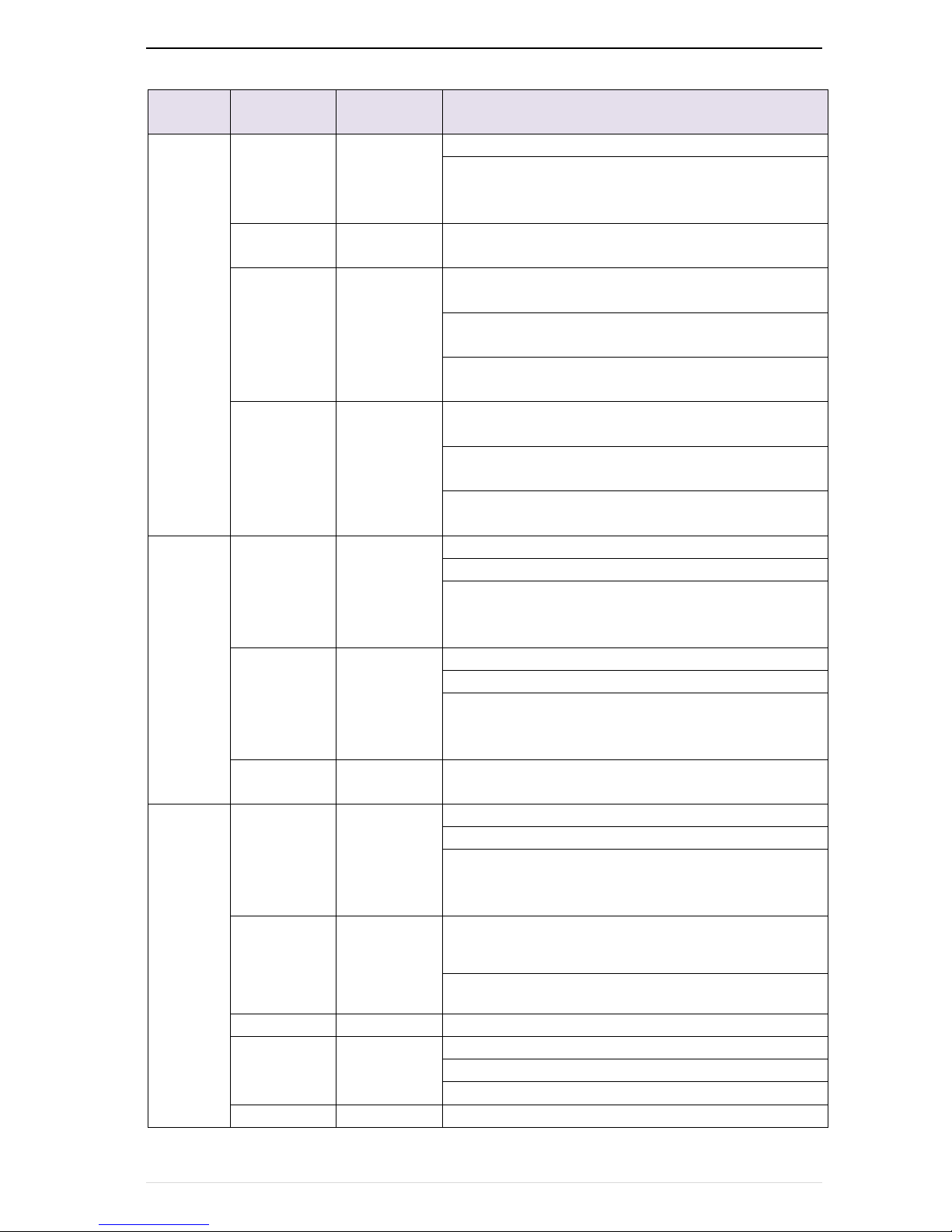

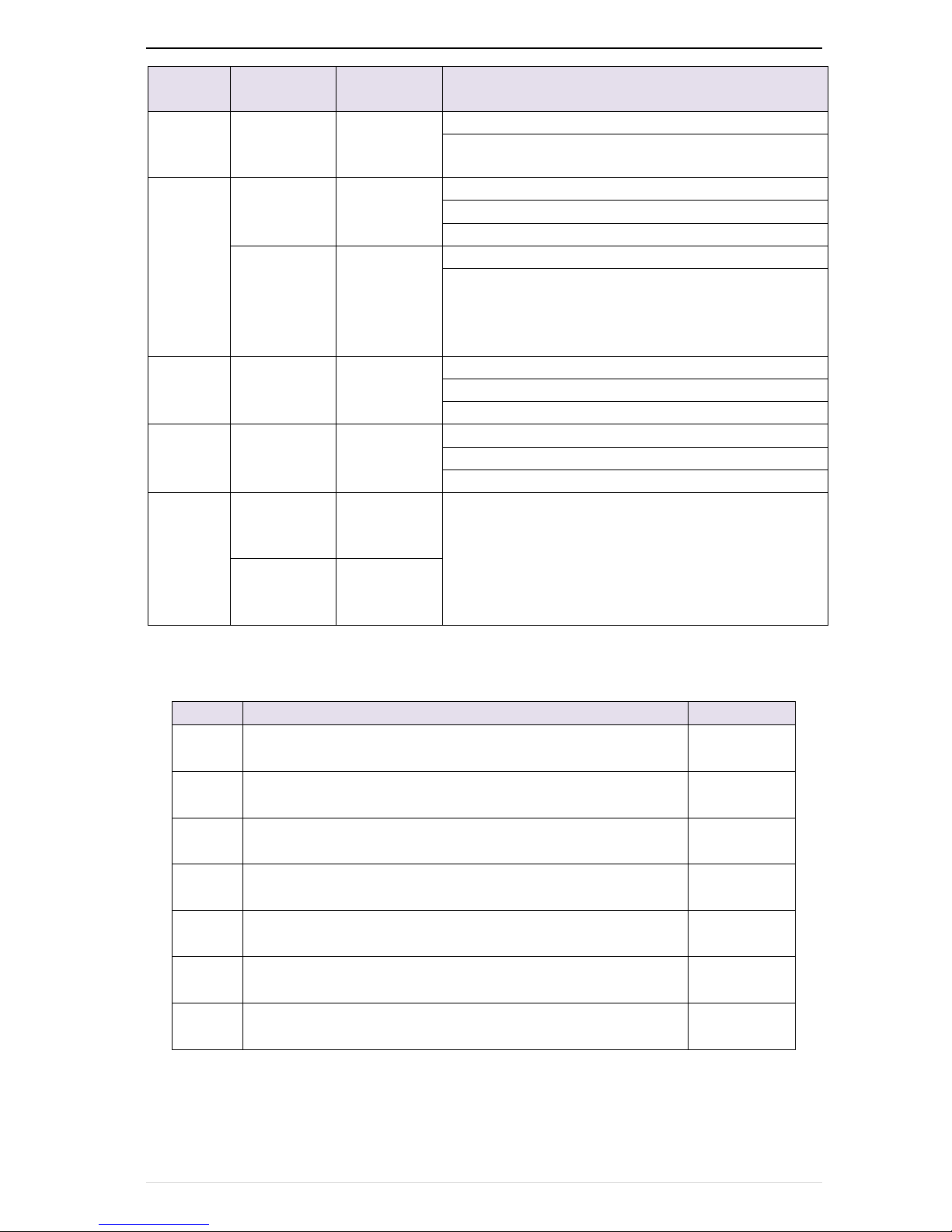

Table 3-3VFD500 control circuit terminal instruction

Type

Terminal

Symbol

Terminal

Name

Terminal function description

Analog

input

voltage

+10V

Input voltage

10.10V±1%

Maximum output current:10mA,it provides power

supply to external potentiometer with resistance range

of:1KΩ~51KΩ

GND

Ananog

ground

Internal isolation from COM

AI1

Analog

input1

Input voltage:0~10V:Impedance 22KΩ,Maximum

input voltage

Input current:0~20mA:Impedance 500Ω,Maximum

input current

Through the jumper switch AI1 0 ~ 10V and 0 ~ 20mA

analog input switch, the factory default voltage input.

AI2

Analog input

2

Input voltage:0~10V:Impedance 22KΩ,Maximum

input voltage

Input current:0~20mA:Impedance 500Ω,Maximum

input current

Through the jumper switch AI1 0 ~ 10V and 0 ~ 20mA

analog input switch, the factory default voltage input.

Analog

input

AO1

Analog

output 1

Output voltage:0~10V:Impedance ≥10KΩ

Output current:0~20mA:Impedance 200Ω~500Ω

Through the jumper switch AO1 0 ~ 10V and 0 ~ 20mA

analog output switching, the factory default voltage

output.

AO2

Analog

output 2

Output voltage:0~10V:Impedance ≥10KΩ

Output current:0~20mA:Impedance 200Ω~500Ω

Through the jumper switch AO1 0 ~ 10V and 0 ~ 20mA

analog output switching, the factory default voltage

output.

GND

Ananog

ground

Internal isolation from COM

Switch

input

+24V

+24V current

24V±10%,Internal isolation from GND

Maximum output current:200mA

To provide 24V power supply, generally used as a

digital input and output terminal power supply and

external sensor power

PLC

Digital input

terminal

common

The factory default setting is connected PLC with

+24V

Terminal for on-off input high and low level switch

When using the external signal to drive DI1~DI5, it

will disconnect the connector slip of PLC with the +24V

COM

+24V ground

Internal isolation from GND

DI1~DI4

Digital input

terminal 1~4

Optocoupler isolation, compatible with bipolar input

Frequency range:0~200Hz

Voltage range:10V~30V

HDI

Digital input

Digital input terminal:same as DI1~DI4

VFD500 high performance vector control frequency inverter user manual Chapter3 Product appearance and wiring

- 17-

Type

Terminal

Symbol

Terminal

Name

Terminal function description

terminal

/High-speed

pulse input

Pulse input frequency input:0~50KHz

Voltage range:10V~30V

Switch

output

DO1

Open

collector

output

Optocoupler isolation

Voltage range:0V~24V

Current range:0mA ~50mA

HDO

Open

collector

output

/High-speed

pulse output

Open collector output:same as DO1

High-speed pulse output:0~50KHz

Relay

output 1

TA/TB/TC

Relay output

T1A-T1B:nomal open

T1A-T1C:nomal close

Contact rating:AC 250V,3A;DC 30V,1A

Relay

output2

(optional)

T2A/T2BT2C

Relay output

T2A-T2B:nomal open

T2A-T2C:nomal close

Contact rating:AC 250V,3A;DC 30V,1A

485 port

485+

485 Positive

differential

signal

Baud rate:

1200/2400/4800/9600/19200/38400/57600/115200bps

485-

485 Negative

differential

signal

Table 3-5 Functional Description of VFD500 Jumper Switch

Name

Function

Defaults

485

485 Termination resistor selection: ON has 100 ohm

terminating resistor, OFF is no terminating resistor

OFF

AI1

AI1 analog type selection: V is the voltage input (0 ~ 10V), I is

the current input (0 ~ 20mA)

V

AI2

AI2 analog type selection: V is the voltage input (0 ~ 10V), I is

the current input (0 ~ 20mA)

V

AO1

AO1 analog type selection: V is the voltage output (0 ~ 10V), I

is the current output (0 ~ 20mA)

V

AO2

AO2 analog type selection: V is the voltage output (0 ~ 10V), I

is the current output (0 ~ 20mA)

V

PE1

GND ground selection: ON is grounded through the safety

capacitor, OFF is not connected

OFF

PE2

COM ground selection: ON is grounded through the safety

capacitor, OFF is not connected

OFF

Analog input terminal instructions

The AI1 and AI2 terminals can accept both analog voltage input and analog current input. They can

be switched by jumpers “AI1” and “AI2” on the IO board. The connection method and jumper switch

Chapter3 product appearance and wiring VFD500 high performance vector control frequency inverter user manual

- 18 -

configuration are shown in the following figure:

Figure 3-11 Analog input terminal wiring diagram

The AO1 and AO2 terminals support the voltage output (0~10V) and the current output (0~20mA). They are selected

by jumpers “AO1” and “AO2” on the IO board. The connection method is as shown in the figure below:

Figure 3-12 Analog output terminal wiring diagram

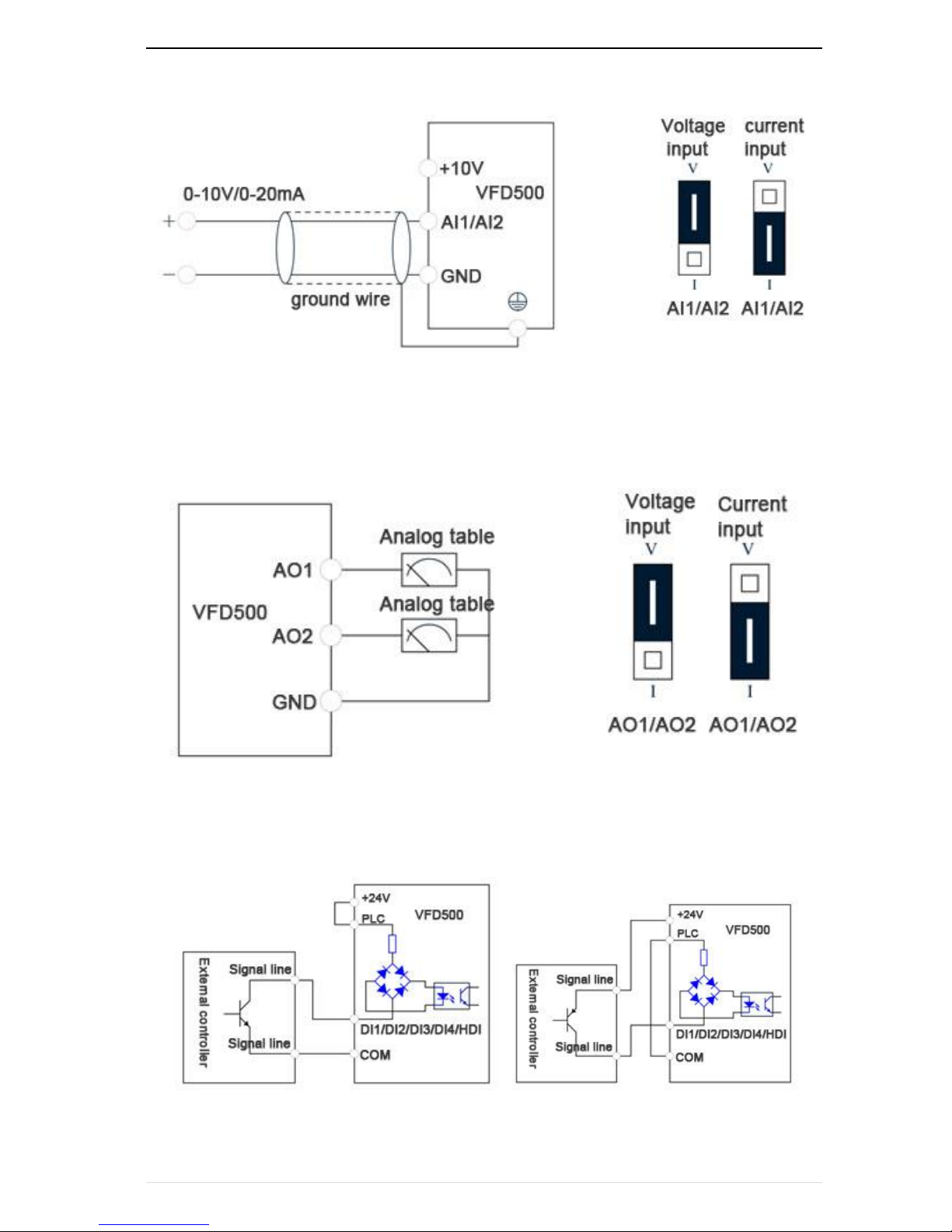

Digital input terminal instructions

A:By internal 24V with NPN modeB:By internal 24V with PNP mode

VFD500 high performance vector control frequency inverter user manual Chapter3 Product appearance and wiring

- 19-

C:NPN mode uses external +24V power supplyD:PNPNPN mode uses external +24V power supply

3-13 Switching Digital input terminal wiring diagram

Note:

When using an external power supply, the shorting tab between +24V and PLC must be removed, otherwise the

product will be damaged!

When using an external power supply, connect the negative terminal of the external power supply to COM when

using HDI, otherwise HDI is invalid!

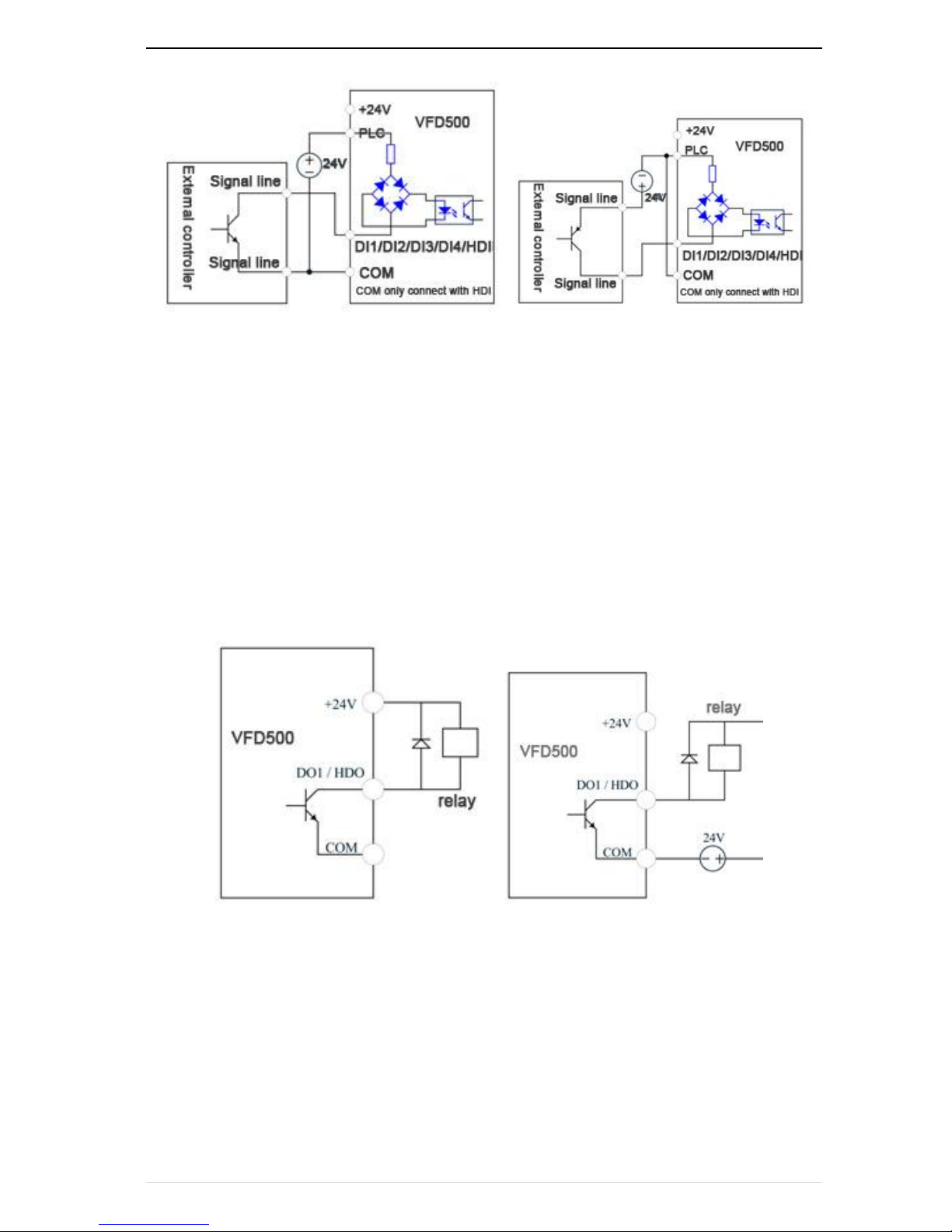

Switch output terminal instructions

The multi-function output terminals DO1 and HDO can be powered by the internal +24V power supply of the inverter

or an external power supply. The wiring diagram is as follows:

A、Use internal power supply B、Use external power supply

3-14 Switchingdigital output terminal wiring diagram

Note:

The multi-function terminal output is an open collector output with a maximum allowable current of 50mA. When

using the internal power supply, if the inductive load is driven, an absorption circuit such as an RC snubber circuit or

a freewheeling diode should be installed. When adding a freewheeling diode, be sure to confirm the polarity of the

diode, otherwise the product will be damaged. For external power supply, connect the negative terminal of the

Chapter3 product appearance and wiring VFD500 high performance vector control frequency inverter user manual

- 20 -

external power supply to the COM terminal.

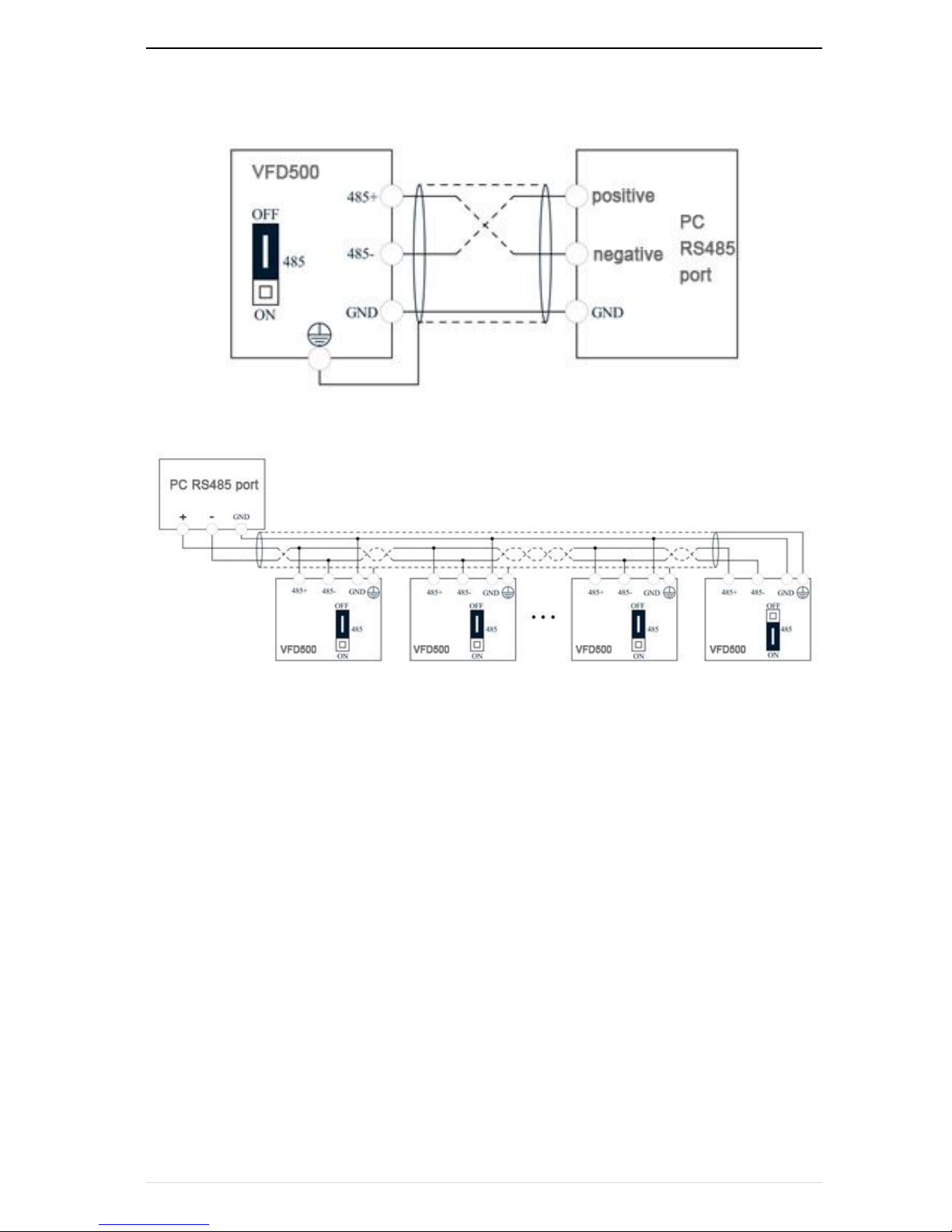

485Communication terminal instructions

3-15Single inverter RS485 directly communicates with the host computer

3-16Multiple inverter RS485 is connected to the host computer for communication

VFD500 high performance vector control frequency inverter user manual Chapter3 Product appearance and wiring

- 21-

3.3EMCquestion and solution

The working principle of the inverter determines that it will certainly produce electromagnetic interference,

affecting and interfering with other equipment. In the meantime, the frequency converter usually works under the

industrial environment with very strong noise,its internal weak signal is also easily disturbed. For safe and

trouble-free operation of the frequency converter, as well as the normal and orderly operation of other equipment,

install the equipment according to the following rules.。

Install the input noise filter,the filter to the inverter input power supply side of the wiring should be as short

as possible.

Filter shell and the installation of the cabinet should be a large area of reliable connection, in order to

reduce the noise current loop impedance.

The wiring distance between inverter and motor should be as short as possible. The motor cable adopts

4-core cable. One end of the ground wire is grounded at the inverter side and the other end is connected

with the motor case. The motor cable is sheathed into the metal pipe.

Input power line and output motor line should be far away from each other.

Easily affected equipment and signal lines should be installed away from the inverter.

The key signal cable should use shielded cable. It is suggested that the shielded cable layer should be

grounded by 360 degree grounding method and set in the metal pipe. As far as possible from the inverter

input power cable and output motor cable, if the signal cable must cross the input power cable or output

motor cable, the two should be orthogonal.

When using the analog voltage and current signals for remote frequency setting, double-stranded,

shielded and shielded cables should be used, and the shield should be connected to the grounding

terminal PE of the inverter. The longest signal cable should not exceed 50 meters.

The control circuit terminals T1A / T1B / T1C, T2A / T2B / T2C and other control circuit terminals should be

separated wiring.

It is forbidden to short-circuit the shield with other signal lines and equipment.

When connecting the inductive load device (magnetic contactor, relay, solenoid valve, etc.) to the inverter,

be sure to use the surge suppressor on the load device coil.

Correct and reliable grounding is safe and reliable operation of the foundation:

(1) Inverter will generate leakage current, the greater the carrier frequency, the greater the leakage current.

Inverter leakage current greater than 3.5mA, the size of the leakage current by the conditions of use, in order to

ensure safety, inverter and motor must be grounded;

(2) Grounding resistance should be less than 10 ohms. Grounding cable diameter requirement, refer to the

same type of input and output cables half of the cross-sectional area selection;

(3) Do not share the ground wire with welding machines and other power equipment;

(4) When using more than two inverters, do not make the ground wire loop.。

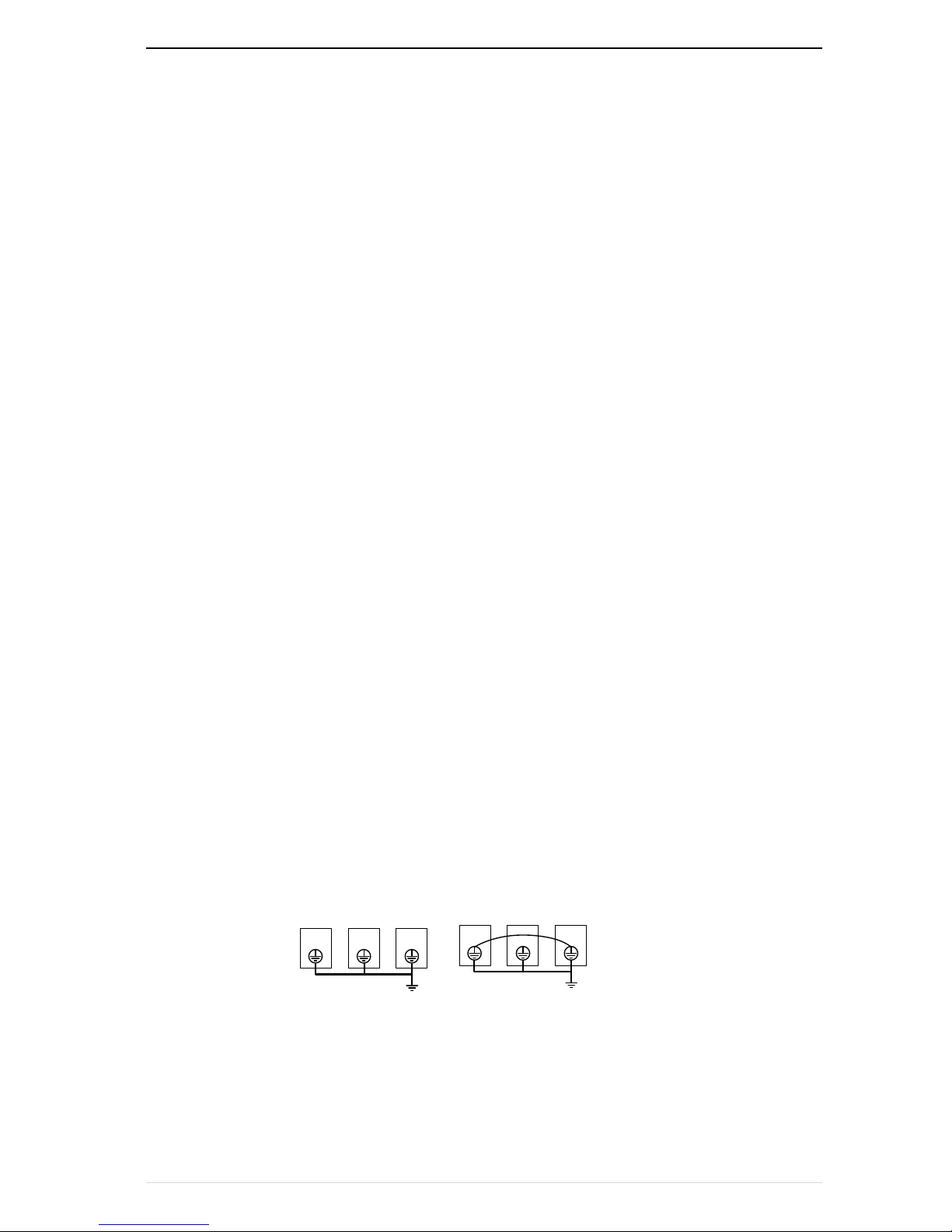

Inverter1 inverter2 inverter3

Invert1 Inverter2 inverter3

Correctincorrect

3-6Ground wire connection diagram

Frequency converter to motor cable length and carrier frequency to maintain the appropriate

relationship

When the cable between the inverter and the motor is long, due to the influence of distributed capacitance, it is easy

to produce electrical resonance, thus generating a large current so that the inverter over-current protection. It is

Chapter3 product appearance and wiring VFD500 high performance vector control frequency inverter user manual

- 22 -

recommended to install the AC output reactor when the motor cable length exceeds 100 meters. Refer to the

following table for carrier frequency setting

.3-3 Inverter output cable length and carrier frequency table

Cable length between drive

and motor

20m below

50m below

100m below

100m above

Carrier frequency(P22.00)

15kHz below

8kHz below

4kHz below

2kHzbelow

Chapter 4 Operation and display VFD500 high performance vector control frequency inverter user manual

- 23-

Chapter 4 Operation and display

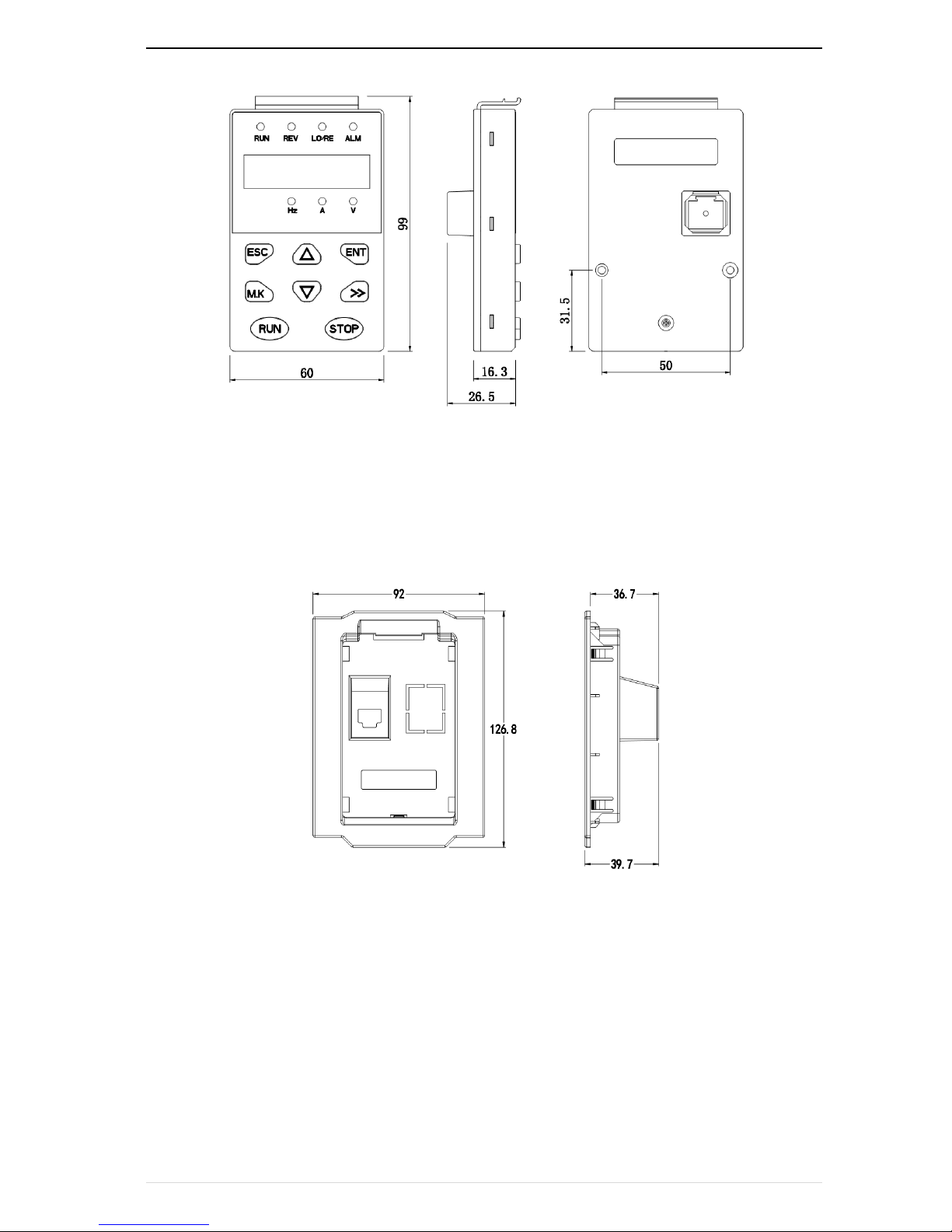

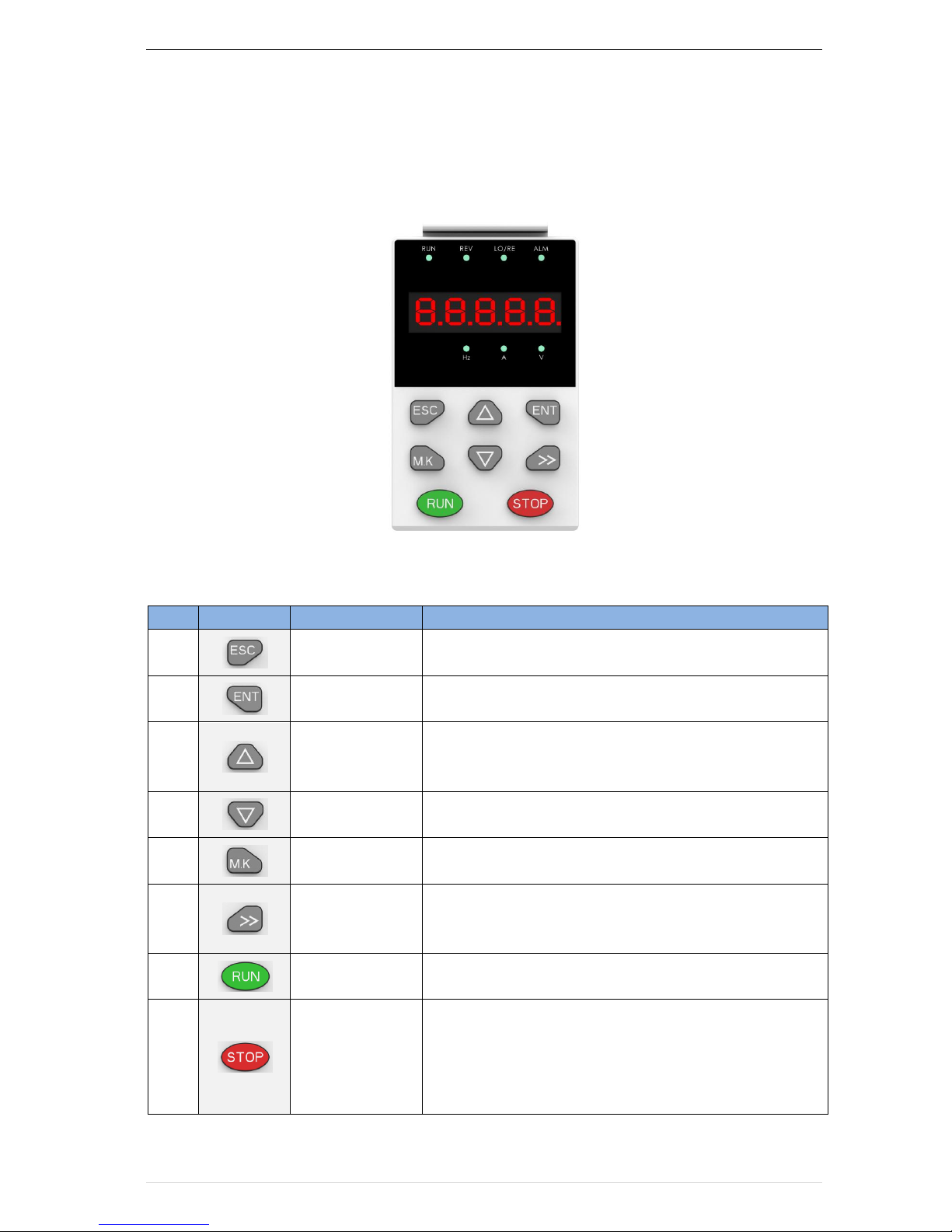

4.1 LED Instruction of operation and display

LED keyboard consists of 5 digital tubes, 7 lights, 8 keys and a potentiometer; can be used to set

the parameters, status monitoring and operation control, LED keyboard shape as shown in Figure 4-1:

Figure 4-1 Operating panel

Description of indicator

Table 4-1 The name and function of each part of the keyboard

No.

Part

Name

Function

1 Exit

•

exit menu level

2 Confirmation

•

Enter the menu interfaces level by level,

•

confirm the parameter setting and save to EEPROM

3 Increment

• The number indicated by the cursor increases by one.

• Next function code.

• Used to switch the left and right screens while in monitor mode

4 Decrement

·The number indicated by the cursor minus one.

• The previous function code.

5

Multi-function

·

Perform function switchover according to the setting of

21.02

6 Shift

• Cursor shift.

• Monitor Status Displays the next monitor volume.

• Switch left and right screens.

7 Run

Start the frequency inverter in the operation panel control

mode

8 Stop/Reset

• During operation, press to stop the operation (restricted by

parameter 21.03).

• In fault status, press this key to reset the fault.

VFD500 high performance vector control frequency inverter user manual Chapter 4 Operation and display

- 24 -

9 Indicator light:Hz

·Indicate the digital display unit, all three lights off menas other

units

10 Indicator light:A

11 Indicator light:V

12 Running lights

• Off: indicates a stop condition.

• On: indicates inverter is running.·

Blinking: Deceleration stopped.

13 Direction indicator

• Used to indicate the sign of the variable when the LED is

displaying one of the variables listed in 27.02;

• In other cases the sign of the output frequency is indicated.

14

Command source

indicator

• Off: The command source is the keyboard.

• On: The command source is terminal.

• Blinking: The command source is communication.

15 Fault indicator

• When it is on, the drive is faulty.

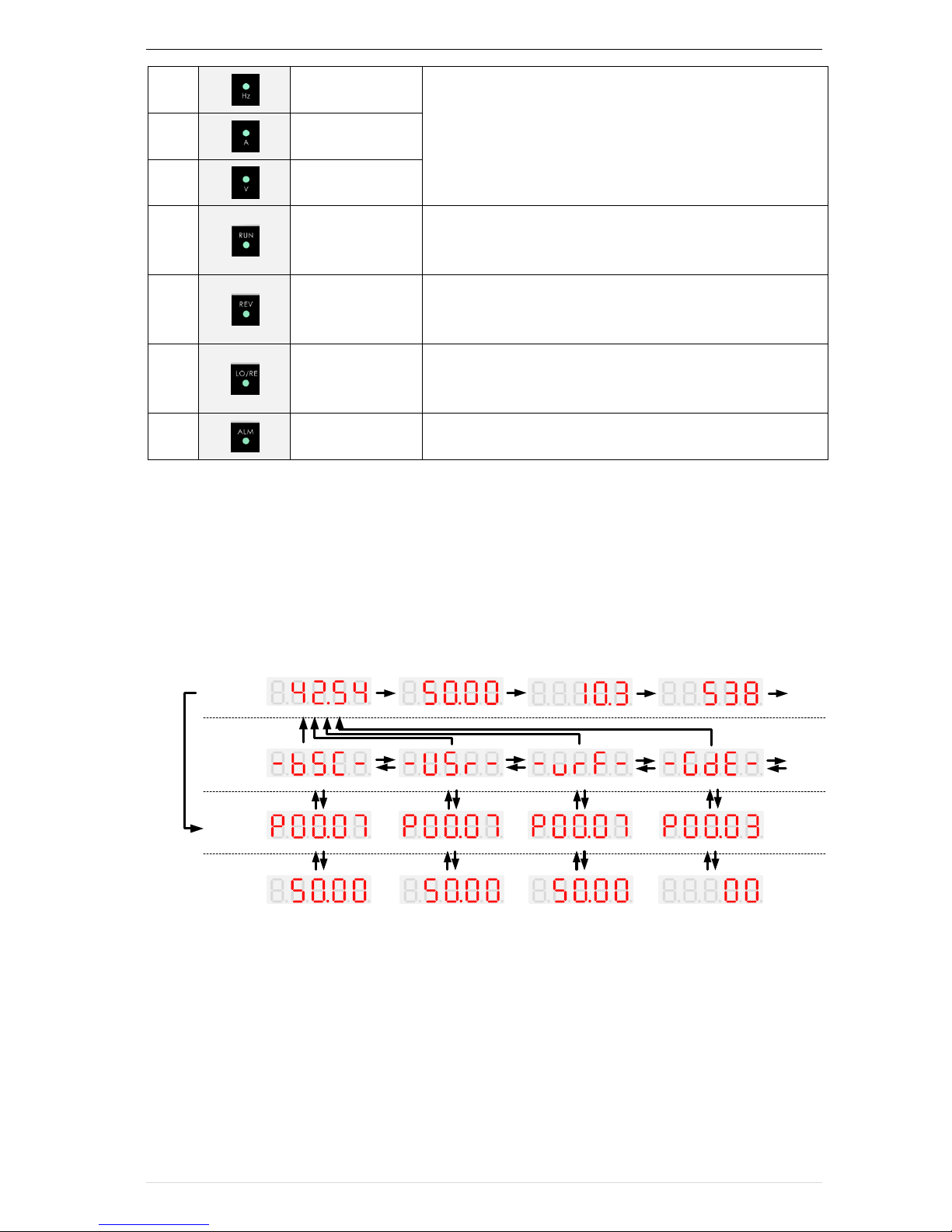

4.2 Display hierarchy and menu mode

VFD500 digital keyboard display is divided into four layers, from top to bottom are: monitoring status, menu

mode selection status, function code selection status, parameter editing / viewing status, as shown in Figure 4-2. In

the menu mode selection status, press 【UP】 or 【DOWN】 key to select menu mode, press 【ENTER】 to enter

the selected menu mode, the following describes several menu modes:

Wizard modeCheck mode

Standard mode

User-difined mode

ENTERESC

ENTERESC

UP

DOWN

UP

DOWN

UP

DOWN

“-bSC-

”

UP

DOWN

SHIF

T

SHIF

T

SHIF

T

SHIF

T

Monitoring volume1 Monitoring volume2

Monitoring volume3

Monitoring volume4

Monitoring

volume1

ESC

MONITO

R

STATUS

MENU

CHOOSE

STATE

COMMAND

CODE

PARAMETER

EDIT/VIEW

STATUS

ESC

ENTERESC ENTERESC

ENTERESC

ENTERESC ENTERESC ENTERESC

【UP、DOWN、SHIFT】 【UP、DOWN】 【UP、DOWN】 【UP、DOWN】

【UP、DOWN、SHIFT】 【UP、DOWN、SHIFT】 【UP、DOWN、SHIFT】 【UP、DOWN、SHIFT】

4-2Keyboard operation diagram

Standard mode(-bSC-)

If access (P00.01) is standard, all the function codes mentioned in this manual are accessible.

If access (P00.01) is the end user (in the state of user password lock), then only some function code can be

accessed.

User-difined mode(-USr-)

In this menu mode, only 20 user-defined parameters defined are displayed.

Chapter 4 Operation and display VFD500 high performance vector control frequency inverter user manual

- 25-

Verify mode(-vrF-)

In this menu mode, only parameters that differ from the factory settings are displayed。

Guide mode(-GdE-)

When users first use the inverter, can guide the user to complete a simple trial run。

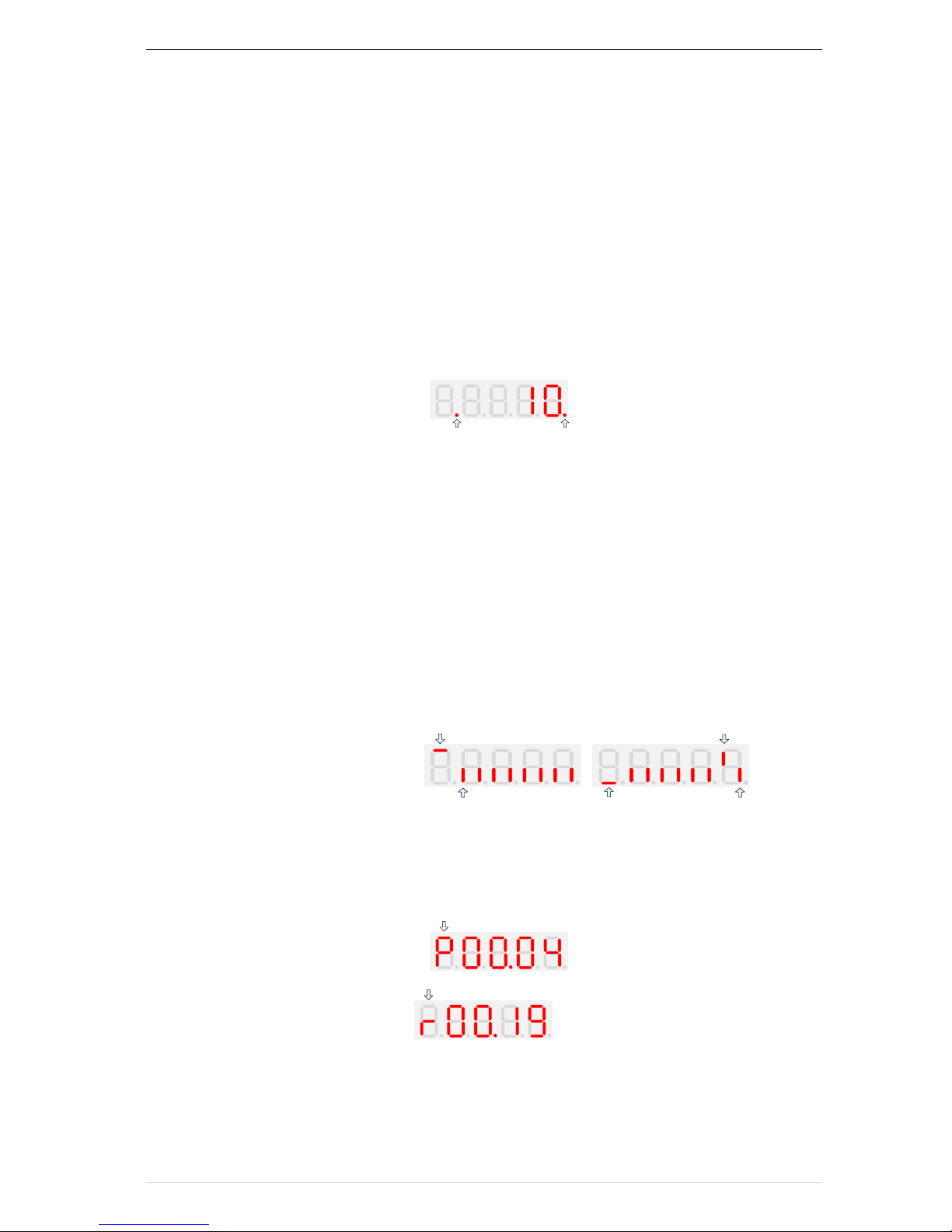

4.3 Digital tube display

Display of decimal data

16 digits:

The range of unsigned numbers is 0 ~ 65535 (without decimal point). The displayed range of signed numbers

is -9999 ~ 32767 (excluding decimal point). The negative numbers less than -9999 will be displayed as -9999.

32 digits:

The left and right screen display, combined with the following figure to illustrate:

Dot5

Dot1

Dot1 is used to distinguish between the left and right screens. On indicates the left panel (upper 5 digits) and turns

off the right screen (lower 5 digits). When the left screen is displayed, Dot5 is used to indicate the sign digit. On

indicates that the value is negative, off indicates the value is Positive.

The display range of 32-bit unsigned numbers is 0 to 4294967295 (excluding decimal point), and the displayed

range of signed numbers is -2147483648 to 2147483647 (excluding the decimal point).

Binary data display

Binary number currently only supports 16 digits, points left and right screen display.

The leftmost digital tube is used to distinguish the left and right screens: the top digit segment lights up for the left

panel and the bottom segment segment lights for the right panel.

Remove the leftmost digital tube, from right to left, followed by Bit0 ~ Bit15. The upper segment is lit to indicate 1, the

lower segment to light to indicate 0.

Means right

screen,low 5bit

Means left screen,high 8bit

bit1=1

bit0=0bit15=0

Parameter attribute identification

Editable parameters The leftmost LED displays "P"; the leftmost LED of the read-only parameter displays "r", as

shown below.

P means can edit

R means read only

Specific symbol

In some cases, the digital tube will display a specific symbol. The meaning of specific symbols is shown in the

following table:Table4-2 Digital tube display symbol and meaning

VFD500 high performance vector control frequency inverter user manual Chapter 4 Operation and display

- 26 -

Symbol

Meaning

tUnE

Motor parameter self-learning

bUSY

Processing parameter read and write requests

End

• Indicates that the parameters have been changed

and saved to the EEPROM

• The mission has been completed

Er.xxx

• Fault code, "XXX" is the fault type, see Chapter 6 for

details

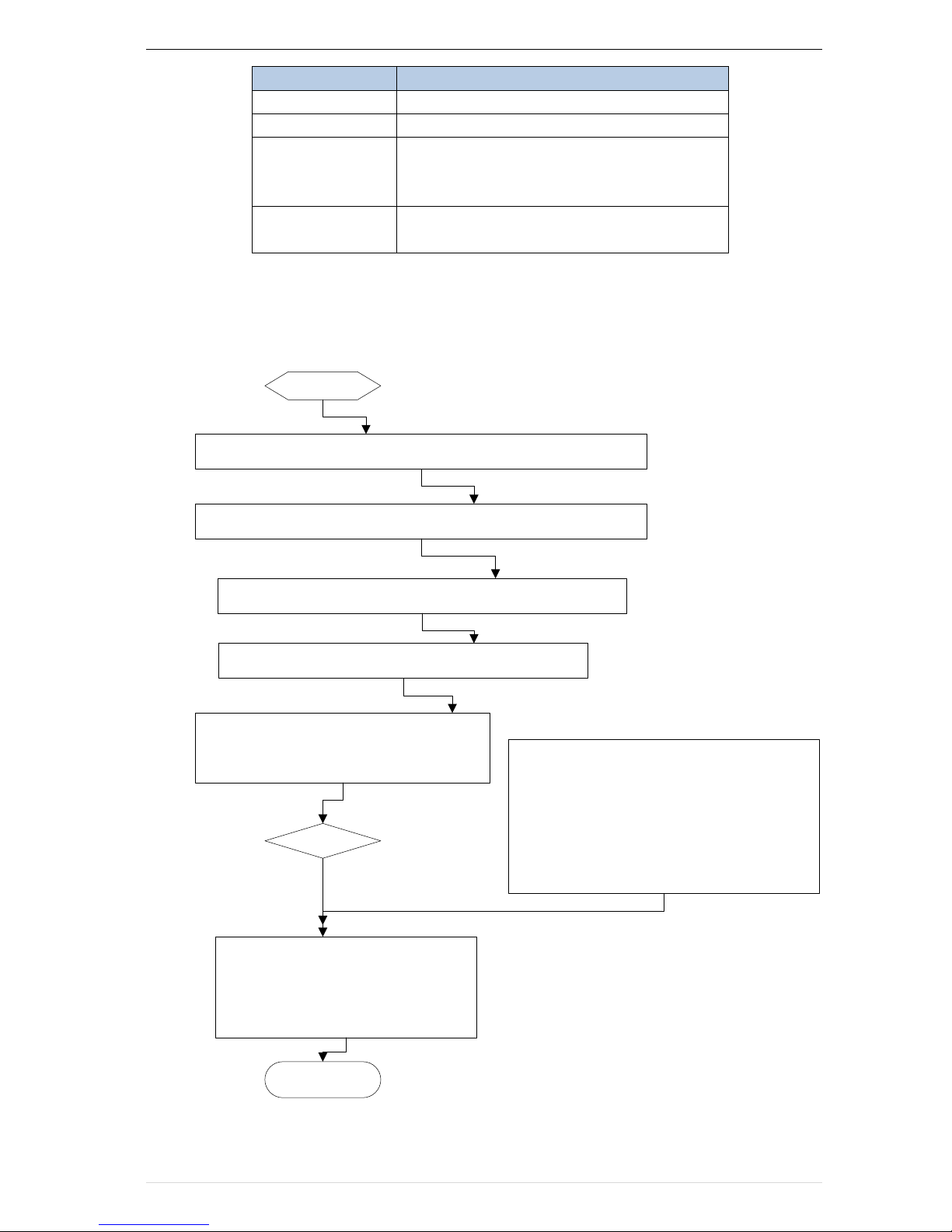

4.4 Test run

Please follow the procedure below to commission the first power-on。

start

Follow the instructions in Chapter 3 to install the inverter and wire it

Make sure the power cable, motor cable and brake unit are connected

correctly

Observe the safety precautions and switch on the power supply

Enter guide mode”-GdE-“

Set each parameter in turn according to the

guidance of the wizard, set the motor selflearning mode P11.10, press the run button,

waiting for the complete of self-learning

· Press “RUN”to Run inverter

· Press “STOP” to stop inverter

While monitoring the output frequency

or command frequency,press

“ENTER”to modify the target

frequency

End

close loop vector control(VC),Before normal

operation, ensure that the encoder P10.03 is in

the correct directionIf rotary self-learning is

performed, the encoder orientation can be

automatically recognized and storedIf it is not

executed, it needs to open the loop control to

run the motor and observe whether the encoder

feedback(r10.12) is in the same direction with

the given direction, if no,change as P10.03

Open control

Y

N

4-3Trial run flow chart

Chapter 5 Function code table VFD500 high performance vector control frequency inverter user manual

- 27-

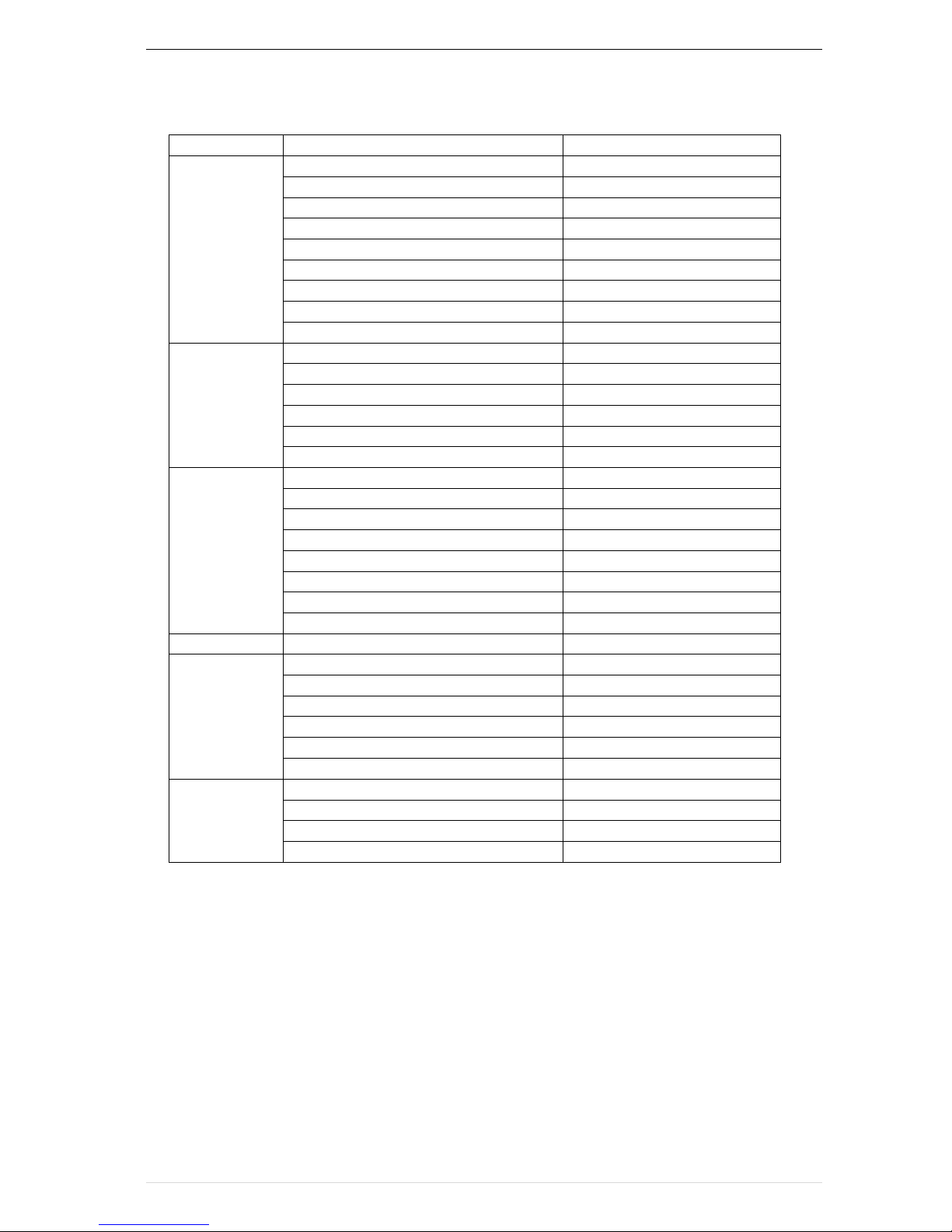

Chapter 5 Function Code Table

The following is the VFD500 parameter distribution list:

classification

Parameter group

Page

Common

parameters

00:Basic function

Page29

01:frequency source selection

Page31

02:start and stop

Page 37

03:Ramp and S curve

Page 39

04: Analog and pulse input

Page 41

05:Analog and pulse output

Page 45

06:Digital input (DI)

Page 46

07:Digital output(DO)

Page 49

08:Digital Output setting

Page 51

Motor control

10:encoder type

Page 53

11:Motor1 parmeter

Page 54

12:Motor1 VFcontrol parameter

Page 56

13:Motor1 Vector controlparameter

Page 58

14:Torque control

Page 59

16:Energy saving control

Page 60

Display and

protection

20:User-defined parameters

Page 61

21:key pad and display

Page 62

22:AC Drive configuration

Page 64

23:Drive protection

Page 66

24:Motor protection

Page 69

25:Fault tracking parameter

Page 71

26:Fault recording parameter

Page 71

27:Monitoring parameter

Page 72

Communication

30:Modbus communication

Page 73

Application

40:Process PID

Page 74

41:Sleep function

Page 78

42:Simply PLC

Page 79

43:Programmable delay unit

Page 81

44:Comparator and logic unit

Page 83

45:Multifunction counter

Page 87

Motor 2

60:motor2 basic parameter

Page 88

61:motor2 parameter

Page 89

62:motor2 VF control parameter

Page 89

63:motor2 vector control parameter

Page 89

Term Description:

The parameter is also called function code; the operation panel is also called the keyboard.

Due to usage habits, different terms may be used in different places in this manual, but all refer to the same

content.

Symbol Description:

"☆" means that the setting value of this parameter can be changed when the inverter is stopped or running.

"★" means that the setting value of this parameter can not be changed when the inverter is running.

"●" indicates that the value of this parameter is the actual test record value, which can not be changed

VFD500 high performance vector control frequency inverter user manual Chapter 5 function code table

- 28 -

Function

code

Parameter name

Description

Default

Property

00Group Basic Function

P00.00

User password

0 ~ 65535

No user password status (P00.01 = 1

after power-on):

Entering the same non-zero value twice in

succession sets a user password and enters

lockout.

password lock state:

Enter the password to enter the unlock state.

unlocked state:

Enter the original password to enter the lock

state; enter the same value twice in a row to

change the password (clear the password if

you enter 0 twice in a row).

0

☆

P00.01

Access authority

0:END USER

Some parameter are not authorized to check

when user password in locked state 1:

Standard

ALL Parameter can be checked

1

★

P00.02

Parametercopy

andbackup

0:No action

11:save all parameter to EEPROM backup

space

12:Restore all parameter from EEPROM

backup space

13:Parameter upload to LCD VFD500

(excluded for motor parameter and auto

tune related parameter)

14: Parameter upload to LCD VFD500

(All parameter except for factory data)

0

★

P00.03

RESET

0:NO ACTION

11:Restore default parameter except for motor

parameter and auto-tune related parameter

and factory parameter

12:Restore default to factory parameter

13:Clear tripping record

0

★

P00.04

Motor Control mode

0:VF

1:SVC(sensorless vector control)

Open loop vector and torque

controlwithout encoder feedback

2:VC Vector control with sensor

Close loop vec tor and torque control

supporting encoder feedback in high

precision or torque control application

0

★

Chapter 5 Function code table VFD500 high performance vector control frequency inverter user manual

- 29-

Function

code

Parameter name

Description

Default

Property

P00.05

Running mode

0:Speed mode

1:Torque mode

If use with DI function,19:Switch between

torque and speed Control and 20: torque

control diabled. Actuall effective running

mode is related with DI status

0

★

P00.06

Source of the

Operation Command

0:keypad

1:terminal

2:communication

Command source: run、stop、forward、

reverse、jog、fast brake stop.etc

If use with DI function, 12:Switching run

command to Keypad and 13:Switching

run command to Communication,Actuall

effective command source is related with

DI status

0

★

P00.07

Numeric frequency

setting

00.00Hz~maximum frequency

50.00Hz

☆

P00.08

Rotation direction

0:Forward

1:Reverse

It is only for keypad control to change

running direction by giving frequency

symbol to be reverse)If command by

keypad/terminal /communication,and not

want to achieve reverse running by

giving frequency symbol to be

reverse,need to change P22.13 in stop

mode(see parameter P22.13)

0

☆

P00.09

Reverse control

0:enable

1:disbale

0

★

P00.10

Motor option

0:motor 1

1:motor 2

If use with DI function,16:Switch between

motor 1 and motor 2,Actuall effective

command source is related with DI status

0

★

P00.11

Special industry

0:standard drive

1:Reserved

0

★

r00.18

Power board software

version

- - ●

r00.19

Control board software

version

- - ●

r00.21

SN 1

- - ●

r00.22

SN 2

- - ●

VFD500 high performance vector control frequency inverter user manual Chapter 5 function code table

- 30 -

Functio

n code

Parameter name

Description

Default

Property

01Group frequency source selction

P01.00

Main frequency source

selction (A)

0:Digital setting

1:AI1

2:AI2

3:AI3(reserved)

4:AI4(reserved)

5:HDI

6:multiple speed

7:communication

8:PID

9:Internal PLC

Notice:DI terminal function code 26-32 superior

than this function code

10

★

P01.01

Auxiliary frequency

source selction (B)

Same as P01.00

Notice:DI terminal function code 33 superior

than this function code

0 ★ P01.02

Reference option for

auxiliary frequency

source

0:Relative to Maximum frequency

1:Relative to main frequency

0

★

P01.03

Auxiliary frequency gains

0.0~300.0

100.0%

☆

P01.04

Frequency source

selection

0:main frequency sourceA

1:auxiliary frequency sourceB

2:Main and auxiliary arithmetic results

3:Switchover between main and auxiliary

frequency

4:switchover between main frequency source

A and A+B Arithmetic results

5:Switchover between B and (A+B)

(*)DI function code 25 effective to

corresponding terminal ,frequency will adopt

the latter

0

★

P01.05

Main and Auxiliary

arithmetic

0:A+B

1:A-B

2:The bigger of main A and Auxliary B

3:The smaller of Main A and Auxiliary B

0

★

P01.06

Maximum frequency

10.00~600.00Hz

50.00Hz

★

P01.07

Upper limit frequency

control

0:digital setting (set through P01.08)

1:AI1

2:AI2

3:Reserved

4:Reserved

5:Pulse setting HDI

6:Reserved

7:Communication setting

0

★

Chapter 5 Function code table VFD500 high performance vector control frequency inverter user manual

- 31-

Functio

n code

Parameter name

Description

Default

Property

P01.08

Upper limit frequency

Lower limit frequency(P01.09)~maximum

frequency (P01.06)

50.00Hz

☆

P01.09

Lower limit frequency

0.00Hz~upper limit frequency

0.00Hz

☆

P01.10

Action when set

frequency lower than

lower limit frequency

0:Run at low limit frequency

1:Stop after delaying P01.11

2:Run at zero speed

0 ★ P01.11

Delay time when set

frequency lower than

lower limit frequency

0.000s~30.000s

0.000s

★

P01.12

Jump frequency start up

protection

Unit/ten/hundred’digit:three jump frequency

1/2/3

0:Disable

1:Enable (avoid risk speed)

000

☆

P01.13

Jump frequency 1 lower

limit

0.00Hz~(P01.14)

0.00Hz

☆

P01.14

Jump frequency upper

limit

P01.13- (P01.06)Maximum frequency

0.00Hz

☆

P01.15

Jump frequency 2 lower

limit

0.00Hz~(P01.16)

0.00Hz

☆

P01.16

Jump frequency 2 upper

limit

P01.15~maximum frequency(P01.06)

0.00Hz

☆

P01.17

Jump frequency 3 lower

limit

0.00Hz~(P01.18)

0.00Hz

☆

P01.18

Jump frequency 3 upper

limit

P01.17~maximum frequency(P01.06)

0.00Hz

☆

Risk speed or Jump frequency start up protection is used to some situation which need avoid motor speed and

speed range,for example,due to mechanical resonance ,P01.12 will be enabled to avoide risk speed in forward or

reverse mode

。

Motor frequency

Giving frequency

P01.13

P01.15

P01.14

P01.17

P01.16

P01.18

P01.19

Multiple speed reference

source

Unit’digit:0 phase reference source

set by

0-multiple speed(P01.21)

1-preset frequency (P00.07)

2:AI1

00

★

VFD500 high performance vector control frequency inverter user manual Chapter 5 function code table

- 32 -

Functio

n code

Parameter name

Description

Default

Property

3:AI2

4:Reserved

5:Reserved

6:HDI pulse

7:Communication

8:PID

Ten’s digit:Combination of multiple speed

0:Combination methord

1:Priority method

K1-K4 Each represent DI multiple terminal 1-4 status ,O represent ineffective ,1 represent effective,M indicates

current output number of speed.Instructions of multiple speed combination

0: Combination method

M = K1 + (K2*2) + (K3*4) + (K4*8)

For example: K0=1,K1=0,K2=1,K3=0,Then M=5,current output fifth phase speed

1: Priority method Multiple speed output 0~4 phase speed,Priority K4>K3>K2>K1。

For example: K4=1, then M=4;

K4=0,K3=1,then M=3;

K4=0,K3=0,K2=1,then M=2;

K4=0,K3=0,K2=0,K1=1, then M=1;

K1~K4 all to be 0, then M=0

P01.20

Multiple speed Rotation

direction

Bit0 ~ 15 corresponding to 0 ~ 15 phase

direction

0:forward direction 1:reverse direction

0

☆

P01.21

Multiple speed 0/in-built

plc 1

Lower limit frequency (P01.09) ~ maximum

frequency (P01.06)

0.00Hz

☆

P01.22

Multiple speed 1/in-built

plc 2

Lower limit frequency(P01.09) ~ maximum

frequency(P01.06)

0.00Hz

☆

P01.23

Multiple speed 2/in-built

plc 3

Lower limit frequency(P01.09) ~ maximum

frequency(P01.06)

0.00Hz

☆

P01.24

Multiple speed 3/in-built

plc 4

Lower limit frequency(P01.09) ~ maximum

frequency(P01.06)

0.00Hz

☆

P01.25

Multiple speed 4/in-built

plc 5

Lower limit frequency(P01.09) ~ maximum

frequency(P01.06)

0.00Hz

☆

P01.26

Multiple speed 5/in-built

plc 6

Lower limit frequency(P01.09) ~ maximum

frequency(P01.06)

0.00Hz

☆

P01.27

Multiple speed 6/in-built

plc 7

Lower limit frequency(P01.09) ~ maximum

frequency(P01.06)

0.00Hz

☆

P01.28

Multiple speed 7/in-built

plc 8

Lower limit frequency(P01.09) ~ maximum

frequency(P01.06)

0.00Hz

☆

P01.29

Multiple speed 8/in-built

plc 9

Lower limit frequency(P01.09) ~ maximum

frequency(P01.06)

0.00Hz

☆

P01.30

Multiple speed 9/in-built

plc 10

Lower limit frequency(P01.09) ~ maximum

frequency(P01.06)

0.00Hz

☆

P01.31

Multiple speed 10/in-built

Lower limit frequency(P01.09) ~ maximum

0.00Hz

☆

Chapter 5 Function code table VFD500 high performance vector control frequency inverter user manual

- 33-

Functio

n code

Parameter name

Description

Default

Property

plc 11

frequency(P01.06)

P01.32

Multiple speed 11/in-built

plc 12

Lower limit frequency(P01.09) ~ maximum

frequency(P01.06)

0.00Hz

☆

P01.33

Multiple speed 12/in-built

plc 13

Lower limit frequency(P01.09)~maximum

frequency(P01.06)

0.00Hz

☆

P01.34

Multiple speed 13/in-built

plc 14

Lower limit frequency(P01.09)~maximum

frequency(P01.06)

0.00Hz

☆

P01.35

Multiple speed 14/in-built

plc 15

Lower limit frequency(P01.09)~maximum

frequency(P01.06)

0.00Hz

☆

P01.36

Multiple speed 15/in-built

plc 16

Lower limit frequency(P01.09)~maximum

frequency(P01.06)

0.00Hz

☆

P01.37

Jog frequency

0.00Hz~maximum frequency(P01.06)

5.00Hz

☆

P01.38

Jog command when

running

0:not responsive

1:responsive

0

★

P01.39

UP/DOWN rates

0.00(auto rates)~600.00Hz/s

1.00Hz/s

☆

P01.40

UP/DOWN Control

Unit’digit:

0:zero clearing in non-running

1:zero clearning when UP/DOWN command

not effective

2:not zero cleaning (decide by remembering

digit when power failure

Ten’s digit:

0:non-zero cleaning at power failure

1:save at power failure UP/DOWN offset

Hundred’s digit: UP/DOWN near to zero

0: forbidden

1:enable

000

★

P01.41

Droop control gains

0.00~1.00

Rotation speed drop value based on Rated

load(relative to maximum frequency)

Frequency drop volume:Max

frequency*P01.41*Current load/rated load

0.00

☆

P01.42

Droop control filtering

time

0.000s~10.000s

0.050s

☆

P01.43

Textile frequency setting

0: relative to center of textile frequency

1: relative to maximum frequency

0

☆

P01.44

Textile frequency

0.0%~100% relative to center of textile

frequency P01.43 = 0Textile frequency Aw =

P01.44 * center frequency

P01.43 = 1: Textile frequency Aw = P01.44 *

max frequency

0.0%

☆

P01.45

Jump frequency

0.0%~50.0% relative to textile frequency

0.0%

☆

P01.46

Textile period

0.1s~3000.0s

10.0s

☆

P01.47

Triangle wave

0.1%~100.0% relative to textile period

50.0%

☆

VFD500 high performance vector control frequency inverter user manual Chapter 5 function code table

- 34 -

Functio

n code

Parameter name

Description

Default

Property

risingtimecoeffcient

This function is mostly used in textile and chemical industry and some application such as traversing and winding so

it is used for balancing the workload allocation when multiple motors are used to drive the same load. The output

frequency of the frequency inverters decreases as the load increases. You can reduce the workload of the motor

under load by decreasing the output frequency for this motor, implementing workload balancing among multiple

motors.P01.44 or P01.46=0,This function disable

Start acceleration

Deceleration stop

Frequency

swing center

Frequency swing

lower limit

Frequency swing range:AW-set the frequency(choose

P01.43)*P01.44 Kick-hop frequency:jw-aw*P01.45

+A

w

-Aw

Frequency swing

cycle (P01.46)

Triangle wave rise time:

P01.47*frequency swing

cycle

Running

command

Frequency

swing limit

Output frequency

Jw

Jw

Chapter 5 Function code table VFD500 high performance vector control frequency inverter user manual

- 35-

Function

code

Parameter name

Description

Default

Property

02 Group Start and stop Control

P02.00

Starting mode

0:direct start

Inverter will start from P02.01,After P02.02,It

will go to setting frequency as per S curve

1:speed tracking/Searching

Inverter will do search for motor speed and

recognize and accelerate and decelerate to

setting frequency.See Parameter

P02.16-P02.19

0

★

P02.01

Startup frequency

0.00Hz~10.00Hz

0.00Hz

★

P02.02

Startup frequency

holding time

0.000s~10.000s

0.000s

★

P02.03

Quick-response

excitation

0:disable

1:enable

Set 1= enable it will automatically calculate

pre-exciation current P02.04 and pre-excitaton

time ,after finishing calculation,this parameter

will reset to 0

0

★

P02.04

Pre-excitation current

0%~200% motor rated current

Depend

★

P02.05

Pre-excitation time

0.00s~10.00s

Pre-excitation enable Asynchronous motor for

magnetic field for higher starting torque

Depend

★

P02.06

DC brake current at

start-up

0~100% motor rated current

100%

☆

P02.07

DC brake time at

start-up

0.000s~30.000s

0.000s

★

P02.08

Stop method

0:ramp to stop

1:free coast to stop

0 ☆ P02.09

Startup frequency of DC

brake at stop

0.00Hz~50.00Hz

1.00Hz

★

P02.10

DC braking current at

stop

0~100% motor rated current(Maximum value

not higher than drive rated current)

100%

☆

P02.11

DC brake time at stop

0.000s~30.000s

0.000s

★

P02.12

Magnetic flux brake gain

1.00~1.50

Over excitation braking convert some kinetic

energy to motor heating by increasing motor

excitation.value 1 means ineffective: value

higher,better performance but output current

bigger

1.00

★

P02.13

Delaying frequency at

stop

0.00Hz~20.00Hz

0.50Hz

★

P02.14

Delaying time at stop

0.000s~60.000s

0.000s:no function for delaying time at stop

>0.000s:it is effective,when output frequency

0.000s

★

VFD500 high performance vector control frequency inverter user manual Chapter 5 function code table

- 36 -

Function

code

Parameter name

Description

Default

Property

decrease lower than delaying frequency at

stop (P02.13),inverter will block pulse output

after delaying time at stop (P02.14).if run

command comes during delaying time,inverter

will restart.it is useful to some application with

jog function

P02.15

The minimum blocking

time after free stop

0.010s~30.000s

Depend

★

P02.16

Speed search mode

Unit’s digit:tracking mode

0 : speed search for maximum output

frequency

1:speed search for frequency at stop

2:speed search for grid frequency

Ten’s digit:direction choosing

0:only search at given frequency direction

1:search on the other direction when failed for

given frequency tracking

10

★

P02.17

Deceleration time for

speed search

0.1s~20.0s

2.0s

★

P02.18

Current for speed search

10%~150% motor rated current

40%

★

P02.19

Speed search

compensation factor

0.00~10.00

1.00

★

Chapter 5 Function code table VFD500 high performance vector control frequency inverter user manual

- 37-

Function

code

Parameter name

Description

Default

Property

03 Group Ramp and S curve

P03.00

Acceleration and

deceleration curve

selection

0:linear

1:S curve A

2:S curve B

0

★

Acceleration and deceleration curve, also known as "Ramp Frequency Generator (RFG)", is used to smooth the frequency

command. VFD300A/500 supports the following acceleration and deceleration curve:

0: linear acceleration / deceleration

The output changes at a constant acceleration or deceleration. Acceleration time refers to the time from when the inverter

accelerates from zero to the reference frequency (selected by P03.15); deceleration time refers to the time required to

decelerate from the reference frequency to zero.

1: S curve method

This acceleration and deceleration curve acceleration "a" changes in a ramp, start and stop relatively flat. Acceleration and

deceleration process as shown below, Tacc and Tdec for the set acceleration and deceleration time.

The acceleration and deceleration curve of the equivalent acceleration and deceleration time:

Acceleration time = Tacc + (Ts1 + Ts2) / 2

Deceleration time = Tdec + (Ts3 + Ts4) / 2

1S

T

t

2S

T

3S

T

4S

T

acc

T

dec

T

Output frequency

recommand

2: S curve method B

The time of this S-curve is defined as in the method A except that in the acceleration / deceleration process, if the target

frequency suddenly approaches or the acceleration / deceleration time changes, the S-curve is re-planned. In addition, when

the target frequency changes, the S Curves avoid "overshoot" as much as possible.

P03.01

Acceleration time 1

Setting value depend on P03.16

P03.16 = 2, 0.00~600.00s;

P03.16 = 1, 0.0s~6000.0s;

P03.16 = 0, 0s~60000s

Depend

on model

☆

P03.02

Deceleration time 1

Setting value depend on P03.16

P03.16 = 2, 0.00~600.00s;

P03.16 = 1, 0.0s~6000.0s;

P03.16 = 0, 0s~60000s

Depend

on model

☆

P03.03

Accelerationtime2

0.01~60000s same as P03.01

Depend

on model

☆

P03.04

Deceleration time2

0.01~60000s same as P03.02

Depend

on model

☆

P03.05

Acceleration time3

0.01~60000s same as P03.01

Depend

on model

☆

P03.06

Deceleration time3

0.01~60000s same as P03.02

Depend

☆

VFD500 high performance vector control frequency inverter user manual Chapter 5 function code table

- 38 -

Function

code

Parameter name

Description

Default

Property

on model

P03.07