Veichi Electric AC60 series User Manual

Manual

AC60 series frequency inverter

Version V2.0

FOREWORD

Thank you for using AC60 series frequency inverter produced by Veich

Electric Co.LTD

AC60 series inverter is a new generation of high-performance universal

frequency inverter independently developed by Veich. With advanced control

method, we can provide products with a high-torque, high-precision, high

reliability and wide –speed- range drive. In the benefit of AC60 series'

multiple function design, users will be satisfied by the simplified PLC,

PID adjustor, programming I/O terminal, RS485 interface, pulse-frequency

I/O interface and other specific control functions for particular

industries. It offers a highly-integrated solution for equipment matching,

facilities upgrading, automation control and other specific industrial

application.

AC60 series adopts G/P all-in-one design, which facilitates users in

choosing and use the proper model.

This manual is the supporting data sheet for AC60

This instruction manual includes instructions (messages) of installing

wiring, parameters setting, troubleshooting, maintenances, related

matters attention and etc... For the best results and safe operations of

the AC60 series, pls carefully read and keep this manual. Make sure it is

handy for the ultimate user of the inverters for reference.

If you need technical support related to the inverter, please contact the

Veich sales office or the dealer from whom you purchased. You can also

contact our Customer Service Center. We will try our best to help you.

We are sparing no effort to upgrade our products, but regret for no prior

notification if there is any revision to this instruction manual. Pray for

your consideration for the inconveniences

Catalog

Chapter one Safety Requirement and Cautions…………………………………1

1.1 Safety definition……………………………………………………………1

1.2 Safety requirement and cautions…………………………………………1

1.3 Cautions in utilization……………………………………………………5

1.4 Cautions in disposal ………………………………………………………7

Chapter two Purchase Inspection and Products Specification ………………8

2.1 Purchase inspection ………………………………………………………8

2.2 Nameplate and models illustration ………………………………………8

2.3 Product technique specifications………………………………………9

2.4 Inverter rated output current …………………………………………11

Charter three Installation ………………………………………………………13

3.1 Installation environmental requirements……………………………13

3.2 Products appearance and components title……………………………14

3.3 Mounting direction and space …………………………………………14

3.4 Dismantle and install tail-hood……………………………………15

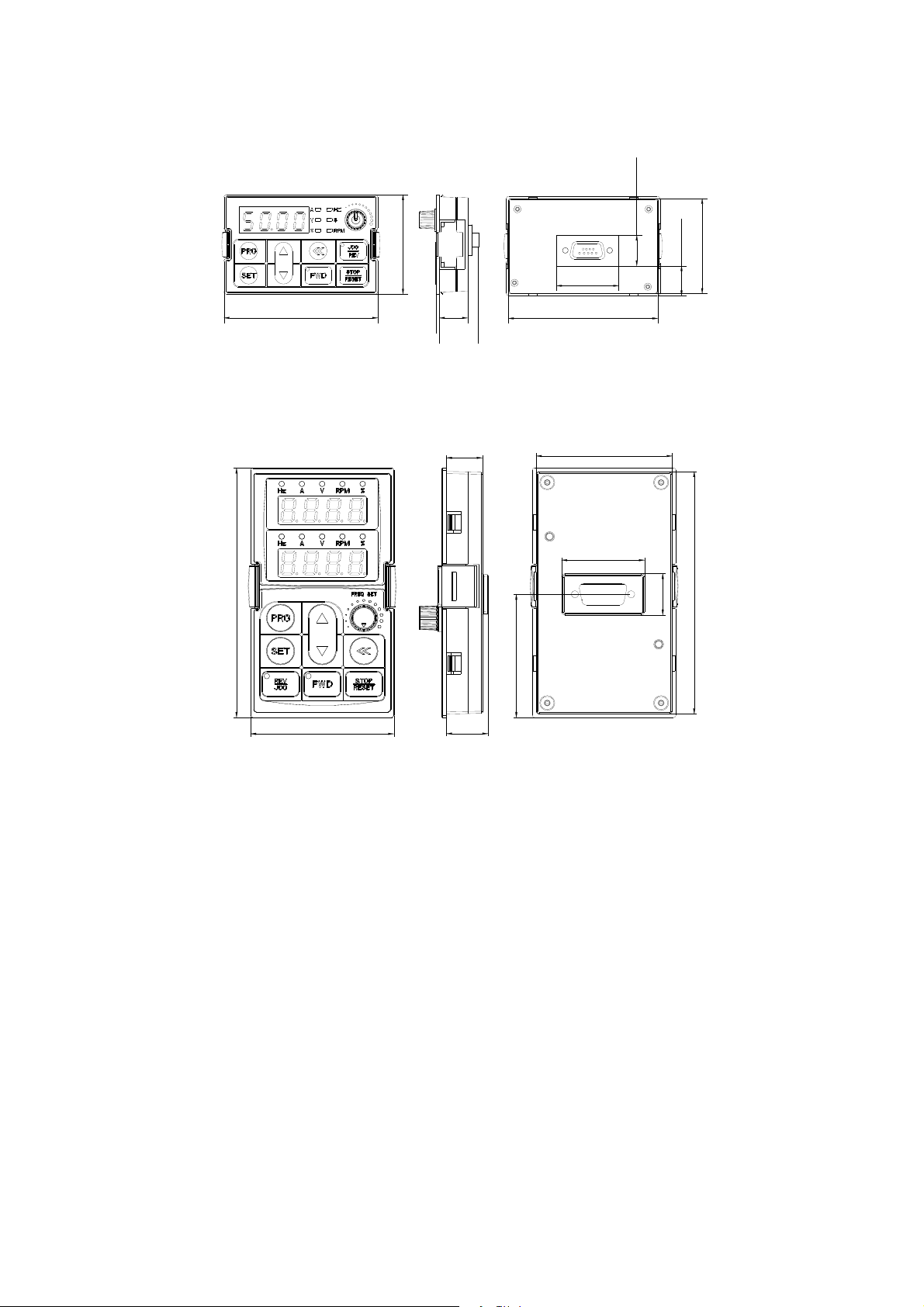

3.5 Dismantle and install keyboard………………………………………16

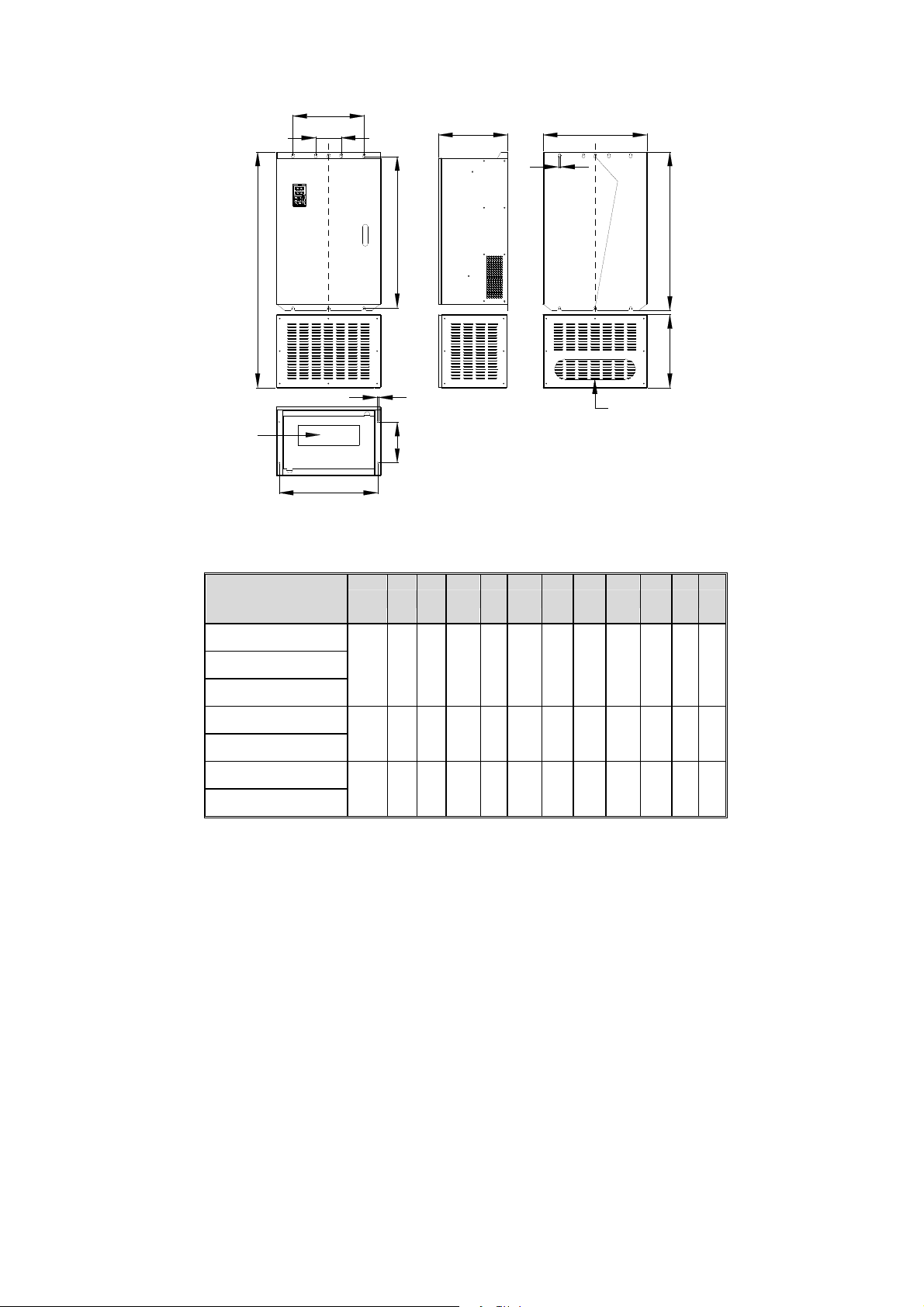

3.6 Installation size ………………………………………………………17

3.7 Operation keyboard size…………………………………………………22

Chapter four Frequency Inverter Wiring………………………………………23

4.1 Wiring attentions ………………………………………………………23

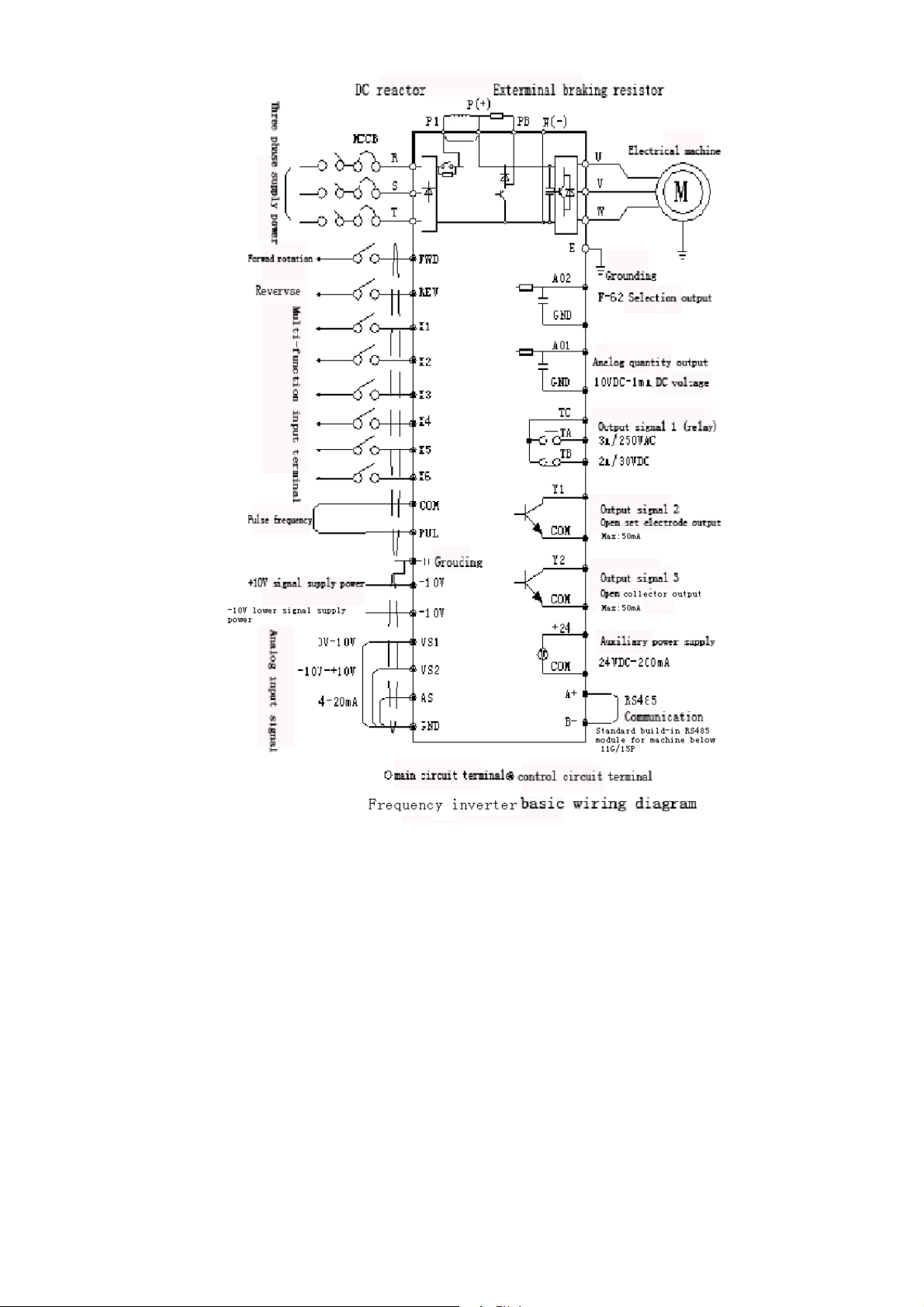

4.2 Basic wiring diagram……………………………………………………25

4.3 Main circuit terminals…………………………………………………27

4.4 Electrical specifications recommendation …………………………29

4.5 Control circuit terminals………………………………………………30

4.6 RS485 communication modules and control panels jump circuit

specification ……………………………………………………………………… 31

4.7 Backup circuit…………………………………………………………… 33

Chapter five Keyboard Operation and Usage……………………………………34

5.1 Keyboard layout and functions specification…………………………34

5.2 Indicating lamp meaning specification………………………………37

5.3 Keyboard operation mode…………………………………………………38

Chapter six Functional Parameter Table…………………………………………43

6.1 Basic parameter……………………………………………………………43

6.2 Exterior terminal parameters……………………………………………50

6.3 Special functions parameter……………………………………………58

Chapter seven Function Detailed Specification………………………………64

7.1 Basic parameters detailed specification……………………………64

7.2 External terminal parameters detailed description………………105

7.3 Special function parameters……………………………………………130

Chapter eight Abnormality Diagnoses and Processing…………………………152

8.1 Fault information and troubleshooting………………………………152

8.2 Common fault and processing methods…………………………………157

Chapter nine Overhaul and Maintenance…………………………………………165

9.1 Inspection and maintenance……………………………………………165

9.2 Components needed periodic replace……………………………………166

9.3 Preservation and maintenance…………………………………………167

9.4 Measurement and judgment………………………………………………167

Chapter ten Optional parts………………………………………………………169

10.1 Alternating current reactor…………………………………………170

10.2 Noise filter………………………………………………………………170

10.3 Braking unit and braking resistor……………………………………170

10.4 Capacitance box…………………………………………………………171

Chapter eleven Quality Guarantee………………………………………………172

11.1 “Three guarantee” service…………………………………………172

11.2 Lifelong paid service…………………………………………………172

11.3 Service provider…………………………………………………………172

11.4 “Three guarantee” service responsibility………………………172

11.5 “Three guarantee” service range……………………………………172

11.6 “Three guarantee” service premise………………………………172

Chapter twelve Appendix ……………………………………………………173

Appendix one: RS485 communication protocol …………………………………174

Chapter one Safety Requirement and Cautions

To ensure safety of your health, equipment and property, please read this

chapter carefully before use the frequency inverter and act in compliance with

the instructions while carrying, installing, debugging, running and

overhauling the frequency inverter.

1.1 Safety definition

Danger: it will cause danger of serious injuries and even death while operating

against the rules

Caution: it will cause danger of light injuries or equipment destruction while

operating against the rules

Note: some information is useful while operating and use frequency inverter.

1.2 Safety requirements and cautions

●Before installation

Danger

1. Only qualified personnel can operate the equipment. Before operating,

be sure to carefully read the manual about safety, installation,

operation and maintenance. The safe operation depends on the proper

processes of choosing models, carrying, installation, operation and

maintenance.

Danger

1. Don’t use the damaged or incomplete frequency inverters; Otherwise,

there is risk of injury.

●Installation

1

Danger

1. Please install the frequency inverter on metal or other nonflammable

material, and keep it away from the combustible material. Otherwise

there is danger of fire;

2. No unauthorized modification to the frequency inverter; Otherwise

there is danger of damaged.

3. Normal frequency inverter, which is not explosion-proof, can not be

installed where with explosive gas or dust; Otherwise there is

danger of explosion.

Attention

1. When two frequency inverters are installed in the same control cabinet,

pleas pay attention to the installing place to guarantee the effective

heat dissipation.

2. When carrying the frequency inverter,please support its bottom.

Wiring

Danger

1. Wire is connected only when the main circuit is cut off, otherwise

there is a danger of shock.

2. Wire is connected by professional person only. Otherwise there is a

danger of shock.

3. Earth must be reliable. Otherwise there is a danger of shock.

4. AC power supply should not be connected with output ports U, V, W;

Otherwise there is a danger of damage to frequency inverter.

5. No drop of bolt, spacer, metal stick, conducting wire or other things

into the inner of frequency inverter; Otherwise there is a danger of

fire or damage to frequency inverter.

Attention

2

1. If the damage to frequency inverter or other equipment is caused by

improper wiring and utilization or unauthorized alteration, the user

should shoulder all responsibilities.

2. Please make sure all wirings meet EMC requirement and satisfy safety

standard in the local area; Please refer to recommendations in this

manual or national standards of wire diameter to avoid accidents.

3. Please connect the braking resistance or braking unit according to the

wire diagram; Braking resistance can not be connected to the terminals

of DC bus P(+)、N(-); Otherwise it will cause fire or damage to frequency

inverter.

4.Human body electrostatic would seriously damage internal MOS

transistor,etc. No touch the printed circuit boards, IGBT or other

internal devices without anti-static measures, otherwise it will cause

the malfunction of frequency inverter.

5. Please don't connet phase shifter capacitance or LC/RC noise filter

to the output circuit of frequency inverter; Otherwise it will damage

the frequency inverter.

6. Please don't connect the magnetic switch or magnetic contactor to the

output circuit of frequency inverter; When frequency inverter is in the

operation with load, magnetic switch or magnetic contactor can make

inverter overcurrent protection function act, that will damage frequency

inverter seriously.

7. Please don't disassemble the panel cover, it only needs to disassemble

the terminal cover when wiring.

8. It is forbidden to do any pressure test on frequency inverter;Otherwise

it will damage the frequency inverter.

●Before electrification

Danger

3

1. Please make sure that voltage grade of power supply is consistent with

frequency inverter's voltage and then check whether the wiring is correct

and firm, and whether there is short circuit in peripheral equipment's

circuit. Otherwise it will damage frequency inverter and other

equipments.

2. Before the frequency inverter is connected to the input power supply,

make sure that the cover has been fixed well. Otherwise it will cause

electric shock.

3. For the frequency inverters whose storage time is over 1 year, when

electrification, the voltage should be raised by booster from low to

high. Otherwise it will damage the frequency inverter.

Attention

1. Check all periphery fittings are wired properly according to the

handbook; Otherwise it will cause accidents.

● After electrification

Danger

1. After electrified, it is forbidden to open the cover, make wiring, and

check up; Otherwise, it will cause the danger of electric shock.

2.After electrified, it is forbidden to contact internal wiring board and

its parts. Otherwise it will cause the danger of electric shock.

3.Do not operate or touch frequency inverter with wet hand. Otherwise there

is dangers of damage to frequency inverter and electric shock.

Attention

1. Pleasea set the parameter of frequency inverter cautiously; Otherwise

it will damage equipment.

●Operation

Danger

4

1. Before running, please check and confirm the application range of the

machine and equipments once more; Otherwise it will cause accidents.

2. Please don't touch the cooling fan and braking resistance to check the

temperature; Otherwise there is a danger of getting burn.

3.Unprofessional workers are banned to check the signals in the running

stage; Otherwise it will cause injuries and damage the equipment.

Attention

1. Please don't turn off the equipment by switching off power; Please cut

off the power supply after the electric machine stops running; Otherwise

it will damage the frequency inverter.

2.Please avoid anything dropping into the equipment when the frequency

inverter is running; Otherwise it will cause electric shock..

●Maintenance

Danger

1. Please don't maintain and repair the equipment with electric; Otherwise

it will cause electric shock.

2. Before maintaining and repairing the frequency inverter, please make

sure the indicator lights of power supply have completely turned off;

Otherwise it may cause electric shock and damage the frequency inverter.

3. Persons who have not passed specialized train are not allowed to conduct

the frequency inverter maintenance; Otherwise it may cause electric

shock and damage the frequency inverter.

1.3 Cautions in utilization

1. The general motor running at a low speed decreases its lifelime for the

heat dissipation effect is quite bad. If low speed running needs to last

for a long time, the frequency inverter special-purpose motor should be

chosen or the load should be lightened.

2. When using the frequency inverter, the temperature of motor is a little

5

higher comparing to the power frequency operation. It is normal phenomena.

3. In application of AC60 series frequency inverter, you have to confirm

all machine insulation to prevent damage to the equipment. Moreover, when

the motor working in tough environment, please periodic inspect the

electrical insulation to ensure the safety of the system work.

4. If the motor adapter is not consistent with frequency inverter's rating

current ( The rating current of the motor is far smaller than that of

frequency inverter), please adjust the protective value to ensure safe

running.

5. In occasions such as load raising, usually there is negative torque and

frequency inverter breaks off for over-current or over-voltagte. In this

case, you should consider to choose matching brake unit.

6. Frequency inverter, in a certain output frequency range, can meet the

load equipment’mechanical resonance. To avoid it, you can set up jumping

frequency.

7. As output voltage of the inverter is pulse-wave type, if there is capacity

which can improve power factor or pressure-sensitive resistance which used

for thunder-proof in the voltage output side, the frequency inverter will

break off or its parts will be damaged, so it is necessary to dismantle

them. Moreover, it is proposed not install switch parts like air switch

and contactor (if it is necessary to install switch on output side, please

make sure the output electricity of frequency inverter is zero when the

switche is working)

8. At over 1,000 meters altitude, the inverter’s heat dissipation function

worsened due to the thin air, it is necessary to derate use.

9. The inverter output voltage is pulse wave type. If use digital multimeter

measurement, deviation of the reading will be great. And the deviation is

different by using different type of digital multimeter. Under normal

circumstances, while RMS 380V, digital multimeter reading is around 450V.

6

1.4 Cautions in disposal

When you dispose frequency inverter, please pay attention to:

1. Electrolytic capacitor: the electrolytic capacitor of main circuit or the

printing plate may explode when they are burned.

2. Plastic: plastic incineration may generate toxic gases.

3. Dispose method: please dispose as industrial waste.

7

Chapter two Purchase Inspections and Products Specification

2.1 Purchase inspection

1. Before unpacking, please confirm whether there is any damage occurred during

transportation.

2. Check whether the details on the nameplate of frequency inverter are in

accordance with your order.

3. AC60 series frequency inverter have undergone a rigorous testing and quality

control before leaving the factory. Please check all of qualified

certification, product manual and warranty cards.

4. Please check the frequency inverter to ensure it without any internal damage.

If it has obvious damage, please do not operate machine and timely contact

the manufacturer or distribution company, in order to avoid the accidents.

Nameplate and models illustration

2.2

1. Nameplate illustrate

2. Models illustration

8

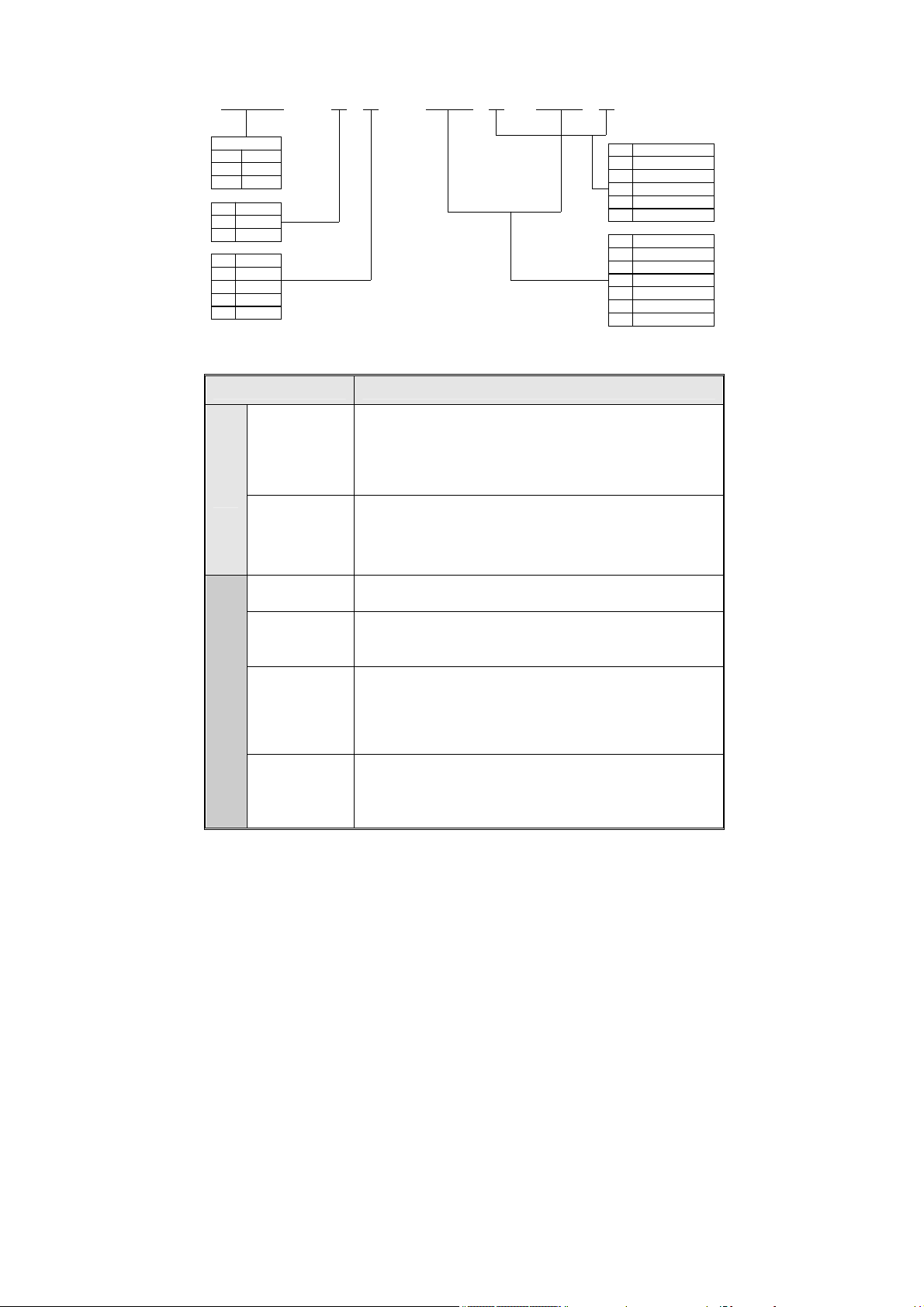

AC60 - T 3 - 015 G /018 P

inverter series

general format

AC60

injrction mold i n g

AC61

machine

draw bench

AC62

voltage class

code

three phase

T

single phase

S

voltage class

code

2 220V

3 380V

6 660V

11 1140V

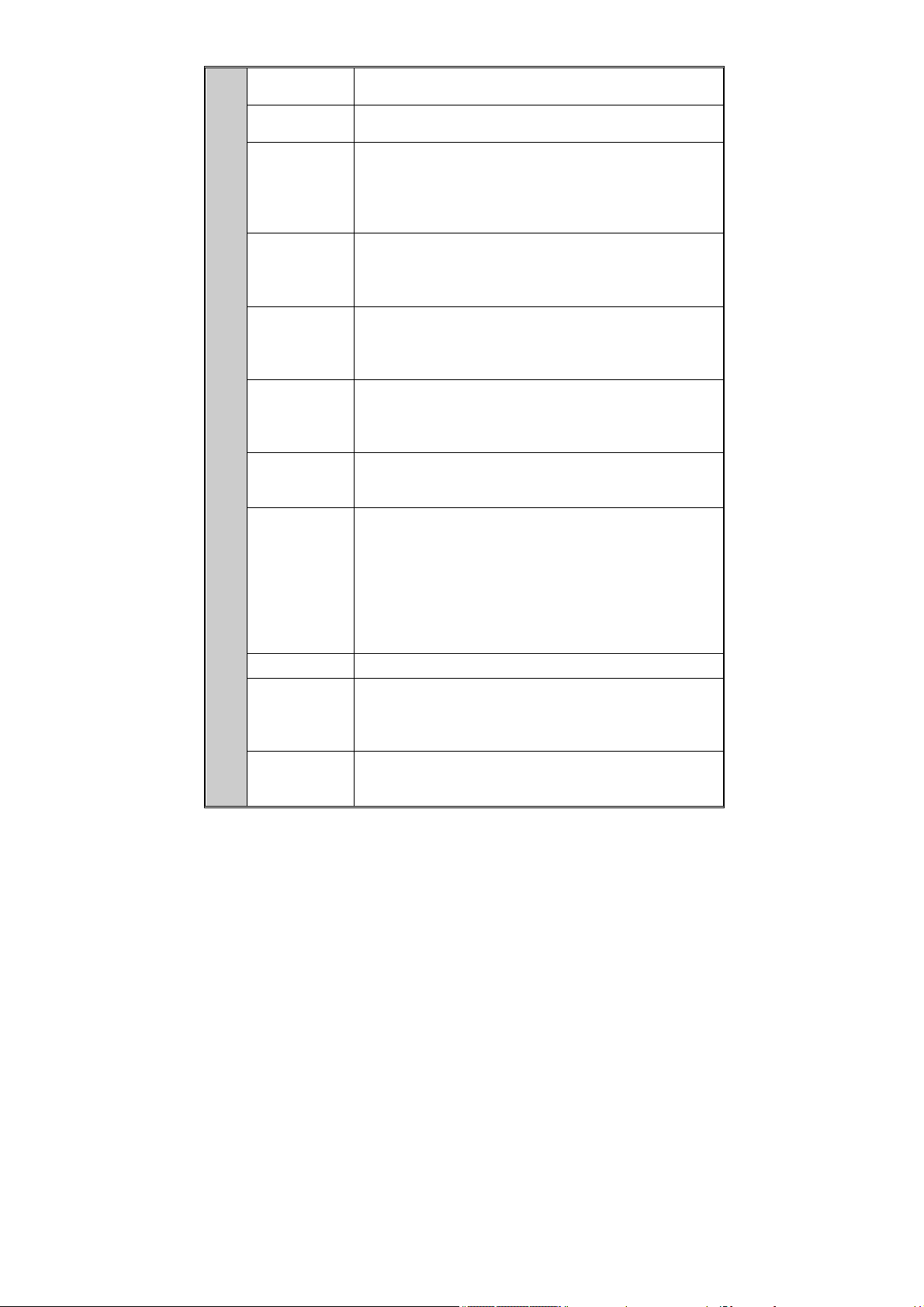

2.3 Product technique specifications

Items Specifications

Single phase 220V 50/60Hz

Voltage 、

frequency

Pow

er

Allowable

fluctuations

Frequency

control range

Output

frequency

accuracy

Con

Frequency

tro

setting

l

resolution

Voltage/freq

uency

characterist

ics

Three phase 220V 50/60Hz

Three phase380V 50/60Hz

Three phase660V 50/60Hz

Three phase 1140V 50/60Hz

voltage:±15%, frequency:±5%

G:0-400Hz P:0-400Hz Z:0-400Hz、

L:0-400Hz H:0-2000Hz

±0.5% of max frequency

0.01Hz:Operating“up”and”down”keys on keyboard

0.2Hz:Potentiometers analog input

Voltage 50% -100% the rated voltage adjustable,

Motor rated frequency 25-400Hz(2000Hz) adjustable

inverter type

code

general format

G

blower and water pump

P

plastic machine

Z

L

draw bench

mid inverter governor

H

fit power of motor(kW)

code

7R5

011

015

018

022

030

7.5

11

15

18

22

30

9

Carrier

frequency

Torque

upgrade

Maximum

Capacity

Acceleration

and

Deceleration

time

Rated output

voltage

Automatic

voltage

adjustment

function

Automatic

energy-savin

g operation

Standard

functions

Brake Energy-consuming braking, DC braking

Frequency

setting input

Signal

Feedback

input

1.0-15.0KHz、Random carrier modulation

0~25.0% adjustable、auto torque upgrade、random V/F

curve optional

G、H、L model:150% for one minute, 180% for 2s, 200%

instant jump.

Z model:150% for one minute, 180% for 30s ,250% instant

jump.

P model:120% for one minute, 150% instant jump.

0.1-6500s

Take advantage of the power supply voltage

compensation function, if motor rated voltage is

100%,the voltage can be set in the 50 -100% scope(the

voltage output should not exceed the input voltage )

When the grid voltage fluctuates, changes in the

output voltage is very small, remained constant V /

F

According to the load conditions, automatic optimize

the V / F curves to implement energy saving operation

PID control, Acceleration and deceleration time

adjustable, Acceleration and deceleration mode

variable, Carrier frequency adjustment, Torque

upgrade, Current limiting, Speed tracking and

restart, Frequency hopping, Frequency fluctuation

limite control, Program running, Multi-steps speed,

Pendulum frequency operation, RS485, Analog output,

Pulse output frequency

Keyboard number settings, keyboard potentiometers、

external terminal VS1 : 0 ~ 10V, external terminal VS2:

- 10V - 10V, the external terminal AS : 4-20mA, RS485

and signal composition and terminal options

External terminal VS1 : 0 ~ 10V, external terminals

VS2:-10V - 10V, external terminal AS : 4-20mA, RS485,

frequency pulse input

10

Start, stop, positive and negative rotating , jog,

Input order

signals

External

output signal

Protection function

Setting Function number、data

Running

Dis

pla

y

Fault

Installation

sites

Temperature,

humidity

Vibration Below 20Hz less than 0.5g

Con

Storage

dit

Temperature

ion

Installation

mode

Protection

degree

Cooling Mode Forced air-cooling

multi-steps speed, free parking, reset, acceleration

and deceleration time choice, frequency settings

channels choice, external malfunctions alarm

Relay output, the collector output, 0-10V output,

4-20mA output, the frequency pulse output

Overvoltage, undervoltage, current limiting,

over-current, overload, electric thermal relays,

overheat, pressure stall, data protection

Output frequency, give frequency, output current,

input voltage, output voltage, motor speed, PID

feedback, quantitative PID, module temperature, input

and output terminal

Overvoltage, undervoltage, overcurrent, short

circuit, phase missing, overload, heat, pressure

stall, current limiting, data protection is damaged,

current fault operating conditions, historical fault

Indoor, elevation of not more than 1000 m, no corrosive

gases and direct sunlight

-10—+40℃, 20%—90%RH(No condensation)

-25—+65℃

Wall-mounted mode, closet mode

IP20

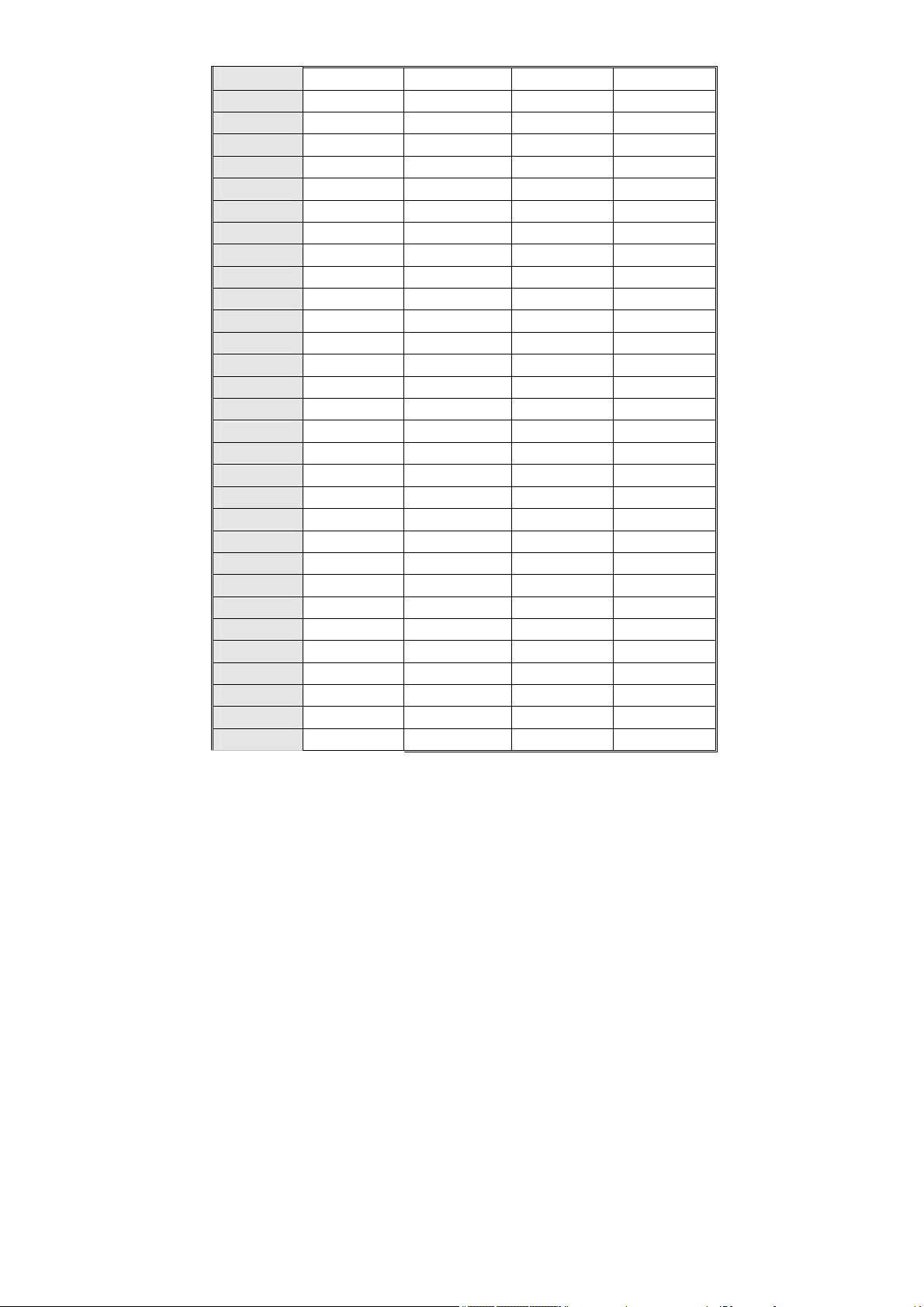

2.4 Inverter rated output current

Input

current

Rated power

0.4 2.5

220V 380V 660V 1140V

Rated output

current(A)

Rated output

current(A)

11

Rated output

current(A)

Rated output

current(A)

0.75 4 2.3

1.5 7 3.7

2.2 10 5.0

3.7 16 8.5

5.5 20 13

7.5 30 17

11 42 25

15 55 32 18

18.5 70 38 22

22 80 45 28

30 110 60 35

37 130 75 45 25

45 160 90 52 31

55 200 110 63 38

75 260 150 86 52

93 320 180 98 58

110 380 210 121 75

132 420 250 150 86

160 550 310 175 105

185 600 340 198 115

200 660 380 218 132

220 720 415 235 144

250 470 270 162

280 510 330 175

315 600 345 208

355 670 380 220

400 750 430 260

500

560 990 600 365

630 1100 680 400

700 1260 750 480

860 540 325

10

15

12

Charter three Installation

3.1 Installation environmental requirements

1.Ambient temperature: -10℃~40℃, good ventilation and heat dissipation. If

the temperature is higher than 40 ℃. The frequency inverter should be

derated to use.

2. Avoid vibration, free of direct sunlight and away from heat sources.

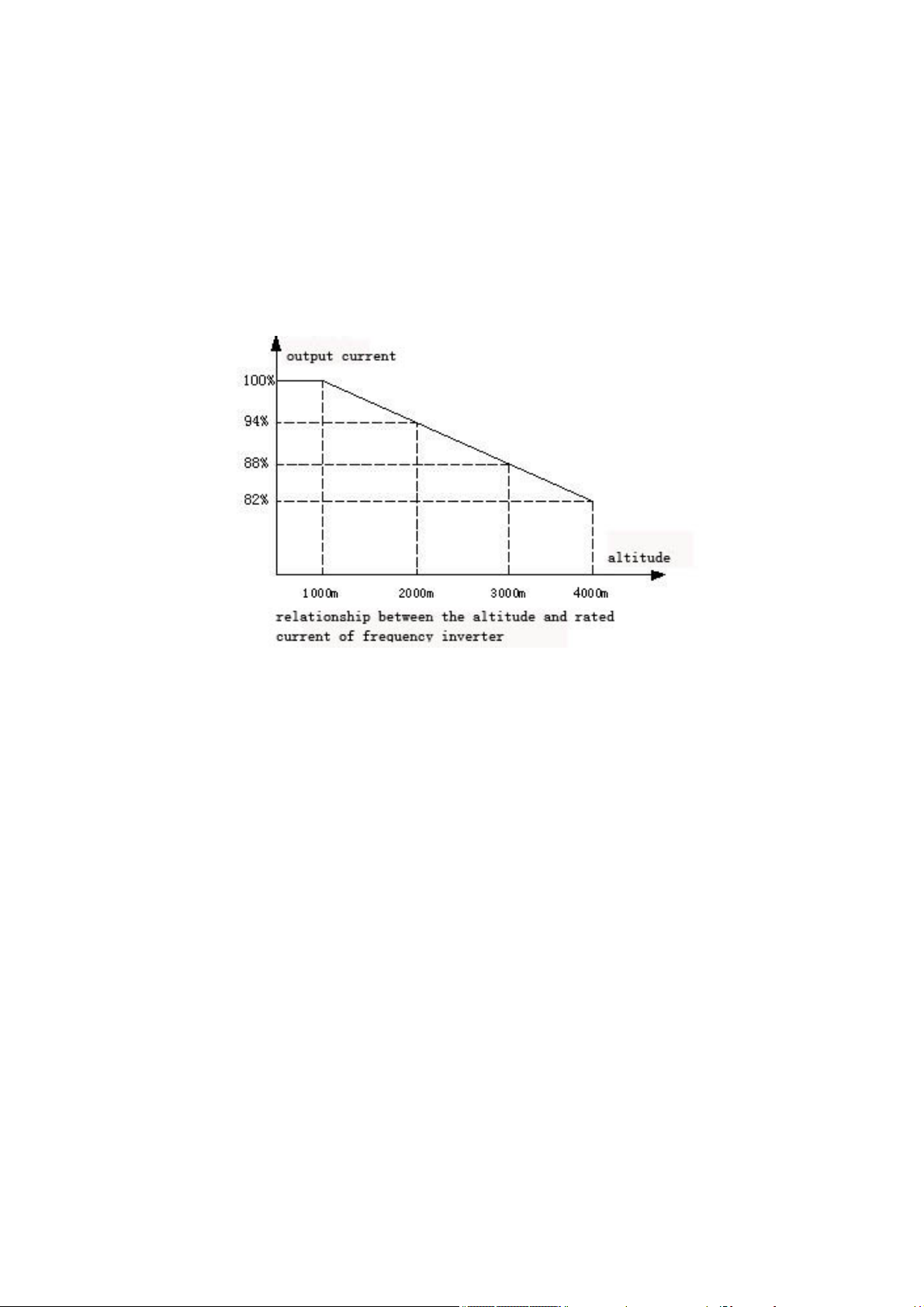

3. Inverter installed under the altitude of 1000m can output rated power. It

needs be derated to use when the altitude is more than 1,000 m . Pls refer

specific figures as below :

4. Humidity should be lower than 90% (no condensation); Avoid high temperature

and high humidity.

5. Be away from oil, salt and corrosive gases.

6. Prevent inverter from intrusion of water drop, steam, dust, wooland metal

dust.

7. Prevent electromagnetic interference, away from sources of interference.

13

8. Prohibit use of flammable, explosive gases, liquids or solids in a dangerous

environment.

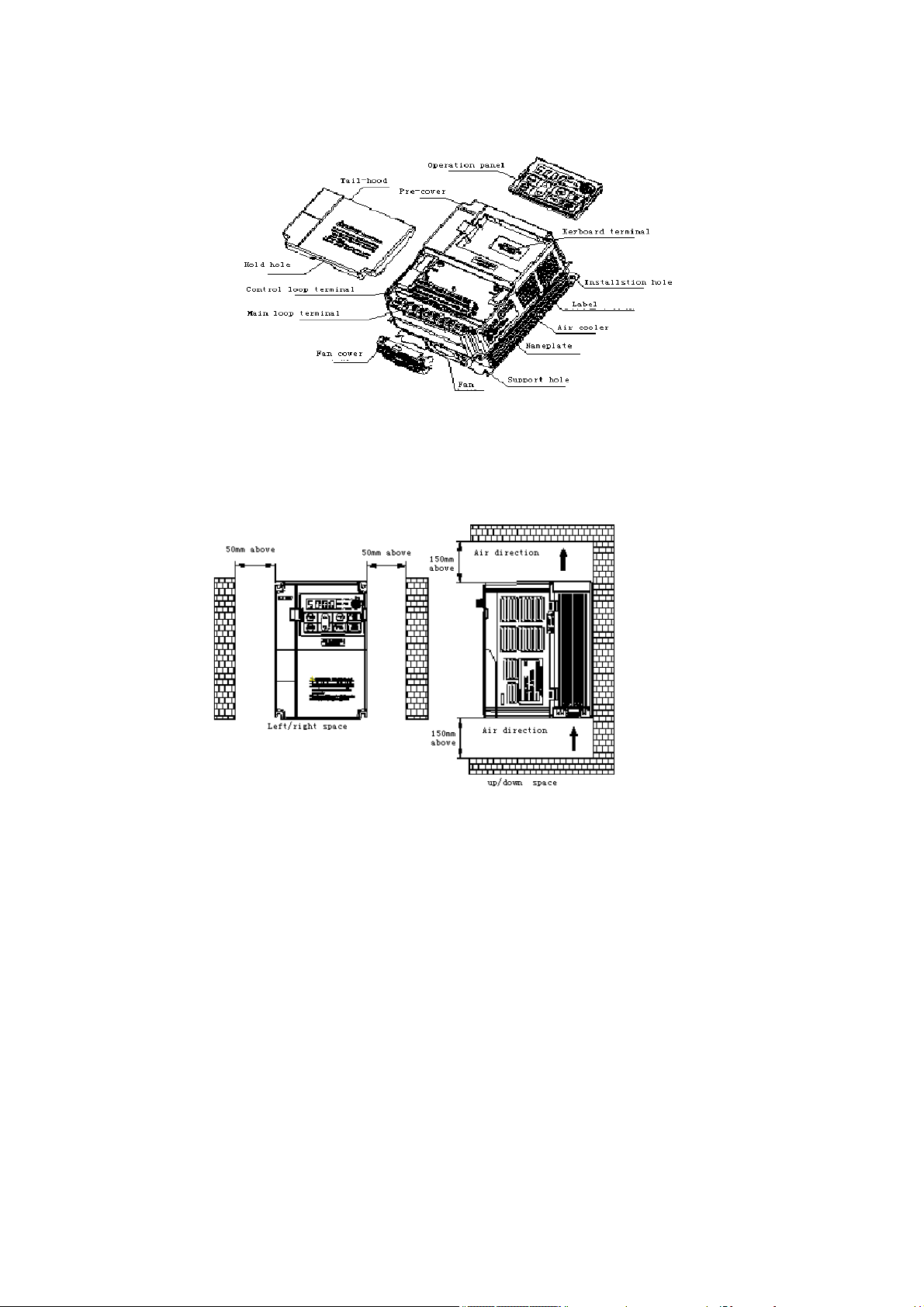

3.2 Products appearance and components titles

3.3 Mounting direction and space

Frequency inverter should be installed in a well-ventilated indoor place, and

adapt wall-mounted or closet-style vertical installation. Enough space with

the surrounding adjacent items or baffle (wall) shound be preserved.

Installation for one frequency inverter

14

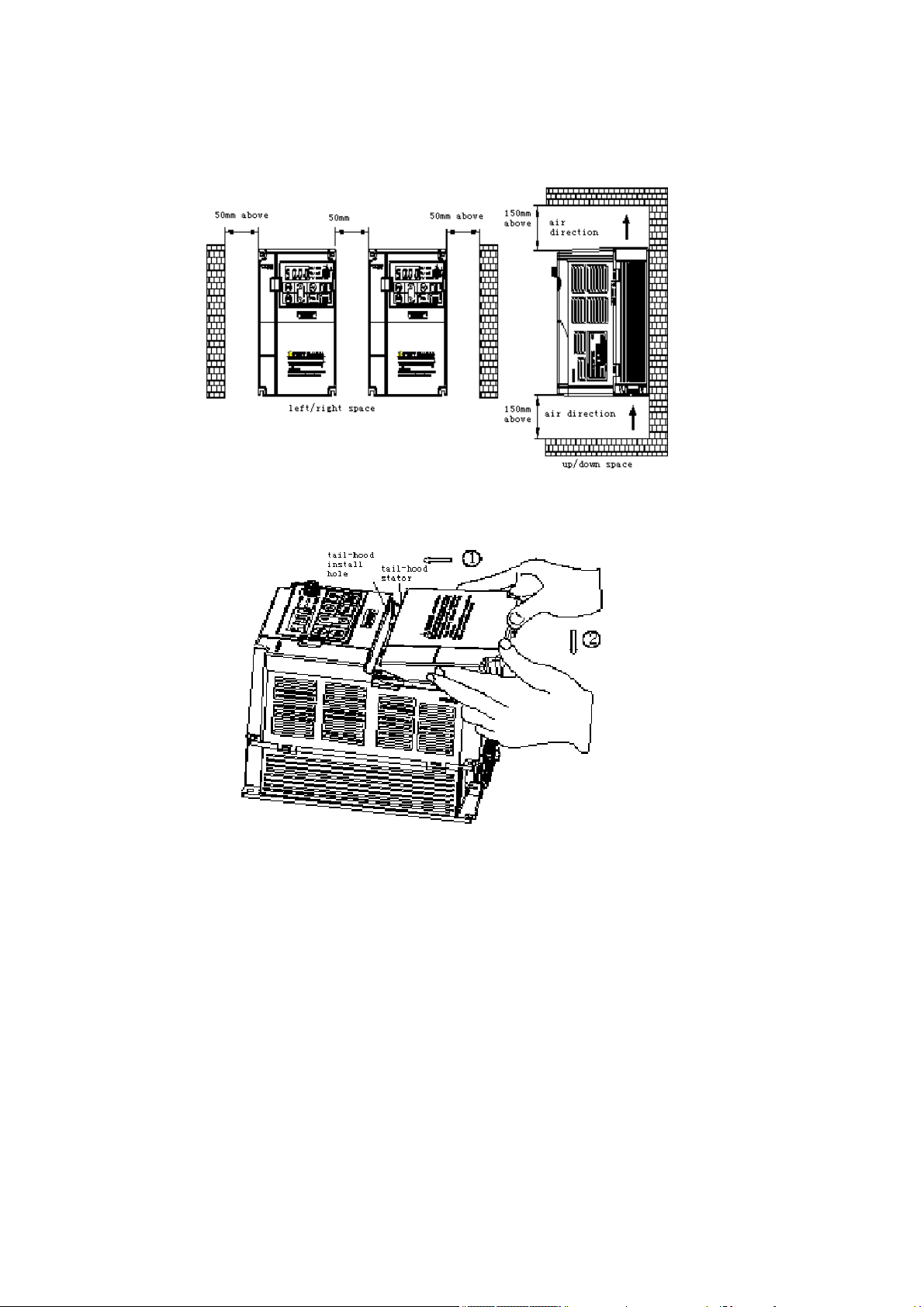

When several frequency inverters are installed in one cabinet, you should pay

attention to the uniformity of each frequency inverter heat dissipation. While

it adopts vertical juxtaposition installation, you should install deflector

plate to avoid the heat of below inverter flows through the above inverter.

Installation for multi frequency inverter

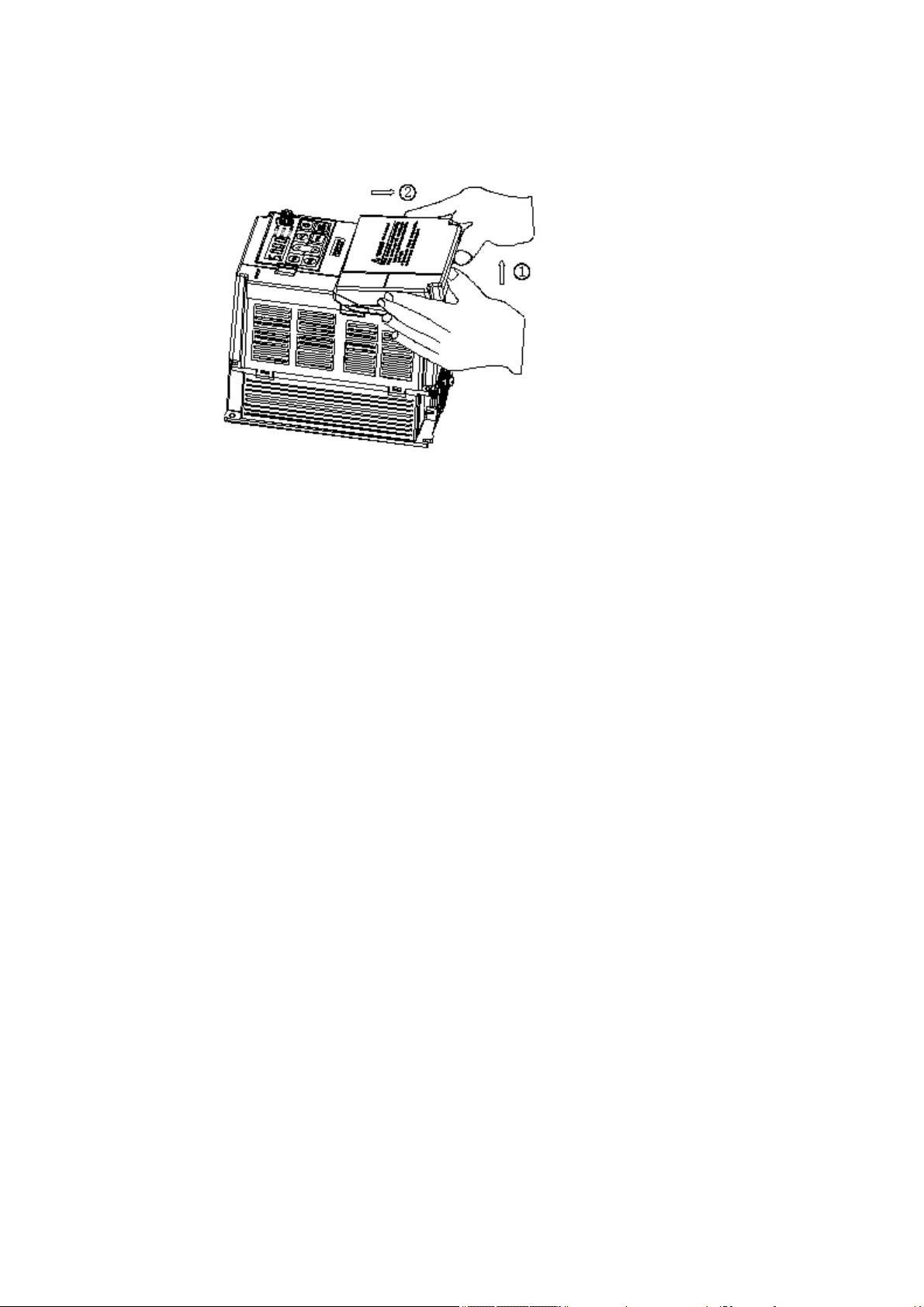

3.4 Dismantle and install tail-hood

15

Installation: First the tail-hood upwardly inclines around 15 degrees and

inserts the top fixed flat into the fixed hole in the front cover. Then slightly

press the tail-hood downward. While your hear "Ka",it means that the tail-hood

is into the place.

Dismantlement: At the tail of the frequency inverter, there is a special

dismantlement hole design. Put your fingers into the hole, upwardly pull the

cover with a little force until the buckle between the tail-hood and the crust

tear off, and then removed tail-hood down.

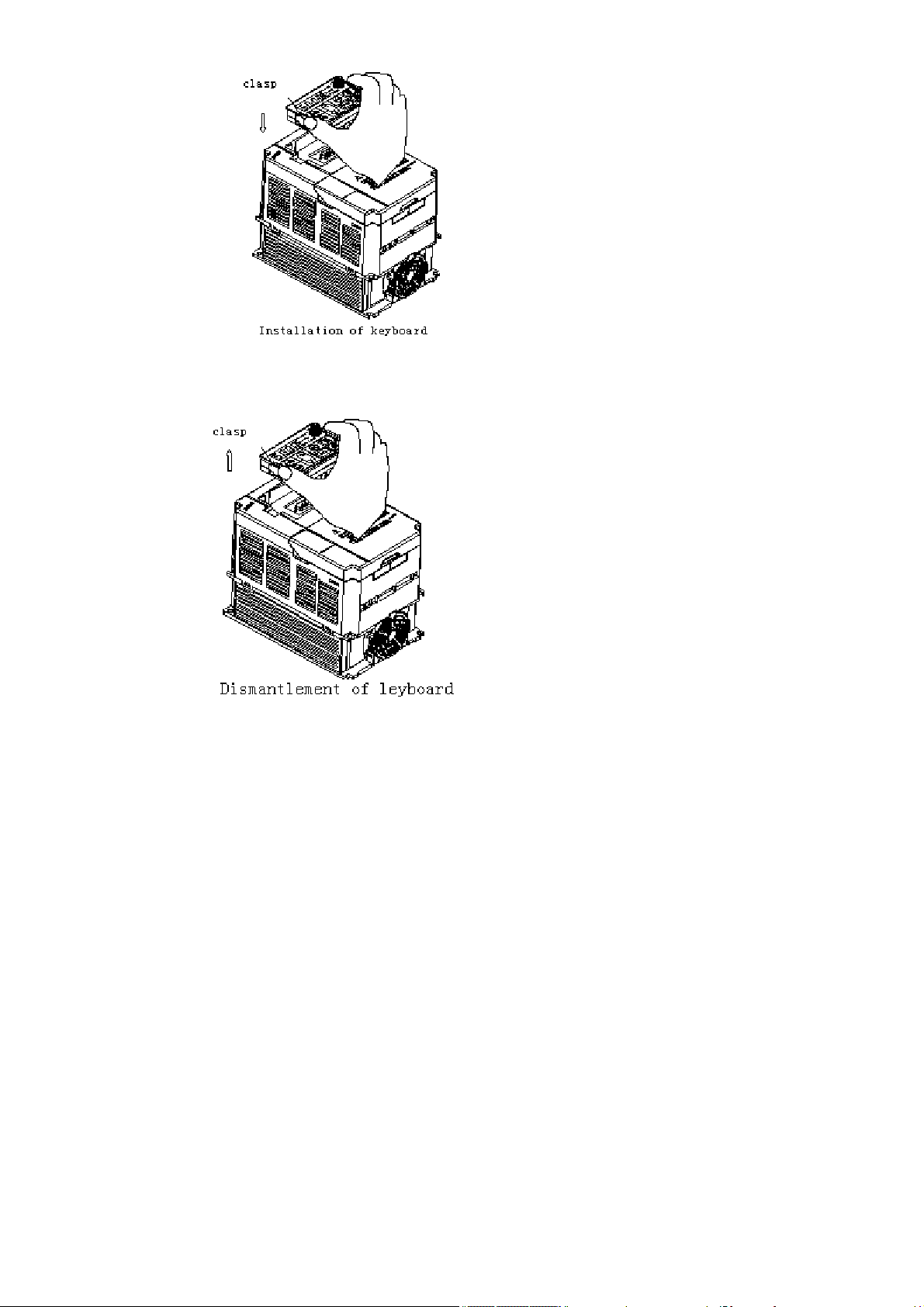

3.5 Dismantle and install keyboard

Installation : Put down the keyboard aimed at keyboard installation groove,

maintain the keyboard and cover parallel, press the keyboard down with uniform

strength until you hear "Ka" which means the installation of the keyboard in

place. Please do not tilt the installation of the keyboard.

16

Dismantlement: Put your finger into the keyboard dismantlement hole and pull

the keyboard out.

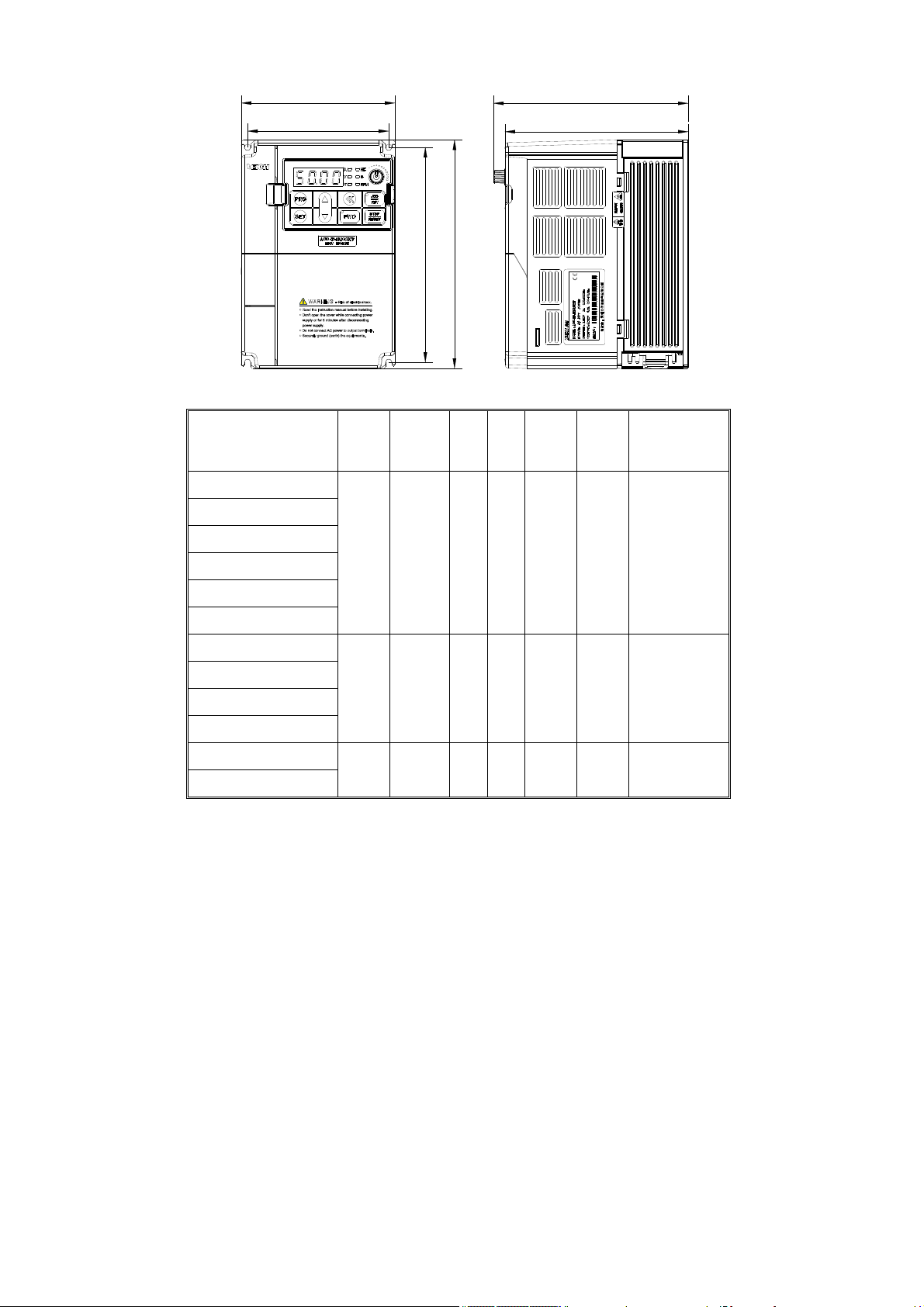

3.6 Installation size(units:mm)

3.6.1 Installation size of machine with plastic cover

17

W

D

W1

Frequency inverter

G: Constant torque load

P: Fans&pump load

AC60-S2-R40G

AC60-S2-R75G

AC60-S2-1R5G

AC60-T3-R75G/1R5P

D1

H

H1

W W1 H H1 D D1

122 112 182 171 154.5 145 ф5

Installation

aperture

AC60-T3-1R5G/2R2P

AC60-T3-2R2G/3R7P

AC60-S2-2R2G

AC60-S2-3R7G

AC60-T3-3R7G/5R5P

AC60-T3-5R5G/7R5P

AC60-T3-7R5G/011P

AC60-T3-011G/015P

3.6.2 Wall-mounted machines installation size

159 147.2 246 236 157.5 148 ф5.5

195 179 291 275 167.5 158 ф7

18

Frequency inverter

G: Constant torque load

P: Fans&pump load

W W1 H H1 D

AC60-T3-015G/018P 238 180 390 377 212 ф7

AC60-T3-018G/022P

Installation

aperture

AC60-T3-022G/030P

281 200 496 476 256 ф9

AC60-T3-030G/037P

AC60-T3-037G/045P

353 200 600 578 286 ф11

AC60-T3-045G/055P

AC60-T3-055G/075P

380 300 645 620 297 ф11

AC60-T3-075G/093P

3.6.3 Wall-mounted & Cabinet-mounted machines installation size

19

.

W1

W2

WD

RPM

VA

Hz

RPM%%

A

V

Hz

PRG

SET

STOP

REV

FWD

JOG

RESET

H

bottom entering

line hole

A1

Frequency inverter

G: Constant torque load

P: Fans&pump load

AC60-T3-093G/110P

VEICH

E

L1

the hole only

to 93-132G

L

H1

C

B1

1.User can enter line from bottom or back, detail according to below list.

2.Machine cabinet can be installed in ground with 4pcs foundation bolts

Size marker mode diagram(4)

H H1 L L1 W W1 W2 D E A1 B1 C

Sepcification

back entering

line hole

AC60-T3-110G/132P

AC60-T3-132G/160P

AC60-T3-160G/185P

AC60-T3-185G/200P

AC60-T3-200G/220P

AC60-T3-220G/250P

1200 450 780 755 515 350 -- 340 ф11 486 200 ф9

1588 440 1188 1155 600 450 150 370 ф13 565 250 ф9

1748 550 1238 1205 700 580 220 380 ф15 665 250 ф9

20

In the table, H is the height of whole machine plus bottom section. The customers

can choose installation made according to demand. Cabinet, lean against the

well, or other installation mode are ok. And you can also choose hang-style

machine and bottom section which consist the cabinet machine installed directly

in installation slot or ground。

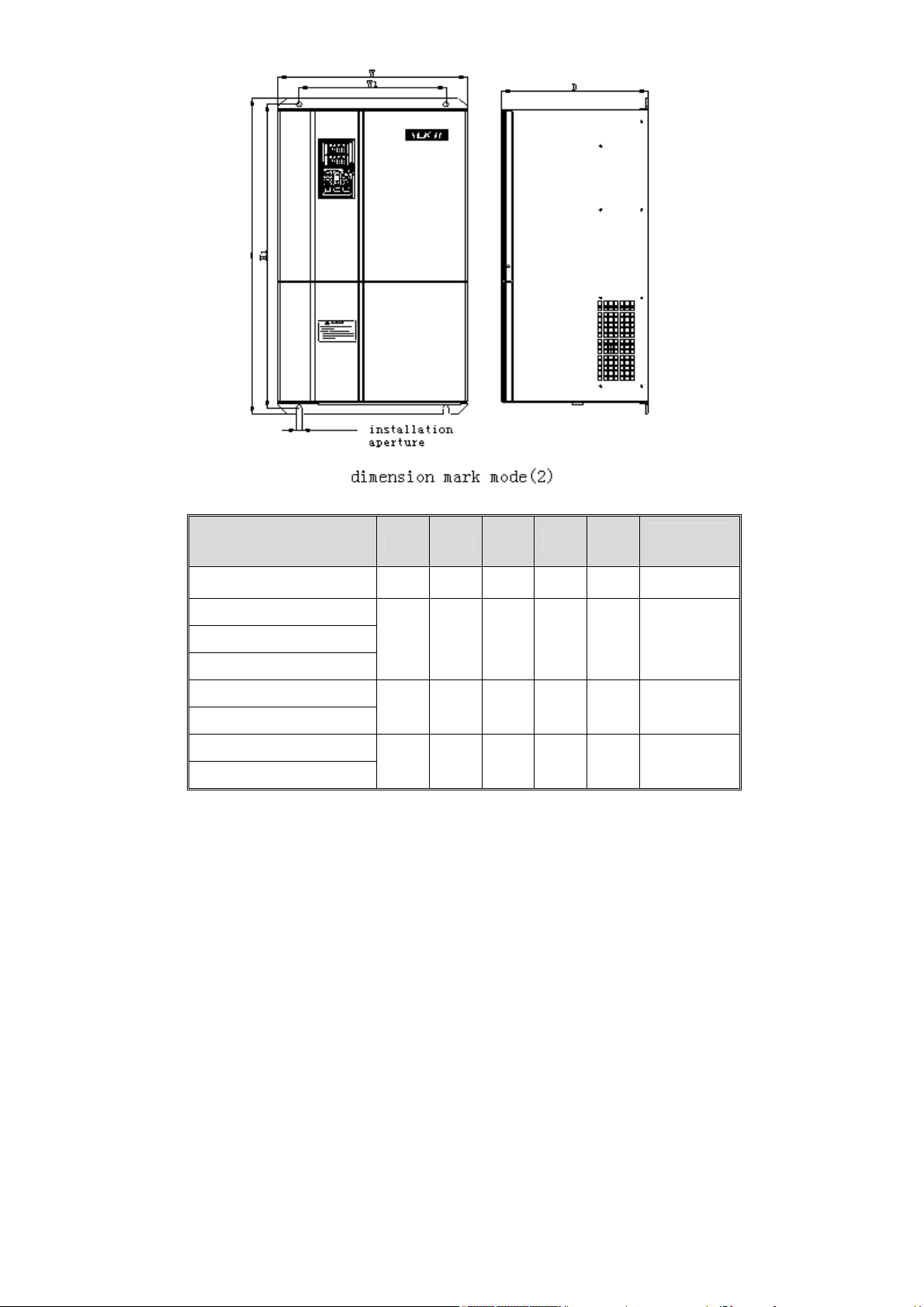

3.6.4 Cabinet-style machines installation size

Insta

Frequency inverter

G: Constant torque load

P: Fans&pump load

W W1 H L1 D

llati

on

apert

ure

AC60-T3-250G/280P

760 540 1700 270 485 ф13

AC60-T3-280G/315P

AC60-T3-315G/355P

AC60-T3-355G/400P

AC60-T3-400G/450P

AC60-T3-450G/500P

AC60-T3-500G/560P

AC60-T3-560G/630P

808 540 1800 270 485 ф13

1200 900 2200 320 550 ф13

21

3.7 Operation keyboard size

3.7.1. Single display keyboard size

56.7

35.1

17.5

17.1

54.2

86.7

3.7.2 Double display keyboard size

113.8

63.8

16

22.2

16

18.6

56.2

84.2

60.6

37

19

110.6

22

Chapter four Frequency Inverter Wiring

4.1 Wiring attentions

1. Wiring job can only be done by qualified professional personnel.

2. Before open the machine, make sure the power is safely cut off more than

10 minutes, otherwise there is a danger of shocking.

3.Absolutely prohibit the power input terminals to be connected to the

frequency inverter U, V or W output terminals;Absolutely prohibit short

circuit between the frequency inverter output terminals;Absolutely

prohibit the short circuit between the frequency inverter output

terminal and grounding terminal.

4. In order to minimize the impact of electromagnetic interference, when

the electromagnetic contactors and relays is very close to inverter,

you should consider the installation of surge absorption device.

5. When the peripheral equipment(filter 、 reactor)of inverter are

installed, the first step is use the 1,000 volts MΩ megger to measure

the grounding insulation resistance to ensure it not less than 4 MΩ.

6. Can not install the progressive phase capacitance and

resistor-capacitor absorbing device in the frequency inverter U, V, W

output terminal because the frequency inverter’ voltage output is PWM

pulse wave. If there is capacity which can improve power factor or

pressure-sensitive resistance which used for thunder-proof in the

voltage output side, the frequency inverter will break off or its parts

will be damaged, so it is necessary to dismantle them.

7. In order to reduce the leakage current of the earth, the motor cables

should be as short as possible. When the carrier frequency is less than

3KHz, the largest distance between frequency inverter and motor should

be less than 50 meters; When the carrier frequency is greater than 4KHz,

you should appropriately reduce this distance; In order to restrain

23

interference of the frequency inverter output side to the other equipment,

you have better to install a special noise filter at the output side of

the frequency inverter and lay the output cables through the metal tubes.

8. If the frequency inverter need to frequently start, do not cut off the

power, you should operate it through the control terminals (COM / F W D.

REV) or keyboard.

9. As analog signals are very easily to be interfered, isolation device

or shield lines are needed for the external control wires of the

inverter and the ground terminals of shield lines are needed to be

connected to the metal closet(ground terminals) of the inverter.

10. Control cables、power cables should be separated from the motor cables.

Generally there should be a sufficient distance between them,

especially between the parallel cables that extend for long distance;

When signal cables have to pass through the power cables, they should

be orthogonal crossing.

11. Main circuit wiring and wire diameter specifications have to be in

accordance with national laws.

12. Pls switch motor or switch power after inverter stop output.

13. While dismantle or change motor, you must cut off the input power of

inverter.

14. In order to avoid accidents, ground terminal E or 〨 must be reliable

grounding (grounding impedance should below 10 Ω). Otherwise there is

a risk of leakage current. For frequency inverter ground point, you

should best adopt the special ground pole. You can also use the share

ground pole, but never use tandem ground line.

15.Pls do not change three phase frequency inverter input into two phase.

Otherwise there may be malfunction. If you have only two-phase power,

please choose single-phase power frequency inverter.

16.The frequency inverter can't be used in the occasions where voltage of

24

power grid excesses the enable input voltage. If the power grid voltage

excesses the inverter voltage limit, please supply power to frequency

inverter with transformer.

17. The wire length between the frequency inverter and the braking unit

should not exceed five meters; The wire length between braking unit and

braking resistance should not exceed 5 meters.

18.If the frequency inverter output terminals drive inductive loads, such

as electromagnetic relays, contactors, etc., surge voltage absorption

circuit should be added, such as RC absorption circuit(be careful that

the leakage current should be lower than the control electromagnetic

relays or contactor' hold current),pressure-sensitive resistance or

freewheel diode(be used in DC electromagnetism circuit, but the polarity

of the freewheel must be paid attention to).The absorption circuit

components must be as close to the relays or winding of the contactor

as possible; Shown as below:

4.2 Basic wiring diagram

The following diagram includs two parts:the main circuit and control

circuit.

25

26

Loading...

Loading...