Veichi SI10 User Manual

Version V1 4 in Year 2015: .

Solar Pump Controller Manual

1

Chapter 1: Safety Requirement and Cautions

To ensure safety of your health, equipment and property, please read this chapter carefully

before use the frequency inverter and act in compliance with the instructions while carrying,

installing, debugging, running and overhauling the frequency inverter.

1.1 Safety definition

Danger: it will cause danger of serious injuries and even death while operating against the

rules

Caution: it will cause danger of light injuries or equipment destruction while operating

against the rules

Note: some information is useful while operating and use frequency inverter.

1.2 Safety requirements and cautions

●Before installation

Danger

1. Only qualified personnel can operate the equipment. Before operating, be sure to carefully

read the manual about safety, installation, operation and maintenance. The safe operation

depends on the proper processes of choosing models, carrying, installation, operation and

maintenance.

Danger

1. Don’t use the damaged or incomplete frequency inverters; Otherwise, there is risk of injury.

●Installation

Danger

2. Please install the frequency inverter on metal or other nonflammable material, and keep it

away from the combustible material. Otherwise there is danger of fire;

3. No unauthorized modification to the frequency inverter; Otherwise there is danger of

damaged.

4. Normal frequency inverter, which is not explosion-proof, can not be installed where with

explosive gas or dust; Otherwise there is danger of explosion.

Attention

1. When two frequency inverters are installed in the same control cabinet, pleas pay attention to

the installing place to guarantee the effective heat dissipation.

2. When carrying the frequency inverter,please support its bottom.

Solar Pump Controller Manual

2

●Wiring

Danger

1. Wire is connected only when the main circuit is cut off, otherwise there is a danger of shock.

2. Wire is connected by professional person only. Otherwise there is a danger of shock.

3. Earth must be reliable. Otherwise there is a danger of shock.

4. AC power supply should not be connected with output ports U, V, W, otherwise there is a

danger of damage to frequency inverter.

5. No drop of bolt, spacer, metal stick, conducting wire or other things into the inner of

frequency inverter; Otherwise there is a danger of fire or damage to frequency inverter.

Attention

1. If the damage to frequency inverter or other equipment is caused by improper wiring and

utilization or unauthorized alteration, the user should shoulder all responsibilities.

2. Please make sure all wirings meet EMC requirement and satisfy safety standard in the local

area; Please refer to recommendations in this manual or national standards of wire diameter

to avoid accidents.

3. Static electricity on human body would seriously damage internal MOS transistor, etc. No

touch the printed circuit boards, IGBT or other internal devices without anti-static measure,

otherwise it will cause the malfunction of frequency inverter.

4. Please don't connect phase shifter capacitance or LC/RC noise filter to the output circuit of

frequency inverter; Otherwise it will damage the frequency inverter.

5. Please don't connect the magnetic switch or magnetic contactor to the output circuit of

frequency inverter; When frequency inverter is in the operation with load, magnetic switch or

magnetic contactor can make inverter over-current protection function act. It will damage

frequency inverter seriously.

6. Please don't disassemble the panel cover, it only needs to disassemble the terminal cover

when wiring.

7. It is forbidden to do any pressure test on frequency inverter, otherwise it will damage the

frequency inverter.

●Before electrification

Danger

1. Please make sure that voltage grade of power supply is consistent with frequency inverter's

voltage and then check whether the wiring is correct and firm, and whether there is short

circuit in peripheral equipment's circuit. Otherwise it will damage frequency inverter and other

equipments.

2. Before the frequency inverter is connected to the input power supply, make sure that the

cover has been fixed well. Otherwise it will cause electric shock.

3. For the frequency inverters whose storage time is over 1 year, when electrification, the

Solar Pump Controller Manual

3

voltage should be raised by booster from low to high. Otherwise it will damage the frequency

inverter.

Attention

1. Check all periphery fittings are wired properly according to the handbook; Otherwise it will

cause accidents.

●After electrification

Danger

1. After electrified, it is forbidden to open the cover, make wiring, and check up; Otherwise, it will

cause the danger of electric shock.

2. After electrified, it is forbidden to contact internal wiring board and its parts. Otherwise it will

cause the danger of electric shock.

3. Do not operate or touch frequency inverter with wet hand. Otherwise there is danger of

damage to frequency inverter and electric shock.

Attention

1. Please set the parameter of frequency inverter cautiously; Otherwise it will damage

equipment.

●Operation

Danger

1. Before running, please check and confirm the application range of the machine and

equipments once more; Otherwise it will cause accidents.

2. Please don't touch the cooling fan and braking resistance to check the temperature;

Otherwise there is a danger of getting burn.

3. Unprofessional workers are banned to check the signals in the running stage; Otherwise it

will cause injuries and damage the equipment.

Attention

1. Please don't turn off the equipment by switching off power; Please cut off the power supply

after the electric machine stops running; Otherwise it will damage the frequency inverter.

2. Please avoid anything dropping into the equipment when the frequency inverter is running;

Otherwise it will cause electric shock.

●Maintenance

Danger

1. Please don't maintain and repair the equipment with electric; Otherwise it will cause electric

shock.

2. Before maintaining and repairing the frequency inverter, please make sure the indicator lights

of power supply have completely turned off; Otherwise it may cause electric shock and

damage the frequency inverter.

Solar Pump Controller Manual

4

3. Persons who have not passed specialized train are not allowed to conduct the frequency

inverter maintenance; Otherwise it may cause electric shock and damage the frequency

inverter.

1.3 Cautions in utilization

1. In application of this series frequency inverter, you have to confirm all machine insulation to

prevent damage to the equipment. Moreover, when the motor working in tough environment,

please periodic inspect the electrical insulation to ensure the safety of the system work.

2. If the motor adapter is not consistent with frequency inverter's rating current (The rating current

of the motor is far smaller than that of frequency inverter), please adjust the protective value to

ensure safe running.

3. In occasions such as load raising, usually there is negative torque and frequency inverter

breaks off for over-current or over-voltage. In this case, you should consider to choose the

matching brake unit.

4. Frequency inverter, in a certain output frequency range, can meet the mechanical resonance of

the load equipment. To avoid it, you can set up jumping frequency.

5. As output voltage of the inverter is pulse-wave type, if there is capacity which can improve

power factor or pressure-sensitive resistance which used for thunder-proof in the voltage

output side, the frequency inverter will break off or its parts will be damaged, so it is necessary

to dismantle them. Moreover, it is proposed not install switch parts like air switch and contactor

(if it is necessary to install switch on output side, please make sure the output electricity of

frequency inverter is zero when the switch is working)

6. At over 1,000 meters altitude, the inverter’s heat dissipation function worsened due to the thin

air, it is necessary to use less.

7. The inverter output voltage is pulse wave type. If using digital multimeter measurement,

deviation of the reading will be great. And the deviation is different by using different type of

digital multimeter. Under normal circumstances, while RMS 380V, digital multimeter reading is

around 450V.

8. Solar panel: many panels string or parallel. For rated voltage 380V controller, we suggest

working voltage between 480V to 560V while MPPT. What means the solar panel open circuit

voltage between 600V to 700V.

Solar Pump Controller Manual

5

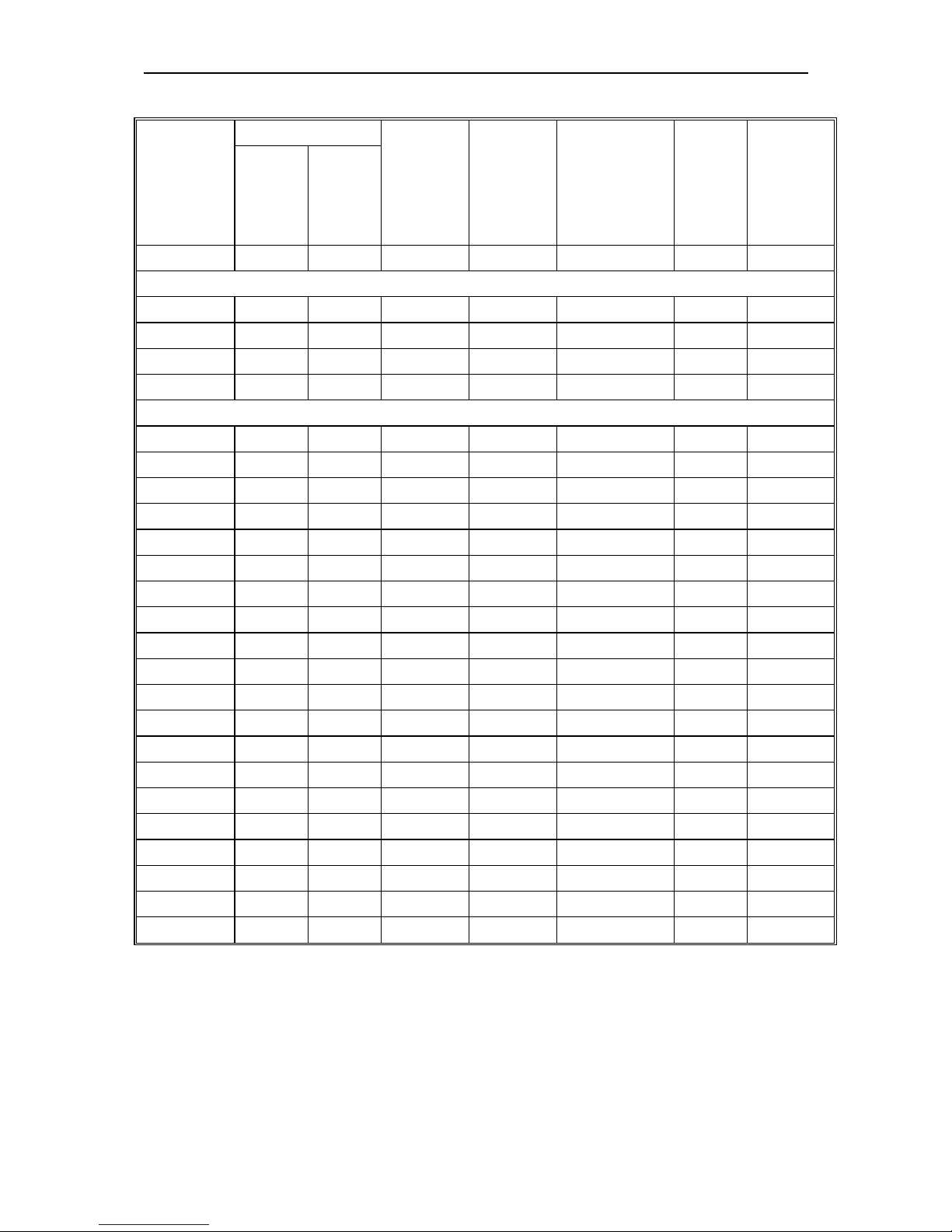

Technical Specification

Solar

pump

controller

power(KW)

Pump motor Max

solar

power

input

(KW)

Max DC

input

voltage V

Recommend

MPPT

voltage (V)

Rated

output

current

(A)

Output

frequenc

y(Hz)

Rated

motor

(KW)

Rated

voltage

(V)

0.75/1.5 0.75/1.5

100-330

1.95 350 100~350 10A 0-60

0.75 0.75 220 1.0 400 220~400 4A 0-60

1.5 1.5 220 1.95 400 220~400 7A 0-60

2.2 2.2 220 2.86 400 220~400 10A 0-60

3.7 3.7 220 4.81 400 220~400 17A 0-60

1.5 1.5 380 2.2 780 480~560 3.7 0-60

2.2 2.2 380 3.3 780 480~560 5.0 0-60

3.7 3.7 380 5 780 480~560 8.5 0-60

5.5 5.5 380 8 780 480~560 13 0-60

7.5 7.5* 380 10 780 480~560 17 0-60

11 11* 380 14.3 780 480~560 25 0-60

15 15 380 19.5 780 480~560 32 0-60

18.5 18.5 380 23.4 780 480~560 38 0-60

22 22 380 28.6 780 480~560 45 0-60

30 30 380 39 780 480~560 60 0-60

37 37 380 48.1 780 480~560 75 0-60

45 45 380 58.5 780 480~560 90 0-60

55 55 380 71.5 780 480~560 110 0-60

75 75 380 97.5 780 480~560 150 0-60

93 93 380 120.9 780 480~560 180 0-60

110 110 380 143 780 480~560 210 0-60

132 132 380 171.6 780 480~560 250 0-60

160 160 380 208 780 480~560 310 0-60

185 185 380 240.5 780 480~560 340 0-60

200 200 380 260 780 480~560 380 0-60

1.4 Cautions in disposal

When you dispose frequency inverter, please pay attention to:

1. Electrolytic capacitor: the electrolytic capacitor of main circuit or the printing plate may explode

when they are burned.

2. Plastic: plastic incineration may generate toxic gases.

3. Dispose method: please dispose as industrial waste.

Solar Pump Controller Manual

6

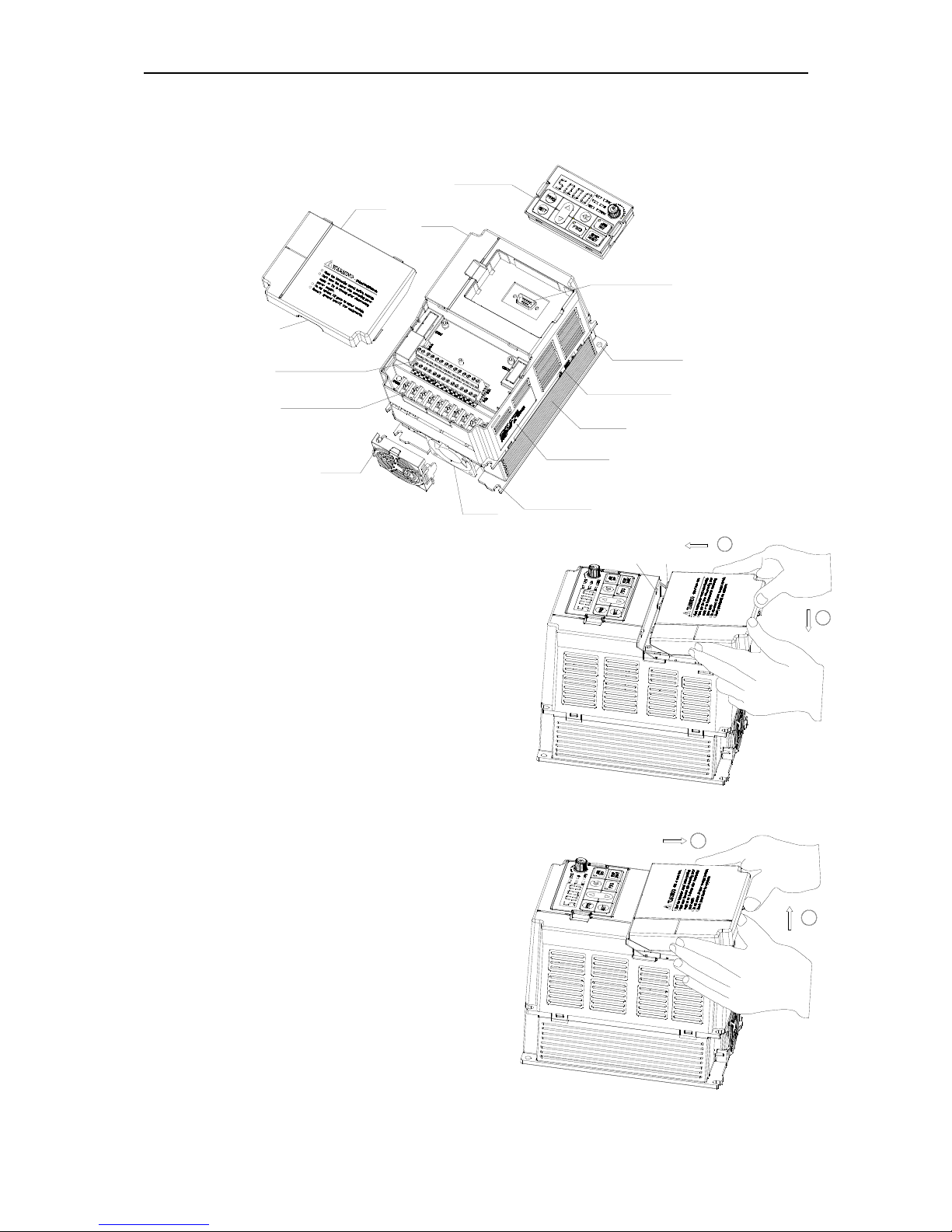

Chapter 2: Installation

2.1 Products appearance and components titles

operation panel

Tail-hood

pre-cover

keyboard terminal

installation hole

label

air cooler

nameplate

fan cover

support

fan

control loop terminal

main loop terminal

hold hole

2.2

Dismantle and install tail-hood

Installation: First the tail-hood upwardly inclines

around 15 degrees and inserts the top fixed flat

into the fixed hole in the front cover. Then slightly

press the tail-hood downward. While your hear "Ka",

it means that the tail-hood is into the place.

Dismantlement: At the tail of the frequency inverter,

there is a special dismantlement hole design. Put

your fingers into the hole, upwardly pull the cover

with a little force until the buckle between the

tail-hood and the crust tear off, and then removed

tail-hood down.

2

1

tail-hood

stator

tail-hood

install hole

2

1

Solar Pump Controller Manual

7

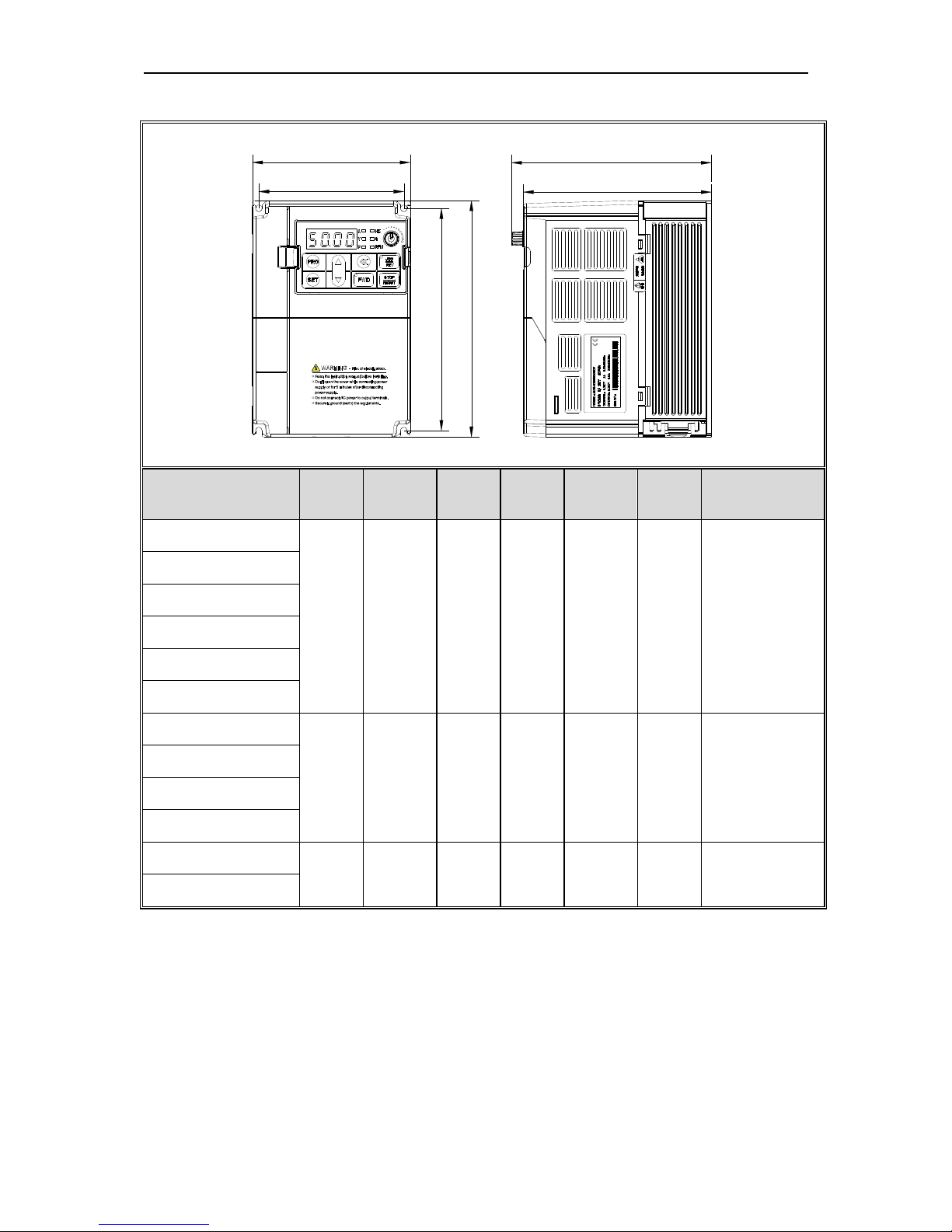

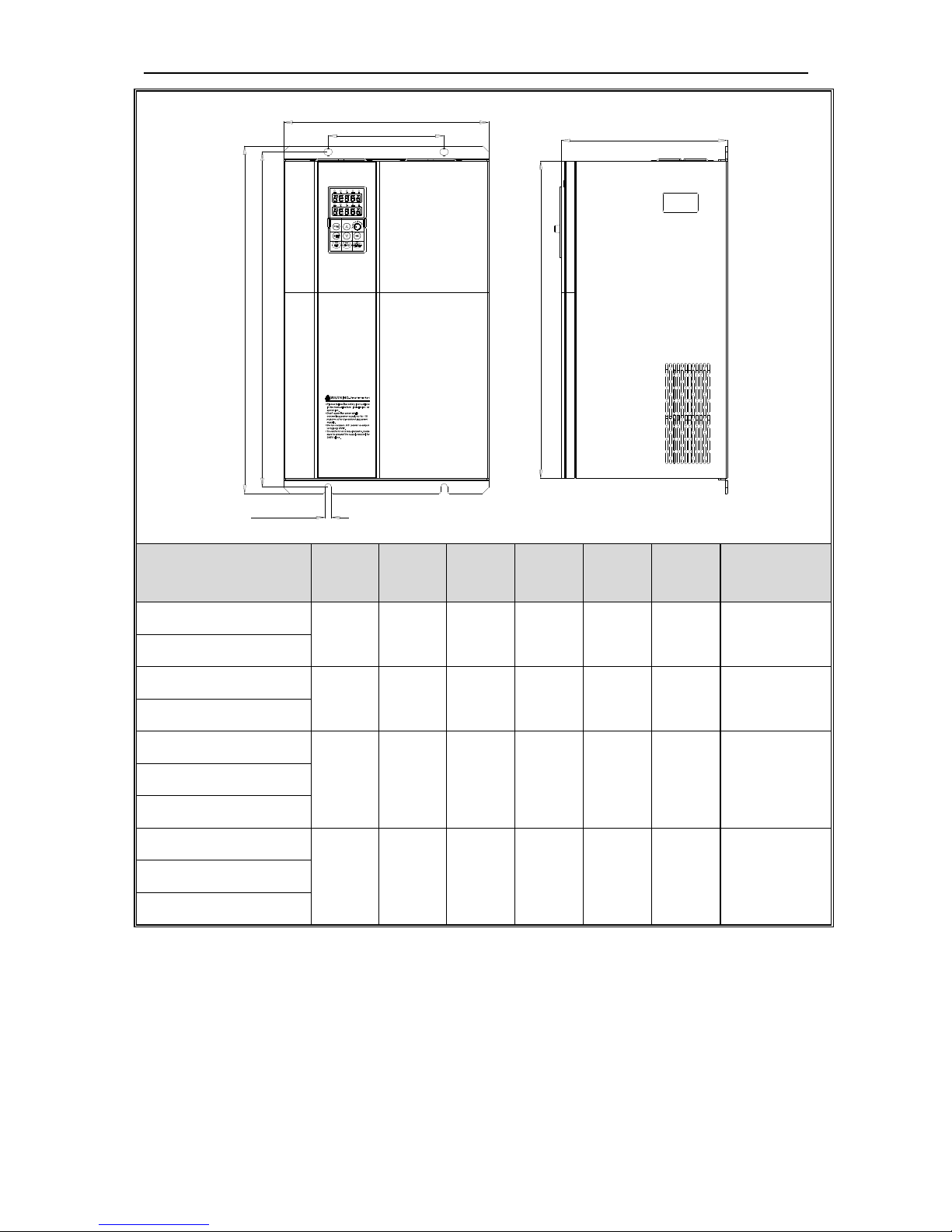

2.3 Installation size(units: mm)

D

D1

H

H1

W

W1

Frequency

inverter

W W1 H H1 D D1

Installation

aperture

SI10-S2-R40G

122 112 182 171 154.5 145 ф5

SI10-S2-R75G

SI10-S2-1R5G

SI10-T3-R75G

SI100-T3-1R5G

SI10-T3-2R2G

SI10-D3-2R2G

159 147.2 246 236 157.5 148 ф5.5

SI10-D3-3R7G

SI10-D5-3R7G

SI10-D5-5R5G

SI10-D5-7R5G

195 179 291 275 167.5 158 ф7

SI10-D5-011G

*D3 stands for 3 phase 220V output with hardware MPPT.

*D5 stands for 3 phase 380V output with hardware MPPT.

Solar Pump Controller Manual

8

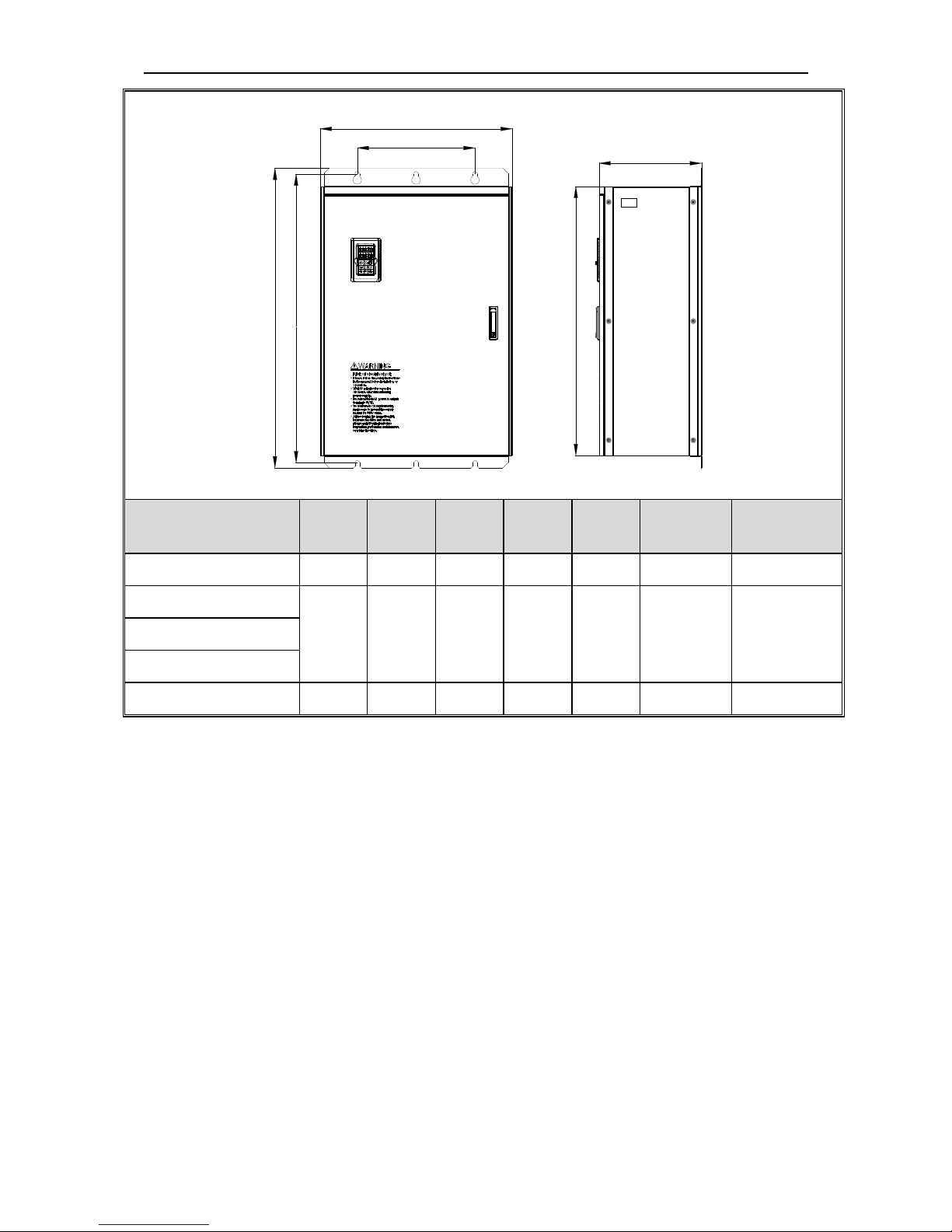

W

W1 D

H

H1

H2

Installation aperture

Frequency inverter

W H D H2 W1 H1

Installation

aperture

SI10-D5-015G

235 345 200 311 160 331.5

ф7

SI10-D5-018G

SI10-D5-022G

255 410 225 370 180 395 Ф7

SI10-D5-030G

SI10-D5-037G

305 570 260 522 180 550 Ф9

SI10-D5-045G

SI10-D5-055G

SI10-D5-075G

380 620 290 564 240 595 ф11

SI10-D5-093G

SI10-D5-110G

Solar Pump Controller Manual

9

H1

H

H2

D

W1

W

Frequency inverter

W H D H2 W1 H1

Installation

aperture

SI10-D5-132G 500 780 340 708 350 755 ф11

SI10-D5-160G

650 1060

400 950 400 1023 ф16

SI10-D5-185G

SI10-D5-200G

SI10-D5-220G 750 1170

400 1050

460 1128 ф18

Solar Pump Controller Manual

10

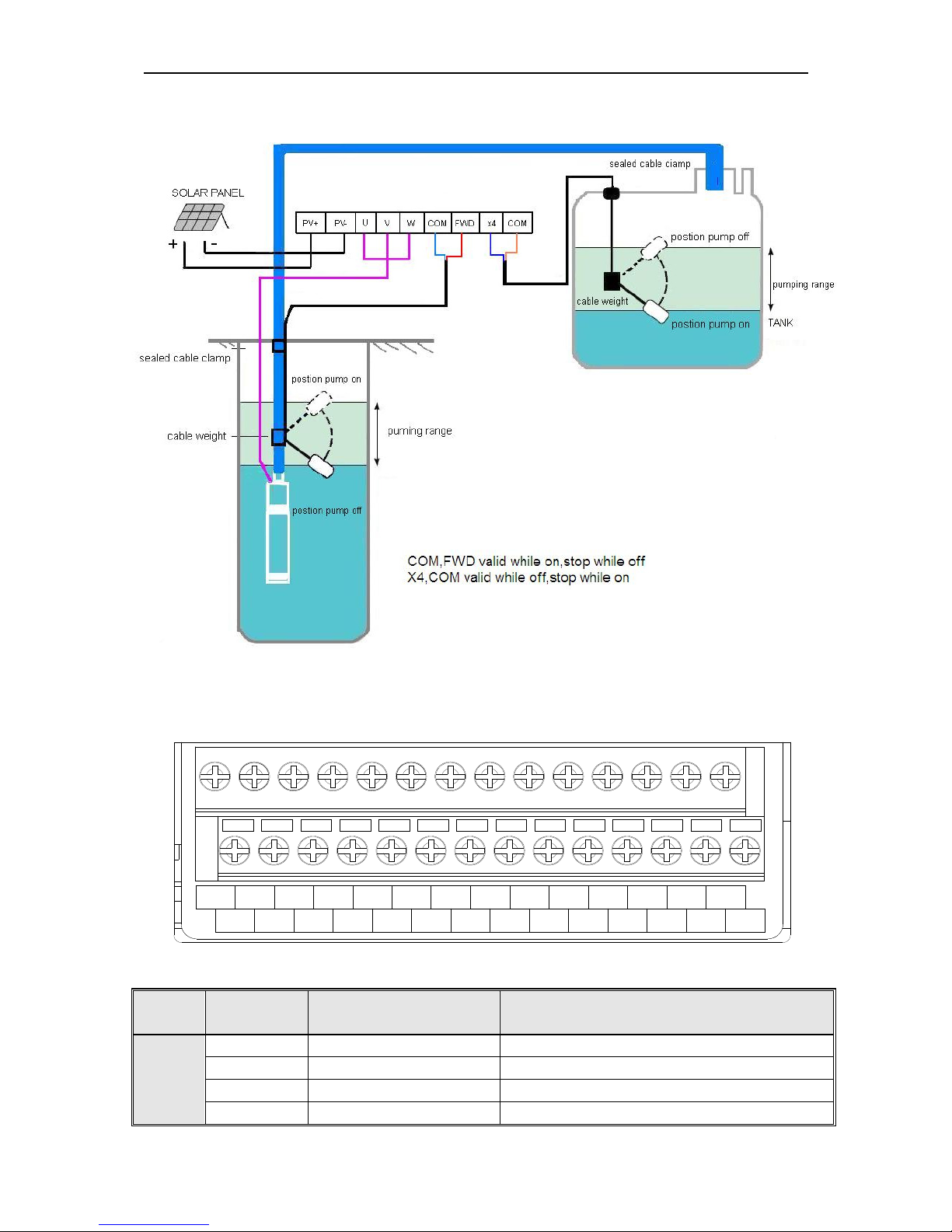

2.4 Solar pump controller wiring

The following diagram includs two parts:the main circuit and control circuit.

stand build-in RS485 module

for machine below 11G

-10V signal supply power

Grounding

Open set electrode output

Output signal 3

Output signal 2

max:50mA

max:50mA

communication

RS485

A+

B-

COM

Y2

Y1

COM

Open set electrode output

GND

A02

F-62 Selection output

Analog input

signal

+10V signal supply power

-10V

GND

Pulse frequency

PUL

REV

REV

X5

Electrical machine

M

V

W

U

Analog quantity output

10VDC-1mA DC voltage

2A/30VDC

3A/250VAC

Auxiliary power

Output signal 1(relay)

24VDC-200mA

PB

N(-)

P1

MCCB

S

T

R

A01

X1

X2

X3

GND

X4

COM

X6

E

FWD

Solar

DC

input

multi-function

input terminal

FWD

TC

TA

TB

+10V

VS2

VS1

+24

AS

COM

main circuit terminal

V

-10V-+10V

4-20mA

cotrol circuit terminal

Earth

Solar Pump Controller Manual

11

Solar pump controller wiring

2.5Control circuit terminals

2.5.1 Sequence of control terminals

TC TA

+24

COM REV

TB Y1 Y2

X2

X1

X3

X4

X5

X6

COM

PUL

GND

AO1 AO2

VS1

VS2

AS

+10V

-10V

GND

A+

B-

FWD

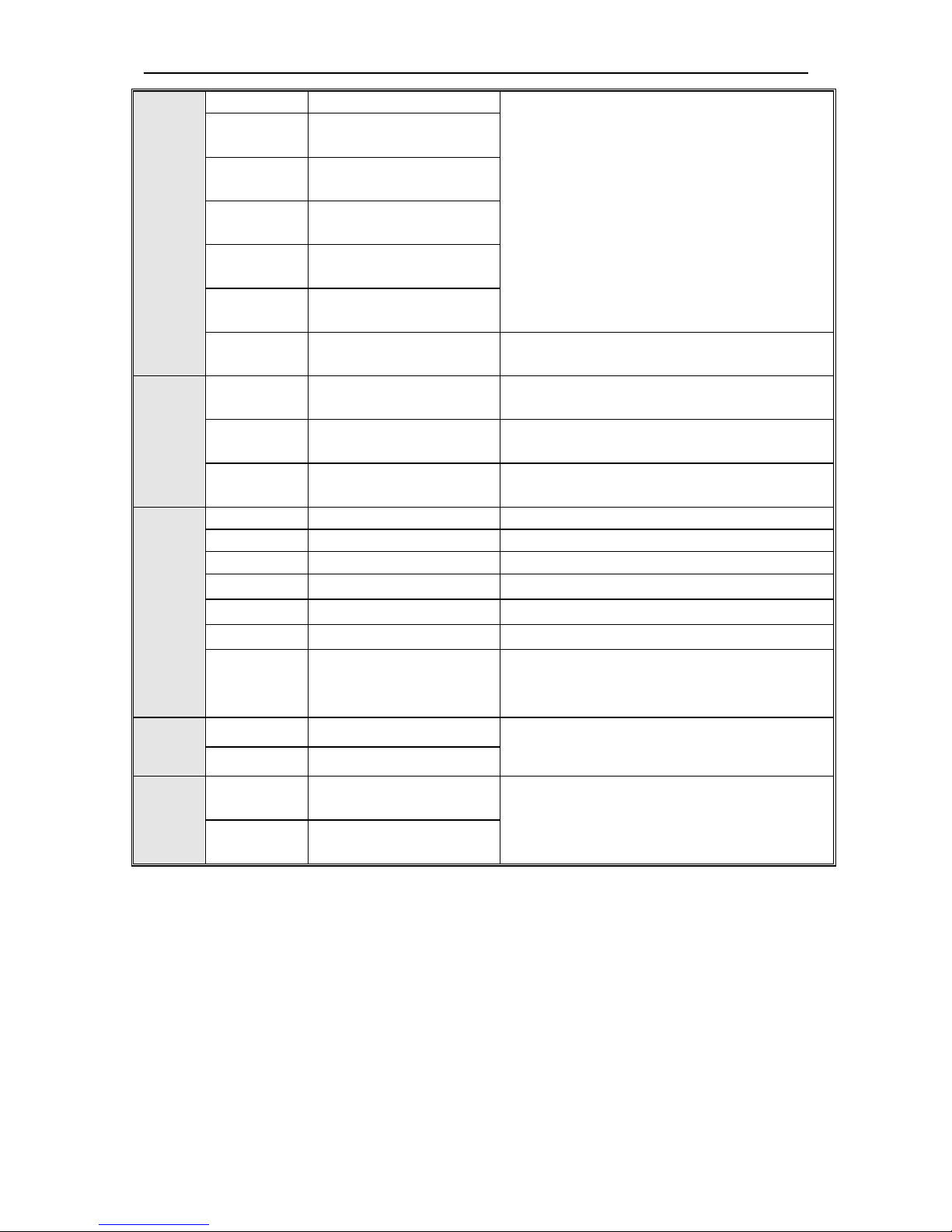

2.5.2 Control terminals menu

Categ

ory

Terminal name Function

Control

signal

COM Common terminal

FWD Forward turn command

Short connect with (COM)is workable

REV Reverse turn command

Short connect with (COM)is workable

X1 Multifunction input Short connect with (COM) is workable

Solar Pump Controller Manual

12

terminalsX1

Multifunction input terminals, please refer to

parameters[F-01~F-06]to set the definitions

by program.

X2

Multifunction input

terminalsX2

X3

Multifunction input

terminalsX3

X4

Multifunction input

terminalsX4

X5

Multifunction input

terminalsX5

X6

Multifunction input

terminalsX6

PUL

Pulse frequency input

signal

0KHz-50KHz, Amplitude 8~24V.

Output

signal

TA,TB,TC Output signal 1

(TA-TC)Normally open, (TB-TC) Normally

close (programmable setting motion targets).

Y1 Output signal 2

Open collector output, programmable setting

motion targets. Max output DC24V/50mA.

Y2 Output signal 3

Open collector output, programmable setting

motion targets. Max output DC24V/50mA.

Analog

output

& input

signal

GND

Output common terminal 3

+10V Signal power

Maximum output +10V/50mA.

-10V Signal power

Maximum output -10V/50mA.

VS2 Voltage input signal

(VS2)terminal -10V~10V.

AS Voltage input signal

(AS)terminal 4~20mA .

A01 Analog output signal 1

(A01)terminal 0V~10V.

A02 Output signal 2

0V~10V, 0V~20mA, 4~20mA, frequency

pulse output, By choices of [F-62] and the

terminal jumper J1, J2 and J3.

Auxiliar

y

power

+24 Power anode terminals

Maximum output 24V/200mA.

COM Common terminal

Comm

unicati

on

A+

Communication

Interface

RS485 Communication Interface.

B-

Communication

Interface

Loading...

Loading...