Veichi AC70-T3-R75G/1R5P, AC70-T3-7R5G/011P, AC70-T3-018G/022P, AC70-T3-015G/018P, AC70-T3-022G/030P User Manual

...

Contents

Chapter1 Overview .............................................................................................................................................. 1

1.1 Safety Requirement and Cautions ............................................................................................................ 1

1.2 Technical Criterion ..................................................................................................................................... 4

Chapter 2 Before Use .......................................................................................................................................... 7

2.1 Purchase Inspection .................................................................................................................................. 7

2.2 Nameplate ................................................................................................................................................. 7

2.3 Rated Output Current ................................................................................................................................ 8

Chapter 3 Installation and Wiring ...................................................................................................................... 9

3.1 Safety Precautions .................................................................................................................................... 9

3.2 Treatment for Inverter after Longtime Store .............................................................................................. 9

3.3 Inverter Stable Running Environment ..................................................................................................... 10

3.4 EMI Protection ......................................................................................................................................... 11

3.5 Machinery Installation .............................................................................................................................. 13

3.6 Electric Installation ................................................................................................................................... 22

Chapter 4 Basic Operation and Trial Run ....................................................................................................... 37

4.1 Safety Precautions .................................................................................................................................. 37

4.2 Keyboard Layout and Function Specification .......................................................................................... 38

4.3 Basic Operation ....................................................................................................................................... 40

4.4 Trial Run .................................................................................................................................................. 45

Chapter 5 Fault Diagnoses and Processing ................................................................................................... 50

5.1 Fault Types .............................................................................................................................................. 50

5.2 Fault Information and Details .................................................................................................................. 50

5.3 Fault Diagnoses Process ........................................................................................................................ 54

Chapter 6 Periodic Overhaul and Maintenance ............................................................................................. 60

6.1 Safety Precautions .................................................................................................................................. 60

6.2 Overhaul .................................................................................................................................................. 60

6.3 Maintenance ............................................................................................................................................ 61

Chapter 7 Peripheral Equipments and Options ............................................................................................. 64

7.1 Safety Precautions .................................................................................................................................. 64

7.2 Peripheral Equipments ............................................................................................................................ 64

7.3 The Use of Peripheral Equipments ......................................................................................................... 66

Chapter 8 Function Parameter Specification ................................................................................................. 69

8.1 Basic Parameters Specification .............................................................................................................. 69

8.2 External Terminal Parameters................................................................................................................. 93

8.3

.Special Function Parameters ............................................................................................................... 108

Chapter 9 Appendix ......................................................................................................................................... 119

9.1 Appendix 1: Function Code Simple List ................................................................................................ 11 9

9.2 Appendix 2: RS485 Communication Protocol ....................................................................................... 135

9.3 Appendix 3: LCD Keyboard Manual ...................................................................................................... 141

AC70 VC CONTROL FREQUENCY INVERTER MANUAL OVERVIEW

1

Chapter 1 Overview

Thanks for using AC70 series sensorless vector control frequency inverter produced by Veichi Electric co.,ltd. This

manual introduces you how to use it perfectly. Please read this manual carefully and fully understand the safety

requirement and cautions before use (installation, wiring, operation, maintain, checking, and etc...).

1.1 Safety Requirement and Cautions

Pls do totally understand this part before using the inverter.

Warning signs and meanings

This manual has used below signs that mean there is an important part of security. While observing against the rules,

there is danger of injury even death or machine system damage.

Danger: Wrong operation may cause death or large accident.

Warning: Wrong operation may cause death or large accident.

Caution: Wrong operation may cause minor wound.

Important: Wrong operation may cause the inverter and other machine system damage

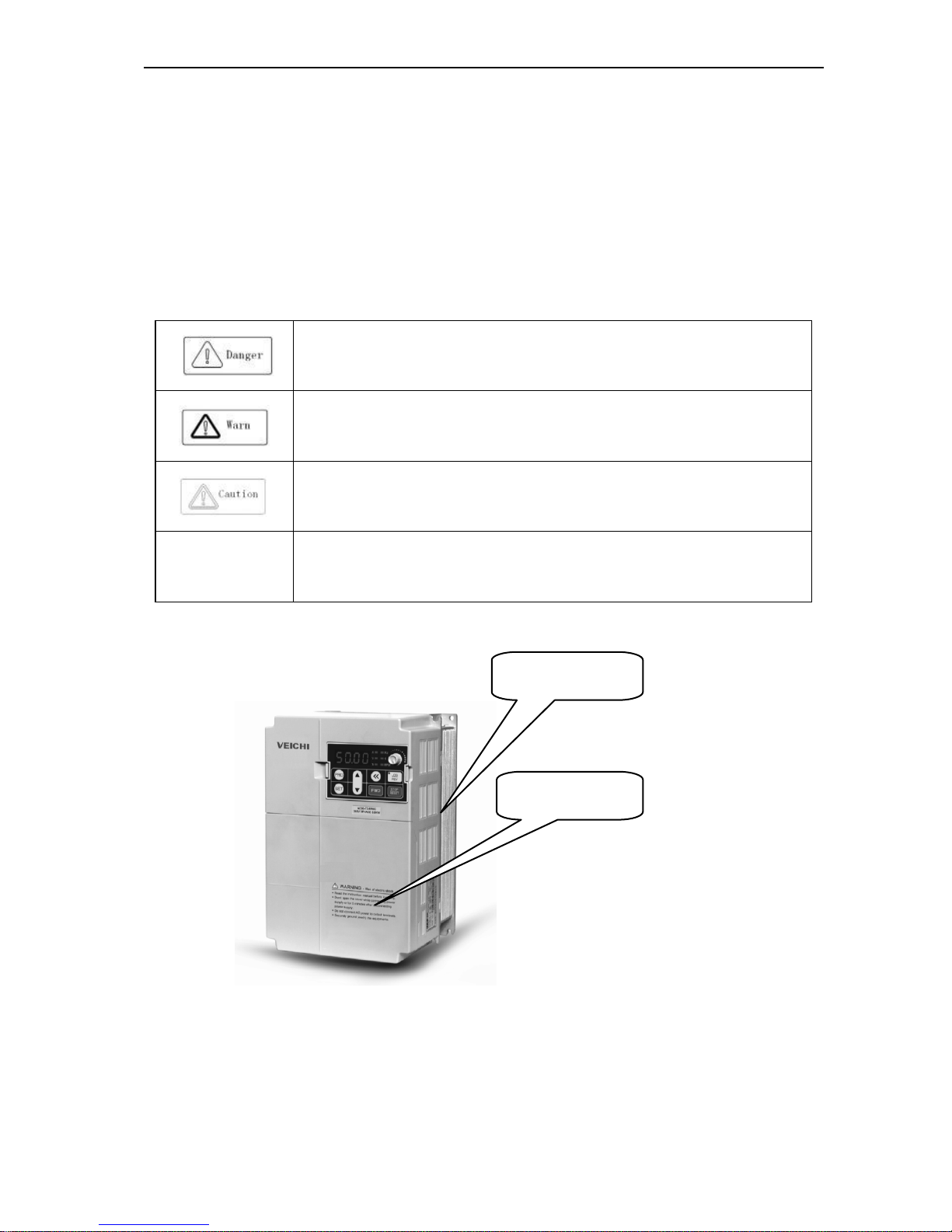

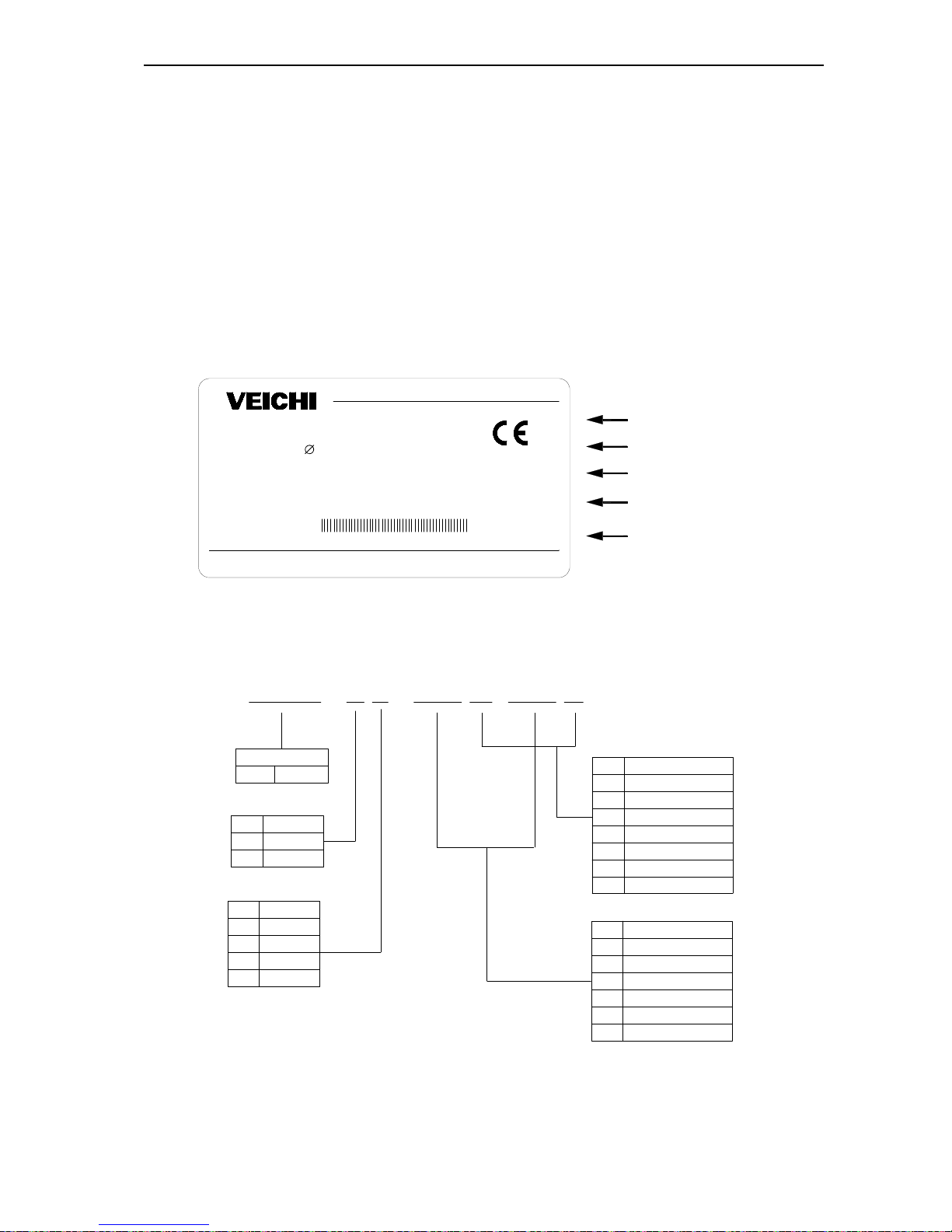

Warning signs position

Drawing 1:Warning positions on crust of AC70 series inverter

Warning position 2

Warning position 1

AC70 VC CONTROL FREQUENCY INVERTER MANUAL OVERVIEW

2

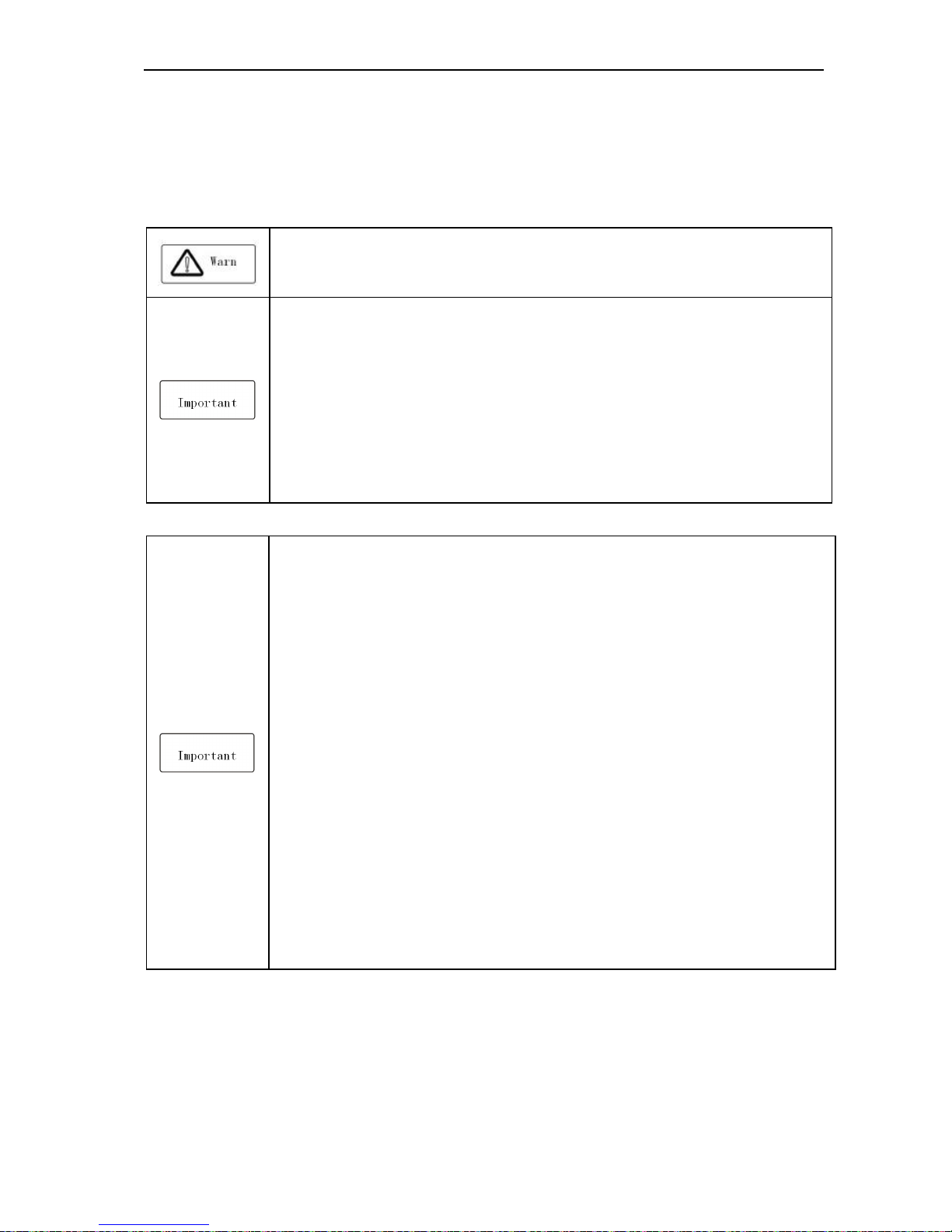

Operation requirement

Only Professional trained person are allowed to operate the equipment such as installation, wiring, running, maintain

and etc. “Professional trained person”in this manual means the workers on this product must experience professional

skill train, must be familiar with installation, wiring, running and maintain and can rightly deal with emergency cases in

use.

Safety guidance

Safety regulations and warning signs come for your security. They are measures to prevent the operator and machine

system from damage. Please carefully read this manual before using and strictly observe the warning signs while

operating. Safety regulations and warning signs are classified into: routine regulation, transport and store regulation,

installation and wiring regulation, running regulation, maintenance regulation, dismantlement and disposal regulation.

● Routine regulation

● This product carries dangerous voltage and controls driver machine with potential danger. If

you don’t abide by the regulations or requirements in this manual, there is danger of body

injury even death and machine system damage.

● Only qualified personnel are allowed to operate the equipment.this product. Before using, the

operator must be familiar with all safety specifications and operation regulations in this

manual. Safe and stable work of the product is based on right operation and maintenance.

● Do not wire while the power is connected. Otherwise, there is danger of death for electric

shock. Before wiring, inspection, maintenance, please cut power supply of all related

equipments and ensure mains DC voltage in safe range. And please operate it after 5 mins.

● Away from children and public.

● Only used in application fields as maker stated. No use in equipments related to special fields

such as emergency, succor, ship, medical treatment, aviation, nuclear and etc.

● Unauthorized alteration or use of accessories which are not sold or recommended by the

maker may cause faults.

● Please make sure this manual is in the final user’ hand before using.

● Before installation and debugging please carefully read and totally understand these safety

regulation and warning signs.

● Transport and store regulation

●Correct transport, store, installation and careful operation an maintenance are important for

inverter safe operation.

● In transport and store process, make sure the inverter is free from impact and vibration. It

must be stored where is dry without corrosive air and conductive dust, and the temperature

must be lower than 60℃.

● Installation and wiring regulation

● Only professional trained person can operate it.

● Power wire, motor wire and control wire should be all connected firmly. Earth must be reliable

and earth resistance must be lower than 10Ω.

● Before opening the inverter, please disconnect all related equipment power supply and make

sure the mains DC voltage is in safe range and operate after 5mins.

● Human body electrostatic will damage inner sensitive components seriously. Before

operation, please follow ESD measures. Otherwise, there is danger of inverter damage.

● Inverter output voltage is pulse wave. If components such as capacitor which improves power

factor and pressure-sensitive resistance for anti-thunder and so on are installed at the output

side, please dismantle them or change to input side.

AC70 VC CONTROL FREQUENCY INVERTER MANUAL OVERVIEW

3

● No switch components such as breaker and contactor at the output side. (If there must be

one, please make sure the output current is 0 while the switch acting).

● The power supply cable and motor cable specifications must satisfy all conditions in table 3-7

3-8 .

● Run regulation

● Inverter runs at high voltage. So dangerous voltage is in some components inevitably.

● No matter where the fault is, there is danger of serious accident, even human body injury

what means dangerous malfunction possibility. So there must be additional external prevent

measures or other safety devices, such as independent current limiting switch, machinery

and so on.

● Maintenance regulation

● Only Shenzhen Veichi Electric co., ltd service department or its authorized service center or

professional person trained and authorized by Veichi can maintain the products. They should

be very familiar with the safety warning and operation gist in this manual.

● Any defective components must be changed in time.

● Before opening the inverter to repair please cut power supply of all related equipments and

ensure mains DC voltage in safe range. And please do operation after 5 mins.

● Dismantlement and disposal regulation

● Packing case can be reused. Please keep them and reuse or send back to maker.

● Dismantled metal components are retractable and can be reused.

●

Some components such as electrolytic capacitor are harmful to environment. Please dispose

according to environmental protection departments.

AC70 VC CONTROL FREQUENCY INVERTER MANUAL OVERVIEW

4

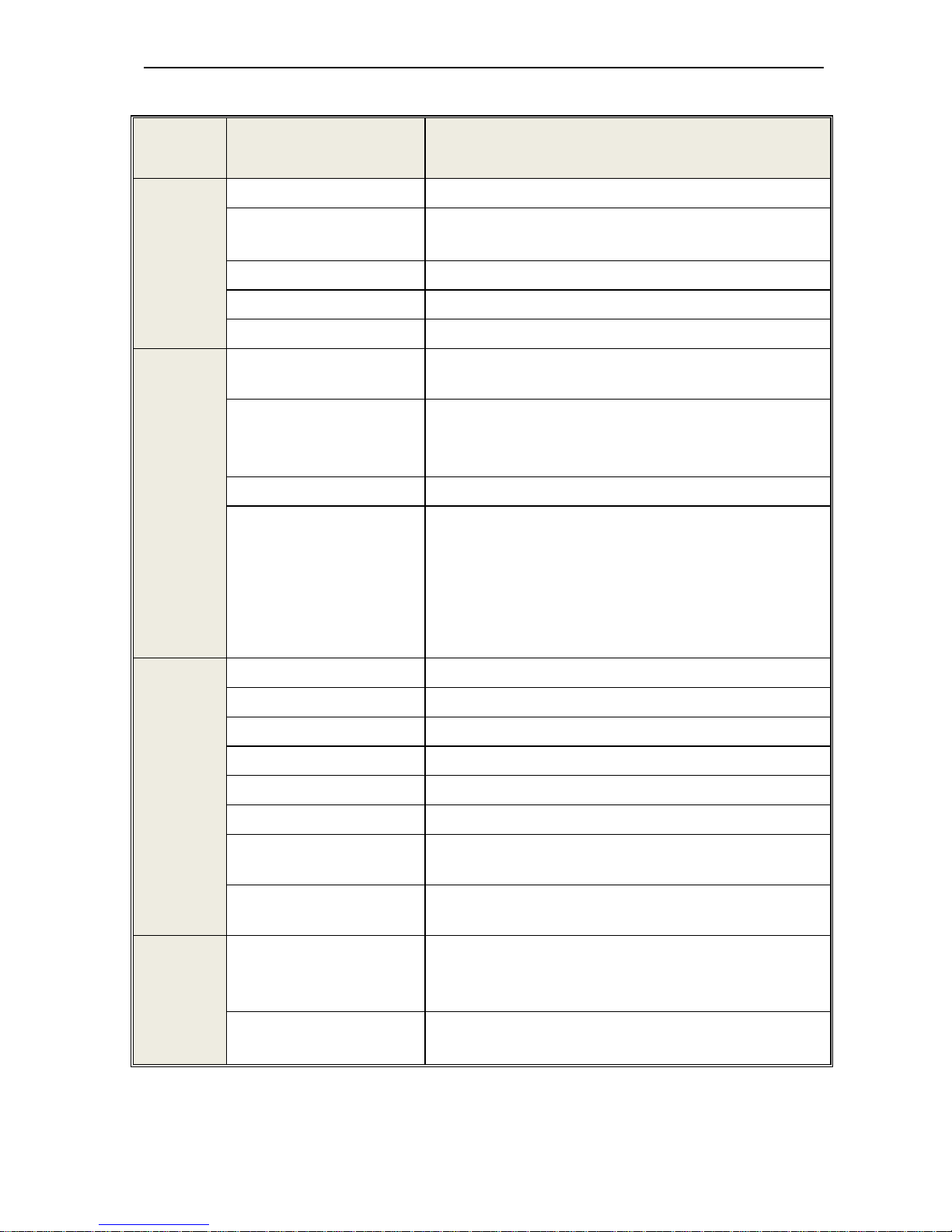

1.2 Technical Specification

Te ch .

Specification

Items Description

Power Input

Voltage, frequency single phase 220V, 3 phase, 220V,380V, 660V and 1140V

Allowable fluctuations

Voltage:<±15%; frequency±5%

Distortion of voltage to confirm to IEC61800-2

Closing striking current

less than rated current

Power Factor

≥0.94( integrated DC reactor)

Efficiency

≥96%

Power

Output

Output Voltage

3 Phase, 0~Input voltage, tolerance less than 5% in standard

rating condition

Frequency Control Range

G type: 0 to 400Hz, P type: 0-400Hz, Z type: 0-400Hz, L type:

0-400Hz,

H type: 0-3000Hz.

Output frequency accuracy

±5% of maximum frequency

Overload Tolerance

Z type: 150% rated current for 60 sec, 180% rated current for 30

sec, 250% rated current for instantaneous

G, H, L type model: 150% of rated output current for 60 sec,180% of

rated current for 10s, 2 00% of rated current for instantaneous

P type: 120% rated current 60 sec, 150% rated current for

instantaneous

Key Control

performance

Motor Control Mode Open loop sensorless vector control without PG, V/F control

Control system

Optimized Space Vector PWM Modulation

Carrier frequency

0.6~15kHz, Randomly-modulated carrier

Speed control range

OLV without PG with rated load: 1:100,

Stable speed control accuracy

OLV without PG: less than 1% rated synchronous speed

Torque response

OLV without PG control mode: ≤20ms

Frequency Accuracy

(Temperature Fluctuation)

Digital inputs: maximum × ±0.01%

Analog inputs: maximum × ± 0.2%

Frequency Setting Resolution

Digital inputs: 0.01 Hz

Analog inputs: 0.5% of maximum output frequency

Standard

Function

DC Braking

Starting Frequency: 0.00 to 50.00Hz,

Braking Time: 0.0 to 60.0s

Braking current: 0.0 to 150% rated current

Torque boost

Auto torque boost:0.0% to 100%

Manual torque boost: 0.0% to 25%

AC70 VC CONTROL FREQUENCY INVERTER MANUAL OVERVIEW

5

V/F curve

5 kinds curve programmable setting:1 user setting, 1 of linear

characteristic torque curve setting. 3 kinds derating torque

setting( 1.5 power, 1.7 power, 2.0 Power curve )

Accel / Decel. curve

Two kinds curve: line Accel/Decel, S curve Accel/Decel.

4 Aceel/Decel time unit is 0.1s, maximum time 6500.0s

Rated output voltage

Power voltage compensation is available, setting range from 50 to

100%( rated voltage), the output voltage can't over than input

AVR( Auto Voltage Regulation

automatic voltage regulation for keeping output voltage stable when

fluctuation of grid

Auto energy saving running

Optimized the output voltage according the load to achieve energy

saving

Auto current limit

Auto current limit during running mode to avoid trip occurs

frequently

Momentary Power Loss with

no stop running function

To achieve continuous running with regenerative enery and DC bus

voltage regulation when momentary power loss

Standard Function

PID control, Carrier frequency adjustable, current limiter, Speed

Search, Momentary Power Loss restart,8 Step Speed (max), 3-wire

Sequence, Slip Compensation, Frequency Jump, Upper/lower

Limits for Frequency Reference, DC Injection Braking at Start and

Stop, Energy Saving Control, Modbus Comm RS485, Fault Restart,

job function, Cooling Fan on/off Switch, timing stop, high pulse

output, programmable auto running, swing frequency, counter,

frequency arriving detect and frequency lever detect.

Frequency Setting Methods

Keypad digital setting, potentiometer of keypad, analog voltage

terminal VS1, analog voltage terminal VS2, analog current terminal

AS, RS485 communication and multiple terminal, main and auxiliary

composition setting.

Feedback Input Channel

voltage terminal VS1, VS2, current terminal AS, communication ,

and pulse input PUL

Running command channel keypad given, external terminal given, communication given

Input command signal

Start, Stop, FEW/Reverse, Job, Multiple speed, free stop, Reset,

Accel/Decel time, Frequency set point channel, External fault

Output signal

2 Photo coupler relays: 2 (24 V, up to 50 mA)

1 Contact relays: 1 (250 Vac/up to 1 A, 30 Vdc/up to 1 A)

0-10V output, 4 to 20mA output

Frequency pulse output

Protection function

Overvoltage, under voltage, current limit, over current, overload,

electric thermal relay, overheat, Stall prevention, parameter lock

AC70 VC CONTROL FREQUENCY INVERTER MANUAL OVERVIEW

6

keypad

Display

LED Display

One line digit-segments LED display to monitor 1 running status

Double line digit-segment display to monitor 1 running status

Parameters copy upload and download parameter code to achieve easy copy

Monitor Function

Output frequency, Frequency set point, Out current, Output voltage,

motor speed, PID feedback value, PID given setting, IGBT module

temperature, I/O terminal status.

Alarms

Overvoltage, under voltage, over current, short circuit, phase loss,

over load, over heat, stall prevention, current limit, parameter lock

damage, running status at present alarm, past trip alarm

Environment

Installation Site

Indoor, Altitude should less than 1000m, Free corrosive gases and

direct sunlight

Running Temperature,

humidity

-10~+40°C ( wall mounting),

20% to 95% RH (No condensation)

Vibration Less than 0.5g when frequency less than 20Hz

Storage Temperature -25—+65°C

Installation mode Wall-mounted mode, floor stand cabinet install

Protection Degree IP20

Cooling Method Forced air-cooling

Table 1: Technical Specification

AC70 VC CONTROL FREQUENCY INVERTER MANUAL BEFORE USE

7

Chapter 2 Before Use

2.1 Purchase Inspection

Pls check whether any package is damaged while receiving the product you ordered. If the package is ok, pls open it

and check the inverter. If damage caused in transport, it is not duty of Veichi company. But please contact Veichi or the

transport company immediately.

After checking the product, please also check if the model is the one you ordered.The model of the product is on the

nameplate “MODEL”column. If the model is not in accordance with your need, please contact the agent or the sales

departments in our company.

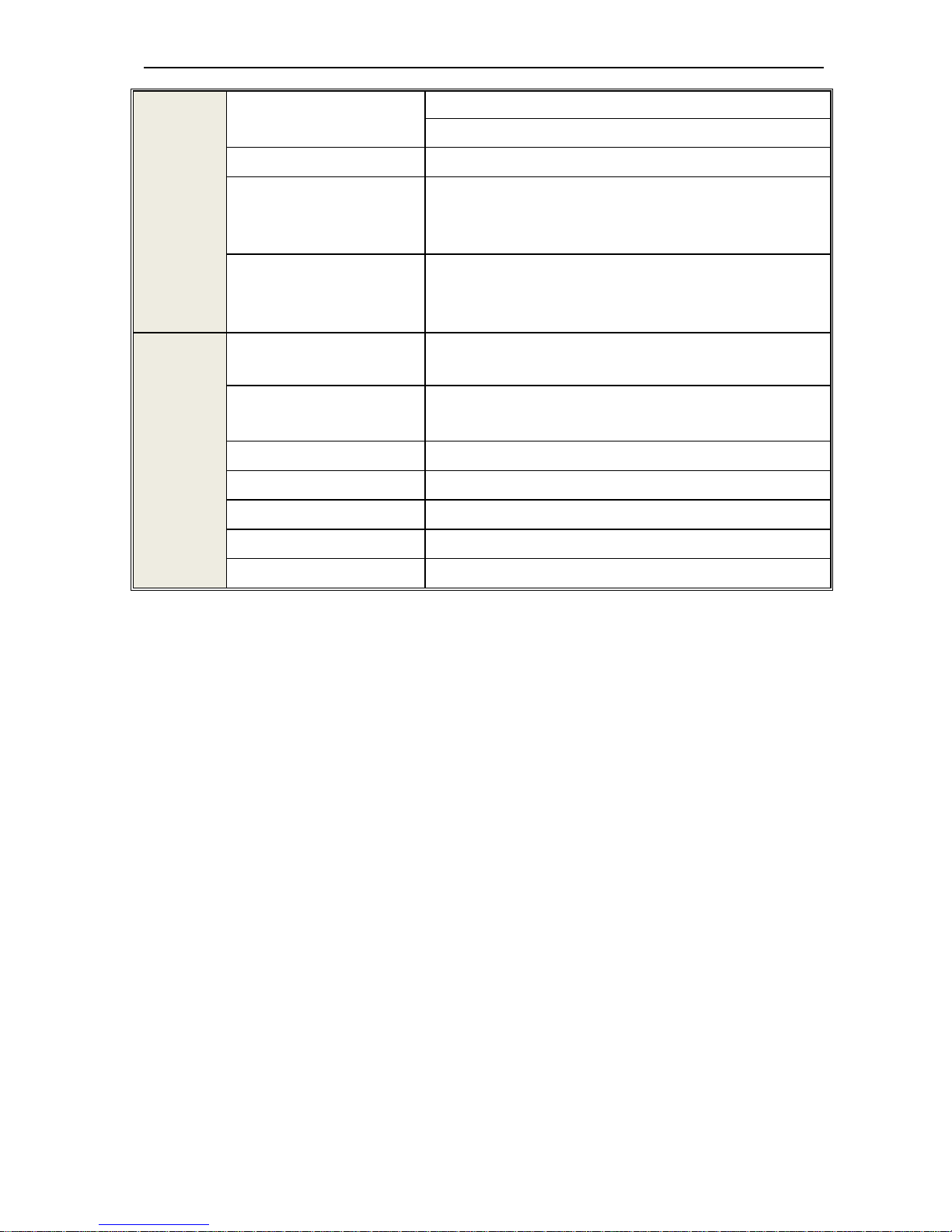

2.2 Nameplate

Nameplate position and content

MODEL: AC70-T3-011G/015P

SOURCE: 3

380V 50/60Hz

OUTPUT1

: 11KW 25A 0.00-400.0Hz

SER NO:

OUTPUT2

: 15KW 32A 0.00-400.0Hz

G models output

Model

P models output

Input power

Production series no

******************

Chart 2-1: AC70 series inverter nameplate

Model explanation

AC70 - T 3 - 011 G /015 P

2 220V

3 380V

6 660V

G

P

Z

7R5

011

015

7.5

11

15

018

022

030

18.5

22

30

L

11

1140V

H

AC70

GD

PD

Cabinet with base

Cabinet with base

code

voltage class

T

three phase

S

single phase

code

voltage class

code

inverter type

general format

blower and water pump

plastic machine

draw bench

mid inverter governor

code

fit power of motor(kW)

General use

inverter series

Chart 2-2: AC70series inverter nameplate meaning and naming rules

AC70 VC CONTROL FREQUENCY INVERTER MANUAL BEFORE USE

8

2.3 Rated Output Current

Input voltage 220V 380V 660V 1140V

Rated power (kw) Rated output current (A)

0.4 2.5

0.75 4 2.3

1.5 7 3.7

2.2 10 5.0

4 16 10

5.5 20 13

7.5 30 17 10

11 42 25 15

15 55 32 18

18.5 70 38 22

22 80 45 28

30 110 60 35

37 130 75 45 25

45 160 90 52 31

55 200 110 63 38

75 260 150 86 52

90 320 180 98 58

110 380 210 121 75

132 420 250 150 86

160 550 310 175 105

185 600 340 198 115

200 660 380 218 132

220 720 415 235 144

250 470 270 162

280 510 330 175

315 600 345 208

355 670 380 220

400 750 430 260

450 810 466 270

500

860 540 325

560 990 600 365

630 1100 680 400

AC70 VC CONTROL FREQUENCY INVERTER MANUAL INSTALLATION AND WIRING

9

Chapter 3: Installation and Wiring

3.1 Safety Precautions

This chapter explains the warnings for safe use and stable running of the product.

Cautions in use

●While install the inverter in the closed cabinet, please build in cooling fan, air-conditioner or

other cooling equipment to ensure the temperature at the air-in port below 40℃. So that the

inverter can work safely and reliably.

●While installing, please use cloth or paper cover the inverter to prevent metal dust, oil, water

and others.And remove it carefully after working.

● While operation, please follow the ESD regulations. Otherwise, the inverter may be

damaged.

● While multi inverters are installed in the same cabinet, enough space must be left for cooling

fan.

●Inverter can not work over rated range.Otherwise, the inverter may be damaged.

●While transporting the inverter, please hold the firm case. If only hold the pre-cover, there is

danger of inverter main body falling, injury or inverter damage.

Cautions in use motor

●Different motor has different max allowable running speed. Motor can not run over the max

allowable running speed.

●While inverter is running at low speed, the motor auto-cool effect is seriously worse. If motor

runs at low speed for long time, it will be damaged for overheat. If needed, please use special

motor for inverter.

●While constant speed machinery runs at inconstant speed, there maybe sympathetic vibration.

Please install vibration-proof rubber under motor rack or use jumping frequency control

function.

●While using frequency inverter or working frequency power supply to drive, the torque

characteristic are different. Please do confirm the torque characteristic of the equipment

connected.

●The rated current of shift gear motor is different from that of standard motor. Please confirm it

and choose the right frequency inverter. Moreover, please do switch the pole while the inverter

input current is 0. Otherwise it may bring inverter protection or damage.

●The rated current of diving motor is higher than that of standard motor, please confirm it and

choose the right inverter.

●While the wire between motor and inverter is long, the max torque of the motor will reduce for

voltage drop. So please use thick cable while the distance between the motor and the inverter

is long.

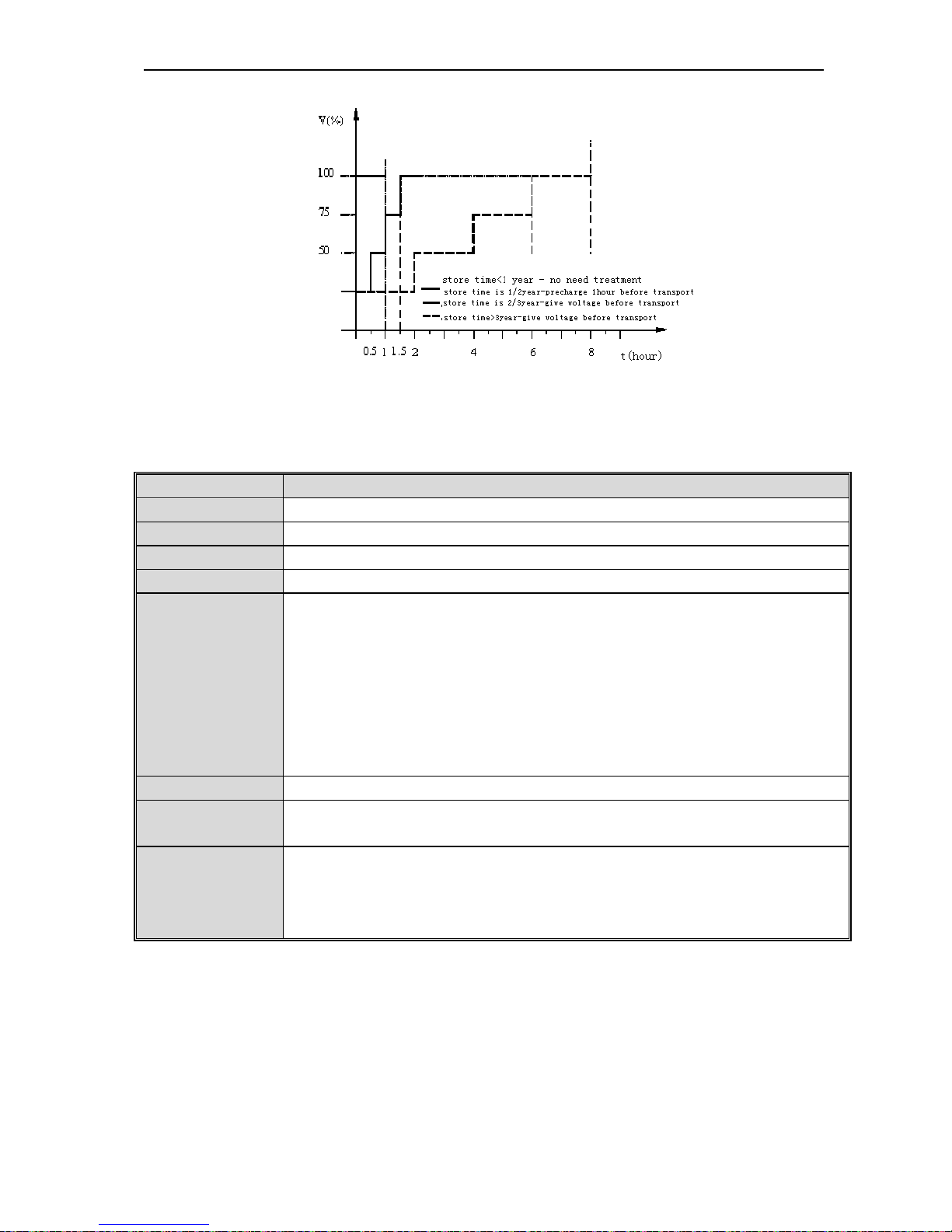

3.2 Treatment for Inverter after Longtime Store

If the inverter store time is over one year, you must pre-charge the aluminum capacitor in the inverter again and install

the inverter after the aluminum capacitor characteristic recovering. For the specific method, please follow the grads in

the chart below and give corresponding proportional voltage for every grad more than 30 mins while the inverter is

no-load.

If the input voltage of one grad is at the action critical point of contactor, fan or other equipment, please increase or

reduce the corresponding input voltage for the grad to avoid any component working under critical state.

AC70 VC CONTROL FREQUENCY INVERTER MANUAL INSTALLATION AND WIRING

10

Chart 3-1: treatment for inverter after longtime store

3.3 Inverter Stable Running Environment

Installation environment is very important to the best use of this product for long time. Pls install this product in the

environment as the following table requirement.

Environment Requirement

Install place Indoor without direct sunshine

Install temperature -10 ~ +40℃

Store temperature -20 ~ +60℃

Humidity <95%RH, no condensation

Surrounding

Please install the inverter in place as follows:

● Place without oil mist, corrosive gases, flammable gas, dust or etc.

● Place without metal dust, oil, water or etc into inverter (please do not install inverter on

flammable material such as food and etc).

● Place without radioactive material or flammable material.

● Place without poisonous gases or liquid.

● Place with very little salification erosion.

● Place whihout direct sunshine.

Altitude <1000m

Vibration

<10~20Hz:9.8m/s2

<20~55Hz:5.9m/s2

Installation and

cooling

● Inverter can not be installed horizontally must be installed vertically.

● Please independently install high heating equipments such as braking resistor and etc which

can not be installed in the same cabinet with inverter, installed at the air-in port of the inverter

is strictly prohibited.

Table 3-1:AC70 series inverter running environment condition

● In order to improve the product stability, pls do not use the inverter where temperature changes sharply. While

using in closed space such as control cabinet, please use cooling fan or air-condition to cool inverter to avoid

temperature over limit range. Please also prevent inverter from freeze, too low temperature may cause components

freeze fault.

AC70 VC CONTROL FREQUENCY INVERTER MANUAL INSTALLATION AND WIRING

11

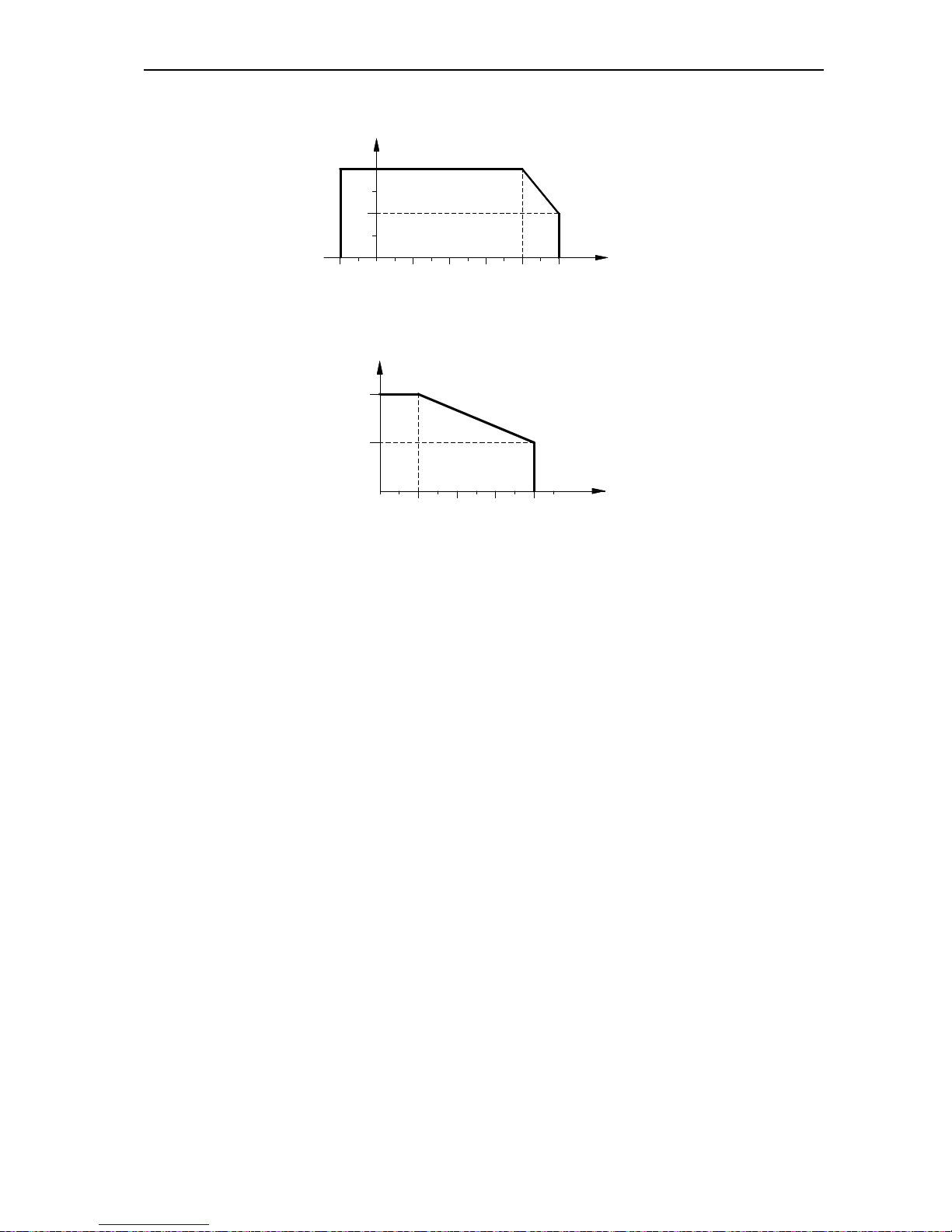

● Derate according to the chart while over temperature limit.

30

25

100

75

50

4020100-10 50

TEMPERATURE(℃)

PERMIT OUTPUT CURRENT(%)

Chart 3-2:AC70 series inverter derating surve while over permit temperature

● Derate according to the chart while over altitude limit.

0 1000 2000 4000

80

100

3000 ALTITUDE(M)

PERMIT OUTPUT CURRENT(%)

Chart 3-3:AC70 series inverter derating surve while over permit altitude

3.4 EMI Protection

The inverter is designed to be used in industrial environment with strong electromagnetic interference. Generally

speaking, if the installation quality is good, it is ensured that the inverter can work safely without fault. Please install the

inverter according to the following rules to ensure stable running and avoid electromagnetic interference impact.

● Ensure that all equipments in the cabinet have been connected reliably to the common Y-type earth point or earth

bus with thick and short cable. The motor earth should be as close as possible. Please do not connect the motor

case to the inverter earth terminal or the protective area of control system.

● Ensure that all equipments connected to the inverter have been reliably connected to the same earth net or Y-type

earth point with thick and short cable.

● The conductor has better to be flat and with multi core, what has lower resistance at high frequency.

●The cutting terminal should be as soigne as possible. Unshielded wire section must be as short as possible.

● In control cable wiring, it should be as far from the power supply cable and motor cable as possible. And

independent cable trough should be used. While the control cable must cross to the power supply cable or motor

cable, it should be 90º vertical cross.

● Ensure that the contactor in the cabinet has wave surge suppresser. Or‘R-C’damping circuit is connected to the

winding of AC contactor. Voltage dependent resistor corresponding to the winding voltage is used. And freewheel

diode or components such as voltage dependent resistor corresponding to the winding voltage are connected to DC

contactor. It is very important while contactor, controlled by output relay of inverter, acts frequently.

● Cable connected to motor should be shielded cable or armoured cable. The two barriers are earthed reliably by

cable grounding card.

● Build noise filters at the input side to reduce electromagnetic interference from other equipments at the power grid

side. The noise filter should be as close to the inverter power input terminal as possible. Meantime, the filter must

earth reliably as the inverter.

● Build noise filters at the output side to reduce radio interference and inductive disturbance. The noise filter must be

as close to the inverter output terminal as possible. Meantime, the filter must earth reliably as the inverter.

AC70 VC CONTROL FREQUENCY INVERTER MANUAL INSTALLATION AND WIRING

12

● Anytime, control circuit wire should be shielded cable.

● Add zero phase reactor in power supply wire near inverter input terminal and add zero phase reactor in the motor

wire near inverter output terminal to reduce electromagnetic interference to the inverter efficiently.

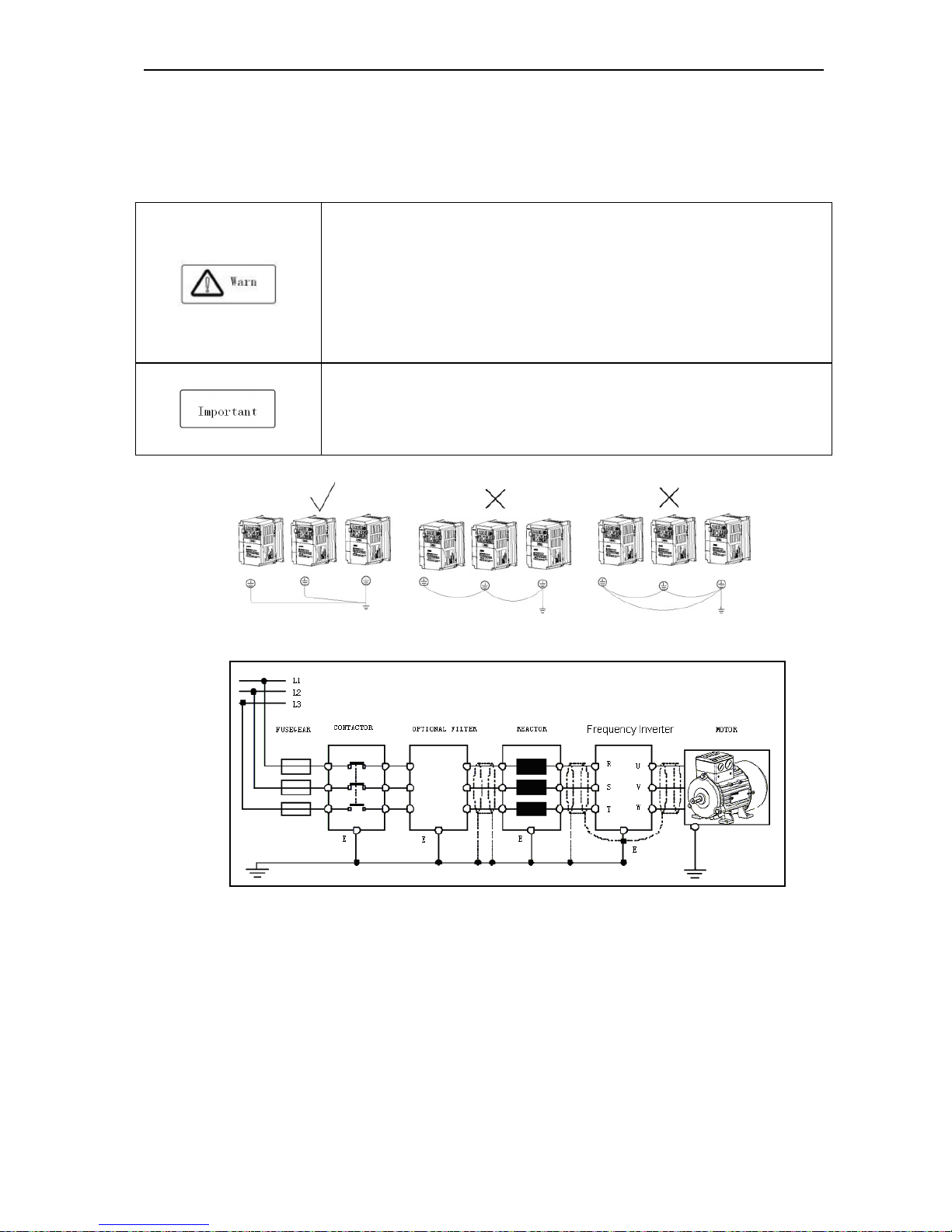

● Earthing Right and reliable earthing is the basic condition of safe and reliable running of the product. For right

earthing, please read the following notice carefully.

●In order to avoid electric shock, earthing cable should be the size as electric

equipment technique standard required and cable length should be as short as

possible. Otherwise, inverter leakage current will cause unstable potential of the

earthing terminal which is far from the earthing point, and electric shock accident will

happen frequently.

●Earth terminal must be earthing. Earth resistance must be below 10Ω. Otherwise,

there is danger of death.

● Please do not share earth cable with welder or other big current/pulse power

equipment. Otherwise, inverter will act abnormally.

●While multi inverters are used at the same time, please do not wind the earth wire to

loop-type. Otherwise, inverter will act abnormally.

Chart 3-4: multi AC70 series inverters united earthing

Chart 3-5:AC70 series inverter system earthing

Remark: motor must earth as close as possible. Motor case can not be connected to the inner earth terminal of the

inverter. It also can not share the earth net with the control system.

● Shield of inverter power cable, motor cable, control cable Cable

Shielding layer (reticulate/armoured) should be winded reliably by cable earth card and fix to inverter earth piece by bolt.

Please refer to the following chart.

AC70 VC CONTROL FREQUENCY INVERTER MANUAL INSTALLATION AND WIRING

13

Chart 3-6:Cable earth card for cables earthing

●Corresponding relationship between inverter/motor cable length and carrier frequency.

While cable distance between inverter and motor is long (especially low frequency output), cable voltage drop will make

motor torque reduce. Further more, cable HF leakage current will increase. Then inverter output current will increase,

that will cause inverter over-current trip. The current detection accuracy and running stability will be impacted. Please

follow as below table to adjust carrier frequency according to the cable length. While the cable distance is over 100m,

please adopt distributed capacity reduce measure (Such as “no metal conductor covers cable”, “wire each phase cable

apart” and so on).

Cable length <20m 20~50m 50~100m >100m

Carrier frequency 0.7~15kHz 0.7~8kHz 0.7~4kHz 0.7~2kHz

Table 3-2: Corresponding relationship between inverter/motor cable length and carrier frequency

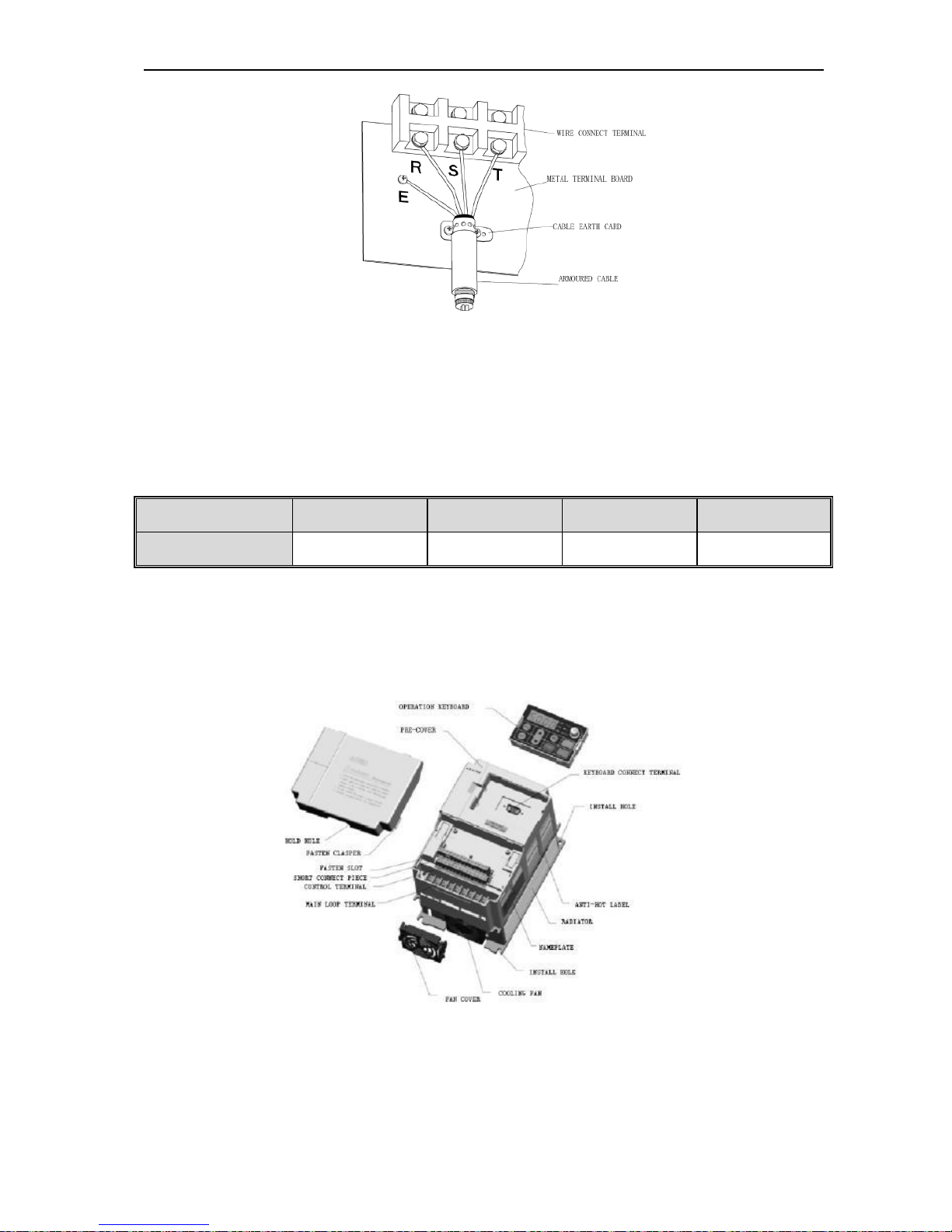

3.5 Machinery Installation

Installation notice and related requirement

● AC70 inverter components

Chart 3-7:AC70 series inverter components

AC70 VC CONTROL FREQUENCY INVERTER MANUAL INSTALLATION AND WIRING

14

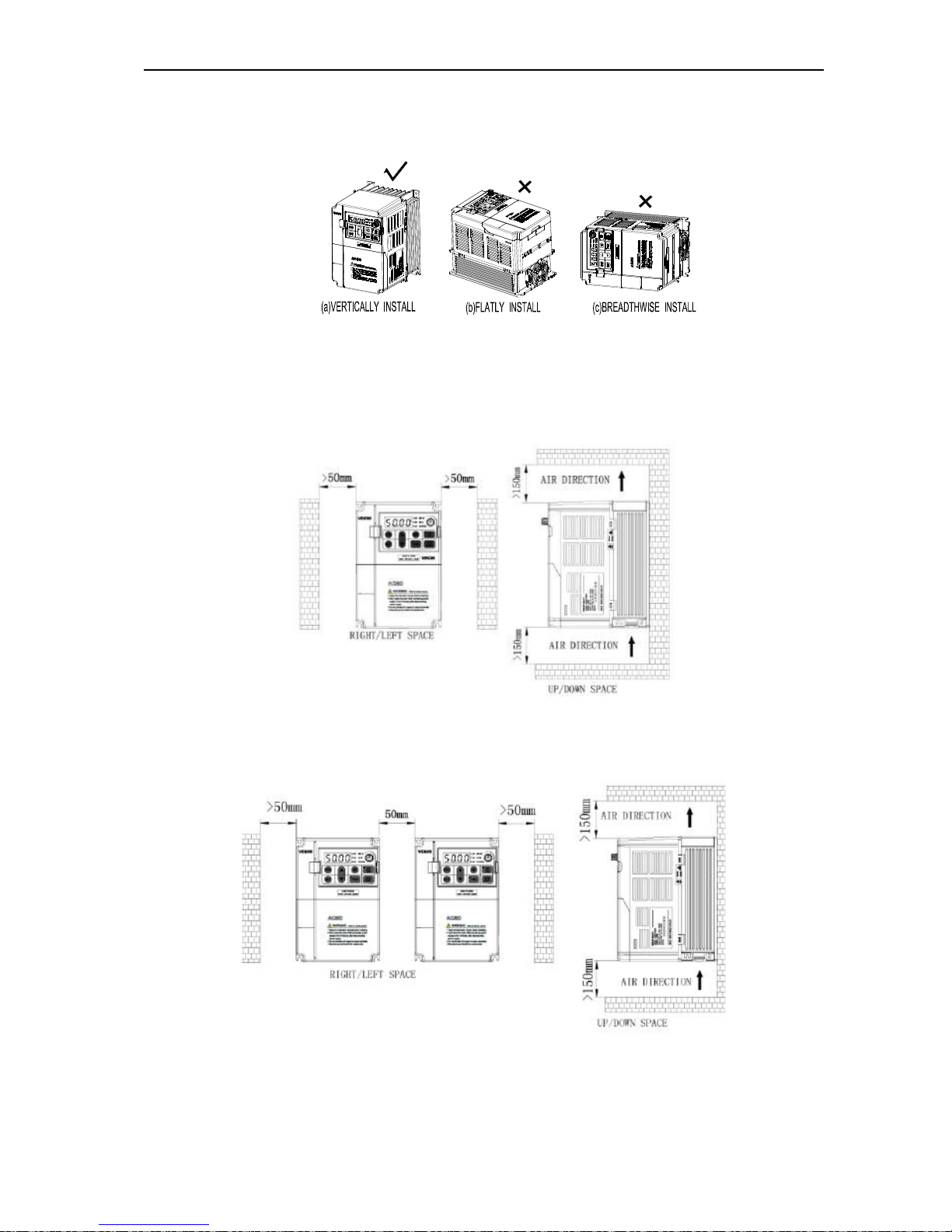

● Installation direction

To prevent inverter cooling effect reducing, please do install the inverter vertically.

Chart 3-8:AC70 series inverter installation direction

● Installation space

Single machine installation: to ensure enough ventilation and wiring space for inverter cooling, please follow installation

conditions as follows. The back of the inverter should stick to the wall. So that the surrounding air of radiator can flow

freely to ensure the cooling effect.

Chart 3-9:Single AC70 series inverter installation space

Multi inverters paratactic installation: while installing multi inverters in cabinet, please ensure installation space as

follows.

Chart 3-10: Multi AC70 series inverters paratactic installation space requirement

AC70 VC CONTROL FREQUENCY INVERTER MANUAL INSTALLATION AND WIRING

15

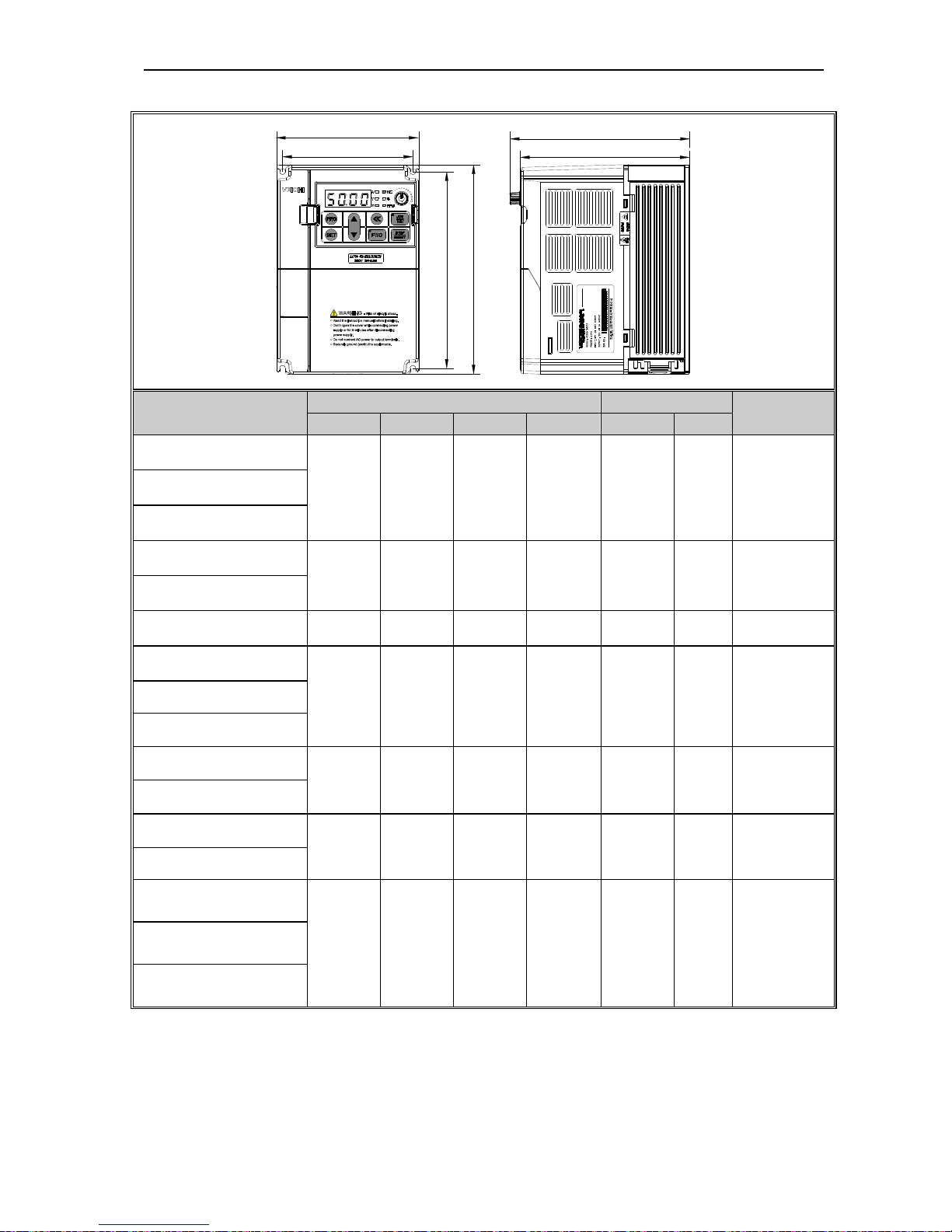

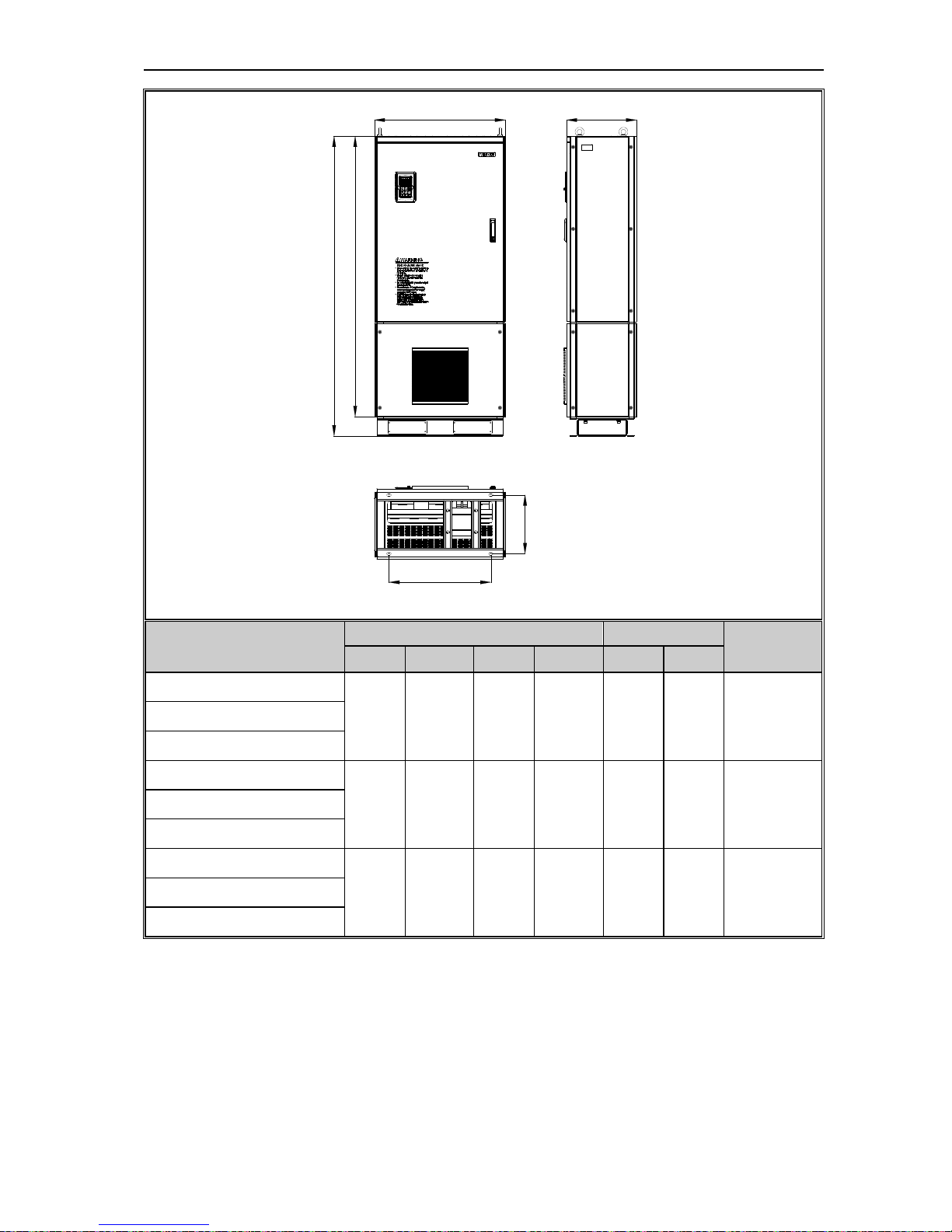

Dimension of Inverter and Keyboard

W

W1

D

D1

H

H1

Inverter model

Inverter size Install size

Install

aperture

W H D D1 W1 H1

AC70-S2-R40G

122 182 154.5 145 112 171 ф5 AC70-S2-R75G

AC70-S2-1R5G

AC70-S2-2R2G

159 246 157.5 148 147.2 236 ф5.5

AC70-S2-004G

AC70-S2-5R5G 195 291 167.5 158 179 275 ф7

AC70-T3-R75G/1R5P

122 182 154.5 145 112 171 ф5

AC70-T3-1R5G/2R2P

AC70-T3-2R2G/004P

AC70-T3-004G/5R5P

159 246 157.5 148 147.2 236 ф5.5

AC70-T3-5R5G/7R5P

AC70-T3-7R5G/011P

195 291 167.5 158 179 275 ф7

AC70-T3-011G/015P

AC70-T3-015G/018P

(plastic cover machine)

230 330 200 190 208 315 Ф7

AC70-T3-018G/022P

(plastic cover machine)

AC70-T3-022G/030P

(plastic cover machine)

AC70 VC CONTROL FREQUENCY INVERTER MANUAL INSTALLATION AND WIRING

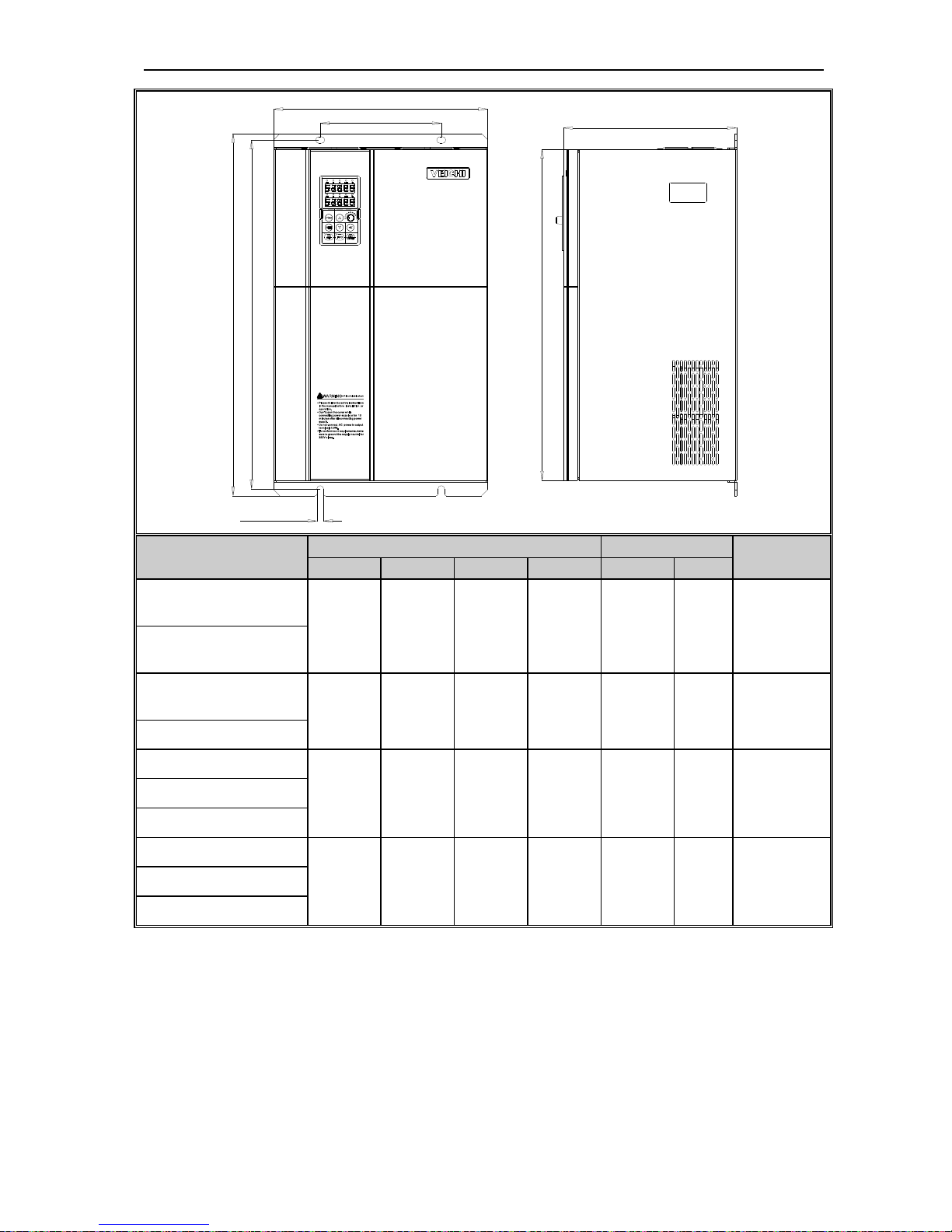

16

W

W1 D

H

H1

H2

Install aperture

Inverter model

Inverter size Install size

Install

aperture

W H D H2 W1 H1

AC70-T3-015G/018P

(steel cover machine)

235 345 200 311 160 331.5

ф7

AC70-T3-018G/022P

(steel cover machine)

AC70-T3-022G/030P

(steel cover machine)

255 410 225 370 180 395 Ф7

AC70-T3-030G/037P

AC70-T3-037G/045P

305 570 260 522 180 550 Ф9 AC70-T3-045G/055P

AC70-T3-055G/075P

AC70-T3-075G/093P

380 620 290 564 240 595 ф11 AC70-T3-093G/110P

AC70-T3-110G/132P

AC70 VC CONTROL FREQUENCY INVERTER MANUAL INSTALLATION AND WIRING

17

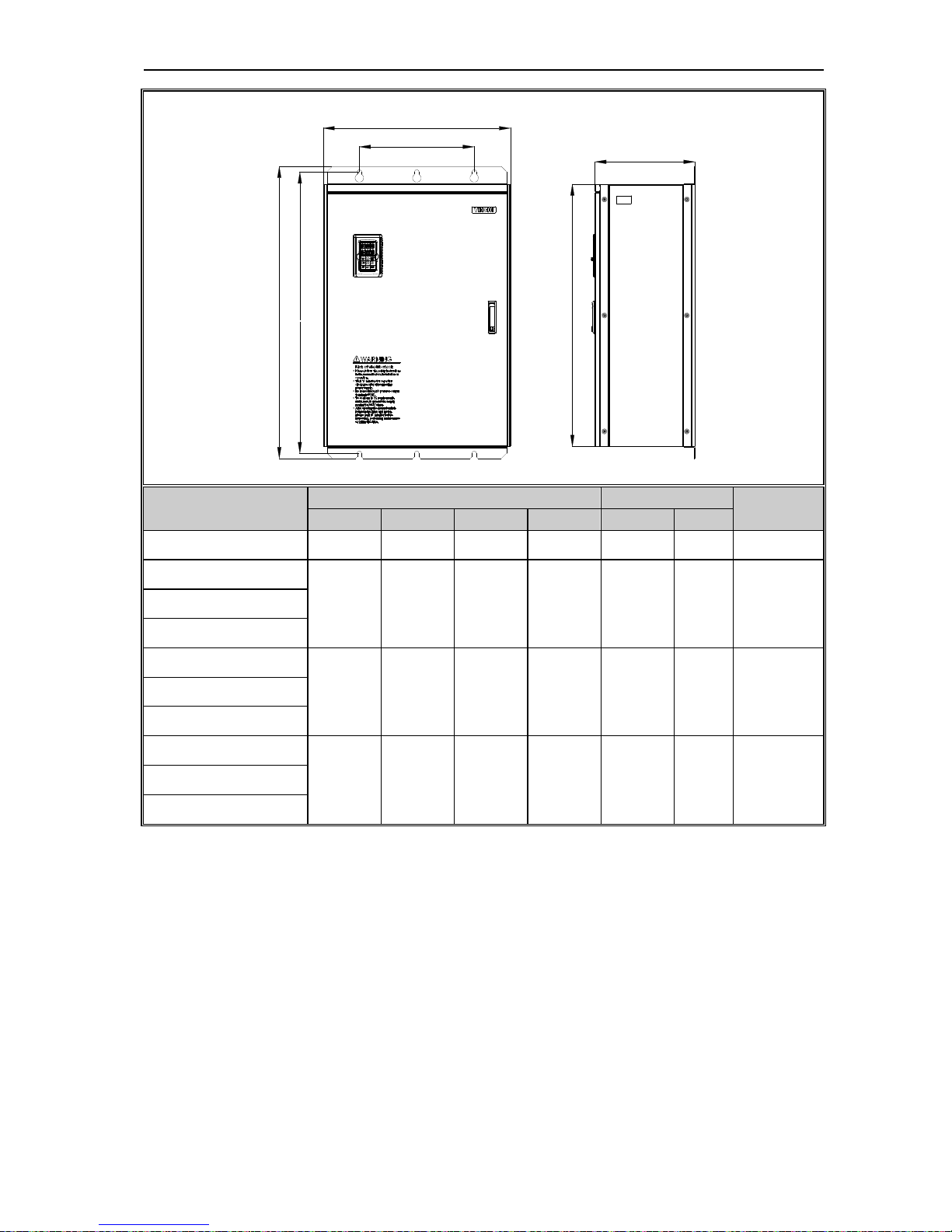

H1

H

H2

D

W1

W

Inverter model

Inverter size Install size

Install

aperture

W H D H2 W1 H1

AC70-T3-132G/160P 500 780 340 708 350 755 ф11

AC70-T3-160G/185P

650 1060 400 950 400 1023 ф16 AC70-T3-185G/200P

AC70-T3-200G/220P

AC70-T3-220G/250P

750 1170 400 1050 460 1128 ф18 AC70-T3-250G/280P

AC70-T3-280G/315P

AC70-T3-315G/355P

850 1280 450 1150 550 1236 ф20 AC70-T3-355G/400P

AC70-T3-400G/450P

NOTE: Without build-in dc reactor

AC70 VC CONTROL FREQUENCY INVERTER MANUAL INSTALLATION AND WIRING

18

D1

W1

D

W

H

H1

Inverter model

Inverter size Install size

Install

aperture

W H D H1 W1 D1

AC70-T3-160GD/185PD

650 1600 400 1500 492 332 ф14 AC70-T3-185GD/200PD

AC70-T3-200GD/220PD

AC70-T3-220GD/250PD

750 1700 400 1600 582 332 ф14 AC70-T3-250GD/280PD

AC70-T3-280GD/315PD

AC70-T3-315GD/355PD

850 1800 450 1700 622 382 ф14 AC70-T3-355GD/400PD

AC70-T3-400GD/450PD

NOTE: With build-in dc reactor

AC70 VC CONTROL FREQUENCY INVERTER MANUAL INSTALLATION AND WIRING

19

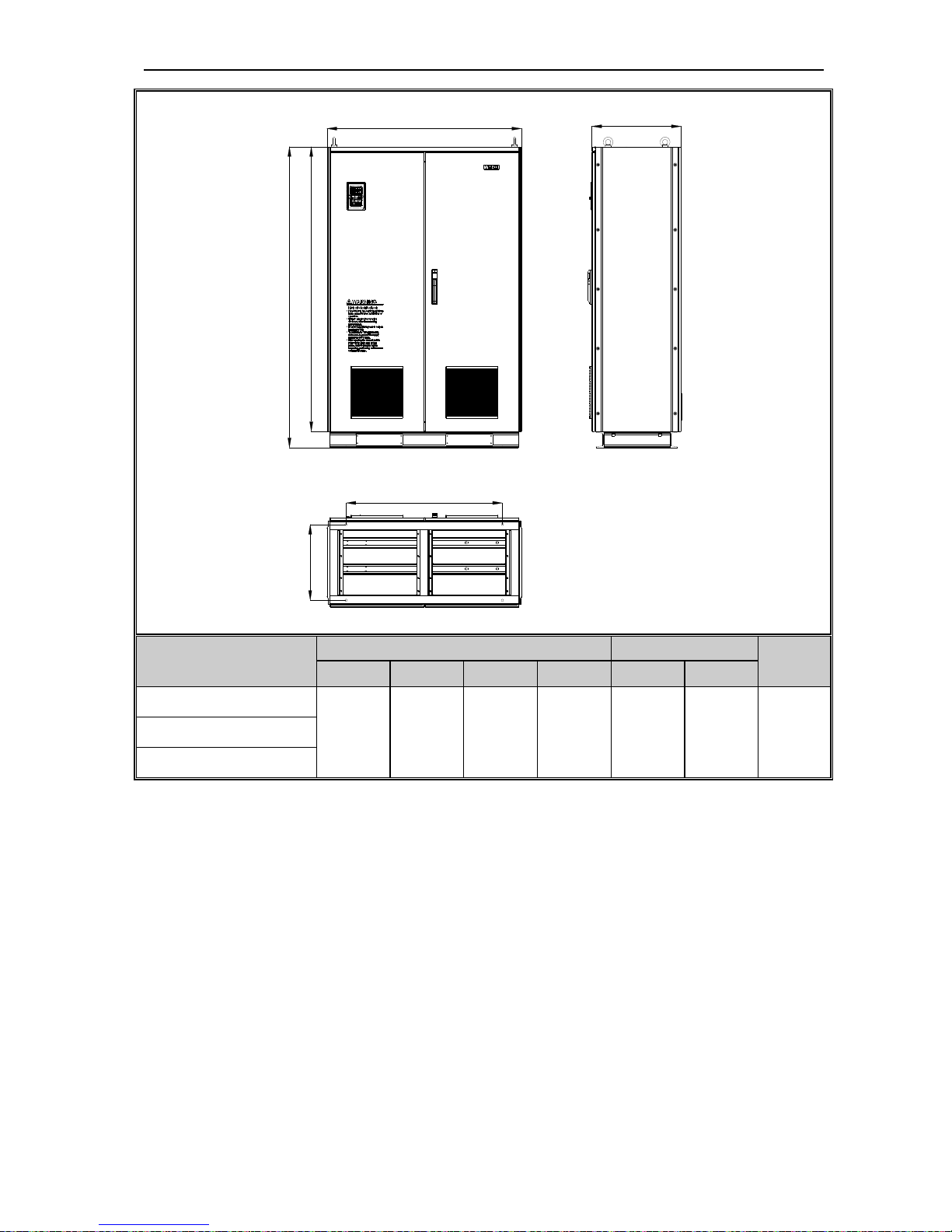

H

H1

D1

W1

D

W

Inverter model

Inverter size Install size

Install

aperture

W H D H1 W1 D1

AC70-T3-450G/500P

1200 1850 550 1750 960 466 ф14 AC70-T3-500G/560P

AC70-T3-560G/630P

Table 3-3:AC70 series inverter dimension

AC70 VC CONTROL FREQUENCY INVERTER MANUAL INSTALLATION AND WIRING

20

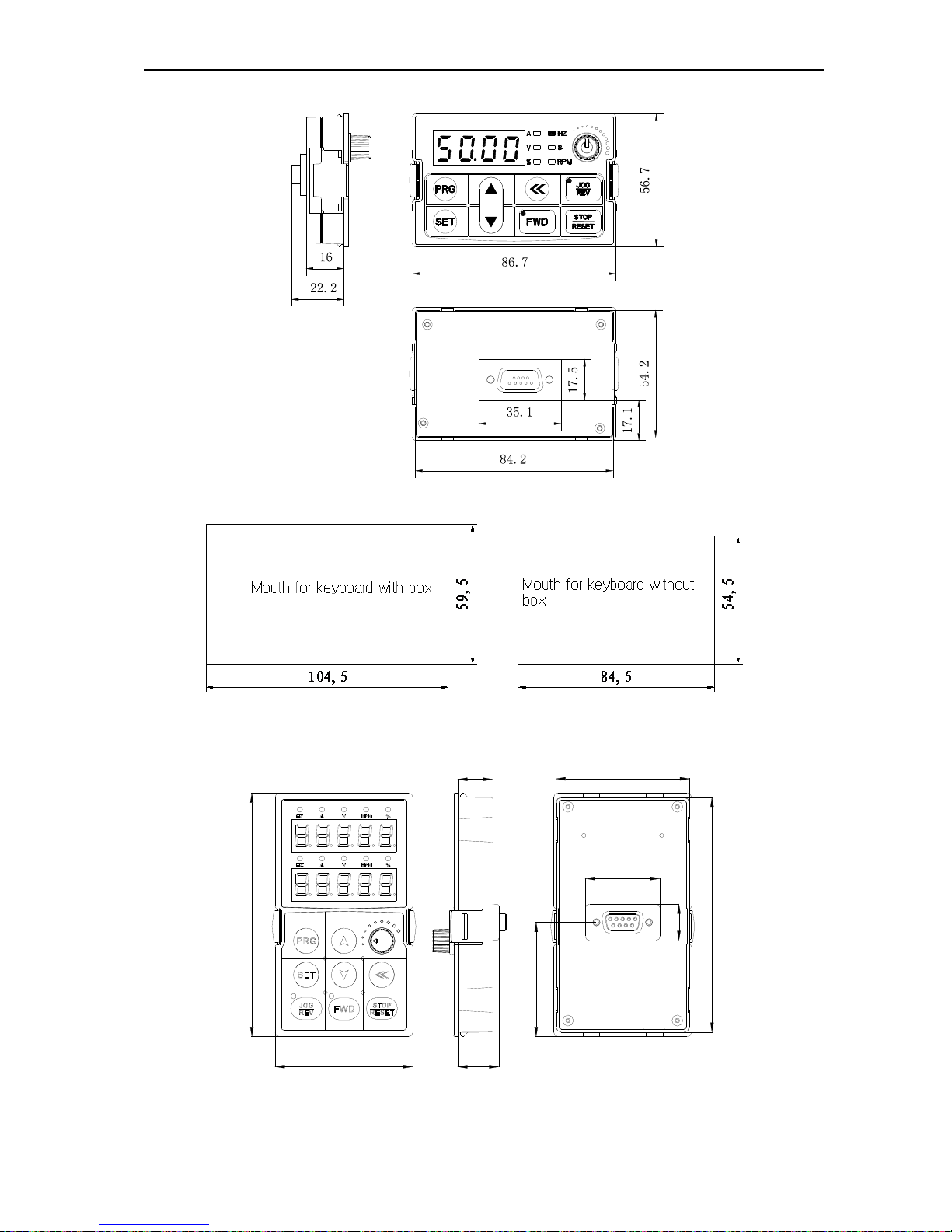

Keyboard dimension

Chart 3-11:AC70 series inverter 1 line LED keyboard dimension

Chart 3-12:AC70 series inverter mouth for 1 line LED keyboard dimension

114.5

65.5

19.5

16.5

17.1

110.5

63.5

35.6

53.75

Chart 3-13:AC70 series inverter 2 line LED keyboard dimension

AC70 VC CONTROL FREQUENCY INVERTER MANUAL INSTALLATION AND WIRING

21

119

70

111

64

142

75

Mouth for keyboard with box

AC70-T3-160G/630P

Mouth for keyboard with box

AC70-T3-015G/132P

Mouth for keyboard with box

Chart 3-14:AC70 series inverter mouth for 2 line LED keyboard dimension

Note: LCD keyboard total same size as LED keyboard.

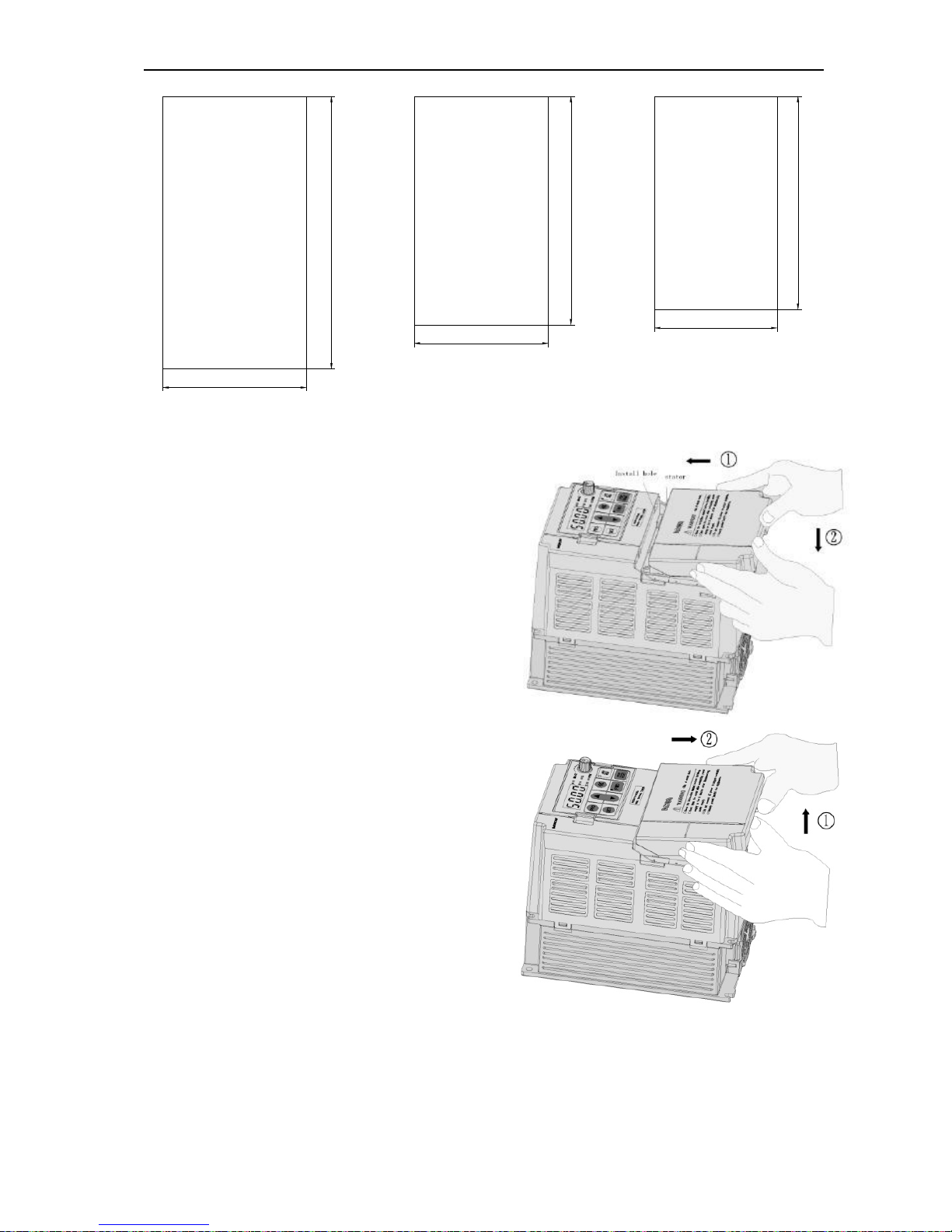

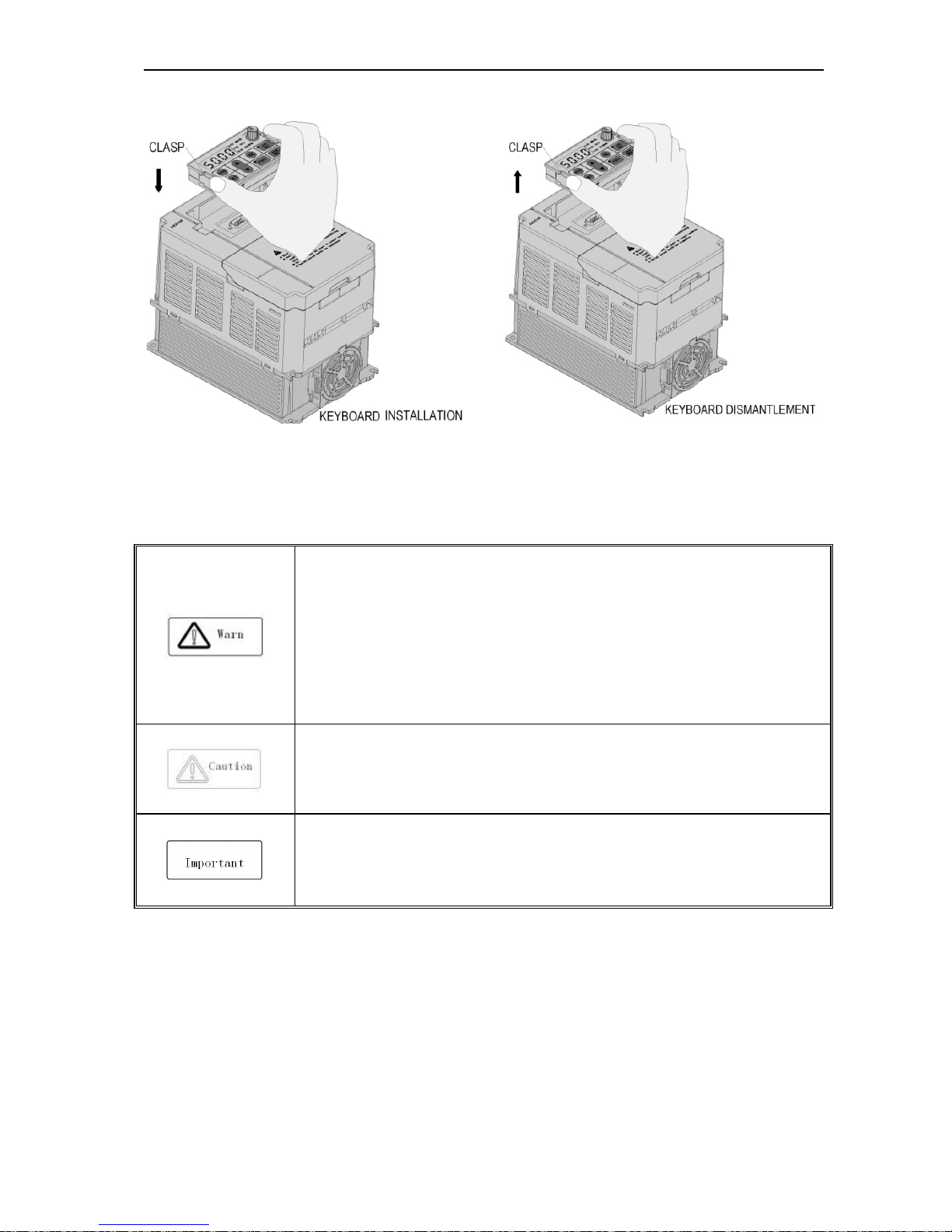

Dismantle and install tail-hood

Installation: First the tail-hood upwardly inclines around 15

degrees and inserts the top fixed flat into the fixed hole in the

front cover. Then slightly press the tail-hood downward. While

your hear "Ka", it means that the tail-hood is into the place.

Chart 3-15:AC70 series inverter tail-hood installation

Dismantlement: At the tail of the frequency inverter, there is a

special dismantlement hole design. Put your finger into the

hole, upwardly pull the cover with a little force until the buckle

between the tail-hood and the crust tear off, and then remove

the tail-hood down.

Chart 3-16:AC70 series inverter tail-hood dismantlement

AC70 VC CONTROL FREQUENCY INVERTER MANUAL INSTALLATION AND WIRING

22

Dismantlement and installation of keyboard

Chart 3-17:AC70 series inverter keyboard installation and dismantlement

3.6 Electric Installation

This chapter explains the regulations that users have to obey to ensure safe use, best performance and reliable

running.

Safety precaution

● Must earth reliably while inverter is running. Otherwise there is danger of casualty and

unstable inverter performance.

● To ensure safe running, only trained professional person can do installation and wiring

job.

● No operation under power connected state. Otherwise there is danger of electric shock

even death.

● Before operation, please cut all related equipments power, ensure that the main circuit

DC current has dropped to safe range. And please operate after 5 mins.

● Control cable, power cable and motor cable must be separated. They can not be in the

same cable trough or cable rack.

● This equipment can only be used as the maker states. Please consult Veichi while using

in special case.

● No insulation test for the inverter or the related cable by HV insulation test equipment.

● If the inverter or the peripheral equipment (filer, reactor and etc) needs insulation test,

firstly 500V megohmmeter should be used to test the insulation resistance which should

not be lower than 4MΩ.

AC70 VC CONTROL FREQUENCY INVERTER MANUAL INSTALLATION AND WIRING

23

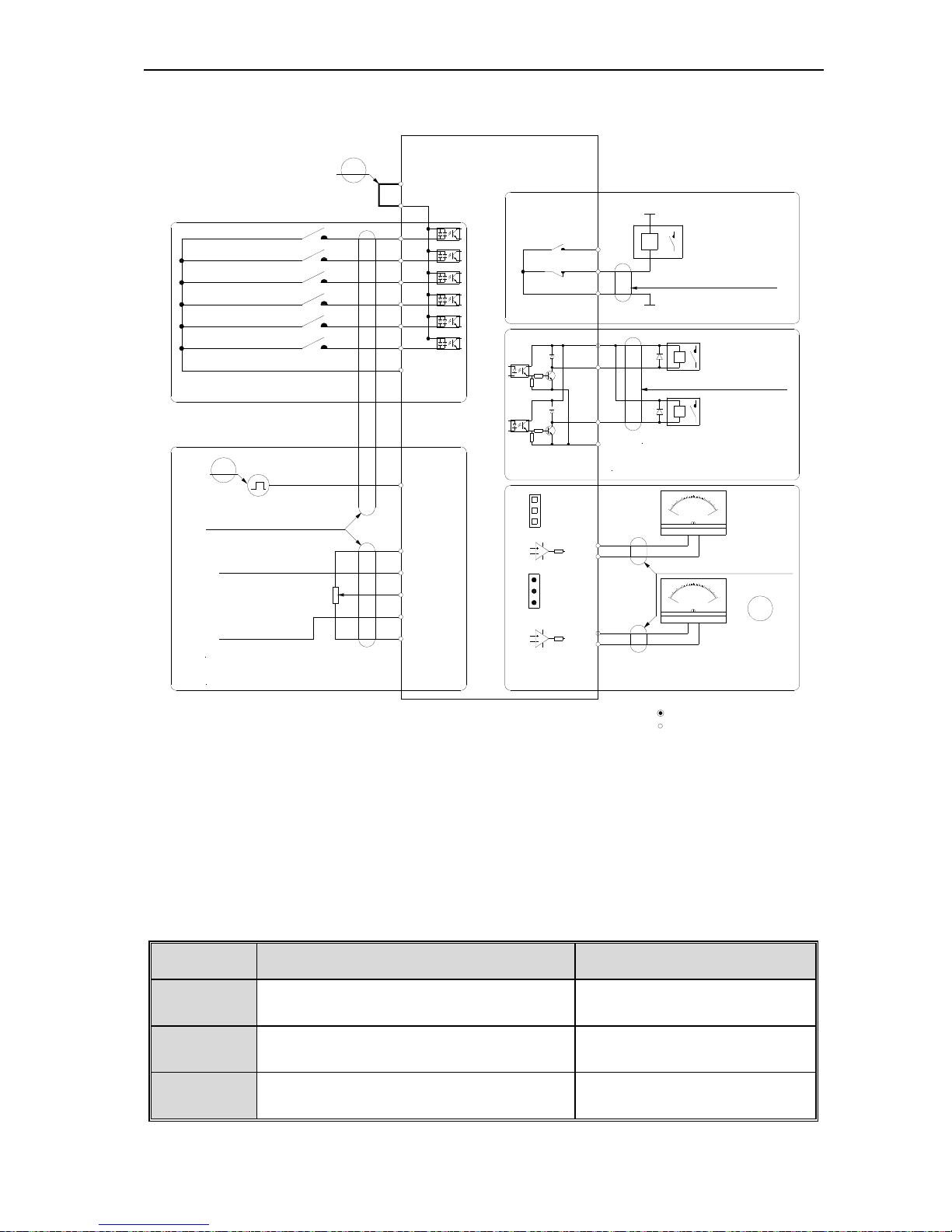

Standard diagram

● Standard diagram

Note1

Note:multiple function digtal input default

setting

TA

TB

TC

+24V

Y1

_

mA

2

0

10

0

-

+

0

5

1

0

V

_

+

-

GND

A01

VR

VR mini

2Kohm

Analog curr ent Input

+10V

Frequency reference setting input

VS2

GND

AS

VS1

twisted-pair shielding line

(grounding nearby)

pulse input

PUL

Multi-function digital input

COM

X3

X4

X6

X5

X1

X2

PLC

+24V

Frequency Inverter

GND

A02

coil

Y2

COM

passive source output

AC220V

AC0V

J1

J2

J3

switch

Maximum output:

3A/240VAC

5A/30VDC

2. VS1/VS2 terminal resistor valuve 89ohm

1 Maximum output 50mA +10V input terminalNote

:

2 Maximum output of Y1/Y2 DC24V/50mA

Note

:

Mark:

1. stand for main loop terminal

(Forward Run/Stop)

(0~5V)/(0~10V)

(0~20mA)/(4~20mA)

3AS terminal resistor valuve 250ohm

J4

J5

(Reverse Run/Stop)

(Jog run forward)

(Jog run Reverse)

(Free stop)

(Fault reset)

Note3

Analog voltage Input

twisted-pair shielding line

(grounding nearby by inverter)

twisted-pair shielding

line (grounding nearby by inverter)

Note: 1

Maximum output of +24V

terminal-DC 24v/100mA

Pin

switch

coil

coil

twisted-pair shielding

line (grounding nearby by inverter)

Note2

Note: Maximum output is 2mA when

A01/A02 as for frequency voltage signal

output

2. stand for control loop terminal

collector type status output

analog monitor signal output

Chart 3-18:AC70 series inverter standard diagram

Note: 1.NPN or PNP transistor signal can be selected as input of multi-function input terminal(X1~X6). Inverter

built-in power supply (+24V terminal) or external power supply (PLC terminal) can be chosen as bias

voltage. Factory setting ‘+24V’ short connect with ‘PLC’.

2. Analog monitor output is special output of meters such as frequency meter, current meter, voltage meter

and etc. It can not be used for control operations such as feedback control.

3. As there are multi pulse styles, please refer to the line connect mode description details.

● Auxiliary terminal output capacity

Terminal Function definition Max output

+10V

10V auxiliary power supply output, constitutes loop

with GND.

50mA

A01/A02 Analog monitor output, constitutes loop with GND.

As frequency,voltage signal, max

output 2mA

+24V

24V auxiliary power supply output, constitutes loop

with COM.

100mA

AC70 VC CONTROL FREQUENCY INVERTER MANUAL INSTALLATION AND WIRING

24

Y1/Y2

Collector open circuit output, can set the

action-object by program.

DC24V/50mA

TA/ TB/TC

Passive connector output,can set the action-object

by program.

3A/240VAC

5A/30VDC

Table 3-4:AC70 series inverter auxiliary terminals output capacity

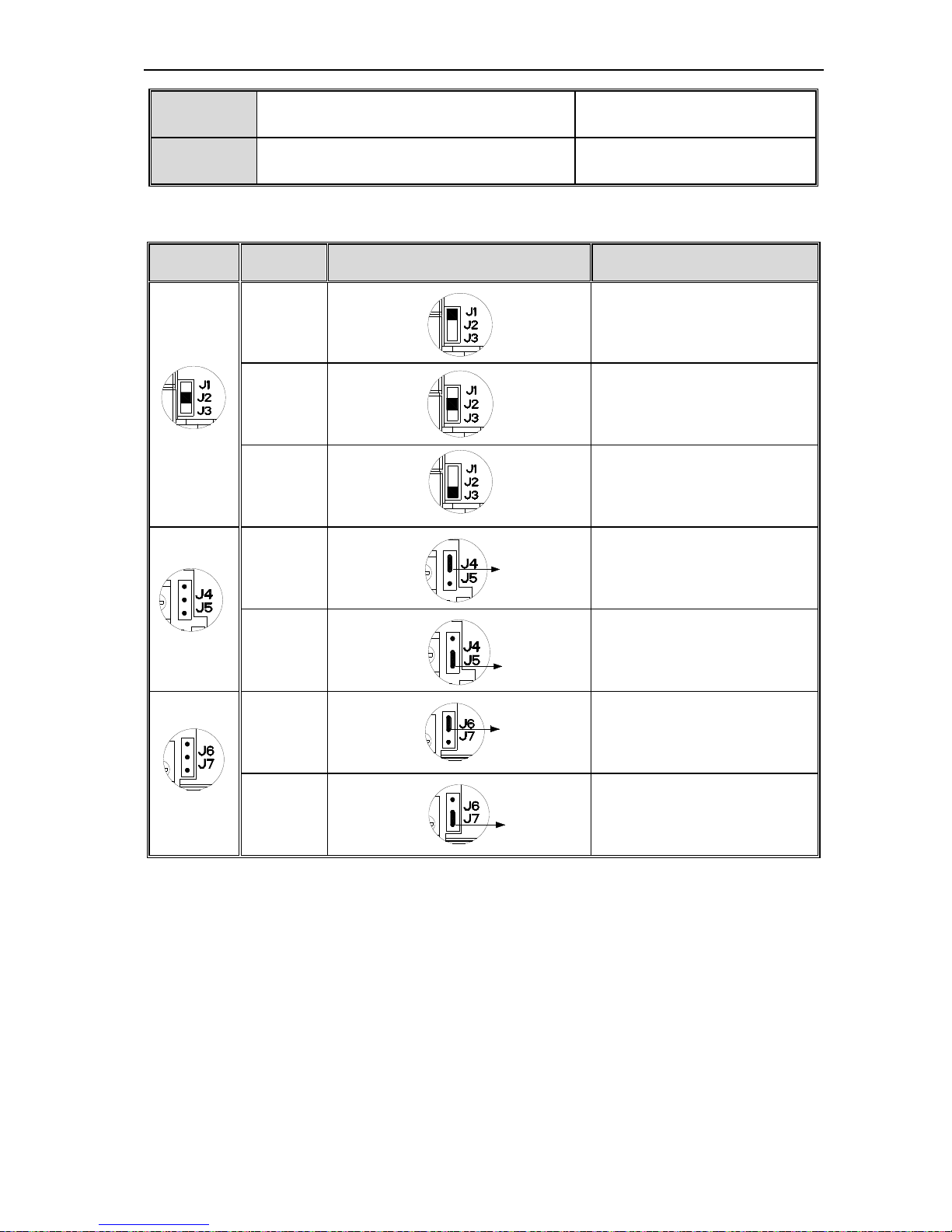

● Switch terminals connection function specification

Switch

terminal

Optional

position

Picture example Function specification

(K2)

J1

(AO2)

0.0~50kHz open collect pole pulse

frequency output

J2

(AO2)

0~20mA current output or

4~20mA current output

J3

(AO2)

0~10V voltage output

(K1)

J4

J4 connect

(AO1)

0~10V voltage output

J5

J5 conne

(AO1)

0~20mA current output or

4~20mA current output

(K3)

J6

J6 conne

RS485 communication initial port

connect matching resistor 120Ω

J7

J7 conne

Matching resistor disconnect

Table 3-5:AC70 series inverter switch terminal connection function specification

AC70 VC CONTROL FREQUENCY INVERTER MANUAL INSTALLATION AND WIRING

25

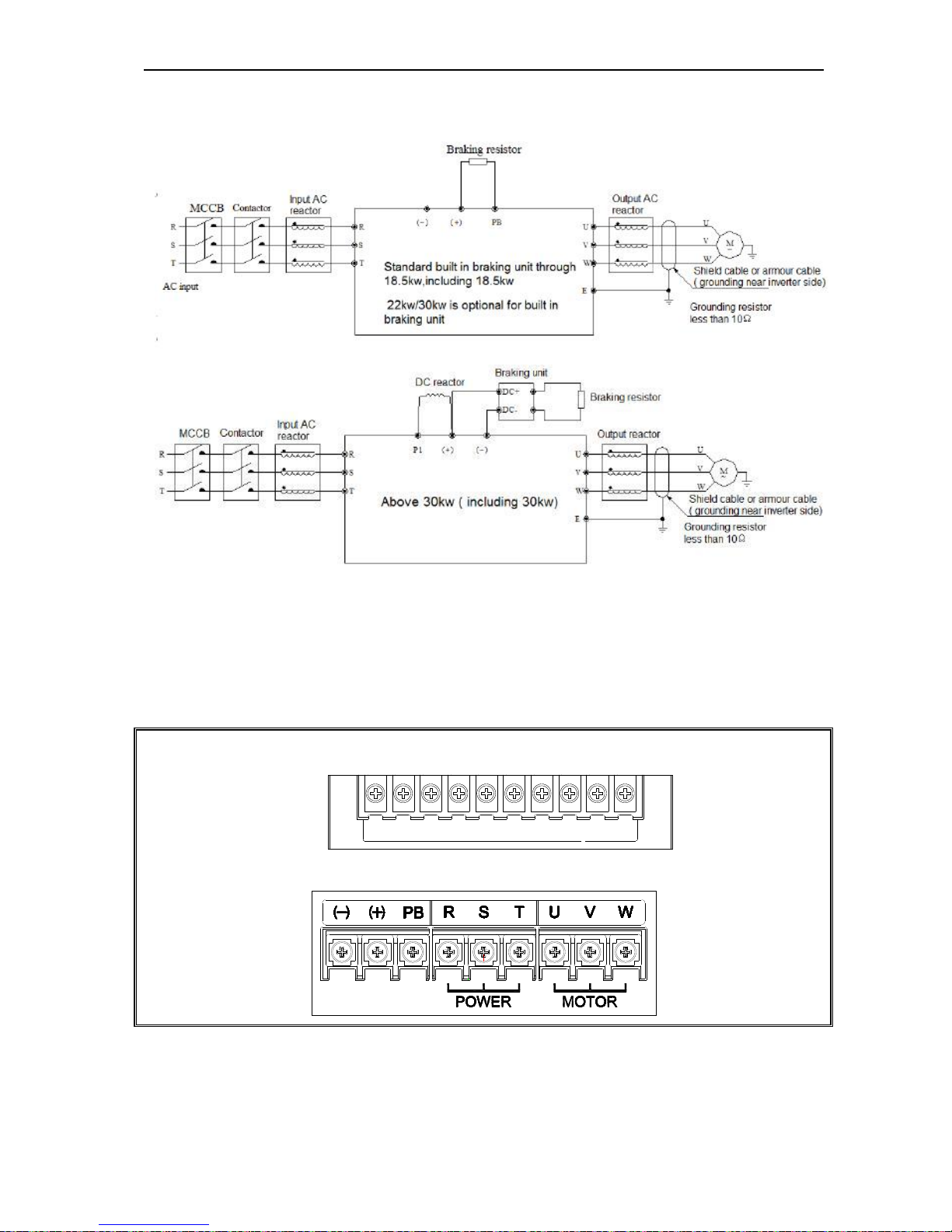

Main circuit wiring

● Main circuit wiring

Chart 3-19:AC70 frequency inverter main circuit wiring

Note: 1, Fuse, dc reactor, braking unit, braking resistor, input actor, input filter,output reactor, output filter are optional

parts, please refer to “peripheral equipment”.

2, P1 terminal and (+) short connect. If need add dc reactor, please take away the short connect part between P1 and

(+).

Main circuit terminals

● Main circuit terminals array and definition

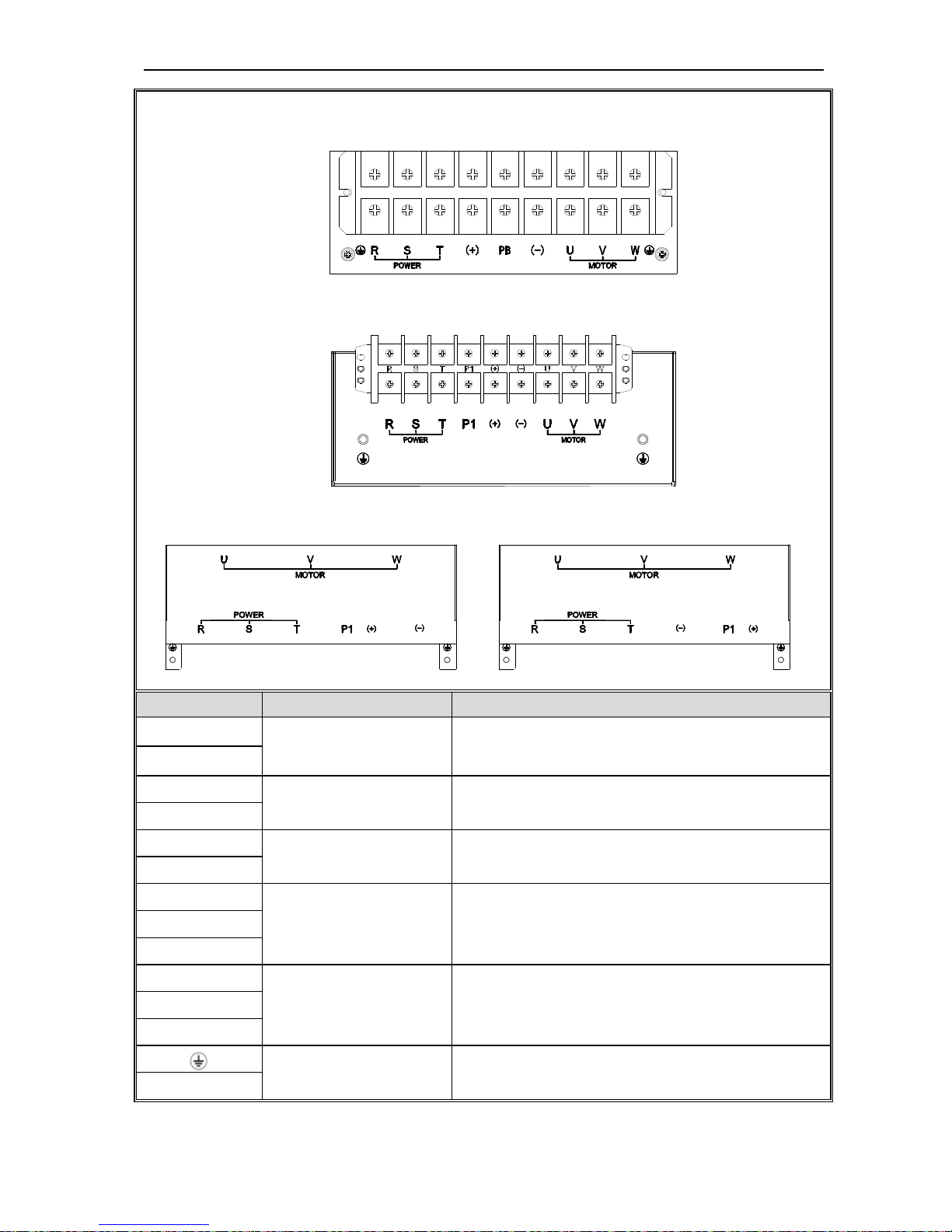

Arrangement sequence of main circuit terminal with 18.5kW or less power(15 ~ 18.5KW for steel cover machine)

(-)

TSR

PB

UWV

(+)

E

Arrangement sequence of main circuit terminal with 15-22KW(15~22KW for plastic cover machine)

AC70 VC CONTROL FREQUENCY INVERTER MANUAL INSTALLATION AND WIRING

26

Arrangement sequence of main circuit terminal with 22~30KW (standard machine without PB terminal)(22KW for steel

cover machine)

Arrangement sequence of main circuit terminal with 37~110kW

Arrangement sequence of main circuit terminal with 132kW: Arrangement sequence of main circuit terminal with 160~560kW

Terminal Name

(-)

DC power terminal

DC power output, (-) means DC bus cathode, (+) means DC

bus anode, used for external braking unit.

(+)

(+)

Braking resistance terminal Used for external braking resistance to realize quick stop.

PB

P1

DC reactor terminal Used for external DC reactor.

(+)

R

Inverter input terminal Used to connect 3-phase AC power supply. S

T

U

Inverter output terminal Used to connect the motor. V

W

Earth Earth terminal, earth resistance<10 OHM

E

Table 3-6:AC70 series inverter main circuit terminals array and definition

AC70 VC CONTROL FREQUENCY INVERTER MANUAL INSTALLATION AND WIRING

27

● 3-phase 380V machine main circuit wiring

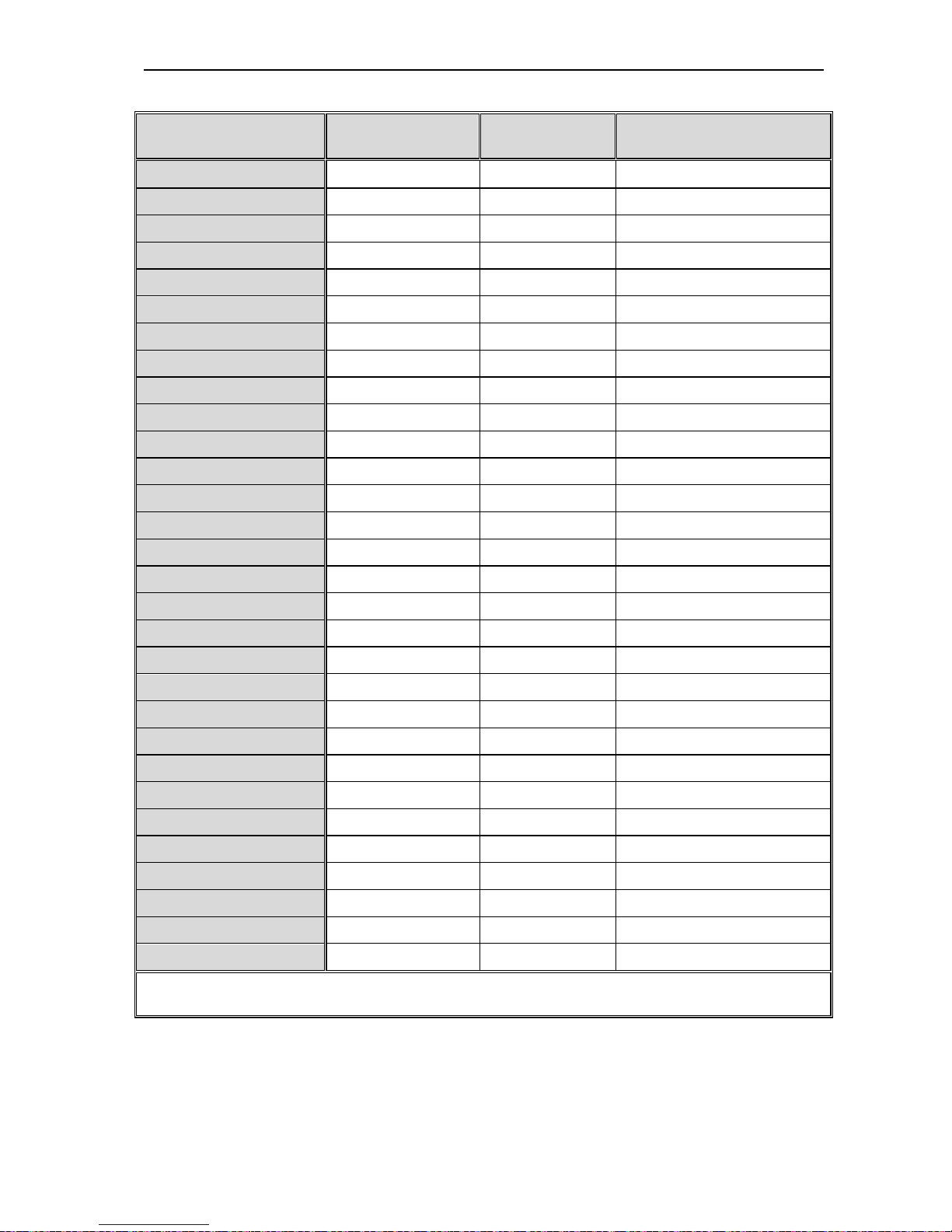

Model

Main circuit terminals

screw specifications

Suggested fixed

moment (N·m)

Suggested Copper-core cable

specification mm

2

(AWG)

AC70-T3-R75G/1R5P M4

1.2~1.5

1.5mm2(14)

AC70-T3-1R5G/2R2P M4 1.2~1.5 2.5mm2(12)

AC70-T3-2R2G/004P M4

1.2~1.5

2.5mm2(12)

AC70-T3-004G/5R5P M4 1.2~1.5 4mm2(10)

AC70-T3-5R5G/7R5P M4

1.2~1.5

6mm2(9)

AC70-T3-7R5G/011P M5 2~2.5 6mm2(9)

AC70-T3-011G/015P M5

2~2.5

10mm2(7)

AC70-T3-015G/018P M6 4~6 10mm2(7)

AC70-T3-018G/022P M6

4~6

16mm2(5)

AC70-T3-022G/030P M8 8~10 16mm2(5)

AC70-T3-030G/037P M8

8~10

25mm2(3)

AC70-T3-037G/045P M8 8~10 25mm2(3)

AC70-T3-045G/055P M8

8~10

35mm2(2)

AC70-T3-055G/075P M10 11~13 35mm2(2)

AC70-T3-075G/093P M10

11~13

50mm2(1)

AC70-T3-093G/110P M10 11~13 50mm2(1/0)

AC70-T3-110G/132P M10

11~13

70mm2(2/0)

AC70-T3-132G/160P M10 11~13 95mm2(3/0)

AC70-T3-160G/185P M12

14~16

95mm2(4/0)

AC70-T3-185G/200P M12 14~16 120mm2

AC70-T3-200G/220P M12

14~16

150mm2

AC70-T3-220G/250P M12 14~16 150mm2

AC70-T3-250G/280P M12

14~16

185mm2

AC70-T3-280G/315P M12 14~16 185mm2

AC70-T3-315G/355P M16

20~23

240mm2

AC70-T3-355G/400P M16 20~23 240mm2

AC70-T3-400G/450P M16

20~23

300mm2

AC70-T3-450G/500P M16 20~23 400mm2

AC70-T3-500G/560P M16

20~23

400mm2

AC70-T3-560G/630P M16 20~23 500mm2

Note: Here we suggest to use copper joins as mains electric connectors of machine over 185KW. Pls refer the cut

section area above.

Table 3-7: Suggested cable diameter and fixed moment 3-phase 380V machine main circuit

AC70 VC CONTROL FREQUENCY INVERTER MANUAL INSTALLATION AND WIRING

28

● Single-phase 220V machine main circuit wiring

Model

Main circuit terminals

screw specifications

Suggested fixed

moment (N·m)

Suggested Copper-core cable

specification mm2 (AWG)

AC70-S2-R40G M4 1.2~1.5 1.5mm2(14)

AC70-S2-R75G M4 1.2~1.5 2.5mm2(12)

AC70-S2-1R5G M4 1.2~1.5 2.5mm2(12)

AC70-S2-2R2G M4 1.2~1.5 4mm2(10)

Table 3-8: Suggested cable diameter and fixed moment single-phase 220V machine main circuit

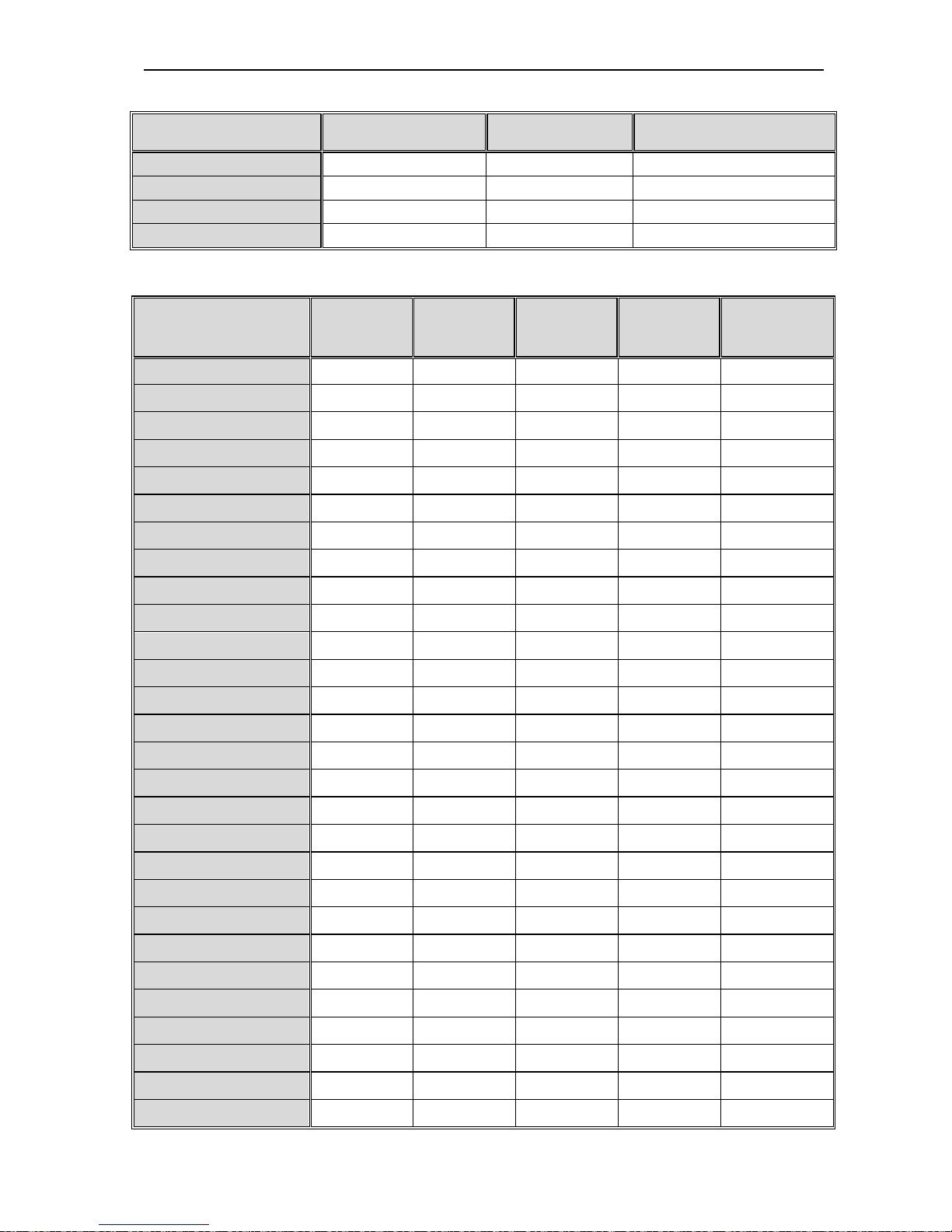

● Suggested main circuit components specification

Model

Contactor

specification

Breaker

specification

DC reactor Input filter Output filter

AC70-T3-R75G/1R5P 10A 10A ------ NFI-005 NFO-010

AC70-T3-1R5G/2R2P 10A 10A ------ NFI-005 NFO-010

AC70-T3-2R2G/004P 16A 15A ------ NFI-010 NFO-010

AC70-T3-004G/5R5P 16A 20A ------ NFI-010 NFO-010

AC70-T3-5R5G/7R5P 25A 20A ------ NFI-020 NFO-020

AC70-T3-7R5G/011P 25A 30A ------ NFI-020 NFO-020

AC70-T3-011G/015P 32A 40A ------ NFI-036 NFO-036

AC70-T3-015G/018P 40A 50A ------ NFI-036 NFO-036

AC70-T3-018G/022P 50A 60A ------ NFI-050 NFO-050

AC70-T3-022G/030P 50A 75A DCL-50 NFI-050 NFO-050

AC70-T3-030G/037P 63A 100A DCL-80 NFI-080 NFO-080

AC70-T3-037G/045P 80A 125A DCL-100 NFI-100 NFO-100

AC70-T3-045G/055P 100A 150A DCL-110 NFI-100 NFO-100

AC70-T3-055G/075P 125A 175A DCL-125 NFI-150 NFO-150

AC70-T3-075G/093P 160A 200A DCL-150 NFI-150 NFO-150

AC70-T3-093G/110P 220A 250A DCL-200 NFI-200 NFO-300

AC70-T3-110G/132P 220A 300A DCL-200 NFI-200 NFO-300

AC70-T3-132G/160P 250A 400A DCL-300 NFI-300 NFO-300

AC70-T3-160G/185P 300A 500A DCL-300 NFI-300 NFO-300

AC70-T3-185G/200P 400A 600A DCL-400 NFI-400 NFO-400

AC70-T3-200G/220P 400A 700A DCL-400 NFI-400 NFO-400

AC70-T3-220G/250P 630A 800A DCL-500 NFI-600 NFO-600

AC70-T3-250G/280P 630A 1000A DCL-600 NFI-600 NFO-600

AC70-T3-280G/315P 630A 1200A DCL-600 NFI-600 NFO-600

AC70-T3-315G/355P 630A 1200A DCL-800 ------ -----AC70-T3-355G/400P 800A 1400A DCL-800 ------ -----AC70-T3-400G/450P 1000A 1600A DCL-1000 ------ -----AC70-T3-450G/500P 1000A 2000A DCL-1000 ------ ------

Loading...

Loading...