Veichi AC300-T3-2R2G, AC300-T3-5R5G, AC300-T3-1R5G, AC300-T3-011G, AC300-T3-018G Technical Manual

...

CONTENT

CHAPTER1OVERVIEW...................................................................................1

CHAPTER2BEFOREUSE.................................................................................7

CHAPTER3INSTALLATIONANDWIRING.........................................................9

CHAPTER4BASICOPERATIONANDTRIALRUN.............................................30

CHAPTER5FAULT DIAGNOSESANDPROCESSING..........................................33

CHAPTER6PERIODICOVERHAULANDMAINTENANCE.................................44

CHAPTER7PERIPHERALEQUIPMENTSANDOPTIONS...................................48

CHAPTER8FUNCTIONPAR AM E TE R SPECIFICATIONS....................................53

CHAPTER9FUNCTIONPAR AM E TE R TABLE..................................................149

APPENDIX1:AC300IOEXPANSIONCARDMANUAL....................................177

APPENDIX2:PGCARDMANUAL................................................................181

AC300 Series Vector Control Inverter Manual Overview

1

Chapter 1 Overview

Thanks for purchasing the AC300 series vector control inverter which designed and manufactured by VEICHI Electric.

This manual describes how to use this product correctly for good returns. Please read this manual carefully before

using the product (installation, wiring, operation, maintenance, inspection, etc.). In addition, please use this product

after fully understanding the safety precautions described in this manual.

1.1 Safety requirement and cautions

Please use the product after fully understanding the safety precautions described in this manual to ensure safe,

reliable and reasonable use of this product.

Warning signs and meanings

This manual has used following signs which means there is an important part of security. While observing against the

rules, there is a danger of injury even death or machine system damage.

Danger: Wrong operation may cause death or large accident.

Warni ng: Wrong operation may cause death or large safety incident.

Caution: Wrong operation may cause minor wound.

Important: Wrong operation may cause damage to this product and associated systems.

Figure 1-1 AC300 series inverter shell warning mark position

Operation requirement

Only professionally trained persons can be allowed to operate the equipment. “Professional trained persons “means

the workers must have experience professional trained skill, and must be familiar with installation, wiring, running and

AC300 Series Vector Control Inverter Manual Overview

2

maintain and can rightly deal with emergency cases in use.

Safety guidance

Safety rules and warning signs come for your security. They are measures to prevent the operator and machine

system from damage. Please carefully read this manual before using and strictly observe the regulations and warning

signs while operating. Safety rules and warning signs are divided into the following categories: general guidance,

guidance for transportation and storage, instructions for installation wiring, instructions for operation, instructions for

maintenance, and guidance for disassembly and disposal.

General guidance

This product carries dangerous voltage and controls driver machine with potential

danger. If you don’t abide by the regulations or requirements in this manual, there

is danger of body injury even death and machine system damage.

Only trained personnel are allowed to operate this product. Before using this

product, please be familiar with all the safety and operating instructions in this

manual. Correct operation and maintenance is a reliable guarantee of this product.

Do not wire while the power is connected. Otherwise, there is danger of death for

electric shock. Before wiring, inspection and maintenance, please cut off power

supply of all related equipment’s and ensure main DC voltage in safe range. And

please operate it after 5 mins.

Prevent children and the public from near the product.

This product can only be used in accordance with the manufacturer's intended,

and may not be used in special fields such as emergency, rescue, shipbuilding,

medical, aviation, nuclear facilities, etc. without permission.

Unauthorized modifications and use of spare parts recommended by the

manufacturer of this product may result faults.

Be sure to deliver this manual to the actual user so that the actual user can read

this manual carefully before use.

Before installing and debugging the inverter, please be sure to read and fully

understand these safety rules and warning signs.

Transportation and storage instructions

Correct transportation, store, installation, careful operation and maintenance are

important for inverter safe operation.

In transport and store process, make sure the inverter is free from impact and

vibration. It must be stored where is dry without corrosive air and conductive dust,

and the temperature must be lower than 60℃.

Guide to installing wiring

AC300 series vector control inverter manual Overview

3

Only trained professionals can operate this product.

Power wire, motor wire and control wire should be all connected firmly. Earth

must be reliable and earth resistance must be lower than 10Ω.

Before turning on the inverter panel, please cut off the power of all related

equipment and confirm that the DC voltage of the main circuit has dropped to a

safe level. Wait for 5 minutes before related operations.

Human body electrostatic will damage inner sensitive components seriously.

Before operation, please follow ESD measures. Otherwise, there is danger of

inverter damage.

Inverter output voltage is pulse wave. If components such as capacitor which

improves power factor and pressure-sensitive resistance for anti-thunder and

so on are installed at the output side, please dismantle them or change to input

side.

No switch components such as breaker and contactor at the output side (If

there must be one, please make sure the output current is 0 while the switch

acting).

● The power cable and motor cable specifications which connected to the inverter

must meet the conditions shown in Table 3-7 3-8 of this manual.

Operational guidance

The frequency inverter operation at high voltages , dangerous voltages are

inevitably present on certain parts of the product.

Regardless of where the fault occurs in the control device, it can cause major

accidents or even personal injury and potentially dangerous faults. Therefore,

additional external precautions or other means for ensuring safe operation must

be taken, for example: Install independent current limiting switch, mechanical

protection and other devices.

In order to ensure that the overload protection of the motor can operate correctly,

the motor parameters of the input inverter must be similar to the actual motor .

Maintenance guidance

Only Veichi Electric co., ltd service department or its authorized service center

can maintain the products. It may cause product fault while using accessories

not authorized or permitted.

Any defective components must be changed in time in maintenance.

Before turning on the equipment for maintenance, make sure to disconnect the

power supply and confirm that the DC voltage of the main circuit has dropped to

a safe level. Wait 5 minutes before related work.

AC300 series vector control inverter manual Overview

4

Guidance on disassembly and waste disposal

The package of the inverter can be reused. Please keep the package for future

use or return it to the manufacturer.

The removed metal parts can recyclable.

Some devices may badly affect the environment, such as electrolytic capacitors,

please handle devices in accordance with the requirements of the environmental

protection department.

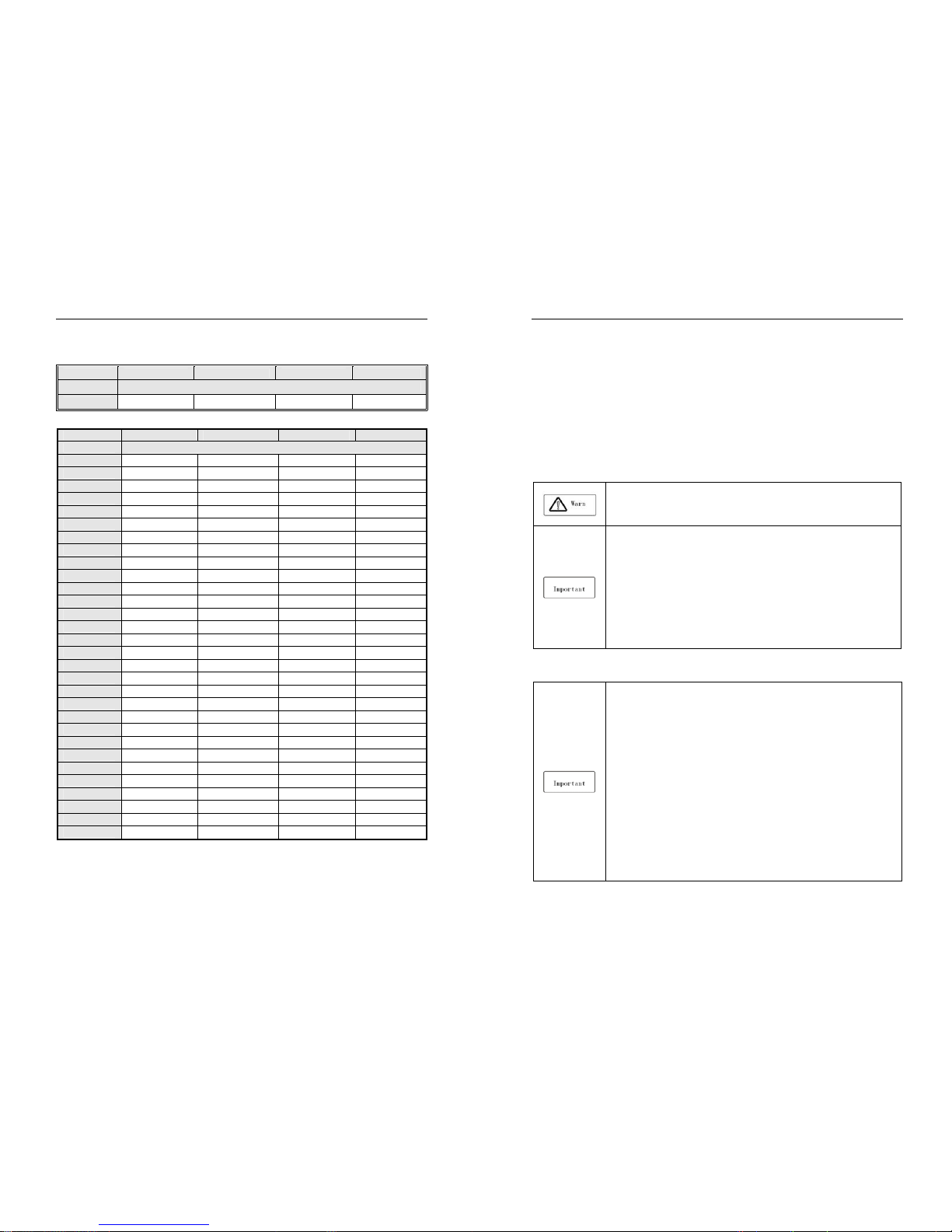

1.2 Technical Specifications

Table 1-1: Technical Specifications

Items Specifications

Powerin

put

Voltage, frequency

Single phase 220V 50/60Hz Three phase 380V 50/60Hz

Three phase 220V 50/60Hz Three phase 660V 50/60Hz

Three phase 1140V 50/60Hz Three phase 480V 50/60Hz

Allowable fluctuations

voltage unbalance rate:<3%; Frequency:±5%; aberration rate: as

IEC61800-2 required

Inrush current Lower than rated current

Power factor ≥0.94(with DC reactor)

Efficiency ≥96%

Output

Output voltage Output under rated condition: 3 phase, 0~input voltage, inaccuracy<5%

Output frequency

range

G/P type:0~600Hz

Output frequency

Max frequency ±0.5%

Overload capacity

G type: 150% rated current/1 min, 180% rated current/10s, 200% rated

current/0.5s

P type: 120% rated current/1 min, 140% rated current/10s, 150% rated

current/0.5s

Main

Controlper

formance

Motor control mode V/F without PG , VC without PG, V/F with PG, VC with PG

Modulation mode Optimized SVPWM mode

Carrier frequency

0.7~16.0kHz

Speed control range VC without PG: rated load 1:100; VC with PG: rated load 1:1000

Steady speed

accuracy

VC without PG: ≤2% rated synchronized speed; VC with PG: ≤0.05% rated

synchronized speed

Starting torque

VC without PG: when 0.5Hz, 150% rated torque; VC with PG: when 0Hz,

Torque response VC without PG: ≤20ms; VC with PG: ≤10ms

AC300 series vector control inverter manual Overview

5

Frequency accuracy Digit setting: max frequency×±0.01%; Analog setting: max frequency×±0.2%

Frequency resolution Digit setting: 0.01Hz; Analog setting: max frequency×0.05%

Basic

functions

DC braking capacity

Starting frequency:0.00~50.00Hz; Braking time:0.0~60.0s; Braking

current:0.0~150.0% rated current

Torque boost

Auto torque upgrade 0.0%~100.0%; Manual torque upgrade 0.0%~30.0%

V/F curve

4 modes: one linearity torque characteristic curve ,one self-setting V/F curve

mode, one drop torque characteristic curve (1.1- 2.0 powers),and square V/F

curve mode.

Acceleration/Deceler

ation curve

2 modes: linear Acceleration/Deceleration and S curve

Acceleration/Deceleration. 4 sets of ACC/DEC, time unit 0.01s selectable,

longest time: 650.00s.

Rated output voltage

Rely on power supply voltage compensate function, while motor rated

voltage is 100%, set it at the range of 50-100%(output can not over input

voltage).

Voltage

auto-adjustment

While power supply voltage fluctuates, it can auto-keep constant output

voltage.

Auto energy-saving

running

While under V/F control mode, according to load situation, auto-optimize

output voltage to save energy.

Auto-limit current Auto-limit the current while running to prevent over current break trouble.

Instant power off

treatment

While instant power off, realize continual operation by bus voltage control.

Standard functions

PID control, speed track, power off restart, jump frequency, upper/lower

frequency limit control, program operation, multi- speed, RS485, analog

output, frequency impulse output.

Frequency setting

channels

Keyboard digital setting, Analog voltage/current terminal AI1, Analog

voltage/current terminal AI2, Communication given and multi-channel

terminal selection, Main and auxiliary channel combination, expansion card,

supporting different modes switch

Feedback input

channel

Voltage/Current Terminal AI1, Voltage/Current Terminal AI12, Communication

given, Low-speed pulse input PUL, extension card

Running command

channel

Operation panel given, external terminal given, communication given,

expansion card given

Input command

signal

Start, stop, FWD/REV, JOG, multi-step speed, free stop, reset, ACC/DEC

time selection, frequency given channel selection, exterior fault alarm.

Exterior output

signal

1 relay output, 1 collector output, 1 AO output: 0~10V output or 4~20mA

output, or frequency pulse output

Protection function

Overvoltage, under-voltage, current limit, over-current, overload, electric

thermal relay, overheat, overvoltage stall, data protection, rapid speed

protection, input/output phase failure protection

AC300 series vector control inverter manual Overview

6

Keyboar

d display

LED display

Single file 5 digital tube display Can monitor one state variable

Two file 5 digital tube display Can monitor two state variables

Parameter copy

Can upload or download function code information of inverter to realize fast

parameter copy.

State monitor

Output frequency, given frequency, output current, input voltage, output

voltage, motor speed, PID feedback, PID given value, module temperature

etc. monitor parameters.

Fault alarm

,Over-voltage, under-voltage, over-current, short circuit, phase failure,

overload, overheat, overvoltage stall, current limit, or data protection

destroyed; Fault running state; Fault history.

Environ

ment

Install place

altitude ≤ 1000m,above 1000m down the rated amount, each increase of

100m down the rated amount of 1%;no condensation, ice ,rain, snow, hail;

solar radiation below 700W/㎡, air pressure 70-106 kPa

Temperature,

humidity

-10~+50℃, above 40℃ down the rated amount, the max temperature:60℃

(no load running)

Vibration

9~200Hz,5.9m/s2(0.6g)

5%—95%RH (no condensation)

Store temperature -30—+60℃

Installation Hanging type, cabinet type

Protection degree IP20

Cooling mode Forced air cooling

AC300 Series Vector Control Inverter Manual Before Use

7

Chapter 2 Before Use

2.1 Purchase Inspection

On receiving your order, please check the package and confirm intact before opening, and check if there’s any

damage, scratch or dirt (damages caused during transportation are not within the company's warranty). If there’s any

damage caused during transportation, please contact us or the transport company immediately.

After confirming the receipt of the goods intact, please re-confirm if the product and your order are consistent. Model

of the product is on the "MODEL" column. If you find the product model is not the one you ordered, please contact the

dealer you purchased the product or the sales department of VEICHI immediately.

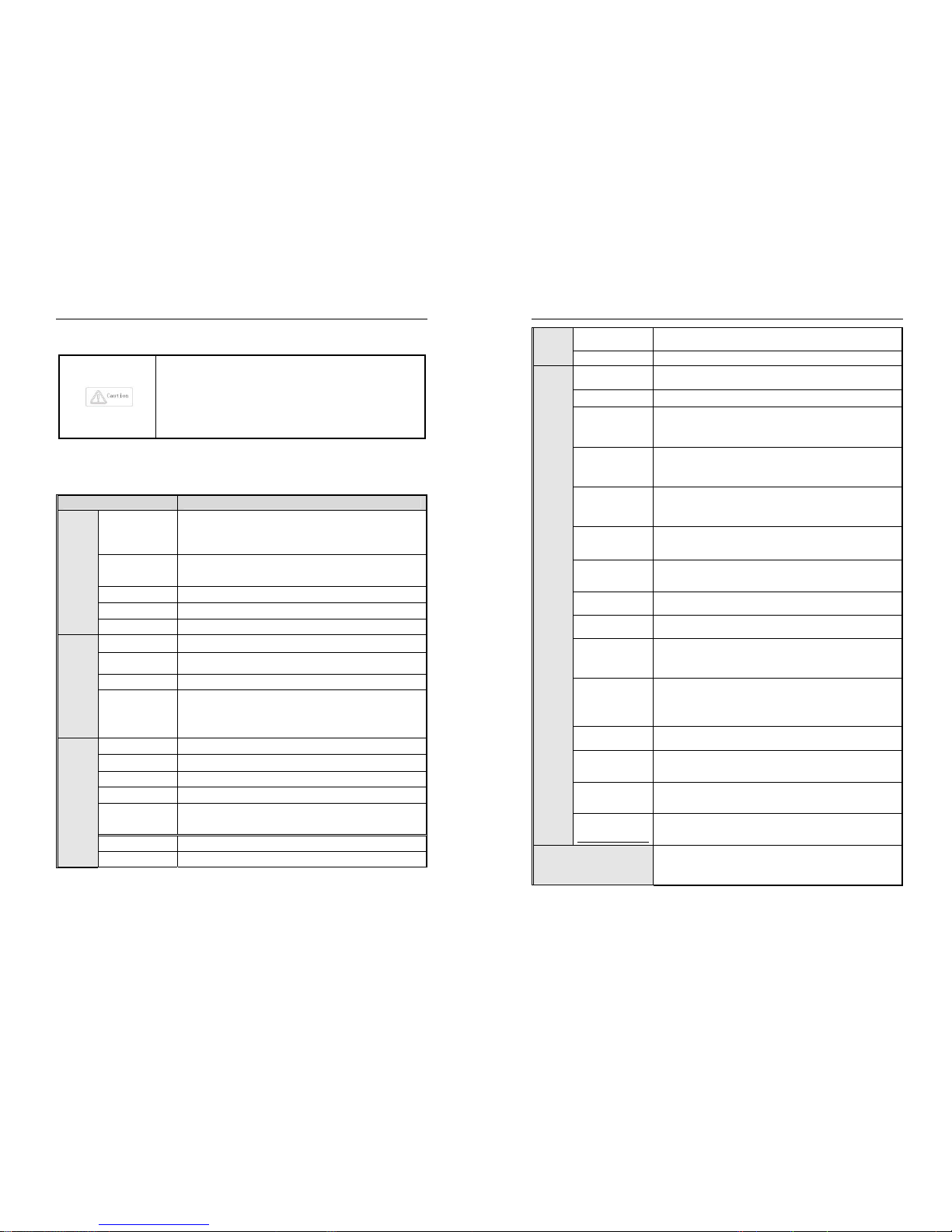

2.2 Nameplate

Nameplate Position and Content

Model Specification

Series

-

B

Code

V-level

2

220V

3

380V

6 660V

Code

V-Level

T

Tri-phase

S

One-phase

Code Inverter Type

G

Heavy load

Code

motor power(KW)

7R5

011

7.5

11

018

132

18.5

132

11

1140V

A

C300

P

Light load

Code

Code Accessory Type

B

Brake unit

AC300

T 3

- 011 G /015P-

AC300 Series Vector Control Inverter Manual Before Use

8

2.3 Inverter Rated Output Current

Input Voltage 220V 380V 660V 1140V

Rated Power Rated Output Current (A)

0.75 4 3

Input Voltage 220V 380V 660V 1140 V

Rated Power Rated Output Current (A)

1.5 7 4

2.2 10 6.0

4 16 10

5.5 20 13

7.5 30 17 10

11 42 25 15

15 55 32 18

18.5 70 38 22

22 80 45 28

30 110 60 35

37 130 75 45 25

45 160 90 52 31

55 200 110 63 38

75 260 150 86 52

90 320 180 98 58

110 380 210 121 75

132 420 250 150 86

160 550 310 175 105

185 600 340 198 115

200 660 380 218 132

220 720 415 235 144

250 470 270 162

280 510 330 175

315 600 345 208

355 670 380 220

400 750 430 260

450 810 466 270

500

860 540 325

560 990 600 365

630 1100 680 400

AC300 Series Vector Control Inverter Manual Installation and Wiring

9

Chapter 3 Installation and Wiring

3.1 Safety Precautions

This chapter explains the warnings that must be followed to ensure that the user can safely use the product,

maximize the performance of the inverter, and ensure reliable operation of the inverter.

Cautions in use

:

● While install the inverter in the closed cabinet, please build in cooling fan, air-conditioner

or other cooling equipment to ensure the temperature at the air-in port below 40℃. So that

the inverter can work safely and reliably.

● While installing, please use cloth or paper cover the inverter to prevent metal dust, oil,

water and others.And remove it carefully after working.

● While operation, please follow the ESD regulations. Otherwise, the inverter may be

damaged.

● While multi inverters are installed in the same cabinet, enough space must be left for

cooling fan.

● Inverter cannot work over rated range. Otherwise, the inverter may be damaged.

● While transporting the inverter, please hold the firm case. If only hold the pre-cover, there

is danger of inverter main body falling, injury or inverter damage.

Cautions in use motor

● Different motor has different max allowable running speed. Motor can not run over the

max allowable running speed.

● While inverter is running at low speed, the motor auto-cool effect is seriously worse. If

motor runs at low speed for long time, it will be damaged for overheat. If needed, please use

special motor for inverter.

● While constant speed machinery runs at inconstant speed, there maybe sympathetic

vibration. Please install vibration-proof rubber under motor rack or use jumping frequency

control function.

● While using frequency inverter or working frequency power supply to drive, the torque

characteristic are different. Please do confirm the torque characteristic of the equipment

connected.

● The rated current of diving motor is higher than that of standard motor, please confirm it

and choose the right inverter.

● While the wire between motor and inverter is long, the max torque of the motor will reduce

for voltage drop. So please use thick cable while the distance between the motor and the

inverter is long.

AC300 Series Vector Control Inverter Manual Installation and Wiring

10

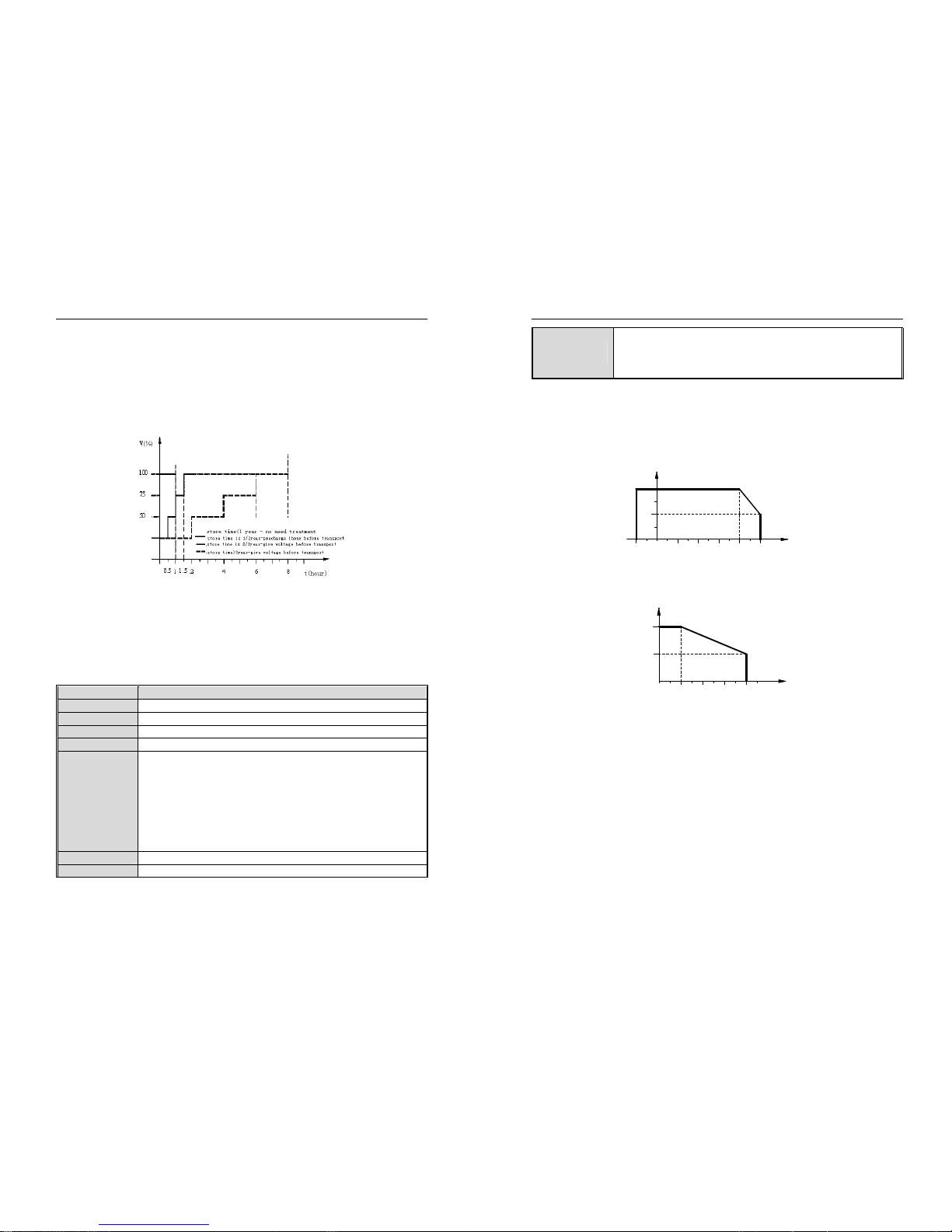

3.2 Treatment for Inverter after Longtime Store

If the inverter store time is over one year, you must pre-charge the aluminum capacitor in the inverter again and

install the inverter after the aluminum capacitor characteristic recovering. For the specific method, please follow the

grads in the chart below and give corresponding proportional voltage for every grad more than 30 mins while the

inverter is no-load.

If the input voltage of one grad is at the action critical point of contactor, fan or other equipment, please increase or

reduce the corresponding input voltage for the grad to avoid any component working under critical state.

Chart 3-1: treatment for inverter after longtime store

3.3 Inverter Stable Running Environment

Installation environment is very important to the best use of this product for long time. Pls install this product in the

environment as the following table requirement.

Table 3-1: Environmental conditions required for reliable operation of AC300 series inverters

Environment Requirement

Install place Indoor without direct sunshine

Install temperature -10 ~ +40℃

Store temperature -30 ~ +60℃

Humidity <95%RH, no condensation

Surrounding

Please install the inverter in place as follows:

● Place without oil mist, corrosive gases, flammable gas, dust or etc.

● Place without metal dust, oil, water or etc into inverter (please do not install inverter on

flammable material such as food and etc).

● Place without radioactive material or flammable material.

● Place without poisonous gases or liquid.

● Place with very little salification erosion.

● Place without direct sunshine.

Altitude <1000m, down power for use over 1000 meters

Vibration At 9 to 200 Hz, 5.9 m/s2 (0.6 g)

AC300 Series Vector Control Inverter Manual Installation and Wiring

11

Installation and

cooling

● Inverter can not be installed horizontally must be installed vertically.

● Please independently install high heating equipment such as braking resistor and etc

which can not be installed in the same cabinet with inverter, installed at the air-in port of

the inverter is strictly prohibited.

● In order to improve the product stability, do please not use the inverter where temperature changes sharply. While

using in closed space such as control cabinet, please use cooling fan or air-condition to cool inverter to avoid

temperature over limit range. Please also prevent inverter from freeze, too low temperature may cause components

freeze fault.

● Derate according to the chart while over temperature limit.

30

25

100

75

50

402010

0

-10 50

TEMPERATURE(℃)

PERMIT OUTPUT CURRENT(%)

Chart 3-2:AC300 series inverter derating curve while over permit temperature

● Derate according to the chart while over altitude limit.

0

1000 2000 4000

80

100

3000 ALTITUDE(M)

PERMIT OUTPUT CURRENT(%)

Chart 3-3:AC300 series inverter derating curve while over permit altitude

3.4 EMI Protection

The inverter is designed to be used in industrial environment with strong electromagnetic interference. Generally

speaking, if the installation quality is good, it is ensured that the inverter can work safely without fault. Please install the

inverter according to the following rules to ensure stable running and avoid electromagnetic interference impact.

● Ensure that all equipment in the cabinet have been connected reliably to the common Y-type earth point or earth

bus with thick and short cable. The motor earth should be as close as possible. Please do not connect the motor case

to the inverter earth terminal or the protective area of control system.

● Ensure that all equipment connected to the inverter have been reliably connected to the same earth net or Y-type

earth point with thick and short cable.

● The conductor has better to be flat and with multi core, what has lower resistance at high frequency.

AC300 Series Vector Control Inverter Manual Installation and Wiring

12

● The cutting terminal should be as soigne as possible. Unshielded wire section must be as short as possible.

● In control cable wiring, it should be as far from the power supply cable and motor cable as possible. And

independent cable trough should be used. While the control cable must cross to the power supply cable or motor cable,

it should be 90º vertical cross.

● Ensure that the contactor in the cabinet has wave surge suppresser. Or‘R-C’damping circuit is connected to the

winding of AC contactor. Voltage dependent resistor corresponding to the winding voltage is used. And freewheel diode

or components such as voltage dependent resistor corresponding to the winding voltage are connected to DC contactor.

It is very important while contactor, controlled by output relay of inverter, acts frequently.

● Cable connected to motor should be shielded cable or armoured cable. The two barriers are earthed reliably by

cable grounding card.

● Build noise filters at the input side to reduce electromagnetic interference from other equipments at the power grid

side. The noise filter should be as close to the inverter power input terminal as possible. Meantime, the filter must earth

reliably as the inverter.

● Build noise filters at the output side to reduce radio interference and inductive disturbance. The noise filter must be

as close to the inverter output terminal as possible. Meantime, the filter must earth reliably as the inverter.

● Anytime, control circuit wire should be shielded cable.

● Add zero phase reactor in power supply wire near inverter input terminal and add zero phase reactor in the motor

wire near inverter output terminal to reduce electromagnetic interference to the inverter efficiently.

● Earthing Right and reliable earthing is the basic condition of safe and reliable running of the product. For right

earthing, please read the following notice carefully.

● In order to avoid electric shock, earthing cable should be the size as electric

equipment technique standard required and cable length should be as short as

possible. Otherwise, inverter leakage current will cause unstable potential of the

earthing terminal which is far from the earthing point, and electric shock accident will

happen frequently.

● Earth terminal must be earthing. Earth resistance must be below 10Ω.

Otherwise, there is danger of death.

● Please do not share earth cable with welder or other big current/pulse power

equipment. Otherwise, inverter will act abnormally.

● While multi inverters are used at the same time, please do not wind the earth

wire to loop-type. Otherwise, inverter will act abnormally.

AC300 Series Vector Control Inverter Manual Installation and Wiring

13

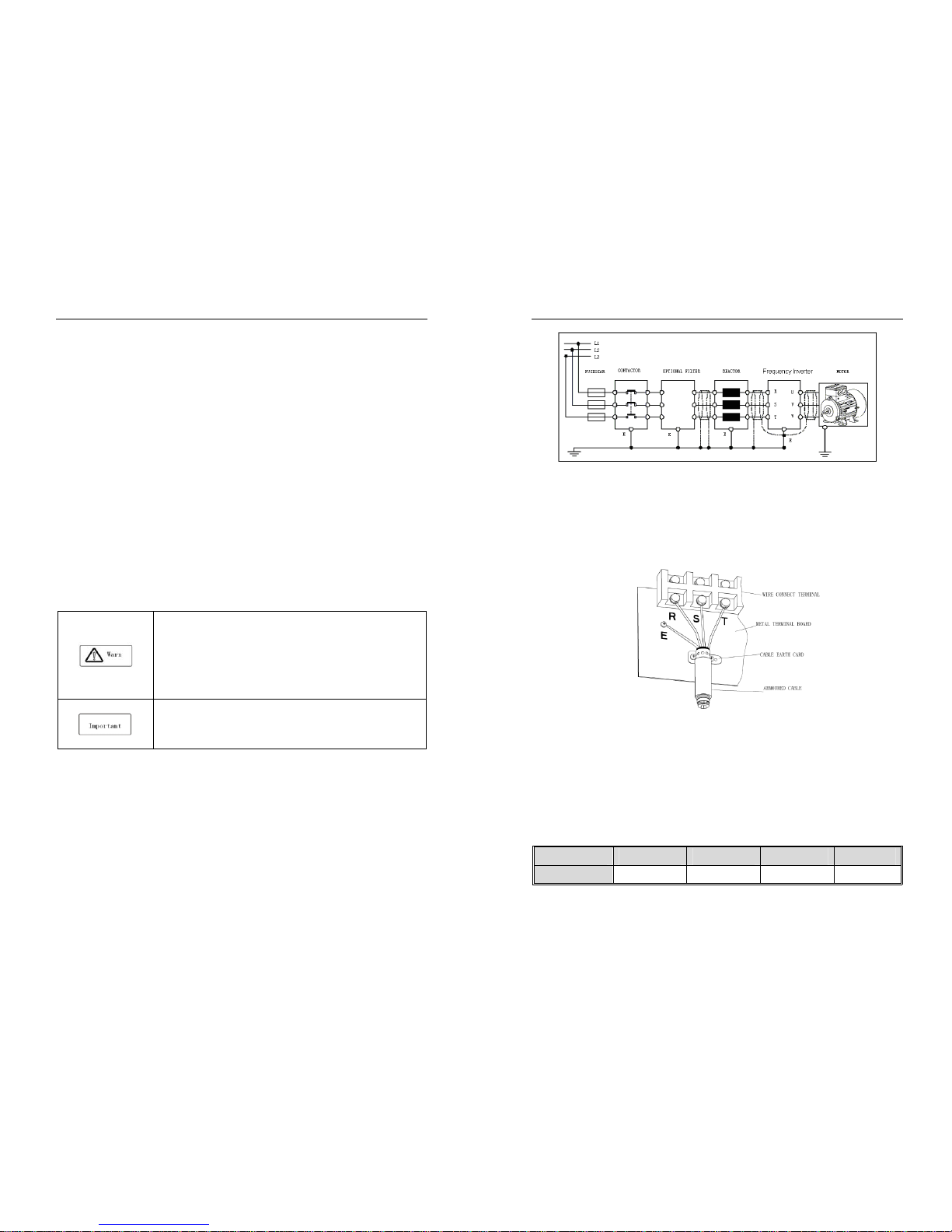

Chart 3-4:AC300 series inverter system grounding

Remark: motor must earth as close as possible. Motor case can not be connected to the inner earth terminal of the

inverter. It also can not share the earth net with the control system.

Shield of inverter power cable, motor cable and control cable

Shielding layer (reticulate/armoured) should be winded reliably by cable earth card and fix to inverter earth piece by

bolt. Please refer to the following chart.

Chart 3-5: Cable earth card for cables grounding

Corresponding relationship between inverter/motor cable length and carrier frequency

While cable distance between inverter and motor is long (especially low frequency output), cable voltage drop will

make motor torque reduce. Further more, cable HF leakage current will increase. Then inverter output current will

increase, that will cause inverter over-current trip. The current detection accuracy and running stability will be impacted.

Please follow as below table to adjust carrier frequency according to the cable length. While the cable distance is over

100m, please adopt distributed capacity reduce measure (Such as “no metal conductor covers cable”, “wire each phase

cable apart” and so on).

Table 3-2: Corresponding relationship between inverter/motor cable length and carrier frequency

Cable length <20m 20~50m 50~100m >100m

Carrier frequency 0.7~16kHz 0.7~8kHz 0.7~4kHz 0.7~2kHz

AC300 Series Vector Control Inverter Manual Installation and Wiring

14

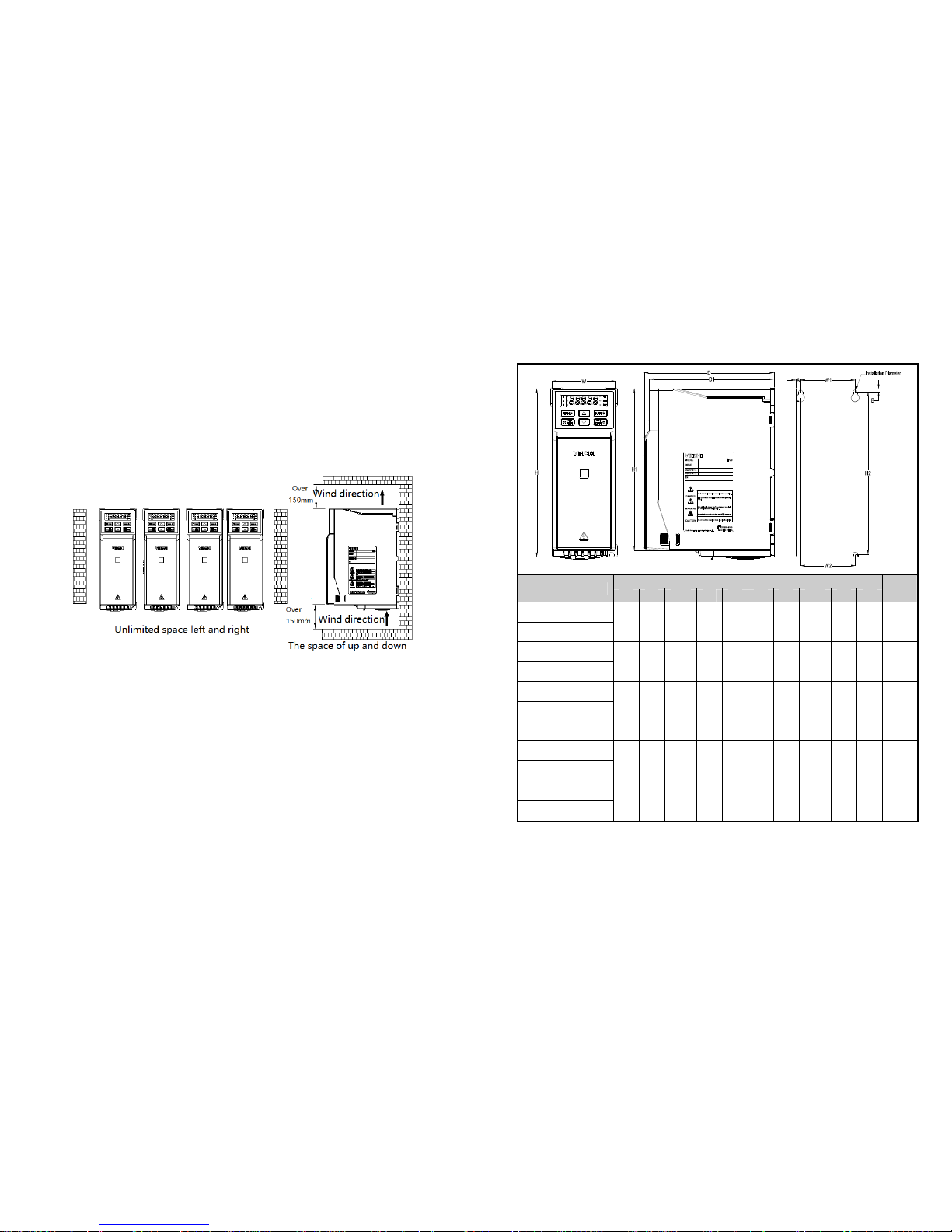

3.5 Machinery Installation

Installation notice and related requirement:

● Installation direction

To prevent inverter cooling effect reducing, please do install the inverter vertically.

● Installation space

Single machine installation: to ensure enough ventilation and wiring space for inverter cooling, please follow

installation conditions as follows. The back of the inverter should stick to the wall. So that the surrounding air of radiator

can flow freely to ensure the cooling effect.

Chart 3-6: Inverters paratactic installation space requirement

AC300 Series Vector Control Inverter Manual Installation and Wiring

15

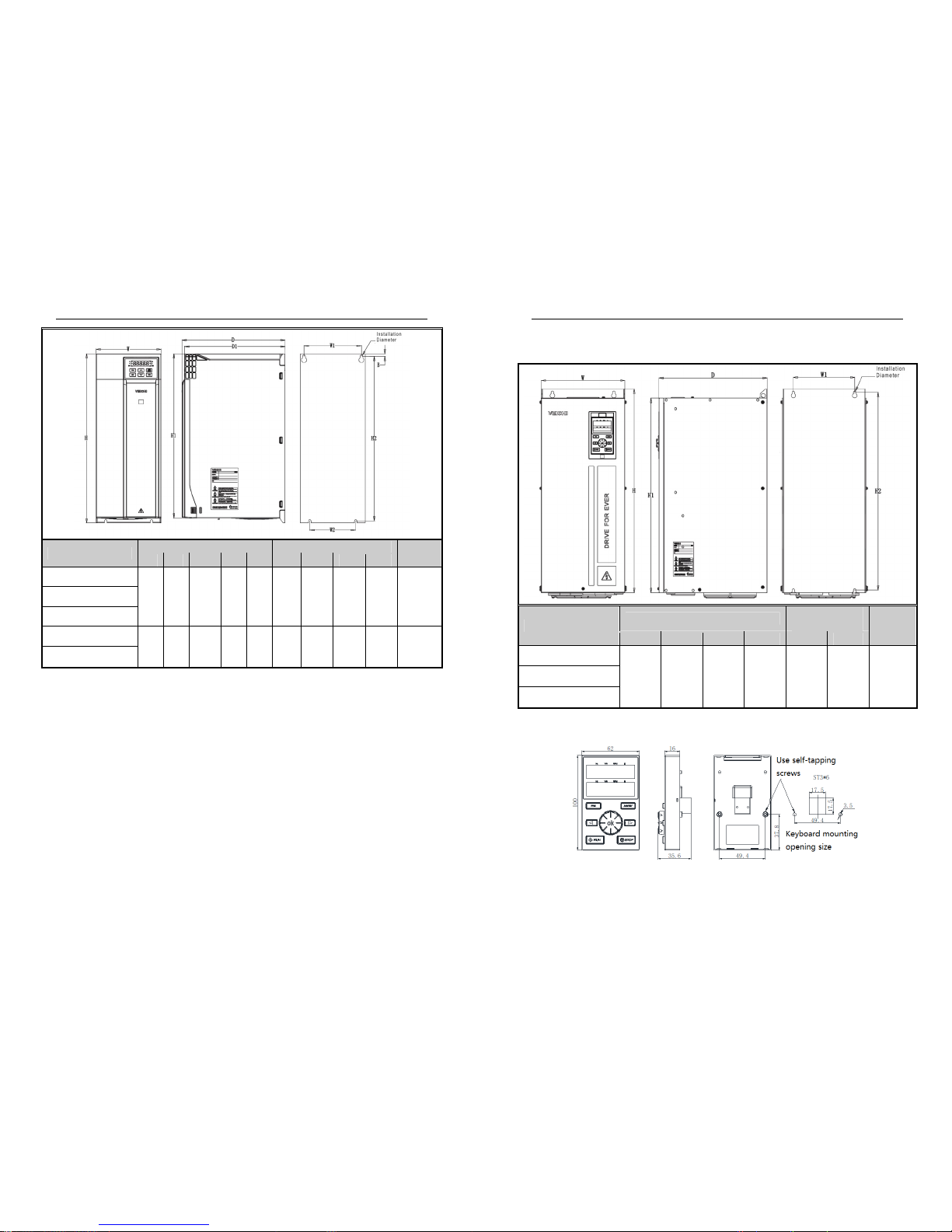

Dimension of Inverter and Keyboard

MODEL

Overall Dimension(mm) Installation Dimension(mm)

Apertu

re

W H H1 D D1 W1 W2 H2 A B

AC300-T/S2-R75G-B

76 200 192 155 149 65 65 193 5.5 4 ф3-M4

AC300- T/S2-1R5G-B

AC300- T/S2-2R2G-B

100 242 231 155 149 84

86.

5

231.5 8 5.5 ф3-M4

AC300- T/S2-004G-B

AC300-T3-R75G/1R5P-B

76 200 192 155 149 65 65 193 5.5 4 ф3-M4 AC300-T3-1R5G/2R2P-B

AC300-T3-2R2G-B

AC300-T3-004G/5R5P-B

100 242 231 155 149 84

86.

5

231.5 8 5.5 ф3-M4

AC300-T3-5R5G/7R5P-B

AC300-T3-7R5G/011P-B

116 320 307.5 175 169 98 100 307.5 9 6 ф3-M5

AC300-T3-011G/015P-B

AC300 Series Vector Control Inverter Manual Installation and Wiring

16

MODEL

Overall Dimension(mm) Installation Dimension(mm)

Aperture

W H H1 D D1 W1 W2 H2 B

AC300-T3-015G/018P -B

142 383 372 225 219 125 100 372 6 ф4-M5 AC300-T3-018G/022P-B

AC300-T3-022G/030P-B

AC300-T3-30G/037P

172 430 / 255 219 150 150 416.5 7.5 ф4-M5

AC300-T3-037G/045P

AC300 Series Vector Control Inverter Manual Installation and Wiring

17

Overall Dimension of Inverter (Steel)

MODEL

Overall Dimension(mm)

Installation

Dimension(mm)

Aperture

W H H1 D W1 H2

AC300-T3-045G/055P

240 560 535 310 176 544 ф4-M6 AC300-T3-055G/075P

AC300-T3-075G/090P

External keyboard shape and opening size

Note: LCD is fully compatible with LED keyboard size and opening size.

AC300 series keyboard and opening size

AC300 Series Vector Control Inverter Manual Installation and Wiring

18

AC300 Keyboard pocket opening size

3.6 Electric Installation

This chapter explains the regulations that users have to obey to ensure safe use, best performance and reliable

running.

Safety precaution

● Must earth reliably while inverter is running. Otherwise there is danger of casualty and

unstable inverter performance.

● To ensure safe running, only trained professional person can do installation and wiring

job.

● No operation under power connected state. Otherwise there is danger of electric shock

even death.

● Before operation, please cut all related equipments power, ensure that the main circuit

DC current has dropped to safe range. And please operate after 5 mins.

● Control cable, power cable and motor cable must be separated. They can not be in the

same cable trough or cable rack.

● This equipment can only be used as the maker states. Please consult Veichi while

using in special case.

● No insulation test for the inverter or the related cable by HV insulation test equipment.

● If the inverter or the peripheral equipment (filer, reactor and etc) needs insulation test,

firstly 500V megohmmeter should be used to test the insulation resistance which

should not be lower than 4MΩ.

AC300 Series Vector Control Inverter Manual Installation and Wiring

19

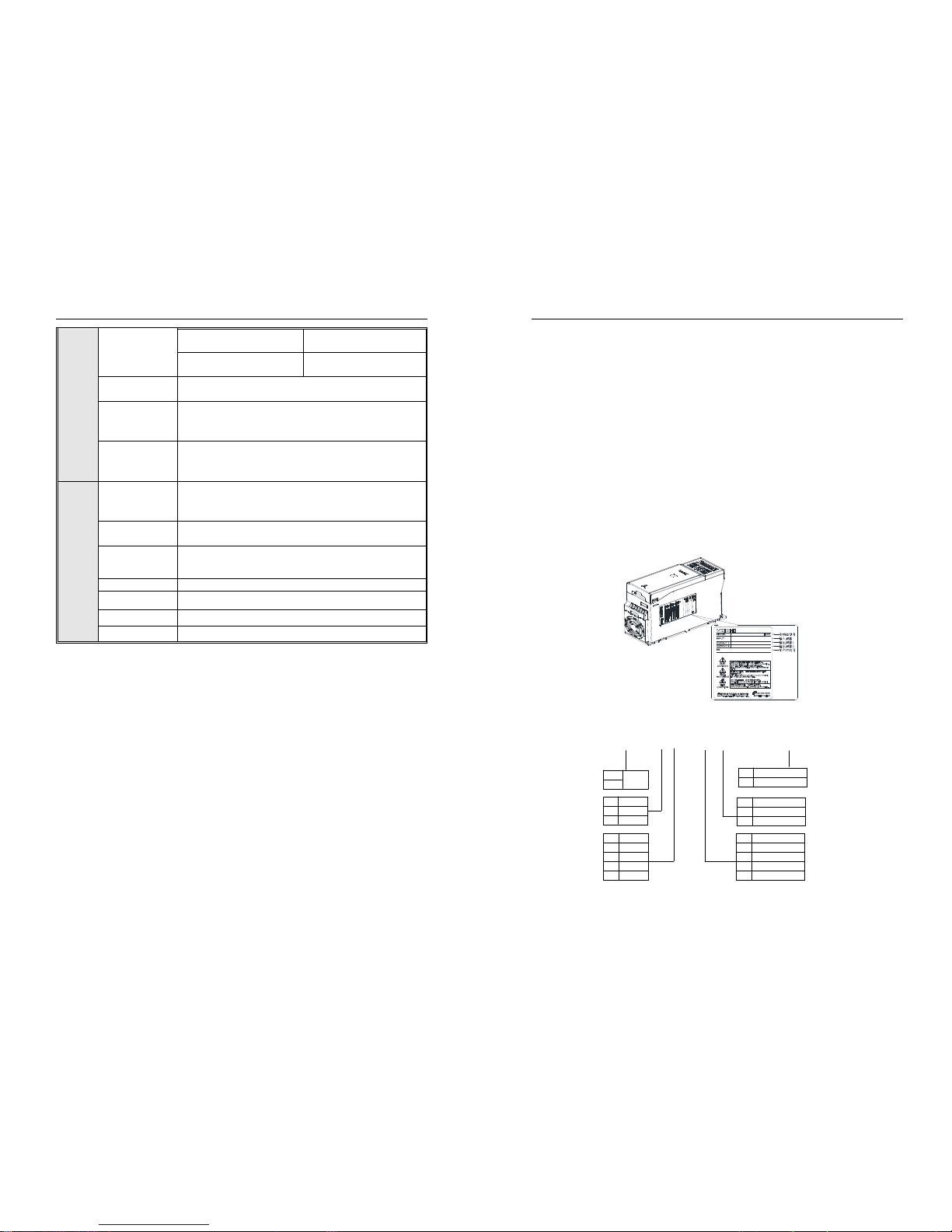

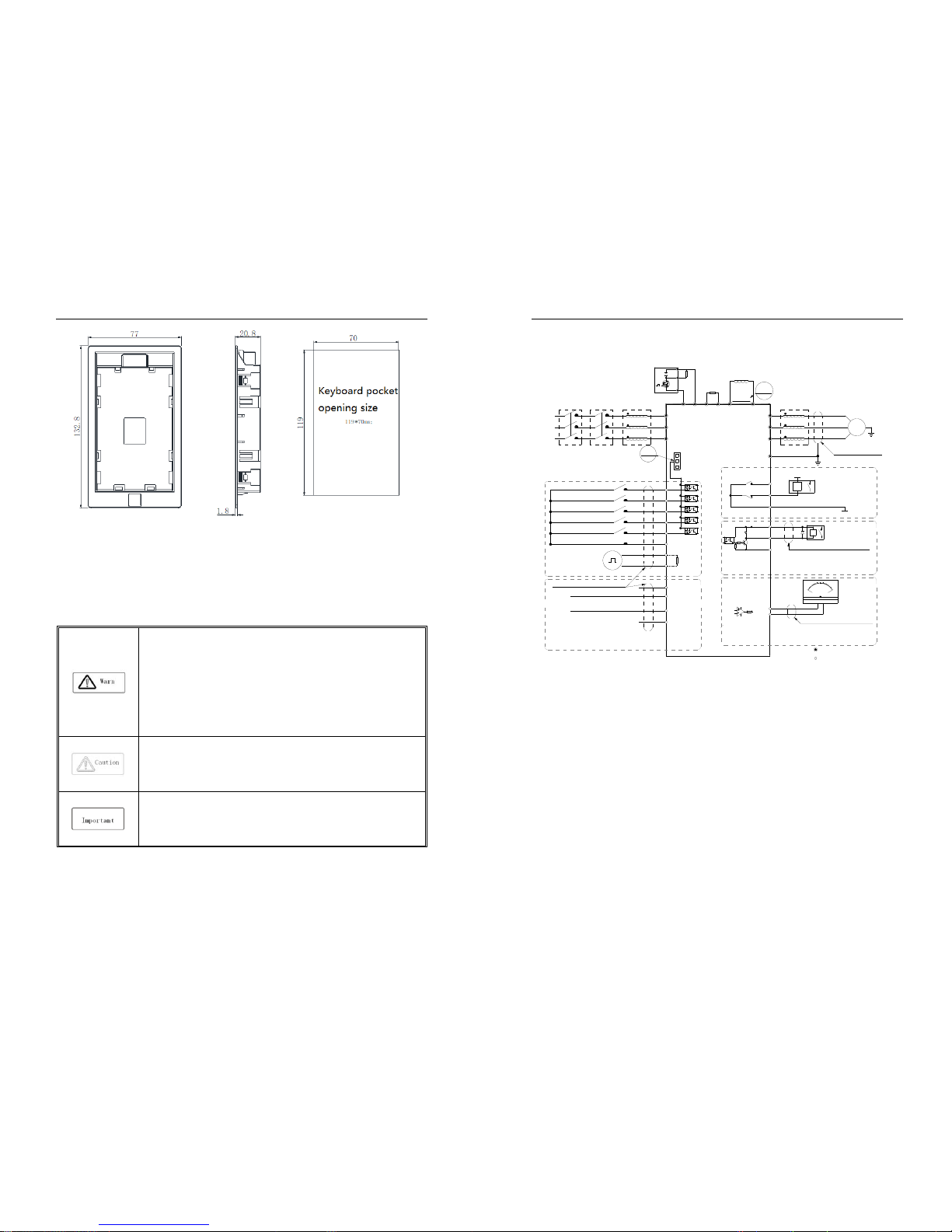

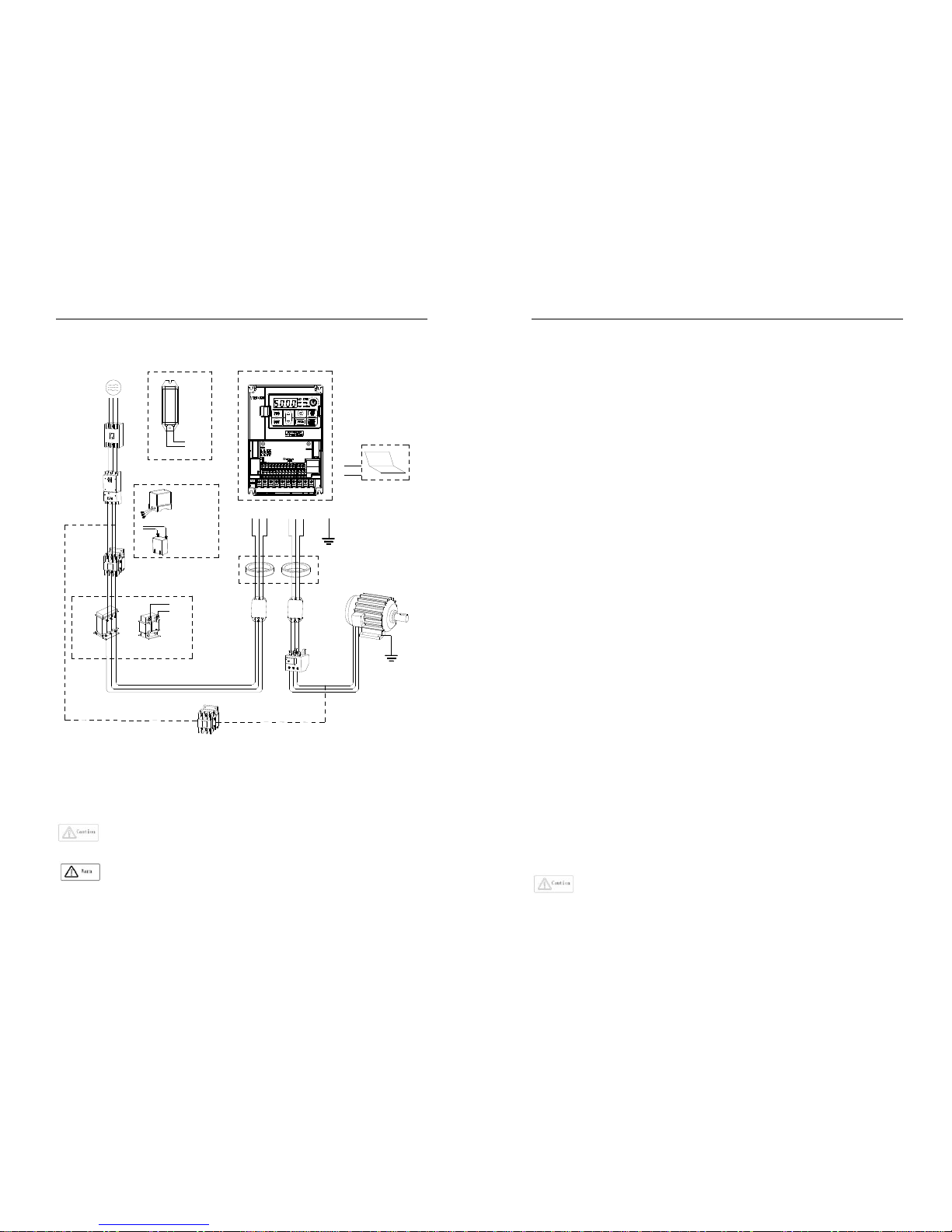

Standard Connection Diagram

Note2

Note:Function description in brackets is

factory default

Note1

Analog monitoring

signal output

TA

TB

TC

+24V

Y

Shielded cable (the

end close to VFD

grounding)

_

mA

2

0

10

0

-

+

V

W

U

M

~

Shielded cable or armoured cable

(the end close to VFD grounding)

E

(The grounding resistance

is less than 10 ohms)

W

V

U

Output Rector

External DC Rector

External

Brake

Resistor

Short

Piece

P1

+

( )

R

External Brake Unit

+10V

Frequency control input

R

T

S

AC POWER INPUT

GND

AI1

AI2

Shielded cable (the end close to

VFD grounding)

Multi function contact input

(REV JOG)

(FWD JOG)

(Reverse)

(Forward)

(Free STOP)

COM

X3

X4

X5

X1

X2

PB

( )+(-)

VFD

S

T

R

GND

A0

Coil

COM

Passive contact

output

AC220V

AC0V

Coil

MAX Output Of Contact:

3A/240VAC

5A/30VDC

1.MAX Output of +24V Port:DC24V/100mA

Note:When output type of AO port as

frequency and Voltage,

Maximum Output:2mA

2.Inner resistance of AI1/AI2 Port

1.MAX Output of +10V port :50mANote:

2.Max Output of Y Port :DC24V/50mA

Note:

represent control circuit terminals.

represent main circuit terminals;

Legend:

1.Symbol

Shielded cable

(the end close

to VFD grounding)

Input Rector

ContactorMCCB

+

( )

PUL

+24V

PLC

COM

Analog Voltage/Current quantity input

A+

B-

RS485 Differential

Communication

120Ω

Open collector(OC)

state output

Analog Voltage/Current quantity input

2.Symbol

Chart 3-8:AC300 series inverter standard diagram

Note:

When installing DC reactor, make sure to dismantle the short connector between terminal P1 and (+).

NPN or PNP transistor signal can be selected as input of multi-function input terminal (X1~X5/PUL) .

Inverter built-in power supply (+24V terminal) or external power supply (PLC terminal) can be chosen as

bias voltage. Factory setting ‘+24V’ short connect with ‘PLC’, which locates between RJ45 and

terminals.

● Auxiliary terminal output capacity

AC300 Series Vector Control Inverter Manual Installation and Wiring

20

Ter min al Function definition Max output

+10V

10V auxiliary power supply output, constitutes loop with

GND.

50mA

A0 Analog monitor output, constitutes loop with GND.

As frequency,voltage signal, max

output 2mA

+24V

24V auxiliary power supply output, constitutes loop with

COM.

100mA

Y

Collector open circuit output, can set the action-object by

program.

DC24V/50mA

TA/ TB/ TC

Passive connector output,can set the action-object by

program.

3A/240VAC

5A/30VDC

● Function Specification of Switch Terminals

Switch Terminal Selecting Position Function Specification

RS485 Terminal Resistor RS485 Communication :connect with 120Ω terminal

A

O Output- frequency

A

O2: 0.0~100kHz frequency output

A

O Output- Current

A

O2: 0~20mA current output or 4~20mA current output

A

O Output- Volt age 0~10V voltage output

A

I1 Input- Current/Voltage AI1: Input 0~20mA or 0~10V

A

I2 Input- Current/Voltage AI2: Input 0~20mA or 0~10V

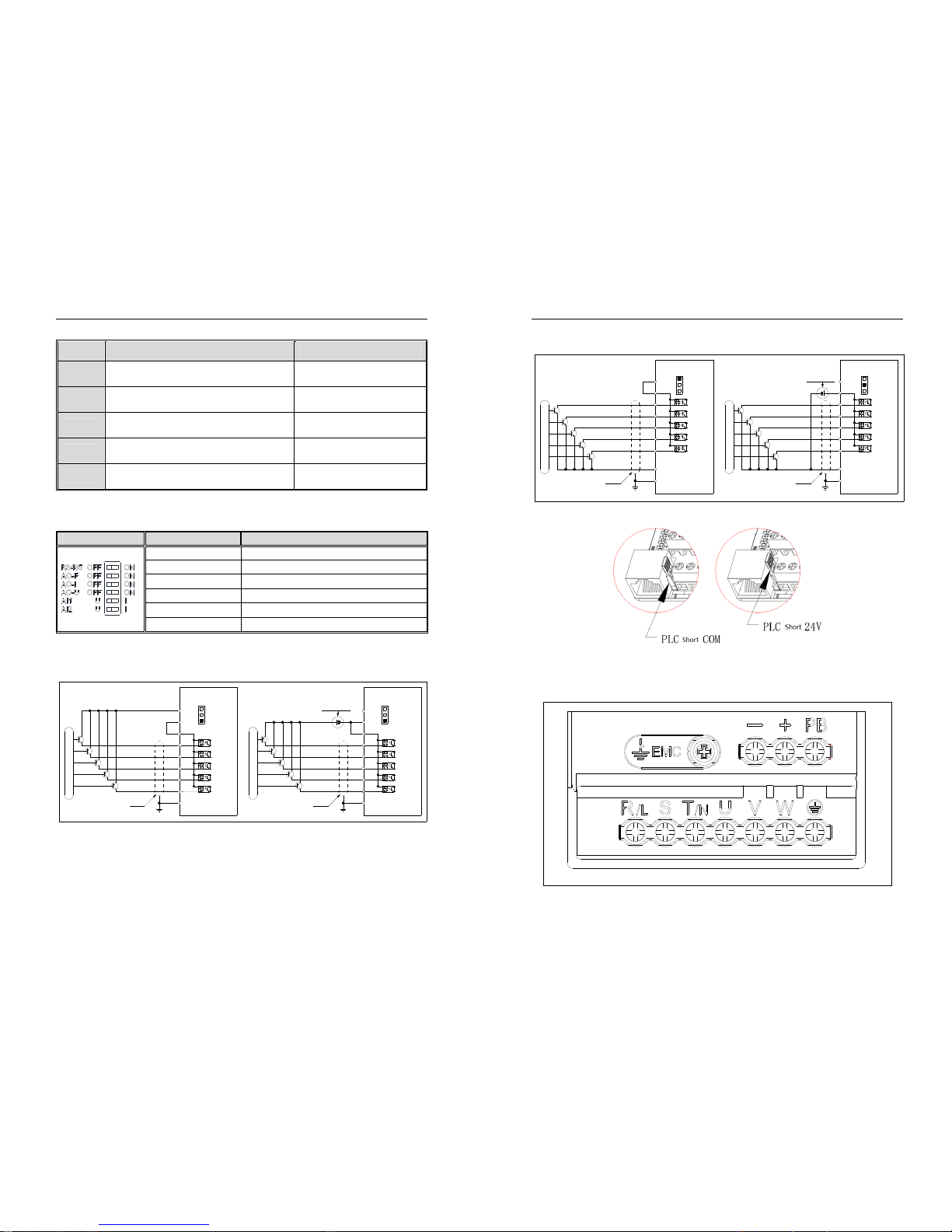

● Multi-function input point connection

PNP transistor connection mode:

-

+

External power supply

E

X5

X3

X4

X2

X1

PLC

+24V

Enabled external 24V power supply

COMCOM

Enabled inner 24V power supply

+24V

PLC

X1

X2

X4

X3

X5

Shield Cable

E

External control signals

+24V

PLC

COM

+24V

PLC

COM

VFD VFD

External control signals

Shield Cable

AC300 Series Vector Control Inverter Manual Installation and Wiring

21

NPN transistor connection mode:

Enabled inner 24V power sup ply

+24V

PLC

X1

X2

X4

X3

X5

COM

Shield Cable

E

(Default short connected )

E

COM

X5

X3

X4

X2

X1

PLC

+24V

Enabled external 24V power supply

External control signals

Shield Cable

Note:

Jumper between"+24V"and"PLC" need be removed

when external 24V power supply was chosen.

External 24V power supply

+

-

+24V

PLC

COM

+24V

PLC

COM

VFD VFD

External control signals

Jumper cap "+24V", "PLC", "COM" connection diagram:

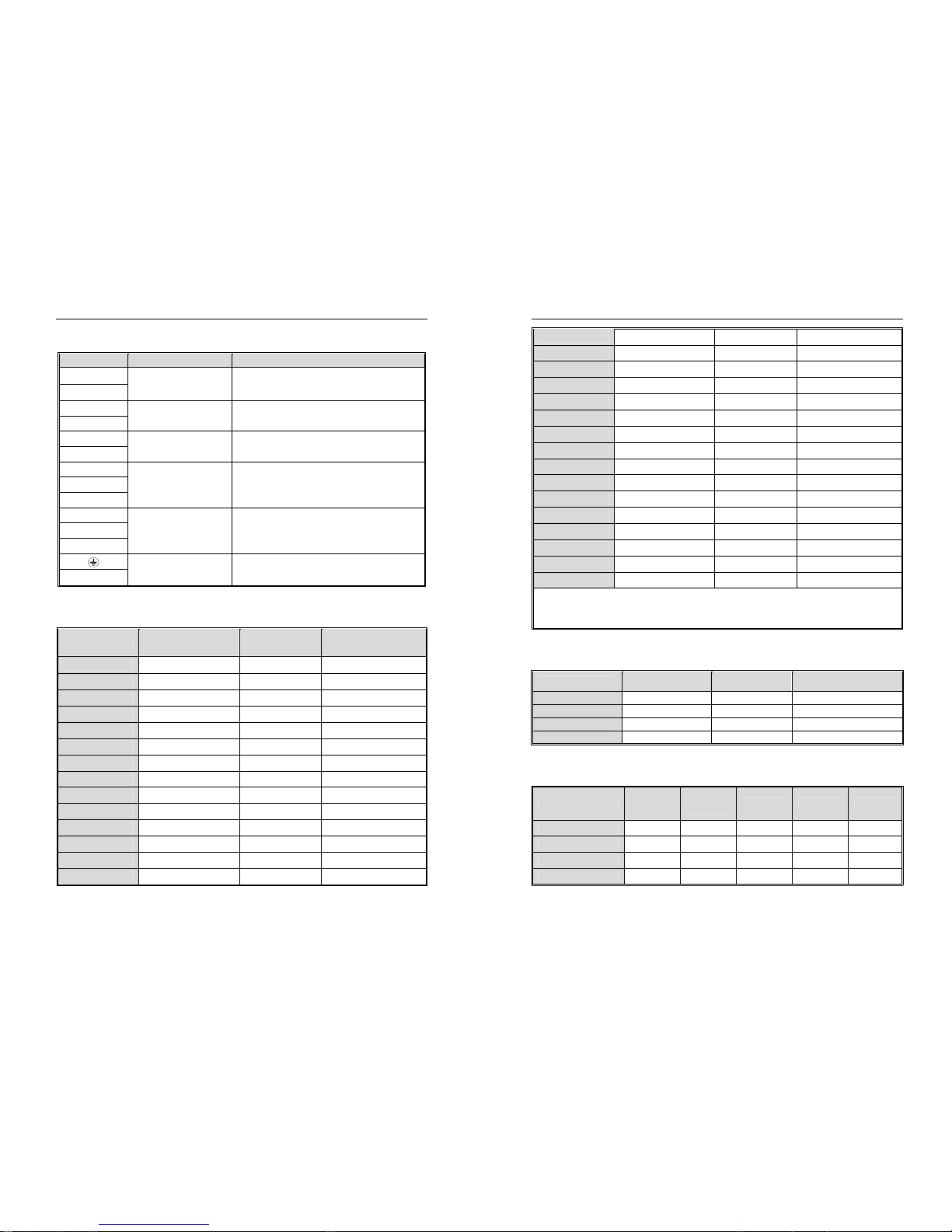

Main circuit wiring

● Main circuit wiring

Terminals array and definition:

AC300 Series Vector Control Inverter Manual Installation and Wiring

22

Table 3-3: Main circuit terminal arrangement and definition of AC300 series inverter

Ter min al Name Definition

(-)

DC power terminal

DC power output, (-) means DC bus cathode, (+) means

DC bus anode, used for external braking unit.

(+)

(+)

Braking resistance terminal Used for external braking resistance to realize quick stop.

PB

P1

DC reactor terminal Used for external DC reactor.

(+)

R

Inverter input terminal Used to connect 3-phase AC power supply. S

T

U

Inverter output terminal Used to connect the motor. V

W

Earth Earth terminal, earth resistance<10 OHM

E

● 3-phase 380V machine main circuit wiring

Table 3-4: Suggested cable diameter and fixed moment 3-phase 380V machine main circuit

Model

Main circuit terminals

screw specifications

Suggested fixed

moment (N·m)

Suggested Copper-core

cable specification mm

2

AC300-T3-R75G M4 1.2~1.5 1.5mm2(14)

AC300-T3-1R5G M4 1.2~1.5 2.5mm2(12)

AC300-T3-2R2G M4 1.2~1.5 2.5mm2(12)

AC300-T3-004G M4 1.2~1.5 4mm2(10)

AC300-T3-5R5G M4 1.2~1.5 6mm2(9)

AC300-T3-7R5G M5 2~2.5 6mm2(9)

AC300-T3-011G M5 2~2.5 10mm2(7)

AC300-T3-015G M6 4~6 10mm2(7)

AC300-T3-018G M6 4~6 16mm2(5)

AC300-T3-022G M6 4~6 16mm2(5)

AC300-T3-030G M8 8~10 25mm2(3)

AC300-T3-037G M8 8~10 25mm2(3)

AC300-T3-045G M8 8~10 35mm2(2)

AC300-T3-055G M10 11~13 35mm2(2)

AC300 Series Vector Control Inverter Manual Installation and Wiring

23

AC300-T3-075G M10 11~13 50mm2(1)

AC300-T3-090G M10 11~13 50mm2(1/0)

AC300-T3-110G M10 11~13 70mm2(2/0)

AC300-T3-132G M10 11~13 95mm2(3/0)

AC300-T3-160G M12 14~16 95mm2(4/0)

AC300-T3-185G M12 14~16 120mm2

AC300-T3-200G M12 14~16 150mm2

AC300-T3-220G M12 14~16 150mm2

AC300-T3-250G M12 14~16 185mm2

AC300-T3-280G M12 14~16 185mm2

AC300-T3-315G M16 20~23 240mm2

AC300-T3-355G M16 20~23 240mm2

AC300-T3-400G M16 20~23 300mm2

AC300-T3-450G M16 20~23 400mm2

AC300-T3-500G M16 20~23 400mm2

AC300-T3-560G M16 20~23 500mm2

Note:

Here we suggest using copper joins as mains electric connectors of machine over 185KW. Please

refer the cut section area above.

● Single-phase 220V machine main circuit wiring

Table 3-5: Suggested cable diameter and fixed moment single-phase 220V machine main circuit

Model

Main circuit terminals

screw specifications

Suggested fixed

moment (N·m)

Suggested Copper-core cable

specification mm2 (AWG)

AC300-S2-R40G M4 1.2~1.5 1.5mm2(14)

AC300-S2-R75G M4 1.2~1.5 2.5mm2(12)

AC300-S2-1R5G M4 1.2~1.5 2.5mm2(12)

AC300-S2-2R2G M4 1.2~1.5 4mm2(10)

● Suggested main circuit components specification

Table 3-6: Suggested mains fittings for 3-phase 380V machine

Model

Contactor

specification

Breaker

specification

DC reactor Input filter Output filter

AC300-T3-R75G 10A 10A ------ NFI-005 NFO-010

AC300-T3-1R5G 10A 10A ------ NFI-005 NFO-010

AC300-T3-2R2G 16A 15A ------ NFI-010 NFO-010

AC300-T3-004G 16A 20A ------ NFI-010 NFO-010

AC300 Series Vector Control Inverter Manual Installation and Wiring

24

AC300-T3-5R5G 25A 20A ------ NFI-020 NFO-020

AC300-T3-7R5G 25A 30A ------ NFI-020 NFO-020

AC300-T3-011G 32A 40A ------ NFI-036 NFO-036

AC300-T3-015G 40A 50A ------ NFI-036 NFO-036

AC300-T3-018G 50A 60A ------ NFI-050 NFO-050

AC300-T3-022G 50A 75A ------ NFI-050 NFO-050

AC300-T3-030G 63A 100A DCL-80 NFI-080 NFO-080

AC300-T3-037G 80A 125A DCL-100 NFI-100 NFO-100

AC300-T3-045G 100A 150A DCL-110 NFI-100 NFO-100

AC300-T3-055G 125A 175A DCL-125 NFI-150 NFO-150

AC300-T3-075G 160A 200A DCL-150 NFI-150 NFO-150

AC300-T3-090G 220A 250A DCL-200 NFI-200 NFO-300

AC300-T3-110G 220A 300A DCL-200 NFI-200 NFO-300

AC300-T3-132G 250A 400A DCL-300 NFI-300 NFO-300

AC300-T3-160G 300A 500A DCL-300 NFI-300 NFO-300

AC300-T3-185G 400A 600A DCL-400 NFI-400 NFO-400

AC300-T3-200G 400A 700A DCL-400 NFI-400 NFO-400

AC300-T3-220G 630A 800A DCL-500 NFI-600 NFO-600

AC300-T3-250G 630A 1000A DCL-600 NFI-600 NFO-600

AC300-T3-280G 630A 1200A DCL-600 NFI-600 NFO-600

AC300-T3-315G 630A 1200A DCL-800 ------ ------

AC300-T3-355G 800A 1400A DCL-800 ------ ------

AC300-T3-400G 1000A 1600A DCL-1000 ------ ------

AC300-T3-450G 1000A 2000A DCL-1000 ------ ------

AC300-T3-500G 1000A 2000A DCL-1200 ------ ------

AC300-T3-560G ------ 2000A DCL-1200 ------ ------

Note: For DC reactor, input filter, output filter and other components specification details and circuit mode, please

refer chapter 7 “peripheral equipments and options”

AC300 Series Vector Control Inverter Manual Installation and Wiring

25

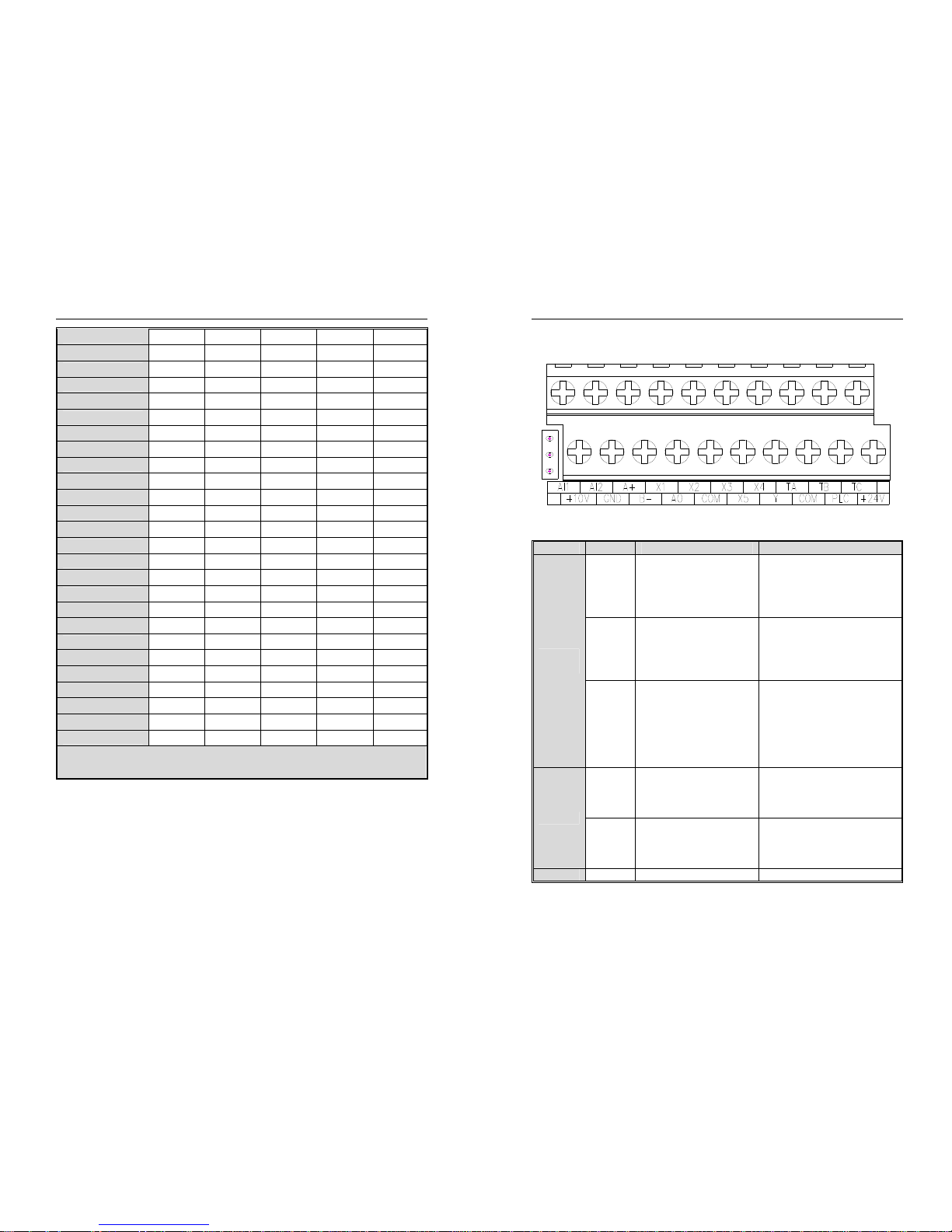

Control loop terminals

● Control loop terminals array

Table 3-7:AC300 series inverter control loop terminals array and definition

Sort Term in al Name Function definition

Power

supply

+10V-GND External +10V power supply

Provide +10V power supply to the outside,

the maximum output current: 50 mA is

generally used as external potentiometer

working power supply, potentiometer

resistance range: 1KΩ ~ 5KΩ

+24V-COM External +24V power supply

Provides +24V power supply to the

outside, generally used as digital input

and output terminal working power supply

and external sensor power supply

Maximum output current: 100 mA

PLC

External

common terminal

Factory default connection with +24V

When using X1~X5/PUL to drive the

external signal, the PLC needs to be

connected to the external power supply

and disconnected from the +24V power

supply (see "+24V", "PLC", "COM"

connection diagram for details)

Analog input

AI1-GND Voltage or current type analog input

1. Input current range: DC 0V ~ 10V / 0mA

~ 20mA

2. Voltage type input impedance: 100KΩ

3. Current input impedance: 500Ω

AI2-GND Voltage or current type analog input

1. Input current range: DC 0V ~ 10V / 0mA

~ 20mA

2. Voltage type input impedance: 100KΩ

3. Current input impedance: 500Ω

Digital input X1-PLC Multi-function contact input 1 Optocoupler isolation, compatible with

AC300 Series Vector Control Inverter Manual Installation and Wiring

26

X2-PLC Multi-function contact input 2 bipolar inputs.

1. Input impedance: 4.4 KΩ

2. High-level input voltage range: 10 ~

30V

3. Low-level input voltage range: 0 ~ 8V

X3-PLC Multi-function contact input 3

X4-PLC Multi-function contact input 4

X5-PLC

Multi-function contact input 5

X5/PUL-PLC Multi-function contact input 5 / high

speed pulse input

In addition to the features of X1 ~ X4, X5

can also be used as a high-speed pulse

input channel

(separate model).

1. Optocoupler isolation, compatible with

bipolar input, maximum input frequency:

100KHZ

2. Input impedance: 1.5KΩ

3. Pulse input level range: 10 ~ 30V

Analog

output

AO1-GND Analog output 1

1. Output voltage range: DC 0V ~ 10V

2. Output current range: DC 0mA ~ 20mA

3. Pulse output range: 0 ~ 50kHz

Digital output Y-C OM Digital output 1

Optocoupler isolation, open collector

output

1. Output voltage range: DC 0V ~ 30V

2. Output current range: DC 0mA ~ 50mA

Relay output

TA-T C Normally open terminal Contact drive capability:

240VAC, 3A

30VDC, 5A

TB-TC Normally closed terminal

communicati

on

Terminal

A+ Communication terminal A+ RS485 communication interface.

Select the RS485 communication access

120ohm terminal resistance by the toggle

switch S4 (see Table 3-5 for details)

B- Communication terminal B-

● Control loop terminal wiring specification

Table 3-8: Control loop terminal wiring specification

Ter min al

Bolt specification

(mm)

Fixed moment

(N·m)

Cable

specification

(mm2)

Cable type

A+ B- M2.5 0.4~0.6 0.75

Twisted-pair

shielded cable

+10V GND A0 AI1 AI2

M2.5 0.4~0.6 0.75

Twisted-pair

shielded cable

+24V COM Y TA TB TC PLC

X1 X2 X3 X4 X5/PUL

M2.5 0.4~0.6 0.75 Shielded cable

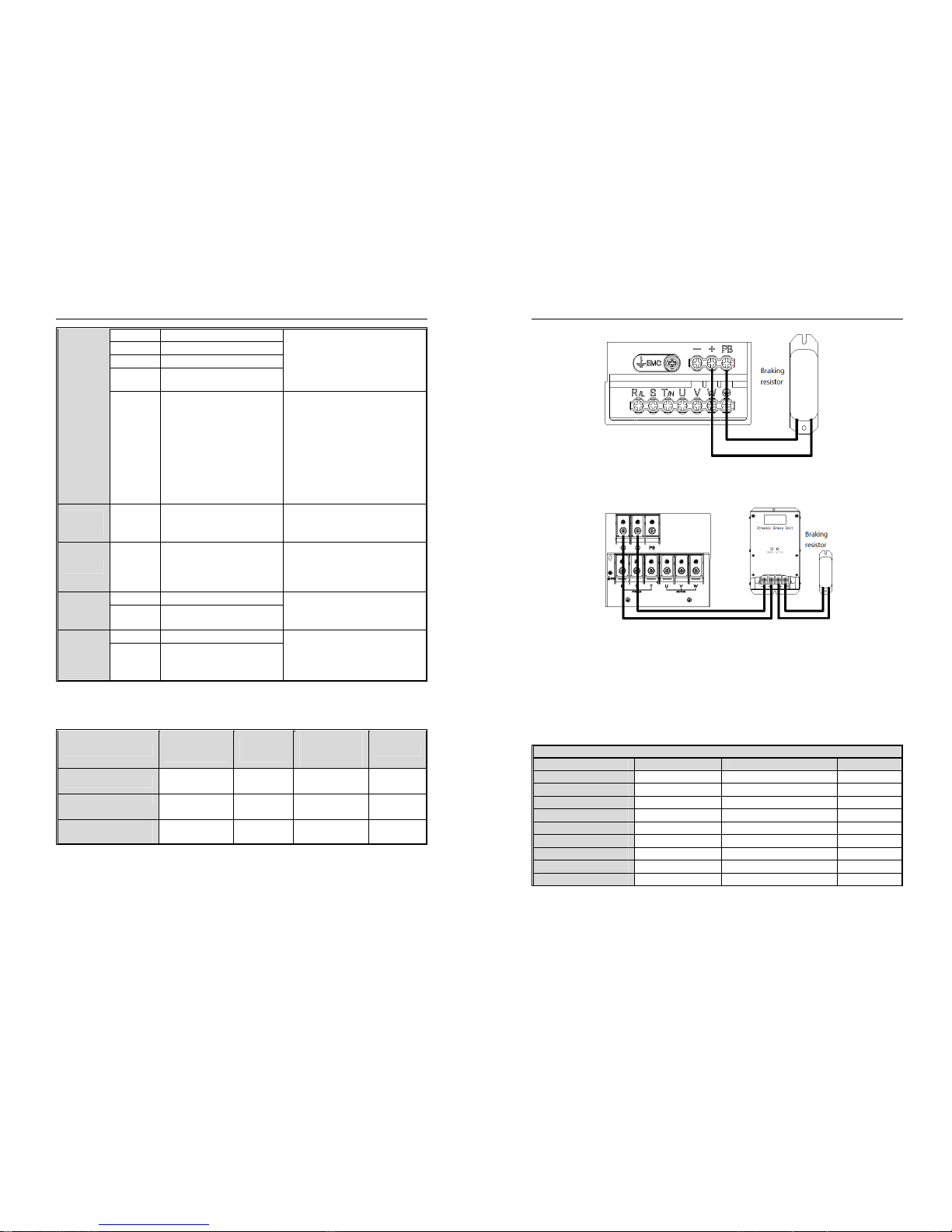

Braking unit (braking resistance) connection

● Brake resistance wiring of machine with 22KW or less power:

AC300 Series Vector Control Inverter Manual Installation and Wiring

27

Fig 3-9: AC300 series frequency inverter brake resistance wiring of machine with 22KW or less power

● Brake resistance wiring of machine with 30KW or above

Fig 3-10: AC300 Series Frequency Inverter Brake resistance wiring of machine with 30KW or above

● Suggested braking resistance specification parameters

Braking resistance value and power in the chart are decided according to common inertia load and intermittent

braking mode. While used in large inertia occasion or long time frequent brake occasion, please adjust resistance value

and power according to the inverter specification and the rated parameter of braking unit. If any problem, please consult

customer service department of Veichi Electric Com., Ltd.

Table 3-9: Suggested braking resistance specification parameters of AC300 series inverter

Three-phase 380V

Motor power(kW) Resistance value(Ω) Resistance power(W)

Braking torque

0.75 kW 750Ω 150W 100%

1.5 kW 400Ω 300W 100%

2.2 kW 250Ω 400W 100%

4.0 kW 150Ω 500W 100%

5.5 Kw 100Ω 600W 100%

7.5 kW 75Ω 780W 100%

11 k W 5 0Ω 1,200W 100%

15 kW 40Ω 1,500W 100%

18.5 kW 32Ω 2,000W 100%

AC300 Series Vector Control Inverter Manual Installation and Wiring

28

22 kW 32Ω 2,000W 100%

30 kW 24Ω 3,000W 100%

37 kW 20Ω 3,700W 100%

45 kW 16Ω 4,500W 100%

55 kW 13Ω 5,500W 100%

75 kW 9Ω 7,500W 100%

90 kW 6.8Ω 9,300W 100%

110 kW 6.2Ω 11,000W 100%

132 kW 4.7Ω 13,000W 100%

160 kW 3.9Ω 15,000W 100%

185 kW 3.3Ω 17,000W 100%

200 kW 3Ω 18,500W 100%

220 kW 2.7Ω 20,000W 100%

250 kW 2.4Ω 22,500W 100%

280 kW 2Ω 25,500W 100%

315 kW 1.8Ω 30,000W 100%

355 kW 1.5Ω 33,000W 100%

400 kW 1.2Ω 42,000W 100%

450 kW 1.2Ω 42,000W 100%

500 kW 1Ω 42,000W 100%

560 kW 1Ω 50,000W 100%

Single-phase 220V

Motor power(kW) Resistance value(Ω) Resistance power(W)

Braking moment

0.4 kW 400Ω 100W 100%

0.75 kW 200Ω 120W 100%

1.5 kW 100Ω 300W 100%

2.2 kW 75Ω 300W 100%

● Build-in braking unit max braking performance

Braking unit of AC300 series product with low power can be selected according to the suggested braking

resistance specification parameters in table 3-11. In large inertia or long time frequent brake occasion, the

moment maybe should be increased. The max braking power is showed in the following table, the range of

which can not be over in use. Otherwise the equipment maybe destroyed. If any problem, please consult Veichi

Electric Com., Ltd customer service department.

Table 3-10:AC300 series inverter build-in braking unit max braking power

Three-phase380V

Inverter model Motor power Max braking current Min resistance

AC300-T3-R75G 0.75 kW 3.5A 200Ω

AC300-T3-1R5G 1.5 kW 3.5A 200Ω

AC300-T3-2R2G 2.2 kW 7A 100Ω

AC300-T3-004G 4 kW 10A 75Ω

AC300 Series Vector Control Inverter Manual Installation and Wiring

29

AC300-T3-5R5G 5.5 KW 10A 75Ω

AC300-T3-7R5G 7.5 kW 14A 50Ω

AC300-T3-011G 11 kW 17A 40Ω

AC300-T3-015G 15 kW 23A 30Ω

AC300-T3-018G 18.5 kW 28A 25Ω

AC300-T3-022G 22 kW 28A 25Ω

Three / Single-phase 220V

Inverter model Motor power Max braking current Min resistance

AC300-T/S2-R40G 0.4 kW 3.8A 100Ω

AC300-T/S2-R75G 0.75 kW 3.8A 100Ω

AC300-T/S2-1R5G 1.5 kW 6.5A 60Ω

AC300-T/S2-2R2G 2.2 kW 10.5A 40Ω

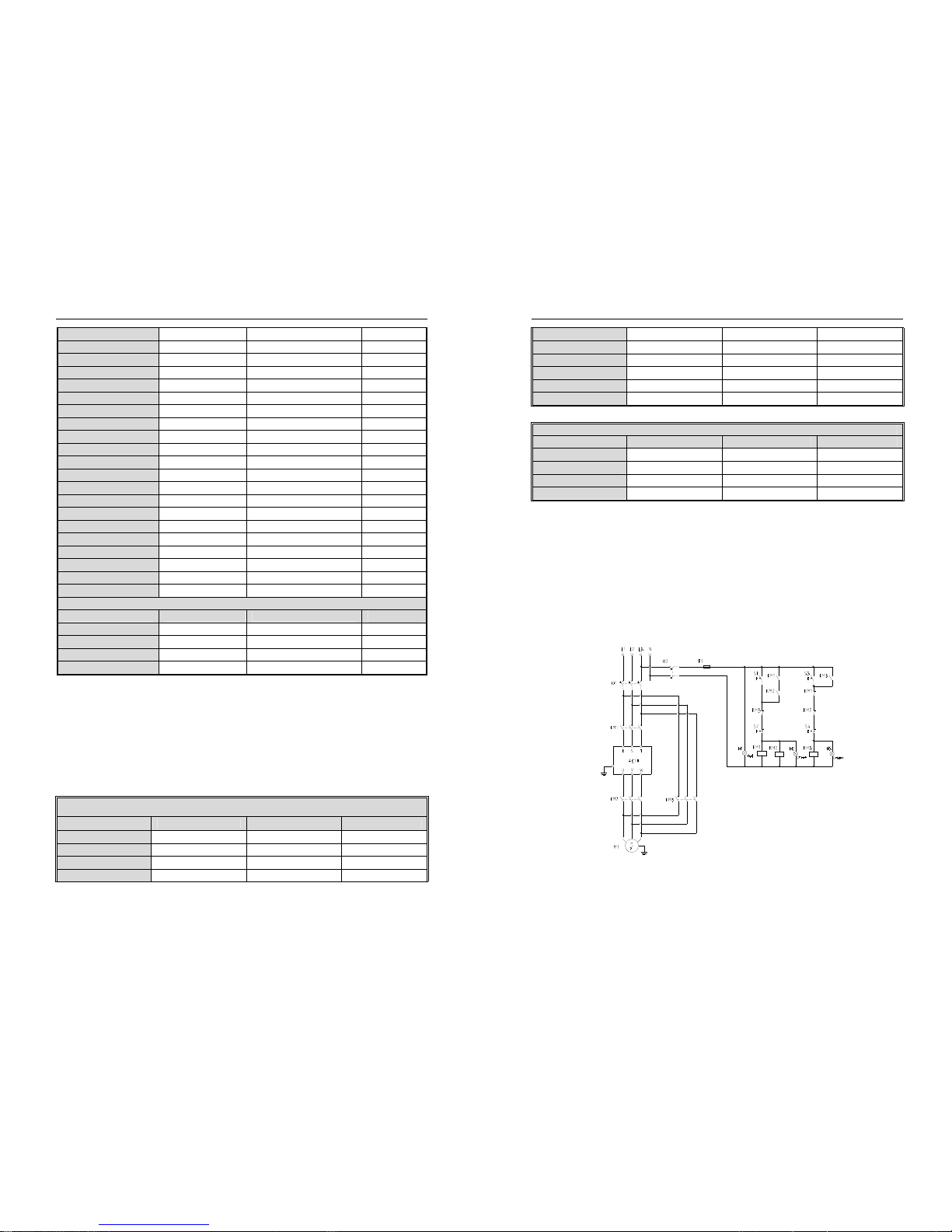

Standby control system

Frequency inverter is composed of semiconductor, passive electronic component and driving part. All of them have

useful time, which means these parts may happen characteristic change or out of use in normal working environment.

And it will cause product fault. To avoid production stop led by the fault, we suggest preparing standby control system

when using the inverter.

Chart 3-11 is a standby control system for manual switch to power supply driving motor at inverter fault. Standby

control systems such as power supply Y/Δ step-down start way driving motor, power supply self-coupling reduction

voltage start mode driving motor, power supply soft start mode driving motor or standby inverter system can be chose to

use according the actual requirement and environment.

Chart 3-11: Standby control system of power supply directly driving mode

AC300 Series Vector Control Inverter Manual Basic Operation and Trial Run

30

Chapter 4 Basic Operation and Trial Run

4.1 Safety Precautions

● No wiring while power supply is connected.Otherwise there is danger of electric shock.

● No operation while the cover is open.Otherwise, there is danger of electric shock.

● Please ensure reliable earth. Otherwise, there is danger of electric shock and fire.

● Before wiring please cut power supply of all related equipments and ensure main DC

voltage in safe range. And please do operation after 5 mins.

● Only professional trained person is allowed to operate this product.

● Please do not dismantle the inverter cover while it is electrified. Otherwise, there is

danger of electric shock.

● Please do not touch the printed circuit board of the inverter while it is electrified.

Otherwise, there is danger of electric shock.

● Please ensure reliable mains cable connection. If the mains cable is loose, thereis

danger of fire caused by joint overheat.

● Before electrifying, please check the power voltage again. Wrong power voltage can

cause fault or damage the inverter, even cause fire.

● Please do not install inverter on flammable material or attach flammable material to the

inverter. Before electrifying, please clear the surroundings.

Important

● While operation, please follow the ESD regulations. Otherwise, the inverter maybe

damaged.

● Please don’t cut the power directly while the inverter drives the motor running. The

power can’t be cut until the motor totally stop. Otherwise, the inverter maybe damaged.

● Please don’t cut or connect motor while the inverter drives the motor running. The motor

can’t be cut or connect until the inverter output is 0. Otherwise, the inverter maybe

damaged.

● Control cable should be twisted-pair shielded cable. The barrier should be connected to

the inverter earth terminal reliably to prevent the inverter from abnormal working.

● Unprofessional person can not operate, install, wiring, debug and maintain.

● Change, dismantle or maintain without permission may cause inverter damage. This

case is not in our quality assurance range.

AC300 Series Vector Control Inverter Manual Basic Operation and Trial Run

31

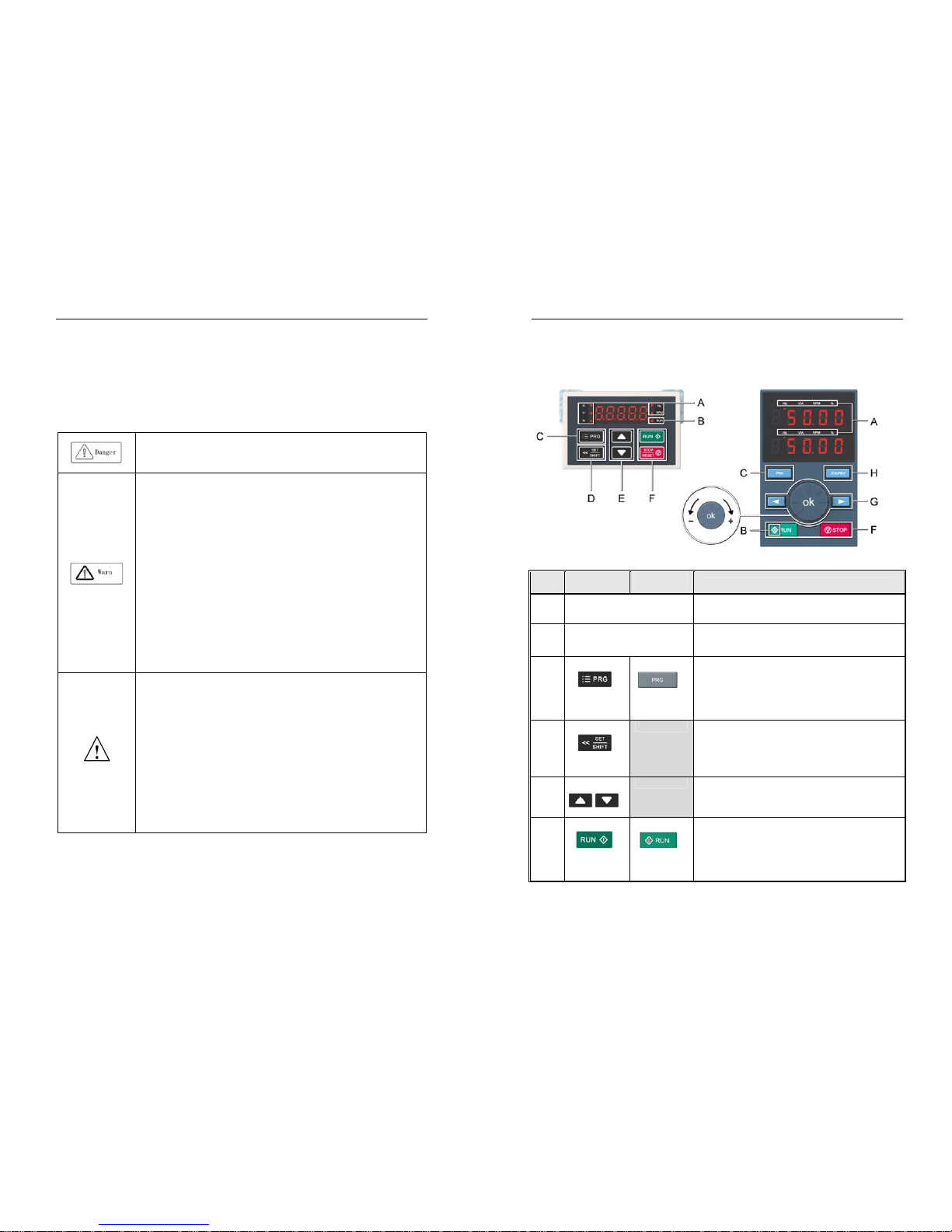

4.2 Keyboard layout and functions specification

● Keyboard name

Integrated keyboard (37KW and below Double-line keyboard (37KW or more machine)

●Key function

Integrated

keyboard

Double-line

keyboard

Function

A

Unit indicator

Hz: Frequency A: Current V: Voltage V/A: Voltage or

current RPM: Speed %: Percentage

B

Status Indicator

On: Forward running status Blinking: Reverse running status Off:

Stop status

C

Menu

Menu

Enter the function menu interface during standby or running;

press this button to exit the modification when the parameter is

modified; press the button (1 second) during standby or running

to enter the status interface directly.

D

Set/Shift

Set function: After modifying the value, press this key to confirm

the modified value.

Shift function: long press this button (1 second) to move the

operation bit, long press is not loose, then cyclic shift

E

Up, Down

The up key increases the operation value and the down key

decreases the operation value.

F

Run

Run

When the run/stop is controlled by the keyboard, press this

button to turn the inverter forward. The status indicator is always

on during forward run, and the status indicator is flashing during

reverse run.

AC300 Series Vector Control Inverter Manual Basic Operation and Trial Run

32

Stop/Reset Stop/Reset

When the command given channel is keyboard control, press

this key to stop the inverter; the parameter [F04.08] can be used

to define whether other command channels are valid; the

inverter resets when pressing the key in fault status.

G

Digital potentiometer: clockwise to increase the operating value,

counterclockwise to decrease the operating value

Set key: After modifying the value, press this key to confirm the

modified value.

Left/Right Shift

Move left and right operation bits

H

Jog/Reverse

Select the function of the key by parameter [F04.07], 0: reverse

1: jog

● Number word comparison table

Table 4-1: Digital Text Comparison Table

AC300 Series Vector Control Inverter Manual Fault Diagnoses and Processing

33

Chapter 5 Fault Diagnoses and Processing

This chapter explains the display content and processing of the inverter fault, alarm and operation fault. It also simply

explains the bad situation caused by inverter or motor fault and how to solve it. For the adjustment guide in trial run,

please refer this chapter too.

5.1 Fault Types

Type Inverter action while fault happens

External fault

In certain application occasions, external related equipments fault signals are considered in

the inverter control system as usage of monitoring, protection or switch control. At this time,

if one multi function terminal is defied as “external fault”, the inverter stops output alarm

signal.

5.2 Fault Information and Details

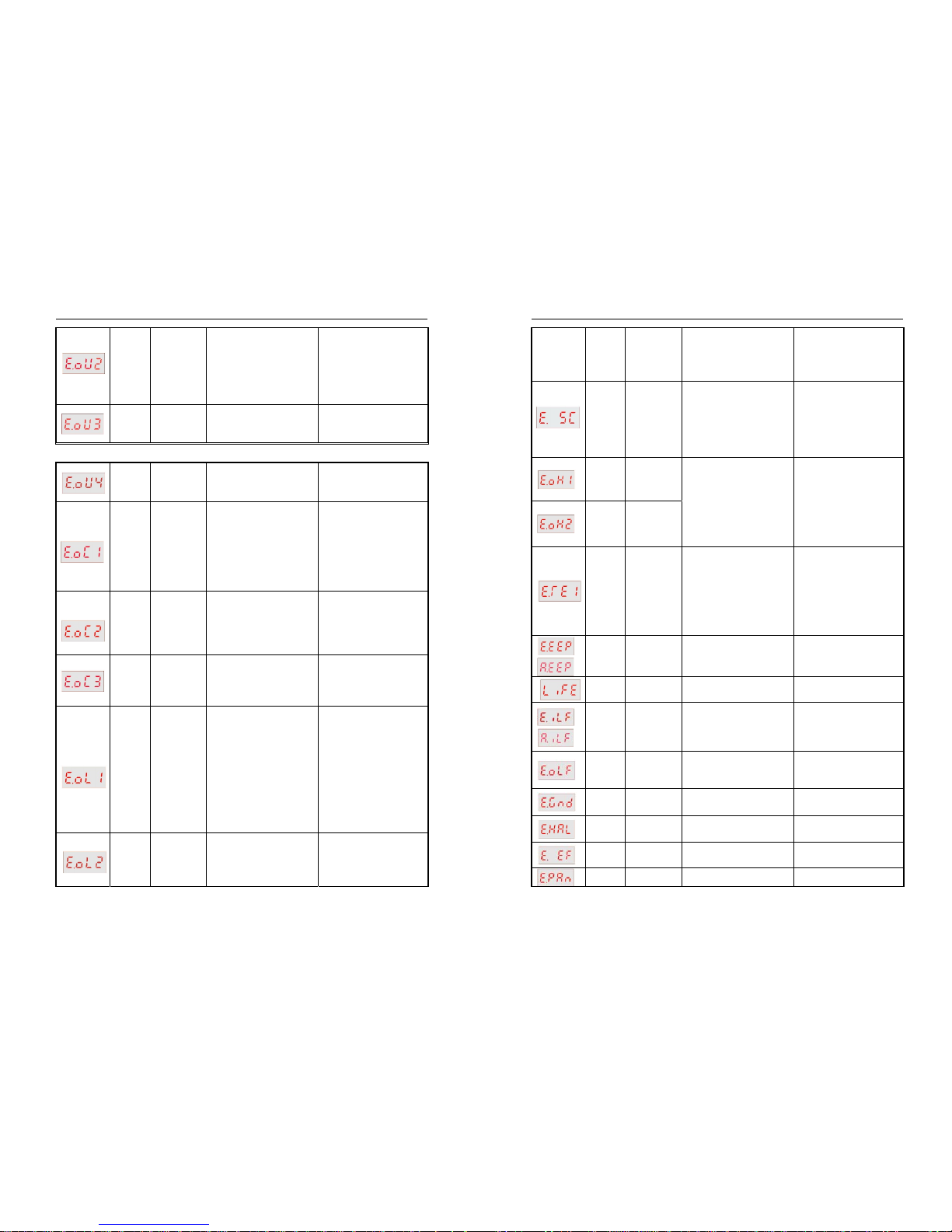

Chart 5-1: Fault information and details

Keyboard

display

Commu

nication

code

Fault type Possible causes Treatment

64

Too low

voltage while

stop

● Power supply is too low

● Voltage detection circuit is

abnormal

● Check input power,clear

fault.

● Seek support from factory.

10

Too low

voltage in run

● Power supply is too low

● Power capacitance is too

small, or there is big impact

current in the power grid.

● Inner DC main contactor is

not connect well

● Check input power,clear

fault.

● Improve power supply.

● Seek support from factory.

7

Accel.

over-voltage

● Power voltage fluctuation

over limit.

● Start when motor is running .

● Detect power voltage and

clear fault.

● Restart motor until it

completely stop.Set E-30 as

1or2.

AC300 Series Vector Control Inverter Manual Fault Diagnoses and Processing

34

8

Decel.

over-voltage

● Deceleration time is too short.

● Load potential energy or

inertia is too large.

● Power voltage fluctuation

over limit.

● Prolong Deceleration time.

● Reduce load inertia or

improve inverter capacitance or

add braking unit.

● Detect power voltage and

clear fault.

9

Constant

speed

over-voltage

● Power voltage fluctuation

over limit.

● Detect power voltage and

clear fault.

● Install input reactor.

28

Over-voltage

while stop

● Power voltage fluctuation

over limit.

● Check input power,clear

fault.

● Seek support from factory.

4

Accel.

over-current

● Acceleration time is too short.

● Start running motor.

● V/F curve setting is not

suitable.Or torque boost too

high.

● Inverter capacitance is too

small.

● Prolong acc time.

● Restart motor until it totally

stop.Set E-30 as 1or2.

● Reset V/F curve or torque

boost value.

● Select inverter with right

capacitance.

5

Decel.

over-current

● Deceleration time is too short.

● Load potential energy or

inertia is too large.

● Power voltage fluctuation

over limit.

● Prolong Deceleration time.

● Connect external braking

resistance or braking unit.

● Select inverter with right

capacitance.

6

Constant

speed

over-current

● Sudden load change.

● Power grid voltage is too low.

● Check load change and clear

it.

● Check input power,clear

fault.

11

Motor

over-load

● V/F curve setting is not

suitable. Or torque boost too

high.

● Power grid voltage is too low.

● incorrect overload protection

setting.

● Locked-rotor run or too heavy

load.

● Universal motor long time low

speed run.

● Reset V/F curve or torque

boost value.

● Check input power,clear

fault.

● Unreasonable H-56 setting.

● Adjust load or select inverter

with right capacitance.

● If need long time low speed

run, please choose special

motor for inverter.

12

Inverter

over-load

● Load is too heavy.

● Acceleration time is too short.

● Start running motor.

● V/F curve setting is not

● Select inverter with right

capacitance.

● Prolong acceleration time

● Restart motor until it totally

AC300 Series Vector Control Inverter Manual Fault Diagnoses and Processing

35

suitable.Or torque boost too

high.

stop.Set E-30 as 1or2.

● Reset V/F curve or torque

boost value.

1/2/3

System

abnormality

● Acceleration time is too short.

● Short circuit between inverter

output phases or earth.

● Module is damaged.

● Electromagnetic disturb.

● Prolong acceleration time.

● Check periphery equipments

and restart after fault cleared.

● Seek support from factory.

● Check system wiring, earth,

shield and deal as required.

16

Inverter

over-heat

● Temperature is too high.

● Air channel is blocked.

● Fan connection parts is loose.

● Fan is damaged.

● Temperature detection circuit

fault

● Make the environment

meeting the requirement.

● Clear the air channel.

● Check and re-connect the

wire

● Change the same new fan.

● Seek support from factory.

17

Rectifier

bridge

over-heat

20

Motor

detection fault

● Detection overtime

● Perform static detection while

motor is running.

● Capacitance difference is too

big between motor and inverter.

● Motor parameter setting

mistake.

● Check motor connection

wire.

● Detect after motor stop

totally.

● Change inverter model.

● Reset parameter according

to nameplate.

21/69

Memory fault

● Electromagnetic disturb in

memory period.

● EEPROM damage.

● re-input and save.

● Seek support from factory.

30 Reserved ●Seek support from factory.

13

/65

Input phase

missing

● 3 input phase missing

● Check 3phase input power

and phase.

● Check 3phase input power

wiring.

14

Output phase

missing

● 3 phase output of inverter

missing connection with motor

● Check wire between inverter

and motor, earth and motor

insulation.

-

Output

Ground

● The output side of the inverter

is shorted to ground.

● Check wiring and motor

insulation.

19

Current

detection fault

● Detect circuit fault.

● Phase imbalance

● Seek for technique support.

● Check motor and wiring.

17

Inverter

external fault

● Peripheral equipment fault

protection.

●Check peripheral equipment.

E.PAn

Keyboard ● Keyboard wire fault. ● Check keyboard wire

AC300 Series Vector Control Inverter Manual Fault Diagnoses and Processing

36

connect fault ● Keyboard component

damage.

● Seek support from factory.

18

RS485

communicatio

n fault

● Baud rate not right.

● Communication connection

not right.

● Communication format not

right.

● Set right Baud rate

● Check communication wiring

● Check Communication

format

E.CPE

Parameter

copy fault

● Parameter copy

communication is fault.

● Copy keyboard is not match

the inverter.

● Check wire.

● Select the specified external

keyboard model.

-

Expansion

card

connection is

abnormal

● The expansion card

communicates with the inverter

for timeout;

● The expansion card does not

match the drive.

● Check the connector and

re-plug the cable;

● Use the expansion card of

the specified model.

27

PG card

connection is

abnormal

● PG card and inverter

connection failure

● Check connection

29

/66

PID feedback

fault

● PID feedback disconnection

alarm upper limit is set

improperly

● PID feedback disconnection

alarm lower limit is set

improperly

● Lose PID feedback wiring

● Feedback sensor failure

● Feedback input loop fault

● Confirm the sensor status

and replace the sensor if it is

damaged.

● Correct wiring

● Confirm the set values of

F11.27 and F11.28

31

Initial position

angle learning

failed

● Check motor parameters

● Check the motor parameters;

● Learn after the motor is

stationary;

● Seek technical support from

manufacturers.

32

/70

Speed

deviation is

too large

●Checkout time or check level

setting is unreasonable

● Motor parameter is abnormal

● Check the motor parameters

and re-learn again;

● Check the F10.24/F10.25

parameter settings;

● Seek technical support from

manufacturers.

33

/71

Speed

protection

● FA.27/FA.28 parameter

setting is abnormal

● Motor parameter is abnormal

● Check the motor parameters

and re-learn again;

● Check the F10.27/F10.28

AC300 Series Vector Control Inverter Manual Fault Diagnoses and Processing

37

● Check the F6 group vector

control parameters

parameter settings;

34

/67

Load

protection 1

● The checkout time or check

level setting is unreasonable

● Check the F10.18/F10.19

parameter settings;

35

/68

Load

protection 2

● The checkout time or check

level setting is unreasonable

● Check the F10.20/F10.21

parameter settings;

36

CPU

time out

● CPU timing timeout

● Seek technical support from

manufacturers.

72

GPS lock

machine

● GPS timing timeout

● Seek technical support from

manufacturers.

73

GPS

disconnection

● GPS communication

disconnection

● Whether the GPS expansion

card is connected properly;

● GPS communication card is

arrears;

● Seek technical support from

manufacturers.

40

Fan short

circuit

● Fan short circuit ● Check if the fan is smooth

39

Motor short to

ground

● Motor short circuit to ground

● Check if the motor is shorted

to ground

AC300 Series Vector Control Inverter Manual Fault Diagnoses and Processing

38

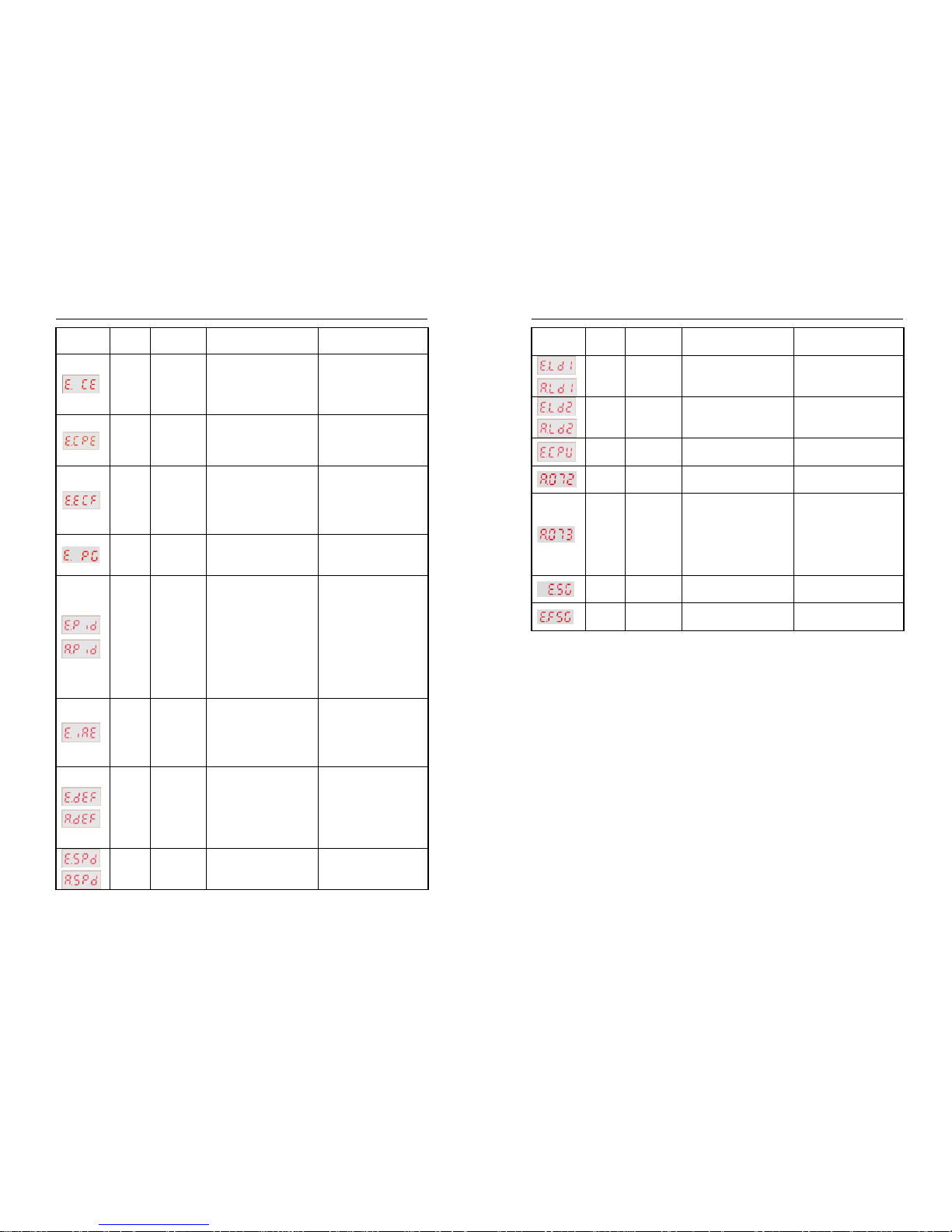

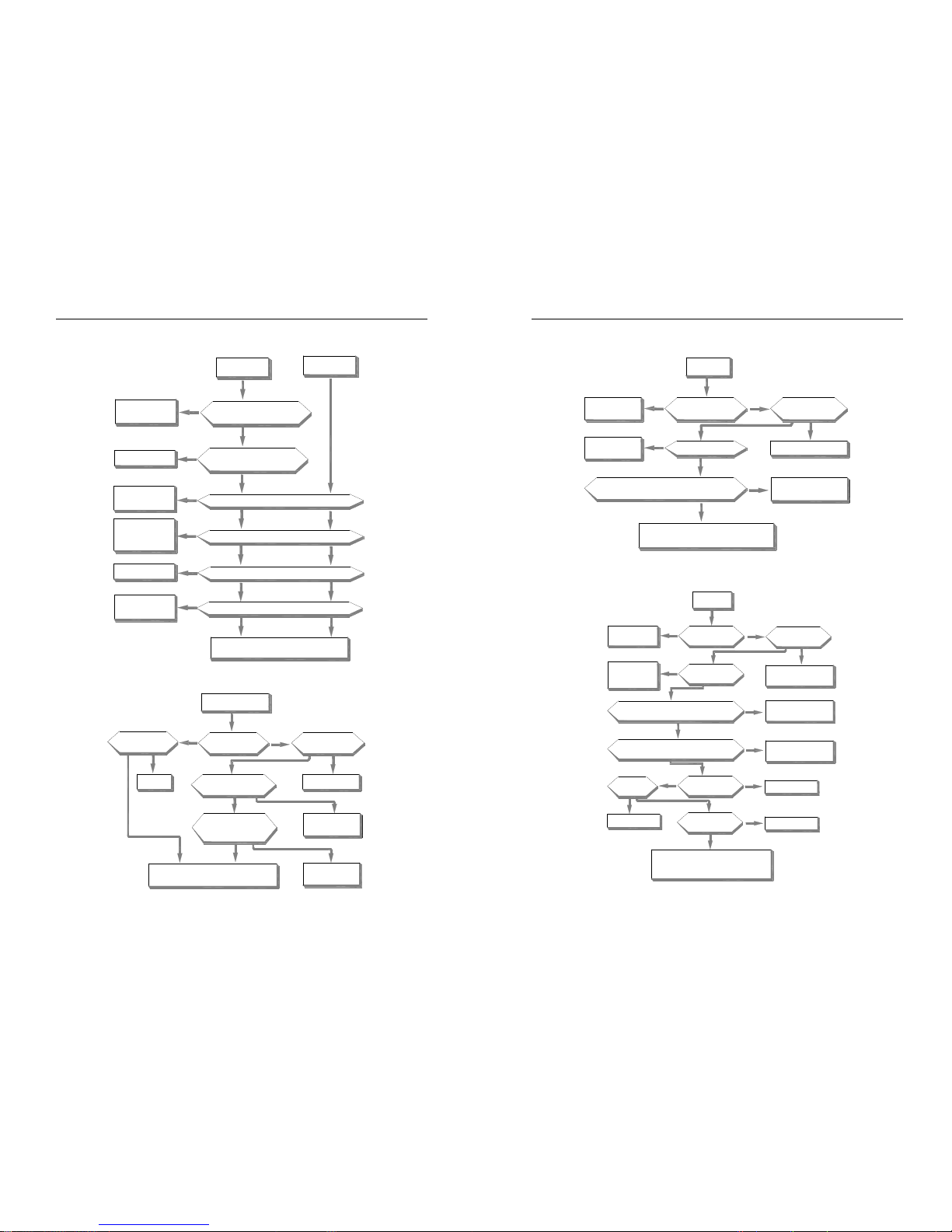

5.3 Fault Diagnoses Process

System fault diagnoses process

reduced or not

valuecan be

system fault

yes

yes

yes

yes

yes

yes

yes

yes

yes

yes

yes

yes

yes

yes

yes yes

yes

yes

no

no

no

no

no

no no

no

no

no

no

no

no

no

Clear short circuit

Whether there is short circuit between outo ut terminal U/V/W and the motor

Short the cable or

add outout reactor

Cable between output te rminal U/V/W and motor

is too long that leakage current cause inverter protection

Clear disturbance

Is there serious electroma gnetic disturbance?

While disconnect output wire and run,whether there is system fault alarm

Three phase outout voltage balance is ok or not?

Whether overload or not?

Connect load and

operate as follows

Reduce load or

enhance power

Display E.SC

while start

Display E.SC

while stop

Display E.SC while

constant speed

Display E.SC while

machine stop

Torque enhance value

is suitable or not

Whether acceleration

time is too short

Whether deceleration

time is too short

Whether load

change suddently

Torque enhance

ACC time can be

prolonged or not

Dec time can be

prolonged or not

Reduce load change

or enhance power

Reduce

Prolong setting time

Check braking mode,

seek tec support

Reduce load or

enhance power

Inverter fault or misaction caused by

noises.Pls find technic support

AC300 Series Vector Control Inverter Manual Fault Diagnoses and Processing

39

Over-current diagnoses process

Check braking mode

and seek for technic support

Reduce load change

or improve power

Reduce load change

or improve power

Whether set longer

decelerationtime

Set longer acceleration

time or not?

Prolong setting time

Whether load

changes suddently

May fault or misaction

caused by noise.Please

find technic support

Is deceleration

time set too short?

Is acceleration time

set too short?

Reduce the value

Whether torque

enhance value is too

Can be reduced?

Reduce load or

enhance power

Whether load is too large

Whether short circuit between output terminal

U/V/W and motor or earth circuit

Clear short circuit

no

no

no

no

no

no

no

no

no

no

no

no

yes

yes

yes

yes

yes

yes

yes

yes

yes

Constant speed

over curent E.0C3

Decelerate over

curent E.0C2

Accelerate over

curent E.0C1

AC300 Series Vector Control Inverter Manual Fault Diagnoses and Processing

40

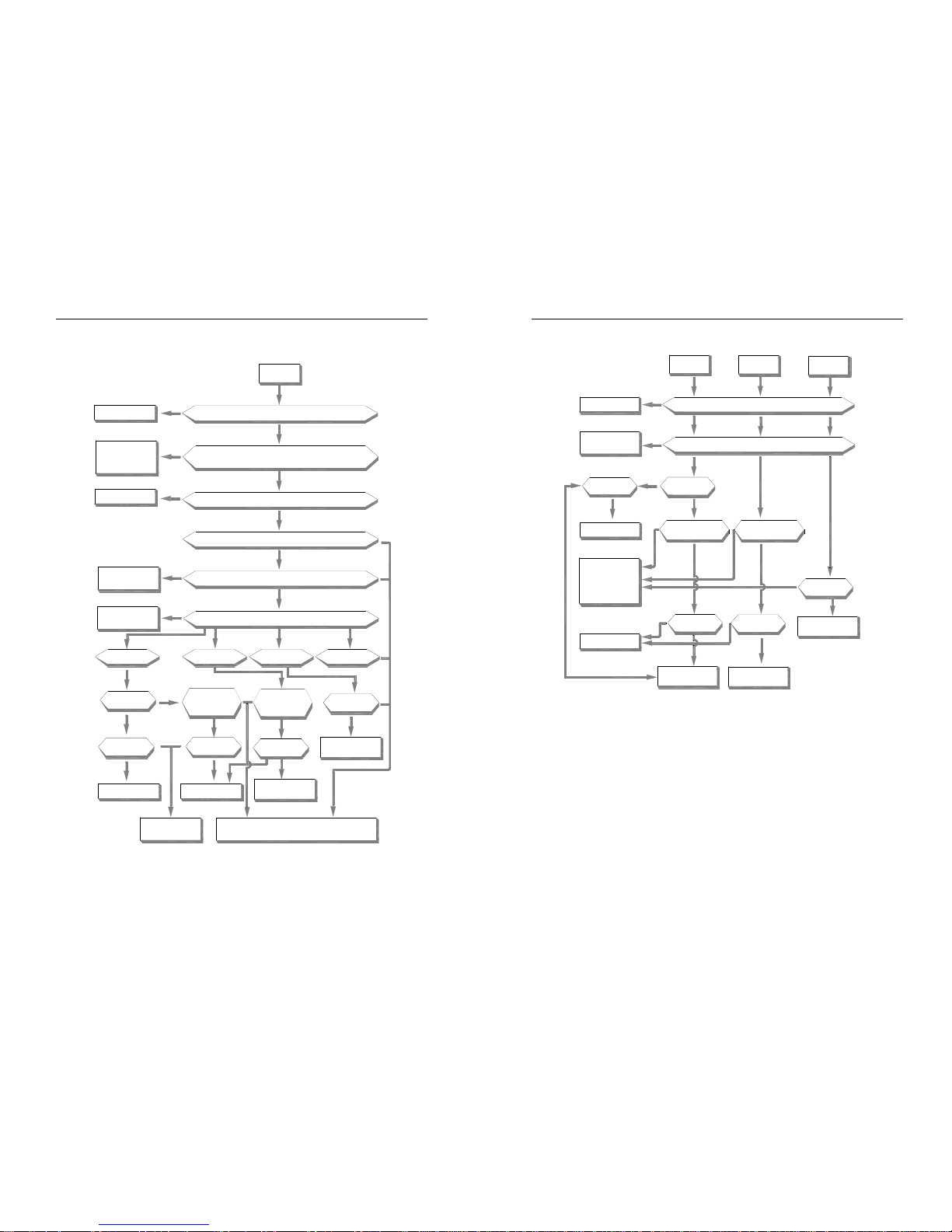

Over-voltage diagnoses process

ACC over

voltage(OU1)

DCC over

voltage(OU2)

Constant speed

over voltage(OU3)

Stop state over

voltage(OU4)

Fower votage in fixed range or not

no

no

no

no

no

no

no

no

no

no

no

no

no

no

no

no no

no

yes

yes

yes

yes

yes

yes

yes yes

yes

yes

yes

yes

yes

yes

yes

yes

Reduce power voltage

into fixed range

Clear short circuit

Phase or earth short cirsuit bwteen U/V/W and motor

Whether it stops while restart the motor

Whether act while load suddently changes to"0"

Whether DC circuit voltage of main loop is above protection value while act

Maybe inverter fault or

misact.Plese seek for

technic support

Whether act while

suddently stop ACC

Can prolong DCC time or not

prolong

ACC time can be

prolong or not

Load intertia can be reduced or not

Whether used braking unit or DC braking function

Please check braking unit and seek for technic support

Use braking unit or DC

braking function

Reduce

Stop motor and restart.

Or DC braking,then start

(E-30:1). Or speed track

start(E-30:2)

AC300 Series Vector Control Inverter Manual Fault Diagnoses and Processing

41

Low-voltage supply

yes

yes

yes

yes

yes

yes yes

no

no

no

no

no

no

no

no

Whether power off,including instant power off

Restart after reset

Change fault component

and correct bad contact

Is there any fault component or bad contact in power circuit

Whether power voltage is in fixed range as required

Is there any big load start or st op under the same power supply

votage between DC circuit P+ and N- in

main loop is over E-55 setting or not

Maybe inverter fault.please seek for tec hnic support

Modify power supply

system as required

Adjust E-55 setting

Voltage is too low

while stop Lu1

Voltage is too low

while running Lu2

Inner inverter over-heat

Whether cooling fan works normally

Whether temperature display(C-09)is

the same as the actual temperature

Whether load and carried frequency

E-20 setting are too high

Whether air cooling channels are air-logged

Whether the temperature is within the fixed range as required

Change fan

Maybe temperature ditection

circuit fault.please seek for

technic support

Reduce load and

carried frequency

Clear the air-logged channel

Adjust the temperature to

the fixed range as required

Maybe machine fault or misact.seek for technic support

no

no

no

no

no

yes

yes

yes

yes

yes

Inner inverter

overheat OH

AC300 Series Vector Control Inverter Manual Fault Diagnoses and Processing

42

Over-load

yesyes

yes

yes

no

no

no

no

no

no

no

yes

yes

yes

no

no

Change torque improving

or V/F curve setting

Prolong ACC/DCC time

Restart after motor stop or

change start mode E-30

to 1/2

Reduce load or

improve capacity

Correct setting value

Change externa

lthermal relay

Maybe inverter fault or misact.Please seek fo r technic support

Whether torque improving or V/F curve setting is suitable

Whether ACC/DCC time is too short

Whether the motor stops while restart

Whether load too high

Whether electric thermal relay overload

relay setting E-50 is suiable

Whether electric thermal relay overload

characteristic matches the motor overload

characteristic

Motor overload OL1

Inverter overload OL2

No display

Inverter keyboard

LED no display

Whether keyboard

connect line is reliable

Whether power indicater

linght on power board is

on or not

Whether circuit breaker

at power side is connect to

contacter

connect

connect

Whether power input

terminals R/S/T is normal

Whether there is short connect

or DC reactor between terminals

P1 and P+l

Maybe

inverter fault or motor heat

caused by noise.Please find technic support

Short connect or

connect DC reactor

yes

yes

yes

yes

yes

no

no

no

no

no

Find our the fault cause

and clear the fault

AC300 Series Vector Control Inverter Manual Fault Diagnoses and Processing

43

Motor heat

motor heat

Adjust torque imporoving

value and V/F characteristic

Whether torque improving and V/

F characteristic are suitable or not

Whether motor continuously

run at low speed

Reduce load or

improve capacity

Whether load is too large

Use special motor for inverter

Whether output terminals U/V/W output

voltage /current three phase balance well

no

no

no

no

yes

yes

yes

yes

Maybe motor fault

Maybe inverter fault or motor heat caused by

noise.Please find technic support

Motor does not rotate

no

no

no

no

no

no

yes

no

yes

yes

yes

yes

yes

yes

yes

yes

should be red uced.If there i s braking or brake uni,

please check whet her it is loose

Maybe motor i s locked because of too large load.Load

value is suitable

Whether torque improvin g

Improve torque

improving value

Motor fault

Whether

wiring is

correct or not

Whether load

is too large

Is there voltag e output on output terminal U/V/W

and three phase balance ok or not?

Correct connect

Maybe inverter fault .Please

find technic su pport

It works after co rrect the

upper frequency or given

frequency

It works after ch ecking the

cause and slving the problem

Have input frequ ency

signal or not

It works after c hecking

the cause and solving

the problem

Have input command

signal or not

Whether keyboard

displays fault information

Work after solving

fault and reset

Motor does

not work

Whether upper frequency limit E-10 or given frequency

is lower than the start frequency E-28 setting

AC300 Series Vector Control Inverter Manual Periodic Overhaul and Maintenance

44

Chapter 6 Periodic Overhaul and Maintenance

6.1 Safety Precautions

This chapter explains the safety rules in overhaul and maintenance.

● No operation under power connected state. Otherwise, there is danger of electric shock even

death.

● Before operation, please cut all related equipments power, ensure that the main circuit DC

current has droped to safe range. And please operate after 5 mins.

● No operation while cover/panel is dismantled. Otherwise there is danger of electric shock

even death.

● Do not dismantle the cover or PCB under power connected state. Otherwise there is danger

of electric shock death.

● Only professional person can maintain or change fittings. Otherwise, there is danger.

Do not wear loose clothes when install, debug, maintain. Related protective tools and

safeguard should be adopted.

● Tighten screw according to named torque. If main circuit wire connection is loose, there is

danger of overheat fire.

● Machine and motor earth must be reliable. Otherwise, there is danger of electric shock if

touch the cover.

● While operation, please follow the ESD regulations. Otherwise, the inverter maybe damaged.

● Do not change the circuit or structure of the inverter. Otherwise, the inverter maybe

damaged.

● Please confirm the rotate direction while no-load. Wrong direction can bring body injury or

huge wealth loss.

● Do not use damaged machine. Otherwise, there is danger of accident.

6.2 Overhaul

Frequency inverter is composed by semi-conductive components, passive electronic component and motive

component. All of these components have useful life. Even under normal working environment, some of the

components can not work after the life time. To avoid malfunction, daily checking, periodic overhaul, component

changing and other maintenance should be carried out to prevent. We suggest one overhaul every 3-4 months after

installation. The overhaul period should be shortened while under cases as below:

High temperature, high altitude;

Start and stop frequently;