Veichi AC300-T3-R75G, AC300-T3-5R5P-B, AC300-T3-1R5P-B, AC300-T3-2R2G-B, AC300-T3-004G User Manual

...

2018

CONTENT

Chapter 1 Overview ............................................................................................................ ............................................. 1

1.1 Safety requirement and cautions ...................................................................................................................................................... 1

1.2 Before Use .......................................................................................................................................................................................... 1

1.3 T echnical criterion ............................................................................................................................................................................... 2

Chapter 2 Installation ...................................................................................................................................................... 4

Chapter 3 Keyboard layout and functions specification .......................................................................................... 8

Chapter 4 Function Parameter Table ........................................................................................................................... 9

4.1 Basic parameters ............................................................................................................................................................................... 9

4.2

Terminal of Input and Output Function Selection ..........................................................................................................................30

4.3 Monitor Code ....................................................................................................................................................................................31

4.4 Fault Code ........................................................................................................................................................................................33

Chapter 5 Periodic Overhaul and Maintenance ........................................................................................................ 34

5.1 Overhaul ............................................................................................................................................................................................34

5.2 Maintenance .....................................................................................................................................................................................35

Appendix: Modbus Communication Protocol .......................................................................................................... 36

1

Chapter 1 Overview

1.1 Safety requirement and cautions

Please do totally unders tand this par t before usin g the inverter.

Warning signs and meanings

This manual has used fo llowing s igns which me ans ther e is an importan t part of secu rity. While observing against the r ules, the re is a danger of

injury even death or machine system damage.

Danger: Wrong operation may cause death or large accident.

Caution: Wrong o peration may cause minor wound.

Operation requirement

Only professionally trained persons can be allowed to operate the equipment. “Profess ional trained persons “m eans the workers mus t have

experience professional trained sk ill, and mus t be fami liar with installatio n, wiring , running a nd mainta in and ca n rightly dea l wi th emergency cases

in use.

Safety guidance

Warning signs come for your s ecurity. They are measures to prev ent the opera tor and m achine system from damage. P lease care fully read this

manual before using and strict ly observe th e regula tions and w arning si gns while operating.

●Correct transpor tation, store, instal lation , careful operation and main tenance are imp ortant for inverter s afe operation. In transport and store

process, make sure the inverter is free from imp act and v ibration. It mus t be stored where is dry without corros ive air and conduc tive dust, and

the temperature must be lower than 60℃.

● This product carries d angerous vol tage and c ontrols dr iver machine with poten tial danger. If you don’t abide by the r egulations or requirements in

this manual, there is da nger of b ody in jury even death and mach ine syste m damage.

● Do not wire while th e power is connec ted. Otherwise , ther e is dan ger of dea th for e lectric sh ock. Before wiring, inspection an d mainte nance,

please cut off power s upply o f all rel ated equipm ent’s and ensure mai n DC vol tage in sa fe range . And p lease oper ate it after 5 mins.

● Power wire, mo tor wire a nd control wire shou ld be al l connecte d firmly. Earth must be reliable and ear th resistance mus t be lower than 10Ω.

● Human body e lectrostatic will damage inner sensi tive components seriously. Before operation, please fo llow ESD m easures. Otherwise, there is

danger of inverter damage.

● Inverter output vo ltage is p ulse wave . If components s uch as capac itor which improves p ower factor and press ure-sensitive res istance for

anti-thunder and so on a re installed at the output side , please disman tle them or change to input si de.

● No switch c omponents such as breaker and contactor at the output side ( If there must be one, pleas e make s ure the o utput cur rent is 0 whil e the

switch acting).

● No matter whe re the fault is , there is danger of serious accide nt. So there must be additional external preven t measures or oth er safety devices.

●Only used in applica tion fields as mak er stated. No use in equipmen ts related to spec ial fields s uch as emerge ncy, succor, ship, medical

treatment, aviation, nuclear and etc.

● Only Veichi Electric co., ltd service departmen t or its authorized service center can mai ntain the products. It may cause p roduct faul t while using

accessories not authorized or permi tted. Any defective components must be changed in time in main tenance.

1.2 Before Use

On receiving your order, please check the package and confirm in tact be fore opening, and check i f there’s any damag e, scratch o r dirt (damages

caused during transportation are n ot with in the company 's warrant y). If there’s any damage caused d uring tr ansportation, please contac t us or the

transport company immediately. After confirming the receip t of the goods intact, pleas e re-confirm if the produc t and your order are consisten t.

2

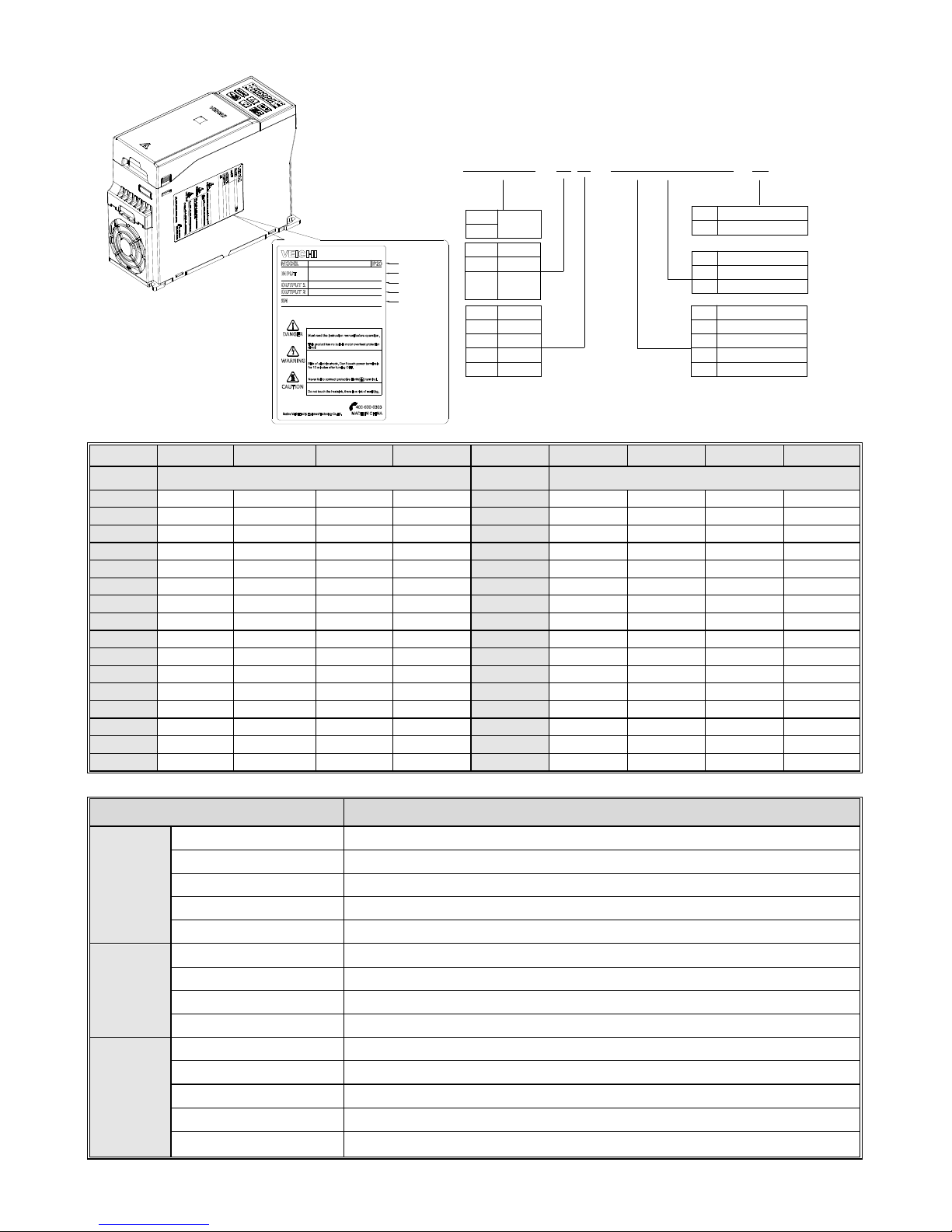

VFD Model

Input Model

Input Model1

Input Model2

Serial No.

Product

Series

AC300 - T 3 - 011 G /015P-B

Symbol

Voltage

2220V

3380V

6660V

T 3-Phase

S

Single

Phase

Code

VFD Type

G

General

Code

Adaptive motor (KW)

7R5

011

7.5

11

018

132

18.5

132

11

1140V

AC300

P

Blower & Pump

Symbol

Code

Accessories type

BBrake Unit

Phase

Symbol

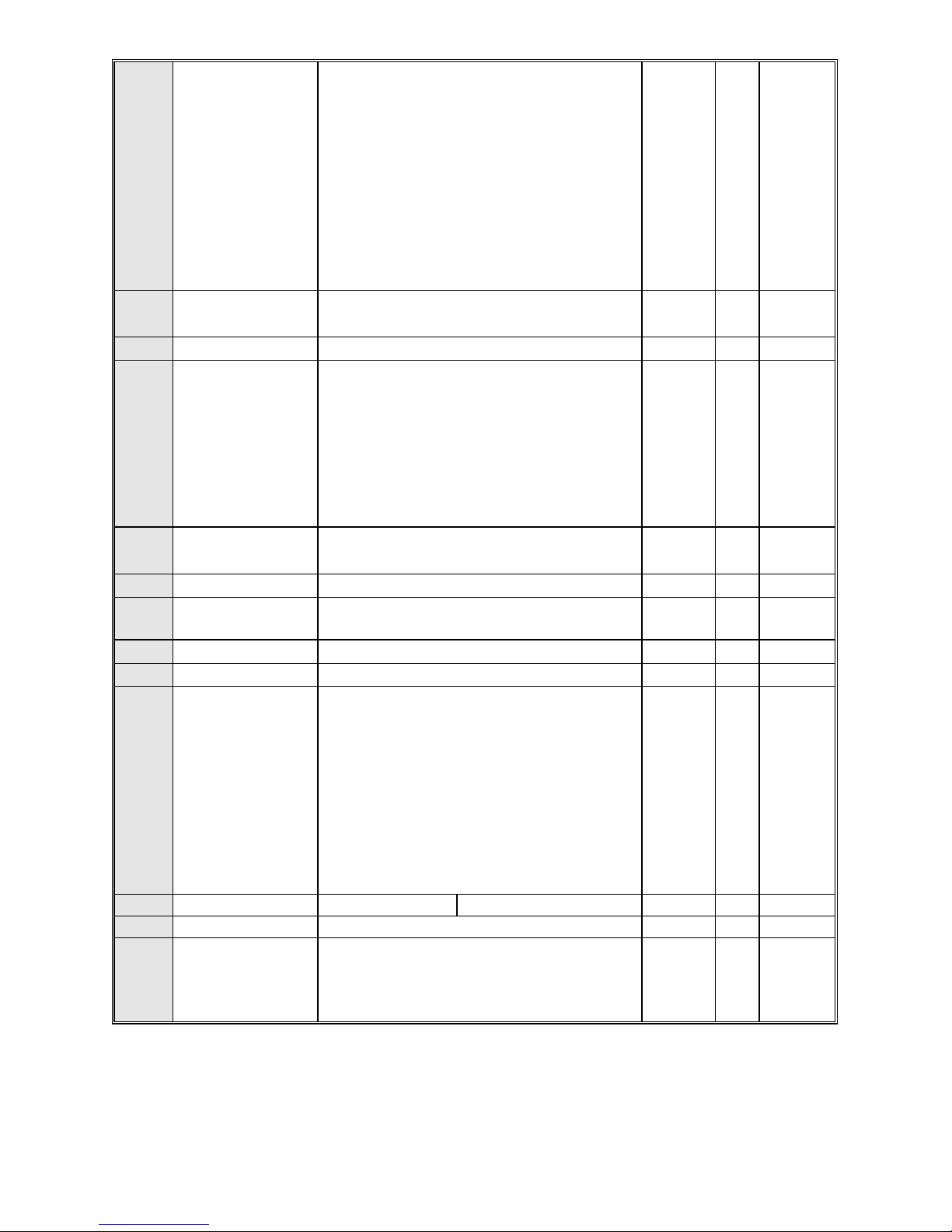

Voltage 220V 380V 660V 1140V Voltage 220V 380V 660V 1140V

Power Rated Output Current (A) Power Rated Output Current (A)

0.75 4 3

110 380

210

121

75

1.5 7 4

132 420

250

150

86

2.2 10 6

160 550

310

175

105

4 16 10

185

600

340

198

115

5.5 20 13

200 660

380

218

132

7.5 30 17 10

220 720

415

235

144

11 42 25 1

5

250

470

270

162

15 5

5

32 1

8

280

510

330

175

18.5 70 38 22

315

600

345

208

22 80 45 2

8 355

670

380

220

30 110 60 3

5

400

750

430

260

37 130 75 4

5

25

450

810

466

270

45 160 90 52

31

500

860

540

325

55 200 110 6

3

38

560

990

600

365

75 260 150 8

6

52

630

1100

680

400

90 320 180 9

8

58

710

1260

760

450

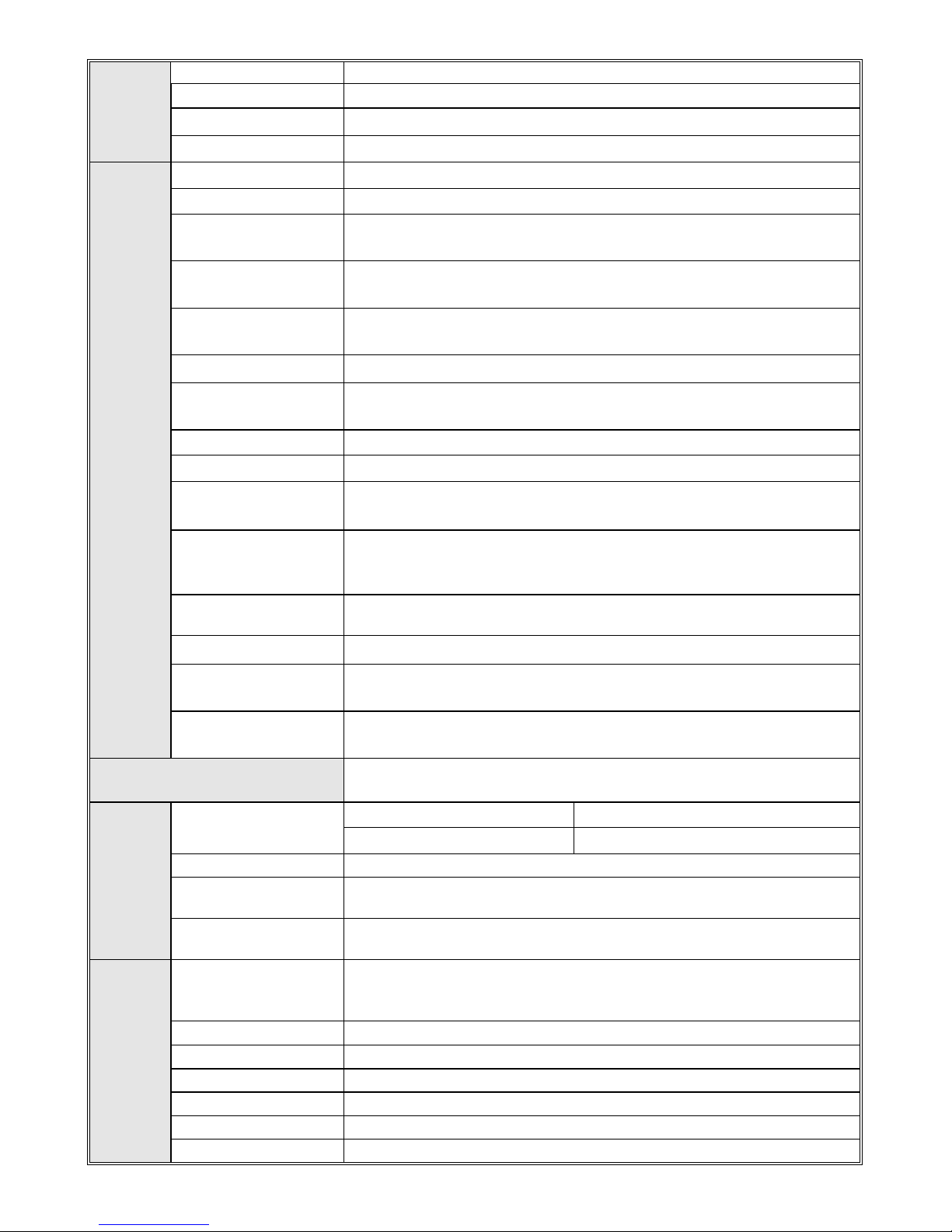

1.3 T echnical criterion

Items Criterion

Power

input

Voltage ,frequency Three phase 380V 50/60Hz ,

Allowable fluctuations voltage unbalance rate:<3%; Frequency:±5%; aberration rate: as IEC6 1800-2 required

Inrush current Lower than rated current

Power factor ≥0.94(with DC reactor)

Efficiency ≥96%

Output

Output voltage Output under rated cond ition: 3 phase , 0~input voltage, inaccuracy<5%

Output frequency range G type:0~600Hz

Output frequency accuracy Max frequency ±0.5%

Overload capacity G type: 150% rated current/1 min, 180 % rated curren t/10s, 200% r ated curren t/0.5s

Main

Control

performance

Steady speed accuracy V/F without PG , VC without PG, V/F with PG , VC w ith PG

Starting torque Optimized SVPWM mode

Steady speed accuracy

0.7~16.0kHz

Starting torque VC without PG: rated load 1:100; VC with PG: r ated load 1:1000

Steady speed accuracy VC without PG: ≤2% rated synchron ized speed; VC with PG : ≤0.05% rated synchronized speed

3

Starting torque VC without PG: when 0.5Hz, 150% rated torque; VC with P G: when 0Hz, 200% rated torque

Torque response VC without PG: ≤20ms; VC w ith PG : ≤10ms

Frequency accuracy Digit setting: max fre quency×±0.01%; A nalog settin g: max freq uency×±0.2 %

Frequency resolution Digit setting: 0.01Hz; Analog se tting: max frequency×0 .05%

Basic

functions

DC braking capacity Starting frequency:0.00~50.00Hz; Braking time:0.0~60.0s; Braking current:0.0~150.0% rated current

Torque boost capacity Auto torque upgrade 0.0%~100.0%; Manual torque upgrade 0 .0%~30.0%

V/F curve

4 modes: one linearity torque char acteristic c urve ,one se lf-settin g V/F cur ve mode, one drop

torque characteristic curve (1.1 - 2.0 powe rs),and square V/F curve mode.

Acceleration/Deceleration

curve

2 modes: linear Acceleration/Dec eleration and S curve Acceleration/D ecelerat ion. 4 se ts of

ACC/DEC, time unit 0.01s selectable , longest time: 650 .00s.

Rated output voltage

Rely on power supply voltage compensate function, w hile motor ra ted voltag e is 100%, se t it at

the range of 50-100%(outp ut can no t over inpu t voltage).

Voltage auto-adj ustment While power supply voltage fluctuates, i t can auto-keep constan t output v oltage.

Auto energy-saving running

While under V/F control mode, accord ing to load situation, auto-op timize outpu t voltage to save

energy.

Auto-limit current Auto-limit the current whi le running to preven t over curren t break trouble.

Instant power off tre atment While instant power off, realize continual oper ation by b us voltage control.

Standard functions

PID control, speed track, power off res tart, jump fr equency, upper/lower frequency limit control ,

program operation, multi- speed , RS485, analo g output, freq uency impuls e output.

Frequency setting channels

Keyboard digital setting, Analog voltage/curren t termina l AI1, Analog voltage/current terminal AI2,

Communication given and multi-chann el termina l selection , Main and auxiliary chan nel

combination, expansion card, supporting differen t modes swi tch

Feedback input channel

Voltage /Current Terminal AI1, Voltage/Current Terminal AI12 , Communication given, Low-s peed

pulse input PUL, extension c ard

Running command channel Operation panel given, extern al termina l given, communica tion given , expansion card given

Input command signal

Start, stop, FWD/REV, JOG, multi-step speed, free stop, res et, ACC /DEC time se lection,

frequency given channel selec tion, exterior faul t alarm.

Exterior output signal

1 relay output, 1 collector ou tput, 1 AO output: 0~10V output or 4~20 mA output, or frequency

pulse output

Protection function

Overvoltage, under-voltage, current l imit, over-current, ove rload, electric thermal relay, overheat,

overvoltage stall, data protec tion, rapid spe ed protecti on, inp ut/output pha se failure protection

Keyboard

display

LED display

Single file 5 digital tube display Can monitor one state variable

Two file 5 digi tal tube display Can monitor two state variables

Parameter copy Can upload or download functi on code in formation o f inverter to realiz e fast param eter copy.

State monitor

Output frequency, given frequency , outpu t current, input vol tage, output v oltage, motor speed,

PID feedback, PID given value, module temperature etc. monitor parameters.

Fault alarm

,Over-voltage, under-voltage, over-current, s hort circui t, phase failure, overload, overhea t,

overvoltage stall, current limit, or da ta protection destroyed; Fault running state; Fault history.

Environme

nt

Install place

altitude ≤ 1000m,above 1000m down the rated amount, each increase of 100m down the r ated

amount of 1%;no condensation, ic e ,rain, snow, hail; solar radiation below 700W/㎡, air pressure

70-106 kPa

T emperature, humidity

-10~+50 , above 40 down the rated amount, t℃℃ he max temperature:60 (no load runni ng)℃

Vibration

9~200Hz,5.9m/s2(0.6g)

Store temperature -30—+60℃

Installation Hanging type, cabinet type

Protection degree IP20

Cooling mode Forced air cooling

4

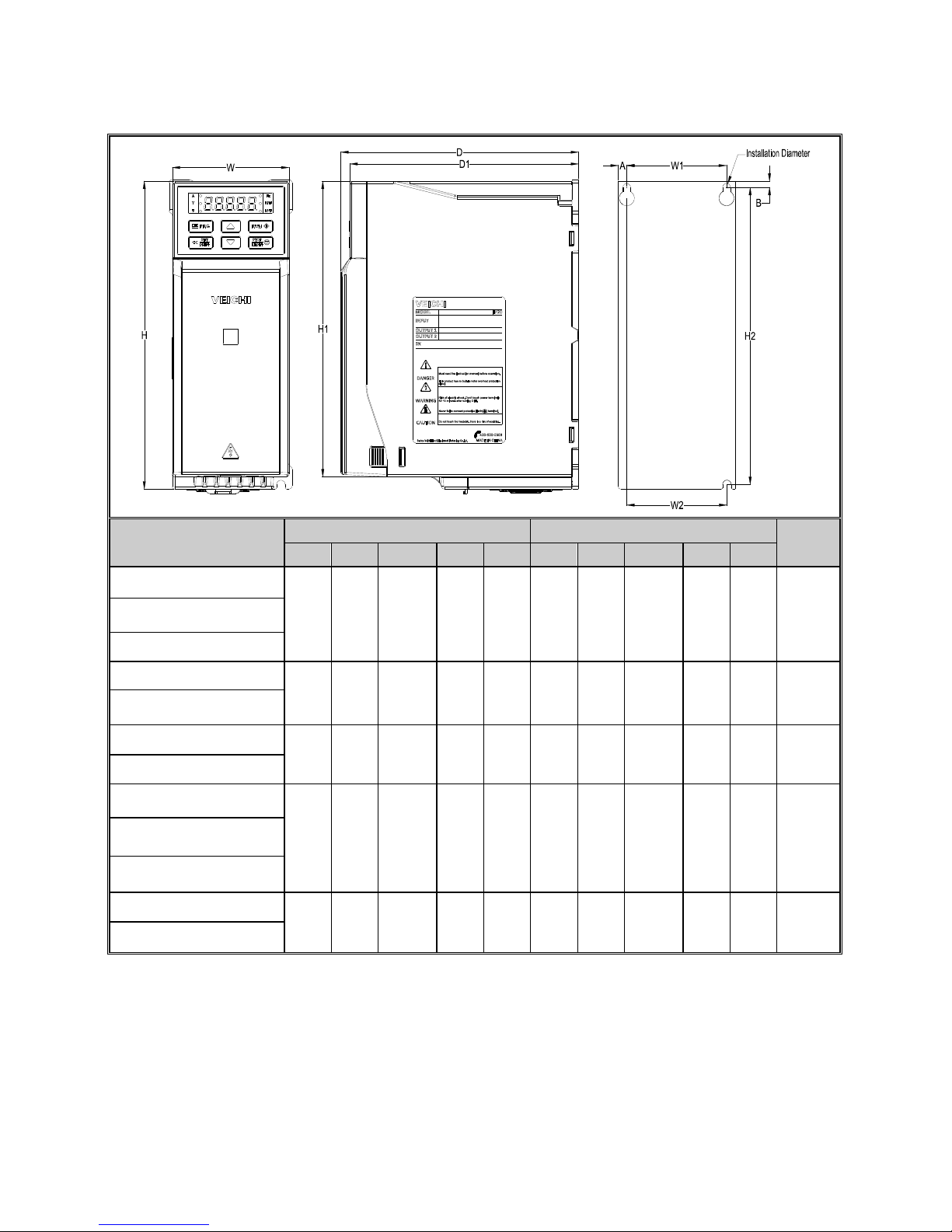

Chapter 2 Installation

This section specifies the co nsiderations necessary for reliab le and sa fe operati on of the product by users.

Overall Dimension of Inverter (Plastic)

MODEL

Overall Dimension(m m) Installation Dimension(mm)

Apertu

re

W H H1 D D1 W1 W2 H2 A B

AC300-T3-R75G/1R5P-B

76 200 192 155 149 65 65 193 5.5 4 ф3-M4

AC300-T3-1R5G/2R2P-B

AC300-T3-2R2G-B

AC300-T3-004G/5R5P-B

100 242 231 155 149 84 86.5 231.5 8 5.5 ф3-M4

AC300-T3-5R5G/7R5P-B

AC300-T3-7R5G/01 1P-B

116 290 277.5 175 169 98 100 277.5 9 6 ф3-M5

AC300-T3-01 1G/015P-B

AC300-T3-015G/018P-B

140 360 349.5 225 219 120 120 350 10 6

ф4-M5

AC300-T3-018G/022P-B

AC300-T3-022G/030P-B

AC300-T3-030G/037P

172 430 / 225 219 150 150 416 11 7.5 ф4-M5

AC300-T3-037G/045P

5

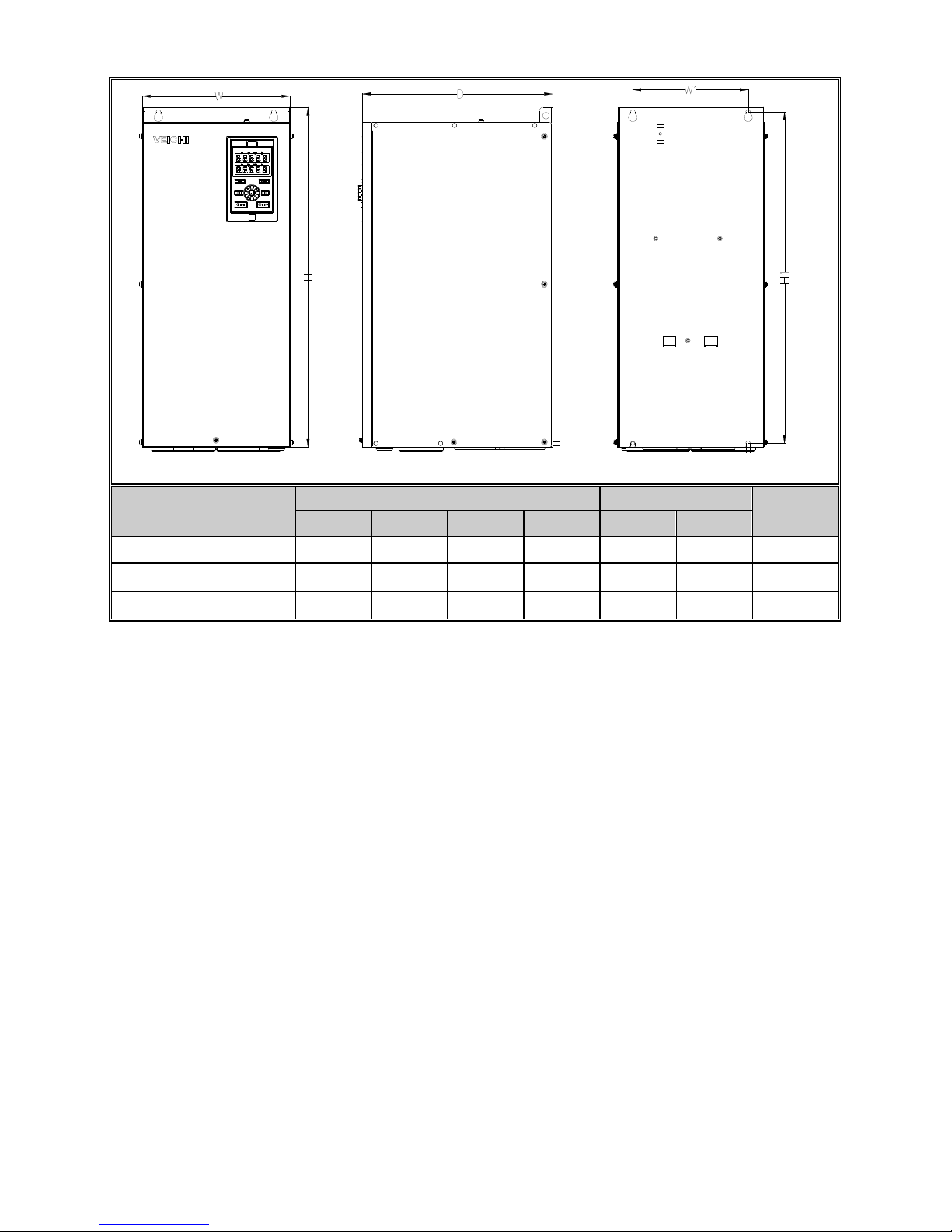

Overall Dimension of Inverter (Ste el)

安装直径

MODEL

Overall Dimension(m m)

Installation

Aperture

W H D H2 W1 H1

AC300-T3-045G/055P 225 523 290 500 176 509 ф7

AC300-T3-055G/075P 225 523 290 500 176 509 ф7

AC300-T3-075G/090P 240 570 340 535 176 551 ф9

Installati on Di amet er

6

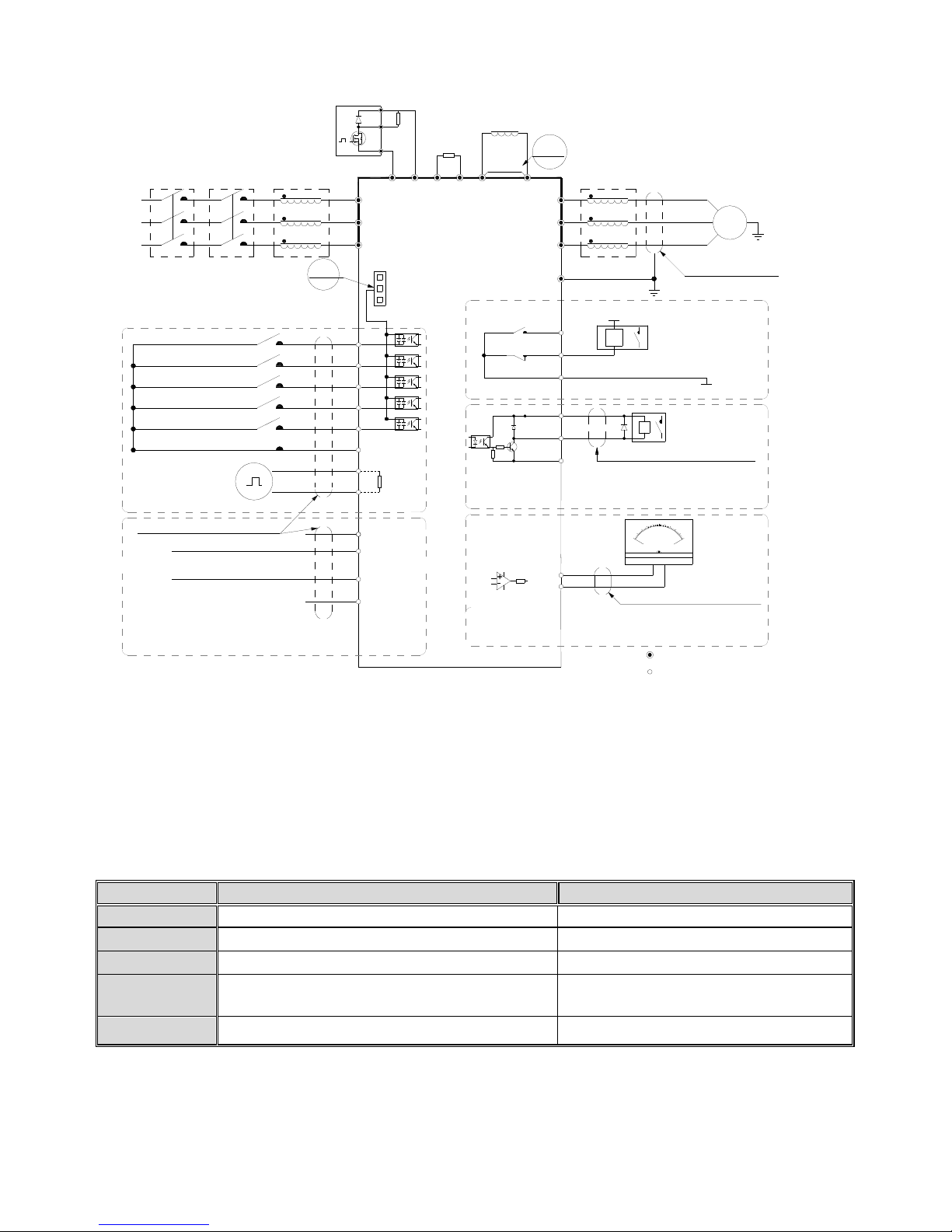

Standard Connection Diagram

Note2

Note:Function description in brackets is

factory default

Note1

Analog monitoring

signal output

TA

TB

TC

+24V

Y

Shielded cable (the

end close to VFD

grounding)

_

mA

2

0

10

0

-

+

V

W

U

M

~

Shielded cable or armoured cable

(the end close to VFD grounding)

E

(The grounding resistance

is less than 10 ohms)

W

V

U

Output Rector

External DC Rector

External

Brake

Resistor

Short

Piece

P1

+

( )

R

External Brake Unit

+10V

Frequency control input

R

T

S

AC POWER INPUT

GND

AI1

AI2

Shielded cable (the end close to

VFD grounding)

Multi function contact input

(REV JOG)

(FWD JOG)

(Reverse)

(Forward)

(Free STOP)

COM

X3

X4

X5

X1

X2

PB

( )

+

(-)

VFD

S

T

R

GND

A0

Coil

COM

Passive contact

output

AC220V

AC0V

Coil

MAX Output Of Contact:

3A/240VAC

5A/30VDC

1.MAX Output of +24V Port:DC24V/100mA

Note:When output type of AO port as

frequency and Voltage,

Maximum Output:2mA

2.Inner resistance of AI1/AI2 Port

1.MAX Output of +10V port :50mANote:

2.Max Output of Y Port :DC24V/50mA

Note:

represent control circuit terminals.

represent main circuit terminals;

Legend: 1.Symbol

Shielded cable

(the end close

to VFD grounding)

Input Rector

ContactorMCCB

+

( )

PUL

+24V

PLC

COM

Analog Voltage/Current quantity input

A+

B-

RS485 Differential

Communication

120Ω

Open collector(OC)

state output

Analog Voltage/Current quantity input

2.Symbol

Note: 1.When installing DC r eactor, make sure to dismantle the shor t connector be tween terminal P1 and (+).

2. NPN or PNP transistor signa l can be selected as input o f multi-functio n inpu t terminal (X1~X5/P UL) . Inver ter built-in power supply

(+24V terminal) or external po wer supply (PLC terminal) can be c hosen as b ias voltage. Factory setting ‘+24V’ sho rt connect with

‘PLC’, which locates between RJ4 5 and terminals.

3. Anal og monito r output is the special output for m eters suc h as fr equency meter, current meter and voltage meter. It can’t be used for

control operations such as fee dback contr ol.

4. As ther e are mu lti puls e styles, pleas e refer to the line conn ect mode de scription de tails.

●

Auxiliary Terminal Output Capacity

Terminal Function Definition Max Output

+10V 10V auxiliary powe r supply output, cons titutes loop with G ND. 50mA

A0 Analog monitor output, constitu tes loop wi th GN D. Max output 2mA as frequency, voltage signal

+24V

24V auxiliary power supply outpu t, constitutes loop with C OM.

100mA

Y

Collector open circuit ou tput; can set the action-o bject by

program.

DC24V/50mA

TA/TB /TC Passive connector output; can set the action-obj ect by program . 3A/240V AC

7

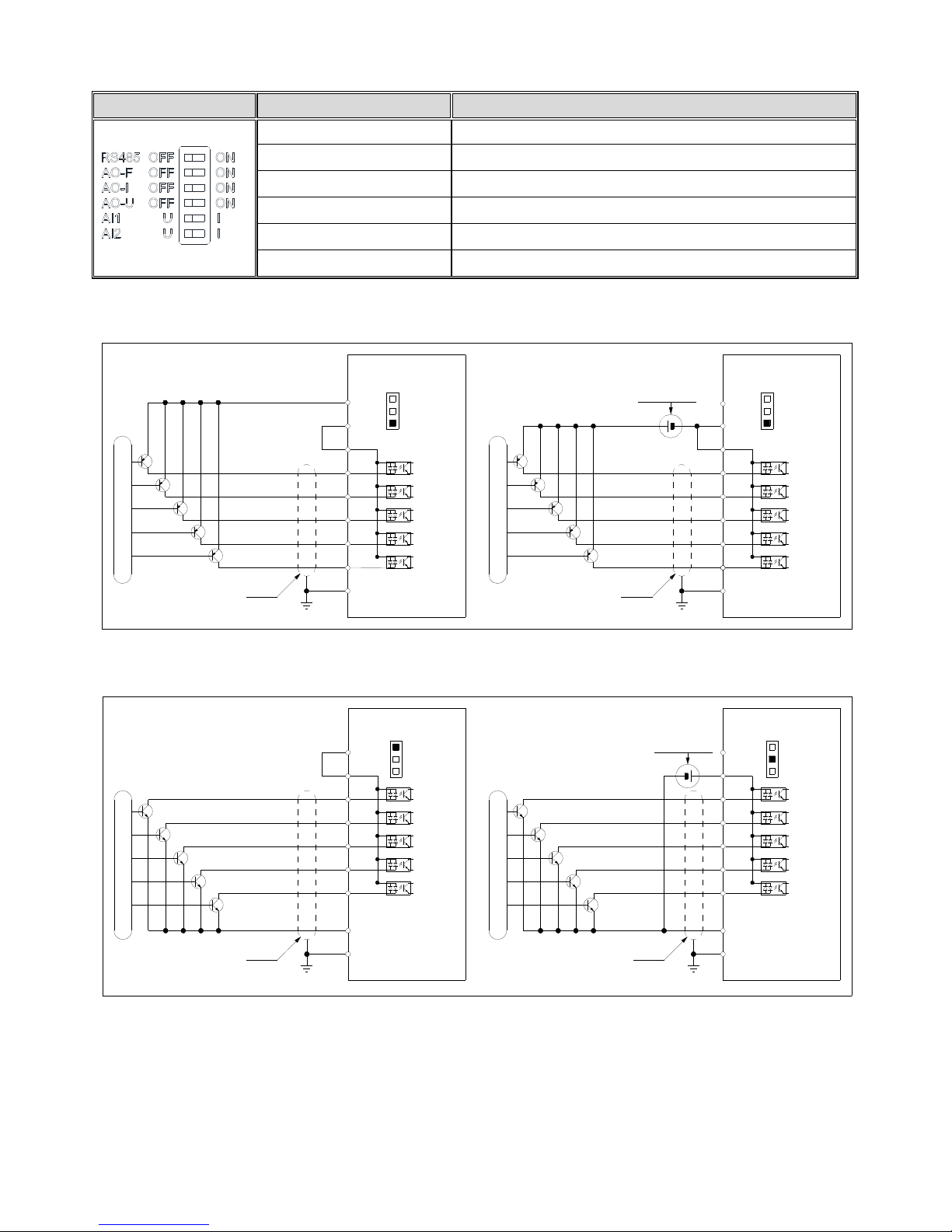

● Fu nction Speci fication of Swi tch Terminals

Switch T erminal Selecting P osition Function Specificati on

RS485 T erminal Resistor

RS485 Communication :connect with 120Ω terminal resistor

AO Output- frequency AO2: 0.0~100kHz frequency output

AO Output- Current AO2: 0~20mA current outpu t or 4~20mA current output

AO Output- Vol tage 0~10V voltage o utput

AI1 Input- Current/Voltage AI1: Input 0~20mA or 0~10V

AI2 Input- Current/Voltage AI2: Input 0~20mA or 0~10V

● Multi-function input point connection

PNP transistor connecti on mode

-

+

External power supply

E

X5

X3

X4

X2

X1

PLC

+24V

Enabled external 24V power supply

COMCOM

Enabled inner 24V power supply

+24V

PLC

X1

X2

X4

X3

X5

Shield Cable

E

External control signals

+24V

PLC

COM

+24V

PLC

COM

VFD VFD

External control signals

Shield Cable

NPN transistor connection mode

Enabled inner 24V power supply

+24V

PLC

X1

X2

X4

X3

X5

COM

Shield Cable

E

(Default short connected )

E

COM

X5

X3

X4

X2

X1

PLC

+24V

Enabled external 24V power supply

External control signals

Shield Cable

Note:

Jumper between"+24V"and"PLC" need be removed

when external 24V power supply was chosen.

External 24V power supply

+

-

+24V

PLC

COM

+24V

PLC

COM

VFD VFD

External control signals

8

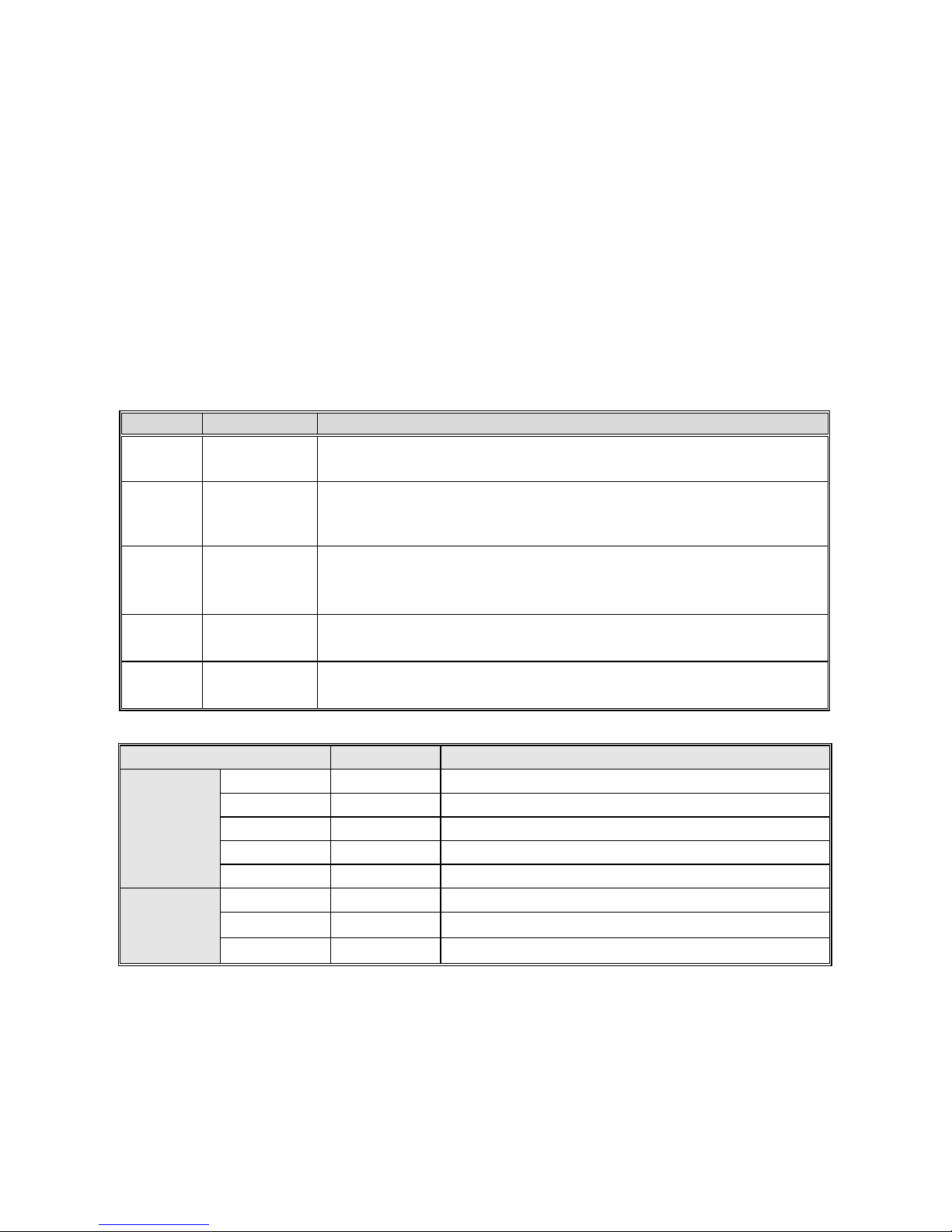

Chapter 3 Keyboard layout and functions specification

●Keyboard Appe arance

●Key function

Key Name Function

Menu key

Enter menu while standby or running . Presses this key to return while m odify param eter . W hile

standby or running, press for 1 sec to enter condition moni toring interface.

Confirm/Shift key

Press to modify parameter while in menu in terf ace. Press again to confirm a fter modifying ;

Press this key for 1 Sec to shift digit, and long press to cycle. Each digit flashes three time to

shift to next digit.

Up/down key

Select parameter group in menu interface. Modify par ameter in modify state. Modify g iven

frequency , ID given whi le at s tandby or moni toring sta te (While g iven freq uency, PID are set by

keyboard and [F4.09] needs to be set.

Run key

While run/stop is controlled by keyboard , press th is key, inverter forward runs, and the in dicator

is always on. While reverse, the indicator sparks.

Stop/reset key

Machine stops if press it while run/stop is controlled by keyboar d. Its effici ency range is defined

by [F4.08]. Inverter resets if press it in fault state (no reset if fault is not solved).

●Indicator Definition

Name State Meaning

Unit indicator

light

Hz Flas h / On Frequency unit

A On Current unit

V On Voltage unit

RPM On Motor speed unit

% Flash / On Percent unit

State

indicator light

RUN On Forward running

RUN Flash Reverse running

RUN Off Stop

9

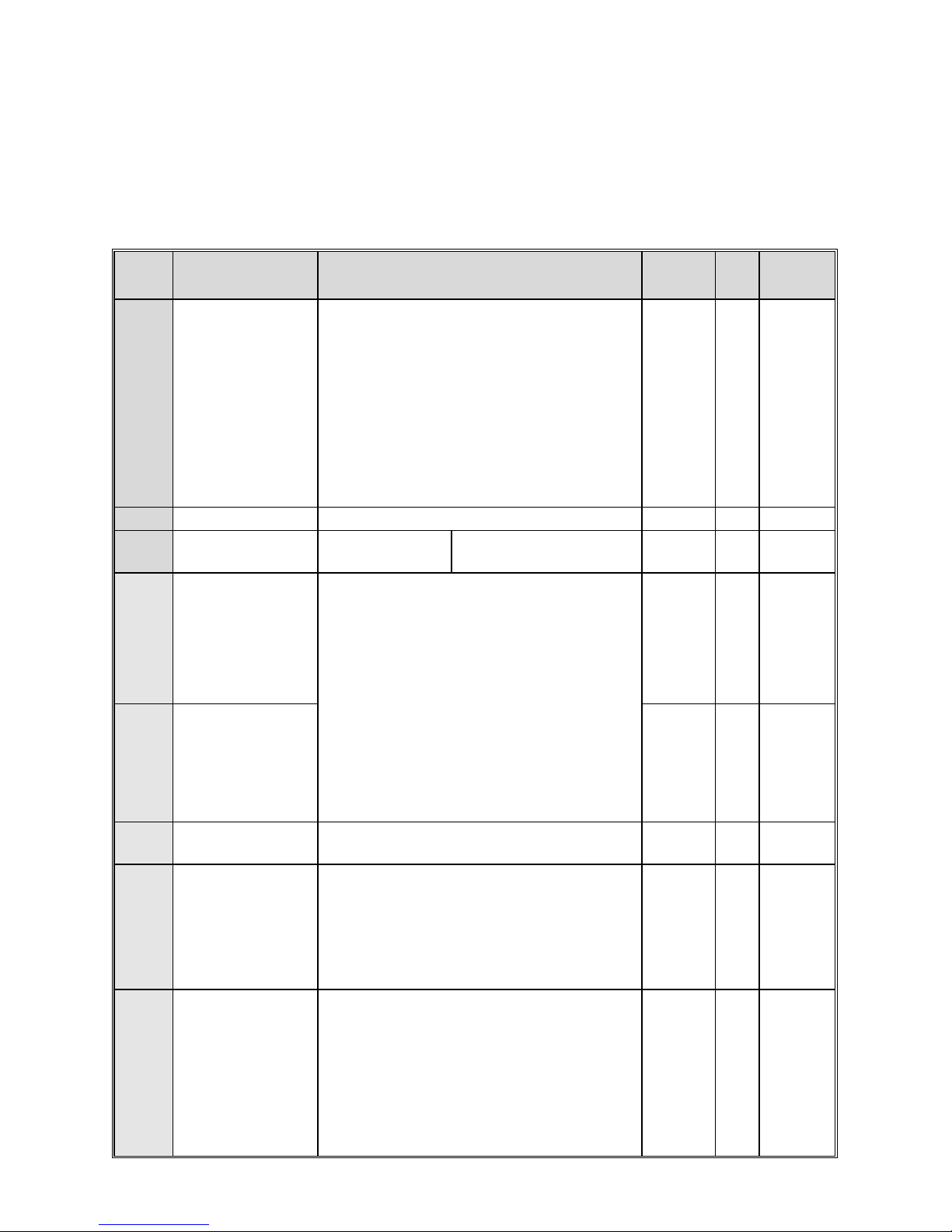

Chapter 4 Function Parameter Table

This chapter just provide s func tion parameter table. Specifica tions refer to AC200 technical manual or inquiry the compa ny.

“●”: Parameter can be changed in the running state.

“〇”: Parameter can’t be changed in the running state.

“×”: Parameter can be read only.

“–”: Factory setting parameter , only factory can set.

“※”: Parameter is related to the model.

4.1 Basic parameters

NO. Function description Range of settings and definition

Factory

default

Fea

ture

Address

F00.00 Motor control mode

Asynchronous motor control mode:

0: V/F control

3: High-performance VC without PG

4: High-performance VC with PG

Synchronous motor contro l mode:

6: High-performance VC without PG

7: VC with PG

Other control:

8:Voltage frequency separation outpu t

1/2/5: Reserved

0 〇 0x000

F00.01 Reserved 0x001

F00.02 Run command channel

0: Keyboard control

1: T erminal control

2: RS485 communication control

3: Reserved

0 ● 0x002

F00.03

Frequency given

source channel A

0: Keyboard number given

1: Reserved

2: Voltage/Current a nalog AI1 given

3: Voltage/Current a nalog AI2 given

4: Reserved

5: T erminal pulse PUL given

6: RS485 communication given

7: Terminal UP/DW control

8: PID control given

9: Program control (PLC) given

10: Optional card

11: Mul ti-steps speed giv en

0 ● 0x003

F00.04

Frequency given

source channel B

1 ● 0x004

F00.05

Frequency channel B

reference source

0: Max. output frequency as reference source

1: Set frequency of channel A as reference source

0 ● 0x005

F00.06

Frequency given

source selection

0: Channel A

1: Channel B

2: Channel A+ Channel B

3: Channel A- Channel B

4: Max. value of Channel A and Channel B

5: Min. value of Channel A and Channe l B

0 ● 0x006

F00.07

Running Command

Binding

LED“0”digit: keyboard command instruction binding

LED“00”digit: terminal command instruction binding

LED“000”digit: communication command instruction

binding

LED“0000”digit: optional card command instruction

binding

0 : no binding

1 : keyboard number given frequency

0000 ● 0x007

10

2 : Reserved

3 : Voltage /Current an alog AI1 given

4 : Voltage /Current an alog AI2 given

5 : Reserved

6 : Terminal pulse PUL given

7: RS485 communication given

8 : Terminal UP/DW cont rol

9 : PID control given

A: Program control (PLC) given

B: Optional card

C: Multi-steps speed given

F00.08

Keyboard digital setting

frequency

0~upper limit 50.00Hz ● 0x008

F00.09 Max frequency output upper limit~600.00Hz 50.00Hz 〇 0x009

F00.10

Upper limit frequency

source selection

0: Upper limit frequency digital given

1: Reserved

2: Voltage/Current a nalog AI1 give

3: Voltage/Current a nalog AI2 given

4: Reserved

5: T erminal pulse PUL given

6: RS485 communication given

7: Optional card

0 ● 0x00A

F00.1 1

Upper frequency limit

digital setting

Lower limit frequency~max frequency 50.00Hz ● 0x00B

F00.12 Lower limit frequency 0.00~upper limit frequency 0.00Hz ● 0x00C

F00.13

Lower limit frequency

running mode

0: Stop output, enter into pa use runnin g state

1: Run at lower limit frequency

1 〇 0x00D

F00.14 ACC time 1 0.01~650.00s

Model set

※ 0x00E

F00.15 DEC time 1 0.01~650.00s

Model set

※ 0x00F

F00.16

Rotary direction

selection

LED“0”digit: running direction takes the opposite

0: Direction unchanged

1: Direction takes the opposite

LED“00”digit: running direction prohibited

0:Forward and reverse commands are allowed

1: Only FWD command allowed

2: Only REV command allowed

LED“000”digit: frequency control direction selection

0: Invalid 1: Valid

LED“0000”digit: reserved

0000 〇 0x010

F00.17 G/P Model Setting 0:G T y pe 1:P Type 0 ● 0x011

F00.18 Reserved 0x012

F00.19 Parameter initialization

0: No action

1: Restore factory defaul t (not restoring motor p arameters)

2: Restore factory defaul t (restoring mo tor param eters)

3: Clear malfunction records

0 〇 0x013

Loading...

Loading...