Veichi AC100-T3-7R5G, AC100-T3-R75G, AC100-T3-5R5G, AC100-T3-011G, AC100-T3-015G User Manual

...

Contents

Chapter 1 Overview……………………………………………………………………………………... 1

1.1 Safety Precautions……………………………………………………………... ….. ….. ….. .1

1.2 Technical Criterion …………………………………………………………………………….. 4

1.3 Specification of Expansion Card …………………………………………………………….. .7

Chapter 2 Before Use………………………………………………………………………………….. 8

2.1 Purchase Inspection………………………………………………………………………….. 8

2.2 Nameplate ……………………………………………………………………………………... 8

2.3 Standard Models and Rated Parameters……………………………………………………9

Chapter 3 Installation and Wiring……………………………………………………………………. 10

3.1 Safety Precautions…………………………………………………………………………. …10

3.2 Dealing Methods for Inverter after Long-term Storage ………… ………………………….11

3.3 Stable Running Environment for Inverter……………………………………………………11

3.4 EMI Protection………………………………………………………………………………... 12

3.5 Machinery Installation………………………………………………………………………….15

3.6 Electrical Installation…………………………………………………………………………. .23

Chapter 4 Basic Operation and Trial Run…………………………………………………………..37

4.1 Safety Precautions…………………………………………………………………….……… 37

4.2 Keyboard Layout and Functions Specification………………………………………………38

4.3 Basic Operation…………………………………………………………………………………41

4.4 LED Keyboard Operation Specification………………………………………………………43

4.5 Trial Run………………………………………………………………………………………... 48

Chapter 5 Fault Diagnoses and Processing……………………………………………………… 56

5.1 Fault Types……………………………………………………………………………………. .56

5.2 Fault Information and Details ……………………………………………………………... . .56

5.3 Fault Diagnoses and Treatment Measures …………………………………………………61

Chapter 6 Regular Inspection and Maintenance……………………………………………………67

6.1 Safety Precautions……………………………………………………………………………. 67

6.2 Inspection………………………………………………………………………………………. 67

6.3 Maintenance………………………………………………………………………………... ... 69

Chapter 7 Peripherals and Options………………………………………………. 72

7.1 Safety Precautions………………………………………………………………………... …. 72

7.2 Peripherals……………………………………………………………………... ………………72

7.3 The Use of Peripherals …………………………………………………………. …………. . 74

Chapter 8 Function Parameter Specification ............................................................................. 77

8.1 Basic Parameters ............................................................................................................ 77

8.2 Running Control Parameter ............................................................................................. 87

8.3

Quantum Digital Terminal Parameter .............................................................................. 93

8.4 Analog Terminal Parameter ........................................................................................... 108

8.5 Keyboard and Display Parameters ................................................................................ 113

8.6 Motor Parameters .......................................................................................................... 117

8.7 VC Control Parameter ................................................................................................... 119

8.8 Torque Control Parameters ........................................................................................... 123

8.9 V/F Control Parameters ................................................................................................. 125

8.10 Malfunction and Protection Parameters ...................................................................... 128

8.11 PID Parameters ........................................................................................................... 133

8.12 Multi-step, PLC Function and Swing Frequency Parameters ...................................... 138

8.13 Communication Control Function Parameters ............................................................ 143

Chapter 9 Appendix .................................................................................................................... 149

9.1 Appendix 1: Function Parameter Table ......................................................................... 149

9.2 Appendix 2: RS485 Communication Protocol ............................................................... 188

9.3 Appendix 3: PG Card Manual ........................................................................................ 196

9.4 Appendix 4: Profibus-DPcard Manual ........................................................................... 204

9.5 Appendix 5:LCD Keyboard ............................................................................................ 206

9.6 Appendix 6: CANopen Card Manual ............................................................................. 210

AC100 HIGH-PERFORMANCE VC INVERTER MANUAL OVERVIEW

1

Chapter 1 Overview

Thanks for using AC100 high-performance VC frequency inverter produced by Shenzhen Veichi Electric Co., Ltd. This

manual explains the proper way of using the product. Please read carefully (installation, wiring, operation, maintenance,

checking, etc) before use.

1.1 Safety Precautions

To ensure safe, reliable and rational use of this product, please fully understand the safety precautions described in this

manual before use.

Warning Signs and Meanings

This manual uses the following marks to indicate the importance of security. If these precautions are not followed,

accidents such as personal injury, damage of the product and associated systems might occur.

Danger: Wrong operation may cause death or major accident.

Warning: Wrong operation may cause death or major accident.

Caution: Wrong operation may cause minor injury.

Important: Wrong operation may cause damage to the inverter and related system

Warning Signs Position

Drawing 1:Warning positions on crust of AC100 series inverter

Warning position 2

Warning position 1

AC100 HIGH-PERFORMANCE VC INVERTER MANUAL OVERVIEW

2

Operation Qualification

All the products must be performed by trained professionals for installation, wiring, operation, maintenance and other

operations. The "trained professionals" referred in this manual must undergo professional training, being familiar with

the installation, wiring, operation and maintenance of the equipment and must be able to handle with all kinds of arising

emergencies.

Safety Guidance

Safety rules and warning signs are set for users’ safety and to prevent personal injury, damage of product and

associated systems; to ensure safe, reliable and rational use of this product, please fully understand the safety

precautions described in this manual before use.

Safety rules and warning signs are divided into the following categories: routine guidance, transportation and storage

guidance, installation guidance wiring, operation and maintenance guidance, as well as dismantlement and disposal

guidance

● Routine Guidance

● This product contains dangerous voltage and it controls the movement mechanism with

potential danger; there might be accidents like personal injury and damage to the product and

associated systems if requirements in this manual are not followed.

● Only trained personnel should operate this product, and before using the product in this

manual the personnel should be familiar with all safety instructions and regulations of the

operation; proper operation and maintenance are the key to achieve security and stability of

the product.

● No wiring when power on. Otherwise, there might be danger of electric shock; when operating

wiring, inspection, maintenance and other operations, please turn off the power of all related

equipment and make sure the main circuit DC voltage has dropped to security level, and wait

for five minutes before any relevant job.

● Away from children and public.

● This product could only be used in special areas specified by the manufacturer and should not

be used in fields like emergency, rescue, marine, medical, aerospace, nuclear facilities

without permission.

● Unauthorized alteration or use of accessories not sold or recommended by the manufacturer

may cause a malfunction.

● Please make sure this manual is in the final user’s hand before use.

● Before installation and debugging please carefully read and totally understand these safety

regulation and warning signs.

● Transportation and Storage Guidance

●Correct transportation, storage, installation, and careful operation and maintenance are

essential for the safe operation of the inverter.

● In transport and store process, make sure the inverter is free from shock and vibration. It must

be stored in places dry without corrosive air and conductive dust, and the temperature must

be lower than 60℃.

AC100 HIGH-PERFORMANCE VC INVERTER MANUAL OVERVIEW

3

● Installation and Wiring Guidance

● Only trained personnel can operate.

● Power lines, motor lines, control lines must be connected tightly, and the ground terminal

must be grounded, and the grounding resistance must be less than 10Ω.

● Before opening the inverter panel, turn off the power of all related equipment, and make sure

the main circuit DC voltage has dropped to a safe level, and wait five minutes before any

relevant job.

● Human body electrostatic would seriously damage the inner sensitive components. Before

operation, please follow ESD measures. Otherwise, there might be danger of inverter

damage.

● The voltage of the inverter outputs in form of pulse wave, and if capacitor that improve power

factor or varistor that is against thunder is installed on the output side, make sure to dismantle

them or modify them to the input side of the inverter.

● No switch components such as breaker and contactor at the output side. (If there must be

one, please make sure the output current is 0 while the switch acting).

● The power supply cable and motor cable specifications must satisfy all conditions in table 3-7

and table 3-8.

● Running Guidance

● Inverter runs at high voltage. So dangerous voltage is in some components inevitably.

● No matter where the fault is, there is danger of serious accident, even human body injury

which means dangerous malfunction possibility. So there must be additional external

preventing measures or other safety devices, such as independent current limiting switch,

machinery fense and so on.

● In order to ensure that the motor overload protection can operate correctly, motor parameters

must exactly match the motor in use.

● Maintenance Guidance

●Maintenance and service of this product can only be done by the service sectors or authorized

service center of Veichi Electric Co., Ltd or professional person trained and authorized by

Veichi. And these personnel should be familiar with the safety warnings and proposed

operating essentials referred in this manual.

● Any defective components must be changed in time.

●

Before opening the equipment, be sure to disconnect the power, and make sure the main

circuit DC voltage has dropped to a safe level, and wait five minutes before any relevant job

● Dismantlement and Disposal Guidance

●The inverter's packaging is reusable, please keep the packaging for future use or please

return it to the manufacturer.

● Dismantlement of metal components can be recycled.

● Some components such as electrolytic capacitor are harmful to the environment. Please

dispose according to the requirements of environmental protection departments.

AC100 HIGH-PERFORMANCE VC INVERTER MANUAL OVERVIEW

4

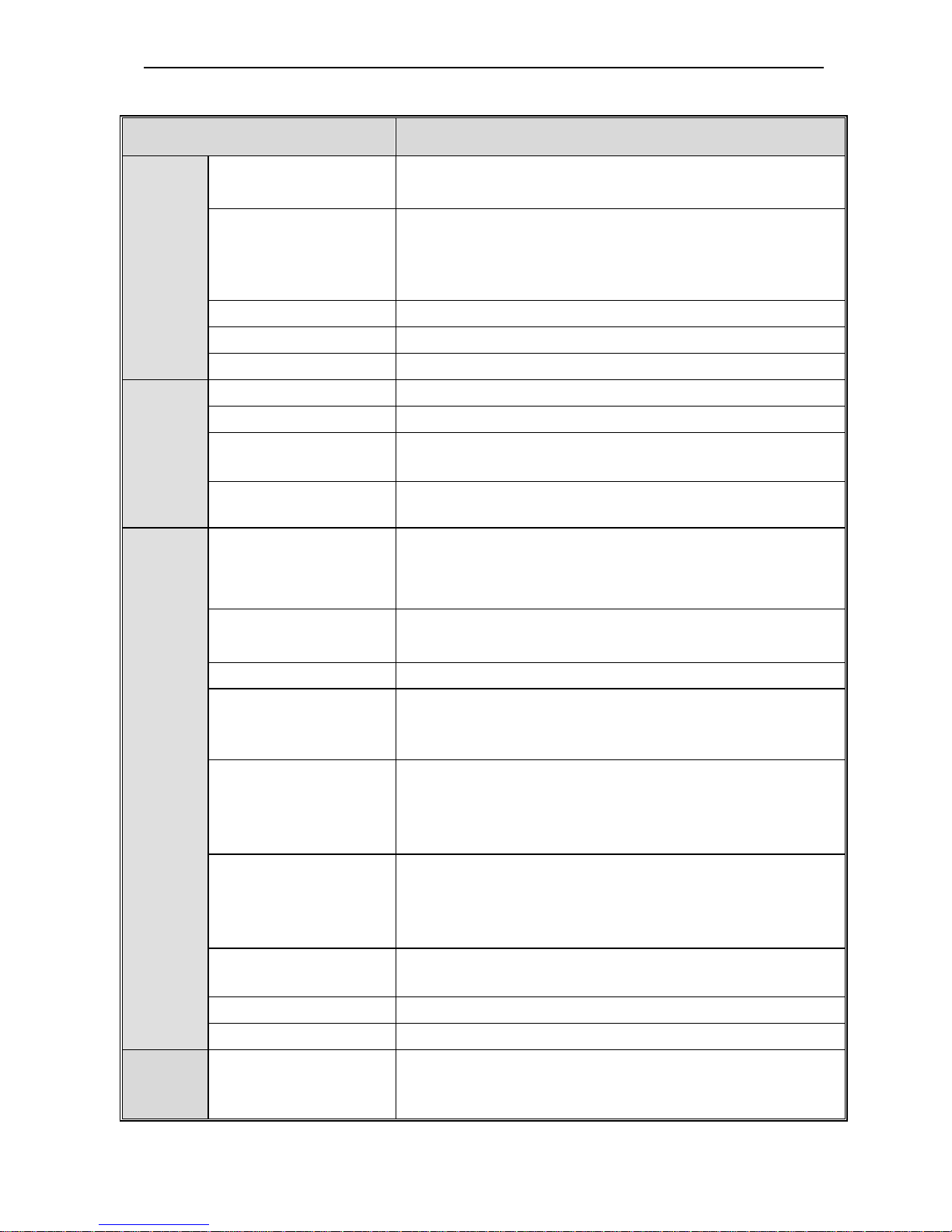

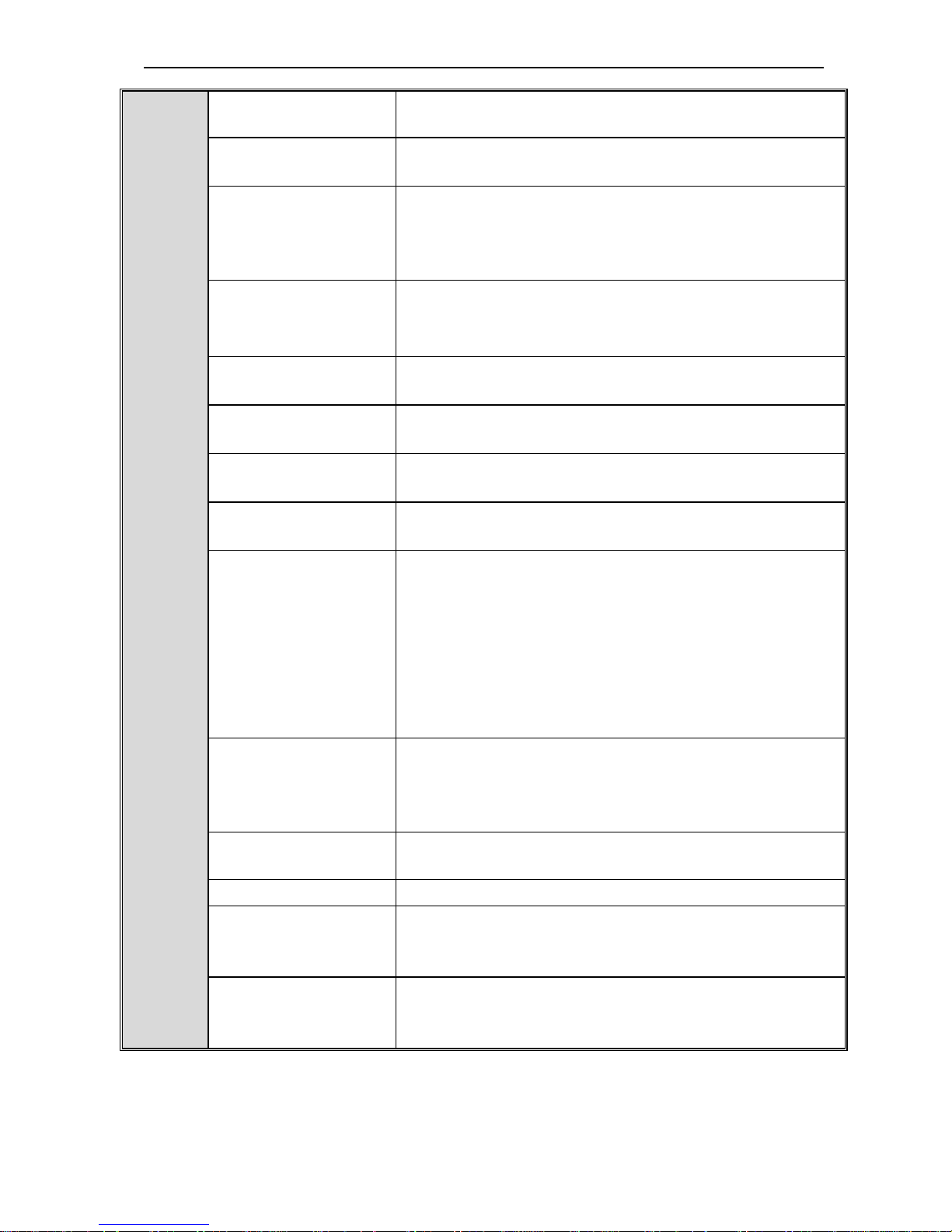

1.2 Technical Criterion

Items Criterion

Power

input

Voltage, frequency

Single-phase 220V 50 / 60Hz three-phase 380V 50 / 60Hz

Three-phase 220V 50 / 60Hz three-phase 660V 50 / 60Hz

Allowable fluctuations

Voltage fluctuation: 320V ~ 440V;

Voltage unbalance rate: <3%;

Frequency fluctuation: ± 5%

Distortion rate: meet IEC61800-2 requirements

Closing inrush current Lower than rated current

Power factor ≥0.94(with DC reactor)

Inverter efficiency ≥96%

Output

Output voltage

Under nominal conditions Output: 3 phase, 0 to the input voltage, the error

Output frequency range 0 ~ 320 Hz (320 Hz or more can be factory customized)

Output frequency accuracy

Error does not exceed 0.01Hz (digital setting) or 0.2% of maximum

frequency (analog reference)

Overload capacity

150% of rated current for 1 minute; 180% of rated current for 10 seconds;

200% of rated current for 0.5 seconds;

Main

Control

performance

Motor control mode

Induction motors: vector control without PG, PG vector control, VF control

Permanent magnet synchronous: no PG vector control, vector control with

PG

Modulate mode

Optimization space vector PWM modulation, continuous adjustment, not

continuous adjustment automatically switch

Carrier frequency 0.6~15.0kHz,randomized carrier-wave

Speed range

VC with PG: 1: 1000

VC without PG (asynchronous): 1: 100

VC without PG (synchronous): 1:50

Steady speed accuracy

VC without PG (asynchronous and synchronous): ≤ 1% rated synchronous

speed

VC with PG (asynchronous and synchronous): ≤ 0.02% rated synchronous

speed

Starting torque

VC without PG (asynchronous): 0.5Hz provide 180% rated torque

VC without PG (synchronous): 2Hz to provide 100% of the rated torque

VC with PG (synchronous and asynchronous): 0Hz provide 200% of the

rated torque

Torque response

VC without PG (synchronous and asynchronous): ≤20ms

VC with PG (synchronous and asynchronous): ≤10ms

Frequency accuracy Digital setting: 0.01Hz; Analog setting: Maximum frequency × ± 0.2%

Frequency resolution Digital setting: 0.01Hz; Analog setting: Maximum frequency × 0.05%

Basic

functions

DC braking capacity

Starting frequency:0.00~50.00Hz

Braking time:0.0~60.0s

Braking current:0.0~150.0% rated current

AC100 HIGH-PERFORMANCE VC INVERTER MANUAL OVERVIEW

5

Torque upgrade capacitance

Auto torque upgrade 0.0%~100.0%

Manual torque upgrade 0.0%~30.0%

V/F curve

VF linear curve, custom multi VF curve, square VF curve;

VF power 1.1-1.9 arbitrary curve;

Acceleration/Deceleration

curve

Two ways: one linear acceleration and deceleration, S-curve acceleration

and deceleration;

Four sets of acceleration and deceleration time, time unit 0.01s, longest

650.00s, the benchmark optional;

Rated output voltage

Using the compensation function of power supply voltage. When the motor

rated voltage range is 100%, it can be set to any value within the range of

50-100% (output voltage can’t exceed the input voltage)

Voltage auto-adjustment

When the grid voltage fluctuates, the constant output voltage can be

automatically maintained.

Energy-saving running

Depending on the load condition, automatically optimizing the output

voltage to save energy.

Current auto-limiting

Auto-limit the current while running to prevent frequent over current break

trouble.

Instant power off treatment

When instant power off, control the bus voltage to realize uninterrupted

operation.

Standard functions

Superposition of main and auxiliary frequency source, running the

command bundle, starting frequency, vector pre-excitation starting, start /

stop of DC braking, speed tracking and power-down re-starting, reverse ban

and reversing dead time setting, zero speed torque holding, jog operation,

frequency hopping, separately set the emergency stop time, FDT detection,

timer function, torque control, flux braking and dynamic braking, failure

recovery, the last three failure record, process PID controller, multi-velocity

and PLC program control, 485 communication interface;

Frequency setting channel

Keyboard digital setting, keyboard potentiometer, analog voltage terminal

VS, analog voltage / current terminals AI, analog current terminal AS, given

and multi-channel communications terminal selection, main and auxiliary

channel combinations

Feedback input channel

Voltage terminal VS1, the voltage / current terminals AI, current terminals

A

S, communication given, pulse input PUL

Running command channel Operation panel given, external terminal given, communication given.

Input command signal

Start, stop, FOR/REV, JOG, multi-velocity, free stop, reset,

Acceleration/Deceleration time selection, frequency set channel selection,

external fault alarm.

External output signal

2 relay outputs, 1-collector output;

0 ~ 10V output, 4 ~ 20mA / 0 ~ 20mA output;

Pulse frequency output;

AC100 HIGH-PERFORMANCE VC INVERTER MANUAL OVERVIEW

6

Protection function

Bus overvoltage, mains under voltage, inverter over-current, module failure,

inverter overload, motor overload, current detection zero drift failure, Hall

failure, E2ROM failure, motor grounding failure, input phase failure, output

phase failure, inverter overheating, communication failure, PG card failure,

PG disconnection failure, motor parameter self-tuning failure;

Special Functions

VC mode

2 modes: 1st mode providing high-performance speed effect; 2ed mode

providing lower and simple performance testing method;

Auto-learning

Asynchronous motors, synchronous motors static parameter learning,

rotation parameter learning;

Static self-learning induction motors all parameters; PG vector control

encoder self-learning;

Supporting multiple

encoders

Incremental encoder (5V, 12V power supply, frequency dividing output),

resolver, SinCos encoders, absolute encoders;

VF separation

function

Frequency, voltage can be independently given and regulated, supporting

multi-channel given way;

T erminals, Analog

quantity

Providing 4-way virtual X terminals, 4-way virtual Y terminals; supporting

delay adjustment of terminal rising and falling;

Extending 3-way X terminals by analog quantity;

Providing more than two points analog quantity for analog calibration;

Motor grounding

short circuit detection

Can detect whether the motor is shorted to ground and the electricity can be

automatically detected;

Servo control

Supporting basic functions like synchronous and asynchronous servo

control, pulse tracking, zero servo positioning servo index location,

supporting quadrature pulse given;

Telecommunication

network

supporting 485 / Modbus protocol, CANopen protocol, profibus-DP protocol;

Modbus freedom protocol, CAN custom protocols, networking and linkage

control between WEICHI inverters can be realized;

Remote and

monitoring function

Supporting remote upgrading, remote monitoring, remote locking function,

can be connected to WEICHI 3G module;

Supporting virtual oscilloscope monitoring and debugging;

Keyboard

display

LED display

Single row 4 digital tube display Can monitor one state variable

Two row 5 digital tube display Can monitor two state variables

Parameter copy

Function code information of frequency inverter can be uploaded and

transferred to realize fast parameter copy.

State monitoring

Output frequency, given frequency, output current, input voltage, output

voltage, motor speed, PID feedback, PID given value, module temperature,

input and output terminal status

Environment

Installation site Indoor, altitude ≤1000m, no corrosive air or direct sunshine

Temperature, humidity -10 ~ +40℃ 20%~90%RH(no condensation)

Vibration Under 20Hz≤0.5g

Storage temperature -25~+65℃

Installation method Hanging type, cabinet type

Protection level IP20

Cooling method Forced air cooling

AC100 HIGH-PERFORMANCE VC INVERTER MANUAL OVERVIEW

7

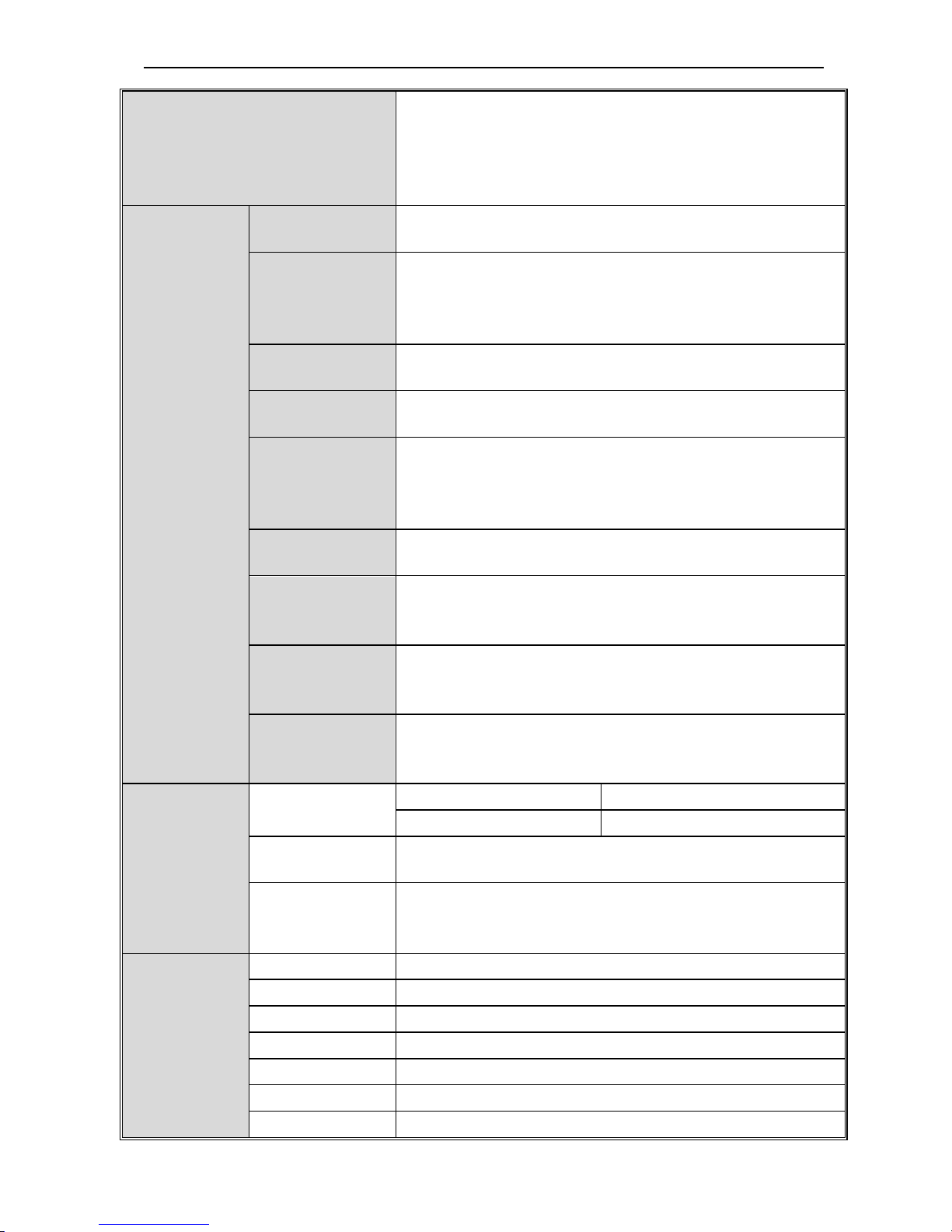

1.3 Expansion/SD Card Specification:

There’s a variety of optional expansion/SD card for AC100, specified in the table below:

Expansion/SD Card Type Model Description

Ordinary photoelectric ABZ

encoder PG card

PG01_ABZ_xx_xx

Applicable for ordinary photoelectric encoder; 5V,

12V power output, OC, divided signal output are all

optional;

Ordinary photoelectric UVW

encoder PG card

PG01_UVW_xx_xx

Applicable for photoelectric encoder with UVW

signals or wire-saving type UVW encoder.

Resolver PG card PG01_RT

Applicable for resolver.

Terminal expansion card EXIO_01

Applicable for increasing the number of common

input terminals, relays, and analog quantity.

Air compressor expansion card

EXIO_02

Applicable for the control of air compressor.

ⅡPG card PG02_ABZ_xx

Applicable for speed measuring and quadrature

pulse given.

DP expansion card ACDP03

Applicable for expansion of profibus-DP

telecommunication

CANopen expansion card CAN01

Applicable for expansion of CANopen

telecommunication

3G telecommunication

expansion card

S200-GPS

Applicable for remote monitoring, software upgrades,

remote locking

Servo expansion card

EXSV_01

Providing differential input and output terminals and

RS232 communication interface.

AC100 HIGH-PERFORMANCE VC INVERTER MANUAL BEFORE USE

8

Chapter 2 Before Use

2.1 Purchase Inspection

On receiving your order, please check the package and confirm intact before opening, and check if there’s any damage,

scratch or dirt (damages caused during transportation are not within the company's warranty). If there’s any damage

caused during transportation, please contact us or the transport company immediately.

After confirming the receipt of the goods intact, please re-confirm if the product and your order are consistent. Model of

the product is on the "MODEL" column. If you find the product model is not the one you ordered, please contact the

dealer you purchased the product or the sales department of VEICHI immediately.

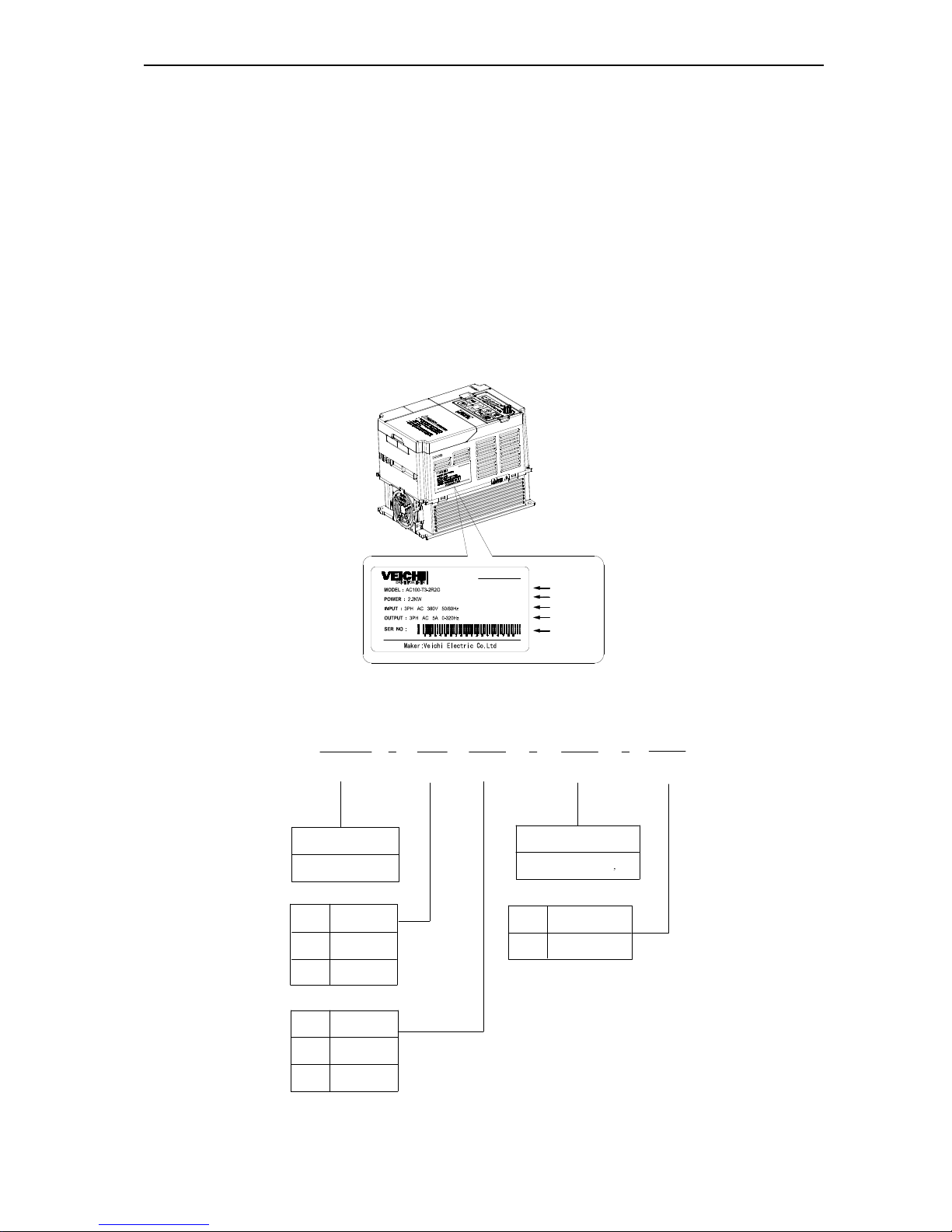

2.2 Nameplate

Nameplate Position and Content

Input

Inverter model

Output

Power range

Series NO.

Drawing2-1:AC100 Series Inverter Nameplate Position

Model Specification

AC100 series

Single-phase

S

T

Symbol

Inverter series

G

(4)

Motor power(kW)

Phase

3-phase

Type

(3)

2R2

(2)

T

(1)

AC100

(5)

3

220V

Voltage

Symbol

2

3

380V

Symbol

G

General

(Pls refer drawing 2-1 2-2)

Drawing 2-2:Meaning and Naming Rules of AC100 Series Inverter Nameplate

AC100 HIGH-PERFORMANCE VC INVERTER MANUAL BEFORE USE

9

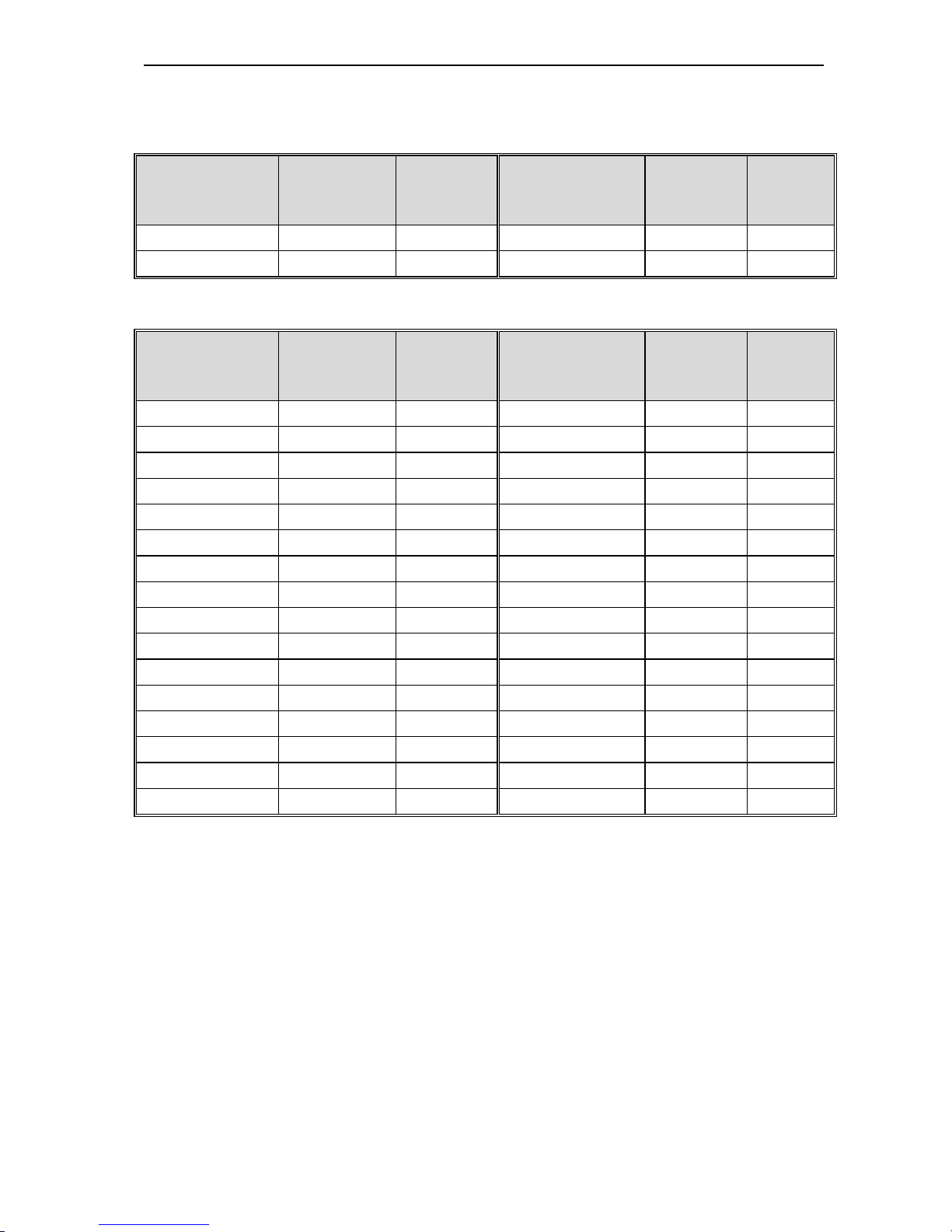

2.3 Standard Models and Rated Parameters

Single phase 220V

Table 2-1:AC100 Single Phase 220V Series Inverter Models and Rated Parameters

Three phase 380V

Table 2-2:AC100 Three Phase 380V Series Inverter Models and Rated Parameters

Model

Max adaptive

motor

Rated current

Model

Max

adaptive

motor

Rated

current

AC100-S2-R40G 0.4kW 2.5A AC100-S2-1R5G 1.5kW 7A

AC100-S2-R75G 0.75kW 4A AC100-S2-2R2G 2.2kW 10A

Model

Max adaptive

motor

Rated current

Model

Max

adaptive

motor

Rated

current

AC100-T3-R75G 0.75kW 2.5A AC100-T3-110G 110kW 210A

AC100-T3-1R5G 1.5kW 3.7A AC100-T3-132G 132kW 250A

AC100-T3-2R2G 2.2kW 5A AC100-T3-160G 160kW 310A

AC100-T3-004G 4kW 10A AC100-T3-185G 185kW 340A

AC100-T3-5R5G 5.5kW 13A AC100-T3-200G 200kW 380A

AC100-T3-7R5G 7.5kW 17A AC100-T3-220G 220kW 415A

AC100-T3-011G 11kW 25A AC100-T3-250G 250kW 470A

AC100-T3-015G 15kW 32A AC100-T3-280G 280kW 510A

AC100-T3-018G 18.5kW 38A AC100-T3-315G 315kW 600A

AC100-T3-022G 22kW 45A AC100-T3-355G 355kW 670A

AC100-T3-030G 30kW 60A AC100-T3-400G 400kW 750A

AC100-T3-037G 37kW 75A AC100-T3-450G 450kW 800A

AC100-T3-045G 45kW 90A AC100-T3-500G 500kW 860A

AC100-T3-055G 55kW 110A AC100-T3-560G 560kW 990A

AC100-T3-075G 75kW 150A AC100-T3-630G 630kW 1100A

AC100-T3-090G 90kW 180A AC100-T3-700G 700kW 1260A

AC100 HIGH-PERFORMANCE VC INVERTER MANUAL INSTALLATION AND WIRING

10

Chapter 3 Installation and Wiring

3.1 Safety Precautions

This section specifies the various considerations necessary for reliable and safe operation of the product by users.

Inverter

●When the inverter is installed in closed cabinet, please ensure the temperature at the air-in

port below 40℃ by way of cooling fans or air conditioners and other cooling equipment to

ensure the safe and reliable operation of the inverter.

●When installing, please cover the inverter with cloth or paper to prevent metal dust, oil, water

and others. And remove these cover carefully after working.

● Please follow the ESD regulations when operating the inverter, otherwise, the inverter may

be damaged.

●If several inverters are installed in a cabinet, enough space must be set aside on the upper

part of the inverter in order to change the cooling fan.

●Inverter can’t work over rated range. Otherwise, the inverter may be damaged.

●When transporting the inverter, please hold the case firmly. There might be danger of inverter

main body falling, personnel injury or inverter damage if only holding the pre-cover.

Motor

●Different motor has different max allowable running speed. Motor can’t run over the max

allowable running speed.

●When inverter is running at low speed, the motor auto-cooling effect would seriously decrease.

If motor runs at low speed for long term, it will be damaged for overheating. If needed, please

use special motor for inverter.

●When constant speed machinery runs at inconstant speed, there might be sympathetic

vibration. Please install vibration-proof rubber under motor rack or use jumping frequency

control function.

●When using frequency inverter or working frequency power supply to drive, the torque

characteristics are different. Please do confirm the torque characteristic of the equipment

connected.

●The rated current of shift gear motor is different from that of standard motor. Please confirm

and choose the right frequency inverter. Moreover, please do switch the pole when the

inverter input current is 0. Otherwise, it may bring inverter damage.

●The rated current of diving motor is higher than that of standard motor, please confirm and

choose the right inverter.

●When the wiring distance between motor and inverter is far, the max torque of the motor

would reduce due to voltage drop. So please use cable thick enough when the distance

between the motor and the inverter is long.

AC100 HIGH-PERFORMANCE VC INVERTER MANUAL INSTALLATION AND WIRING

11

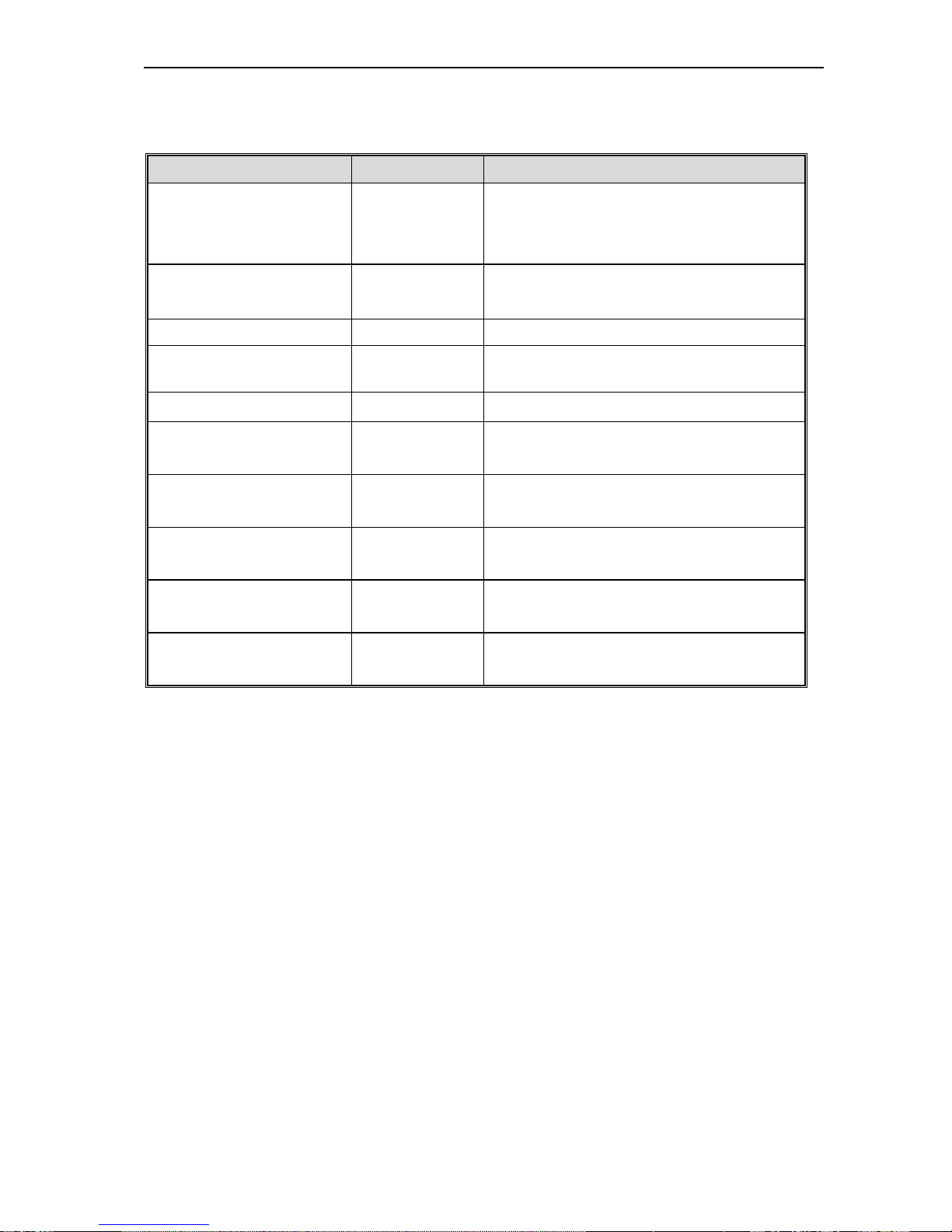

3.2 Dealing Methods for Inverter after Long-term Storage

If the inverter storage time is over one year, the aluminum capacitor in the inverter must be pre-charged again and

make sure the aluminum capacitor characteristic recovered before installation. For specific method, please follow the

grads in the chart below and give more than 30 mins corresponding proportional voltage for every grad when the

inverter is no-load.

If the input voltage of one grad is at the critical point of contactor, fan or other equipments, please increase or reduce

the corresponding input voltage for the grad to avoid any related components working under critical state.

Chart 3-1: Dealing Methods for Inverter after Long-term Storage

3.3 Stable Running Environment for Inverter

Installation environment is very important to maximize the performance of this product and maintain long-term function,

so please install the product in the environment as required in the following chart.

Environment Requirement

Installation site Indoor without direct sunshine

Operating

temperature

-10 ~ +40℃(hanging type)

-10 ~ +45℃(cabinet type)

Storage temperature -20 ~ +60℃

Environment humidity <95%RH, no condensation

Surroundings

Please install the inverter in place as follows:

● Place without oil mist, corrosive gases, flammable gas, dust, etc.

● Place where metal dust, oil, water would not get inside the inverter (please do not install

inverter on flammable material such as wood, etc).

● Place without radioactive material or flammable material.

● Place without poisonous gases or liquid.

● Place with little salt corrosion.

● Place without direct sunshine.

Altitude <1000m

Vibration

<10~20Hz:9.8m/s2

<20~55Hz:5.9m/s2

Installation and

cooling

● Inverter must be installed vertically and longitudinally, and it can’t be installed horizontally.

● Please independently install high heating equipments such as braking resistor and it can’t be

installed in the same cabinet with inverter. Installation of high heating equipments at the air-in

port of the inverter is strictly prohibited.

Chart 3-1:AC100 Series Inverter Running Environment Condition

AC100 HIGH-PERFORMANCE VC INVERTER MANUAL INSTALLATION AND WIRING

12

●To improve product reliability, please use the inverter where temperature would not change suddenly; when using in a

closed cabinet, cooling fan or air conditioning for cooling is needed to prevent the internal temperature from

exceeding allowed temperature; please avoid freezing of the inverter since low temperatures may cause malfunction

of some devices due to freezing.

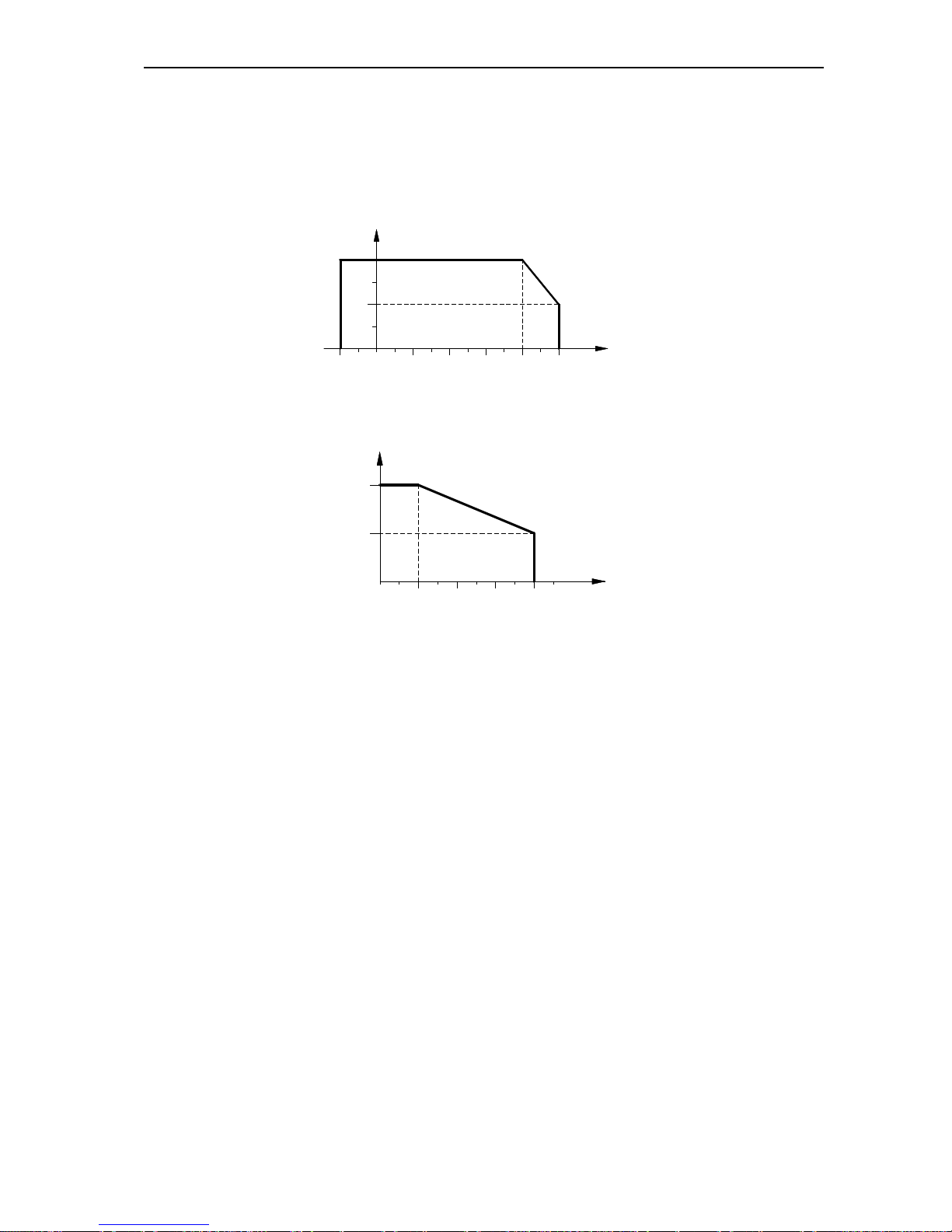

● Derate according to the chart when temperature exceeds limit.

30

25

100

75

50

4020100-10 50

TEMPERATURE(℃)

PERMIT OUTPUT CURRENT(%)

Chart 3-2:AC100 Series Inverter Derating Curve When Exceeding Permitted Temperature

● Derate according to the chart when altitude exceeds limit.

0

1000 2000 4000

80

100

3000 ALTITUDE(M)

PERMIT OUTPUT CURRENT(%)

Chart 3-3:AC100 Series Inverter Derating Curve When Exceeding Permitted Altitude

3.4 EMI Protection

The designing features of inverter allow it to run with strong electromagnetic interference. Generally, if the quality of the

installation is good, the safe and trouble-free operation of the inverter can be guaranteed. Please implement installation

according to the following rules to ensure reliable and effective installation of inverters and avoiding electromagnetic

interference.

● Make sure that all equipments in the cabinet have been connected reliably to the public Y-type earth point or earth

bus with thick and short cable. The motor earth should be as close as possible. Please do not connect the motor

shell to earth terminal of the inverter or the protective area of control system.

● Make sure that all devices connected to the inverter are connected to the same earth net or Y-type earth point with

thick and short cable.

● It would be better for conductors to be flat and multi-core since they have lower impedance at high frequencies.

● When cutting off the tip, the cable should be as neat as possible to make sure that the unscreened wires are as short

as possible.

● Wiring of control cable should be away from the power supply cable and motor cable as far as possible; separate

trunk should be used and a 90º vertical cross must be used when the supply power cable and the motor cable

intersect.

● Make sure that the contactor should be installed in a cabinet with a surge suppressor. Alternatively, the AC contactor

coil is connected with 'R-C' damping circuit, using a coil voltage corresponding varistor; the DC contactor coil is

connected with 'flywheel' diodes or pressure thermistor type devices corresponding to the coil voltage, which is

particularly important when the contactor frequently operates and when contactor is controlled by the output relay of

the inverter.

● Cable connected to motor should be shielded cable or armored cable. The two barriers are earthed reliably by cable

AC100 HIGH-PERFORMANCE VC INVERTER MANUAL INSTALLATION AND WIRING

13

earthing card.

● Installation of 'Input Noise Filter' can reduce electromagnetic interference from other devices of the grid side, 'Input

Noise Filter' must be as close to the inverter input terminals, at the same time, the filter must earth reliably as the

inverter.

● Installation 'output side noise filter' can reduce interference from radio interference and induction noise. 'Output side

noise filter' must be as close to the inverter output terminals, at the same time, the filter must earth reliably as the

inverter.

● Control circuit cable should be shielded cables all the time;

● Adding zero phase reactor in power supply wire near inverter input terminal, adding zero phase reactor in the motor

wire near inverter output terminal and adding zero phase reactor in control wire near inverter control terminal to

efficiently reduce electromagnetic interference to the inverter.

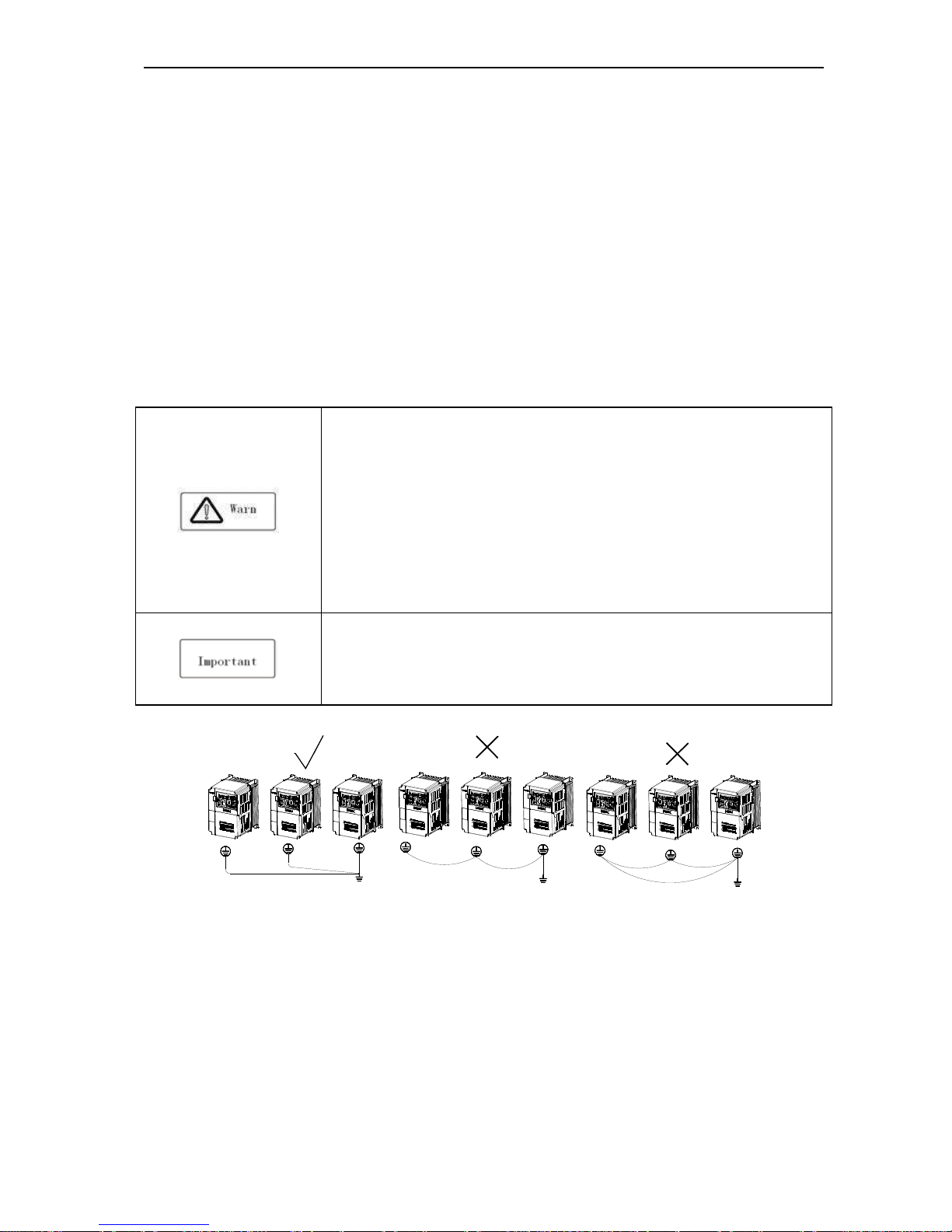

● Earth

Right and reliable earth is the basic condition of safe and reliable running of the product. For right earth, please read the

following notice carefully.

●To avoid electric shock, earth cable should be the size as specified in the technical

standards for electrical equipment. And cable length should be as short as possible.

Otherwise, leakage current of inverter would cause unstable potential of the earth

terminal which is far from the earth point, and electric shock accident would happen

frequently.

● Be sure to ground the ground terminal. Grounding resistance 10Ω or less, it may

cause injury or death

●Earth terminal must be earth. Earth resistance must be below 10Ω. Otherwise, there

is danger of injury and death.

●Please do not share earth cable with welder or other big current/pulse power

equipment. Otherwise, inverter would act abnormally.

●When multi inverters are used at the same time, please do not wind the earth wire to

loop-type. Otherwise, inverter will act abnormally.

Chart 3-4: Multi AC100 Series Inverters United Earth

AC100 HIGH-PERFORMANCE VC INVERTER MANUAL INSTALLATION AND WIRING

14

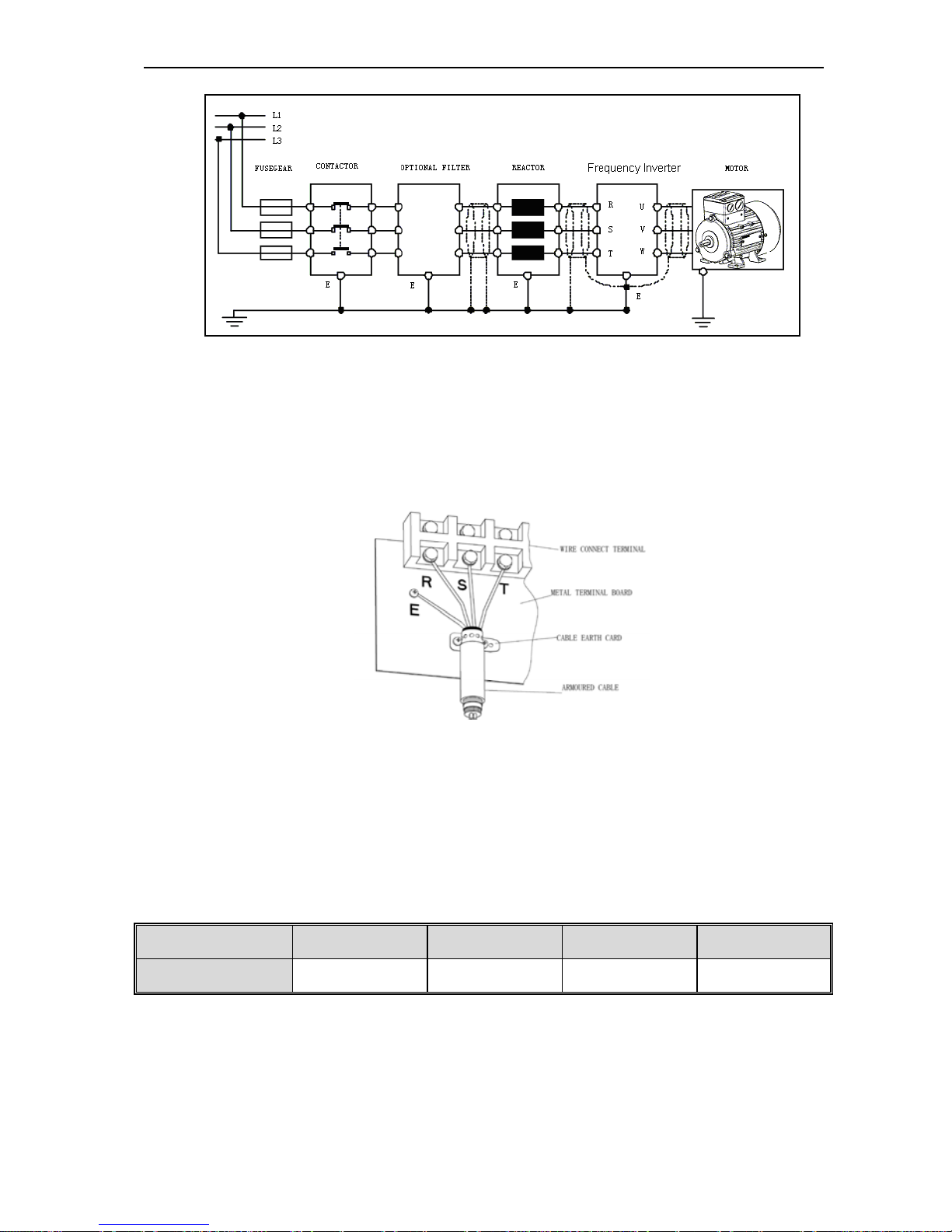

Chart 3-5:AC100 Series Inverter System Earth

Note: motor must earth as close as possible. Motor shell can’t be connected to the inner earth terminal of the inverter

and it can’t share the earth net with the control system either.

●Power cable, motor cable, control cable of inverter

Shielding layer (reticulate/armored) should be winded reliably by cable earth card and then fixed to inverter earth piece

by bolt. Please refer to the following chart.

Chart 3-6:Cable Earth Card for Cable Earth

● Correspondence between inverter and motor cable length and carrier frequency

When wiring distance between inverter and motor is long (especially low-frequency output), cable voltage drop will

cause the motor torque reduction. Moreover, high-frequency leakage current will increase, thereby causing an increase

of inverter output current, which would cause the inverter over current trip. And the current detection accuracy and

running stability would be seriously affected. Please refer to the cable length in the following table to adjust the carrier

frequency. When system requires the wiring distance to be more than 100m, please adopt distributed capacity reduce

measure (Such as “no metal conductor covers cable”, “wire each phase cable apart” and so on)

Cable length <20m 20~50m 50~100m >100m

Carrier frequency 0.6~16kHz 0.6~8kHz 0.6~4kHz 0.6~2kHz

Chart 3-2:Correspondence between Inverter and Motor Cable Length and Carrier Frequency

AC100 HIGH-PERFORMANCE VC INVERTER MANUAL INSTALLATION AND WIRING

15

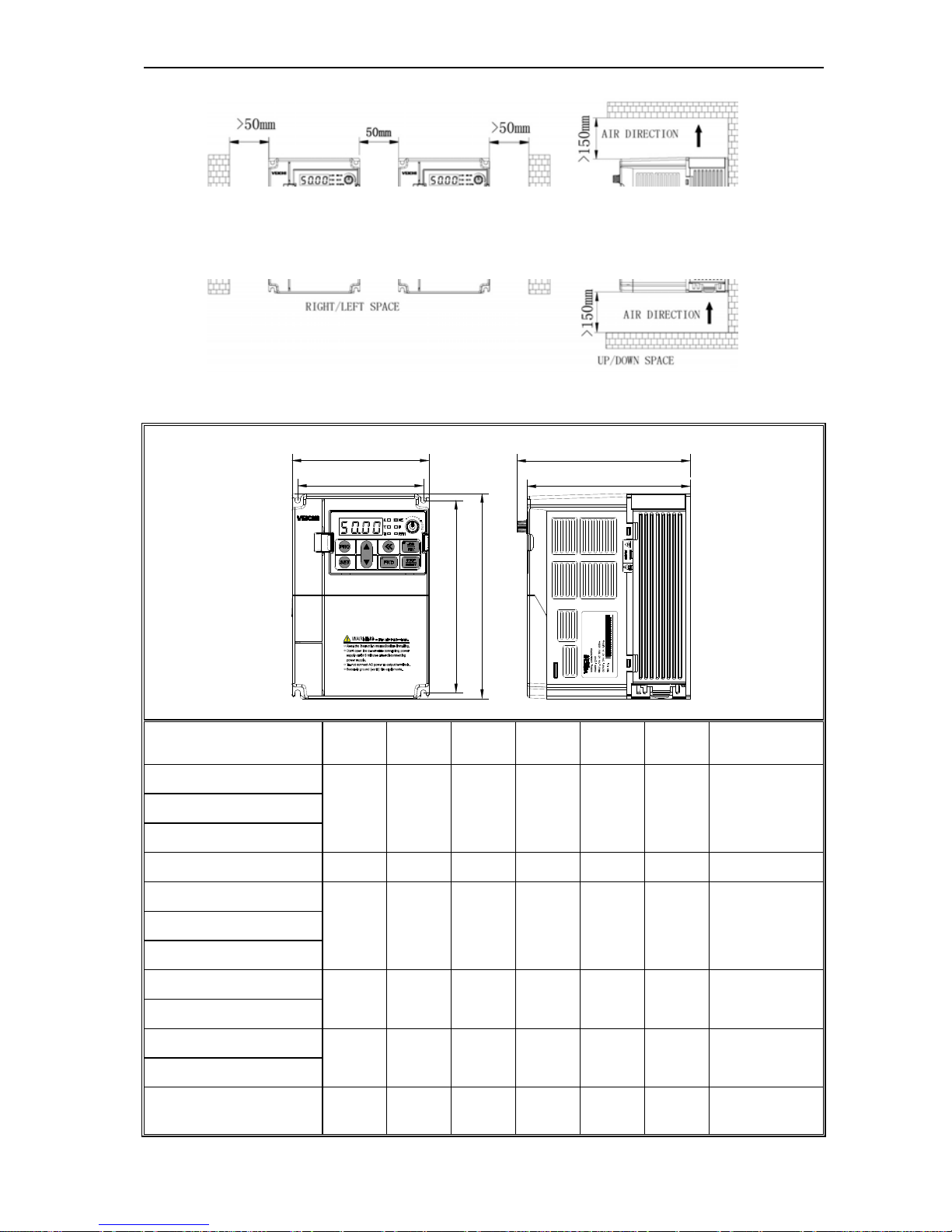

3.5 Machinery Installation

Installation Notice and Related Requirement

● AC100 inverter components

Chart 3-7:AC100 Series Inverter Components

● Installation Direction

To prevent reduction of inverter cooling effect, please do install the inverter longitudinally-mounted.

Chart 3-8:AC100 Series Inverter Installation Direction

● Installation Space

Single machine installation: to ensure enough ventilation and wiring space for inverter cooling, please follow installation

conditions as follows. The back of the inverter should stick to the wall so that the surrounding air of radiator can flow

freely to ensure the cooling effect.

Chart 3-9:Single AC100 Series Inverter Installation Space

Multi inverters paratactic installation: when installing multi inverters in cabinet, please ensure installation space as

required below.

AC100 HIGH-PERFORMANCE VC INVERTER MANUAL INSTALLATION AND WIRING

16

Chart 3-10: Multi AC100 Series Inverters Paratactic Installation Space Requirement

Overall Dimension of Inverter and Keyboard

W1

W

H1

H

D1

D

MODEL W W1 H H1 D D1

INSTALLATION

APERTURE

AC100-S2-R40G

122 112 182 171 154.5 145 ф5 AC100-S2-R75G

AC100-S2-1R5G

AC100-S2-2R2G 159 147.2 246 236 157.5 148 ф5.5

AC100-T3-R75G

122 112 182 171 154.5 145 ф5 AC100-T3-1R5G

AC100-T3-2R2G

AC100-T3-004G

159 147.2 246 236 157.5 148 ф5.5

AC100-T3-5R5G

AC100-T3-7R5G

195 179 291 275 167.5 158 ф7

AC100-T3-011G

AC70-T3-015G/018P

(plastic cover machine)

230 208 330 315 200 190 ф7

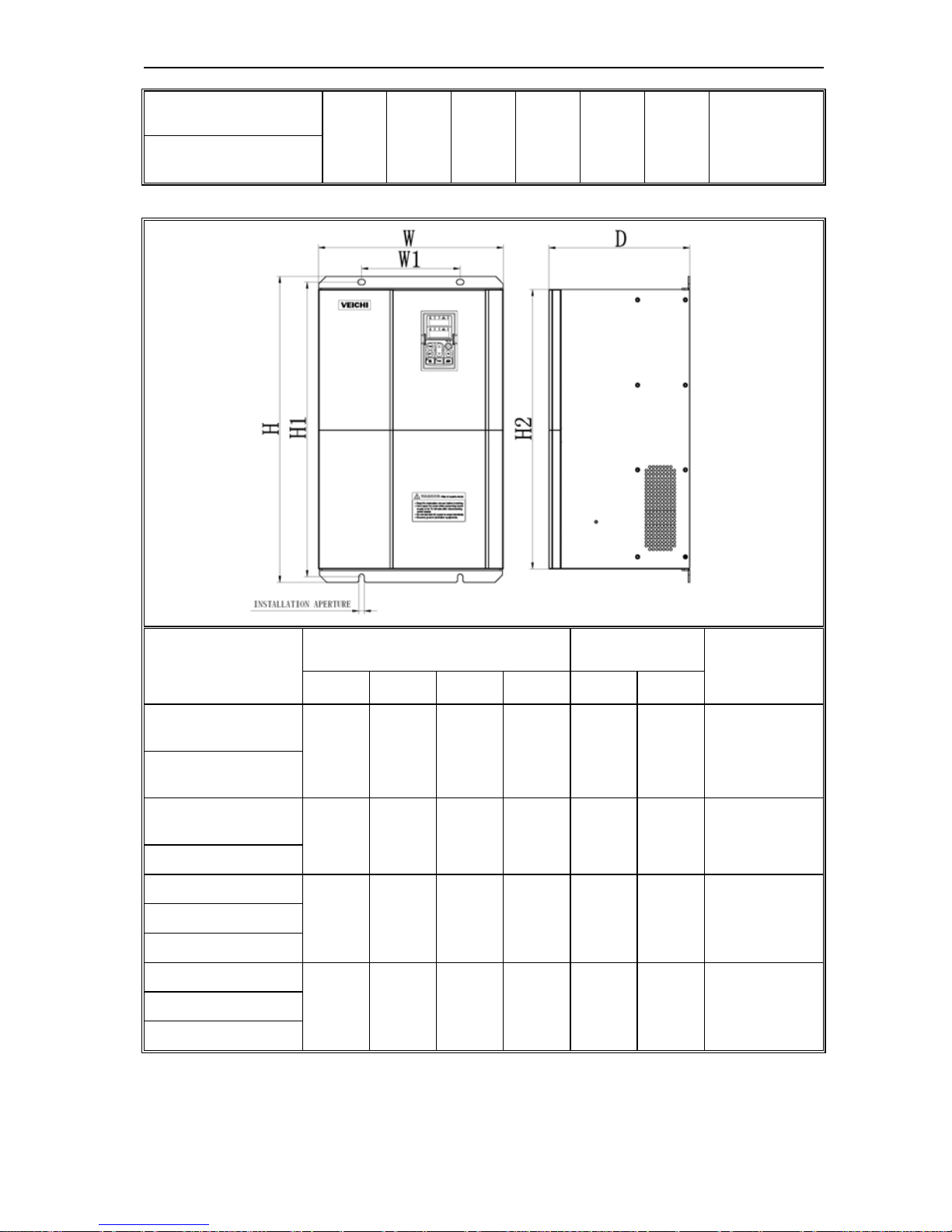

AC100 HIGH-PERFORMANCE VC INVERTER MANUAL INSTALLATION AND WIRING

17

AC70-T3-018G/022P

(plastic cover machine)

230 208 330 315 200 190 ф7

AC70-T3-022G/030P

(plastic cover machine)

MODEL

Overall Dimension

Instillation

Position

INSTALLATION

APERTURE

W H D H2 W1 H1

AC100-T3-015G

(steel cover machine)

235 345 200 311 160 331.5 ф7

AC100-T3-018G

(steel cover machine)

AC100-T3-022G

(steel cover machine)

255 410 225 370 180 395 Ф7

AC100-T3-030G

AC100-T3-037G

305 570 260 522 180 550 Ф9 AC100-T3-045G

AC100-T3-055G

AC100-T3-075G

380 620 290 564 240 595 ф11

AC100-T3-090G

AC100-T3-110G

AC100 HIGH-PERFORMANCE VC INVERTER MANUAL INSTALLATION AND WIRING

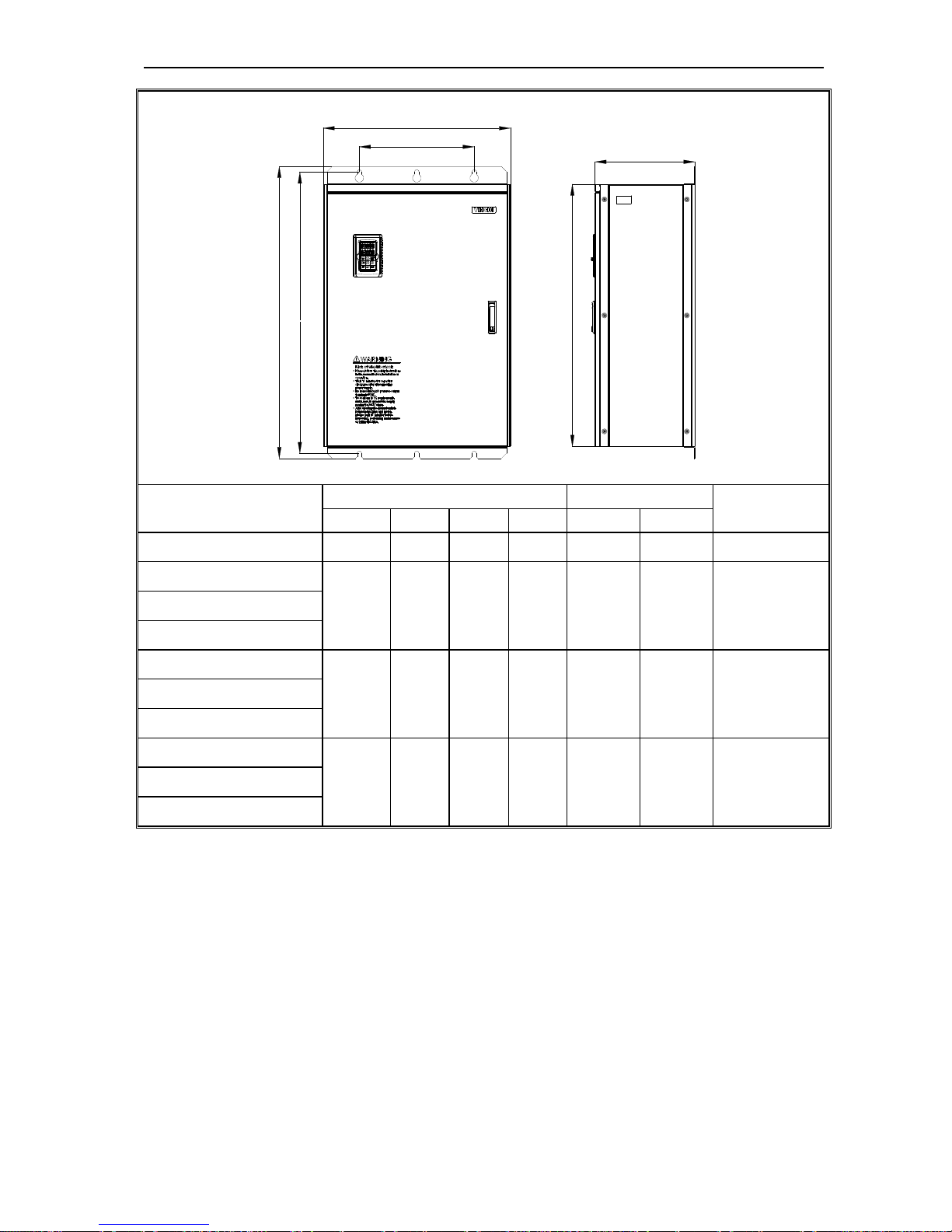

18

H1

H

H2

D

W1

W

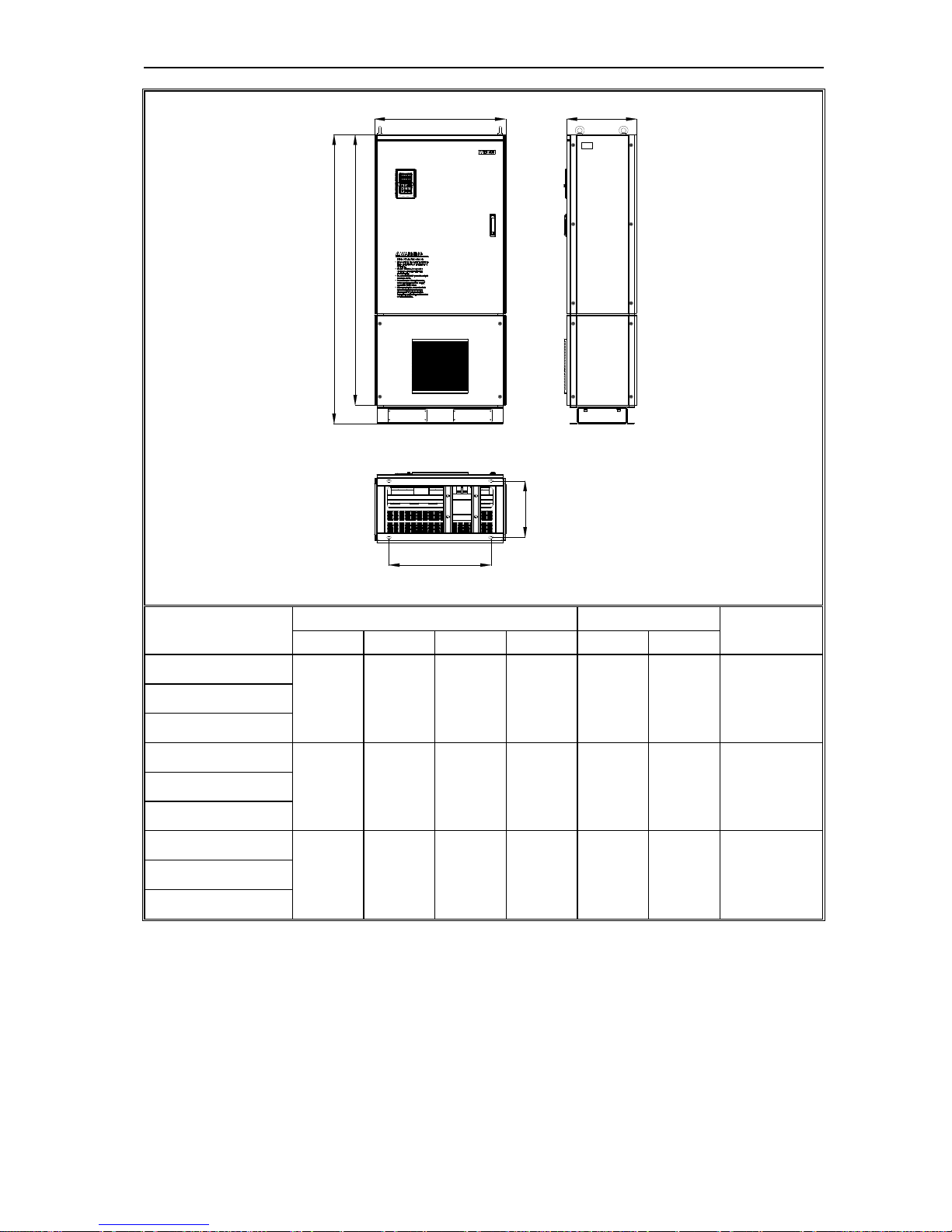

MODEL

Overall Dimension Instillation Position

INSTALLATION

APERTURE

W H D H2 W1 H1

AC100-T3-132G

500 780 340 708 350 755 ф11

AC100-T3-160G

650 1060 400 950 400 1023 ф16 AC100-T3-185G

AC100-T3-200G

AC100-T3-220G

750 1170 400 1050 460 1128 ф18 AC100-T3-250G

AC100-T3-280G

AC100-T3-315G

850 1280 450 1150 550 1236 ф20 AC100-T3-355G

AC100-T3-400G

Notice: No DC Reactor Inside

AC100 HIGH-PERFORMANCE VC INVERTER MANUAL INSTALLATION AND WIRING

19

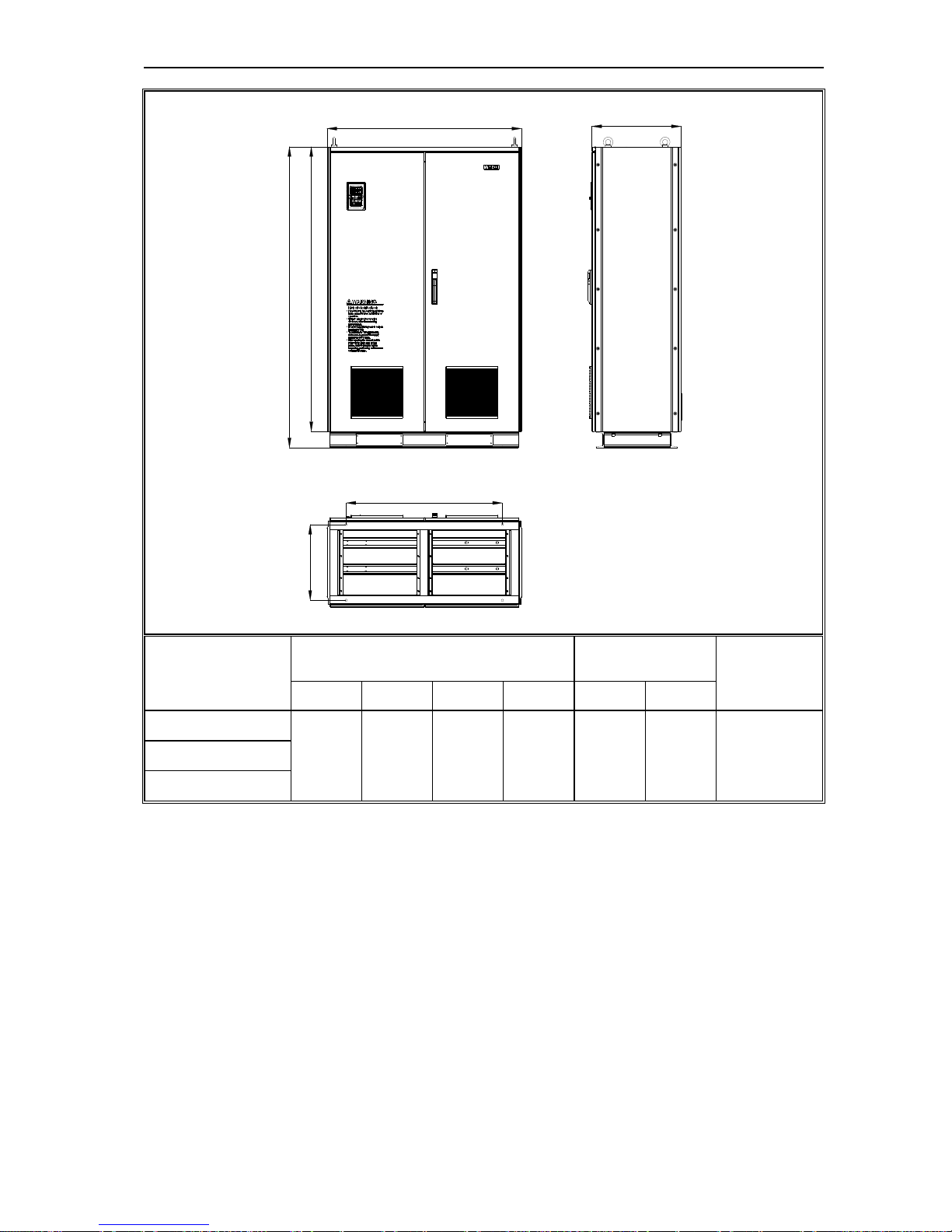

D1

W1

D

W

H

H1

MODEL

Overall Dimension Instillation Position

INSTALLATION

APERTURE

W H D H1 W1 D1

AC100-T3-160GD

650 1600 400 1500 492 332 ф14 AC100-T3-185GD

AC100-T3-200GD

AC100-T3-220GD

750 1700 400 1600 582 332 ф14 AC100-T3-250GD

AC100-T3-280GD

AC100-T3-315GD

850 1800 450 1700 622 382 ф14 AC100-T3-355GD

AC100-T3-400GD

Notice: DC Reactor Inside

AC100 HIGH-PERFORMANCE VC INVERTER MANUAL INSTALLATION AND WIRING

20

H

H1

D1

W1

D

W

MODEL

Overall Dimension Instillation Position

INSTALLATIO

N APERTURE

W H D H1 W1 D1

AC100-T3-450G

1200 1850 550 1750 960 466 ф14 AC100-T3-500G

AC100-T3-560G

Chart 3-3:AC100 Series Inverter Overall Dimension

AC100 HIGH-PERFORMANCE VC INVERTER MANUAL INSTALLATION AND WIRING

21

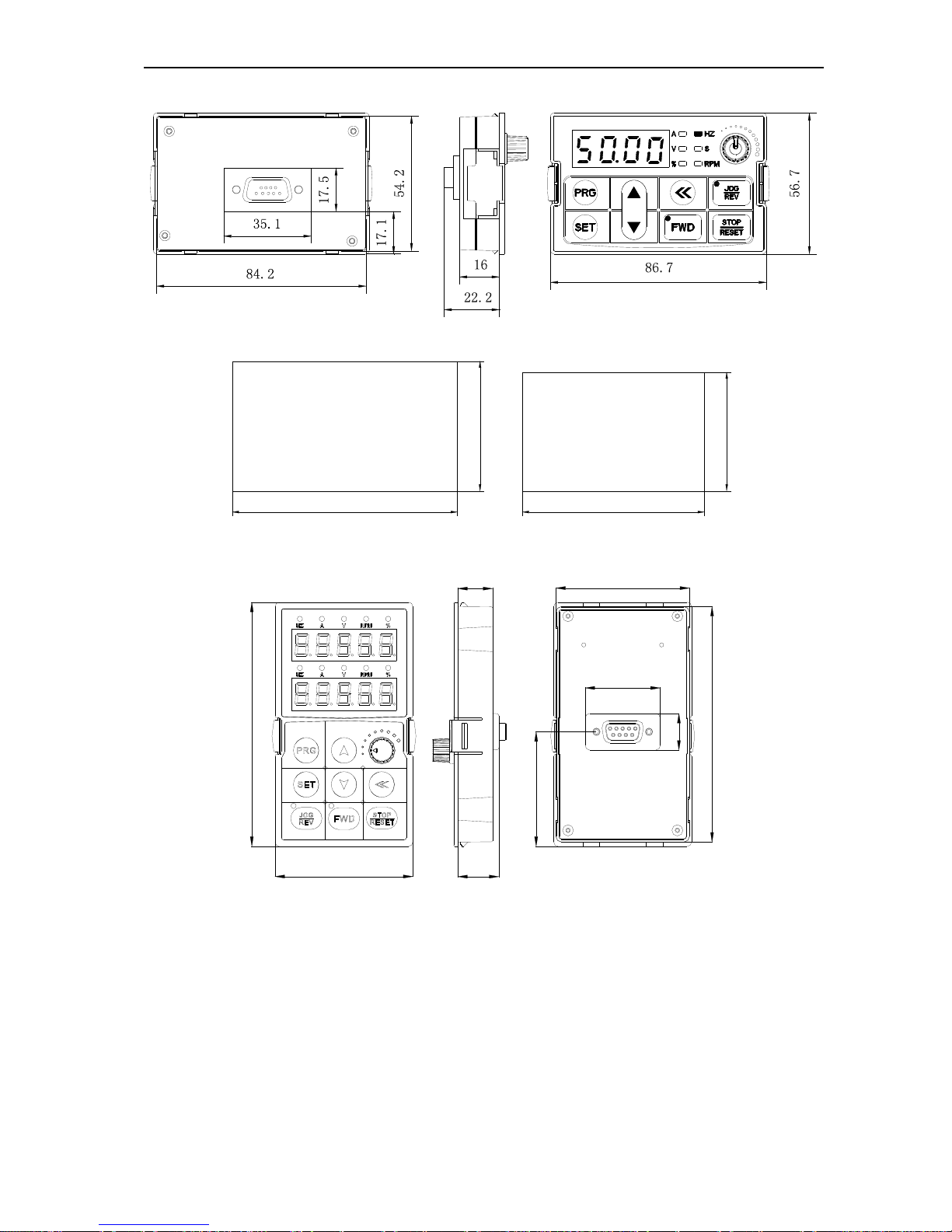

Keyboard Shape and Mouth Dimension

Chart 3-11:AC100 Series Inverter Single Line LED Keyboard Overall Dimension

59,5

104,5

54,5

84,5

Mouth keyboard with box

Mouth keyboard without box

Chart 3-12:AC100 Series Inverter Mouth Dimension for Single Line LED Keyboard Case

114.5

65.5

19.5

16.5

17.1

110.5

63.5

35.6

53.75

Chart 3-13: AC100 Series Inverter Double Line LED Keyboard Overall Dimension

AC100 HIGH-PERFORMANCE VC INVERTER MANUAL INSTALLATION AND WIRING

22

119

70

Mouth keyboard with box

T3-015G/018P

to

T3-132G/160P

111

64

Mouth keyboard without box

142

75

Mouth keyboard with box

T3-160G/185P

to

T3-560G/630P

Chart 3-14: AC100 Series Inverter Mouth Dimension for Double Line LED Keyboard Case

Note: LCD and LED keyboard overall dimensions and the opening dimensions are fully compatible.

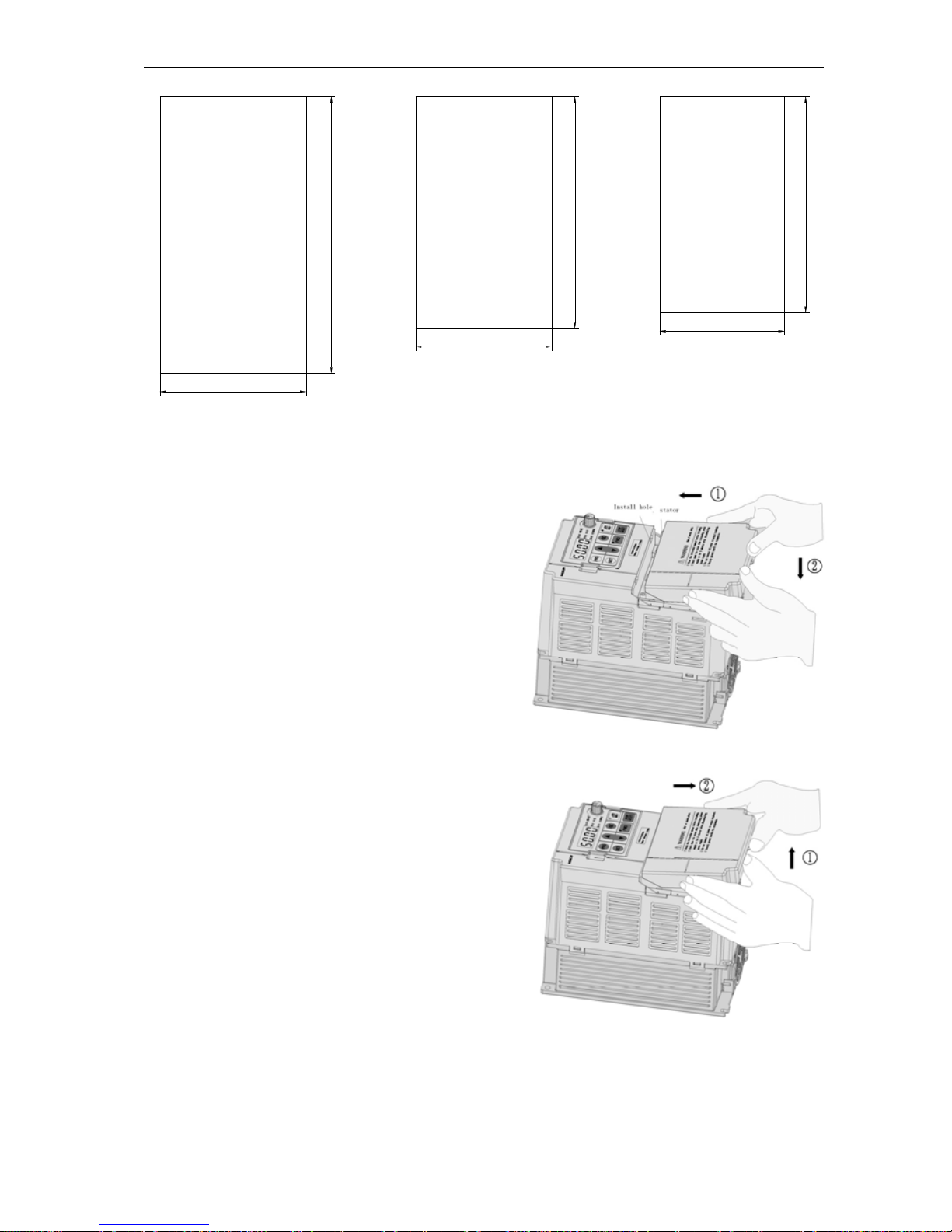

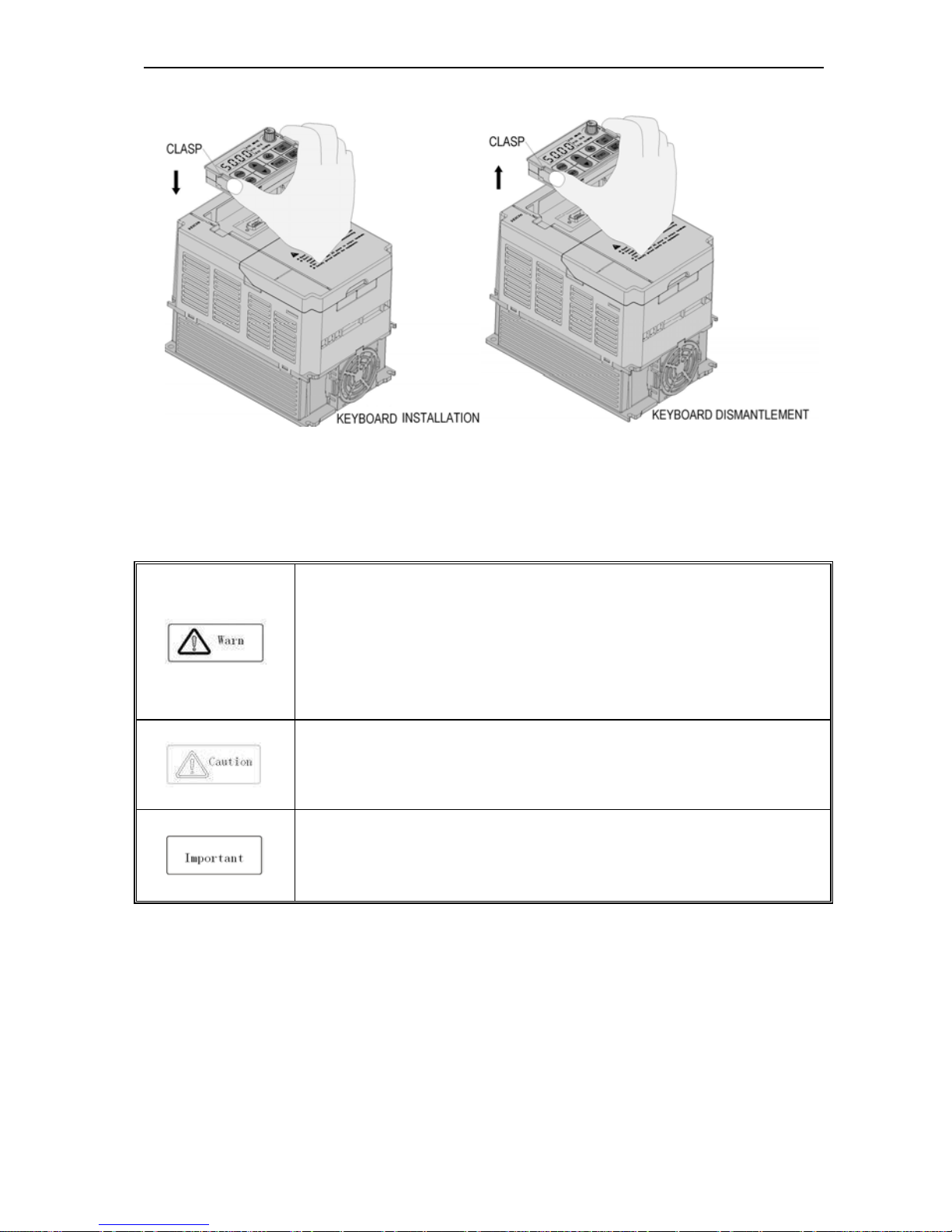

Installation and Dismantlement of Tail-hood

Installation: First the tail-hood upwardly inclines around 15

degree and then inserts the top fixed flat into the fixed hole in

the front cover. Then slightly press the tail-hood downward.

When you hear "Ka", it means that the tail-hood is installed

in place.

Chart 3-15:AC100 Series Inverter Tail-hood Installation

Dismantlement: At the tail of the frequency inverter, there’s a

special dismantlement hole design. Put your finger through the

hole, upwardly pull the cover slightly until the buckle between

the tail-hood and the crust tear off, and then remove the

tail-hood.

Chart 3-16:AC100 Series Inverter Tail-hood Dismantlement

AC100 HIGH-PERFORMANCE VC INVERTER MANUAL INSTALLATION AND WIRING

23

Installation and Dismantlement of keyboard

Chart 3-17:AC100 Series Inverter Keyboard Installation and Dismantlement

3.6 Electrical Installation

To ensure safe, reliable and rational use of this product, please fully understand the safety precautions described in this

manual before using.

Safety Precautions

● Inverter must earth reliably when running. Otherwise there is danger of casualty and

unstable inverter performance.

● To ensure safety running, only trained personnel can do installation and wiring job.

● No operation under power connected state. Otherwise there might be danger of electric

shock even death.

● Please turn off the power of all related equipment, and make sure the main circuit DC

voltage has dropped to a safe level, and wait five minutes before any relevant job.

●The wiring of control cables, power cables and motor connection cables must be isolated

from each other and do not put them in the same cable though or cable racks.

●

The device can only be used as specified by the manufacturer, Please consult Veichi

when using in special case.

● No insulation tests for the inverter or the related cable by HV insulation test equipment.

● If the inverter or the peripheral equipment (filer, reactor and etc) needs insulation test,

firstly 500V meter should be used to test the insulation resistance, which should not be

lower than 4MΩ.

AC100 HIGH-PERFORMANCE VC INVERTER MANUAL INSTALLATION AND WIRING

24

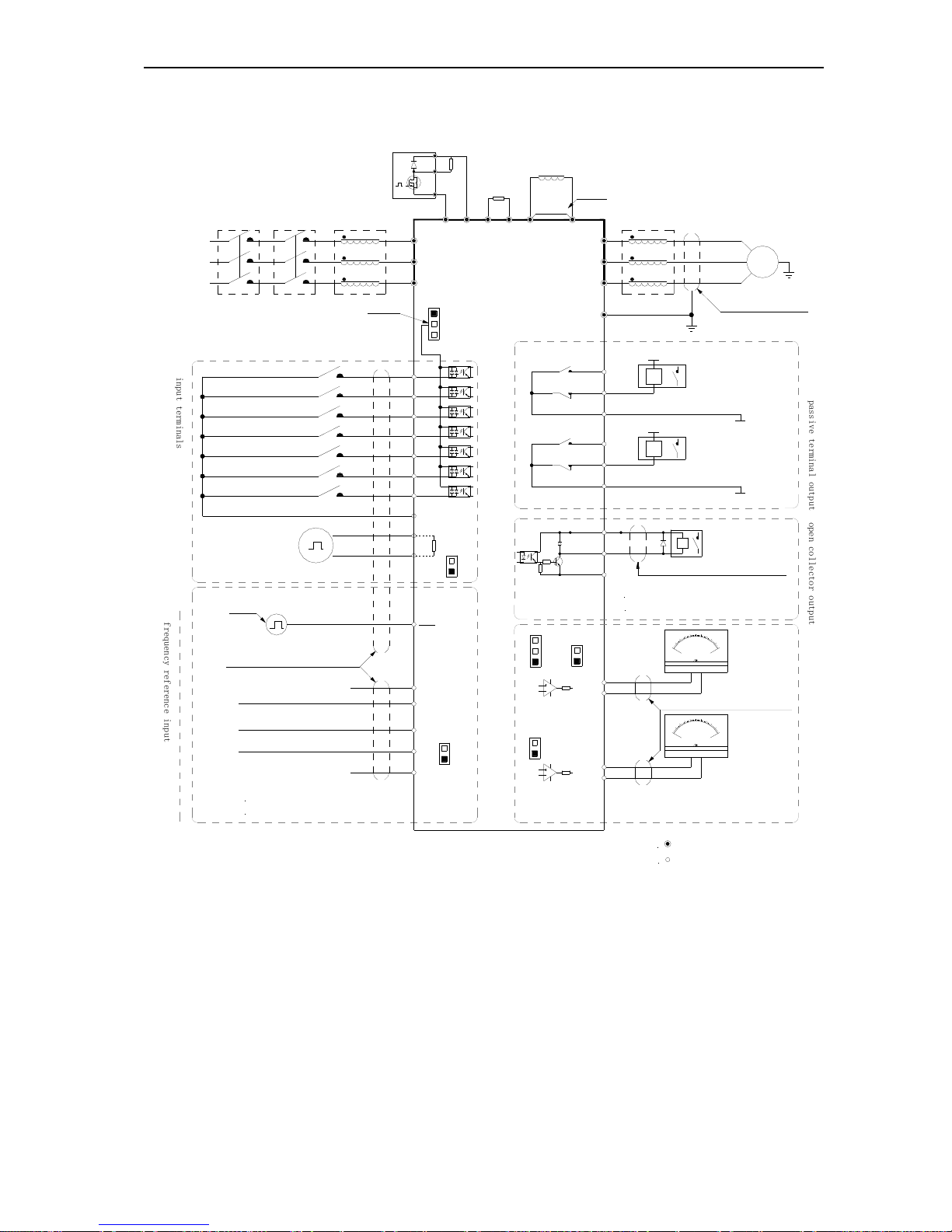

Standard Connection Diagram

● Standard Connection Diagram

notice 2

notice:default settings in bracket

notice 1

TA1

TB1

TC1

+24V

Y

shielded twisted pair cable

_

mA

2

0

10

0

-

+

0

5

1

0

V

_

+

-

GND

A01

V

W

U

M

~

shielded cables

(near inverter groud )

E

(ground resistor low

than 10

Ω

)

W

V

U

output reactor

DC reactor

brake

resistor

short

circuit

P1

+

( )

R

brake module

voltage model analog input

current model analog input

+10V

R

T

S

AC input

AI

GND

AS

VS

shielded twisted pair line)

input pulse

X7

(reversal jog running)

(forward jog running)

(reversal running)

(forward running)

(free stop)

(fault reset)

(none)

COM

X3

X4

X6

X5

X1

X2

PB

( )

+

(-)

inverter

S

T

R

GND

A02

COM

p

a

s

s

i

v

e

t

e

r

m

i

n

a

l

o

u

t

p

u

t

AC220V

AC0V

K3

K4

max output

3A/240VAC

5A/30VDC

1+24Vmax output:DC24V/100mA

A01/A02 used as frequency or

voltage outp ut

,max current

2mA

2VS/AIterminal resistor:75K

Ω

1.+10V terminals max input 50mA

notice:

2Y max output:DC24V/50mA

notice:

2

stand for control circuit terminal

notice:

stand for main circuit terminal

1

shielded twisted pair

cable(near inverter ground)

input reactorconnector

circuit

breaker

(

0~5V

)/(

0~10V

)

(

0~20mA

)/(

4~20mA

)

3AS term in al resistor:250

Ω

notice:

+

( )

notice 4

PUL

X7

PUL

+24V

PLC

COM

current/voltage analog input

J1

J2

J3

K1

K2

K5

K6

TA2

TB2

TC2

AC220V

AC0V

o

p

e

n

c

o

l

l

e

c

t

o

r

o

u

t

p

u

t

A+

B-

RS485 communication

120

Ω

K7

K8

analog output monitor

i

n

p

u

t

t

e

r

m

i

n

a

l

s

f

r

e

q

u

e

n

c

y

r

e

f

e

r

e

n

c

e

i

n

p

u

t

Chart 3-18:AC100 Series Inverter Standard Connection Diagram

Note: 1.When installing DC reactor, make sure to dismantle the short connector between terminal P1 and(+).

2.NPN or PNP transistor signal can be selected as input of multi-function input terminal(X1~X7/PUL).

Inverter built-in power supply (+24V terminal) or external power supply (PLC terminal) can be chosen as

bias voltage. Factory setting ‘+24V’ short connect with ‘PLC’.

3. Analog monitor output is the special output for meters such as frequency meter, current meter and voltage

meter. It can’t be used for control operations such as feedback control.

4. As there are multi pulse styles, please refer to the line connect mode description details.

AC100 HIGH-PERFORMANCE VC INVERTER MANUAL INSTALLATION AND WIRING

25

● Auxiliary Terminal Output Capacity

Terminal Function Definition Max Output

+10V

10V auxiliary power supply output, constitutes loop

with GND.

50mA

A01/A02 Analog monitor output, constitutes loop with GND.

Max output 2mA as frequency,

voltage signal,

+24V

24V auxiliary power supply output, constitutes loop

with COM.

100mA

Y

Collector open circuit output; can set the

action-object by program.

DC24V/50mA

TA1/TB1/TC1

TA2/TB2/TC2

Passive connector output; can set the action-object

by program.

3A/240VAC

5A/30VDC

Chart 3-4:AC100 Series Inverter Auxiliary Terminals Output Capacity

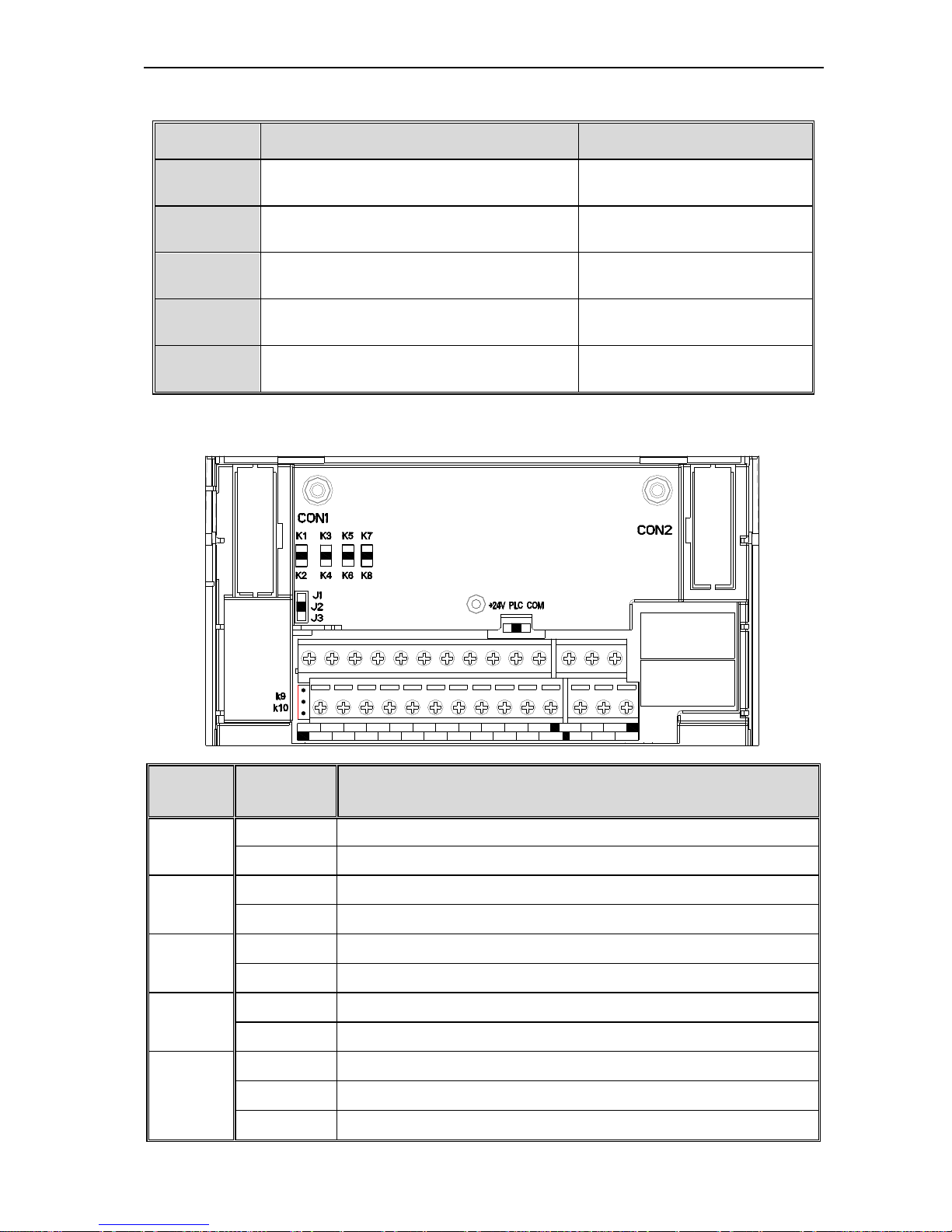

●Connection Function Specification of Switch Terminals

AS

VS

GND

GND

AO2 AO1

X1

X2

AI

+10V

COM

TC1

PLC TA1

A+

+24V

X7/PUL

X4

X3

X5

TB2

X6

TA2

B- Y

TB1

COM

TC2

Switch

Treminal

Selecting

Position

Function Specification

S1

K1 AO1:0~20mA or 4~20mA current output

K2 AO1:0~10V voltage output

S2

K3 AI:0~20mA or 4~20mA input current

K4 AI: 0~10V input voltage

S3

K5 AO2: 0.0~50kHz (J1 on), open collector circuit output

K6 AO2:0.0~50kHz (J1 on), active source output

S4

K7 RS485: connect with 120Ω terminal resistor

K8 RS485:connect without 120Ω terminal resistor

S5

J1 AO2:0.0~50kHz frequency output

J2 AO2:0~20mA or 4~20mA current output

J3 AO2:0~10V voltage output

AC100 HIGH-PERFORMANCE VC INVERTER MANUAL INSTALLATION AND WIRING

26

S6

+24V Short +24V terminal and PLC terminal

PLC PLC terminal receiving external power input, detailed in Drawing 3-22,3-23

COM Short PLC terminal and COM terminal

S7

K9 Disconnect GND terminal and PE discharge loop

K10 Connect GND terminal and PE discharge loop

Chart 3-5:AC100 Series Inverter Switch Terminal Connection Function Specification

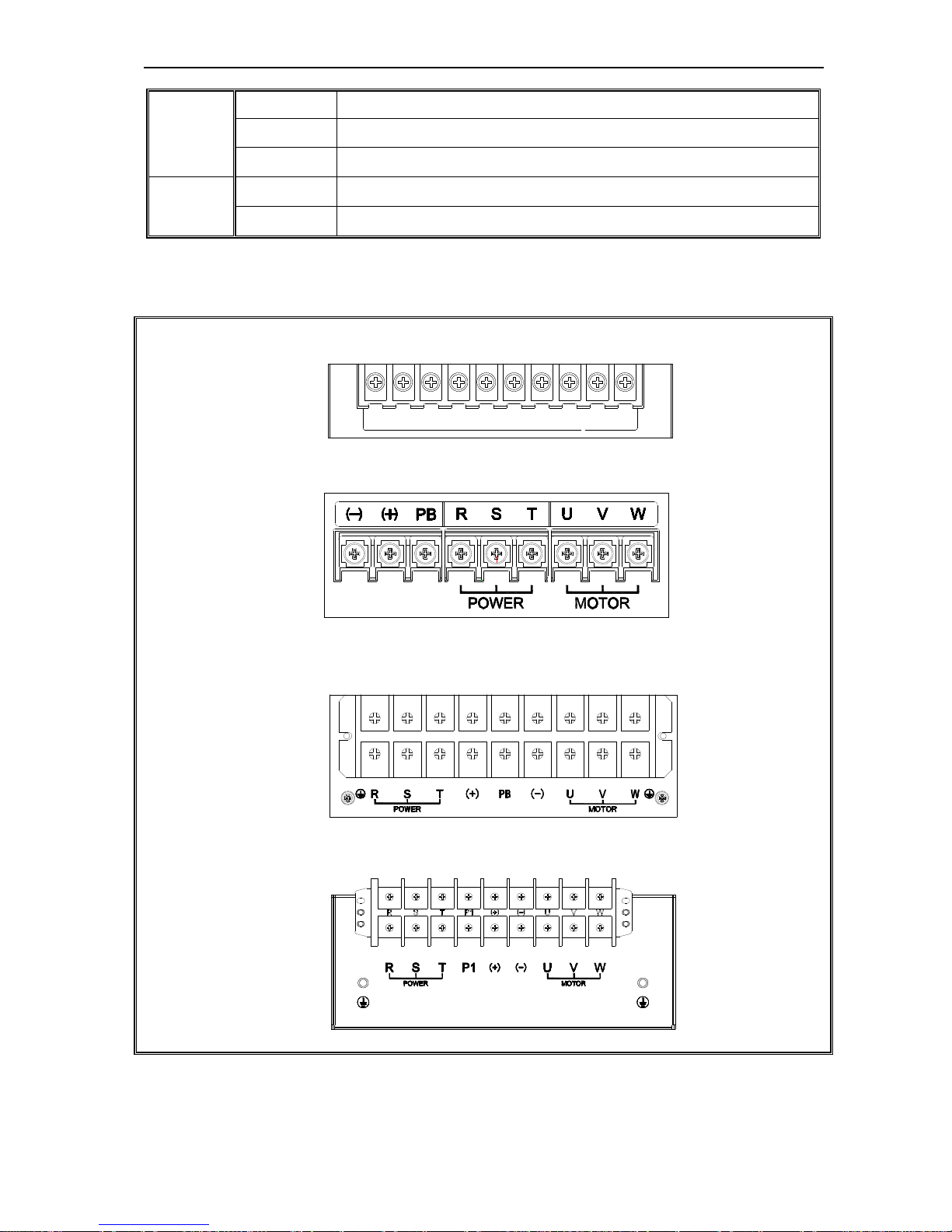

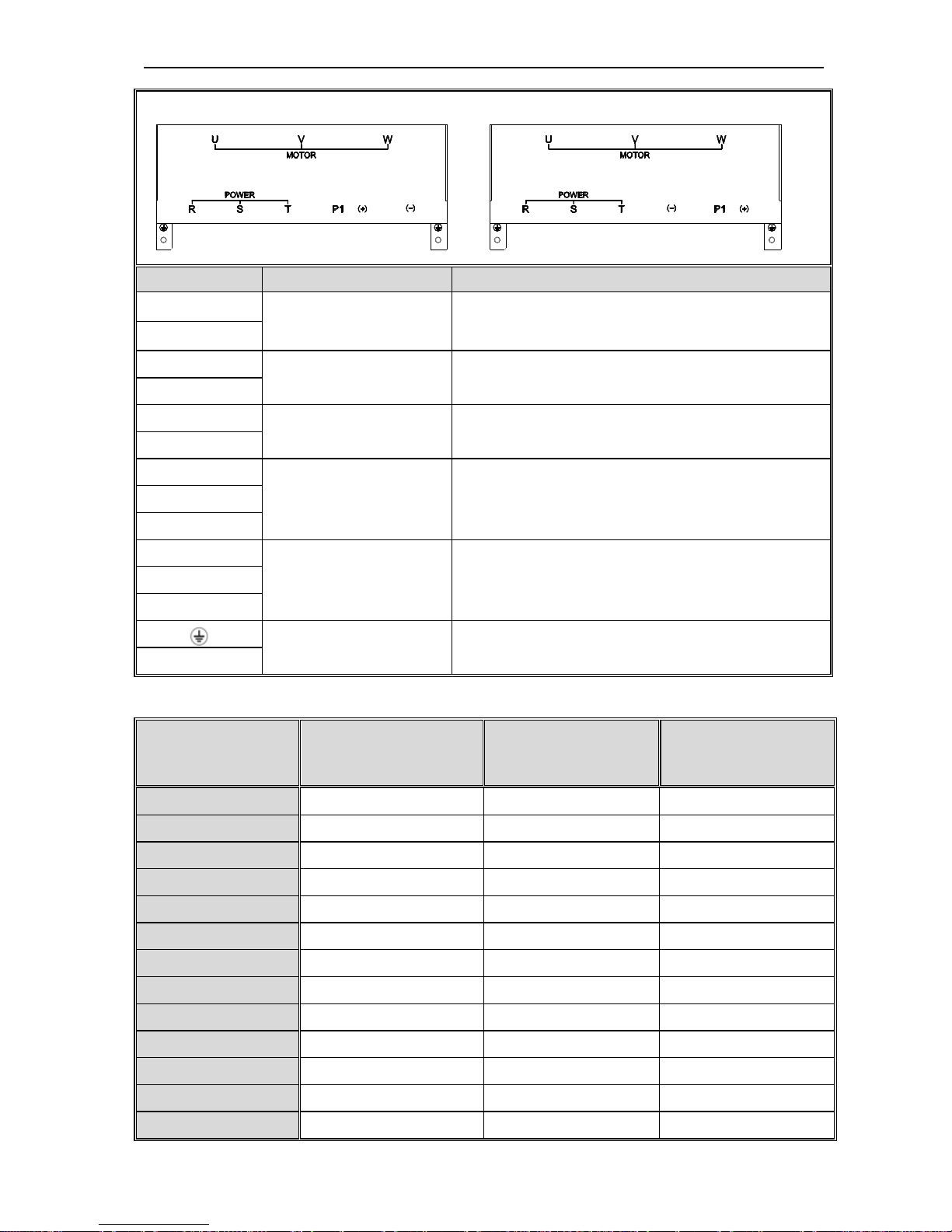

Main Circuit Terminals

● Main circuit terminals array and definition

Arrangement sequence of main circuit terminal with 18.5kW or less power(15 ~ 18.5KW for steel cover machine)

(-)

TSR

PB

UWV

(+)

E

Arrangement sequence of main circuit terminal with 15-22KW(15~22KW for plastic cover machine)

Arrangement sequence of main circuit terminal with 22~30KW (standard machine without PB terminal)(22KW for steel

cover machine)

Arrangement sequence of main circuit terminal with 37~110kW

AC100 HIGH-PERFORMANCE VC INVERTER MANUAL INSTALLATION AND WIRING

27

Arrangement sequence of main circuit terminal with 132kW: Arrangement sequence of main circuit termi nal with 160~560kW

Terminal Symbol Name Function Definition

(-)

DC power terminal

DC power output, (-) means DC bus cathode, (+) means DC

bus anode, used for external braking unit.

(+)

(+)

Braking resistance terminal Used for external braking resistance to realize quick stop.

PB

P1

DC reactor terminal Used for external DC reactor.

(+)

R

Inverter input terminal Used to connect 3-phase AC power supply. S

T

U

Inverter output terminal Used to connect the motor. V

W

Earth Earth terminal, earth resistance<10Ω

E

Chart 3-6:AC100 Series Inverter Main Circuit Terminals Array and Definition

● 3-phase 380V Machine Main Circuit Wiring

Model

Main Circuit Terminals

Screw Specifications

Suggested Fixed Moment

(N·m)

Suggested Copper-core

Cable Specification mm

2

(AWG)

AC100-T3-R75G M4 1.2~1.5 1.5mm2(14)

AC100-T3-1R5G M4 1.2~1.5 2.5mm2(12)

AC100-T3-2R2G M4 1.2~1.5 2.5mm2(12)

AC100-T3-004G M4 1.2~1.5 4mm2(10)

AC100-T3-5R5G M4 1.2~1.5 6mm2(9)

AC100-T3-7R5G M5 2~2.5 6mm2(9)

AC100-T3-011G M5 2~2.5 10mm2(7)

AC100-T3-015G M6 4~6 10mm2(7)

AC100-T3-018G M6 4~6 16mm2(5)

AC100-T3-022G M8 8~10 16mm2(5)

AC100-T3-030G M8 8~10 25mm2(3)

AC100-T3-037G M8 8~10 25mm2(3)

AC100-T3-045G M8 8~10 35mm2(2)

AC100 HIGH-PERFORMANCE VC INVERTER MANUAL INSTALLATION AND WIRING

28

AC100-T3-055G M10 11~13 35mm2(2)

AC100-T3-075G M10 11~13 50mm2(1)

AC100-T3-090G M10 11~13 50mm2(1/0)

AC100-T3-110G M10 11~13 70mm2(2/0)

AC100-T3-132G M10 11~13 95mm2(3/0)

AC100-T3-160G M12 14~16 95mm2(4/0)

AC100-T3-185G M12 14~16 120mm2

AC100-T3-200G M12 14~16 150mm2

AC100-T3-220G M12 14~16 150mm2

AC100-T3-250G M12 14~16 185mm2

AC100-T3-280G M12 14~16 185mm2

AC100-T3-315G M16 20~23 240mm2

AC100-T3-355G M16 20~23 240mm2

AC100-T3-400G M16 20~23 300mm2

AC100-T3-450G M16 20~23 400mm2

AC100-T3-500G M16 20~23 400mm2

AC100-T3-560G M16 20~23 500mm2

Note: Here we suggest using copper joins for mains electric connectors for machine over 185KW. Please refer to

diagram above for the cut section area.

Chart 3-7: Suggested Cable Diameter and Fixed Moment of 3-phase 380V Machine Main Circuit

● Single-phase 220V Machine Main Circuit Wiring

Model

Main Circuit Terminals

Screw Specifications

Suggested Fixed

Moment (N·m)

Suggested Copper-core

Cable Specification mm

2

(AWG)

AC100-S2-R40G M4 1.2~1.5 1.5mm2(14)

AC100-S2-R75G M4 1.2~1.5 2.5mm2(12)

AC100-S2-1R5G M4 1.2~1.5 2.5mm2(12)

AC100-S2-2R2G M4 1.2~1.5 4mm2(10)

Chart 3-8: Suggested Cable Diameter and Fixed Moment Single-phase 220V Machine Main Circuit

● Suggested Main Circuit Components Specification

Model

Contactor

Specification

Breaker

Specification

DC Reactor Input Filter Output Filter

AC100-T3-R75G 10A 10A ------ NFI-005 NFO-010

AC100-T3-1R5G 10A 10A ------ NFI-005 NFO-010

AC100-T3-2R2G 16A 15A ------ NFI-010 NFO-010

AC100-T3-004G 16A 20A ------ NFI-010 NFO-010

AC100-T3-5R5G 25A 20A ------ NFI-020 NFO-020

AC100-T3-7R5G 25A 30A ------ NFI-020 NFO-020

AC100-T3-011G 32A 40A ------ NFI-036 NFO-036

AC100-T3-015G 40A 50A ------ NFI-036 NFO-036

AC100 HIGH-PERFORMANCE VC INVERTER MANUAL INSTALLATION AND WIRING

29

AC100-T3-018G 50A 60A ------ NFI-050 NFO-050

AC100-T3-022G 50A 75A DCL-50 NFI-050 NFO-050

AC100-T3-030G 63A 100A DCL-80 NFI-080 NFO-080

AC100-T3-037G 80A 125A DCL-100 NFI-100 NFO-100

AC100-T3-045G 100A 150A DCL-110 NFI-100 NFO-100

AC100-T3-055G 125A 175A DCL-125 NFI-150 NFO-150

AC100-T3-075G 160A 200A DCL-150 NFI-150 NFO-150

AC100-T3-090G 220A 250A DCL-200 NFI-200 NFO-300

AC100-T3-110G 220A 300A DCL-200 NFI-200 NFO-300

AC100-T3-132G 250A 400A DCL-300 NFI-300 NFO-300

AC100-T3-160G 300A 500A DCL-300 NFI-300 NFO-300

AC100-T3-185G 400A 600A DCL-400 NFI-400 NFO-400

AC100-T3-200G 400A 700A DCL-400 NFI-400 NFO-400

AC100-T3-220G 630A 800A DCL-500 NFI-600 NFO-600

AC100-T3-250G 630A 1000A DCL-600 NFI-600 NFO-600

AC100-T3-280G 630A 1200A DCL-600 NFI-600 NFO-600

AC100-T3-315G 630A 1200A DCL-800 ------ -----AC100-T3-355G 800A 1400A DCL-800 ------ -----AC100-T3-400G 1000A 1600A DCL-1000 ------ -----AC100-T3-450G 1000A 2000A DCL-1000 ------ -----AC100-T3-500G 1000A 2000A DCL-1200 ------ -----AC100-T3-560G ------ 2000A DCL-1200 ------ ------

Note: For specification details and circuit mode of DC reactor, input filter, output filter and other components, please

refer to Chapter 7 “Peripheral Equipments and Options”.

Chart 3-9: Suggested Mains Fittings for 3-phase 380V Machine

Control Loop Te rminals

● Control Loop Terminals Array:

AS

VS GND

GND

AO2 AO1

X1

X2

AI

+10V

COM

TC1

PLC TA1

A+ +24V

X7/PUL

X4

X3

X5

TB2

X6

TA2

B- Y

TB1

COM

TC2

AC100 HIGH-PERFORMANCE VC INVERTER MANUAL INSTALLATION AND WIRING

30

Category

Terminal Symbol Name Function Definition

Power

+10V-GND +10V power supply

Supply +10V power, max output current: 50

mA ,usually used for potentiometer supply,

resistance of potentiometer range: 1KΩ~5KΩ

+24V-COM +24V power supply

Supply +24V power, usually used for digital

input/output terminals and external sensors, max

output current:100 mA

PLC Public terminal

Connect with +24V terminal by factory default.

When using external signal to drive X1-X7/PUL,PLC

must be connected with external power, and be

disconnected with +24V terminal (detailed in Drawing

3-22, 3-23)

Analog

input

AS-GND Current analog input

1.input current range: DC 0mA~20mA

2.input impedance: 500Ω

VS-GND Voltage analog input

1.input voltage range: DC 0V~10V

2.input impedance: 75 KΩ

AI-GND

Voltage or current analog

input

1.input range: DC 0V~10V/0mA~20mA,decided

by switch S2(detailed in Drawing 3-5)

2.voltage input impedance: 75 KΩ

3.current input impedance: 500Ω

Chart 3-10:AC100 Series Inverter Control Loop Terminals Array and Definition

● Control Loop Terminal Wiring Specification

Terminal

Bolt Specification

(mm)

Fixed Moment

(N·m)

Cable specification

(mm2)

Cable Type

A+ B- M2.5 0.4~0.6 0.75

Twisted-pair shielded

cable

+10V GND A01 A02 AS

VS AI

M2.5 0.4~0.6 0.75

Twisted-pair shielded

cable

+24V COM Y TA 1 TB1

TC1 TA2 TB2 TC2 PLC

X1 X2 X3 X4 X5 X6

X7/PUL

M2.5 0.4~0.6 0.75 Shielded cable

Chart 3-11:Control Loop Terminal Wiring Specification

Braking Unit (Braking Resistance) Connection

● Brake resistance wiring of machine with 18.5KW or less power(15KW-18.5KW for steel cover machine)

(-)

(+)

PB

R

ST

U

V

WE

Brakeing

resistor

Fig 3-19: AC100 Series Frequency Inverter Brake resistance wiring of machine with 18.5KW or less power

AC100 HIGH-PERFORMANCE VC INVERTER MANUAL INSTALLATION AND WIRING

31

● Brake resistance wiring of machine with 15-22KW(for plastic cover machine)

Brakeing

resistor

Fig 3-20: AC100 Series Frequen cy Inverter Brake resistance wiring of machine with 15-22KW(for plastic cover machine)

● Brake resistance wiring of machine with 22KW and 30KW(built-in brake is optional)(22KW for steel cover machine)

TSR

PB

UWV

POWER INPUT MOTOR OUTPUT

Brakeing

resistor

(-)(+)

Fig 3-21: AC100 Series Frequency Inverter Brake resistance wiring of machine with 22KW and 30KW(built-in

brake is optional)(22KW for steel cover machine)

● Brake resistance wiring of machine with 37KW or above

TSR

PB

UWV

POWER INPUT MOTOR OUTPUT

Dynamic Brake Unit

POWER

ACTIVE

-

++

PB

Brakeing

resistor

(-)(+)

Fig 3-22: AC100 Series Frequency Inverter Brake resistance wiring of machine with 37KW or above

●

Suggested braking resistance specification parameters

The braking resistance value and resistance power in the chart below are in accordance with the general inertia of the

load and intermittent braking mode, In large inertia and long braking frequent occasions, adjust resistance value and

power according to the inverter specification and the rated parameter of braking unit. If any problem, please consult

customer service department of Shenzhen Veichi Electric Co., Ltd.

AC100 HIGH-PERFORMANCE VC INVERTER MANUAL INSTALLATION AND WIRING

32

Three-phase 380V

Motor power(kW) Resistance value(Ω) Resistance Power(kW) Braking Moment (%)

0.75 kW 750Ω 150W 100%

1.5 kW 400Ω 300W 100%

2.2 kW 250Ω 400W 100%

4.0 kW 150Ω 500W 100%

5.5 kW 100Ω 600W 100%

7.5 kW 75Ω 780W 100%

11 kW 50 Ω 1,200W 100%

15 kW 40Ω 1,500W 100%

18.5 kW 32Ω 2,000W 100%

22 kW 28Ω 2,200W 100%

30 kW 24Ω 3,000W 100%

37 kW 20Ω 3,700W 100%

45 kW 16Ω 4,500W 100%

55 kW 13Ω 5,500W 100%

75 kW 9Ω 7,500W 100%

90 kW 6.8Ω 9,300W 100%

110 kW 6.2Ω 11,000W 100%

132 kW 4.7Ω 13,000W 100%

160 kW 3.9Ω 15,000W 100%

185 kW 3.3Ω 17,000W 100%

200 kW 3Ω 18,500W 100%

220 kW 2.7Ω 20,000W 100%

250 kW 2.4Ω 22,500W 100%

280 kW 2Ω 25,500W 100%

315 kW 1.8Ω 30,000W 100%

355 kW 1.5Ω 33,000W 100%

400 kW 1.2Ω 42,000W 100%

450 kW 1.2Ω 42,000W 100%

500 kW 1Ω 42,000W 100%

560 kW 1Ω 50,000W 100%

Single-phase 220V

Motor power(kW) Resistance value(Ω) Resistance power(kW) Braking moment (%)

0.4 kW 400Ω 100W 100%

AC100 HIGH-PERFORMANCE VC INVERTER MANUAL INSTALLATION AND WIRING

33

0.75 kW 200Ω 120W 100%

1.5 kW 100Ω 300W 100%

2.2 kW 75 Ω 300W 100%

Chart 3-12: Suggested Braking Resistance Specification Parameters of AC100 Series Inverter

● Build-in braking unit max braking performance

Braking unit of AC100 series product with low power can be selected according to the suggested braking resistance

specification parameters in chart 3-11. In large inertia or long time frequent braking occasion, the moment should be

increased. The max braking power is stated in the following chart and the range of which can’t be exceeded in use.

Otherwise the equipment may be damaged. If any problem, please consult customer service department of Shenzhen

Veichi Electric Co., Ltd.

Three-phase380V

Inverter Model Motor Power Max Braking Current Min Resistance

AC100-T3-R75G 0.75 kW 3.5A 200Ω

AC100-T3-1R5G 1.5 kW 3.5A 200Ω

AC100-T3-2R2G 2.2 kW 7A 100Ω

AC100-T3-004G 4 kW 10A 75Ω

AC100-T3-5R5G 5.5 KW 10A 75Ω

AC100-T3-7R5G 7.5 kW 14A 50Ω

AC100-T3-011G 11 kW 17A 40Ω

AC100-T3-015G 15 kW 23A 30Ω

AC100-T3-018G 18.5 kW 28A 25Ω

Single-phase 220V

Inverter Model Motor Power Max Braking Current Min Resistance

AC100-S2-R40G 0.4 kW 3.8A 100Ω

AC100-S2-R75G 0.75 kW 3.8A 100Ω

AC100-S2-1R5G 1.5 kW 6.5A 60Ω

AC100-S2-2R2G 2.2 kW 10.5A 40Ω

Chart 3-13:AC100 Series Inverter Build-in Braking Unit Max Braking Power

AC100 HIGH-PERFORMANCE VC INVERTER MANUAL INSTALLATION AND WIRING

34

Multi-functional Contact Input Connection

● NPN transistor connection mode

Use inner 24V power

+24V

PLC

X1

X2

X4

X3

X7

X6

X5

COM

shielded cable

E

(factory short connect)

E

COM

X5

X6

X7

X3

X4

X2

X1

PLC

+24V

Use innner 24V power

exterior

control

signal

exterior

control

signal

shielded cable

Note:Disconnect '+24V'with'PLC' when using exterior power

exterior 24V power

+

-

+24V

PLC

COM

+24V

PLC

COM

PUL PUL

inverter inverter

Chart 3-23: NPN Transistor Digital Input Signal Connection Mode

● PNP transistor connection mode

-

+

use exterior 24 power

E

X5

X6

X7

X3

X4

X2

X1

PLC

+24V

Use inner 24V power

COM

Use inner 24V power

shielded cable

exterior

control

signal

+24V

PLC

COM

PUL

inverter

+24V

PLC

COM

exterior

control

signal

shielded cable

E

X5

X6

X7

X3

X4

X2

X1

PLC

+24V

COM

PUL

inverter

Chart 3-24: PNP Transistor Digital Input Signal Connection Mode

Digital output signal connection

shielded twisted

pair cable

COM

winding

E

Y1

+24V

COM

inverter

exterior 24V power

- +

inverter

shield twisted pair cable

winding

COM

Y1

+24V

E

COM

Chart 3-25:AC100 Series Inverter Digital Output Signal Connection Mode

AC100 HIGH-PERFORMANCE VC INVERTER MANUAL INSTALLATION AND WIRING

35

Analog Output Signal Connection

shielded twisted pair cable

shielded twisted pair cable

GND

E

AO1

shielded twisted pair cable

-

+

_

V

1

0

5

0

AO2 terminal use as 0~10V output indicator

inverter

AO1 terminal use as 0~10V output indicator

0

5

1

0

V

_

+

-

AO1terminal use as 0~20mA output indicator

0

10

2

0

mA

_

AO2 terminal use as 0.2~50kHz active source pulse output

kHz

5

0

25

0

-

+

+

-

shielded twisted pair cable

AO2 terminal use as 0~20mA output indicator

0

10

2

0

mA

_

-

+

shielded twisted pair cable

K1

K2

K1

K2

J1

J2

J3

J1

J2

J3

shielded twisted pair cable

AO2 terminal use as 0.2~50kHz open collector circuit pulse output

kHz

5

0

25

0

+

-

J1

J2

J3

K5

K6

bias resistor

-

+

exterior power

inverter

inverter inverter

GND

E

AO2

GND

E

AO2

GND

E

AO2

GND

E

AO2

GND

E

AO2

inverter

inverter

J1

J2

J3

K5

K6

Chart 3-26:AC100 Series Inverter Analog Output Signal Connection Mode

Connection of Pulse Input Signal

connection of passive source pulse signal input

connection of active source pulse signal input

E

COM

PUL

COM

pulse signal source

shielded twisted pair source

inverter

+24V

PLC

COM

X7

PUL

shielded twisted pair source

pulse signal source

PUL

COM

E

COM

X7

PUL

inverter

+24V

PLC

COM

Chart 3-27: Pulse Input Signal Connection Mode of AC100 Series Inverter

AC100 HIGH-PERFORMANCE VC INVERTER MANUAL INSTALLATION AND WIRING

36

Standby Control System

Frequency inverter is composed of semiconductor, passive electronic component and driving part. And these devices

have working life even under normal working conditions and these devices may also have characteristic variation or

failure. These characteristics change or failure would inevitably lead to failure of the product. Setting standby control

system when using the inverter is highly recommended to prevent lost production caused by product failure.

Figure 3-28 is the standby control system for manual switch converting to direct driving motor of power supply when

inverter fails. Standby control systems such as power supply Y/Δ step-down start way driving motor, power supply

self-coupling reduction voltage start mode driving motor, power supply soft start mode driving motor or standby inverter

system can be chose to use according to the actual needs and environment.

Figure 3-28: Standby Control System of Power Supply Direct Driving Mode

AC100 HIGH-PERFORMANCE VC INVERTER MANUAL BASIC OPERATION AND TRIAL RUN

37

Chapter 4 Basic Operation and Trial Run

4.1 Safety Precautions

● No wiring while power supply is connected. Otherwise there is danger of electric

shock.

● No operation when the cover is open. Otherwise, there is danger of electric shock.

● Please ensure reliable earth. Otherwise, there is danger of electric shock and fire.

● Before wiring please cut power supply of all related equipments and ensure main

DC voltage in safe range. And please do operation after 5 mins.

● Only trained personnel is allowed to operate this product.

● Please do not dismantle the inverter cover when it is electrified. Otherwise, there is

danger of electric shock.

● Please do not touch the printed circuit board of the inverter while it is electrified.

Otherwise, there is danger of electric shock.

● Please ensure reliable mains cable connection. If the mains cable is loose, there is

danger of fire caused by joint overheat.

● Before electrifying, please check the power voltage again. Wrong power voltage can

cause fault or damage of the inverter, or even fire.

● Please do not install inverter on flammable material or attach flammable material to

the inverter. Before electrifying, please clear the surroundings.

Important

● When operating, please follow the ESD regulations. Otherwise, the inverter may be

damaged.

● Please don’t cut the power directly when the inverter drives the motor running.

The power can’t be cut until the motor totally stop. Otherwise, the inverter may be

damaged.

● Please don’t cut or connect motor when the inverter drives the motor running.

The motor can’t be cut or connect until the inverter output is 0. Otherwise, the

inverter may be damaged.

● Control cable should be twisted-pair shielded cable. The barrier should be

connected to the inverter earth terminal reliably to prevent the inverter from

abnormal working.

● Unprofessional personnel can’t do operation like installing, wiring, debugging or

maintenance.

● Changing, dismantlement or maintenance without permission may cause inverter

damage, which is not in our quality assurance range.

AC100 HIGH-PERFORMANCE VC INVERTER MANUAL BASIC OPERATION AND TRIAL RUN

38

4.2 Keyboard Layout and Function Specification

● Keyboard Appearance

● Key Function

Key Name Function

Menu key

Enter function menu when standby or running. Press this key to return

when modifying parameter. Press for 1 sec to enter condition monitoring

interface when in standby or running condition.

Confirm/modify

key

Press to modify parameter when in menu interface. Press again to

confirm after modifying. Press to change LED monitoring items at down

time when in standby or running condition.

Up/down key

Select parameter group in menu interface. Modify parameter in modifying

interface. Modify given frequency, PID, given torque or magnetic powder

clutch given torque when at standby or condition monitoring state (When

given frequency, PID, given torque or magnetic powder clutch given

torque are set by keyboard, please set [F4.04])

Shift key

Select digit of function number modified by up/down key; Select

parameter digits modified by up/down key.

Forward run key

When run/stop is controlled by keyboard, press this key, the inverter

forwardly rotate and the indicator is always on. When reverse, the

indicator sparks.

Jog/reverse key

This key function can be defined by parameter [F4.02]. Press it, the

machine reverses and indicator is off if this key is defined as REVERSE;

the machine jogs and indicator is on if this key is defined as JOG.

Stop/reset key

The machine stops if press it while run/stop is controlled by keyboard. Its

efficiency range is defined via function no [F4.03]. Inverter resets if press

it in fault state (the machine would not reset if the fault is not solved).

Keyboard

potentiometer

Can be used as input channel for given frequency, upper frequency limit,

given torque, given PID or PID feedback setting.

AC100 HIGH-PERFORMANCE VC INVERTER MANUAL BASIC OPERATION AND TRIAL RUN

39

● Indicator light meanings

Name State Meaning

Unit Indicator

Light

Hz Spark Digital display given frequency.

Hz On Digital display output frequency.

A On Digital display actual output current.

V On Digital display input voltage.

V Spark Digital display output voltage.

S On Time unit is second.

S Spark Time unit is ms, min, or h.

RPM On Digital display motor speed.

% Spark Digital display given PID.

% On Digital display PID feedback.

State

Indicator Light

FWD On Inverter is forwardly rotating.

FWD Spark Inverter is reversely rotating.

FWD Off Inverter stops.

Function

indicator light

REV/JOG On Jog.

REV/JOG Off Reverse.

Chart 4-1: Indicator Light Meanings

● Number and Character Chart

Chart 4-2:Number and Character Chart

AC100 HIGH-PERFORMANCE VC INVERTER MANUAL BASIC OPERATION AND TRIAL RUN

40

●LCD Keyboard Function Meaning

Icon Meaning

Inverter at stop state

Stand for forward running state

Stand for reverse running state

Stand for JOG running state

Auxiliary sign Of reverse running state

Remind to press“ ”button

Remind to press “ ”button

Cursor shift up

Cursor shift down

sparkling means fault state

Reminder of what the arrow points to

Terminal off

Terminal on

Two kinds of relay output: one is open while the other is close.

● Basic LED Operation

It displays frequency at 50.00Hz when stop. Here F0.09=100.00 setting is an example to explain the basic LED

operation.

Chart 4-1: Basic LED Operation

AC100 HIGH-PERFORMANCE VC INVERTER MANUAL BASIC OPERATION AND TRIAL RUN

41

4.3 Basic Operation

● Parameter Initialization

Set F0.19=1, and the parameter initialization is completed. Operation details as follows:

Chart 4-2: Parameter Initialization

●Control Mode Selection of Motor 1

Here we set F0.00=0(AM VC without PG)as an example to introduce.

Chart 4-3: Control Mode Selection of Motor 1

● Start-up Mode Selections

Three start-up modes: 0: direct start-up, 1: braking firstly, then start by start-up frequency, 2: speed track and

start-up. Here we set F1.00=2(speed track and start-up) as an example:

Chart 4-4: Start-up Mode Selections

● Motor Parameter Setting

Set[F5.02](motor rated power),[F5.03](motor rated frequency),[F5.04](motor rated speed), [F5.05]

(motor rated voltage) according to the motor nameplate. Other parameter setting can be obtained by inverter

self-study.

Please refer to the following operation mode chart:

AC100 HIGH-PERFORMANCE VC INVERTER MANUAL BASIC OPERATION AND TRIAL RUN

42

Chart 4-5: Motor Parameter Setting

● Parameter Copy Function Selection

Set F4.05=1, send inverter parameter to keyboard and save:

Chart 4-6: Send Inverter Parameter to Keyboard and Save

Set F4.05=2, send keyboard parameter to inverter:

Chart 4-7: Send Keyboard Parameter to Inverter and Save

AC100 HIGH-PERFORMANCE VC INVERTER MANUAL BASIC OPERATION AND TRIAL RUN

43

● Run Monitoring Setting

Chart 4-8: Run Monitoring Setting

4.4 LCD Keyboard Operation Instructions

● Monitoring Selection Setting Steps

Set of monitoring parameter at stop state as an example. Operations detailed in Chat 4-9. Set keyboard first-line

displays when inverter stops under function parameter F4.11.Factory seting includes four-group parameters

such as input frequency, output frequency, output current and input voltage. Press to change display

content when inverter stops. Press to change displays of uplink monitoring parameter group.

Chart 4-9:Display Change of Uplink Monitoring Parameter Group

● Operation Process of Fault Display

Operation of rectifier bridge overheat fault display as an example, details in Chart 4-10. When keyboard

displays fault, please press to check fault reasons, and press to return back. Press and

to check other fault reasons. Press to reset fault in whole operation.

AC100 HIGH-PERFORMANCE VC INVERTER MANUAL BASIC OPERATION AND TRIAL RUN

44

Chart 4-10:Rectifier Bridge Fault Display

● Operations of Third-level Menu

(1)Operation process of changing lines: Operation of parameter initialization under function code of F0.19 as

an example; set F0.19=1, and the parameter initialization is completed. Details in Chart 4-11.

Chart 4-11:Operations Process of Changing Lines

(2)Operation process of data modifying: Setting of main channel gain under function code of F0.04 as an

example; set F0.04=2.000%. Details in Chart 4-12.

AC100 HIGH-PERFORMANCE VC INVERTER MANUAL BASIC OPERATION AND TRIAL RUN

45

Chart 4-12:Operation Process of Data Modifying

(3)Operation process of groups: Setting carrier frequency characteristic under function code of F0.08. Set ‘1.

Related to output frequency’ in group 2, Details in Chart 4-13.

Chart 4-13:Operation Process of Groups

AC100 HIGH-PERFORMANCE VC INVERTER MANUAL BASIC OPERATION AND TRIAL RUN

46

● Operation Process of Parameters Copy

Operation process of parameters copy in Chart 4-14; download process in Chart 4-15.

Chart 4-14:Operations of Parameter Copy

Chart 4-19:Operations of Parameter Download

AC100 HIGH-PERFORMANCE VC INVERTER MANUAL BASIC OPERATION AND TRIAL RUN

47