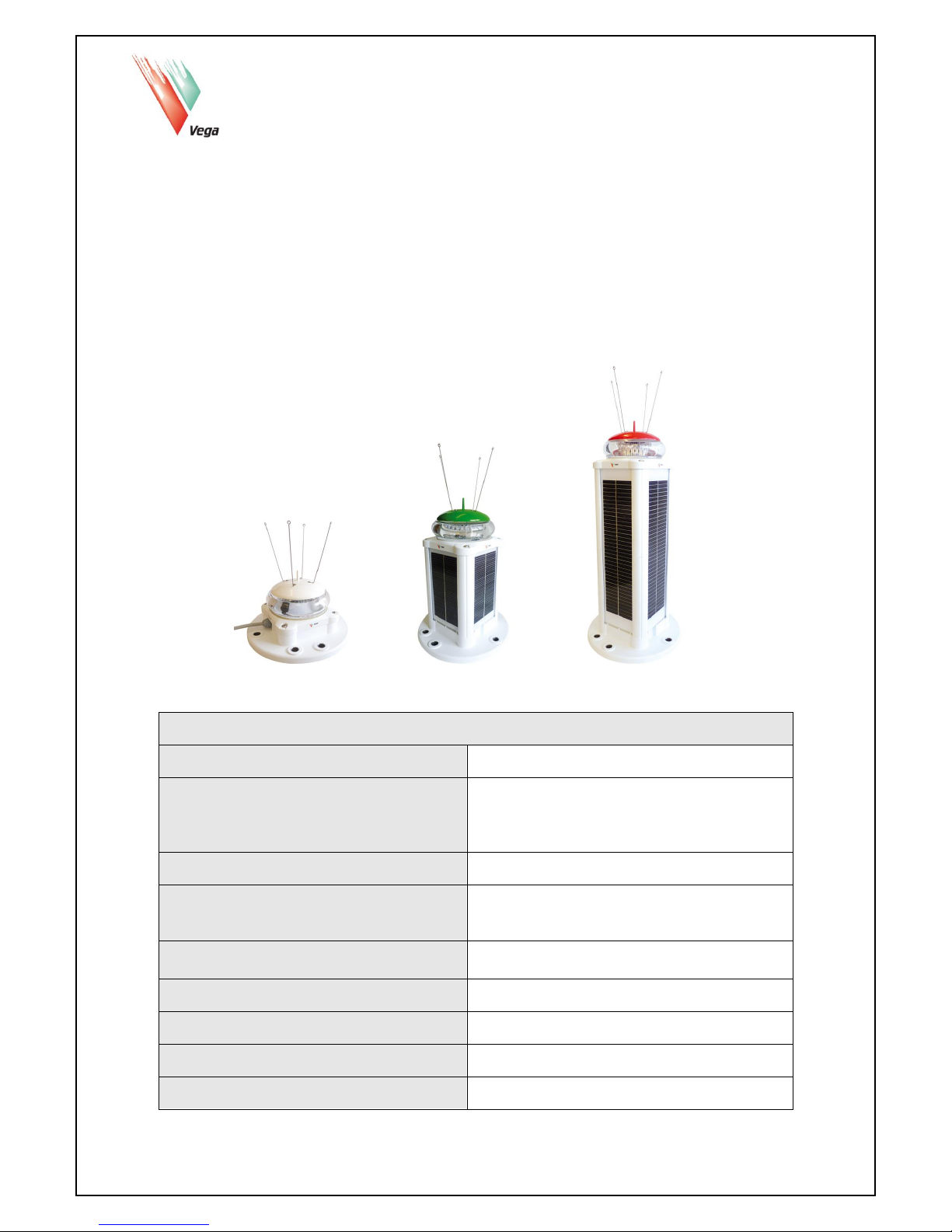

VLB-67 LED Beacon

Installation and Operation Manual

STAND ALONE & SELF CONTAINED

Marine Beacon

Bridge Light

Aircraft Hazard Light

VLB-67 Product Manual

Available colour range

Red, Green, White, Yellow or Blue

Available models

SA-Stand Alone (No Solar panels)

SS-Standard Solar 8W with 12Ah battery

LS1-Large Solar 16W with 12Ah Battery

LS2-Large Solar 16W with 24Ah Battery

Vertical divergence

7° Marine Beacon and Obstacle Light

Options

Internal GPS for synchronising

RS232 Data port (RS485 optional)

Sync and monitor wire

Product Version

SA and SS version: 4.00

LS1 and LS2 version: 5.00

Software version:

7.11

Manual version:

1.0.17

Date released:

24 July 2014

Status:

AHT Released

VEGA INDUSTRIES LIMITED

VLB-67-SA-Stand Alone

VLB-67-SS-Standard Solar

VLB-67-LS-Large Solar

Instruction Manual VLB-67 LED Beacon © Vega Industries Ltd, July 2014

VLB-67 LED Beacon Page 2 of 52 VLB-67 V1.0.17

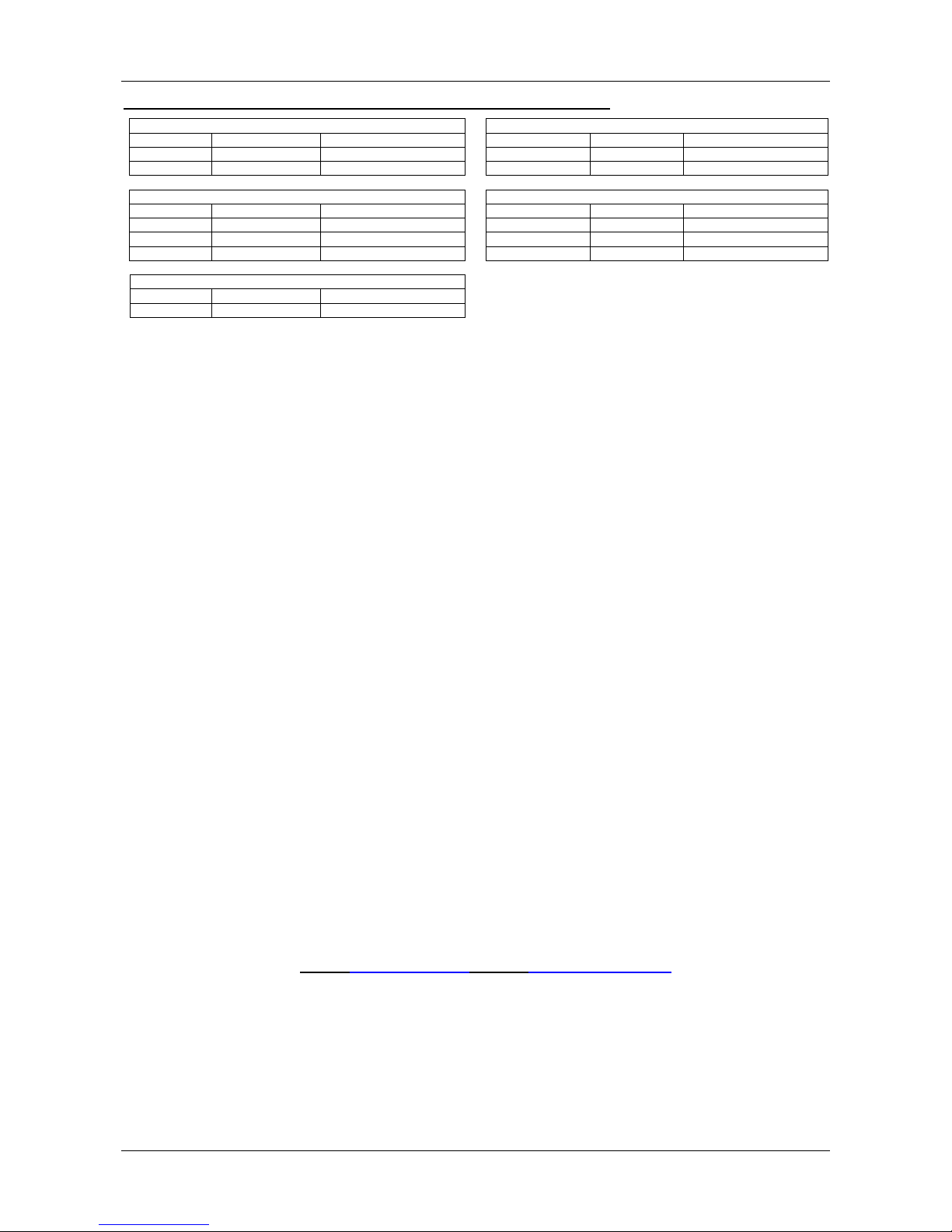

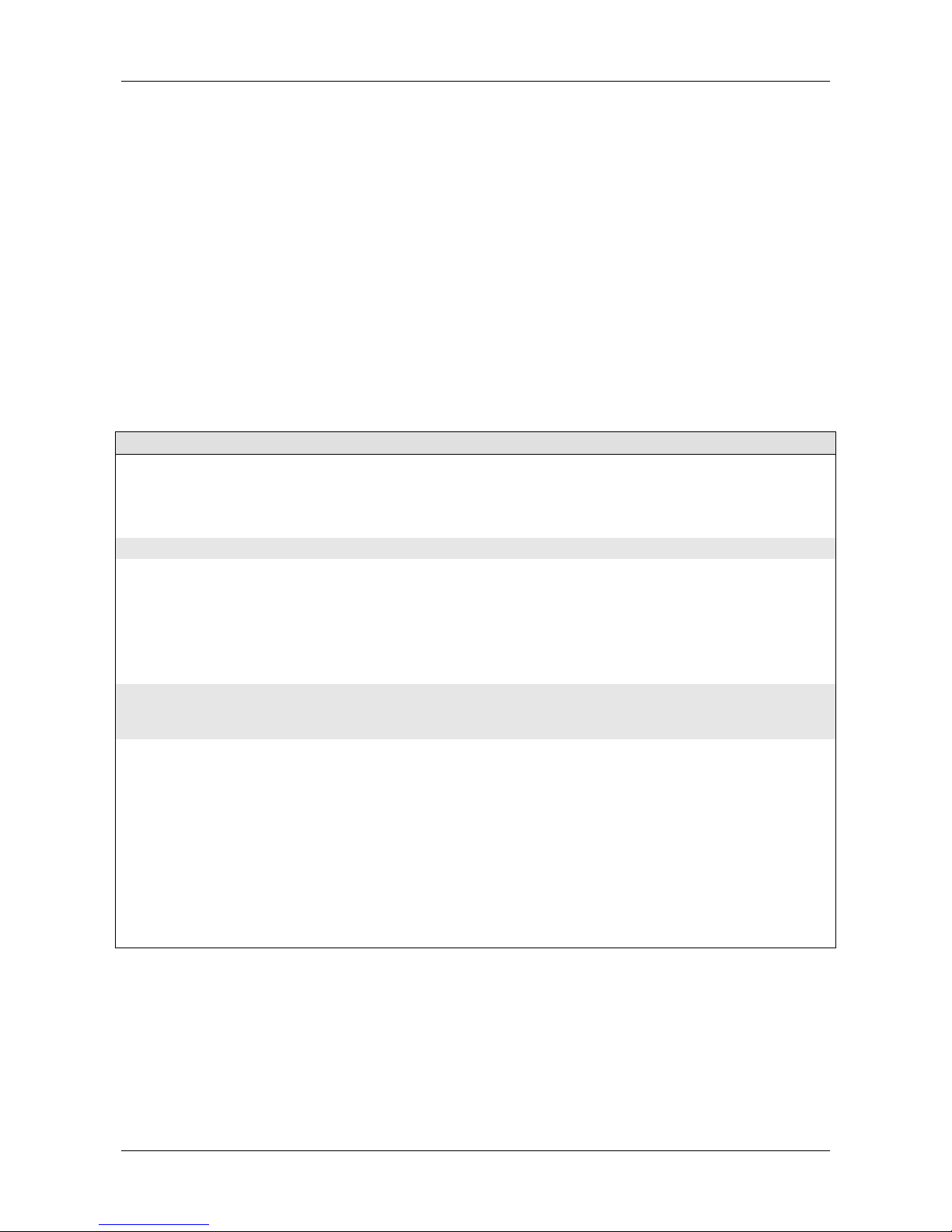

Manual revision history

Manual Version

Released

Description of Change

Software version

VLB-67 Serial number

1.0

Dec 2009

First issue.

1.0.1

8 Mar 2010

Correction to Yellow Appendix A currents for

intensities below 37cd.

(Not affected)

Applicable to all

1.0.2

17 Mar 2010

Update version of vertical profiles.

Alteration of Appendix H.

1.0.3

5 July 2010

Update bird spikes dimensions on Appendix G.

1.0.4

25 Sept 2010

Combine Product and Program manuals.

Addition transport Options.

4.04

1.0.5

1st April 2011

Combine USCG and International manual.

Range increase to 5NM.

4.04

1.0.6

20 July 2011

Option to allow sync wire to turn light off.

4.07

1.0.7

13 Aug 2011

Baud rate adjustment function added.

Red and green LEDs changed.

5.00

67-3820+

1.0.8

5 Dec 2011

Software updates.

From this release onwards, Prog01 V1.2 or later for

IrDA configuration is required for compatibility.

7.03

67-8000 to 67-8076+

1.0.9

18 Jan 2012

Update to software version.

7.04

67-8076 to 67-8407

1.0.10

18 Jan 2012

Update to software version.

7.05

67-8408+

1.0.11

16 Feb 2012

29 Mar 2012

Update to software version: auto storage function

with fixed character corrected.

Update to software version: fix beacon sync issue.

7.06

V7.07, V7.08

67-8634+

67-8946+

1.0.12

30 July 2012

Additional information on battery replacement

No change

No change

1.0.13

13 Sep 2012

Add 3 additional steps to Day/Night control table

7.10

67-10153+

1.0.14

4 April 2013

Higher capacity solar panels for LS models

No Change

67-12900+

1.0.15

7 August 2013

Addition of Obstacle Light

No Change

67-12900+

1.0.15

18 Sep 2013

Tidy up of interrupt firmware

7.11

67-13884+

1.0.16

25 Nov. 2013

Higher capacity solar panel for SS model

7.11

67-15063+

1.0.17

24 July 2014

Update VPP-67 to VLB-67-OBC-SAP Wiring

Diagram

Update to VPP-67 solar power packs

Correct SC intensity correction on multiple flash

characters

7.12

67-16611+

Instruction Manual VLB-67 LED Beacon © Vega Industries Ltd, July 2014

VLB-67 LED Beacon Page 3 of 52 VLB-67 V1.0.17

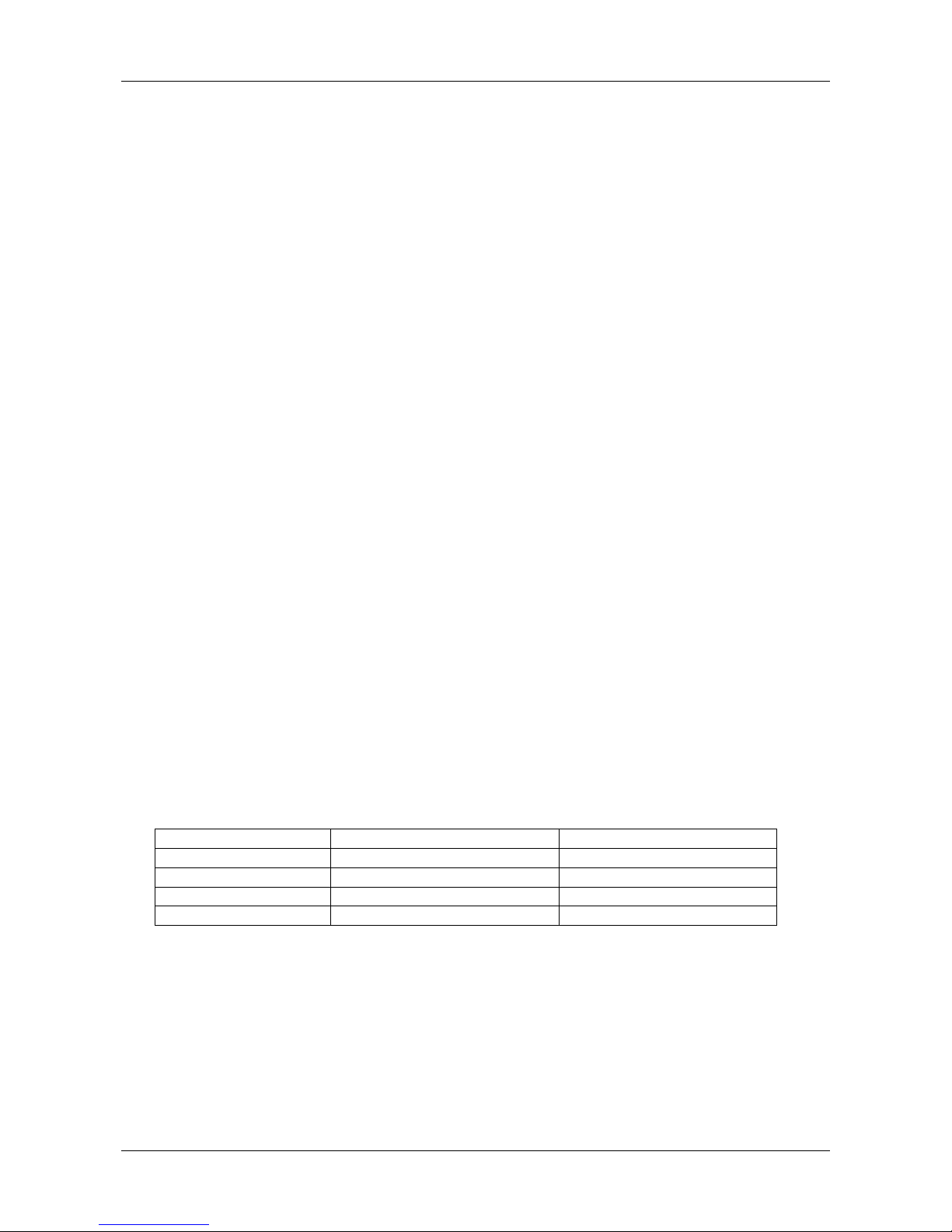

VLB-67 LED Versions by colour, release date and serial number

RED LED

GREEN LED

LED Version

Release Date

VLB-67 Serial Number

LED Version

Release Date

VLB-67 Serial Number

Vega 116

Dec 2009

Vega 223

Dec 2009

Vega 163

Aug 2011

67-3820+

Vega 263

Aug 2011

67-3820+

WHITE LED

YELLOW LED

LED Version

Release Date

VLB-67 Serial Number

LED Version

Release Date

VLB-67 Serial Number

Vega 422

Dec 2009

Vega 320

Dec 2009

Vega 423

May 2011

Vega 463

July 2013

VLB-67-OBC

BLUE LED

LED Version

Release Date

VLB-67 Serial Number

Vega 525

Dec 2009

VEGA INDUSTRIES LIMITED

21 Heriot Drive, Porirua 5022, New Zealand

Tel: +64 4 238 0200; Fax: +64 4 237 4392

E-mail: sales@vega.co.nz Web: http://www.vega.co.nz

Product Warranty

Vega warrants that all products supplied are free from labour and material defects, and will repair or replace (at its option ) the whole or

any part of the products found to be faulty. The standard warranty is valid for 12 months from the date of dispatch. Vega is not to be

liable for any charge beyond the point of delivery, including installation, alignment or testing. To claim under warranty th e product must

be returned to the Vega factory in New Zealand at the users expense.

Legal Notice

Information in this document is subject to change without notice. Vega Industries Ltd. makes no warranty of any kind with re gards to

this material, including but not limited to, the implied warranties of merchantability and fitness for purpose. Vega Industries Ltd. shall not

be liable for errors contained herein or for incidental or consequential damages in connection with the use of this material. No part of

this document may be photocopied, reproduced, or translated to another language without prior written consent of Vega Industries Ltd.

The Vega logo is a registered trademark of Vega Industries Ltd. All other trademarks belong to their respective proprietors.

Instruction Manual VLB-67 LED Beacon © Vega Industries Ltd, July 2014

VLB-67 LED Beacon Page 4 of 52 VLB-67 V1.0.17

Table of Contents

SECTION 1 OVERVIEW OF THE VLB-67 LED BEACON .............................................. 6

1.0 Introduction to the VLB-67 LED Beacon ...................................................................... 6

1.1 Options Available ................................................................................................................... 6

1.2 Additional Factory Options ..................................................................................................... 7

1.3 Approvals ............................................................................................................................... 7

2.0 Range and Power........................................................................................................ 7

2.1 Effective Intensity Settings ..................................................................................................... 7

2.2 Automatic Schmidt Clausen Correction .................................................................................. 7

3.0 Mechanical Description ............................................................................................... 8

3.1 Construction ........................................................................................................................... 8

3.2 Solar Body Breather Vent ....................................................................................................... 9

3.3 Sealing ................................................................................................................................... 9

4.0 Electrical ...................................................................................................................... 9

4.1 Electrical Connections ............................................................................................................ 9

5.0 Battery Charging on VLB-67 SS and LS Beacons ...................................................... 9

SECTION 2 SETTING UP AND USING THE VLB-67 BEACON ..................................... 9

1.0 Getting Started ............................................................................................................ 9

2.0 Solar Calculations ..................................................................................................... 10

3.0 Shipping of the VLB-67 ............................................................................................. 10

3.1 From the Factory .................................................................................................................. 10

4.0 Infra-red Programming .............................................................................................. 10

5.0 The Initial Power Up .................................................................................................. 10

5.1 Stand Alone Model ............................................................................................................... 10

5.2 Self Contained Model ........................................................................................................... 10

6.0 Programming ............................................................................................................. 11

7.0 Installing the VLB-67 Beacon .................................................................................... 11

7.1 Bird Spikes ........................................................................................................................... 11

7.2 Wiring from VLB-67-SA & SAP Stand Alone Beacon ........................................................... 11

7.2.1 VLB-67 Base Compartment ............................................................................................... 11

7.3 Mounting the VLB-67 Beacon............................................................................................... 12

7.3.1 Levelling the Beacon ......................................................................................................... 12

7.3.2 Mounting Structure ............................................................................................................ 12

8.0 VLB-67 Factory Options ............................................................................................ 12

8.1 Hardwire Synchronization .................................................................................................... 12

8.2 Internal GPS Synchronization .............................................................................................. 13

8.3 Alarm Monitor wire ............................................................................................................... 13

8.4 Data Port .............................................................................................................................. 13

SECTION 3 MAINTENANCE .......................................................................................... 13

1.0 Maintenance Cleaning ............................................................................................... 13

2.0 Inspection Check ....................................................................................................... 13

3.0 Changing the Battery on Self Contained Models ....................................................... 14

Instruction Manual VLB-67 LED Beacon © Vega Industries Ltd, July 2014

VLB-67 LED Beacon Page 5 of 52 VLB-67 V1.0.17

SECTION 4 PROGRAMMING ....................................................................................... 14

1.0 Programming Methods .............................................................................................. 14

1.1 Using the Vega Remote TVIR Programmer .......................................................................... 15

1.2 Using a Computer ................................................................................................................ 15

2.0 Default Settings ......................................................................................................... 15

3.0 Programming Syntax ................................................................................................. 15

4.0 Visual Feedback when using the TVIR Programmer ................................................. 16

4.1 The VLB-67 Will Not Enter Programming Mode ................................................................... 17

4.2 Becoming Familiar with the Syntax and Flash Feedback ...................................................... 17

4.3 Deciding what Settings are required ..................................................................................... 19

4.3.1 Programming or Reading Multiple Settings ....................................................................... 19

5.0 Programming Features .............................................................................................. 19

5.1 Flash Character.................................................................................................................... 19

5.2 Custom Flash Character. ..................................................................................................... 20

5.3 Day/Night Use of the Light ................................................................................................... 20

5.4 Intensity Settings .................................................................................................................. 20

5.5 Synchronising Options ......................................................................................................... 21

5.5.1 Additional Sync Options .................................................................................................... 21

5.6 Operation Mode ................................................................................................................... 22

5.6.1 Auto Leave Storage........................................................................................................... 22

5.6.2 Auto Storage ..................................................................................................................... 22

5.7 Programming Mode .............................................................................................................. 23

5.8 Battery Thresholds ............................................................................................................... 23

5.9 System Checks .................................................................................................................... 23

5.10 Security PIN Number .......................................................................................................... 24

5.11 Calendar ............................................................................................................................ 24

User Notes ......................................................................................................................... 26

Appendix A Programming Table .................................................................................. 27

Appendix B VLB-67 Intensity Settings And Currents ................................................ 31

Appendix C Worksheet for a Custom Character ........................................................ 34

Appendix D VLB-67 Settings ........................................................................................ 35

Appendix E VLB-67 Solar Power Calculation example .............................................. 36

Appendix F Electrical Connections to VLB-67 Beacon .............................................. 39

Appendix G VLB-67 Data Port Protocol ...................................................................... 41

Appendix H VLB-67 Beacon Dimensions .................................................................... 43

Appendix I 7° Marine light Vertical Divergence Profiles ............................................ 45

Appendix J Specifications of VLB-67 Beacon ............................................................ 46

Appendix K Flash Character Table with Programming Codes ................................. 49

Appendix L VLB-67 Beacon Product Codes ............................................................... 52

Instruction Manual VLB-67 LED Beacon © Vega Industries Ltd, July 2014

VLB-67 LED Beacon Page 6 of 52 VLB-67 V1.0.17

SECTION 1 OVERVIEW OF THE VLB-67 LED BEACON

1.0 Introduction to the VLB-67 LED Beacon

The VLB-67 is a feature rich product allowing the user to program many advanced features not

normally required for standard navigation applications. How the beacon has been programmed

can be checked using the read settings option with the TVIR remote programmer or the PROG-01

IRDA Computer programming option. If it is uncertain how the beacon has been programmed the

VLB-67 can be reset to the factory default settings. The procedure to do this is detailed in Section

4, Clause 5.6

For the self-contained solar powered models of the VLB-67 beacon it is critical that the solar

irradiation for the location where the beacon is to be used is checked to ensure there is enough

energy available to support the intended range, and flash character. Vega provides an on line web

calculator for the VLB-67 on www.vega.co.nz to assist in the correct usage of the VLB-67. Please

note that reducing the range and the duty cycle of the beacon can lower the power requirement.

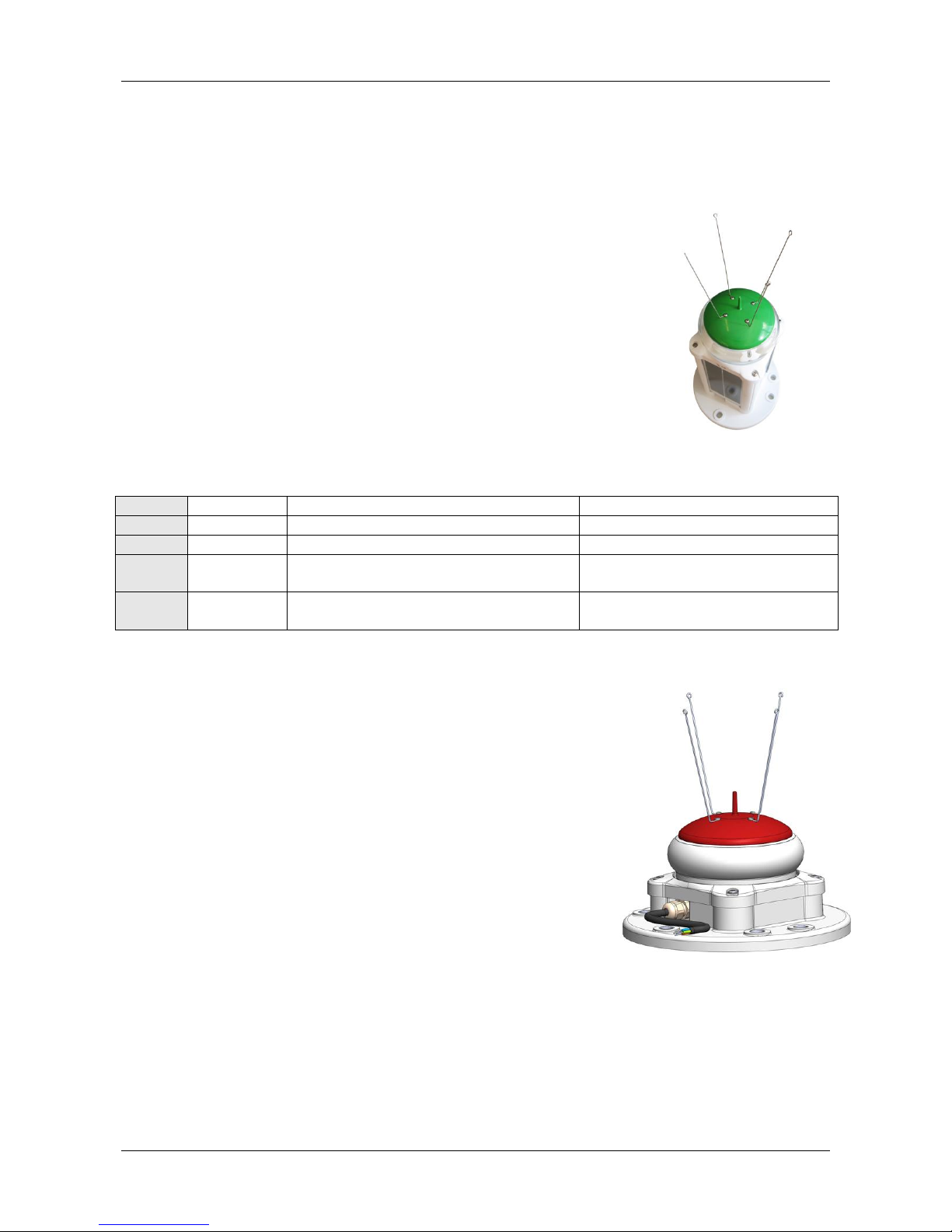

1.1 Options Available

There are two lens options for the VLB-67 beacon. The 7° divergence (±3.5°) symmetrical lens

provides a horizontal fan bean for marine beacon applications. The Obstacle lens is an

asymmetrical lens with the peak intensity occurring at +8° above the horizontal and is designed to

provide the beacon profile required for aircraft hazard lights for ICAO Type A and Type B and for

use as bridge marking lights.

The VLB-67 Marine Beacon can be programmed for an operating range at:

2 to 5NM at 0.74T visibility and

2.25 to 6NM at 0.85T visibility

The VLB-67 Obstacle Light can be programmed between 1 and 54 candela effective measured at

+6 and +10 degrees from the horizontal. ICAO Aircraft Hazard Light requires the following intensity

at these angles:

Type A hazard light 10 candela

Type B hazard light 32 candela

Five LED colours are available red, green, white, yellow, and blue. Each colour has a different

power requirement to achieve any particular intensity. Detail on power consumption is provided in

Appendix B.

The Vega VLB-67 Beacon is available in four models.

Body size

Solar Panel Capacity

Battery Capacity

SA=Stand Alone

Nil

Nil

SS=Standard Solar

8Watt (4x 2W panels)

12Ah Gel Lead acid

LS1=Large Solar

16Watt (4x 4W panels)

12Ah Gel Lead acid

LS2=Large Solar

16Watt (4x 4W panels)

2x12Ah Gel Lead acid

The self-contained solar power models use a 12VDC long life GEL battery that can operate down

to low temperatures. The battery has been specifically designed for the mounting arrangement in

the VLB-67. Only use a Vega --67 battery should a replacement battery be required.

The SS-Standard Solar unit will cover most self-contained applications. The large solar LS models

are available for use in higher latitude and/or high duty applications.

For bridge marking application the VLB-67 obstacle lens can be separated from the solar power

pack and mounted separately. This allows the light head to be mounted under a bridge while

locating the power pack where it can receive solar energy. The separate components consist of

Instruction Manual VLB-67 LED Beacon © Vega Industries Ltd, July 2014

VLB-67 LED Beacon Page 7 of 52 VLB-67 V1.0.17

the Stand Alone (SAP) light head and VPP-67 solar body. Note that the solar power regulator is

located in the lantern and not in the VPP-67 Solar Power Pack. In applications requiring more solar

power the solar power pack can be substituted with the larger capacity VPP-66.

The VLB-67 is designed with many features to allow the user to customise the beacon for any

application. Programming is done using the Vega Remote-02 Infrared Programmer or by a

computer using the PROG-01 Programming kit. Both the Remote-02 and Prog-01 items need to

be ordered separately.

1.2 Additional Factory Options

Additional Factory options for the VLB-67:

GPS synchronising.

Data Plug incorporating RS232 or RS422 data connection, alarm/monitor wire, and sync

wire

External charging plug and sync wire for self contained models SS and LS

Alarm/Monitor output (Beacon Healthy)

Note: Hard wire synchronisation is provided as standard on the SA model

1.3 Approvals

The VLB-67 LED beacon has been approved under US Coast Guard regulations CFR33 part 67

for use as a Class B or C light for artificial islands and structures in the Gulf of Mexico (USCG

District 8).

2.0 Range and Power

2.1 Effective Intensity Settings

The VLB-67 beacon supports a number of effective Candela settings.

Appendix B of the manual provides the following information:

The Effective Intensity settings available for each colour

The current the beacon will use at each intensity

The Peak Candela and Peak Current of each colour

While the VLB-67 is normally only used at night it is possible to operate the beacon during the day

using a different intensity setting than is used at night.

2.2 Automatic Schmidt Clausen Correction

Effective intensity is the intensity required to see a continuously “on” light (fixed character) at a

certain distance. For example 39 Candela is required to see a fixed “on” light at 4NM when the

atmospheric visibility is 10 miles (0.74T).

When a light is flashed the intensity must be increased to maintain the lights visibility at the

required distance. This increase of intensity is the “Peak” intensity for the flash character. The

VLB-67 automatically handles this process according to the Schmidt Clausen multiplier for LED

lights: (Flash period in seconds+0.2)/Flash period in seconds

The VLB-67 beacon will not operate above its maximum candela capability. When programming a

flash character the user should check that the peak candela required for a flash character at the

required range is below the maximum intensity. The VLB-67 will cap the intensity at the maximum

candela allowed, reducing the range of the light.

Instruction Manual VLB-67 LED Beacon © Vega Industries Ltd, July 2014

VLB-67 LED Beacon Page 8 of 52 VLB-67 V1.0.17

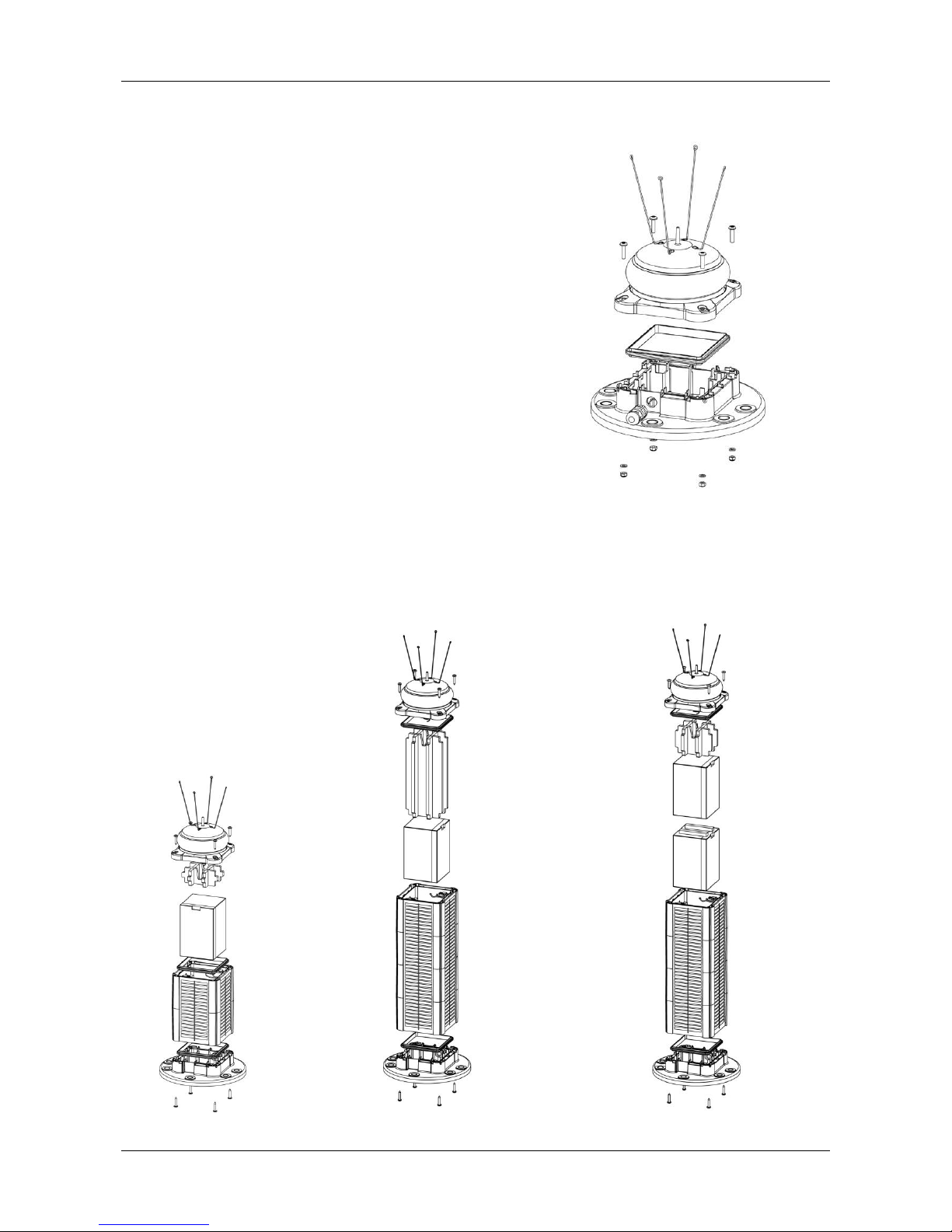

3.0 Mechanical Description

3.1 Construction

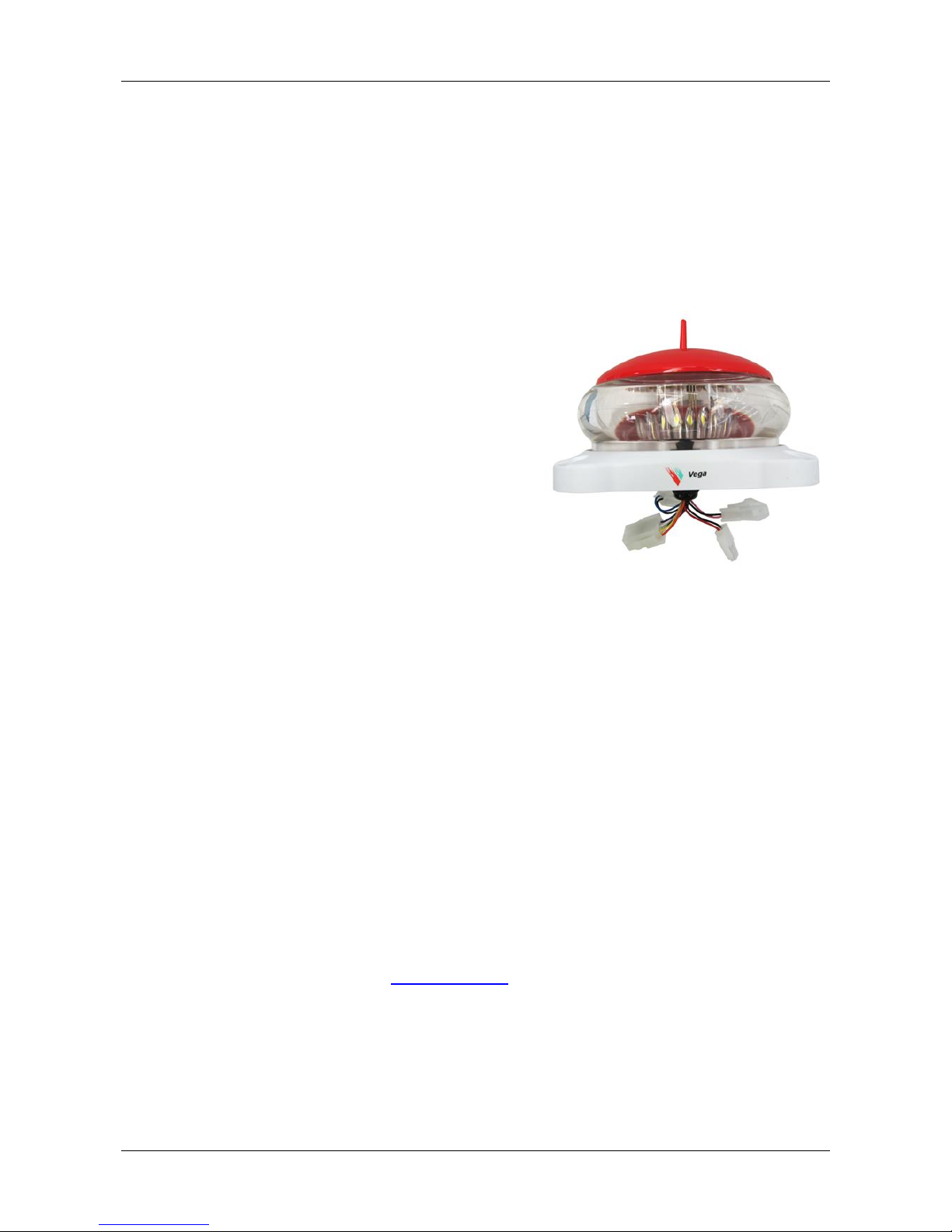

The common parts of the VLB-67 are the beacon head, the

base, and the connecting seal.

The SA-Stand Alone model consists of these 3 parts and

has a 1.5metre 3 core cable fitted to provide the power

connection for the beacon. This cable also contains the

wire for the sync signal.

The SS-Standard Solar and LS1 and LS2- Large Solar self-

contained models have the solar power system consisting

of solar panel assembly and battery.

The plastic body and base of the VLB-67 beacon is made

from Nylon and has a 30 percent glass fill. The coloured

top of the Beacon is made from ASA plastic. The lens is

moulded from optical grade acrylic.

The VLB-67 LED Beacon is assembled and sealed using

self-tapping fasteners into the Glass Filled Nylon parts.

This assembly method is not designed for frequent

disassembly and reassembly of the beacon. There should

be no need to disassemble the beacon other than to

change the battery once or twice during the Beacon’s

lifetime. Disassembly of the Beacon should be kept to a

minimum to ensure the proper sealing.

Beacon head

Base

VLB-67-SA Stand Alone &

VLB-67-SAP Stand Alone

Seal

VLB-67-SS Standard Solar

Solar Body

VLB-67-LS2 Large Solar

VLB-67-LS1 Large Solar

Battery

Battery

Solar Body

Instruction Manual VLB-67 LED Beacon © Vega Industries Ltd, July 2014

VLB-67 LED Beacon Page 9 of 52 VLB-67 V1.0.17

3.2 Solar Body Breather Vent

The solar body has been fitted with a membrane vent to allow pressure equalization, and to

release any hydrogen gas that may build up from the battery. The membrane vent is located at the

top of the body behind one of the solar panels. The vent should not be tampered with as any

damage may cause water to enter the battery compartment.

3.3 Sealing

The beacon is sealed against the ingress of moisture, dust, insects and other environmental

contaminants. Because the beacon does not need to be opened for programming, these seals can

remain undisturbed for extended periods. If the power pack is opened for inspection or to change

the battery, do not let any water accumulate in the battery compartment.

4.0 Electrical

4.1 Electrical Connections

There are four connectors at the bottom of the VLB67

lantern. These are used to connect the battery/power

supply, solar panels, data port, sync wire, and monitor

wire. What connectors are used on any VLB-67 Beacon

will depend on the options ordered.

There should be no need for the user to access these

connections other than when a battery is being replaced

on the self-contained units.

Details of the electrical connections are provided in

Appendix F

5.0 Battery Charging on VLB-67 SS and LS Beacons

The solar charger in the VLB-67 Beacon monitors the temperature and the voltage and will charge

the batteries when the voltage level at the solar panels exceeds the voltage of the battery.

Protection is provided to prevent the overcharging of the battery. Charging will stop at minus 20

degrees Celsius in order to protect the battery from damage. The beacon will continue to draw

power from the battery at temperatures below minus 20 degrees Celsius.

The solar charger is designed for Lead Acid batteries with GEL construction. The battery on the

VLB-67 has been specifically designed for the mounting configuration used in the VLB-67. If a

replacement battery is required please obtain the correct battery from Vega or one of Vega’s

Distributors. Other batteries may cause damage to the beacon

SECTION 2 SETTING UP AND USING THE VLB-67 BEACON

1.0 Getting Started

If using a self-contained model check there is sufficient solar energy at the location to

support the range and flash Character. See Appendix E. Alternatively use the selector

program on the Vega website www.vega.co.nz under “Calculators”

For Self-Contained models change the operating mode from “Storage” to “Normal”

Program the Beacon (Section 4).

Fit the Bird Deterrents (Clause 7)

Install the VLB-67 LED Marine Beacon (Clause 7)

Check the beacon is working (Section 3)

Instruction Manual VLB-67 LED Beacon © Vega Industries Ltd, July 2014

VLB-67 LED Beacon Page 10 of 52 VLB-67 V1.0.17

2.0 Solar Calculations

If the solar calculations are being done manualy it is necessary to determine the energy

contribution for each solar panel taking into account the azimuth and inclination angles. Examples

for the solar calculations are provided in Appendix E. The solar panels should provide more

energy than the beacon uses during the worst solar month of the year.

The 4 solar panels on the VLB-67 Beacon are mounted 90 degrees apart from each other in

azimuth. The inclination of the solar panels is 90 degrees from the horizontal.

3.0 Shipping of the VLB-67

3.1 From the Factory

The VLB-67 beacon will be delivered with factory default settings. The default settings are detailed

in Appendix A. Please note the following defaults:

TVIR Remote-02 programming only. The IRDA port will need to be enabled to program the

beacon with a Computer.

Self Contained units will be shipped in Storage mode in order to

maintain the battery charge. The Operating mode will need to be

changed to “Normal” in order to get the beacon operating

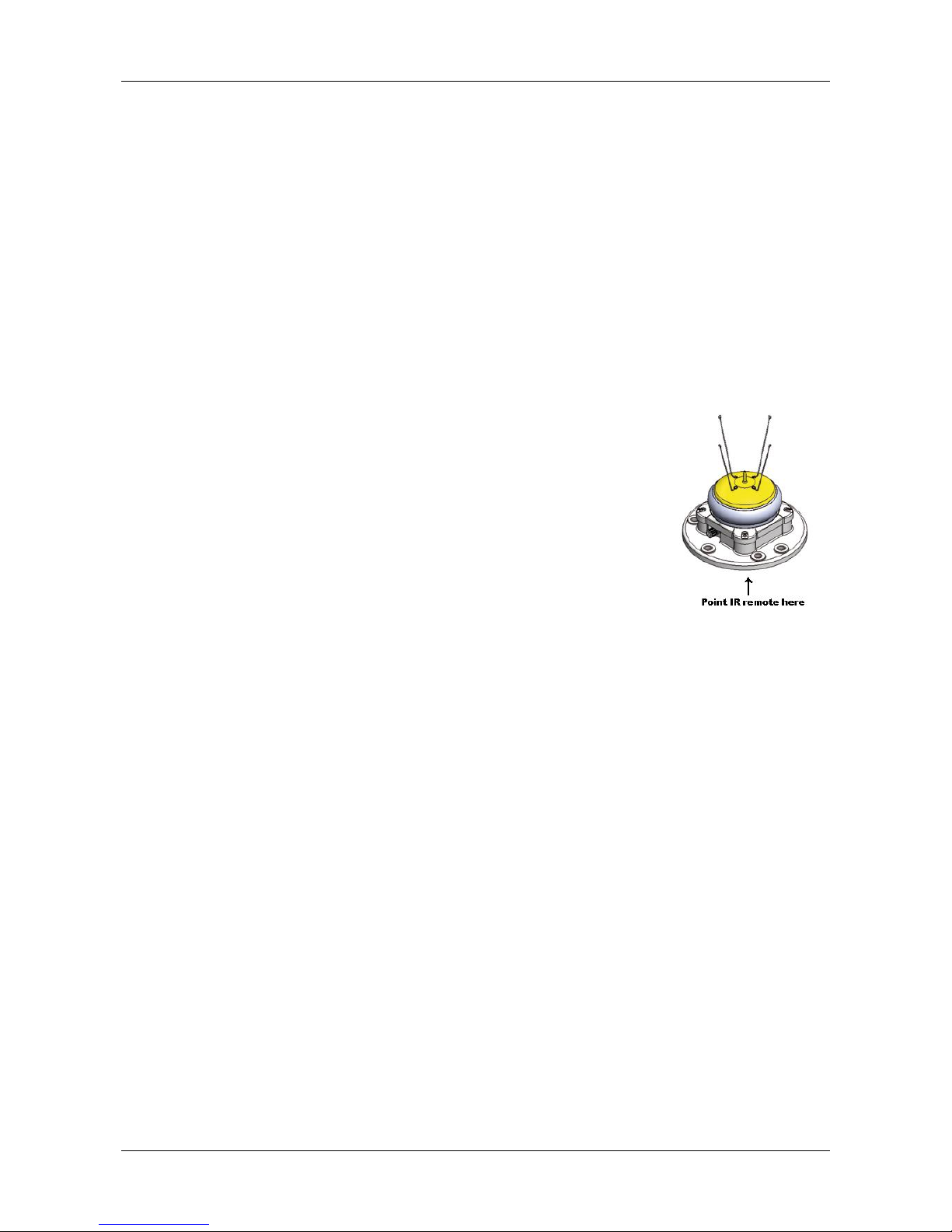

4.0 Infra-red Programming

The infrared receiver for programming the beacon is located behind the

LED ring. To program the Beacon, point the Vega TVIR programmer or

the Vega IRDA sensor at the lens. Best results can be achieved by using

the programmers at the position indicated in the diagram.

5.0 The Initial Power Up

5.1 Stand Alone Model

At power-on when a battery is first connected, the beacon will remain inactive for about 30

seconds then start in night mode with the beacon flashing with the programmed flash character.

After a further 16 to 20 seconds the beacon will begin to monitor the ambient light level. If

day is detected and the beacon is set for night operation only the beacon will turn off.

After a further 14 seconds the beacon will begin to monitor the voltage for the low level

threshold (factory setting 11 Volts). If the threshold is reached the beacon will turn off. The

beacon will not return to normal operation until the voltage is above high voltage threshold

(factory setting 12.8 volts).

If the battery terminals (+ / -) are connected in reverse the beacon will not power up. No damage

will be caused by reverse connecting the beacon.

5.2 Self Contained Model

The self-contained models of the VLB-67 beacons are shipped from the factory in “Storage“ Mode

and must be changed to “Normal” Mode to operate.

When in “Storage” Mode the TVIR receiver in the Beacon only looks for the programmer every 60

seconds. To get the Self-Contained unit into “Normal” Mode:

Hold the red button down for up to 60 seconds until the VLB-67 flashes four times to

indicate the beacon is in program mode.

Enter 15000 ensuring the beacon flashes between each key entry from the programmer.

The VLB-67 will flash when each key of the programmer is pressed

The VLB-67 will then flash back the complete code 15000 in a series of flashes

If no other programming instructions are done the beacon will respond with 2 quick flashes

followed by as space then two more quick flashes and leave the programming mode.

See Section 4 on how the Beacon responds on entering and leaving the program mode.

Instruction Manual VLB-67 LED Beacon © Vega Industries Ltd, July 2014

VLB-67 LED Beacon Page 11 of 52 VLB-67 V1.0.17

6.0 Programming

The VLB-67 Beacon has many program options and settings. It is important that the user

understands the programming syntax and the options available. It is suggested the user works

through the programming examples provided in Section 4 and the description on the various

options and features before deciding the setup of the Beacon for a particular application

7.0 Installing the VLB-67 Beacon

7.1 Bird Spikes

The beacon is supplied with 4 stainless steel bird spikes.

Each spike is attached to the lid by a 4 gauge x ¼” (6mm) stainless steel

screw fixed through the loop on the end of the wire. It is important that

only the Vega supplied screws are used for this purpose as longer or

larger diameter screws may puncture the lid and allow water inside the

beacon.

7.2 Wiring from VLB-67-SA & SAP Stand Alone Beacon

The power and synchronizing connections are provided in a 1.5-meter length of 3 or 4-core (If

alarm/monitor option ordered) 0.75mm² cable. Wiring identification is as follows:

The VLB-67 SA Beacon is a sealed unit. If shortening the power cable the user must tin each

cable core and reseal both external sheath and internal cores with

heat shrink and marine sealant.

7.2.1 VLB-67 Base Compartment

The base of the VLB-67 Beacon is designed to provide space to fit

a AC to DC switch-mode power supply to allow the VLB-67-SA

Stand Alone model to be mains powered. Vega will only supply

the Stand Alone model as a 12VDC unit and if a mains supply is

required the needs to be done by the user.

The user has the responsibility to ensure the mains power

conversion meets the local electrical regulation requirements.

The base is fitted with mounting points to accept a TRACO AC/DC

converter. This unit can be purchased from RS Components

(www.RS-Online.com) part number #RS 3221840.

The space in the base can also be used for other user equipment such as for a monitoring

interface or for sync signal conversion.

The VLB-67 Beacon is a sealed unit. Where any item is fitted into the base of the beacon extreme

care should be taken to ensure the sealed integrity of the beacon is maintained.

SA Unit

SAP Unit

Brown

+12 Volts

Battery positive

Battery positive

Blue

0 Volts

Battery negative

Battery negative

Green

Sync

Do not connect to battery negative

unless using advanced sync functions

N/A

White

Solar

Power

N/A

For connecting to VPP-67 Solar

Power Pack

Instruction Manual VLB-67 LED Beacon © Vega Industries Ltd, July 2014

VLB-67 LED Beacon Page 12 of 52 VLB-67 V1.0.17

7.3 Mounting the VLB-67 Beacon

The base of the VLB-67 Beacon has been designed for 3 or 4 holes

mounting on a 200mm diameter PCD. The base has through holes sized

to take 316 Stainless steel M12 (1/2” UNC) bolts or rod. The mounting

holes are fitted with stainless inserts to prevent compression of the

plastic base when the fasteners are tightened.

7.3.1 Levelling the Beacon

The mounting surface needs to be level to ensure the VLB-67 has a

horizontal beam. This can be checked by placing a builder’s level on the

mounting surface then moving the level 90 degrees at a time checking

the surface is level in at least two directions. If the mounting surface is

not level take appropriate measures to ensure it is level before

permanently installing the beacon.

Alternative levelling mechanisms can be used, such as adjustable rods.

If the mounting surface cannot provide 3 or 4 holes mounting on a

200mm PCD an adapter plate would be required.

When the beacon is mounted on a floating structure (buoy), the beacon needs be level when the

buoy is floating freely in calm air and water.

7.3.2 Mounting Structure

Movement of the mounting structure needs to be constrained to a level where the VLB-67 beacon

can be visible to the intended user. This includes the sway on a fixed structure and the roll of a

buoy.

The vertical divergence of the VLB-67 beacon is 7 degrees. At ± 3.5°the intensity is at 50%, and at

± 7.0°the intensity is approximately 10% of the peak intensity

8.0 VLB-67 Factory Options

All options are factory installed and must be included in the purchase order. None of the options

can be fitted in the field after the VLB-67 beacon has been manufactured.

8.1 Hardwire Synchronization

The VLB-67-SA Stand Alone beacon comes with the hardwire sync wire included in the power

cable. Because of the nature of the self-contained beacon no external wiring is supplied with the

standard option.

The Vega hardwire sync operates as a positive to negative transition. The start of the flash

character can be delayed between 0 and 9.9 seconds should it be desirable to have a different

start time to other beacons connected to the synchronising wire.

The sync wire can provide additional control such as turning the beacon off when grounded. This

can be useful when a standby light option is required. Refer to Section 4 Clause 5.5.1.

Other beacon manufacturers may not use a negative transition signal and will not be able to

synchronise with Vega Beacons. If there is a requirement to synchronise with beacons with a

positive transition signal it may be possible to use the signal inverter module (Vega 167-600). The

VLB-67 beacon will only operate in Slave Sync mode when connected to the signal inverter

module.

Instruction Manual VLB-67 LED Beacon © Vega Industries Ltd, July 2014

VLB-67 LED Beacon Page 13 of 52 VLB-67 V1.0.17

8.2 Internal GPS Synchronization

It is necessary to take into account the power consumption of the GPS unit in any power

calculations. The GPS sync unit only operates when the beacon is programmed to run (night or

day/night). The clock is updated from the GPS satellites every 20 minutes and the typical

acquisition time is around 2 minutes. The GPS current is detailed in Appendix B

If GPS synchronisation is required for a number of beacons that are in close proximity it is possible

to fit only one GPS unit and to connect the other beacons using hardwire synchronising.

8.3 Alarm Monitor wire

The alarm monitor wire is used to provide an indication when the VLB-67 is not working. This

alarm monitors the current of the Beacon and the supply voltage.

Output is connected to ground when

No voltage or low voltage is present.

No LED current or low current is detected when the VLB-67 beacon should be on.

Alarm is being tested using Operation mode 1-5-007 (Section 4 Clause 5.6)

The monitor output operates as an electronic relay with one side connected to ground (battery

negative). A 0 to 20VDC can be applied to the alarm/monitor output. The maximum current the

monitor output can handle is 400mA DC. Do not connect to battery positive. For additional details

refer to the specification section.

8.4 Data Port

The RS232/RS485 data port can operate continuously or “on demand. The “on demand” mode

uses less power than the continuous mode. When the data port is used the additional power must

be taken into account when calculating the overall power requirement if the VLB-67.

The data port shares common circuitry with the IRDA port that is used for programming the VLB-67

from a computer. Only one data port can be used by the VLB-67 at any time. Operation of the

data ports is selectable using the Vega Remote TVIR programmer.

Details of the data port protocol and the beacon parameters available are contained in Appendix G

SECTION 3 MAINTENANCE

1.0 Maintenance Cleaning

Vega LED beacons require little to no maintenance.

Solar panels on the VLB-67 SS and LS models should be inspected and cleaned occasionally to

ensure maximum solar energy capture. Use warm soapy water to wash the outside of the beacon

and rinse off with clean water. Do not use any solvent-based cleaner.

2.0 Inspection Check

Periodically check that the beacon remains firmly secured and level, and the mounting fasteners

are still in good condition. Investigate any corrosion and take appropriate preventive action.

The Beacon can be tested by programming for the “test “mode or if daytime covering the lens

briefly to simulate night time operation. When the light is flashing check it is displaying the correct

flash character.

Remember to remove any lens cover before leaving the site.

Instruction Manual VLB-67 LED Beacon © Vega Industries Ltd, July 2014

VLB-67 LED Beacon Page 14 of 52 VLB-67 V1.0.17

3.0 Changing the Battery on Self Contained Models

Ensure the correct replacement battery is being used. This should be an EBAT-VGA-SL12-12U

available from Vega or a Vega Distributor.

It is recommended that the O-rings on the solar body seals be replaced at the same time as the

battery. The replacement battery will be shipped with 2 O-rings for the seal where the solar body is

opened. If additional O-rings are required the part number for ordering is Oring130EPDM. When

new O-rings are fitted ensure they have a coating of silicon grease before reassembly.

To change the battery on the Self Contained models of the VLB-67

Unscrew the 4 screws holding the lantern head to the solar body.

Lift off the lantern head ensuring the head seal with the two O-rings remains attached to the

lantern head.

Unplug the battery cable and solar cables from the lantern head and set the lantern head

aside.

Remove the battery and the foam packing

Fit the new charged battery as shown in the photo with the battery leads next to the solar

body vent and refit the foam packing making sure the vent is not blocked.

With the sealing ring containing the 2 O-rings attached to the lantern head reconnect the

battery and solar cables to the lantern head. Arrange the cables inside the solar body and

under the foam packing so that the cables cannot interfere with the sealing ring.

Carefully replace the lantern head onto the Solar Body keeping the lantern head as

horizontal as possible. Hold the cables and connectors in place with one hand as the

lantern head is put in place on the solar body with the other hand. Once the lantern head is

in place apply some pressure and check that it feels properly in place. If there is any doubt

about the position of the cables or connectors under the head, lift the lantern head and

repeat this step.

Reattach the lantern head using the original 4 screws. The torque value for the assembly

screws is 2.2 to 2.4Nm. Using torque above this value will cause damage and prevent the

VLB-67 Beacon from sealing properly.

Visually check the beacon from all four sides to ensure the lantern head is level relative to

the base.

The Self Contained versions of the VLB-67

LED Marine Beacon are assembled and

sealed using self-tapping fasteners into

the Glass Filled Nylon parts. This

assembly method is not designed for

frequent disassembly and reassembly of

the lantern. There should be no need to

disassemble the beacon other than to

change the battery once or twice during

the life of the product. Disassembly of the

Beacon should be kept to a minimum to

ensure the proper sealing.

SECTION 4 PROGRAMMING

1.0 Programming Methods

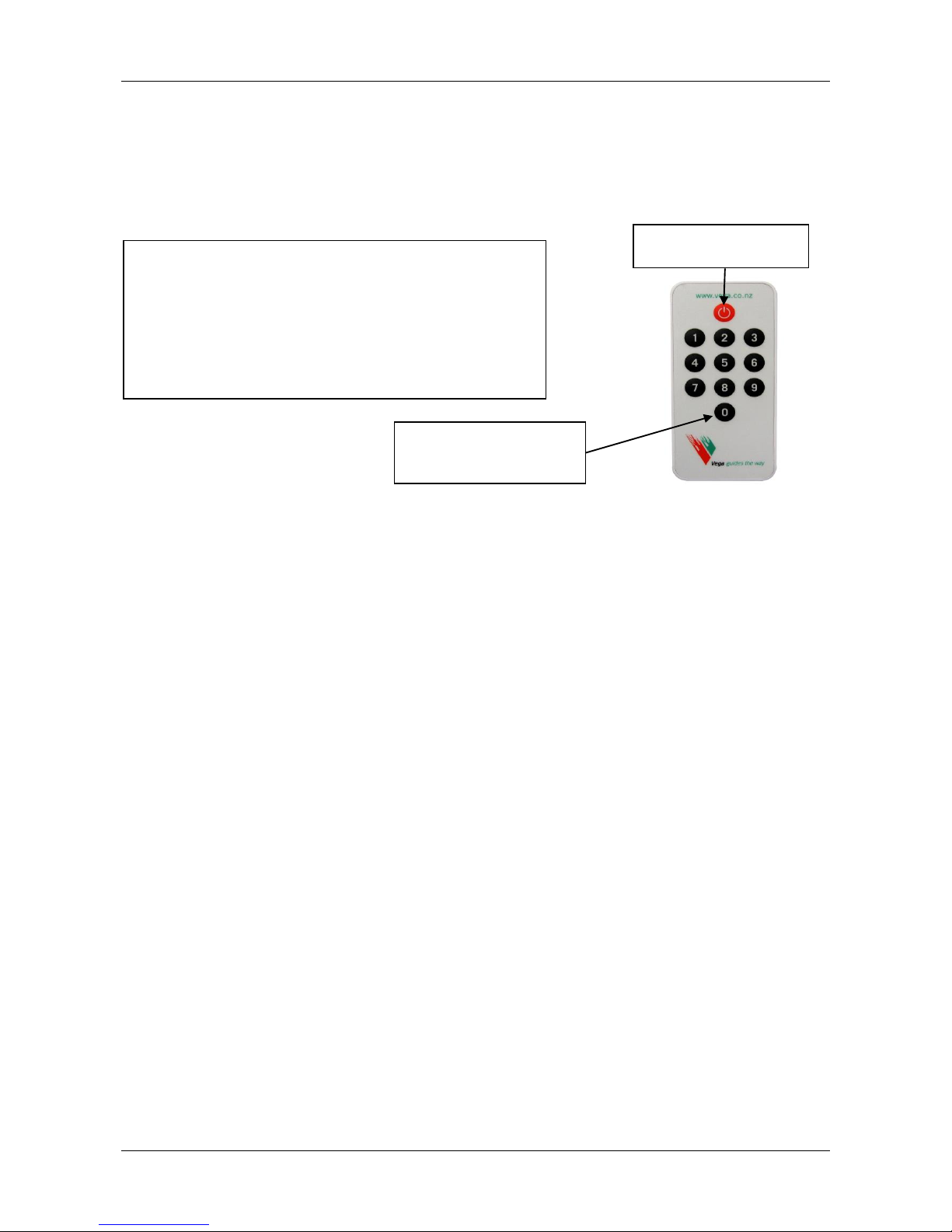

There are two methods of programming the VLB-67 Beacon.

Using the Vega remote TVIR Programmer (Remote-02)

Using a Computer with the VLB-67 Programming Kit (Prog-01)

Instruction Manual VLB-67 LED Beacon © Vega Industries Ltd, July 2014

VLB-67 LED Beacon Page 15 of 52 VLB-67 V1.0.17

Red standby key, used to

enter programming mode.

IMPORTANT

Before attempting to use the Programmer for the first

time, please pull the plastic insulating strip out of the

battery holder – you do not need to remove the battery

holder to do this.

The programmer will not work if the plastic strip is left in

place.

The Beacon will be shipped with a default setting for programming with the Remote TVIR

Programmer. The programming mode will have to be changed to allow computer programming.

1.1 Using the Vega Remote TVIR Programmer

During programming the VLB-67 the beacon will provide visual feedback by flashing as the keys

are operated on the IR programmer. On completion of a program option the beacon will provide

visual feedback by repeating the code of the programmed function by a series of flashes.

1.2 Using a Computer

Two-way IRDA communication to the Beacon is provided via a USB to IR adapter plugged into a

computer. All programming options for the VLB-67 will be displayed on the screen. The program

settings can be sent to or read from the VLB-67 Beacon. Copies of the program settings can also

be saved or recalled from memory.

For Computer programming please refer to the PROG-01 Instruction Manual. The programming

described in the rest of this manual relates to the infrared TVIR programmer only.

Computer programming of the VLB-67 is more straightforward than using the Remote TVIR

programmer as all features of the Beacon can be set at once and or can be verified by down

loading the settings from the Beacon.

The VLB-67 has two data ports, IRDA and the RS232/RS485. The RS232/RS485 port is only

fitted if requested at time of order. The VLB67 can only operate with one of the data ports at any

time. The port being used is selectable using the Programming Mode options. The IRDA data port

is required to be enabled to allow programming to occur from a Computer.

When either the IRDA or RS232/RS485 port is enabled the VLB-67 will use more power. When

programming is finished the IRDA should be turned off before the Beacon is installed in order to

reduce the power consumption.

2.0 Default Settings

The VLB-67 Beacon is delivered from the Factory with default settings. These settings are

detailed in Appendix A. If there is a need to return the light to the default settings use the option to

allow this in the in the “Operating Mode”.

3.0 Programming Syntax

All programming of uses the syntax of: OPERATION_FEATURE_VALUE

There are six OPERATION items

Programming Operation 1

Creating a Custom Character Operation 2

Numeric keypad, used to

configure the programmable

features of the light.

Instruction Manual VLB-67 LED Beacon © Vega Industries Ltd, July 2014

VLB-67 LED Beacon Page 16 of 52 VLB-67 V1.0.17

System Information Operation 3

Calendar Control Operation 4

Optional PIN code Operation 7

Read settings Operation 9

FEATURE items represent the features of the light such as flash character and intensity.

VALUES are the actual settings or value of the various features.

Appendix A of this manual provides a Table for the programming features of the VLB-67 Beacon.

Please take the time to become familiar with the table before continuing.

4.0 Visual Feedback when using the TVIR Programmer

The VLB-67 will provide visual feedback of the programming instructions it receives from the TVIR

programmer. It is important to understand the feedback that is provided to ensure the light will be

programmed correctly.

Programmer Keys

Light response

Enter Programming Mode

By pressing red standby key for 5 seconds

4 quick flashes (0.1sec on 0.1sec off)

If the VLB-67 has been programmed for

Calendar or auto storage mode the flash

response will be different.

Numeric key when programming

1 flash for each key pressed

When programming code recognised

The 3 or 4 digit value code is repeated using a

series of flashes of 0.1sec on and 0.1 sec off

with a gap of 0.5 sec between each number of

the code. A zero is represented by a 2 second

on flash.

Proper termination of custom character

programming: the feedback code will be 000

When programming code is not recognised

3 quick flashes (0.1sec on 0.1sec off)

The light will remain in programming mode

waiting for a new programming instruction.

Exiting Programming mode

No programming activity for 10 Seconds

The light will give two quick flashes followed by

a short pause followed by another two quick

flashes.

If the VLB-67 has been programmed for

Calendar or auto storage mode the flash

response will be different.

After this the beacon will resume normal

operation. The light will flash its character for

16 seconds while it checks the day/night

settings. If it is daytime and the light is set to

operate at night only the light will turn off.

Instruction Manual VLB-67 LED Beacon © Vega Industries Ltd, July 2014

VLB-67 LED Beacon Page 17 of 52 VLB-67 V1.0.17

The flash sequence for entering and exiting the programming mode is adjusted if the VLB-67 has

been programmed to use Calendar or Auto Storage. This has been done in order to provide an

indication that the VLB-67 has been programmed in either of these modes. The background

power consumption of the VLB-67 will be higher if these functions are used. Flash sequence when

entering and leaving the program mode is as follows:

Action

Flash Sequence

Entering TVIR Mode Normal

4 quick flashes (0.1sec on 0.1sec off)

When Calendar or Auto Storage is being used

2 slow flashes (0.3sec on 0.3sec off)

2 quick flashes (0.1sec on 0.1sec off)

2 slow flashes (0.1sec on 0.1sec off)

Exiting TVIR Mode Normal

2 quick flashes (0.1sec on 0.1sec off)

1 gap of (0.3 sec)

2 quick flashes (0.1sec on 0.1sec off)

When Calendar or Auto Storage is being used

2 quick flashes (0.1sec on 0.1sec off)

1 gap of (0.3 sec)

2 slow flashes (0.3sec on 0.3sec off)

4.1 The VLB-67 Will Not Enter Programming Mode

If you find the VLB-67 will not enter the programming mode it will be caused by one of 4 reasons:

The battery in the TVIR Programmer is missing, or the plastic battery insulator has not been

removed, or the battery has low voltage.

There is no 12VDC supply connected to the light.

The light has been set to storage or Calendar mode and is hibernating. In this case the red

button may have to be held for 60 seconds in order for the VLB-67 to see the TVIR

Programmer. Once in programming mode the Operating or Calendar settings can be checked

or reprogrammed. Refer Clause 5.6 for the Operating Modes and Clause 5.11 for the Calendar

settings.

Beacon needs a security PIN to allow programming. Refer Clause 5.10.

4.2 Becoming Familiar with the Syntax and Flash Feedback

If you have not used the Vega TVIR Programmer before, spend some time learning how the light

will respond to the various programming actions. Make sure the light is connected to a 12VDC

supply and experiment with the following.

Enter and Exit Program mode

1. Enter program mode

Press the red standby button

for 5 seconds

The light will give 4 quick flashes to indicate it has entered programming

mode

If the VLB-67 has been programmed for Calendar or auto storage mode the

flash response will be different.

2. Exit program mode

Leave the programmer idle for

10 seconds

The light will give two quick flashes followed by a short pause followed by

another two quick flashes.

If the VLB-67 has been programmed for Calendar or auto storage mode the

flash response will be different.

After this it will resume normal operation. The light will flash its character for

16 seconds while it checks the day/night settings. If it is daytime and the

light is set to operate at night only the light will turn off.

Program a Flash Character with a flash character of Q 1s 0.4. (0.4 “on” 0.6 “off”)

To program this Flash Character find the three-digit code from Appendix K, “Flash character table

with program codes”. (Flash Q 1s 0.4 = code 602). Determine the programming Syntax from

Appendix A for the setting:

Operation =Programming =1

Feature =Flash Character =0

Value =Code =602

Instruction Manual VLB-67 LED Beacon © Vega Industries Ltd, July 2014

VLB-67 LED Beacon Page 18 of 52 VLB-67 V1.0.17

The programming sequence to enter this flash character is 10602

0. Enter programming mode

Press the red standby button

for 5 seconds

The light will give 4 quick flashes to indicate it has entered programming

mode

If the VLB-67 has been programmed for Calendar or auto storage mode the

flash response will be different.

2. Enter the programming

sequence for the flash character

(10602)

The light will flash once each time a key on the programmer is operated.

When the sequence is completed and accepted the light will repeat the value

602 in a series of flashes. Six quick flashes followed by a 0.5sec gap

followed by a 2 second flash (for a zero) followed by a 0.5 second gap

followed by two quick flashes

1. Exit programming mode

Leave the programmer idle for

10 seconds

The light will give two quick flashes followed by a short pause followed by

another two quick flashes.

If the VLB-67 has been programmed for Calendar or auto storage mode the

flash response will be different.

After this it will resume normal operation. The light will flash its character for

16 seconds while it checks the day/night settings. If it is daytime and the

light is set to operate at night only the light will turn off.

Create a programming error by attempting to enter an invalid Operation Mode code 003

Determine the programming Syntax from Appendix A for the setting:

Operation =Programming =1

Feature =Operation Mode =5

Value =Code =003

The programming sequence to enter this Operation Mode is 15003

Enter programming mode

Press the red standby button for 5 seconds

The light will give 4 quick flashes to indicate it has

entered programming mode

If the VLB-67 has been programmed for Calendar or auto

storage mode the flash response will be different.

Enter the programming sequence for the

Operation Mode (15003)

The light will flash once each time a key on the

programmer is operated.

When the sequence is completed the value will be

rejected and an error indicated by 3 quick flashes.

The beacon will then return to programming mode and is

ready for a new instruction.

Exit programming mode

Leave the programmer idle for 10 seconds

The light will give two quick flashes followed by a short

pause followed by another two quick flashes.

If the VLB-67 has been programmed for Calendar or auto

storage mode the flash response will be different.

After this it will resume normal operation. The light will

flash its character for 16 to 20 seconds while it checks

the day/night settings. If it is daytime and the light is set

to operate at night only the light will turn off.

Instruction Manual VLB-67 LED Beacon © Vega Industries Ltd, July 2014

VLB-67 LED Beacon Page 19 of 52 VLB-67 V1.0.17

Read System Information

To read the current level of the battery or 12VDC supply, determine the Syntax from Appendix A:

Operation =System Checks =3

Feature =Battery Voltage =1

The programming sequence to get the information is 31

1. Enter programming mode

Press the red standby button for 5 seconds

The light will give 4 quick flashes to indicate it has

entered programming mode

If the VLB-67 has been programmed for Calendar or auto

storage mode the flash response will be different.

2. Enter the programming sequence for the

information (31)

The light will flash once each time a key on the

programmer is operated.

When the sequence is completed and accepted the light

will provide the voltage level in a series of flashes

(13.2VDC). One quick flash followed by a 0.5sec gap

followed by 3 quick flashes followed by a 0.5 second gap

followed by two quick flashes.

3. Exit programming mode

Leave the programmer idle for 10 seconds

The light will give two quick flashes followed by a short

pause followed by another two quick flashes.

If the VLB-67 has been programmed for Calendar or auto

storage mode the flash response will be different.

After this it will resume normal operation. The light will

flash its character for 16 to 20 seconds while it checks

the day/night settings. If it is daytime and the light is set

to operate at night only the light will turn off.

4.3 Deciding what Settings are required

Appendix D contains tables for noting the program settings of the VLB-67.

As the VLB-67 is delivered from the factory with default settings and it is only necessary to

program the settings that need to be changed. The “Read Settings” feature can be used to note

the values already programmed.

Once the required settings are known use the second table in Appendix D to note the correct

syntax and programming code from programming tables in Appendix A.

4.3.1 Programming or Reading Multiple Settings

Each feature can be programmed one at a time as done in the examples given in Clause 4, by

entering and exiting the program mode each time a feature is programmed. However this can be

extremely time consuming to enter multiple settings as it is necessary to wait for the VLB-67 to

flash its response and return to normal operation before entering the programming mode again.

To avoid this difficulty the various settings can be programmed sequentially. Once the VLB-67 has

accepted a program sequence and has flashed back the value code, the next program sequence

can be entered. If there is a delay of more than 10 seconds after the confirmation flashes before

entering the next program sequence the VLB-67 will exit the program mode.

The use of the table in Appendix D will allow all the programming sequences to be pre determined

and allow for a quick entry of the program settings without the need to exit the programming mode.

5.0 Programming Features

(Refer to Appendix A for the full list).

5.1 Flash Character

Vega lights are pre-programmed with 246 standard characters represented by a 3-digit code XYY.

The first digit of the code represents a flash type such as 1YY for Isophase characters. If flash

characters are required that are not included in the standard set these can be loaded as a custom

Instruction Manual VLB-67 LED Beacon © Vega Industries Ltd, July 2014

VLB-67 LED Beacon Page 20 of 52 VLB-67 V1.0.17

set if advised to Vega at the time of order. These would then be available for programming under

Custom character type 9YY.

Operation =Program (or read) =1 (or 9)

Feature =Flash character =0

Value =Select from Appendix K =XYY

5.2 Custom Flash Character.

When programmed the flash character code for the custom character is 999.

To program the custom character the details of the on and off periods of the flash character has to

be recorded.

The programming a custom character has its own Syntax and this needs to be followed correctly to

be able to program the character successfully.

Operation =Custom Character =2

Value =Code for the character

The code is entered in a series of 3 digit values representing an on period or off period. Each 3digit value is a multiple of 0.05 seconds. The 3-digit code for a 1 second on or off period would be

020 (20 multiplied by 0.05 seconds is 1 second).

The following restrictions apply:

The minimum period that can be programmed is 0.1 second or the code of 002.

The maximum period that can be programmed is 12.75 seconds or the code of 255. For

longer periods than 12.75 seconds an ADD code can be entered

There are two special codes used as part of the custom character programming

The ADD code to get on or off periods greater than 12.75 seconds = 001

The termination code when the programming of the custom character is finished = 000

Appendix C provides a work sheet, and an example, for programming a Custom Character

If an error occurs when entering a custom character the VLB-67 will flash the error code of 3 quick

flashes.

Programming a custom character creates a flash character with code 999. To get the VLB-67 to

use the custom character the value of 999 must be entered as the flash character.

5.3 Day/Night Use of the Light

The VLB-67 is capable of operation at night only or both day and night. The default setting when

the beacon is shipped is to operate at night only.

How the VLB-67 transitions from day to night mode and vice versa is determined by the

programmed day and night Lux levels. There are 12 different day/night transition light levels

allowing for a shorter or longer night.

Operation =Program (or read) =1 (or 9)

Feature =Day/Night Control =4

Value =Select from Appendix A =XYY

The first digit of the Day/Night Control value programs Day or Day/Night operation.

0YY allows night time operation only

1YY allows day and night operation

The YY digits of the Day/Night Control Value determine when the Day/Night transition occurs. The

Lux levels of the 12 settings are detailed in Appendix A. The accuracy of the light sensor is ±10%.

5.4 Intensity Settings

A different effective intensity can be programmed for both day and night operation. By having

different intensity settings the lights can be dimmed during the night. The programmable effective

intensity settings for the VLB-67 are provided in Appendix B.

Instruction Manual VLB-67 LED Beacon © Vega Industries Ltd, July 2014

VLB-67 LED Beacon Page 21 of 52 VLB-67 V1.0.17

It is the effective intensity of the VLB-67 that is programmed. The peak intensity is controlled

automatically according to the flash character (Schmidt-Clausen correction) to maintain the

required effective intensity.

Operation =Program (or read) =1 (or 9)

Feature =Intensity =1 for night intensity, 2 for day intensity

Value =Select from Appendix B =XXX or XXXX

5.5 Synchronising Options

The synchronisation options available are as follows:

Product

Hard wired

GPS

VLB-67 Self Contained LED

beacon

Factory Option

Internal GPS option or

External GPS using Vega VSU-29 If sync

wire available on beacon

VLB-67 Stand Alone beacon

Yes

Internal GPS option or

External GPS using Vega VSU29 If sync

wire available on beacon

For Vega LED products the sync pulse has a positive to negative transition.

The sync pulse will occur at the start of the flash character. Where the lights connected are all

masters the first light to send a sync pulse will control the other lights.

Each light can be set to be a sync master or sync slave. As a slave the VLB-67 will not operate

unless receiving sync pulses, however the slave will still generate a sync pulse when operating.

In slave mode the VLB-67 will operate on the basis of the sync pulses received and will stop

operating after a programmed number of flash cycles after the sync pulse is lost.

Operation =Program (or read) =1 (or 9)

Feature =Synchronisation =3

Value =XYY (999 disables synchronisation)

X determines if the light is a master or slave unit.

0YY Master

1YY Slave

YY allows for the start of the flash character to be delayed from 0.0 seconds to 9.9 seconds in

0.1second increments. For example YY=25 would provide a delay of 2.5 seconds.

Where an internal GPS unit is used the flash character will always synchronise to the GPS time

pulse. The GPS synchronisation will not be accurate until the GPS has acquired a valid time

signal. When using GPS Synchronising the VLB-67 must be set for Sync Master (0YY)

When an external GPS sync unit is used, such as the VSU-29, refer to the manual for this device.

5.5.1 Additional Sync Options

To program a slave VLB-67 beacon unit to keep running for a number of flash cycles after the loss

of the master sync pulse.

Operation =Program (or read) =1 (or 9)

Feature =Flash count on Loss of Sync =7

Value =0YY where YY is the number of

flashes (999 = never stops flashing)

To program the VLB-67 beacon to use the sync wire to turn the beacon off when the sync wire is

grounded.

Operation =Program (or read) =1 (or 9)

Feature =Flash count on Loss of Sync =7

Value =998

Instruction Manual VLB-67 LED Beacon © Vega Industries Ltd, July 2014

VLB-67 LED Beacon Page 22 of 52 VLB-67 V1.0.17

5.6 Operation Mode

The Operation Mode provides control of how the VLB-67 will operate.

Normal (000) Allows General Operation with no advanced options

Storage (009) Allows Operation in low power mode (Asleep). A TVIR programmer

is required to put the VLB-67 in and out of this mode. The VLB-67

self-contained units are shipped from the factory in Storage mode in

order to preserve the battery charge. Storage mode should always

be used when storing the self-contained beacons in a place where

they are likely to see daylight.

Auto Leave Storage Allows the VLB-67 to automatically revert from “Storage” to “Normal”

after the beacon sees daylight for a predetermined period. This

allows the VLB-67 to be programmed, put in storage mode, then

automatically return to normal operation without the need to use a

TVIR programmer.

Auto Storage Allows the VLB-67 to automatically enter “Storage “ mode if daylight

is not seen for 24hours. The beacon reverts back to “Normal” in the

same manner as “Auto Leave Storage”. This allows the beacon to

be stored and redeployed without the need to use the TVIR

programmer.

Test (007) Allows the testing of the Alarm/Monitor option on the VLB-67

Reset (999) Allows the Beacon to be reset to the factory default settings. The

calendar “on/off” dates are not altered during the reset.

To change the mode from Storage to Normal the red standby key on the TVIR programmer must

be held down for the time necessary for the VLB-67 to recognise the programmer. This could take

up to 1 minute. Once in programming mode the Operation Mode of the light can be changed to

Normal operation by pressing 15000.

Operation =Program (or read) =1 (or 9)

Feature =Operation Mode =5

Value =YYY where 000 is normal mode.

(Refer to Appendix A for other codes)

5.6.1 Auto Leave Storage

Operation =Program (or read) =1 (or 9)

Feature =Operation Mode =5

Value =1N9

N determines how long the VLB-67 has to see daylight before switching form “Storage” to “Normal”

mode. N can be set from 0 to 9. Each increment increases the time the VLB-67 has to see

daylight before switching by 10 minutes.

N=0 Switch time is 2 minutes of daylight

N=1 Switch time is 12 minutes of daylight

N=3 Switch time is 22 minutes of daylight

Etc

Once the Auto Leave Storage mode is programmed the VLB-67 must see 2 minute of darkness

before the mode is activated.

5.6.2 Auto Storage

Operation =Program (or read) =1 (or 9)

Feature =Operation Mode =5

Value =2NY

The VLB-67 will go into storage mode when daylight is not seen for 24hours.

N determines how long the VLB-67 has to see daylight before switching form “Storage” to “Normal”

mode. N can be set from 0 to 9. Each increment increases the time the VLB-67 has to see

daylight before switching by 10 minutes.

Instruction Manual VLB-67 LED Beacon © Vega Industries Ltd, July 2014

VLB-67 LED Beacon Page 23 of 52 VLB-67 V1.0.17

N=0 Switch time is 2 minutes of daylight

N=1 Switch time is 12 minutes of daylight

N=3 Switch time is 22 minutes of daylight

etc.

Y determines how the VLB will activate the Auto Store mode.

Y=0 VLB-67 will turn off when no daylight seen for 24 hours

Y=9 VLB-67 goes immediately to Storage mode. After the beacon sees 1

minute of darkness it remains in Storage and reverts to Y=0.

5.7 Programming Mode

Programming Mode controls the operation of the IRDA and RS232/RS485 data ports. Only one of

the ports can be used at any time. When in use the background power consumption of the VLB-67

will be higher and this must be taken into account when calculating the power usage of the

beacon.

The IRDA port is used for Computer programming of the VLB-67. To begin using a Computer for

programming the IRDA port will need to be turned on using the TVIR remote programmer.

Information on the IRDA operation is provided in the Supplementary Programming manual (PROG-

01). Remember to turn the IRDA port off before the VLB-67 is installed to reduce the background

power consumption of the beacon.

Monitoring using the IRDA or RS232/RS485 port can be continuous or on demand when data is

requested by an external device. The on demand option will use less power.

Protocol for the RS232/RS485 port is provided in Appendix G

Operation =Program (or read) =1 (or 9)

Feature =Operation Mode =6

Value =000 has both IRDA and RS232 port disabled.

See Appendix A for other settings

5.8 Battery Thresholds

The VLB-67 has programmable battery threshold settings designed to protect a battery from

damage by being over discharged. If the low threshold is reached the beacon will turn off until

the battery voltage is above the high voltage threshold. Where no batteries are used the low

voltage threshold can be disabled.

Operation =Program (or read) =1 (or 9)

Feature =Operation Mode =8 Low battery threshold (9 High battery threshold)

Value =YYY in tenths of Volts

The value range for the Low Threshold is 000 to 119 (999 disables the Low voltage threshold).

The value range for the High Threshold is 080 to 138 (999 sets the default setting 12.8VDC).

Take care in setting the high threshold to ensure the voltage of the battery will reach this voltage

during charging. If the high threshold is set too high, the light may not resume operation after a

low voltage threshold shutdown. Disconnecting and reconnecting the battery or putting the light

into TVIR programming mode will reset the high voltage threshold restart.

5.9 System Checks

The VLB-67 beacon contains details of manufacture including calibration details, firmware version,

and LED type used. This information is useful should there either be a problem with the VLB-67 or

where it is necessary to locate the correct manual for the serial number of the beacon.

The supply voltage to the VLB-67 can also be read as a quick means of checking battery voltage.

Operation =Read Only =3

Feature =Operation Mode =1 for battery voltage, (see Appendix A for others)

Value =Series of flashes providing the requested value.

Instruction Manual VLB-67 LED Beacon © Vega Industries Ltd, July 2014

VLB-67 LED Beacon Page 24 of 52 VLB-67 V1.0.17

All information is in numeric format and represented by a series of flashes 0.1 sec on, 0.1 sec off,

separated by 0.5 sec gap between numbers. The Voltage level is provided in tenths of a volt.

5.10 Security PIN Number

The VLB-67 is shipped from the factory without any security protection. If there is concern about

unauthorised programming it is possible to have a 3digit PIN number for security access. Use of

the PIN code is only necessary to change settings. It is possible to read settings without using the

PIN code

For setting a Security PIN

Enter TVIR programming mode by operating the standby button for 5 seconds.

Operation =7 =PIN

Feature =1 =Set PIN

Value =XXX =PIN Code (Value 000 no PIN)

The VLB-67 will then flash back the three numbers in a series of flashes.

To change settings when a Security PIN is used.

Enter TVIR programming mode by operating the standby button for 5 seconds.

Operation =7 =PIN

Feature =7 =Check PIN

Value =XXX =PIN Code

The VLB-67 will flash back the number using a series of flashes. You can then continue onto

programming your beacon.

Note: Where a PIN has been set, and a user attempts changing any settings, an error message

will be generated and no changes will actually occur.

If you lose your PIN number, please contact Vega for further instruction.

5.11 Calendar

The VLB-67 allows the programming of 5 pairs of calendar dates where the beacon will turn off at

the first date, hibernate, and then return to “Normal” operation on the second date. Because the

Calendar operation continues when the beacon is in hibernation the background power is higher

than if the VLB-67 was in Storage mode.

The default setting for the Calendar is “disabled” and the feature must be turned “on” and the

current date and time set in order to enable the function. The VLB-67 handles the programmed on

and off dates in a sequential manner and care needs to be taken that the off periods are not

overlapped. Overlapped the off periods may result in operation that is not as expected. A setting

of 0000 will disable the ON or OFF date and all ON/OFF dates can be disabled by using Feature

50 and entering 0000.

Enter TVIR programming mode by operating the standby button for 5 seconds.

Operation =4 =Calendar

Feature =See table below

Value =See table below

Program and reading of settings are done using a different feature code.

The Calendar in the VLB-67 does not support daylight savings. All date settings are referenced to

the real time that is entered. If this is standard time then all the on and off dates must be

programmed in standard time.

The Day of the month is a number between 01 and 31. The VLB-67 does not check the days

entered against a particular month. The 31st of February for example would be seen by the VLB67 as the 3rd of March.

Instruction Manual VLB-67 LED Beacon © Vega Industries Ltd, July 2014

VLB-67 LED Beacon Page 25 of 52 VLB-67 V1.0.17

Feature

Value

Flash response from VLB-67

00 Calendar Enable/Disable

000 Disable

001 Enable

000 Disable

001 Enable

011 Enabled and Hibernating

01 Read Enable/Disable

000 Disable

001 Enable

011 Enabled and Hibernating

10 Set Year

YYYY (i.e. 2010)

YYYY (i.e. 2010)

11 Read Year

YYYY (i.e. 2010)

20 Set Month/Day/Hour/Minute

MMDDHHMM

MM is month (01 to 12)

DD is day (01 to 31)

HH is hour (00 to 23)

MM is minute (00 to 59)

Take care with day setting.

31 Feb will be 3rd of March.

MMDDHHMM

MM is month (01 to 12)

DD is day (01 to 31)

HH is hour (00 to 23)

MM is minute (00 to 59)

21 Read Month/Day/Hour/Minute

MMDDHHMM

MM is month (01 to 12)

DD is day (01 to 31)

HH is hour (00 to 23)

MM is minute (00 to 59)

30 Set 1st OFF date

MMDD (0000 Disables)

MM is month (01 to 12)

DD is day (01 to 31)

Daylight saving is not

supported by the Calendar

Feature. All dates must be

programmed relative to the

real time programmed in

Feature 10 and 20

MMDD

MM is month (01 to 12)

DD is day (01 to 31)

40 Read 1st OFF date

MMDD

MM is month (01 to 12)

DD is day (01 to 31)

31 Set 1st ON date

MMDD (0000 Disables)

MM is month (01 to 12)

DD is day (01 to 31)

MMDD

MM is month (01 to 12)

DD is day (01 to 31)

41 Read 1st ON date

MMDD

MM is month (01 to 12)

DD is day (01 to 31)

32 Set 2nd OFF date

42 Read 2nd OFF date

33 Set 2nd ON date

43 Read 2

nd

ON date

34 Set 3rd OFF date

44 Read 3rd OFF date

35 Set 3rd ON date

45 Read 3

rd

ON date

36 Set 4th OFF date

46 Read 4th OFF date

37 Set 4th ON date

47 Read 4

th

ON date

38 Set 5th OFF date

48 Read 5th OFF date

39 Set 5th ON date

49 Read 5

th

ON date

50 Clear All ON/OFF dates

0000 Disable

0000

Instruction Manual VLB-67 LED Beacon © Vega Industries Ltd, July 2014

VLB-67 LED Beacon Page 26 of 52 VLB-67 V1.0.17

User Notes

Instruction Manual VLB-67 LED Beacon © Vega Industries Ltd, July 2014

VLB-67 LED Beacon Page 27 of 52 VLB-67 V1.0.17

APPENDIX A PROGRAMMING TABLE

Operation

Feature

Value

1 = Program Mode

9 = Read Settings

0 = Flash Character

Default 601

QFL 1sec (0.3 on)

000 – Fixed character

1YY – Isophase (ISO)

2YY – Occulting (OC)

3YY – Flash (Fl)

4YY - Multiple Flash (Fl(x))

5YY - Very Quick (VQ)

6YY - Quick (Q)

7YY – Long (LF)

8YY – Morse (MO)

9YY – Custom (CCG Codes)

1 = Night Effective Intensity

Default 0025

25 candela effective

Four Digit Value – Enter value as a number 0000 to

9999.

0000 Sets minimum allowed value.

9999 sets maximum allowed value.

2 = Day Effective Intensity

Default 0025

25 candela effective

Four Digit Value – Enter value as a number 0000 to

9999.

0000 Sets minimum allowed value.

9999 sets maximum allowed value.

3 = Synchronisation

Default 000

Master sync no delay

999 – Disable Synchronisation

998 – Beacon activated by holding sync low.

Synchronization not possible since sync line used.

0YY Light in normal mode

1YY Light operates only when sync pulse present

YY=sync delay seconds (0.0 to 9.9 seconds )

4 = Day/Night Control

Default 005

Night operation

IALA recommended transition

0YY Light operates night only

1YY Light operates day and night

YY= Day/Night transition Lux Level

Night Lux. Day Lux

YY=01 40 100 shortest night

YY=02 50 150