VEGA Grieshaber KG PULS40 User Manual

Operating Instructions

VEGAPULS 42 and 44

4 … 20 mA; HART

®

compact sensor

Level and Pressure

Contents

Safety information ........................................................................ 3

Note Ex area ................................................................................ 3

Quick start

Quick start with the PC ................................................................ 4

Quick start with adjustment module MINICOM ......................... 5

1 Product description

1.1 Function ................................................................................. 7

1.2 Application features ............................................................. 9

1.3 Adjustment .......................................................................... 10

1.4 Antennas ............................................................................. 12

2 Types and versions

2.1 Survey................................................................................. 15

2.2 Configuration of measuring systems ............................... 17

3 Technical data

3.1 Technical data ..................................................................... 25

3.2 Approvals ........................................................................... 30

3.3 Dimensions ......................................................................... 31

Contents

4 Mounting and installation

4.1 General installation instructions ........................................ 34

4.2 Measurement of liquids ..................................................... 36

4.3 Measurement in standpipe (surge or bypass tube) ...... 38

4.4 False echoes ...................................................................... 48

4.5 Common installation mistakes ........................................... 50

2 VEGAPULS 42 and 44 – 4 … 20 mA

Contents

5 Electrical connection

5.1 Connection and connection cable .................................... 53

5.2 Connection of the sensor .................................................. 54

5.3 Connection of the external indicating instrument

VEGADIS 50 ....................................................................... 56

6 Setup

6.1 Adjustment methods .......................................................... 57

6.2 Adjustment with PC ............................................................ 57

6.3 Adjustment with adjustment module MINICOM ............... 75

6.4 Adjustment with HART® handheld ..................................... 82

7.2 Error codes ........................................................................ 87

7 Diagnostics

7.1 Simulation ............................................................................ 87

Safety information

Please read this manual carefully, and also take

note of country-specific installation standards

(e.g. the VDE regulations in Germany) as well

as all prevailing safety regulations and accident prevention rules.

For safety and warranty reasons, any internal

work on the instruments, apart from that involved in normal installation and electrical connection, must be carried out only by qualified

VEGA personnel.

VEGAPULS 42 and 44 – 4 … 20 mA 3

Note Ex area

Please note the approval documents (yellow

binder), and especially the included safety

data sheet.

Quick start

In the majority of applications, the radar sensor displays the distance to the product

surface immediately after the power supply is

switched on. You only have to carry out the

empty and full adjustment so that at your

required empty and full distances, 4 mA and

20 mA, respectively, are outputted.

However, it is always useful, especially under

difficult measurement conditions (process

tanks, stirrers, filling stream, vessel installations), to carry out a sensor optimisation, see

chapter "6 Setup“.

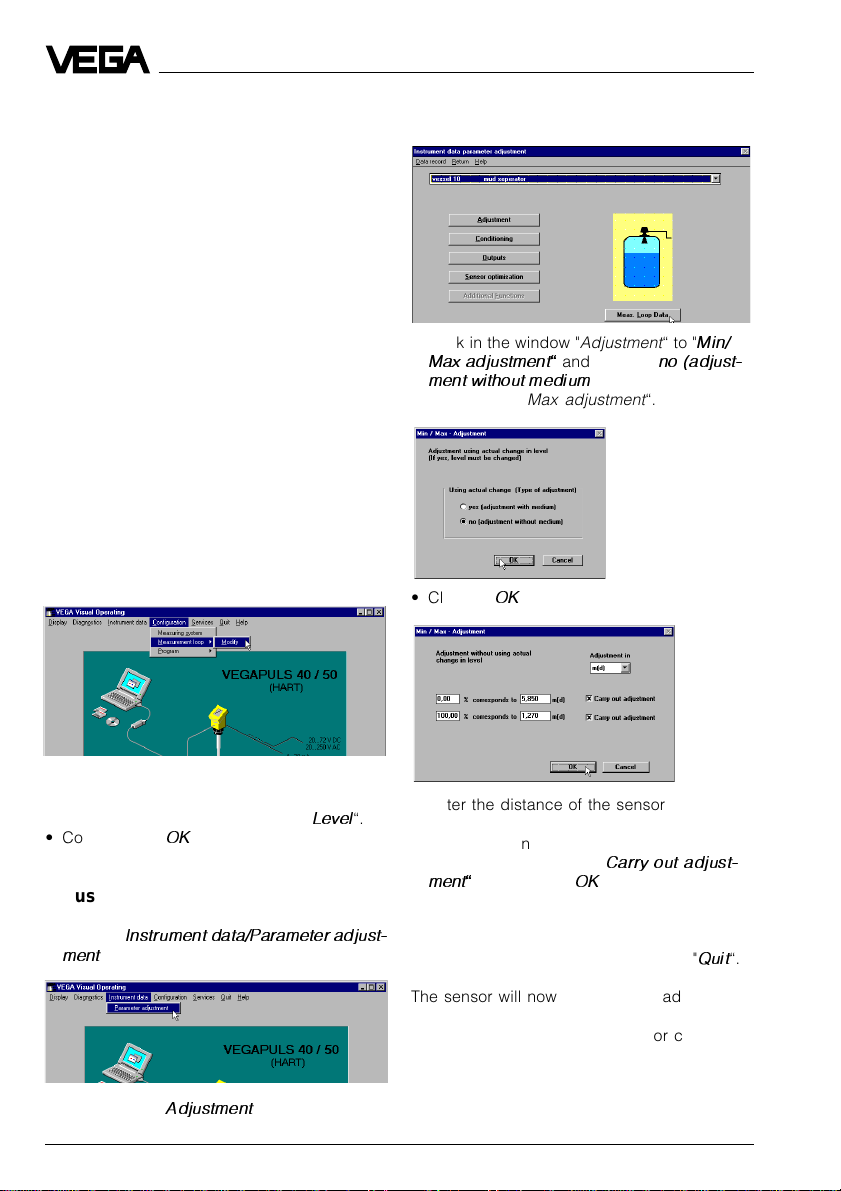

Quick start with the PC

Configuration

Start the adjustment software VVO ³2.60 with

the user level "

Planning

“.

• Click in the window "

Max adjustment and choose "

ment without medium)“ in the following

window „

Min/Max adjustment

Adjustment

“.

“ to "

no (adjust-

Quick start

Min/

• Click to …

… and enter a name for the measurement

loop.

• Choose under "

• Confirm with "OK“.

Application

“ e.g. "

Level

Adjustment

• Click to "

ment

• Then click to "

4 VEGAPULS 42 and 44 – 4 … 20 mA

Instrument data/Parameter adjust-

“.

Adjustment

“.

• Click to „OK“.

• Enter the distance of the sensor to the

“.

product surface at 0 % (empty) and at

100 % (full) in meters.

• Activate the two boxes "

ment and click to „OK“.

You are again in the window "

• Click in the window "

The sensor will now output at the adjusted

empty distance 4 mA and at the full distance

20 mA. In the example, the sensor calibrates

the span of 5.85 m to 1.27 m

to the signal range of 4 … 20 mA.

Carry out adjust-

Adjustment

Adjustment

“ to "

Quit

“.

“.

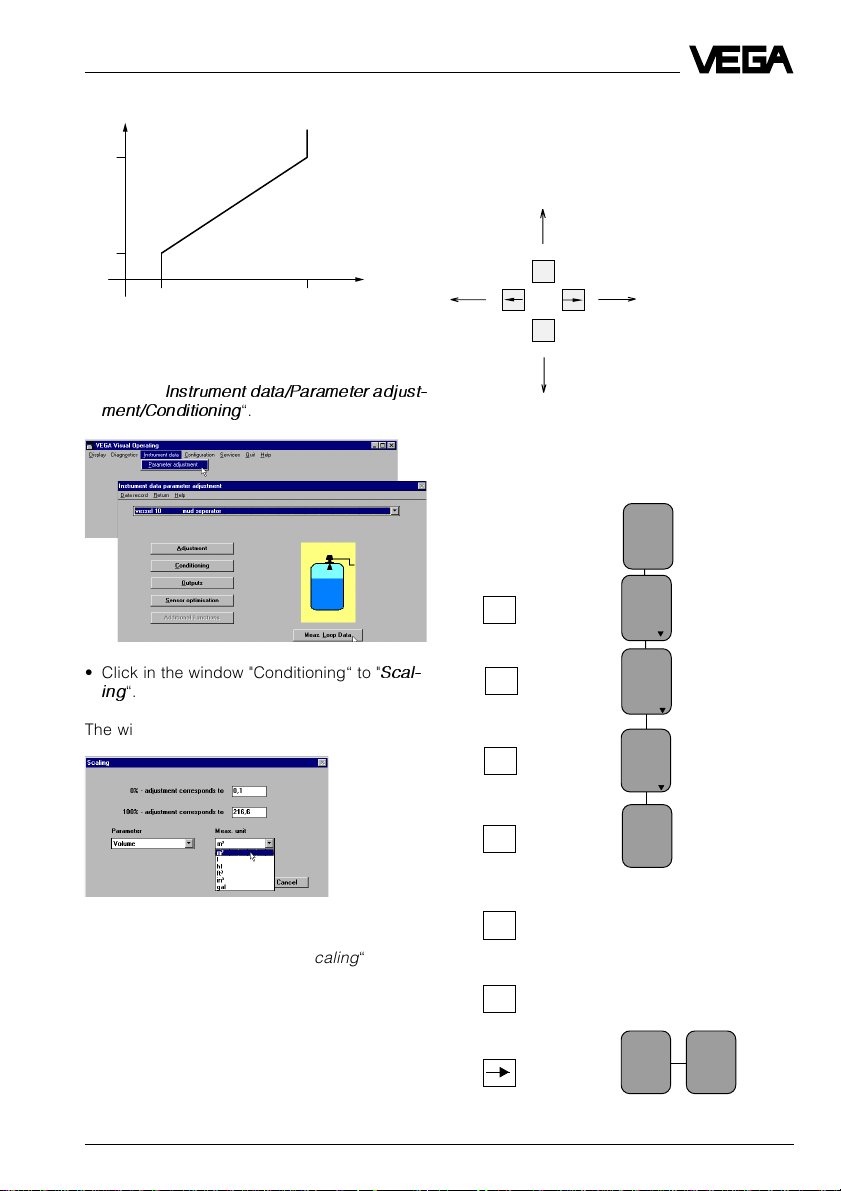

Quick start

m

5,85

1,27

mA

420

Scaling of the measured value display

• Click to "

ment/Conditioning

• Click in the window "Conditioning“ to "

ing

Instrument data/Parameter adjust-

“.

Scal-

“.

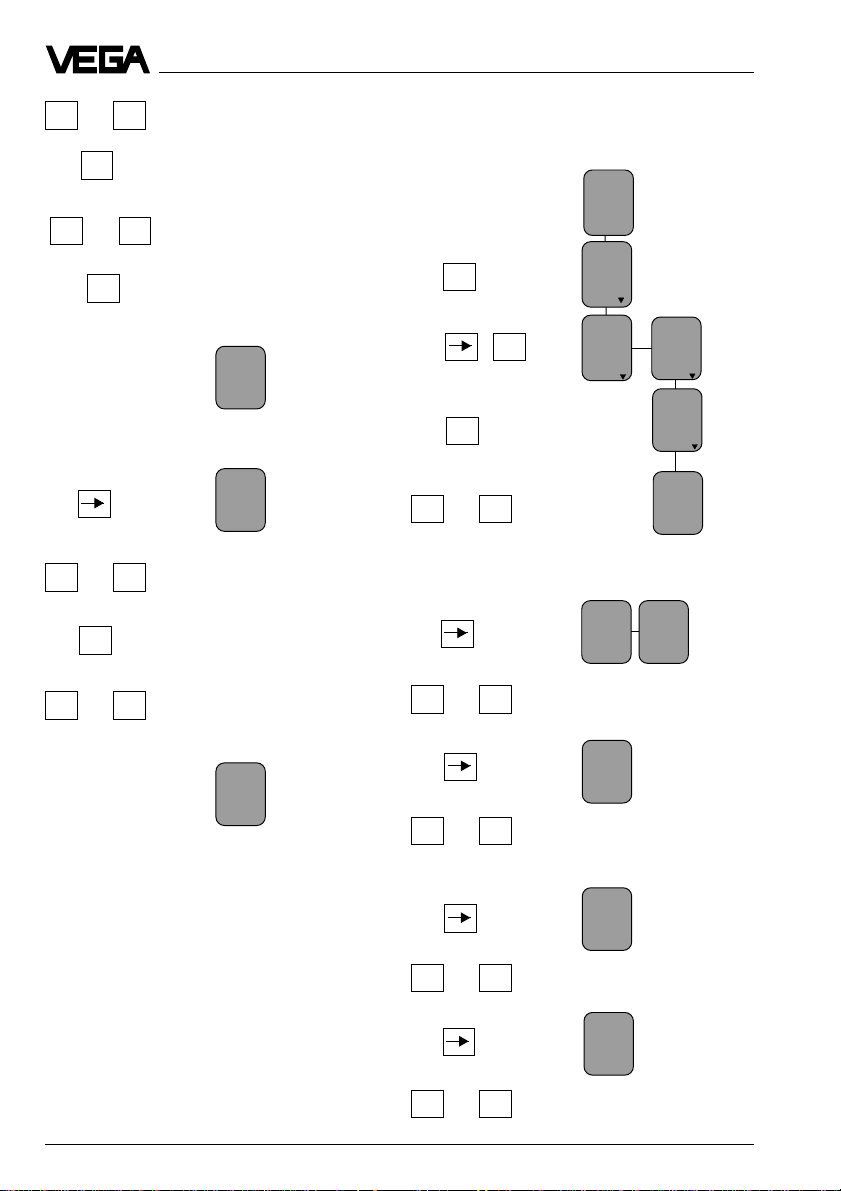

Quick start with adjustment module MINICOM

In the menu field you can move with these keys to the left, right,

top and bottom.

ESC

OK

Empty adjustment

Key Display text

Sensor

m(d)

4.700

Para-

OK

OK

meter

Adjustment

The window …

opens.

Allocate in the menu window "

Scaling

“ a

OK

OK

+

The display text flashes and

you can choose between

"feet“ and "m“.

w.out

medium

Adjustment

in

m(d)

(Min. adjustment)

physical quantity and the unit of measurement to the 0 % and 100 % values. Here you

inform the sensor, e.g. that at 0 % filling there

are still 0.1 m3 and at 100 % filling 216.6 m3 in

the vessel. The sensor display then indicates

0.1 m3 (0 %) for an empty vessel and

OK

Confirm the adjustment with

"OK“.

m(d)

0.0%

at

m (d)

XX.XXX

Adjustment

in

216.6 m3 (100 %) for a full vessel.

VEGAPULS 42 and 44 – 4 … 20 mA 5

Quick start

+ –

or

Enter 0 %.

The 0 % value is allocated to

OK

the following distance and the

distance indication flashes.

+ –

or

OK

Enter the empty distance, e.g.

5.85 m.

The value pair 0 % and 5.85 m

is written into the sensor.

Full adjustment

+ –

or

OK

+ –

or

Enter 100 %.

The 100 % value is allocated

to the following distance and

the distance indication flashes.

Enter the distance with full

vessel, e.g. 1.27 m.

0.0%

at

m (d)

5,85

100.0%

at

m (d)

XX.XXX

(Max. adjustment)

Scaling of measured value display

Key Display text

Sensor

m(d)

4.700

Para-

OK

OK

OK

+ –

or

Enter the figure for the filling at 0 %, e.g.

0001.

+ –

or

Enter the figure of the 100 %

filling, e.g. 2166 for 216.6 m

meter

Adjustment

0 %

corres

ponds

XXXX

Conditioning

Scaling

0 %

corres

ponds

100 %

corres

ponds

XXXX

XXXX

3

Deci-

100.0%

at

m (d)

1,27

+ –

or

Enter the position of the

comma, so that 216.6 is dis-

mal

point

888.8

played.

prop.

to

Volume

+ –

or

+ –

or

6 VEGAPULS 42 and 44 – 4 … 20 mA

Choose the physical unit, e.g.

volume.

Unit

3

m

Choose the unit of measurement, e.g. m3.

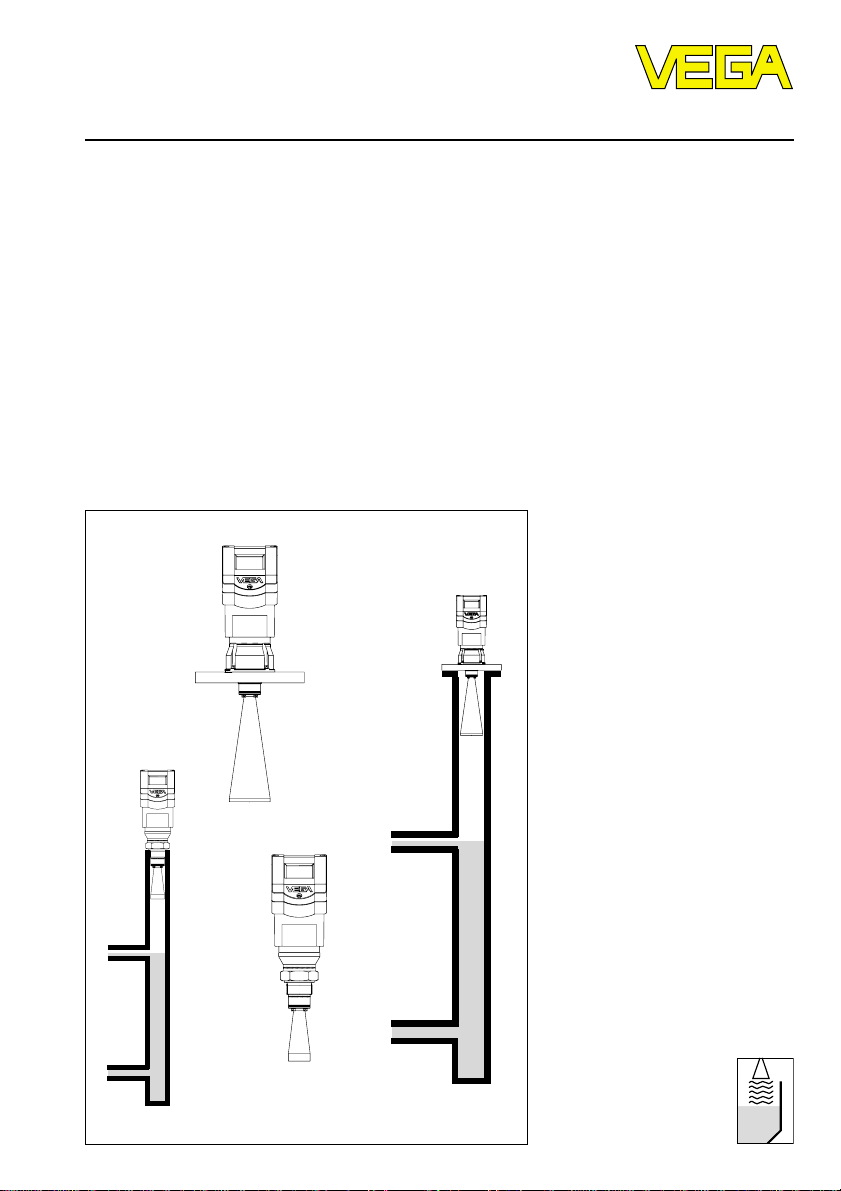

Product description

1 Product description

VEGAPULS series 40 sensors are a newly

developed generation of extremely compact

radar sensors for high resolution and accuracy. They are characterised by very good

focussing features for applications in narrow

spaces. With very modest space requirements, they were developed for measuring

distances of 0 … 10 m/20 m and are the right

choice for standard applications such as

storage vessels, reservoirs and buffer tanks

as well as process tanks.

Due to small housing dimensions and process fittings, the compact sensors are an

obstrusive, and most of all, very reasonable

solution for your level measurement applications. With the integrated display they enable

high precision level measurements and can

be used for applications in which the advantages of non-contact measurement could

never before be realized.

VEGAPULS 40 radar sensors are perfectly

suited to two-wire technology. The supply

voltage and the output signal are transmitted

via one two-wire cable. As output or measuring signal, the instruments produce an analogue 4 … 20 mA output signal.

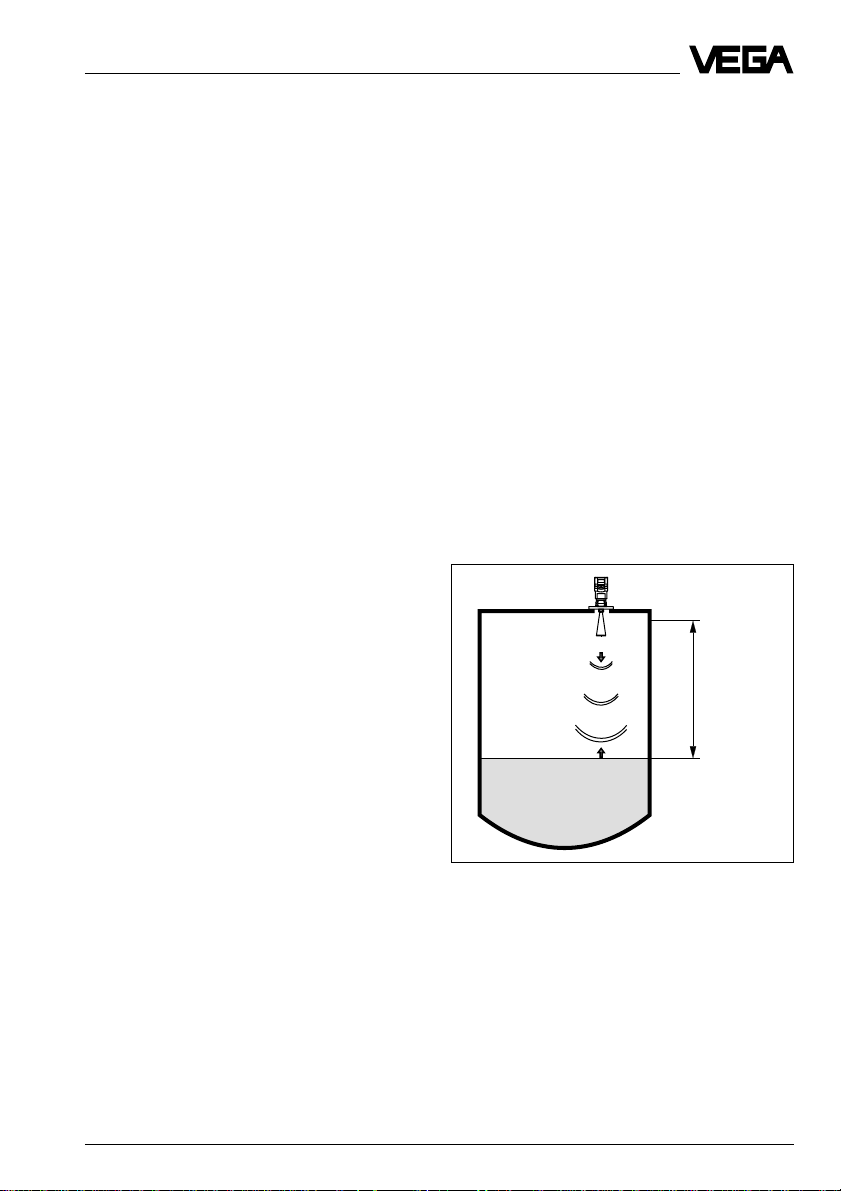

1.1 Function

Radio detecting and ranging: Radar.

VEGAPULS radar sensors are used for noncontact, continuous distance measurement.

The measured distance corresponds to a

filling height and is outputted as level.

Measuring principle:

emission – reflection – reception

Tiny 24 GHz radar signals are emitted from

the antenna of the radar sensor as short

pulses. The radar impulses reflected by the

sensor environment and the product are

received by the antenna as radar echoes.

The running period of the radar impulses

from emission to reception is proportional to

the distance and hence to the level.

Meas.

distance

emission - reflection - reception

VEGAPULS 42 and 44 – 4 … 20 mA 7

1 ns

278 ns

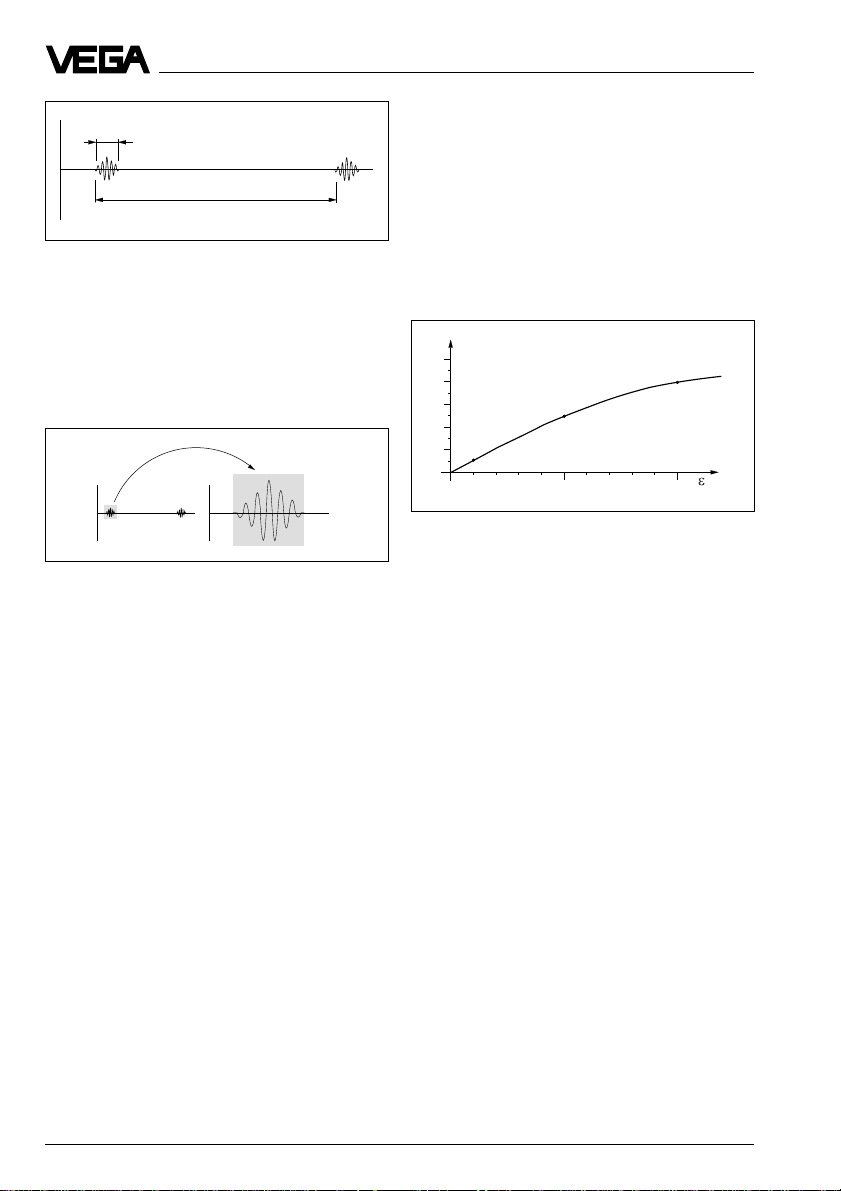

Pulse sequence

VEGAPULS radar sensors can accomplish

this through a special time transformation

procedure which spreads out the more than

3.6 million echo images per second in a slowmotion picture, then freezes and processes

them.

t

t

Product description

The radar impulses are emitted by the antenna system as pulse packages with a

pulse duration of 1 ns and pulse intervals of

278 ns; this corresponds to a pulse package

frequency of 3.6 MHz. In the impulse intervals, the antenna system operates as receiver. Signal running periods of less than

one billionth of a second must be processed

and the echo image must be evaluated in a

fraction of a second.

%

50

40

30

20

10

5 %

5

0

2

0

25 %

4 6 8 12 14 16 18

10

Reflected radar power dependent on the dielectric

constant of the measured product

40 %

20

r

Time transformation

Hence, it is possible for the VEGAPULS 40

radar sensors to process the slow-motion

pictures of the sensor environment precisely

and in detail in cycles of 0.5 to 1 second

without using time-consuming frequency

analysis (e.g. FMCW, required by other radar

techniques).

Virtually all products can be measured

Radar signals display physical properties

similar to those of visible light. According to

the quantum theory, they propagate through

empty space. Hence, they are not dependent on a conductive medium (as e.g. sound

waves in air), and spread out like light at the

speed of light. Radar signals react to two

basic electrical properties:

- the electrical conductivity of a substance

- the dielectric constant of a substance.

All products which are electrically conductive

reflect radar signals very well. Even slightly

conductive products ensure a sufficient reflection for a reliable measurement.

All products with a dielectric constant er of

more than 2.0 reflect radar impulses sufficiently (note: air has a dielectric constant er of

1).

The signal reflection increases with the conductivity or with the dielectric constant of the

product. Hence, virtually all products can be

measured.

With standard flanges of DN 50 to DN 250,

ANSI 2“ to ANSI 10“ or G 11/2 A and 11/2“ NPT,

the sensor antenna systems can be adapted

to the various measured products and measurement environments.

The high-quality materials can also withstand

extreme chemical and physical conditions.

The sensors deliver a stable, reproducible

analogue or digital level signal with reliability

and precision, and have a long useful life.

8 VEGAPULS 42 and 44 – 4 … 20 mA

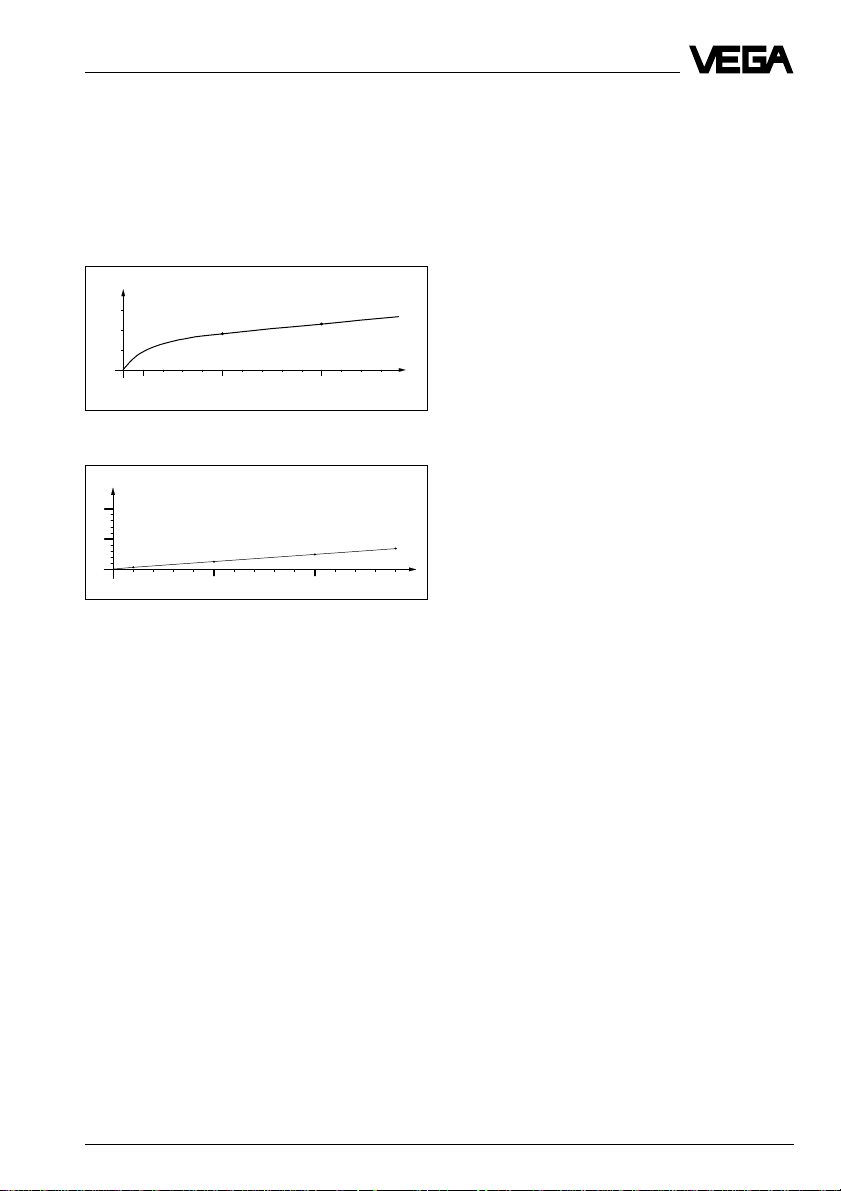

Product description

Continuous and reliable

Unaffected by temperature, pressure and

individual gas atmospheres, VEGAPULS

radar sensors are used for quick and reliable

continuous level measurement of various

products.

%

0,03

0,02

0,01

0

100 500 1000 1300 ˚C

0

0,018 %

Temperature influence: Temperature error absolutely

zero (e.g. at 500°C 0.018 %)

%

10

5

0,29 %

0

10

0

1,44 %

20 30 40 60

50

Pressure influence: Error with pressure increase very

low (e.g. at 50 bar 1.44 %)

VEGAPULS 40 sensors enable level measurement with radar in facilities where previously, due to high cost, it was completely out

of the question.

0,023 %

2,8 %

70 80 90 110 120 130 140

100

3,89 %

bar

1.2 Application features

Applications

• level measurement of liquids

• measurement also in vacuum

• all slightly conductive materials and all

substances with a dielectric constant > 2.0

can be measured

• measuring range 0 … 10 m (type 42).

measuring range 0 … 20 m (type 44).

Two-wire technology

• supply and output signal on one two-wire

cable (Loop powered)

• 4 … 20 mA output signal or HART® output

signal.

Rugged and abrasion proof

• non-contact

• high-resistance materials

Exact and reliable

• accuracy 0.05 %.

• resolution 1 mm.

• unaffected by noise, vapours, dusts, gas

compositions and inert gas stratification

• unaffected by varying density and temperature of the medium

• measurement in pressures up to 40 bar

and product temperatures up to 200°C

Communicative

• integrated display of measured value

• optional display module separate from

sensor

• adjustment with detachable adjustment

module, pluggable in the sensor or in the

external display

• adjustment from the PLC level with the PC

• adjustment with HART® handheld

Approvals

• CENELEC, ATEX, PTB, FM, CSA, ABS,

LRS, GL, LR, FCC.

VEGAPULS 42 and 44 – 4 … 20 mA 9

Product description

1.3 Adjustment

Each measuring situation is unique. For that

reason, every radar sensor needs some

basic information on the application and the

environment, e.g. which level means "empty“

and which level "full“. Beside this "empty and

full adjustment“, many other settings and

adjustments are possible with VEGAPULS

radar sensors.

The adjustment and parameter setting of

radar sensors are carried out with

- the PC

- the detachable adjustment module MINICOM

- the HART

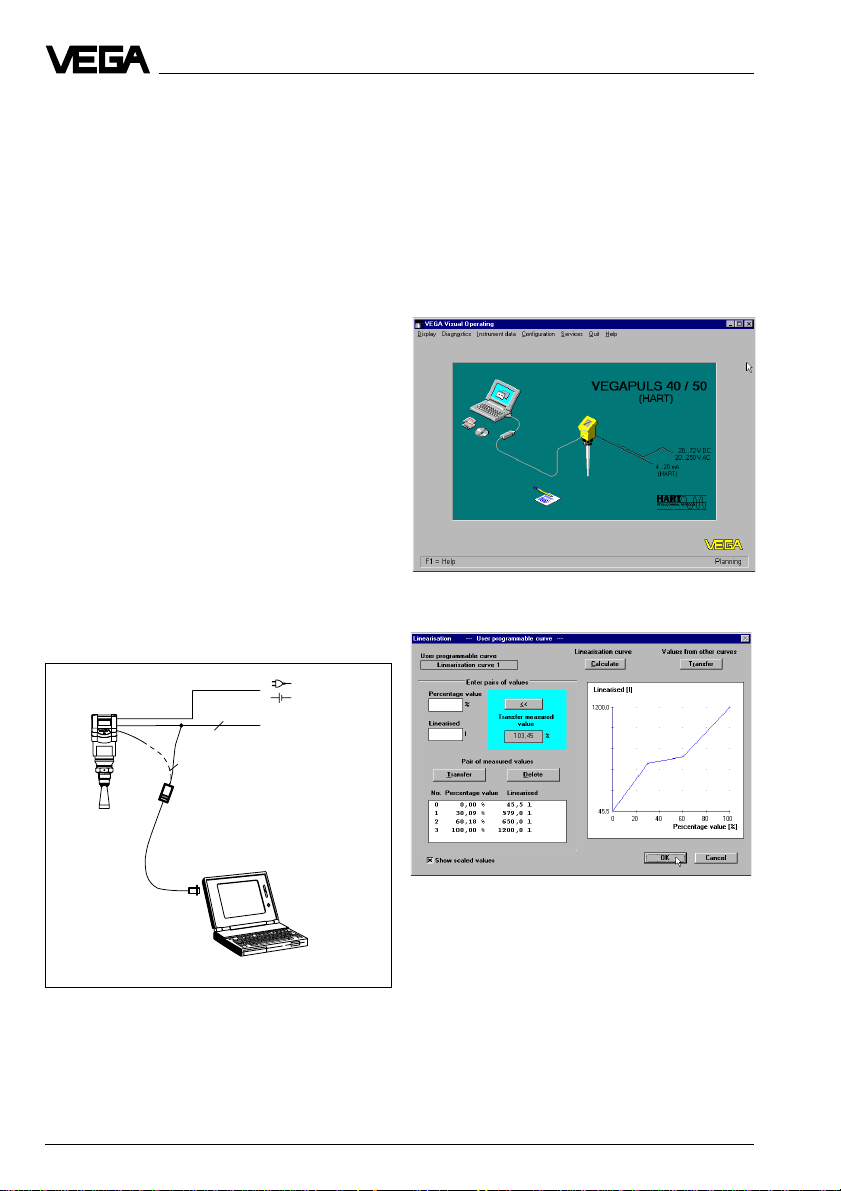

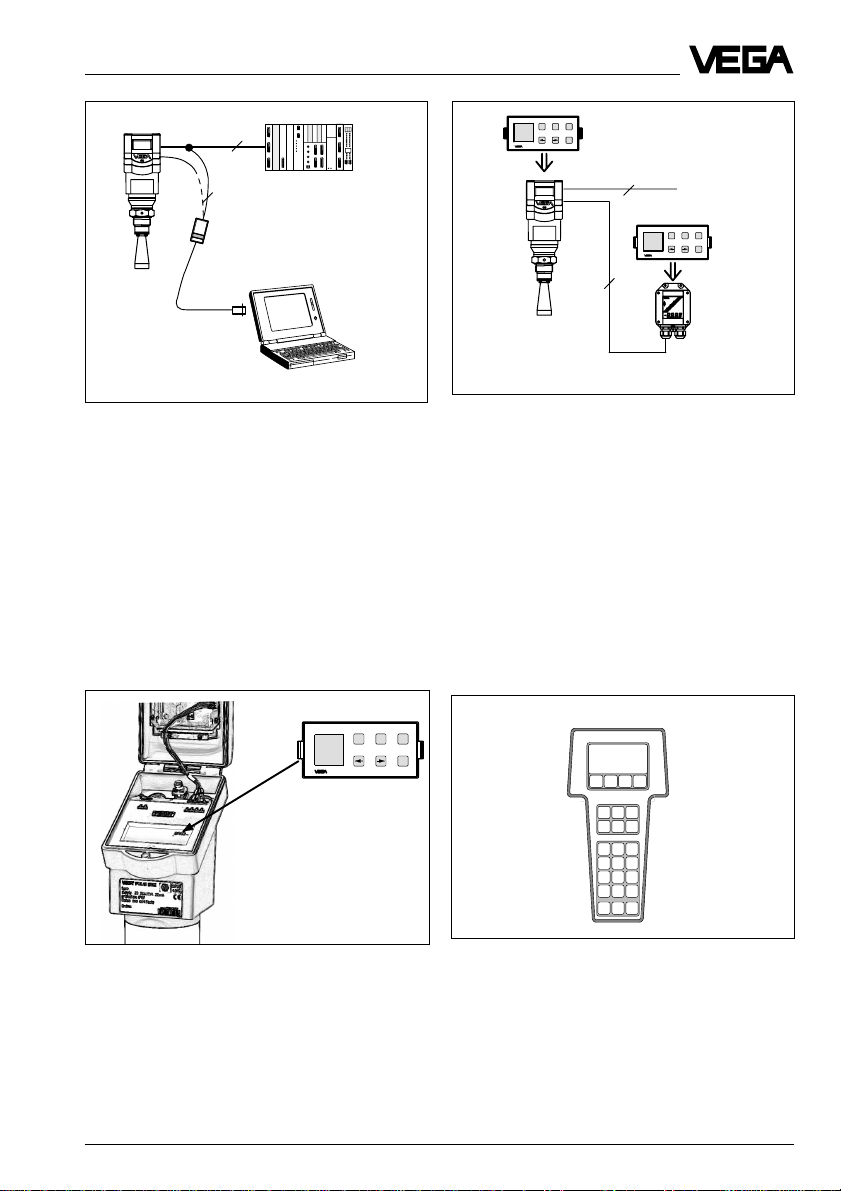

Adjustment with PC

The setup and adjustment of the radar sensors is generally done on the PC with the

adjustment program VEGA Visual Operating

(VVO) under Windows®. The program leads

quickly through the adjustment and parameter setting by means of pictures, graphics

and process visualisations.

®-

handheld

The PC can be connected at any location in

the system or on the signal cable. It is connected by means of the two-wire PC interface

converter VEGACONNECT 2 to the sensor or

the signal cable. The adjustment and parameter data can be saved with the adjustment

software on the PC and can be protected by

passwords. On request, the adjustments can

be quickly transferred to other sensors.

The adjustment program recognises the sensor type

2

4 ... 20 mA

2

Visualised input of a vessel linearisation curve

Adjustment with the PC on the analogue 4 … 20 mA

signal and supply cable or directly on the sensor

(four-wire sensor)

10 VEGAPULS 42 and 44 – 4 … 20 mA

Product description

ESC

+

-

Tank 1

m (d)

12.345

2

OK

PLC

2

Adjustment with the PC on the 4 … 20 mA signal and

supply cable or directly on the sensor (figure: a twowire sensor)

Adjustment with adjustment module

MINICOM

With the small (3.2 cm x 6.7 cm) 6-key adjustment module with display, the adjustment

can be carried out in clear text dialogue. The

adjustment module can be plugged into the

radar sensor or into the optional, external

indicating instrument.

Tank 1

m (d)

12.345

ESC

+

-

OK

2

4 ... 20 mA

ESC

+

-

Tank 1

m (d)

12.345

OK

4

Adjustment with detachable adjustment module. The

adjustment module can be plugged into the radar

sensor or the external indicating instrument VEGADIS

50.

Adjustment with HART® handheld

Series 40 with 4 … 20 mA output signal can

also be adjusted with the HART® handheld.

A special DDD (Data Device Description) is

not necessary, so that the sensors can be

adjusted with the HART® standard menus of

the handheld.

HART Communicator

Detachable adjustment module MINICOM

HART® handheld

Unauthorised sensor adjustments can be

prevented by removing the adjustment module.

VEGAPULS 42 and 44 – 4 … 20 mA 11

Product description

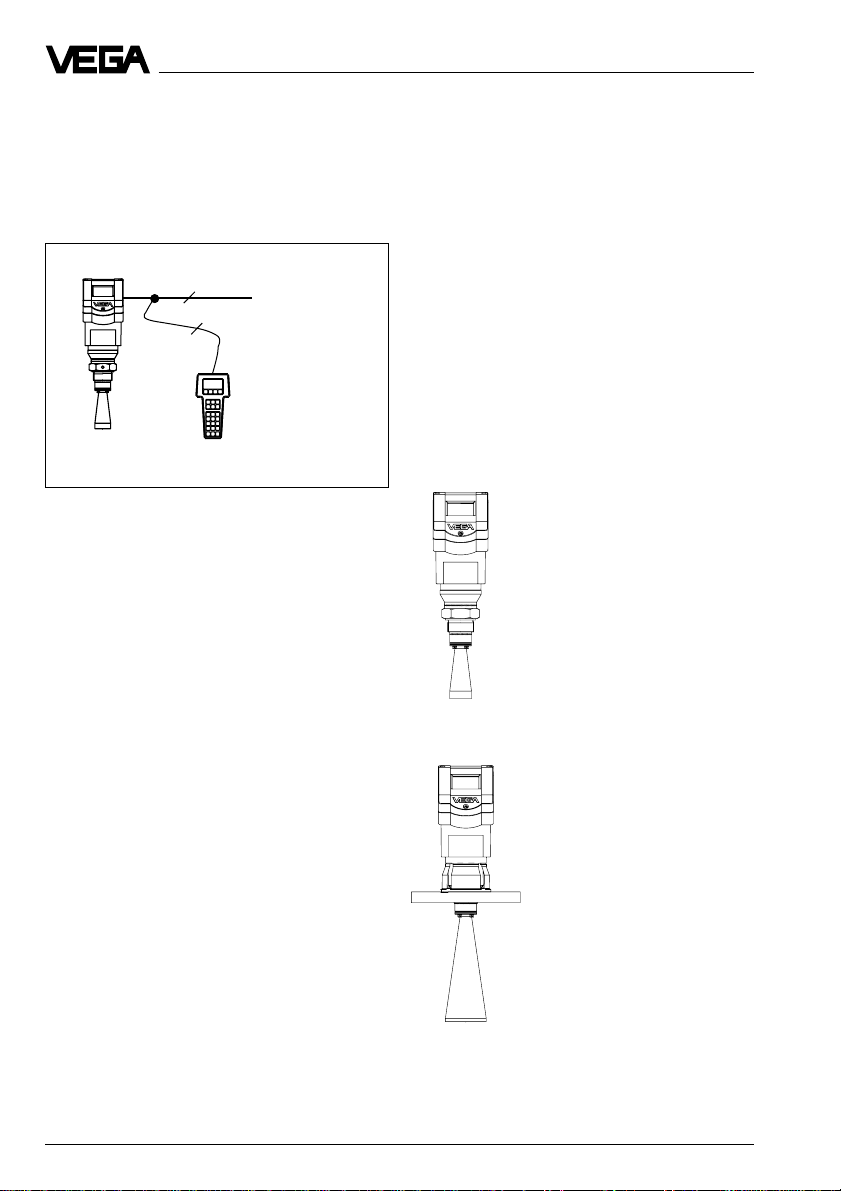

For adjustment, just connect the HART® handheld to the 4 … 20 mA output signal cable or

insert the two communication cables of the

HART® handheld into the adjustment jacks on

the sensor.

2

4 ...20 mA

2

HART® handheld on the 4 … 20 mA signal cable

1.4 Antennas

The antenna is the eye of the radar sensor.

An uninitiated observer would probably not

realise how carefully the antenna geometry

must be adapted to the physical properties

of electromagnetic fields.

The geometrical form determines focal properties and sensitivity - the same way it determines the sensitivity of a unidirectional

microphone.

Four antenna systems are available for different applications and process requirements.

Horn antennas

Horn antennas focus the

radar signals very well.

Manufactured of 1.4435

(stainless steel) or Hastelloy C22, they are very rugged, and are physically as

well as chemically, resistant.

They are suitable for pressures up to 40 bar and for

product temperatures up to

150°C. The horn diameters

determine the focussing of

the radar signals. The an-

VEGAPULS 42

tenna gain grows stronger

with increasing diameter

(40, 48, 75, 95 mm). The

antenna gain represents

the ratio of emitted energy

to received echo energy.

VEGAPULS 44

12 VEGAPULS 42 and 44 – 4 … 20 mA

Product description

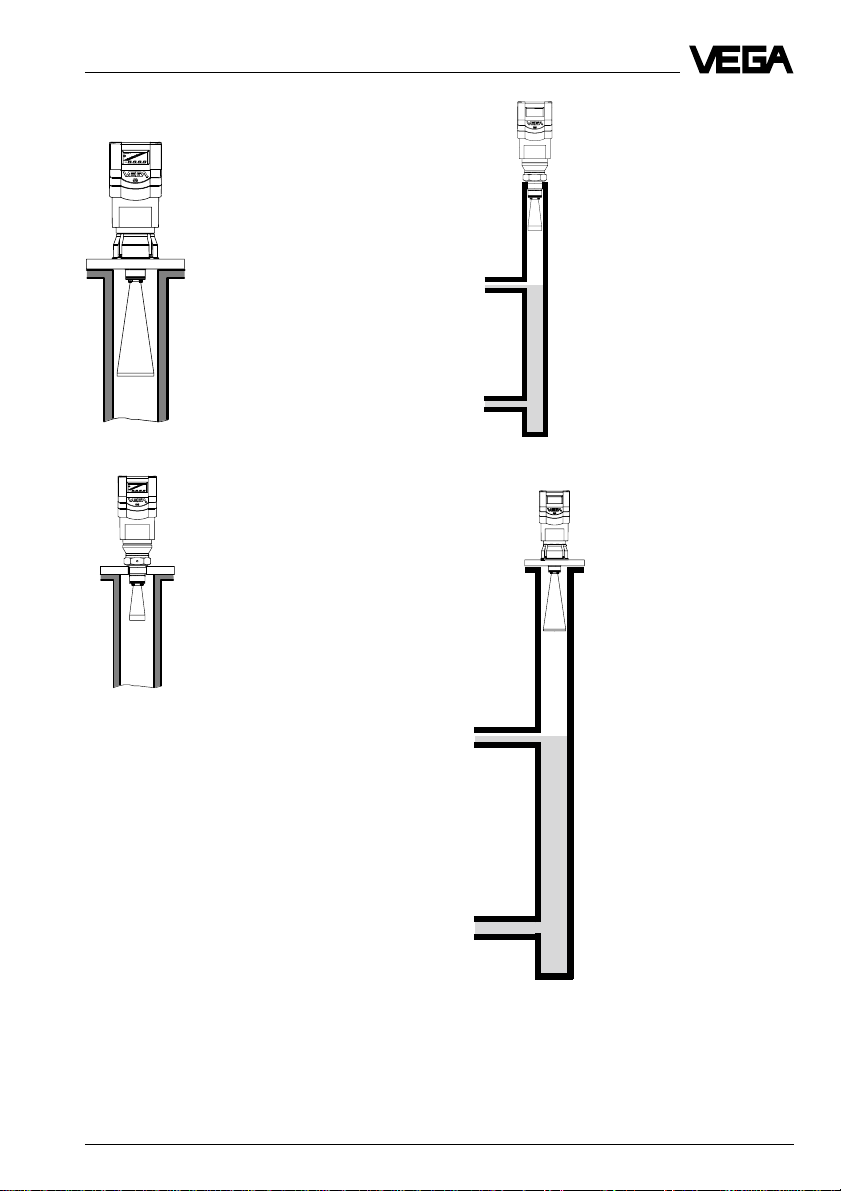

Pipe antennas

The pipe antennas on surge

or bypass tubes only form a

complete antenna system in

conjunction with a measuring

tube (which can also be

curved). The measuring tube

acts as a conductor for

radar signals. The running

period of the radar signals

changes in the tube and is

dependent on tube diameter.

The tube inner diameter must

be programmed in the sensor so that it can take the

altered running time into

account and deliver precise

level signals. Pipe antennas

are especially suitable for

processes with intense

product movements or products with low dielectric constant.

The antennas are characterised by very high gain. High

reliability can be achieved

even with products with very

poor reflective features.

VEGAPULS 42 on bypass tube

VEGAPULS 44 on bypass tube

VEGAPULS 42 and 44 – 4 … 20 mA 13

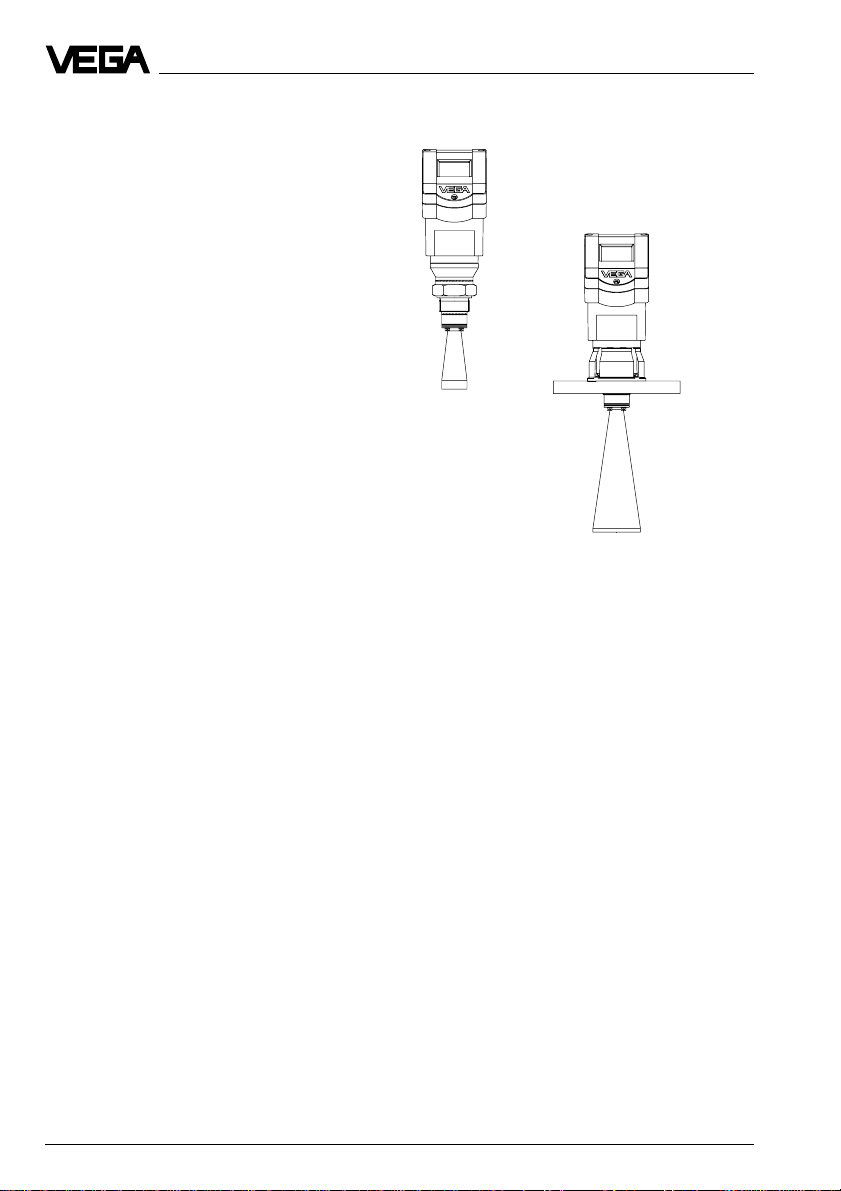

2 Types and versions

Types and versions

Series 40 sensors are manufactured in two

basic versions, VEGAPULS 42 and VEGAPULS 44.

VEGAPULS 42 are characterised by a

G 11/2 A or 11/2“ NPT thread as process fitting.

These sensors are equipped as standard

versions with a ø 40 mm horn as antenna.

VEGAPULS 44 are characterised by a DIN or

ANSI flanges as process fitting. In standard

version they are manufactured with DN 50,

80, 100 and 150 as well as with ANSI 2“, 3“,

4“ and 6“. The bigger flanges come

equipped with respectively larger antenna

horns (ø 48, 75 and 95 mm).

Generally: The bigger the antenna horn, the

better the focussing characteristics, and the

better the antenna gain. This ensures that

even a weak product echo can be detected

reliably as level echo.

VEGAPULS 42

VEGAPULS 44

14 VEGAPULS 42 and 44 – 4 … 20 mA

Types and versions

2.1 Survey

General features

• Application preferably for liquids in storage tanks, reservoirs and process vessels with

increased accuracy requirements.

• Measuring range 0 … 10 m or 0 … 20 m.

• Ex approved in zone 1 (IEC) or zone 1 (ATEX) classification

EEx ia [ia] IIC T6.

• Integrated display of measured values.

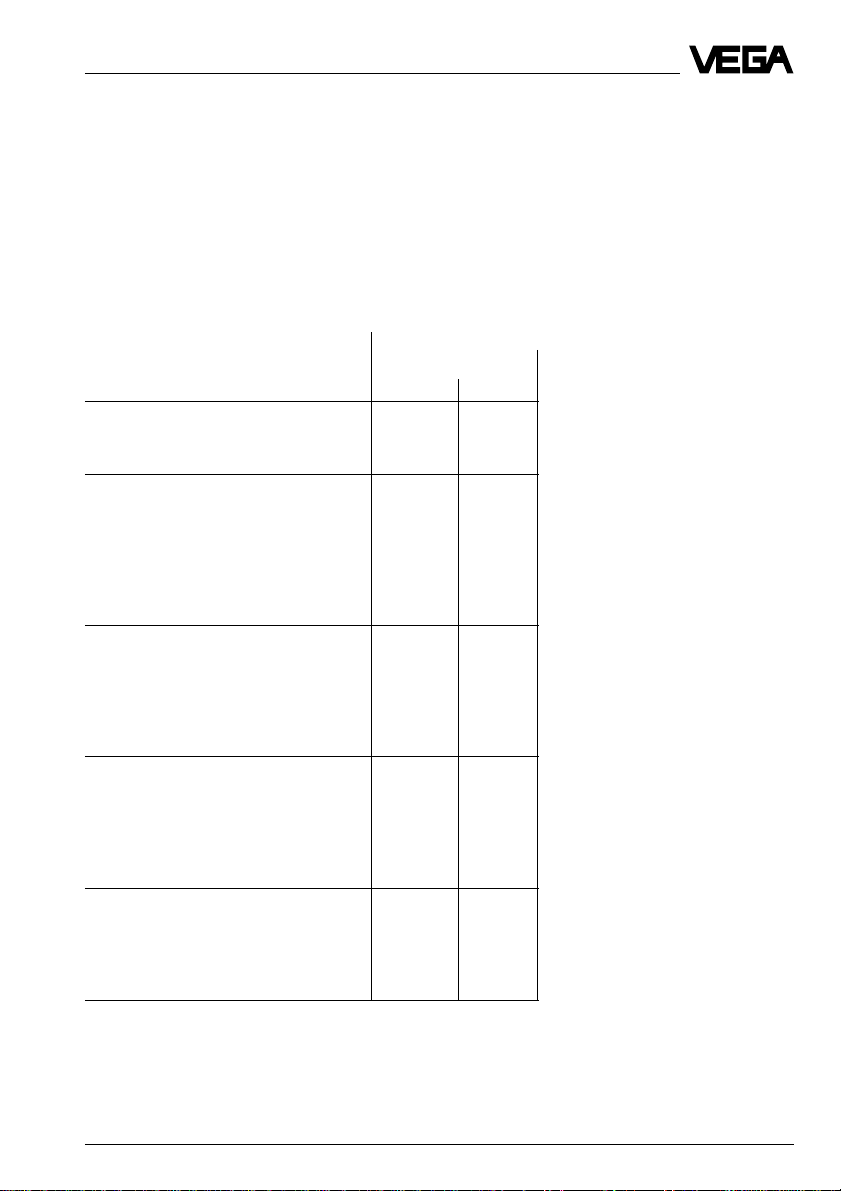

Survey

VEGAPULS …

42 44

Signal output

– active (4 … 20 mA) ••

– passive (4 … 20 mA loop powered) ••

Voltage supply

– two-wire technology (voltage

supply and signal output

via one two-wire cable) ••

– four-wire technology (voltage

supply separate from the signal

cable) ••

Process fitting

– G 11/2 A; 11/2“ NPT •–

– DN 50; ANSI 2“–•

– DN 80; ANSI 3“–•

– DN 100; ANSI 4“–•

– DN 150; ANSI 6“–•

Adjustment

– PC ••

– adjustment module in the sensor ••

– adjustment module in external

indicating instrument ••

– HART® handheld ••

Measuring range max.

–ø 40 mm horn 10 m –

–ø 48 mm horn 15 m 15 m

–ø 75 mm horn 20 m 20 m

–ø 95 mm horn 20 m 20 m

VEGAPULS 42 and 44 – 4 … 20 mA 15

Type code

Types and versions

PS 42 .XX X X X XXX X X

K - Plastic housing PBT, M20 x 1,5 cable entry

N - Plastic housing PBT,

1

/2“ NPT cable entry

A - Aluminium housing, M20 x 1,5 cable entry

D - Aluminium housing, 1/2“ NPT cable entry in Exd connection

housing

V - Seal of the antenna system: Viton

A - Seal of the antenna system: Kalrez

G - Process fitting G 11/2 A

N - Process fitting 11/2“ NPT

ABC- Pr ocess fitting DN 50 PN 16

BBE- Process fitting DN 80 PN 16

CBG- Process fitting DN 100 PN 16

DBG- Process fitting DN 150 PN 16

ARC- Process fitting ANSI 2“ 150 psi

BRE- Process fitting ANSI 3“ 150 psi

CRG- Process fitting ANSI 4“ 150 psi

DRG- Process fitting ANSI 6“ 150 psi

YYY- Process fitting on request

X - without display

A - with integrated display

X - without adjustment module MINICOM

B - with adjustment module MINICOM (mounted)

B - 20 … 72 V DC; 20 … 250 V AC; 4 … 20 mA, HART

(four-wire)

D - Two-wire (loop powered), 4 … 20 mA, HART

®

®

E - Supply via signal conditioning instrument

G - Segment coupler for Profibus PA

XX - FTZ (standard telecommunication approval Germany)

AX - Approval in Ex-Zone 1, EEx ia IIC T6

CX - Approval in Ex-Zone 0, EEx ia IIC T6

BX - Approval in Ex-Zone 1 (Exd connection housing)

DX - Approval in Ex-Zone 0 (Exd connection housing)

Type 42:with screw-on process fitting

Type 44: instrument series with flange process fitting

PS: Series 40 radar sensors

16 VEGAPULS 42 and 44 – 4 … 20 mA

2

4 … 20 mA

-

+

1)

4

Types and versions

2.2 Configuration of measuring systems

A measuring system consists of a sensor

with a 4 … 20 mA signal output and a module

that evaluates and further processes the

level-proportional current signal.

On the following pages you will see various

measuring systems, each consisting of a

different instrument configuration (several

also with signal conditioning).

Measuring systems in two-wire technology:

• 4 … 20 mA shown without processing unit,

(bottom)

• 4 … 20 mA on active PLC,

• 4 … 20 mA in Ex area on active PLC

(page 18)

(Ex ia

page 20, Ex d PAGE 23)

• 4 … 20 mA in Ex area on passive PLC,

(page 21)

• 4 … 20 mA in Ex area on VEGADIS 371 Ex

indicating instrument,

(page 22)

Measuring systems in four-wire technology:

• 4 … 20 mA shown without signal conditioning instrument,

(non Ex page 19, Ex d

page 23)

Measuring systems with VEGAPULS 42 or 44 connected to any 4 … 20 mA signal

processing unit

• Two-wire technology (loop powered), supply and output signal via one two-wire cable.

• Output signal 4 … 20 mA (passive).

• Optional external indicating instrument with analogue and digital display (can be mounted

up to 25 m separated from the sensor).

• Adjustment with PC, HART® handheld or the adjustment module MINICOM (can be plugged

into the sensor or into the external indicating instrument VEGADIS 50).

VEGADIS 50

1)

If the resistance of the processing systems

connected to the 4 … 20 mA signal output is less

than 250 W, a resistor must be connected to the

connection cable during adjustment to get a loop

resistance of 250 W.

The digital adjustment signal would otherwise be

severely damped or short-circuited due to

insufficient resistance of the connected

processing system. Communication with the PC

would not be ensured.

VEGAPULS 42 and 44 – 4 … 20 mA 17

VEGACONNECT 2

HART® handheld

Types and versions

Measuring system with VEGAPULS 42 or 44 on active PLC

• Two-wire technology, supply by active PLC.

• Output signal 4 … 20 mA (passive).

• Measured value display integrated in the sensor.

• Optional external indicating instrument (can be mounted up to 25 m separated from the

sensor in Ex area).

• Adjustment with PC, HART® handheld or the adjustment module MINICOM (can be plugged

into the sensor or into the external indication instrument).

VEGADIS 50

4

2 2

2

VEGACONNECT 2

1)

If the resistance of the processing systems

connected to the 4 … 20 mA signal output is less

than 250 W, a resistor must be connected to the

connection cable during adjustment to get a loop

resistance of 250 W.

The digital adjustment signal would otherwise be

severely damped or short-circuited due to

insufficient resistance of the connected processing

system. Communication with the PC would not be

ensured.

4 … 20 mA

passive

2

1)

2)

PLC (active)

HART® handheld

2)

4 … 20 mA passive means that the sensor

3)

consumes a level-dependent current of

4 … 20 mA. The sensor reacts electrically like a

varying resistor (consumer) to the PLC.

3)

Active means that the PLC powers the passive

sensor as voltage source.

18 VEGAPULS 42 and 44 – 4 … 20 mA

Types and versions

Measuring system with VEGAPULS 42 or 44 in four-wire technology

• Four-wire technology, supply and output signal via two separate two-wire cables.

• Output signal 4 … 20 mA active.

• Optional external indicating instrument with analogue and digital display (can be mounted

up to 25 m separated from the sensor).

• Adjustment with PC, HART® handheld or adjustment module MINICOM (can be plugged into

the sensor or into the external indicating instrument VEGADIS 50).

• Max. resistance on the signal output (load) 500 W.

VEGADIS 50

2

4

1)

³ 250 W

VEGACONNECT 2

2

2

2

-

+

4 … 20mA

2)

(active)

HART® handheld

1)

If the resistance of the processing systems

connected to the 4 … 20 mA signal output is less

than 250 W, a resistor must be connected to the

connection cable during adjustment to get a loop

2)

4 … 20 mA active means that the sensor delivers

a level-dependent current of 4 … 20 mA (source).

The sensor reacts electrically to the processing

system (e.g. display) like a current source.

resistance of 250 W.

The digital adjustment signal would otherwise be

severely damped or short-circuited due to

insufficient resistance of the connected

processing system. Communication with the PC

would not be ensured.

VEGAPULS 42 and 44 – 4 … 20 mA 19

Types and versions

Measuring system with VEGAPULS 42 or 44 via separator in Ex area on active PLC

• Two-wire technology (loop powered), supply via the signal line of the PLC; output signal

4 … 20 mA (passive).

• Separator transfers the non intrinsically safe PLC circuit to the intrinsically safe circuit, so

that the sensor can be used in Ex zone 1 or Ex zone 0.

• Optional external indicating instrument with analogue and digital display (can be mounted

up to 25 m separated from the sensor).

• Adjustment with PC, HART® handheld or adjustment module MINICOM (can be plugged into

the sensor or into the external indicating instrument VEGADIS 50).

VEGADIS 50

4

Zone 0 or

Zone 1

Ex area

EEx ia

Non Ex area

Separator (e.g. Stahl)

(see "3.2 Approvals“)

2

VEGACONNECT 2

1)

4 … 20 mA

passive

2

2)

2

2

PLC (active)

HART® handheld

1)

If the resistance of the processing systems

connected to the 4 … 20 mA signal output is less

than 250 W, a resistor must be connected to the

connection cable during adjustment to get a loop

resistance of 250 W.

2)

4 … 20 mA passive means that the sensor

consumes a level-dependent current of

4 … 20 mA. The sensor reacts electrically like a

varying resistor (consumer) to the PLC. The PLC

operates active, i.e. as current or voltage source.

The digital adjustment signal would otherwise be

severely damped or short-circuited due to

insufficient resistance of the connected

processing system. Communication with the PC

would not be ensured.

20 VEGAPULS 42 and 44 – 4 … 20 mA

Types and versions

Measuring system with VEGAPULS 42 or 44 via separator (Smart-Transmitter) on passive PLC

• Two-wire technology (loop powered), intrinsically safe ia supply via the signal cable of the

separator for operation of the sensor in Ex zone 1 or Ex zone 0.

• Output signal sensor 4 … 20 mA passive.

Output signal separator 4 … 20 mA active.

• Optional external indicating instrument with analogue and digital display (can be mounted

up to 25 m separated from the sensor).

• Adjustment with PC, HART® handheld or adjustment module MINICOM (can be plugged into

the sensor or into the external indicating instrument VEGADIS 50).

VEGADIS 50

4

Zone 0 or

Zone 1

Ex area

EEx ia

Non Ex area

Separator (e.g. VEGATRENN 149 Ex see

"3.2 Approvals“)

-

+

2

4 … 20 mA

(active)

2

2

VEGACONNECT 2

1)

2)

PLC (passive)

3)

HART® handheld

1)

If the resistance of the processing systems

connected to the 4 … 20 mA signal output is less

than 250 W, a resistor must be connected to the

connection cable during adjustment to get a loop

resistance of 250 W.

The digital adjustment signal would otherwise be

severely damped or short-circuited due to

insufficient resistance of the connected

processing system. Communication with the PC

2)

4 … 20 mA active means that the separator

delivers a level-dependent current of 4 … 20 mA

(source). The separator reacts electrically to the

PLC like a current source.

3)

4 … 20 mA passive means that the PLC consumes

a level-dependent current of 4 … 20 mA. The PLC

reacts electrically like a varying resistor

(consumer) to the PLC.

would not be ensured.

VEGAPULS 42 and 44 – 4 … 20 mA 21

Types and versions

Measuring system with VEGAPULS 42 or 44 on VEGADIS 371 Ex indicating

instrument with current and relay output

• Two-wire technology (loop powered), intrinsically safe ia supply via the signal cable of the

VEGADIS 371 Ex indicating instrument for operation of the sensor in Ex zone 1 or Ex

zone 0.

• Optional external indicating instrument with analogue and digital display (can be mounted

up to 25 m separated from the sensor).

• Adjustment with PC, HART® handheld or adjustment module MINICOM (can be plugged into

the sensor or into the external indicating instrument VEGADIS 50).

VEGADIS 50

4

Zone 0 or

Zone 1

Ex area

EEx ia

Non Ex area

2

2

2

VEGACONNECT 2

1)

4 ... 20 mA

(passive)

-

+

VEGADIS

371 Ex

(see "3.2 Approvals“)

HART® handheld

Relay

0/4 … 20 mA

(active)

1)

If the resistance of the processing systems

connected to the 4 … 20 mA signal output is less

than 250 W, a resistor must be connected to the

connection cable during adjustment to get a loop

resistance of 250 W.

The digital adjustment signal would otherwise be

severely damped or short-circuited due to

insufficient resistance of the connected

processing system. Communication with the PC

would not be ensured.

22 VEGAPULS 42 and 44 – 4 … 20 mA

Types and versions

VEGAPULS 42 Ex or 44 Ex (loop powered) with pressure-tight encapsulated

terminal compartment on active PLC

• Two-wire technology, supply via the signal cable of active PLC on Exd connection housing

for operation in Ex zone 1 (VEGAPULS …Ex) or Ex zone 0 (VEGAPULS …Ex0).

• Output signal 4 … 20 mA (passive).

• Measured value display integrated in the sensor.

• Optional external indicating instrument (can be mounted up to 25 m separated from the

sensor in Ex area).

• Adjustment with PC, HART® handheld or adjustment module MINICOM (can be plugged into

the sensor or into the external indicating instrument VEGADIS 50).

Ex area

VEGADIS 50 Ex

4

1)

If the resistance of the processing systems

Non Ex-area

2

VEGACONNECT 2

2

2

connected to the 4 … 20 mA signal output is less

than 250 W, a resistor must be connected to the

connection cable during adjustment to get a loop

resistance of 250 W.

The digital adjustment signal would otherwise be

severely damped or short-circuited due to

insufficient resistance of the connected

processing system. Communication with the PC or

the HART® handheld would not be ensured.

4 … 20 mA

2)

passive

2

PLC (active)

HART® handheld

2)

4 … 20 mA passive means that the sensor

consumes a level-dependent current of

4 … 20 mA. The sensor reacts electrically like a

varying resistor (consumer) to the PLC.

VEGAPULS 42 and 44 – 4 … 20 mA 23

Technical data

VEGAPULS 42 Ex or 44 Ex with pressure-tight encapsulated connection

compartment in four-wire technology

• Four-wire technology, supply and output signal via two separate two-wire cables for use in

Ex zone 1 (VEGAPULS …Ex) or Ex zone 0 (VEGAPULS …Ex0).

• Output signal 4 … 20 mA (active).

• Optional external indicating instrument with analogue and digital display (can be mounted

up to 25 m separated from the sensor in Ex area).

• Adjustment with PC, HART® handheld or adjustment module MINICOM (can be plugged into

the sensor or into the external indicating instrument VEGADIS 50).

• Load max. 500 W.

Ex area

VEGADIS 50 Ex

4

1)

If the resistance of the processing systems

Non Ex area

VEGACONNECT 2

2

2

connected to the 4 … 20 mA signal output is less

than 250 W, a resistor must be connected to the

connection cable during adjustment to get a loop

resistance of 250 W.

The digital adjustment signal would otherwise be

severely damped or short-circuited due to

insufficient resistance of the connected

processing system. Communication with the PC or

the HART® handheld would not be ensured.

2

-

+

2

> 250 Ω

2)

4 … 20 mA active means that the sensor delivers

4 … 20mA

2)

active

HART® handheld

a level-dependent current of 4 … 20 mA (source).

The measuring signal of the sensor reacts

electrically to the processing system (e.g. display)

like a current source.

24 VEGAPULS 42 and 44 – 4 … 20 mA

Technical data

3 Technical data

3.1 Technical data

Power supply

Supply voltage

- four-wire sensor 24 V DC (20 … 72 V DC)

- two-wire sensor 24 V DC (14 … 36 V DC)

- two-wire Ex ia sensor 24 V DC (14 … 29 V DC)

- two-wire Ex d ia sensor 24 V DC (20 … 36 V DC)

Current consumption

- four-wire sensor max. 60 mA

- two-wire sensor max. 22.5 mA

Power consumption

- four-wire sensor max. 200 mW, 1.2 VA

- two-wire sensor 55 … 810 mW

Load

- four-wire sensor max. 500 Ohm

- two-wire sensor see diagram

230 V AC (20 … 250 V AC), 50/60 Hz

fuse 0.2 A TR

Ω

975

1000

900

max. load Non Ex

max. voltage limit

Non Ex and

Ex d ia sensors

Adjustment

resistor

(HART® and

VEGACONNECT)

720

670

250

800

600

400

700

500

300

200

100

max. load Ex ia

0

15

14

19,5

20

max. load Ex d ia

Non Ex and Ex ia

25,5

25

Exd ia

29

min. voltage limit when using the HART

adjustment resistor:

- Non Ex and Ex ia sensors

- Ex d ia sensors

30 35

36

V

max. voltage limit

Ex ia sensors

®

VEGAPULS 42 and 44 – 4 … 20 mA 25

Technical data

Measuring range

1)

VEGAPULS 42 (ø 40 mm horn)

- optional 0 … 10 m

ø 48 mm horn 0 … 15 m

ø 75, 95 mm horn 0 … 20 m

VEGAPULS 44

- DN 50, ANSI 2“ 0 … 15 m

- DN 80, 100, ANSI 3“, 4“, 6“ 0 … 20 m

Standpipe measurement in DN 50 standpipe

- VEGAPULS 42 0 … 20 m

- VEGAPULS 44 0 … 20 m

Standpipe measurement in DN 100 standpipe

- VEGAPULS 42 0 … 20 m

- VEGAPULS 44 0 … 20 m

Output signal

4 … 20 mA current signal in two or four-wire technology

Integration time 0 … 999 seconds (adjustable)

Load

-4 … 20 mA two-wire

Non Ex: max 975 W

Ex d ia: max. 720 W

Ex ia: max. 670 W

-4 … 20 mA four-wire 500 W

Two-wire technology 4 … 20 mA:

The analogue 4 … 20 mA output signal (measuring signal) is transmitted together with the

power supply via one two-wire cable.

Four-wire technology 4 … 20 mA:

Separate power supply. The analogue 0/4 … 20 mA output signal (measuring signal) is led

in a cable separate from the supply voltage.

Measured value display (optional)

Liquid-crystal display

- in the sensor scalable output of measured values as graph

and digital value

- powered externally from the sensor scalable output of measured values as graph

and digital value. Measured value display can

be mounted up to 25 m away from the sensor.

Adjustment

- PC and adjustment software VEGA Visual Operating

- adjustment module MINICOM

- HART® handheld

1)

Min. distance of the antenna to the medium 5 cm

26 VEGAPULS 42 and 44 – 4 … 20 mA

Technical data

Accuracy

2)

(typical values under reference conditions, all statements relate to the nominal measuring

range)

Characteristics linear

Deviation in characteristics including

linearity, reproducibility and

hysteresis (determined acc. to the

limit point method) < 0.05 %

Linearity better than 0.05 %

Average temperature coefficient of the

zero signal 0.06 %/10 K

Resolution in general max. 1 mm

Resolution of the output signal 0.01 % or 1 mm

Characteristics

1)

(typical values under reference conditions, all statements relate to the nominal measuring

range)

Min. span between

full and empty > 10 mm (recommended > 50 mm)

Frequency 24 GHz technology

Intervals

- two-wire sensor (4 … 20 mA) 1 s

- two-wire sensor (digital) 0.6 s

- four-wire sensor 0.5 s

Beam angle (at –3 dB)

- VEGAPULS 42 22°

optional 18°, 10° and 8° when using bigger coupling

horn deviating from nominal size

- VEGAPULS 44

DN 50, ANSI 2“ 18°

DN 80, ANSI 3“ 10°

DN 100, ANSI 4“ 8°

DN 150, ANSI 6“ 8°

Adjustment time (response time) > 1 s (depending on parameter setting)

Influence of the process temperature not measurable at 0 bar; at 5 bar 0.004 %/10 K;

at 40 bar 0.03 %/10 K

Influence of the process pressure 0.0265 %/bar

Adjustment time

Radar emitted power (average) 0.717 µW

Received average emitted power

2)

3)

> 1 s (depending on parameter setting)

- distance 1 m 0.5 … 1.5 nW pro cm² (0.5 … 1.5 x 10-9W/cm²)

- distance 5 m 0.02 … 0.6 nW pro cm²

1)

Similar to DIN 16 086, reference conditions acc. to IEC 770, e.g.

temperature 15°C … 35°C; moisture 45 % … 75 %; pressure 860 mbar … 1060 mbar

2)

The adjustment time (also actuating time, response time or adjustment period) is the time the sensor

requires to output the correct level (with max. 10% deviation) after a quick level change.

3)

Average emitted power reaching an object (electromagnetic energy) per cm² directly in front of the antenna.

The received emitted power depends on the antenna version and the distance.

VEGAPULS 42 and 44 – 4 … 20 mA 27

Loading...

Loading...