Please direct all questions to your local VeEX Sales Office, Representative, Distributor or contact VeEX Technical

Support at www.veexinc.com.

No part of this manual may be reproduced, translated into a foreign language, or be transmitted electronically without

prior agreement and written consent of VeEX Incorporated as governed by International copyright laws. Information

contained in this manual is provided “as is” and is subject to change without notice. Trademarks of VeEX

Incorporated have been identified where applicable, however the absence of such identification does not affect the

legal status of any trademark.

Copyright © 2018 VeEX Incorporated. All rights reserved. MPA_e_manual_D07-00-129P_RevA00

MPA USER MANUAL

The Verification Experts

Software Feature Set 8.2

MPA_e_manual_D07-00-129P_RevA00

1

MPA_e_manual_D07-00-129P_RevA00

Table of Contents

MPA_e_manual_D07-00-129P_RevA00

Table of Contents

Getting Started .............................................................................................................. 11

Getting Started .......................................................................................................... 11

General Information ................................................................................................... 11

General Information Overview................................................................................ 11

Safety Guidelines ................................................................................................... 12

Copyright ................................................................................................................ 14

Customer Technical Support .................................................................................. 15

Warranty and Return Policies ................................................................................ 16

Return Shipping Instructions .................................................................................. 17

Configuring the IP Address ........................................................................................ 19

Configuring the IP Address Overview .................................................................... 19

Changing the IP Address with a USB Flash Drive.................................................. 21

Changing the IP Address with the Remote GUI Client ........................................... 26

Changing the MCH module’s IP Address ............................................................... 28

Remote Client Application ......................................................................................... 34

Remote Client Application Overview ...................................................................... 34

DLI Remote Client Requirements........................................................................... 35

Remote Client Installation ................................ ...................................................... 36

DLI Remote Client Removal ................................................................................... 37

Automating the DLI Remote Client Icon ................................................................. 38

Troubleshooting the Remote Client Application ..................................................... 40

VNC Connection ........................................................................................................ 41

iii

Table of Contents

MPA_e_manual_D07-00-129P_RevA00

Virtual Network Computing (VNC) Connection ...................................................... 41

VNC Viewer Configuration ..................................................................................... 42

Multiple Remote VNC Desktops ............................................................................. 46

Common Function Buttons ........................................................................................ 52

Common Function Buttons ..................................................................................... 52

Error Insert ............................................................................................................. 53

Stopping a Test ...................................................................................................... 53

Restarting a Test .................................................................................................... 54

Presets Function .................................................................................................... 54

Saving and Printing Statistics and Settings Reports .............................................. 55

Test Setup Button .................................................................................................. 58

Saving a Customized Settings Configuration ......................................................... 59

Restoring a Settings Configuration or Factory Defaults ......................................... 60

Clearing LED History and Resetting Results .......................................................... 61

Locking/Unlocking Screen Access ......................................................................... 62

Shutdown or Reboot the Processor from the GUI .................................................. 63

Common Tasks.......................................................................................................... 65

Common Tasks Overview ...................................................................................... 65

Software Upgrade .................................................................................................. 66

Timed Licenses ...................................................................................................... 68

MPA Shutdown Procedure ..................................................................................... 69

Fiber-Optic Cleaning Procedure ............................................................................. 72

Understanding Test Units .......................................................................................... 74

iv

Table of Contents

MPA_e_manual_D07-00-129P_RevA00

Understanding Test-Units ...................................................................................... 74

MPM Test Module Cards and Slot Locations ......................................................... 75

Lock Icon Overview ................................................................................................ 77

Locking and Unlocking a Test Unit ......................................................................... 79

Adding Notes to a Test Unit ................................................................................... 80

MPA Chassis ................................................................................................................. 83

MPA Chassis Overview ............................................................................................. 83

MPA 1st Generation Chassis (5-Slots): .................................................................. 83

MPA 2nd Generation Chassis (5-Slots): ................................................................ 83

MPA 3rd Generation Chassis (6-Slots): ................................................................. 84

MPA Rackmount Installation ...................................................................................... 85

MPA Chassis Dimensions ...................................................................................... 85

Chassis Mounting Brackets .................................................................................... 86

How to install the chassis into a rack ..................................................................... 87

MPA Power Connections ........................................................................................... 87

For the 110v/220v AC Power Supply: .................................................................... 88

For the -48v DC power chassis: ............................................................................. 89

EMI Shielding, Airflow, Air Filter and Fan Trays ........................................................ 90

EMI Shielding and Airflow Warning ........................................................................ 90

Dual Cooling Units (Fan Trays) .............................................................................. 91

Air Filter Swap ........................................................................................................ 91

Swapping and Inserting new test modules ................................................................ 91

Test Module Removal ............................................................................................ 92

v

Table of Contents

MPA_e_manual_D07-00-129P_RevA00

Test Module Insertion ............................................................................................. 92

SCM-210 (System Controller Module) ....................................................................... 94

MCH (MicroTCA Carrier Hub) .................................................................................... 95

AM4022 Processor .................................................................................................... 97

MPM-10G Test Module Overview .............................................................................. 98

MPM-100G Test Module Overview .......................................................................... 101

MPM-100AR Test Module Overview ........................................................................ 103

MPM-400G Test Module Overview .......................................................................... 106

Protocol Tabs .............................................................................................................. 111

Protocol Processor Tabs ......................................................................................... 111

MLD Tab .................................................................................................................. 111

MLD Tab Overview .............................................................................................. 111

Screens and Function Descriptions ...................................................................... 116

Specific Tasks ...................................................................................................... 172

OTN Tab .................................................................................................................. 177

OTN Tab Overview .............................................................................................. 177

Screens and Function Descriptions ...................................................................... 179

OTN Specific Tasks ............................................................................................. 257

SONET Tab ............................................................................................................. 271

SONET Tab Overview .......................................................................................... 271

Screens and Function Descriptions ...................................................................... 272

SONET Specific Tasks ......................................................................................... 374

SDH Tab .................................................................................................................. 391

vi

Table of Contents

MPA_e_manual_D07-00-129P_RevA00

SDH Tab Overview .............................................................................................. 391

Screens and Function Descriptions ...................................................................... 392

SDH Specific Tasks ............................................................................................. 501

Packet Tab .............................................................................................................. 519

Packet Tab Overview ........................................................................................... 519

Ethernet (LAN and WAN) - Screens and Function Descriptions .......................... 520

Ethernet (LAN and WAN) - Specific Tasks ........................................................... 599

Fibre Channel - Screen Functions and Description .............................................. 638

Fibre Channel - Specific Tasks ............................................................................ 675

GFP - Screens and Function Descriptions ........................................................... 684

GFP - Specific Tasks ........................................................................................... 738

GUI System Tab .......................................................................................................... 749

System Tab ............................................................................................................. 749

Misc Screen ............................................................................................................. 749

Miscellaneous System Settings............................................................................ 749

Update License Keys ........................................................................................... 750

Set the Unit's Date, Time, Time Zone, and Daylight Saving Time option ............. 751

About This Product ............................................................................................... 755

Check for Upgrade ............................................................................................... 757

Changing the Protocol Mode ................................................................................ 758

Restoring Factory Defaults ................................................................................... 759

Saving and Restoring Global Settings Configurations .......................................... 759

Setting the Chassis Clock ................................ .................................................... 760

vii

Table of Contents

MPA_e_manual_D07-00-129P_RevA00

External Clock In Status ....................................................................................... 767

IO Settings Screen ................................................................................................... 768

I/O Settings .......................................................................................................... 768

Ethernet Port Settings .......................................................................................... 769

Rebooting the Test Set ........................................................................................ 771

File Services Screen ................................................................................................ 771

File Services......................................................................................................... 771

Deleting Files ....................................................................................................... 772

Deleting Directories .............................................................................................. 772

Renaming Files .................................................................................................... 772

Printing Saved Files ............................................................................................. 773

Viewing Saved Report Files ................................................................................. 774

Creating a New Directory ..................................................................................... 775

Security Screen ....................................................................................................... 775

Security Settings Screen ...................................................................................... 775

Adding a New User .............................................................................................. 776

Deleting a User .................................................................................................... 777

Updating a User Profile ........................................................................................ 777

Enabling/Disabling Security System Lock ............................................................ 778

Resetting the System ........................................................................................... 778

User Preference Screen .......................................................................................... 779

User Preference ................................................................................................... 779

Changing the Tab Name for Protocol Processors ................................................ 780

viii

Table of Contents

MPA_e_manual_D07-00-129P_RevA00

Restoring Default Tab Names for the Go To Label .............................................. 780

Setting the Alarm Beeper Status .......................................................................... 781

Sending Email Alerts ............................................................................................ 782

Displaying All Test Status ........................................................................................ 787

Expanded Alarm and Status Indicators ................................................................ 788

Conditional LED Option ........................................................................................ 788

Multi-Page Display ............................................................................................... 789

All Ether Ports .......................................................................................................... 789

Service Disruption .................................................................................................... 791

To measure Service Disruption activity: ............................................................... 791

To stop monitoring Service Disruption measurement activity: .............................. 792

Monitoring SCPI Commands ................................................................................... 792

To open the monitor: ............................................................................................ 793

To issue SCPI commands to the unit: .................................................................. 793

Chatting ................................................................................................................... 793

Faults ....................................................................................................................... 795

To view system faults: .......................................................................................... 795

To clear the system fault log: ............................................................................... 795

Term Definitions .......................................................................................................... 797

ix

MPA_e_manual_D07-00-129P_RevA00

Getting Started

MPA_e_manual_D07-00-129P_RevA00

Getting Started

Getting Started

This section includes information to help you to use your system. It is broken into the

following topics:

• General Information: Contains a broad range of information about VeEX, MPA

Safety Guidelines, Customer Support, RMA Policies and Warranty information

• Configuring the IP Address: Contains instructions for changing the MPA unit's

IP Address

• Remote Client Application: Contains information on how to connect and control

the MPA unit via Remote Client software

• VNC Connection: Contains information on how to connect and control the MPA

unit with a VNC viewer application

• Common Row Function Buttons: Contains detailed information about the

common function buttons located at the bottom of GUI

• Common Tasks: Contains general instructions for performing common tasks, as

well as common screen components, and other useful information on how to use

the MPA product

• Understanding Test Units: Contains information about what a Test Unit is, and

how to Lock and Unlock Test Units

You may also navigate through the topics by using the Contents tab and window that

appear on the left side of the screen.

General Information

General Information Overview

This section contains a broad range of information about the VeEX, MPA Safety

Guidelines, Customer Support, RMA Policies and Warranty information. For tasks that

are protocol processor specific, refer to the appropriate protocol processor section.

Please use the Contents tab and window (left side of the screen) to select, open, and

view the information in this section.

• Safety Guidelines

• Copyright and Patent Information

• Customer Technical Support

• Warranty and Return Policies

• RMA Shipping Instructions

11

General Information

MPA_e_manual_D07-00-129P_RevA00

Safety Guidelines

The instrument has been designed to ensure safe operation, however, please observe

all warnings, cautions, and instructions marked on the product and included in this

document. The following safety precautions are provided to avoid personal injury and

prevent damage to this product or any products connected to it during installation and

normal operation. Safety precautions should be observed during all phases of operation

of this instrument. VeEX Inc. assumes no liability for the customer's failure to comply

with safety precautions and requirements.

• Environmental Safety : This product may contain lead-based solder materials and

a lithium battery for computer support. Please return all VeEX products to the

factory for proper disposal. Operation of this product is not hazardous to the

environment.

This is a Class A product per EN55022. In a domestic environment, this product

may cause radio interference in which case the user may be required to take

adequate measures.

• Do Not Operate in Hazardous Conditions: This instrument is not intended for

outdoor use. To avoid injury or fire hazard, do not operate this instrument in wet,

damp, or other hazardous conditions. Do not operate this instrument in the

presence of flammable gases or fumes or in an explosive or combustible

environment.

• ESD: Always wear an ESD wrist strap and follow appropriate ESD procedures when

installing or servicing the unit and its components.

• Air Flow: To ensure proper air flow and cooling, always make sure that the test

modules are properly installed into the correct slot locations. An empty slot should

never be exposed. Always have an empty slot covered by the appropriate blank

faceplate when a circuit pack is removed for any period of time.

• Laser Safety: The unit contains Class 1 laser devices. CDRH Accession No.

0021615. When fiber is not attached to the optical ports, always leave protective

covers on optical connectors to prevent damage and prevent laser emissions.

12

Getting Started

MPA_e_manual_D07-00-129P_RevA00

• Eye Protection: Users should never stare into unterminated optical connectors or

fiber optic cables. In addition, fiber optic cables and optical connectors should

always be handled as if they were emitting laser light.

• Installation: The unit is configured and shipped to mount into a 19-inch rack. A

minimum of four mounting screws are required to attach the unit to a rack’s

mounting rails. Mounting screws (and/or clips) are the responsibility of the customer.

• Field Service: This equipment is not intended to be serviced in the field. With the

exception of card swapping, all service is intended to be completed by VeEX.

For 110v/220v AC power supply module:

Turn off the unit’s power switch when making power input connections. Refer to

Chapter 4 for the proper shutdown method before connecting or disconnecting the

DC power cord or swapping the DC power supply.

Use Proper Power Cord: To avoid fire hazard, only use the power cord specified

for this instrument. For use in North America, use a power cord (maximum sixfoot length) with a type SJT, 18 AWG, two-conductor with ground, IEC 60320-C13

connector on one end and a NEMA 5-15P connector on the other end.

For use outside of North America, use an HO5VV-F power cord with a 1-mm2,

two-conductor plus ground, IEC 60320 C-13 connector on one end, and a wallsocket plug on the other end that is certified for use in the country of installation.

The entire cord set must be certified for use in the country of installation.

The AC Power Supply also supports a Self-Locking connector to prevent the

power cord from accidentally being unplugged.

13

General Information

MPA_e_manual_D07-00-129P_RevA00

Avoid Electric Overload: This unit is designed to be powered from 110-265VAC

(auto-range), 50–60 Hz, 600 Watts. To avoid electric shock, fire hazard, or

damage to the instrument, do not apply a higher voltage.

Ground the Instrument: The unit is grounded through the grounding conductor of

the power cord. To avoid electric shock, the grounding conductor must be

connected to earth ground. Before making connections to the input or output

terminals of the instrument, ensure that the product is properly grounded.

For the -48v DC supply module:

Turn off the unit’s power switch when making power input connections.

This product is intended to operate from a -48 VDC, 420 Watt, source derived

from batteries, SELV, or an NEC Class II device.

Verify that the input power requirements (-42 VDC to -56 VDC) are met before

installing the unit.

The DC Power supply is designed for redundant power sources, with dual-

input 7W2 D-Sub connector receptacles.

Ground the Instrument: To avoid electric shock using a DC power supply,

ensure that the chassis is properly grounded to earth ground using the ground

connector on the rear of the chassis, before making input power connections to

the device.

Copyright

Copyright © VeEX Inc. - All rights reserved.

VeEX reserves the right to revise and improve this document, as well as the contents of

this document as it sees fit. This publication describes the state of this product at the

time of its publication and may not represent the product at all times in the future.

For conditions of use and permission to use these materials for publication in other than

the English language, contact VeEX Inc.

14

Getting Started

MPA_e_manual_D07-00-129P_RevA00

Patent Information

The rack mounted Multi-Protocol Analyzer (MPA) system and the various Protocol

Processors described in this publication may be protected by one or more patents on

file with the United States Patent Office.

Trademarks

VeEX; Verification Experts; MPA; Multi-Protocol Analyzer; Digital Lightwave; and the

rectangular “jewel” logo are registered trademarks of VeEX Inc. and/or its affiliates in

the United States and/or in other countries.

Customer Technical Support

Our Customer Technical Support representatives are available to help you.

Standard business hours are from 8:30 AM to 5:30 PM Eastern Time, Monday through

Friday.

+1-877-929-4357 (Toll-Free in USA and Canada)

+1-727-475-1206 (International, and local area)

ServiceAndSupport@veexinc.com (Emails will be replied to during the standard

business hours.)

Company Address

VeEX Florida Inc.

2100 Tall Pines Drive

Largo, Florida 33771, USA

+1-800-548-9283 (Main Receptionist)

+1-727-536-3541 (FAX)

15

General Information

MPA_e_manual_D07-00-129P_RevA00

Warranty and Return Policies

Warranty Period: The warranty period for hardware, software and firmware varies

based on product, configuration, and customer contract. Please contact Customer

Technical Support for questions.

Hardware Coverage: VeEX Inc. warrants hardware products against defects in

materials and workmanship. During the warranty period, VeEX will, at its sole discretion,

either:

• Repair the products

• Replace hardware which proves to be defective

provided that the products that the customer elects to replace is returned to VeEX Inc.

by the customer along with proof of purchase within thirty (30) days of the request by

the customer, freight prepaid.

Software Coverage: VeEX Inc. warrants software and firmware materials against

defects in materials and workmanship. During the warranty period, VeEX will, at its sole

discretion, either

• Repair the products

• Replace the software and/or firmware which prove to be defective

provided that the products that the customer elects to replace is returned to VeEX Inc.

by the customer along with proof of purchase within thirty (30) days of the request by

the customer, freight prepaid.

Additionally, during the warranty period, VeEX Inc. will provide, without charge to the

customer, all fixes, patches and enhancements to the purchased software, firmware and

software options. VeEX Inc. does not warrant that all software or firmware defects will

be corrected. New enhancements attached to a software option require the option to be

purchased (at the time of order or the time of upgrade) in order to benefit from such

enhancements.

Limitations: The warranty is only for the benefit of the customer and not for the benefit

of any subsequent purchaser or licensee of any merchandise (hardware, software,

firmware and/or accessories).

Revoking the warranty: VeEX Inc. does not guarantee or warrant that the operation of

the hardware, software or firmware will be uninterrupted or error-free. The warranty will

not apply in any of the following cases:

• Improper or inadequate maintenance by the customer

• Damage due to software installed by the customer on the unit without prior

authorization (written) from VeEX Inc.

16

Getting Started

MPA_e_manual_D07-00-129P_RevA00

• Unauthorized alteration or misuse

• Damage occurred from operating the unit

Return Policy

Approval must be obtained from Seller, prior to return of any merchandise. All material

returned without a Seller Return Material Authorization (RMA) number may be refused

automatically. The first purchaser must return the product in original package and in

good condition, without its serial numbers or any part thereof altered, defaced or

removed and accompanied by a specification in writing or previously provided to

Customer Support of the defects involved. The first purchaser shall notify Seller in each

instance when first purchaser intends to return goods which first purchaser believes are

not in accordance with this Limited Warranty and Seller shall be entitled, at Seller’s

option, to examine such goods at first purchaser’s facilities prior to return.

EXCEPT FOR THE WARRANTIES EXPRESSLY SET FORTH IN WRITING IN THIS

WARRANTY POLICY AND IN SELLER’S TERMS AND CONDITIONS OF SALE,

SELLER MAKES NO OTHER WARRANTY, WHETHER WRITTEN, ORAL OR

IMPLIED. ANY IMPLIED WARRANTY OF MERCHANTABILITY, TITLE, NONINFRINGEMENT OR FITNESS FOR A PARTICULAR PURPOSE IS HEREBY

DISCLAIMED BY SELLER AND EXCLUDED FROM ANY AGREEMENT BETWEEN

BUYER AND SELLER.

SELLER SHALL NOT BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL

LOSSES, DAMAGES OR EXPENSES, DIRECTLY OR INDIRECTLY ARISING FROM

THE SALE, HANDLING OR USE OF THE PRODUCTS, OR FROM ANY OTHER

CAUSE WITH RESPECT TO THE PRODUCTS OR THIS LIMITED WARRANTY

WHETHER SUCH CLAIM IS BASED UPON BREACH OF CONTRACT, BREACH OF

WARRANTY, NEGLIGENCE, STRICT LIABILITY IN TORT OR OTHER LEGAL

THEORY. THE EXCLUSION OR LIMITATION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES MAY NOT APPLY IN SOME STATES.

Return Shipping Instructions

Note: Do not ship the unit in for service without first obtaining an RMA number.

If it is necessary to return the unit, obtain a Return Material Authorization (RMA) number

and shipping address by contacting Customer Technical Support between 8:30 am to

5:30 pm Eastern Time, Monday through Friday.

• Please be prepared to provide the following information:

17

General Information

MPA_e_manual_D07-00-129P_RevA00

• Unit Serial Number

• Brief description as to why the unit needs to be returned

• Customer contact name, telephone number and email address

• Return shipping address

Note: If the unit is not under Warranty then an RMA Quotation will be provided, if

needed to obtain a Purchase Order.

Shipping with the Original Container

If you have the original shipping container (box):

1. Place the unit into the original shipping container, as the unit was originally

shipped to you. Do not include personal items such as jumper cords or

connectors. VeEX is not responsible for these items.

2. Use the original inserts or foam padding to protect all six sides of the unit.

3. Securely seal the shipping container and mark FRAGILE on the container to

ensure careful handling.

4. Include the RMA number on the outside of the shipping container.

5. Contact Customer Technical Support for the repair department’s return shipping

address.

Shipping Without the Original Container

If you do not have the original shipping container:

• You may purchase a shipping container from VeEX, custom designed for the size

and shape of your test unit, or

• You can use the following general instructions to repack the unit using

commercially available materials:

1. Use a strong shipping container, similar to the original unit shipping box.

2. Verify that the substitute container is rated at 350 lbs. per square inch

3. Make sure that the unit is satisfactorily protected by using a layer of

pressure durable.

Antistatic ESD Polyurethane (PU) shock-absorbing foam material. The

18

Getting Started

MPA_e_manual_D07-00-129P_RevA00

foam padding must be 3" to 4" inches in thickness (70 to 100 mm) and

applied to all six (6) sides of the unit to provide adequate protection.

4. Make sure that the unit cannot move or shift within the container.

5. Securely seal the shipping container and mark FRAGILE on the container

to ensure careful handling.

6. Include the RMA number on the outside of the shipping container.

7. Contact Customer Technical Support for the repair department’s return

shipping address.

Shipping Charges

The customer is responsible for paying all shipping charges (including insurance, duties,

taxes, customs fees, and/or other charges) for RMA units being shipped to VeEX, from

any location within or outside of the United States.

When the service is complete, your unit will be returned to the customer postage paid

(excluding Calibration RMA's), if the shipment is within the United States. Customers

outside the United States are responsible for all shipping charges.

Configuring the IP Address

Configuring the IP Address Overview

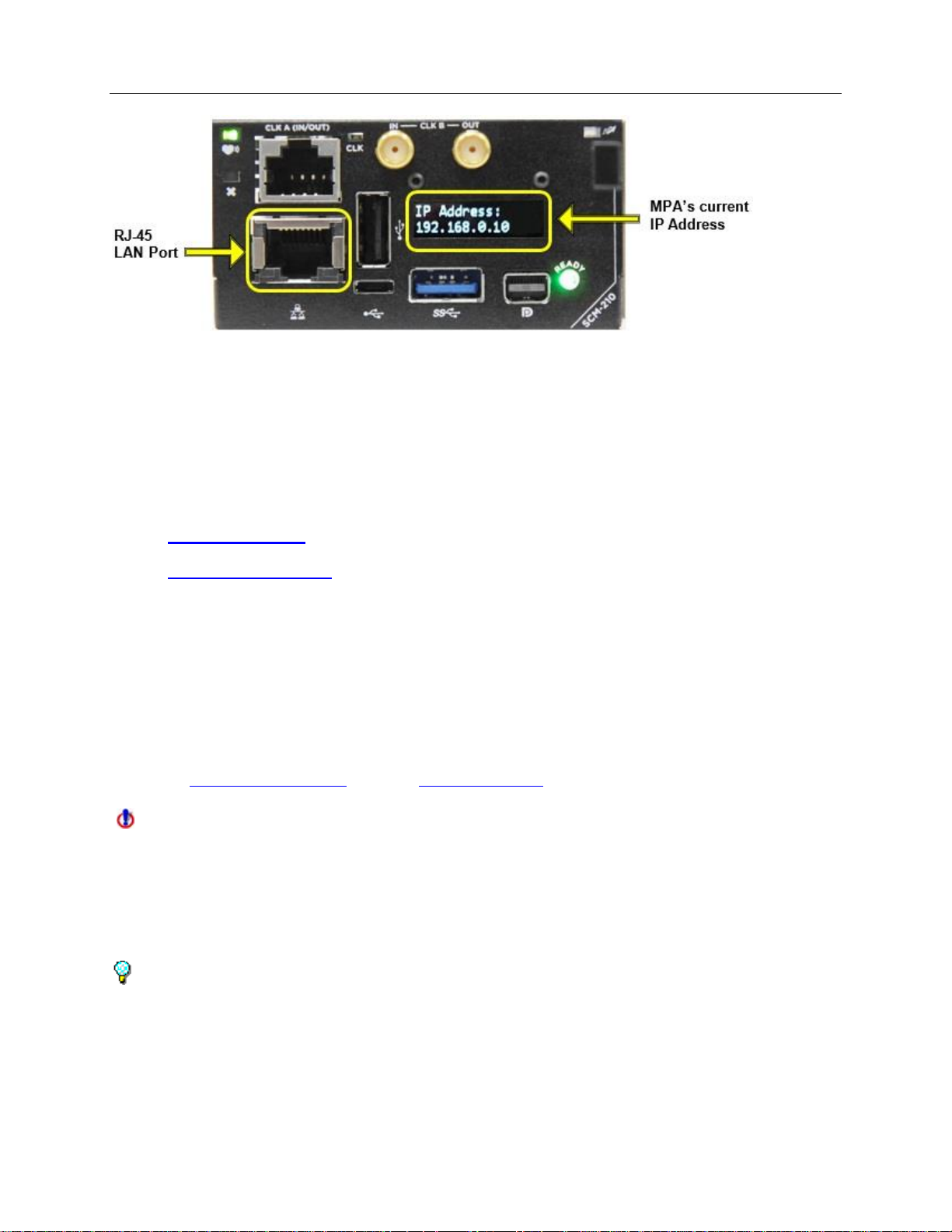

SCM-210 Controller Card

This section describes how to configure the IP Address programmed on MPA systems,

containing the SCM-210 (System Controller Module) card.

For MPA system containing an AM4022 processor and MCH controller card, please

refer to the section below for configuring the IP Address.

The MPA’s IP Address is configured on the SCM-210 controller card and is used for all

Ethernet communication to the MPA system, such as Remote GUI, VNC and SCPI, via

the RJ-45 LAN Port.

The MPA’s current IP Address is displayed on the OLED display screen.

19

Configuring the IP Address

MPA_e_manual_D07-00-129P_RevA00

• When the system is shipped from the factory, the SCM-210 controller card's

default IP Address is set to 192.168.0.10, with a Subnet Address of

255.255.255.0

The following methods can be used for changing the SCM-210’s IP Address:

• USB flash drive (preferred method)

• Remote GUI Client (must currently be connected by the Remote GUI client or

VNC)

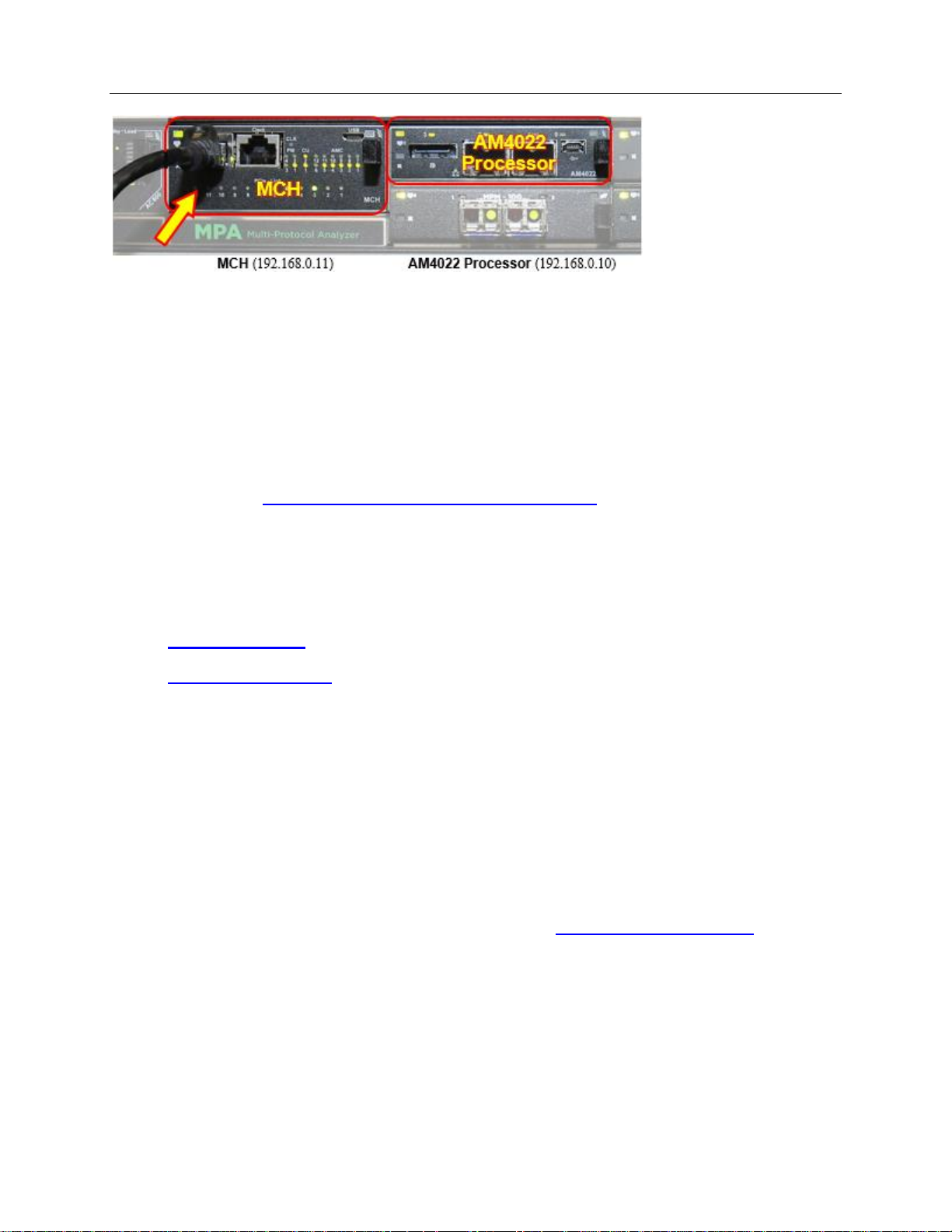

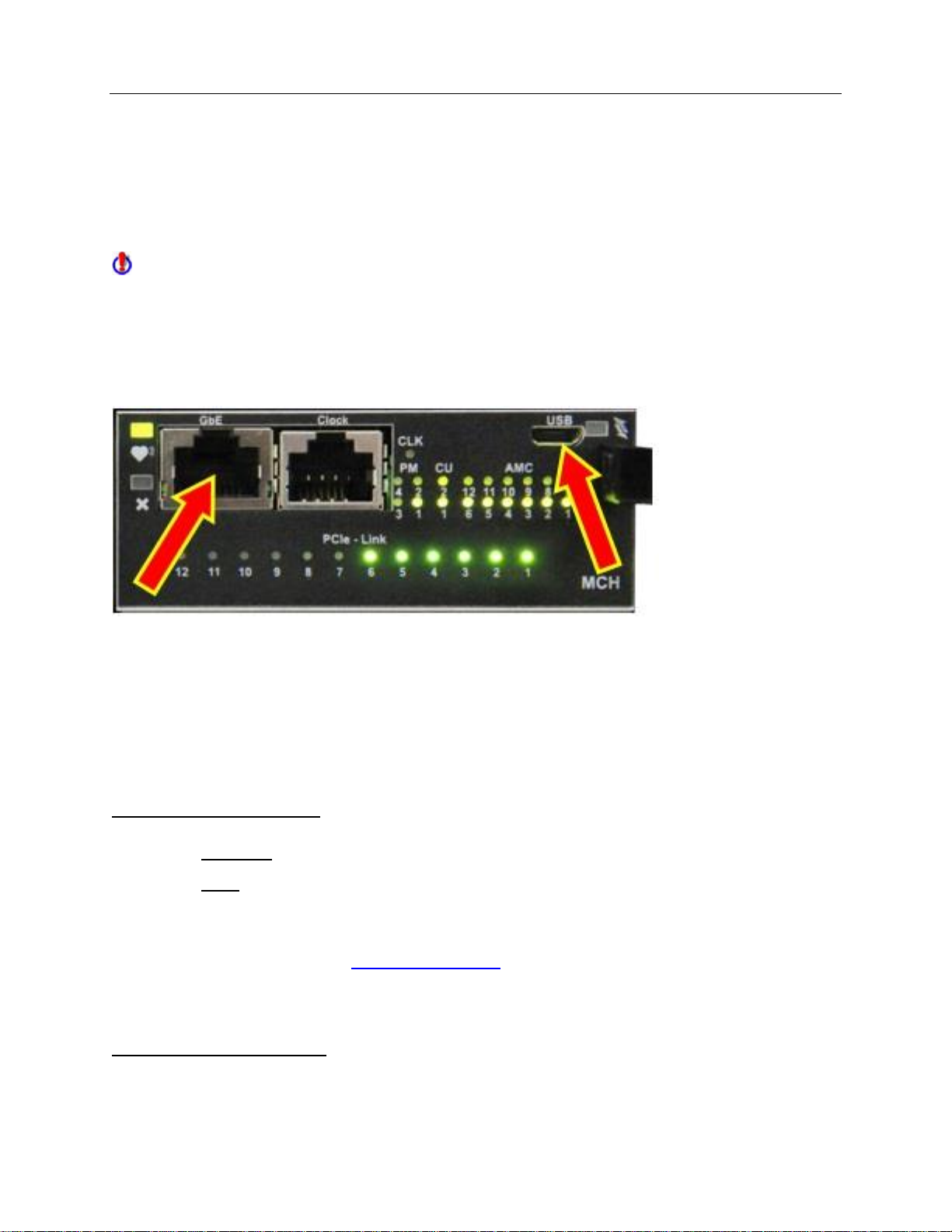

AM4022 Processor and MCH Controller cards

This section describes how to configure the IP Address programmed on the MPA

system’s AM4022 processor and the MCH controller card combination.

For MPA system containing an SCM-210 controller card, please refer to the section

above for configuring the IP Address.

The MPA’s IP Address is configured on the AM4022 processor card and is used for all

Ethernet communication to the MPA system, such as Remote GUI, VNC and SCPI, via

the MCH’s GbE port (as illustrated below).

Ethernet communication flows internally through the MCH’s GbE port to the AM4022

processor. The two RJ-45 connectors on the AM4022 processor are not used.

20

Getting Started

MPA_e_manual_D07-00-129P_RevA00

• When the system is shipped from the factory, the AM4022 processor’s default IP

Address is set to 192.168.0.10, with a Subnet Address of 255.255.255.0

• The MCH controller module’s default IP Address is set to 192.168.0.11, with a

Subnet Address of 255.255.255.0

o The MCH’s IP Address is only required if an External BITS/SETS chassis

clock is plugged into the RJ-48 Clock In/Out port

o See Changing the MCH module’s IP Address for changing the MCH

module’s IP Address

The following methods can be used for changing the AM4022’s IP Address:

• USB flash drive (preferred method)

• Remote GUI Client (must currently be connected by the Remote GUI client or

VNC)

Note: Regardless which card type or method you use to change the MPA's IP Address,

you will need to reboot the MPA in order for the setting to take effect.

For assistance with changing the IP Address, contact Customer Tech Support.

Changing the IP Address with a USB Flash Drive

The ability to change the MPA's IP Address with a USB flash drive (e.g., pen drive) is a

very simple and easy method of changing the IP Address, especially if you do not know

the MPA's current IP Address.

21

Configuring the IP Address

MPA_e_manual_D07-00-129P_RevA00

By attaching a USB flash drive containing the mpa_ipconfig configuration file to

either the SCM-210 or AM4022 Processor (depending on your unit's configuration), this

will automatically change the MPA’s IP Address to whatever IP Address is programmed

in the mpa_ipconfig file.

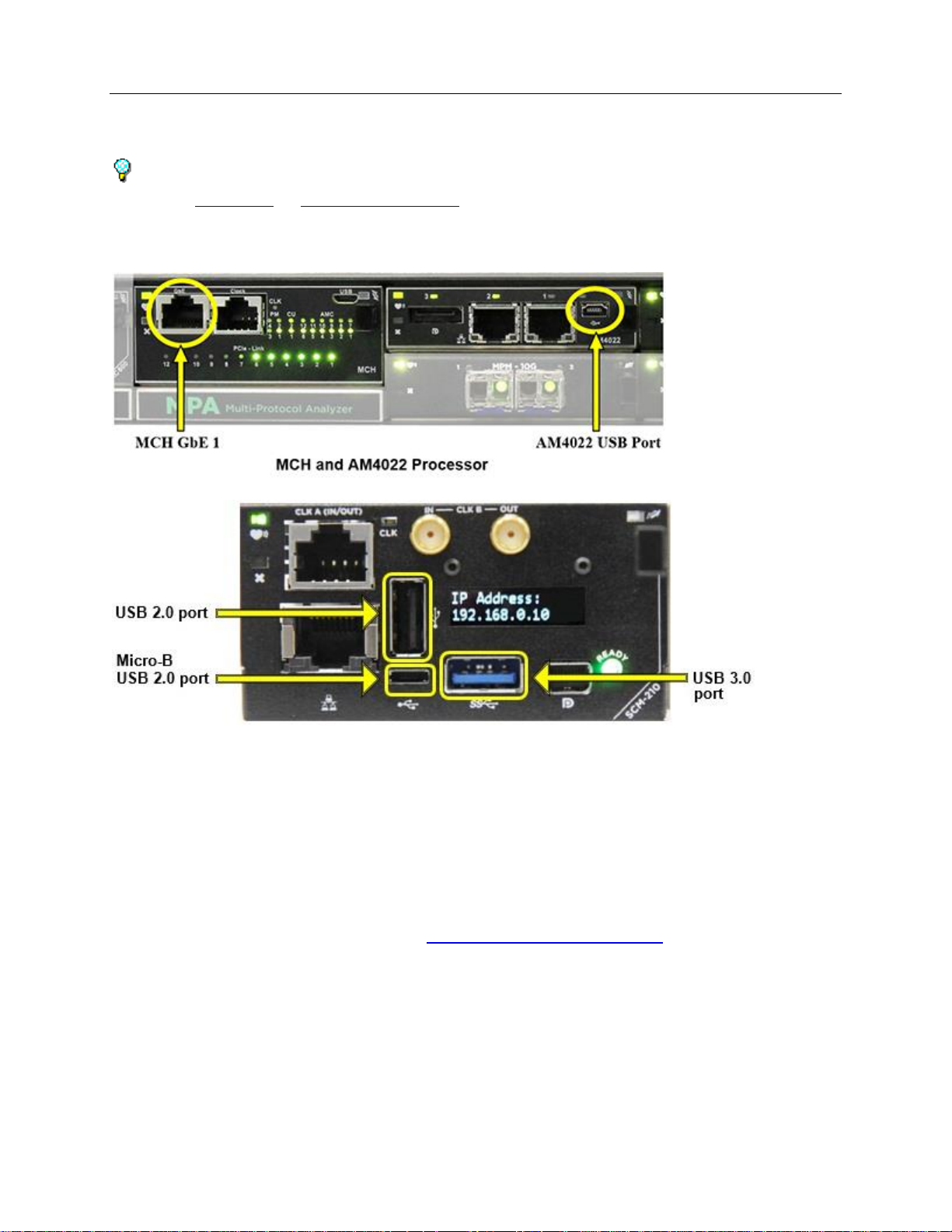

SCM-210 card (3x USB ports to choose from)

Software Requirements

• mpa_ipconfig (Editable text file)

This file is included in the USB drive that was shipped with the MPA system, also

it can be provided by contacting Customer Technical Support.

Hardware Requirements

• Standard USB flash drive (20KB of free space)

22

Getting Started

MPA_e_manual_D07-00-129P_RevA00

• PC with any text file editing software program (i.e., Notepad, Notepad++, or

Wordpad)

Wordpad tends to display the settings in an easier to read layout than

Notepad

• USB 2.0 Mini-A cable (only required for systems containing an AM4022

Processor)

(Two USB cables are shipped with the MPA systems containing the MCH card

and AM4022 Processor; a USB 2.0 Mini-A connector type for use with the

AM4022 Processor, and a USB 2.0 Micro-B connector type for use with the MCH

card)

Changing the Processor’s IP Address with USB Flash

1. The mpa_ipconfig file will need to be edited using any text-editor, and then

saved to a USB flash drive’s root directory.

a. The mpa_ipconfig file is a text file, but it does not have a file extension.

b. Do not rename the mpa_ipconfig file, nor give it a file extension.

c. If you downloaded the mpa_ipconfig.zip file our website or a customer

support email, then extract the mpa_ipconfig file out of the .zip file

before editing it.

2. To configure the MPA system for a Static IP Address:

a. Change the file’s IP Address, Subnet Mask, and Gateway to the

appropriate settings for your network.

b. By default, this file contains the following text, including a Carriage

Return and Line Feed control characters at the end of each line.

# MPA IP address configuration file.

IPADDR=192.168.0.10

NETMASK=255.255.255.0

GATEWAY=192.168.0.1

23

DNS1=8.8.8.8

DNS2=8.8.4.4

Configuring the IP Address

IP addresses 192.168.138.0 through 192.168.138.255 are reserved

and should not be used. A serious system conflict can occur if an IP

address in this range is assigned to the processor.

If you use an IP address in the range of 192.168.x.y (where x is not 138),

then you must set the Subnet Address to 255.255.255.0.

MPA_e_manual_D07-00-129P_RevA00

c. The default Primary and Secondary DNS Server addresses are

configured for 8.8.8.8 / 8.8.4.4, which are public DNS addresses created by

Google, and only need to be modified if being replaced with networkspecific DNS addresses.

3. To configure the MPA system to Obtain an IP Address from a DHCP server:

Note: Verify that an Ethernet cable linked to a DCHP server or router is

connected before setting the IP Address to DHCP.

a. Change the IP Address to the letters “DHCP”

# MPA IP address configuration file.

IPADDR=DHCP

b. When IPADDR=DHCP is used, all further Addresses in this file are

ignored.

4. Copy the reconfigured mpa_ipconfig file to the USB flash drive, if it is not

already on one.

5. Ensure the MPA system has been turned on for at least 4 to 5 minutes, and that

either the SCM-210's Ready LED is solid green or that the AM4022 Processor’s

status LED in the top left corner of the processor is solid green.

6. Close all open remote software connections to the MPA system, such as

Remote GUI, VNC, and/or SCPI.

7. Connect the configured USB flash drive to the MPA's processor card.

• For units with an AM4022 Processor, the USB flash drive connects to the

AM4022 processor's USB port using the USB Mini-A adaptor cable that

came with the system.

• For units with an SCM-210 card, the USB flash drive can be connected to

the most appropriate of the three USB ports available. The three USB

ports provided on the SCM-210 card include a standard USB 2.0 port, a

standard USB 3.0 port, and a Micro-B USB 2.0 port (which requires a USB

Micro-B adaptor cable).

24

Getting Started

MPA_e_manual_D07-00-129P_RevA00

• See images above for the location of the usb ports on both processor

cards.

8. Typically, within less than 30 seconds the file on the flash drive will automatically

reconfigure the IP Address and Reboot the MPA system.

• For units with an AM4022 Processor, when the AM4022 Processor

reboots, you will see the LED’s above the Ethernet ports, the USB port

and Display port (labeled 0 – 3) briefly turn Red for a couple of seconds,

and back to Green (or off), as the processor reboots.

• For units with an SCM-210 card, the SCM-210’s OLED display screen will

go blank and the green READY LED will turn off, indicating that the

system is rebooting.

Note: If after 30 to 45 seconds the MPA system does not reboot, this could

indicate one of the following conditions:

• The IP Address configured in the mpa_ipconfig file is the same as that

already programmed on the MPA system

• The mpa_ipconfig file was possibly renamed, or given a file extension

• The mpa_ipconfig file was possibly saved to a sub-folder on the USB flash

drive, and not to the root directory

• The USB flash drive was not recognized the first time was inserted and

may need to unplugged and plug it back in again.

• The system may not have been fully booted prior to connecting the USB

flash drive, in which case wait a few minutes and try it again.

9. After the MPA begins the reboot process, disconnect the USB flash drive.

10. Wait for 4 to 5 minutes for the MPA system to finish booting up and verify that

you can now Ping and remotely connect to the processor’s new IP Address.

11. For units with an SCM-210 card, the new IP Address is displayed on the OLED

screen and the MPA is fully booted and operational again when the green

READY LED illuminates.

25

Configuring the IP Address

MPA_e_manual_D07-00-129P_RevA00

Changing the IP Address with the Remote GUI Client

The Remote Client software is a Windows PC based Graphical User Interface (GUI)

that remotely controls the MPA system, via the MPA’s IP Address.

If you are able to Ping the processor’s current IP Address, and are able to login to the

MPA via the Remote GUI client software, then you can change the processor’s IP

Address from the Remote GUI client.

You can also change the MPA’s IP Address from the remote desktop GUI via a VNC

connection, or from the local GUI via DisplayPort video monitor and USB mouse.

Software Requirements

• Remote Client software

• Current IP Address information for the MPA system

• New IP Address information for the MPA system

Hardware Requirements

• A Personal Computer with a 300-MHz Pentium processor or faster

• A standard 10/100/1000 Base-T Ethernet cable for connectivity between the PC

and the MPA system

• optional: Computer monitor with DisplayPort cable and a USB mouse connected

to the AM4022 or SCM-210

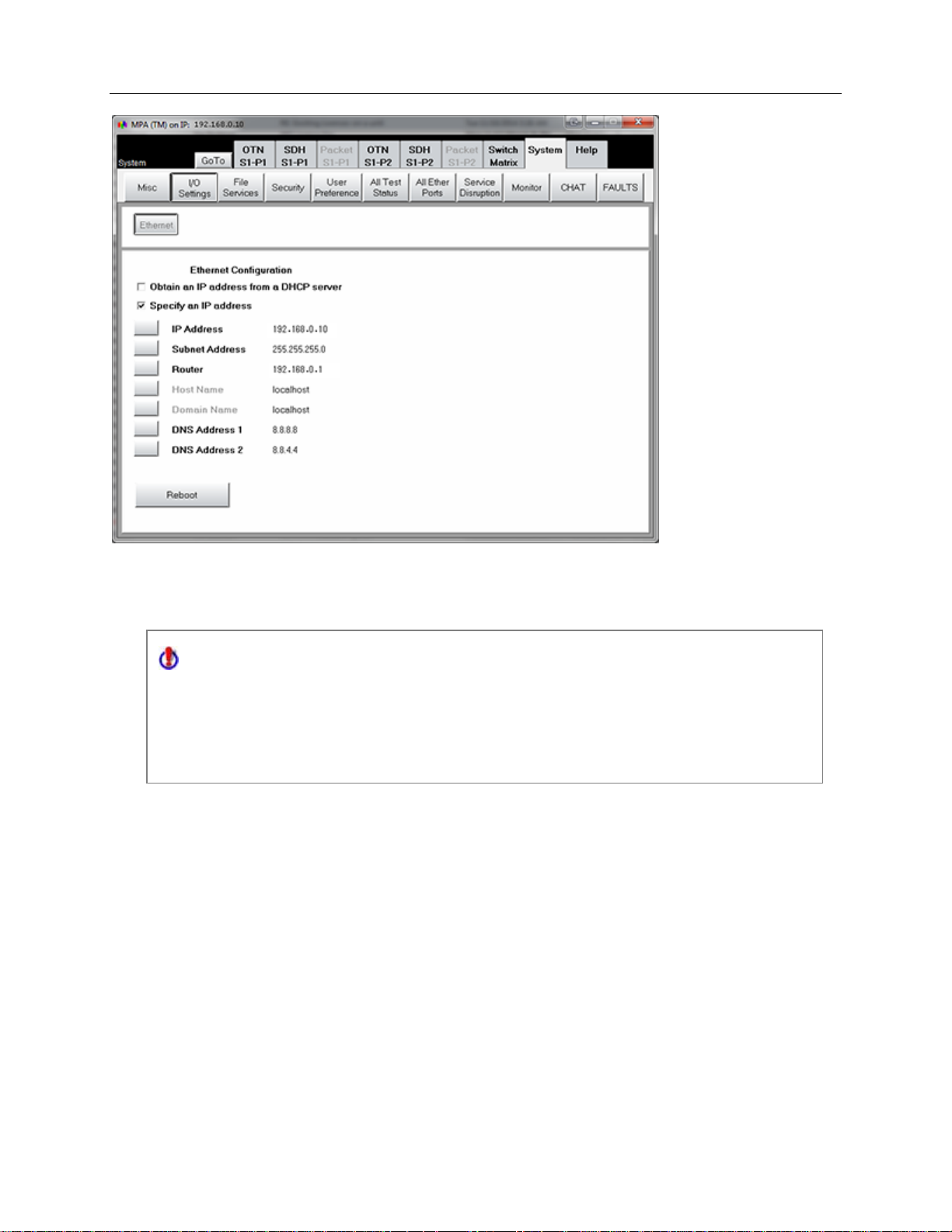

Changing the Processor’s IP Address from the Remote GUI

1. Establish a remote GUI connection to the MPA system, as described in DLI

Remote Client Application.

2. Select the System tab, and select the I/O Setting button.

3. The Ethernet Configuration screen appears.

4. Select Specify an IP address.

a. Only choose Obtain an IP Address from DHCP if know how to retrieve the new

IP Address automatically assigned from the DHCP server, or your MPA has an SCM210 card which displays the obtained IP address.

26

Getting Started

IP addresses 192.168.138.0 through 192.168.138.255 are reserved and

should not be used. A serious system conflict can occur if an IP address in

this range is assigned to the processor.

If you use an IP address in the range of 192.168.x.y (where x is not 138), then

you must set the Subnet Address to 255.255.255.0.

MPA_e_manual_D07-00-129P_RevA00

4. Enter the new IP Address, Subnet Address, and Router/Gateway Address to

the appropriate settings for your network.

6. The DNS Addresses should only be modified if specific DNS Addresses need to

be entered for your network, otherwise the default DNS Addresses do not need

to be changed.

a. By default, the DNS Address 1 (Primary DNS) is configured for 8.8.8.8,

and the DNS Address 2 (Secondary DNS) is configured for 8.8.4.4. These

are public DNS addresses established by Google, and only need to be

modified if being replacing with a network-specific addresses.

7. Reboot the unit using the Reboot button for the changes to take effect.

8. The current Remote GUI session will close.

9. Allow 4 to 5 minutes for the system to reboot, and for all of the internal software

applications to finish loading before connecting to the new IP Address.

27

Configuring the IP Address

MPA_e_manual_D07-00-129P_RevA00

Changing the MCH module’s IP Address

This procedure shows how to connect to the MicroTCA Carrier Hub (MCH) module, and

issue commands to configuring the MCH’s IP Address settings.

This procedure does not apply if your MPA unit has an SCM-210 card.

Communication to the MCH module can be via an Ethernet (Telnet) connection to the

MCH’s GbE Ethernet port (Option 1), or via a USB (Serial) connection to the MCH’s

micro-USB port (Option 2).

Note: After establishing a connection to the MCH card via either of the two options, then

you can View the MCH current IP Address, or Change the MCH IP Address.

Software Requirements

• For Ethernet, any Telnet client application software, such as PuTTY

• For USB, the nat_mch.inf driver file (included in USB flash drive, and available

upon request), and any Serial port terminal software, such as PuTTY

(PuTTY is included on the USB flash drive shipped with the MPA system, or can

be downloaded free from http://www.putty.org/)

Hardware Requirements

• A Personal Computer

28

Getting Started

MPA_e_manual_D07-00-129P_RevA00

• For Ethernet, a standard 10/100/1000BaseT RJ-45 Ethernet cable, connected

to a network or directly to a PC

• For USB, a USB 2.0 Micro-B cable (provided with system)

(Two USB cables are shipped with the new systems; a USB 2.0 Mini-A connector

type for use with the AMC Processor, and a USB 2.0 Micro-B connector type for

use with the MCH)

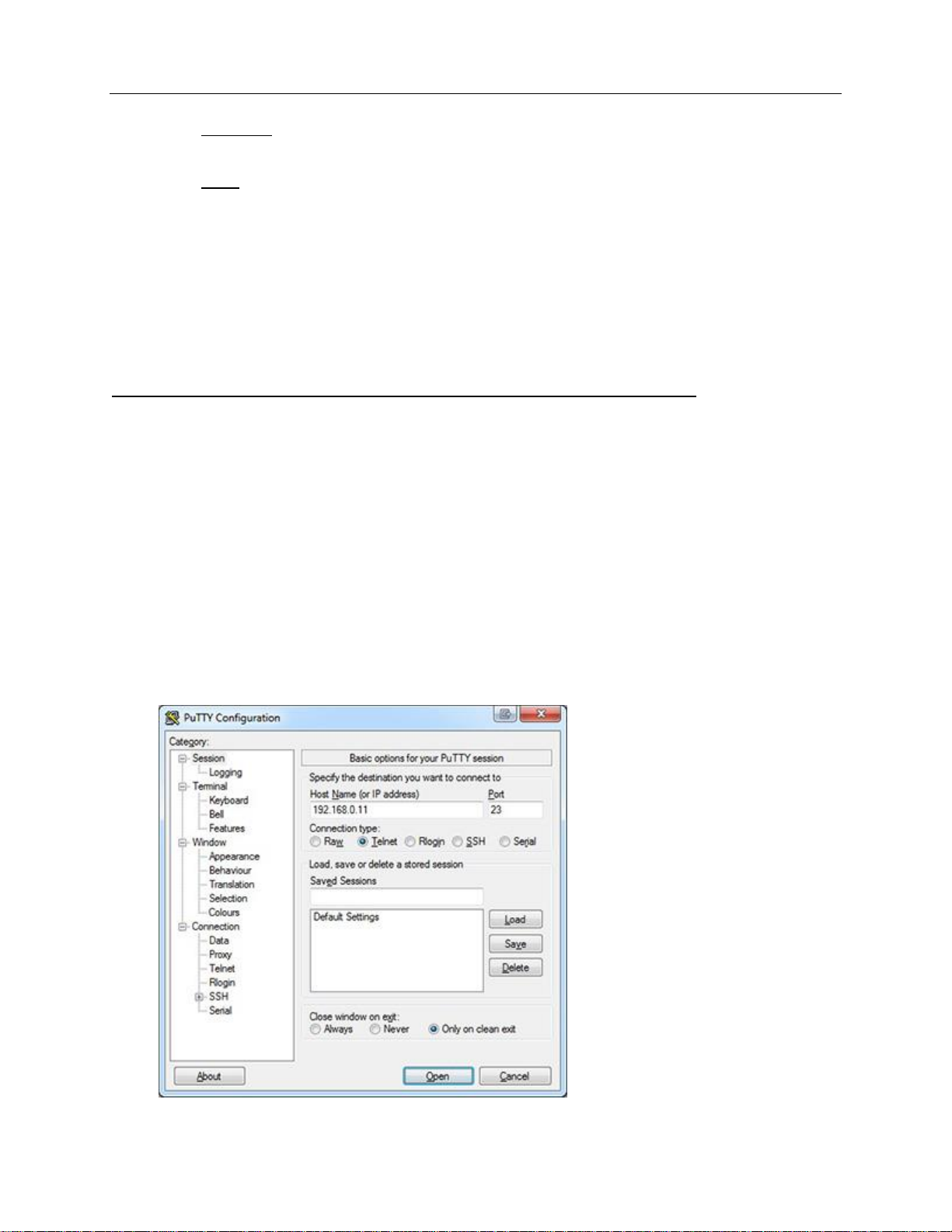

Option 1: Establish a connection to the MCH via Ethernet (Telnet):

1. To communicate with the MCH via Telnet, the MCH’s GbE current IP Address

must be known and responsive to Ping requests.

• The MCH’s default IP Address is 192.168.0.11 (for units built after of May of

2014)

• If the MCH’s current IP Address is unknown or does not respond to Ping

requests, then precede to the USB instructions

2. Launch the PuTTY utility, and select the Telnet Connection type (Port #23).

3. Enter the MCH’s current IP Address into the Host Name text box and click

Open.

29

Configuring the IP Address

MPA_e_manual_D07-00-129P_RevA00

4. A console window will appear stating Welcome to NAT-MCH, followed by a nat>

command prompt.

5. Verify the connection by pressing the Enter key to confirm that a second nat>

prompt appears.

Option 2: Establish a connection to the MCH via USB (Serial):

1. To communicate with the MCH via Serial, you will need a USB 2.0 Micro-B

cable, and the nat_mch.inf driver file (accessible from the Utilities folder in the

USB flash drive shipped with the MPA system or saved to a known location on

your PC).

a. Connect the PC to the MCH with the USB cable before installing the

driver.

b. If you have already installed the nat_mch.inf driver from a previous

connection, then skip this rest of this step.

c. If Windows displays an error stating the “Device driver software was not

successfully installed”, the nat_mch.inf driver will need to be manually

installed.

d. Open Device Manager and look for Unknown Device (with yellow

exclamation mark) listed under Ports or Other Devices.

e. Right-click on Unknown Device and select Update Diver Software.

f. Next, select “Browse my computer for driver software”, and browse to

the folder where the nat_mch.inf driver is located.

g. If a message appears stating “Windows can’t verify the publisher of

this driver software”, select “Install this driver software anyway”.

h. Once the driver has installed, Device Manage should show NAT-MCH

USB CDC Console listed under Ports, with a COM port number in

parenthesis.

i. Take note of the COM Port number assigned for this USB connection.

2. Launch the PuTTY utility.

30

Getting Started

MPA_e_manual_D07-00-129P_RevA00

3. Select Serial from the Connection branch listed under Category, to configure

the Serial port settings.

4. Enter the COM Port number that was automatically assigned for this USB

connection in Device Manage.

5. Configure the rest of the Serial Port settings as the following:

• Speed (Baud): 19200

• Data Bits: 8

• Stop Bits: 1

• Parity: None

• Flow Control: None

6. Click Open to establish the connection and wait for the console window to

appear.

7. Press the Enter key to display the nat> command prompt.

8. Verify the connection by pressing Enter again to confirm that a second nat>

prompt appears.

Viewing the MCH current IP Address (Telnet or Serial):

31

Configuring the IP Address

IP addresses 192.168.138.0 through 192.168.138.255 are reserved and

should not be used. A serious system conflict can occur if an IP address in

this range is assigned to the processor.

If you use an IP address in the range of 192.168.x.y (where x is not 138), then

you must set the Subnet Address to 255.255.255.0.

MPA_e_manual_D07-00-129P_RevA00

1. In order to view the MCH’s GbE port’s IP Address, first establish either a Telnet

or Serial connection to the MCH as described above, and verify the cursor

appears next to the nat> command prompt.

2. To view the currently configure IP Address settings, type ifconfig from the nat>

command prompt, and press Enter.

• The default GbE port’s IP Address is 192.168.0.11, with a Subnet Address of

255.255.255.0.

Changing the MCH IP Address (Telnet or Serial):

1. In order to change the MCH’s IP Address, first establish either a Telnet or Serial

connection to the MCH as described above, and verify the cursor appears next to

the nat> command prompt.

2. To change the IP Address settings, type ip from the nat> command prompt, and

press Enter.

3. The cursor appears after the current IP Address.

a. To change the IP Address, press the Backspace key to delete the

current Address (one digit at a time), then type the new Address followed

by Enter to proceed to the next setting.

4. The cursor then appears after the current IP Net Mask.

a. To change the Subnet Mask Address, press the Backspace key to

delete the current Address, then type the new Address followed by Enter

to proceed to the next setting.

5. The cursor then appears after the current IP Broadcast Addr.

a. To change the Broadcast Address, press the Backspace key to delete

the current Address, then type the new Address followed by Enter to

proceed to the next setting.

32

Getting Started

MPA_e_manual_D07-00-129P_RevA00

6. The cursor then appears after the current IP Gateway Addr.

a. To change the Gateway Address (Router Address), press the

Backspace key to delete the current Address, then type the new

Address followed by Enter to proceed to the next setting.

7. After the Gateway Address has been changed, a confirmation message appears

asking “Are you really sure?”

a. Press Y to Apply the new settings, followed by Enter.

b. Press N to Cancel the new settings, followed by Enter.

8. When the nat> command prompt reappears, the system will need to be turned

Off and back On.

a. Warning! Do not turn the chassis Power off without first deactivating MCH

and AMC cards.

9. Close the PuTTy connection as well as all remote software connections to the

MPA system such as the Remote Client GUI, VNC, SCPI or other software

connections to either the MCH or AMC Processor.

10. Follow the steps outlined in the Shutdown Procedure for turning the system’s

power Off.

a. After the power to the chassis is turned off, then push both of the

Unlock/Extraction handles back in and turn the power switch back On.

b. Wait about 4 to 5 minutes for the system to fully reboot, and then verify

that you can Ping or login into the MCH module, via the newly configure IP

Address settings.

33

Remote Client Application

If using Windows Vista or later, you may need configure Windows to run

the Remote GUI with Administrator permissions, even if you are already logged

in as an Administrator.

To do this Right-click on the DLI Remote Client icon and select Properties.

Then from the Compatibly tab, enable the “Run this program as

Administrator” option, and click OK.

MPA_e_manual_D07-00-129P_RevA00

Remote Client Application

Remote Client Application Overview

The Remote Client is a remote GUI (Graphical User Interface) application that allows

you to remotely connect to and control MPA products from a Windows based PC.

Before using the Remote Client:

• Verify the minimum software and hardware requirements.

• Verify that the Ethernet parameters have been entered into your test set.

• Verify that you have security access to the unit.

• Install the DLI Remote Client on to your PC.

To start the Remote Control Application:

1. Double-click the DLI Remote Client shortcut icon that appears on your PC's

desktop.

2. Enter the remote unit's IP address, and your User ID and Password.

The default User ID is Admin (case sensitive), and the default Password is

Admin1 (case sensitive)

3. Select OK.

• When attempting to connect to an MPA with the Remote Client

application for the first time, or for the first time after a software update,

the application tends to become unresponsive after the file transfer

process.

• If this happens, click Cancel or End Task on the Remote Client

application, then reconnect to the MPA a second time.

4. Once the connection is made, the remote unit's GUI appears. The title bar

contains the product name and connection method. Use your mouse to select

functions.

34

Getting Started

Important: Files that are created when using the Remote Control Application are

saved on your PC in the Remote Control’s compatibility directory.

If you want to keep these files, copy and save the following to a backup directory on

your PC that is not in the compatibility directory’s path:

• Any file with the .pdf, .set, .stat, .health, .evt, .aps, .perf, .rep, or .bmp

extension.

MPA_e_manual_D07-00-129P_RevA00

To automate the log on process, select Automating the Remote Control Icon

for more information.

5. If any problems are experience when installing or using the Remote Client, see

Troubleshooting Remote Client Application for solutions.

DLI Remote Client Requirements

Software

The minimum software requirements are:

• Windows XP, Vista, 7, 8, 10 or newer Windows operating systems.

• Microsoft Internet Explorer 5.0 or greater.

• TCP/IP Network Protocol

• Host domain and IP address information for LAN access.

Make sure that this information is entered into your unit. Refer to Ethernet Port

Configuration for more information.

Hardware

The minimum hardware requirements are:

• A personal computer with a 500-MHz Pentium processor or faster.

• 128 MB RAM (256 MB RAM recommended for optimum performance)

• 60 MB of free disk space

• An SVGA monitor with a minimum screen resolution of 800 x 600 pixels and 256

colors (1024 x 768 or higher recommended for optimum viewing), with the

Display Setting set to 100% DPI.

35

Remote Client Application

If you connect the unit directly to your PC, you will need the following:

• An Ethernet network interface card installed in your PC.

• Either a straight-through or a crossover Ethernet cable for connectivity

between the MPA and the PC's network interface card.

You need to install the Remote Client application upon your first use of the MPA

system and should upgrade to the latest Remote Client version when upgrading

your MPA to a major Feature Set change. For example, from Feature Set 7.0 to 8.0.

You must be logged into your Windows based PC/Laptop with Local Admin

Permissions, in order to install the Remote Client software application.

MPA_e_manual_D07-00-129P_RevA00

• USB flash drive (shipped with the MPA system), or web browser (if installing from

the DLI web site) for software installation.

• A standard 10/100/1000BaseT Ethernet cable for connectivity between the unit

and the network.

Remote Client Installation

The Remote Client software application is a Graphical User Interface (GUI) that

connects to the MPA via an Ethernet connection, from any Windows based PC, and

allows users to remotely control the MPA test modules.

The Remote Client software is supplied on the USB flash drive shipped with the MPA

system, and can also be downloaded from our website, or provided by email upon

request.

To install from the supplied USB drive:

1. Insert the USB drive into a standard USB port.

2. Open Windows Explorer and select the USB drive to display the contents and

open the Remote Client folder.

3. Double-click on SETUP.EXE to begin installing the Remote Client.

36

Getting Started

Important: Reports that were saved to the Compatibility folders, located in the

Remote Client application directory (for example, C:\Program

Files\DLI\RemoteClient\Compat700060032) will be deleted during the uninstall

process.

To save historical reports, copy and save data files with the following file extensions

to a folder located outside of the Remote Client application directory before

MPA_e_manual_D07-00-129P_RevA00

4. Select Next and follow the on-screen instructions to install the software into a

directory and create a program folder. The default directory is C:\Program

Files\DLI\RemoteClient.

5. When prompted for "How do you want to maintain the Remote GUI files on

your PC?", the default option is (A) Create Multiple Directories.

a. Use the (A) Create Multiple Directories default option for the fastest

execution when repeatedly connecting to the same test set, or to other

test sets with the same Feature Set version.

b. Select option (B) Create one GUI directory only if space is limited on

your PC’s hard disk drive, as this will require the Remote GUI files to

transfer from the test set to your PC every time you remotely connect to

the test set.

6. Select Finish to complete installation.

7. After the installation is complete, a DLI Remote Client shortcut icon appears on

the desktop. Open the application by double-clicking the DLI Remote Client

icon.

8. This completes the installation.

To install from the Internet or Email:

1. Contact Tech Support for a link to Remote Control installation file, or visit

www.veexinc.com to download the Remote Control installation file from our

website.

2. Double-click on the installation file to begin installing the Remote Client.

3. Refer to Step 4 above for the remaining installation instructions.

DLI Remote Client Removal

37

Remote Client Application

proceeding with the uninstall process.

• Any file with the .pdf, .set, .stat, .health, .evt, .aps, .perf, .rep, or .bmp

extension.

MPA_e_manual_D07-00-129P_RevA00

To remove the Remote Control Application

1. Close the DLI Remote Client application.

2. Click the Windows Start button and choose Settings.

3. Select Control Panel and choose Programs and Features.

4. Select DLI Remote Client and click the Uninstall/Change button.

5. Follow the on-screen instructions.

6. Open Windows Explorer and locate the Remote Client application directory. For

example, C:\Program Files\DLI\RemoteClient.

7. Delete the RemoteClient folder.

8. Install the new DLI Remote Client application, if upgrading to a newer remote

version.

Automating the DLI Remote Client Icon

The DLI Remote Client software is a graphical user interface (GUI) that allows you to

remotely control portable and rackmount products from a PC. An icon for the DLI

Remote Client software is created and placed on your desktop when the software is

installed.

Once installed, you can add a specific IP address, User ID, and Password parameters

to the icon to automate the login process.

1. From the desktop, right-click on the DLI Remote Client application icon.

2. Select Properties and choose the Shortcut tab.

3. Place the cursor at the end of the Target text box.

4. Press the space bar and then type:

ip=x.x.x.x, uid=y,pw=z

• x.x.x.x is the unit's IP address

• y is the user ID (case sensitive)

The default user ID is Admin

38

Getting Started

If an invalid parameter is entered, the automatic login will fail, and you must enter

the appropriate data.

MPA_e_manual_D07-00-129P_RevA00

• z is the password (case sensitive)

The default password is Admin1

• do not include any spaces between fields

Example: "C:\Program Files\DLI\RemoteClient\Galaxy.exe"

ip=10.1.8.21,uid=Admin,pw=Admin1

5. Click OK.

6. Now when you double click the DLI Remote Client application's icon, a

connection is automatically made, and the remote system's GUI appears.

Multiple DLI Remote Client applications can be running on the same PC at the same

time, each connected to the either same or different test sets.

Multiple DLI Remote Client icons can copied to your desktop, each with a

dedicated IP Address for connecting to multiple test sets.

1. Create a copy of the DLI Remote Client shortcut icon to your desktop.

2. Right-click on the copied DLI Remote Client application icon and select

Rename.

3. Rename the icon to the dedicated IP Address for the test set that this icon will

be configured to connect to, using the above procedure.

4. Follow the steps in the above procedure to configure this copy of the DLI

Remote Client icon to automatically connect to the test set's designated IP

Address.

5. Repeat this process for as many test sets as needed.

39

Remote Client Application

Symptom

Resolution

Remote Client will

not install

• Close all other running applications

• Reboot your PC/Laptop, and install the Remote Client

before opening any other software programs

"Transient" error

message when

attempting to connect

to the MPA

• Verify that you can Ping the MPA, and no other device

on your network has the same IP Address as the MPA

• Verify the network Ethernet cable is connected to the

MCH card's GbE port

• Verify you have Local Admin permissions on your

PC/Laptop

Initial remote file

transfer does not

complete

• Verify you have Local Admin permissions on your

PC/Laptop

• Temporarily disable any Firewall applications that

might be blocking the file transfer

Initial remote file

transfer completes,

but the GUI does not

launch

• Click the Cancel button, or End Task on the Remote

Client if required to close the application

• Launch the Remote Client again, and connect to the

unit a second time

• The remote file has already been transferred, so the

GUI should now launch as expected

MPA_e_manual_D07-00-129P_RevA00

Troubleshooting the Remote Client Application

This topic is intended to aid in resolving common Remote Client application problems.

For additional assistance, please contact Customer Service.

40

Getting Started

The GUI does not

look right, spaces

between tabs, etc

• The Remote Client requires the PC’s display setting’s

DPI to be set to 100%.

• Right-click on your desktop and select Display

Settings. Then adjust the setting labeled "Change the

size of text, apps and other items" to 100%. This

should resolve the look of the GUI, however you may

also need to adjust your screen resolution to

compensate for the change in font size

The GUI is open but

all of the settings are

disabled

• In order to change any of the settings, you will need to

click the padlock icon on the GUI and select Lock and

Exit. Refer to the Lock Icon for more information

The GUI is open but

only the System tab

and Help tab is

displayed

• Follow the proper Reboot instructions to reboot the

MPA

• Contact Customer Technical Support

MPA_e_manual_D07-00-129P_RevA00

VNC Connection

Virtual Network Computing (VNC) Connection As of Feature Set version 8.1.45 (and later), a VNC Server has been added to MPA

systems as another method of remotely controlling the system’s Graphical User

Interface (GUI) client software. In addition to the standard multi-user Windows based

Remote GUI client, the VNC Server on an MPA unit can also support simultaneous

VNC Viewer connections, allowing multiple users to remotely control a single MPA

system.

VNC works on a Viewer/Server model. Up to ten (10) VNC Viewers can simultaneously

be connected to the VNC Server running on the MPA, via the MPA’s IP Address

followed by a colon and a VNC Port number from 1 to 10, with one user per VNC Port.

Example: 192.168.0.10:1 to 192.168.0.10:10

The maximum number of simultaneous connections is subject to change pending

further evaluation.

41

VNC Connection

MPA_e_manual_D07-00-129P_RevA00

Advantages of using the VNC viewer to remotely control an MPA system:

• VNC viewers are supported on multiple OS platforms including; Windows, Mac

OS X, iOS, Android, and Linux, and are available for most portable devices such

as; Laptops, Tablets, and Smartphones.

• Remote Control operation without the need to install a dedicated Remote Client

application.

• No interference from Firewall software or other network restrictions.

• Since the Remote GUI client is displayed in full-screen mode within VNC viewers

that support the option to stretch and resize, the Remote GUI client can

effectively operate at any desirable viewing size.

• VNC viewer applications such as RealVNC (version 5.1 or newer),TightVNC,

UltraVNC, or whichever VNC viewer application is supported by your PC/device,

can typically be downloaded from the Internet for free.

VNC connection to MPA:

When the MPA is connected to the same network as your VNC equipped PC, or directly

connected to your PC’s Ethernet port, you can log into the MPA using the VNC viewer

to remotely control the user interface.

• Verify that the MPA’s IP Address has been configured, and you can Ping the IP

Address.

• Verify each concurrent VNC connection to the same MPA uses a different VNC

Port # (from 1 to 10). Example: 192.168.0.10:1 to 192.168.0.10:10

• Refer to VNC Viewer Configuration for the recommended configuration settings,

based on the VNC viewer application you are using.

• VNC viewers only require a login Password. A Username is not required.

• The default VNC Password for the MPA is Admin1.

• Refer to Multiple Remote VNC Desktops for multiple remote VNC desktop

connections.

VNC Viewer Configuration

For Optimal Performance, verify that your VNC viewer settings are configured for the following:

• Picture Quality should be set to the Highest setting available

• Scaling should be set to Automatic or Window Size

• Toolbar should be disabled

42

Getting Started

MPA_e_manual_D07-00-129P_RevA00

Below are recommended settings options for a few of the most popular VNC viewers.

Real VNC versions 4.1 and older do not support Preserve Aspect Ratio, and should not be

used.

Real VNC: version 5.1.x

1. Select Options.

2. From either the Basic tab or the Advanced Display tab, change/verify the following

options:

• Select: Scale to Window Size

• Enable (check): Preserve Aspect Ratio

• Disable (uncheck): Enable Toolbar

3. Enter the MPA’s IP Address in the VNC Server field, followed by colon (:) and the VNC

Port #.

• Verify the VNC Port # (from 1 to 10) being entered is not being used by another

• Example:

43

user.

VNC Connection

MPA_e_manual_D07-00-129P_RevA00

4. Click on Connect.

5. If an Unencrypted Connection message appears select (check) Don’t warn me about

this again and click Continue.

6. Enter the MPA’s VNC Password and click OK.

• The default VNC Password for the MPA is Admin1.

Real VNC: version 6.1.x

1. Select New Connection from the File menu.

2. From the Options tab, select the following options:

• Set the Picture Quality to High

• Disable (uncheck): View-only

• Set the Scaling to Automatic

• Enable (check): Preserve Aspect Ratio

• Enable (check): Pass Media Keys …

• Enable (check): Pass Special Keys …

3. From the Expert tab, scroll down and highlight the Enable Toolbar parameter.

• Set the Value to False.

4. Enter the MPA’s IP Address in to the VNC Server field on the General tab, followed by

colon (:) and the VNC Port #.

44

Getting Started

MPA_e_manual_D07-00-129P_RevA00

• Verify the VNC Port # (from 1 to 10) being entered is not being used by another

user.

• Example:

5. Leave the Name section empty for shortcut icon to be labeled as the IP Address and

Port #, or enter a “Friendly Identifier” name, associated with this MPA and Port #.

6. Click OK to add the newly created VNC shortcut icon to the VNC viewer’s desktop

section.

7. Double-click the VNC shortcut icon to connect to the MPA.

8. If an Unencrypted Connection message appears select (check) Don’t warn me about

this again and click Continue.

9. Enter the MPA’s VNC Password and click OK.

• The default VNC Password for the MPA is Admin1.

TightVNC: version 2.8.x

1. Select Options from the main menu.

• Disable (uncheck): 256 colors in the Format and Encodings section, if enabled.

• Set the Scale By to Auto in the Display section.

• Select Track Remote Cursor Locally in the Mouse Cursor section.

• Select Do Not Show in the Local Cursor Shape section.

• Leave the remaining options as set by default.

45

VNC Connection

MPA_e_manual_D07-00-129P_RevA00

2. Select Configure from the main menu.

• Disable (uncheck): Show Toolbars by Default, in the User Interface section.

• Leave the remaining options as set by default.

3. From the Main Menu, enter the MPA’s IP Address in the Remote Host field, followed by

colon (:) and the VNC Port #.

• Verify the VNC Port # (from 1 to 10) being entered is not being used by another

user.

• Example:

4. Click on Connect.

5. Enter the MPA’s VNC Password and click OK.

• The default VNC Password for the MPA is Admin1.

Multiple Remote VNC Desktops

In addition to the standard multi-user Windows based Remote GUI client, the VNC

Server on an MPA unit can also support simultaneous VNC Viewer connections,

allowing multiple users to remotely control a single MPA system from any Operating

System.

46

Getting Started

MPA_e_manual_D07-00-129P_RevA00

When connecting to the MPA with VNC, each VNC Port # (1 to 10) has its own

dedicated desktop. Example: 192.168.0.10:1 to 192.168.0.10:10

Each of the ten VNC remote desktops include a shortcut icon for the Remote Client

software, which can be launched and run independently of the other VNC desktops, as

well as a copy of this MPA User's Manual.

This multiple remote VNC desktop approach allows up to ten concurrent, and

completely independent, remote logins to a single MPA unit via VNC.

Remote GUI Login

1. Refer to Virtual Network Computing (VNC) Connection to establish a VNC

connection to the MPA unit.

2. From the VNC desktop, double-click the MPA REMOTE GUI icon to launch the

Remote Client.

• Unlike the VNC connection, the Remote Client connection requires both a

User ID and a Password.

3. Enter the GUI’s User ID and Password and click OK to login.

• Any User ID created on that MPA can also be used to login to the Remote

GUI.

• The default User ID is Admin and the default Password is Admin1.

• See the MPA User’s Manual for details on Adding a New User.

4. The GUI will appear, filling the VNC viewer window.

47

VNC Connection

MPA_e_manual_D07-00-129P_RevA00

Resizing the Remote GUI

Notice that the initial size of the VNC window may have reset to a default size upon

launching the Remote GUI application.

Since the Remote GUI runs in full-screen mode within the VNC viewer window, users