OTDR Series e-Manual, D07-00-076P-RevC00 Page 1 of 107

OTDR Series e-Manual, D07-00-076P-RevC00 Page 1 of 107

• FX150

• FX300

• MTTplus-410

• RXT-4100

• TX300s

OTDR Series

OTDR Series e-Manual, D07-00-076P-RevC00 Page 2 of 107

Table of Contents

1.0 ABOUT THIS USER MANUAL ..................................................................................... 5

2.0 PRODUCT INTRODUCTION ........................................................................................ 6

2.1 PLATFORM HIGHLIGHTS (FX150/FX300/MTTPLUS/RXT/TX300S) .............................................. 6

2.2 KEY FEATURES .......................................................................................................................... 7

2.3 PACKAGE CONTENTS ................................................................................................................. 8

3.0 SAFETY INFORMATION .............................................................................................. 9

4.0 THEORY OF OPERATION ......................................................................................... 10

4.1 OTDR ...................................................................................................................................... 10

4.2 LIGHT SOURCE ......................................................................................................................... 11

4.3 OPTICAL POWER METER .......................................................................................................... 11

4.4 VISUAL FAULT LOCATOR .......................................................................................................... 11

5.0 BASIC OPERATION ................................................................................................... 12

5.1 TEST PORTS AND INTERFACES ................................................................................................. 12

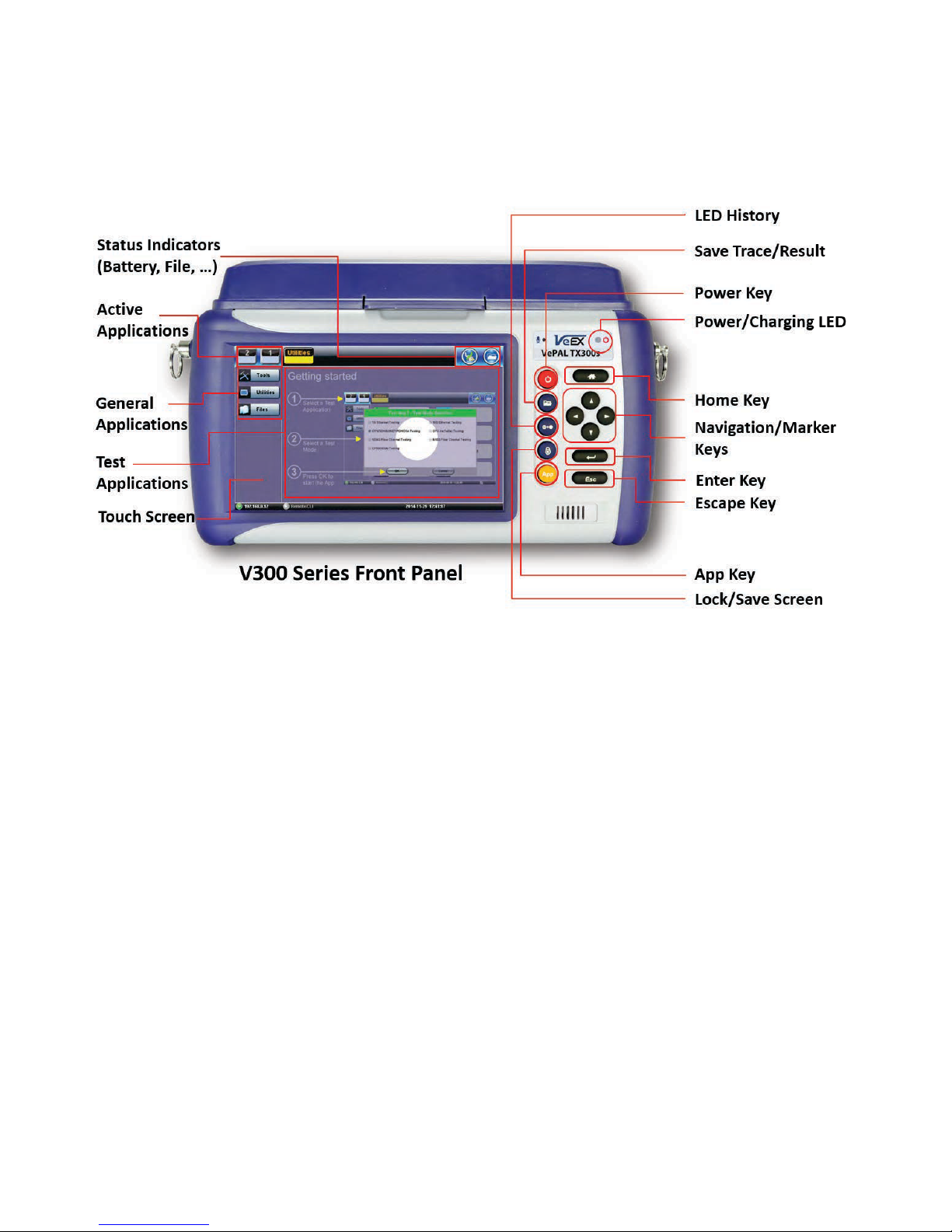

5.2 FRONT PANEL LAYOUT ............................................................................................................. 14

5.2.1 LED Indicators ...................................................................................................................................... 14

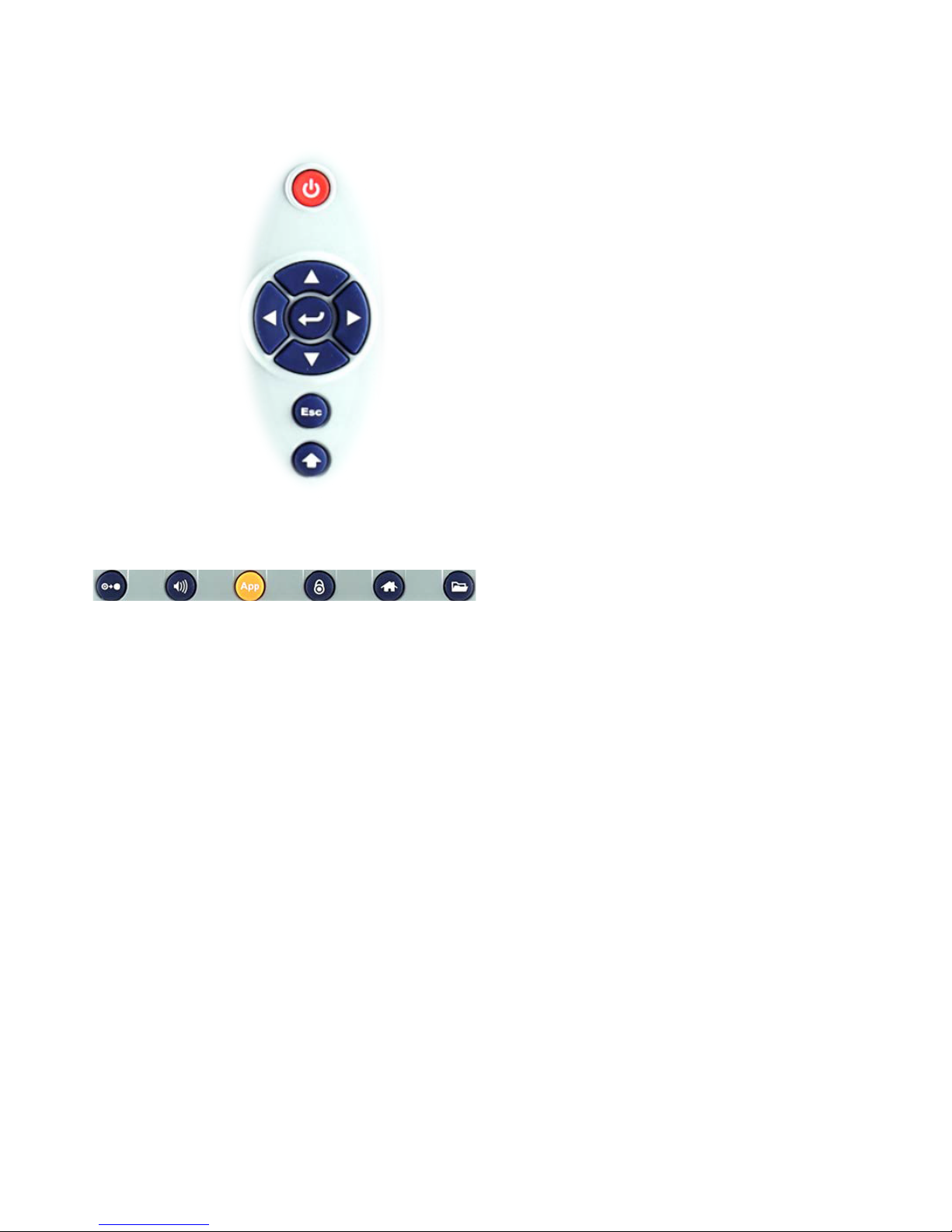

5.2.2 Rubber Keypad ..................................................................................................................................... 14

5.2.3 Menu Navigation .................................................................................................................................. 15

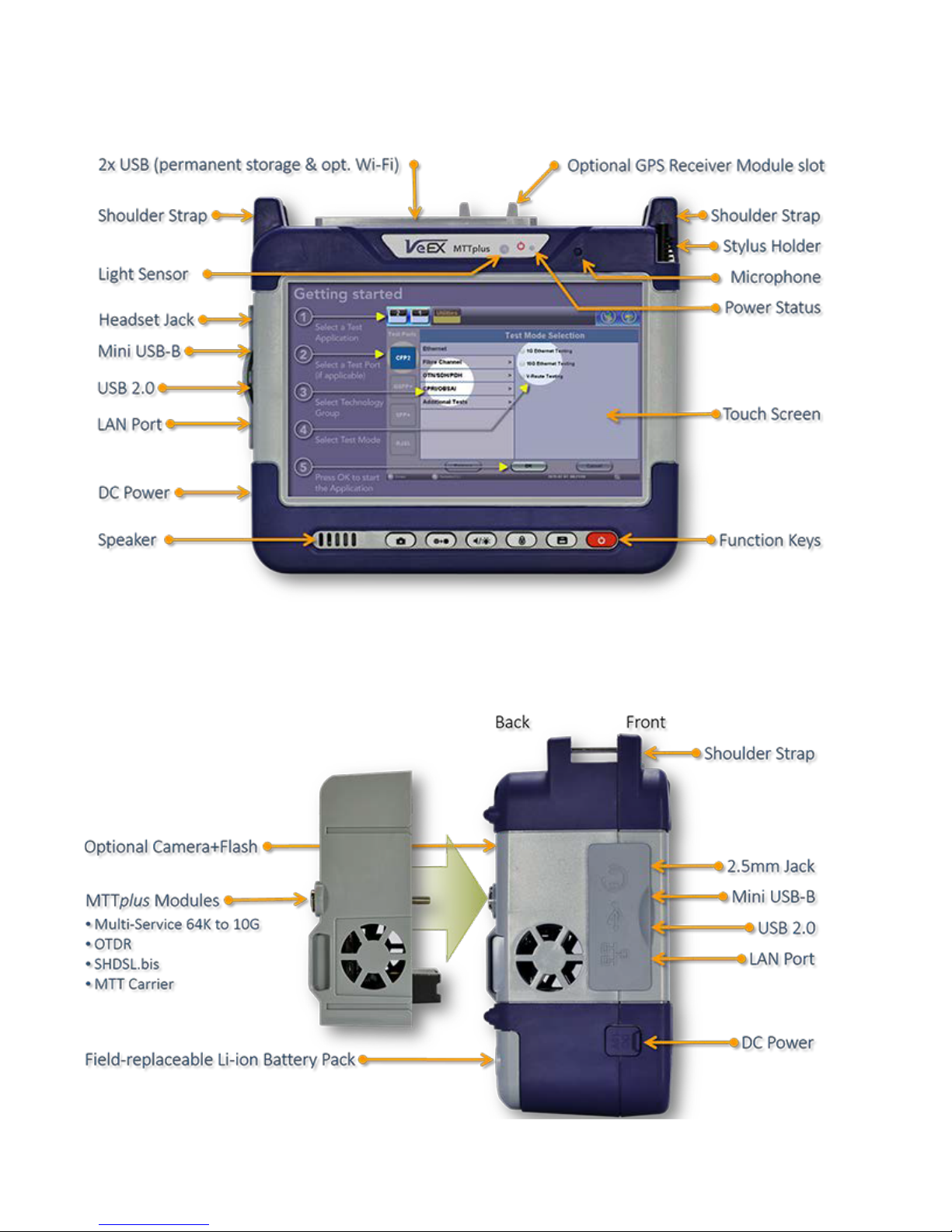

5.3 MTTPLUS OVERVIEW ............................................................................................................... 16

5.3.1 MTTplus Side View ............................................................................................................................... 16

5.3.2 MTTplus Control Panel ........................................................................................................................ 17

5.3.3 MTTplus OTDR Module Top View ....................................................................................................... 17

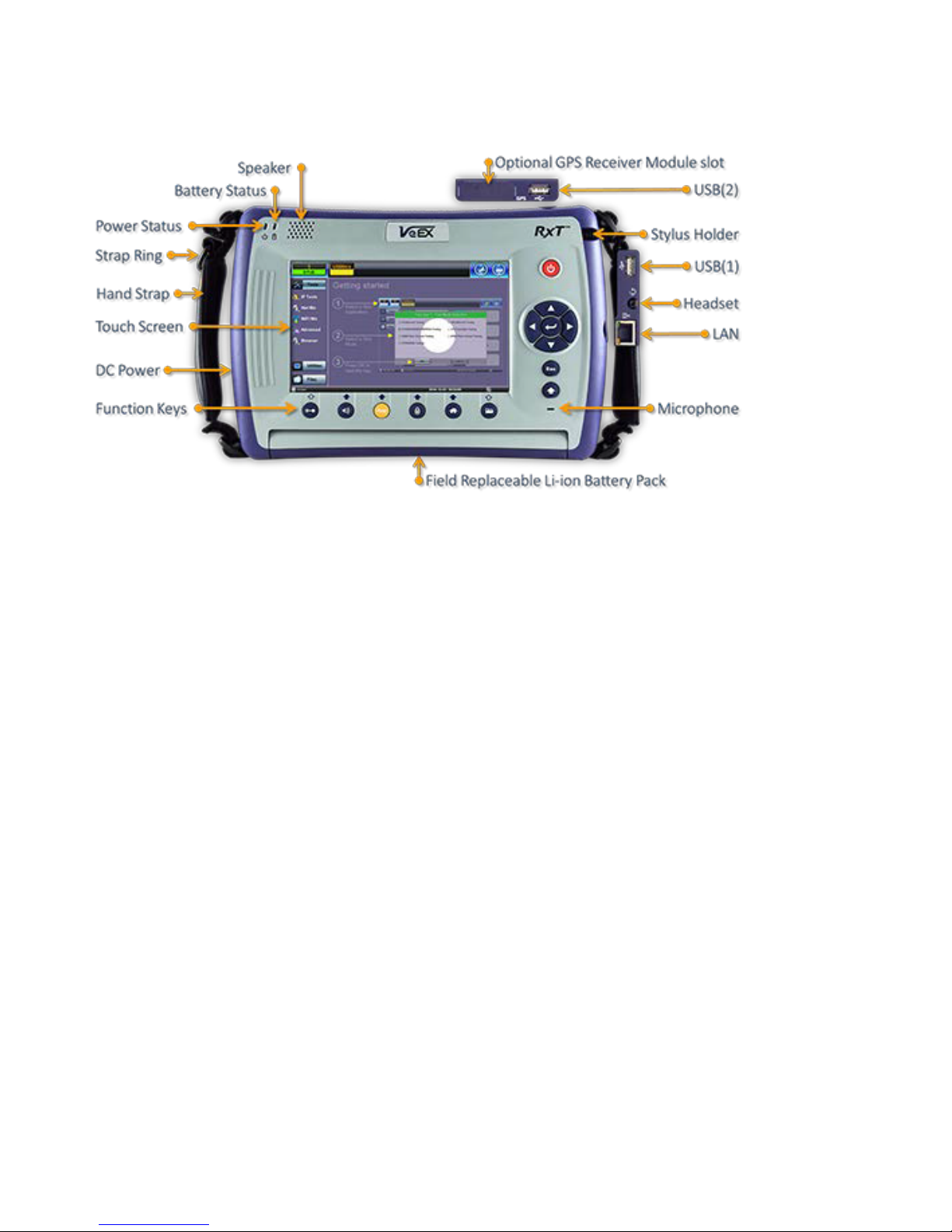

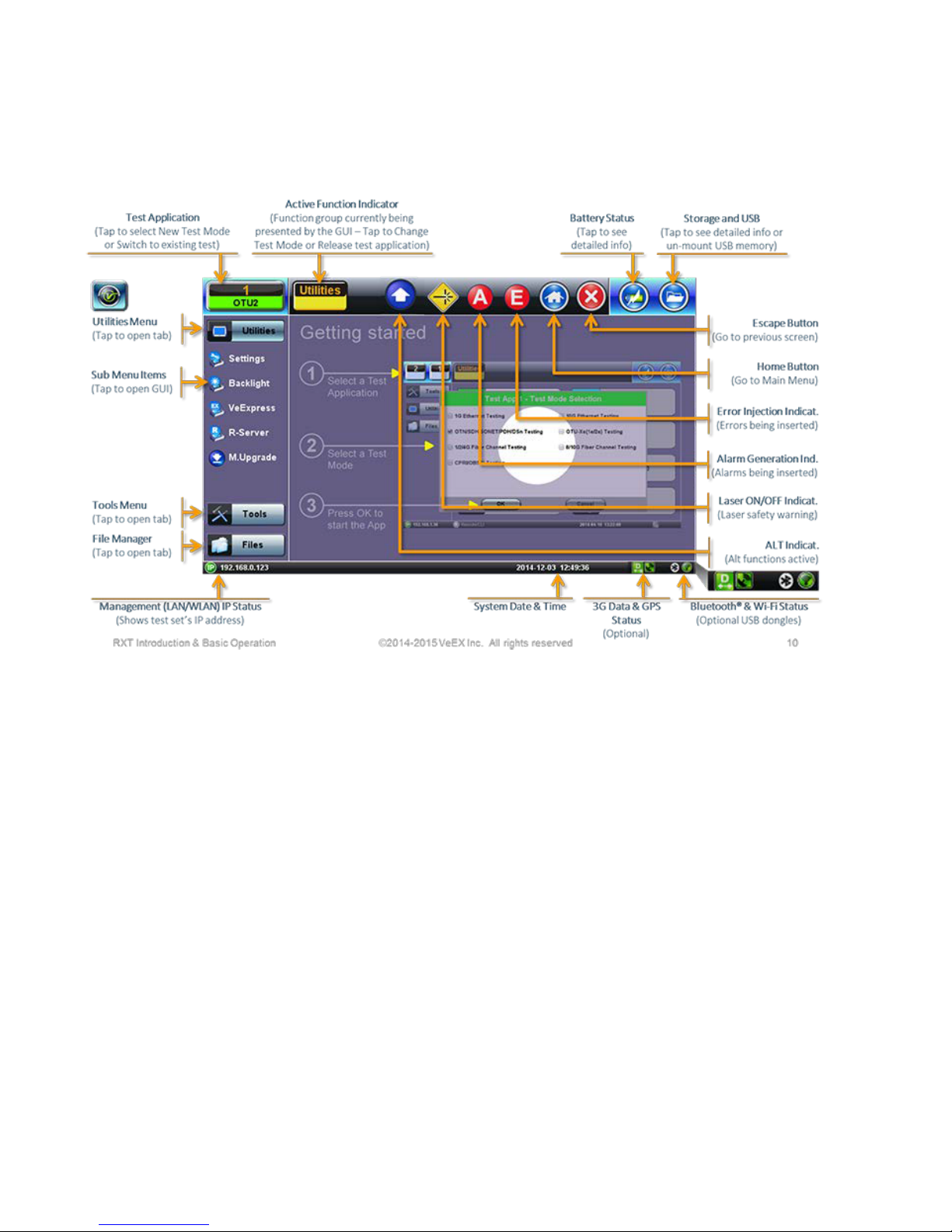

5.4 RXT OVERVIEW ........................................................................................................................ 18

5.4.1 RxT Front Panel .................................................................................................................................... 19

5.4.2 Getting Started ..................................................................................................................................... 20

5.5 FX150 OVERVIEW .................................................................................................................... 21

5.5.1 FX150 Test Ports .................................................................................................................................. 21

5.5.2 FX150 Keypad ....................................................................................................................................... 21

5.5.3 FX150 Screen Navigation .................................................................................................................... 22

5.5.3.1 View/Hide side menu panels ......................................................................................................... 23

5.5.4 Setting up FX150 WiFi ......................................................................................................................... 24

5.5.4.1 Access WiFi option ........................................................................................................................ 24

5.5.4.2 Connect to a WiFi network ............................................................................................................ 25

5.6 CUSTOMIZING YOUR TESTER .................................................................................................... 26

6.0 TEST FIBER AND INITIAL PREPARATION INTRODUCTION ................................. 28

6.1 CONTAMINATION ...................................................................................................................... 29

6.2 INSPECTION .............................................................................................................................. 29

6.3 CLEANING PROCEDURE ............................................................................................................ 30

6.4 BEST PRACTICES ..................................................................................................................... 31

6.5 CONNECTORS .......................................................................................................................... 32

6.5.1 Connector Types .................................................................................................................................. 32

6.5.2 Connector Performance and Polishing .............................................................................................. 34

6.6 FIBER CABLES AND FIBER PATCHCORDS .................................................................................. 36

6.6.1 Fiber Cable ............................................................................................................................................ 36

6.6.2 Fiber Patchcord .................................................................................................................................... 37

6.7 INSERTING THE FIBER ............................................................................................................... 39

6.7.1 Preventing Inaccurate Readings ........................................................................................................ 39

6.8 FIBER SCOPE UTILITY (FX150, FX300, MTTPLUS, RXT) ........................................................... 39

OTDR Series e-Manual, D07-00-076P-RevC00 Page 3 of 107

6.8.1

Fiber Scope Overview .......................................................................................................................... 39

6.8.2 Connecting the Fiber Scope ............................................................................................................... 40

6.8.3 Setup ..................................................................................................................................................... 41

6.8.4 Analysis ................................................................................................................................................ 41

6.8.5 Capture Screen ..................................................................................................................................... 42

6.8.6 Captured Files ...................................................................................................................................... 43

6.8.7 Connector Face Analysis .................................................................................................................... 44

6.8.8 Connector Face Analysis Results Table ............................................................................................ 45

6.8.8.1 HTML Report ................................................................................................................................. 46

6.8.8.2 PDF Report .................................................................................................................................... 47

6.8.9 Managing Fiberscope Results with File Manager ............................................................................. 48

6.8.9.1 File Manager Filters ....................................................................................................................... 49

6.8.10 Fiber Scope Image Management Software (ViS400D only) ......................................................... 50

6.8.11 Fiber Scope Image Management Software (VS-500 and DI-1000 only) ....................................... 51

6.9 VISUAL FAULT LOCATOR (VFL) ................................................................................................ 54

6.9.1 Using the VFL ....................................................................................................................................... 55

6.10 OPTICAL LIGHT SOURCE (OLS) ................................................................................................ 56

6.10.1 Accessing and setting up the Optical Light Source ..................................................................... 57

6.10.2 Using the Optical Light Source ...................................................................................................... 58

6.11 OPTICAL POWER METER (OPM) ............................................................................................... 59

6.11.1 Setting up the Optical Power Meter ............................................................................................... 59

6.11.1.1 USB OPM Setup Options .............................................................................................................. 60

6.11.1.2 Setting Pass/Fail Limits ................................................................................................................. 61

6.11.2 Using the built-in OPM .................................................................................................................... 62

6.12 OPTICAL LOSS TEST SET (OLTS) (NOT CURRENTLY SUPPORTED) ............................................. 64

6.13 RESULTS .................................................................................................................................. 64

7.0 WORKING WITH THE OTDR ..................................................................................... 66

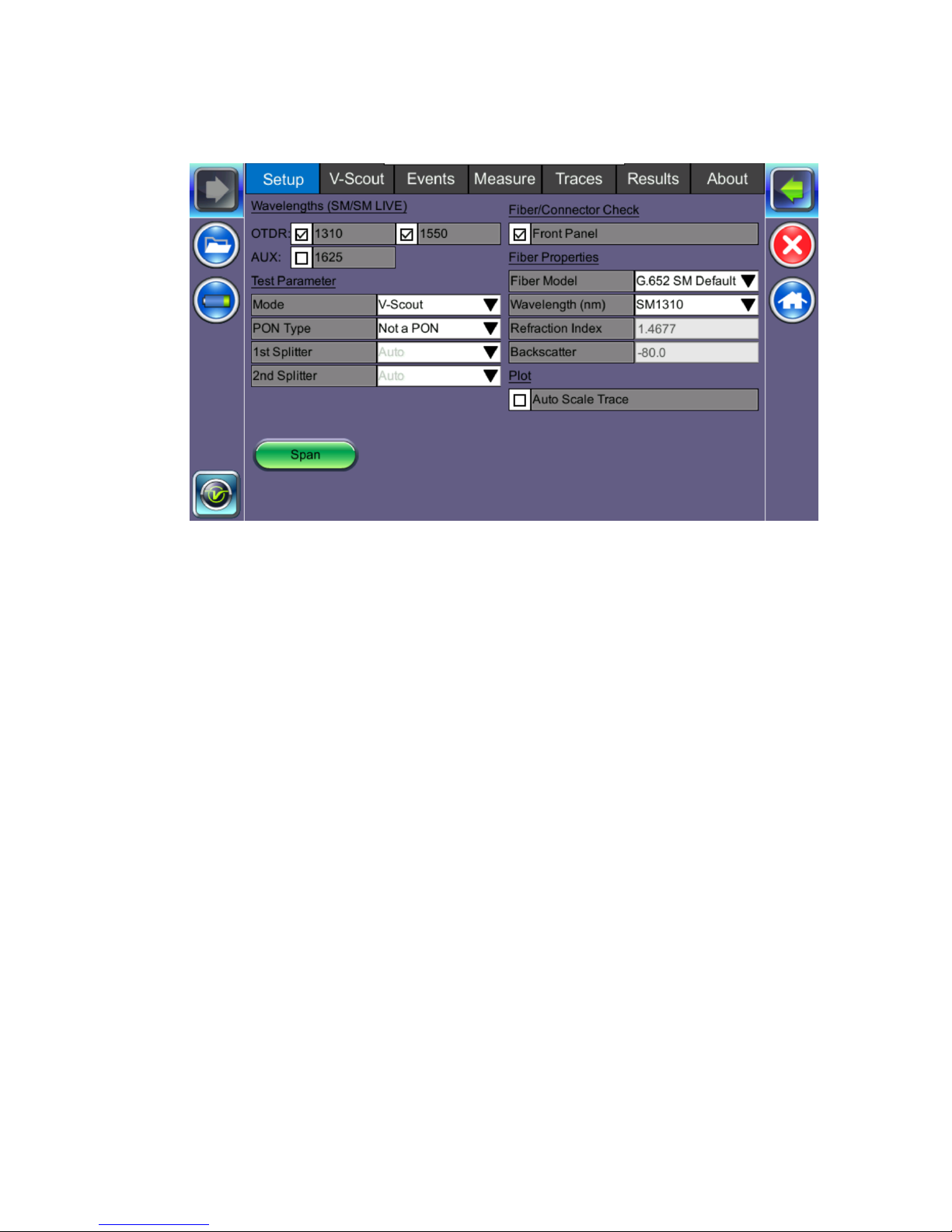

7.1 TEST SETUP ............................................................................................................................. 66

7.1.1 Initial Settings ....................................................................................................................................... 66

7.1.2 Manual mode ........................................................................................................................................ 67

7.1.3 Auto mode ............................................................................................................................................ 70

7.1.4 V-Scout mode (optional) ...................................................................................................................... 71

7.1.4.1 Setting up and Using V-Scout mode ............................................................................................. 73

7.1.4.2 V-Scout symbols ............................................................................................................................ 74

7.2 THRESHOLDS ........................................................................................................................... 76

7.2.1 Analysis Thresholds ............................................................................................................................ 76

7.2.2 Pass/Fail Thresholds ........................................................................................................................... 77

7.2.3 Event Table ........................................................................................................................................... 78

7.2.4 Autosave Parameters .......................................................................................................................... 78

7.2.5 Cloud Credentials ................................................................................................................................ 80

7.3 MAKING MEASUREMENTS ......................................................................................................... 81

7.3.1 Trace Display ........................................................................................................................................ 81

7.4 EVENTS .................................................................................................................................... 82

7.4.1 Event Table ........................................................................................................................................... 82

7.4.2 Event Types .......................................................................................................................................... 83

7.4.3 Event Editing ........................................................................................................................................ 83

7.5 MEASURE MODE ...................................................................................................................... 84

7.5.1 Markers Controls .................................................................................................................................. 84

7.5.1.1 Marker Operation ........................................................................................................................... 84

7.5.1.2 Zoom/Scroll Controls ..................................................................................................................... 85

7.5.2 Distance Measurements ...................................................................................................................... 86

7.5.3 Loss Measurements ............................................................................................................................. 86

7.5.3.1 Two Point Loss (2-Pt Loss) ........................................................................................................... 86

7.5.3.2 Two Point LSA (2-Pt LSA) ............................................................................................................. 87

7.5.4 Splice Loss Measurement ................................................................................................................... 87

7.5.5 Reflectance Measurement ................................................................................................................... 88

OTDR Series e-Manual, D07-00-076P-RevC00 Page 4 of 107

7.5.6

ORL Measurement ............................................................................................................................... 89

7.6 TRACES ................................................................................................................................... 90

7.6.1 Trace Properties ................................................................................................................................... 91

7.6.2 Saving OTDR Traces ............................................................................................................................ 93

7.6.3 Saving OTDR Traces with Embedded GPS and Camera Image ...................................................... 94

7.6.3.1 Obtaining GPS Coordinates .......................................................................................................... 94

7.6.4 Adding GPS to OTDR file (optional feature) ...................................................................................... 94

7.6.5 Adding Camera Image OTDR file (MTTplus only) ............................................................................. 95

7.7 RESULTS .................................................................................................................................. 97

7.7.1 File Management .................................................................................................................................. 98

7.7.2 Saving/Printing Traces to PDF/USB/Bluetooth ................................................................................. 99

7.7.3 File Operations ................................................................................................................................... 100

7.8 ABOUT TAB ............................................................................................................................ 101

8.0 REVEAL SOFTWARE .............................................................................................. 102

9.0 WARRANTY AND SOFTWARE ............................................................................... 103

10.0 PRODUCT SPECIFICATIONS ................................................................................. 105

11.0 CERTIFICATIONS AND DECLARATIONS .............................................................. 106

12.0 ABOUT VEEX ........................................................................................................... 107

OTDR Series e-Manual, D07-00-076P-RevC00 Page 5 of 107

1.0 About This User Manual

This user manual is suitable for novice, intermediate, and experienced users and is intended to

help you successfully use the features and capabilities of the FX150, FX300, MTTplus, RXT,

and TX300s OTDR series. It is assumed that the user has basic computer experience and

skills, and is familiar with Optical Fiber, telecommunication concepts, terminology, and safety.

Every effort was made to ensure that the information contained in this user manual is accurate.

Information is subject to change without notice and we accept no responsibility for any errors

or omissions. In case of discrepancy, the web version takes precedence over any printed

literature. The content in this manual may vary from the software version installed in the unit.

© Copyright 2006-2017 VeEX, Inc. All rights reserved.

VeEX, VePAL, Sunrise Telecom, Agizer, Optixsoft, Sunlite, Sunset, RXT, MTT, FX, TX, OPX,

and Fiberizer are trademarks of VeEX, Inc. and/or its affiliates in the USA and certain other

countries. All trademarks or registered trademarks are the property of their respective

companies. No part of this document may be reproduced or transmitted electronically or

otherwise without written permission from VeEX, Inc.

This device uses software either developed by VeEX, Inc. or licensed by VeEX, Inc. from third

parties. The software is confidential and proprietary of VeEX, Inc. The software is protected by

copyright and contains trade secrets of VeEX, Inc. or VeEX's licensors. The purchaser of this

device agrees that it has received a license solely to use the software as embedded in the

device, and the purchaser is prohibited from copying, reverse engineering, decompiling, or

disassembling the software.

For more technical resources, visit the VeEX, Inc. web site at www.veexinc.com.

If you need assistance or have questions related to the use of this product, call or e-mail our

customer care department for customer support. Before contacting our customer care

department, you must have your product serial number and software version ready. Please

provide this number when contacting VeEX customer service.

Customer Care:

Phone: + 1 510 651 0500

E-mail: customercare@veexinc.com

Website: www.veexinc.com

OTDR Series e-Manual, D07-00-076P-RevC00 Page 6 of 107

2.0 Product Introduction

The FX150, FX300, MTTplus, RXT, and TX300s feature an OTDR optimized for the installation

and troubleshooting of FTTx, PON, CATV, Mobile Backhaul, and Metro fiber networks.

2.1 Platform Highlights (FX150/FX300/MTTplus/RXT/TX300s)

• Robust, compact hand-held design for demanding field test environments

• High resolution, TFT color touch-screen viewable in any lighting condition. See the

platform’s datasheet for screen size.

• Fast boot-up time essential for fiber restoration

• Internal data storage varies with model. See the platform’s datasheet for more

information at www.veexinc.com.

• USB-A Host Interface supporting (FX300/MTTplus/RXT/TX300s):

• USB flash drives (not available on FX150)

• Fiber inspection probe connection (FX150 requires OTG cable)

• Bluetooth option available

• 3G UMTS data card support (not available on all models). See the platform’s

datasheet for more information at www.veexinc.com.

• Micro USB interface OTG to support (FX150):

• USB flash drives

• Fiber inspection probes

• Ethernet (10/100T) LAN Interface supporting(FX300/MTTplus/RXT/TX300s):

• Remote control

• Transfer OTDR test data

• Perform software upgrades

• Basic IP testing (Ping, Trace route, Web browser)

• Built-in Wireless and Bluetooth options supporting (FX150 standard;

FX300/MTTplus/RXT optional. See the platform’s datasheet for availability at

www.veexinc.com.):

• Software upgrades and uploading test data via wireless connection

• Pairing applications with Mobile Smartphones and Tablet PCs

• Rechargeable Li-Ion battery with capacity indicator, low voltage alarm and Auto-off

function:

• FX150 platform – 10,000 mAH battery

• FX300/TX300s platform – 5200 mAH battery

• MTTplus platform – 5400 mAH battery

• RXT platform - 8400 mAH battery

OTDR Series e-Manual, D07-00-076P-RevC00 Page 7 of 107

• Continuous operation of > 8 hours per Bellcore TRNWT-001138 (platform dependent)

• ReVeal software to transfer fiber test data, upgrade software and perform remote

control (check with factory on availability)

• Fiberizer Cloud to upload fiber test data

• VeExpress to check/upgrade software and installed options status (not available on

FX300 or FX150)

2.2 Key Features

• FTTx optimized parameters for best dead zones

• Filtered 1625 or 1650 nm OTDR port for in-service measurements

• Live fiber detection with embedded power meter

• Dynamic range up to 50 dB (model dependent)

• Event dead zone < 1m, attenuation dead zone < 4m

• Singlemode wavelength options - 1310, 1490, 1550, 1625 and 1650 nm (CWDM and

DWDM C-band also available)

• Multimode wavelength options - 850 and 1300 nm

• Telcordia SR-4731.sor file formats

• Generate and save traces in sor, pdf or csv format (model dependent)

• Auto mode with automated trace diagnostics, simplified setup and events detection

• Optional V-Scout mode – Intelligent Link Mapping using intuitive icons derived from

multiple test acquisitions

• Markers for distance, attenuation, reflectance and splice loss measurements

• Optional universal interface with interchangeable optical adaptors (SC, ST, FC, LC) for

OTDR port

• Power meter, light source, fiber inspection probe and VFL options

• Remote measurement via USB or WiFi connection using Fiberizer Desktop software

OTDR Series e-Manual, D07-00-076P-RevC00 Page 8 of 107

2.3 Package Contents

• OTDR (FX300, FX150, TX300S OTDR blade, RXT-4100 module or MTTplus-410

module)

• AC/DC adaptor

• Input: 100-240 VAC (50/60 Hz), 1.5A max - (MTTPLUS: 5.3A max; FX150: 1.5A

max)

• Output: 16VDC - (MTTPLUS: 15VDC; FX150: 12VDC)

• Ethernet cable (FX300, TX300S OTDR blade, RXT module or MTTplus module)

• Li-Ion battery (capacity depends on platform)

• USB memory stick or CD-ROM containing:

• OTDR Users’ Manual (pdf)

• Reveal and Fiberizer Desktop software

• Software Upgrade Instructions

• Nylon Soft Carry case

OTDR Series e-Manual, D07-00-076P-RevC00 Page 9 of 107

3.0 Safety Information

Safety precautions should be observed during all phases of operation of this instrument. The

instrument has been designed to ensure safe operation however please observe all safety

markings and instructions. Do not operate the instrument in the presence of flammable gases

or fumes or any other combustible environment. VeEX Inc. assumes no liability for the

customer's failure to comply with safety precautions and requirements.

Optical Connectors

The test platform displays a laser warning icon when the laser source is active to alert the user

about a potentially dangerous situation. Make sure that optical sources are inactive before

connecting fiber to the test set to avoid skin or eye damage, or damage to the unit. It is

recommended to:

• Deactivate the laser before connecting or disconnecting optical cables or patchcords.

• Never look directly into an optical patchcord or an optical interface (e.g. CFP, CFP2,

CFP4, QSFP+, SFP+, SFP, OTDR, LS, VFL) while the laser is enabled. Even though

optical transceivers are typically fitted with Class 1 lasers, which are considered eye

safe, optical radiation for an extended period can cause irreparable damage to the eyes.

• Never use a fiber microscope to check the optical connectors when the laser source is

active.

Electrical Connectors

Telephone lines may carry dangerous voltages. Always connect the electrical test ports to

known test interfaces which carry low level signals.

OTDR Series e-Manual, D07-00-076P-RevC00 Page 10 of 107

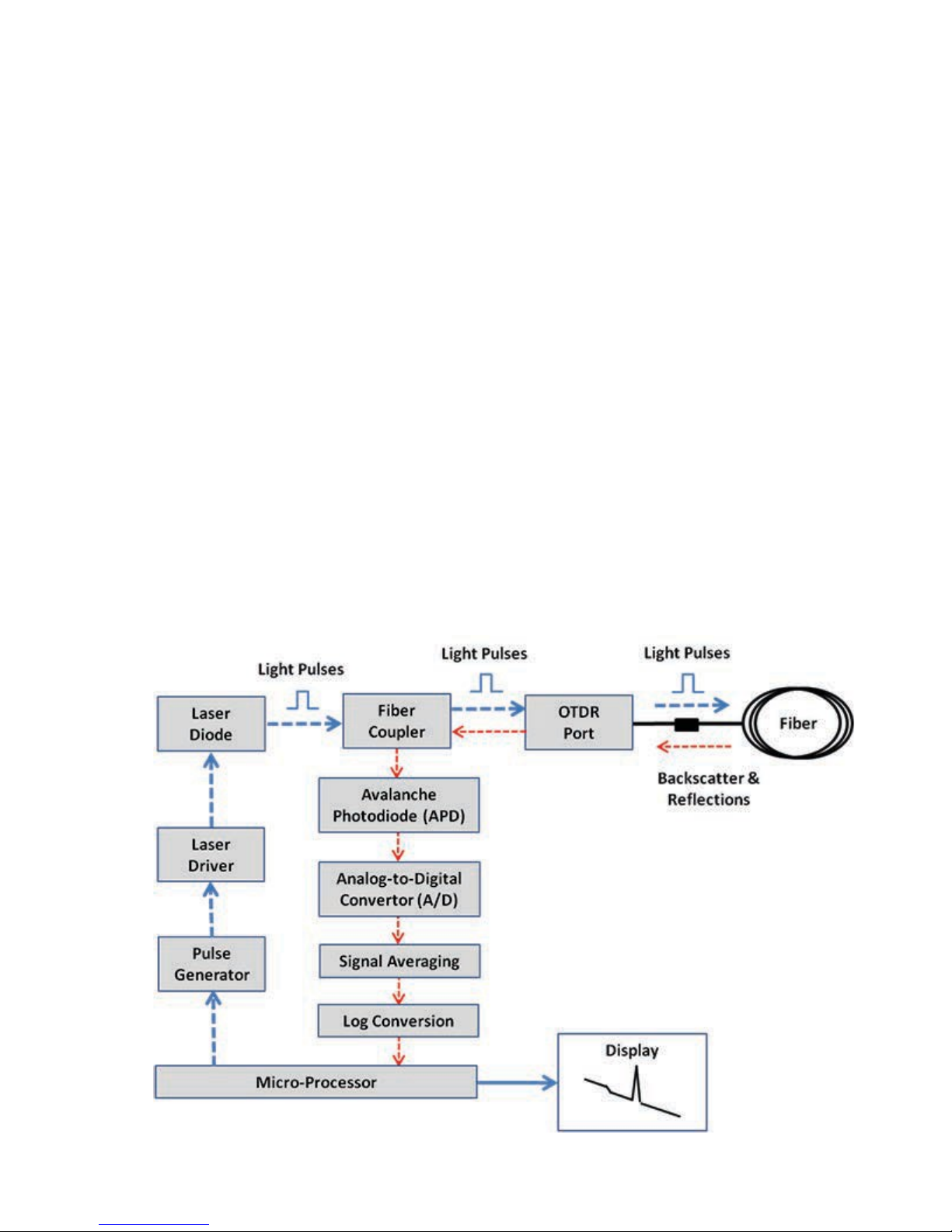

4.0 Theory of Operation

4.1 OTDR

The principle of OTDR operation is based on measuring the Rayleigh back scattering signal

when a single powerful optical pulse passes through an optical fiber. The weak back scattering

signal is registered by an optical receiver, converted into digital form and averaged many

times.

The OTDR calculate distance with next formula:

Distance = c * t / (2 * n)

where c – light speed in vacuum, n – optical fiber index of refraction, t – time

delay between pulse emit and it

registration by receiver

Each sample converted by ADC into digital form is registered in the RAM. To measure the

back-scattering signal precisely, repeated triggering optical pulses is performed. The processor

averages samples, corresponding to the same points of the optical fiber that leads to the

increasing signal-noise ratio. After several cycles, the obtained signal values are transferred

from RAM and displayed. Then, the process of measuring, averaging, and cleaning RAM

registers is repeated again.

OTDR – Principle of Operation

OTDR Series e-Manual, D07-00-076P-RevC00 Page 11 of 107

4.2 Light Source

An optional light source is available and designed for generating continuous optical radiation.

The light source output is the same as the OTDR port and uses the same laser diodes and

optical splitter. The radiation power is stabilized with the help of external photodiode and power

stabilization circuit.

The light source has two operation modes: Continuous and Modulated/tone (270, 1000 and

2000Hz).

The average power at modulation mode is 2 times lower (3dB) than in continuous mode of

operation.

4.3 Optical Power Meter

The OPM is equipped with an InGaAs photodiode (1mm diameter) to measure optical power.

For standard power PM1 measurement range (+10dBm), radiation falls directly on the

photodiode. The OPM will support both MM and SM fiber with the APC or UPC connector type.

For extended measurement PM2 range (+25dBm), an integrating sphere with a photodiode is

used. Input power is attenuated by the integrating sphere by approximately 100 times.

The current of the photodiode is amplified and converted into digital form with the help of

analog-digital converter. The received digital signal is processed by microprocessor and the

value of the measured optical power is displayed.

4.4 Visual Fault Locator

The unit is equipped with an optional Visual Light Locator (VFL) to visually identify breaks in

the fiber typically hidden in the OTDR dead zone.

• Output power: 0 dBm (Typical)

• Operation modes: Continuous wave (CW) or 2Hz modulation

OTDR Series e-Manual, D07-00-076P-RevC00 Page 12 of 107

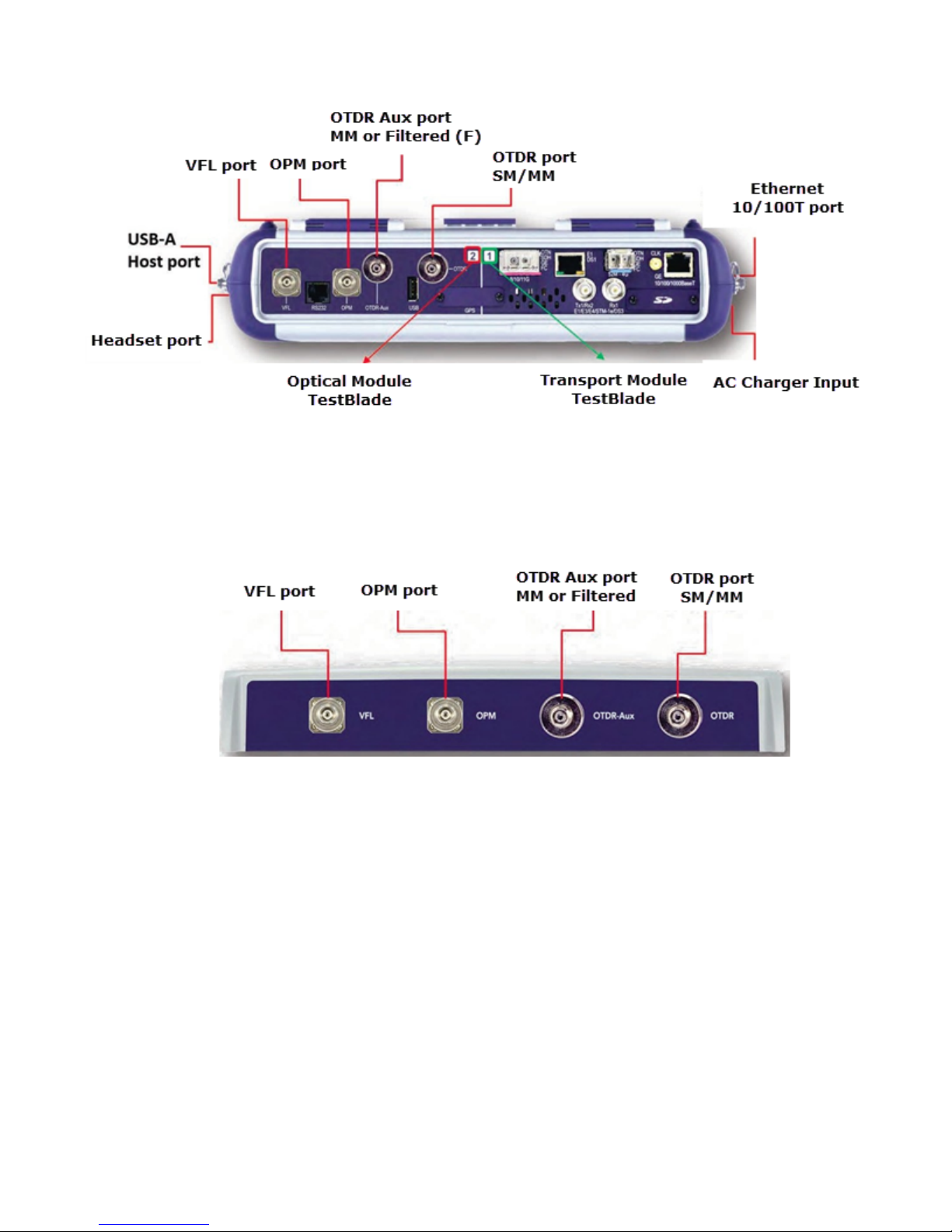

5.0 Basic Operation

5.1 Test Ports and Interfaces

OTDR testing: The optical fiber under test is connected to either the OTDR or OTDR Aux

(Filtered SM or MM) port on the top panel. The type of the optical fiber connector must

correspond to the OTDR connector or adaptor type, including the connector polish.

Optical Power Meter (OPM) testing: The optical fiber is connected to the OPM port on the

top panel. Depending on fiber connector type, use interchangeable adaptors. FC, SC, ST or

LC type are supplied standard.

Visual Fault Locator ((VFL) testing: The optical fiber is connected to the VFL port on the top

panel. The VFL interface is fitted with universal 2.5mm sleeve accepting all 2.5 mm connector

ferrules.

Note:

Optical Connections - The optical fiber connector must be cleaned prior to connecting to the

fiber under test. Dust and dirt severely impacts optical performance.

Refer to Fiber handling procedures for cleaning tips and information.

OTDR Series e-Manual, D07-00-076P-RevC00 Page 13 of 107

TTXX330000ssTTooppVViieeww

RRxxTT--44110000OOTTDDRRMMoodduullee

OTDR Series e-Manual, D07-00-076P-RevC00 Page 14 of 107

5.2 Front Panel Layout

The picture below depicts the TX300s. Layout will vary depending on FX150, FX300, MTTplus,

or RXT platforms.

5.2.1 LED Indicators

Power/Charge LED - indicates battery charging is in progress. LED turns off when battery is

fully charged.

Note: The device is powered from the built-in Li-Ion battery and can be operated with the AC/

DC adaptor plugged in.

5.2.2 Rubber Keypad

• Home Key: Resets user interface to Main menu

• Navigation/Marker Keys: Used to move markers or navigate menus (in the event

touch screen is disabled for any reason) Enter Key: Enters the desired value or selects

active menu, check box or radio button

• Escape Key: Exits the menu

• App Key: Toggles between active test applications (OTDR, OLS, OPM, VFL)

• Lock/Save Screen Key: Locks the touch panel or saves the screen (bmp) depending

on setting defined in Utility menu

• LED History Key: Resets LED condition (depends on test application)

• Save Trace/Result Key: Saves test result file (OTDR, OPM, Ethernet, Fiberscope -

depends on active application and unit configuration)

OTDR Series e-Manual, D07-00-076P-RevC00 Page 15 of 107

5.2.3 Menu Navigation

Navigate between test applications, setup menus, tabs, or active functions using the supplied

stylus or by using up/down arrows followed by “Enter.”

“Getting started” information is displayed after power up.

Select a Test Application

• FX150: Application #1 is loaded by default. Select OTDR, VFL, OPM, OLS by clicking

the icon on the main menu. The Fiberscope icon can be found on the Advanced Tools

screen.

• TX300s: Select Application 2, which corresponds to the optical test function blade #2,

located on the top connector panel. Select OTDR, VFL, OPM, or OLS by clicking the

icon on the main menu

• FX300/MTTplus/RXT: Select Application 1, which corresponds to the module, inserted

into the module slot. Select Fiber testing from the Test mode selection and press OK.

The OTDR, VFL, OPM, and OLS test functions will be displayed on the main menu.

Note:

Touch Screen Navigation - The unit is equipped with a state of art, full color, LCD TFT touch

screen. When used properly, the screen is designed to give years of reliable and precise

operation. Always use the stylus supplied with the unit to operate the touch screen. Never use

any sharp object such as a ballpoint pen, screwdriver, or similar item as this will damage the

screen and void the warranty.

OTDR Series e-Manual, D07-00-076P-RevC00 Page 16 of 107

5.3 MTTplus Overview

5.3.1 MTTplus Side View

OTDR Series e-Manual, D07-00-076P-RevC00 Page 17 of 107

option).

5.3.2 MTTplus Control Panel

• Power: Press for 2 seconds to turn the test set ON or OFF (prevents

accidental ON/OFF) If a test is running when the power off is started, test

is terminated and results may not be automatically saved.

• Save Test Results: Saves the current Test Results with customized or

auto naming.

• Lock/Unlock Touch Screen or Screen Capture: Can also be

programmed to Capture Screen images. Go to >Utilities >Settings

>Global >Save Settings to set save and image compression options.

• Volume and Brightness Control: (it also acts as the MTT F1 key, when

the is active) Brings up the Sound and screen Brightness controls; Use

cursor buttons to adjust the levels.

• Clear History: Resets blinking LED reminders of past Errors or Alarms

Test results are not affected. (not used with OTDR)

• Camera App: Launches the optional Camera App to help document the

job site, damage, connections, etc. Requires the camera (factory-installed

5.3.3 MTTplus OTDR Module Top View

OTDR Series e-Manual, D07-00-076P-RevC00 Page 18 of 107

5.4 RxT Overview

OTDR Series e-Manual, D07-00-076P-RevC00 Page 19 of 107

affected. (not used in OTDR)

5.4.1 RxT Front Panel

• Power: Press for 2 seconds to turn

the test set ON or OFF (prevents

accidental ON/OFF)

• Cursor Keys: Application

dependent; May offer alternative

GUI Navigation to touch screen

(e.g. while wearing gloves in cold

weather)

• Enter: Application dependent

• Escape: Application dependent

• Alt Alternate function: Links the

buttons to the GUI soft Function

Keys (MTT Emulation Mode only)

• Clear History: Resets blinking

LED reminders of past Errors or

Alarms. Test results are not

• Volume and Brightness Control:

(it also acts as the MTT F1 key,

when the Alt key is active) Brings

up the Sound and screen

Brightness controls; Use cursor

buttons to adjust the levels

• Test Application Selector (it also

acts as the MTT F2 key, when the

Alt key is active): Quickly switches

back and forth between the active

Test Application and RXT platform.

Utilities functions; Active test is not

affected.

• Lock/Unlock Touch Screen: Can

also be programmed to capture

Screen Shots (>Utilities

>Settings>Global>Save Settings)

• Home: Quickly bring users back to

the Main Menu

• Save Test Results: Saves the

current Test Results with

customized or auto naming format

OTDR Series e-Manual, D07-00-076P-RevC00 Page 20 of 107

5.4.2 Getting Started

A Quick Guide is always present in the Home screen after boot up.

This screen can be displayed at any time from any screen.

The test port group is assigned to the Fiber application when the 410 module is installed. All

options associated with the 410 OTDR module will be installed.

OTDR Series e-Manual, D07-00-076P-RevC00 Page 21 of 107

Main menu

5.5 FX150 Overview

5.5.1 FX150 Test Ports

5.5.2 FX150 Keypad

FFXX115500PPllaattffoorrmm

VVFFLL//OOPPMM//AAuuxx--OOTTDDRR//OOTTDDRR--OOLLSS

• Save: Saves the screen (bmp)

• Power: Press for 2 seconds to turn

the test set ON or OFF (prevents

accidental ON/OFF)

• Home: Resets user interface to

OTDR Series e-Manual, D07-00-076P-RevC00 Page 22 of 107

5.5.3 FX150 Screen Navigation

OOTTDDRRSSccrreeeenn

Use the top tabs of the FX150 screen to access test measurement controls and view results.

On the bottom bar, you can see:

• IP address, when connected

• Remote control connection status

• Date and time

• Bluetooth and WiFi connection indicators

OTDR Series e-Manual, D07-00-076P-RevC00 Page 23 of 107

access the Utilities screen.

screen.

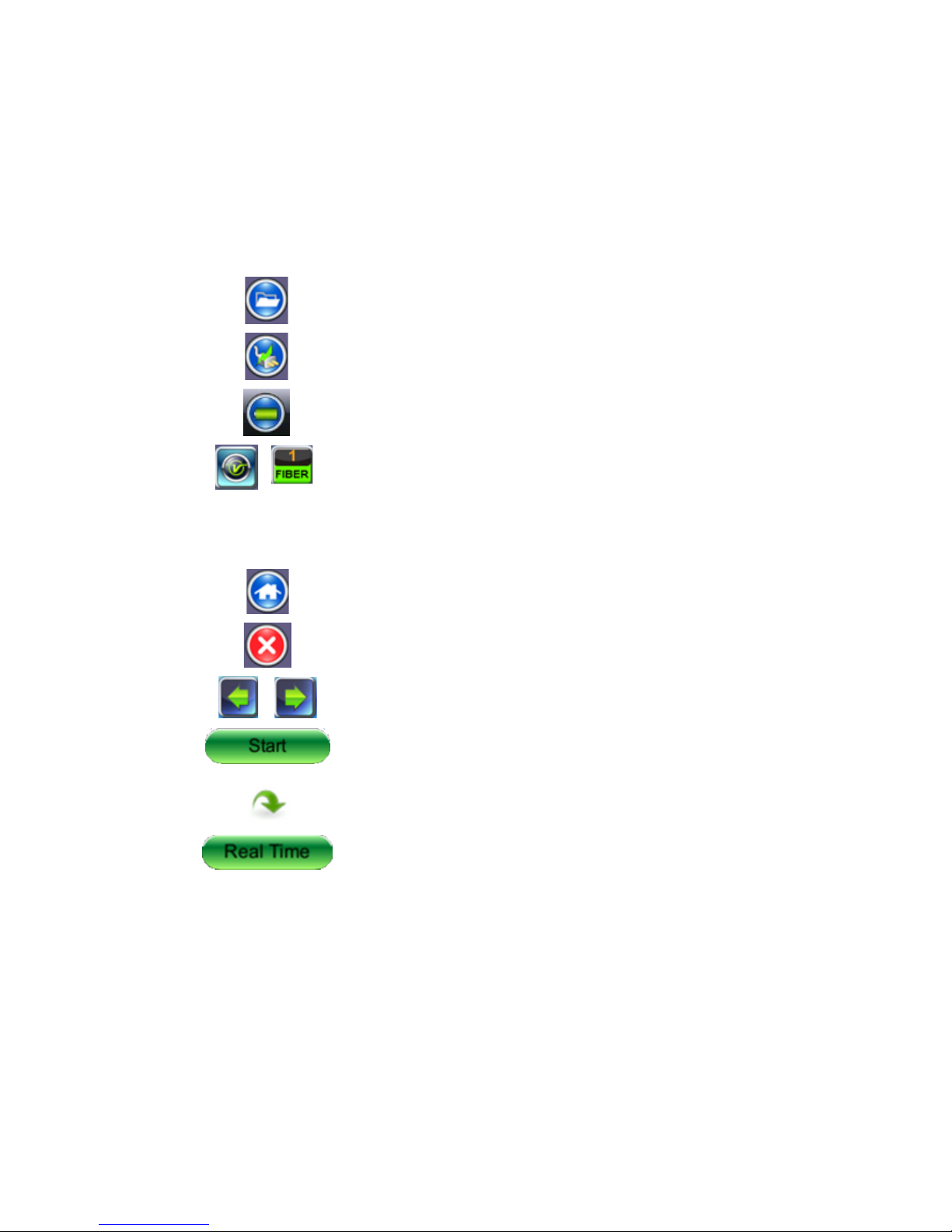

5.5.3.1 View/Hide side menu panels

The left and right panels of the display provide icons to access key functions of the FX150.

These panels can be turned on or off to enable a better view of the application screens.

Use the shift keys located on the left and right sides of the unit to toggle on/off the left

and right menu panels.

Press the LEFT SHIFT KEY to access:

File Storage – Tap to see the size and current capacity

of the internal SSD storage.

Power Source Indicator– Indicates when unit is

powered by external AC power and battery charging

level. Tap to see battery charge status.

V key / Fiber – Tap to access all Fiber Test Modes or

Press the RIGHT SHIFT KEY to access test control buttons and the following:

Home – Tap to return to the OTDR Main Menu.

Escape/Exit – Tap to return to the previous screen.

Arrow – Tap to enter the unit System Settings and Tools

Start – Begin trace.

Green arrow – Switch λ active trace

Real Time OTDR – See trace in real time.

OTDR Series e-Manual, D07-00-076P-RevC00 Page 24 of 107

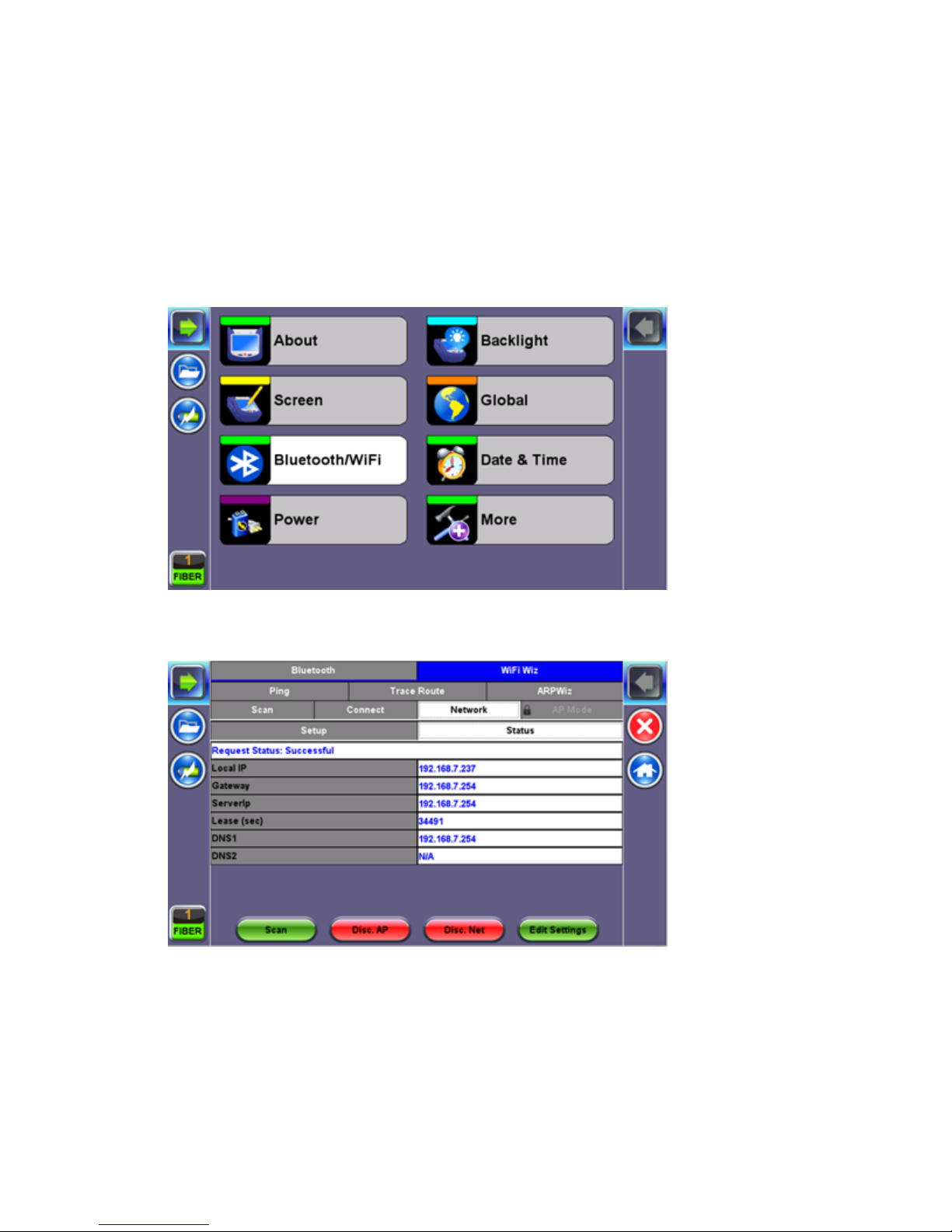

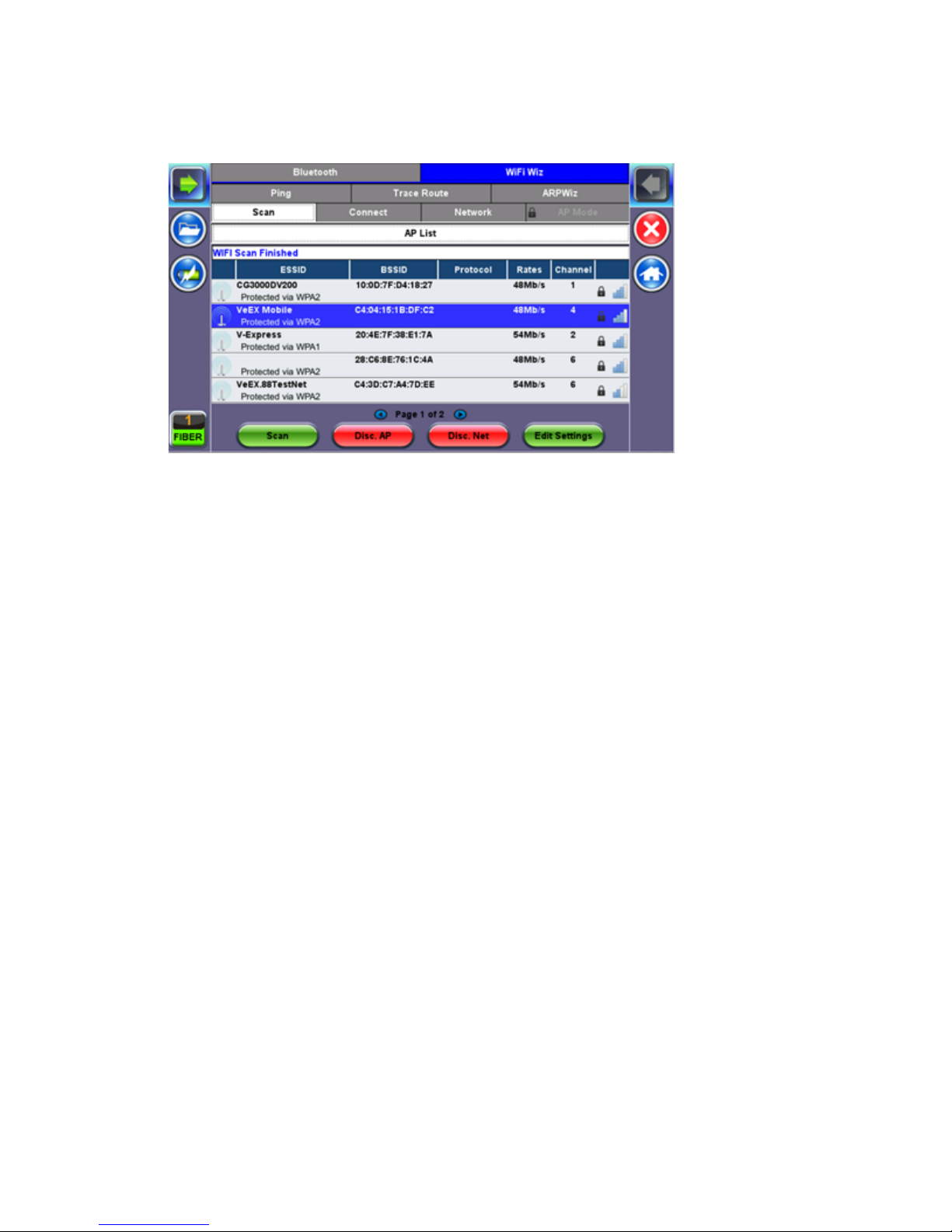

5.5.4 Setting up FX150 WiFi

The FX150 unit contains an optional built-in WiFi interface allowing you to easily transfer

OTDR traces and upgrade software on the unit.

5.5.4.1 Access WiFi option

1. Press Utilities or the HOME key, and then press Bluetooth/WiFi.

2. Select the WiFi Wiz tab.

OTDR Series e-Manual, D07-00-076P-RevC00 Page 25 of 107

5.5.4.2 Connect to a WiFi network

1. Press Scan to see all networks

2. Select one of the available networks and the Edit Settings key will appear to the right.

Once selected, an Edit Settings function key appears to the right.

3. Tap on Edit Settings to change the Encryption Type and enter the WiFi Key or Connect

AP. The label will change to Disc. AP upon successful connection and the Connect Net

key will appear.

Encryption Type: Supported encryption types include WEP, WPA, and WPA2.

Password: Security phrase or password necessary to access SSID and network. Tap the

Password field to enter the network password on the pop-up keypad (ASCII formatting

supported).

4. Press Apply after selecting the Encryption Type and entering the Key.

5. If the encryption menu was accessed via Connect AP, the test set will connect to the AP

automatically after hitting Apply.

6. If the encryption menu was accessed via Edit Settings, press Connect AP to connect to

the AP.

7. After a successful connection to the Access Point, press Connect Net to obtain an IP

address and access the additional IP tests like Ping, Trace Route etc.

Note: Passwords are case sensitive. If the user enters the wrong network key, the test set will

still connect to the Access Point, but will not be able to connect to the web or perform the Ping

test.

OTDR Series e-Manual, D07-00-076P-RevC00 Page 26 of 107

5.6 Customizing Your Tester

You can customize the settings on your OTDR device in the Utilities>Settings menu:

• About: Displays serial #, MAC address, software version, software options installed and

related product information

• Screen: Displays calibration menu.

Activating Touchscreen Calibration Mode

You can activate the Touchscreen Calibration Mode using the

keypad by pressing SAVE + HOME keys simultaneously, then

releasing. Press SAVE + HOME again to start a new calibration.

• Backlight: User defined settings when unit is used on Battery or AC power including

Brightness settings

OTDR Series e-Manual, D07-00-076P-RevC00 Page 27 of 107

• Global: Various settings including:

• General

• Language: English, German, French, Chinese, Japanese, Korean and others (de-

pends on software version). You must reboot the device to fully activate the new

language

• Unit: Metric or US

• Audible alarm: sounds alarm when battery runs low or other alarm condition is met

• Show Password: Shows/Hides password in IP setups and other menus where

password is displayed.

• User Interface: International or USA

• WiFi Auto Connect: On or Off

• Auto Color Scheme: On or Off

• RTU-410 (OTDR) Emulation Mode: On or Off

• OTG Port Mode: Host or Device

• Telnet: On or Off

• Share Result: On or Off

• Storage Settings

• File name prefix (for setting prefix for OTDR sor files or other test results):

• Profile deleting: Auto or Prompt user before Deleting

• Profile saving: Auto or Prompt user before Overwrite

• Result saving: Manual or prompt user before saving

• Advance saving: Enables/Disables advanced saving properties

• Save Settings

• Lock/Save Screen: Lock Screen or Save Screen (compression level and maximum

number of screenshots that can be saved.

OTDR Series e-Manual, D07-00-076P-RevC00 Page 28 of 107

6.0 Test Fiber and Initial Preparation Introduction

Dirt, dust, and other contaminants severely impact high-speed data transmission in optical

fibers and dirty connector end-faces are often the #1 cause of link failures. High insertion loss

and/or high back reflection can result in transmission loss or high bit errors and poor BER.

Furthermore, most measurement variations and test repeatability conditions in fiber-optic

systems can be traced back to the cleanliness of optical connections. Contamination of fiber

end faces not only affects optical power levels but also impacts back reflectance performance

and levels which is harmful to sensitive optical components.

OTDR Series e-Manual, D07-00-076P-RevC00 Page 29 of 107

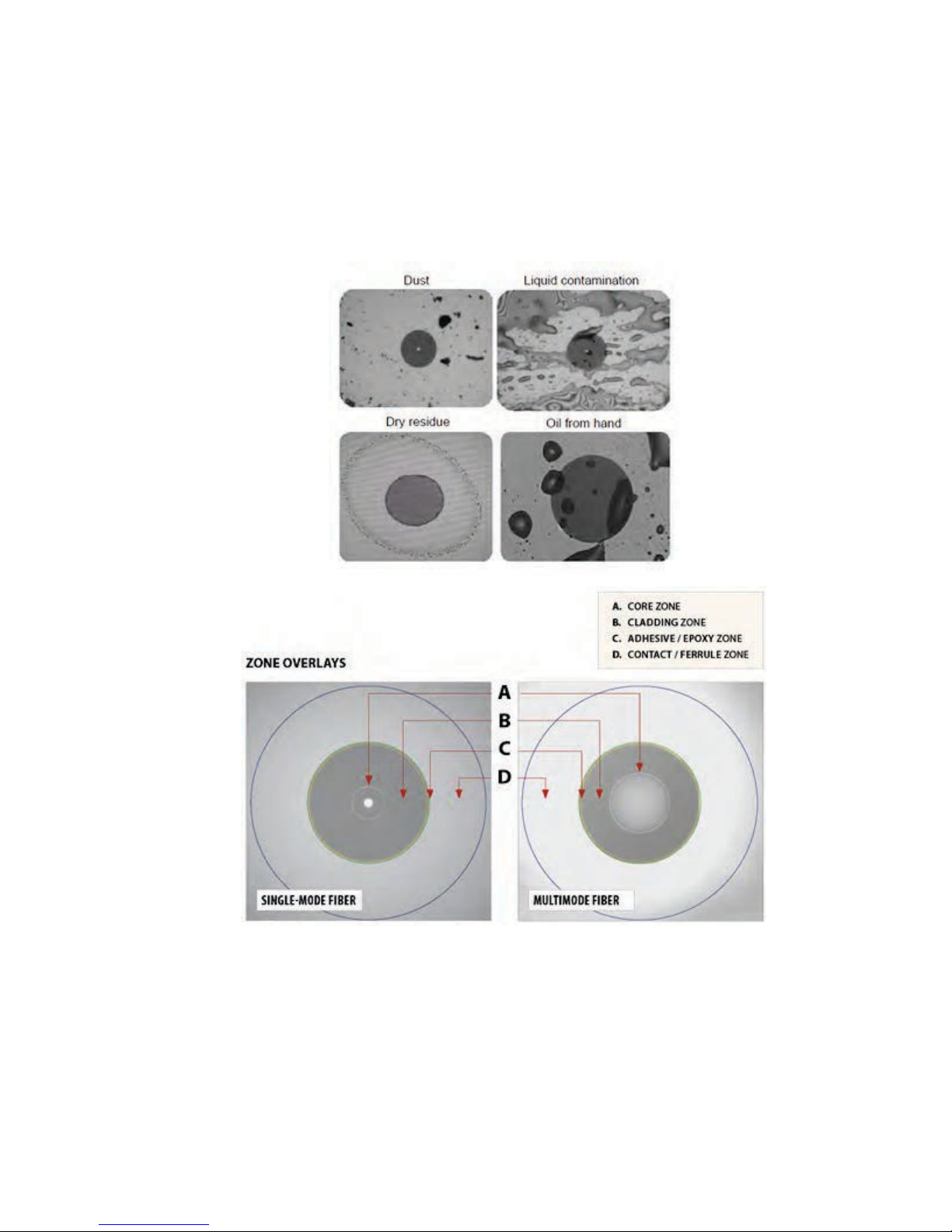

6.1 Contamination

Optical connectors are susceptible to contamination from air borne particles and human body

oils when exposed. Left over liquid residue from improper cleaning can also leave the fiber end

face contaminated. The smaller the fiber core, the more severe the problem is likely to be,

especially when you consider that fiber core diameters can range from 62.5 microns all the

way down to 8 microns in size. Below are some examples viewed by a 400x Fiber microscope:

6.2 Inspection

Whenever possible, inspect the fiber-optic connection (connectors, bulkheads, and test

interfaces) with a fiber microscope. It is recommended to wear laser safety glasses when you

work with fiber-optic connections, and always check that you disconnect the laser or

transmitter before you begin cleaning the connector end faces.

OTDR Series e-Manual, D07-00-076P-RevC00 Page 30 of 107

6.3 Cleaning Procedure

To ensure proper and effective cleaning of optical fiber connectors and interfaces, please

equip yourself with the following cleaning materials:

• Isopropyl alcohol

• Lint free soft tissues

• Ferrule cleaners (1.25mm and 2.5mm versions)

• Connector reel cleaners (CleTop or similar)

Procedure

1. Dab the contaminated connector end-face with a wipe that has been dampened with

Isopropyl alcohol - the solvent will dissolve and remove contaminants that have dried and

attached to the connector or fiber end-face.

2. Rub the fiber end-face perpendicularly against a dry lint free wipe several times.

3. Alternatively, use compressed air to dry the surface quickly. Do not blow or allow the

connector end face to air dry as this may leave a residue behind which is often more

difficult to clean and which can attract even more dirt.

4. Re-inspect the fiber end-face with an optical microscope to check that all the contaminants

have been removed properly - if not, please repeat the process.

Note:

Using Compressed Air - In some clean air situations, you can use filtered air, which is free of

oil and moisture to remove debris and clean a fiber optic connection. However, unless you

follow very strict cleaning procedures, air-driven contaminants can cause more problems.

If you need to use compressed air, hold the can upright. If the can is held at a slant, propellant

could escape and dirty your optical device. First spray into the air, as the initial stream of

compressed air could contain some condensation or propellant. Such condensation leaves

behind a filmy deposit.

OTDR Series e-Manual, D07-00-076P-RevC00 Page 31 of 107

6.4 Best Practices

• Never touch the end face of an optical fiber connector with your hands or fingers.

• Always install dust caps on unplugged fiber connectors.

• Store unused dust caps in a re-sealable plastic bag to prevent dust accumulating.

• Never re-use optic cleaning swabs or lint free wipes. Always discard materials that have

been used.

• Ensure all alcohol or solvent residues are removed after using wet cleaning techniques

• It is recommended to re-inspect the bulkhead receptacles and connector end face using

a fiber microscope following the cleaning and prior to use.

• The flow diagram below describes a best practice prior to connecting your optical fiber.

OTDR Series e-Manual, D07-00-076P-RevC00 Page 32 of 107

6.5 Connectors

6.5.1 Connector Types

In fiber optic networks, you will come into contact with many different connector types, the

most common being described below:

ST Connector

ST stands for Straight Tip-a quick release bayonet style connector developed by AT&T. STs

were predominant in the late 80s and early 90s and are still one of the most commonly used

fiber optic connectors in networking applications. They are cylindrical with twist lock coupling,

2.5mm keyed ferrule.

ST connectors are used both short distance applications and long line systems. The ST

connector has a bayonet mount and a long cylindrical ferrule to hold the fiber.

FC Connector

FC stands for Fixed Connection - it is fixed by way of a threaded barrel housing. FC

connectors are typical in test and measurement environments and for single- mode

applications.

FC is the fiber optic connector standard for Nippon Telephone & Telegraph (NTT) installations,

developed with Nippon Electric Co. (NEC).

Note: The FC screws on firmly, but make sure you have the key aligned in the slot properly

before tightening.

OTDR Series e-Manual, D07-00-076P-RevC00 Page 33 of 107

LC Connector

LC stands for Lucent Connector. It is a small form-factor fiber optic connector that uses a 1.25

mm ferrule, which is half the size of the ST / SC connectors.

It uses a standard ceramic ferrule connector. The LC has good performance and is highly

favored for both multimode and single mode applications, especially in high-density connector

facilities. The LC connector is available in simplex or duplex cables.

SC Connector

SC officially stands for Subscriber Connector; however, some people believe that “Square

Connector,” is the correct name. It is a general purpose push/pull style connector. It was

developed by NTT, which has an advantage in LAN/enterprise networks where duplex cabling

to support TX/RX channels are commonly used.

SC Connectors are frequently used network applications. The connector is square and keyed

with push-pull mating, 2.5mm ferrule, and molded housing for protection. The SC is a snap-in

connector that is widely used in singlemode systems due in part for its performance. The snapin connector latches with a simple push-pull motion.

OTDR Series e-Manual, D07-00-076P-RevC00 Page 34 of 107

E2000 Connector

Developed by Diamond, this connector has proven its performance worldwide in CATV and

telecommunication networks. The connector features a spring-loaded shutter used to protect

the ferrule from dust and scratches, and to provide increased safety protection. It uses a high

precision Zirconia full ceramic ferrule with an insertion loss of 0.1dB. The APC version has a

return loss of better than 85dB. The connector is especially suited for installation in global high

performance networks.

The E2000 patchcords is available in simplex and duplex versions and comply with IEC 61

754-15 and TIA/EIA 604-16 standards

6.5.2 Connector Performance and Polishing

Polishing of fiber optic connectors is the process of polishing the end-face of the ceramic

ferrule within the fiber optic connector. The purpose is to improve the light transfer between the

mating of connectors, in order to minimize optical losses and reducing reflections. This is an

important aspect of fiber optic communications as losses affect the quality of the light signals.

There are two main types of losses that are affected by the style and quality of polishing, which

dictate the optical performance level of terminated fiber optic connectors:

• Insertion Loss (IL) - The most important performance indicator of a fiber optic

connection. This is the loss of light signal, measured in decibels (dB), during the

insertion of a fiber optic connector.

• Return Loss (RL) - Also known as back reflection, is the portion of the light signal that

is reflected back to the original light source. This occurs as the light is reflected off the

connector and travels back along the fiber to the light source. This indicator is measured

in negative decibels (dB). When reading return loss figures, the higher the absolute

value of the decibel unit means the better the performance of the interconnection.

The amount of insertion loss is affected by fiber alignment, and/or the quality of the finishing on

the end of ferrule, while reflectance is affected by the style of polishing on the ceramic ferrule

in a connector. There are three different styles of polishing, reflected by their shape of the

finish:

• Physical Contact (PC) - In the PC style finish, the fiber is polished to a smooth curve.

As the name implies (i.e. physical contact), the ferrules of adjoining fibers come into

physical contact and this reduces the air gap between the contacting ferrules, resulting

in lower insertion losses. The smooth curve in the PC style is designed to reduce the

return loss by reflecting the light out of the fiber. However, the PC polishing style incurs

more return loss than other styles.

OTDR Series e-Manual, D07-00-076P-RevC00 Page 35 of 107

• Ultra Physical Contact (UPC) - The UPC style ferrule has the shape of the PC style,

except they are polished with several grades of polishing film that allows for an ultrasmooth surface. The main difference between UPC and PC is that the former have

lower return loss.

• Angled Physical Contact (APC) - The APC style produces the lowest return loss when

compared to other styles. The ferrule is polished to an angle of 8 degrees. The angle is

calculated so that it is less than the critical angle, which ensures light is not propagated

back along the fiber.

Connector Polish and Performance

Typical Return loss values are:

Polished Connector ~ -45dB

Ultra-Polished Connector ~ -55dB

Angled Polished Connector up to ~ -65dB

OTDR Series e-Manual, D07-00-076P-RevC00 Page 36 of 107

6.6 Fiber Cables and Fiber Patchcords

6.6.1 Fiber Cable

Styles of Fiber Optic Cable vary in outer appearance, materials, application, features, and

benefits. In OTDR applications, you will regularly come across the following types:

Bare Fiber

• Usually Spooled in 25km spools

• 250 to 400um acolyte buffer / polyimide

• PM Light Sensitive Bare

• Fiber Adaptor is a useful accessory and provides quick connection to check fiber

length/continuity

PVC or Plenum Jacketed

• Many colors that mean very little

• Used mostly in internal applications

900um

• Patchcords

• Simplex (single fiber) or Duplex (two fibers) construction

• Singlemode or Multimode

• Pig tails

• Outer Diameter is usually 1.6mm, 2.0mm, and 3.0mm

• Duplex versions - Zip cord with outer diameters of 1.6mm, 2.0mm, 3.0mm

Break Out

• Both Multimode and Singlemode

• Indoor / Outdoor applications

• 1.6mm, 2.0mm, and 3.0mm sub units

• 2, 4, 6, 8, 12, 24, 48, 72 or greater fiber counts Outer Jacket can be of a variety of

materials

• Terminated with all styles of connectors

• Often field terminated

Distribution

• Both Multimode and Singlemode

• Indoor / Outdoor applications

• 900um sub units

OTDR Series e-Manual, D07-00-076P-RevC00 Page 37 of 107

2, 4, 6, 8, 12, 24, 48, 72, 144 or greater fiber counts

• Outer Jacket can be of a variety of materials

• Usually longer runs and can be terminated with almost any style of connector

Ribbon

• Commonly used in LAN and PON applications with MTP/MPO connectors

6.6.2 Fiber Patchcord

A fiber patch cord is a piece of fiber cable that is used to connect the OTDR to the fiber under

test. In a typical installation, fibers comprising the incoming cable will be “broken out” and

terminated in a patch panel or wiring closet. One end of the patch cord is usually connected to

the OTDR while the other end is progressively moved along the patch panel as measurements

are made on each fiber.

The patchcord plays a critical role in fiber measurements and users should ensure that a high

quality patchcord is always used, because this can and will have profound performance on test

results and traces.

Factors affecting the choice of patchcord include:

• Fiber type – singlemode, multimode or ribbon

• Connector type (ST, SC, FC, LC, E2000, MTP/MPO, etc.)

• Dead-zone requirements (Refer to Section 4.2) Back reflection performance

• Insertion Loss

• Durability and Longevity

• Bend Limitation

OTDR Series e-Manual, D07-00-076P-RevC00 Page 38 of 107

Color Code of Jacket

Definition or Meaning

Yellow

Singlemode fiber

Orange

Multimode fiber

Aqua

10G laser-optimized 50/125um multimode optical fiber

Grey

Obsolete color code for multimode fiber

Blue

Sometimes used to designate polarization maintaining fiber

Color Code of Connector Boot

Definition or Meaning

polarization-maintaining optical fiber.

Singlemode only, not available for multimode fibers

Black

Physical Contact (PC), 0°

White

Physical Contact (PC), 0°

Raman pumps

Color Coding

The buffer or jacket on patchcords is often color-coded to indicate the type of fiber used.

Connector boot

The strain relief “boot” that protects the fiber from bending at a connector is color-coded to

indicate the type of connection.

Connectors with a plastic shell (such as SC or E2000) typically use a color-coded shell.

Standard color coding for jackets and boots (or connector shells) are shown below:

Blue Physical Contact (PC), 0°

Mostly used for singlemode fibers; some manufacturers use this for

Green Angle Polished (APC), 8°

Red High optical power. Sometimes used to connect external pump lasers or

OTDR Series e-Manual, D07-00-076P-RevC00 Page 39 of 107

6.7 Inserting the Fiber

Carefully align the optical fiber connector to the port to avoid rubbing the fiber against the

external part of the port or any other surface. If the interface of the connector has an alignment

key, make sure to insert it correctly into the corresponding groove.

Push the connector in and make sure the optical cables are inserted to guarantee sufficient

contact. If the connector has screw bushing, screw down the connector to fix in the optical

fiber. Do not over-screw the connector or it will damage the optical fiber and the port.

6.7.1 Preventing Inaccurate Readings

To achieve maximum power and prevent false readings, clean the optical fiber connector

interfaces before inserting them into the test port.

Please ensure the correct fiber connector type is used before inserting it into the test port or

connector. Mismatched connector types will damage the optical end faces and the test set.

Note: If the optical fiber is not aligned properly and/or completely connected, it will

cause serious loss and reflection.

6.8 Fiber Scope Utility (FX150, FX300, MTTplus, RxT)

6.8.1 Fiber Scope Overview

DI-1000 Digital Fiber Scope

The DI-1000 uses auto focus and capture the image and grade the connector’s health and

cleanliness after it is polished or cleaned. It is compatible with the FX300, RX-1200, and

TX300S platforms.

VS-500 Video Fiber Scope

The VS-500 features a single-finger focusing knob, brightness control, and a digital sensor with

detectable resolution to 0.5 µm. It is compatible with the FX300, MTTplus, RXT-1200, and

TX300S platforms.

OTDR Series e-Manual, D07-00-076P-RevC00 Page 40 of 107

6.8.2 Connecting the Fiber Scope

Note: VS-400D, VS-500 and DI-1000 Fiber Inspection Scopes are currently supported if the

Fiber Scope Expert option is installed.

1. Connect the Fiber Scope to the test set, using any available USB port (Older analog fiber

scopes require a USB adapter). To connect to the FX150 microUSB port, use an approved

OTG cable.

2. Select the Utilities or button on the top-left corner of the screen.

3. Tap the Tools menu item, and then tap Advanced Tools.

4. Select the Fiber Scope options.

Note: The OTDR Viewer app is for the portable USB/Bluetooth OPX BOX micro

OTDR option. The Optical Power Meter app is for the UPM-100 USB dongle option.

OTDR Series e-Manual, D07-00-076P-RevC00 Page 41 of 107

6.8.3 Setup

• File Prefix: Enter any name to identify the cable, site, technician, job, etc.

• Starting #: Enter the initial sequence number. This number will increase with each

image captured.

• Scope mode: Select Local or Remote operation.

6.8.4 Analysis

To begin the analysis:

• Select the Connector Analyze Profile and press the green Activate button.

Note: Currently, no IEC Analysis is available for MTP/MPO connectors.

OTDR Series e-Manual, D07-00-076P-RevC00 Page 42 of 107

6.8.5 Capture Screen

• Freeze / Resume: Stops the real time video so users can look at the static picture.

• Analysis On / OFF: Turn the Auto Analysis ON and OFF (software option).

• Auto Freeze: Turn On and OFF the ability to freeze the image automatically, when in

Focus.

• Rectangles / Dots: Dots draw a red contour around scratches and defects. Rectangles

highlight scratches and defects without obstructing the view.

• Shake: Turn On or OFF the ability to Auto Freeze and Analyze when probe image is

unsteady.

• Save: Saves the fiber picture that is on the screen (in Freeze mode) or just Tap the

Screen.

Notes:

1. When the DI-1000 Fiber Scope is plugged into USB, a blue LED will emit. The round

FOCUS knob is on top. Turn right or left to focus.

2. When the VS-400 Fiber Scope is plugged into USB, a white light will emit. The FOCUS

adjustment is located at base of barrel.

OTDR Series e-Manual, D07-00-076P-RevC00 Page 43 of 107

6.8.6 Captured Files

Use check boxes to select one (View) or two (Compare) files.

• Clear All: Deletes all files saved in memory.

• Delete: Deletes all selected files.

• Compare: If two files are selected, they can be compared. For example, pictures of the

same connector before and after cleaning.

• Analyze: Open the connector face analysis feature.

OTDR Series e-Manual, D07-00-076P-RevC00 Page 44 of 107

6.8.7 Connector Face Analysis

Select a file from the Captured Files screen and press the Analysis button.

• Open: Provides a visual navigation tool to select files. Use the stylus to slide left or right

until the correct file is in view, tap on the image to load it.

• Show/Hide Overlay: Enables or disables the analysis mask and defect detection.

• Comments: Add information about the fiber ends, comment about the result, status or

any other meaningful information about connector, application, or case. This information

will be included in the report.

• Save Report: Generates a test report for the selected file (html format). Test set can

convert reports to PDF and send them to USB memory sticks.

• Return: Exit and return to Captured Files Tab.

OTDR Series e-Manual, D07-00-076P-RevC00 Page 45 of 107

6.8.8 Connector Face Analysis Results Table

Select the Result Table tab. The test set displays a table with all numeric results from the

analysis. Catalogs, Defect and Scratch events found for all four zones.

Scratch requirements refer to width.

Note: This table will also be included in the reports.

OTDR Series e-Manual, D07-00-076P-RevC00 Page 46 of 107

6.8.8.1 HTML Report

The Fiber Scope test report can be viewed in HTML format.

OTDR Series e-Manual, D07-00-076P-RevC00 Page 47 of 107

6.8.8.2 PDF Report

The Fiber Scope test report can be viewed in PDF format.

OTDR Series e-Manual, D07-00-076P-RevC00 Page 48 of 107

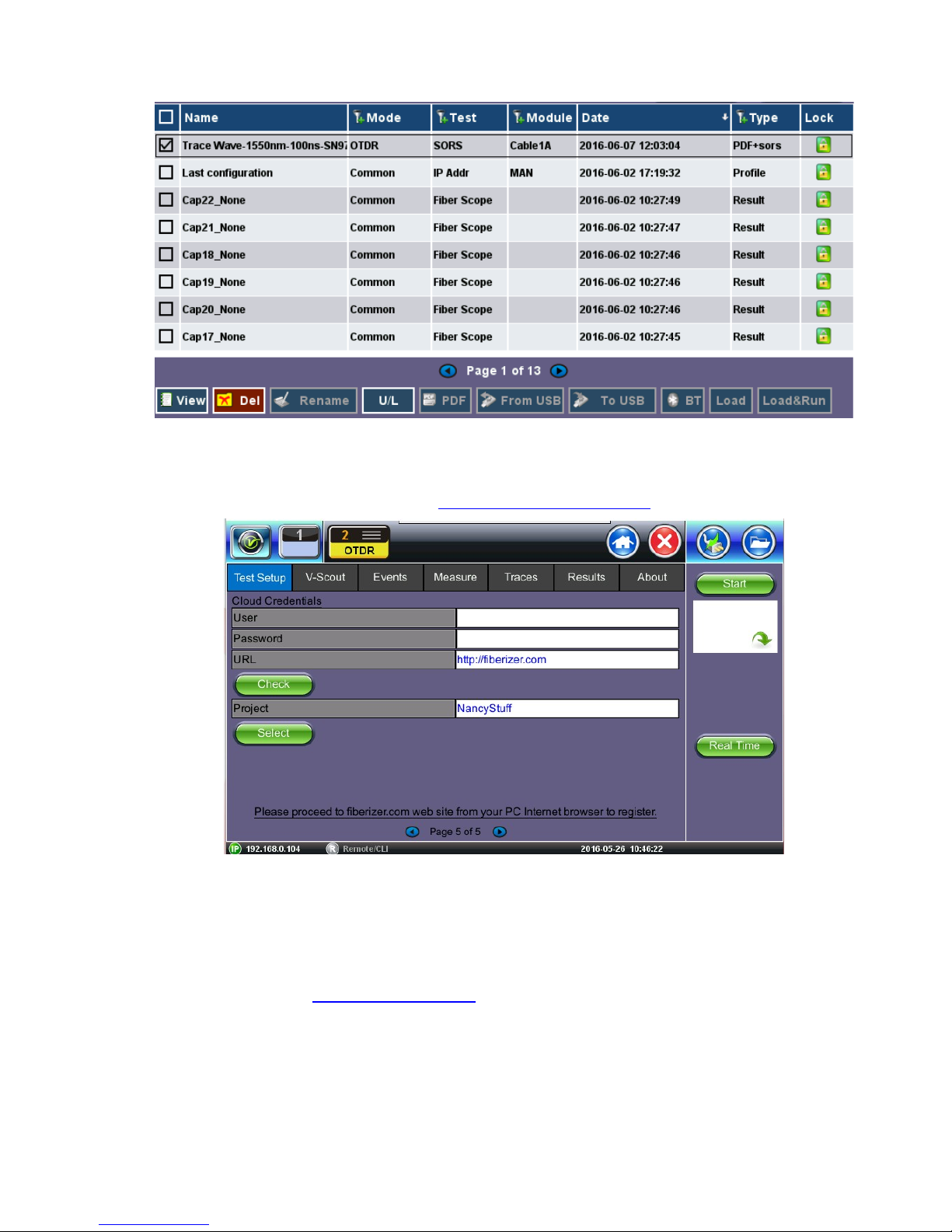

6.8.9 Managing Fiberscope Results with File Manager

1. Go to Utilities >Files >Saved. All results stored in the test set are displayed.

2. Use the to select the desired files.

3. Tap on any column header to sort by that specific parameter (FS Analysis or Fiber Scope).

Tap again to change the sorting order.

• U/L: Unlock or locks files to prevent accidental deletion.

• PDF: Converts all selected files: Requires FAT32 USB Memory stick.

To backup and restore files, use a USB Memory stick.

• To USB: Copies all selected files to the stick.

• From USB: Restores all files from the stick.

• BT: (Bluetooth®) File Transfer the requires compatible USB dongle.

OTDR Series e-Manual, D07-00-076P-RevC00 Page 49 of 107

6.8.9.1 File Manager Filters

File Filters make it easier to isolate desired types of results from all other test results stored in

the test set. It also reduces the number of pages displayed.

To activate filters, use the stylus to tap the + icon.

Fiber inspection test results belong to Common Mode and Fiber Scope Tests. Filter

parameters can be combined.

To reset filters, press the Show All button.

To make locating test results and reports easier, sort the results by tapping a header to sort by

that field’s type, in ascending or descending order.

OTDR Series e-Manual, D07-00-076P-RevC00 Page 50 of 107

6.8.10 Fiber Scope Image Management Software (ViS400D only)

Detailed PC-based Fiber Inspection Monitor & Analysis: Compatible with VIS400D

• IEC 61300-3-35 Profiles

• SMF UPC >45 dB

• SMF APC

• SMF PC RL>26 dB

• MMF PC

• Manual & Auto Analysis

• Focus level indicator

• Report Generation

• Optical Power Measurement: Compatible with UPM-100 OPM

OTDR Series e-Manual, D07-00-076P-RevC00 Page 51 of 107

6.8.11 Fiber Scope Image Management Software (VS-500 and DI-1000 only)

Detailed PC-based Fiber Inspection Monitor & Analysis: Compatible with DI-1000 Fiber Scope

• IEC 61300-3-35 Profiles

Analysis Profile Parameters:

• AnalysisParam1: SMF UPC >45 dB

• AnalysisParam2: SMF APC

• AnalysisParam3: SMF PC RL>26 dB

• AnalysisParam4: MMF PC

Video Mode:

• Start: Activate Real Time viewing mode

• Stop: Halt Real time viewing mode and display last image

• Analysis: Turn ON/OFF Auto IEC Analysis when image is in Focus

• Shake: Turn ON/OFF Shake function to facilitate auto-freeze and analysis when image

is unsteady

• Rect: Toggle between dot or rectangular marking of events

OTDR Series e-Manual, D07-00-076P-RevC00 Page 52 of 107

• AutoFreeze: Turn ON/OFF Auto Freeze when Fiber Scope image is in Focus

• UnFocus before Freeze: Select if you wish to unFocus Image prior to Freezing image

• Show Table: Select to switch from connector image to Table view

Click the to pop up the File Management Window.

• OpenFile: To View saved files

• SaveFile: To Save Fiber Scope results

• Generate Pdf Report: To save Fiber Scope results in pdf file format.

OTDR Series e-Manual, D07-00-076P-RevC00 Page 53 of 107

• About: To check the Fiberizer Scope software revision for the Fiber Scope

• Exit: To quit the Fiberizer Scope program.

OTDR Series e-Manual, D07-00-076P-RevC00 Page 54 of 107

6.9 Visual Fault Locator (VFL)

The unit is equipped with an optionally built-in Visual Fault Locator (VFL) to trace and visually

identify breaks in ODFs, bare fibers (900 µm), and patch cords that are typically hidden in the

OTDR dead zone.

The VFL works by injecting a 650nm visual red light into the fiber (up to 5 kilometers/3 miles)

to bend a single fiber strand and force light to exit the center of the fiber. It traces it to identify

faults through light leakage. It identifies fiber strands, connectors, breaks, bends and other

potential problems or anomalies on events.

To see the most recent VFL specifications, go www.veexinc.com.

PROTECT YOUR EYES!

Never look directly into the VFL’s light. It is a Class II laser and emits

laser radiation that will harm your eyes.

Use the Home icon (FX150/FX300) or App key (FX300) to toggle between active test

applications (OTDR, OPM, VFL).

VFL can be used with OTDR simultaneously.

OTDR Series e-Manual, D07-00-076P-RevC00 Page 55 of 107

6.9.1 Using the VFL

To operate the VFL:

1. Make sure laser is turned off. Remove connector covers from the cable.

2. Connect the fiber to the VFL port located at the top of the unit. The VFL interface is fitted

with universal 2.5mm sleeve accepting all 2.5 mm connector ferrules.

3. Use Test App 1 – Test Mode Selection Fiber testing to display the VFL App.

4. Press Visual Fault Locator on the main menu. The Caution screen appears.

5. Select the operation mode.

CW: Continuous Wave. Select this option to turn on the VFL continually to check for

faults.

1 Hz: Pulse. Select this option to send intermittent light pulses. In some cases, this

makes it easier to identify faults (than continuous light). It can also be used with audible

detectors (toners) that can identify faint light or in well-lit (bright) environments.

6. Press Auto Off. When VFL application is exited, the VFL powers down automatically.

7. Press Turn ON to power the laser. The Caution box turns yellow.

8. You will observe that a red light emits from the end of the fiber to confirm continuity. This

red light will also appear at splices, joints, connectors, ODLs, etc. if any light is leaking.

OTDR Series e-Manual, D07-00-076P-RevC00 Page 56 of 107

9. Press Turn OFF.

10. Disconnect the cable and replace covers.

When not in use, disconnect the cord from the port, replace dust covers,

and keep the port cap securely closed.

For patchcords with dark cabling or any outdoor cable or bend-insensitive

patchcords (armored cables), VFL will not work because there is no way

to bend fibers.

6.10 Optical Light Source (OLS)

The unit can be equipped with an optional Optical Light Source (OLS) to use in conjunction

with the OPM and test the entire fiber infrastructure. It identifies microbends, bad

splices/connectors, and fiber breaks through visible laser light leakage. Use the automated

feature to control both units at each end and test the fiber (multimode or singlemode) at

different wavelengths. The OLS radiates continuously or in pulses.

To see the most recent OLS specifications, go www.veexinc.com.

PROTECT YOUR EYES!

Never look directly into the OPL’s light. The laser radiation emitted will harm

your eyes.

OTDR Series e-Manual, D07-00-076P-RevC00 Page 57 of 107

6.10.1 Accessing and setting up the Optical Light Source

To access and set up the OLS option:

1. Make sure that the Optical Light Source option is installed on the test unit.

2. Power on the unit. Test App 1 – Test Mode Selection is loaded by default. Select Fiber

testing, and then press OK.

3. Press Optical Light Source on the main menu. The OLS screen appears with the Caution

warning.

4. In the Lasers drop-down list box, select the calibrated wavelength (1550nm/1310nm) to

match the signal being measured.

5. Select the operation mode (CW, 270 Hz, 1000 Hz, or 2000 Hz) for the test.

CW (Continuous Wave): Select to continually measure level, loss, and reflectance

in optical components.

270 Hz, 1000 Hz, 2000 Hz (Pulse). Select this option to send intermittent light

pulses. In some cases, this makes it easier to identify faults (than continuous light). It

can also be used with audible detectors (toners) that can identify faint light or in welllit (bright) environments.

OTDR Series e-Manual, D07-00-076P-RevC00 Page 58 of 107

6.10.2 Using the Optical Light Source

To use the OLS:

1. Connect a patchcord between the OLS and OPM test ports.

2. Select Optical Light Source from the main menu. The OLS screen appears.

3. Tap Turn ON to power on the OLS.

4. If WaveID is available, tap Loop mode, to auto cycle through all available wavelengths on

the test port. The laser will change every three seconds.

5. When testing is complete, tap Turn OFF to power off the OLS, and then disconnect the

cable and replace the port covers.

RXT-4111DWDM OTDR Laser Stabilization

The RXT-4111 DWDM OTDR test module offers advanced TEC laser

stabilization for hot and color weather operating conditions. If the

optimal temperature for usage has not been reached, a Laser

Stabilization message appears.

LLaasseerrSSttaabbiilliizzaattiioonnmmeessssaaggee

OTDR Series e-Manual, D07-00-076P-RevC00 Page 59 of 107

6.11 Optical Power Meter (OPM)

The unit can be equipped with an optionally built-in Optical Power Meter (OPM). It can also

access an external Optical Power Meter using the Micro-USB port. It works by testing average

output power from a light source and can be used to measure the span loss in dB of an optical

fiber systems. On the test set display, view measurement loss in real-time.

Note: Only optical power meters (e.g. Built-in, UPM-100 or FX40 series meters) approved by

VeEX are supported.

To see the most recent OPM specifications, go www.veexinc.com.

Use the Home icon (FX150/FX300) or App key (FX300) to toggle between active test

applications (OTDR, OPM, VFL).

6.11.1 Setting up the Optical Power Meter

To access and set up the external OPM:

1. Make sure the external Optical Power Meter is connected to the Micro-USB port via an

OTG cable.

2. Power on the unit. Test App 1 – Test Mode Selection is loaded by default. Select Fiber

testing, and then press OK.

3. On the Home menu left panel, tap Tools>Advanced.

4. On the main menu, tap Optical Power Meter. The OPM setup screen appears.

Accessing the Optical Power Meter module shuts down GPS and the

atomic service.

OTDR Series e-Manual, D07-00-076P-RevC00 Page 60 of 107

To access and set up the internal OPM:

1. Check the test ports to ensure that the Optical Power Meter option is installed on the test

unit.

2. Power on the unit. Test App 1 – Test Mode Selection is loaded by default. Select Fiber

testing, and then press OK.

3. Press Optical Power Meter on the main menu. The OPM screen appears with the Caution

warning.

See 6.11.2 Using the built-in OPM for information on using the built-in OPM.

6.11.1.1 USB OPM Setup Options

Use the following options to configure the OPM:

• Wavelength: Provides a list of calibrated wavelengths to match the signal being

measured.

• Test Mode: Select between Power or Loss measurements.

• Power Meter (OPM): In Power Meter mode, the test set presents the direct power

readings, which are displayed in dBm, mW or uW units. You can perform unit

conversions by using the dBm, mW or uW buttons.

• Loss Meter: In Loss Meter mode, the test set reports the difference in power

readings between the Laser Source (LS) output being used and what is currently

present at the connector after being attenuated by the fiber. The results are

presented in dB.

Loss meter must be referenced (calibrated) to the Laser Source output.

OTDR Series e-Manual, D07-00-076P-RevC00 Page 61 of 107

To calibrate the Loss meter to the LS:

1. Connect the LS the OPM using a short patch cord.

2. Tap the Reference button to record the 0dB point. A reference point is established and the

calibrated LS can be connected to the far-end of the fiber to measure the loss.

• Hold: Freezes the last power or loss reading on the screen. Hold appears on the white

screen when tapped. Tap Hold again to unfreeze it.

• Save: Records instantaneous power or loss readings in the Results tab. The Save

button must be used to record these individual readings (e.g. same cable at different

wavelength). Use the Folder button to save the complete set of results.

Saving the power or loss readings is useful when measuring multiple

fibers or testing one fiber with multiple wavelengths.

• Reference (Reference Power Level for Loss Meter Test Mode): Sets the output

reference level to measure against when a short and clean optical patch cord for the LS

is connected directly to the unit’s OPM port.

Press Set to store the reading or press Cancel to keep the previously stored value.

6.11.1.2 Setting Pass/Fail Limits

Whether measuring optical power or loss, there are always power input limits (saturation and

loss) or attenuation allowances that determine whether the fiber cable meets the requirements

for the desired application or network elements.

• Power Limits: Select the Power Limits (dBm) checkbox and enter the Minimum and

Maximum power levels allowed for the application (e.g. in line with the transceiver’s

dynamic range). If the power reading falls beyond those limits, the power measurement

reading will turn red.

• Loss Limits: Select the Loss Limits checkbox and enter the Minimum and Maximum

amounts of optical power loss that are acceptable for the application or specified for the

cable or installation. You can specify the total amount of attenuation in dB, or select the

dB/km or dB/mi if the results are being compared against cable specifications. If

needed, enter the Length of the cable under test for the test set to make the

conversion.

OTDR Series e-Manual, D07-00-076P-RevC00 Page 62 of 107

6.11.2 Using the built-in OPM

1. Connect the fiber to the OPM port located at the top of the unit.

2. Power on the unit.

3. Select Test App 1 or Fiber to see the OTDR/VFL/OLS/OPM selection screen.

4. Tap Optical Power Meter. The OPM menu appears.

5. If the light source has a WaveID option, tap Wave ID to detect the wavelength of the

incoming signal automatically.

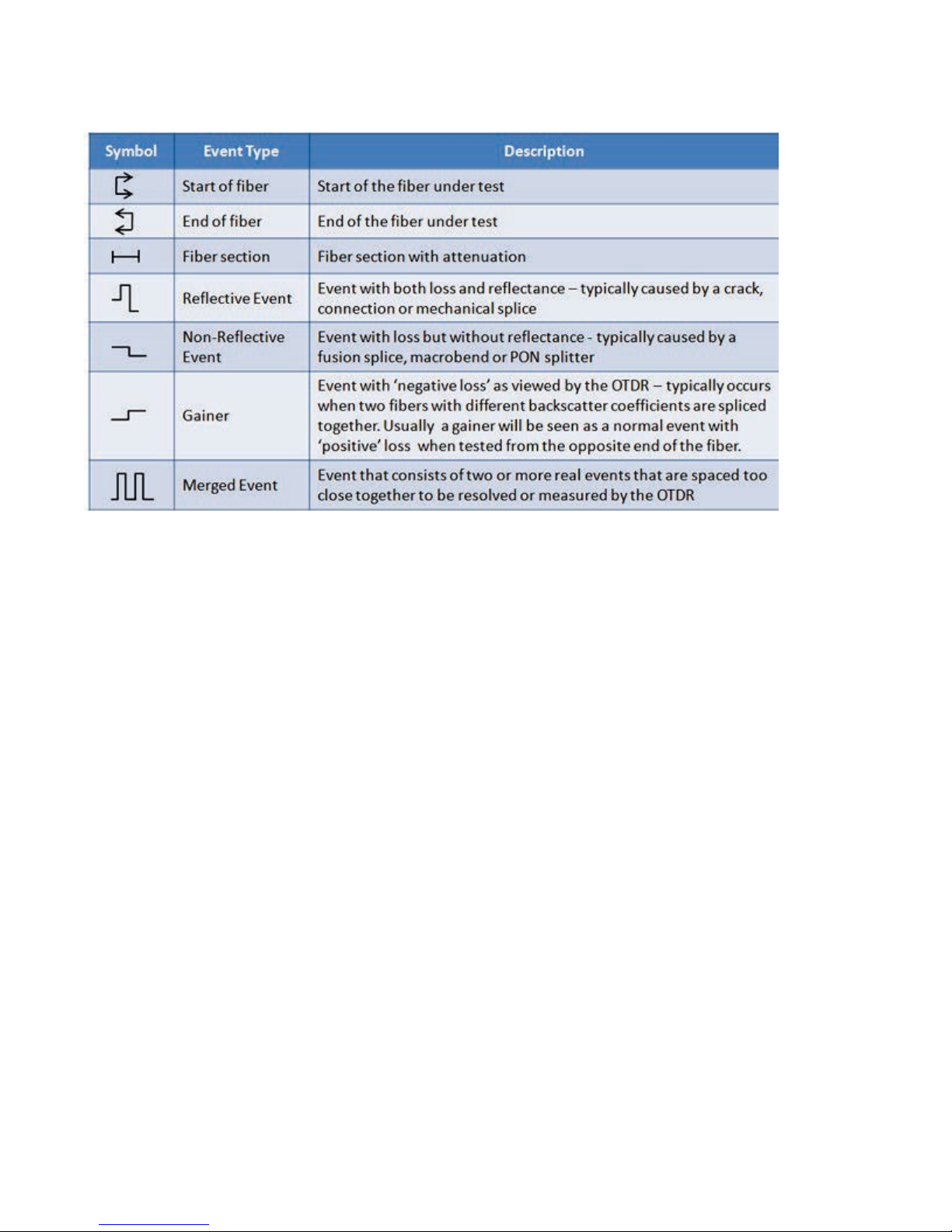

6. When testing is complete, tap Turn OFF to power down the OLS, and then disconnect the

cable and replace the port covers.

Use the following options to configure the OPM:

• Wavelength: Matches the calibrated wavelength to the signal being measured.

• Wave ID: Detects the incoming wavelength automatically. Use when operating the OLS

in CW mode with or without Loop enabled.

• Mode: Designates the measurement specification built-in: PM1 or PM2. For specific

information on the PM1 or PM2 specifications, see the platform’s datasheet at

www.veexinc.com.

OTDR Series e-Manual, D07-00-076P-RevC00 Page 63 of 107

To calibrate the Loss meter to the LS:

Note: For more information on patchcords, see 6.6.2 Fiber Patchcord.

1. Connect the LS to the OPM using a patch cord.

2. Tap the green dB button.

3. Go to OLS and select the laser wavelength or Loop mode. The wavelength should match

the light source wavelength, unless Wave ID is available.

4. Press Set to record the 0.00 dB point. A reference point is established and the calibrated

LS can be connected to the far-end of the fiber to measure the loss.

• dB/dBm: Switches between dB and dBm measurement units.

• Set: Sets the reference value for the current wavelength.

• Enter: Edits reference values.