Veethree EGM Installation Manual

1

Marine Engine Gateway

Monitor (EGM)

Installation Guide

2

Contents

1. Installing the Displays ............................................................................... 3

1.1 Mounting the Display .............................................................................. 3

1.2 Power Connections to the Display (all engine types) ............................. 3

1.3 Attaching to NMEA 2000 (optional) ........................................................ 3

1.4 Attaching to a J1939 Engines (CAN-bus) ................................................. 4

1.5 Attaching to an Engine via Analogue Signals .......................................... 4

1.6 Attaching to a Rudder Angle Sender ....................................................... 4

1.7 Attaching to a Fuel Level Sender ............................................................. 5

1.8 Attaching to a Trim/Tilt Sender ............................................................... 5

1.9 Attaching to a GPS NMEA 0183 Signal .................................................... 5

2 Commissioning the System ............................................................................ 6

2.1 ‘System Configuration’ Menu ................................................................. 6

2.2 Engine ID ............................................................................................. 7

2.2 Data Sources ....................................................................................... 7

2.3 NMEA 2000 Settings............................................................................ 9

2.4 J1939 Settings ................................................................................... 10

2.5 Analogue Settings ............................................................................. 11

2.6 Fuel Management Settings ............................................................... 13

2.7 Diagnostics ........................................................................................ 14

3

1. Installing the Displays

The EGM supports up to three engine types (Non-electric, J1939 or NMEA

2000) and each display can be allocated to be Port (or single), Starboard or

Centre. When mounting the displays the allocation of position is not

important as this is done during the commissioning sequence. Multi station

capability is a built-in feature and is provided across the NMEA 2000 network

using the gateway function. Adjustable items like language selection and

backlight are shared across the network so that all displays are synchronised

with the same settings.

1.1 Mounting the Display

Contained in the box you have received is a Fixing template, place this on the

area where the display is to be fitted, and use it to mark the holes in the

Dash, Fit the studding, from the “Fitting Kit” supplied, into the four positions

at the rear of the display. Make sure the Rubber Seal is securely in place at

the rear of the display over the USB Port access and then feed the studding

through the four holes and use the nuts to fix the display in place. The display

has an integrated rubber gasket to help seal the display to the dash.

Depending on access you may also need to fit the supplied cable harness to

the display before mounting the display.

1.2 Power Connections to the Display (all engine types)

The display can be powered from the engine battery, this way the display will

be able to monitor the engine battery voltage, however, while the engine is

cranking the display may cut out. Alternatively you can connect the display to

the domestic battery supply; this will prevent cut outs while the engine is

cranking. In either case the supply is fed via the black and red wires on the

harness (there are two blacks and either can be used). The supply should be

fused at 500mA or 1A max to protect the wiring.

1.3 Attaching to NMEA 2000 (optional)

Find the NMEA 2000 backbone if already fitted on the vessel, and use a TPiece to connect the NMEA 2000 Cable from the display to the backbone. You

should check that the NMEA backbone is properly terminated, you do this by

4

finding each end, and making sure they have a NMEA 2000 termination

device at each end of the backbone. If there is no pre-existing backbone you

will need to fit this before connecting the display. If you have a dual station

system you will need to connect to the NMEA 2000 network to share data

between EGM’s even if you don’t have any other NMEA 2000 equipment.

1.4 Attaching to a J1939 Engines (CAN-bus)

You will need to find the CAN-Low and the CAN-High from the Engine ECU or

off of the Transmission – see engine manual for this information. You will

then need to connect the Blue wire to the CAN-Low and the White wire to

the CAN-High. They should remain twisted together. You will also want to

check that the J1939 CAN Network is properly terminated. (You can do this

by measuring the resistance between CAN-High and CAN-Low. Once

connected it should read around 90-150 Ohms if it does not, you will need to

add a 120 Ohm resistor between the CAN-High and the CAN-Low).

1.5 Attaching to a Non-electronic Engine

In this case the engine senders will be directly connected to the display

harness. The standard minimum is for Engine Speed (Tacho), Oil Pressure and

Coolant Temperature. The display will also measure engine hours (when the

RPM is greater than 400) and battery voltage of the supply it’s connected to

(engine battery or domestic) without additional connections as these are

Automatic.

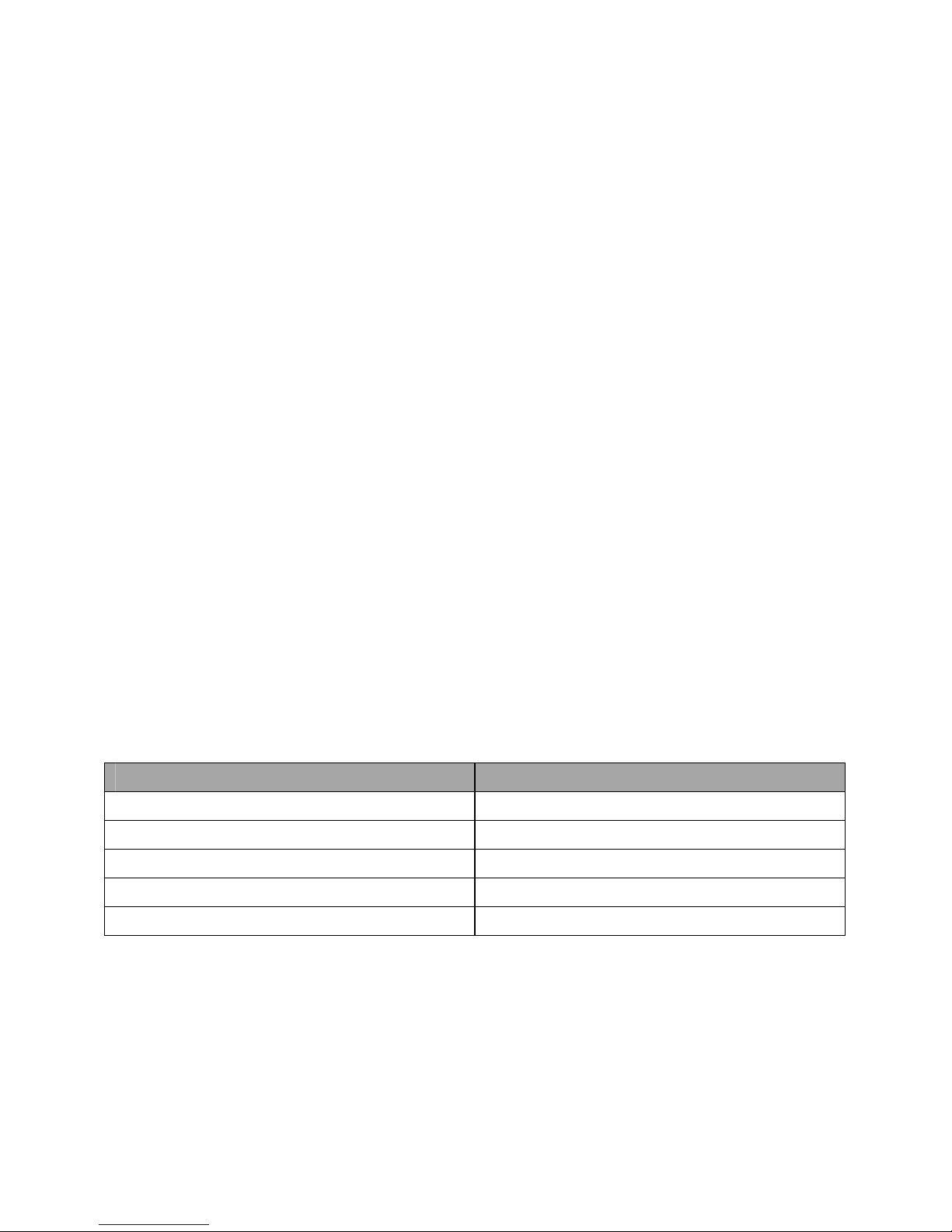

Wire

Sensor Signal

Black/White

Oil Pressure

Brown/White

Coolant Temperature

Red/White

Boost Pressure

Yellow

Oil Temperature

Violet

Tachometer (from Alternator

W)

1.6 Attaching to a Rudder Angle Sender

The rudder angle can be measured from the Veethree rudder angle sender.

Connect the signal from the sender to the Yellow/White wire of the display

5

harness. The rudder sensor ground is connected to the spare black wire from

the display (used for all analogue senders).

1.7 Attaching to a Fuel Level Sender

The fuel level (one tank per display) can be measured from standard two wire

fuel senders. The sender signal should be connected to the blue wire of the

display harness. The sender ground is connected to the spare black wire from

the display (used for all analogue senders).

1.8 Attaching to a Trim/Tilt Sender

The tilt/trim (one per display) can be measured from standard two wire

tilt/trim senders. The sender signal should be connected to the orange wire

of the display harness. The sender ground is connected to the spare black

wire from the display (used for all analogue senders).

1.9 Attaching to a GPS NMEA 0183 Signal

A NMEA 0183 GPS can be attached to the unit to allow is to display SOG

(speed over ground) and COG (course over ground). The NMEA 0183 transmit

of the GPS should be linked with the green wire of the display harness.

Loading...

Loading...