Page 1

Introduction

A new standard of performance and functionality in a compact preset

counter. The V454502 Dual Preset Counter offers a pre-settable

counter with full calibration for a variety of applications.

The bright red LED display provides simultaneous count and preset

indication. The use of annunciators and simple key sequences makes

operator changes quick and easy. A variety of count sources are

accommodated, including relay and pushbutton contacts, photocells

and proximity switches and uni- or bi-directional incremental encoders.

The open collector output can interface to light duty devices and the

relay contacts offer heavy duty load switching.

Set-up and installation are simplified

through

front panel entry of configuration

parameters

and a unique “no tools required” panel

mounting bracket.

The V454500 family of preset counters

combines state-of-the-art circuitry and

electronic assembly techniques with an

ergonomic package design that results

in the most cost-effective ,

high-performance counter value

on the market.

Features

Dual four-digit displays for Count

*

and Preset values

10kHz count speed

*

Add/Subtract or bi-directional

*

count inputs

Digital calibrator and

*

programmable decimal point

Accepts current sinking or

*

sourcing devices

Key reset, remote reset and auto

*

reset modes

Reset to zero or preset number

*

Relay (SPDT) and open collector

*

outputs

Accessory sensor power supply

*

Universal 90 - 264V AC power

*

requirements

NEMA 4/IP65 sealed front panel

*

Designed to comply with

*

EN50081 and EN50082 EMC

specifications

Index

Overview

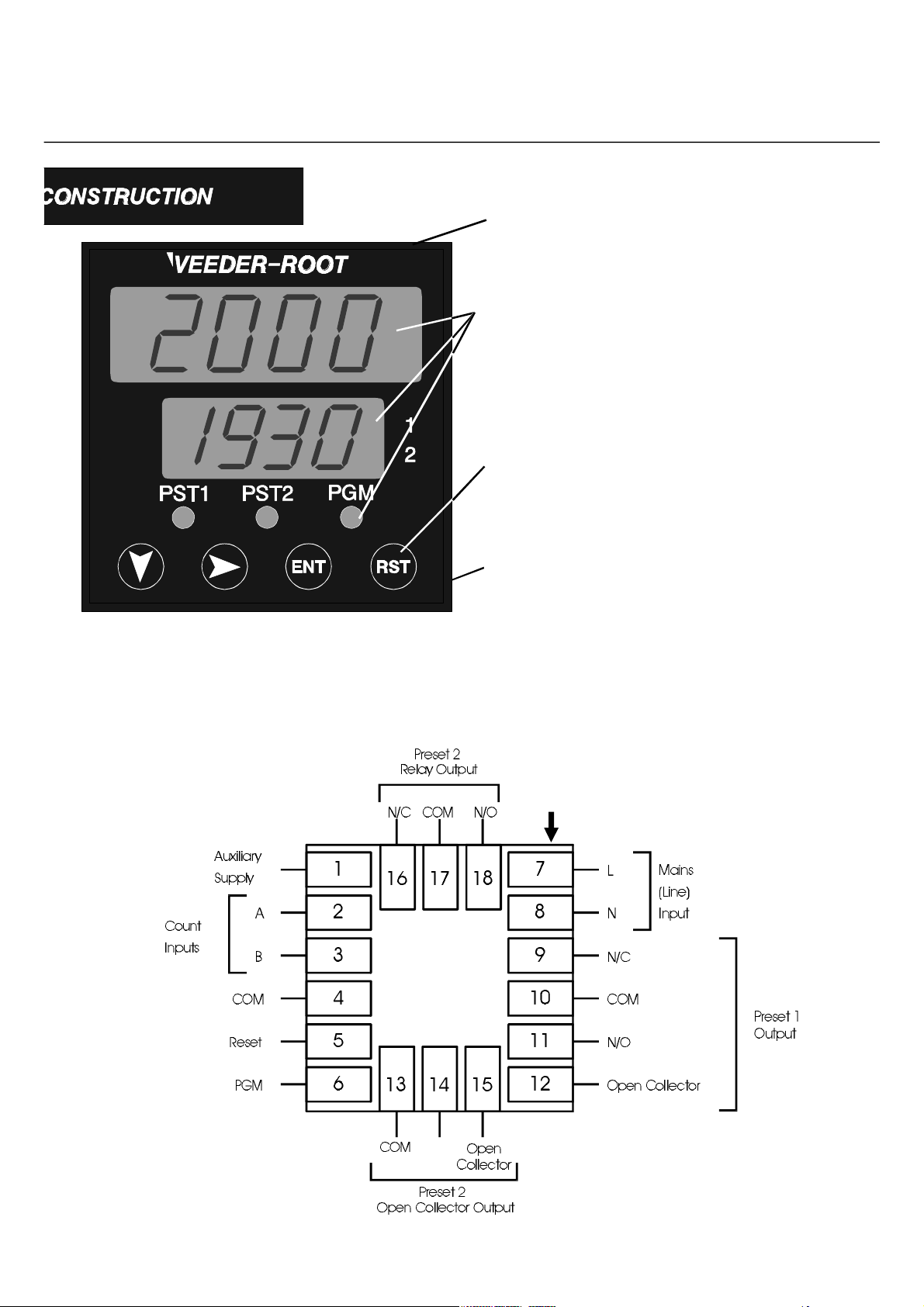

Construction Page 2

Installation

Wiring Page 3

Panel Mounting Page 4

Operation

Front Panel Page 5

Programming

Viewing Preset Value Page 6

Changing Preset Value Page 6

Program Mode Page 7

Configuration Mode Page 8

Appendix A - Specifications Page 9

Order Codes Page 12

Page 2

Compact Design

Uses only 48mm of panel space. 110mm behind-panel depth.

Dual Four-character Display

Simultaneous display of Count and Preset data. Red LED

display. Annunciators show input, display and output status.

Ergonomic Keypad

Simple key sequences to view and edit Presets.

Front Panel Reset key can be disabled.

Front Panel Seal

NEMA 4/IP65-rated when installed with panel mount gasket

supplied.

Rear Terminal Connections

Top of Counter

Page 3

I N S T A L L A T I O N

IMPORTANT: In severe electrical noise environments, shielded cable is

recommended for inputs and outputs. Connect the shield only to the

building earth (ground).

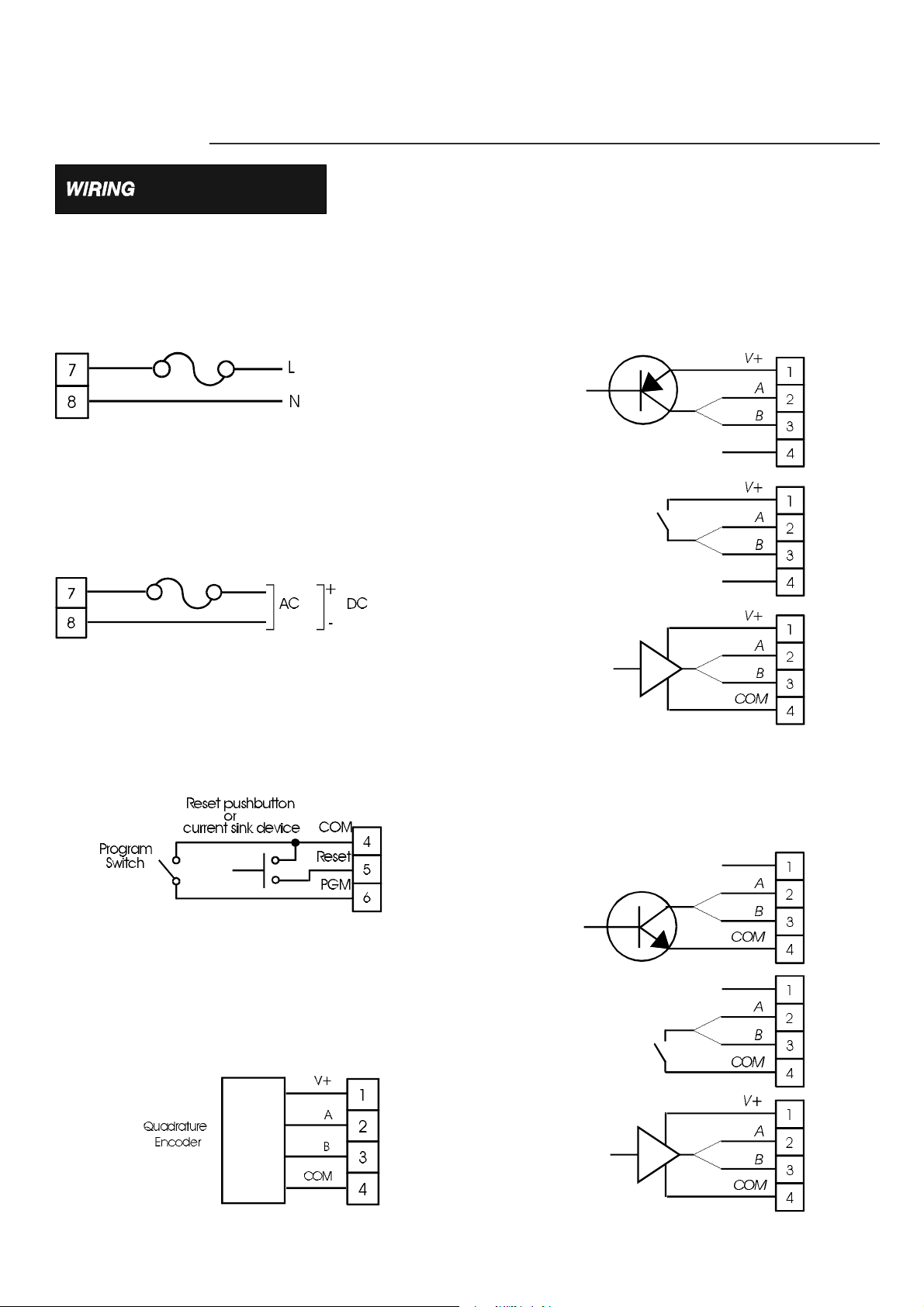

AC Power Input

Connect AC power to Terminal 7 (Line) via a 1A

slow-blow fuse and to Terminal 8 (Neutral) - see below.

AC power should be from a separate branch circuit

which is noise-free and does not feed heavy loads.

DC/Low Voltage AC Power Input

Connect DC/low voltage AC power to Terminal 7 (+)

via a 0.5A slow-blow fuse and to Terminal 8 (–) - see

below. DC power should have low ripple and be

noise-free.

Reset and Program Inputs

Current Sourcing (PNP) Count Inputs

Connect Add count input to Terminal 2 (A) and/or Subtract

count input to Terminal 3 (B) - see below. In Configuration

Mode, set PuLL parameter to no and, for Add/Subtract

operation, set InPu parameter to A-B .

PNP Open Collector

Contact Closure

Current Source or

Line Driver

Connect Reset pushbutton or current sink device to Reset

(Terminal 5) and COM (Terminal 4). Connect Program

switch or jumper to PGM (Terminal 6) and COM

(Terminal 4).

Bi-directional Quadrature Inputs

Connect Quadrature Encoder to V+ (Terminal 1), A input

(Terminal 2), B input (Terminal 3) and COM (Terminal 4) as

shown below. In Configuration Mode, set InPu parameter to

QuAd . For NPN open collector devices with no pullup

resistors, set PuLL parameter to YES .

Current Sinking (NPN) Count Inputs

Connect Add count input to Terminal 2 (A) and/or Subtract

count input to Terminal 3 (B) - see below. In Configuration

Mode, set PuLL parameter to YES and, for Add/Subtract

operation, set InPu parameter to A-B .

NPN Open Collector

Contact Closure

Current Sink or

Line Driver

Page 4

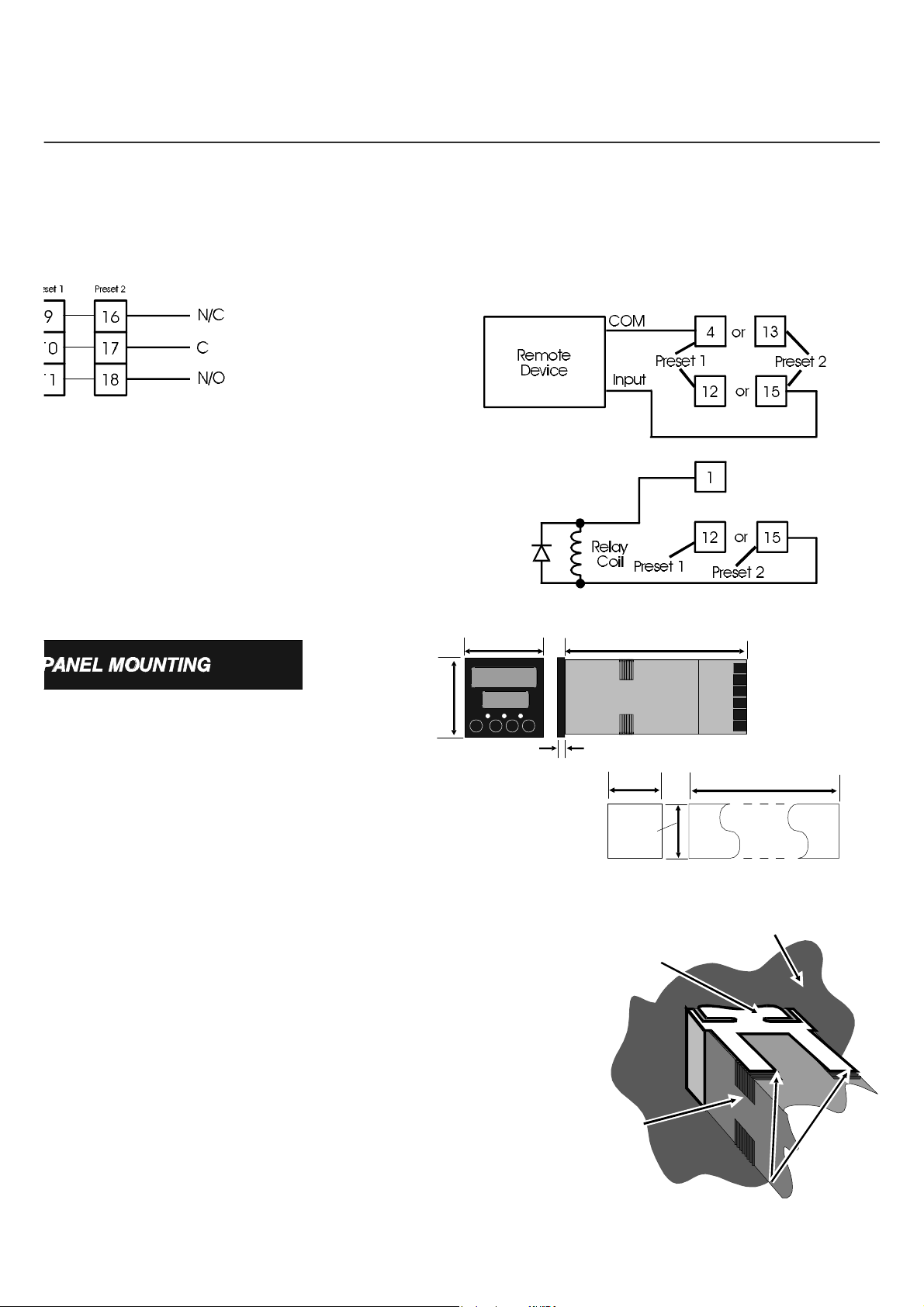

Open Collector Output

below (upper circuit). To drive DC relay coils, connect Terminal 12

switching transients with a suppression diode, connected as shown.

Connect Terminals 12 (Preset 1 open collector) and 4 (COM) or 15

(Preset 2 Open Collector) and 13 (COM) to solid state devices as

or 15 and V+ (Terminal 1) as below (lower circuit). Suppress

48m

48m

Panel Mounting

Make cut-out(s) according to the details in

the diagram on the right. The maximum

panel thickness is 6 mm.

Insert the rear of the Counter housing

through the cut-out (from the front of the

mounting panel) and hold the Counter

lightly in position against the panel. Ensure

that the panel gasket is not distorted and that

the Controller is positioned squarely against

the mounting panel. Apply pressure to the

front panel bezel only. Slide the mounting

bracket in place (see right) and push it

forward until it is firmly in contact with the

rear face of the mounting panel (tongues on

the bracket should engage in matching

rachet positions on the Counter housing and

the mounting bracket springs should push

firmly against the mounting panel rear face).

110

10mm (approx.)

45m

45m

Single

Installatio

Rear face of mounting panel

Mounting bracket

Counter

housing

Tongues on mounting bracket

engage in ratchet slots on Counter housing

(48n - 4)mm

Multiple Installation (n

Counters)

Page 5

O P E R A T I O N

10. Preset 1 Annunciator

(ON when Preset 1 shown

on lower display)

1. Upper Display

2. Lower Display

3. Preset Output Displays

(ON when active)

4. Program

5. Preset 2 Annunciator

(ON when Preset 2 shown

on lower display)

NOTE

ENT.

IMPORTANT

ENT key within

9. Down Key

8. Next Key

Down key

Operator Mode: Used to change the

currently-selected (flashing) digit.

Depressing this key will decrement the

value (wrap-around from 0 to 9). If the

key is held continuously, the value will

decrement at the rate of 2/sec.

Program Mode: Used to advance from

one parameter to the next. Once a

parameter value has been selected for

editing (through use of the Next key),

depressing this key will decrement the

value (wrap-around from 0 to 9). If the

key is held continuously, the value will

decrement at the rate of 2/sec.

Configuration Mode: Used to advance

from one parameter to the next.

ENT key

Operator Mode/Program Mode:

Confirms an edited value (display will

cease flashing after the ENT key is

depressed).

Configuration Mode: Confirms

setting/value selection (display will cease

flashing after the ENT key is depressed).

7. Enter

6. Reset Key

Next key

Operator Mode: Used to select a

parameter for editing (left-most digit will

start to flash) and to move between the

digits. Once the proper digit is selected

(flashing) with the Next key, its value can

be altered through use of the Down key.

Program Mode: Used to select a

parameter for editing (left-most digit will

start to flash) and to move between the

digits. Once the proper digit is selected

(flashing) with the Next key, its value can

be altered through use of the Down key.

For Decimal Point Position, this key

scrolls through the available choices.

Configuration Mode: Used to select a

parameter for editing and to scroll through

available choices.

RST key

Operator Mode/Program Mode: Resets

count value to either zero or Preset value

(based on the setting of the Count

Direction parameter in Configuration

Mode). Also releases latched outputs.

Configuration Mode: Exits

Configuration Mode when held down for 2

seconds.

NOTE: The RST key will not be active

unless enabled in Configuration Mode.

For information on Operator Mode, see Page 6.

For information on Program Mode, see Page 7.

For information on Configuration Mode, see Page 8.

Page 6

The Operator Mode is used for viewing the

Count value and viewing/changing the Preset

1/Preset 2 value.

Counter value

Preset 1 or Preset 2 value

NOTE

To abort an edit

operation (before the

new value is confirmed),

press the Down and Next

keys together.

WARNING!

Caution should be

observed if it is

necessary to change

the preset value while

the process is

operating. Do not set

values which are

already exceeded by

the count value without

resetting the counter.

Press the Next key to enter Edit Mode.

The most significant digit of the Preset

Data display will then flash. Press the

Next key repeatedly as required to select

the desired digit.

Press the Down key to change the value

of the selected digit (there is wrap-round

from 0 to 9).

When all digits are as required, press the

ENT key to confirm the changes; the

display will stop flashing.

IMPORTANT

You must press the ENT key within 15

seconds of the last keypress when entering a

new value, otherwise the new value will be

discarded and the old value will be retained.

Page 7

digit to be adjusted, and adjust digit value using Down key. When adjustment

WARNING!

Changing Program

Mode parameter values

while the process is

operating may be

hazardous to the

operator and/or the

controlled equipment.

Use extreme caution

and stop the process

before attempting to

change Program Mode

parameter values.

IMPORTANT

You must press the ENT

key to implement new

parameter values.

To enter Program Mode, set the PGM input active (low) e.g. by tying it to COM.

Whilst in Program Mode, the PGM indicator will be ON.

Function

Pre-scaler

Output 1 Time

Parameter

Description

(Upper Display)

Meaning

Pre-scales counter operation.

Value = Count units displayed

Count pulses input

Sets momentary ON time for

PRESET 1 output (0.01 -

99.99s; 0.00 for latched

operation)

NOTE

Possible Decimal Point

Position settings are:

Output 2 Time

Decimal Point

Operator Mode:

Preset 1

Preset 2

1. To adjust Pre-scaler, Out Time or either Preset value (as selected), press

Next key to enter Edit Mode (digits will flash), use Next key to select each

is complete, press ENT key to exit Edit Mode (digits will become static).

None

None

NOTES

Sets momentary ON time for

PRESET 2 output (0.01 -

99.99s; 0.00 for latched

operation)

Defines decimal point position

Shows Preset 1 value

Shows Preset 2 value

2. To adjust decimal point position, select that parameter, press Next key to

enter Edit Mode, then use Next key to position decimal point. Press ENT key

when finished.

To exit Program Mode, set the PGM input inactive (High).

Page 8

To enter Configuration Mode,

power-down the Counter and

remove it from its housing. Change

the position of the lnk jumper on

the CPU PCB (the actual position is

irrelevant, as long as the position is

changed). Replace the Counter in

its housing and power-up. The PGM

indicator will flash whilst the

Counter is in Configuration Mode.

Counter

(Top view)

To edit a parameter, use the Down key to step through the parameters; when the desired

parameter description is shown in the upper display, press the Next key to enter Edit Mode and

to scroll through the available settings. When the desired setting is shown, press the ENT key.

The Configuration Mode parameters, in order of appearance, are:

Parameter

Counter Speed

Input Operation

Panel Reset Key

Auto Reset

Input Pull-Ups

Count Direction

Parameter

Description

(Upper Display)

Available Settings

20Hz 200Hz 10kHz

A-B

(Add/Subtract)

Enable Disable

Enable Disable

Yes

(current-sinking

Up-countin Down-countin

Quadrature

(bi-directional)

No

(current-sourcing

Down key steps

through parameters

Lock Strategy

None

Preset

Lock

Partial

Program

Lock

Preset &

Program

Lock

LOCK STRATEGY:

None = No security; all parameters available through regular methods of access

Preset Lock = Preset 1 and Preset 2 become Read Only

Partial Lock = Output ON times are Read Only

Both = Operator Mode parameters and Output ON times are Read Only.

To exit Configuration Mode, either momentarily remove power from the Counter

or press and hold down the RST key for at least two seconds.

Page 9

A P P E N D I X A

Input Power

AC: Terminals 7 (Line) and 8 (Neutral)

90 - 264V 50/60Hz (standard)

20 - 50V AC 50/60Hz (option)

DC: Terminals 7 and 8; 22 - 65V (option)

Power consumption: 4W approx.

Output Power

DC: Terminals 1 (+) and 4 (COM)

9 - 15V DC (unregulated)

0 - 100mA. 0.5V ripple

Main Counter

Decades: 4, Bi-directional

Presets: 2 (4 decades each)

Operation: Add/Subtract (Input A counts up, Input B

counts down) or bi-directional

(quadrature;

counts up when Signal A leads Signal B).

Direction: Up (reset-to-zero) or Down

(set-to-a-number)

Count Rate

High: 10kHz max.

Medium: 200Hz max.

Low: 20Hz max.

Resets: Manual or automatic.

Selectable reset-to-zero

or reset-to-Preset

Calibrator

Range: 0.001 to 9.999

Common to Inputs A and B.

Count Inputs

Signal A: Terminal 2

Signal B: Terminal 3

Input Voltage

High: 3.0V (source)

3.0V or open (sink)

Low: 2.0V or open (source)

2.0V (sink)

Max.: 30V DC

Input Impedance

Source: 10kΩ to COM

Sink: 4.7kΩ to +V

Input Response: 0.05ms (high speed)

(Source or sink) 2.5ms (medium speed)

25.0ms (low speed)

Control Inputs

Remote Reset: Terminal 5 (edge-sensitive)

Program Mode: Terminal 6 (level-sensitive)

Input Voltage: High - 3.0V or open

Input Impedance: 4.7kΩ to +V

Input Response: 25.0ms

Max.: 30V DC

Low - 2.0V

Front Panel Keys

Type: Mechanical switches under sealed

membrane overlay.

Display

Type: LED (red) 4 digit

Height: Upper - 0.4" (10mm)

Lower - 0.3" (7mm)

Security

Preset data can be protected (selectable in Configuration Mode).

Program data is accessible only if the PGM input is active.

Output

Operation: Output 1 energised when

SOLID STATE (OPEN COLLECTOR)

Terminal Nos.: 12 (Preset 1) and 15 (Preset 2)

Type: Open collector, current sink to COM.

RELAY

Terminals: Preset 1: 9 (N/C), 10 (C), 11 (N/O)

Type: Form C (SPDT)

Rating: 5A resistive @ 110V AC

Count = Preset 1

Output 1 released when Hold time

elapses or reset occurs

Output 2 energised when

Count = Preset 2 (Up mode) or

Count = 0 (Down mode)

Output 2 released when Hold time

elapses or reset occurs

30V DC max. 100mA max.

Preset 2: 16 (N/C), 17 (C), 18 (N/O)

3A resistive @ 240V AC

Mechanical

Cut-Out: 45mm x 45mm (

Depth: 110mm

Weight: 0.2kg approx.

1

16

-DIN)

Environmental

Operating Temp.: 0 - 55oC (32 - 131oF)

Storage Temp.: –20 - 80oC (–4 - 176oF)

Relative Humidity: 20 - 95% non-condensing

Front Panel Seal: NEMA 4/IP65 when installed with

panel gasket (supplied)

Page 10

Page 11

11

Page 12

The order codes for the Veeder-Root 454502 Dual Preset Counter are shown below:

Dual Preset Counter (USA) V45450-2

Dual Preset Counter (UK/Europe) V45450E2

Dual Preset Counter (USA) - Low Voltage AC/DC supply V45450-22

Dual Preset Counter (UK/Europe) - Low Voltage AC/DC supply V45450E22

This instrument is warranted to be free from defects in workmanship and material for a period

of three years from the date of despatch. In the unlikely event of a fault, call the appropriate

number below for a Return Material Authorisation (RMA) number.

The obligation of the Company under this warranty is limited to the repair or replacement of

this instrument. Should the cause of the fault be due to misuse or abuse of the instrument or the

warranty period has expired, the customer shall be informed before any repair work is started.

In the UK:

Veeder-Root Division

West Instruments Limited

The Hyde

Brighton

E. Sussex BN2 4JU

Tel. +44 (0) 1273 606271

Fax: +44 (0) 1273 609990

1675 N. Delany Road

Gurnee, IL

60031-1282

Tel. 708.662.2666

In France:

Veeder-Root SARL

8 Place de la Loire

94583 Rungis Cedex

Tel. 33-146870981

Fax: 33-146868004

In Germany:

Veeder-Root GmbH

Morikestrasse 30

73761 Neuhausen ADF

Tel. 49-71589003-0

Fax: 49-71589003-32

In Brazil:

Veeder-Root do

Brasil

Rua Ado Benatti No-92

Caixa Postal, 8343

CEP 05037-010

São Paulo

Tel. 55-118612155

Fax: 55-118611982

Loading...

Loading...