Page 1

Manual No: 577013-401 ● Revision: K

Application Guide

TLS Consoles Point-of-Sale (POS)

Page 2

Notice

Veeder-Root makes no warranty of any kind with regard to this publication, including, but not limited to, the implied warranties of

merchantability and fitness for a particular purpose.

Veeder-Root shall not be liable for errors contained herein or for incidental or consequential damages in

connection with the furnishing, performance, or use of this publication.

The information contained in this publication may be subject to change without notice.

This publication contains proprietary information which is protected by copyright. All rights reserved. No part of this publication may be

photocopied, reproduced, or translated to another language without the prior written consent of Veeder-Root.

©Veeder-Root 2018. All rights reserved

ii

.

Page 3

Introduction

Business Inventory Reconciliation (BIR) ...........................................................................1

In-Station Diagnostics (ISD) - TLS-350R Consoles Only .........................................1

TLS-350R BIR and ISD Capabilities .................................................................................1

TLS-350R with BIR only and TLS-350R with BIR and ISD ......................................1

TLS-350R with ISD only ...........................................................................................1

Manifolded Tank Applications for BIR ......................................................................1

TLS-350R System Requirements for BIR and ISD ..........................................................2

Business Inventory Reconciliation............................................................................2

In-Station Diagnostics...............................................................................................2

TLS-450/TLS-450PLUS BIR Capabilities .........................................................................2

Manifolded Tank Applications...................................................................................3

TLS-450/TLS-450PLUS System Requirements for BIR ...........................................3

Supported POS Systems ..................................................................................................3

Other Applications ....................................................................................................4

DIM Descriptions

Mechanical Dispenser Interface Module (MDIM) &

Low Voltage Dispenser Interface Module (LVDIM) ...........................................................5

Electronic Dispenser Interface Module (EDIM) .................................................................5

Current Loop Dispenser Interface Module (CDIM) ...........................................................5

LAN Dispenser Interface Module (LDIM) - TLS-350R only ...............................................5

International Forecourt Standards Forum Dispenser Interface

Module (IFSF) - TLS-350R, TLS-450PLUS ......................................................................6

TCP/IP DIM Module (TDIM) - TLS-350R ..........................................................................6

TCP/IP DIM (TDIM) - TLS-450/TLS-450PLUS .................................................................6

DIM And Installation Kit Ordering Guide ...........................................................................7

Table of Contents

DIM Installation Examples

Bennett POS System ......................................................................................................16

Veeder-Root Software Requirements.....................................................................16

Veeder-Root Hardware Requirements (Ref. Table 2) ............................................16

Bennett System Limitations ....................................................................................16

Installation Notes ....................................................................................................16

Gilbarco TCRG, TCRG2, T-11, and T-12 POS Systems ................................................18

TLS Console Software Requirements ....................................................................18

Veeder-Root Hardware Requirements (Ref. Table 2) ............................................18

Specific Limitations.................................................................................................18

Wiring Diagram for a Transac Current Loop Interface............................................19

Wiring Diagram for an Excentus Current Loop Interface ........................................20

Gilbarco TS-1000 POS and PAM Systems .....................................................................21

TLS Console Software Requirements ....................................................................21

Veeder-Root Hardware Requirements (Ref. Table 2) ............................................21

Gilbarco POS and Dispensing System Requirements ...........................................21

Specific Limitations.................................................................................................21

Wiring to a Universal Distribution Box Interface .....................................................21

Gilbarco G-Site™ POS Systems ....................................................................................23

TLS Console Software Requirements ....................................................................23

Veeder-Root Hardware Requirements (Ref. Table 2) ............................................23

Specific Limitations.................................................................................................23

Wiring Diagram.......................................................................................................23

AutoGas Storemaster and Gilbarco Dispenser Systems ................................................25

TLS Console Software Requirements ....................................................................25

Veeder-Root Hardware Requirements (Ref. Table 2) ............................................25

iii

Page 4

Table of Contents

Gilbarco POS and Dispensing System Requirements ...........................................25

System Limitations .................................................................................................25

Installation Notes ....................................................................................................25

Gilbarco SmartCrind Dispenser Systems .......................................................................30

TLS Console Software Requirements ....................................................................30

Veeder-Root Hardware Requirements (Ref. Table 2) ............................................30

System Limitations .................................................................................................30

Installation Notes ....................................................................................................30

Tokheim Dispensing Systems .........................................................................................31

TLS Console Software Requirements ....................................................................31

Veeder-Root Hardware Requirements ...................................................................31

Tokheim DHC Requirements..................................................................................31

Specific Limitations.................................................................................................31

Other POS Consoles ..............................................................................................31

Installation Notes ....................................................................................................31

Wayne Dispensing Systems ...........................................................................................34

TLS Console Software Requirements ....................................................................34

Veeder-Root Hardware Requirements ...................................................................34

POS System Requirements and Limitations ..........................................................34

Supported Wayne Systems ....................................................................................34

Supported Wayne POS Terminals .........................................................................34

Installation Notes ....................................................................................................35

Schlumberger POS Systems ..........................................................................................37

TLS Console Software Requirements ....................................................................37

Veeder-Root Hardware Requirements (Ref. Table 2) ............................................37

System Limitations .................................................................................................37

MicroMax/Allied Hardware Requirements ..............................................................37

Installation Notes ....................................................................................................37

GasBoy CFN Systems ....................................................................................................40

TLS Console Software Requirements ....................................................................40

Veeder-Root Hardware Requirements (Ref. Table 2) ............................................40

GasBoy System Requirements for BIR Interface ..................................................40

Connecting to the Site Controller II.........................................................................40

BIR Protocol DIM ............................................................................................................42

POS System Requirements and Limitations ..........................................................42

Mechanical Dispensers ...................................................................................................43

TLS-350 MDIM Applications...................................................................................43

TLS-450/TLS-450PLUS MDIM Applications...........................................................43

LVDIM Applications ........................................................................................................48

PetroVend System 2 Controller..............................................................................48

Kraus Micon 200 Electronic Dispensers.................................................................50

Wiring to GasBoy 9800 or Tokheim 2600 Series Electronic Dispensers................52

Figures

Figure 1. Simplified DIM Connections To Various Dispensing Systems ..............15

Figure 2. Bennett Pump Fuelomat Dispenser Interface Installation Diagram..........17

Figure 3. Transac Series Current Loop Interface .................................................19

Figure 4. Excentus Current Loop Interface ..........................................................20

Figure 5. Universal Distribution Box Interface ......................................................22

Figure 6. Example G-Site Installations .................................................................24

Figure 7. AutoGas 510 CRIND Controller With Current Loop Interface ...............26

Figure 8. AutoGas 510 CRIND Controller With Serial Interface ..........................27

Figure 9. AutoGas 510 CRIND Controller ............................................................28

iv

Page 5

Table of Contents

Figure 10. AutoGas 507 CRIND Controller ............................................................29

Figure 11. SmartCrind Installation .........................................................................30

Figure 12. Tokheim DHC Standalone Installation ..................................................32

Figure 13. Tokheim Vision 100/200 Installation .....................................................32

Figure 14. Tokheim Dispenser Controller With Single CAB Installation ................33

Figure 15. Wayne Dispenser Data Box Current Loop (TLS-350R and TLS-450)......35

Figure 16. Wayne IDPOS Dispensers (TLS-350R and TLS-450) ..........................35

Figure 17. Example CAB Connections In

Wayne Nucleus Data Box (TLS-350R Only) .........................................36

Figure 18. MicroMax POS W/Allied Station Site Controller Box

Current Loop Interface ..........................................................................37

Figure 19. MicroMax POS with Allied Protocol Box Current Loop Interface ..........38

Figure 20. Pro Series Or MicroMax POS With SAM Or XPIC Controller Box

And RS-232 CAB Interface ...................................................................38

Figure 21. MicroMax POS with Tokheim DCHC Controller Box and

RS-232 CAB Interface ..........................................................................39

Figure 22. Verifone With SAM And RS-232 CAB Interface ...................................39

Figure 23. Gasboy Console Loop Connection .......................................................41

Figure 24. Wiring Diagram Of TLS-350 MDIM Using Two 1871/7697 Series

Pulse Transmitters And Required Barriers ...........................................43

Figure 25. Wiring Diagram Of TLS-450/TLS-450PLUS MDIM Using

Two 1871/7697 Series Pulse Transmitters & Required Barriers..............44

Figure 26. Mechanical Dispenser Applications

Using 7874 Series Pulser/Totalizer ......................................................45

Figure 27. TLS-350 Meter Stand Application Using

1871/7697 Series Pulser/Totalizer ........................................................46

Figure 28. TLS-450/TLS-450PLUS Meter Stand Application Using

1871/7697 Series Pulser/Totalizer ........................................................47

Figure 29. TLS-350 LVDIM Installation With PetroVend

System 2 Site Controller .......................................................................48

Figure 30. TLS-450/TLS-450PLUS LVDIM Installation With

PetroVend System 2 Site Controller .....................................................49

Figure 31. TLS-350 LVDIM Installation Kraus Micon 200 Series

Electronic Dispensers (Not UL Approved) ............................................50

Figure 32. TLS-450/TLS-450PLUS LVDIM Installation

Kraus Micon 200 Series Electronic Dispensers (Not UL Approved) ........51

Figure 33. LVDIM Installation With GasBoy 9800 Or

Tokheim 2600 Series Electronic Dispenser Head ................................52

Figure 34. TLS-450/TLS-450PLUS LVDIM Installation With

GasBoy 9800 Or Tokheim 2600 Series Electronic Dispenser Head ........ 53

Tables

Table 1. Supported POS Systems ..........................................................................3

Table 2.- Dispenser DIM and Installation Kits ..........................................................7

Table 3. POS Systems Supporting BIR Protocol DIM ..........................................42

v

Page 6

Introduction

This guide provides assistance in selecting Dispenser Interface Modules (DIMs) that enable a properly fitted TLS

Console to interface supported Point-of-Sale (POS) devices and provide enhanced product inventory and/or

product vapor recovery monitoring. Veeder-Root offers two console upgrades that interface with POS devices:

Business Inventory Reconciliation (BIR)

Business Inventory Reconciliation is a console option that automatically collects dispensing data, in-tank

inventories and deliveries, and reconciles the totals at the end of each shift, day, and month. When used with

AccuChart™, an automatic tank calibration feature, BIR enhances reconciliation accuracy by comparing the tank’s

metered sales data to the tank’s probe data.

IN-STATION DIAGNOSTICS (ISD) - TLS-350R CONSOLES ONLY

In-Station Diagnostics (ISD) is an option that enables the TLS-350R Console to continuously monitor the vapor

recovery equipment and Enhanced Vapor Recovery (EVR) systems at gasoline dispensing facilities, maintain test

records, provide test reports, and generate warnings or alarms following equipment failures.

TLS-350R BIR and ISD Capabilities

TLS-350R WITH BIR ONLY AND TLS-350R WITH BIR AND ISD

• Support up to 36 fueling positions

• Support up to 6 meters (hoses) per fueling position

• Support manifolded tanks

• Support blending dispensers that separately meter each product prior to blending. Gilbarco, Tokheim, and

Wayne electronic blending dispensers are supported.

• Do not support dispensers that blend fuel prior to the metering process. Schlumberger electronic blending dispensers, and mechanical dispensers fitted with fixed-ratio ratios are not supported.

TLS-350R WITH ISD ONLY

• Supports up to 36 fueling positions

• Supports up to 6 meters (hoses) per fueling position

• Supports manifolded tanks

• Supports all blending dispensers in this guide, including those in this guide labeled as not to be used with BIR.

• Must monitor all petrol fueling positions.

• Does not monitor diesel fueling positions.

MANIFOLDED TANK APPLICATIONS FOR BIR

The TLS-350R can perform automatic BIR on tanks in a siphon-manifolded set. However, to perform AccuChart,

the following requirements must be met:

1. Maximum of 2 tanks in a set.

2. Maximum of 4 sets of siphon-manifolded tanks.

3. The combined tank capacity of a set shall not exceed 30,000 gallons.

4. The diameters of the tanks in a set shall not differ by more than 6 inches.

5. The manifolding method must be siphon, not line, manifolding.

1

Page 7

POS App Guide Introduction

Reconciliation reports will be generated for the manifolded set as a single product. Individual adjusted delivery

reports will be provided followed by an adjusted manifolded delivery report.

Both Version 310 software (or later), and a Memory Expansion Module are required to perform BIR for manifolded

tanks.

TLS-350R System Requirements for BIR and ISD

BUSINESS INVENTORY RECONCILIATION

• TLS-350R with BIR option

• A Mag 1 (0.1 gph) magnetostrictive (standard or Mag Plus) probe is required for each tank that will be

monitored and reconciled. The Mag 1 probe for alternative fuels is also supported.

• ECPU board with the following software versions;

- w/106 [or later] software for BIR,

- w/311 [or later] software and a Memory Expansion Module for BIR with manifolded tanks, or

- w/116 or 316 [or later] software for BIR with variance analysis

• Dispenser Interface Module

For electronic dispensers, one DIM is required for each TLS-350R. Up to 3 DIMs can be installed to support

sites with multiple POS systems. For mechanical dispensers, the TLS-350R can support up to 8 mechanical

DIMs. Each mechanical DIM supports up to 4 mechanical dispensers.

One installation kit may be required for each DIM (ref. Table , “,” on page 7). The installation kits vary for each

DIM and include all required adapter boxes and cables.

IN-STATION DIAGNOSTICS

• TLS-350R with ISD option

• ECPU2 board with 325 or later software and a NVMEM203 board.

• A Mag 1 (0.1 gph) magnetostrictive (standard or Mag Plus) probe is required for each gasoline tank. The Mag 1

probe for alternative fuels is also supported.

• Dispenser Interface Module - For electronic dispensers, one DIM is required for each TLS-350R. Up to 3 DIMs

can be installed to support sites with multiple POS systems. For mechanical dispensers, the TLS-350R can

support up to 8 mechanical DIMs. Each mechanical DIM supports up to 4 mechanical dispensers.

• DIM installation kit - One installation kit may be required for each DIM (ref. Table , “,” on page 7). The installation

kits vary for each DIM and include all required adapter boxes and cables.

• Additional ISD monitoring equipment as defined by the site’s requirements, e.g., dispenser mounted Air Flow

Meters and Pressure Sensor, console Smart Sensor Modules, etc. - refer to appropriate ISD Installation Manual

for specifics.

TLS-450/TLS-450PLUS BIR Capabilities

• Support for up to 72 fueling positions

• Support for up to 6 meters (hoses) per fueling position

• Support for manifolded tanks

• Support for blending dispensers that separately meter each product prior to blending. Gilbarco, Tokheim, and

Wayne electronic blending dispensers are supported. Dispensers that blend fuel prior to the metering process,

2

Page 8

POS App Guide Introduction

such as Schlumberger electronic blending dispensers and mechanical dispensers fitted with fixed-ratio blenders

are not supported.

MANIFOLDED TANK APPLICATIONS

• Maximum number of tanks in a set: unlimited

• Maximum number of siphon manifold tanks: number of tanks divided by 2. Limit: 8

• Manifolded set tank capacity: unlimited

• No requirements on diameter differences, no 6 inch limit.

Reconciliation reports will be generated for the manifolded set as a single product. Individual adjusted delivery

reports will be provided followed by an adjusted manifolded delivery report.

TLS-450/TLS-450PLUS SYSTEM REQUIREMENTS FOR BIR

The following components are required to perform BIR:

• TLS-450/TLS-450PLUS with BIR option

• Version 2.X or higher software (TLS-450), Version 6.X or higher software (TLS-450PLUS)

• Mag 1 (0.1 gph) magnetostrictive (standard or Mag Plus) probe in each tank. The Mag 1 probe for alternative

fuels is also supported.

• A Dispenser Interface Module (DIM) - The DIM allows the TLS-450 to interface to most Gilbarco, Wayne, and

3rd Party POS systems that implement the VR BIR Protocol (ALLIED ANDI, EXCENTUS, BENNETT). For

electronic dispensers, one DIM is required for each TLS-450. Up to 3 DIMs can be installed to support sites

with multiple POS systems.

• DIM installation kit - One installation kit may be required for each DIM (ref. Table , “,” on page 7). The installation

kits vary for each DIM and include all required adapter boxes and cables.

Supported POS Systems

The TLS-350R, TLS-450 and TLS-450PLUS consoles can interface to many POS terminals as well as the VeederRoot mechanical dispenser (TLS-350R only). This guide provides specific information on each application. The

supported POS systems are shown in

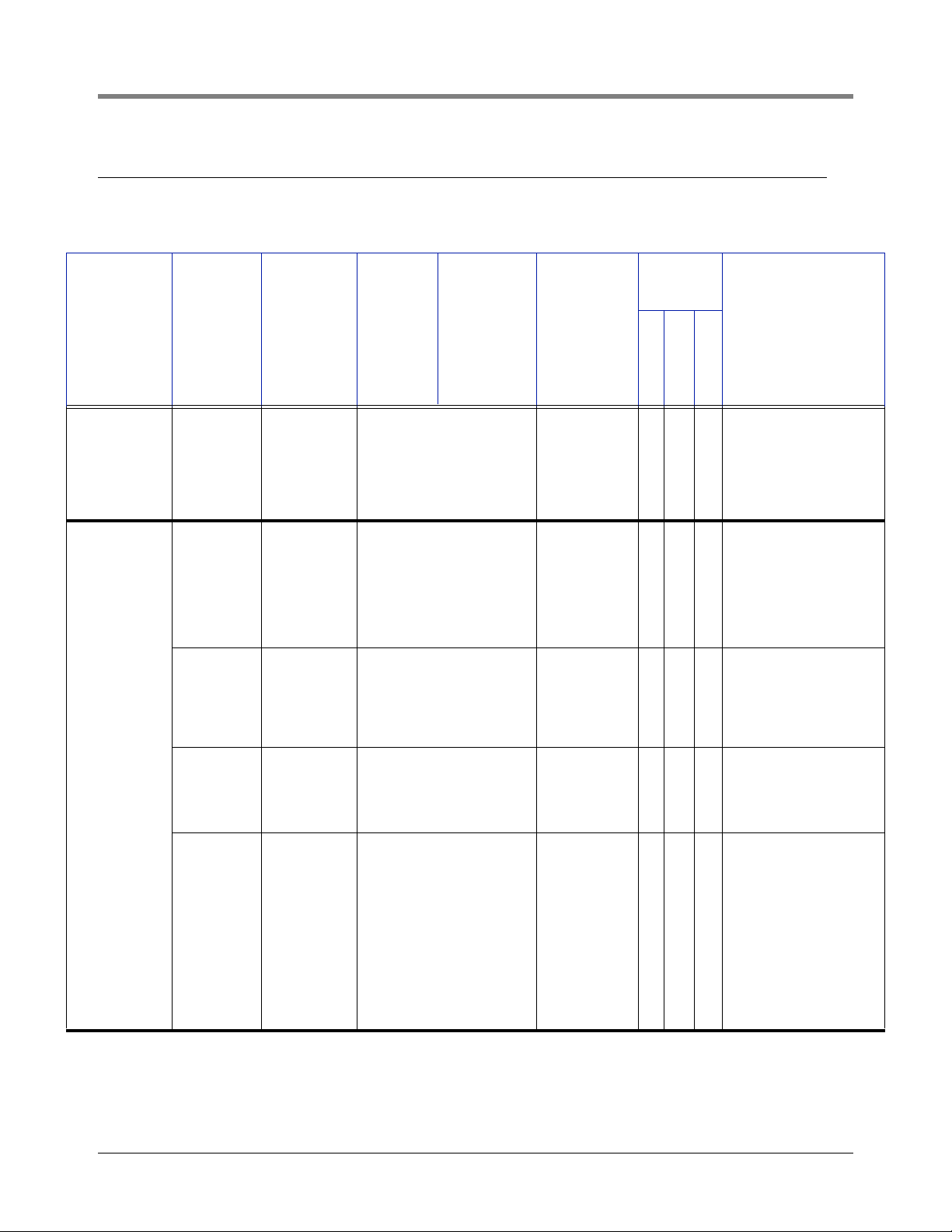

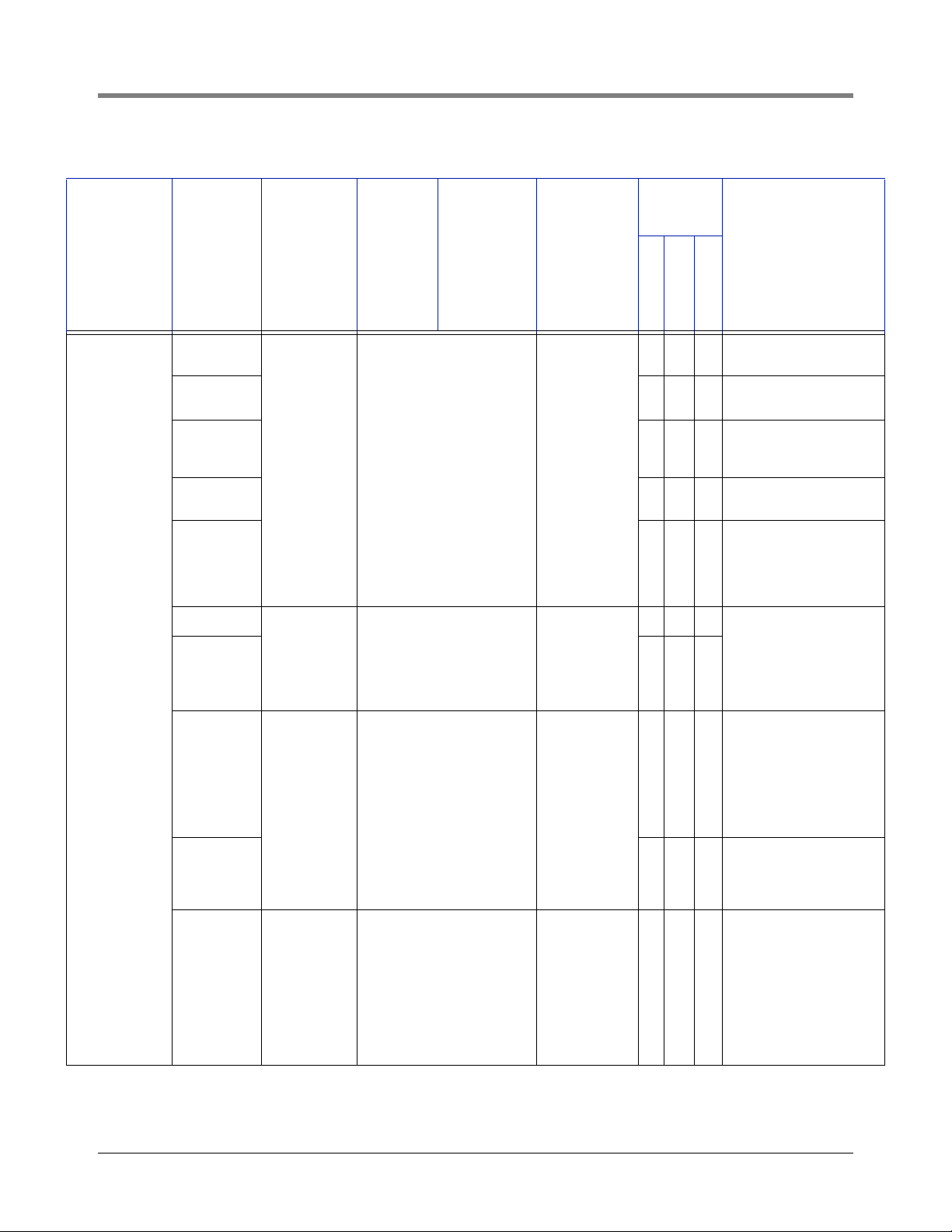

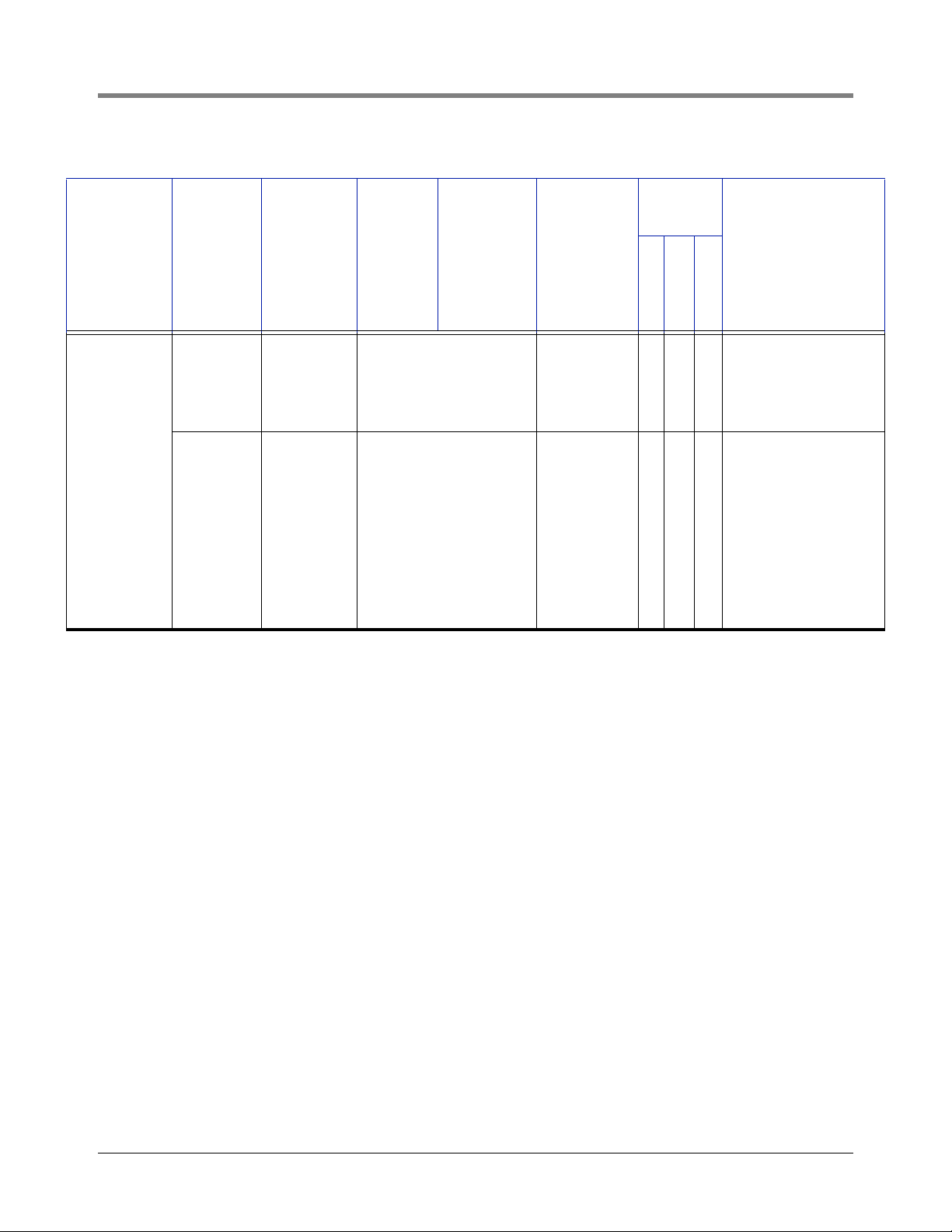

Manufacturer POS/Dispensing System TLS-350R TLS-450 TLS-450PLUS

TCRG, TCRG2, T-11, T-12, TS-1000, PAM,

Gilbarco

Tokheim

Wayne

G-Site, Passport, Storemaster, SmartCrind, ANDI,

CFN2, Excentus

MEMS IV, MEMS V, Vision 100/200, DHC with all

other POS, CFN2, ANDI, Columbus, Schlumberger

MicroMax XPIC/DHC, 67/A - 98, 67/B

Wayne Site Controller, Excentus, ANDI X X X

IDPOS X X X

Table 1.

Table 1. Supported POS Systems

X X X

X

Schlumberger

GasBoy CFN2 & ProfitPoint, CFN1, ANDI X

MicroMax/Pro series, MicroMax/Allied, SAM/XPIC,

ANDI

3

X

Page 9

POS App Guide Introduction

Table 1. Supported POS Systems (Continued)

Manufacturer POS/Dispensing System TLS-350R TLS-450 TLS-450PLUS

Bennett 92D X

Mechanical, Mechanical

noncomp, or Mechanical

V-R meter

CFN2, Petrovend, ANDI X X X

OTHER APPLICATIONS

Many POS / dispenser systems are similar to those identified in this guide. Veeder-Root is constantly evaluating

and supporting new applications. If your application is not listed in this guide, contact your Veeder-Root Sales

Representative.

4

Page 10

DIM Descriptions

Mechanical Dispenser Interface Module (MDIM) & Low Voltage Dispenser Interface

Module (LVDIM)

• The mechanical dispenser interface modules enable the TLS console to monitor either high voltage (MDIM), or

low voltage (LVDIM) volume pulses and calculate dispensed volume.

• MDIM and LVDIM terminal connections are on the front of the modules’s bracket.

Electronic Dispenser Interface Module (EDIM)

• Installs in a communication slot of TLS-350R or TLS-450/TLS-450PLUS. EDIMs are used to communicate via

RS-232 to point of sale or system controllers.

• More than one EDIM can be installed in any combination with other DIM types.

• EDIMs have one 25-pin D connector (TLS-350R), or one 9-pin D connector (TLS-450/TLS-450PLUS) outside

of the port.

• TLS-350R EDIMs only - when onboard red LED is turned On, EDIM is transmitting to external device; when

onboard green LED is turned On, external device is transmitting to EDIM.

• TLS-450 and TLS-450PLUS hardware is standard equipment.

• TLS-450 requires BIR to activate DIM.

Current Loop Dispenser Interface Module (CDIM)

• TLS-350R console - Installs in comm slots 1, 2, or 3; TLS-450 console - installs in comm slots 1, 2, or 4

(preferred); TLS-450PLUS console - installs in comm slots 1 or 2. Factory installed in TLS4 console.

• TLS-450 and TLS-450PLUS require module kit P/N 330020-665.

• Various CDIM monitoring applications include current loop, RS-232, and RS-422.

• More than one CDIM can be installed in combination with other DIM types.

• CDIMs have three RJ-45 modular connectors (TLS-350R) or 2 to 3 RJ-45 modular connectors (TLS-450/TLS-

450PLUS).

• CDIMs cannot transmit to external device.

• Connects via 4-wire cable to cable adapter box. Adapter box converts target communication format to RS-422

format for CDIM. Adapter boxes are configured with 2-wire flying leads, 25-pin D or 9-Pin D, T-cable connectors

for various applications.

• TLS-450 requires BIR to activate DIM.

LAN Dispenser Interface Module (LDIM) - TLS-350R only

• Installs in a communication port of TLS-350R to communicate with or monitor POSs, dispensers or system

controllers using RS-485 communication standard.

• An LDIM can be installed in combination with other DIM types.

• LDIMs have a 5-wire phoenix connector.

• Red and green LEDs are on this board. When red LED is turned On, LDIM is transmitting to external device;

when green LED is turned On, external device is transmitting to LDIM.

• Can be used in 4-wire or 2-wire, RS-485 and RS-422 applications.

- DIP switch default in OPEN position, loopback jumper on LED side for RUN mode

- R1 - 331076-001 - RS-485 two wire

5

Page 11

POS App Guide DIM Descriptions

- R2 - 331076-002 - RS-422 four wire

- R3 - 331076-003 - DIM RS-485 two wire (install in TLS-350R only)

- R4 - 331076-004 - DIM RS-422 four wire (install in TLS-350R only)

International Forecourt Standards Forum Dispenser Interface Module (IFSF) - TLS350R, TLS-450PLUS

• Required for TLS consoles that are connected to IFSF networks.

• Uses Echelon 2-wire FTT10-A medium, as defined by the IFSF standards.

• There are 3 LEDs on this board:

- Green LED On when IFSF board is transmitting information to the TLS.

- Red LED On when TLS is transmitting information to the IFSF board.

- Amber LED Off indicates normal state of the IFSF board processor.

• There are no LED indicators for network communication.

TCP/IP DIM Module (TDIM) - TLS-350R

• Installs in a communication port of the TLS-350R to communicate with or monitor the Wayne IDPOS dispenser.

• Minimum system requirements for TDIM Module operation:

- Console system software: Version 15 or higher - Version 21 or higher is recommended

- Network connection to a PC requires a hub. Connecting to a hub requires a straight CAT 5 cable

- Direct connection to a PC requires an Ethernet crossover cable

- Connection to a LAN or WAN

• There are 2 LEDs on the PC board of this module:

- Green LED indicates that the TDIM module is transmitting information to the TLS.

- Red LED indicates the TLS is transmitting information to the TDIM module.

• There is no communication alarm for this module.

TCP/IP DIM (TDIM) - TLS-450/TLS-450PLUS

• Installs in a communication port of the TLS-450/TLS-450PLUS to communicate with or monitor the Wayne

IDPOS dispenser.

• Minimum system requirements for TDIM module operation:

- Console system software: Version 4H or higher

- Network connection to a PC requires a hub. Connecting to a hub requires a straight CAT 5 cable

- Direct connection to a PC requires an Ethernet crossover cable

- Connection to a LAN or WAN

• There is no communication alarm for this module.

• TLS-450 and TLS-450PLUS hardware is standard equipment.

• TLS-450 requires BIR to activate DIM.

6

Page 12

POS App Guide DIM Descriptions

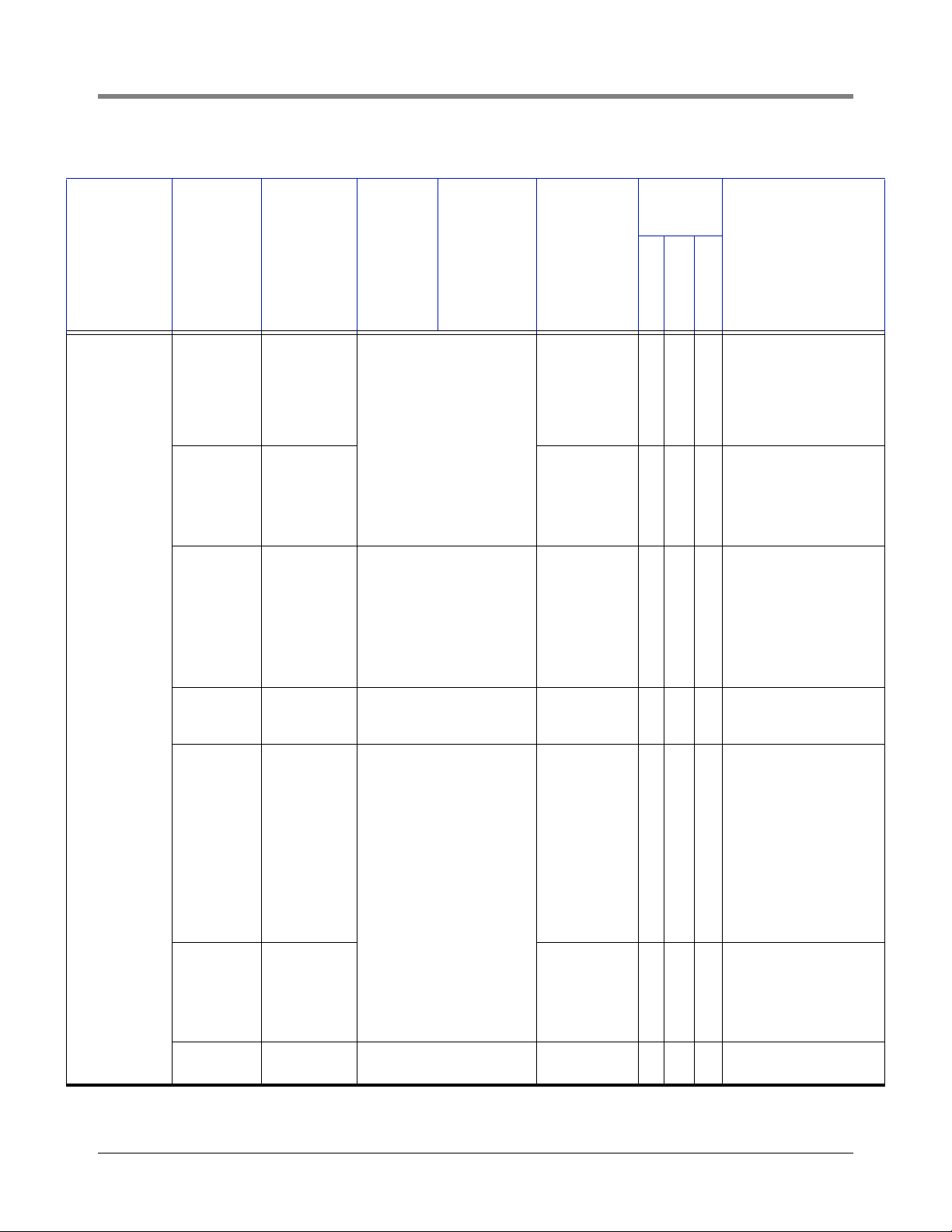

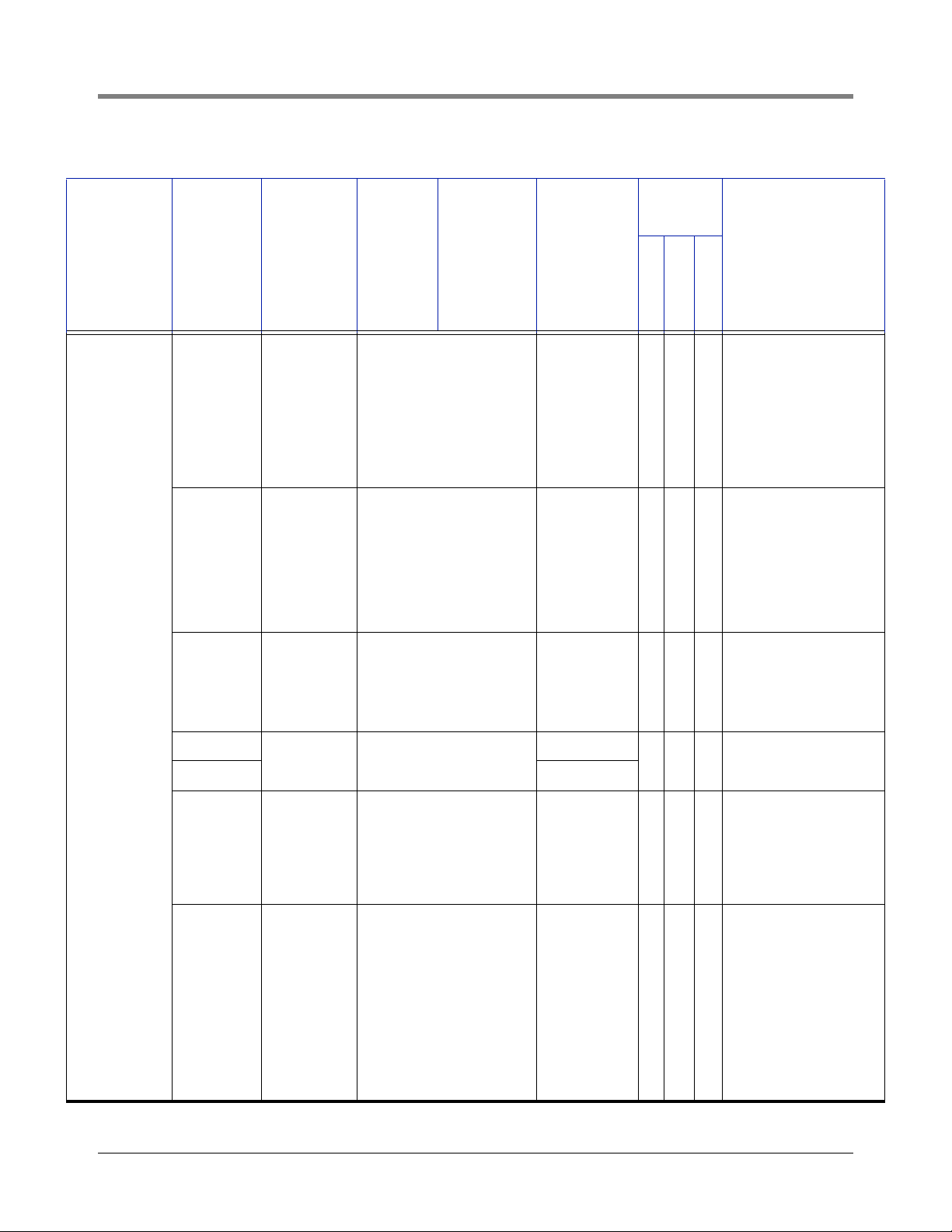

DIM And Installation Kit Ordering Guide

Table 2.- Dispenser DIM and Installation Kits

Console

Compati-

bility

Dispenser

Dispenser

Bennett 92D 330404-040 None 848705-XXX Y N N

Gasboy

Controller/

POS Type

CFN2 &

Profit Point

ANDI,

ALLIED

ANDI,

ALLIED

NEXTGEN

CFN1 331001-002 None 331088-XXX Y N N

TLS-350R

DIM P/N

w/Console

331001-003 None 331088-XXX Y N N

330280-001 Standard In Gauge

TLS-450

DIM P/N

w/Console

TLS-450PLUS

DIM P/N

w/Console

DIM Install Kit

P/N

None

required

TLS-350R

TLS-450

Y Y Y

TLS-450PLUS

For Bennett 92D controllers. DIM kit has 2

CABs in it. One CAB is

needed per current

loop. Only one or two

dispensers are on one

current loop.

A Gasboy site controller version 2.0 or later

is required. A Gasboy

junction box Gasboy

part # C05020 should

be ordered for installation. No Blending. Network POS Required.

Allied ANDI. Gilbarco

dispenser with T-14

(Australia). PEC with

8850. POSTEC with

RCC. Wayne with Marketer 2000 (Sweden).

This is a TLS-350 RS422 interface to the

Network. NOT to be

used for BIR or ISD

applications.

Notes

Radiant 330280-001 Standard In Gauge

7

None

required

Y Y Y

Radiant Systems

Series P1550 set-up

on the TLS must have

a DIM string programmed in. The DIM

string is B9DNHG and

needs to be programmed in DIM Diagnostics. You will need

to use a twisted pair

RJ-11 cable to the port

on the POS with the

pin outs of 2,3,7.

Page 13

POS App Guide DIM Descriptions

Table 2.- Dispenser DIM and Installation Kits

Console

Compati-

bility

Dispenser

Gilbarco

Dispenser

Controller/

POS Type

TCRG

TLS-350R

DIM P/N

w/Console

TLS-450

DIM P/N

w/Console

TLS-450PLUS

DIM P/N

w/Console

DIM Install Kit

P/N

TLS-350R

TLS-450

Y Y Y

TCRG2 Y Y Y

T-11 Y Y Y

330404-020 330020-665 848702-XXX

T-12 Y Y Y

Excentus Y Y Y

TS-1000

Y Y Y One kit is needed per

330404-020 330020-665 848722-XXX

PAM Y Y Y

G-Site

Y Y Y

330280-401 Standard In Gauge 331063-XXX

TLS-450PLUS

Notes

Model TCRG

PA0180-121

Model TCRG2

PA0180-121

Model T-11 PA0132XXXX and PA0141XXXX

Model T-12 PA0188XXXX

Excentus Dispenser

Tank Monitor Interface

Kit (Excentus P/N 080Veeder Root Kit) is

required.

dispenser current loop.

For controller with a

RS-485 Distribution

Box, use kit P/N

848741-XXX.

To support this DIM

and the TLS-350R, the

G-site must be

upgraded to include

the EMC interface.

Uses Controller types

C2, C15, 486 and Pentium Site controllers.

Passport,

Passport/

EDH

Storemaster

Y Y Y

330404-020 330020-665 848741-XXX Y Y Y

8

Verify BIR protocol is in

version of Passport

software used at customer’s site.

One Gilbarco Dispenser Distribution Box

PA0133000 should be

available. Up to 12

Highliner/MPD Fueling

positions are supported. An Autogas

Storemaster POS and

Autogas 507 controller

are required.

Page 14

POS App Guide DIM Descriptions

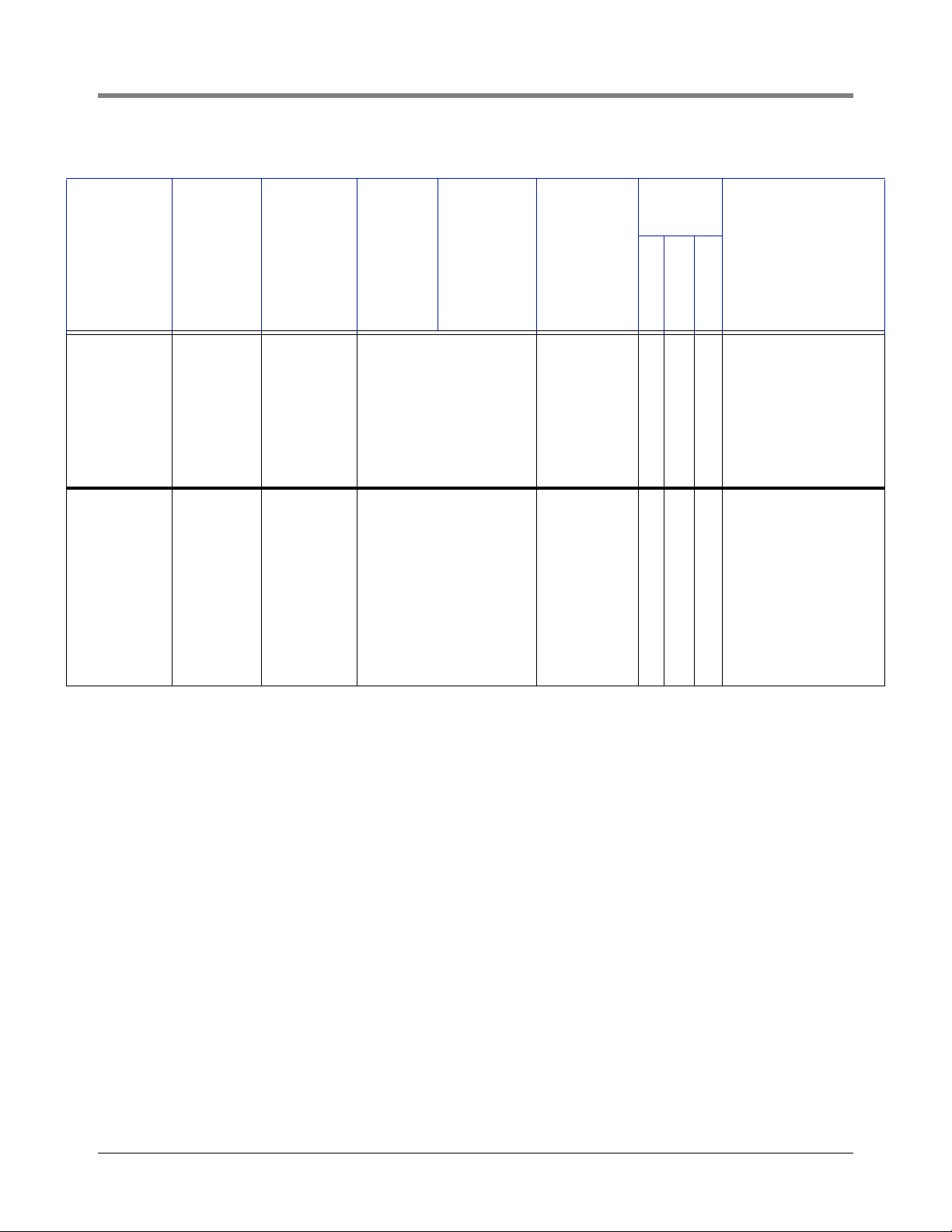

Table 2.- Dispenser DIM and Installation Kits

Console

Compati-

bility

Dispenser

Gilbarco

(Cont’d.)

Dispenser

Controller/

POS Type

SmartCrind

TLS-350R

DIM P/N

w/Console

330020-538

TLS-450

DIM P/N

w/Console

TLS-450PLUS

DIM P/N

w/Console

DIM Install Kit

P/N

None

required

TLS-350R

TLS-450

Y Y Y

Standard In Gauge

ANDI,

ALLIED

ANDI,

ALLIED

330280-001

None

required

Y Y Y

NEXTGEN

CFN2 331001-003 None 331088-XXX Y N N

Wayne

Nucleus

330404-200 330020-665 848722-XXX Y Y Y

TLS-450PLUS

Notes

TCPIP Interface for Gilbarco SmartCrind dispensers only. Wal-Mart

is currently the only

customer ordering this

interface for this dispenser.

Allied ANDI. Gilbarco

dispensers with T-14

(Australia). PEC with

8850. POSTEC with

RCC. Wayne with Marketer 2000 (Sweden)

A Gasboy site controller version 2.0 or later

is required. A Gasboy

junction box Gasboy

part # C05020 should

be ordered for installation. Single product

dispensers only. No

Blending.

Wayne Nucleus POS

with Gilbarco Dispensers.

Radiant 330280-001

Verifone

Com-

330280-001 None Y Y Y

mander

Wayne

Fusion

330280-001 None None Y N N

Standard In Gauge

9

None Y Y Y

Radiant Systems

Series P1550 set-up

on the TLS must have

a DIM string programmed in. The DIM

string is B9DNHG and

needs to be programmed in DIM Diagnostics. You will need

to use a twisted pair

RJ-11 cable to the port

on the POS with the

pin outs of 2,3,7.

Requires Verifone

13652-01 Connector(450) or Verifone

13581-01 Connector

(350) & V/R 331134xxx cable.

Page 15

POS App Guide DIM Descriptions

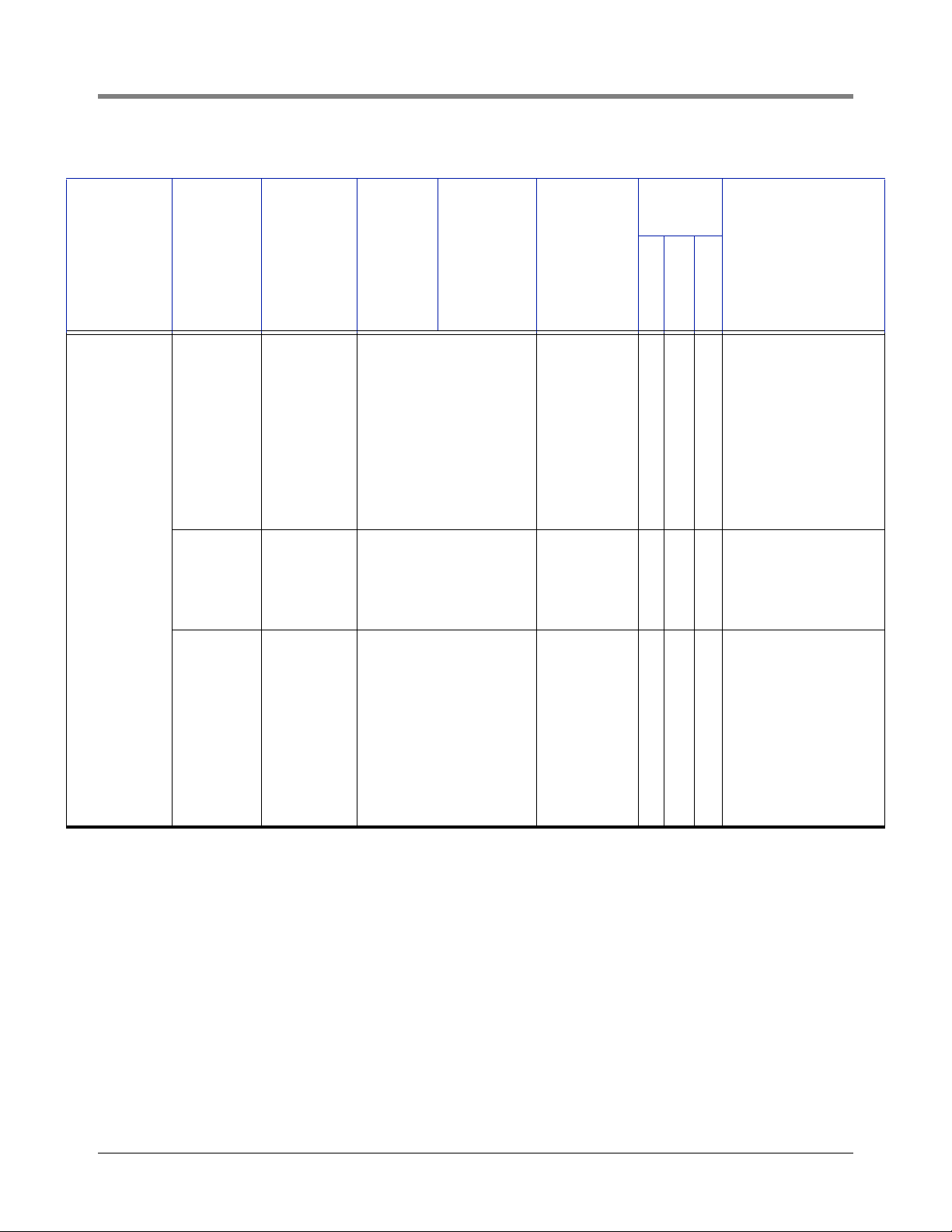

Table 2.- Dispenser DIM and Installation Kits

Console

Compati-

bility

Dispenser

Dispenser

Controller/

POS Type

TLS-350R

DIM P/N

w/Console

TLS-450

DIM P/N

w/Console

TLS-450PLUS

DIM P/N

w/Console

DIM Install Kit

P/N

TLS-350R

TLS-450

Mechanical CFN2 331001-003 None 331088-XXX Y Y Y

Mechanical

Mechanical

non-comp, or

Petrovend 331214-001 330020-800 None Y Y Y

Mechanical

V-R meter

TLS-450PLUS

Notes

A Gasboy site controller version 2.0 or later

is required. A Gasboy

junction box Gasboy

part # C05020 should

be ordered for installation. Single product

dispensers only. No

Blending. Network

POS required.

One or more pulser/

totalizer kits are

needed PN 787491-

003. Each mech DIM

supports up to 4 mech

dispensers. Up to 8

may be installed in the

high power compartment of the TLS-350R.

Other modules

installed will reduce the

number of slots available.

10

Page 16

POS App Guide DIM Descriptions

Table 2.- Dispenser DIM and Installation Kits

Console

Compati-

bility

Dispenser

Mechanical

Dispenser

Controller/

POS Type

TLS-350R

DIM P/N

w/Console

TLS-450

DIM P/N

w/Console

TLS-450PLUS

DIM P/N

w/Console

DIM Install Kit

P/N

TLS-350R

TLS-450

None 331214-001 330020-800 None Y Y Y

ANDI 330280-001 Standard In Gauge None Y Y Y

Radiant 330280-001 Standard In Gauge None Y Y Y

TLS-450PLUS

Notes

One or more pulser/

totalizer kits are

needed PN 787491-

003. Each mech DIM

supports up to 4 mech

dispensers. Up to 8

may be installed in the

high power compartment of the TLS-350R.

Other modules

installed will reduce the

number of slots available.

Allied ANDI. Gilbarco

dispensers with T-14

(Australia). PEC with

8850.POSTEC with

RCC. Wayne with Marketer 2000 (Sweden).

Radiant Systems

Series P1550 set-up

on the TLS must have

a DIM string programmed in. The DIM

string is B9DNHG and

needs to be programmed in DIM Diagnostics. You will need

to use a twisted pair

RJ-11 cable to the port

on the POS with the

pin outs of 2,3,7.

11

Page 17

POS App Guide DIM Descriptions

Table 2.- Dispenser DIM and Installation Kits

Console

Compati-

bility

Dispenser

Schlumberger

Dispenser

Controller/

POS Type

TLS-350R

DIM P/N

w/Console

TLS-450

DIM P/N

w/Console

TLS-450PLUS

DIM P/N

w/Console

DIM Install Kit

P/N

TLS-350R

TLS-450

ANDI,

ALLIED

ANDI,

330280-001 Standard In Gauge None Y Y Y

ALLIED

NEXTGEN

Radiant 330280-001 Standard In Gauge None Y Y Y

TLS-450PLUS

Notes

Allied ANDI. Gilbarco

with T-14 (Australia).

PEC with 8850. POSTEC with RCC. Wayne

with Marketer 2000

(Sweden).

Radiant Systems

Series P1550 set-up

on the TLS must have

a DIM string programmed in. The DIM

string is B9DNHG and

needs to be programmed in DIM Diagnostics. You will need

to use a twisted pair

RJ-11 cable to the port

on the POS with the

pin outs of 2,3,7.

12

Page 18

POS App Guide DIM Descriptions

Table 2.- Dispenser DIM and Installation Kits

Console

Compati-

bility

Dispenser

Tokheim

Dispenser

Controller/

POS Type

TLS-350R

DIM P/N

w/Console

TLS-450

DIM P/N

w/Console

TLS-450PLUS

DIM P/N

w/Console

DIM Install Kit

P/N

TLS-350R

TLS-450

MEMS IV,

MEMS V,

Vision 100/

200,

330280-201 None 331390-XXX Y N N

DHC with

all other

POS

CFN2 331001-003 None 331088-XXX Y N N

ANDI,

ALLIED

ANDI,

330280-001 Standard In Gauge None Y Y Y

ALLIED

NEXTGEN

TLS-450PLUS

Notes

Use 331354-001 for

67A/B or 98 instead.

This DIM is being

phased out. A Tokheim

Dedicated Hose Controller (DHC) is

required, and should

have software version

5.6 dated 11/89 or

later.

A Gasboy site controller version 2.0 or later

is required. A Gasboy

junction box Gasboy

part # C05020 should

be ordered for installation. Single product

dispensers only. No

Blending

1

Allied ANDI. Gilbarco

dispenser with T-14

(Australia). PEC with

8850. POSTEC with

RCC. Wayne with Marketer 2000 (Sweden).

67/A - 98

331354-001 None

331391-XXX

Y N N

67/B 848744-XXX

Columbus 330280-001 Standard in Gauge None Y Y Y

Radiant 330280-001 Standard in Gauge None Y Y Y

13

Tokheim controller

only.

For Rockport cable kits

order Quantity (2)

320449-18 from

Tokheim. For Digi/Stargate order Quantity (2)

320449-9 Cable kits

from Tokheim.

Radiant Systems

Series P1550 set-up

on the TLS must have

a DIM string programmed in. The DIM

string is B9DNHG and

needs to be programmed in DIM Diagnostics. You will need

to use a twisted pair

RJ-11 cable to the port

on the POS with the

pin outs of 2,3,7.

Page 19

POS App Guide DIM Descriptions

Table 2.- Dispenser DIM and Installation Kits

Console

Compati-

bility

Dispenser

Wayne

Dispenser

Controller/

POS Type

Wayne Site

Controller

TLS-350R

DIM P/N

w/Console

TLS-450

DIM P/N

w/Console

TLS-450PLUS

DIM P/N

w/Console

DIM Install Kit

P/N

TLS-350R

TLS-450

330404-010 330020-665 848703-XXX Y Y Y

ANDI,

ALLIED

ANDI,

330280-001 Standard in Gauge None Y Y Y

ALLIED

NEXTGEN

Excentus 330404-010 330020-665 848702-XXX Y Y Y

IDPOS 330020-501 Standard in Gauge None Y Y Y

Radiant 330280-001 Standard in Gauge None Y Y Y

TLS-450PLUS

Notes

A Wayne site controller

and Wayne dispensers are required. Any

POS may be connected to the Wayne

site controller.

Allied ANDI. Gilbarco

dispenser with T-14

(Australia). PEC with

8850. POSTEC with

RCC. Wayne with Marketer 2000 (Sweden).

Excentus Dispenser

Tank Monitor Interface

Kit (Excentus P/N 080Veeder Root Kit) is

required.

TCPIP interface for

Wayne IDPOS dispensers only

Radiant Systems

Series P1550 set-up

on the TLS must have

a DIM string programmed in. The DIM

string is B9DNHG and

needs to be programmed in DIM Diagnostics. You will need

to use a twisted pair

RJ-11 cable to the port

on the POS with the

pin outs of 2,3,7.

Verifone

Com-

330280-001 None None Y N N

mander

Wayne

Fusion

1

This restriction does not apply to ISD only installations.

330280-001 None None Y N N

14

Page 20

DIM Installation Examples

Mechanical

Dispenser

Dispenser

Controller

Network

Junction

Box

Distribution Box

Cable Adaptor

Box

CDIM

LVDIM

MDIM

EDIM

LDIM, IFSF,

& TDIM

Dispenser

Dispenser

Electronic

or

Mechanical

Dispenser

Comm Bay

installed DIMs

TLS-350 Power Bay installed DIMs

TLS-450 Model Bay installed DIMs

Barrier

401-6.eps

TLS Console

(TLS-350 only)

Various example DIM installation diagrams are shown in Figure 1 below for reference only. For specific DIM

installation details, refer to the appropriate Veeder-Root DIM installation manual.

Figure 1. Simplified DIM Connections To Various Dispensing Systems

15

Page 21

POS App Guide DIM Installation Examples

Bennett POS System

The information collected via the interface allows TLS-350R business inventory reconciliation to compare tank

totals to fuel transactions for end of day, end of shift, or end of month, running variances.

VEEDER-ROOT SOFTWARE REQUIREMENTS

• System software Version 17 (or higher)

• Peripheral controller software 330269-00B (or later)

• DIM software 349780-001A (or later)

VEEDER-ROOT HARDWARE REQUIREMENTS (REF. TABLE 2)

The following equipment is required to interface the TLS to the Bennett POS system:

• One Bennett Current Loop Dispenser Interface Module for up to 6 fueling positions

• One installation kit (for every 2 current loops (up to 12 fueling positions)

BENNETT SYSTEM LIMITATIONS

TLS-350R with BIR and TLS-350R with BIR and ISD

• Only non-blending, type 92D dispensers with Orpak controllers are supported.

TLS-350R with ISD

• All type 92D dispensers with Orpak controllers are supported.

INSTALLATION NOTES

The interface to Bennett dispensing equipment requires one CAB per dispenser current loop (for up to 6 fueling

positions) and one Bennett DIM installation kit for every 2 current loops. Typically one or two loops are required for

a single dispenser having two fueling positions. For this reason the interface kit includes two CABs with

supportivecabling. Supportive cabling required is sold in lengths, which are identified in the last three digits of the

kit form number. The length requirement is determined by the distance between the components.

Figure 2 is an example Bennett dispenser connection diagram. Each CAB has a three position input and a RJ-45

cable output to a dispenser loop. Use the “PUMP COMM” input side and the RJ-45 cable output.

16

Page 22

POS App Guide DIM Installation Examples

{

{

0

1

ALARM

WARNING

POWER

TLS-350R Console

CDIM

RJ-45

BENNETT PUMP

INTERFACE BOX

Dispenser

Terminal

Block

Communications Cable

GRN GROUND

RJ-45

Communications Cable

CONSOLE

COMM

Cable Adapter Box

for Bennett System

CURRENT LOOPS

ORG DATA (+)

17123 456 78 9111213 14 15 18 19 20 21

YEL DATA (-)

ORG DATA (+)

YEL DATA (-)

PUMP

COMM

PUMP

COMM

White

Black

Shield

CONSOLE

COMM

White

Black

Shield

2216

Cable Adapter Box

for Bennett System

Shielded 2 Wire

Flying Lead Cable

6 feet

401-7.eps

shield

GRN

Disconnect orange wire (+) from terminal 17 and

connect to white wire (+) from CAB with wire nut.

Attach black wire (-) from CAB to terminal 17. Connect

cable shield to terminal block ground connection.

Figure 2. Bennett Pump Fuelomat Dispenser Interface Installation Diagram

shield

CONDUIT

Disconnect orange wire (+) from terminal 19 and connect to

white wire (+) from CAB with wire nut. Attach black wire (-)

from CAB to terminal 17. Connect cable shield to terminal

block ground connection.

17

Page 23

POS App Guide DIM Installation Examples

Gilbarco TCRG, TCRG2, T-11, and T-12 POS Systems

TLS CONSOLE SOFTWARE REQUIREMENTS

TLS-350R with BIR Software Requirements

• System software Version 17 (or higher)

• Peripheral controller software 002B (or later)

• DIM software 349634-003C (or later)

TLS-450/TLS-450PLUS with BIR Software Requirements

• TLS-450 System software Version 2.x (or higher)

• TLS-450PLUS System software Version 6.x (or higher)

• BIR option required (TLS-450)

VEEDER-ROOT HARDWARE REQUIREMENTS (REF. TABLE 2)

The following equipment is required to interface the TLS to the Transac POS:

• One Gilbarco Current Loop Dispenser Interface Module for up to 3 current loops

• One Gilbarco dispenser distribution box PA0133000

• One Gilbarco Transac DIM installation kit required per current loop. Up to 16 fueling positions are supported

per current loop.

The following POS consoles are supported:

• Transac-1e1 (PA0132, PA0141)

• Transac-12 (PA0134, PA0142)

• Transac-12A (PA0151, PA0152)

• Transac-12B (PA0173)

• Transac-12C (PA0188)

• Transac-12G (PA0203)

• TCRG (PA0180-121)

• TCRG2 (PA0180-121)

• Excentus Reward Fuel Controller

TM

, Gilbarco Dispenser Interface, V1.0.160

SPECIFIC LIMITATIONS

Only Gilbarco electronic dispensers are supported. Also, dispensers that feature a blender and a single-product

dispenser at one fueling position are not supported.

In-Dispenser credit card readers (CRINDS) or G-Site systems are not supported by the Gilbarco CDIM.

Other POS systems that use Gilbarco dispensers and the Gilbarco Pump Access Module (PAM) may also be

supported - contact Veeder-Root for assistance.

Special Note on T-11/T-12 Pre-Pay Applications

In T-11/T-12 Pre-Pay applications, cashiers should be urged to close out each transaction promptly. Failure to

close-out promptly can cause the TLS-350R to delay reconciliation reports, and impact the system’s ability to

maximize tank calibration.

18

Page 24

POS App Guide DIM Installation Examples

Shielded 2 Wire

Flying Lead Cable

Connects to

CDIM

TLS Console

401-8.eps

WIRING DIAGRAM FOR A TRANSAC CURRENT LOOP INTERFACE

A PA0133 distribution box is shown in Figure 3 below. Other box models are slightly different.

Figure 3. Transac Series Current Loop Interface

19

Page 25

POS App Guide DIM Installation Examples

WIRING DIAGRAM FOR AN EXCENTUS CURRENT LOOP INTERFACE

These cables and terminal

block supplied by Excentus

+

WHT +

BLK -

RJ-45

Set sw

to RUN

VR 6-foot, 2-conductor

1

DIM Assembly Cable

(P/N 331105-001)

VR CAB

2

(P/N 330591-00X)

CONSOLE

COMM.

RUN

BYPASS

VEEDER-ROOT

Environmental Products

P/N

S/N

PUMP

COMM.

POS/Controller

RJ-45

RJ-45

Excentus Interface Box

Tank

Console

Dbox

Monitor

RJ-45

RJ-45

RJ-45

WHT +

BLK -

401-9.eps

Gilbarco

Distribution Box

Figure 4. Excentus Current Loop Interface

VR CDIM

3

Adaptor Cable

(P/N 330592-XXX)

3 numbered items

contained in V-R kit

(P/N 848702-XXX)

RJ-45

TLS Console

Connects to CDIM

20

Page 26

POS App Guide DIM Installation Examples

Gilbarco TS-1000 POS and PAM Systems

The Veeder-Root Gilbarco TS-1000 DIM and DIM installation kit supports the Gilbarco TS-1000 and any POS

system using the Gilbarco PAM (Pump Access Module) dispenser controller and Gilbarco dispensers.

TLS CONSOLE SOFTWARE REQUIREMENTS

TLS-350R with BIR Software Requirements

• System software Version 17 (or higher)

• DIM software 349634-003C (or later)

TLS-450/TLS-450PLUS with BIR Software Requirements

• TLS-450 System software Version 2.x (or higher)

• TLS-450PLUS System software Version 6.x (or higher)

• BIR option required (TLS-450)

VEEDER-ROOT HARDWARE REQUIREMENTS (REF. TABLE 2)

The following equipment is required to interface the TLS to the TS-1000 POS:

• One Gilbarco Current Loop Dispenser Interface Module for up to 3 current loops

• One installation kit for each current loop

GILBARCO POS AND DISPENSING SYSTEM REQUIREMENTS

• Gilbarco dispenser distribution box, PA02420000000

• Gilbarco dispenser distribution box, PA02610000010

• Gilbarco dispenser distribution box, PA02610000020

• Gilbarco pump controller, model PA02410000000

• Gilbarco Transac System 1000 Console, model PA0240000000

• Gilbarco Transac System 1000 Console, model PA02400001010

• Excentus Reward Fuel Controller™, Gilbarco Dispenser Interface, V1.0.160 (Excentus P/N 080 - Veeder Root

Kit) is required.

SPECIFIC LIMITATIONS

• Up to 48 Gilbarco single product or blending dispenser fueling positions are supported. Dispensers that feature

a blender and a single-product dispenser at one fueling position are not supported.

• Only Gilbarco dispensers are supported.

• In-dispenser credit card readers in these POS systems are not supported by the Gilbarco Current Loop Dispenser Interface Module.

• The Gilbarco Current Loop Dispenser Interface Module does not support Gilbarco G-Site applications.

WIRING TO A UNIVERSAL DISTRIBUTION BOX INTERFACE

The diagram in Figure 5 is a typical interconnection diagram for a PAM or Transac System 1000 interface (a

PA0261 distribution box is shown, the PA0241 is slightly different).

21

Page 27

POS App Guide DIM Installation Examples

PAM or Transac 1000 Site Controller

cab&dim\vrgbts.eps

CDIM

connection

TLS Console

401-10.eps

Figure 5. Universal Distribution Box Interface

22

Page 28

POS App Guide DIM Installation Examples

Gilbarco G-Site™ POS Systems

TLS CONSOLE SOFTWARE REQUIREMENTS

TLS-350R with BIR Software Requirements

• System software Version 17 (or higher)

• DIM software 349634-003C (or later)

TLS-450/TLS-450PLUS with BIR Software Requirements

• TLS-450 System software Version 2.x (or higher)

• TLS-450PLUS System software Version 6.x (or higher)

• BIR option required (TLS-450)

VEEDER-ROOT HARDWARE REQUIREMENTS (REF. TABLE 2)

The following equipment is required to interface the TLS to the G-Site POS:

• One Gilbarco Interface Module

• One installation kit for each current loop

SPECIFIC LIMITATIONS

Up to 36 Gilbarco Uni-Hose/MPD fueling positions are supported by the TLS-350R, and up to 72 fueling

positions are supported by the TLS-450/TLS-450PLUS.

In-dispenser credit card readers (CRINDS) are supported.

To support a DIM and the TLS-350R, the G-Site must be upgraded to include EMC interface capability. This has

been released in the following G-Site versions (EMC Interface capability will be released into the Generic G-Site

version 6):

• Exxon - version 25.0.243

• Shell - version 33.1.23

•Chevron Canada - version 8.1.10

The 331063-xxx installation kit contains two gender mender adapters. One gender mender is used for PC G-SITE

applications while both are used for C-2 G-SITEs

. The gender mender adapters are not identical. As shown in

Figure 6, be sure to use the correct part at the connection points for your particular installation.

WIRING DIAGRAM

G-Site wiring examples are shown in Figure 6 below:

23

Page 29

POS App Guide DIM Installation Examples

Tank

Gauge

25 pin D / RJ-45 Adapter

(Q13180-03/331138-001)

PC G-SITE

RJ45 Modular Cable

Connects

to EDIM

Connects

to EDIM

25 pin D / RJ-45 Adapter

(Q13180-03/331138-001)

G-Site

C-2 G-SITE

Tank

Gauge

Connect RJ-45 plug into

25 pin D / RJ-45 Adapter (331138-002)

Connect RJ-45 plug into

25 pin D / RJ-45 Adapter (331138-001)

Connect RJ-45 plug into

25 pin D / RJ-45 Adapter (331138-001)

Connect 25 pin D / RJ-45 Adapter (331138-002)

to Tank Guage port

RJ45 Modular Cable

Diagram A

Diagram B

Connect RJ-45 plug

directly to Tank Mon port

TLS Console

TLS Console

401-11.eps

Figure 6. Example G-Site Installations

24

Page 30

POS App Guide DIM Installation Examples

AutoGas Storemaster and Gilbarco Dispenser Systems

TLS CONSOLE SOFTWARE REQUIREMENTS

TLS-350R with BIR Software Requirements

• System software Version 17 (or higher)

• DIM software 349634-003C (or later)

TLS-450/TLS-450PLUS with BIR Software Requirements

• TLS-450 System software Version 2.x (or higher)

• TLS-450PLUS System software Version 6.x (or higher)

• BIR option required (TLS-450)

VEEDER-ROOT HARDWARE REQUIREMENTS (REF. TABLE 2)

The following equipment is required to interface the TLS to the AutoGas Storemaster system:

• One Gilbarco Interface Module (for up to 3 current loops)

• One installation kit for each current loop other than RS-422/RS-485 OR One Gilbarco installation kit for each

RS-422/RS-485 current loop

GILBARCO POS AND DISPENSING SYSTEM REQUIREMENTS

• Gilbarco Dispenser Distribution Box PA-2420000000

• Gilbarco Dispenser Distribution Box PA02610000010

• Gilbarco Dispenser Distribution Box PA02610000020

• Gilbarco Dispenser Distribution Box PA0281XXXXXX0

An AutoGas 507 controller is required with the AutoGas Storemaster POS.

SYSTEM LIMITATIONS

• Up to 36 Gilbarco single product or blending fueling positions are supported.

• Only Gilbarco dispensers are supported.

• The Gilbarco current loop dispenser interface module does not support Gilbarco G-Site applications.

The Cable Adaptor Box install kits are designed to be installed on either a Gilbarco 2-wire distribution box input

using 9-pin ‘D shell’ style connectors or a Gilbarco RS-422/RS-485 input to the distribution box, also using 9-pin

‘D shell’ style connectors.

To identify the distribution input communication type, refer to the Gilbarco Universal Distribution Box Installation

Manual (MDE2713) noting the position choices for jumper 12 and 10 on the Universal Distribution Box Card

which is communicating to the PAM, POS, or computer controlling the hydraulic dispenser status. Both of these

jumpers should be in the horizontal position. (If vertical, the pump input is RS-422 and that kit should be used [see

Table on page 7]).

INSTALLATION NOTES

Example wiring diagrams are shown in Figure 7 to Figure 10 below.

25

Page 31

POS App Guide DIM Installation Examples

Communications Cable

"Y" cable & 2

9-pin "D" Style

connectors

POS

401-12.eps

Universal Distribution Box

AutoGas 510 CRIND

Controller with

Current Loop Dispenser

Interface Module

CRIND

Loop

Current

Loop

CRIND

Loop

Current

Loop

Cable

Adapter

Box

Connects

to CDIM

TLS Console

Figure 7. AutoGas 510 CRIND Controller With Current Loop Interface

26

Page 32

POS App Guide DIM Installation Examples

Communications Cable

"Y" cable & 2

9-pin "D" Style

connectors

401-13.eps

Universal Distribution Box

AutoGas 510

CRIND Controller

with Serial Interface

CRIND

Loop

Current

Loop

Cable

Adapter

Box

PAM

Serial Data

Current

Loop

CRIND

Loop

POS

Connects to

CDIM

TLS Console

Figure 8. AutoGas 510 CRIND Controller With Serial Interface

27

Page 33

POS App Guide DIM Installation Examples

Communications Cable

"Y" cable & 2

9-pin "D" Style

connectors

Generic POS

401-14.eps

Universal Distribution Box

AutoGas 510

CRIND Controller

CRIND

Loop

Current

Loop

Current

Loop

Cable

Adapter

Box

Serial or

Current Loop

Data

CRIND

Loop

Connects to

CDIM

TLS Console

Figure 9. AutoGas 510 CRIND Controller

28

Page 34

POS App Guide DIM Installation Examples

Communications Cable

401-15.eps

Universal Distribution Box

AutoGas 507

CRIND Controller

CRIND

Loop

Current

Loop

Cable

Adapter

Box

To Cable Adapter Box

To Controller UDB

Storemaster

POS

CRIND

Loop

Computer

Connection

Connects to

CDIM

TLS Console

PUMP

CONTROLLER

POINT

OF SALE

CONSOLE

COMM.

DB9 M DB9 M

Figure 10. AutoGas 507 CRIND Controller

29

Page 35

POS App Guide DIM Installation Examples

401-16.eps

PC (e.g.,

back office)

Plugs into PC

Ethernet card

Ethernet cable

Ethernet

cable

TLS Console

Plugs into RJ45

connector

in TDIM module

Hub

Do not

use uplink

connector!

X

Gilbarco SmartCrind Dispenser Systems

TLS CONSOLE SOFTWARE REQUIREMENTS

TLS-350R with BIR Software Requirements

• System software Version 17 (or higher)

• DIM software 349806-001 (or higher)

TLS-450/TLS-450PLUS with BIR Software Requirements

• TLS-450 System software Version 2.X (or higher)

• TLS-450PLUS System software Version 6.X (or higher)

• BIR option required (TLS-450)

VEEDER-ROOT HARDWARE REQUIREMENTS (REF. TABLE 2)

The following equipment is required to interface the TLS to the SmartCrind network:

• One TCP/IP (TDIM) Interface Module

• Ethernet cable

SYSTEM LIMITATIONS

• Up to Gilbarco single product or blending fueling positions are supported.

• Only Gilbarco SmartCrind dispensers are supported.

INSTALLATION NOTES

Example wiring diagrams are shown in Figure 11 below.

Figure 11. SmartCrind Installation

30

Page 36

POS App Guide DIM Installation Examples

Tokheim Dispensing Systems

• Tokheim Vision 100/200, MEMS IV, or MEMSV controllers

• CFN2 controllers

• ANDI or Columbus controllers

• Schlumberger MicroMax XPIC/DHC

• 67/A - 98 or 67/B controllers

TLS CONSOLE SOFTWARE REQUIREMENTS

TLS-350R with BIR Software Requirements

• System software Version 17 (or higher)

TLS-450/TLS-450PLUS

• Not supported

VEEDER-ROOT HARDWARE REQUIREMENTS

Specific DIMS and installation kits are listed in Table 2 on page 7.

TOKHEIM DHC REQUIREMENTS

• SCS 1200 default setting for serial port J2

• SCS 9600 default setting for serial port J4

• Version 5, rev 6, dated 11/1989 (or later)

The Tokheim DHC itself can be:

• Standalone (and used with a third party POS). or

• An internal component of a Tokheim Vision 100 Vision 200, MEMS IV, or MEMS V Console

SPECIFIC LIMITATIONS

Only Tokheim dispensers are supported. Tokheim electronic blenders are supported. The dispensers may feature

electronic card readers. Mechanical blenders that blend fuel prior to the metering process are not supported (not a

restriction for ISD only applications).

OTHER POS CONSOLES

Other POS consoles that interface to the Tokheim DHC may also be supported. Contact Veeder-Root for

assistance.

INSTALLATION NOTES

Connection examples for Tokheim dispenser systems are shown in Figure 12 - Figure 14 below.

31

Page 37

POS App Guide DIM Installation Examples

DHC

Cable from kit

(P/N 330408-XXX)

401-17.eps

ALARM

WARNING

POWER

T1: PREMIUM UNLEADED

VOLUME

ULLAGE

90% ULLAGE

TC VOLUME

HEIGHT

WATER VOL

WATER

TEMP

T1: REGULAR GASOLINE

VOLUME

ULLAGE

90% ULLAGE

TC VOLUME

HEIGHT

WATER VOL

WATER

TEMP

4208 GALS

5792 GALS

4792 GALS

4194 GALS

41.02 INCHES

0 GALS

0.00 INCHES

65.0 DEG F

9038 GALS

962 GALS

0 GALS

8950 GALS

81.37 INCHES

28 GALS

1.37 INCHES

74.9 DEG F

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

To Dispensers

To Third

Party

POS

Connects to

EDIM

TLS-350R Console

25 Pin D (P/N 330408-XXX)

ALARM

WARNING

POWER

T1: PREMIUM UNLEADED

VOLUME

ULLAGE

90% ULLAGE

TC VOLUME

HEIGHT

WATER VOL

WATER

TEMP

T1: REGULAR GASOLINE

VOLUME

ULLAGE

90% ULLAGE

TC VOLUME

HEIGHT

WATER VOL

WATER

TEMP

4208 GALS

5792 GALS

4792 GALS

4194 GALS

41.02 INCHES

0 GALS

0.00 INCHES

65.0 DEG F

9038 GALS

962 GALS

0 GALS

8950 GALS

81.37 INCHES

28 GALS

1.37 INCHES

74.9 DEG F

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

Vision 100/200

Manufacturer Supplied Cable

401-18.eps

Connects to

EDIM

Connects to J2 or J4 on

rear panel

TLS-350R Console

Figure 12. Tokheim DHC Standalone Installation

Figure 13. Tokheim Vision 100/200 Installation

32

Page 38

POS App Guide DIM Installation Examples

401-19.eps

ALARM

WARNING

POWER

T1: PREMIUM UNLEADED

VOLUME

ULLAGE

90% ULLAGE

TC VOLUME

HEIGHT

WATER VOL

WATER

TEMP

T1: REGULAR GASOLINE

VOLUME

ULLAGE

90% ULLAGE

TC VOLUME

HEIGHT

WATER VOL

WATER

TEMP

4208 GALS

5792 GALS

4792 GALS

4194 GALS

41.02 INCHES

0 GALS

0.00 INCHES

65.0 DEG F

9038 GALS

962 GALS

0 GALS

8950 GALS

81.37 INCHES

28 GALS

1.37 INCHES

74.9 DEG F

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

Cable connects

to J7 or J8

on rear panel

CAB

RJ-45

RJ-45

Dispenser Controller

Dispenser Interface Box

Tokheim 67A

Tokheim 67B

Tokheim 98

DB9

Barrel

Connectors

DB9

Barrel

Connectors

P/N: 330902-XXX

- P/N 331394-001 (for Tokheim 67A or 98)

- P/N 331394-002 (for Tokheim 67B)

Cable 331392-001 Cable 331393-001

Connects to

CDIM

Break Connection

TLS-350R Console

Figure 14. Tokheim Dispenser Controller With Single CAB Installation

33

Page 39

POS App Guide DIM Installation Examples

Wayne Dispensing Systems

TLS CONSOLE SOFTWARE REQUIREMENTS

TLS-350R with BIR Software Requirements

• System software Version 17 (or higher)

• Peripheral controller software 330269-00B (or higher)

TLS-450/TLS-450PLUS with BIR Software Requirements

• TLS-450 System software Version 2.x (or higher)

• TLS-450PLUS System software Version 6.x (or higher)

• BIR option required (TLS-450)

VEEDER-ROOT HARDWARE REQUIREMENTS

The required DIMs and installation kits for use with Wayne Dispensing systems are listed in Table 2 on page 7.

POS SYSTEM REQUIREMENTS AND LIMITATIONS

Current Loop Installations (TLS-350R/ TLS-450/TLS-450PLUS)

• A Wayne site controller and Wayne dispensers are required.

• Any POS system may be connected to the Wayne site controller.

• The dispensers may feature electronic card readers.

TDIM Installations

• Wayne IDPOS dispenser software 2.29 (TLS-350R and TLS-450)

SUPPORTED WAYNE SYSTEMS

• Wayne 186 System with Site Controller model 880179-001 and Dispenser Data Box (CAB) model DD/

SY2400/08.

• Wayne 386 System with Site Controller model WP/SC and Dispenser Data Box (CAB) model WP/DD.

SUPPORTED WAYNE POS TERMINALS

• Wayne 186 based 2400

• Wayne 186 based Plus 2

• Wayne 186 based Plus 3

• Wayne 386

In addition, third party POS vendors supply POS systems that interface to Wayne Site Controllers and dispensers.

The Wayne DIM supports POS systems that interface to the Site Controller using a Wayne Pump Interface Board

(PIB). A partial list of these systems include:

• GasBoy

•Omron

• Panasonic

• S.A.S.I.

•Suntronics

•Verifone

•EDS C-Serve

The third party POS system will be supported by the Veeder-Root DIM if it communicates to the Wayne Site

Controller using the Wayne PIB.

34

Page 40

POS App Guide DIM Installation Examples

POS

401-20.eps

Cable (P/N 330592-XXX)

Cable (P/N 330592-XXX)

Cable (P/N 331105-001)

Wayne Nucleus

Data Box

(Pump

Distribution Box)

Wayne

Site

Controller

Connect to

CDIM

TLS Console

CAB

('Left')

CAB

('Right')

'Left' Current Loop

'Right' Current Loop

INSTALLATION NOTES

All Wayne electronic blenders are supported.

An example Wayne interconnection diagram for current loop installations is shown in Figure 15. An example

Wayne connection diagram for IDPOS dispenser installations is shown in Figure 16. Figure 17 contains an

example of CAB connections in a Wayne Nucleus Data Box.

Plugs into PC

Ethernet card

PC (e.g.,

back office)

401-16.eps

Figure 15. Wayne Dispenser Data Box Current Loop (TLS-350R and TLS-450)

Ethernet cable

Hub

X

Do not

Figure 16. Wayne IDPOS Dispensers (TLS-350R and TLS-450)

use uplink

connector!

Ethernet

cable

TLS Console

Plugs into RJ45

connector

in TDIM module

35

Page 41

POS App Guide DIM Installation Examples

TB5

TB3

TB1

TB4

TB2

123456

Data

In

Data

Out

TB6

123456

Data

In

Data

Out

To CAB

marked

'Left'

To CAB

marked

'Right'

Left Current Loop Right Current Loop

Set adjacent toggle switch

to right ('Auto' position)

Set adjacent toggle switch

to right ('Auto' position)

Wht

Blk

Wht

Blk

Alternative

'Left' CAB connections

(see text)

Alternative

'Right' CAB connections

(see text)

Wayne Data Box PC board

( cover plate removed)

401-21.eps

Figure 17. Example CAB Connections In Wayne Nucleus Data Box (TLS-350R Only)

36

Page 42

POS App Guide DIM Installation Examples

ALARM

WARNING

POWER

Communications

Cable

Communications

Cable

6-inch VR Supplied,

Short 25-Pin to

25-Pin Patch Cable

POS

401-22.eps

Schlumberger

MicroMax 3000

or Equivalent

(Note: This port is only to be

used with Allied Protocol Box))

Cable

Adapter

Box

RJ-45

RJ-45

Allied

Station Site Controller

(SSC)

(Pump Distribution Box)

C1

Connects to

CDIM

TLS-350R Console

PUMP

CONTROLLER

PUMP

CONTROL

CONSOLE

COMM

POINT

OF SALE

Schlumberger POS Systems

TLS CONSOLE SOFTWARE REQUIREMENTS

TLS-350R with BIR Software Requirements

• System software Version 17 (or higher)

• Peripheral controller software 002B (or higher)

• DIM software 330435-001 (or higher)

VEEDER-ROOT HARDWARE REQUIREMENTS (REF. TABLE 2)

The following equipment is required to interface the TLS to the Schlumberger POS system:

• One Schlumberger Current Loop Dispenser Interface Module (for up to 32 fueling positions), or One Schlumberger SAM Dispenser Interface Module (for up to 36 fueling positions)

• One installation kit, for one of the following POSs; MicroMax/Allied, Pro Series/XPIC/SAM, or MicroMax/XPIC/

DHC

SYSTEM LIMITATIONS

Schlumberger SAM Controllers or Highway systems, are not supported by this DIM. In-dispenser credit readers

are supported by the Schlumberger DIM. Blending of any type is not supported by the Schlumberger DIM (not a

restriction for ISD only applications).

MICROMAX/ALLIED HARDWARE REQUIREMENTS

• An Allied Protocol Box (PCB) or an Allied Station Site Controller (SSC) box.

• Schlumberger MicroMax POS console (other POS terminals are not supported).

• Schlumberger, Gilbarco, Wayne, or Tokheim dispensers may be used.

INSTALLATION NOTES

Figure 18. MicroMax POS W/Allied Station Site Controller Box Current Loop Interface

37

Page 43

POS App Guide DIM Installation Examples

Wire Nut Connector Required

1 2 3 4

To C able

Adaptor Box

To

MicroMax

POS

Schlumberger MicroMax 3000 or Equivalent

TB1

(Note: These two 25 pin “D”

connectors are only to be

used with Allied Station

Site Controller Box)

Two Conductor Wire

Supplied By Contractor

(Maximum of 2 feet)

Connects to

CDIM

TLS-350R Console

ALARM

WARNING

POWER

Communications

Cable

401-24.eps

Cable

Adapter

Box

RJ-45

RJ-45

POS

CONTROLLER

XPIC

or

SAM

PORT 1

POS

PORT 2

25 Pin "D"

9 Pin "D"

25 Pin "D"

25 Pin Serial M/F

Communications Cable

9 Pin "D"

Port 5

Schlumberger Pro Series or MicroMax

Connects to

CDIM

TLS-350R Console

ALARM

WARNING

POWER

RJ-45

Cable Adapter Box

RJ-45

Communications Cable

Allied Protocol Box

(PCB)

(Pump Distribution Box)

(+)

(–)

TB1

Figure 19. MicroMax POS with Allied Protocol Box Current Loop Interface

401-23.eps

Figure 20. Pro Series Or MicroMax POS With SAM Or XPIC Controller Box And RS-232 CAB Interface

38

Page 44

POS App Guide DIM Installation Examples

ALARM

WARNING

POWER

Communications

Cable

401-25.eps

25 Pin Serial M/F

Communications Cable

Schlumberger MicroMax

Cable

Adapter

Box

RJ-45

RJ-45

POS

CONTROLLER

25 Pin "D"

Tokheim DHC

Port 2

Port 5

POS

Connects to

CDIM

TLS-350R Console

ALARM

WARNING

POWER

401-26.eps

Cable

Adapter

Box

POS

POS

CONTROLLER

SAM

Port 1

Port 2

25 pin female to 9 pin

female "D" connector

9 pin male to 25 pin

male "D" connector

9 pin "D" male

connector

9 pin "D" female

connector

6 foot cable

9 pin "D" male

connector

Communications cable w/ RJ-45

connectors at each end

Connects to

CDIM

TLS-350R Console

Figure 21. MicroMax POS with Tokheim DCHC Controller Box and RS-232 CAB Interface

Figure 22. Verifone With SAM And RS-232 CAB Interface

39

Page 45

POS App Guide DIM Installation Examples

GasBoy CFN Systems

TLS CONSOLE SOFTWARE REQUIREMENTS

TLS-350R with BIR Software Requirements

• System software Version 17 (or higher)

VEEDER-ROOT HARDWARE REQUIREMENTS (REF. TABLE 2)

The following equipment is required to interface the TLS to the Gasboy CFN system:

• One Gasboy Dispenser Interface Module

• One installation kit

GASBOY SYSTEM REQUIREMENTS FOR BIR INTERFACE

• Console must be Site Controller II, version 2.0 or later and have “Send All Messages” feature.

• GasBoy junction box (P/N C05020).

• All Profit Point Broadcast messaging enabled.

• Non-blended dispensers (not a restriction for ISD only applications).

CONNECTING TO THE SITE CONTROLLER II

The TLS-350R must be connected to the Console Loop of the Site Controller II to receive BIR data from the CFN

(see

Figure 23).

40

Page 46

POS App Guide DIM Installation Examples

To Regulated

Outlet

Port 1

Port 0

Port 3

Port 2

Cons

Island

AC

Ground

8-foot RS-422 Phone Cable

(Supplied by Gasboy)

SITE CONTROLLER II

To Console or other

Junction Boxes

ALARM

WARNING

POWER

GND

BLUE/WHITE STRIPE

WHITE/BLUE STRIPE

ORANGE/WHITE STRIPE

WHITE/ORANGE STRIPE

401-27.eps

To Plug-In Connector

on LDIM

123 45

TX+

GND TX-TX+ RX- RX+

123 45

TX- RX+ RX- GND

Terminal block inside

RS-422 junction box

Gasboy P/N C05020

Cable shield

C05020

Junction Box

TLS-350R Console

Figure 23. Gasboy Console Loop Connection

41

Page 47

POS App Guide DIM Installation Examples

BIR Protocol DIM

POS SYSTEM REQUIREMENTS AND LIMITATIONS

Any POS system can conform to established Veeder-Root protocol, to allow the TLS to collect the metered sales

data necessary to perform BIR and AccuChart tasks.

This protocol is separate and distinct from the inventory protocol commonly used by POS and other systems to

collect inventory data from Veeder-Root TLS Consoles.

Table 3 lists POS systems known to have implemented the Veeder-Root protocol, and thus support BIR protocol

DIM.

Table 3. POS Systems Supporting BIR Protocol DIM

Manufacturer System TLS-350R

Allied Station Site Controller (SSC) / NextGen X X

Gilbarco T-14 (Australia) X X

PEC 8850 X X

POSTEC RCC X X

Wayne Marketer 2000 (Sweden) / Fusion X X

NCR/Radiant Tiger Box / Panther X X

Retalix X X

TLS-450/TLS-

450PLUS

42

Page 48

POS App Guide DIM Installation Examples

MECHANICAL DISPENSER INTERFACE MODULE

401-28.eps

Barrier

P/N: 7859

Barrier