Page 1

TLS-HLD

Site Prep Manual

Manual No: 577013-784 ● Revision: C

Page 2

Notice

Veeder-Root makes no warranty of any kind with regard to this publication, including, but not limited to, the implied warranties of

merchantability and fitness for a particular purpose.

Veeder-Root shall not be liable for errors contained herein or for incidental or consequential damages in connection with the

furnishing, performance, or use of this publication.

Veeder-Root reserves the right to change system options or features, or the information contained in this publication.

This publication contains proprietary information which is protected by copyright. All rights reserved. No part of this publication

may be photocopied, reproduced, or translated to another language without the prior written consent of Veeder-Root.

DAMAGE CLAIMS

1. Thoroughly examine all components and units as soon as they are received. If damaged, write a complete and detailed

description of the damage on the face of the freight bill. The carrier's agent must verify the inspection and sign the description.

2. Immediately notify the delivering carrier of damage or loss. This notification may be given either in person or by telephone.

Written confirmation must be mailed within 48 hours. Railroads and motor carriers are reluctant to make adjustments for

damaged merchandise unless inspected and reported promptly.

3. Risk of loss, or damage to merchandise remains with the buyer. It is the buyer's responsibility to file a claim with the carrier

involved.

RETURN SHIPPING

For the parts return procedure, please follow the appropriate instructions in the "General Returned Goods Policy" and "Parts

Return" pages in the "Policies and Literature" section of the Veeder-Root North American Environmental Products price list.

©Veeder-Root 200

6. All rights reserved

.

Page 3

Introduction

Regulatory Agency Console Documentation ....................................................................1

Related Manuals ............................................................................................................... 1

Safety Symbols .................................................................................................................2

Site Considerations

Control Drawing ................................................................................................................3

National Electrical Code Compliance ................................................................................4

Probe- to-Console Wiring .........................................................................................4

Probe Junction Boxes...............................................................................................4

Probe Wiring Safety Issues .............................................................................................. 5

Selecting a Console Location ........................................................................................... 5

Console Installation

Mounting the Console .......................................................................................................7

Wiring the Console ...........................................................................................................9

Mag Probe Assembly

Attaching Probe Canister Spacer Rings .........................................................................10

Assembling Floats onto Probe Shaft ..............................................................................10

Attaching Cable Connector to Probe Canister ................................................................10

Table of Contents

Probe Installation

Probe Manhole Installation .............................................................................................13

Probe Installation ............................................................................................................13

Probe Conduit Installation ...............................................................................................14

Wiring Run Methods .......................................................................................................15

Buried Rigid Conduit...............................................................................................15

Pulling Wires for Probes .................................................................................................15

Direct Burial Cable.................................................................................................. 15

Sealing Field Connections ..............................................................................................17

Wiring Run Through Rigid Conduit.........................................................................17

Direct Burial Cable.................................................................................................. 17

Connecting Probes to the Console .................................................................................18

Probe Wiring Precautions ...............................................................................................19

Input/Output Wiring Positions and Labeling ...........................................................19

Connecting Probes to the Console - Observe Polarity...........................................19

Applying Power to System

TLS-HLD Cold Boot - Initial Power Up ............................................................................21

TLS-HLD Cold Boot - RAM Clear ...................................................................................21

TLS-HLD Warm Boot ......................................................................................................21

RS-232 Communications

RS-232 Peripheral Equipment Requirements .................................................................22

RS-232 Connections ....................................................................................................... 22

To a Device Less Than 50 Feet from the Console.................................................22

To a Device More Than 50 Feet from the Console ................................................22

Surge Protection for Communication Devices ................................................................23

Restricting System Programming Access .......................................................................24

Serial Security ........................................................................................................24

setup Security.........................................................................................................24

i

Page 4

Dip Switch Settings.................................................................................................24

RS-232 Serial Communication Setup .............................................................................24

DB-9 Connector Pin-Outs ...............................................................................................25

RS-232 Commands

TLS-HLD RS-232 Serial Commands ..............................................................................26

Function Code: ........................................................................................................ 001 27

Function Code: ........................................................................................................ 003 28

Function Code: 201 ........................................................................................................29

Function Code: 205 ........................................................................................................30

Function Code: 504 ........................................................................................................31

Function Code: 50C ........................................................................................................32

Function Code: 517 ........................................................................................................33

Function Code: 601 ........................................................................................................34

Function Code: 608 ........................................................................................................35

Function Code: 881 ........................................................................................................36

Function Code: 882 ........................................................................................................37

Function Code: 883 ........................................................................................................38

Function Code: 884 ........................................................................................................39

Function Code: 902 ........................................................................................................40

Function Code: A01 ........................................................................................................41

Function Code: A02 ........................................................................................................42

Function Code: A10 ........................................................................................................43

Function Code: A11 ........................................................................................................44

Function Code: A12 ........................................................................................................45

Table of Contents

Troubleshooting

Dual-Function Front Panel Keys ..................................................................................... 46

Probe Diagnostic Menu ..................................................................................................46

Probe Diagnostic Report .................................................................................................48

Replacing the CPU Board ...............................................................................................48

PROM Chip Replacement (Software Upgrade) ..............................................................50

Replacing the Power Supply Board ................................................................................53

Display Messages ...........................................................................................................53

Tank Parameters ....................................................................................................53

Alarms .............................................................................................................................53

Alarm Cause/Action Table .............................................................................................. 54

Console Specifications

Physical Specifications...........................................................................................55

Environmental Specifications .................................................................................55

Electrical Specifications.......................................................................................... 55

Signal Input Specifications .....................................................................................55

Signal Output Specifications...................................................................................55

Front Panel User Interface .....................................................................................55

TLS-HLD Probe Circuit Codes ........................................................................................56

ii

Page 5

Figures

Table of Contents

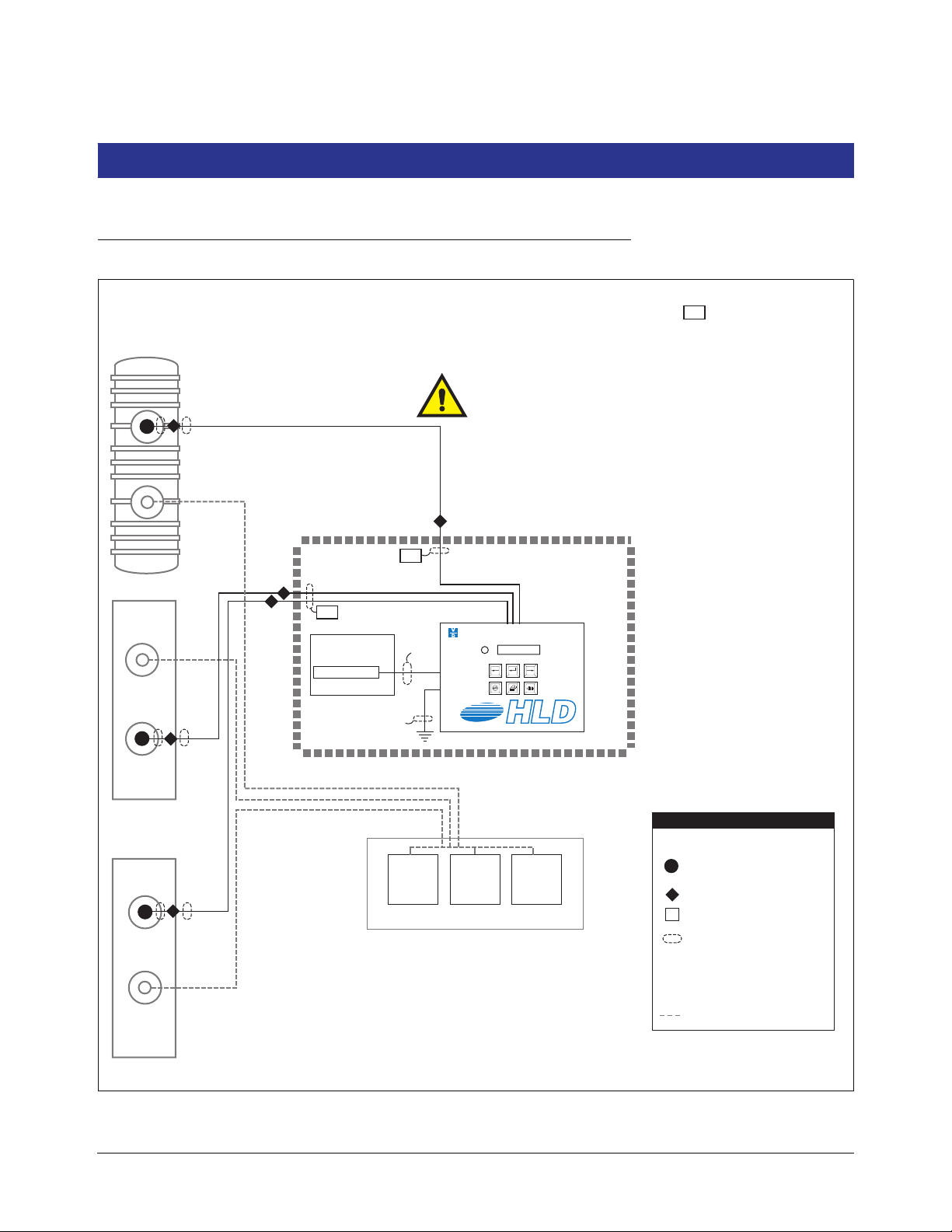

Figure 1. Control Drawing - Example TLS-HLD System Site Layout .......................3

Figure 2. Recommended Mounting of Console.........................................................7

Figure 3. Console Dimensions and Designated Conduit Knockouts ........................8

Figure 4. Wiring AC Power to the Console ...............................................................9

Figure 5. Installing Probe Canister Spacer Rings ...................................................11

Figure 6. Probe Float/Boot Installation ................................................................... 12

Figure 7. TLS-HLD Probe Installation Example - Underground Storage Tank........13

Figure 8. TLS-HLD Probe Installation Example - Above ground Storage Tank .....14

Figure 9. Example Probe Wiring Run in Buried Rigid Conduit ...............................15

Figure 10. Example Probe Wiring Run Via Direct Burial Cable ................................16

Figure 11. Probe Field Wiring Connection ................................................................ 17

Figure 12. Epoxy Sealing Connections ....................................................................18

Figure 13. Probe Installation Directory .....................................................................19

Figure 14. Connecting Probe Wiring to Console ......................................................20

Figure 15. Console Connected to a Remote Device Via Short-Haul Modem ...........23

Figure 16. Console Dip Switch Settings ................................................................... 24

Figure 17. DB9, RS-232 Pin-Outs ............................................................................ 25

Figure 18. Dual-Function Keys .................................................................................46

Figure 19. CPU Board Voltage Test Points .............................................................. 49

Figure 20. Removing PROM Chip ............................................................................51

Figure 21. Replacing PROM Chip ............................................................................52

iii

Page 6

Introduction

This manual describes the site preparation and console installation procedures for the TLS-HLD Console.

This manual assumes that you installing the TLS-HLD in a new site (before pavement is put down and with no wiring

runs in place). Among the topics covered are:

• Site layout considerations.

• Installing the console and connecting wiring from the 120 or 240 Vac power panel.

• Probe assembly and installation procedures.

• Installing wiring conduit between the console and its probes.

• Probe-to-console field junction box wiring diagram.

• Attaching probe wiring to the console.

• RS-232 serial communication connection requirements and serial commands.

• Troubleshooting information that contains diagnostic and maintenance information.

• System specifications.

After the console is wired to its power source and probes, you should program the console following the setup

instructions contained in the TLS-HLD Setup manual.

Regulatory Agency Console Documentation

The UL Console Form Numbers are listed by Underwriters Labs, in File Number: MH11766.

Related Manuals

577013-785 TLS-HLD Setup manual

576013-635 RS-232 Serial Interface manual

576013-859 Direct Burial Cable Installation manual

1

Page 7

Introduction Safety Symbols

Safety Symbols

The following safety symbols may be used throughout this manual to alert you to important safety hazards and

precautions

EXPLOSIVE

Fuels and their vapors are extremely

explosive if ignited.

ELECTRICITY

High voltage exists in, and is supplied

to, the device. A potential shock hazard exists.

NO SMOKING

Sparks and embers from burning cigarettes or pipes can ignite fuels and

their vapors.

NO POWER TOOLS

Sparks from power tools (such as

drills) can ignite fuels and their

vapors.

WEAR EYE PROTECTION

Fuel spray from residual pressure in

the lines can cause serious eye injuries. Always wear eye protection.

FLAMMABLE

Fuels and their vapors are extremely

flammable.

TURN POWER OFF

OFF

Live power to a device creates a

potential shock hazard. Turn Off

power to the device and associated

accessories when servicing the unit.

NO OPEN FLAMES

Open flames from matches, lighters,

welding torches, etc. can ignite fuels

and their vapors.

USE SAFETY BARRICADES

Unauthorized people or vehicles in

the work area are dangerous. Always

use safety cones or barricades,

safety tape, and your vehicle to block

the work area.

INJURY

Careless or improper handling of

materials can result in bodily injury.

GLOVES

Wear gloves to protect hands from

irritation or injury.

READ ALL RELATED MANUALS

Knowledge of all related procedures

before you begin work is important.

Read and understand all manuals

thoroughly. If you do not understand

a procedure, ask someone who does.

2

Page 8

Site Considerations

g

Control Drawing

Double Wall Tank

MP

MP

I.S.

Circuit breaker panel

or Fused, switched,

neon indication spur

120 or 240 Vac

12 AWG barrier

ground wire

I.S.

NOTE: Intrinsically safe wiring (marked ) shall be installed in

accordance with Article 504-20 of the NEC, ANSI/NFPA 70.

Note: conduit requirements are dependent on local electrical regulations.

For probe-to-console wiring, shielded cable is required regardless of

conduit requirements.

WARNING:

Substitution of components may impair intrinsic safety.

Circuitry within the TLS-HLD Console barrier forms an intrinsically safe,

energy-limited system. This system makes TLS-HLD probes safe for use

in a Class I, Group D hazardous location. TLS-HLD probe wiring is

intrinsically safe only when connected to Veeder-Root's TLS-HLD

Console. Reference Console Form Number 8469 and Probe Form

Numbers 8462, 8463, 8468, and 8473.

I.S.

Non-Hazardous

Area

VEEDER-ROOT

PA

Hazardous

Area

TLS-50

TLS

Height Level Display

Single Wall Tank

MP

le Wall Tank

Sin

DP

DISPENSERS

Hazardous Area

LEGEND

Magnetostrictive Probe

MP

Expoxy Sealed Connection in

a Weatherproof Junction Box

Seal-Off

Terminal Connection

1/2'' (12.7 mm) Rigid Conduit

IS

Conduit Enters Console in an

Intrinsically Safe Area Knockout

PA

Conduit Enters Console in a

Power Area Knockout

Product piping

consoles\hldsysdia.eps

Figure 1. Control Drawing - Example TLS-HLD System Site Layout

3

Page 9

Site Considerations

National Electrical Code Compliance

National Electrical Code Compliance

The following information is for general reference and is not intended to replace recommended National Electric Code

(NEC) procedures. It is important for the installer to understand that electrical equipment and wiring located in Class I,

Division 1 and 2 installations shall comply with the latest appropriate articles found in the National Electric Code (NFPA

70) and the Automotive and Marine Service Station Code (NFPA 30A), or other local code such as the CEC,

Canadian Electrical Code..

PROBE- TO-CONSOLE WIRING

Shielded Cable or Veeder-Root Direct Burial Cable Required

To ensure the best operating systems available, Veeder-Root REQUIRES the use of shielded cable for all probes

regardless of conduit material or application. In these installations, shielded cable must be rated less than 100 picofarad

per foot and be manufactured with a material suitable for the environment, such as Carol

8760.

Note: Throughout this manual, when mentioning any cable being used for probe-to-console wiring, it will be referring to

shielded cable.

Wire Length

Improper system operation could result in undetected potential environmental and health hazards if the probe-to-console

wire runs exceed 1000 feet. Wire runs must be less than 1000 feet to meet intrinsic safety requirements.

™

C2534 or Belden™ 88760,

Splices

Veeder-Root recommends that no splices be made in the wire run between a probe junction box and the console. Each

splice degrades signal strength and could result in poor system performance.

Wire Gauges - Color coded

• Shielded cable must be used in all installations. Probe-to-console wires should be #14 - #18 AWG stranded copper

wire and installed as a Class 1 circuit. As an alternate method when approved by the local authority having

jurisdiction, #22 AWG wires such as Belden 88761 may be suitable in installations with the following provisions:

- Wire run is less than 750 feet

- Capacitance does not exceed 100 pF/foot

- Inductance does not exceed 0.5 μH/foot

• Wires carrying 120 or 240 Vac from the power panel to the console should be #14 AWG copper wire for line, neutral

and chassis ground (3); and #12 AWG copper wire for barrier ground (1).

PROBE JUNCTION BOXES

Weatherproof electrical junction boxes with a gasketed cover are required on the end of each probe conduit run at the

manhole location. Gasketing or sealing compound must be used at each entry to the junction box to ensure a waterproof

junction. The interior volume of each junction box must be a minimum of 16 cubic inches.

Veeder-Root recommends the following junction box or equivalent:

• Appleton Electric Co. - JBDX junction box, JBK-B cover, and JB-GK-V gasket.

• Crouse-Hinds Co. - GRFX-139 junction box, GRF-10 cover, and GASK-643 gasket.

4

Page 10

Site Consid era tion s Probe Wi ring Safety Issues

Probe Wiring Safety Issues

WARNING

Probes operate in area s wher e flammabl e l iquid s and ex plos ive v apors may be

present.

Improper installation may result in fire or explosi on causing serious injury or

death.

Practice the following:

1. Read thoroughly and f ollow the instructions shipped with each probe.

2. Probe wiring must enter the consol e only through their designated a reas.

3. Power wires and condui t must not enter the intr insically safe

compartment of the console.

4. Substitution of components may impair intri nsic safety.

Wiring between the console and the probes is of limited electrical power so that there is insufficient energy to ignite fuel.

In the console, the low power probe wiring is considered intrinsically safe because it is physically isolated f rom all high

power wiring. To maintain the integrity of this safety feature probe wiring can not share the same conduit with power

wiring. In addition, probe cables can only enter the console through the designated intrinsically safe area knockouts.

If the TLS-HLD System is being retrofitted into a paved site, you can cut grooves in the pavement, run direct burial

cable to the probes, and then seal over the cable grooves, subject to approval of the local authority having jurisdiction.

Before trenching, you should diagram all conduit runs between the console’s intended location and its deployed probes.

Your site diagram will help you calculate conduit and wiring lengths, and necessary quantities of junction boxes, sealing

boxes, clamps, brackets, etc.

Throughout this planning process and in the actual installation, you must follow all latest National Electric Codes, and

applicable federal, state, and local codes as regards conduit type, depth below grade, sealing, grounding, wire capacities,

direct burial (if permitted), etc.

Selecting a Console Location

WARNING

Explosive vapors or flammable liquid s could be pre sent near locations wher e

fuels are stored or being dispensed. The TLS-HLD Console is not explosion

proof.

An explosion or fire resulting in serious injury or death, property loss and

equipment damage could occur if the console is installed in a volatile,

combustible or explosive atmosphere (Class I, Division 1 or 2).

Do not install this c onsole in a v olati le, comb ustib le, or e xpl osive atmosph ere.

Select a mounting location on the inside of any building. The console must be protected from severe vibration, extremes

in temperature and humidity, rain, and other conditions that could harm computerized electronic equipment.

The equipment is designed to operate safely under the following range of conditions:

•

Temperature range 0 to 40°C - (storage temperature range of -40 to +74°C).

5

Page 11

Site Considerations Selecting a Console Location

• A maximum relative humidity of 95% RH (non-condensing) at temperatures up to 40°C.

• Console may be powered by either 120 or 240 Vac. A switch-mode power supply automatically detects the input

voltage (no jumpers required).

• Main supply voltage fluctuations not exceeding ±10%.

• Pollution Degree Category 2.

• Installation Category II.

Consoles must be installed within the interior of buildings. They are not suitable for any external location.

Ensure that the console is located where neither the console nor its associated cabling will be damaged by doors,

furniture, barrows, etc. Consider the ease of routing wiring, ducting, and probe cables to the console. Check that the

mounting surface material is strong enough to support the console’s weight of about 4 pounds.

If the unit requires cleaning, do not use any liquids, wipe only with a clean, dry cloth.

6

Page 12

Console Installation

Mounting the Console

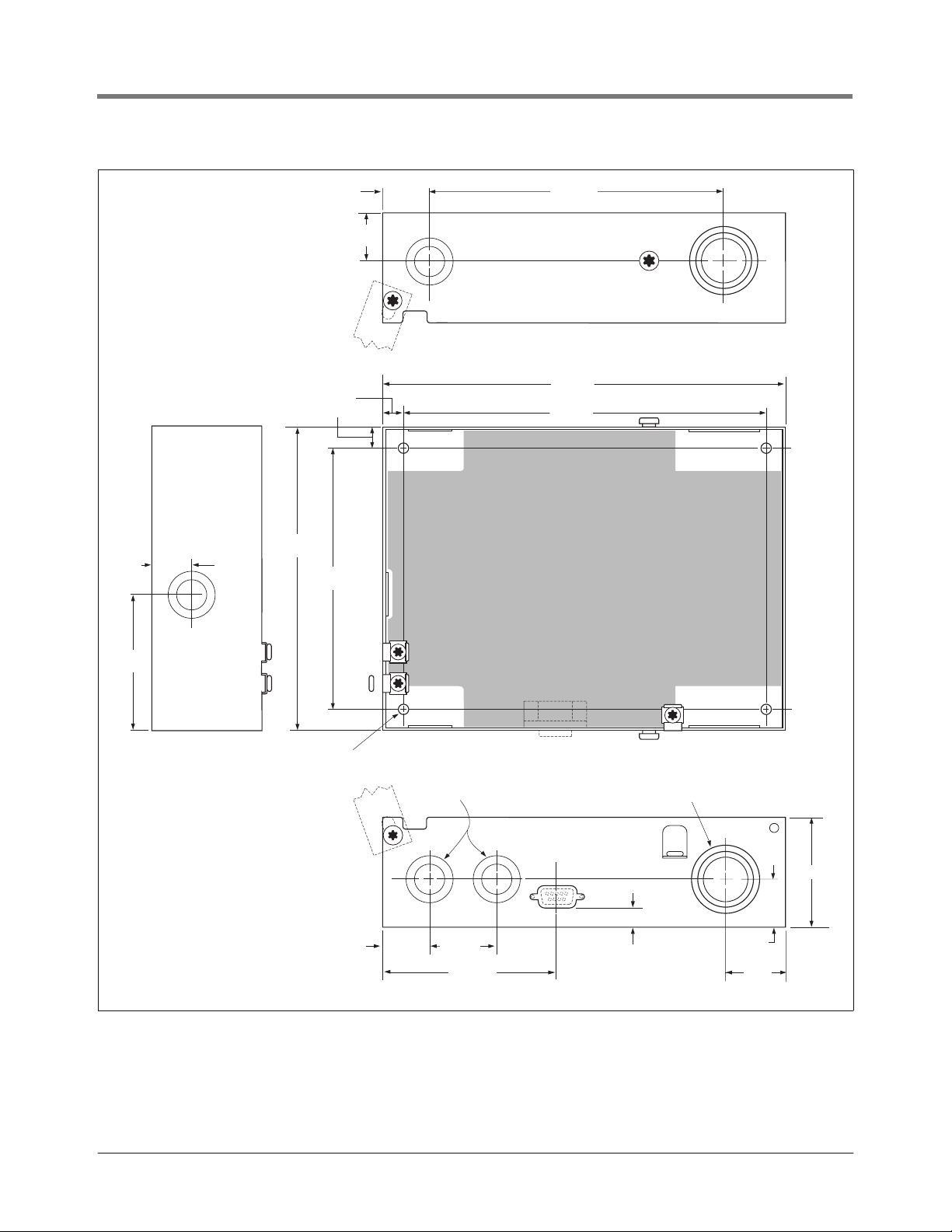

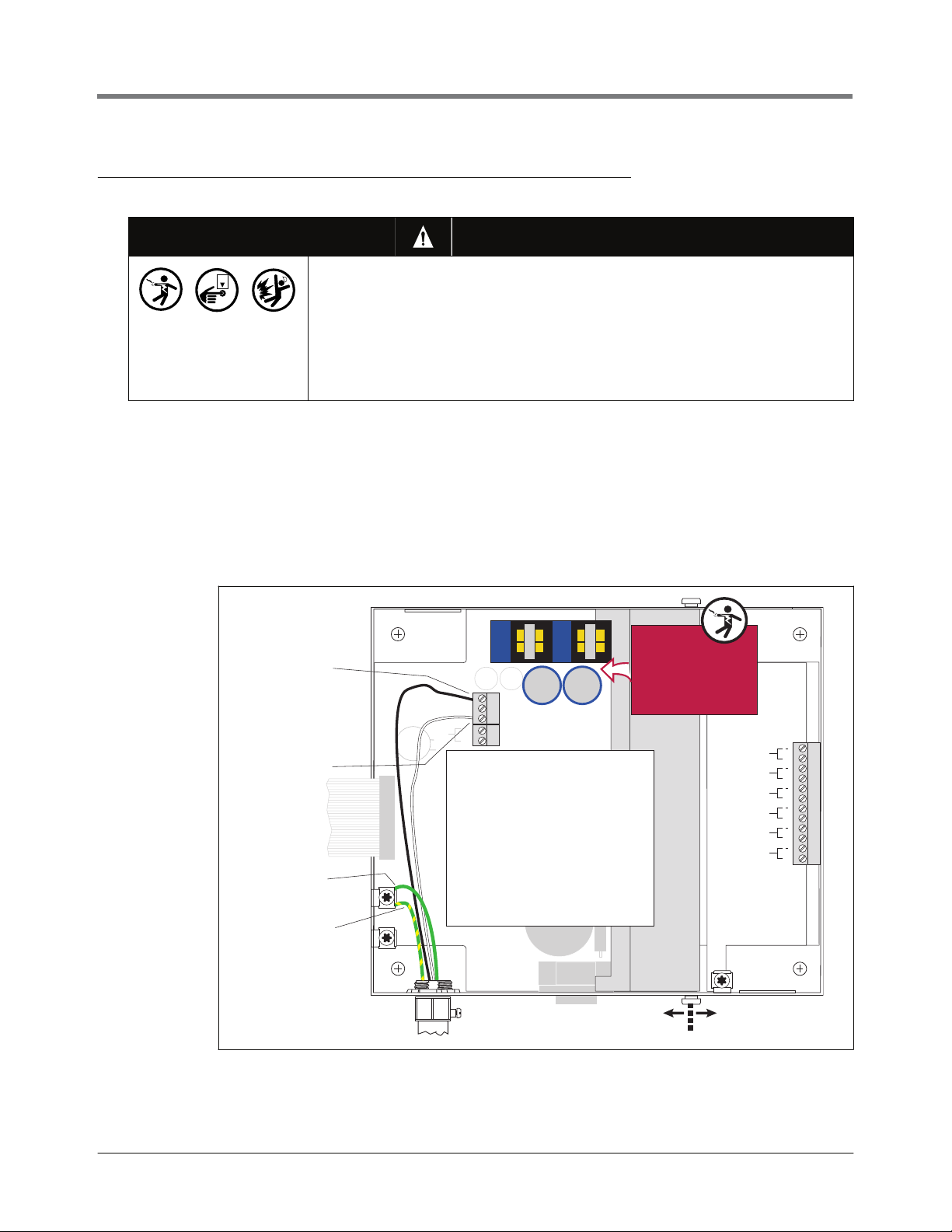

Figure 2 illustrates recommended console mounting. Install the console fastening devices to the mounting surface using

the hole pattern (6.7” x 5.7”) shown in Figure 3. Mounting screws up to 3/16” diameter may be used.

Install metal conduit (1/2” I.P.S.) between the console and the power panel. Figure 3 shows the three designated

knockouts (one each on top, left side, and bottom) through which power wiring can safely enter the console.

1000 mm

(Maximum)

VEEDER-ROOT

To an external alarm (i.e., Forecourt Alarm)One 2 ampere fused, switched, neon indication

spur or a dedicated circuit breaker rated

for 120 Vac or 240 Vac. NOTE, circuit breaker

must be marked as the external alarm

disconnect for the console.

One 5 ampere fused, switched, neon

indication spur (for 240 Vac), or a dedicated

circuit breaker rated for 15 amperes, 120 Vac

or 240 Vac. NOTE, circuit breaker must be

marked as the power disconnect for the console.

From an independent 24 hour supply at the distribution

panel, run three 2.5 mm (minimum) standard color coded

wires; live, neutral, and earth, to the fused spur. Run one

4 mm wire, color coded green/yellow, from the earth bus

bar at the distribution panel direct to the console location.

Leave at least 1 metre of free cable for connection to the

console.

Communication

cable

consoles\hldmnt.eps

TLS

Height Level Display

1000 mm

(Maximum)

1500 mm

(Maximum)

Conduit for probe

field cables

Figure 2. Recommended Mounting of Console

7

Page 13

Console Installation Mounting the Console

0.7''

(17,8)

consoles\tls50dimen.eps

6.4''

(163 mm)

0.93''

(23,6 mm)

0.93''

(23,6 mm)

0.34''

(8,6 mm) typ.

5.7''

(145 mm)

5.3''

(135 mm)

7.4"

(188 mm)

6.7"

(170 mm)

2.6''

(66)

0.22'' (5,6 mm) dia.

console mounting

holes (4 places)

0.93''

(24 mm)

1/2-inch IPS and .56 inch (22 & 14 mm)

Power wiring only - conduit knockouts

(4 places)

1.25''

(32 mm)

3.75"

(95mm)

1/2, 3/4, & 1 inch IPS (22, 28, & 35 mm)

Intrinsically safe wiring only - conduit knockouts

(2 places)

0.93''

0.4''

(10 mm)

(24 mm)

1.18''

(30 mm)

Figure 3. Console Dimensions and Designated Conduit Knockouts

2" (51 mm)

8

Page 14

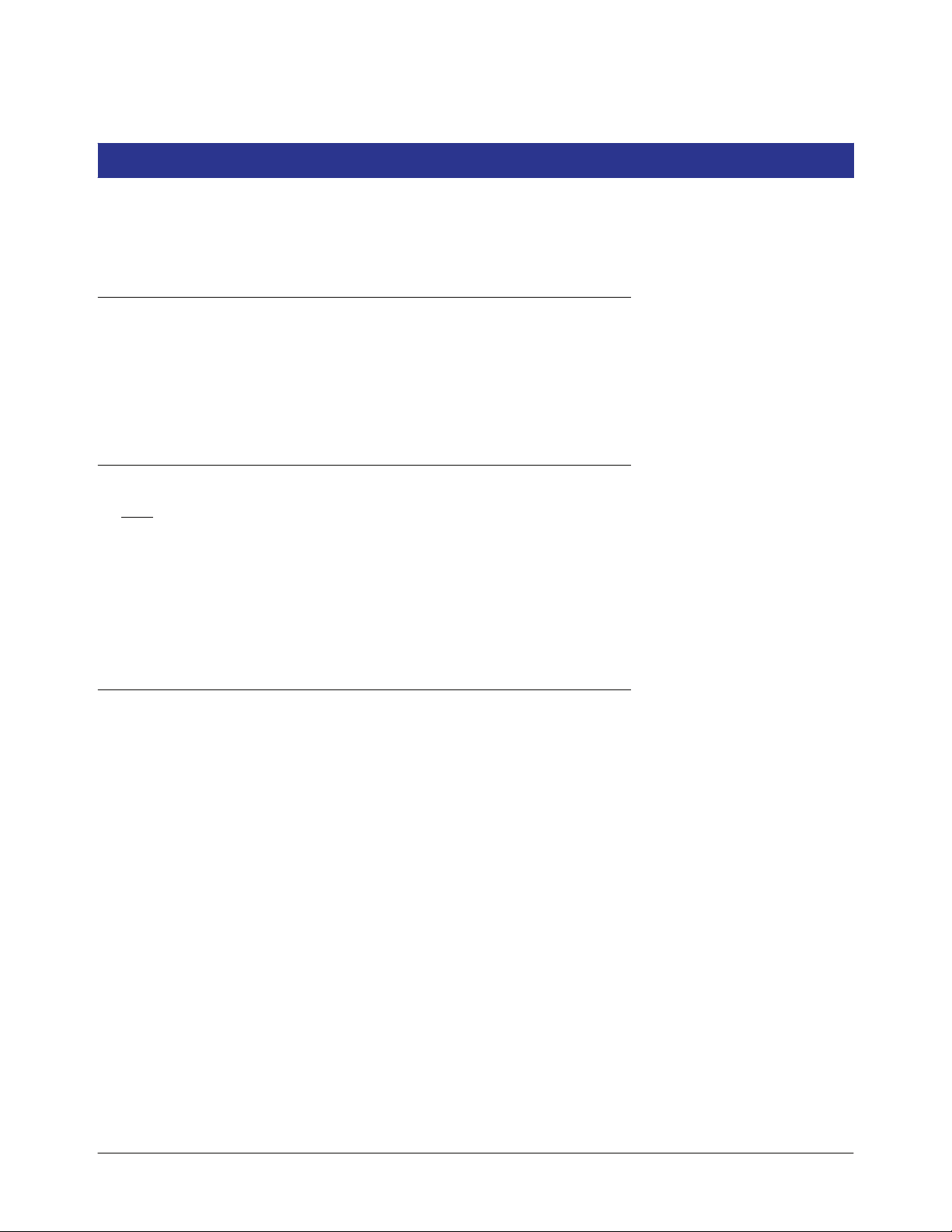

Console Installation Wiring the Console

Wiring the Console

WARNING

OFF

The console contains voltages which can be lethal. It is connected to devices

that must be intrinsically safe.

Connecting power wires to a live circuit can cause electrical shock that may

result in serious injury or death.

1. Turn power off at the circuit breaker connecting the power supply wires.

2. Attach conduit from the power panel to the console's Power Area

knockouts only (1 on top and bottom, ref. Figure 3).

1. Pull four wires between the power panel and the console; three #14 AWG (2.5 mm2) color-coded wires for AC line

(L), AC neutral (N) and chassis ground; and one #12 AWG (4 mm

2

) green and yellow wire for barrier ground.

For international applications using 240 Vac, pull four wires between the power panel and a 5 A fused, switched,

neon indication spur; three #14 AWG color-coded wires for AC line (L), AC neutral (N) and chassis ground; and one

#12 AWG green and yellow wire for barrier ground. Pull four identical wires between the spur and the console.

2. Open the right door of the console and connect the four power/ground wires as shown in [Figure 4]. Do not connect

the power wires to breaker panel at this time.

L2 L4

WARNING!

Attach neutral wire to top

terminal ("N") of J4

Attach hot wire to bottom

terminal ("L") of J4

Attach chassis ground

wire to ground lug

Protective Earthing

Conductor (Green and

Yellow) Attach #12AWG

2

(4 mm

) barrier ground

wire to ground lug

CONSOLE

POWER

RELAY RATING

120/240 VAC

2 A MAX

N

J4

C24 C27

L

J5

1234

OPEN

SW1

SEC

SETUP

J3

POWER WIRING NOTES:

1. Barrier ground must be #12 AWG (4 mm

or larger diameter.

2. Check to be sure that the electrical resistance

between the console ground lug and a known

good earth ground is less than 1 ohm.

3. Connect the power supply wires in the power

panel to a separate dedicated circuit.

4. Electrical rating power input -- 120 Vac or

240 Vac, 50/60 Hz, 2 A maximum.

5. See the "Console Dimensions and Designated

Conduit Knockouts" figure for actual locations of

power conduit knockouts into the console. Power

wiring must enter only in Power Area conduit

knockouts.

Shock hazard. Do not

touch metal ends of

capacitors C24/C27

or the metal bands

on chokes L2/L4.

2

)

WARNING

SUBSTITUTION OF COMPONENTS

MAY IMPAIR INTRINSIC SAFETY.

NO REPAIRS SHOULD BE ATTEMPTED.

REFER SERVICING TO QUALIFIED

PERSONNEL ONLY.

PROBE 6

PROBE 5

PROBE 4

PROBE 3

PROBE 2

PROBE 1

AVERTISSEMENT

LA SUBSTITUTION DE COMPOSANTS

PEUT COMPROMETTRE LA SECURITE

INTRINSEQUE.

+

+

+

+

+

+

consoles\tls50\50powr.eps

Power

Side

Intrinsically

Safe Side

Figure 4. Wiring AC Power to the Console

9

Page 15

Mag Probe Assembly

The following assembly instructions are for Global Mag Plus an Mag Plus probes. For other probe types follow assembly

instructions included with probe.

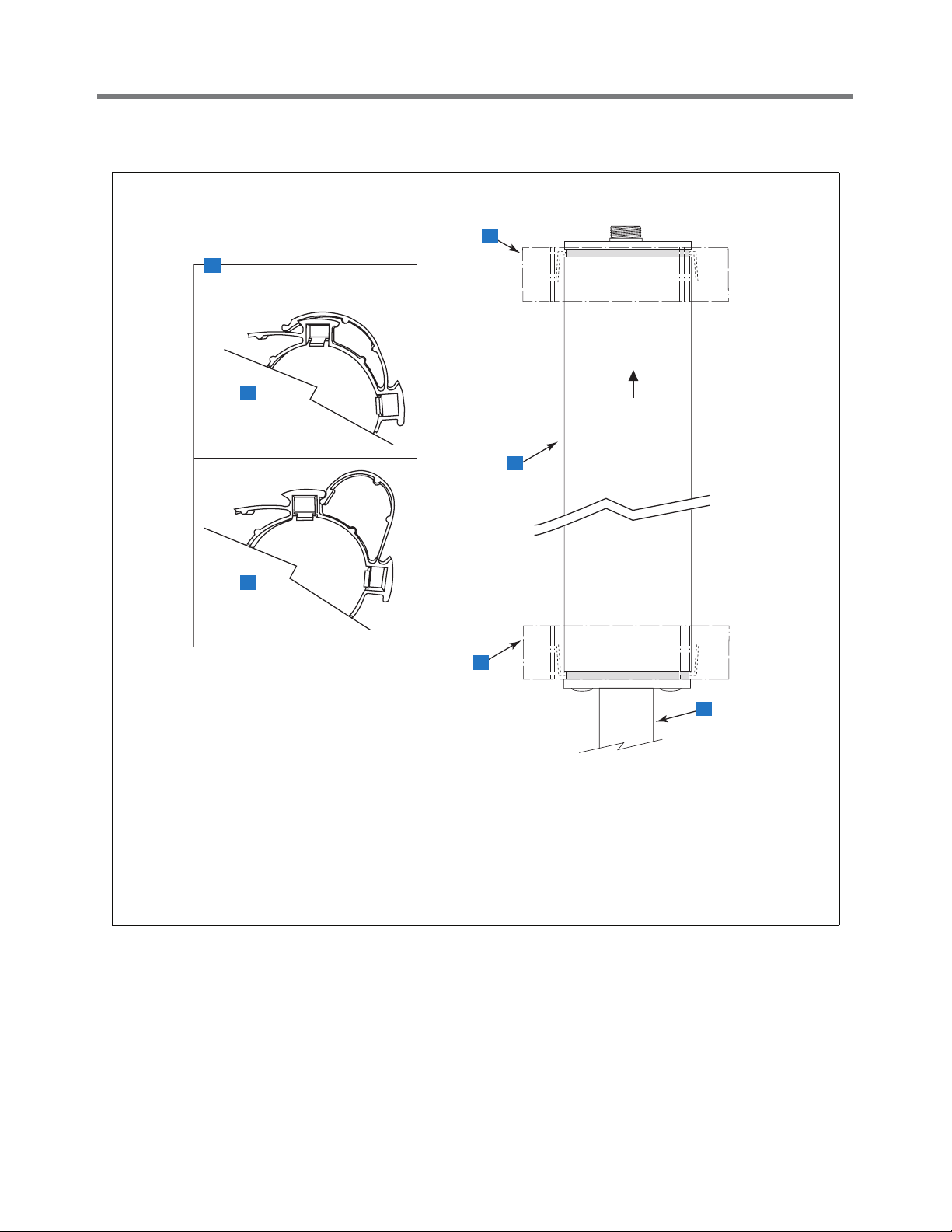

Attaching Probe Canister Spacer Rings

1. Open the probe shipping carton so that you have access to the probe. Also open the installation kit.

2. After setting the spacer vanes for a 3- or 4-inch riser (see Figure 5), install the two spacer rings as shown. Note: you

must slide the bottom spacer over the probe and onto the lower end of the canister. NOTE: spacers are not required

for a 2-inch riser.

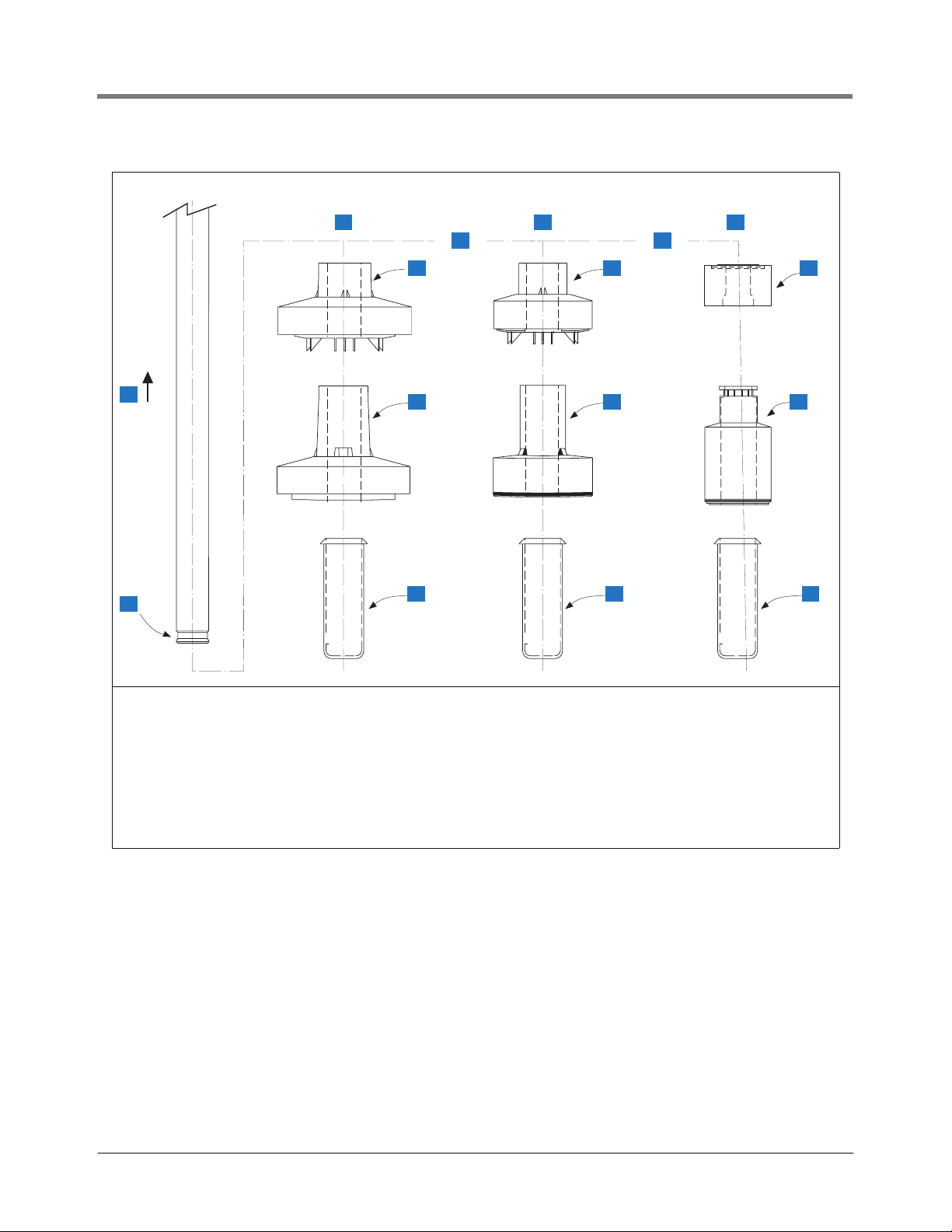

Assembling Floats onto Probe Shaft

The Product floats, Water Floats (if ordered), and Boots from Probe Installation Kits are assembled on the probe shafts in

the exact

IMPORTANT! Failure to push the boot as far as possible onto the probe shaft could cause the boot and float(s) to fall

into the tank. The boot must be pushed on until it “locks” on the probe shaft. Also, water floats must be installed, if

ordered, for the probe to operate correctly.

Handle the probe carefully. Striking or dropping the probe will result in loss of calibration and could cause permanent

damage.

sequence and orientation shown in Figure 6.

Attaching Cable Connector to Probe Canister

Attach the connector end of the probe cable to the threaded connector on top of the probe canister and tighten down the

integral nut.

This completes the probe assembly. Save the remaining kit components. They will be needed to install the probe into the

tank.

10

Page 16

Mag Probe Assembly Attaching Cable Connector to Probe Canister

1

5

6

2

7

3

tls2/figure12.eps

Legend for numbered boxes

1 After setting vanes (see insert) install top spacer ring. Orient locking tabs as shown, and then slide ring over top of canister

until tabs snap into groove in canister.

2 Probe canister

3 After setting vanes (see insert) install bottom spacer ring. Orient locking tabs as shown, and then slide ring over probe and

onto canister, until tabs snap in groove.

4Probe shaft

5 Spacer Ring Riser Adjustment

6 For 3"riser - set 4 spacer ring vanes as shown.

7 For 4"riser - set 4 spacer ring vanes as shown.

Figure 5. Installing Probe Canister Spacer Rings

4

11

Page 17

Mag Probe Assembly Attaching Cable Connector to Probe Canister

3 8 9

7 7

4 4 4

1

2

Legend for numbered boxes

1Up

2 Bottom of probe shaft

3 4-Inch Floats

4 Product float - slide on probe shaft first

5 Water float - (Optional) slide on probe shaft second.

6 Boot - slide on probe shaft last

7 Or (different float size)

8 3-Inch Floats

9 2-Inch Floats

5 5 5

6 6 6

tls2/figure13.eps

Figure 6. Probe Float/Boot Installation

12

Page 18

Probe Installation

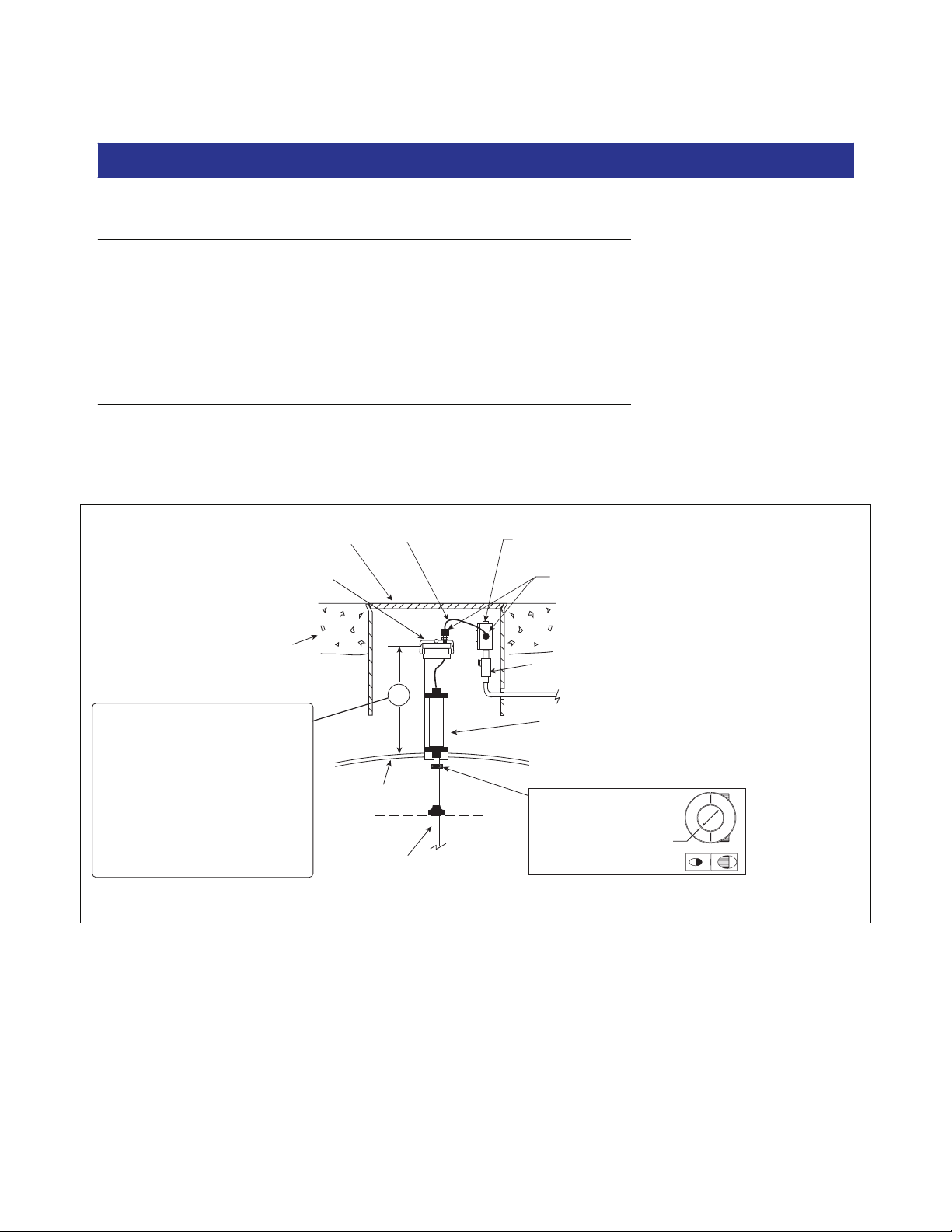

Probe Manhole Installation

At each underground probe location, install a 14-inch (355 mm) minimum diameter approved manhole according to the

manufacturer’s instructions (Note: probes should be located at least 24 inches (610 mm) from the submersible pump to

avoid erroneous probe readings when the pump is running).

Position the manhole so that there is necessary clearance for junction box installation and wiring.

Probe Installation

Each probe supplied by Veeder-Root is accompanied by an assembly manual which details the assembly of the probe.

Figure 7 and Figure 8 illustrate how to install the assembled probe either in an underground tank, and in an above ground

tank.

14'' min. dia. manhole

Riser cap with cord grip

bushing and nut

Concrete slab or packed

earth per NFPA 80

A = 18" minimum for standard mag

probes or 14" minimum for global

mag plus/mag plus probes. When

installing a probe longer than the

the tank diameter, increase this

minimum dimension to compensate.

(Example: a 7'-6'' diameter tank will

use an 8' probe, in which case you

must add 6" to minimum riser length

'A', i.e., 24" or 18" depending on

probe type).

Probe cable

.

.

.

.

.

.

.

.

.

.

.

..

.

Tank

Mag Probe

(rests on bottom)

Weatherproof junction box with 1/2" NPT

threads (16 cubic inch minimum)

Cord grip seals

.

.

.

.

.

.

.

.

.

.

.

..

.

Seal-off, epoxy seal per NFPA spec

A

1/2" Rigid conduit (to Console)

Riser pipe - 2, 3, or 4'' API schedule 40 depending

on probe type (To prevent erroneous probe readings,

install probe riser a minimum of 24'' from the submersible

pump.)

Split-Ring Collar

(P/N 576008-617)

required if probe

enters the riser.

Top view

3/4" ID

Side view

probes\pbinstcen.eps

Figure 7. TLS-HLD Probe Installation Example - Underground Storage Tank

13

Page 19

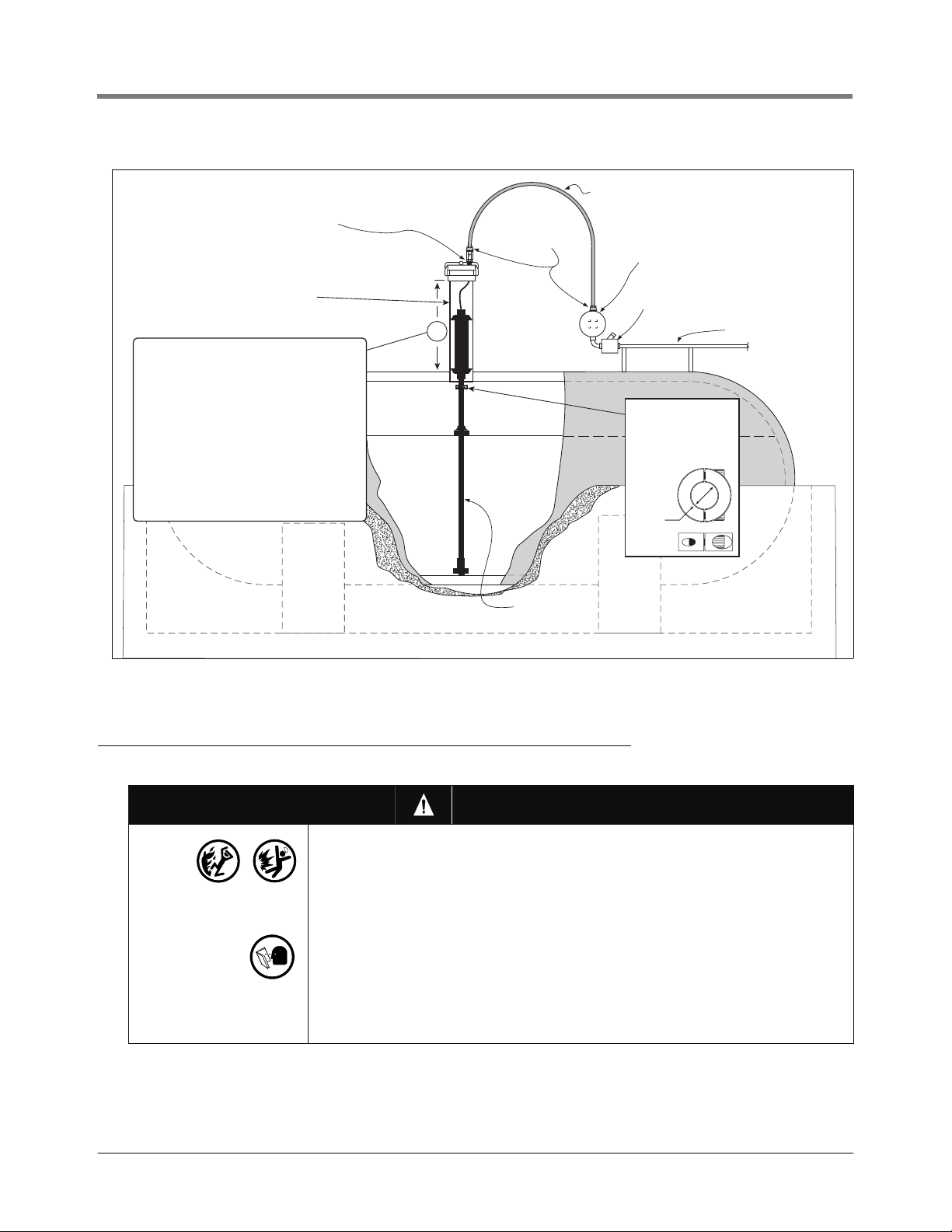

Probe Installation

Probe Conduit Installation

Use bushing and body of grip

fitting supplied with probe and

Adaptor nut supplied with

AST kit.

Riser pipe - 2, 3, or 4'' API

schedule 40 - depending on

probe type

A = 18" minimum for standard mag

probes or 14" minimum for global

mag plus/mag plus probes. When

installing a probe longer than the

the tank diameter, increase this

minimum dimension to compensate.

(Example: a 7'-6'' diameter tank will

use an 8' probe, in which case you

must add 6" to minimum riser length

'A', i.e., 24" or 18" depending on

probe type).

probes\astpbins.eps

Flexible metal conduit

supplied with AST kit

Liquidtight

fittings from

AST kit

A

Mag Probe

(rests on bottom)

Figure 8. TLS-HLD Probe Installation Example - Above ground Storage Tank

Weatherproof junction box with

1/2" NPT threads (16 cubic inch

minimum)

Epoxy seal per NFPA specs

Rigid conduit

Split-Ring Collar

(P/N 576008-617)

required if probe

enters the riser.

Top view

3/4" ID

Side view

Probe Conduit Installation

Probes operate in areas where flammable liquids and explosive vapors may be

present.

Improper installation may result in fire or explosion causing serious injury or

death.

Practice the following:

1. Read thoroughly and follow the instructions shipped with each probe.

2. Probe wiring conduit must not contain any other wires.

3. Probe wiring and conduits must enter the console only through their

4. Power and communication wires and conduit must not enter the

WARNING

designated areas (see Figure 3).

intrinsically safe compartment of the console. (see Figure 3).

14

Page 20

Probe Installation Wiring Run Methods

Wiring Run Methods

Two wiring run methods are commonly used for probes - Shielded wiring pulled through buried, sealed 1/2” rigid

conduit; or direct burial cable.

BURIED RIGID CONDUIT

The preferred method, especially in new sites before driveway surfaces are paved, is to pull probe wiring through buried

1/2” rigid conduit [Figure 9].

Weatherproof junction

box with 1/2-inch N.P.T.

threads (16 cubic inch

Splice Closure

Seal-Off

minimum)

Cord grip seals

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. .

Epoxy seal per NFPA spec

1/2'' rigid conduit (to console)

Tank

probes\pconduit.eps

Figure 9. Example Probe Wiring Run in Buried Rigid Conduit

Pulling Wires for Probes

Pull shielded cable consisting of two conductors, color-coded #14-18 AWG (2.5 - 0.8 mm2) strande d co pper w ire ,

between the console and the junction box at each

with no splices to ensure optimum signal strength.

probe location (do not gang wires together). Use single lengths of wire

IMPORTANT! Maximum probe-to-console cable length is 1000 feet (305m).

Since wires for multiple probes may enter the console through a single conduit, it is recommended that you use a

different color-code for each wire or individually mark each wire to identify probe inputs. Also, if the intrinsically safe

wires enter the building in a wiring trough, only intrinsically safe wires (f rom TLS-HLD probes) can be in the trough.

Keep all low power (intrinsically safe) wiring physically isolated from high power wires in all wiring troughs per the

NEC.

DIRECT BURIAL CABLE

An alternative to trenching through existing pavem ent is to use direct burial cable.

Prior to installing direct burial cable with epoxy splices, consult with the local authority having jurisdiction. Use of direct

burial cable is only allowed in locations where local codes permit the use of buried cable.

15

Page 21

Probe Installation Pulling Wires for Probes

G

Splice closure

n.

WARNING

Direct burial cable can be installed in hazardous locations where fuel and

vapor may be present. It is specifically designed for certain uses only. It must

be installed in the correct manner.

Installing the cabl e incorr ectl y or without pr oper precauti ons can resul t in fire,

explosion, ele ctr ical shock, hazardous conditions as well as equipment

damage or inaccurate inventory control.

Perform the following:

1. Use direct burial cable for intrinsically-safe wiring only. Do not use for

power wiring.

2. Do not share conduit f or intr insica lly- safe p robes wi th wiri ng of an y oth er

type or from any other system.

3. Maintain a physical separation of at least 2 inches between probe w iring

to all other wiring.

4. When cutting trenches for direct burial cable ensure that you do not cut

through exist ing fuel or wiri ng systems. Obtain as much site information

as possible befor e cutting the trench.

5. When grinding trenches in existing pavement for direct burial cables,

wear approved breat hing and hearing protection, goggles, and gloves.

The direct burial method requires grinding a 1/4” to 3/8” wide by 1-1/4” deep groove (adding 1/4” of depth for each

additional cable) in the pavement surface, laying Veeder-Root supplied direct burial cable down in the bottom of the

groove, laying an expanded polyethylene foam backer rod over the cable(s), and then a placing a 1/4” to 1/2” bead of

Veeder-Root recommended silicone sealant over the backer rod to within a minimum of 3/8” below the pavement surface

[see Figure 10]. If you decide to use the direct burial method, you should order the Veeder-Root Direct Burial Cable

Preparati on Kit, P/N 848100-500.

Epoxy filled

Cord grip

splice

enclosure

rade

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

Tank

probes\pdburialcen.eps

Drill oversized hole

in manhole for DB cable

1

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

..

.

CONCRETE

.

.

.

.

.

..

.

.

890-SL silicone sealant

SOF ROD backer rod

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

2

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

...

EARTH

1

Dow Corning Silicone Pavement Sealant

2

Expanded polyethylene foam rod - trademark of

Applied-Extrusion Technologies.

Seal-off

Rigid conduit

. .

.

.

ASPHALT

3'' Mi

Figure 10. Example Probe Wiring Run Via Direct Burial Cable

16

Page 22

Probe Installation Sealing Field Connections

Figure 11 diagrams a typical probe field wiring connection in the junction box.

Do not ground drain wire

in junction box

To

PROBE

Terminal

Block In

Console

Seal-off

Black

From

Probe

White

1/2'' rigid

conduit

probes\3mpwir.eps

Epoxy sealed connections in a

weatherproof junction box

Figure 11. Probe Field Wiring Connection

Sealing Field Connections

WIRING RUN THROUGH RIGID CONDUIT

1. Pull the wires from the probe canister into the junction box. Pull two wires from the console through the seal-off box

and into the junction box.

2. Using wire nuts, connect the two wires from the probe to the two wires coming from the console. Be sure to observe

color codes or tags when making these connections.

3. Do NOT terminate drain wire at this location, ground drain wire at console only.

4. Seal wire nuts with epoxy sealant using one bag for two-wire nut connections (Figure 12).

CAUTION: Epoxy sealant is irritating to eyes, respiratory system, and skin. Can cause allergic skin reaction.

Contains: epoxy resin and cycloaliphatic epoxycarboxylate. Precautions: Wear suitable protective clothing, gloves,

eye, and face protection. Use only in well ventilated areas. Wash thoroughly before eating, drinking, or smoking.

5. Push the tie-wrapped, epoxy sealed bag into the junction box. Replace and tighten the junction box cover.

DIRECT BURIAL CABLE

When using direct burial cable for probe- or sensor-to-console wiring runs, the sealing materials and procedure are

completely different. If you are using Direct Burial Cable you must follow the sealing instructions in the Direct Burial

Cable Installation Manual.

17

Page 23

Probe Installation

Connecting Probes to the Console

ACB

Instructions:

NOTE: When temperature is below 50˚F (10˚C), keep

resin in a warm place prior to mixing (e.g., in an

inside pocket next to body).

1. Open epoxy sealant package, and remove resin pak.

2. Holding resin pak as shown in A, bend pak along long

length.

3. As shown in B, firmly squeeze the RED SIDE of the

resin, forcing it through the center seal and into

BLACK SIDE.

Connecting Probes to the Console

From probe,

sensor, or

transducer

Make sure that

the ends of cable

sheathing are submerged in sealant

4. Mix thoroughly to a uniform color by squeezing

contents back and forth 25-30 times.

5. Squeeze mixed, warm resin into one end of bag and

cutoff other end.

6. Slowly insert wiring connections into sealing pack

until they fit snugly against the opposite end as

shown in C.

7. Twist open end of bag and use tie wrap to close it off

and position the tie wrapped end up until the resin

jells.

Figure 12. Epoxy Sealing Connections

To console

Tie wrap

Wire nuts

consoles\epxy2w.eps

WARNING

The equipment is used in location where lethal voltages and explosive vapors

or flammable fuels may be present.

Care must be taken when installing, servicing or replacing parts in the system

or serious injury or death from explosion, fire or shock may occur.

For this system:

1. Comply with the latest National Electric Code, federal, state, and local

codes, and any other applicable safety codes. In addition, take necessary

precautions during installation, service, and repair to prevent personal

injury, property loss and equipment damage.

2. Refer servicing to trained and qualified personnel only.

3. Substitution of components may impair intrinsic safety.

OFF

4. Be sure AC power is “OFF” before opening the console panel cover and

connecting probe wires. Do not short any voltage across any barrier

terminal including probes.

18

Page 24

Probe Installation Probe Wiring Precautions

Probe Wiring Precautions

To The Installer! You Must Read And Understand This Information.

INPUT/OUTPUT WIRING POSITIONS AND LABELING

In all cases, the devices wired to the console’s input/output terminal blocks must be recorded to prevent improper

replacement during installation or service. A circuit directory is listed below for this purpose.

During programming, the probes wired to each position are identified and stored in memory. If a probe is removed and

reconnected to a different set of input terminals after programming, the system will not properly recognize the data being

received.

Wiring Assignments

1. Identify all probe wires according to their terminal block location using the self-adhesive numbering labels furnished.

Accurately record on the circuit directory in Figure 13 the location of each probe as you attach wires to the probe

input terminal block.

2. IMPORTANT! Once a device has been wired to certain terminals and the system has been programmed, the wires

from that device may not be relocated to other terminals without reprogramming the system

Probe Number

PROBE 1 IN

PROBE 2 IN TANK

PROBE 3 IN TANK

PROBE 4 IN TANK

PROBE 5 IN TANK

PROBE 6 IN TANK

TANK

TANK Number & Product

consoles\tls50\prbtnk.eps

Figure 13. Probe Installation Directory

Grounding Probe Shields and Drain Wires

Connect probe cable shields and drain wires to ground in the console only, not at the field junction boxes. Do not ground

both ends of the shield.

CONNECTING PROBES TO THE CONSOLE - OBSERVE POLARITY

Connect the two color-coded/marked wires from the each probe to the appropriate terminals of the Probe Terminal Block

as shown in Figure 14.

19

Page 25

Probe Installation Probe Wiring Precautions

g

g

WARNING

SUBSTITUTION OF COMPONENTS

MAY IMPAIR INTRINSIC SAFETY.

SW1

OPEN

1234

SEC

SETUP

NO REPAIRS SHOULD BE ATTEMPTED.

REFER SERVICING TO QUALIFIED

PERSONNEL ONLY.

PROBE 6

PROBE 5

PROBE 4

PROBE 3

PROBE 2

PROBE 1

+

+

+

+

+

+

Black wire from probe

connects to terminal

White wire from probe

connects to + terminal

SW 1

J3

Attach probe cable shield and/or

drain wire to

rounding lu

AVERTISSEMENT

LA SUBSTITUTION DE COMPOSANTS

PEUT COMPROMETTRE LA SECURITE

INTRINSEQUE.

consoles\tls50\50prbwir.eps

Figure 14. Connecting Probe Wiring to Console

20

Page 26

Applying Power to System

TLS-HLD Cold Boot - Initial Power Up

Once all devices are connected to the TLS-HLD Console attach the console power wires to the appropriate power panel

connections. Close the front panel of the console. Switch on the AC power breaker. The system will automatically run a

cold boot self-diagnostic program when you power up the TLS-HLD for the first time:

Test Passed

RAM TEST - OK RAM FAIL Replace CPU board

ROM TEST - OK ROM FAIL “ “ “

COLD BOOT

EEPROM TEST - OK EEPROM FAIL “ “ “

STARTUP COMPLETE

Following a cold boot, if the probes and console are configured correctly, the display will read:

ALL FUNCTIONS NORMAL

Following a cold boot, if the probes and console are not configured correctly, the display will read:

NO TANKS CONFIGURED

Follow the Setup instructions in the TLS-HLD Setup manual to program the system.

Test Fa iled Action (If Failed)

TLS-HLD Cold Boot - RAM Clear

If the system has previously been setup, a cold boot can be initiated and the system reset (such as for a software upgrade)

as follows:

Move the RAM clear jumper (J3 in Figure 4) off of pins 1 and 2 and onto pins 2 and 3. The display will acknowledge the

RAM clear request with the message: RAM CLEAR, then turn the power Off. Move the jumper back onto pins 1 and 2.

TLS-HLD Warm Boot

Once the system is setup, every time power to the TLS-HLD is switched Off and On, the software will run a selfdiagnostic warm boot program and display the test results:

Test Passed

RAM TEST - OK RAM FAIL Replace CPU board

ROM TEST - OK ROM FAIL “ “ “

WARM BOOT

STARTUP COMPLETE

If a fault is detected an error message will be displayed and the system will halt. When the warm boot completes the

display returns to the top level status message. Once the Boot Up successfully completes, go to the Setup manual to

program the console.

Test Fa iled Action (If Failed)

21

Page 27

RS-232 Communications

RS-232 Peripheral Equipment Requirements

Any peripheral equipment connected to an RS-232 serial port must meet the following criteria:

1. Peripheral equipment must be UL listed.

2. The equipment must have an EIA standard RS-232C or RS-232D communications protocol.

3. The equipment must NOT be installed over or in a hazardous location.

RS-232 Connections

TO A DEVICE LESS THAN 50 FEET FROM THE CONSOLE

Veeder-Root recommends that you use a null-modem cable no longer than 50 feet (15 m) for direct connections between

the console and a remote device. Cable runs longer than 50 feet can result in data errors, component damage, or both.

TO A DEVICE MORE THAN 50 FEET FROM THE CONSOLE

If cable runs longer than 50 feet are needed, two short-haul modems should be used, one at the console and one at the

remote device. We recommend an asynchronous short-haul modem, Black Box model ME800A, or equivalent at the

console and at the remote device. For more information, you can contact Black Box at - phone: 1-724-746-5500, fax: 1724-746-0746, or at their Internet address http://www.blackbox.com

Figure 15 illustrates how to connect two short-haul modems between the console RS-232 Interface Module’s or

Auxiliary RS-232 Interface Module’s DB-25 connector and the remote device.

Connections to telephone lines must meet the following criteria:

• Connection to telephone equipment is subject to local regulations.

• Maximum short circuit current: 0 amperes.

• Maximum open circuit voltage: 0 volts.

22

Page 28

RS-232 Communications Surge Protection for Communication Devices

r

DCE

DB-9

Connector

To

Available

Port

DB-25

Connector

Color 1

Color 1

Color 2

Computer

Color 2

RTS/DTR

CONTROL

DB-25 Connector

EN

DIS

Console

VEEDER-ROOT

TLS

DB-9 Connector

2 Twisted Pairs (24 - 26 AWG)

Height Level Display

DCE

consoles\tlshld\shmodm.eps

Color 1

Color 2

Color 1

Color 2

RTS/DTR

CONTROL

DB-25 Connecto

EN

DIS

S1

DTE

TD RD

Flash red & green

Gnd

TX-

TX +

RX-

RX+

Black Box Model: ME800A

Loopback

Normal

S2

= Required selection

S1

DTE

TD

Flash red & green

TX +

Gnd

TX-

RX-

RX+

RD

S2

Loopback

Normal

Black Box Model: ME800A

Figure 15. Console Connected to a Remote Device Via Short-Haul Modem

Surge Protection for Communication Devices

In locations that are subject to high levels of noise and power surges, the use of a surge protector is recommended. The

following models are available from B&B Electronics, telephone 1-815- 433-5100, or at their Internet address http://

www.bb-elec.com:

• Telephone Line Surge Protector, model TLSP

• RS-232 Surge Protector, model 232DSP

23

Page 29

RS-232 Communications Restricting System Programming Access

Restricting System Programming Access

To protect against unauthorized access to system operation, two security features can be enabled. These switches are

located on the Power Supply Board next to the power wiring terminals (see Figure 16 below). Consoles are shipped from

the factory with all switches in the open position.

SERIAL SECURITY

Enabling Switch position 1 allows the operator to enter a 6-digit security code before the system will respond to a serial

command. The default serial security code is 000000. The security code itself can be changed with a serial command.

However, the serial security code switch must be reset to the Open position to inhibit the security code requirement.

SETUP SECURITY

A switch in the console can be set to prevent access to the setup and diagnostic menus after initial programming. Closing

or turning on Switch position 4 inhibits use of the setup and diagnostic menus.

COMM

1 2 3 4

Security

OPEN

Security switches

(shown enabled)

SETUP

DIP SWITCH SETTINGS

In Figure 16 above, rocker switches 1 and 4 are shown in the closed (enabled) position. Switch 1 is Communications;

Switch 4 is Setup and Diagnostics. To inhibit a function, press the left side of the switch down to the Open position.

Switch 2 and Switch 3 are not used and can be in any position.

(Switches 2 & 3

are not used)

Setup

consoles\tlshld\dipswitch.eps

Figure 16. Console Dip Switch Settings

RS-232 Serial Communication Setup

• Interface mode type: printer, modem, serial; default serial

• Baud rate options: 300, 600, 1200, 2400, 4800, 9600; default 9600

• Parity options: None, Odd, or Even; default None

• Data length options: 8 or 7; default 8

• Number of stop bits options: 1 or 2; default 1

• Handshaking options: None, XON/XOFF, or Hardware; default XON/XOFF

• Printer page eject options: Yes or No; default No

• Answer On options: 0 to 9; default 1

24

Page 30

RS-232 Communications DB-9 Connector Pin-Outs

• Serial Language options: English; default English

• Veeder-Root RS-232 command protocol format. For more information on the command format, consult the Veeder-

Root Serial Interface Manual.

DB-9 Connector Pin-Outs

Communicating with the Console from a remote computer is done through a RS-232 serial port (DB-9 connector) on the

bottom of the console.

Pin layout to connect the Console’s Serial Interface DB-9 connector to a 25-pin computer terminal connector are shown

in Figure 17. These connections are standard for “AT” style modem cables.

Console

(DB-9 Connector)

CD 1 DCD

RXD 2 TXD

TXD 3 RXD

DTR 4 DTR

GND 5 GND

DSR 6 DSR

RTS 7 RTS

CTS 8 CTS

N/C 9 Ring Indicator

consoles\tls50\\rs-232.eps

Computer Terminal

(DB-25 Connector)

8

2

3

20

7

6

4

5

22

Figure 17. DB9, RS-232 Pin-Outs

25

Page 31

RS-232 Commands

TLS-HLD RS-232 Serial Commands

001 System Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 27

003 Remote Alarm Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 28

201 In-Tank Inventory Report . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 29

205 In-Tank Status Report . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 30

504 Set RS-232 Security Code. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 31

50C Set Printer Page Eject Enable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 32

517 Set Units of Measurement and Language (ext. lang. set) . . . . . . . . . . . . . . . . . . . . . page 33

601 Set Tank Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 34

608 Set Tank Tilt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 35

881 Set Communication Port Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 36

882 Initialize Communication Port Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 37

883 Set Communication Port Language. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 38

884 Set Serial Port Handshaking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 39

902 System Revision Level Report . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 40

A01 Probe Type and Serial Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 41

A02 Probe Calibration Values. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 42

A10 Probe Last Sample Buffers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 43

A11 Probe Fast Average Buffers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 44

A12 Probe Standard Average Buffers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 45

26

Page 32

RS-232 Commands Function Code: 001

Function Code: 001

Function Type: System Reset Version 1

Command Format:

Display: <SOH>S00100

Computer: <SOH>s00100

Typical Response Message, Display Format:

<SOH>

S00100

<ETX>

Typical Response Message, Computer Format:

<SOH>s001000000000000&&CCCC<ETX>

Notes:

1. 0000000000 - Not Used.

2. && - Data Termination Flag

3. CCCC - Message Checksum

27

Page 33

RS-232 Commands Function Code: 003

Function Code: 003

Function Type: Remote Alarm Reset Version 1

Command Format:

Display: <SOH>S00300

Computer: <SOH>s00300

Typical Response Message, Display Format:

<SOH>

S00300

<ETX>

Typical Response Message, Computer Format:

<SOH>s0030000000000&&CCCC<ETX>

Notes:

1. 0000000000 - Not Used

2. && - Data Termination Flag

3. CCCC - Message Checksum

28

Page 34

RS-232 Commands Function Code: 201

Function Code: 201

Function Type: In-Tank Inventory Report Version 1

Command Format:

Display: <SOH>I201TT

Computer: <SOH>i201TT

Typical Response Message, Display Format:

<SOH>

I201TT

TANK HEIGHT WATER TEMP

1 48.9 0.0 37.3

<ETX>

Typical Response Message, Computer Format:

<SOH>i201TT0000000000TT0ssssNNFFFFFFFF...

TTpssssNNFFFFFFFF...&&CCCC<ETX>

Notes:

1. 0000000000 - Unused

2. TT - Tank Number (Decimal, 00 = all)

3. 0 - Unused

4. ssss - Tank Status Bits:

Bit 1 - (LSB) Unused

Bit 2 - Unused

Bit 3 - Invalid Fuel Height Alarm (MAG Probes Only)

Bit 4-16 - Unused

5. NN - Number of eight character Data Fields to follow (Hex)

6. FFFFFFFF - ASCII Hex IEEE float:

1. Unused

2. Unused

3. Unused

4. Height

5. Water

6. Temperature

7. Unused

7. && - Data Termination Flag

8. CCCC - Message Checksum

29

Page 35

RS-232 Commands Function Code: 205

Function Code: 205

Function Type: In-Tank Status Report Version 1

Command Format:

Display: <SOH>I205TT

Computer: <SOH>i205TT

Typical Response Message, Display Format:

<SOH>

I205TT

TANK STATUS

1 ALL FUNCTIONS NORMAL

<ETX>

Typical Response Message, Computer Format:

<SOH>i205TT0000000000TTnnAA...

TTnnAA&&CCCC<ETX>

Notes:

1. 0000000000 - Unused

2. TT - Tank Number (Decimal, 00 = all)

3. nn - Number of alarms active for tank (Hex, 00 = none)

4. AA - Active tank alarm type:

01 = Unused

02 = Unused

03 = Unused

04 = Unused

05 = Tank Low Product Alarm

06 = Unused

07 = Unused

08 = Unused

09 = Tank Probe Out Alarm

10 = Unused

11 = Unused

12 = Unused

13 through 26 = Unused

27 = Tank Low Temperature Warning

5. && - Data Termination Flag

6. CCCC - Message Checksum

30

Page 36

RS-232 Commands Function Code: 504

Function Code: 504

Function Type: Set System (RS-232) Security Code Version 1

Command Format:

Set:

Display: <SOH>S50400aaaaaa Display: <SOH>I50400

Computer: <SOH>s50400aaaaaa Computer: <SOH>i50400

Typical Response Message, Display Format:

<SOH>

I50400

aaaaaa

<ETX>

Typical Response Message, Computer Format:

<SOH>i504000000000000aaaaaa&&CCCC<ETX>

Notes:

1. 0000000000 - Not Used.

2. aaaaaa - Current Security Code (6 ASCII characters from 20 Hex - 7E Hex)

3. && - Data Termination Flag

4. CCCC - Message Checksum

Inquire:

31

Page 37

RS-232 Commands Function Code: 50C

Function Code: 50C

Function Type: Set Remote Printer Page Eject Flag Version 1

Command Format:

Set:

Display: <SOH>S50C00f Display: <SOH>I50C00

Computer: <SOH>s50C00f Computer: <SOH>i50C00

Typical Response Message, Display Format:

<SOH>

I50C00

f

<ETX>

Typical Response Message, Computer Format:

<SOH>i50C000000000000f&&CCCC<ETX>

Notes:

1. 0000000000 - Not Used

2. f - Page Eject Flag:

0 = Disabled

1 = Enabled

3. && - Data Termination Flag

4. CCCC - Message Checksum

Inquire:

32

Page 38

RS-232 Commands Function Code: 517

Function Code: 517

Function Type: Set System Type & Language Flags Version 1

Command Format:

Set:

Display: <SOH>S51700ULL Display: <SOH>I51700

Computer: <SOH>s51700ULL Computer: <SOH>i51700

Typical Response Message, Display Format:

<SOH>

I51700

U

LL

<ETX>

Typical Response Message, Computer Format:

<SOH>i517000000000000ULL&&CCCC<ETX>

Notes:

1. 0000000000 - Not Used.

2. U - System Units:

1 = U.S

2 = Metric

3. LL - System Language:

1 = English

2 = French

3 = Spanish

4 = Not Used

5 = Portuguese

6 = Not Used

7 = Not Used

8 = Not Used

9 = Not Used

10 = Not Used

11 = Not Used

12 = Not Used

13 = Not Used

14 = Not Used

15 = Chinese

4. && - Data Termination Flag

5. CCCC - Message Checksum

Inquire:

33

Page 39

RS-232 Commands Function Code: 601

Function Code: 601

Function Type: Set Tank Configuration Version 1

Command Format:

Set:

Display: <SOH>S601TTf Display: <SOH>I601TT

Computer: <SOH>s601TTf Computer: <SOH>i601TT

Typical Response Message, Display Format:

<SOH>

I601TT

f

<ETX>

Typical Response Message, Computer Format:

<SOH>i601TT0000000000TTf...

TTf&&CCCC<ETX>

Notes:

1. 0000000000 - Not Used

2. TT - Tank Number (Decimal, 00 = all)

3. f - Tank Configuration Flag:

0 = Off

1 = On

4. && - Data Termination Flag

5. CCCC - Message Checksum

Inquire:

34

Page 40

RS-232 Commands Function Code: 608

Function Code: 608

Function Type: Set Tank Tilt Version 1

Command Format:

Set:

Display: <SOH>S608TTHHH.HH Display: <SOH>I608TT

Computer: <SOH>s608TTFFFFFFFF Computer: <SOH>i608TT

Notes:

1. TT - Tank Number (Decimal, 00 = all)

2. HHH.HH - Tank Tilt, (Decimal)

3. FFFFFFFF - Tank Tilt, (ASCII Hex IEEE float)

Typical Response Message, Display Format:

<SOH>

I608TT

TT HHH.HH

<ETX>

Typical Response Message, Computer Format:

<SOH>i608TT0000000000TTFFFFFFFF...

TTFFFFFFFF&&CCCC<ETX>

Notes:

1. 0000000000 - Not Used.

2. TT - Tank Number (Decimal, 00 = all)

3. FFFFFFFF - Tank Tilt, (ASCII Hex IEEE float)

4. && - Data Termination Flag

5. CCCC - Message Checksum

Inquire:

35

Page 41

RS-232 Commands Function Code: 881

Function Code: 881

Function Type: Set Communication Port Data Version 1

Command Format:

Set:

Display: <SOH>S881CCBBBBBPSDTAA Display: <SOH>I881CC

Computer: <SOH>s881CCBBBBBPSDTAA Computer: <SOH>i881CC

Typical Response Message, Display Format:

<SOH>

I881CC

CC BBBBB P S D T AA

<ETX>

Typical Response Message, Computer Format:

<SOH>i881CC0000000000CCBBBBBPSD0AA&&CCCC<ETX>

Notes:

1. 0000000000 - Not Used

2. CC - Communication Port Number (1)

3. BBBBB - Baud Rate (Decimal)

4. P - Parity (Decimal; 0=None, 1 or 2)

5. S - Stop Bit (Decimal; 1 or 2)

6. D - Data Bit (Decimal; 7 or 8)

7. 0 - Not Used

8. AA - Number of Rings before Answer (Decimal, 0 - 9)

9. && - Data Termination Flag

10. CCCC - Message Checksum

Inquire:

36

Page 42

RS-232 Commands Function Code: 882

Function Code: 882

Function Type: Initialize Communication Port Data Version 1

Command Format:

Set:

Display: <SOH>S882CC149 Display: <SOH>I882CC

Computer: <SOH>s882CC149 Computer: <SOH>i882CC

Notes:

1. 149 - This verification code must be sent to confirm the command

Typical Response Message, Display Format:

<SOH>

I882CC

CC BBBBB P S D T AA

<ETX>

Typical Response Message, Computer Format:

<SOH>i882CC0000000000CCBBBBBPSD0AA&&CCCC<ETX>

Notes:

1. 0000000000 - Not Used.

2. CC - Communication Port Number (1)

3. BBBBB - Baud Rate (Decimal)

4. P - Parity (Decimal; 0= None, 1 or 2)

5. S - Stop Bit (Decimal; 1 or 2)

6. D - Data Bit (Decimal; 7 or 8)

7. 0 - Not Used

8. AA - Number of Rings before Answer (Decimal)

9. && - Data Termination Flag

10. CCCC - Message Checksum

Inquire:

37

Page 43

RS-232 Commands Function Code: 883

Function Code: 883

Function Type: Set Serial Communication Language Version 1

Command Format:

Set:

Display: <SOH>S88300LL Display: <SOH>I88300

Computer: <SOH>s88300LL Computer: <SOH>i88300

Typical Response Message, Display Format:

<SOH>

I88300

LL

<ETX>

Typical Response Message, Computer Format:

<SOH>i883000000000000LL&&CCCC<ETX>

Notes:

1. 0000000000 - Not Used

2. LL - System Language:

1 = English

2 = French

3 = Spanish

4 = Not Used

5 = Portuguese

6 = Not Used

7 = Not Used

8 = Not Used

9 = Not Used

10 = Not Used

11 = Not Used

12 = Not Used

4. && - Data Termination Flag

5. CCCC - Message Checksum

Inquire:

38

Page 44

RS-232 Commands Function Code: 884

Function Code: 884

Function Type: Set Serial Handshaking Version 1

Command Format:

Set:

Display: <SOH>S88400f Display: <SOH>I88400

Computer: <SOH>s88400f Computer: <SOH>i88400

Typical Response Message, Display Format:

<SOH>

I88400

f

<ETX>

Typical Response Message, Computer Format:

<SOH>i884000000000000f&&CCCC<ETX>

Notes:

1. 0000000000 - Not Used

2. f - Handshaking method:

0 = Disabled

1 = Hardware

2 = XON/XOFF

3. && - Data Termination Flag

4. CCCC - Message Checksum

Inquire:

39

Page 45

RS-232 Commands Function Code: 902

Function Code: 902

Function Type: System Revision Level Report Version 1

Command Format:

Display: <SOH>I90200

Computer: <SOH>i90200

Typical Response Message, Display Format:

<SOH>

I90200

SOFTWARE# 349787-vvv-rrr B

CREATED - YY.MM.DD.HH.mm

<ETX>

Typical Response Message, Computer Format:

<SOH>i902000000000000SOFTWARE# 347871-vvv-rrrCREATED YY.MM.DD.HH.mm&&CCCC<ETX>

Notes:

1. 0000000000 - Not Used

2. vvv - Software version number (ASCII text string)

3. rrr - Software revision level (ASCII text string)

4. YY.MM.DD.HH.mm - Date and time of software creation

5. && - Data Termination Flag

6. CCCC - Message Checksum

7. Unused

8. B = 2 (Serial Package installed)

40

Page 46

RS-232 Commands Function Code: A01

Function Code: A01

Function Type: Probe Type and Serial Number Version 1

Command Format:

Display: <SOH>IA01TT

Computer: <SOH>iA01TT

Typical Response Message, Display Format:

<SOH>

IA01TT

TT PP KKKK LLLL.LL SSSSSS cccc

<ETX>

Notes:

1. TT - Tank Number (Decimal, 00 = all)

2. PP - Probe Type: - MAG1

3. LLLL.LL - Probe Length (Decimal)

4. SSSSSS - Probe Serial Number (Decimal)

5. cccc - Probe Date Code (Hex)

Typical Response Message, Computer Format:

<SOH>iA01TT0000000000TT0PPKKKKFFFFFFFFSSSSSScccc...

TT0PPKKKKFFFFFFFFSSSSSScccc&&CCCC<ETX>

Notes:

1. 0000000000 - Not Used.

2. TT - Tank Number (Decimal, 00 = all)

3. 0 - Not used

4. PP - Probe Type: 03 = MAG1

5. KKKK - Circuit Code (Hex)

6. FFFFFFFF - Probe Length (ASCII Hex IEEE float)

7. SSSSSS - Probe Serial Number (Decimal)

8. cccc - Probe Date Code (Hex)

9. && - Data Termination Flag

10. CCCC - Message Checksum

41

Page 47

RS-232 Commands Function Code: A02

Function Code: A02

Function Type: Probe Factory Dry Calibration Values Version 1

Command Format:

Display: <SOH>IA02TT

Computer: <SOH>iA02TT

Typical Response Message, Display Format:

<SOH>

IA02TT

TT PP CCC.CCCC

<ETX>

Notes:

1. TT - Tank Number (Decimal, 00 = all)

2. PP - Probe Type: 03 = MAG1

3. CCC.CCCC - Probe Data (Decimal)

Typical Response Message, Computer Format:

<SOH>iA02TT0000000000TT0PPNNFFFFFFFF...

TT0PPNNFFFFFFFF...&&CCCC<ETX>

Notes:

1. 0000000000 - Not Used.

2. TT - Tank Number (Decimal, 00 = all)

3. 0 - Not used

4. PP - Probe Type: 03 = MAG1

5. NN - Number of eight character Data Fields to follow (Hex)

6. FFFFFFFF - Calibration Value (ASCII Hex IEEE float)

7. && - Data Termination Flag

8. CCCC - Message Checksum

42

Page 48

RS-232 Commands Function Code: A10

Function Code: A10

Function Type: Probe Last Sample Buffers Version 1

Command Format:

Display: <SOH>IA10TT

Computer: <SOH>iA10TT

Typical Response Message, Display Format:

<SOH>

IA10TT

TT PP nnnnn

ssss.sss ssss.sss ssss.sss ssss.sss ssss.sss ssss.sss ssss.sss ssss.sss

ssss.sss ssss.sss ssss.sss ssss.sss ssss.sss ssss.sss ssss.sss ssss.sss

ssss.sss ssss.sss ssss.sss ssss.sss ssss.sss ssss.sss ssss.sss ssss.sss

ssss.sss ssss.sss

<ETX>

Notes:

1. TT - Tank Number (Decimal, 00 = all)

2. PP - Probe Type:03 - MAG1

3. nnnnn - Sample Number (Decimal)

4. ssss.sss - Probe Data (Decimal)

Typical Response Message, Computer Format:

<SOH>iA10TT0000000000TT0PPSSSSNNFFFFFFFF...

TT0PPSSSSNNFFFFFFFF...&&CCCC<ETX>

Notes:

1. 0000000000 - Not Used