Page 1

Install, Setup, & Operation Manual

Pressure Management Control

For VST Processors

Manual No: 577013-801 • Revision: E

Page 2

Notice

Veeder-Root makes no warranty of any kind with regard to this publication, including, but not limited to, the implied warranties of

merchantability and fitness for a particular purpose.

Veeder-Root shall not be liable for errors contained herein or for incidental or consequential damages in connection with the furnishing,

performance, or use of this publication.

Veeder-Root reserves the right to change system options or features, or the information contained in this publication.

This publication contains proprietary information which is protected by copyright. All rights reserved. No part of this publication may be

photocopied, modified or translated to another language without the prior written consent of Veeder-Root. Contact TLS Systems

Technical Support for additional troubleshooting information at 800-323-1799.

DAMAGE CLAIMS / LOST EQUIPMENT

Thoroughly examine all components and units as soon as they are received. If any cartons are damaged or missing, write a complete

and detailed description of the damage or shortage on the face of the freight bill. The carrier's agent must verify the inspection and sign

the description. Refuse only the damaged product, not the entire shipment.

Veeder-Root must be notified of any damages and/or shortages within 30 days of receipt of the shipment, as stated in our Terms and

Conditions.

VEEDER-ROOT’S PREFERRED CARRIER

1. Contact Veeder-Root Customer Service at 800-873-3313 with the specific part numbers and quantities that were missing or

received damaged.

2. Fax signed Bill of Lading (BOL) to Veeder-Root Customer Service at 800-234-5350.

3. Veeder-Root will file the claim with the carrier and replace the damaged/missing product at no charge to the customer. Customer

Service will work with production facility to have the replacement product shipped as soon as possible.

CUSTOMER’S PREFERRED CARRIER

1. It is the customer’s responsibility to file a claim with their carrier.

2. Customer may submit a replacement purchase order. Customer is responsible for all charges and freight associated with

replacement order. Customer Service will work with production facility to have the replacement product shipped as soon as

possible.

3. If “lost” equipment is delivered at a later date and is not needed, Veeder-Root will allow a Return to Stock without a restocking fee.

4. Veeder-Root will NOT be responsible for any compensation when a customer chooses their own carrier.

RETURN SHIPPING

For the parts return procedure, please follow the appropriate instructions in the "General Returned Goods Policy” pages in the

"Policies and Literature" section of the Veeder-Root North American Environmental Products price list. Veeder-Root will not accept

any return product without a Return Goods Authorization (RGA) number clearly printed on the outside of the package.

FCC INFORMATION

This equipment complies with the requirements in Part 15 of the FCC rules for a Class A computing device. Operation of this

equipment in a residential area may cause unacceptable interference to radio and TV reception requiring the operator to take whatever

steps are necessary to correct the interference.

INSTALLATION IN THE STATE OF CALIFORNIA

Please refer to the California Air Resources Board Vapor Recover Certification Phase II EVR Executive Order web site

(www.arb.ca.gov/vapor/eo-evrphaseII.htm) for the latest manual revisions pertaining to VR 203 (VST Phase II EVR System).

©Veeder-Root 2012. All rights reserved

.

ii

Page 3

Introduction

Site Requirements ............................................................................................................1

Contractor Certification Requirements ..............................................................................1

Related Manuals ...............................................................................................................2

Safety Precautions ............................................................................................................2

Installation

Installing TLS Console Modules - General Notes .............................................................3

Circuit Directory........................................................................................................4

Vapor Pressure Sensor ....................................................................................................4

Smart Sensor Interface Module ........................................................................................4

NVMEM203 Board ............................................................................................................5

Probe Interface Module ....................................................................................................5

I/O Combination or 4-Relay Module ..................................................................................5

Multiport Card for Vapor Processor Communication ........................................................5

TLS Console with VST ECS Membrane Processor ..........................................................5

Setup

Introduction .......................................................................................................................7

Smart Sensor Setup .........................................................................................................7

Output Relay Setup - VST ECS Membrane Processor & VST Green Machine ................8

PMC Setup .......................................................................................................................9

Table of Contents

Operation

Alarms .............................................................................................................................10

Overview of TLS console Interface.........................................................................10

Warning Posting .....................................................................................................11

Alarm Posting .........................................................................................................11

PMC Alarm Summary .....................................................................................................12

PMC Status Report .........................................................................................................13

Viewing PMC Reports Via RS-232 Connection ..............................................................13

Connecting Laptop to Console ...............................................................................13

Connecting Laptop to Console ...............................................................................14

Sending Console Commands.................................................................................17

Diagnostics

Automatic Control ...........................................................................................................22

Manual control ................................................................................................................22

PMC Diagnostic Menu ....................................................................................................22

iv

Page 4

Figures

Table of Contents

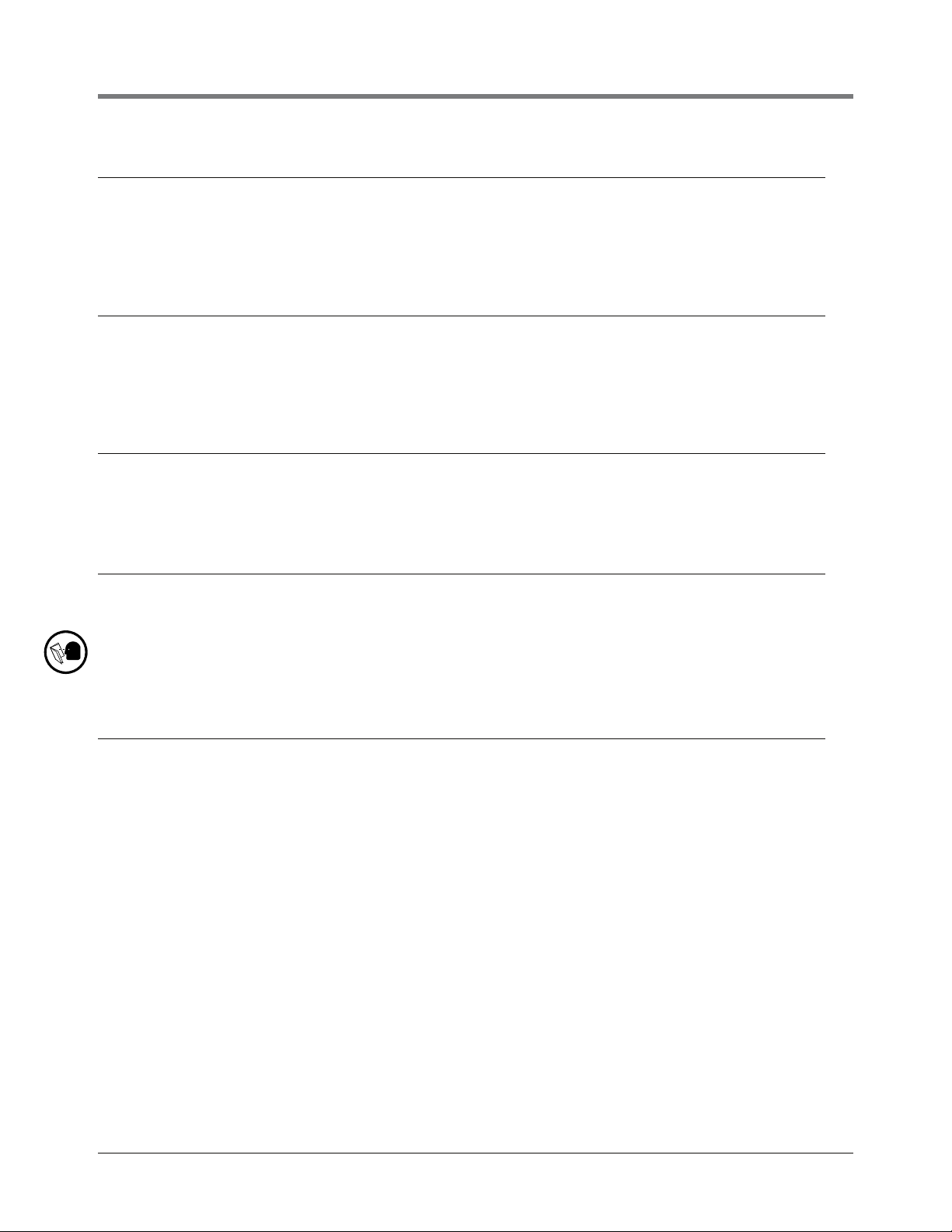

Figure 1. TLS console Interface Module Bays...........................................................3

Figure 2. VST ECS Membrane Processor or VST Green Machine

Connections to TLS Console......................................................................6

Figure 3. Smart Sensor Setup...................................................................................7

Figure 4. Output Relay Setup for VST ECS Membrane Processor...........................8

Figure 5. Output Relay Setup Printout Examples for TLS Console

Controlled Processor..................................................................................8

Figure 6. PMC Setup.................................................................................................9

Figure 7. TLS console alarm interface.....................................................................10

Figure 8. TLS console warning example .................................................................11

Figure 9. TLS console alarm example.....................................................................11

Figure 10. PMC Status Report ..................................................................................13

Figure 11. Connecting laptop to TLS console for serial communication ...................14

Figure 12. Connection Description window ...............................................................15

Figure 13. Connect To window..................................................................................15

Figure 14. Console comm port settings printout example .........................................16

Figure 15. HyperTerminal main window....................................................................17

Figure 16. Vapor Processor Status Report Details - Serial to PC Format.................18

Figure 17. Vapor Processor Runtime Diagnostic Report - Serial to PC Format........19

Figure 18. Percent Hydrocarbon Diagnostic Report - Serial to PC Format...............20

Figure 19. Priority Alarm History Report - Serial to PC Format.................................20

Figure 20. Non-Priority Alarm History Report - Serial to PC Format .........................21

Figure 21. PMC Diagnostic Menus............................................................................22

Tables

Table 1. Related Manuals .......................................................................................2

Table 2. TLS-350 (PMC) Alarm Troubleshooting Summary ..................................12

Table 3. Serial Commands for PMC Diagnostic Reports ......................................18

v

Page 5

Introduction

This manual provides instructions to install, setup, and operate the components of Veeder-Root Pressure

Management Control (PMC) equipment. The PMC feature is an option for the TLS console platform, and as such,

many of the installation/setup/operation instructions for non-PMC specific tasks are covered in TLS-3XX supplied

literature. Do not use this manual when PMC is installed with ISD. Use the ISD Setup & Operation Manual,

577021-800.

Site Requirements

Below are the requirements for all PMC installations:

• V-R TLS-350R/EMC w/BIR, TLS-350 Plus/EMC Enhanced, TLS-350/EMC and ProMax consoles with ECPU2

- install as per TLS-3XX Site Prep manual, setup following instructions in TLS-3XX System Setup Manual.

• A flash memory board (NVMEM203) for PMC software storage - installed on the ECPU2 board in place of the

console’s 1/2 Meg RAM board - install as per TLS-350 Series Board and Software Replacement Manual, no

setup required.

• Smart Sensor Module and Vapor Pressure Sensor. Install and connect following instructions in the Vapor

Pressure Sensor installation Guide.

• Multiport card connected to a hydrocarbon sensor module installed according to processor manufacturers

specifications.

• A 4-Relay or I/O Combination Module to control the vapor processor motor and setup as instructed in this

manual.

• An RS-232 Port will be available for use by contractor or government inspectors.

Contractor Certification Requirements

Veeder-Root requires the following minimum training certifications for contractors who will install and setup the

equipment discussed in this manual:

Installer (Level 1) Certification: Contractors holding valid Installer Certification are approved to perform wiring and

conduit routing; equipment mounting; probe, sensor and carbon canister vapor polisher installation; wireless equipment

installation; tank and line preparation; and line leak detector installation.

ATG Technician (Level 2/3 or 4) Certification: Contractors holding valid ATG Technician Certifications are approved

to perform installation checkout, startup, programming and operations training, system tests, troubleshooting and

servicing for all Veeder-Root Series Tank Monitoring Systems, including Line Leak Detection. In addition, Contractors

with the following sub-certification designations are approved to perform installation checkout, startup, programming,

system tests, troubleshooting, service techniques and operations training on the designated system.

• Wireless 2

•Tall Tank

VR Vapor Products Certification: Contractors holding a certification with the following designations are approved to

perform installation checkout, startup, programming, system tests, troubleshooting, service techniques and operations

training on the designated system.

• ISD – In Station Diagnostics

• PMC – Pressure Management Control

• CCVP - Veeder-Root Vapor Polisher

• Wireless – ISD/PMC Wireless

• A current Veeder-Root Technician Certification is a prerequisite for the VR Vapor Products course.

Warranty Registrations may only be submitted by selected Distributors.

1

Page 6

Introduction Related Manuals

OFF

OFF

Related Manuals

The manuals in Table 1 below are shipped with the equipment on the V-R Tech Docs CD-ROM and will be needed

to install specific equipment.

Table 1. Related Manuals

V-R Manual Part Number

TLS-3XX Site Prep Manual 576013-879

Vapor Pressure Sensor For Vent Stacks Installation Guide

(For Sensor P/N 861190-X0X)

Pressure Sensor Installation Guide

(For Sensor P/N 331946-001)

TLS-3XX Series Consoles System Setup Manual 576013-623

TLS-3XX Series Consoles Operator’s Manual 576013-610

Serial Comm Modules Installation Guide 577013-528

TLS-350 Series Board and Software Replacement Manual 576013-637

577014-019

577013-797

Safety Precautions

The following symbols may be used throughout this manual to alert you to important safety hazards.

ELECTRICITY

High voltage exists in, and is supplied to, the device. A potential

shock hazard exists.

READ ALL RE LATED MANUALS

Knowledge of all related procedures before you begin work is

important. Read and understand

all manuals thoroughly. If you do

not understand a procedure, ask

someone who does.

TURN POWER OFF

Live power to a device creates a

potential shock hazard. Turn Off

power to the device and associated accessories when servicing

the unit.

WAR N ING

Heed the adjacent instructions to

avoid equipment damage or personal injury.

WARNING

The console contains high voltages which can be lethal. It is also connected to

low power devices that must be kept intrinsically safe.

Turn power Off at the circuit breaker. Do not connect the console AC power

supply until all devices are installed.

FAILURE TO COMPLY WITH THE FOLLOWING WARNINGS AND SAFETY

PRECAUTIONS COULD CAUSE DAMAGE TO PROPERTY, ENVIRONMENT,

RESULTING IN SERIOUS INJURY OR DEATH.

2

Page 7

Installation

OFF

console\350rjmods.eps

Intrinsically

Safe Bay

Permissible

Modules

(Limit 8

per console)

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

12 34

I.S. Bay

Slot Numbers

Power Bay

Slot Numbers

Comm Bay

Slot Numbers

Comm Cage*

This section discusses the installation and wiring of the hardware required to enable the TLS console to perform

pressure management of the site’s gasoline vapor processor equipment:

• Vapor Pressure Sensor

• Smart Sensor Interface Module

• NVMEM203 board

• Multiport Card

• 4-Relay or I/O Combination Module

All field wiring, its type, its length, etc., used for TLS console sensors must conform to the requirements outlined in

the Veeder-Root TLS-3XX Site Prep manual (P/N 576013-879) and to additional field wiring requirements

specified in related connected components, such as for Pressure Sensors.

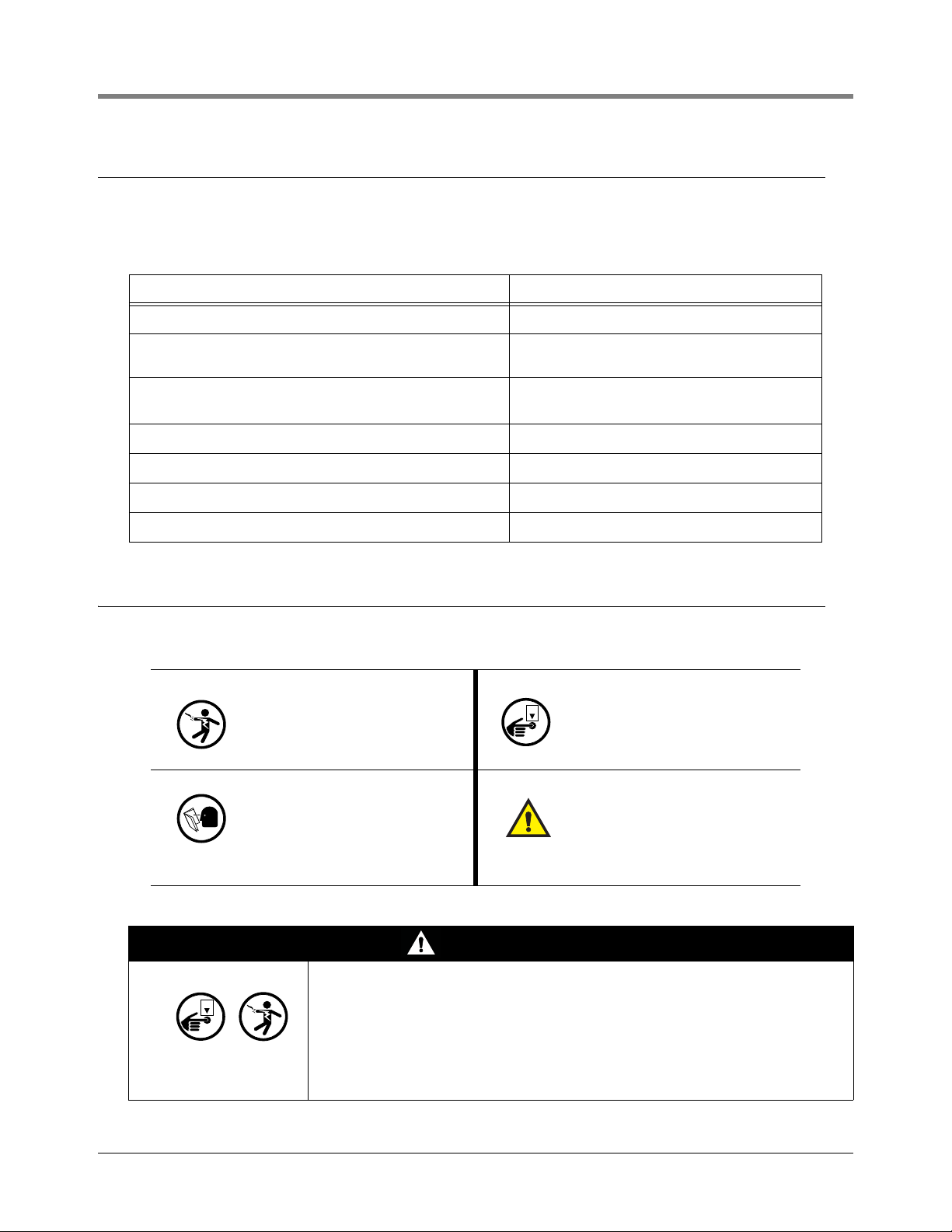

Installing TLS Console Modules - General Notes

TLS consoles have three bays in which interface modules can be installed; Comm bay, Power bay and IntrinsicallySafe bay (ref. Figure 1). Probe Interface modules and Smart Sensor modules are installed in the Intrinsically-Safe

bay and the Mod Bus module is installed in the Comm bay.

In all cases, the position of the modules, their respective connectors and the devices wired to the

connectors must be recorded to prevent improper replacement during installation or service. A circuit

directory for Power and I.S. bay Interface Modules is adhered to the back of the right-hand door for

this purpose.

Switch off power to the TLS console before you install modules and connect sensor wiring.

Figure 1. TLS console Interface Module Bays

3

Page 8

Installation Vapor Pressure Sensor

OFF

CAUTION! During programming, module positions and the devices wired to each module are identified and stored

in memory. If a connector is removed and reinstalled on a different module after programming, or if an entire module

with its connector is removed and reinstalled in a different module slot, the TLS console will not identify correctly

the data being received.

Module Position

1. Record on the circuit directory the type of module in each slot location.

2. If a system contains multiple modules of a single type (i.e., two Smart Sensor Modules), they may be swapped

between their respective slot locations, however, the connectors must remain with their original locations,

not with the original modules.

Connector Position

1. Identify all connectors according to their slot location using the self-adhesive numbering labels furnished with

each module. Accurately record on the circuit directory the location of each device wired to the connector as

you attach wires to the module.

2. Once a device has been wired to certain terminals on a connector and the system has been programmed, the

wires from that device may not be relocated to other terminals without reprogramming the system.

Grounding Probe and Sensor Shields

Connect probe and sensor cable shields to ground at the console only. Do not ground both ends of the shield.

CIRCUIT DIRECTORY

A circuit directory is adhered to the inside of the right-hand door. It should be filled out by the installer as the

module’s connectors are being wired.

The following information should be recorded for each slot:

• Module Type: record what type of module has been installed in the slot, e.g., Smart Sensor Module.

• Position Record: record the physical location and/or type of device wired to each terminal of the module

connector in the slot, e.g., VPS: FP1&2.

Vapor Pressure Sensor

Install one vapor pressure sensor as detailed in the applicable Pressure Sensor Installation Guide shown in Table 1.

Smart Sensor Interface Module

The Smart Sensor Interface Module 8 input or 7 input w/embedded pressure versions monitor the Vapor Pressure

Sensor (VPS) inputs.

Switch off power to the TLS console while you install modules and connect sensor wiring.

Open the right door of the console and slide the necessary Smart Sensor modules into empty I.S. Bay slots.

Connect the field wiring from the sensor following instructions in the Vapor Pressure Sensor manual. Setup the

Smart Sensor module(s) following instructions in this manual.

4

Page 9

Installation NVME M203 Board

NVMEM203 Board

Verify that a NVMEM203 board is installed in the TLS console (ref. Figure 2-7 in the V-R TLS-3XX Series

Consoles Troubleshooting Manual P/N 576013-818, Rev Q or later). This board contains flash EEPROM and

RAM needed to run PMC software. No setup is required.

Probe Interface Module

Verify that a Probe Interface Module(s) is installed (Intrinsically-Safe bay) and that a Mag probe is in each gasoline

tank and is connected to the module(s). Program the Mag probes following instructions in the TLS-3XX System

Setup manual.

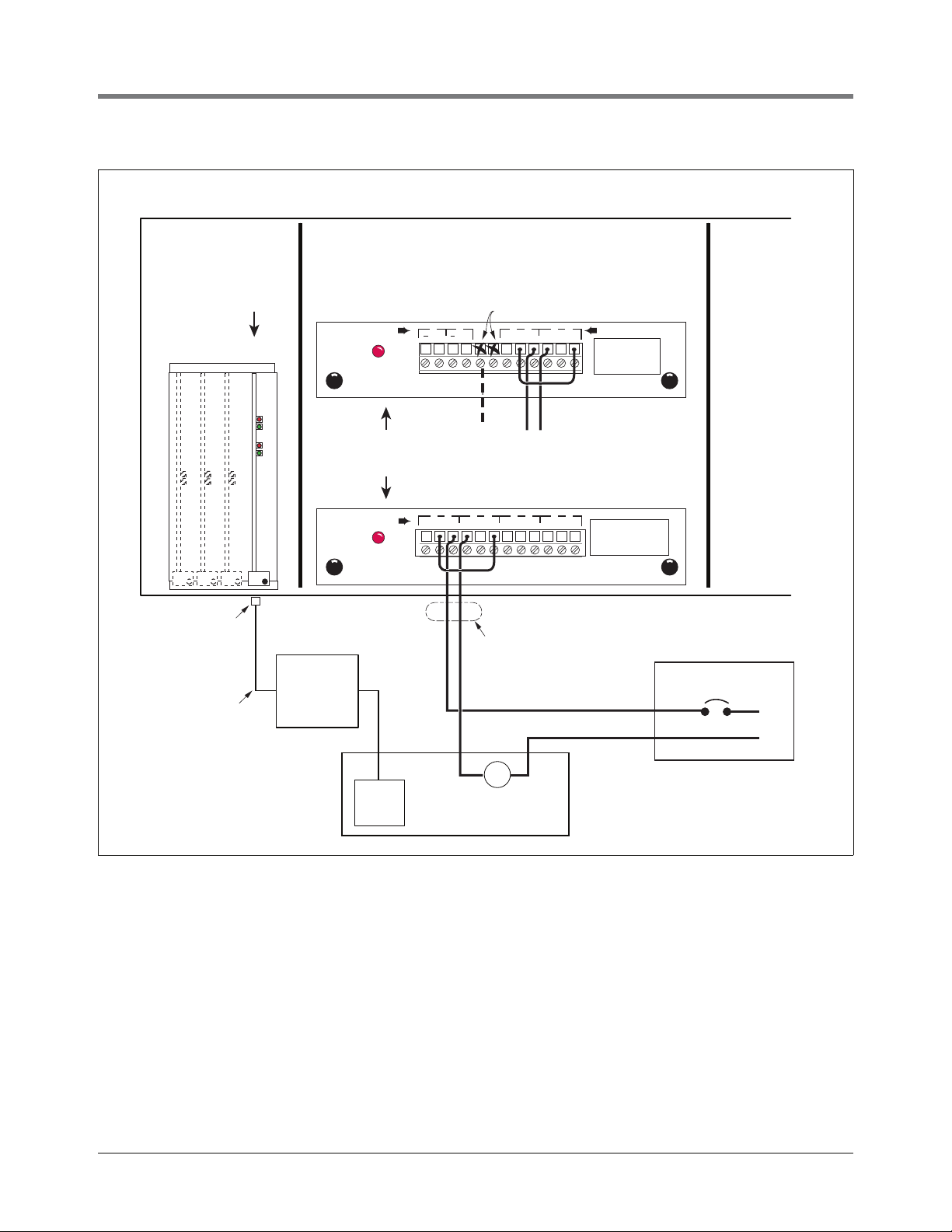

I/O Combination or 4-Relay Module

Connect the vapor processor motor control relay to two relays on either the 4-Relay or I/O Combination module as

shown in Figure 2.

Multiport Card for Vapor Processor Communication

A Multiport card is needed for RS-485 communication with the TLS console and is required with VST ECS

membrane processor installations. Verify that a Multiport card is installed in slot 4 of the card cage in the

communications bay of the TLS console (ref. Figure 2). When installing this card, refer to the V-R Serial Comm

Modules Installation Guide (577013-528) for instructions. Connect this card to the vapor processor as shown in

Figure 2. Program the card as instructed in this manual.

TLS Console with VST ECS Membrane Processor

Figure 2 shows the interconnection wiring between a TLS console and a VST ECS Membrane Processor.

5

Page 10

Installation TLS Console with VST ECS Membrane Processor

Motor Control

Relay

Multiport

Card

HC

Sensor

Modbus

Protocol

RS-485

TLS Console

Power Panel

VST ECS Membrane Processor

and VST Green Machine

RJ-45

Connector

COMMUNICATION BAY

POWER BAY I.S. BAY

RELAY

RELAY RATINGS

Form C Contacts

120 VAC, 2A Max; or

24 VDC, 2A Max.

1 2

4-RELAY OUTPUT MODULE

NC NO C

1

NC NO C

2 3

NC NO C3NC NO C

44

Rigid Conduit (enters

Console through a

Power Bay knockout)

INPUT

RELAY RATINGS

Form C Contacts

120 VAC, 2A Max; or

24 VDC, 2A Max.

I/O COMBINATION MODULE

3

NC NO C3NC NO C

44

+ +

1 2

RELAY

L1

115 Vac Breaker

Wire as shown

on 4-Relay module

N

Not Used

Use either

module

801-5.eps

12 34

HC Sentry

Interface

Module

Figure 2. VST ECS Membrane Processor or VST Green Machine Connections to TLS Console

6

Page 11

Setup

C

Change

B

Backup

E

Enter

S

Step

M

Mode

F

Function

Advance Cursor

Print

T P

1

2

Key press

sequence

Repress until

desired message

appears in display

Key Legend

Tank

Sensor

S

801-7.eps

C

C

E

S

E

S

E

S

P

F

SMARTSENSOR SETUP

PRESS <STEP> TO CO NTINUE

SETUP MODE

PRESS <FUNCTION> TO CONT

M

C

C

Select sensor category

(e.g., Vapor Pressure Sensor)

Press this button and select type.

Note: User can only change assigment

if device has not identified itself. If

actual device disagrees with assigned

type, actual type overrides assigned

type.

The first of the installed SS modules appears

in this display. If this is not the module to

which the Vapor Pressure Sensor (VPS) is

connected, press the Tank/Sensor button to

select another SS module.

Press once and the first position blinks. If

the VPS is connected to the first position of

the SS module, press this button again and

the X changes to a 1.

Press this button and

the X changes to the

number of the VPS

connection (2-8).

Prints out a copy of the

SmartSensor Setup.

See example at right.

Press this button and enter a

label for the sensor, e.g., VP

Sensor.

If the VPS is connected to a position other

than the first, continue to press this button

until the VPS connected position blinks.

SMARTSENSOR SETUP

---------------------S01:VP SENSOR

CATEGORY VAPOR PRESSURE

S1: SELECT SS CATEGORY

UNKNOWN

SS CONFIG - MODULE 1

SLOTX - X X X X X X X X

ENTER SMARTSENSOR LABEL

sX:

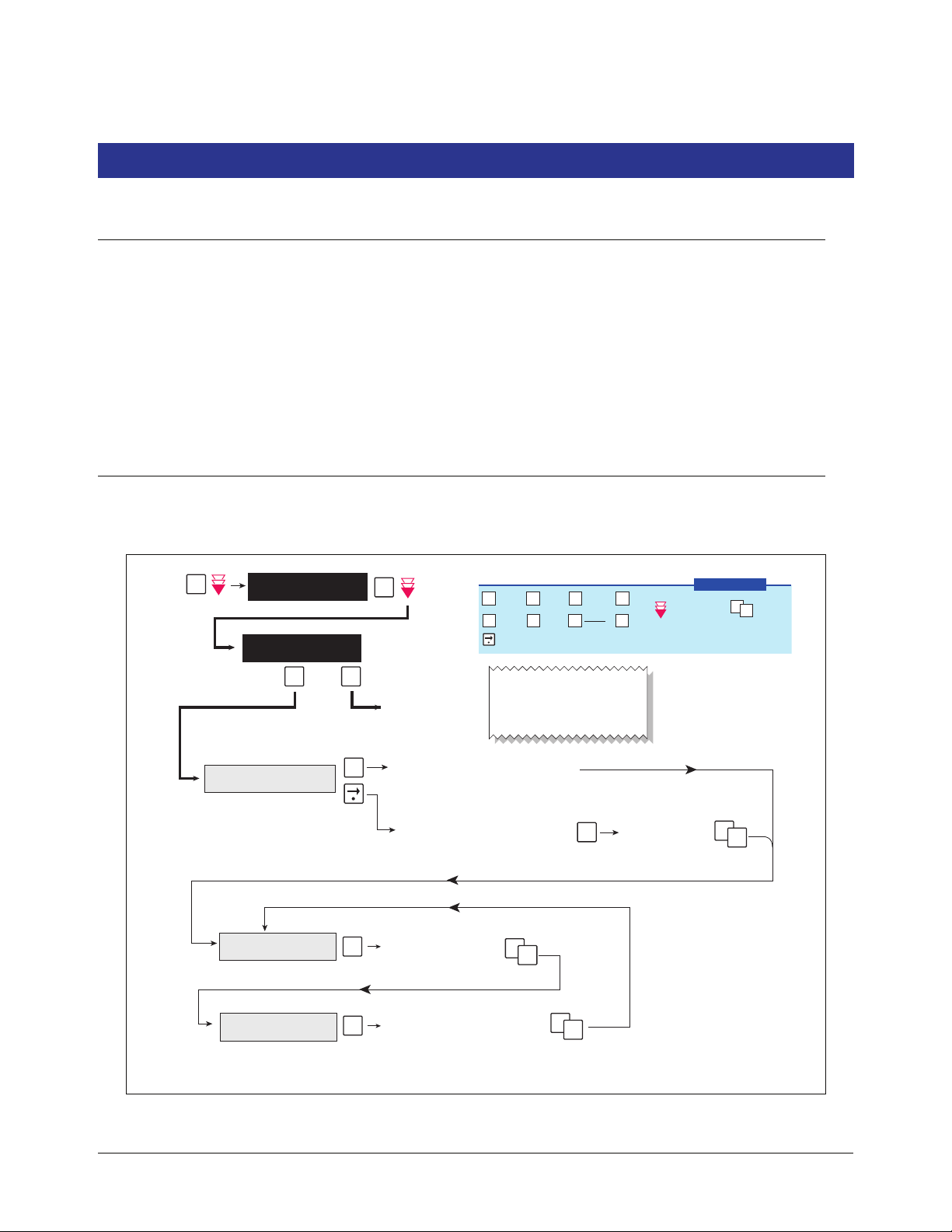

Introduction

This section describes how to perform PMC setup using the TLS console’s front panel buttons and display. The

procedures in this manual follow standard TLS console setup programming input, i.e., keypad/display interaction. If

necessary, refer to Section 2 of the TLS-3XX System Setup manual (P/N 576013-623) to review entering data via

the front panel keypads.

All PMC-related equipment must be installed in the site and connected to the TLS console prior to beginning the

setups covered in this section. As with all TLS connections, you cannot change sensor wiring or module slots after

programming or the console may not operate properly. Reference the section entitled “Connecting Probe/Sensor

Wiring to Consoles” in the TLS-3XX Site Prep and Installation manual (P/N 576013-879) for rewiring precautions.

Smart Sensor Setup

The Smart Sensor Interface Module is installed in the Intrinsically-Safe bay of the TLS console. This module

monitors the Vapor Pressure Sensor. Figure 3 diagrams the Smart Sensor setup procedure.

Figure 3. Smart Sensor Setup

7

Page 12

Setup Output Relay Setup - VST ECS Membrane Processor & VST Green Machine

SETUP MODE

PRESS <FUNCTION> TO C ONT

OUTPUT RE LAY SETU P

PRESS <STEP> TO CO NTINUE

Prints out a copy of the Output Relay Setup entries. See examples in figure below.

In our example R1 is the relay used by PMC to control the processor, R2 is the relay

used to shutoff the processor when the High Product Alarm is active.

M

P

S

S

S

F

ENTER RELAY DESIGNATION

R1 :

R1 : SELE CT RELAY TYPE

STANDARD

R2 : SELE CT RELAY TYPE

STANDARD

R2 : SELE CT TANK

NONE

R1 : SELECT ORIENTATION

NORMALLY OPEN

R2 : SELE CT ORIENTATION

NORMALLY OPEN

R2 : VP SHUTOFF

IN-TANK ALARMS: NO

Press Change

and enter

VAPOR PROCESSOR

for the relay

Note: If using an I/O

Combo Module

there are just 2 slots.

801-6.eps

C

Press Change

and enter

VP SHUTOFF

for the relay

C

C

E

S

E

S

E

S

RELAY CONFIG - MODULE X

SLOT # — X, X, X, X

T

ENTER RELAY DESIGNATION

R2 :

S

S

C

E

S

Vapor Processor

Standard

C

E

S

Standard

Vapor Processor

C

E

S

E

S

Normally Open

Normally Closed

Normally Closed

Normally Open

C

E

S

YES

NO

R2 : IN-TANK ALAR MS

HI PRODUCT: NO TANKS

C

E

S

ALL TANKS

NO TANKS

C

Change

B

Backup

M

Mode

E

Enter

S

Step

F

Function Print

T P

1

2

Key press

sequence

Repress until

desired message

appears in display

Key Legend

Tank

Sensor

Press once and

the 2nd X changes

to a 2.

C C

Press once and the first

position blinks, press

again and the X changes

to a 1.

Press once and

the second

position blinks

OUTPUT RELAY SETUP

----------------------

R 1: VAPOR PROCESSOR

TYPE:

VAPOR PROCESSOR

NORMALLY OPEN

- NO ALARM ASSIGNMENTS -

OUTPUT RELAY SETUP

----------------------

R 2: VP SHUTOFF

TYPE:

STANDARD

NORMALLY CLOSED

IN-TANK ALARMS

ALL HIGH PRODUCT ALARMS

isd-evr\ortlscntrlvpsetprt.eps

Output Relay Setup - VST ECS Membrane Processor & VST Green Machine

The Output Relay setup programs an output relay so that the TLS console can switch a controlled vapor processor

on and off as shown in Figure 4.

Figure 5 shows example setup printouts of the Output Relays setup.

Figure 5. Output Relay Setup Printout Examples for TLS Console Controlled Processor

Figure 4. Output Relay Setup for VST ECS Membrane Processor

8

Page 13

Setup PMC Setup

PMC SETUP

PRESS <STEP> TO CONTIN UE

SETUP MODE

PRESS <FUN CTION> TO CONT

VAPOR PROCESSOR TYPE

NONE

INCHES -0.20

INCHES -0.60

M

P

F

TURN OFF VAPOR PROCESSOR

TURN ON VAPOR PROCESSOR

HYDROCARBON SELECT

PRESS <ENTER>

DUTY CYCLE LIMIT

xx.xx %

SET ANALYSIS TIME

PRESS <ENTER>

S

SET TEST START TIME

TIME: hh:mm

SET POST DELAY DURATION

DELAY MINUTES: mmm

801-4.eps

PMC SETUP

---------------------PMC VERSION: 01.04

VAPOR PROCESSOR TYPE

VST ECS PROCESSOR

PROCESSOR CONTROL LEVEL:

FULL

ON: -0.200 INCHES

OFF:-0.600 INCHES

OVER PRESSURE LIMIT

xx.xx PERCENT%

EFFLUENT EMISSIONS LIMIT

0.649 LB/1KG

DUTY CYCLE LIMIT

xx.xx

ANALYSIS TIMES

TIME 11:59 PM

DELAY MINUTES 1

Prints out a copy of the

PMC Setup entries. See

Example at right.

Range checking is enforced:

0<xx.xx<100

Default: 75%

S

C

S

S

S

S

S

S

E

E

Sets vapor processor Off point.

Range: -8<Off setting<On setting.

For more info see example at right.

VST ECS PROCESSOR

VST GREEN MACHINE

Sets vapor processor On point.

Range: Off setting<On setting<+3.

For more info see example at right.

Vapor Processor On/Off example

P/V valve opens

Absolute

Range

(IWC)

Ullage vapor pressure

+3

-8

+0.2

-0.2

0

Turn On

vapor processor

Turn Off

vapor processor

Use <ENTER> key to make selection

MODBUS Sensor default enabled

This menu appears for

VST ECS Membrane

Processor only

Use <CHANGE> key to enter.

Default Start time - 11:59 PM

Use <CHANGE> key to enter.

0<delay<=720

Default: =001

NOTE: If delay minutes = 0, the results

will be posted as soon as they become

available, else mmm minutes after start

time.

Data collected 5 minutes before the

Start of Test time is omitted from test.

C

Change

B

Backup

M

Mode

E

Enter

S

Step

F

Function Print

T P

1

2

Key press

sequence

Repress until

desired message

appears in display

Key Legend

Tank

Sensor

S

VST ECS Membrane

Processor only

ECS Membrane

Green Machine

+0.20

+0.20

-0.20

-2.00

Processor turn on turn off

E C

E

S

Press Tank to view the next pressure

sensor, change status as required.

T

S

PRESSURE SENSOR SELECT

PRESS <ENTER>

LABEL: (PS label)

SN#: (10 char) DISABLED

LABEL: (PS label)

SN#: (10 char) ENABLE D

S

NONE

PMC Setup

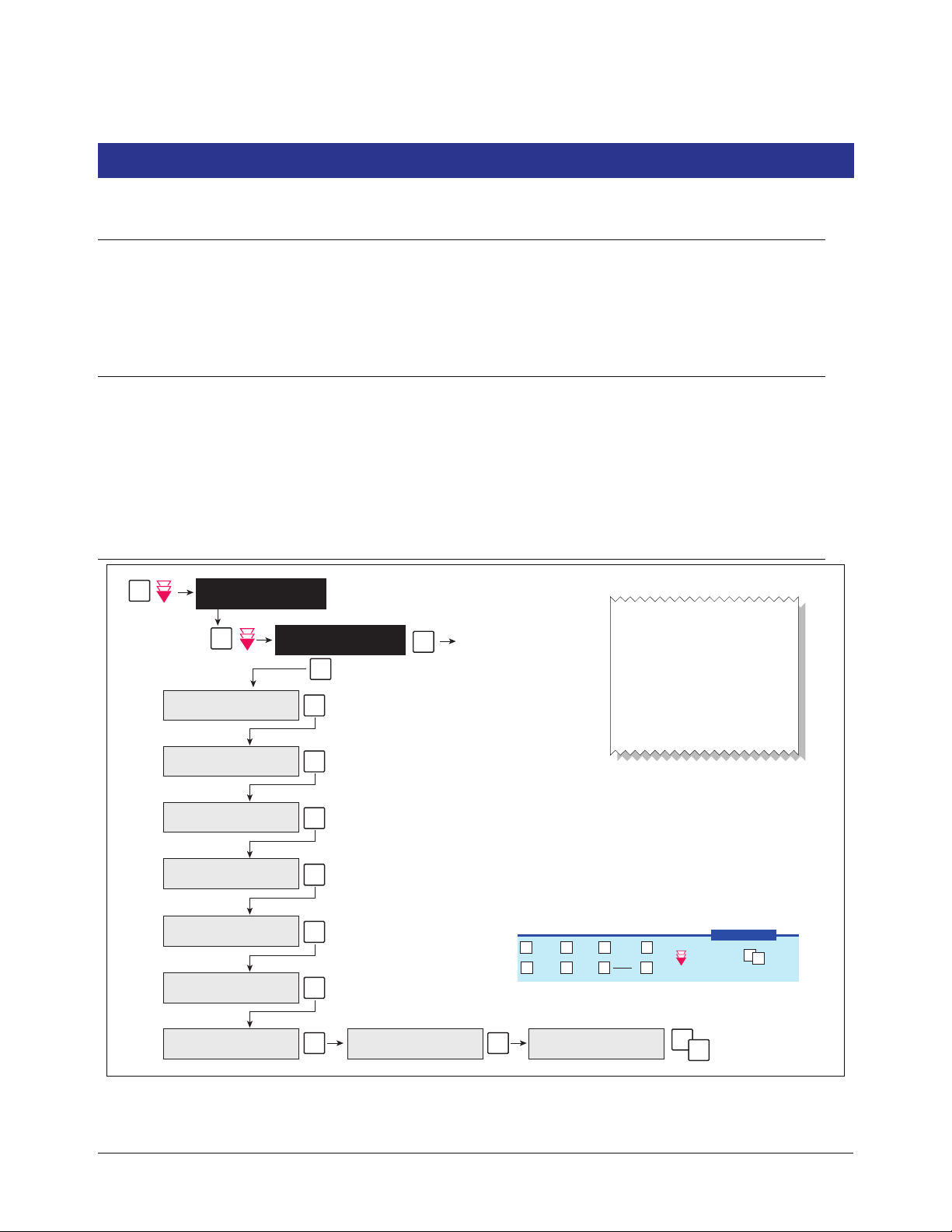

Figure 6 diagrams the PMC setup programming.

Figure 6. PMC Setup

9

Page 14

Operation

MODE

BACKUP

FUNCT-

TION

PRINT CHANGE STEP

PAPER

FEED

ENTER

QZ.

ABC

DEF

GHI JKL MNO

PRS TUV WXY

ALARM

TEST

TANK

SENSOR

,

+/-

0

789

123

456

consoles\qh\1.eps

ALARM

WARNING

POWER

16-01-98 11:23:17 AM

ALL FUNCTIONS NORMAL

Liquid Crystal Display

(showing normal operating display)

Alarm Indicator Light

Warning Indicator Light

Power Indicator Light

Operating Keys Alphanumeric Keys

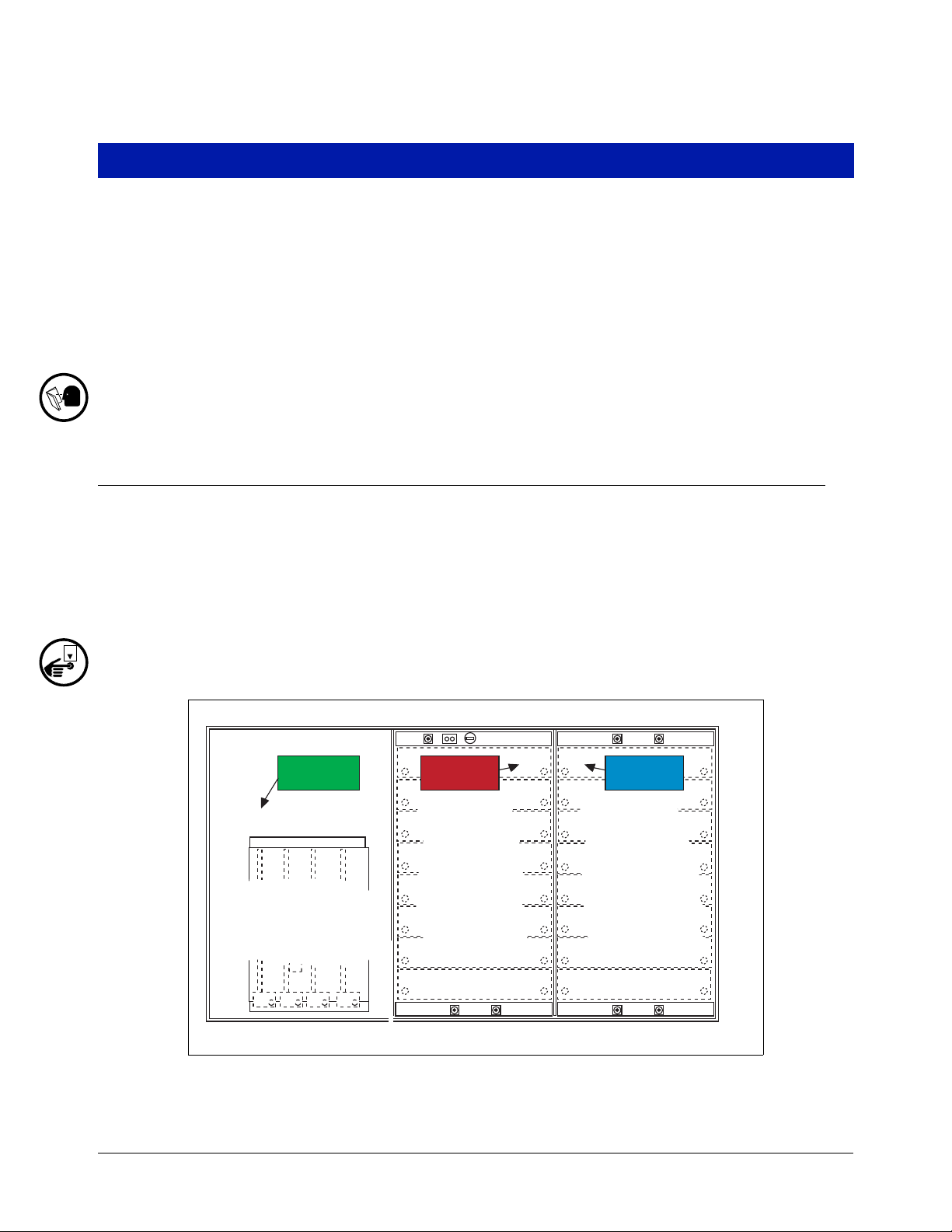

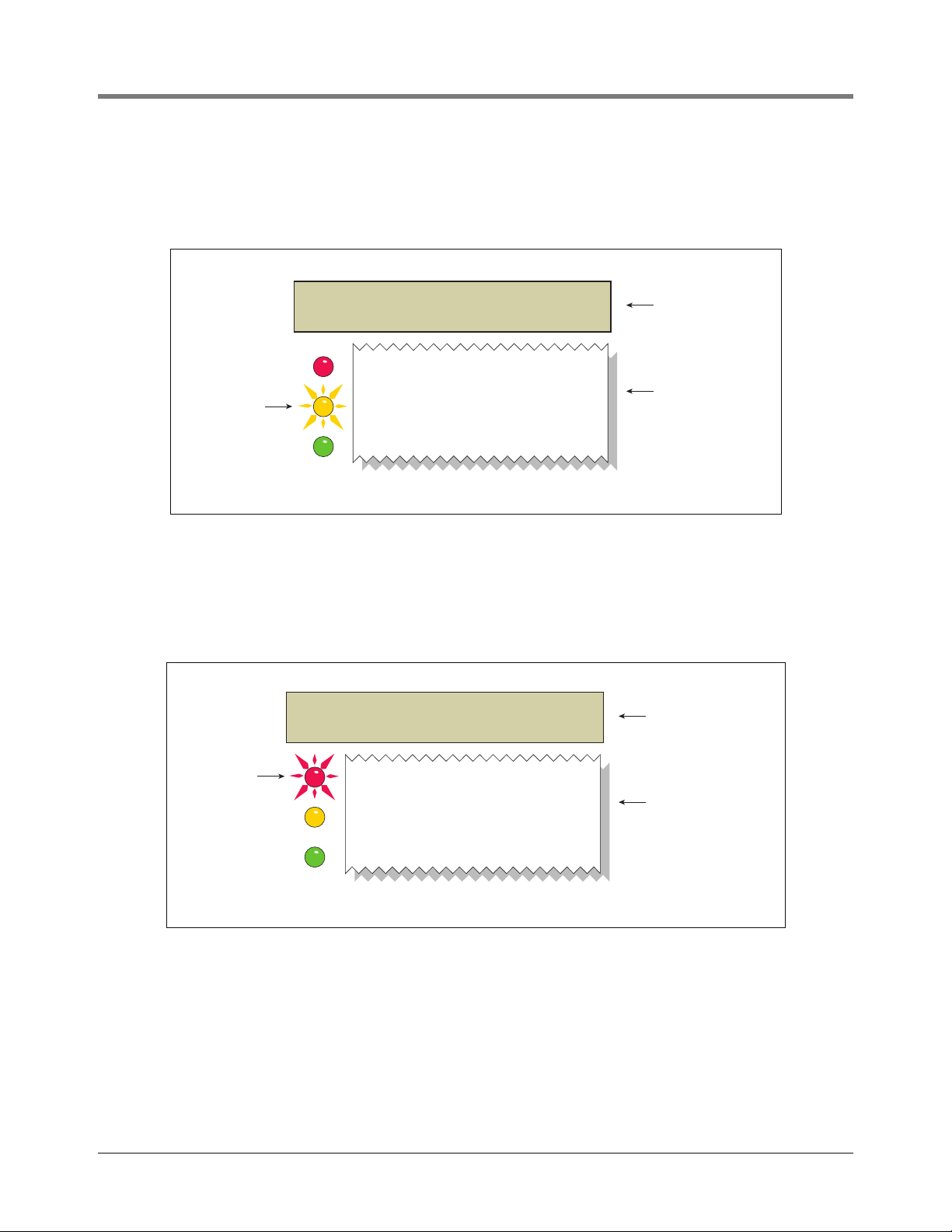

Alarms

OVERVIEW OF TLS CONSOLE INTERFACE

The TLS console is continuously monitoring the vapor recovery system and PMC sensors for alarm conditions.

During normal operation when the TLS console and monitored PMC equipment is functioning properly and no

alarm conditions exist, the "ALL FUNCTIONS NORMAL" message will appear in the system status (bottom) line

of the console display, and the green Power light will be On (see Figure 7).

If an alarm condition occurs the system displays the condition type and its location. If more than one condition

exists, the display will continuously cycle through the appropriate alarm messages. The system automatically prints

an alarm report showing the alarm type, its location and the date and time the alarm condition occurred.

Warning and alarm posting causes the TLS console-based system to activate warning or failure indicator lights, an

audible alarm, and an automatic strip paper printout documenting the warning or alarm.

Figure 7. TLS console alarm interface

10

Page 15

Operation Alarms

WARNING POSTING

Displayed messages alert you to the type of warning. Printed messages show the type of warning and the time the

warning was posted (see Figure 8). Warnings are logged into the Non-Priority Alarm History in the TLS.

MMM DD, YYYY HH:MM XM

VP EMISSIONS WARN

TLS console

display message

---- PMC ALARM --- VP EMISSIONS WARN

TLS console

warning light

flashes

Figure 8. TLS console warning example

MMM DD, YYYY HH:MM XM

isd-evr\pmc\fig5.eps

TLS console

printout message

ALARM POSTING

Displayed Messages alert you to the type of alarm. Printed messages show the type of alarm and the time the

alarm was posted. Alarm example in Figure 9. PMC Alarms are logged into the Priority Alarm History in the TLS.

MMM DD, YYYY HH:MM XM

VP EMISSIONS FAIL

TLS console

display message

TLS console

alarm light

flashes

---- PMC ALARM --- VP EMISSIONS FAIL

MMM DD, YYYY HH:MM XM

Figure 9. TLS console alarm example

11

isd-evr\pmc\fig6.eps

TLS console

printout message

Page 16

Operation PMC Alarm Summary

PMC Alarm Summary

Table 2 contains a listing of the PMC generated alarms including their displayed message and cause. TLS

Console PMC alarms may be interspersed amongst non-PMC alarms, please see TLS-350 Series manuals for

more information.

Table 2. TLS-350 (PMC) Alarm Troubleshooting Summary

Displayed Message Description

VP EMISSION WARN Mass emission exceeded the certified

VP EMISSION FAIL 2nd Consecutive mass emission

PMC SETUP FAIL PMC is not configured or missing

VP DUTY CYCLE WARN

VP DUTY CYCLE FAIL

PMC SE NSOR FAULT Component used by PMC has failed

1

daily threshold

failure

components.

1

Duty cycle exceeds 18 hours per day

0r 75% of 24 hours

2nd Consecutive Duty Cycle Failure Red

or reported an error condition. See

Troubleshooting section for complete

description of sensors and associated

conditions that can cause a sensor

fault.

Light

Indicator Suggested Troubleshooting

Yellow • Troubleshooting Guide

Red

Red • Troubleshooting Guide

Yellow • Troubleshooting Guide

Red Check for Smart Sensor Device

www.vsthose.com.

• Exhibit 8

• Exhibit 9

www.vsthose.com

• See ISD Troubleshooting Guide,

P/N 577013-819

• Exhibit 8

• Exhibit 9

www.vsthose.com.

• TLS-350 PMC Setup Procedure

• Exhibit 4

• Exhibit 9

• Exhibit 10

Alarm or Fault.

1

VST ECS Membrane Processor Only

12

Page 17

Operation PMC Status Report

PMC VERSION 01.04

PRESS <STEP> TO CONTINUE

MMM:DD, YYYY HH:MM:SS XM

ALL FUNCTIONS NORMAL

EFFLUENT EMISSIONS TEST

STATUS: PASS

VP DUTY CYCLE TEST

STATUS: PASS

801-8.eps

Prints out a copy of the

PMC Status report.

See example at right.

ECS Membrane

Processor Only

ECS Membrane

Processor Only

PMC STATUS

---------------------PMC VERSION: 01.04

EFFLUENT EMISSIONS TEST

0.000 LB/1KG PASS

VP DUTY CYCLE TEST

STATUS: 0.00% PASS

P

F

PMC STATUS

PRESS <STEP> TO CONTINUE

C

Change

B

Backup

E

Enter

S

Step

M

Mode

F

Function

Print

T P

1

2

Key press

sequence

Repress until

desired message

appears in display

Key Legend

Tank

Sensor

S

S

S

PMC Status Report

Viewing PMC Reports Via RS-232 Connection

CONNECTING LAPTOP TO CONSOLE

Connect your laptop to the TLS console’s RS-232 or Multiport card using one of the methods shown in the

examples in Figure 11 below.

Figure 10. PMC Status Report

13

Page 18

Operation Viewing PMC Reports Via RS-232 Connection

ALARM

WARNING

POWER

TLS Console

RS-232 card (DB25 female)

(Slots 1, 2, or 3)

DB25

male

DB9

male

Multiport card (DB9 female)

(Slot 4)

ATEN USB to

See table below

for cable requirements

OR

DB9

female

OR

DB9 serial adapter**

DB9 male

USB male

OR

Cable** Requirements for

Terminal Mode Connection to TLS

Connector at Connector at

PC (DTE) TLS (DTE) Null Modem

DB9 DB9 male Required

DB9 DB25 male Not required

DB25 DB9 male Not required

DB25 DB25 male Required

Figure 11. Connecting laptop to TLS console for serial communication

CONNECTING LAPTOP TO CONSOLE

DB25

DB9

DB25

OR

**Customer supplied.

DB9 male

Serial I/O

PC Card**

Plugs into

PCMCIA port

Laptop**

laptop requires terminal mode software

such as Microsoft HyperTerminal.

1. Open your laptop’s serial communication program, e.g., HyperTerminal. You can typically find HyperTerminal

under: Start/Programs/Accessories/Communications.

14

Page 19

Operation Viewing PMC Reports Via RS-232 Connection

2. After opening the terminal software program, ignore (cancel) any modem/dialing related request windows since

you will be directly connecting to the console via serial communications. When the Connection Description

window appears (Figure 12), enter a connection name, e.g., TLSDIRECT, and click the OK button.

Figure 12. Connection Description window

3. After clicking the OK button, you may see a repeat of the modem/dialing windows, in which case ignore

(cancel) them all.

4. When the Connect To window appears (Figure 13), depending on your connection method, select either

COM1 (If RS-232 port on laptop), USB-Serial Controller (if using USB port on laptop), or Serial I/O PC Card

(if using PCMCIA port on laptop) in the ‘Connect using’ drop down box, then click OK button.

.

Figure 13. Connect To window

5. Next you should see the ‘Port Settings’ window.

IMPORTANT! The settings of the laptop’s com port must match those of the console’s com port to

which you are connected.

15

Page 20

Operation Viewing PMC Reports Via RS-232 Connection

SETUP MODE

PRESS <FUNCTION> TO CONT

COMMUNICATIONS SETUP

PRESS <STEP> TO CONTINUE

PORT SETTINGS

PRESS <ENTER>

PORT SETTINGS

COMM BOARD: 1 (RS-232)

BAUD RATE: 2400

PARITY: ODD

STOP BIT: 1 STOP

DATA LENGTH: 7 DATA

RS-232 SECURITY

CODE: DISABLED

isd\801-1.eps

This number is the assigned by the console and indicates the slot

in which the RS-232 module is installed. It could be 1, 2, or 3.

However, for the RS-232 port of a Multiport module, which is installed

in slot 4, this number would be 6.

If no RS-232 Security Code has been entered, you will see disabled.

If a code has been entered, e.g., 000016, that 6-digit number would

appear here. If a code appears, you will need to enter this code with

each command you send to the console.

Bits per second

Data Bits

a. Go to the console front panel press the MODE key until you see:

b. Press the FUNCTION key until you see the message:

c. Press the STEP key until you see the message:

d. Press the PRINT key to printout the port settings for all communication modules installed in the console.

Figure 14 shows an example port settings printout with the RS-232 module installed. Using the console

port settings in the example below, your HyperTerminal ‘Port Settings’ window entries would be Bits per

second - 2400, Data bits - 7, Parity - Odd, Stop Bits - 1. For the ‘Flow Control’ entry select None. Click OK.

In the example port settings printout above, the RS-232 Security Code is disabled. If the code was enabled you

would see a 6-digit number which you will need to enter to access the console (refer to the ‘Sending Console

Commands’ paragraph below for more information).

Figure 14. Console comm port settings printout example

16

Page 21

Operation Viewing PMC Reports Via RS-232 Connection

IV8200

IV8200 9999FF1B

6. After entering your port settings, the program’s main window appears (Figure 15).

Figure 15. HyperTerminal main window

SENDING CONSOLE COMMANDS

Table 3 shows four important PMC console commands: IV8200, IV8000, IV8100 and I11100. The <SOH>

shown in the table means that you must press and hold the Ctrl key while you press the A key.

For example, let’s say you want to see the Vapor Processor Status Report.

Note: If you want to see the characters of the command as you type them in, click on File menu, then select

Properties/Settings (tab)/ASCII Setup and click the check box for ‘Echo typed characters locally’, then click OK to

close the window(s) and return to the main screen.

If the RS-232 Security Code is disabled - press and hold the Ctrl key while you press the A key, then type in

IV8200. If the RS-232 Security Code is enabled (e.g., 000016) you must enter the security code before the

command - press and hold the Ctrl key while you press the A key, then type in 000016IV8200.

You will see the typed command on the screen: followed by the response (report) from the console. The

symbol indicates CrtlA and the ♥ symbol indicates the end of the response.

If the console recognizes the command the response displays as soon as the command is typed in.

If the console does not recognize the command you would see something like which

indicates the console did not recognize the command.

All responses (Reports) can be printed or saved to a file. See the terminal program’s help file for instructions.

17

Page 22

Operation Viewing PMC Reports Via RS-232 Connection

Table 3. Serial Commands for PMC Diagnostic Reports

Report Type Serial Command (PC to Console)*

VST ECS Membrane

Processor Only

VST ECS Membrane

Processor Only

Vapor Processor Status Report

<SOH>IV8200

(See example Figure 16)

Vapor Processor Runtime Diagnostic Report

<SOH>IV8000

(See example Figure 17)

Percent Hydrocarbon Diagnostic Report (See

<SOH>IV8100

example Figure 18)

Priority Alarm History Report

<SOH>I11100

(See example Figure 19)

Non-Priority Alarm History Report

<SOH>I11200

(See example Figure 20)

*<SOH> = Control A. For more information on TLS console serial commands, refer to

the V-R Serial Interface Manual.

<SOH>

IV8200

JUN 1, 2002 8:07 AM

(SITE NA ME)

(SITE ST REET)

(CITY, STATE)

(PHONE NUMBER)

VAPOR PROCESSOR STATUS REPORT

PMC VERSION: 01.04

VAPOR PROCESSOR TYPE: VST ECS PROCESSOR

PMC MONITORING TEST PASS/FAIL THRESHOLDS

PERIOD BELOW ABOVE

H2O

VAPOR PROCESSOR MASS EMISSION FAIL 1DAYS ---- 0.32 LBS/1KG

VAPOR PROCESSOR DUTY CYCLE FAIL 1DAYS ---- 75.00 %

EFFLUENT EMISSIONS TEST : PASS (0.15 LBS/1KG)

VP DUTY CYCLE TEST : PASS (17.54%)

VP INPUT STATUS : NOTEST

RUN TIME HOURS : 4.2

DAILY THROUGHPUT : 8421 GALS

AVG HC PERCENT : 8.85 %

Figure 16. Vapor Processor Status Report Details - Serial to PC Format

18

Page 23

Operation Viewing PMC Reports Via RS-232 Connection

IV8000

AUG 30, 2007 11:52 AM

(SITE NAME)

(SITE ST REET)

(CITY, STATE)

(PHONE NUMBER)

VAPOR PROCESSOR

ELAPSED PRESSURE INCHES H2O RUNTIME

DATE-TIME ON MINUTES ON OFF FAULT

3-08-07 8:52PM 5.53 0.209 -0.211 NO

3-08-07 8:58PM 0.98 0.303 -0.203 NO

3-09-07 5:03AM 26.60 0.221 -0.205 NO

3-09-07 1:15PM 17.92 0.278 -0.268 NO

3-10-07 3:01AM 7.70 0.200 -0.223 NO

3-10-07 4:30AM 4.02 0.202 -0.224 NO

3-10-07 7:54PM 23.62 0.306 -0.245 NO

3-11-07 11:24PM 6.55 0.256 -0.213 NO

3-12-07 11:31PM 21.23 0.228 -0.203 NO

3-13-07 3:44PM 23.95 0.926 -0.230 NO

3-15-07 1:35AM 30.00 0.202 0.154 YES

3-15-07 2:36AM 6.87 0.200 -0.205 NO

3-15-07 3:24AM 30.00 0.201 0.442 YES

3-16-07 3:10AM 4.33 0.202 -0.205 NO

3-16-07 1:28PM 20.78 0.234 -0.264 NO

3-16-07 2:38PM 1.30 0.220 -0.219 NO

3-17-07 12:44AM 6.52 0.206 -0.200 NO

3-17-07 2:00PM 27.47 0.254 -.210 NO

Figure 17. Vapor Processor Runtime Diagnostic Report - Serial to PC Format

19

Page 24

Operation Viewing PMC Reports Via RS-232 Connection

IV800

SEP 21, 2010 8:52 AM

HYDROCARBON SENSOR DIAGNOSTIC

DATE/TIME READING%

9-25-10 8:57 AM 1.174

9-25-10 8:57 AM 1.188

9-25-10 8:57 AM 1.168

9-25-10 8:57 AM 1.182

9-25-10 8:57 AM 1.182

9-25-10 8:57 AM 1.182

9-25-10 8:57 AM 1.174

9-25-10 8:57 AM 1.188

9-25-10 8:57 AM 1.182

9-25-10 8:57 AM 1.194

9-25-10 8:57 AM 1.188

9-25-10 8:57 AM 1.200

9-25-10 8:56 AM 1.188

I11100

APR 17, 2008 12:30 AM

<Site Name>

<Site Address>

<Site Address>

<Site Address>

PRIORITY ALARM HISTORY

ID CATEGORY DESCRIPTION ALARM TYPE STATE DATE TIME

T 2 TANK Premium 91 PROBE OUT CLEAR 4-04-08 12:14PM

T 2 TANK Premium 91 PROBE OUT ALARM 4-04-08 12:14PM

T 2 TANK Premium 91 LOW PRODUCT ALARM CLEAR 4-04-08 12:04PM

T 2 TANK Premium 91 PROBE OUT CLEAR 4-04-08 12:04PM

T 1 TANK Unlead 87 PROBE OUT CLEAR 4-04-08 11:37AM

T 1 TANK Unlead 87 PROBE OUT ALARM 4-04-08 10:51AM

T 2 TANK Premium 91 PROBE OUT ALARM 4-04-08 10:42AM

T 2 TANK Premium 91 LOW PRODUCT ALARM ALARM 4-04-08 10:42AM

s 8 OTHER PRES SEN 2 DISP 1-2 COMMUNICATION ALARM CLEAR 3-26-08 1:39PM

s 8 OTHER PRES SEN 2 DISP 1-2 COMMUNICATION ALARM ALARM 3-26-08 1:37PM

SYSTEM BATTERY IS OFF CLEAR 3-10-08 8:00AM

SYSTEM BATTERY IS OFF ALARM 3-10-08 8:00AM

Figure 18. Percent Hydrocarbon Diagnostic Report - Serial to PC Format

Figure 19. Priority Alarm History Report - Serial to PC Format

20

Page 25

Operation Viewing PMC Reports Via RS-232 Connection

I11200

DEC 9, 2010 4:20 AM

<Site Name>

<Site Address>

<Site Address>

<Site Address>

NON-PRIORITY ALARM HISTORY

ID CATEGORY DESCRIPTION ALARM TYPE STATE DATE TIME

T 3 TANK DIESEL LOW TEMP WARNING CLEAR 12-08-10 3:00PM

T 3 TANK DIESEL LOW TEMP WARNING ALARM 12-08-10 3:00PM

T 3 TANK DIESEL HIGH PRODUCT ALARM CLEAR 12-08-10 3:00PM

T 3 TANK DIESEL HIGH PRODUCT ALARM ALARM 12-08-10 2:56PM

SYSTEM PRINTER ERROR CLEAR 11-17-10 10:51AM

SYSTEM PAPER OUT CLEAR 11-17-10 10:51AM

SYSTEM PAPER OUT ALARM 11-17-10 10:50AM

SYSTEM PRINTER ERROR ALARM 11-17-10 10:50AM

Figure 20. Non-Priority Alarm History Report - Serial to PC Format

21

Page 26

Diagnostics

PMC VERSION: 01.04

PRESS <STEP> TO CONTINUE

S

VAPOR PRESSURE

INCHES H2O: -X.XXX

VAPOR PROCESSOR MODE

AUTOMATIC

<CHANGE> selects

AUTOMATIC (default) / MANUAL

VAPOR PROCESSOR STATE

VP STATE: OFF

If VP mode = MANUAL, and relay

configured Then, <CHANGE> selects

ON / OFF

HYDROCARBON SENSOR

HC SENSO R: XX.XXX%

CLEAR TE ST AFTE R REPAIR

PRESS <ENTER>

801-3.eps

Prints out a copy of the

PMC Diagnostic report.

See example at right.

PMC DIAGNOSTICS

---------------------PMC VERSION: 01.04

VAPOR PROCESSOR MODE

AUTOMATIC

VAPOR PROCESSOR STATE

VP STATE ON

PMC DIAGNOSTIC

PRESS <STEP> TO CONTINUE

DIAG MODE

PRESS <FUNCTION> TO CONT

M

P

F

C

Change

B

Backup

E

Enter

S

Step

M

Mode

F

Function

Print

T P

1

2

Key press

sequence

Repress until

desired message

appears in display

Key Legend

Tank

Sensor

S

S

S

S

S

E

E

E

C

PROCESSOR STATUS TEST

PRESS <ENTER>

CLEAR TE ST AND LOG

ARE YOU SURE? NO

CLEAR TE ST AND LOG

ARE YOU SURE? YES

S

Automatic Control

Under Automatic control, vapor pressure readings are compared to user programmable thresholds to determine

the appropriate Pressure Management Device (PMD) state. When the PMD is off and the TURN ON VAPOR

PROCESSOR is exceeded, an internal relay is enabled and remains so until the pressure drops below the TURN

OFF VAPOR PROCESSOR threshold. Automatic control is the default mode.

Manual control

If PMC mode is Manual, the diagnostic menu allows the PMD to be directly turned on/off through the relay. This

feature is to support unit operational testing without waiting for the pressure to hit limits. The current UST ullage

space vapor pressure will also be available through the diagnostic menu. The VC1 RS232 command allows for

remote control of the PMD when the PMD control is manual. Note: If the PMD is on and the PMC mode is

Automatic, changing the control mode to Manual mode will turn the PMD off.

When set to Manual mode, the system will revert to Automatic mode after 4 hours.

PMC Diagnostic Menu

Figure 21. PMC Diagnostic Menus

22

Page 27

For technical support, sales or

other assistance, please visit:

www.veeder.com

Loading...

Loading...