Page 1

Manual No: 577014-110 ● Revision: B

Operator’s Manual

TLS-450PLUS / TLS4

Page 2

Notice

Veeder-Root makes no warranty of any kind with regard to this publication, including but not

limited to, the implied warranties of merchantability and fitness for a particular purpose.

Veeder-Root shall not be liable for errors contained herein or for incidental or consequential

damages in connection with the furnishing, performance, or use of this publication.

The information contained in this publication may be subject to change without notice.

This publication contains proprietary information which is protected by copyright. All rights

reserved. No part of this publication may be photocopied, reproduced, or translated to another

language without the prior written consent of Veeder-Root.

©Veeder-Root 2016. All rights reserved.

Page 3

Introduction

Contractor Certification Requirements ..............................................................................1

Related Documents ..........................................................................................................1

Console Touch Screen Overview

Console Home Screen ......................................................................................................2

Front Panel Status Lights .........................................................................................2

Example Touch Screen Status Bar Notifications .....................................................2

Touch Screen Icon Descriptions .......................................................................................3

Entering Changes On A Touch Screen ............................................................................4

Console Comm Ports ........................................................................................................4

TLS4 Comm Ports - Menu>Setup>Communication .................................................4

TLS-450PLUS Comm Ports - Menu>Setup>Communication...................................5

Alarm Limit Settings - Menu>Setup>Tank>Limits .............................................................5

Security Login ...................................................................................................................6

Using On-Board Help - Actions>Help ...............................................................................6

On-board Help Topics of Interest - Actions>Help.....................................................6

System Maintenance Screen Examples ...........................................................................7

Backup System Data - Menu>Software Maintenance>DB Backup..........................7

To View The Console’s Software Version - Menu>Overview>About .......................7

To Download Console Software - Menu>Software Maintenance>Download ...........7

Table of Contents

Initial Setup Of The Console Using Workflow Wizard

Initial Screen - Menu>Setup>Workflow Wizard>Setup Workflow .....................................9

Setup>Display>Language/Units ...............................................................................9

Setup>Date and Time ..............................................................................................9

Setup>Display>Date/Time Format .........................................................................10

Setup>Display>Number Format .............................................................................10

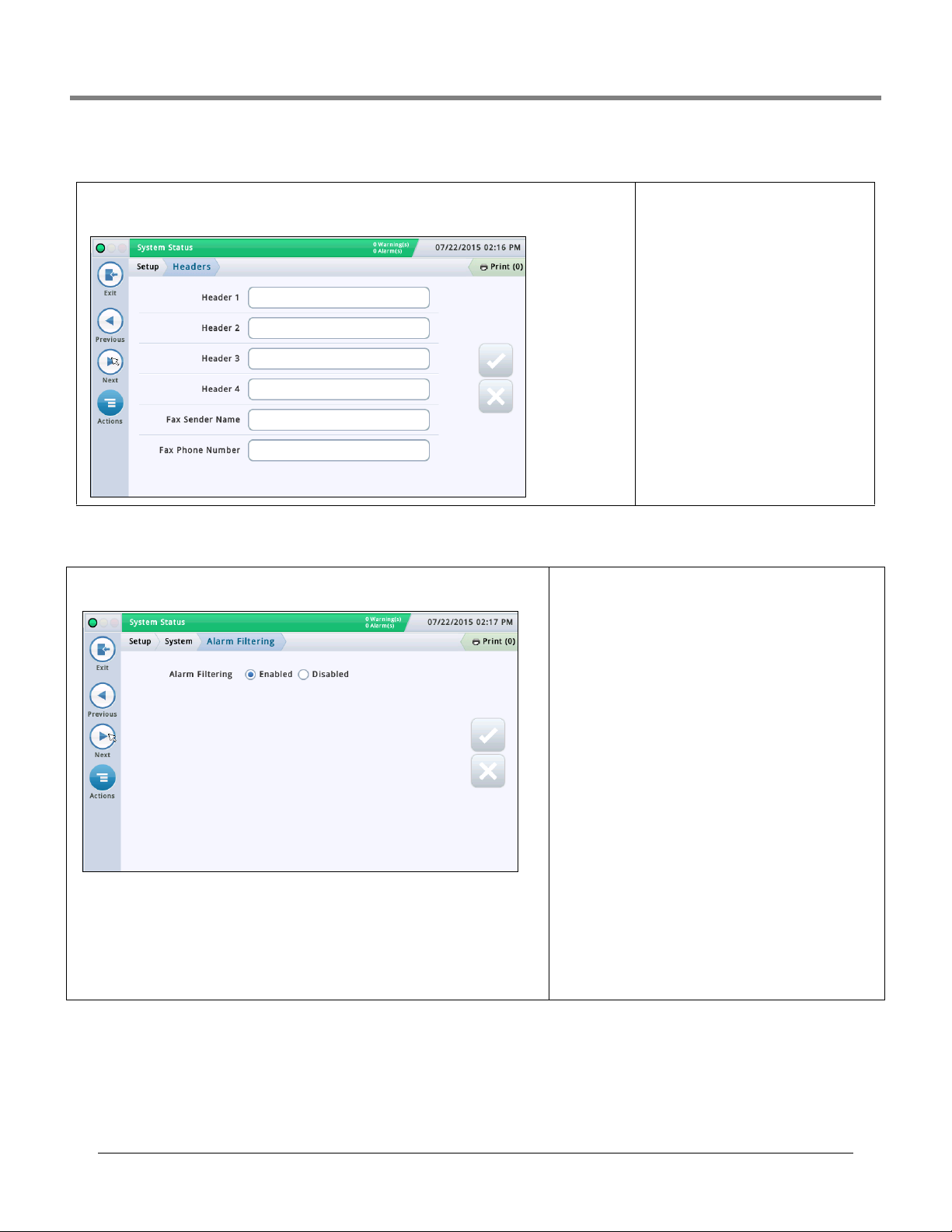

Setup>Headers ......................................................................................................11

Setup>System>Alarm Filtering...............................................................................11

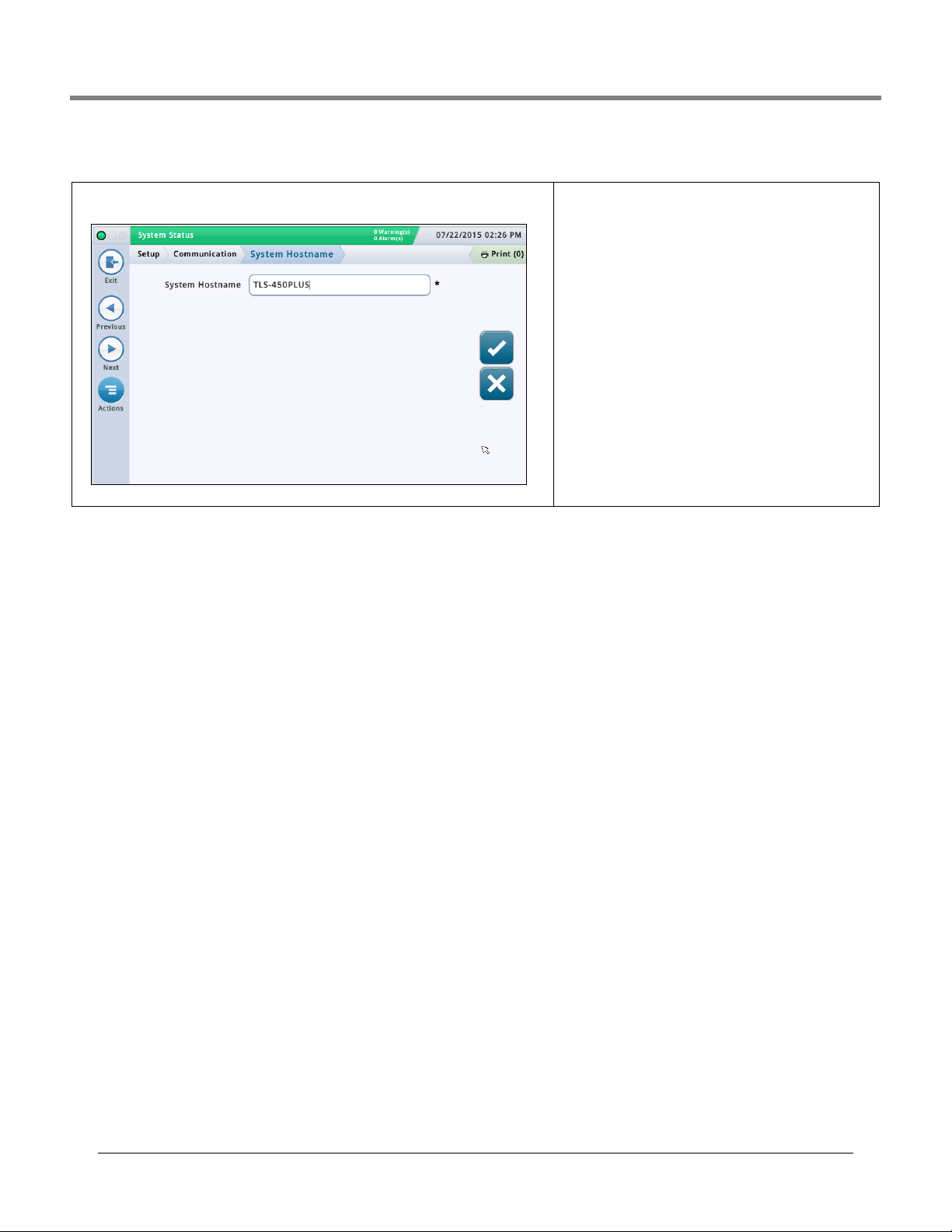

Setup>Communication>System Hostname............................................................12

Setup>Communication>Ethernet Port....................................................................13

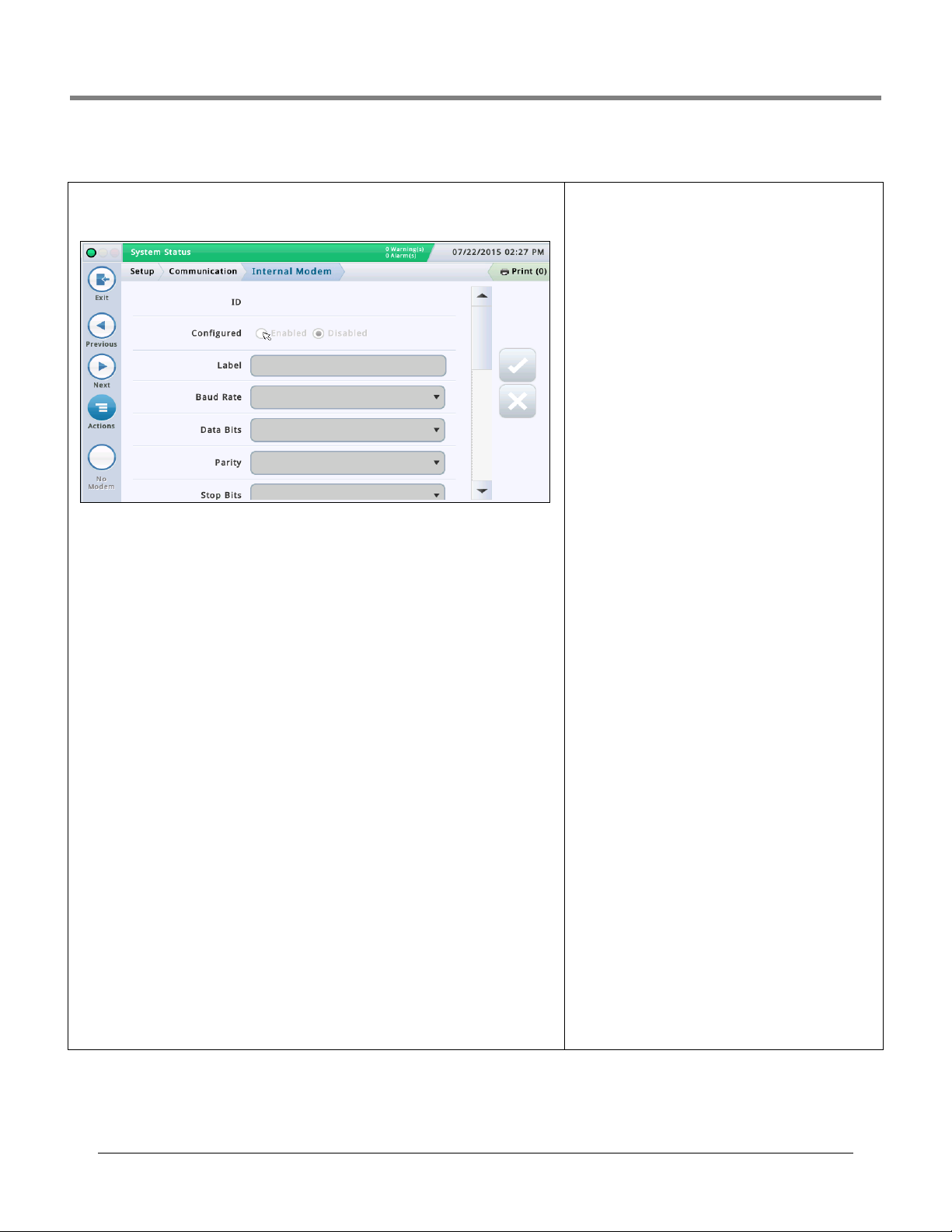

Setup>Communication>Internal Modem................................................................14

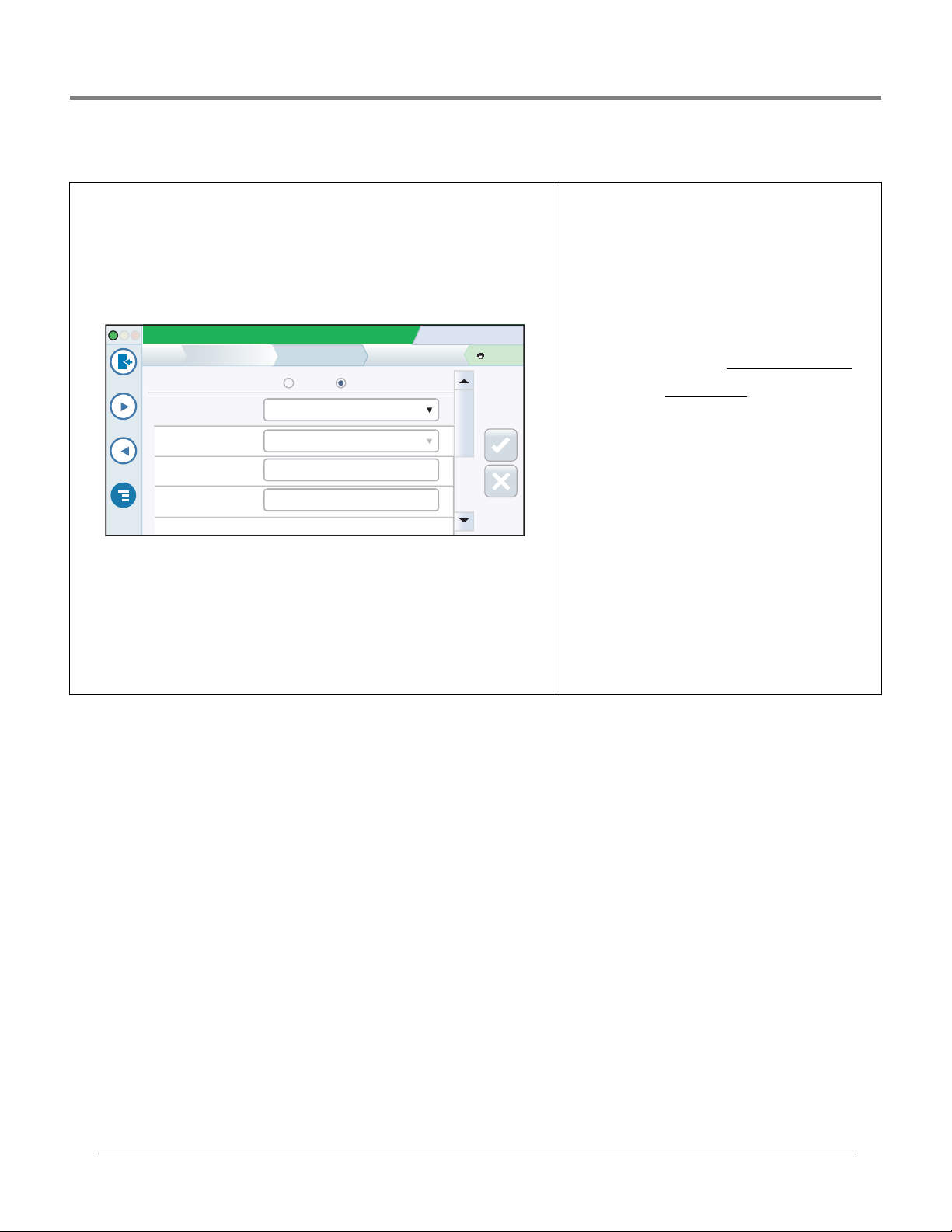

Setup>Communication>CDIM Port ........................................................................15

Setup>Communication>TDIM Port.........................................................................15

Setup>Communication>IFSF .................................................................................16

Setup>Communication>Serial Port ........................................................................17

Setup>Communication>SMTP Relay.....................................................................18

Setup>Devices ......................................................................................................19

Setup>BIR>General ...............................................................................................24

Setup>BIR>Threshold Alarm..................................................................................25

Setup>Tank>General .............................................................................................26

Setup>Tank>Limits.................................................................................................28

Setup>Tank>Limits - Concluded ............................................................................29

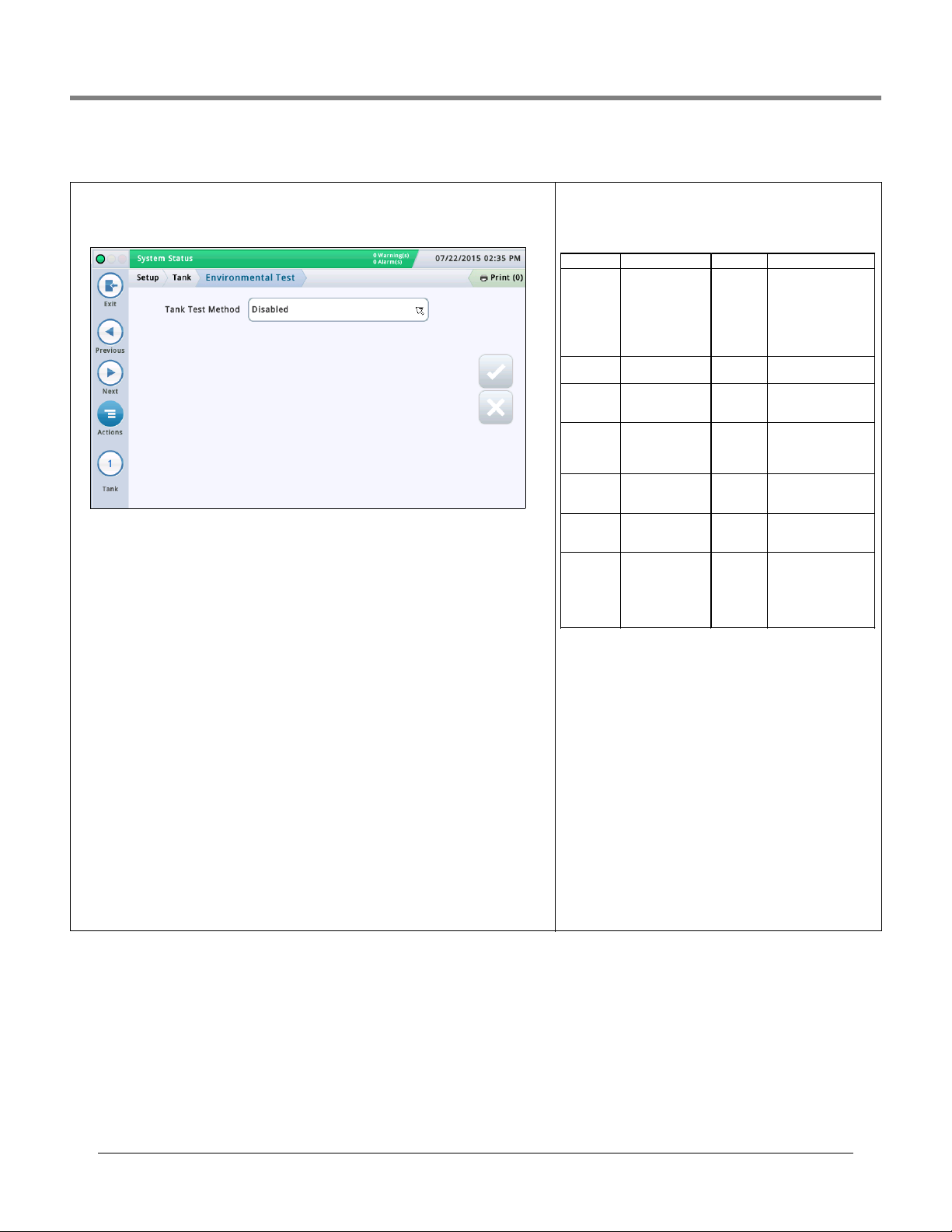

Setup>Tank>Environmental Test ..........................................................................30

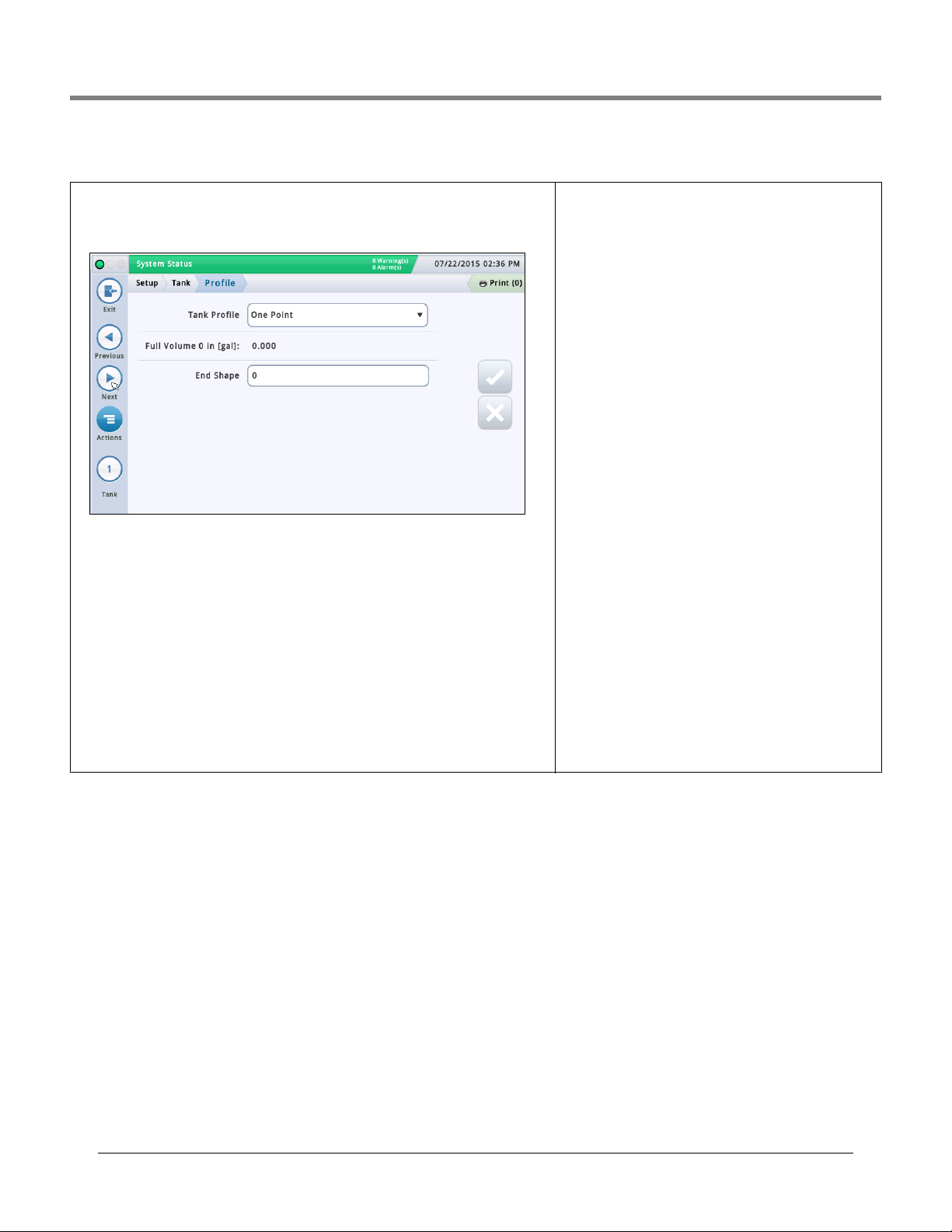

Setup>Tank>Profile................................................................................................32

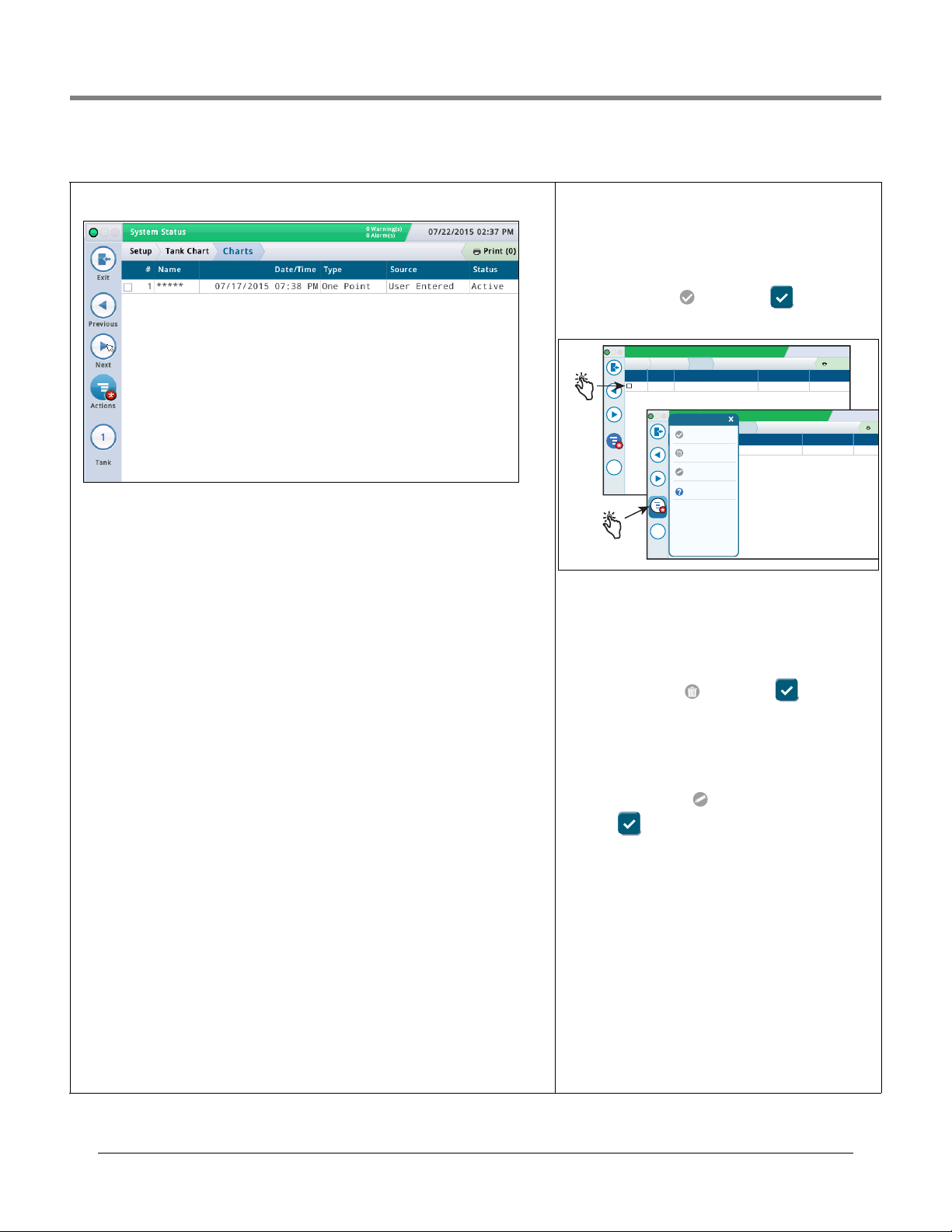

Setup>Tank Chart>Charts......................................................................................33

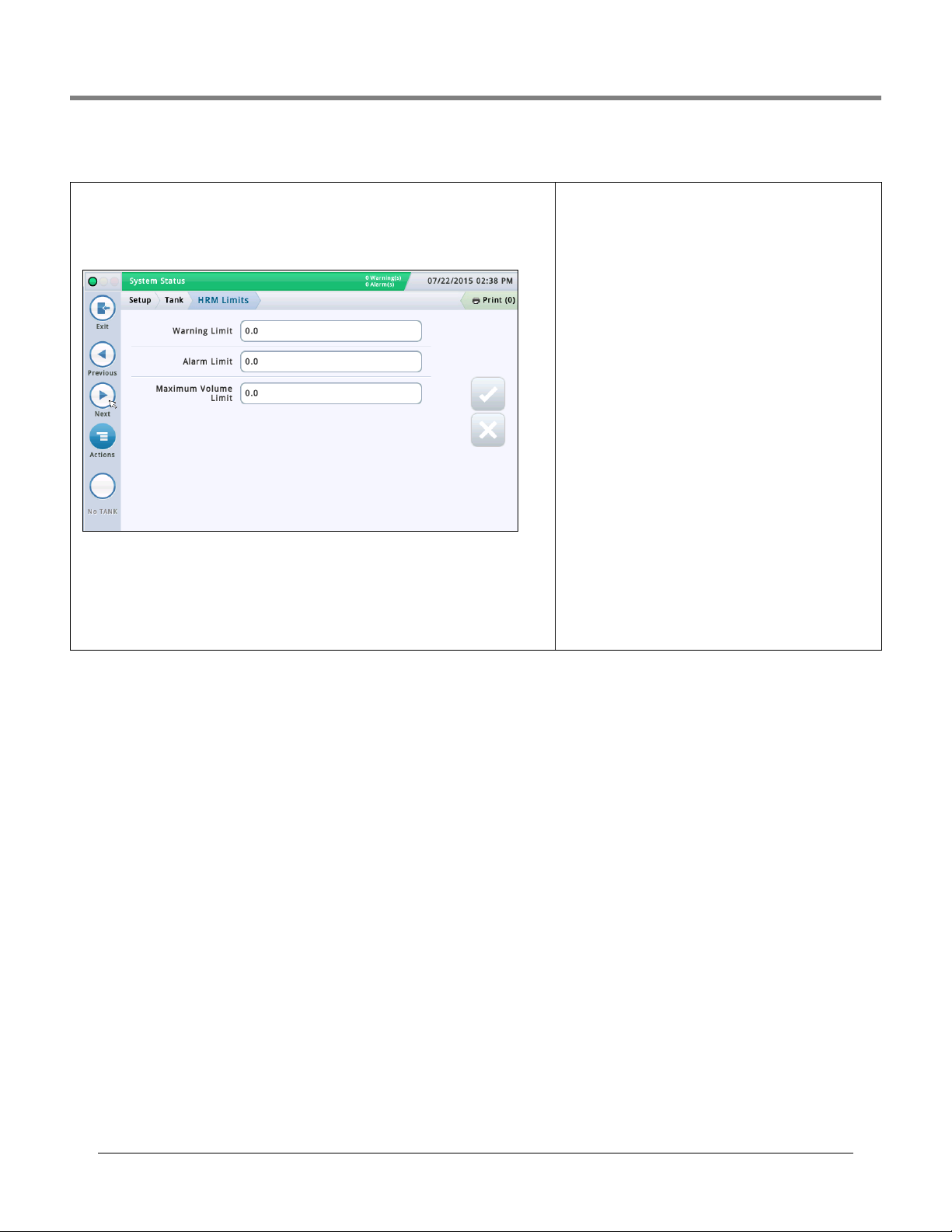

Setup>Tank>HRM Limits (International Option).....................................................34

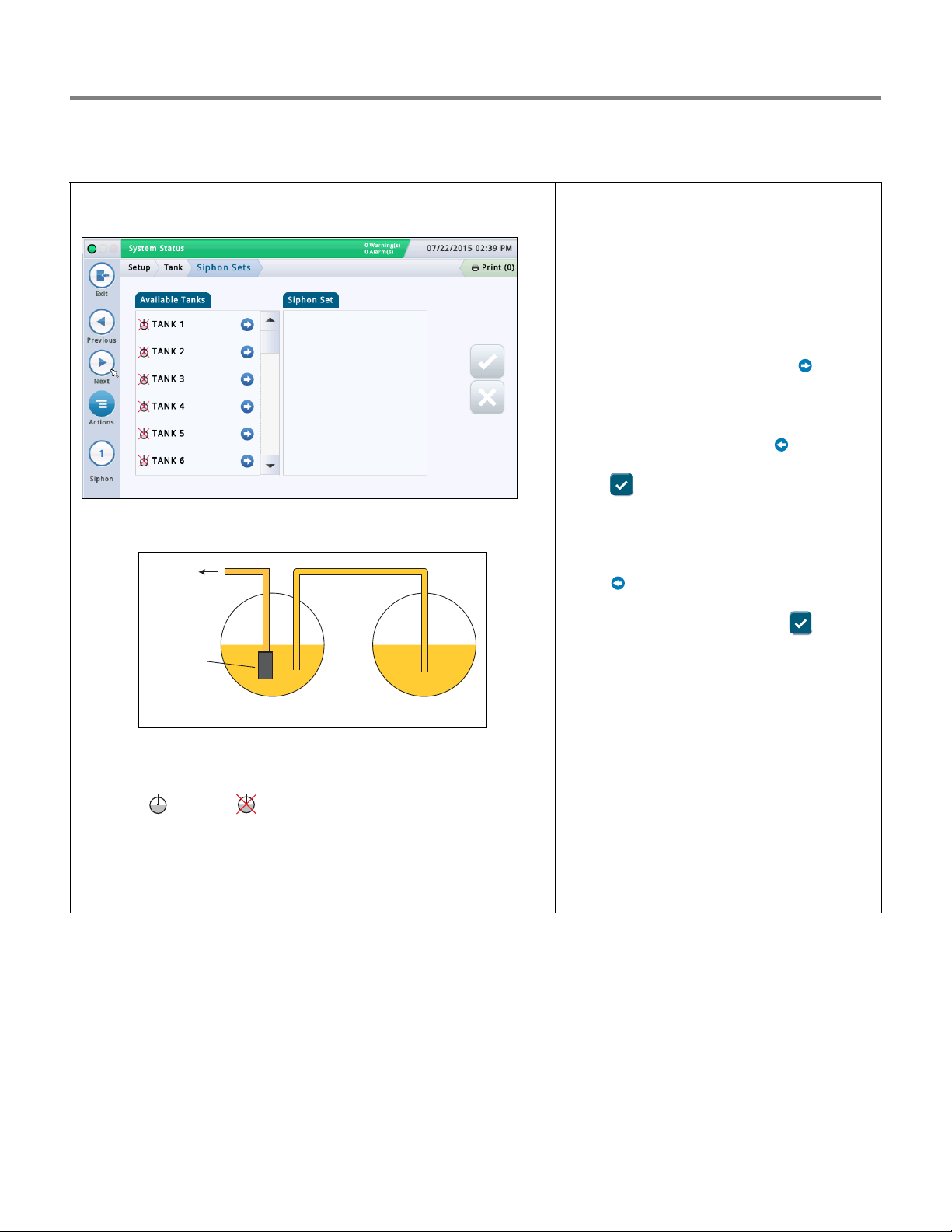

Setup>Tank>Siphon Sets.......................................................................................35

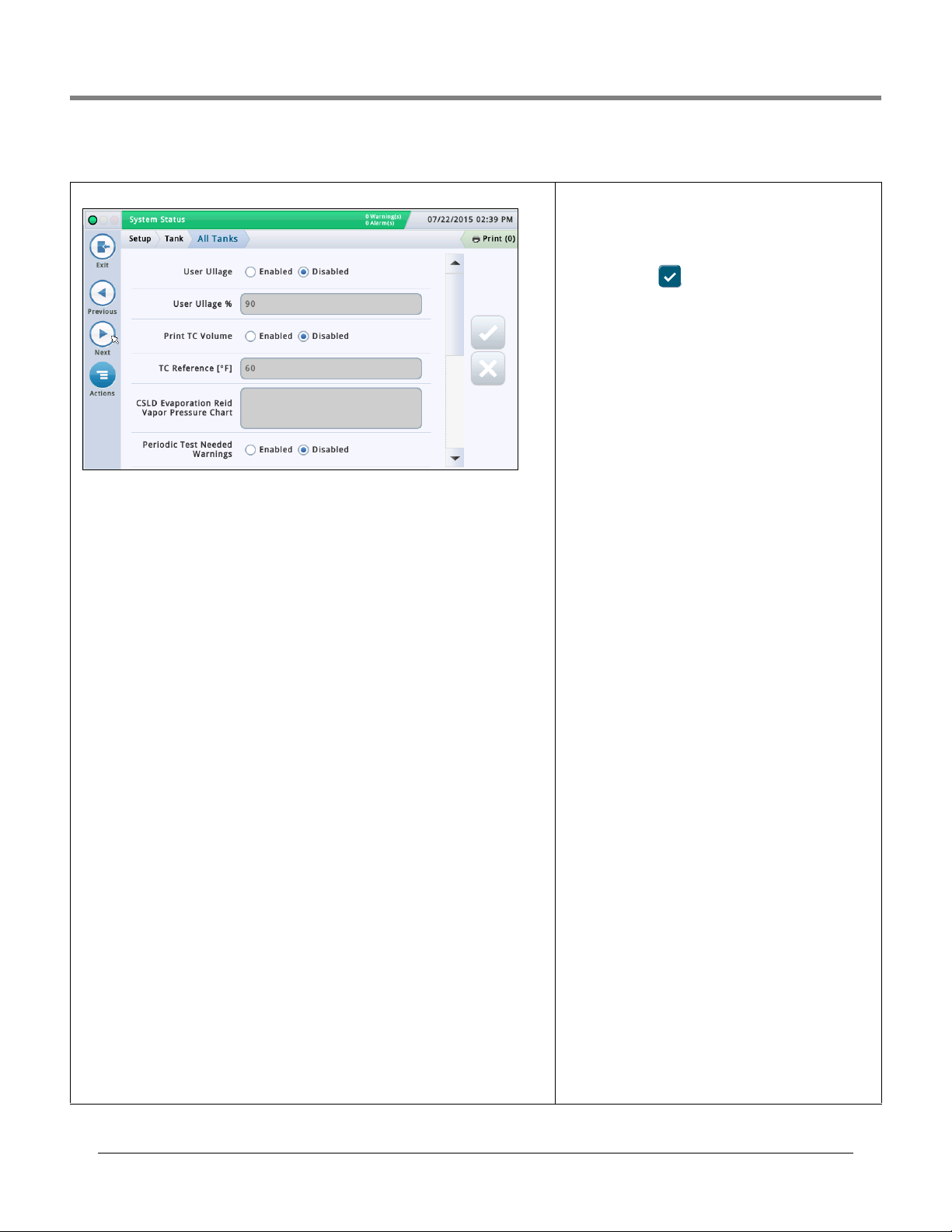

Setup>Tank>All Tanks ...........................................................................................36

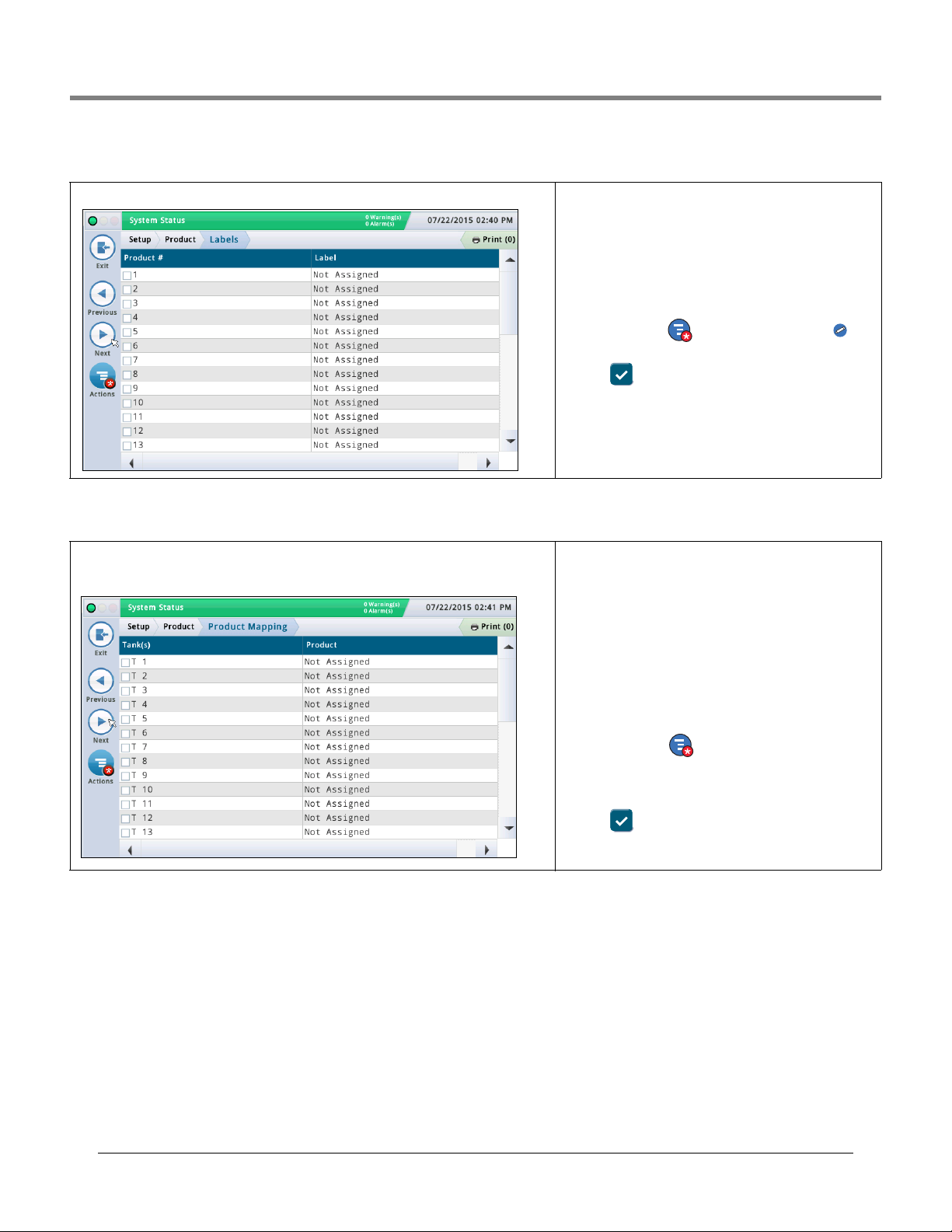

Setup>Products>Labels .........................................................................................37

Setup>Product>Product Mapping ..........................................................................37

Setup>Tank Chart>AccuChart ...............................................................................38

Setup>Pumps and Lines>Pumps...........................................................................40

Setup>Pumps and Lines>Line ...............................................................................41

iii

Page 4

Setup>Pumps and Lines>PLLD .............................................................................42

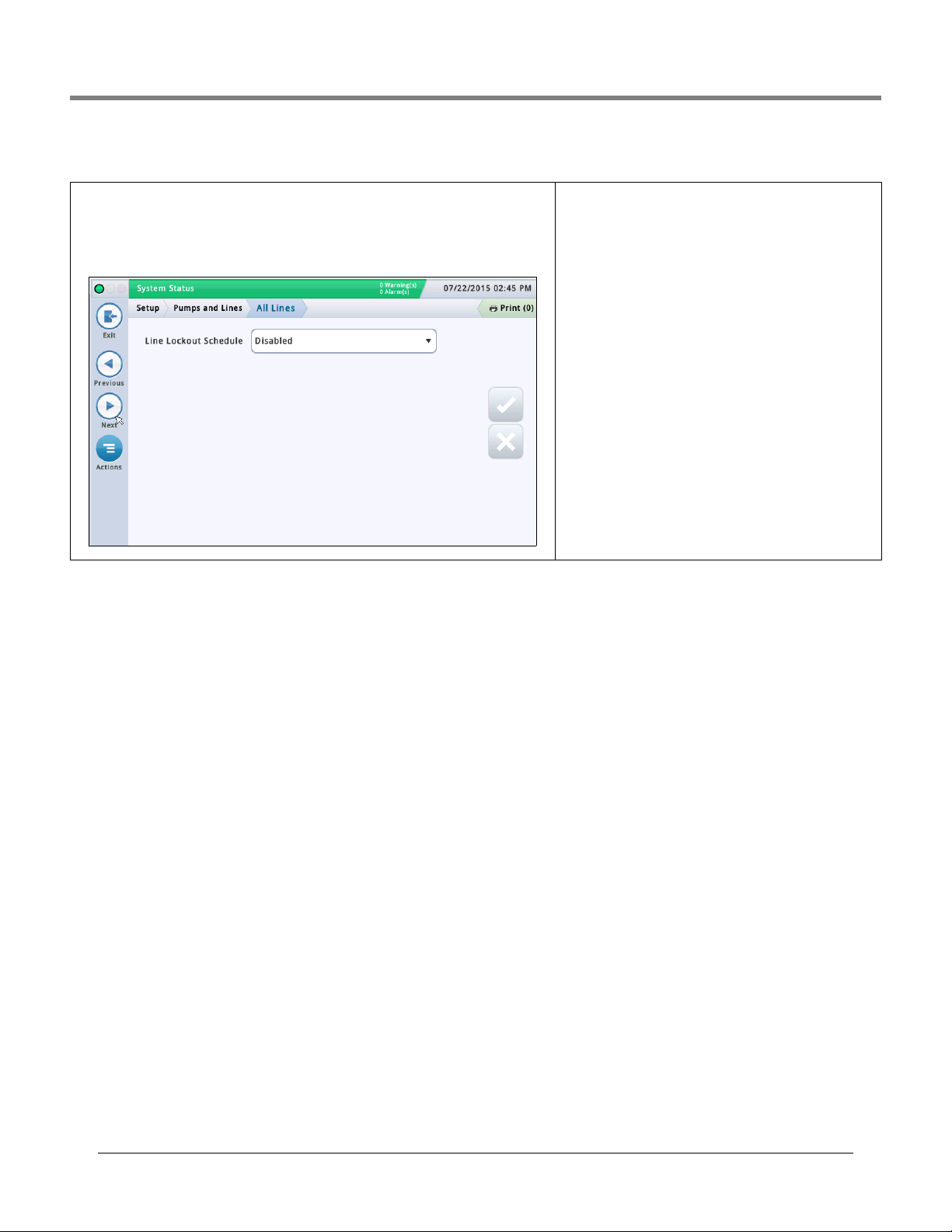

Setup>Pumps and Lines>All Lines.........................................................................44

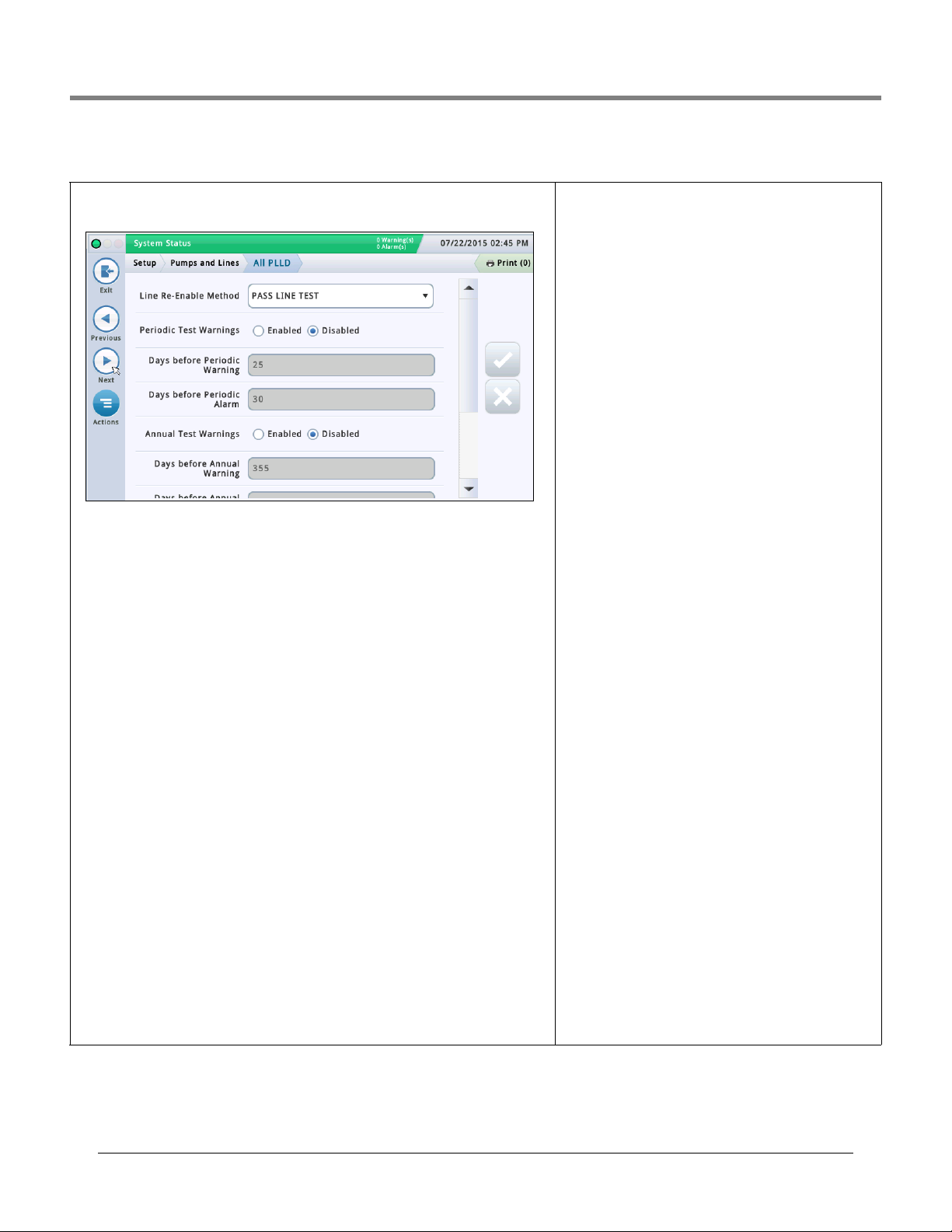

Setup>Pumps and Lines>All PLLD ........................................................................45

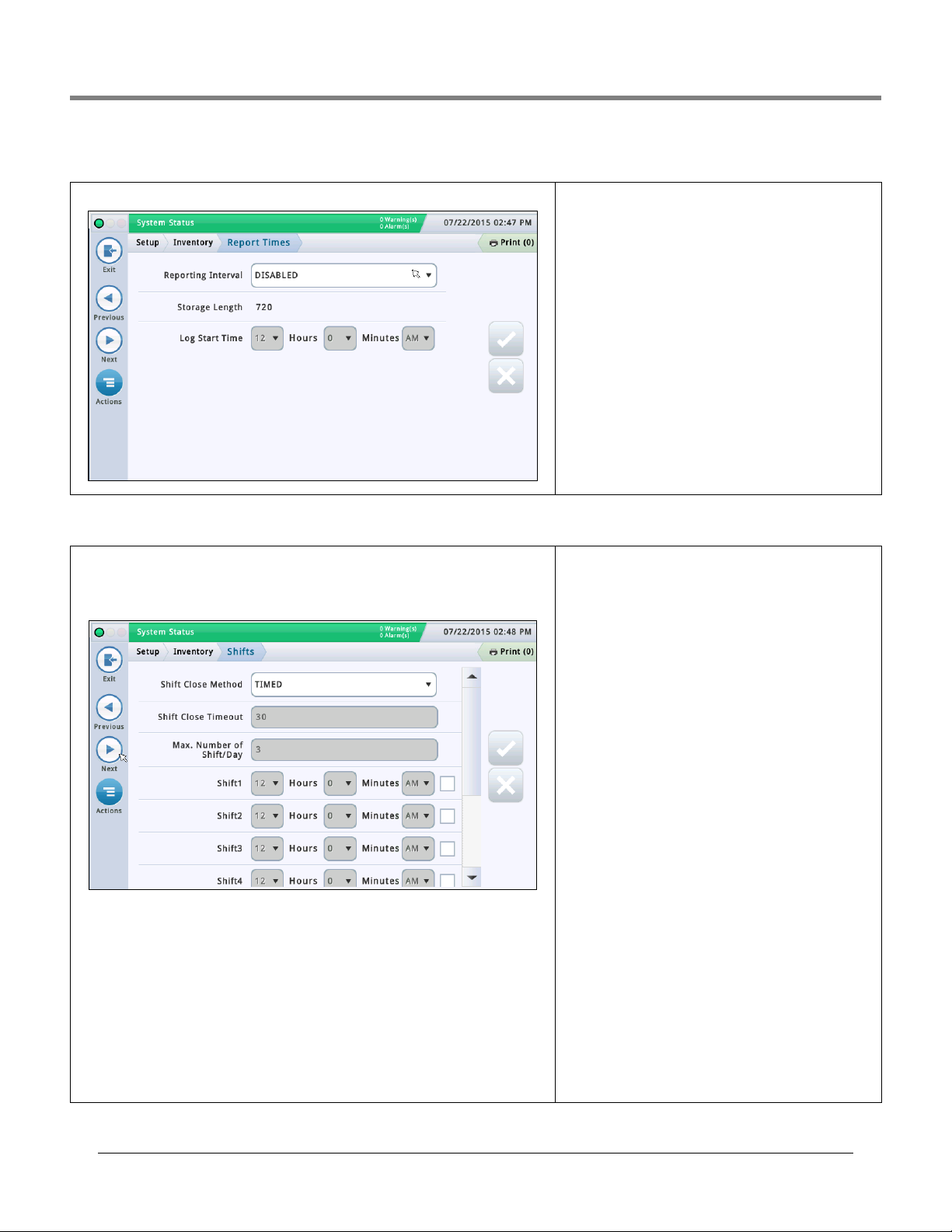

Setup>Inventory>Report Times..............................................................................46

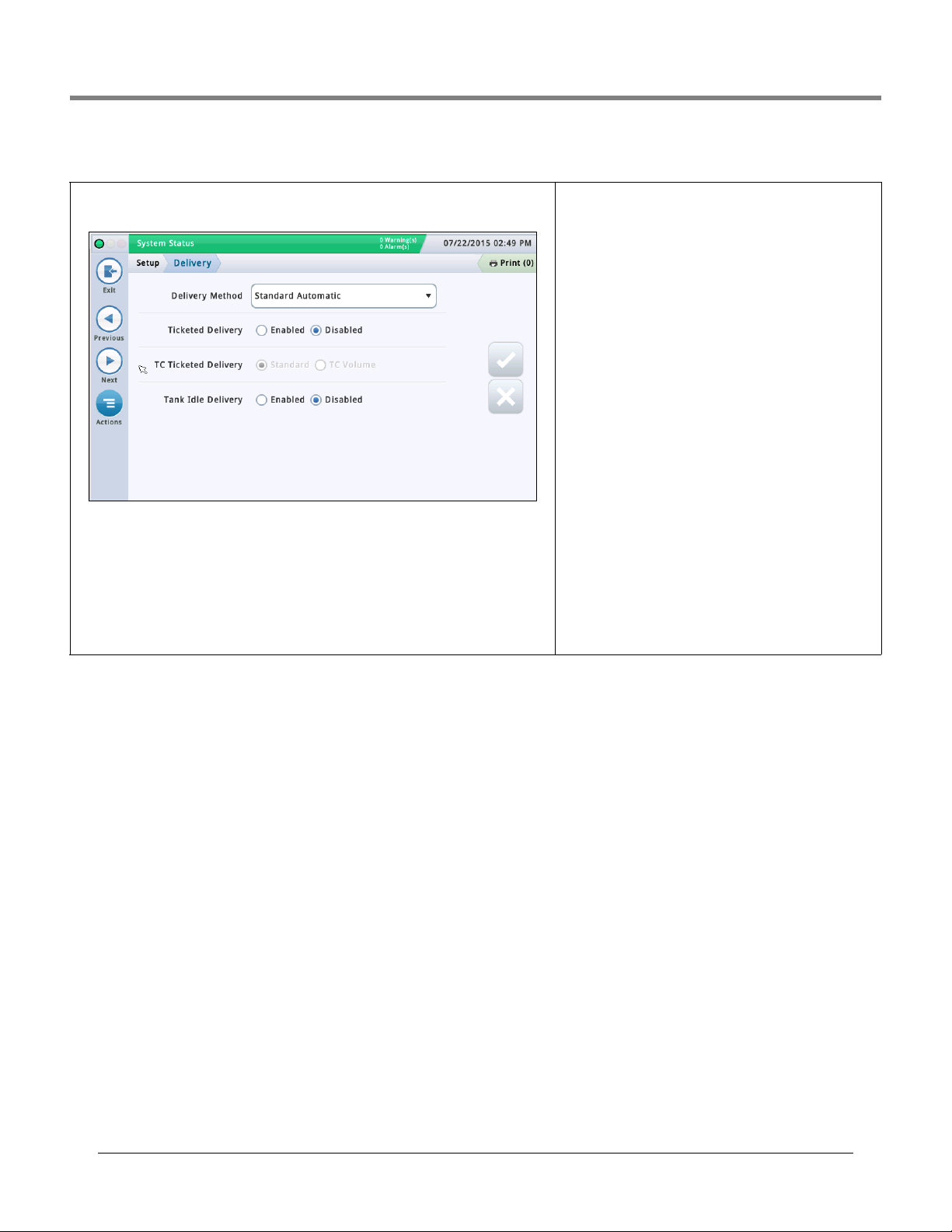

Setup>Inventory>Shifts ..........................................................................................46

Setup>Delivery .......................................................................................................47

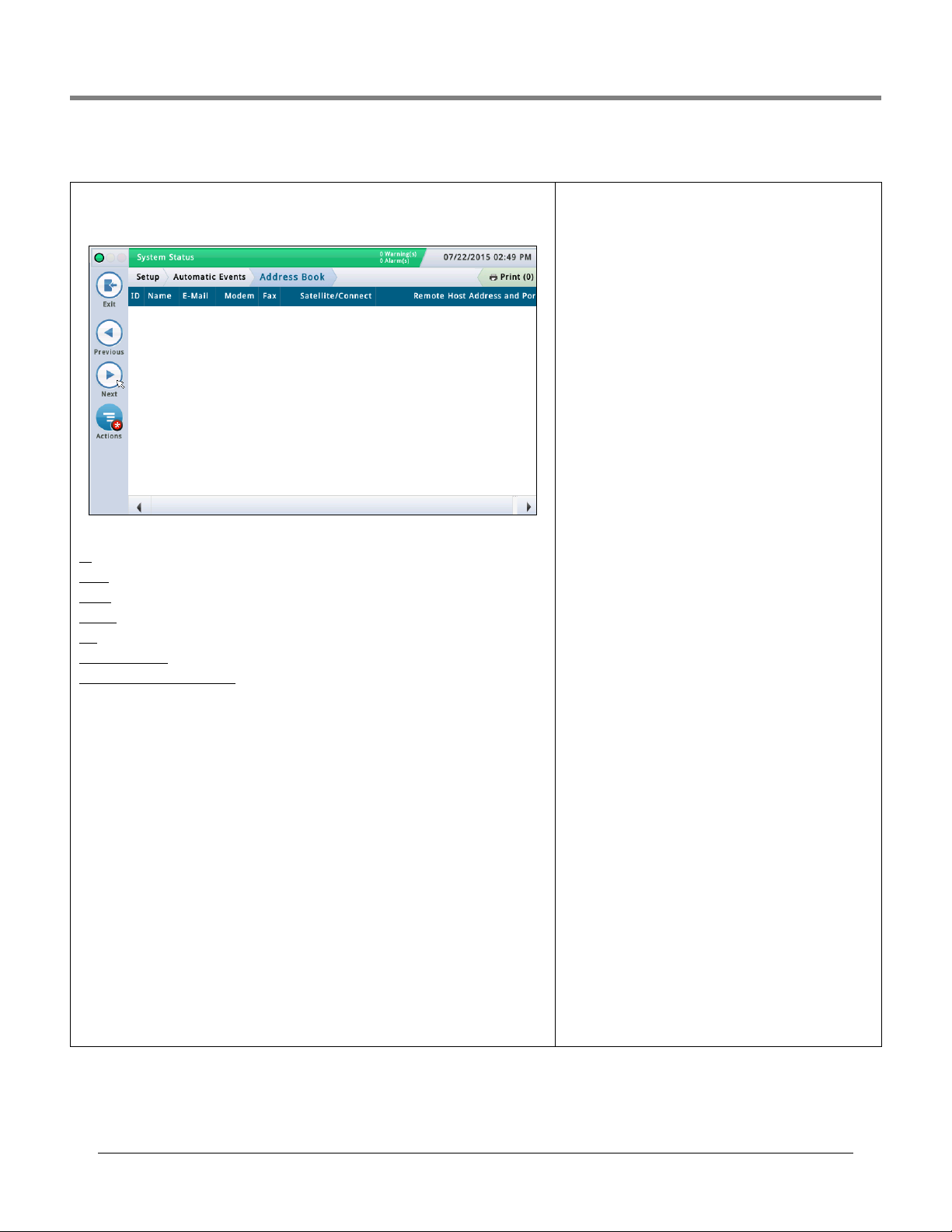

Setup>Automatic Events>Address Book................................................................48

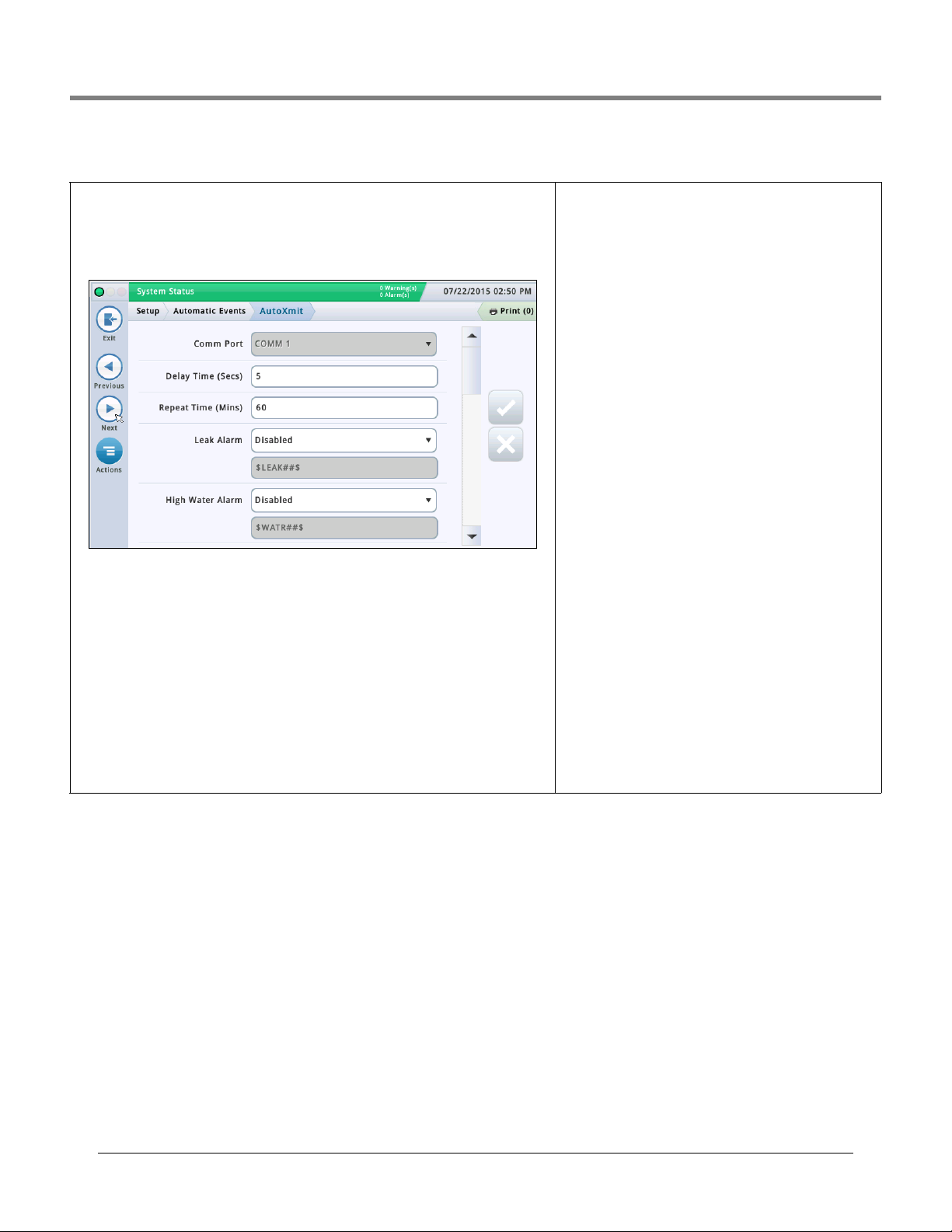

Setup>Automatic Events>AutoXmit .......................................................................49

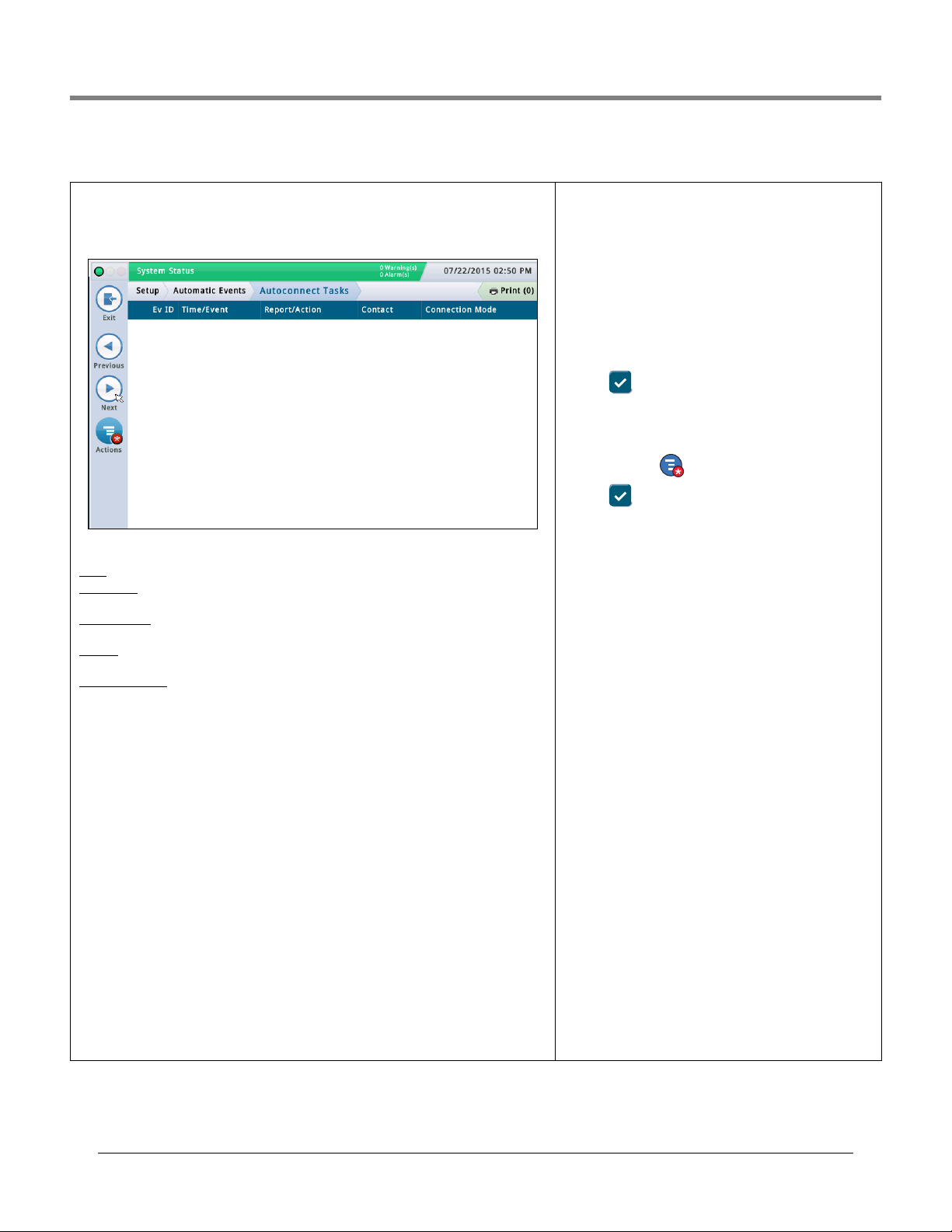

Setup>Automatic Events>Autoconnect Tasks .......................................................50

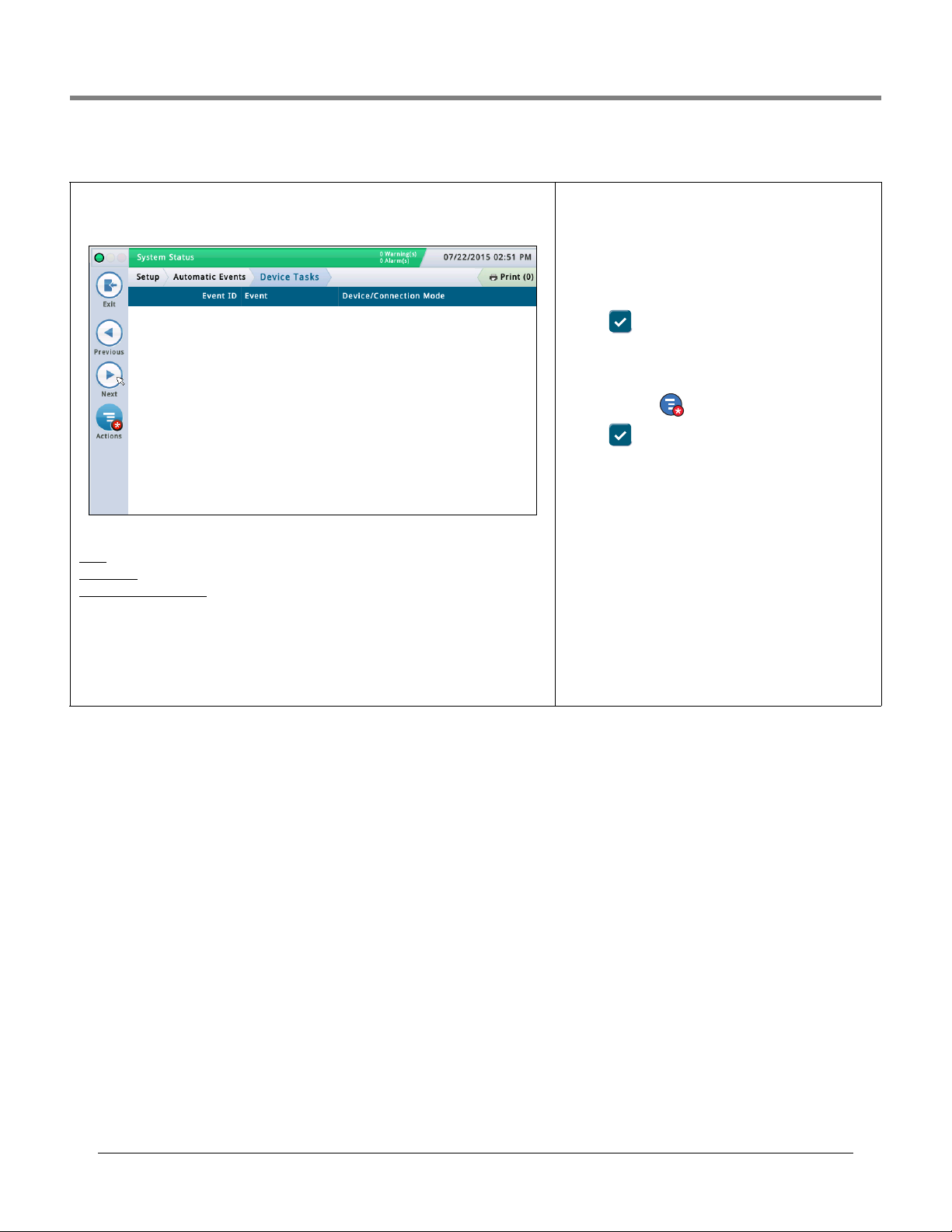

Setup>Automatic Events>Device Tasks ................................................................51

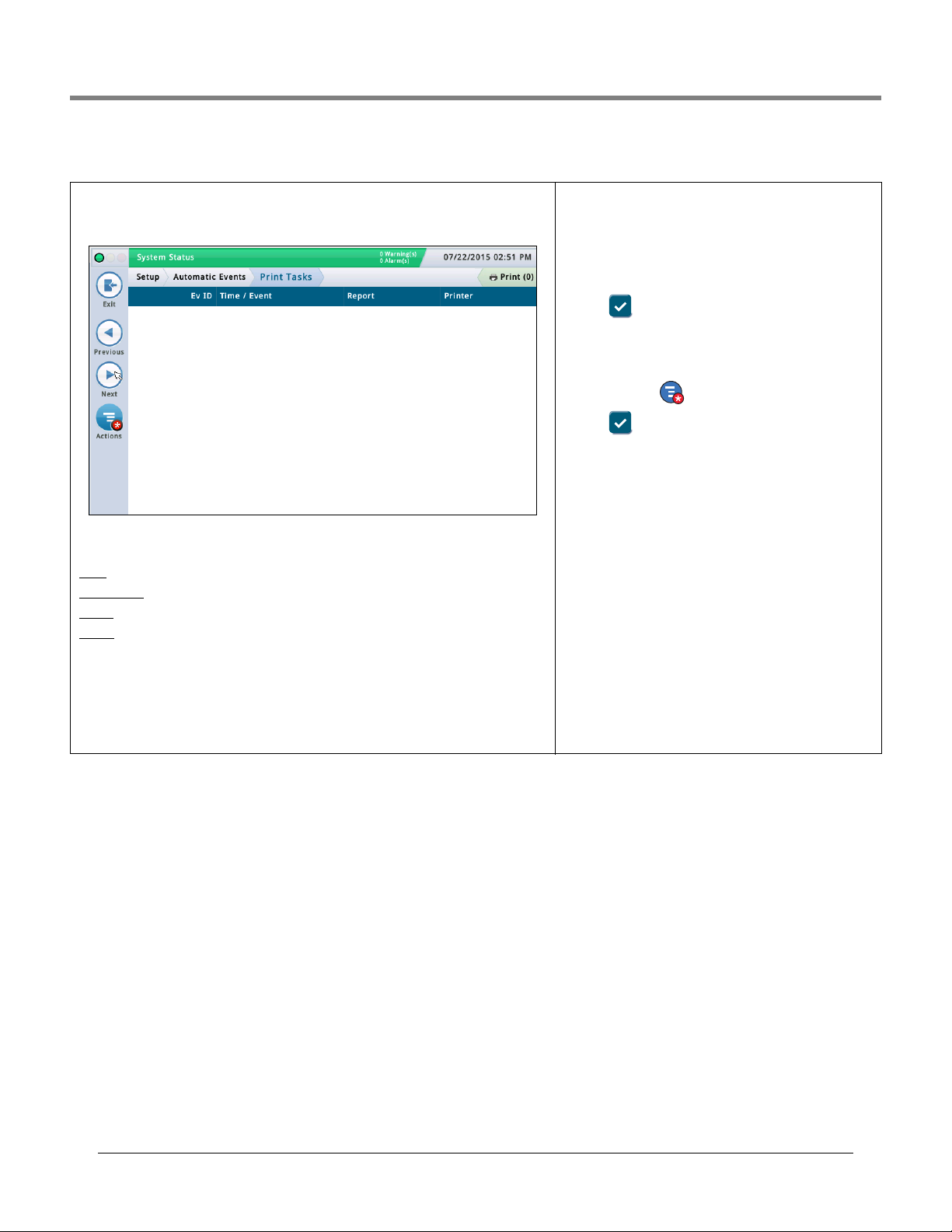

Setup>Automatic Events>Print Tasks....................................................................52

Setup>Automatic Events>All Tasks .......................................................................53

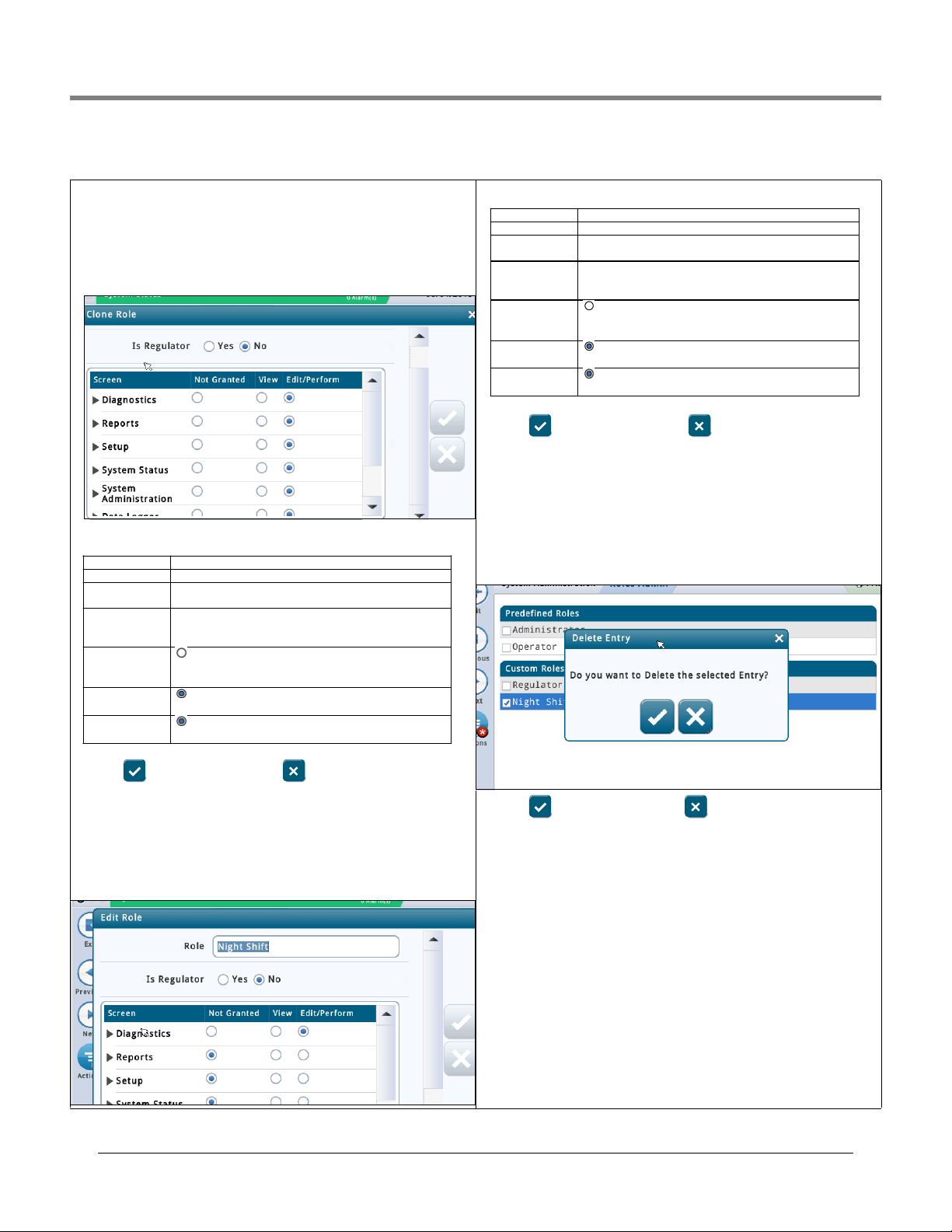

System Administration>Roles Admin .....................................................................54

System Administration>Users Admin .....................................................................56

Setup>System>Security.........................................................................................57

Software Maintenance

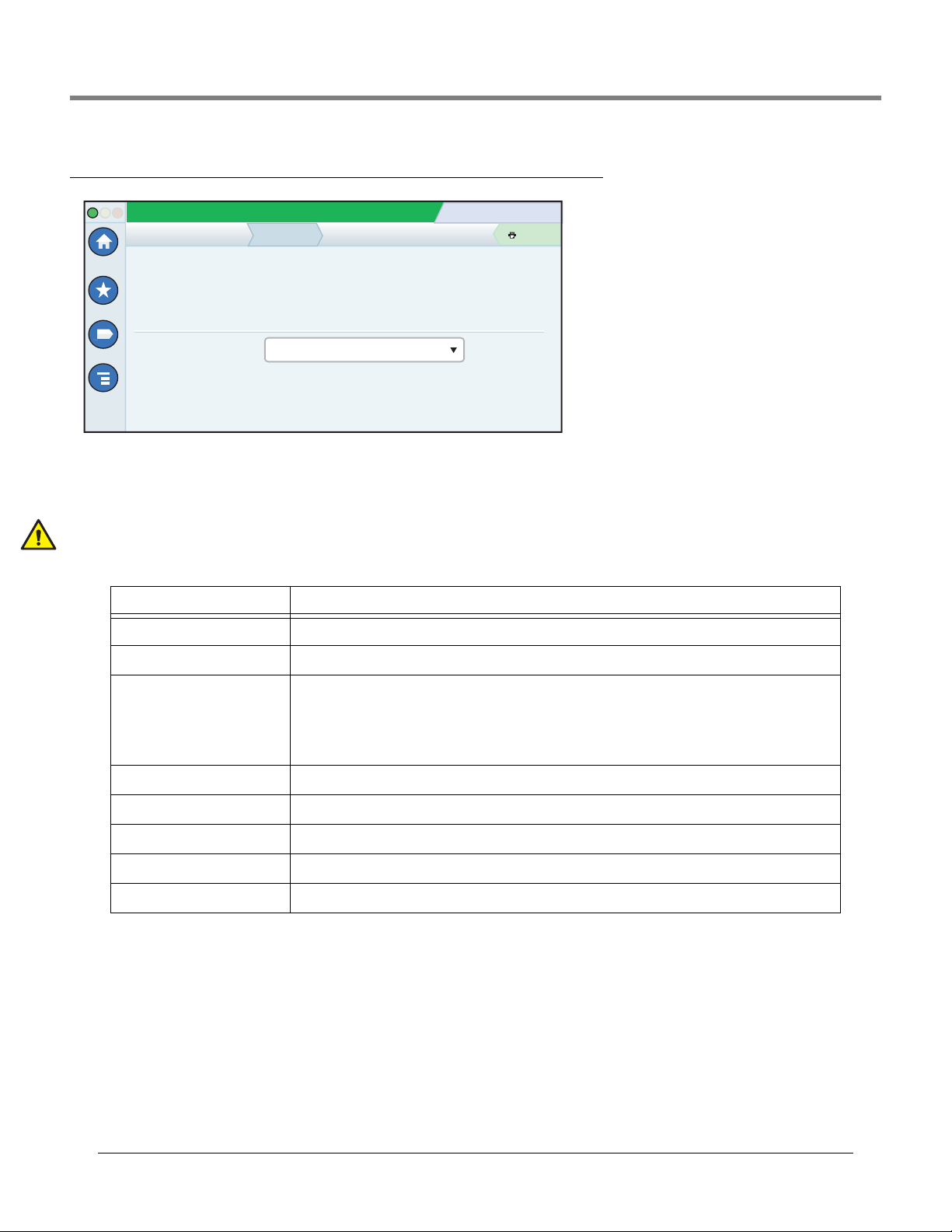

Activate/Revert Screen (Menu>Software Maintenance>Activate/Revert) ......................58

Notes on Reverting to a Previous Software Version ..............................................59

DB Backup (Menu>Software Maintenance>DB Backup) ................................................60

Example Database Backup Procedure...................................................................60

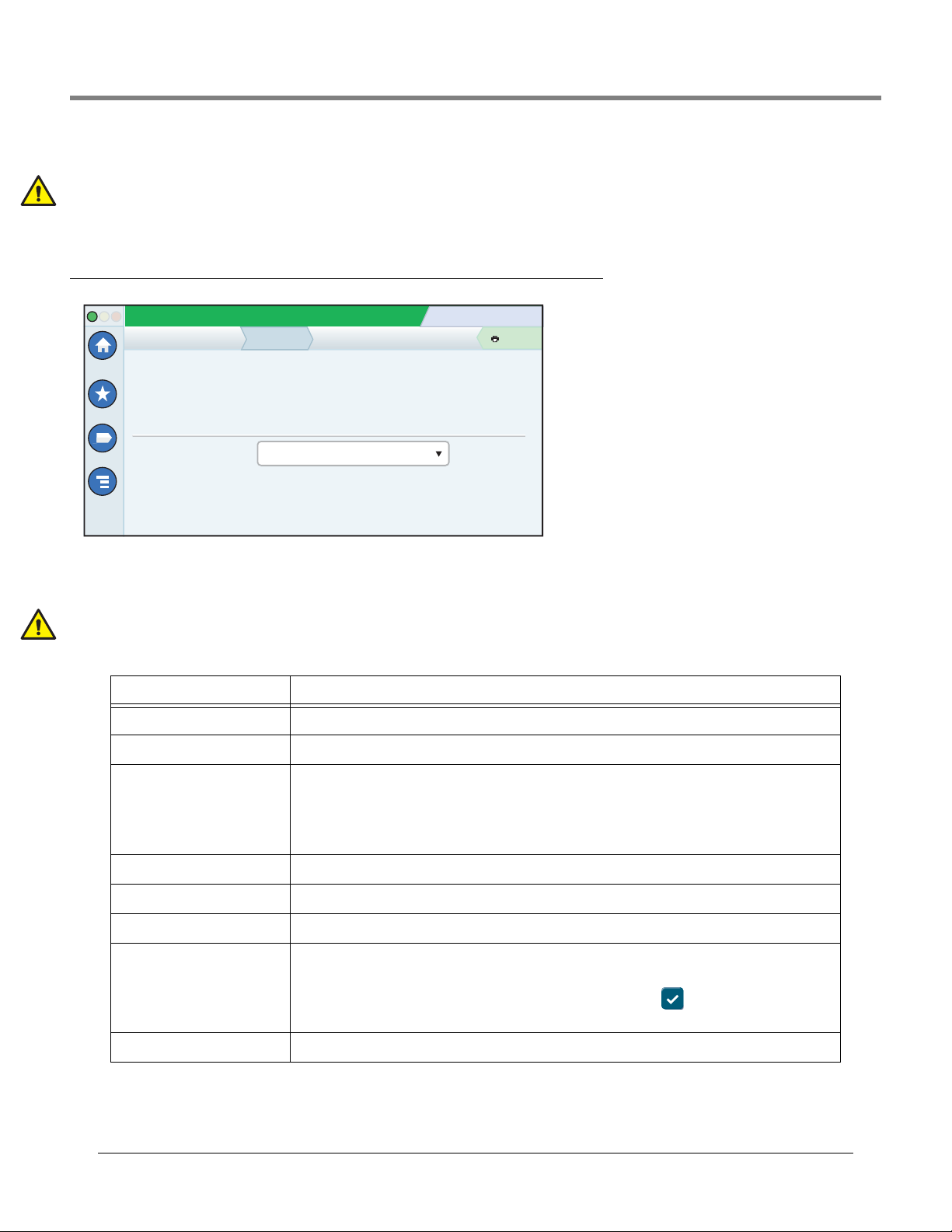

DB Restore (Menu>Software Maintenance>DB Restore) ..............................................61

Download (Menu>Software Maintenance>Download) ....................................................62

Example Software Download Procedure................................................................62

System Snapshot (Menu>Software Maintenance>System Snapshot) ...........................63

Example System Snapshot Procedure...................................................................64

Upgrade Features (Menu>Software Maintenance>Upgrade Features) ..........................64

Table of Contents

Figures

Tables

Figure 1. TLS4 Comm Ports ..................................................................................4

Figure 2. TLS-450PLUS Comm Ports ....................................................................5

Figure 3. Initial Setup Home Screen ......................................................................8

Figure 4. Accessing Workflow Wizard Setup .........................................................8

Figure 5. Software Maintenance Screen ..............................................................58

Table 1. Activate/Revert Screen Field Descriptions ..............................................59

Table 2. DB Backup Screen Field Descriptions ....................................................60

Table 3. DB Restore Screen Field Descriptions ....................................................61

Table 4. Download Screen Field Descriptions ......................................................62

Table 5. System Snapshot Screen Field Descriptions ..........................................63

Table 6. Upgrade Features Screen Field Descriptions .........................................64

iv

Page 5

Introduction

This manual contains instructions for using the Workflow Wizard Setup Application in the TLS450PLUS and TLS4/8601

Series consoles. Workflow Wizard guides the user through the Veeder-Root recommended setup screens during the

console’s initial commissioning.

This manual assumes all devices are connected the console and that a site diagram of all probes, sensors and tanks is at

hand to assist in determining the correct console addresses for these devices. The procedures herein are intended to be

followed using the console’s touch screen. Other setup interface methods vary in feature and accessibility options.

Some of the screens are only visible if the applicable features/devices are installed in your console. Skip over programming

instructions for any features/devices that are not installed in your console.

Contractor Certification Requirements

Veeder-Root requires the following minimum training certifications for contractors who will install and setup the equipment

discussed in this manual:

Installer (Level 1) Certification: Contractors holding valid Installer Certification are approved to perform wiring and

conduit routing; equipment mounting; probe, sensor and carbon canister vapor polisher installation; wireless equipment

installation; tank and line preparation; and line leak detector installation.

ATG Technician (Level 2/3 or 4) Certification: Contractors holding valid ATG Technician Certifications are approved to

perform installation checkout, startup, programming and operations training, system tests, troubleshooting and servicing for

all Veeder-Root Series Tank Monitoring Systems, including Line Leak Detection. In addition, Contractors with the following

sub-certification designations are approved to perform installation checkout, startup, programming, system tests,

troubleshooting, service techniques and operations training on the designated system.

Related Documents

577014-073 TLS450PLUS Site Prep Manual

577014-075 TLS-450PLUS Troubleshooting Guide

577014-022 TLS4 Site Prep Manual

577014-058 TLS4 Troubleshooting Manual

577013-465 Electronic Line Leak Detectors Application Guide

577013-770 Media-Isolated Mag Plus Probe LPG-ISO Kit Installation Guide

577013-773 Media-Isolated Mag Plus Probe Chem-ISO Kit Installation Guide

577014-056 Mag-FLEX Probe Low Level Water Float Kit Installation Guide

1

Page 6

Console Touch Screen Overview

T 1: DELIVERY NEEDED 01/20/2016 06:01 PM

Tank Overview

TANK 1: reg

Fuel Volume 3655

Fuel Height 38.6

Ullage 100% 6345

Temperature 61.9

Water Height 3.0

1 Warning(s)

0 Alarms(s)

Print (0)

Home

Favorites

Menu

Actions

Overview

!

See Example

Status Bar

Types Below

Bread Crumbs

0

M

)

0

)

P

)

p

le

Bar

Date & Time

Print Button

SYSTEM STATUS

0 Warning(s)

0 Alarms(s)

SAVING

0 Warning(s)

0 Alarms(s)

T2: DELIVERY NEEDED

1 Warning(s)

0 Alarms(s)

L 10: FUEL ALARM

0 Warning(s)

1 Alarms(s)

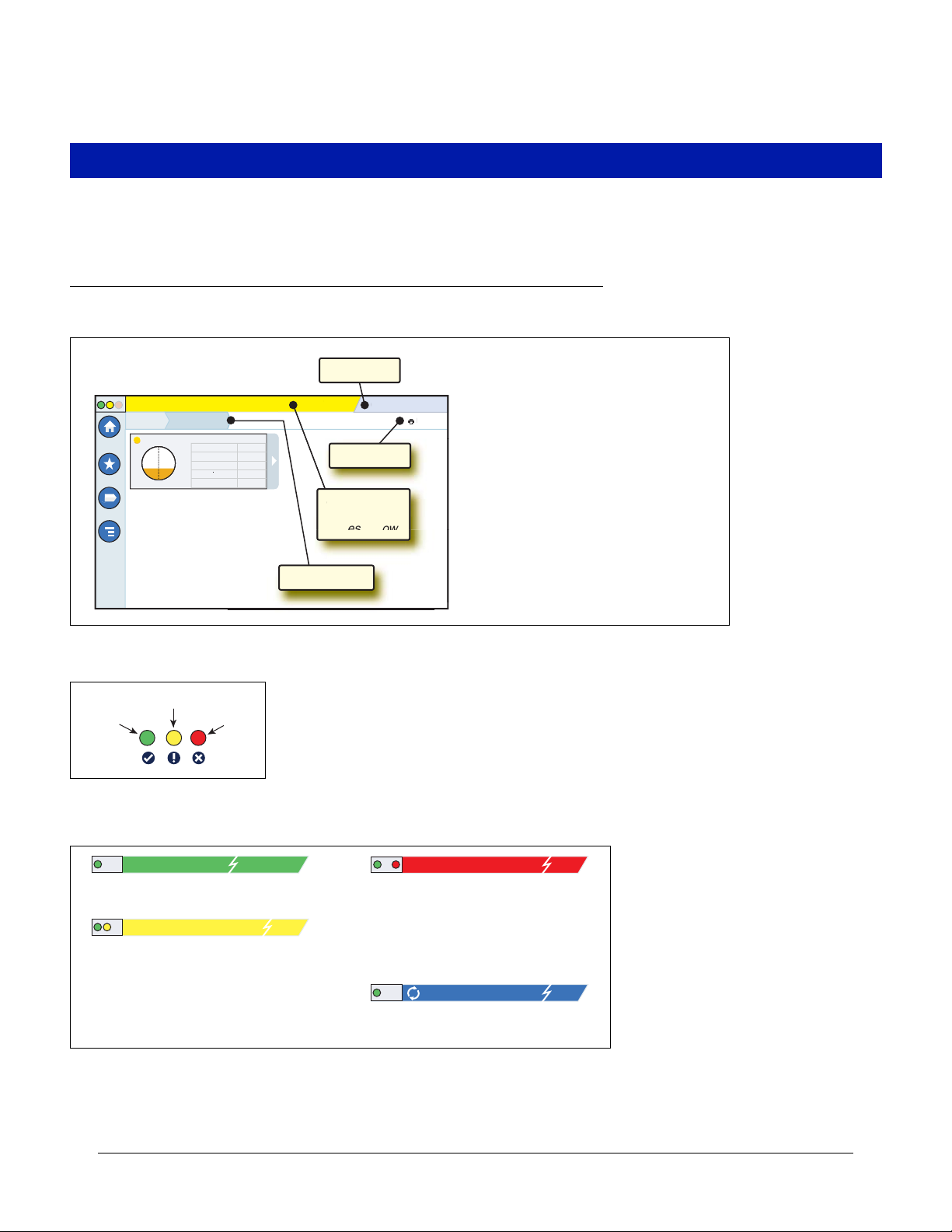

Power On to console and no warnings or

alarms from system.

System tasks message bar.

Something needs to be reviewed and/or assessed. In

this state, touching the status/warning bar brings you

to the Reports > Alarms > Active screen so you can

see the cause of the warning. While in that screen,

touching the status/warning bar again acknowledges

the warning and shuts off the beeper.

Something needs to be acted upon immediately. In

this state, touching the status/warning bar brings you

to the Reports > Alarms > Active screen so you can

see the cause of the alarm. While in that screen,

touching the status/warning bar again acknowledges

the alarm and shuts off the beeper.

The following section console features, touch screen layout and how to access and navigate the setup procedure using the

touch screen controls.

Console Home Screen

An example Tank Overview Screen (Default Home Screen) is shown below which has 2 Tanks Monitored and 1 active

Warning

1 Warning(s

Alarms(s

1/20/2016 06:01 P

rint (0

ee Exam

Front Panel Status Lights

Warning

Normal

Alarm

Example Touch Screen Status Bar Notifications

2

Page 7

Console Touch Screen Overview Example Touch Screen Status Bar Notifications

1

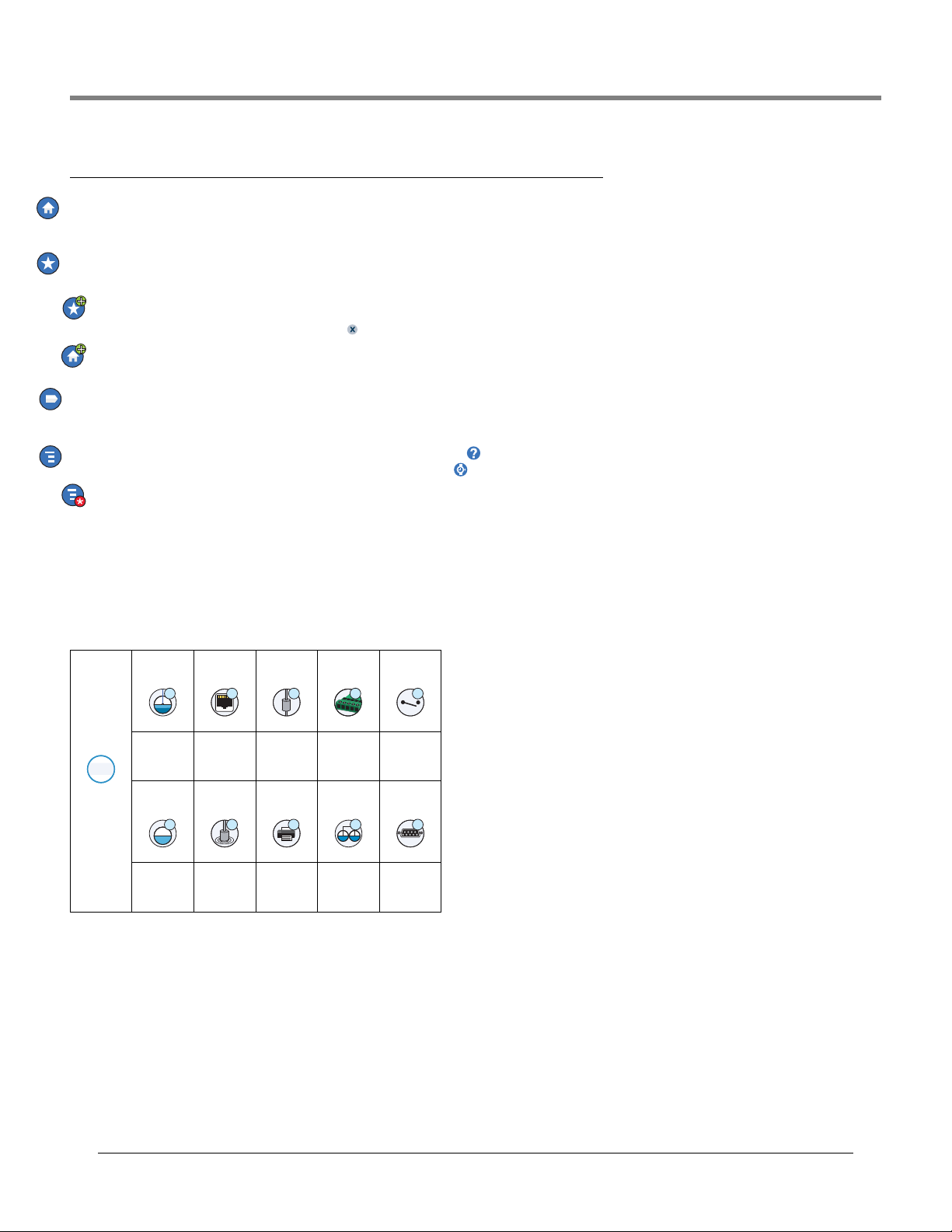

Touch Screen Icon Descriptions

Home Screen Icon - Touch to navigate to the home screen. Default is the Tank Overview screen (Home screen shown

above).

Favorites Screen Icon - Touch to setup/access your favorite screens and designate which screen will be the home

(default) screen.

Touch to add the current screen to your Favorites list. You can have up to six Favorites screens. If you want to delete a

screen from your Favorites list, touch next to that screen.

Touch to set the current screen as the home screen.

Menu Icon - Touch to access System Setup Menus, Reports, Diagnostics and other screens (Administrator assigned

access). For initial setup of the console, touch Menu>Setup>Workflow Wizard which steps you through the console setup

screens in the proper sequence. See Workflow Wizard setup

Actions Icon - Touch to access Help. Touch the Help icon to open On-Board Help. Also, if the Shifts feature is set up,

touching the Actions icon will display the Close Shift icon which can be touched to close a shift.

Unrelated to the choices above, when entering data in any screen, a Red Circle may appear on the Actions icon to indicate that additional tasks/menu choices for that screen.

Screen Dependent Icons - The number in the circle under the Actions icon indicates the device you are viewing or

setting up. Touching the circled number displays all of the similar devices in a row along the bottom of the screen (other

tanks, ports, probes, etc.) that you have set up. Touching the circled number again hides the device icon row. A highlighted

icon indicates the device you are viewing or setting up. Some of the device icons you may see depending on system

features installed in your console are shown below:

1

Tank Ethernet

Port

Device

Product Sensor Printer Siphon

Probe External

Input

Set

Relay

Serial

Port

3

Page 8

Console Touch Screen Overview TLS4 Comm Ports - Menu>Setup>Communication

4

n

e

a

printers

g

h

r

t

w

o

e

c

nge to a

touch the ke

USB port (1) upper

USB port (2) lower

SWITCH ETH 2 & 3 - shown

in Setup menu as

Ethernet Port 2 (Optional)

Factory Installed,

Optional Module

Area

VR Bus port Ethernet port (1) RS-232 or RS-485 DB9 ports

EXPANSION

SERIAL 1

SERIAL 2

ETH 2

ETH 3

USB 1

USB 2

ETH 1

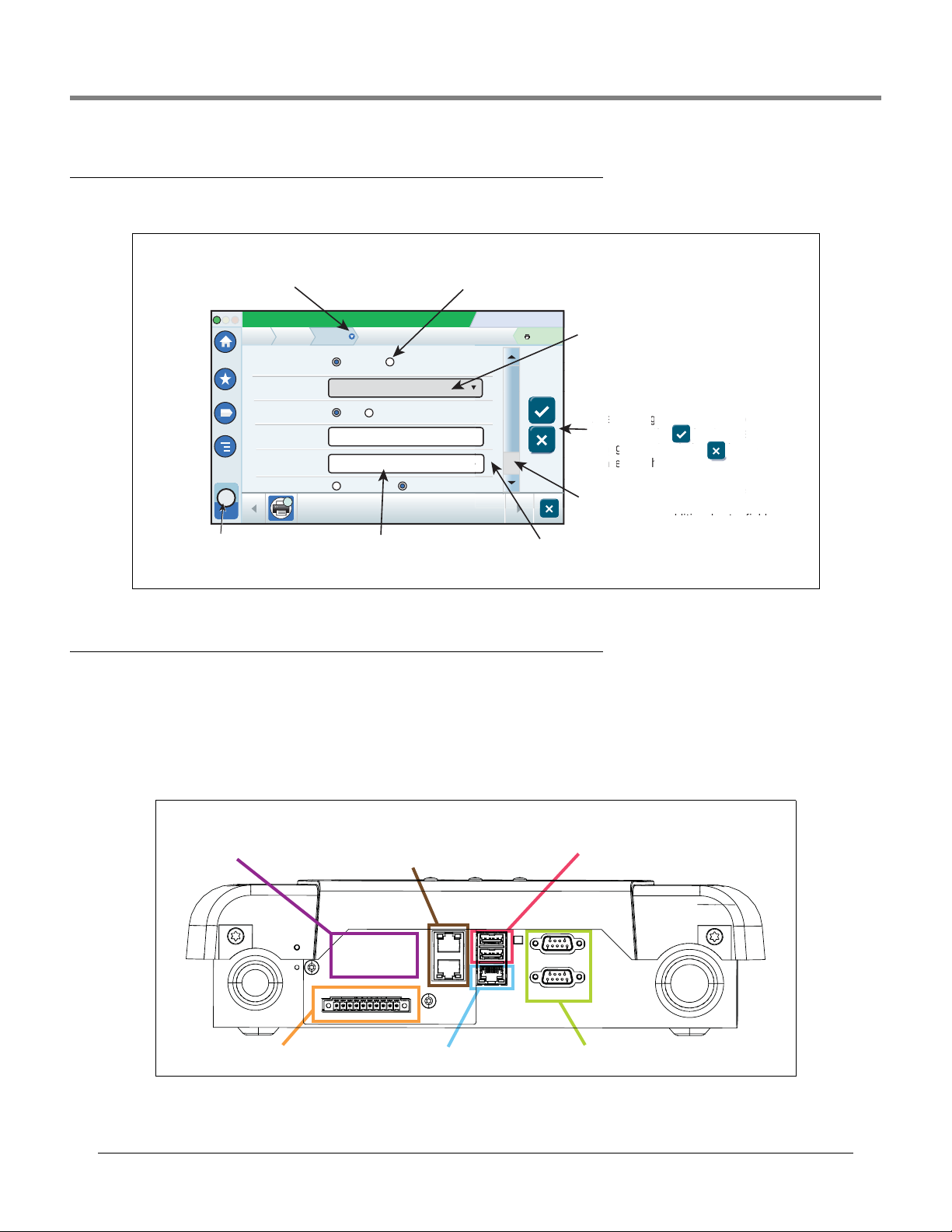

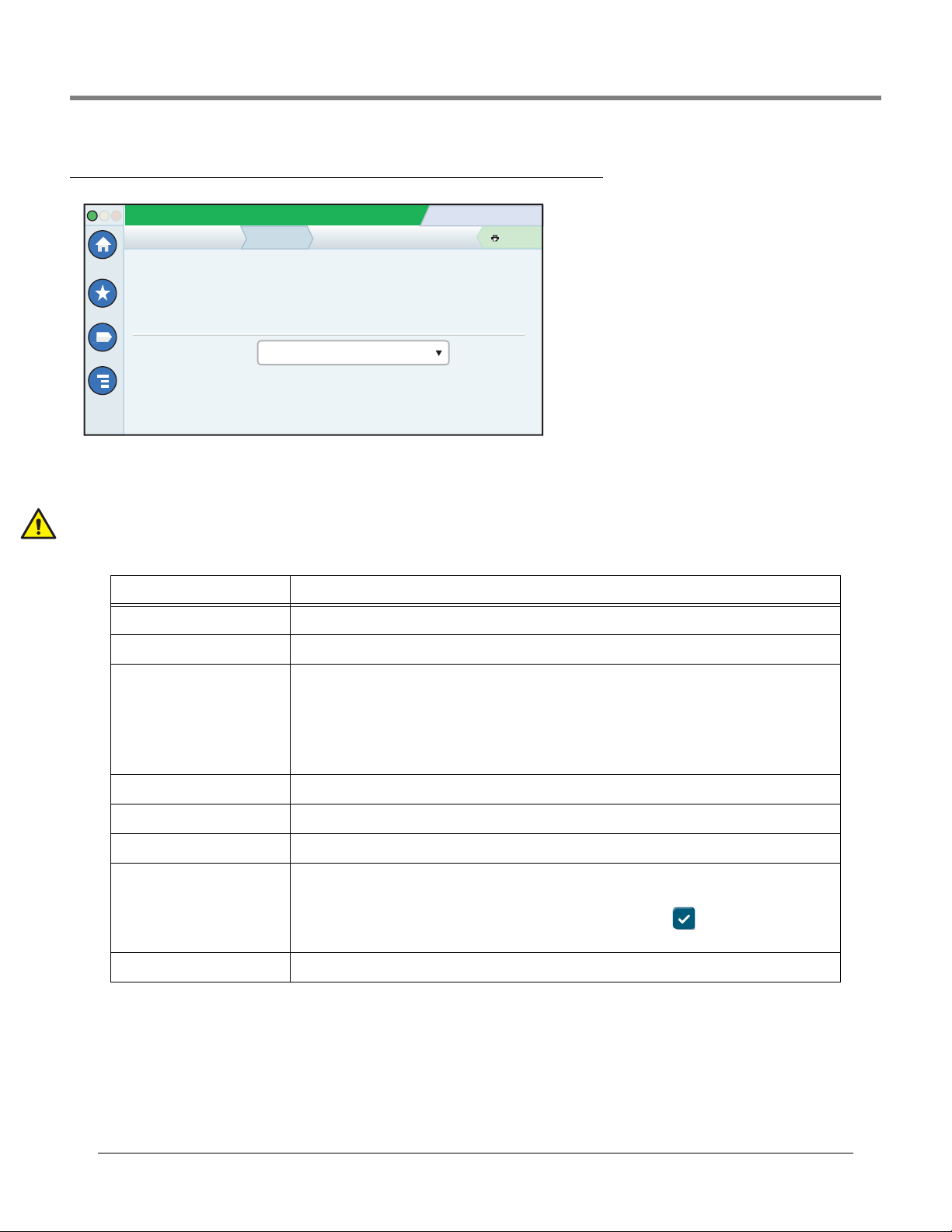

Entering Changes On A Touch Screen

The screen example below describes entering data into the screen’s field windows.

Touch down arrow in a menu

breadcrumb to view all additional setup

s

creens, select any in list to jump

White (empty) radio button indicates item is not selected.

Touch radio button to select Disabled and deselect Enabled.

to that screen

System Status

Printers

Home

Favorites

Menu

Actions

1

Printer

Setup

Configured

Driver Selection

Setup

Printer

Is Default

Label

URI

1

Selected device. Touch to select

additional devices to be programmed,

in this case additional printers.

0 Warning(s)

07/20/2013 09:01 AM

0 Alarms(s)

Enabled Disabled

APS_CP324HRS_640_USB_1

Yes No

TLSIntegralPrinter

dev/bus/usb?type=usb+vid=6868+pld=4

Automatic Manual

4

Touching in a white field displays

a pop-up keyboard/keypad to enter

or modify an entry.

Print (0)

*

A grayed-in field cannot be changed.

In this example, if there two or more

printers, the field would be white and

touching the down arrow would display

the additional printers.

After making any change to a screen

Aft

entry, touch the key to accept the

ent

change(s) or touch the key to

ch

cancel the change(s).

ca

If page scroll is visible, touch the up/down

makin

touc

(s) o

l the c

scroll

i

.

ange(s).

s visible, touch th

creen

pt the

to

up/d

arrows or slide bar with finger to scroll up

or down to view additional entry fields.

An asterisk (*) next to a field indicates you

changed

an entry for that field before you have accepted or

saved the change in a dialog window.

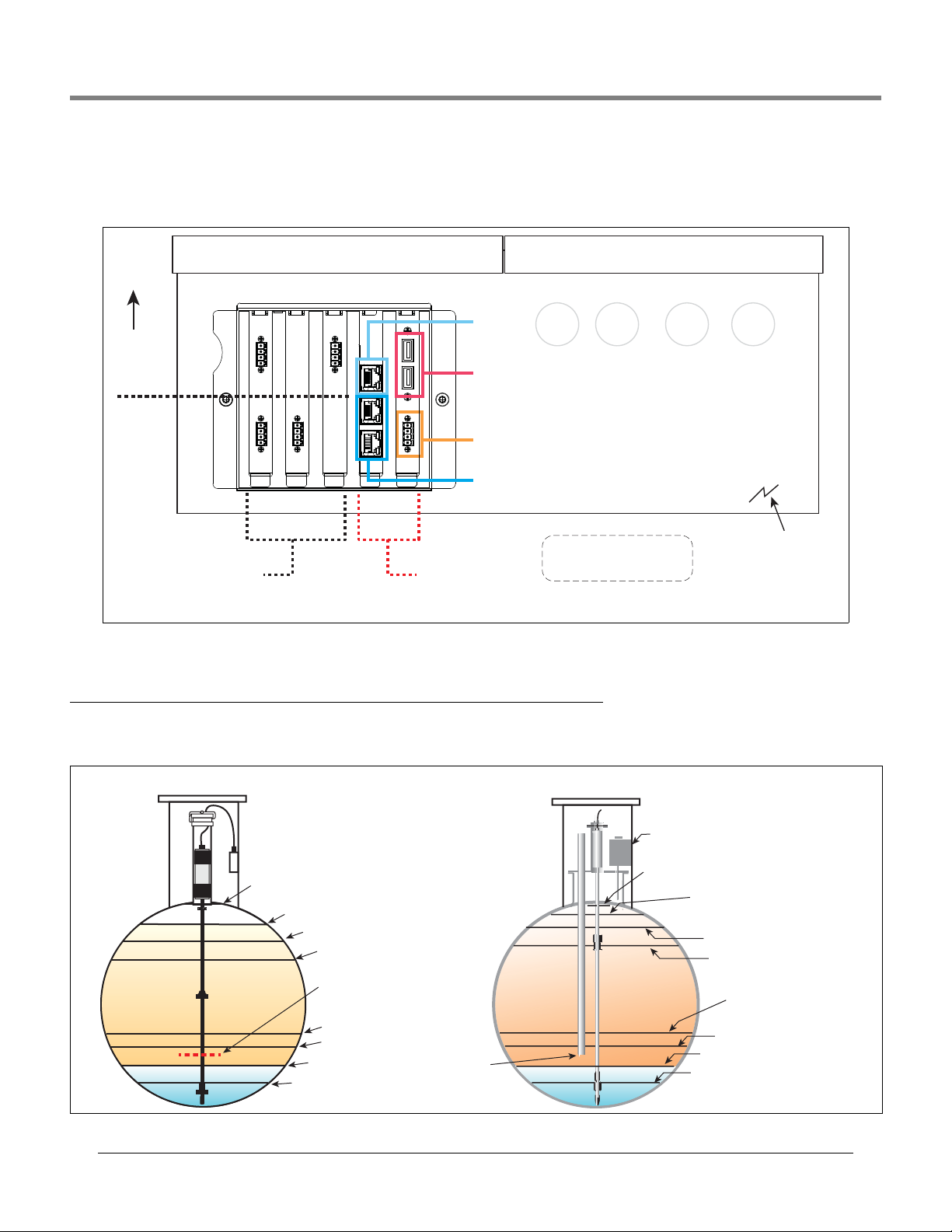

Console Comm Ports

When setting up comm ports, you should verify the connections to the console’s comm ports prior to entering their setup

parameters.

TLS4 Comm Ports - Menu>Setup>Communication

Your console’s Comm Port configuration will depend on features ordered. Note: Ethernet ports 2 and 3 are programmed as

the same ethernet device.

Figure 1. TLS4 Comm Ports

4

Page 9

Console Touch Screen Overview TLS-450PLUS Comm Ports - Menu>Setup>Communication

USB ports: (1) upper, (2) lower

Future expansion port

*Both ports of ethernet 2

are programmed the same.

Ethernet port:

(1) upper

Ethernet port 2:

middle and lower switched*

Front of

Console

Port 2

Bottom of

console

Port 1

Selectable Comm

Device slots

Fixed Comm

Device slots

12345

High Water Warning

High Water Alarm

Low Product

Delivery Overfill

Delivery Overfill

High Product

Max (Label) Volume

Full Volume (Ref.)

Full Volume (Ref.)

Pump Inlet (Ref.)

Delivery Limit

Delivery Limit

SAFE WORKING CAPACITY

Maximum Product Alarm Level

("Label" Volume)

High Product Alarm Level

Fuel Draw

Off Level

(Ref.)

High Water Warning Level

Low Product Alarm Level

High Water Alarm Level

Interstitial Sensor/Sump Sensor

Typical European TankTypical North American Tank

TLS-450PLUS Comm Ports - Menu>Setup>Communication

Your console’s available Comm Port configuration will depend on features ordered.

Figure 2. TLS-450PLUS Comm Ports

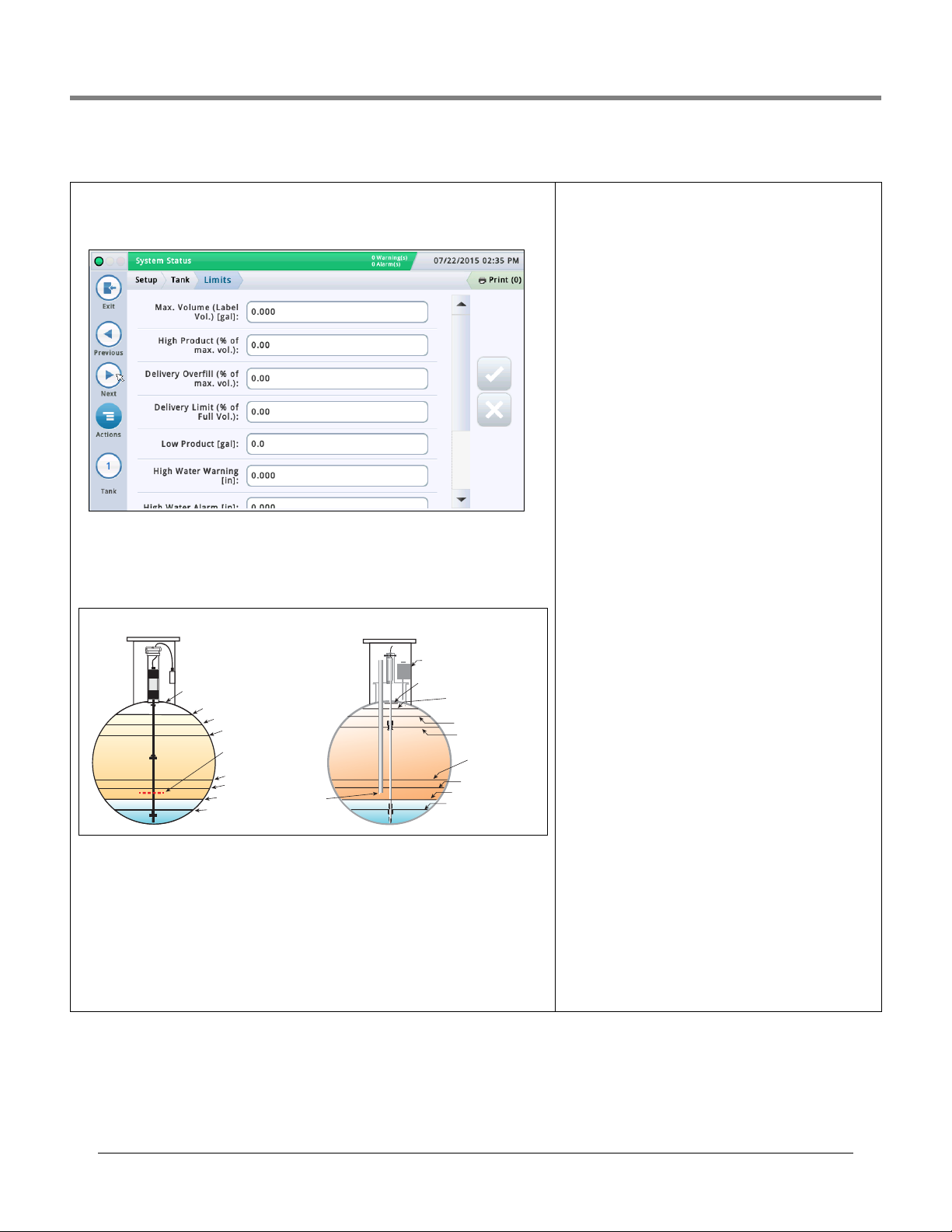

Alarm Limit Settings - Menu>Setup>Tank>Limits

The diagrams below show the relative position of tank alarm (Limit) settings. See “Setup>Tank>Limits” on page 27 for

more information about tank alarm limits.

5

Page 10

Console Touch Screen Overview On-board Help Topics of Interest - Actions>Help

Username:

Password:

Language:

Sign In Cancel

Default

Logout

Security Login

If the console Security Feature is Enabled - Touch the Login button to open the login screen so you can login as a

Login

user:

Once the screen displays, log in to the system

with your Username and Password. NOTE: If you

do not log in, you are only permitted to view

system status screens and to print out end-user

reports.

Touch the Logout button to log out of

the console. NOTE: If the console is inactive for

15 minutes, the console will automatically log

you out. You will need to log back in to access

your user account.

Using On-Board Help - Actions>Help

Note: On-board help covers all console features, some of which may not be on visible/applicable if they were not ordered

with your console.

To access On-Board Help touch the Actions icon then touch the Help icon .

Upon entering Help, the topic associated with the currently displayed screen will be visible. Repeatedly touch the side

scroll bar up/down arrows to scroll through a topic. You can also drag and pan through a topic. Touch the ‘X’ in the right

corner of the Help screen title bar to return to the TLS4/TLS-450PLUS screen you were viewing.

•To show or hide the help Table of Contents (TOC) pane on left side of screen - Quickly tap the text (Show TOC or Hide

TOC) twice with your finger.

•To expand ( ) or close ( ) a book - Touch the icon of the book once with your finger.

•To go to a topic ( ) within a book - Quickly tap the book topic twice with your finger.

•Touch the side TOC scroll bar, and either move your finger up (to scroll down) or move your finger down (to scroll up).

•Repeatedly touch the side TOC scroll bar upper arrow to scroll up, or repeatedly touch the side scroll bar down arrow to

scroll down.

On-board Help Topics of Interest - Actions>Help

• Understanding ATG -This help section explains the fundamentals of automatic tank gauges (ATG) as implemented by

Veeder-Root.

• Configuration and Maintenance - This help book discusses Comm Ports, Initial Console Setup Sequence, and Periodic

Maintenance recommendations.

• Welcome (Help Intro) , Screen Icons, On-Screen Keyboards, and Touchscreen navigation are essential help topics which

you can view in the On-Board Help’s Table of Contents.

• Reference Tables - This help section contains topics that cover a wide variety of useful information replaceable fuses, VR acronyms, system device identifiers, tank tilt calculation information, DIM data, etc.

6

Page 11

Console Touch Screen Overview Backup System Data - Menu>Software Maintenance>DB Backup

System Status

07/20/2013 09:10 AM

0 Warning(s)

0 Alarms(s)

Print (0)

Home

Favorites

Menu

Actions

Software Maintenance

Current Version

Available Version

Current Operations

Backup Destination

Version

1.gB 230.4

Not available

Select a source to retrieve versions available

IDLE

DB Backup

Select destination device

System Status

07/20/2013 09:18 AM

0 Warning(s)

0 Alarms(s)

Print (0)

Home

Favorites

Menu

Actions

Overview

Console Series # 8601

Software Part # 342004-001.gB230.4r71119

ATG Functionality

Email Notification

Custom On-Board Help

Custom Alarms

Web Enabled

Extended Storage L2

Created Jul 29 2013 17:43:52

About

Hardware Description

Installed Features

Serial #

CPU 11260090

iButton 000D016283f20b

UNIV SENS I/O MODULE (B1.S1) 000D016283f20b

Max Allowed Ports 9

System Status

07/20/2013 09:10 AM

0 Warning(s)

0 Alarms(s)

Print (0)

Home

Favorites

Menu

Actions

Software Maintenance

Current Version

Available Version

Current Operations

Backup Destination

Version

1.gB 230.4

Not available

Select a source to retrieve versions available

IDLE

Download

Select Source

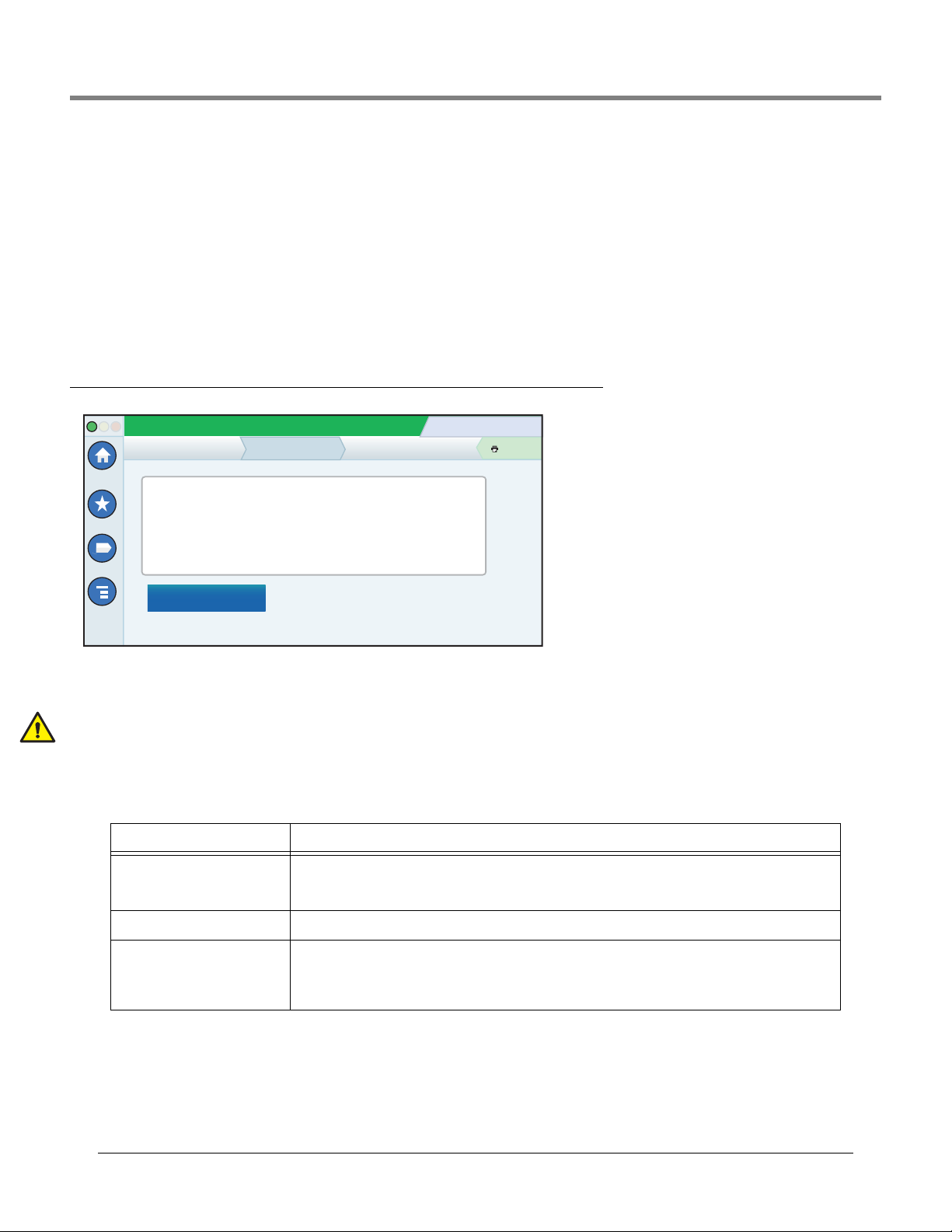

System Maintenance Screen Examples

Backup System Data - Menu>Software Maintenance>DB Backup

Insert your Fat 32 formatted thumb drive (mini-

mum 4 GB) in a USB port and touch the down

arrow in the Backup Destination field to select

the thumb drive, then follow the on-screen

instructions to backup console data.

You should perform a DB Backup weekly.

To View The Console’s Software Version - Menu>Overview>About

This screen provides important information about

your console's software version and installed

features. If you should be experiencing problems

with the console, please have the information on

this screen available with you before contacting

us.

The Veeder-Root Technical Support number is

(800) 323-1799.

To Download Console Software - Menu>Software Maintenance>Download

Insert your valid V-R Code thumb drive in a USB

port and touch the down arrow in the Backup

Destination field to select the coded thumb drive,

then follow the on-screen instructions to begin

the download. Once the download process has

completed, you must activate the software (see

“Activate/Revert Screen (Menu>Software

Maintenance>Activate/Revert)” on page 58).

7

Page 12

Initial Setup Of The Console Using Workflow Wizard

After the console has been installed and connected to the power panel and to all site monitored devices, apply power to

the console and let it boot up and display the Home Screen (see below).

Figure 3. Initial Setup Home Screen

Access Workflow Wizard Setup by touching Menu>Setup>Workflow Wizard>Setup Workflow:

Figure 4. Accessing Workflow Wizard Setup

8

Page 13

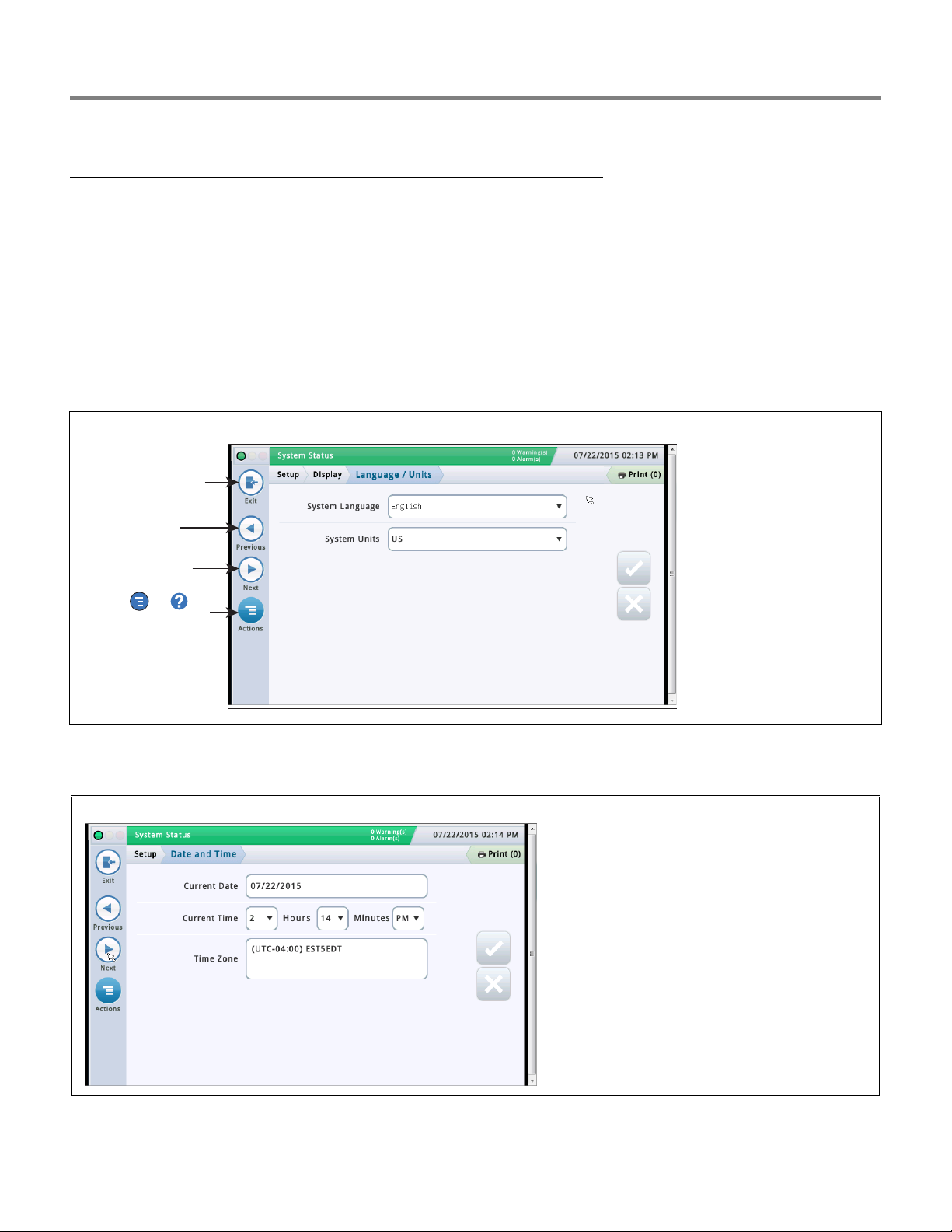

Initial Setup Of The Console Using Workflow Wizard Setup>Display>Language/Units

Touch the Exit icon to quit

Workflow Wizard and return

to the Home screen

Touch to step back to

previous screen

Touch to step forward to

next screen

Touch the and icons

to access online help for the

current screen

Initial Screen - Menu>Setup>Workflow Wizard>Setup Workflow

The initial setup screen in the Workflow Wizard app is shown below. Note that the Workflow Wizard steps through the

setup screens in a V-R recommended sequence for initial setup of the console. This manual assumes all devices are

connected and recommends you are accessing WW setup from the console GUI. Other setup interface methods vary in

feature and accessibility options.

Navigating Workflow Wizard is described in the figure below. When you exit the Workflow Wizard app, or it times out,

reentering the app always returns you to the initial screen. To return to the screen you were working on after exiting the app,

touch the Next button repeatedly until the desired screen is displayed.

Once the console is setup and functioning and a screen needs modification, the user would likely use the standard quicker

path (from the home screen) to the desired screen, e.g., Menu>Setup>etc>etc..

Setup>Display>Language/Units

System Language

Touch to select the system lan-

guage used for all displays and

reports.

System Units

Touch to select U.S., Metric or

Imperial units to be used in all

displays and calculations.

Setup>Date and Time

This screen lets you enter the current date and time for the console.

Current Date

Touch to enter current date.

Current Time

Touch each field to enter time.

Note: the default time format is 12 hour AM/PM (hh:mm AP).

If 24 hour time is desired, enter the correct time on this

screen then select hh:mm in the Time Format field in the

next Workflow Wizard screen.

Note: Switching to and from Daylight Savings Time is automatic based upon your time zone entry below

.

Time Zone

Touch and scroll to select local time zone.

9

Page 14

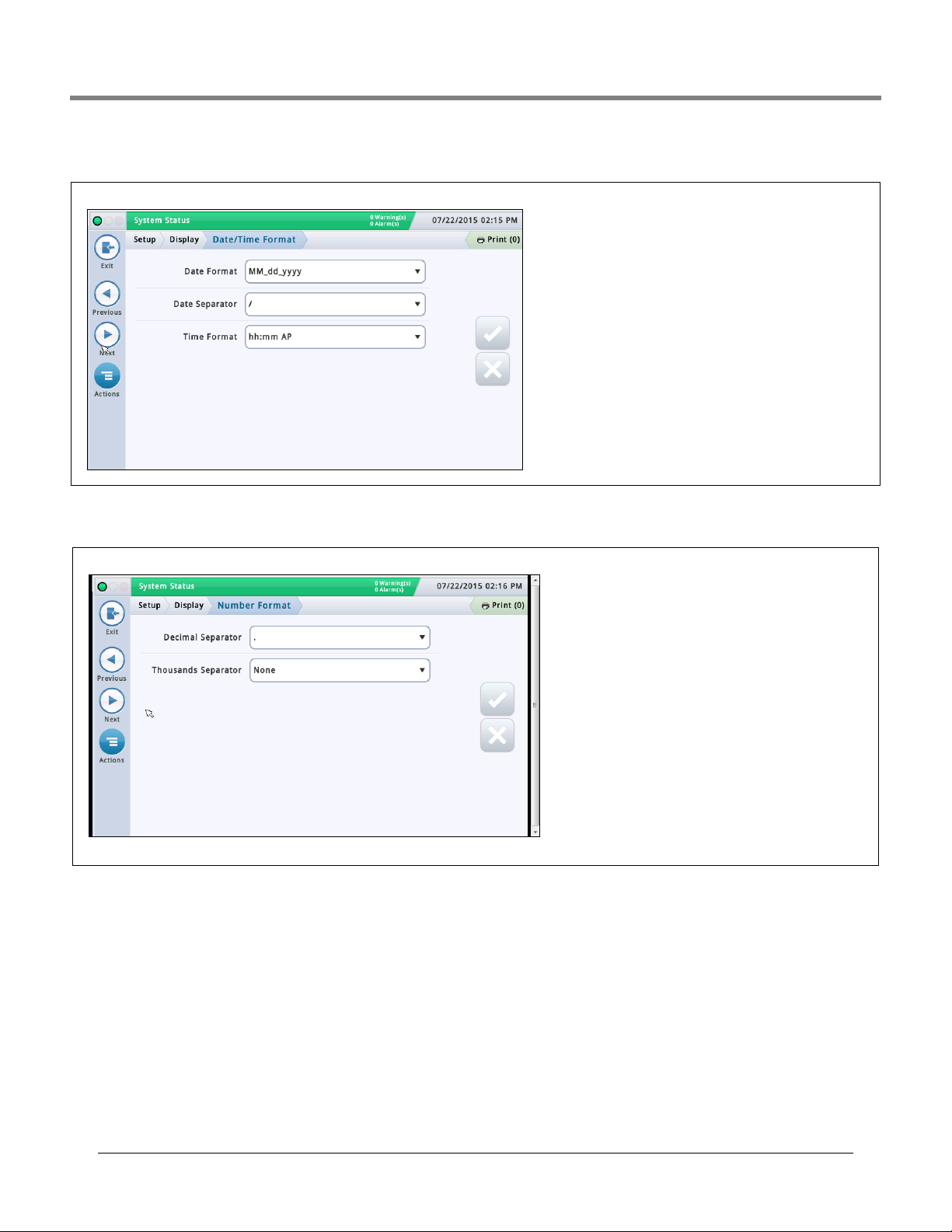

Initial Setup Of The Console Using Workflow Wizard Setup>Display>Date/Time Format

Setup>Display>Date/Time Format

This screen lets you select the date and time format used in all screens and reports.

Date Format

Touch to enter desired date format.

Date Separator

Touch to enter desired date separator.

Time Format

Touch to select 24 hr time (hh:mm) or 12

hour AM/PM time (hh:mm AP).

Setup>Display>Number Format

This screen lets you select the numerical separators used in all screens and reports.

Decimal Separator

Touch to enter desired decimal separator.

Thousands Separator

Touch to enter desired thousands separator.

10

Page 15

Initial Setup Of The Console Using Workflow Wizard Setup>Headers

Setup>Headers

This screen lets you enter information to identify your site location, address, phone number, etc. This infor-

mation appears on the top of most inventory and BIR reports. This screen also lets you enter a fax sender

name and fax number when sending faxes.

Header 1 - 4

Touch to enter desired Site Name (1),

Street (2), City and State (3) and Phone (4) up to 20 characters each header.

Fax Sender Name

Touch to enter data printed at top of transmitted faxes from console - up to 30 alphanumeric characters.

Fax Phone Number

Touch to enter phone number to which the

console will dial to send faxes - up to 40

digits.

Setup>System>Alarm Filtering

This screen lets you enable/disable Alarm Filtering. Alarm Filtering reduces the total num-

ber of alarms without compromising the reporting of critical alarms.

Alarm Filtering

When this feature is enabled, the console manipulates a combination of the detection time

(the time before an alarm sounds) and the clear time (the time before an alarm is reset) for

certain alarms that often go in and out of an alarm state in a short period of time. In addition, some alarm reports during the clear time are consolidated, reducing their number

without eliminating the alarm reports.

Mag Sensors

The following Mag Sensor alarms will be filtered:

• Mag sensor fault, install and communication alarms - NOTE:

Mag Sensor alarms are reset if the Mag Sensor is replaced

or deconfigured and then reconfigured.

Analog Sensors

The following Liquid, Vapor, Groundwater, Type A (2-wire) and

Type B (3-wire) alarms will be filtered:

• Open, Short, Water, Water Out, Liquid Warning, Low Liquid,

High Liquid and Fuel - NOTE: Liquid Warning, High Liquid,

Low Liquid and Fuel alarms are posted immediately even

when filtered.

DIMs (Dispenser Interface Modules)

The following DIM alarm will be filtered:

•Communication Alarm - NOTE: If there is more than one DIM

card in the console, each card is filtered independently. DIM

alarm filtering takes into account the possibility of lost POS

sales data by monitoring dispensing during the clear time,

but the possibility exists that the filter may not identify all

cases when POS sales data may be lost. Unfiltered DIM

Communication Alarm reports are available by contacting

Veeder-Root Technical Support.

Probes

The following Probe alarm will be filtered:

•Probe Out

11

Page 16

Initial Setup Of The Console Using Workflow Wizard Setup>Communication>System Hostname

Setup>Communication>System Hostname

This screen lets you specify and change the host name of this console (i.e., what the console

is called on the customer's network, such as "MyTLSConsole").

System Hostname

Touch to select the host name of the console as it appears on

the customer’s network, in this example TLS-450PLUS.The

default host name can be changed to accommodate the customer’s network needs.

A blank host name is not allowed. The host name may contain only ASCII letters ‘a’ through ‘z’ (case-insensitive), digits ‘0’ through ‘9’ and the hyphen ‘-’ with no spaces or other

characters allowed.

(Note: the console converts any uppercase letters in the host

name to lower case when they are saved.)

12

Page 17

Initial Setup Of The Console Using Workflow Wizard Setup>Communication>Ethernet Port

Setup>Communication>Ethernet Port

MAC Address [Read-only field] Physical address of the Ether-

net board and is automatically updated by the system (for example,

01:23:45:67:89:ab).

Serial Command Port

Address of serial port used for communications in the console

(default port is 10001). If the customer is using port 10001 already

for another device, you can select another port.

NOTES:

• Do not use ports 20001, 22, 80, or 443. These are used for other

communication purposes within the console.

• If each Ethernet comm device on the console has a different IP

address they can be setup with the same serial command port. Otherwise, when setting up two or more Ethernet devices with the

same IP address on the same serial command serial port, communications may be compromised and no warning messages will be provided.

• When the serial command port is disabled on the “Setup>System>Security” screen, the Serial Command Port field on this

This screen lets you configure the ethernet port(s) on the console which is used for

remote connectivity to a POS, remote printer, etc.. NOTE: Changes made in this screen

may take 10 - 15 seconds before they take effect and then display on the screen. The

fastest way to see changes is to accept the changes, go to the Home screen, then back

to this screen.

The default port selection is Ethernet Port 1. If more than one Ethernet Port is installed

(as in the example above), complete all of the entries for port 1, then select the next

Ethernet port from the icon list on the bottom of the screen that you want to configure

and repeat the complete field entry process for port 2.

IP Address Type

Dynamic - An Ethernet comm device can have a different IP address every time it connects to the network. This address is usually administered by a network service such as

DHCP (Dynamic Host Configuration Protocol).

Static [Default] - An Ethernet comm device will have a permanent IP address every

time it connects to the network. This is entered once on the console.

IP Address

[Field only available if IP Address Type is set to Static]

Enter an IP address that was assigned by the customer's IT department (the default

setting of 192.168.11.100 won't work).

IP Subnet Mask

[Field only available if IP Address Type is set to Static]

Default is 255.255.255.0 and is typical of console configurations. Do not change unless

assigned something different by the customer's IT department.

IP Gateway Address

[Field only available if IP Address Type is set to Static]

Enter a Gateway address that was assigned by the customer's IT department (the

default setting of 192.168.11.100 won't work).

IP Default Gateway

When set to Enabled, makes this Ethernet port the default pathway for outbound communications, such as email.

Primary DNS

[Field only available if ‘IP Address Type’ is set to Static]

Enter a Primary DNS address that was assigned by the customer's IT department.

Secondary DNS

[Field only available if ‘IP Address Type’ is set to Static]

Enter a Secondary DNS address that was assigned by the customer's IT department.

screen is not available.

SSH Port

A secure port that is required by the console to ensure protection on

the communication side of the device. The default port is 22 and

should not be changed.

NOTE: Any changes to this field will affect the same field for the

other Ethernet comm device (if one exists).

HTTPS port

A secure port used by the browser to ensure security on the

browser’s side of the device. The default port is 443 and should not

be changed.

NOTE: Any changes to this field will only affect the specific Ethernet

port being programmed.

Changes to the HTTPS port will affect web enable access.

Serial Command Security

Enables or disables the requirement of entering a security code to

make changes to the Ethernet comm ports.

Security Code

[Field available if Serial Command Security field is enabled]

Enter a security code (6 alphanumeric characters) that will be

required to make any change to the Ethernet comm port(s).

ETX Characters Display

[Field enabled only if RSR 232 End of Message field is enabled]

End-Of-Text (ETX) character. ETX is programmable if enabled via the

S53100f command. If it is disabled, the ETX is a fixed Control-C character (ASCII 03).

ETX Characters Computer

[Field enabled only if RSR 232 End of Message field is enabled]

End-Of-Text (ETX) character. ETX is programmable if enabled via the

S53100f command. If it is disabled, the ETX is a fixed Control-C character (ASCII 03).

13

Page 18

Initial Setup Of The Console Using Workflow Wizard Setup>Communication>Internal Modem

Setup>Communication>Internal Modem

This screen lets you configure the internal modem (TLS-450PLUS consoles only) which is used

for data collection (Note: in the above example screen no internal modem is installed).

Configured

Determines if the internal modem is enabled or disabled.

Label

Name of the internal modem.

Baud Rate

Choices are: 300, 600, 1200, 2400, 4800, 9600, 19200, 38400, 57600, 115200. The default is

9600.

Byte Size/Data Bits

Choices are: 8 or 7

Parity

Choices are: Odd Parity, Even Parity, or None

Stop Bits

Choices are: 1 or 2

Use Handshaking

Choice is: No Handshaking

Modem Dial Type

Choices are: Tone or Pulse

Dial Tone Interval

Choose interval to wait if there is no dial tone: From 0001 to 9999 hours

Answer On

Choose answer on the number of rings selected: From 0 to 9

Dial In Config

Advanced setting. Leave blank unless directed by Support.

Dial Out Config

Advanced setting. Leave blank unless directed by Support.

Serial Command Security

Select Enable to require all incoming serial commands to

have a security code.

Security Code

[Field available and required if Serial Command Security

field is enabled].

This the security code that all serial commands must have

to be accepted by the console. Valid security codes must be

exactly 6 digits (0 - 9) long.

RS232 End of Message

Enables or disables the End of Message RS232 protocol.

This protocol is used by third party devices that may want

to interrogate the console for inventory or other related

data. These devices require an End-Of-Text command that

signals to the device when the communication string from

the console ends.

Please refer to the customer's third party device for the

type of code to enter in the ETX Characters Display and ETX

Characters computer fields below.

ETX Characters Display

[Field enabled only if RSR 232 End of Message field is

enabled]

End-Of-Text (ETX) character. ETX is programmable if

enabled via the S53100f command. If it is disabled, the ETX

is a fixed Control-C character (ASCII 03).

ETX Characters Computer

[Field enabled only if RSR 232 End of Message field is

enabled]

End-Of-Text (ETX) character. ETX is programmable if

enabled via the S53100f command. If it is disabled, the ETX

is a fixed Control-C character (ASCII 03).

14

Page 19

Initial Setup Of The Console Using Workflow Wizard Setup>Communication>CDIM Port

Setup>Communication>CDIM Port

DIM Protocol

This screen lets you configure the DIM protocol for the

optional CDIM (Current Loop Dispenser Interface Module).This module is used by the system to collect dispenser

transactions for the BIR feature.

Select a CDIM port from the icon list on the bottom of the

screen that you want to configure. NOTE: This field will be

grayed out for DIMs that do not support ‘pass-through’ com-

munications.

Touch to select a DIM Protocol. Choices are:

• Gilbarco CL

•Wayne CL

• Unknown

Setup>Communication>TDIM Port

This screen lets you configure the TCP/IP DIM (Dispenser Interface Module) port. This is

used at sites where the console communicates to the dispensers via Ethernet (TCP/IP)

instead of the typical serial communications pathway.

Select a TDIM port from the icon list on the bottom of the screen that you want to configure.

Repeat the entry process for each TDIM Port.

Configured

Touch the radio button to enable or disable this port. NOTE:

When the card is auto-detected, this field will be enabled but

grayed out.

Label

Touch to enter a unique label (up to 20 alphanumeric characters) for the DIM device.

Port Number

Communications port number assigned to this device

(default is 35555). Note: this port is known as the listening

port.

Protocol

Touch to select applicable DIM protocol for your TDIM port.

Choices are:

GilbarcoEDIM, VRProtocolDIM, or Unknown.

Units Reported

Touch to select units for this protocol. Choices are: U.S.,

Metric, or Imperial.

15

Page 20

Initial Setup Of The Console Using Workflow Wizard Setup>Communication>IFSF

System Status

07/07/2016 09:10 AM

0 Warning(s)

0 Alarms(s)

Print (0)

Exit

Actions

Previous

Next

Setup

EnabledConfigured Disabled

Device

LON Module

Communication IFSF

Node Id

01

UDP Port

3485

TCP Port

9000

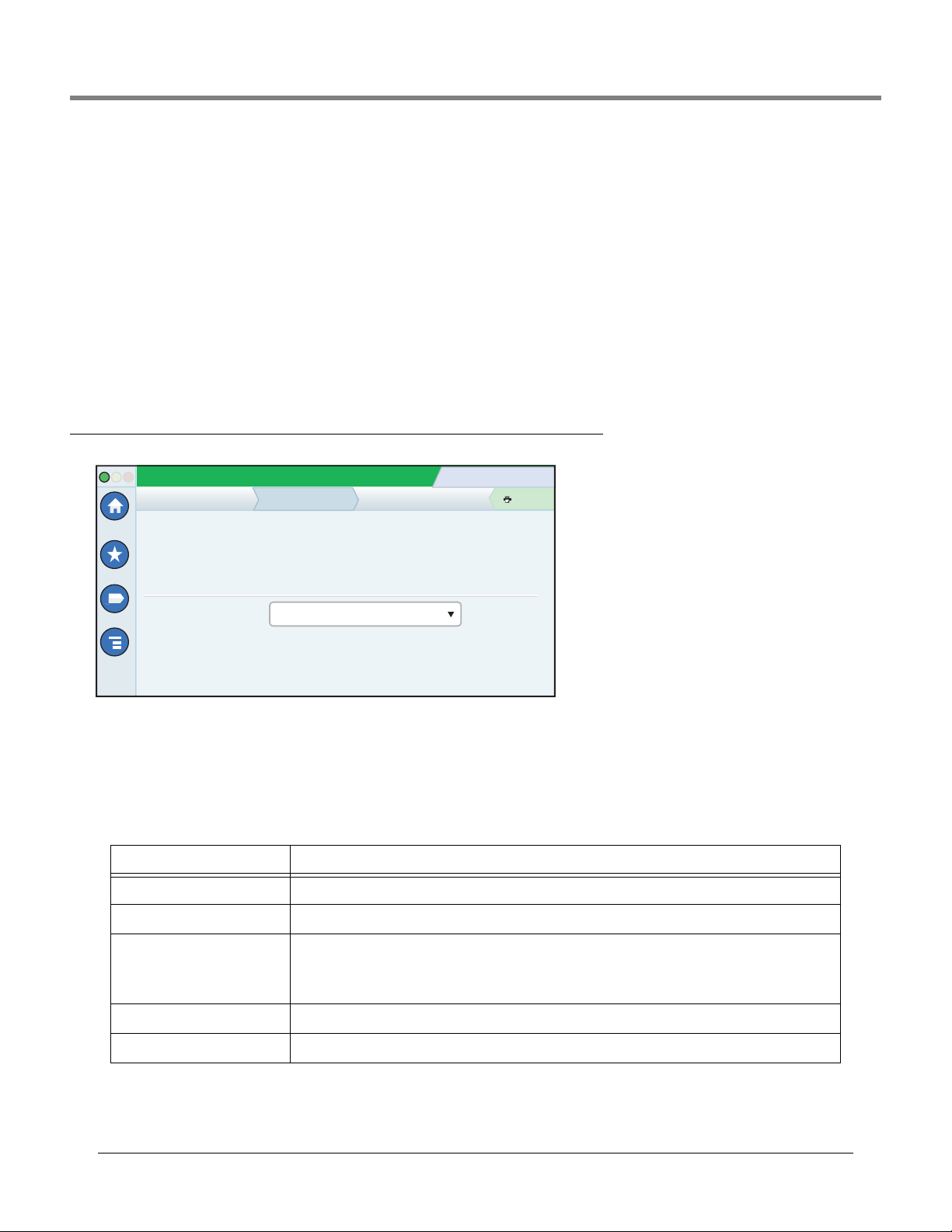

Setup>Communication>IFSF

This screen lets you configure communication based on International Forecourt Standards

Forum (IFSF) standards for a TLS over TCP/IP or a LonWorks

®

card (LON Module). These

international standards for petroleum retail facilitate the interoperability of service stations

and equipment.

NOTE: A single console cannot support both TCP/IP and LON Module communications simultaneously, even though a site may have a mixed configuration on different consoles. The

maximum number of tanks a site can support is 30.

Configured

Touch the radio button to enable or disable IFSF communication.

Device

The device used for communication. Choices are: LON Module (if installed) or Eth1 for Ethernet Port 1 (for TCP/IP), depending on your hardware configuration.

NOTE: On the TLS450PLUS, Ethernet Ports 2a and 2b are not available for IFSF configuration.

Protocol

The protocol used for IFSF. The choice is: IFSF-China1. This

field is not available with the LON Module device option.

Node Id

The ATG Node Identifier. Each IFSF tank gauge present on a

network must have a unique node ID. The default is 01, but

you can change it as required. This field is not available with

the LON Module device option.

NOTE: With a LonWorks

®

card, the Node ID is set using the

IFSF Node Address Dip Switch on the IFSF Interface Module

during installation. Refer to the Console Troubleshooting

section of the TLS-450PLUS Troubleshooting manual (P/N

577014-075) or the Troubleshooting section of the TLS4 /

8601 Series Consoles Troubleshooting manual (P/N 577014-

058), as appropriate, for more information on IFSF module

cable connector assembly and Node ID switch settings.

UDP Port

The port used for User Datagram Protocol (UDP) communication. The default is 3486, but this field can be edited if you

need to use a different port (1024-65535). This field is not

available with the LON Module device option.

TCP Port

The port used for Transmission Control Protocol (TCP) connection requests. The default is 9000, but this field can be

edited if you need to use a different port (1024-65535). This

field is not available with the LON Module device option.

16

Page 21

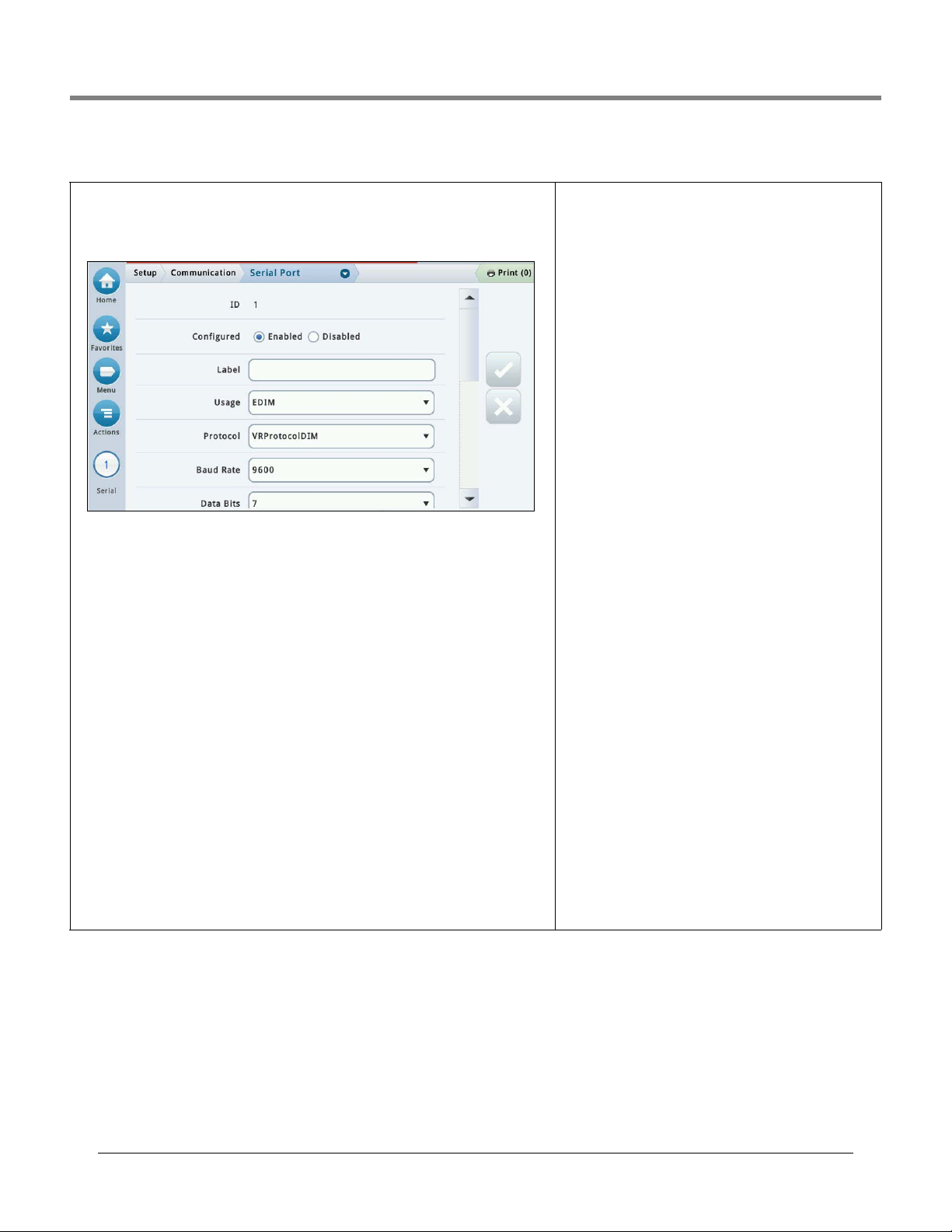

Initial Setup Of The Console Using Workflow Wizard Setup>Communication>Serial Port

Setup>Communication>Serial Port

This screen lets you configure the serial ports which may be used for data collection or diag-

nostics purposes. Select a serial port from the icon list on the bottom of the screen that you

want to configure. Repeat the entry process for each Serial Port.

Configured

Touch to enable or disable the Serial Port.

Label

Touch to enter a name for this port.

Usage

Touch to select the type of communication card (board) in the console

Choices are: RS-232, RS485, EDIM, Satellite HJBox, Satellite SSAT, VMCI, Digicom GSM.

Protocol (only visible if EDIM is selected for Usage)

Touch to select applicable DIM protocol for your EDIM port.

Choices are: GilbarcoEDIM, VRProtocolDIM, Sinopec EDIM.

Baud Rate

Touch to select the communication data rate of this serial port. Choices are: 300, 600, 1200,

2400, 4800, 9600, 19200, 38400, 57600, 115200. The default is 9600.

Stop Bits

Choices are: 1 or 2

Byte Size/Data Bits

Choices are: 8 or 7

Parity

Choices are: Odd Parity, Even Parity, or None

Use Handshaking

Choice is: No Handshaking, RTSCTS or XON XOFF

Serial Command Security

Select Enable to require all incoming serial commands to

have a security code.

Security Code

[Field available and required if Serial Command Security

field is enabled].

This the security code that all serial commands must have to

be accepted by the console. Valid security codes must be

exactly 6 digits (0 - 9) long.

RS232 End of Message

Enables or disables the End of Message RS232 protocol.

This protocol is used by third party devices that may want to

interrogate the console for inventory or other related data.

These devices require an End-Of-Text command that signals

to the device when the communication string from the console ends.

Please refer to the customer's third party device for the type

of code to enter in the ETX Characters Display and ETX Characters computer fields below.

ETX Characters Display

[Field enabled only if RSR 232 End of Message field is

enabled]

End-Of-Text (ETX) character. ETX is programmable if enabled

via the S53100f command. If it is disabled, the ETX is a fixed

Control-C character (ASCII 03).

ETX Characters Computer

[Field enabled only if RSR 232 End of Message field is

enabled]

End-Of-Text (ETX) character. ETX is programmable if enabled

via the S53100f command. If it is disabled, the ETX is a fixed

Control-C character (ASCII 03).

17

Page 22

Initial Setup Of The Console Using Workflow Wizard Setup>Communication>SMTP Relay

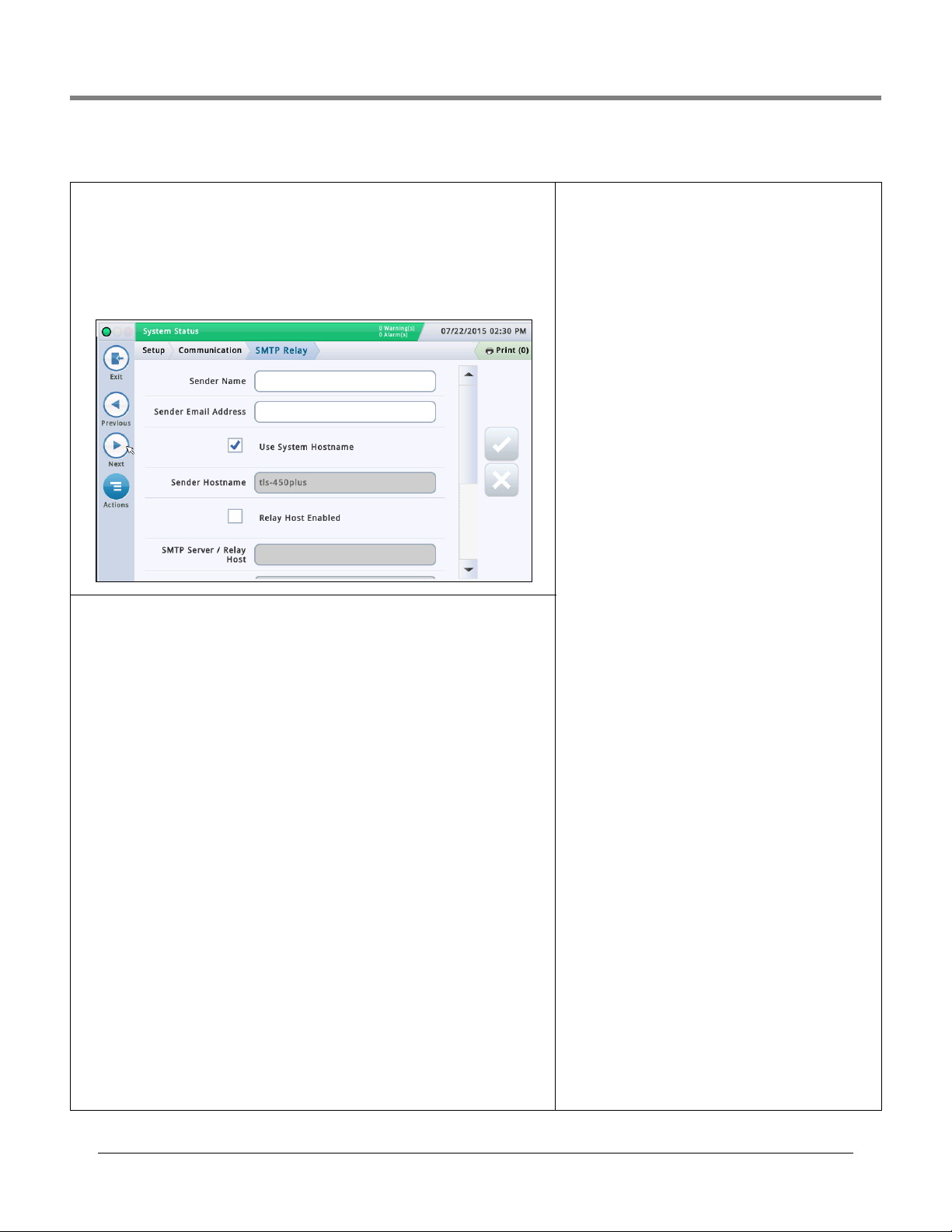

Setup>Communication>SMTP Relay

The system supports Simple Mail Transfer Protocol (SMTP), an Internet standard for email

transmission. This screen lets you configure this feature, which allows the console to act as

a mail client, using SMTP to send messages to a mail server.

NOTES:

1. Some fields require the Total Control Feature.

2. Sender Email Address, System Hostname, SMTP Relay and SMPT Server Password

must be provided by the ISP (Internet service provider).

Sender Name

Touch to enter the name that will display as the sender of the email. Maximum of 40 characters.

Sender Email Address

Touch to enter valid sender’s email address (using the standard format, such as technicalsupport@veeder.com). Maximum of 254 characters.

This entry specifies the originating email address. It also appears in the ‘From:’ header field

within the email message.

NOTE: If you leave this field blank, the email message is set to the Linux account on the console that is sending email, followed by @[hostname].[domainname](your hostname and

domain name).

Use System Hostname

If enabled, the system hostname is used and is displayed below. If disabled, you can enter a

valid hostname in the field below. The default is enabled.

Sender Hostname

Touch to enter the name that is sent to the SMTP server (used for SMTP tasks such as connecting remote mail servers). Some mail servers require a valid Internet hostname when

other mail servers connect. Usually this the hostname that your IP address resolves to and

would be included in the information from your ISP. It should never be the domain name or

the relayhost name.

Relay Host Enabled

If disabled, these fields are not available. If enabled, SMTP is used for email and the following fields are available:

• SMPT server/Relay Host

•Port Number

• Authentication Type

• SMTP Server Username

• SMTP Server Password

• SMTP Server Requires SSL

SMTP Server / Relay Host [Relayhost/Smart

host]

Touch to enter the IP address or hostname of the SMTP

server/relay host that the console is attempting to connect

with. When this field is used, all mail is forwarded through

this host and not sent directly to recipients. NOTE: a URL is

not valid for this field.

SMTP uses this field to determine the appropriate internet

destination. Some ISPs block email traffic until it is sent

through their mail server.

Port Number [Relayhost/Smarthost Port]

The port on the server where the email should be sent. This

field is populated when the SMTP server is entered. The

default port number is 25.

NOTE: if the ‘SMTP Server Requires SSL’ field below is

enabled, this port number should be 465 or 587.

Authentication Type

Touch to enter the type of SMTP authentication that is

required by the remote server:

• No Authentication - no username and password is

required.

• CRAM MD5 - secure transmission of username and password.

Plain - the username and password are sent as human-

•

readible text to the server (without encryption).

• Login - he username and password are sent as humanreadible text to the server (without encryption).

NOTE: you should select the most secure method allowed by

your server. Check with your ISP if you have questions.

SMTP Server Username [Relayhost/Smart

host Server User Name]

Touch to enter the server name for authentication - maxi-

mum 60 characters.

SMTP Server Password [Relayhost/Smart

host Password]

Touch to enter the server password or ‘shared secret’ for

the server - maximum 25 characters.

SMTP Server Requires SSL [Relay Requires

SSL]

When enabled it forces the use of SSL encryption for the

entire session when communicating with the server.

Generally this should not be enabled (checked) because the

console will automatically use SSL encryption if the server

supports it. It should be enabled only for older email servers

where the entire communication must be wrapped in SSL.

This selection should not be enabled for modern servers that

negotiate encryption after connecting or the connection will

fail. If the relay server port number is 25 (default), this

selection should not be enabled.

18

Page 23

Initial Setup Of The Console Using Workflow Wizard Setup>Devices

Actions

1

Probe

Water

Next

Actions

1

Probe

Probe

1 2 3 4

Serial Number

Type

Float Type [inch

Previous

Next

Actions

1

Probe

Probe

1 2 3 4

Address

Label

Serial Number

Type

Float Type [inch

External Input

Liquid Sensor

Type A Sensor

Type B Sensor

Line Pressure Sensor

LVDI M

ATM Pressure Sensor

Vapor Pressure Sensor

Ground Water Sensor

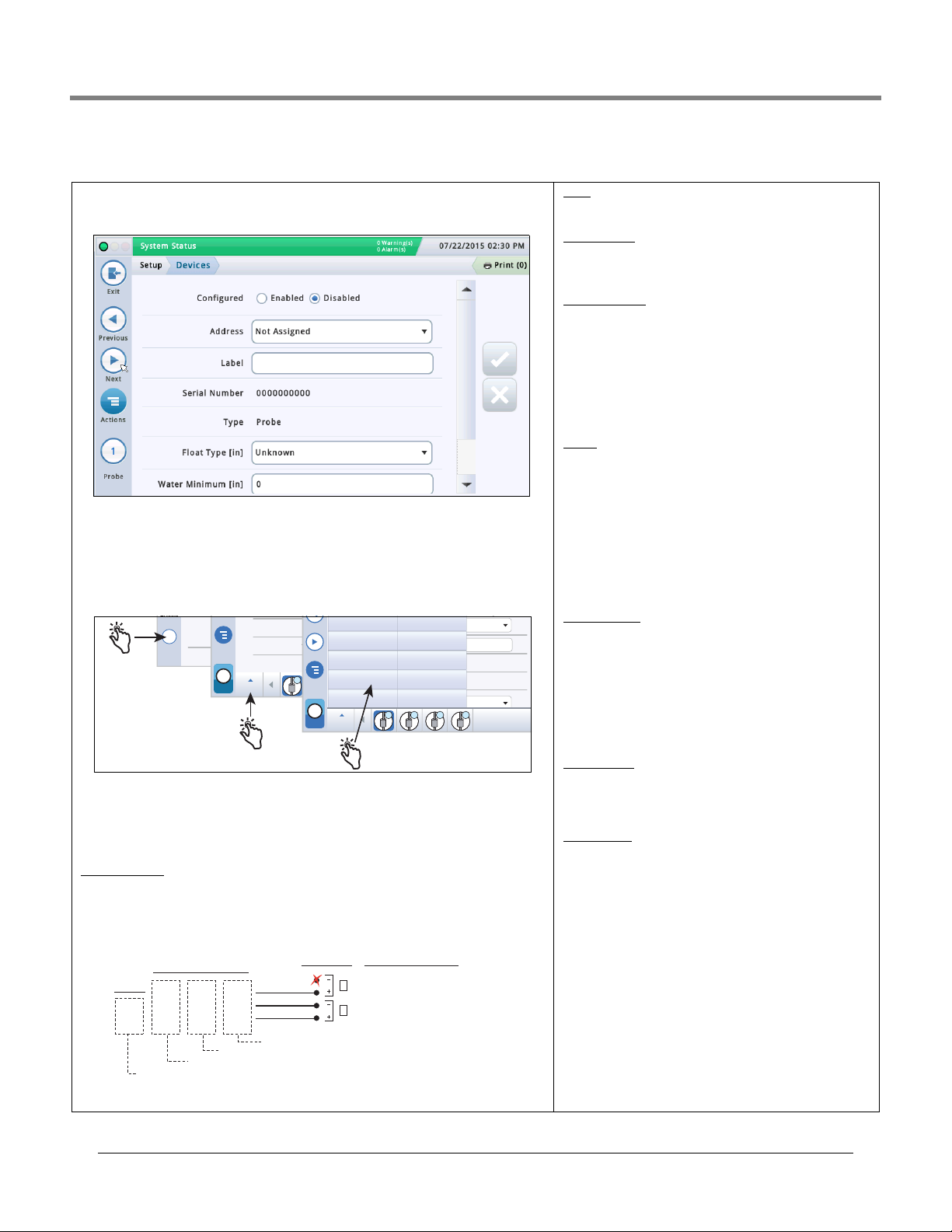

Setup>Devices

The Setup>Device screens let you configure each of the monitored devices that is connected to the console (probes, sensors, relays, external inputs) and (LVDIM/MDIM modules

- TLS-450PLUS only).

Selecting A Device Type

Initially the first device type to be displayed in Workflow Wizard setup is Probe 1. To select

another probe, touch the probe 1 button on the lower left of the screen and select the

desired probe from the icon list along the bottom of the probe device screen. To select

another device type, use the touch sequence shown in the illustration below to view the

device matrix, then touch the desired device type button to open that device’s setup screen.

Selecting A Device Address

IMPORTANT! You must know to which console connector a device is wired to select the correct address for that device. Some general rules discussed below concern device

addresses.

TLS4 Consoles

Probes/Sensors connected to the console will display the following address code in the

Address Field: B1:S2:X , where x is the connector input to which the device is attached

(from 1 to 16). NOTE: 3-wire sensors require three connector inputs (2 ‘+’ channels and 1 ’

– ‘ channel) so each 3-wire sensor takes up two of the available intrinsically safe ports and

uses two addresses (see 2- and 3-wire connection examples below):

All

2-Wire

Sensors

BLK

WHT*

*Red wire instead of White for:

• Interstitial Sensor - Steel Tanks (794380-4X0)

• CSTP Liquid Switch

• Position Sensitive Interstitial Sensor - Steel Tanks (794380-333)

3-Wire

Sensors

WHT

WHT

RED

BLK

WHT

GRN

GRN

RED

BLK

Groundwater Sensor

Vapor Sensor

4Site Pan/Sump (Type B) - Standard and Optical

Console

Connections

Not used with

3-wire sensor

Example Port Address

Selections

2

B1:S1:2 Address 2 Field Selection

1

B1:S1:1 Address Field Selection

19

Relay will display the following possible address codes in the

Address Field: B1:S1:X , where X = 14 (relay connector

input 1) or 15 (relay connector input 2).

External Input will display the following possible address

codes in the Address Field: B1:S1:X , where X = 12 (Ext.

Input connector input 1) or 13 (Ext. Input connector input 2).

TLS-450PLUS Consoles

Probes/Sensors connected to the console will display the

following possible address ports in the Address Field:

B1:Sx:X, where Sx is the slot in which the USM module is

installed (from 1 to 4) and X is the connector input to which

the device is attached (from 1 to 16). NOTE: 3-wire sensors

require three connector inputs (2 ‘+’ channels and 1’ – ‘

channel) so each 3-wire sensor takes up two of the available

intrinsically safe ports and has two addresses (Address field

and Address 2 field (see 3-Wire Sensor Addresses Example

illustration above).

Relays connected to the I/O module will display the following possible address codes in the Address Field: B1:Sx:X,

where Sx is the slot in which the I/O module is installed

(from 1 to 4) and X is the connector input to which the device

is attached (from 5 to 9). Note: The relay address B1:S7:1

refers to the single input Power Bay relay which, if used,

would connect to the site’s Overfill Alarm.

Relays connected to a 10 AMP Controller module will display

the following possible address codes in the Address Field:

B1:S4x:X, where S4 is the only slot in which the 10 AMP Controller module is installed and X is the connector input to

which the device is attached (from 1 to 6).

External Inputs

connected to the I/O module will display the

following possible address codes in the Address Field:

B1:Sx:X, where Sx is the slot in which the I/O module is

installed (from 1 to 4) and X is the connector input to which

the device is attached (from 1 to 4 and 10 to 14).

External inputs connected to a 10 AMP Controller module will

display the following possible address codes in the Address

Field: B1:S4x:X, where S4 is the only slot in which the 10

AMP Controller module is installed and X is the connector

input to which the device is attached (from 7 to 12).

LVDIM inputs

connected to the console will display the following possible address codes in the Address Field: B1:Sx:X,

where Sx is the slot in which the LVDIM module is installed

(from 1 to 4) and X is the connector input to which the device

is attached (from 1 to 12).

MDIM inputs connected to the console will display the following possible address codes in the Address Field: B1:Sx:X,

where Sx is the slot in which the MDIM module is installed

(from 1 to 4) and X is the connector input to which the device

is attached (from 1 to 12).

Page 24

Initial Setup Of The Console Using Workflow Wizard Setup>Devices

waterfloat

densitywaterfloat(1.5inch

minimumwaterlevel)

densitywaterfloat(1inch

minimumwaterlevel)

B7053686719512

S/N: 13240161

Example Density Code

Example Serial Number

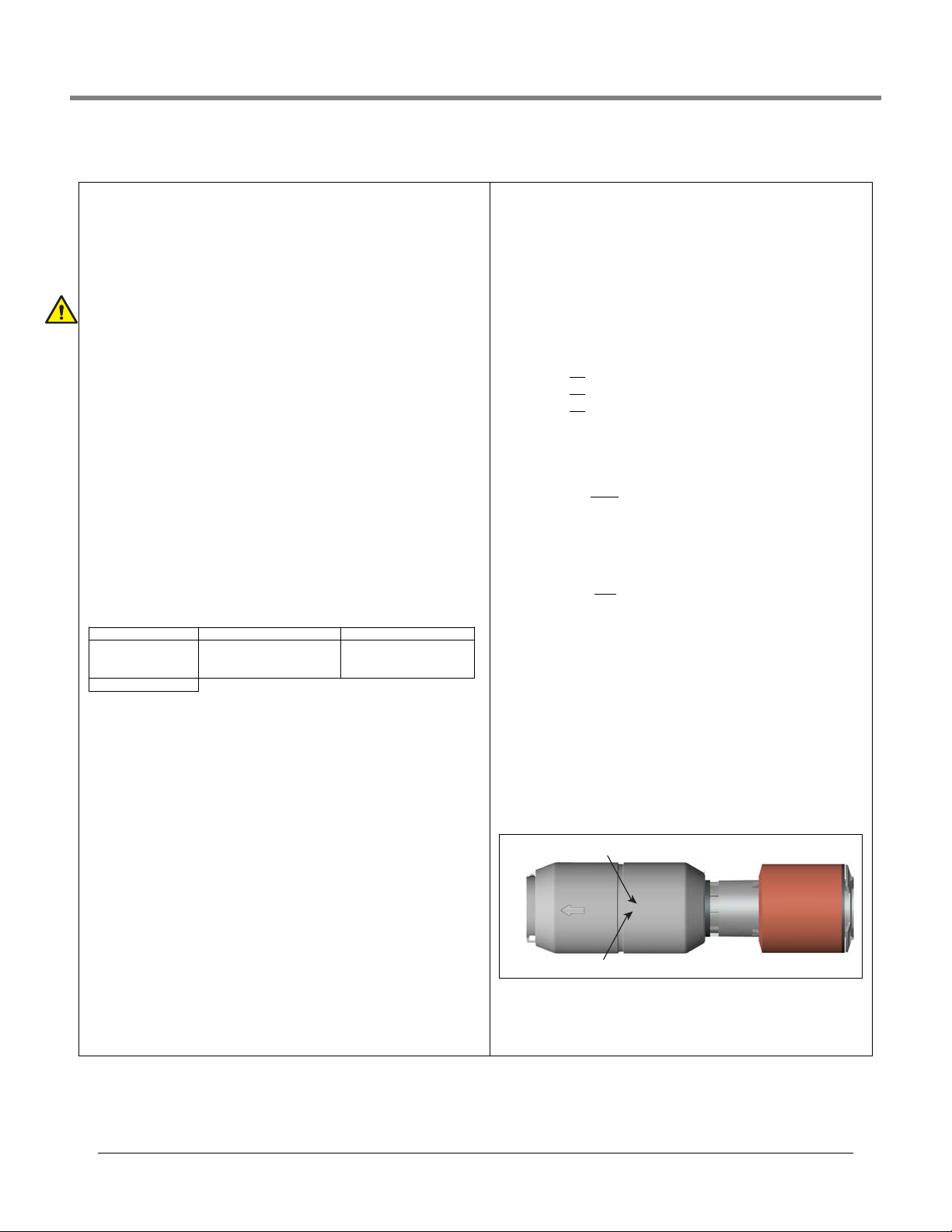

Setup>Devices - Continued

PROBE SETUP

Set up each probe being monitored before selecting the next device type.

Configured

Touch the radio button to enable or disable configuration of the selected

probe.

NOTES:

Do not enable probe configuration until its address is assigned!

•

• Once enabled, do not disable a probe if it is assigned to a tank. You must

first unassign the probe from the tank before the probe can be disabled.

(see Setup > Tank > General).

Address

Touch and select the address of this probe.

Label

Touch to enter a description of this probe (up to 20 alphanumeric characters)

that will appear on the console screens and in reports.

Serial Number

[Read Only] Console auto-detected serial number of this device.

Type

[Read Only] Console auto-detected type of this device.

Float Type

Installed Mag probe float type (the console will display only the applicable

float size options for this device). For example, depending on the probe

installed the float sizes below could display in the drop down list:

•4.0in •4.0inphaseseparation •3.0in

•2.0innon‐density

•Custom

NOTES:

• Only circuit codes D004, D005 and D006 are allowed to set the float type to

4.0 in phase separation.

• If the probe is changed and the previous float is supported by the new

probe, the float assignment will remain the same. Otherwise the default

float will be assigned to the new probe.

• Only select Custom if the literature that was shipped with probe float kit

specifically states that you must choose this Float Type. Currently only

three mag probes use Custom Float Types: Chem-ISO mag probes, LPG-ISO

mag probes and the Mag-FLEX probe with low level water floats.

When Custom float type is selected, the Fuel Offset, Water Offset, Water

Minimum and Invalid Fuel parameter fields below are enabled for edit.

Refer to the appropriate installation kit manual for these entries (see

“Related Documents” on page 1).

Fuel Offset -Touch to enter the Fuel Offset value listed in the appropriate

kit manual (577013-770, 577013-773 or 577014-056).

Water Offset (Mag-FLEX probes with Low Level Water Float only) Touch to enter the Water Offset value listed in the 577014-056 manual.

Water Minimum (Mag-FLEX probes with Low Level Water Float only) Touch to enter the Water Minimum value listed in the 577014-056 manual.

Invalid Fuel - Touch to enter the Invalid Fuel value listed in the appropriate kit manual (577013-770, 577013-773 or 577014-056).

•2.0instandard‐standard

•2.0inlowwater‐ lowwater

Density Code

This field stores specifications for a density probe. It must be exactly 14

characters, and is composed of four parts as described below:

The density code has the following format: FGGGGGGMMMMDDD, e.g.,

B7053686719512, and is impressed in the float body (see image below).

Where:

F = Fuel Type: A for gasoline and B for diesel.

Using the example density code above: B = Diesel, G = Gauss

The last two digits are the gauss readings for each magnet in the den-

sity float. The prefix is always 7 and is omitted from the density code.

Using the example density code above:

70 Gauss = 77.0

53 Gauss = 75.3

for top magnet in grams

for middle magnet in grams

68 Gauss = 76.8 for bottom magnet in grams

M = Mass

The last four digits of the mass of the float. The prefix is always 1 and is

omitted from the density code.

Using the example density code above:

6719 = Mass of 16.719

grams

D = Density of the float

The prefix is dependent on the fuel type and is omitted from the density

code. A = 7 (gasoline) and B = 8 (diesel).

Using the example density code above:

512 = density of 851.2

kg/m3 for a fuel type of diesel.

NOTE: If you change the Density Code, the Density Offset History is

cleared and current Density Offset is set to zero. See Diagnostics>

Probe>Density Offset screen for details on console density values.

Density Float Serial Number

Touch this field to enter the density float’s serial number.

NOTE: if you change the density float serial number, the Density Offset

History is cleared and the current Density Offset is reset to zero.

The density float serial number has the following format - yywwxxxx,

e.g., 13240161, and is impressed in the float body (see image below).

Where;

YY = the last two digits of the year it was manufactured’

WW = the number of the week it was manufactured,

XXXX = a unique integer for the density float

20

Page 25

Initial Setup Of The Console Using Workflow Wizard Setup>Devices

Setup>Devices - Continued

RELAY SETUP

Set up each relay being monitored before selecting the next device type.

Configured

Touch the radio button to enable or disable configuration of the selected

relay.

Address

Touch and select the address of this relay.

Label

Touch to enter a description of this relay (up to 20 alphanumeric characters)

that will appear on the console screens and in reports.

Relay Type

Touch to select relay type:

• Standard - On/Off state is determined by assigned alarms or warnings.

• Momentary - On/Off state is determined by the assigned alarms or warnings (relay returns to the inactive state after the alarm is acknowledged).

Pump Control Output - Relay state is controlled by the console pump/

•

line controller (TLS-450PLUS only).

Relay Orientation

Touch to select relay orientation:

•Normally Open

•Normally Closed

EXTERNAL INPUT SETUP

Set up each external input being monitored before selecting the next device

type.

Configured

Touch the radio button to enable or disable configuration of the selected

external input.

Address

Touch and select the address of this external input.

Label

Touch to enter a description of this external input (up to 20 alphanumeric

characters) that will appear on the console screens and in reports.

Type

Touch to select external input type:

Standard - Generates an external input alarm when it is active.

•

•

Generator - Generates the ON and OFF messages for CSLD on a genera-

tor.

Pump Sense - Indicates the On/Off state and the state of hook signal for

•

a dispenser and also is used to configure PLLD (TLS-450PLUS only);

Acknowledge Alarm - External Input is used as an ALARM/TEST key (for

•

example, a remote push button) and also generates the external input

alarm.

•

Pump Relay Monitor [Available with PLLD] - Generates a pump relay

alarm when the console suspects a relay is stuck closed or when the pump

has been running continuously for a period exceeding the Max Run (set in

“Setup>Pumps and Lines>PLLD”) (TLS-450PLUS only).

Orientation

Touch to select External Input orientation:

•Normally Open

•Normally Closed

LIQUID SENSOR SETUP

Set up each liquid sensor being monitored before selecting the next device

type.

Configured

Touch the radio button to enable or disable configuration of the selected liquid sensor.

Address

Touch and select the address of this liquid sensor.

Label

Touch to enter a description of this liquid sensor (up to 20 alphanumeric

characters) that will appear on the console screens and in reports.

Model

Touch and select the model of this liquid sensor:

• Tri-State (Single Float) - Single float, liquid sensor.

• Normally Closed - Liquid sensor whose normal state is closed, and activates an alarm when it is in an open state (NOT recommended).

Dual Point Hydrostatic - Liquid sensor used in liquid-filled, double-wall

•

tanks.

• Dual Float Discriminating - Liquid sensor with two floats, discriminates

between water and fuel, generally used in containment sumps.

• Dual Float High Vapor - Liquid sensor with two floats, discriminates

between high and low vapor, generally used in containment sumps.

Interceptor Sensor - European type, liquid sensor.

•

Category

Touch to select liquid sensor category:

• Annular Space • Dispenser Pan • Monitoring Well •STP Pump

•Containment Pump •Other

TYPE A SENSOR (2-WIRE CL) SETUP

Set up each Type A sensor being monitored before selecting the next device

type.

Configured

Touch the radio button to enable or disable configuration of the selected

Type A sensor.

Address

Touch and select the address of this Type A sensor.

Label

Touch to enter a description of this Type A sensor (up to 20 alphanumeric

characters) that will appear on the console screens and in reports.

Model

Touch and select the model of this Type A sensor:

Discriminating Interstitial - Discriminating sensor used in dry, double-

•

wall tanks.

•

Ultra 2 - Older version of discriminating sensor used in dry, double-wall

tanks.

Category

Touch to select Type A sensor category:

• Annular Space • Dispenser Pan • Monitoring Well • STP Pump

•Containment Pump • Other

21

Page 26

Initial Setup Of The Console Using Workflow Wizard Setup>Devices

Setup>Devices - Continued

TYPE B SENSOR (3-WIRE CL) SETUP

Set up each Type B sensor being monitored before selecting the next device

type.

Configured

Touch the radio button to enable or disable configuration of the selected

Type B sensor.

Address

Touch and select address 1 of the 3-wire Type B sensor.

Label

Touch to enter a description of this Type B sensor (up to 20 alphanumeric

characters) that will appear on the console screens and in reports.

Address 2

Touch and select the next sequential address for the third wire of the Type B

sensor (e.g., if the Address field above is B1:S2:2, then this address should

be B1:S2:3).

Model

Touch and select the model of this Type B sensor:

Ultra/Z-1 - 4Site Pan/Sump - Standard.

•

• Ultra/Z-1 HV - 4Site Pan/Sump - High Vapor.

Category

Touch to select Type B sensor category:

• Annular Space •Dispenser Pan • Monitoring Well • STP Pump

•Containment Pump •Other

MAG SENSOR SETUP

Set up each Mag sensor being monitored before selecting the next device

type.

Configured

Touch the radio button to enable or disable configuration of the selected Mag

sensor.

Address

Touch and select the address of this Mag sensor.

Label

Touch to enter a description of this Mag sensor (up to 20 alphanumeric characters) that will appear on the console screens and in reports.

Serial Number

[Read Only] Console auto-detected serial number of this Mag sensor.

Alarm Delay

Touch to enter the time in hours following the triggering of un-cleared warnings before they are upgraded to alarms.

Fuel Alarm

Touch to enter the height at which this Mag sensor will activate the fuel

alarm.

Fuel Warning

Touch to enter the height at which this Mag sensor will activate the fuel

warning.

Water Alarm

Touch to enter the height at which this Mag sensor will activate the water

alarm.

MAG SENSOR SETUP - Concluded

Water Warning

Touch to enter the height at which this Mag sensor will activate the water

warning.

GROUNDWATER SENSOR SETUP

Set up each groundwater sensor being monitored before selecting the next

device type.

Configured

Touch the radio button to enable or disable configuration of the selected

groundwater sensor.

Address

Touch and select address 1 of the 3-wire groundwater sensor.

Label

Touch to enter a description of this groundwater sensor (up to 20 alphanumeric characters) that will appear on the console screens and in reports.

Address 2

Touch and select the next sequential address for the third wire of the

groundwater sensor (e.g., if the Address field above is B1:S2:4, then this

address should be B1:S2:5).

Category

Touch to select this groundwater sensor category:

• Annular Space • Dispenser Pan • Monitoring Well • STP Pump

•Containment Pump •Other

VAPOR SENSOR SETUP

Set up each vapor sensor being monitored before selecting the next device

type.

Configured

Touch the radio button to enable or disable configuration of the selected

groundwater sensor.

Address

Touch and select address 1 of the 3-wire vapor sensor.

Label

Touch to enter a description of this vapor sensor (up to 20 alphanumeric

characters) that will appear on the console screens and in reports.

Address 2

Touch and select the next sequential address for the third wire of the

vapor sensor (e.g., if the

Address field above is B1:S2:6, then this

address should be B1:S2:7).

Threshold

Touch to enter the vapor level which identifies a leak or serious spillover and

that triggers the vapor alarm. Thresholds are in ohms and must be calculated for each vapor sensor (see Vapor Sensor Threshold topic for determin-

ing value).

Category

Touch to select this vapor sensor category:

• Annular Space • Dispenser Pan • Monitoring Well • STP Pump

•Containment Pump • Other

22

Page 27

Initial Setup Of The Console Using Workflow Wizard Setup>Devices

Setup>Devices - Concluded

LINE PRESSURE SENSOR SETUP

Set up each line pressure sensor being monitored before selecting the next

device type.

Configured

Touch the radio button to enable or disable configuration of the selected line

pressure sensor.

Address

Touch and select the address of this line pressure sensor.

Label

Touch to enter a description of this line pressure sensor (up to 20 alphanumeric characters) that will appear on the console screens and in reports.

Serial Number

[Read Only] Console auto-detected serial number of this line pressure sensor.

ATM PRESSURE SENSOR SETUP

Set up each ATM pressure sensor being monitored before selecting the next

device type.

Configured

Touch the radio button to enable or disable configuration of the selected ATM

pressure sensor.

Address

Touch and select the address of this ATM pressure sensor.

Label

Touch to enter a description of this ATM pressure sensor (up to 20 alphanumeric characters) that will appear on the console screens and in reports.

Serial Number

[Read Only] Console auto-detected serial number of this ATM pressure sensor.

VAPOR PRESSURE SENSOR SETUP

Set up each vapor pressure sensor being monitored before selecting the

next device type.

Configured

Touch the radio button to enable or disable configuration of the selected

vapor pressure sensor.

Address

Touch and select the address of this vapor pressure sensor.

Label

Touch to enter a description of this vapor pressure sensor (up to 20 alphanumeric characters) that will appear on the console screens and in reports.

Serial Number

[Read Only] Console auto-detected serial number of this vapor pressure

sensor.

LVDIM/MDIM SETUP (TLS-450PLUS only)

Configured

Touch the radio button to enable or disable configuration of the selected

LVDIM/MDIM input.

Address

Touch and select the address of this LVDIM/MDIM input.

Label

Touch to enter a description of this LVDIM/MDIM input (up to 20 alphanumeric characters) that will appear on the console screens and in reports.

Unit Conversion

Touch to select US, Imperial, or Metric units.

Pulse Conversion

Touch to select the number of pulses per unit volume.

23

Page 28

Initial Setup Of The Console Using Workflow Wizard Setup>BIR>General

Setup>BIR>General

In this screen you set up reconciliation parameters for your inventory reports if the BIR

function is enabled (ref. “Meter Data Present” on page 26).

Product Threshold Alarm

Touch to enable an alarm that is triggered when your periodic reconciliation data exceeds a

preset product threshold value (see Setup > BIR > Threshold Alarms for details about this

alarm).

Daily Close Time

Touch to enter a time when you want the system to store the data for the current day

(default is 02:00 AM).

BIR needs approximately 2-5 minutes of quiet time to generate a report. Because 2:00 AM is

normally the quietest time of the day, we recommend using that time (unless there is a business need to do it at another time).

Week Close Time

Touch to enter the Day of the week when you want the system to store the data for the current week (used in weekly reports.

Alarm Threshold Delivery Type

Touch to select how the BIR variance amount is calculated:

• Standard - does not use delivery receipts in the BIR variance amount calculation.

Ticketed Delivery - uses delivery receipts in the BIR variance amount calculation. Select

•

this if the ticketed delivery feature is enabled in the Setup>Delivery screen.

Temperature Compensation

Touch to enter the method for calculating BIR volumes:

• Standard - use when the meters are not temperature

compensated (TC).

TC Volume - use when meters are temperature compen-

•

sated (TC).

Meter Calibraton Offset %

If you have meters that require a calibration offset, use this

field to enter a meter calibration % to compensate (applies

to all dispenser meters and is used in the calculated dispensed amount). For most domestic (US) sites, the default of

0% is fine.

BIR Daily Close Warning Enable