Page 1

Site Prep & Installation Manual

TLS RF Wireless System

Manual No: 577013-839 ● Revision: L

Page 2

Notice

Veeder-Root makes no warranty of any kind with regard to this publication, including, but not limited to, the implied warranties of

merchantability and fitness for a particular purpose.

Veeder-Root shall not be liable for errors contained herein or for incidental or consequential damages in connection with the furnishing,

performance, or use of this publication.

Veeder-Root reserves the right to change system options or features, or the information contained in this publication.

This publication contains proprietary information which is protected by copyright. All rights reserved. No part of this publication may be

photocopied, reproduced, or translated to another language without the prior written consent of Veeder-Root.

Contact TLS Systems Technical Support for additional troubleshooting information at 800-323-1799.

DAMAGE CLAIMS / LOST EQUIPMENT

Thoroughly examine all components and units as soon as they are received. If any cartons are damaged or missing, write a complete

and detailed description of the damage or shortage on the face of the freight bill. The carrier's agent must verify the inspection and sign

the description. Refuse only the damaged product, not the entire shipment.

Veeder-Root must be notified of any damages and/or shortages within 30 days of receipt of the shipment, as stated in our Terms and

Conditions.

VEEDER-ROOT’S PREFERRED CARRIER

1. Contact Veeder-Root Customer Service at 800-873-3313 with the specific part numbers and quantities that were missing or

received damaged.

2. Fax signed Bill of Lading (BOL) to Veeder-Root Customer Service at 800-234-5350.

3. Veeder-Root will file the claim with the carrier and replace the damaged/missing product at no charge to the customer. Customer

Service will work with production facility to have the replacement product shipped as soon as possible.

CUSTOMER’S PREFERRED CARRIER

1. It is the customer’s responsibility to file a claim with their carrier.

2. Customer may submit a replacement purchase order. Customer is responsible for all charges and freight associated with

replacement order. Customer Service will work with production facility to have the replacement product shipped as soon as

possible.

3. If “lost” equipment is delivered at a later date and is not needed, Veeder-Root will allow a Return to Stock without a restocking fee.

4. Veeder-Root will NOT be responsible for any compensation when a customer chooses their own carrier.

RETURN SHIPPING

For the parts return procedure, please follow the appropriate instructions in the "General Returned Goods Policy” pages in the

"Policies and Literature" section of the Veeder-Root North American Environmental Products price list. Veeder-Root will not accept

any return product without a Return Goods Authorization (RGA) number clearly printed on the outside of the package.

FCC INFORMATION

This equipment complies with the requirements in Part 15 of the FCC rules for a Class A computing device. Operation of this

equipment in a residential area may cause unacceptable interference to radio and TV reception requiring the operator to take whatever

steps are necessary to correct the interference.

WARRANTY

Please see next page, iii.

©Veeder-Root 2010. All rights reserved

.

ii

Page 3

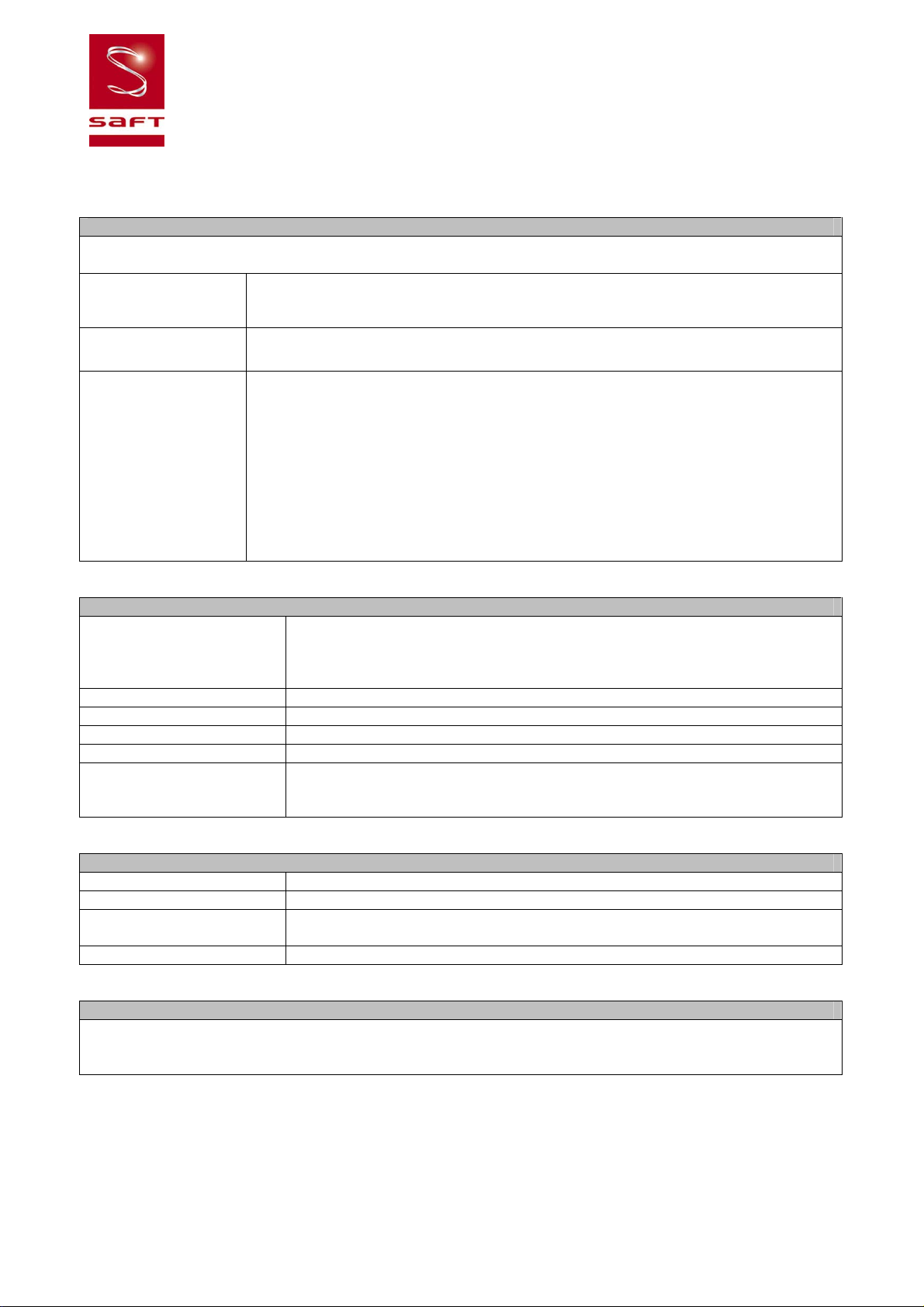

Warranty

TLS-350R, TLS-350 PLUS, TLS-350J AND TLS-300I/C, AND TLS-2 MONITORING SYSTEMS

We warrant that this product shall be free from defects in material and workmanship for a period of one (1) year

from the date of installation or twenty-four (24 months) from the date of invoice, whichever occurs first. During

the warranty period, we or our representative will repair or replace the product, if determined by us to be

defective, at the location where the product is in use and at no charge to the purchaser. LAMPS, FUSES, AND

LITHIUM BATTERIES ARE NOT COVERED UNDER THIS WARRANTY.

We shall not be responsible for any expenses incurred by the user.

This warranty applies only when the product is installed in accordance with Veeder-Root’s specifications, and

a Warranty Registration and Checkout Form has been filed with Veeder-Root by an authorized Veeder-Root

Distributor. This warranty will not apply to any product which has been subjected to misuse, negligence,

accidents, systems that are misapplied or are not installed per Veeder-Root specifications, modified or

repaired by unauthorized persons, or damage related to acts of God.

If “Warranty” is purchased as part of the Fuel Management Service, Veeder-Root will maintain the equipment

for the life of the contract in accordance with the written warranty provided with the equipment. A Veeder-Root

Fuel Management Services Contractor shall have free site access during Customer’s regular working hours to

work on the equipment. Veeder-Root has no obligation to monitor federal, state or local laws, or modify the

equipment based on developments or changes in such laws.

MODULES, KITS, OTHER COMPONENTS (PARTS PURCHASED SEPARATE OF A COMPLETE

CONSOLE)

We warrant that this product, exclusive of lithium batteries, shall be free from defects in material and

workmanship for a period of fifteen (15) months from date of invoice. We warrant that the lithium batteries shall

be free from defects in material and workmanship for a period of 90 days from date of invoice. We will repair

or replace the product if the product is returned to us; transportation prepaid, within the warranty period, and

is determined by us to be defective. This warranty will not apply to any product which has been subjected to

misuse, negligence, accidents, systems that are misapplied or are not installed per Veeder-Root

specifications, modified or repaired by unauthorized persons, or damage related to acts of God.

We shall not be responsible for any expenses incurred by the user.

iii

Page 4

Table of Contents

Introduction ................................................................................................................................................................................... 1

Component Compatibility............................................................................................................................................................................. 1

Contractor Certification Requirements ..................................................................................................................................................... 2

Probe Transmitter Considerations ............................................................................................................................................................. 2

Related Documents ....................................................................................................................................................................................... 2

Safety Precautions ......................................................................................................................................................................................... 2

General Precautions ................................................................................................................................................................................. 2

Special Tools Required ............................................................................................................................................................................ 3

Safety Symbols .......................................................................................................................................................................................... 3

Site Considerations - Control Drawing .................................................................................................................................. 4

National Electrical Code Compliance ....................................................................................................................................................... 5

TLS RF Unit-TO-TLS CONSOLE WIRING ........................................................................................................................................ 5

TLS RF Power Wiring .............................................................................................................................................................................. 5

TLS RF Wireless System Overview .......................................................................................................................................... 6

Equipment Dimensions .............................................................................................................................................................. 7

TLS RF Installation ...................................................................................................................................................................... 9

Selecting a Location for the TLS RF ......................................................................................................................................................... 9

Mounting the TLS RF .................................................................................................................................................................................... 9

Wiring the TLS RF ....................................................................................................................................................................................... 10

Wireless Component Installation .......................................................................................................................................... 15

Transmitter Installation ................................................................................................................................................................................ 15

Mag Probe Sump .................................................................................................................................................................................... 15

Mag Sump Sensor Installations - STP Sump ........................................................................................................................................ 19

Mag Sump Sensor Installations - Dispenser Pan Sump .................................................................................................................... 20

Connecting cables to the Transmitter ................................................................................................................................................ 22

Receiver Installation ..................................................................................................................................................................................... 23

Repeater Installation .................................................................................................................................................................................... 25

Network Setup ............................................................................................................................................................................ 27

Hardware Overview ..................................................................................................................................................................................... 27

Identifying Devices in the TLS RF Site Network ................................................................................................................................... 27

Site Startup Procedure ............................................................................................................................................................. 28

Troubleshooting ......................................................................................................................................................................... 30

iiv

Page 5

Table of Contents

Antenna Propagation Basics ..................................................................................................................................................................... 30

Antenna Operation .................................................................................................................................................................................. 30

Free Space Loss...................................................................................................................................................................................... 30

Attenuation ................................................................................................................................................................................................ 30

Scattering .................................................................................................................................................................................................. 30

Radio Line of Sight .................................................................................................................................................................................. 31

Antenna Polarization ............................................................................................................................................................................... 31

Interference ............................................................................................................................................................................................... 31

Probe Troubleshooting................................................................................................................................................................................ 32

Resetting Data in the TLS RF Unit ........................................................................................................................................................... 34

Appendix A: Site Survey for Wireless Probes

Appendix B: Regulatory Information

Appendix C: Device DIP Switch Settings

Appendix D: Lithium Battery Safety Data

v

Page 6

Installation Guide Contractor Certification Requirements

Introduction

This manual describes site preparation and installation procedures for the Veeder-Root TLS RF Wireless

System. This system is designed for standard tank monitoring and leak detection* applications in which inground probe wiring is either impractical or non-existent.

Procedures contained within this manual include:

• Mounting the TLS RF Wireless Interface Unit (TLS RF) and connecting power wiring.

• Installing TLS RF Wireless System’s receiver, transmitter, and repeater components throughout the

site.

• Connecting the TLS RF to the TLS console.

Other required devices, such as the TLS console and necessary magnetostrictive (mag) probes/mag sump

sensors, are to be installed following instructions shipped with those devices.

After installing the TLS RF Wireless System, you must configure the probes and sensors in the TLS console

following instructions contained in the console’s System Setup Manual.

*Certified SLD (Static) & CSLD (Continuous) Leak Detection for single tanks and Mag Sump Sensor monitoring, where ambient

interference is not a factor.

Component Compatibility

The Veeder-Root Form Number/Part Number TLS RF Wireless System compatible components are as

follows:

• 8466 TLS-IB console

• 8469 TLS-50 console

• 8470 TLS-350 console

• 8482 TLS-350R console

• 8485 TLS-300 console

• 8560 TLS2 console

332235-011 Transmitter with 332425-011 Battery Pack will monitor probe/sensor form numbers listed

below:

• 8462, 8463 and 8563 Mag Plus Probe

• 8468 Global Mag Probe

• 8570 Mag Sump Sensor

1

Page 7

Installation Guide Safety Precautions

Contractor Certification Requirements

Veeder-Root requires the following minimum training certifications for contractors who will install and setup

the equipment discussed in this manual:

Installer Certification: Contractors holding valid Installer Certification are approved to perform wiring and

conduit routing; equipment mounting; probe, sensor and carbon canister vapor polisher installation; wireless

equipment installation; tank and line preparation; and line leak detector installation.

TLS-350 Technician Certification: Contractors holding valid TLS-350 Technician Certifications are

approved to perform installation checkout, startup, programming and operations training, system tests,

troubleshooting and servicing for all Veeder-Root TLS-300 or TLS-350 Series Tank Monitoring Systems,

including Line Leak Detection and associated accessories.

Wireless TLS Technician Certification: Contractors holding valid Wireless TLS Technician Certifications

are approved to perform installation checkout, startup, operations, troubleshooting and servicing for all

Veeder-Root TLS Wireless Systems, including the RF Console and associated accessories such as

transmitters, receiver and repeater.

Warranty Registrations may only be submitted by selected Distributors.

Probe Transmitter Considerations

Installation of this equipment in wet or below grade locations requires that the installer take steps to ensure

that the equipment is mounted above the maximum water level and install a suitable water pump for removing

water inside the applicable sump.

CAUTION! – The transmitter will not function properly in water. Also, submersion of the

transmitter in water can cause permanent damage to the internal electronics.

Related Documents

576013-623 TLS-3XX System Setup Manual

331940-012 TLS RF System Control Drawing

Safety Precautions

FAILURE TO COMPLY WITH THE FOLLOWING WARNINGS AND SAFETY PRECAUTIONS COULD

CAUSE DAMAGE TO PROPERTY, ENVIRONMENT, RESULTING IN SERIOUS INJURY OR DEATH.

Retain and follow all product safety and operating instructions. Observe all warnings on the product and in the

operating instructions. To reduce the risk of bodily injury, electric shock, fire, or damage to the equipment,

observe the following precautions.

GENERAL PRECAUTIONS

Heed service markings: Opening or removing the console cover may expose you to electric shock.

Servicing of Veeder-Root equipment must be done by Veeder-Root authorized service contractors.

2

Page 8

Installation Guide Safety Precautions

procedure, ask someone who does.

Use product with approved equipment: This product should be used only with Veeder-Root components

identified as suitable for use with the TLS RF Wireless System.

Use the correct external power sources: This product should be operated only from the type of power

sources indicated on the electrical ratings labels affixed to the components. If you are not sure of the type of

power source required, consult your Veeder-Root authorized service contractor.

SPECIAL TOOLS REQUIRED

• #15 Torx driver

• Small blade screwdriver (maximum blade width 3/32”)

• Wire strippers

Although not required for installation, a laptop computer, RS-232 serial communication cable (TLS RF has a

female DB9 connector) and terminal mode software may be necessary for troubleshooting.

SAFETY SYMBOLS

The following safety symbols are used throughout this manual to alert you to important safety hazards and

precautions:

EXPLOSIVE

Fuels and their vapors are extremely

explosive if ignited.

ELECTRICITY

High voltage exists in, and is supplied

to, the device. A potential shock hazard

exists.

WARNING

Heed the adjacent instructions to avoid

equipment damage or personal injury.

FLAMMABLE

Fuels and their vapors are extremely flammable.

TURN POWER OFF

Live power to a device creates a potential shock

hazard. Turn Off power to the device and

associated accessories when servicing the unit

READ ALL RELATED MANUALS

Knowledge of all related procedures before you

begin work is important. Read and understand all

manuals thoroughly. If you do not understand a

3

Page 9

Installation Guide Safety Precautions

Site Considerations - Control Drawing

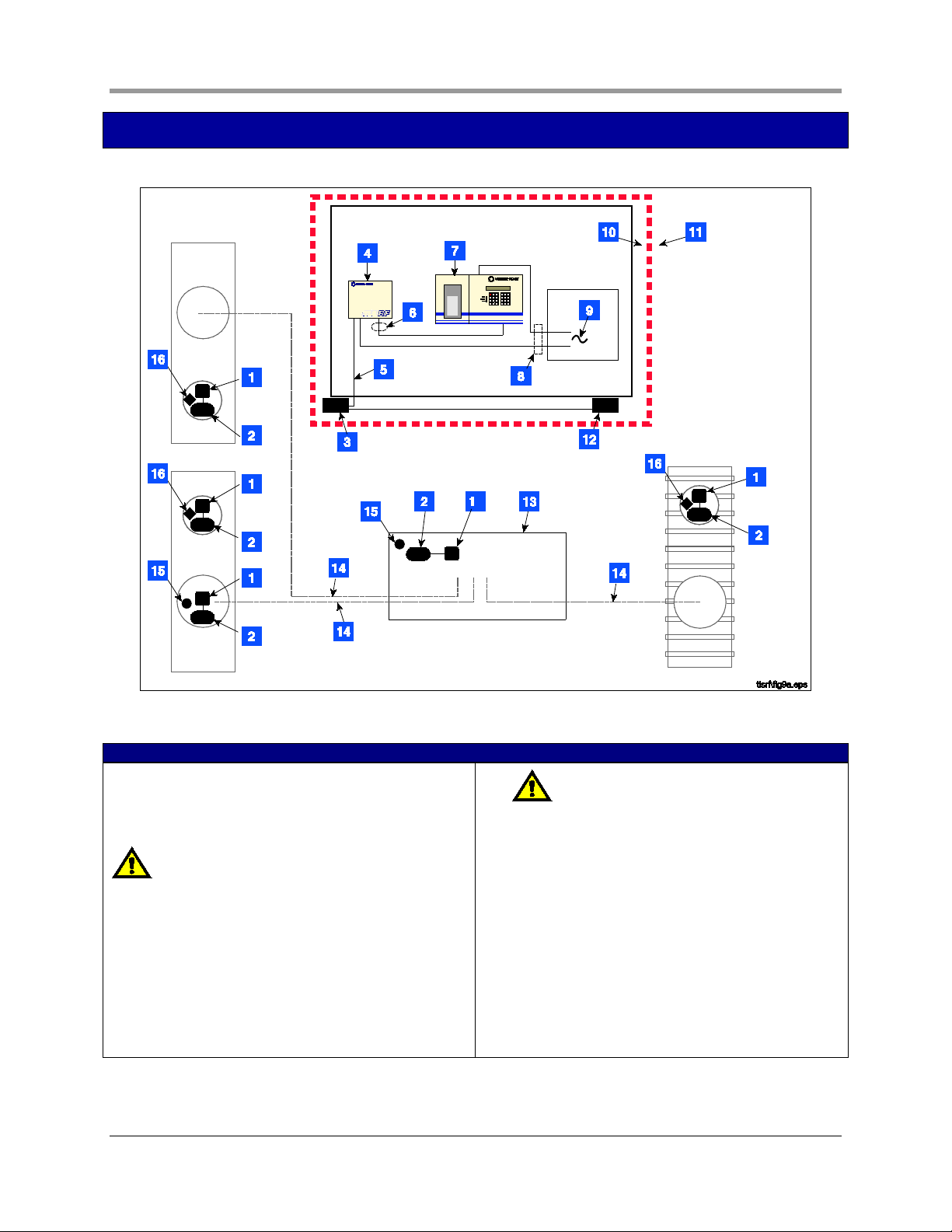

Figure 1. Control Drawing - Example TLS RF Wireless System Site Layout

LEGEND FOR NUMBERED BOXES IN FIGURE 1

To be installed in accordance with the National Electrical

Code, NFPA 70 and the Code for Motor Fuel Dispensing

Facilities and Repair Garages (NFPA 30A), or other local

code such as the CEC, Canadian Electrical Code.

WARNING! Substitution of components may impair

intrinsic safety.

Circuitry within the console barrier forms an intrinsically

safe, energy-limited system. This system is intrinsically safe

for use in a Class I, Group D hazardous location.

1. Battery Pack

2. Transmitter

3. Receiver

4. TLS RF (Vm = 250 V)

5. RS-485 Cable (Belden #3107A or equiv.)

6.

7. TLS console (Vm = 250 V)

8. Conduit that enters power wiring knockout.

9. 120 or 230 Vac from power panel.

10. Non-hazardous area

11. Hazardous area (Class I, Div. 1, Group D)

12. Repeater (1)

13. Dispenser sump

14. Underground product line

15. Sump sensor

16. Mag probe

NOTE: Intrinsically safe wiring shall be installed

in accordance with Article 504-20 of the NEC, ANSI/

NFPA 70. Maximum probe/sensor cable length 1000

ft. (304 m).

4

Page 10

Installation Guide National Electrical Code Compliance

National Electrical Code Compliance

The following information is for general reference and is not intended to replace recommended National

Electric Code (NEC) procedures. It is important for the installer to understand that electrical equipment and

wiring located in Class I, Division 1 and 2 installations shall comply with the latest appropriate articles found in

the National Electric Code (NFPA 70) and the Code for Motor Fuel Dispensing Facilities and Repair Garages

(NFPA 30A), or other local code such as the CEC, Canadian Electrical Code.

TLS RF UNIT-TO-TLS CONSOLE WIRING

Wire Type

To ensure the best operating systems available, Veeder-Root REQUIRES the use of shielded cable for probe

outputs regardless of conduit material or application. In these installations, shielded cable must be rated less

than 100 picofarad per foot and be manufactured with a material suitable for the environment, such as Carol™

C2534 or Belden™ 88760, 8760, or 8770.

Wire Length

Improper system operation could result in undetected potential environmental and health hazards if the TLS

RF-to-TLS Console wire runs exceed 1000 feet. Wire runs must be less than 1000 feet to meet intrinsic

safety requirements.

Splices

Veeder-Root recommends that no splices be made in the wire run between the TLS RF and the TLS Console.

Each splice degrades signal strength and could result in poor system performance.

Wire Gauges - Color coded

Shielded cable must be used in all installations. TLS RF-to-TLS console wires should be #14-#18 AWG

stranded copper wire and installed as a Class 1 circuit. As an alternate method when approved by the local

authority having jurisdiction, 22 AWG wire such as Belden 88761 may be suitable in installations with the

following provisions:

- Wire run is less than 750 feet

- Capacitance does not exceed 100 pF/foot

- Inductance does not exceed 0.2 µH/foot

TLS RF POWER WIRING

Wires carrying 120 or 240 Vac from the power panel to the TLS RF should be #14 AWG copper wire for line,

neutral and chassis ground (3); and #12 AWG copper wire for barrier ground (1).

5

Page 11

Installation Guide National Electrical Code Compliance

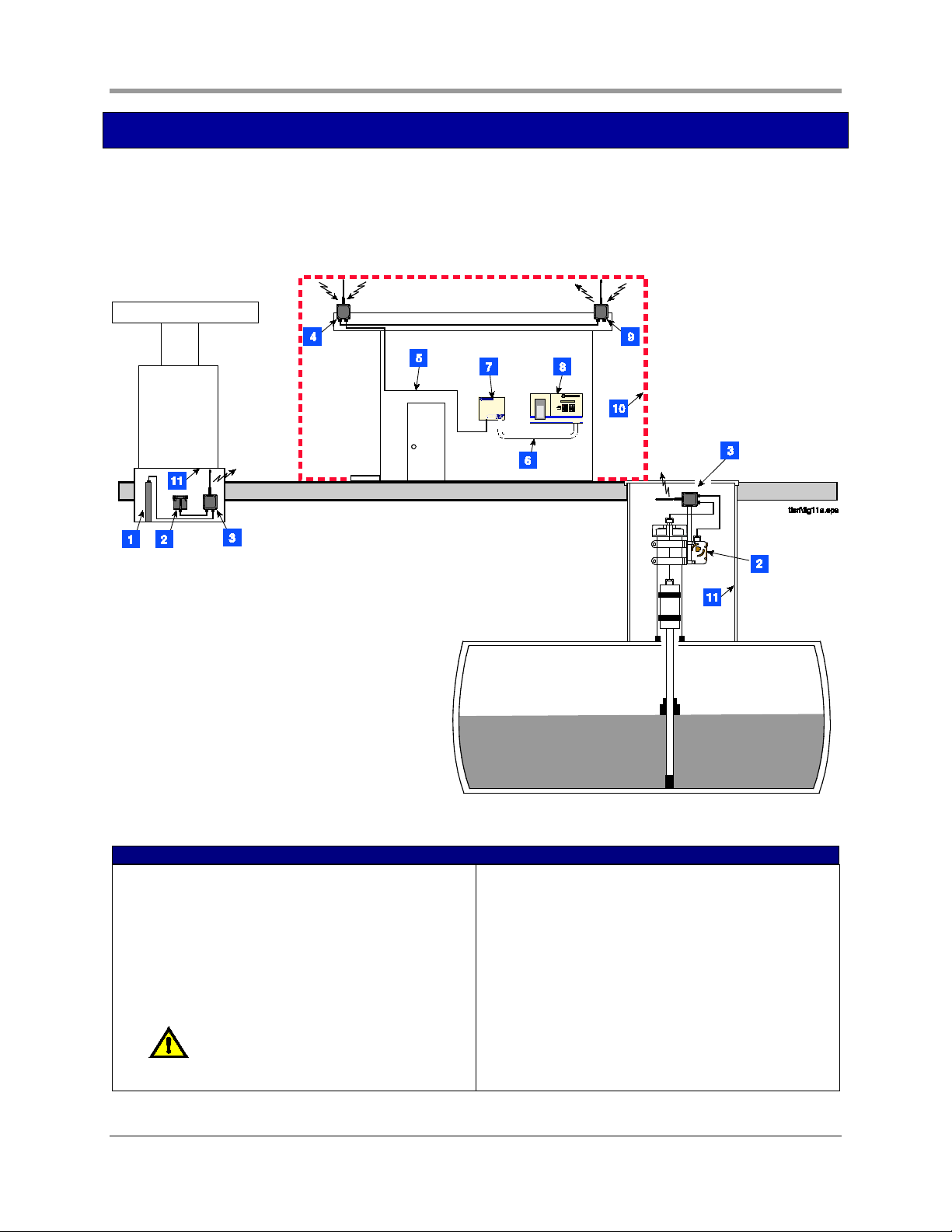

TLS RF Wireless System Overview

Figure 2 illustrates an example TLS RF Wireless System installation. In the figure only one tank is shown, but

each tank being monitored by a Mag probe would require a battery pack/transmitter pair. The repeater

component may be required if the system receiver, mounted on building’s outside wall, has difficulty receiving

signals from any of the transmitters.

Figure 2. Example TLS RF Wireless System component installation

LEGEND FOR NUMBERED BOXES IN FIGURE 2

1. Dispenser pan Mag Sump sensor

2. Battery Pack

3. Transmitter

4. Receiver

5. RS-485 cable (Belden #3107A or equiv.)

6. Probe wiring (up to 8 Mag probes/Mag Sump

sensors) - conduit connects via intrinsically safe

knockouts on both consoles.

NOTE: Intrinsically safe wiring shall be

installed in accordance with Article 504-20 of the

NEC, ANSI/NFPA 70.

7. TLS RF

8. TLS console

9. Repeater

10. Non-hazardous area

11. Hazardous area, Class I, Div. 1, Group D

6

Page 12

Installation Guide National Electrical Code Compliance

0.34''

(8,6 mm) typ.

7.4"

(188 mm)

6.4''

(163 mm)

5.7''

(145 mm)

2" (51 mm)

5.3''

(135 mm)

consoles\tlsrf\fig3.eps

0.22'' (5,6 mm) dia.

3.75"

(95mm)

0.4''

(10 mm)

0.93''

(23,6 mm)

0.93''

(24 mm)

1.25''

(32 mm)

0.93''

(23,6 mm)

2.6''

(66)

0.7''

(17,8)

0.93''

(24 mm)

6.7"

(170 mm)

1.18''

(30 mm)

1

1

2

1

2

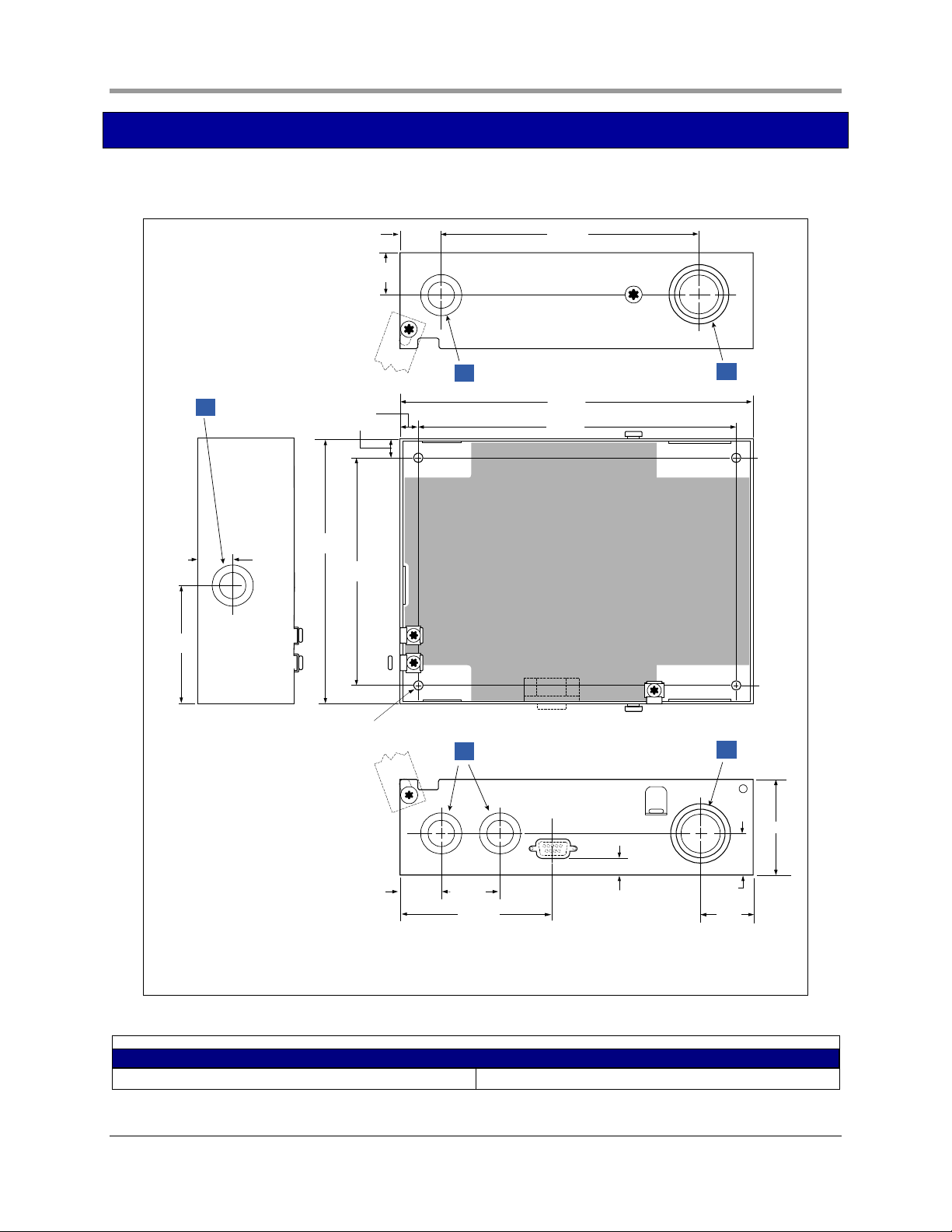

Equipment Dimensions

Dimensions of the TLS RF are shown in Figure 3.

Figure 3. TLS RF dimensions and designated conduit knockouts

LEGEND FOR NUMBERED BOXES IN FIGURE 3

1. Designated power wiring knockouts. 2. Designated intrinsically-safe wiring knockouts.

7

Page 13

Installation Guide National Electrical Code Compliance

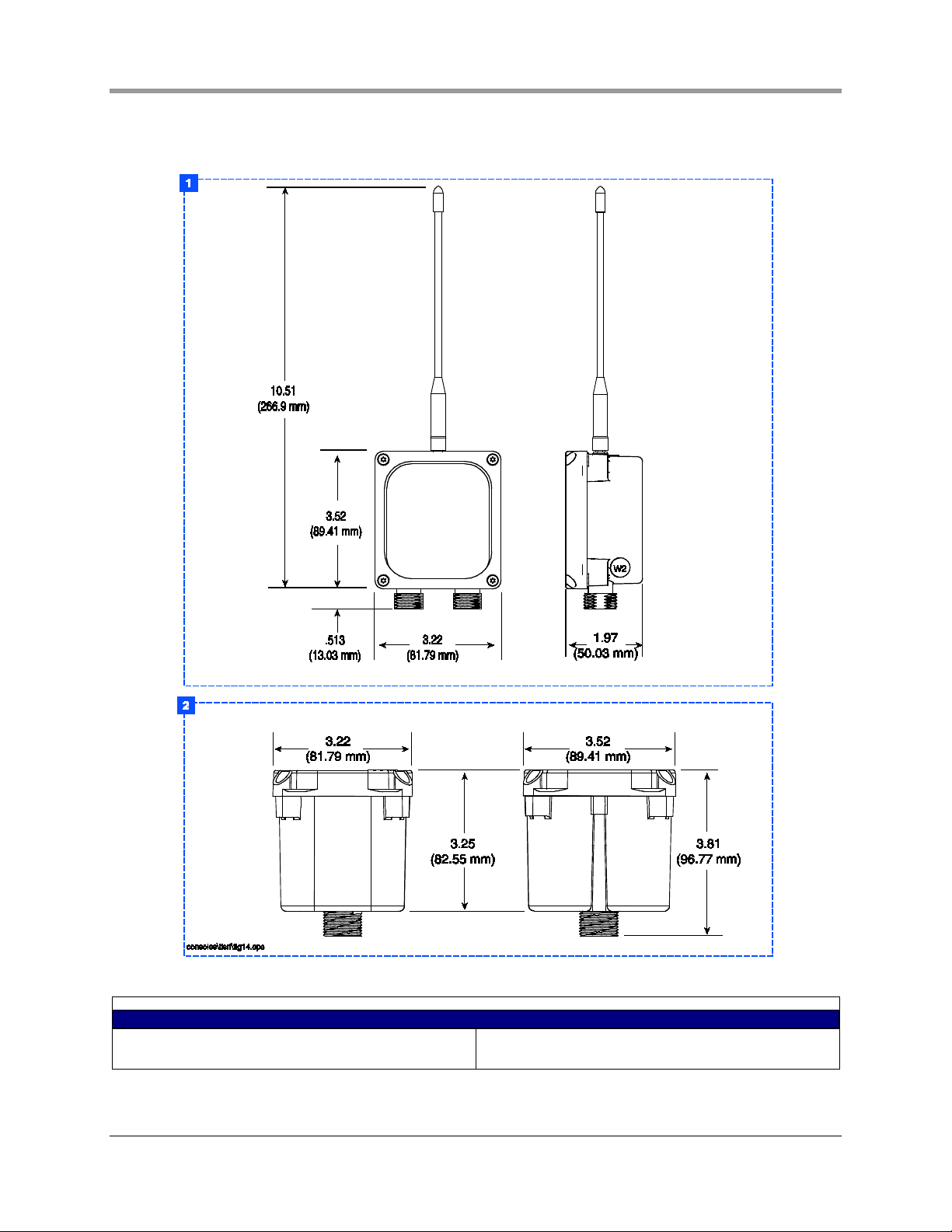

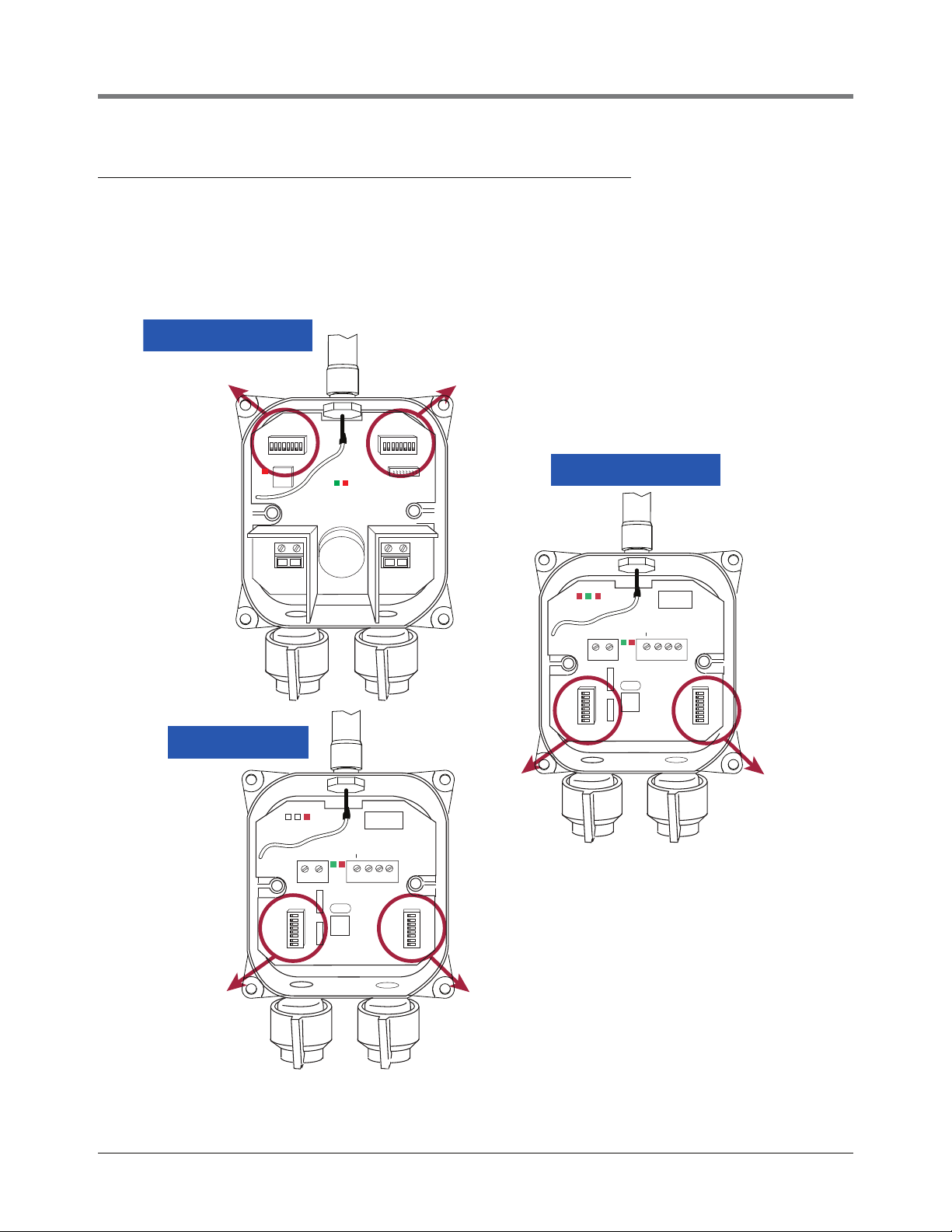

Dimensions of the receiver, transmitter, repeater, and battery housing are shown in Figure 4.

Figure 4. Wireless component dimensions

LEGEND FOR NUMBERED BOXES IN FIGURE 4

1. Receiver, transmitter, and repeater dimensions 2. Battery housing dimensions

8

Page 14

Installation Guide Wiring the TLS RF

TLS RF Installation

Selecting a Location for the TLS RF

WARNING

Explosive vapors or flammable liquids could be present near locations where fuels

are stored or being dispensed. The TLS RF is not explosion proof.

An explosion or fire resulting in serious injury or death, property loss and

equipment damage could occur if the console is installed in a volatile, combustible

or explosive atmosphere (Class I, Division 1 or 2).

Do not install this unit in a volatile, combustible, or explosive atmosphere..

The TLS RF must be mounted indoors, protected from severe vibration, extremes in temperature and humidity,

and other conditions that could harm computerized electronic equipment.

Ensure that the TLS RF is located where neither it nor its associated cabling will be damaged by doors,

furniture, etc. Consider the ease of routing wiring, and ducting to the TLS console. Check that the mounting

surface is strong enough to support the unit’s weight of about 4 pounds.

Mounting the TLS RF

Install the unit’s fastening devices to the mounting surface using the hole pattern (6.7” x 5.7”) shown in Figure

3. Mounting screws up to 3/16” diameter may be used.

Install metal conduit (1/2-inch I.P.S.) between the upper power side knockout on the unit and the power panel.

Figure 3 shows the three designated knockouts (one each on top, left side, and bottom) through which power

wiring can safely enter the unit.

Also install metal conduit (1/2-inch I.P.S.) between the lower intrinsically-safe wiring knockout on the TLS RF

and an intrinsically-safe wiring knockout on the TLS console for device data wiring.

9

Page 15

Installation Guide Wiring the TLS RF

Wiring the TLS RF

WARNING

The unit contains voltages which can be lethal.

Connecting power wires to a live circuit can cause electrical shock that may result

in serious injury or death.

Turn power off at the circuit breaker before connecting wiring to the TLS RF.

Attach conduit from the power panel to the unit’s power wiring knockouts only (1

on top and 1 on bottom, ref. Figure 3)

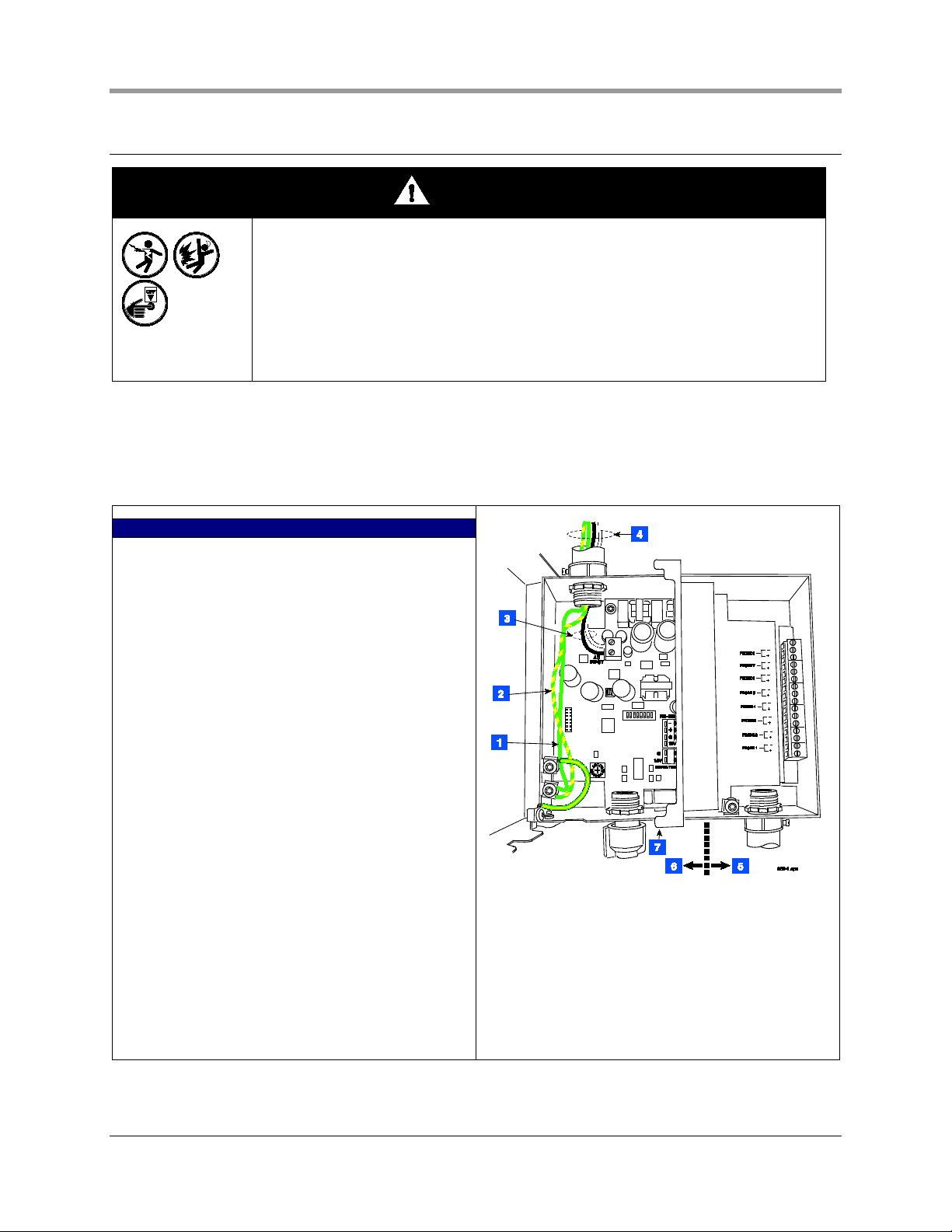

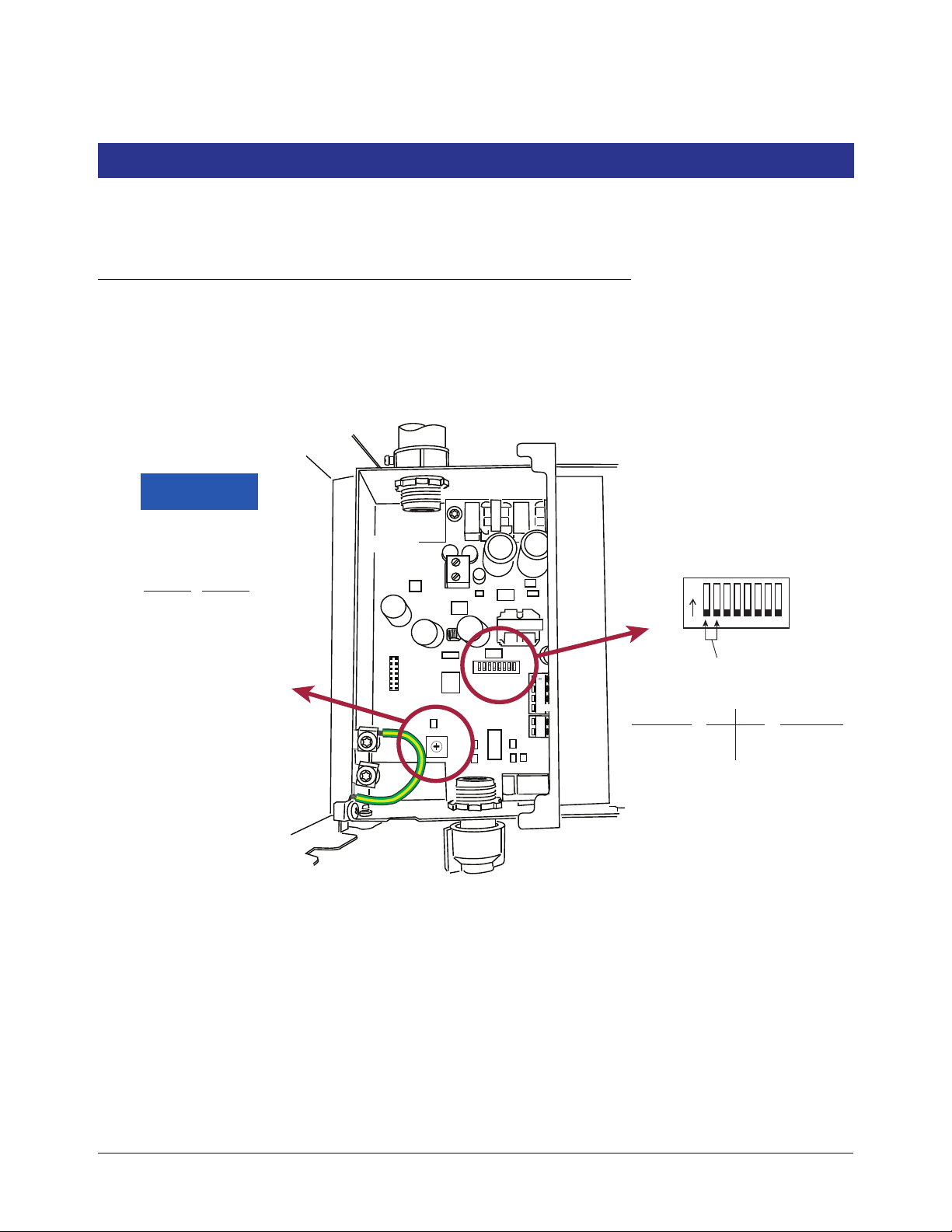

To connect power wiring see Figure 5. To connect receiver wiring see Figure 6. To daisy chain two TLS RFs,

see Figure 8 and

Figure 9. To connect TLS RF data output wiring to the TLS console see Figure 10.

LEGEND FOR NUMBERED BOXES IN FIGURE 5

1. Attach chassis ground wire (#14 AWG) to ground lug.

2. Protective earthing conductor (green and yellow).

Attach #12AWG barrier ground wire to ground lug.

Ground must be the same as the supply and less

than 1.0 ohms to ground.

3. AC power input wires (#14 AWG) to AC INPUT

terminals.

4. POWER WIRING NOTES:

- Barrier ground must be #12 AWG or larger

diameter.

- Check to be sure that the electrical resistance between the unit ground lug and a known good earth

ground is less than 1 ohm.

- Connect the power supply wires in the power panel

to a separate dedicated circuit.

- Electrical rating power input - 120 Vac or 240 Vac,

50/60 Hz, 2 A max.

- See Figure 3 for actual locations of power conduit

knockouts into the unit. Power wiring must enter

only in one of these knockouts.

5. Intrinsically-safe side

6. Power side

7. RS-232 diagnostic port:

- Baud rate - 9600

- Data length - 8

- Parity - None

- Stop bits - 1

Figure 5. Wiring AC power to the TLS RF

10

Page 16

Installation Guide Wiring the TLS RF

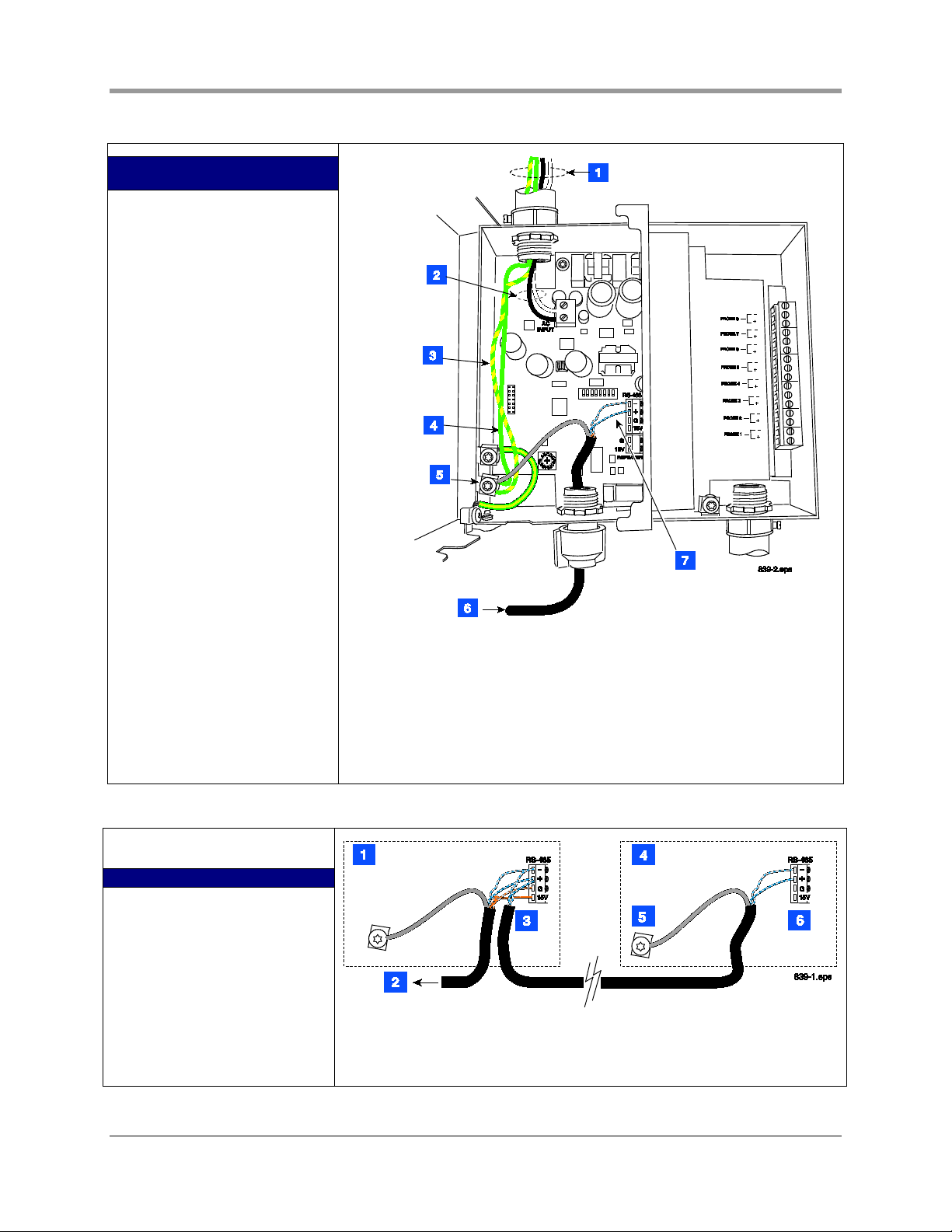

LEGEND FOR NUMBERED BOXES

IN FIGURE 6

1. Connect the shield of the RS-

485 cable to the ground lug.

2. Cord grip

3. RS-485 cable to Receiver

4. Power side

5. Intrinsically-safe side

6. NOTE: Attach one end of RS-

485 cable to RS-485 terminals

in the TLS RF and other end to

RS-485 terminals in the

Receiver. One twisted pair

connects to terminals - and +

(RS-485 signals) and the

second twisted pair connects

to terminals +15 and G

(Receiver power). You must

connect each wire of each pair

to the same terminals in the

Receiver (e.g., white w/blue

stripes to “-“ and white w/blue

stripes to “-“). (ref. Figure 24

on page 25). NOTE: see Figure

7 for wire connection tips.

NOTE: In sites with two daisychained TLS RFs, the receiver

is only connected to the

master TLS RF.

Figure 6. Wiring receiver to the TLS RF

LEGEND FOR NUMBERED BOXES IN FIGURE 7

1. Use small blade screwdriver and loosen terminal by

turning top screw over desired terminal counter

clockwise. DO NOT raise screw head above top of

hole or it may disengage from clamp.

2. Insert ¼” striped wire into terminal clamp’s side

opening and tighten screw clockwise until wire

cannot be moved in or out.

Figure 7. Connecting RS-485 Wiring

11

Page 17

Installation Guide Wiring the TLS RF

LEGEND FOR NUMBERED BOXES

IN FIGURE 8

1. POWER WIRING NOTES:

- Barrier ground must be #12

AWG or larger diameter.

- Check to be sure that the

electrical resistance - between

the unit ground lug and a

known good earth ground is

less than 1 ohm.

- Connect the power supply

wires in the power panel to a

separate dedicated circuit.

- Electrical rating power input

- 120 Vac or 240 Vac, 50/60 Hz,

2 A max.

- See Figure 3 for actual

locations of power conduit

knockouts into the unit. Power

wiring must enter only in one

of these knockouts.

2. AC power input wires (#14

AWG) to AC input terminals.

3. Protective earthing conductor

(green and yellow). Attach

#12AWG barrier ground wire

to ground lug. Ground must be

the same as the supply and

less than 1.0 ohms to ground.

4. Attach chassis ground wire

(#14 AWG) to ground lug.

5. Connect the shield of the RS-

485 cable to the ground lug.

6. RS-485 cable from master TLS

RF.

7. See Figure 9 for connections.

Figure 8. Power connections to a daisy chained TLS RF

FIGURE 9

1. TLS RF Master

2. RS-485 cable to Receiver.

3. RS-485 cable to TLS RF. Cut

the unused twisted pair back

to the cable’s jacket at each

end of the cable.

4. TLS RF Auxiliary

5. Connect the shield of the RS-

485 cable to the ground lug.

6. Connect like colored wires of

the twisted pair to like

Figure 9. RS-485 cable connections when daisy chaining two TLS RFs

12

Page 18

Installation Guide Wiring the TLS RF

terminals in both TLS RFs.

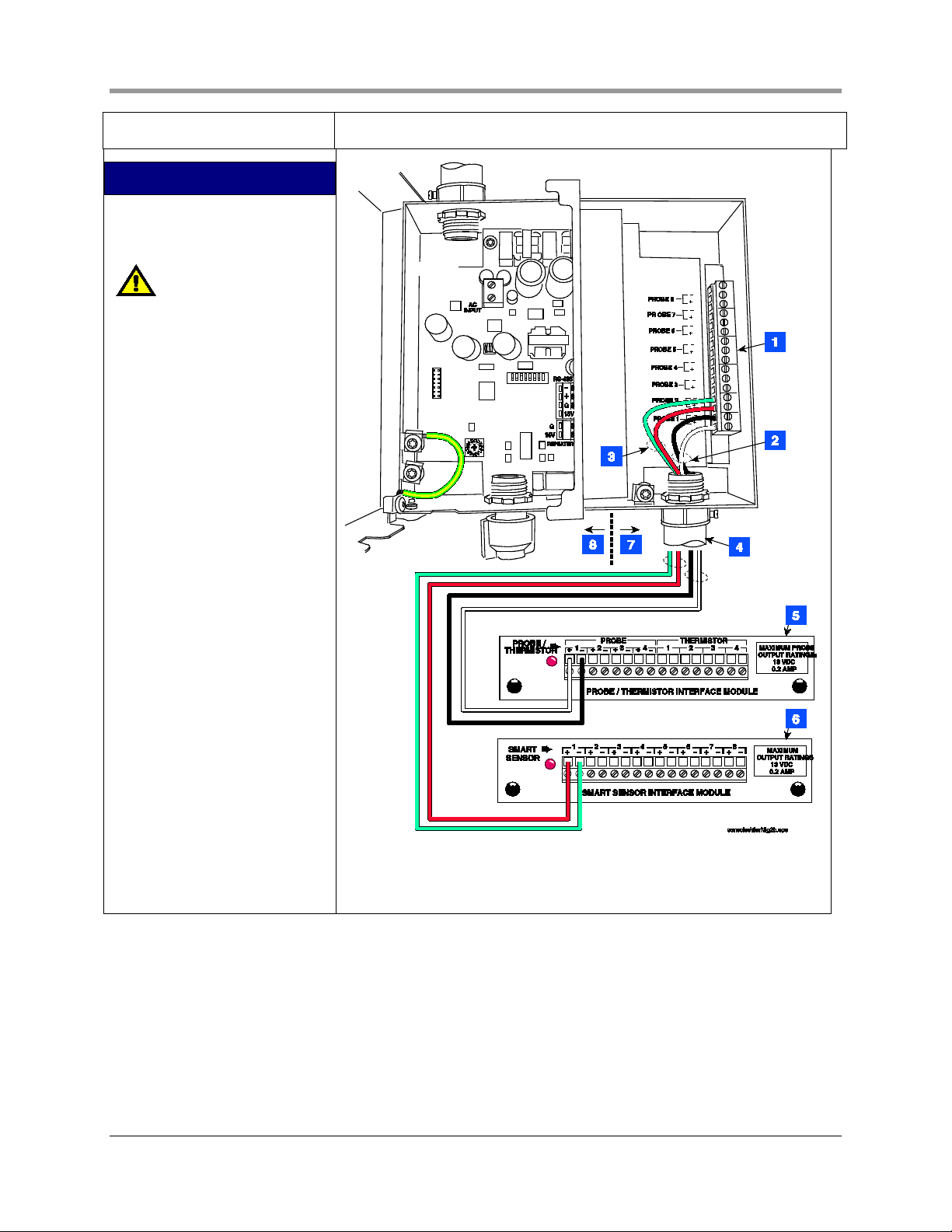

LEGEND FOR NUMBERED BOXES

Note: Output wiring from the TLS

RF to the TLS console is an

intrinsically safe circuit.

wiring shall be installed in

accordance with Article 504-20 of

the NEC, ANSI/NFPA 70.

1. Received transmitter data

2. In this example, device output

3. In this example, device output

4. 1/2” i.p.s. conduit to TLS

5. Probe interface module in TLS

6. SmartSensor interface module

7. Intrinsically-safe side

8. Power side

IN FIGURE 10

NOTE: Intrinsically safe

output terminals (1-8).

1 is a Mag probe - Observe

polarity. Note: each time a

transmission is received from

this device, LED 1 (see item 5

in Figure 11) will flash.

2 is a Mag Sump Sensor Observe polarity. Note: each

time a transmission is received

from this device, LED 2 (see

item 5 in Figure 11) will flash.

console

console.

in TLS console

Figure 10. Wiring Data Outputs from TLS RF to TLS Console

Figure 11 locates the diagnostic lights and setup switches in the TLS RF.

Each TLS RF in the site network must have a unique device set number (0 or 1). The factory default setting is

‘0’. You must select ‘0’ for the master TLS RF unit. The site’s Receiver must also be connected to the master

TLS RF.

If a second TLS RF is required, enter ‘1’ in the auxiliary TLS RF.

13

Page 19

Installation Guide Wiring the TLS RF

LEGEND FOR NUMBERED BOXES

IN FIGURE 11

1. These LEDs flash when there is

comm activity on RS-232 port

(Red = TX, Green = RX).

2. These LEDs flash when there is

comm activity on the RS-485

network (between TLS RF and

receiver).

3. Red LED is lit when TLS RF is

powered on.

4. Device timeout rotary switch

selects the maximum allowed

time to wait for communication

from transmitter before a

Probe Out/Comm alarm is

posted by TLS console (see

Appendix C for selections).

Position 1 (10 minutes) is the

factory default setting.

5. These red LEDs flash when a

message is received from a

transmitter in the monitored

device set. LED 1 is the device

wired to I.S. output terminal 1.

LED 2 is the device wired to

output terminal 2, etc.

6. Red LED flashes when TLS

console is polling for device

data.

7. S2 DIP switches 1 – 2 enter

device set address (see

Appendix C).

Figure 11. TLS RF diagnostic LEDs and switch locations

14

Page 20

Installation Guide Transmitter Installation

Wireless Component Installation

Transmitter Installation

MAG PROBE SUMP

A transmitter / battery pack pair must be installed in every tank’s probe/dispenser pan that will be monitored

by the TLS RF. Follow the steps below to install the transmitter assembly.

1. Connect the two conduit hangers from the kit (2- or 4-inch as required) to the battery pack support

bracket as shown in Figure 12.

2. Attach two conduit clamps to the battery pack support bracket as shown in Figure 13. Do not tighten

screws at this time.

LEGEND FOR NUMBERED BOXES IN

FIGURE 12

1. 2-inch or 4-inch conduit hanger [as

required] - 2 places

2. 1/4 x 20 hex head nut - 2 places

3. 1/4 x 20 x 1.25” hex head bolt - 2

places

4. Battery pack support bracket

5. 1/4 x 20 x 0.5” hex head bolt - 2

places

6. 1/4 x 20 hex head nut - 2 places.

Figure 12. Attaching hangers to battery pack support bracket

15

Page 21

Installation Guide Transmitter Installation

LEGEND FOR NUMBERED BOXES IN

FIGURE 13

1. #10 x 1/2’’ screw - 2 places

2. Clamp - 1/2” conduit - 2 places

3. #10 x 1/2’’ hex nut - 2 places.

Figure 13. Attaching conduit clamps to battery pack support bracket

3. Attach two conduit clamps to the transmitter as shown in Figure 14. Do not tighten screws at this time.

LEGEND FOR NUMBERED

BOXES IN FIGURE 14

1. #10 x 1/2’’ taptite screw -

2 places

2. Clamp - 1/2” conduit - 2

places

3. Transmitter housing

Figure 14. Attaching conduit clamps to transmitter housing

4. Loosen the probe cable cord grip and remove the riser cap. Thread the probe cable through the two

conduit hangers as you slide the hanger/bracket assembly onto the riser. Adjust the conduit hangers until

the top one is 3 - 4 inches below the top of the riser as shown in Figure 15. Tighten the two conduit

16

Page 22

Installation Guide Transmitter Installation

hanger bolts to secure the bracket on the riser. Loosen the cord grip in the top of the riser cap and push

the probe cable up through the cord grip and replace the riser cap and tighten the probe cable cord grip.

Insert a piece of ½-inch conduit or ducting into the loosened conduit clamps in the battery pack support

bracket. The conduit can be positioned below the manhole cover from 1 to 6 inches, as required for best

signal reception. Place a mark on the conduit above the top clamp. Remove the conduit to a nonhazardous location and cut off the excess length. Push the conduit down through the two clamps until the

top clamp is below the mark on the conduit and tighten the two clamps.

LEGEND FOR NUMBERED BOXES

1. 1/2” conduit or ducting

2. Clamp - 1/2” conduit - 2 places

3. Conduit hanger bolts - 2 places

4. Riser cap

5. Cord grip

6. Probe cable

IN FIGURE 15

(not visible in this view)

Figure 15. Installing transmitter support conduit

5. Loosen the clamps on the back of the transmitter and slide the two clamps down over the conduit as

shown in Figure 16. Position the transmitter until the top clamp is about 1/4” below the top of the conduit

and tighten the clamps just enough to keep the transmitter from sliding down.

17

Page 23

Installation Guide Transmitter Installation

LEGEND FOR NUMBERED BOXES IN

1. See Step 6 below.

2. Clamps - 2 places

FIGURE 16

Figure 16. Installing transmitter onto support conduit

6. Rotate the transmitter until its antenna is oriented relative to the repeater/receiver antennas as shown in

Figure 17 and tighten the two clamps on the back of the transmitter.

LEGEND FOR NUMBERED BOXES IN FIGURE 17

1. Building

2. Receiver

3. Approximate midpoint between repeater and

receiver.

4. Repeater

5. Transmitter antenna - orient antenna until it is

perpendicular to a point that is approximately

the midpoint between the repeater and the

receiver.

Figure 17. Orienting transmitter to receiver & repeater

18

Page 24

Installation Guide Mag Sump Sensor Installations - STP Sump

7. Insert the battery pack into the battery support bracket as shown in Figure 18.

8. Attach power/probe cables as described in the section below entitled “Connecting cables to the

Transmitter”.

LEGEND FOR NUMBERED

BOXES IN FIGURE 18

1. Tie wrap cables

2. Probe cable

NOTE: Intrinsically

safe wiring shall be

installed in accordance with

Article 504-20 of the NEC,

ANSI/NFPA 70.

3. Probe Riser

4. Red battery ID labels - 2

places

5. Battery pack - insert into

support bracket

Figure 18. Mag Probe Installation Example (in operational configuration)

Mag Sump Sensor Installations - STP Sump

A transmitter/battery pack pair can be installed with a Veeder-Root Mag Sump sensor within the STP sump.

The transmitter /battery pack installs similar to the way it installs in probe sumps. The exception is that the

support brackets will attach to the pump’s 2-inch discharge piping rather than to the STP’s 4-inch riser as

shown in Figure 18.

Install the Mag Sump sensor using the included universal sensor mounting kit and following the instructions

included with the sensor.

Once the sensor/battery pack is installed, attach power/sensor cables as described in the section below

entitled “Connecting cables to the Transmitter”.

19

Page 25

Installation Guide Mag Sump Sensor Installations - Dispenser Pan Sump

Mag Sump Sensor Installations - Dispenser Pan Sump

1. A transmitter /battery pack pair can be installed with a Veeder-Root Mag Sump sensor within the

dispenser sump.

2. Install the Mag Sump sensor in the dispenser’s pan area following instructions accompanying the sensor.

3. Using two taptite screws from the kit, attach the transmitter housing to the side of the battery support

bracket that has the two circular slots (see Figure 19). Do not tighten screws at this time.

4. Get the 1 inch by 6 inch slotted flat bar from the kit and two ¼ x 3-inch bolts and two nuts. Clamp the

bracket to a section of the square support tubing in the sump, below the shear valve (see Figure 20).

5. Rotate the transmitter antenna as close as possible to a horizontal position then tighten two mounting

screws in housing.

6. Insert the battery pack into its support bracket - do not connect battery cable to battery pack at this time.

7. Attach power/sensor cables as described in the section below entitled Connecting cables to the

Transmitter.

LEGEND FOR NUMBERED BOXES IN FIGURE 19

1. Transmitter

2. #10 x 1/2” taptite screws (2)

3. Battery support bracket

Figure 19. Attaching transmitter to battery support bracket

20

Page 26

Installation Guide Mag Sump Sensor Installations - Dispenser Pan Sump

Figure 20. Example transmitter installation in dispenser sump (in operational configuration)

LEGEND FOR NUMBERED BOXES IN FIGURE 20

1. Shear valve

2. Transmitter

3. Battery pack

4. Using 1 x 6 slotted flat bar and two ¼ x 3 bolts from kit, clamp battery support bracket to square tubing support.

5. Battery caution label attached to battery cable (2 places)

6. Dispenser mag sump sensor

7. Sensor cable

NOTE: Intrinsically safe wiring shall be installed in accordance with Article 504-20 of the NEC,

ANSI/NFPA 70.

8. Dispenser sump

21

Page 27

Installation Guide Mag Sump Sensor Installations - Dispenser Pan Sump

CONNECTING CABLES TO THE TRANSMITTER

1. Remove the cover of the transmitter and set it aside Make sure the battery/dc power cable is not

connected to the battery pack or dc power source at this time.

2. Push the probe/sensor cable through the left cord grip bushing and the battery cable through the right

cord grip (see Figure 21). Strip the cable leads as shown in Figure 22.

WARNING! To prevent ignition of flammable or combustible atmosphere disconnect power

before servicing.

3. Set S1 and S2 DIP switches as desired (ref. Appendix C).

4. Connect the Mag probe/Mag Sump sensor cable to the PROBE terminal block (white to PWR and black

to GND) and the battery pack/dc power cable to the BATTERY terminal block (white to +IN and black to IN) as shown in Figure 21.

5.

TRANSMITTER WIRING

1. Green LED – Unit status.

2. Red LED – Radio status.

3. S2 DIP switch

4. Red LED – Flashes only when radio is

5. Battery power in terminals (+IN and –

6. Cable from battery pack – observe

7. Cable from probe or sensor

8. Probe/sensor input terminals (PWR

9. S1 DIP switch

Hand tighten both cable entry cord grip nuts to prevent water entry!

LEGEND FOR NUMBERED BOXES IN

FIGURE 21

powered on in Diagnostic Mode.

IN). Observe polarity!

polarity!

and GND) - observe polarity!

22

Figure 21. Wiring the Transmitter

Page 28

Installation Guide Receiver Installation

Figure 22. Connecting wiring to transmitter terminal blocks.

LEGEND FOR NUMBERED BOXES IN FIGURE 22

1. Strip back cable and wire jackets the amount shown.

2. Use a screwdriver with the proper blade width

3. Insert the probe cable ends through the housing and into the proper lower openings in the terminal block as you

tighten down the retaining screws.

Both wires must be tight in terminals!

6. To assure a water-tight seal between the cover and the enclosure, follow these steps:

a. Insert the four cover screws through the cover and then press on the retaining washers to hold the

screws in place.

b. Make sure that the cover gasket is free of dirt and debris on both sides of the gasket and that the inside

of the cover is clean in the gasket area.

c. Position the gasket into the cover groove, assuring that it is pressed fully into the groove and sitting

completely flat.

d. Assemble the cover onto the enclosure, tightening the screws in a couple of turns each. Using an

alternating ‘X’ pattern, continue to tighten the screws until they are all tight.

7. Attach the red battery ID labels from the installation kit to the battery cable at both ends as shown in

Figure 18.

8. Refer to the Site Startup Procedure before attaching battery cable to battery pack connector.

Receiver Installation

1. One receiver is required per site and it is mounted in the vertical position (antenna up) on the outer wall of

the same building housing the TLS RF. The receiver is attached to its mounting bracket with #10 x 1/2”

taptite screws from its install kit (see Figure 23). The L-bracket is then mounted on the outer wall of the

building using appropriate fasteners (customer supplied). NOTE: Locate the receiver on the side of the

building facing the tanks to provide an unobstructed signal path. When locating the mounting position,

keep in mind that the RS-485 cable connecting the receiver to the TLS RF must be less than 250 feet in

length. Avoid placing the receiver near motors (e.g., power roof vents), fluorescent lighting (min. 1 foot

separation), pumps, welders.

2. Run the RS-485 cable (Belden #3107A or equiv.) from the TLS RF through the building’s wall to the

receiver. Caulk the cable where it passes through wall openings. Use cable clamps at appropriate

intervals to secure the cable to the walls.

23

Page 29

Installation Guide Receiver Installation

3. Note that the receiver cover label indicates the cord grip to be used for the RS-485 cable from the TLS

RF. Loosen that cord grip then remove the cover of the receiver and set it aside.

4. Note that the Receiver cover label indicates the cord grip to be used for the RS-485 cable from the TLS

RF and the cable to the Repeater (if used). If you are installing a Repeater in this site, loosen both cord

grip nuts, otherwise loosen the TLS RF cord grip, then remove the cover of the Receiver and set it aside.

5. Push the TLS RF RS-485 cable through the loosened cord grip. Strip back the jacket from the end of the

cable as shown in Figure 22. Note that there are two twisted pair color-coded wires in the cable (e.g., a

white with blue stripe and blue with white stripe pair and a white with orange strip and orange with white

stripe pair).

6. One of the pairs is for RS-485 communication (- & + terminals) and the other pair is for receiver power

(+15 Vdc & Gnd). Using Figure 24 as a guide, connect the wires of the two twisted pairs to the RS-485

terminals.

Record which wire attaches to each terminal to help you attach the other end of that wire to the identically

marked terminal in the TLS RF.

7. Referring to your connection notes in step 5 above, connect the other end of the RS-485 cable to the RS-

485 terminal block in the TLS RF (ref. Figure 6 on page 11).

8. If a Repeater is used and powered by the Receiver, push the two wire power cable (to Repeater) through

the +15 Vdc cord grip of the Receiver. Strip back the jacket from the end of the cable as shown in Figure

22. Attach the dc power cable (white to +15 and black to GND) to the Repeater terminal block (item 9 in

Figure 24).

LEGEND FOR NUMBERED BOXES IN FIGURE

1. Receiver or repeater

2. 0.280” diameter hole (2) – mount this

narrow side of bracket to wall or post

3. Mounting bracket

4. #10 x 1/2” taptite screws

Receiver is only suitable for use in and

over a non-hazardous location.

23

Figure 23. Attaching mounting bracket to receiver or repeater

9. Set S1 and S2 DIP settings as desired (ref. Appendix C).

10.

Hand tighten both cord grip nuts to prevent water entry!

11. To assure a water-tight seal between the cover and the enclosure, follow these steps:

a. Insert the four cover screws through the cover and then press on the retaining washers to hold the

screws in place.

b. Make sure that the cover gasket is free of dirt and debris on both sides of the gasket and that the inside

of the cover is clean in the gasket area.

c. Position the gasket into the cover groove, assuring that it is pressed fully into the groove and sitting

completely flat.

24

Page 30

Installation Guide Repeater Installation

d. Assemble the cover onto the enclosure, tightening the screws in a couple of turns each. Using an

alternating ‘X’ pattern, continue to tighten the screws until they are all tight.

LEGEND FOR NUMBERED BOXES IN FIGURE 24

RECEIVER

1. RS-485 Comm Activity

XMIT (Red) LED – flashes when message

transmitted to TLS-RF

RCV (Green) LED – flashes when message

received from TLS- RF

PWR (Red) LED – receiver power-on indicator

2. Green LED – Unit status

3. Red LED – Radio status

4. Connect the like color pairs of the RS-

485/power cable to the same RS-485

terminals in both the receiver and the master

TLS RF (ref. Figure 6 on page 11).

5. S1 DIP switch

6. RS-485 cable

7. A solid bushing must be installed to seal the

receiver when this cord grip is unused. In sites

where a repeater is powered from the receiver,

the repeater’s power cable enters through this

cord grip and attaches to item 9.

Hand tighten both cord grip nuts to

prevent water entry!

8. S2 DIP switch

9. +15 Vdc power source for the repeater.

Figure 24. Wiring the receiver

Repeater Installation

1. One repeater is installed per site which relays transmitter signals to the site’s receiver. The repeater is

mounted in a vertical position on same side of the building as the receiver (preferably), and in a direct line

of sight with the receiver (ref. Figure 17 on page 18).

2. The repeater is attached to its mounting bracket with #10 x 1/2” taptite screws from its install kit (ref.

Figure 23 on page 24). The L-bracket is then mounted on the outer wall of the building using appropriate

fasteners (customer supplied).

3. Note the cover of the repeater indicated the cord grip to be used for the cable connecting the repeater to

its dc power source. Loosen the +15 Vdc labeled cord grip, then remove the cover of the repeater and

set it aside. Push the 2-wire power cable through the power cable cord grip and into the Repeater.

4. Set S1 and S2 as desired (refer to Appendix C).

5. Connect the 2-wire dc power cable to the repeater terminal block white to +15 and black to GND (see

item 7 in Figure 25).

25

Page 31

Installation Guide Repeater Installation

6. To assure a water-tight seal between the cover and the enclosure, follow these steps:

a. Insert the four cover screws through the cover and then press on the retaining washers to hold the

screws in place.

b. Make sure that the cover gasket is free of dirt and debris on both sides of the gasket and that the inside

of the cover is clean in the gasket area.

c. Position the gasket into the cover groove, assuring that it is pressed fully into the groove and sitting

completely flat.

d. Assemble the cover onto the enclosure, tightening the screws in a couple of turns each. Using an

alternating ‘X’ pattern, continue to tighten the screws until they are all tight.

7.

Hand tighten both cable entry cord grip nuts to prevent water entry!

8. The other end of the repeater’s dc power cable connects to the receiver’s +15 Vdc output terminal (ref.

item 9 in Figure 24), or to a non-interruptible, Class 2, 15 Vdc power source.

LEGEND FOR NUMBERED BOXES IN FIGURE 25

REPEATER

1. Red LED – on when power is applied.

2. Green LED – Unit status

3. Red LED – Radio status

4. S1 DIP switch

5. DC Power input cable

6. S2 DIP switch

7. DC power input terminals ( +15 Vdc and ground

)

Pay close attention to the polarity of the +15 V.

Reversing the connections can cause damage to the

TLS RF!

Repeater is only suitable for use in and over a

non-hazardous location.

26

Figure 25. Wiring the repeater

Page 32

Installation Guide Identifying Devices in the TLS RF Site Network

Network Setup

Hardware Overview

An example TLS RF site network illustrating a 16 transmitter configuration is shown in Figure 26. The

maximum number of transmitters permissible in a TLS RF Wireless site is 16 (requires 2 TLS RF units).

LEGEND FOR NUMBERED BOXES IN

FIGURE 26

1. Site Network

2. Wireless network

3. VR bus

4. Up to 16 transmitters are

supported in this example site.

5. Repeater

6. Receiver

7. TLS RF, one required per 8

transmitters

8. TLS-350R console

Figure 26. Example Site Network diagram

NOTE: The device type (i.e., mag probe or mag sump sensor) and quantity permissible in your site’s

network is dependent on the capabilities of the installed TLS console.

Identifying Devices in the TLS RF Site Network

The Site ID must be identical for all transmitters, the repeater, and the receiver in the site’s wireless network.

Each transmitter in the site’s wireless network must have a unique device ID number (from 1 – 16)

Each repeater in the site’s wireless network must have a unique repeater ID number (from 0 – 15)

The receiver on the site’s VR bus must have a unique VR bus address (from 0 – 3).

Each TLS RF in the site’s network must have a unique Device Set address (Master at 0 and Auxiliary at1).

All ID numbers are converted into binary form and entered using DIP switches located in each device.

You must enter the IDs in each device before it is installed.

Create a site network worksheet in which you list each transmitter, its location and its Site ID. Using this

worksheet when setting device DIP switches and connecting signal wires will help ensure the TLS console is

receiving the intended data transmissions.

27

Page 33

Installation Guide Identifying Devices in the TLS RF Site Network

Site Startup Procedure

After installing and wiring all equipment, follow the startup steps below.

1. Open the cover of the TLS RF, then power it up. The green/red LEDs indicating RS-485 network activity

between the receiver and TLS RF should be flashing rapidly (ref. item 2 in Figure 11 on page 14). If Yes,

continue to the next step. If No, check the red LED. If it is not flashing, replace the TLS RF. If the green

LED is not flashing, the receiver is not responding. Go the receiver and remove its cover. Check the RS485 wiring connections to verify that each wire of the twisted pairs is connected to the same terminal in

the receiver that its other end is connected to in the TLS RF. If the wiring connections are correct, the

PWR LED (item 1 in Figure 24) and green LED (item 2 in Figure 24) should be lit. If the PWR LED is lit,

but the green LED is not lit, the receiver is inoperative and needs replacing. If the PWR LED is not lit,

measure the voltage across the twisted pair power wires, it should be +15 Vdc. To isolate a faulty cable,

measure the voltage across the +15 and GND terminals of the RS-485 terminal strip in the TLS RF (ref.

Figure 6 on page11). Replace the cable, TLS RF, or receiver as necessary.

2. Referencing your site network worksheet, go to the first transmitter and connect its power cable to the

battery pack. This will put the transmitter into the continuous mode, ‘forcing’ it to transmit every 6 seconds

for 30 minutes (default).

3. At the TLS RF, you should see one of the 8 red transmission received LEDs flashing every 6 seconds,

indicating receipt of each transmission from the transmitter (item 5 in Figure 11 on page 14). If yes, record

on your site network worksheet which number LED is flashing for this transmitter and then go to step 3a. If

one of the LEDs is not flashing, go to step 3b.

a. Go back to the transmitter and replace the sump lid, or if a dispenser, close the sump’s access

cover. Return to the TLS RF and verify that the same LED continues to flash every 6 seconds. If

yes, the receiver is continuing to communicate with the transmitter after the manhole cover or

other obstruction was replaced. Go back to the same transmitter, remove the manhole cover and

disconnect the power cable from the battery pack and continue to step 4. If the LED is not

flashing every 6 seconds, the receiver is not picking up the transmitter’s signal. Return to the

transmitter and remove the obstruction. Referring to your site network worksheet, verify that the

correct Site ID is entered. Verify that the transmitter’s antenna is oriented to the receiver as

shown in Figure 17 on page 18, if it is move it around and recheck at the TLS RF to see if the

new position helps. Replace the obstruction and recheck the LED in the TLS RF. If it is not

flashing, try moving the transmitter down in the sump, then replace the obstruction and recheck

the LED in the TLS RF. If reorienting the antenna or moving the transmitter doesn’t help, make a

note on your worksheet that the signal from this transmitter is not being received, disconnect the

transmitter power cable at the battery pack, and continue to Step 4.

b. Remove the cover of the problem transmitter. The green LED (item 1 in Figure 21 on page 22)

should flash indicating that the probe is being read. The red LED should also flash indicating the

transmitter linked with the receiver and transmitted the probe’s data. This green/red flash

sequence should occur every 6 seconds while the transmitter is in continuous mode. If there is no

green flash, check the probe cable’s wiring connections. If the green LED flashes every 6

seconds, but the red LED doesn’t flash, then the transmitter is reading the probe data, but for

some reason is not linking with, and transmitting to the receiver. However, you will have to wait

until you check additional transmitters before determining that the receiver is not functioning

correctly. If the green LED is blinking quickly (about a tenth of a second) every 6 seconds, it can

mean one of several probe errors depending on the number of blinks. Before continuing to step

4, disconnect the transmitter power cable at the battery pack.

28

Page 34

Installation Guide Identifying Devices in the TLS RF Site Network

4. Repeat Steps 2 and 3 for each of the remaining transmitters. As you power up each of the remaining

transmitters and check their reception at the TLS RF, make notes on your site network worksheet as to

whether the transmitter signals are being received successfully, which one of the 8 red transmission

received LEDs in the TLS RF is flashing every 6 seconds, probe problems, etc., for later troubleshooting.

5. If each transmitter is being received at the TLS RF(s), go around to each transmitter, reconnect the

transmitter’s power cable to the battery, and replace the sump or dispenser cover as appropriate. Go to

the TLS console and configure all site probes and mag sump sensors. Check for any probe out/comm

alarms. If none are observed, the startup is complete.

If some transmitters are not being received at the TLS RF, you will have to install additional repeaters as

necessary. The repeater requires a Class 2, 15 Vdc power source.

29

Page 35

Installation Guide Antenna Propagation Basics

Troubleshooting

Antenna Propagation Basics

The Veeder-Root TLS RF Wireless site consists of one Master (Receiver) and one or more Slave units

(Transmitters/Repeaters) and uses the Frequency Hopping Spread Spectrum (FHSS) method of signal

transmission in which each transceiver is programmed to follow a set of channels called the ‘Hopset’. Federal

Communication Commission (FCC) regulations state that for FHSS: each transceiver may dwell on any given

frequency in the Hopset for no more than 400 milliseconds in any 30 second period. Authorized channel

bandwidth is 1 MHz and channel spacing is 25 kHz.

The propagation of radio waves in FHSS applications, i.e., the TLS RF Wireless System, is influenced by

several factors:

ANTENNA OPERATION

The antenna is a transducer, which converts radio frequency electrical energy fed to it (via the transmission

line) to an electromagnetic wave propagated into space. Assuming that the operating frequency in both cases

is the same, as in the TLS RF Wireless System, this process is reciprocal in nature - the antenna will perform

identically in Transmit or Receive mode. The same Antenna and Transmission Line path is used for both

transmit and receive functions.

FREE SPACE LOSS

Signal power is diminished by geometric spreading of the wavefront, commonly known as Free Space Loss

(FSL). For TLS Wireless sites having relatively small distances between the Receiver and Transmitters, FSL is

not an issue.

ATTENUATION

When the RF signal passes though solid objects, some of the signal power is absorbed. The most convenient

way to express this is by adding an “allowed loss” to the Free Space loss. Attenuation can vary greatly

depending upon the structure of the object the signal is passing through. Metal in the barrier greatly increases

the attenuation. Thickness also increases the loss. General rules of thumb for attenuation are:

• Trees account for 10 to 20 dB of loss per tree in the direct path. Loss depends upon the size and type of

tree. Large trees with dense foliage create greater loss.

• Walls account for 10 to 15 dB depending upon the construction. Interior walls are on the low end and

exterior walls, especially those with stucco, create more loss.

• Floors of buildings account for 12 to 27 dB of loss. Floors with concrete and steel are at the high end and

wood floors are at the low end.

• Mirrored walls have very high loss because the reflective coating is conductive.

SCATTERING

RF signals can reflect off of many things and the direct signal combines with signals that have reflected off of

objects that are not in the direct path. This effect is usually described as multipath, fading, Rayleigh fading or

signal dispersion. When RF signals combine they can be distorted. The distortion degrades the ability the

receiver to recover the signal in a manner much like signal loss.

30

Page 36

Installation Guide Probe Troubleshooting

RADIO LINE OF SIGHT

Radio Line of Sight (LOS) refers to the ability of the receiver to ‘see’ the transmitter. In TLS RF Wireless sites,

the preferred positioning of the Receiver is one that is visible from the Transmitter’s location. When Radio line

of sight is impossible, e.g., tanks are on opposite sides of the building, a Repeater should be installed that is

positioned at a point that is both visible from the Transmitter and from the Receiver.

ANTENNA POLARIZATION

Polarized omni-directional antennas (used in the TLS Wireless System) are subject to severe pattern distortion

in the direction of their mounting (vertically or horizontally). For this reason, the TLS RF Wireless System

Receiver’s antenna must be mounted vertically and the Transmitter’s antenna mounted horizontally (90

degrees apart).

INTERFERENCE

Interference may be caused by several possible sources:

• In-band signals originating from other systems

• Reflections, multipath

• Receiver front-end overload, produced by adjacent transmitters such as a microwave tower, etc.

The nature of Frequency Hopping Spread Spectrum systems is such that interference would tend to degrade

throughput, rather than cause the cessation of link operation. Even in such instances, the inherent immunity to

interference provides that extra margin of safety. When all antenna orientation possibilities are tried and one or

more transmitters still cannot be received, additional repeater(s) will have to be installed.

31

Page 37

Installation Guide Probe Troubleshooting

Probe Troubleshooting

1. Attach your laptop to the TLS RF’s RS-232 serial port (see Figure 27).

LEGEND FOR NUMBERED BOXES IN

1. RS-232 (DB9 female)

2. Standard RS-232 cable (customer

supplied)

3. USB to DB9 serial cable (customer

supplied)

4. PCMCIA to serial cable (customer

supplied)

5. PCMCIA card (customer supplied)

6. Laptop with a serial communications

program, such as HyperTerminal

(customer supplied).

FIGURE 27

Figure 27. Laptop to TLS RF Wireless Interface Unit example connections

Open a serial communications program, such as HyperTerminal (available in Windows under

Start\Programs\Accessories\Communications). Set the comm port settings to: 9600 Baud, 8 data bits, no

parity, 1 stop bit.

2. Perform the following steps on a PC with the HyperTerminal application program running. TLS

commands are case sensitive and use a Control-A to identify the start of a command. Enter a Control-A

by holding the Ctrl key down while pressing the A key, then release the Ctrl key. Next, type in the

command, I31500 and click on the SEND button. An example of the 315 command response in a site

with 8 transmitters is shown below.

NOTE: MAG SN = Mag Sump Sensor

DEV column

The TLS RF supports 8 devices (Mag probes or Mag Sump sensors), numbered 01 thru 08. The device

number corresponds to its I.S. data-out terminal wiring position on the TLS RF unit.

32

Page 38

Installation Guide Probe Troubleshooting

TXID Column

A site's wireless system can support up to 16 transmitters and each must have an unique ID. This column

shows the ID that was set in the transmitter when it was installed.

STATE Column

The device state is OK or OUT. When the state is OUT, the TLS RF unit will not respond to the TLS

console polling for this device. The OUT state will cause the TLS console to post a Probe-Out or Comm

alarm for this device.

REASON Column

There are four reasons for a device to have an OUT state:

NO_CNST

In order to conserve energy the transmitter sends messages in 3 groups: constant data, fuel/water data,

and fuel/water/temperature data.

For a given sensor, constant data never changes so it only needs to be transmitted once. It is however

transmitted for two-minutes following transmitter power-up, or the triggering of its service switch

(magnetically activated reed switch) and then settles down to once every 4-hours. The TLS RF unit will

store the constants in non-volatile memory so that the constant data can be restored after a power cycle.

The status of a device will be OUT if the constant data has not been received (NO_CNST).

NO_DATA

Fuel/Water data is transmitted at different rates depending on activity and power-up/service switch status.

The maximum transmission period is 2-minutes, the minimum 5-seconds.

Temperature does not have to be read as often as fuel/water data. It is transmitted once every 2 minutes

along with the fuel/water data. The status of a device will be OUT if it has not received

fuel/water/temperature data (NO_DATA).

TIMEOUT

If no transmissions are received for the timeout duration programmed in the TLS RF unit, the device OUT

status’s reason will be set to TIMEOUT. This state overrides all other states.

NO_READ

The transmitter can detect when a device is not responding correctly. In this case the transmitter will

transmit a device-out message. In turn the TLS RF will set the status of a device to OUT (NO_READ).

On power-up the TLS RF unit will read its non-volatile memory to restore constant data. If the constant

data is available it will then set the device to the OUT condition with the reason code: NO_DATA. When

fuel/water level and temperature data are received the NO_DATA condition will be removed and the

device will be set to the OK status. If there is no constant data the device OUT reason code will be

NO_CNST. The device will be removed from this state when constant and fuel/water/temperature data

are received. If no transmissions are being received from the device the TIMEOUT reason code will

replace the previous reason code.

TYPE and SN Columns

If the device constants are available, the device type and device serial number will be placed in these

columns. If the constants are not available the type column will be filled in with ‘?????’ and the serial

column with all zeros (000000).

33

Page 39

Installation Guide Resetting Data in the TLS RF Unit

TOTL COMMS

A running total of all messages received from this device. This includes messages that were repeated by a

repeater(s).

REPT COMMS Column

This column displays a running total of all messages received from this device that were repeated from a

repeater. Subtracting the repeated total from the total comms value will result in the total number of direct

messages received: Total Direct Messages = TOTL COMMS - REPT COMMS.

LAST COMM Column

This column displays the duration since the last message received from this device. Display is in

days:hours:minutes:seconds format. The 9999:99:99:99 time indicates no messages have been received

since the TLS RF unit has been powered on.

Resetting Data in the TLS RF Unit

NOTE: The data is reset when the TLS RF unit is power cycled or reset with the serial command S001

(except Constants which are in stored in flash memory).

It is also possible to reset the Total and Repeater Comms totals remotely with the following command:

S315ss149.

34

Page 40

Appendix A: Site Survey for Wireless Probes

OBJECTIVE

The objective of the site survey are:-

• To acquire information that will ensure that all the items necessary to complete the installation are ordered and

supplied.

• To establish where the system assemblies will be best located, so that this information can be passed on to the

installation team.

• To establish any site conditions or anomalies that will affect the installation

• Ultimately to ensure the completed installation is of the required high standard

METHOD

A trained person certified by GVR should undertake the site survey: this person will collect the necessary

information and then submit this information in a specified format.

Instructions to Survey Engineer

OBJECTIVE

The Survey engineer needs to provide accurate site information so that when the System is installed and

commissioned it will function reliably, and meet the requirements of the customer.

METHOD

The need for a survey will be triggered by a sales enquiry: The surveyor will require the following basic information:-

• Site name and address.

•Customer

• Telephone number

• Gauge type

• Number of tanks to be gauged

• Additional sensors

• Special instructions

Completion of Site Survey Form

OBJECTIVE

The aim of the survey sheets (or PC software) is to record data collected at the time of the survey to enable

correct equipment specification, identify all works necessary before the installation date, special tools or

equipment required for installation, and site specific data required for a successful commissioning.

A-1

Page 41

Appendix A: Site Survey for Wireless Probes Key Information

METHOD

Take all details and measurements necessary to complete the site survey.

The form has to be completed in the same format by all surveyors. This is so that when or orders are placed with

the local distributor the administrator will understand clearly the information on the survey, and will be able to

compile an accurate parts list.

Note: The local installer will be responsible for the labor element and any locally supplied parts, the survey should

provide enough information for them to be able to do this successfully.

Key Information

SURVEYORS DETAILS

• Name of surveyor

•Company

• Date of survey

• Name/address/telephone number of installation company

GENERAL SITE DETAILS

• Site name and address (include country and local postcode)

• Telephone number (s)

• Site contact name

• Oil company (or group company name)

TAN K I N F O R M AT I ON

• Number of tanks to be monitored

• No of any tanks not to be monitored

• State available probe entry size for each tank

• Check that there are no internal obstructions to the probe

• Determine the tank diameter (height) and probe length required

• Identify any tank lid that has no entry and advise action required

• Note product type of each tank

• Note SWC’s for each tank

• Note max tank capacity of each tank if available (e.g. dipstick top mark or dipchart)

• State whether the tank is single tank, and indicate the end shape if known

• State if the tank is siphon or line manifolded

• Indicate the number of lids on the tank

• Indicate if the tank has a STP fitted

• State whether the tank is single or double wall

• State the material the tank is made of

A-2

Page 42

Appendix A: Site Survey for Wireless Probes Key Information

• If double walled, does it have a leak monitoring device fitted, or are we to provide same

• State whether the tank is direct fill or offset fill

• State the approximate age of the tank

MANHOLE CHAMBER INFORMATION

• Manhole construction

- Shape (circular, square etc.)

- Wall material (concrete, etc.)

- Wall profile (smooth, ribbed)

• Manhole depth (Underside of cover to top surface of lid)

• Indicate if the manhole is less than 18 inches in depth

•Lid material

• Ease of removal (Two-man, special lifter required etc.)

• Accessibility (any restrictions?)

• Vehicle parking (are vehicles regularly parked for long periods)

PROBE RISER SPECIFICATION

• Fittings required to adapt a 2” riser to the riser entry orifice

• Max allowable riser length (formula = manhole depth – [transmitter unit height – 3 inches])

PROBE TRANSMITTER CONSIDERATIONS

• The transmitter needs to be installed towards the centre of the manhole chamber, away from metal edges.

• They should be installed as high up in the chamber as possible, but no closer than 1 inch from the cover.

• Manholes that have vehicles parked over them for any length of time should be avoided.

• The antenna will need to be horizontal and bisecting the angle between the receiver and the repeater

• The most suitable type of fixing bracket will need to be specified for each manhole.

TLS CONSOLE