Page 1

System Setup Manual

TLS-3XX Series Consoles

Manual No: 576013-623 • Revision: AM

Software Version X33

Page 2

Notice

Veeder-Root makes no warranty of any kind with regard to this publication, including, but not limited to, the implied warranties of

merchantability and fitness for a particular purpose.

Veeder-Root shall not be liable for errors contained herein or for incidental or consequential damages in connection with the

furnishing, performance, or use of this publication.

Veeder-Root reserves the right to change system options or features, or the information contained in this publication.

This publication contains proprietary information which is protected by copyright. All rights reserved. No part of this publication

may be modified or translated to another language without the prior written consent of Veeder-Root.

Contact TLS Systems Technical Support for additional troubleshooting information at 800-323-1799.

DAMAGE CLAIMS / LOST EQUIPMENT

Thoroughly examine all components and units as soon as they are received. If any cartons are damaged or missing, write a

complete and detailed description of the damage or shortage on the face of the freight bill. The carrier's agent must verify the

inspection and sign the description. Refuse only the damaged product, not the entire shipment.

Veeder-Root must be notified of any damages and/or shortages within 30 days of receipt of the shipment, as stated in our Terms

and Conditions.

VEEDER-ROOT’S PREFERRED CARRIER

1. Contact Veeder-Root Customer Service at 800-873-3313 with the specific part numbers and quantities that were missing

or received damaged.

2. Fax signed Bill of Lading (BOL) to Veeder-Root Customer Service at 800-234-5350.

3. Veeder-Root will file the claim with the carrier and replace the damaged/missing product at no charge to the customer.

Customer Service will work with production facility to have the replacement product shipped as soon as possible.

CUSTOMER’S PREFERRED CARRIER

1. It is the customer’s responsibility to file a claim with their carrier.

2. Customer may submit a replacement purchase order. Customer is responsible for all charges and freight associated with

replacement order. Customer Service will work with production facility to have the replacement product shipped as soon as

possible.

3. If “lost” equipment is delivered at a later date and is not needed, Veeder-Root will allow a Return to Stock without a restocking

fee.

4. Veeder-Root will NOT be responsible for any compensation when a customer chooses their own carrier.

RETURN SHIPPING

For the parts return procedure, please follow the appropriate instructions in the "General Returned Goods Policy” pages in the

"Policies and Literature" section of the Veeder-Root North American Environmental Products price list. Veeder-Root will not

accept any return product without a Return Goods Authorization (RGA) number clearly printed on the outside of the package.

©Veeder-Root 2014. All rights reserved

.

Page 3

1 Introduction

Contractor Certification Requirements ...........................................................................1-1

Related Manuals ............................................................................................................1-1

Safety Precautions .........................................................................................................1-2

Safety Warnings ............................................................................................................1-2

2 Front Panel Keypads

Arrangement of Keys .....................................................................................................2-1

Operating Keys......................................................................................................2-1

Alphanumeric Keys................................................................................................2-1

Blue Key (Maintenance Tracker - TLS-350 Only)..................................................2-2

White Key (Maintenance Report - TLS-350 Only).................................................2-2

Using the Operating Keys ..............................................................................................2-2

Using the Alphanumeric Keys ........................................................................................2-3

Entering Alphanumeric Data..................................................................................2-4

Special Characters and Cursor Movement............................................................2-4

3 Setup Mode Organization

Functions .......................................................................................................................3-1

Steps ..............................................................................................................................3-1

Setup Mode Programming Table ...................................................................................3-1

Table of Contents

4 Prior to Applying AC Power to the Console

Security Code Enable/Disable .......................................................................................4-1

TLS-300 Consoles.................................................................................................4-1

TLS-350 Consoles.................................................................................................4-1

Battery Backup ..............................................................................................................4-6

Applying AC Power to the Console ................................................................................4-6

5 System Setup

Programming Guidelines ...............................................................................................5-1

Automatic Return to Operating Mode ............................................................................5-1

Setup Data Warning ......................................................................................................5-1

Printing a Setup Data Report .........................................................................................5-1

Selecting the System Setup Function ............................................................................5-2

System Language ..........................................................................................................5-2

System Units ..................................................................................................................5-2

Setting the Date and Time Format .................................................................................5-3

Current Date ..................................................................................................................5-3

Current Time ..................................................................................................................5-4

Report Headers .............................................................................................................5-4

Shift Start Times ............................................................................................................5-4

Shift BIR Printouts .........................................................................................................5-5

Daily BIR Printouts .........................................................................................................5-5

Ticketed Delivery ...........................................................................................................5-5

TC Ticketed Delivery .....................................................................................................5-6

Close Day of Week ........................................................................................................5-6

Variance Reports ...........................................................................................................5-6

Daily Delivery Variance Reports............................................................................5-6

Weekly Delivery Variance Reports ........................................................................5-6

Periodic Delivery Variance Reports.......................................................................5-7

iii

Page 4

Table of Contents

Daily Book Variance Reports.................................................................................5-7

Weekly Book Variance Reports.............................................................................5-7

Periodic Book Variance Reports............................................................................5-7

Daily Variance Analysis Reports ...........................................................................5-7

Weekly Variance Analysis Reports........................................................................5-7

Periodic Variance Analysis Reports ......................................................................5-8

Tank Periodic Test Needed Warnings ...........................................................................5-8

Enable Tank Periodic Test Needed Warnings and Alarms ...................................5-8

Disable Tank Periodic Test Needed Warnings......................................................5-9

Tank Annual Test Needed Warnings .............................................................................5-9

Enable Tank Annual Test Needed Warnings and Alarms .....................................5-9

Disable Tank Annual Test Needed Warnings and Alarms ..................................5-10

Line Re-Enable Method ...............................................................................................5-10

Line Periodic Test Needed Warnings ..........................................................................5-10

Enable Line Periodic Test Needed Warnings and Alarms...................................5-11

Disable Line Periodic Test Needed Warnings .....................................................5-11

Line Annual Test Needed Warnings ............................................................................5-11

Enable Line Annual Test Needed Warnings and Alarms ....................................5-12

Disable Line Annual Test Needed Warnings and Alarms....................................5-12

Remote Printer Page Eject ..........................................................................................5-13

Print TC Volumes .........................................................................................................5-13

Temperature Compensation Value ..............................................................................5-13

Tanker Load Report - International Option ..................................................................5-14

Stick Height Offset - International Option ....................................................................5-14

Ullage ...........................................................................................................................5-14

H-Protocol Data Format - International Option ............................................................5-14

Precision Test Duration (PLLD/WPLLD Only) .............................................................5-15

Precision Line Test Auto-Confirm ................................................................................5-15

Daylight Savings Time .................................................................................................5-16

Re-direct Local Printout ...............................................................................................5-16

QPLD Monthly Printout - International Option ..............................................................5-17

Euro Protocol Prefix .....................................................................................................5-17

BDIM Trans Alarm Delay .............................................................................................5-17

System Security Code .................................................................................................5-17

Maintenance History ....................................................................................................5-18

Tank Chart Security .....................................................................................................5-18

Custom Alarm Labels ..................................................................................................5-19

Service Notice (TLS-350 Consoles Only) ....................................................................5-27

Inventory Alarms Threshold Units ................................................................................5-28

System Beeper ............................................................................................................5-29

Mass/Density ...............................................................................................................5-30

Fiscal Height Security ..................................................................................................5-30

Alarm Reduction ..........................................................................................................5-31

6 Communications Setup

Selecting the Communications Setup Function .............................................................6-1

Port Settings ..................................................................................................................6-1

Note: Port Settings - International Installations With SiteLink modems.................6-1

Baud Rate..............................................................................................................6-1

Parity .....................................................................................................................6-2

Stop Bit ..................................................................................................................6-2

Data Length...........................................................................................................6-2

Dial Type ...............................................................................................................6-3

iv

Page 5

Table of Contents

Answer On.............................................................................................................6-3

Security Code........................................................................................................6-3

Setting the Modem Type (international Installations) ............................................6-4

Modem Setup String..............................................................................................6-4

Dial Tone Interval ..................................................................................................6-4

DTR Normal State .................................................................................................6-4

Specifying Port Settings for Additional Communication Modules..........................6-5

Continue Communications Setup..........................................................................6-5

Auto-Transmit Setup (RS-232 or RS-232/RS-485 Modules Only) .................................6-5

Auto-Transmit Method...........................................................................................6-5

Auto Delay Time ....................................................................................................6-6

Auto Repeat Time..................................................................................................6-6

Continue Communications Setup..........................................................................6-6

Phone Directory Setup ...................................................................................................6-7

Receiver Configuration ..........................................................................................6-7

Receiver Location..................................................................................................6-7

Receiver Telephone Number.................................................................................6-7

Select Modem........................................................................................................6-8

Receiver Type .......................................................................................................6-8

Retry Number ........................................................................................................6-8

Retry Delay Time...................................................................................................6-9

Confirmation Report ..............................................................................................6-9

Setting Up Additional Phone Numbers ..................................................................6-9

Continue Communications Setup..........................................................................6-9

Auto-Dial Setup ............................................................................................................6-10

Receiver Report List ............................................................................................6-10

Auto Dial Method: All Phones/Single Phone .......................................................6-11

Auto-Dial Frequency: Specific Date.....................................................................6-11

Auto-Dial Frequency: Annually............................................................................6-12

Auto-Dial Frequency: Monthly .............................................................................6-13

Auto-Dial Frequency: Weekly..............................................................................6-13

Auto-Dial Frequency: Daily..................................................................................6-14

Auto-Dial Frequency: BIR End ............................................................................6-14

Setting Up the Frequency for Additional Receivers

(Single Phone Only) ............................................................................................6-15

Continue Communications Setup........................................................................6-15

Auto-Dial Alarm Setup .................................................................................................6-15

In-Tank Alarms ....................................................................................................6-16

Remaining Alarm Groups ....................................................................................6-17

Liquid Sensor Alarms ..........................................................................................6-17

Vapor Sensor Alarms ..........................................................................................6-17

External Inputs Alarms ........................................................................................6-17

Line Leak Alarms (VLLD) ....................................................................................6-17

Groundwater Sensor Alarms ...............................................................................6-17

2 Wire C.L. Sensor Alarms ..................................................................................6-18

3 Wire C.L. Sensor Alarms ..................................................................................6-18

Receiver Alarms ..................................................................................................6-18

Power Side DIM Alarms ......................................................................................6-18

Reconciliation Alarms ..........................................................................................6-18

Pressure Line Leak Detector (PLLD) Alarms ......................................................6-18

Wireless Pressure Line Leak Detector (WPLLD) Alarms ....................................6-19

Communication Side DIM Alarms........................................................................6-19

Smart Sensor Alarms ..........................................................................................6-19

Pump Relay Monitor Alarm..................................................................................6-19

VMCI Dispenser Interface Alarms .......................................................................6-19

VMC Alarms ........................................................................................................6-19

v

Page 6

Setting Up Auto-Dial Alarms for Additional Destinations .....................................6-20

RS-232 End of Message ..............................................................................................6-20

7 In-Tank Setup

Selecting the In-Tank Setup Function ............................................................................7-1

Tank Configuration ........................................................................................................7-1

How the System Configures In-Tank Probes ........................................................7-1

Specifying In-Tank Probe Positions.......................................................................7-1

Product Labels ...............................................................................................................7-2

Product Code .................................................................................................................7-2

Coefficient of Thermal Expansion ..................................................................................7-3

Tank Density ..................................................................................................................7-4

Tank Diameter ...............................................................................................................7-5

Tank Profile ....................................................................................................................7-5

Tank Profile Selections..........................................................................................7-5

Procedure ..............................................................................................................7-6

Full Volume ....................................................................................................................7-6

4 or 20 Point Tank Profiles Height/Volume Entries ...............................................7-7

50 Point Tank Profile Height/Volume Entries (Tank Chart Security Disabled) ......7-7

50 Point Tank Profile Entries With Tank Chart Security Enabled..........................7-9

Meter Data Present ......................................................................................................7-11

Vapor Loss Factor - International Option .....................................................................7-11

End Factor ...................................................................................................................7-12

Calibration Update .......................................................................................................7-12

Float Size .....................................................................................................................7-13

Water Warning .............................................................................................................7-14

High Water Limit ..........................................................................................................7-15

Water Alarm Filter ........................................................................................................7-15

Programmable Minimum Water Threshold ..................................................................7-16

Max or Label Vol ..........................................................................................................7-16

Overfill Limit .................................................................................................................7-16

High Product ................................................................................................................7-17

Delivery Limit ...............................................................................................................7-17

Low Product .................................................................................................................7-17

Leak Alarm Limit ..........................................................................................................7-18

Sudden Loss Limit .......................................................................................................7-18

Tank Tilt .......................................................................................................................7-18

Calculating Tank Tilt (H2)....................................................................................7-19

Entering the Tank Tilt Value ................................................................................7-19

Probe Offset .................................................................................................................7-20

Siphon Manifolded Tank Status ...................................................................................7-20

Line Manifolded Tank Status .......................................................................................7-21

Leak Minimum Periodic ...............................................................................................7-21

Leak Minimum Annual .................................................................................................7-22

Periodic Test Type .......................................................................................................7-22

Annual Test Fail ...........................................................................................................7-22

Periodic Test Fail .........................................................................................................7-23

Gross Test Fail ............................................................................................................7-23

Annual Test Averaging ................................................................................................7-23

Periodic Test Averaging ...............................................................................................7-24

Tank Test Notify ...........................................................................................................7-24

Tank Test Siphon Break ..............................................................................................7-24

Table of Contents

vi

Page 7

Stick Offset (International Option) ................................................................................7-24

HRM Reconciliation Warning Limit (International Option) ............................................7-25

HRM Reconciliation Alarm Limit (international Option) ................................................7-25

Delivery Report Delay Time .........................................................................................7-26

Pump Threshold ..........................................................................................................7-26

Setting Up Additional Tanks ........................................................................................7-26

8 In-Tank Leak Tests

Selecting the In-Tank Leak Test Setup Function ...........................................................8-1

Leak Test Method: All Tank/Single Tank .......................................................................8-1

Leak Test Frequency .....................................................................................................8-2

Test On Date .........................................................................................................8-2

Annual Test ...........................................................................................................8-3

Monthly Test ..........................................................................................................8-3

Weekly Test...........................................................................................................8-4

Daily Test...............................................................................................................8-4

Automatic Test.......................................................................................................8-4

CSLD - Option .......................................................................................................8-5

Gross Test Auto-Confirm ...............................................................................................8-7

Leak Test Start Time .....................................................................................................8-7

Leak Test Rate ..............................................................................................................8-7

Leak Test Duration ........................................................................................................8-8

Leak Test Early Stop .....................................................................................................8-8

CSLD Report Only .........................................................................................................8-9

Leak Test Report Format ...............................................................................................8-9

Setting Up Additional Tanks ..........................................................................................8-9

Table of Contents

9 Fuel Management

Selecting the Fuel Management Function .....................................................................9-1

Delivery Warning Days ..................................................................................................9-1

Daily Time to Print Fuel Management Report ................................................................9-1

Average Daily Sales ......................................................................................................9-2

10 Pressurized Line Leak Detection

Line Manifolding Implications for AccuChart ................................................................10-1

PLLD Setup .................................................................................................................10-1

Activating PLLDs .........................................................................................................10-1

Labeling PLLDs ...........................................................................................................10-1

Piping Type ..................................................................................................................10-2

Piping Length ...............................................................................................................10-2

Entering Line Length for Dual Size Flexible Pipe Types .....................................10-3

Entering Line Length for 2.0/3.0 In. Fiberglass Pipe Type ..................................10-3

User Defined Pipe Type - Setup Parameters ...............................................................10-3

Thermal Coefficient ......................................................................................................10-4

0.2 gph (0.76 lph) Line Leak Test Scheduling .............................................................10-4

0.1 gph (0.38 lph) Line Leak Test Scheduling .............................................................10-5

Passive 0.1 gph Line Leak Testing ..............................................................................10-5

Shutdown Rate ............................................................................................................10-6

Low Pressure Alarm Shutoff ........................................................................................10-6

Tank Selection .............................................................................................................10-7

Selecting a Dispense Mode .........................................................................................10-7

Auto Active Switchover........................................................................................10-8

Pressure Transducer Type ..........................................................................................10-8

vii

Page 8

Pressure Offset ............................................................................................................10-9

Venting The Line .................................................................................................10-9

Determining a Pressure Offset Value for each Transducer...............................10-10

Entering the Pressure Offset Value for each Transducer..................................10-10

Mechanical Blenders .................................................................................................10-11

Setting Up Additional PLLDs .....................................................................................10-11

11 Wireless Pressurized Line Leak Detection

Line Manifolding Implications for AccuChart ................................................................11-1

WPLLD Setup ..............................................................................................................11-1

Activating WPLLDs ......................................................................................................11-1

Labeling WPLLDs ........................................................................................................11-2

Piping Type ..................................................................................................................11-2

Piping Length ...............................................................................................................11-2

0.2 gph (0.76 lph) Line Leak Test Scheduling - Option ...............................................11-3

0.1 gph (0.38 lph) Line Leak Test Scheduling - Option ...............................................11-4

Shutdown Rate ............................................................................................................11-4

Pressure Offset ............................................................................................................11-4

Venting The Line .................................................................................................11-5

Determining a Pressure Offset Value for each Transducer.................................11-5

Entering the Pressure Offset Value for each Transducer....................................11-6

Tank Selection .............................................................................................................11-6

Selecting a Dispense Mode .........................................................................................11-6

Setting Up Additional WPLLDs ....................................................................................11-7

Table of Contents

12 Volumetric Line Leak Detection

VLLD Setup .................................................................................................................12-1

Activating VLLDs .........................................................................................................12-1

Pipe Label and Tank Identification ...............................................................................12-1

Enter Dispense Mode ..................................................................................................12-2

Fuel Type .....................................................................................................................12-3

Piping Length and Type ...............................................................................................12-3

Pump Pressure ............................................................................................................12-4

Shutdown Rate ............................................................................................................12-5

Pumpside Test .............................................................................................................12-5

Wait Mode ....................................................................................................................12-6

New Blender Protocol (NBP) Partner ...........................................................................12-6

Last Annual Test Passed .............................................................................................12-7

Setting Up Additional Line Leak Detectors ..................................................................12-7

13 Volumetric Line Leak Tests

Selecting the Line Leak Test Setup Function ..............................................................13-1

Leak Test Setup Method: All Lines/Single Lines .........................................................13-1

Leak Test Frequency ...................................................................................................13-2

On Date ...............................................................................................................13-2

Annual Test .........................................................................................................13-2

Monthly Test ........................................................................................................13-3

Weekly Test.........................................................................................................13-3

Daily Test.............................................................................................................13-4

Leak Test Start Time ...................................................................................................13-4

Leak Test Rate ............................................................................................................13-4

Setting Up Additional Lines ..........................................................................................13-5

viii

Page 9

14 Line Leak Test Lockout

Selecting the Line Leak Test Lockout Function ...........................................................14-1

Lockout Schedule ........................................................................................................14-1

Daily Schedule .............................................................................................................14-1

Individual Schedules ....................................................................................................14-2

Entering Additional Test Lockout Schedules ...............................................................14-3

15 Pump Sense Setup

Selecting the Pump Sense Function ............................................................................15-1

Pump Sense Configuration ..........................................................................................15-1

How the System Configures Pump Sense Modules............................................15-1

Specifying Pump Sense Positions.......................................................................15-1

Pump Sense Tank Number .........................................................................................15-2

Pump Sense Dispense Mode ......................................................................................15-2

Auto Active Switchover........................................................................................15-3

16 Pump Relay Monitor Setup

Selecting the Pump Relay Monitor Function ................................................................16-1

Pump Relay Monitor Configuration ..............................................................................16-1

How the System Configures Pump Relay Monitor Modules ................................16-1

Specifying Pump Relay Monitor Positions...........................................................16-1

Labeling Pump Relay Monitors ....................................................................................16-2

Pump Relay Monitor Relay Input .................................................................................16-2

Pump Relay Monitor Delay Input .................................................................................16-2

Table of Contents

17 Reconciliation Setup

Dispenser Module Data String .....................................................................................17-1

Automatic Daily Closing ...............................................................................................17-1

Automatic Shift Closing ................................................................................................17-2

Periodic Reconciliation Mode ......................................................................................17-2

Periodic Reconciliation Alarm ......................................................................................17-3

Remote Report Format ................................................................................................17-4

Temp Compensation ...................................................................................................17-4

Meter Calibration Offset ...............................................................................................17-5

Modify Tank/Meter Map ...............................................................................................17-5

18 Liquid Sensor Setup

Selecting the Liquid Sensor Setup Function ................................................................18-1

Liquid Sensor Configuration ........................................................................................18-1

How the System Configures Liquid Sensors .......................................................18-1

Specifying Liquid Sensor Positions .....................................................................18-1

Liquid Sensor Location ................................................................................................18-2

Liquid Sensor Type ......................................................................................................18-2

Liquid Sensor Category (RS-232 and Remote Display) ..............................................18-3

Setting Up Additional Liquid Sensors ..........................................................................18-3

19 Vapor Sensor Setup

Selecting the Vapor Sensor Setup Function ................................................................19-1

Vapor Sensor Configuration ........................................................................................19-1

How the System Configures Vapor Sensors .......................................................19-1

Specifying Vapor Sensor Positions .....................................................................19-1

Vapor Sensor Location ................................................................................................19-2

Vapor Threshold ..........................................................................................................19-2

ix

Page 10

Before You Begin ................................................................................................19-2

Specifying Vapor Threshold Levels .....................................................................19-3

Vapor Sensor Category ...............................................................................................19-3

Setting Up Additional Vapor Sensors ..........................................................................19-4

20 Groundwater Sensor Setup

Selecting the Groundwater Sensor Setup Function .....................................................20-1

Groundwater Sensor Configuration .............................................................................20-1

How the System Configures Groundwater Sensors............................................20-1

Specifying Groundwater Sensor Positions ..........................................................20-1

Groundwater Sensor Location .....................................................................................20-2

Groundwater Sensor Category ....................................................................................20-2

Setting Up Additional Groundwater Sensors ...............................................................20-2

21 2-Wire C.L. Sensor Setup

Selecting the 2-Wire C.L. Sensor Setup Function .......................................................21-1

2-Wire C.L. Sensor Configuration ................................................................................21-1

How the System Configures 2-Wire C.L. Sensors...............................................21-1

Specifying 2-wire C.L. Sensor Positions..............................................................21-1

2-Wire C.L. Sensor Location ........................................................................................21-2

2-Wire C.L. Sensor Type .............................................................................................21-2

2-Wire C.L. Sensor Category .......................................................................................21-2

Setting Up Additional 2-Wire C.L. Sensors ..................................................................21-3

Table of Contents

22 3-Wire C.L. Sensor Setup

Selecting the 3-Wire C.L. Sensor Setup Function .......................................................22-1

3-Wire C.L. Sensor Configuration ................................................................................22-1

How the System Configures 3-Wire C.L. Sensors...............................................22-1

Specifying 3-Wire C.L. Sensor Positions.............................................................22-1

3-Wire C.L. Sensor Location ........................................................................................22-2

3-Wire C.L. Sensor Mode ............................................................................................22-2

3-Wire C.L. Sensor Category .......................................................................................22-2

Setting Up Additional 3-Wire C.L. Sensors ..................................................................22-3

23 External Input Setup

Selecting the External Input Setup Function ................................................................23-1

External Input Configuration ........................................................................................23-1

How the System Configures Input Devices .........................................................23-1

Specifying Input Positions ...................................................................................23-1

External Input Name ....................................................................................................23-2

External Input Type ......................................................................................................23-2

Switch Orientation ........................................................................................................23-3

External Input Emergency Generator Data ..................................................................23-3

Pump Sense Setup Data .............................................................................................23-4

Selecting a Dispense Mode.................................................................................23-4

Auto Active Switchover........................................................................................23-5

Setting Up Additional Inputs ........................................................................................23-5

24 Output Relay Setup

Selecting the Output Relay Setup Function .................................................................24-1

Relay Configuration .....................................................................................................24-1

How the System Configures Output Relays ........................................................24-1

Specifying Output Relay Positions ......................................................................24-1

x

Page 11

Table of Contents

Relay Designation ........................................................................................................24-2

Selecting Relay Type ...................................................................................................24-2

Assignment Method .....................................................................................................24-3

In-Tank Alarms ....................................................................................................24-3

Remaining Alarm Groups ....................................................................................24-5

Liquid Sensor Alarms ..........................................................................................24-5

Vapor Sensor Alarms ..........................................................................................24-5

External Inputs Alarms ........................................................................................24-5

Line Leak Alarms (VLLD) ....................................................................................24-5

Groundwater Sensor Alarms ...............................................................................24-5

2 Wire C.L. Sensor Alarms ..................................................................................24-6

3 Wire C.L. Sensor Alarms ..................................................................................24-6

Power Side DIM Alarms ......................................................................................24-6

Reconciliation Alarms ..........................................................................................24-6

Pressure Line Leak Detector (PLLD) Alarms ......................................................24-6

Wireless Pressure Line Leak Detector (WPLLD) Alarms ....................................24-6

Communication Side DIM Alarms........................................................................24-7

Smart Sensor Alarms ..........................................................................................24-7

Pump Relay Monitor Alarm..................................................................................24-7

VMCI Dispenser Interface Alarms .......................................................................24-7

VMC Alarms ........................................................................................................24-7

Setting Up Additional Relays .......................................................................................24-8

25 Line Disable Setup

Selecting the PLLD, WPLLD, or VLLD Line Disable Setup Function ...........................25-1

Alarm Assignment Notes.....................................................................................25-1

In-Tank Alarms ............................................................................................................25-1

Remaining Alarm Groups ....................................................................................25-2

Liquid Sensor Alarms ..........................................................................................25-3

Vapor Sensor Alarms ..........................................................................................25-3

External Input Alarms ..........................................................................................25-3

Line Leak Alarms.................................................................................................25-3

Groundwater Sensor Alarms ...............................................................................25-3

2 Wire C.L. Sensor Alarms ..................................................................................25-3

3 Wire C.L. Sensor Alarms ..................................................................................25-4

Power Side DIM Alarms ......................................................................................25-4

Reconciliation Alarms ..........................................................................................25-4

Pressure Line Leak Detector (PLLD) Alarms ......................................................25-4

Wireless Pressure Line Leak Detector (WPLLD) Alarms ....................................25-4

Communication Side DIM Alarms........................................................................25-5

Smart Sensor Alarms ..........................................................................................25-5

Pump Relay Monitor Alarm..................................................................................25-5

VMCI Dispenser Interface Alarms .......................................................................25-5

VMC Alarms ........................................................................................................25-5

Setting Up Additional Disables ....................................................................................25-6

26 Smart Sensor Setup

Selecting the Smart Sensor Setup Function ................................................................26-1

Sensor Configuration ...................................................................................................26-1

Smart Sensor Label .....................................................................................................26-2

Selecting Sensor Category ..........................................................................................26-2

Mag Sensor Setup .......................................................................................................26-3

Vac Sensor Setup ........................................................................................................26-4

xi

Page 12

27 VMC Setup

Selecting the VMC Setup Function ..............................................................................27-1

Add a VMC Serial Number ..........................................................................................27-1

Edit a VMC Serial Number ...........................................................................................27-1

Remove a VMC Serial Number ....................................................................................27-2

28 Archive Utility

Accessing the Archive Utility Function .........................................................................28-1

Archiving Setup Data ...................................................................................................28-1

Restoring Archived Setup Data ...................................................................................28-2

Clearing Archived Setup Data .....................................................................................28-3

Table of Contents

Figures

Tables

Appendix A: Calculating Tank Tilt - International

Entering the Tank Tilt Value ................................................................................. A-3

Appendix B: Setup Parameters for TLS-300 System - International

System Setup ...............................................................................................................B-1

Comm Board (1, 2, etc.) Setup ..................................................................................... B-2

In-Tank Setup ............................................................................................................... B-2

Leak Test Method Setup ............................................................................................... B-3

Appendix C: Setup Parameters for TLS-350 System - International

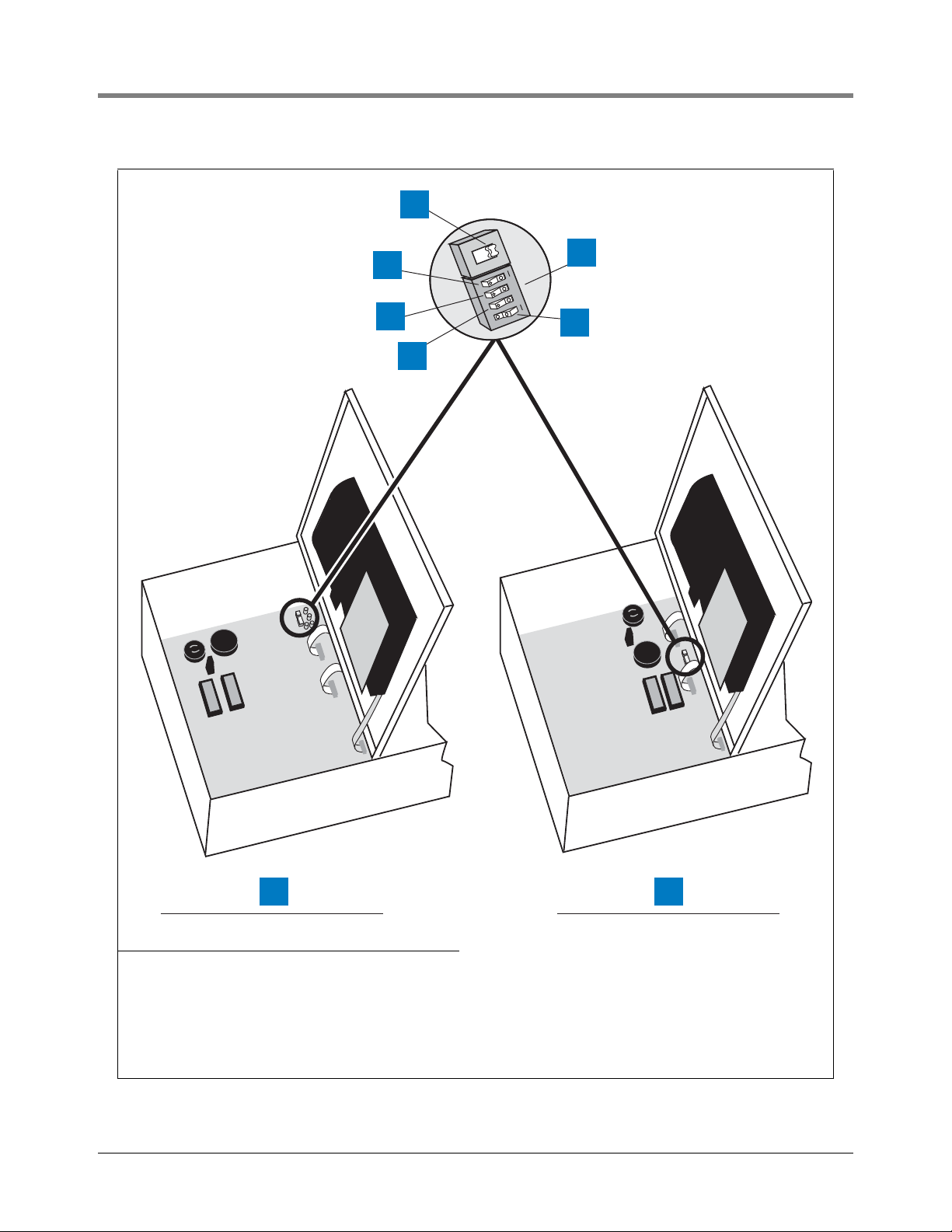

Figure 4-1. Battery Backup Switch and DIP Switch Location - TLS-300

Console ................................................................................................4-3

Figure 4-2. Battery Backup Switch and DIP Switch Location TLS-350

Consoles with CPU Board ...................................................................4-4

Figure 4-3. Battery Backup Switch and DIP Switch Location TLS-350

Consoles with ECPU Board .................................................................4-5

Figure 7-1. Relative Positions of Tank Alarm Limits ............................................7-14

Figure 7-2. Siphon Manifolded Tanks ..................................................................7-20

Figure 7-3. Line Manifolding A Siphon Manifolded Set To A Single Tank ...........7-21

Table 2-1. Character Assignments for Numeric Keys .............................................2-4

Table 5-1. Alarm Labels ........................................................................................5-21

Table 5-2. Configurations For Setting Inventory Alarm Thresholds .......................5-29

Table 6-1. SiteLink Modem Default Port Settings ....................................................6-1

Table 6-2. Alarm List .............................................................................................6-21

Table 7-1. Typical Thermal Coefficients ..................................................................7-3

Table 7-2. Tank Tilt Calculation Worksheet ...........................................................7-19

Table 10-1. Reference of Absolute Pressure Offsets at Various Altitudes ..............10-8

Table 12-1. Submersible Pump Nominal Pressures ................................................12-4

Table A-1. Typical Tank Offset Values ................................................................... A-1

Table B-1. System Setup ........................................................................................B-1

Table B-2. Comm Board Setup ............................................................................... B-2

Table B-3. In-tank Setup .........................................................................................B-2

Table B-4. Leak Test Method Setup ....................................................................... B-3

Table C-1. System Setup ........................................................................................C-1

Table C-2. Comm Board (1, 2, Etc.) Setup .............................................................C-2

Table C-3. In-tank Setup .........................................................................................C-3

Table C-4. Leak Test Method Setup .......................................................................C-4

Table C-5. Reconciliation Setup ..............................................................................C-5

xii

Page 13

1 Introduction

This manual lists programming instructions for every available TLS-3XX Console Setup Function. The manual is

divided into sections for each Setup Function beginning with Section 5, System Setup. Depending on your

console type and its installed features, you may only see (and be able to program) some of the Functions and/or

Steps. Skip over the material in this manual that does not apply to your particular installation. You cannot perform

these setup procedures until the console, probes, and sensors have been installed and connected.

Contractor Certification Requirements

Veeder-Root requires the following minimum training certifications for contractors who will install and setup the

equipment discussed in this manual:

Installer Certification (Level 1): Contractors holding valid Installer Certification are approved to perform wiring

and conduit routing; equipment mounting; probe, sensor and carbon canister vapor polisher installation; wireless

equipment installation; tank and line preparation; and line leak detector installation.

Technician Certification (Level 2/3): Contractors holding valid Technician Certifications are approved to

perform installation checkout, startup, programming and operations training, system tests, troubleshooting and

servicing for all Veeder-Root Series Tank Monitoring Systems, including Line Leak Detection. In addition,

Contractors with the following sub-certification designations are approved to perform installation checkout, startup,

programming, system tests, troubleshooting, service techniques and operations training on the designated system.

• Wireless 2

• Tall Tank

VR Vapor Products Certification: Contractors holding a certification with the following designations are

approved to perform installation checkout, startup, programming, system tests, troubleshooting, service techniques

and operations training on the designated system.

• ISD – In Station Diagnostics

• PMC – Pressure Management Control

• CCVP - Veeder-Root Vapor Polisher

• Wireless – ISD/PMC Wireless

• A current Veeder-Root Technician Certification is a prerequisite for the VR Vapor Products course.

Warranty Registrations may only be submitted by selected Distributors.

Related Manuals

576013-610 TLS-3XX Series Consoles Operator’s Manual

576013-879 TLS-3XX Series Consoles Site Prep Manual

577013-874 Maintenance Service Code Quick Help

1-1

Page 14

1 Introduction Safety Precautions

OFF

Safety Precautions

The following safety symbols may be used in this manual to alert you to important safety hazards and precautions.

Safety Warnings

EXPLOSIVE

Fuels and their vapors are extremely

explosive if ignited.

TURN POWER OFF

Live power to a device creates a

potential shock hazard. Turn Off power

to the device and associated accessories when servicing the unit.

ELECTRICITY

High voltage exists in, and is supplied

to, the device. A potential shock hazard

exists.

FLAMMABLE

Fuels and their vapors are extremely

flammable.

READ ALL RELATED MANUALS

Knowledge of all related procedures

before you begin work is important.

Read and understand all manuals thoroughly. If you do not understand a procedure, ask someone who does.

WAR NING

Heed the adjacent instructions to avoid

damage to equipment, property, environment or personal injury.

WARNING

This system operates near highly combustible fuel storage tanks.

FAILURE TO COMPLY WITH THE FOLLOWING WARNINGS AND SAFETY

PRECAUTIONS COULD CAUSE DAMAGE TO PROPERTY, ENVIRONMENT,

RESULTING IN SERIOUS INJURY OR DEATH.

Leaking tanks can create serious environmental and health hazards. Improper

programming and operation may also result in equipment self-test failures and

submersible pump shutdowns. It is the owner’s responsibility to:

1. Ensure that this equipment is properly programmed.

2. Promptly investigate any alarm conditions.

3. Operate this equipment in accordance with the instructions in this manual.

1-2

Page 15

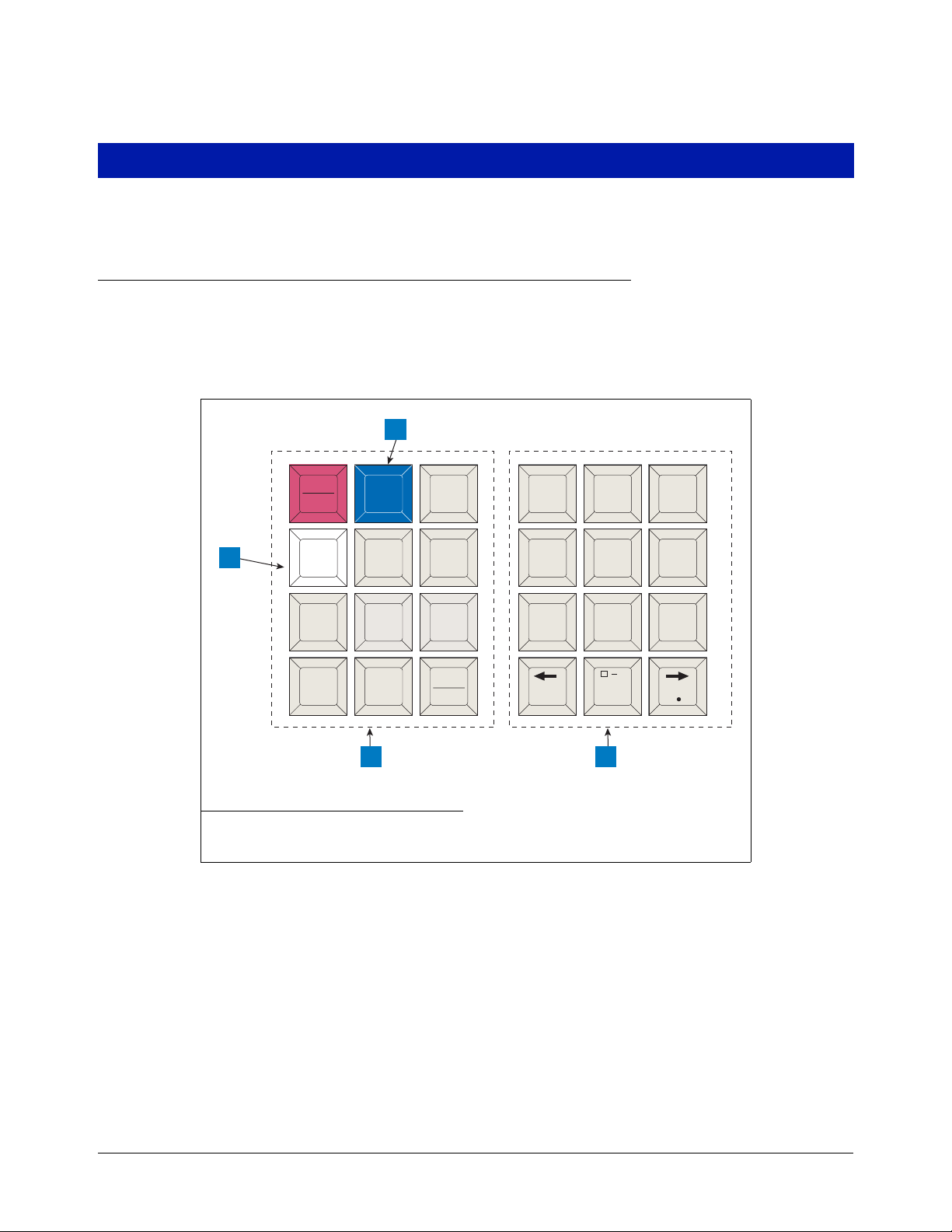

2 Front Panel Keypads

consoles\keypad.eps

MODE

BACKUP

FUNCT-

TION

PRINT CHANGE STEP

PAPER

FEED

ENTER

QZ.

ABC

DEF

GHI JKL MNO

PRS TUV WXY

ALARM

TEST

TANK

SENSOR

,

+/-

0

789

123

456

1

4 3

2

You use the front panel keypads to enter information into the system.

Arrangement of Keys

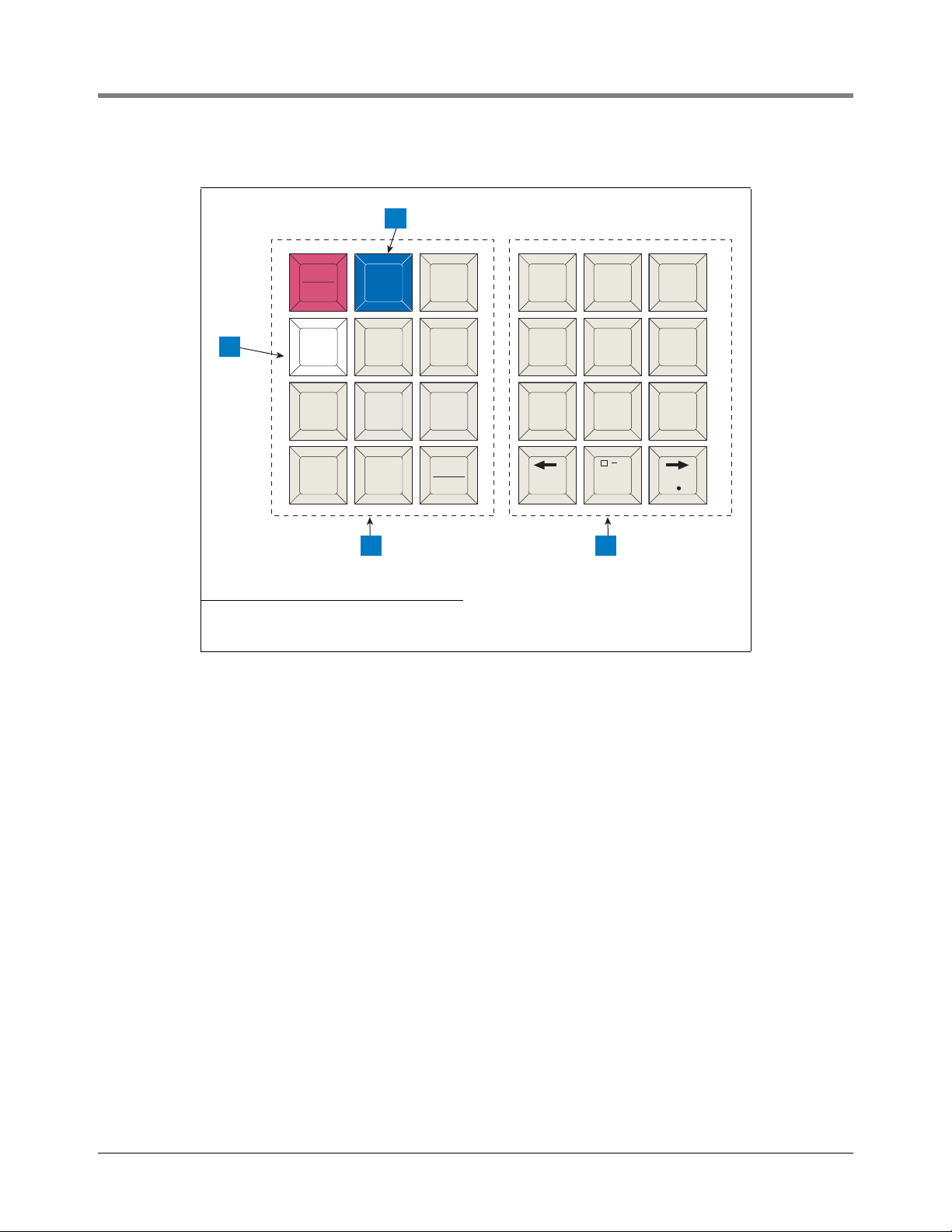

The keypads (see Figure 2-1) consist of two groups of 12 keys. The functions for each key have been established

to make movement within the setup mode, entry of setup data, and selection of setup choices as simple as

possible

.

Legend for numbered boxes:

1. Maintenance Report (white) key 3. Alphanumeric keypad

2. Maintenance Tracker (blue) key 4. Operating keypad

Figure 2-1. Console Keypads

OPERATING KEYS

The 12 left-hand keys are operating keys. They allow you to access and print data, start and stop in-tank leak test

procedures, program the system, test system operation and review diagnostic information. (See “Using the

Operating Keys” on page 2-2.)

ALPHANUMERIC KEYS

The 12 right-hand keys have alphanumeric and cursor movement functions for entering setup information.

2-1

Page 16

2 Front Panel Keypads Using the Operating Keys

MODE

FUNCTION

STEP

If a numeric value is required for entry of a particular setup parameter, the keys provide only numeric functions. If

either alphabetic or numeric characters may be entered, the keys provide both alphabetic and numeric functions.

(See “Using the Alphanumeric Keys” on page 2-3).

BLUE KEY (MAINTENANCE TRACKER - TLS-350 ONLY)

Contractor plugs a valid ID Key into the TLS and presses the blue key to log in for a work session. Note: This key

is available in consoles with Version 27 and higher software. In addition to certain hardware requirements, the

Maintenance Tracker feature must be enabled for this key to function.

WHITE KEY (MAINTENANCE REPORT - TLS-350 ONLY)

Press the white key to printout up to the last 75 maintenance history records. Additional records going back up to

3 years are also selectable. Note: This key is available in consoles with Version 27 and higher software and is

functional only if the Maintenance History or Maintenance Tracker feature enabled.

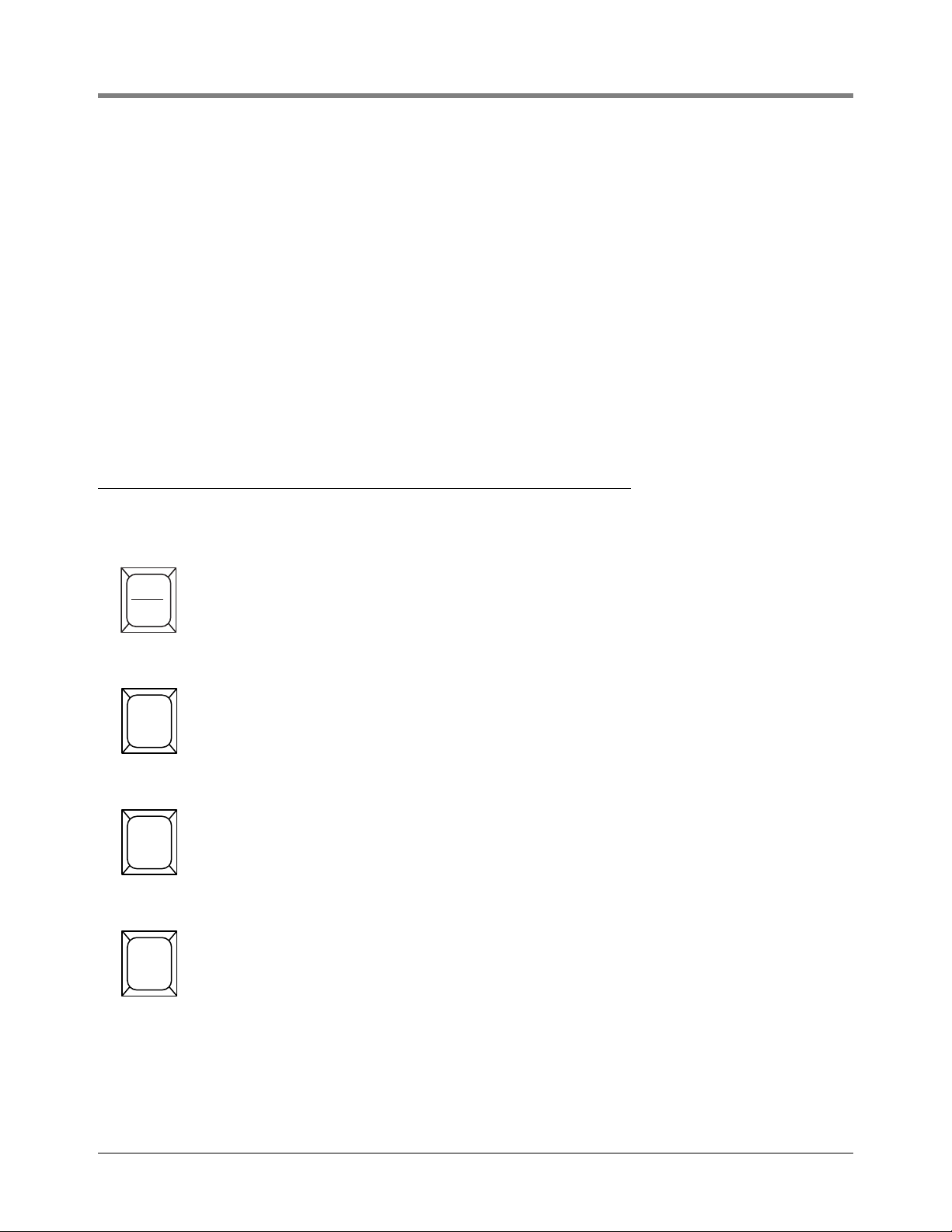

Using the Operating Keys

Operating key functions are summarized below.

ALARM

TEST

ALARM/TEST

Shuts off audible alarm and clears alarms that have returned to normal condition. Will not shut off

display indicators or disable alarm function. If your system has a printer, it will print an alarm or

warning report when this button is pressed.

Used to activate and de-activate output relays when OUTPUT RELAY TEST function is used.

MODE

Select operating modes: Normal Mode, Setup Mode, Diagnostic Mode.

If MODE is pressed while in a Function or Step, the system will advance to the next Mode.

FUNCTION

The FUNCTION key is used to scroll through and access functions within a Mode.

If FUNCTION is pressed while in a Step, the system will advance to the next Function.

STEP

Use the STEP key to move from one procedure to the next within a Function.

2-2

Page 17

2 Front Panel Keypads Using the Alphanumeric Keys

TANK

SENSOR

CHANGE

ENTER

BACKUP

PRINT

TAN K/ S EN S OR

The TANK/SENSOR key is used to advance by tank or sensor through setup procedures or displayed data.

CHANGE

CHANGE is used in Normal and Setup modes to enter data, revise existing data or change an

entry.

ENTER

ENTER completes a selection or enters data into a function. It is also used to start certain functions such as leak tests.

BACKUP

BACKUP lets you move back through Steps, Functions and Modes to access data or entries you

have already passed in the normal progression. It eliminates the need to move completely

through a function or mode to access a step recently passed.

BACKUP will move through the hierarchy of commands as follows: through Steps within a Function to that Function; then back through Functions to Mode; then back through Modes.

PRINT

Press PRINT to generate inventory, delivery, leak test, status, setup, diagnostic and alarm history

reports.

Using the Alphanumeric Keys

You use alphanumeric keys to enter data during the setup process. When a numeric value is required (i.e.gallons,

time, etc.), the keys provide only a numeric function. When you can enter either alphabetic or numeric characters

(i.e. station headers, sensor locations, etc.), the keys provide both functions.

2-3

Page 18

2 Front Panel Keypads Using the Alphanumeric Keys

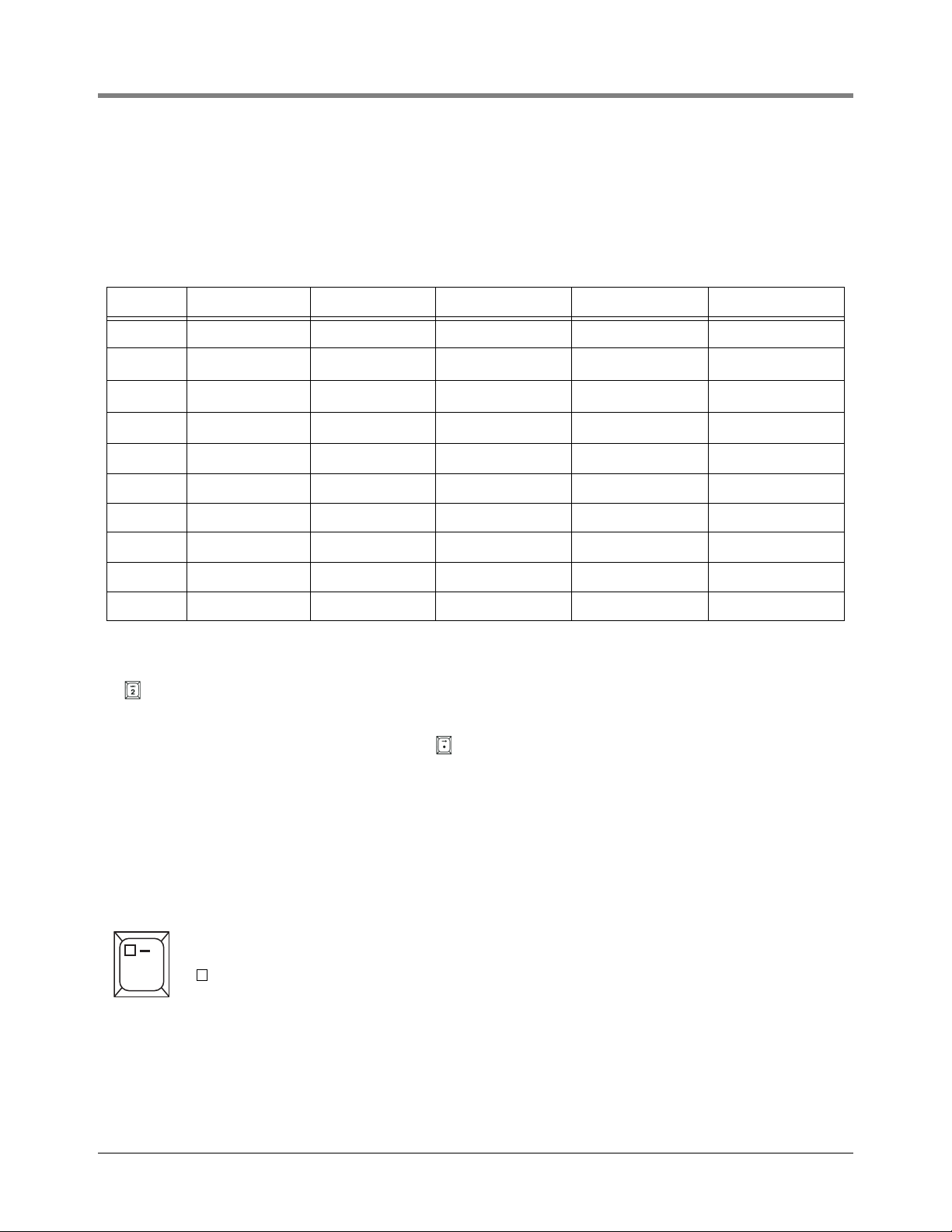

ENTERING ALPHANUMERIC DATA

Keys 0 through 9 provide both alphabetic and numeric capability by activating each character shown on the key

with successive pushes of the key. Table 2-1 shows characters assigned to each of the numeric keys for all

languages except Japanese, Russian, Turkish, and Greek.

Table 2-1. Character Assignments for Numeric Keys

Key 1st Key Press 2nd Key Press 3rd Key Press 4th Key Press 5th Key Press

Key 0 ‘space’ ‘-’ ‘,’ ‘0’ ‘*’

Key 1 ‘Q’ ‘Z’ ‘.’ ‘1’ ‘&’

Key 2 ‘A’ ‘B’ ‘C’ ‘2’ ‘=’

Key 3 ‘D’ ‘E’ ‘F’ ‘3’ ‘%’

Key 4 ‘G’ ‘H’ ‘I’ ‘4’

Key 5 ‘J’ ‘K’ ‘L’ ‘5’

Key 6 ‘M’ ‘N’ ‘O’ ‘6’

Key 7 ‘P’ ‘R’ ‘S’ ‘7’

Key 8 ‘T’ ‘U’ ‘V’ ‘8’

Key 9 ‘W’ ‘X’ ‘Y’ ‘9’

1

Character only available when entering the Modem Setup String.

1

1

1

For example, to enter an “A” in a station header, which accepts either alphabetic or numeric characters, you press

the key once. Push the key again to change the character to a “B”, again to enter a “C”, and again to enter a “2”.

The period (.) is on key “1”.

When the correct selection is displayed, press the key to move the cursor to the next position and enter the

required character as described. When all the characters have been entered, press ENTER.

If you enter an incorrect character, you may use the arrow keys to move the cursor to the character, press

CHANGE, and enter the correct character.

SPECIAL CHARACTERS AND CURSOR MOVEMENT

Several keys let you enter special characters and move the cursor as follows:

The Zero key has a comma (,) plus two special characters that can be used in making alphanumeric

entries. They are:

,

0

= Space (no character)

— = Dash

(a “*” character is generated by pressing this key 5 times).

2-4

Page 19

2 Front Panel Keypads Using the Alphanumeric Keys

+/-

The Right-Arrow key lets you advance the cursor to the right when making alphanumeric entries

such as station headers and when selecting certain parameters such as module configurations.

The step-by-step setup instructions will identify when this function should be used. The . (decimal)

is used in numeric entries as required. It is not used as a period for text entries.

The Left-Arrow key lets you move the cursor to the left.

The +/- is used to identify a positive or negative value.

2-5

Page 20

3 Setup Mode Organization

The Setup Mode is used to enter information and operating parameters that govern the way your system monitors

your installation. Setup data is entered via the front panel keypads. The previous section describes in detail the

functions of each key.

Functions

Functions are the major groups in the Setup Mode of the console.

IMPORTANT! The list below contains all of the available Setup Mode functions. However, only the functions

relevant to your console and its installed options and connected detection systems will be accessible in setup.

• System Setup

• Communications Setup

• In-Tank Setup

• Fuel Management Setup

• In-Tank Leak Test Setup

• Pressure Line Leak Setup

• WPLLD Line Leak Setup

• Line Leak Detector Setup [VLLD]

• Line Leak Test Setup

• Line Leak Lockout Setup

• Pump Sensor Setup

• Pump Relay Monitor Setup

• Reconciliation Setup

• Liquid Sensor Setup

• Vapor Sensor Setup

• Groundwater Sensor Setup

• 2-Wire C.L. Sensor Setup

• 3-Wire C.L. Sensor Setup

• External Input Setup

• Output Relay Setup

• PLLD Line Disable Setup

• WPLLD Line Disable Setup

• Line Disable Setup [VLLD]

• Smart Sensor Setup

• VMC Setup

• Archive Utility

Steps

Within each FUNCTION are STEPS at which you enter setup data.

Setup Mode Programming Table

The table below takes you through the complete setup mode as it appears in the console display with all features

installed (all choices may not appear on your TLS). Always press the ENTER key after entering data. If you press

the STEP, FUNCTION, or MODE key without pressing ENTER, the data will not be saved. It is a good idea to print

3-1

Page 21

3 Setup Mode Organization Setup Mode Programming Table

a setup report for record keeping purposes after completing your system’s setup. In the System Setup Table

below,

FUNCTION or STEP refers to pressing that key on the front panel.

Setup Mode Table

FUNCTION SYSTEM SETUP

STEP

STEP

STEP

STEP

STEP

STEP

STEP

STEP

STEP

STEP

STEP

STEP

STEP

STEP

STEP

STEP

STEP

STEP

STEP

STEP

STEP

STEP

STEP

STEP

STEP

STEP

STEP

STEP

STEP

STEP

STEP

STEP

STEP

STEP

STEP

STEP

STEP

STEP

STEP

STEP

STEP

System Language - English/ and second language as ordered

System Units (U.S./Metric/Imperial Gallons)

Date/Time Format

Set Month Day Year

Set Time

Station Header Line 1 (Line 2/Line 3/Line 4)

Shift #1 Start Time (Shift 2/Shift 3/Shift 4)

Shift BIR Printouts (Enable/Disable)

Daily BIR Printouts (Enable/Disable)

Ticketed Delivery (Enable/Disable)

TC Ticketed Delivery (Enable/Disable)

Close Day Of Week

Daily Dlvy Var Rpts (Disable/Enable)

Weekly Dlvy Var Rpts (Disable/Enable)

Periodic Dlvy Var Rpts (Disable/Enable)

Daily Book Dlvy Var Rpts (Disable/Enable)

Weekly Book Dlvy Var Rpts (Disable/Enable)

Periodic Book Dlvy Var Rpts (Disable/Enable)

Daily Var Analy Rpts (Disable/Enable)

Weekly Var Analy Rpts (Disable/Enable)

Periodic Var Analy Rpts (Disable/Enable)

Tank Per Tst Needed Wrn (Disable/Enable)

Tank Per Tst Needed Wrn Days

Tank Per Tst Needed Alm Days

Tank Ann Tst Needed Wrn Days

Tank Ann Tst Needed Alm Days

Line Reenable Method (Pass Line Test/Alarm Acknowledge)

Line Per Tst Needed Wrn (Disable/Enable)

Line Per Tst Needed Wrn Days

Line Per Tst Needed Alm Days

Line Ann Tst Needed Wrn (Disable/Enable)

Line Ann Tst Needed Wrn Days

Line Ann TsT Needed ALM Days

Remote Printer Page Eject

Print Tc Volume

Temp Compensation

Tanker Load Report

Stick Height Offset (Disable/Enable)

Ullage (90%/95%)

H-Protocol Data Format

Precision Test Duration (12 - 744 hrs [w/o CSLD]/60 - 744 hrs [w/CSLD])

3-2

Page 22

3 Setup Mode Organization Setup Mode Programming Table

FUNCTION

STEP

STEP

STEP

STEP

STEP

STEP

STEP

STEP

STEP

STEP

STEP

STEP

STEP

STEP

STEP

STEP

STEP

0.2 gph (0.76 lph) Line Test Auto-Confirm (Enable/Disable)

0.1 gph (0.38 lph) Line Test Auto-Confirm (Enable/Disable)

Daylight Savings Time (Disable/Enable)

HRM-QPLD Printouts (Enable/Disable)

Re-direct Local PrintouT (Enable/Disable)

Euro Protocol Prefix

Bdim Trans Alarm Delay

System Security Code

Maintenance History (Enable/Disable)

Tank C h a rt Se c u rity

Custom Alarms

Service Notice

Inventory Alarms Threshold Units (Standard, All % Full, All Volume, All Height, Custom)

System Beeper (Enable/Disable)

Mass/Density

Fiscal Height Security

Alarm Reduction (Enable/Disable)

COMMUNICATION SETUP

STEP

Comm Board Port Settings - Repeat for each board (Baud Rate/Parity/Stop Bit/Data Length/

Dial Type/Answer On/Code/Modem Setup String/Dial Tone Interval/DTR Normal State

STEP

Auto Transmit Setup (Transmit Message Setup/Auto-Transmit Delay Time/Auto-Transmit Repeat

Time)

STEP

STEP

STEP

STEP

Phone Directory Setup

Auto Dial Setup

Auto Dial Alarm

RS-232 End Of Message

FUNCTION

IN-TANK SETUP

STEP

STEP

STEP

STEP

STEP

STEP

STEP

STEP

STEP

STEP

STEP

STEP

STEP

STEP

STEP

STEP

STEP

STEP

STEP

Tank Config Module 1 (Up To 3)

Product Label

Product Code

Thermal Coeff.

Tank Density

Tank Diameter

Tank Profile (1 Pt/4 Pts/20 Pts/linear/50 Pts)

Full Volume

Meter Data Present

Vapor Loss Factor

End Factor (None/Flat/Hemispherical/Other)

End Value

Calibration Update

Float Size