Page 1

TLS Magnetostrictive Probes

International Installation Instructions

Manual No: 577014-031 ● Revision: C

Page 2

Notice

Veeder-Root makes no warranty of any kind with regard to this publication, including but not

limited to, the implied warranties of merchantability and fitness for a particular purpose.

Veeder-Root shall not be liable for errors contained herein or for incidental or consequential

damages in connection with the furnishing, performance, or use of this publication.

The information contained in this publication may be subject to change without notice.

This publication contains proprietary information which is protected by copyright. All rights

reserved. No part of this publication may be photocopied, reproduced, or translated to another

language without the prior written consent of Veeder-Root.

Full GVR EMEA contact information contact information and product documentation is available

for viewing and download by distributors from the GVR Extranet: www.mygvr.com

Distributors requiring GVR Extranet login details should contact Eumarketing@gilbarco.com to

obtain an ID and password.

©Veeder-Root 2014. All rights reserved.

Page 3

Introduction

General .............................................................................................................................1

Product Description ..........................................................................................................1

Systems....................................................................................................................1

In–Tank Probes ........................................................................................................1

Surge Protectors.......................................................................................................1

Health And Safety .............................................................................................................2

Safety Symbols.........................................................................................................2

General.....................................................................................................................2

Equipment Protection ...............................................................................................2

Equipotential Grounding...........................................................................................3

Minimization Of Electrostatic Hazards......................................................................3

Lightning And Surge Protection................................................................................3

EC-Type Certificates for an Intrinsically Safe System ..............................................3

These are the conditions for safe use when installing a Mag probe.........................4

Before You Begin ..............................................................................................................4

Procedures for Installing Mag Probes ...............................................................................5

Mag Plus Probe Installation Kits

The Mag Plus Probe Installation kit. .................................................................................7

Cable Seal Kit ...................................................................................................................7

Surge Protector Kits ..........................................................................................................8

Process Connections ........................................................................................................9

51MM Cap and Gland ..............................................................................................9

76MM Cap and Gland ............................................................................................10

Mag Probe Process Connection (Gland) ................................................................10

Table of Contents

Figures

Probe Installation

Access Chamber Installation ..........................................................................................11

General...................................................................................................................11

Provision for Probe Risers......................................................................................12

Probe and Riser Installation Criteria ...............................................................................13

Probe Installation Using Process Connection ........................................................14

Determining the Correct Probe Length ...................................................................15

Determining the Minimum Access Chamber Depth................................................16

Probe Riser Pipe Installation ..........................................................................................17

Probe Spacer Assembly .........................................................................................18

Field Wiring .....................................................................................................................20

Probe to TLS console.............................................................................................20

Maximum Cable Lengths........................................................................................20

Splicing Probe Field Wiring ....................................................................................20

Surge Protector ...............................................................................................................23

Installation (If Required) .........................................................................................23

Appendix A - Surge Protection Risk Assessment

Figure 1. Procedures For Installing Mag Probes Using Wired Connections .............5

Figure 2. Procedures For Installing Mag Probes Using Wireless Connections .........6

Figure 3. Mag Plus Probe Installation Kit 846402 .....................................................7

Figure 4. Cable Seal Kit.............................................................................................7

Figure 5. Surge Protector Kit For Wired Installations -

Dual Channel Surge Protector BA-350 Or Equivalent................................8

iii

Page 4

Table of Contents

Figure 6. Surge Protector Kit For Wireless Installations -

Single Channel P/N 848100-001................................................................9

Figure 7. 51mm Threaded Riser Cap Assembly P/N 705-100-2203 .........................9

Figure 8. 76mm Riser Cap Assembly......................................................................10

Figure 9. Mag Probe Process Connection (Gland) P/N 501-000-1206 ...................10

Figure 10. Typical Tank Lid Access Chamber Installation w/o Surge Protector ........11

Figure 11. Typical Tank Lid Access Chamber Installation w/Surge Protector...........11

Figure 12. Tank Lid Access Chamber — Critical Dimensions (in mm)......................12

Figure 13. Typical Probe Installations In Riser Pipe..................................................13

Figure 14. Installation Of A Mag Probe With A Process Connection (Gland)............14

Figure 15. Dimensions Needed To Calculate Custom Probes And Risers ...............15

Figure 16. Veeder-Root Riser Cap Assemblies.........................................................17

Figure 17. Example Probe Canister Sleeve/Adapter Assembly ................................18

Figure 18. Connection Diagram For A Mag Probe In A Riser Pipe

With And Without Optional Surge Protection ...........................................19

Figure 19. Splice Length Dimensions........................................................................20

Figure 20. Splice Connections...................................................................................21

Figure 21. Removing Sealing Compound Clip ..........................................................22

Figure 22. Pouring Sealing Compound Into Sleeve ..................................................22

Figure 23. Securing Splice Enclosure With Cable Tie...............................................23

Figure 24. Example Wireless Installation With Process Connection

And Single Channel Surge Protector .......................................................24

Figure 25. Example Wireless Installation With Riser Pipe

And Single Channel Surge Protector .......................................................24

Tables

Table 1. Calculation sheet for determining the correct probe length .....................16

Table 2. Dimensions for Steel Riser Pipes and Mag Probe Floats .......................17

iv

Page 5

Introduction

General

This document describes the procedures necessary to prepare a site for the installation of the Veeder-Root TLS

Series Underground Storage Tank Monitoring Systems in locations governed by the ATEX Directive 94/9/EC or

locations that recognize the IECEx scheme.

For installing UL/cUL approved Mag Probes use Manual No. 577013-744.

Veeder–Root maintains a continuous process of product development and therefore product specifications may

not be as described in this manual. Please contact the Veeder-Root office nearest you, or visit our website at

www.veeder.com for information on new or updated products. Changes affecting products or procedures

described in this manual will be reported in subsequent revisions. Veeder–Root has taken every care in the

compilation of this manual; however it is the installers' responsibility to take every precaution to safeguard

themselves and others.

Every person working with Veeder–Root equipment is expected to take every safety precaution possible and to

have read this manual, particularly the sections referring to health and safety.

Deviation from the specifications contained in this manual can result in rework, delays in system installation and

additional installation charges.

Contractors are advised to contact their nearest Veeder–Root office where local conditions may preclude using

the specifications contained in this manual.

Product Description

SYSTEMS

All Veeder–Root systems have been designed for ease of operation. System consoles have liquid crystal display

screens and one-touch function keys to guide the user through all operating functions. The status of all in-tank

probes and leak detection sensors is available immediately on the LCD screen, on the system's printer or, through

the system's communication facilities, on the point-of-sale terminal or back office computer.

IN–TANK PROBES

Magnetostrictive probes are ATEX certified as: eII 1/2 G Ex ia IIA T4, II 1 G Ex ia IIA T4, per CERTIFICATE

NO. 06 ATEX 0508841X

And, IECEx certified as: Ex ia IIA T4 Ga/Gb, Ex ia IIA T4 Ga, per Certificate No. IECEx

UL 06.0001X

Mag Probe ingress protection rating is IP 68 at a depth of 3 meters with a duration of 30 days as tested by the

notified body (ExNB) UL LLC.

Depending on probe type, canister material may be aluminum or black conductive polymer.

For further information on the performance and specification of in-tank probes, please contact your local Veeder-

Root representative.

SURGE PROTECTORS

In a Veeder-Root system, each Intrinsically Safe Device may use an optional surge protector in place of the

weatherproof junction box located in Zone 1. Surge protectors consist of a certified in-line device or a simple

apparatus conforming to the requirements of Standard No. IEC/EN 60079-14, Electrical installations design,

selections and erection.

Surge Protectors are either an ATEX Certified Device as

13 ATEX 13060507X or are Simple Apparatus. Surge Protectors can also be an IECEx certified device per

Certificate No. IECEx UL 13.0074X.

e II 2 G Ex ia IIA Gb T4 per Certificate No. DEMKO

1

Page 6

TLS Magnetostrictive Probes International Installation Guide Health And Safety

Health And Safety

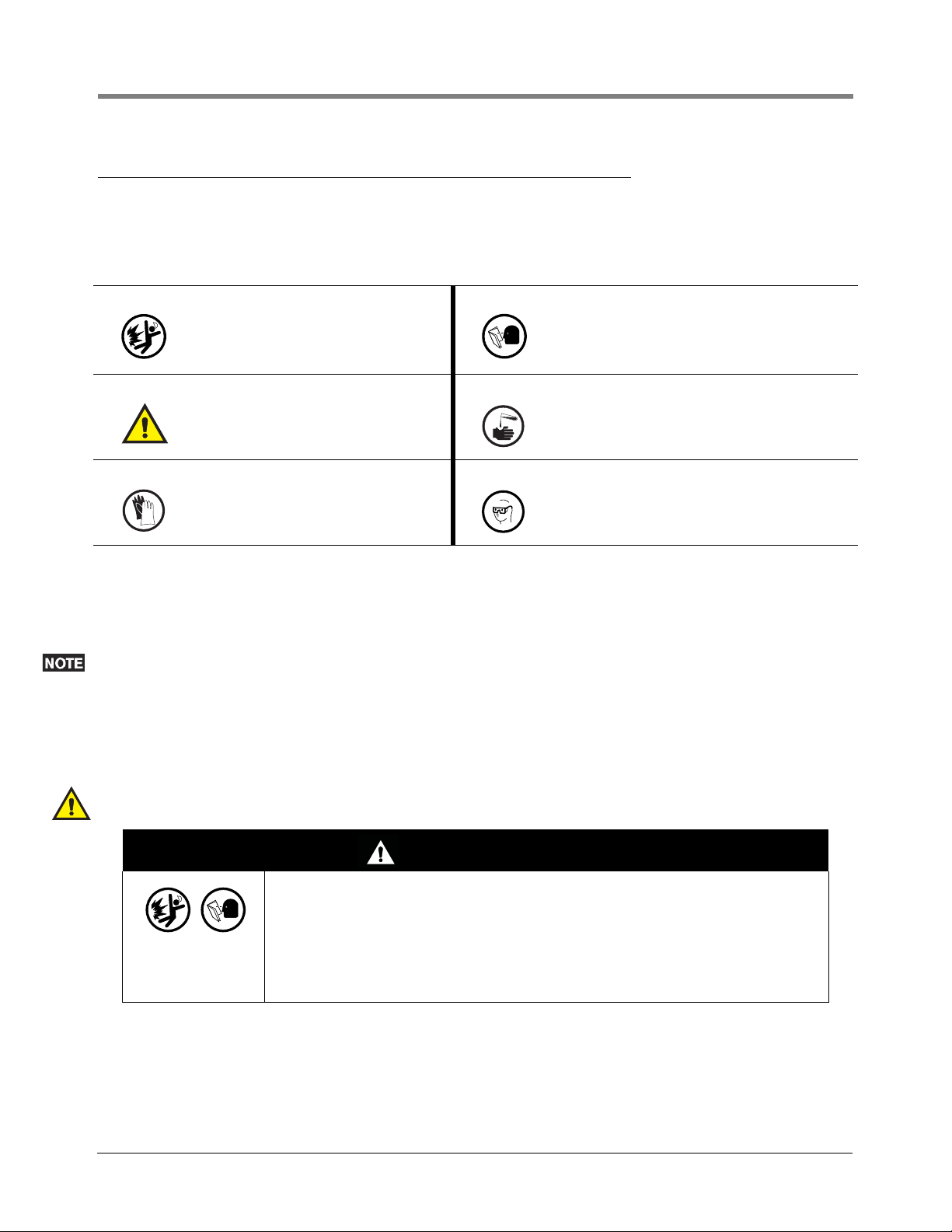

SAFETY SYMBOLS

The following safety symbols are used throughout this manual to alert you to important safety hazards and

precautions.

Explosive

Fuels and their vapors are extremely

explosive if ignited.

WARNING

Heed the adjacent instructions to avoid

equipment damage or personal injury.

GLOVES

Wear gloves to protect hands from irritation or injury.

Read All Related Manuals

Knowledge of all related procedures before you

begin work is important. Read and understand

all manuals thoroughly. If you do not understand

a procedure, ask someone who does

INJURY

Careless or improper handling of epoxy sealant

materials can result in bodily injury.

WEAR EYE PROTECTION

Epoxy sealant in contact with eyes can cause

serious injury. Always wear eye protection when

sealing wire splices.

GENERAL

Ensure that all local council, E.C. laws and regulations are complied with. Also ensure that all recognised safety

codes are followed.

Every person working with Veeder–Root equipment is expected to take every safety precaution possible in the

installation of TLS Systems.

Contractors must ensure that supervisory personnel on the installation site are aware of their presence and

requirements, especially the provision of safe working areas and isolation from AC electrical power.

Leaking underground tanks can create serious environmental and health hazards. It is the contractor's

responsibility to comply with the instructions and warnings found in this manual.

Substitution of specified components may impair intrinsic safety.

WARNING

Explosion could occur if other wires share ducts with intrinsically safe probe or

sensor wiring. Ducting for probes and sensors must not contain any other wiring

circuits except where permitted by local wiring codes and regulations.

FAILURE TO COMPLY WITH THE FOLLOWING WARNINGS AND SAFETY

PR ECAUTI ONS COULD CAU SE DAMAGE TO PROPE RTY, ENVI RON M ENT,

RESULTING IN SERIOUS INJURY OR DEATH.

EQUIPMENT PROTECTION

TLS monitoring equipment, including the Magnetostrictive Probe, is designed and certified to comply with the

Directive 94/9/EC (ATEX) and the IECEx scheme. The installer must consider any local regulations, which may

differ or be more stringent, prior to installing any equipment. The suitability/safety of any installation is ultimately

determined by the local authority having jurisdiction.

2

Page 7

TLS Magnetostrictive Probes International Installation Guide Health And Safety

The Magnetostrictive Probe that is part of the TLS Monitoring System is equipment Category 1 intended to be

installed in a Zone 0 hazardous location. Extreme care must be taken when determining the suitability of the

installation conditions and operation of the TLS Monitoring System. Procedures for installing either in a process

connection or riser pipe are detailed beginning on

aid in the determination if a probe is to be installed in a process connection or riser pipe:

1. Equipotential grounding of the installation site,

2. Minimizing static hazards associated with the underground storage of flammable liquids, and

3. Protection of the system against lightning strikes and any other source of possible electrical surges caused by

electrical railway systems, high voltage direct current facilities and the like.

page 13. At least the following items must be considered and will

EQUIPOTENTIAL GROUNDING

Consult any local regulations prior to installing a Magnetostrictive Probe into any tank. Veeder-Root supplies

approved process connections for installations where direct connection between the probe body and tank structure

is required (see Probe Installation Using Process Connection instructions below).

The intrinsically safe circuit in the TLS Monitoring System is derived from a fuse protected zener diode intrinsic safety

barrier. This type of explosion protection requires that the intrinsically safe electric circuit is referenced to the safety

ground associated to the mains circuit. If the site has a submersible pump (DIN/EN 15268) connected to the same

mains safety ground as the TLS Monitoring System Console and it is installed in a metallic riser of a metallic storage

tank, the zener diode barrier must be referenced to the same earth (safety) ground.

MINIMIZATION OF ELECTROSTATIC HAZARDS

Consult any local regulations prior to installing a Magnetostrictive Probe into any tank. Veeder-Root supplies

approved process connections for installations where direct connection between the probe body and tank structure

is required (see Probe Installation Using Process Connection instructions below).

The magnetostrictive probe housing complies with the 500 volt electrical strength requirements in IEC/EN 60079-

11. In addition, the probe housing provides an electrostatic dissipative path to the zener diode barrier earth ground

that must be referenced to the common grounding system. The electrostatic resistive path is less than 1 megohm.

All TLS Consoles provide an alarm if either of the two wires to the magnetostrictive probe is disconnected or short

circuited due to a malfunction.

If a probe must be serviced or replaced, observe any required relaxation time prior to opening any covers and

removing the probe.

LIGHTNING AND SURGE PROTECTION

Consult any local regulations prior to installing a Magnetostrictive Probe into any tank. Local rules or regulations may

require surge arrestors when installing equipment that crosses from a less restrictive zone, e.g., zone1 to zone 0

independent of the risk assessment. When required Veeder-Root can supply appropriate surge protection devices.

In locations where the intrinsically safe cables or circuits are considered to be at risk of developing hazardous

potential differences within Zone 0, an external surge protection device may be needed. Perform the lightning risk

analysis to determine if surge protection is required, and if necessary, the surge protector shall be installed in

accordance with IEC/EN 60079-25 and IEC/EN 60079-14. Reference

locations for a surge protector.

When they are deemed necessary, Veeder-Root requires the installation of external surge protection devices that are

classified as simple apparatus only. Only gas-discharge type surge protectors that comply with Clause 12 of IEC/EN

60079-25 are acceptable. Additional installation requirements for surge protection devices are defined in Clause

12.3 of standard IEC/EN 60079-14.

The Surge Risk Protection Assessment checklist (SRPA) is available on the Veeder-Root Tech Docs CD and on our

website at http://www.veeder.com/page/Probe_Manuals. An example of the SRPA appears in Appendix A of this

manual.

Figure 14 and Figure 15 for mounting

EC-TYPE CERTIFICATES FOR AN INTRINSICALLY SAFE SYSTEM

TLS Monitoring Systems are installed according to the conditions specified in the applicable Certificates. ATEX

Certificate Number DEMKO 06 ATEX 137480X and IECEx ULD 08.0002X are referred to as the system certificate

or parent certificate for all of the equipment in a TLS Monitoring System.

3

Page 8

TLS Magnetostrictive Probes International Installation Guide Before You Begin

Except for the cables used to connect intrinsically safe apparatus, information contained on the system certificate

and each of the device certificates, provide the safety related information (Ex ia) required to install a TLS

Monitoring System. Cables used to connect intrinsically safe apparatus must be considered in determining

compliance and are limited to the maximum allowable cable parameters listed in this manual. For assistance in

calculating the required (Ex ia) safety parameters, contact GVR as described on the inside cover of this manual.

For European Community (EC) installations, additional equipment compliance information is available on the EC

Declaration of Conformity including reference to the technical standards applied by the Notified Body in creating

the respective ATEX Certificates.

THESE ARE THE CONDITIONS FOR SAFE USE WHEN INSTALLING A MAG PROBE

1. The devices have been evaluated in conjunction with the intrinsic safety system defined in DEMKO 06 ATEX

137480X. The descriptive system documents and manuals included with the aforementioned certificate must

be followed during installation and the appropriate Veeder Root accessories must be used. Manual 577014031 details applicable process connections in accordance with EN 60079-26.

2. The following condition of safe use applies to the Mag Sump Sensor: Before installing or taking into a

hazardous area, earth the unit in a Safe Area to remove any static charge. Then immediately transport the unit

to the installation site; do not rub or clean the unit prior to installation. Cleaning is not required under normal

service conditions; do not rub or clean the device after installation. If the unit is not fixed to a known earth

point when installed, ensure that a separate earth connection is made to prevent the potential of static

discharge. When fitting or removing the unit, use of anti-static footwear & clothing is required.

3. The enclosure contains aluminum. Care must be taken to avoid ignition hazards due to impact of friction.

ATTENTION!

Important Considerations - Read Prior to Installation - Metallic/Steel Tanks

Process Connection (gland): Must be used in locations where it is mandatory that the Mag Probe be

equipotentially bonded to the tank structure.

Riser Pipe: May be used in locations that do not require bonding between the Mag Probe and the tank structure.

Reference European Norm IEC/EN 60079-14: Explosive atmospheres - Part 14: Electrical installations design,

selection and erection.

Cathodically Protected Tanks: Installation selection is dependent on the considerations listed above for the

Process Connection and the Riser Pipe.

Only install TLS Magnetostrictive Probes according to one of the four procedures listed below:

Wired Connections – Mag Probe to ATG Console wiring - see Figures 1 and 18.

1. Process Connection (gland) – Zone 1 installation, Surge Protector not required

2. Riser Pipe – Zone 0 installation, Surge Risk Protection Assessment (SRPA) required

Wireless Communication – Mag Probe with RF hardware - see Figures 2, 24 and 25

3. Process Connection (gland) – Zone 1 installation, surge protector not required

4. Riser Pipe – Zone 0 installation, Surge Protector required

Before You Begin

1. Consult any local regulations prior to proceeding to determine the best installation method. The instructions

below detail how to safely install probes with process connections or in a riser pipe and will also help in

determining when surge protection is required or may be necessary.

2. Depending on the considerations above, perform a Surge Risk Protection Assessment (SRPA) of equipment

in the site. A (SRPA) checklist is available on our website at http://www.veeder.com/page/Probe_Manuals.

3. Verify the equipment needed to complete the installation as described in this manual, and, if necessary, any

equipment required following completion of the site Surge Risk Protection Assessment (SRPA).

4

Page 9

TLS Magnetostrictive Probes International Installation Guide Procedures for Installing Mag Probes

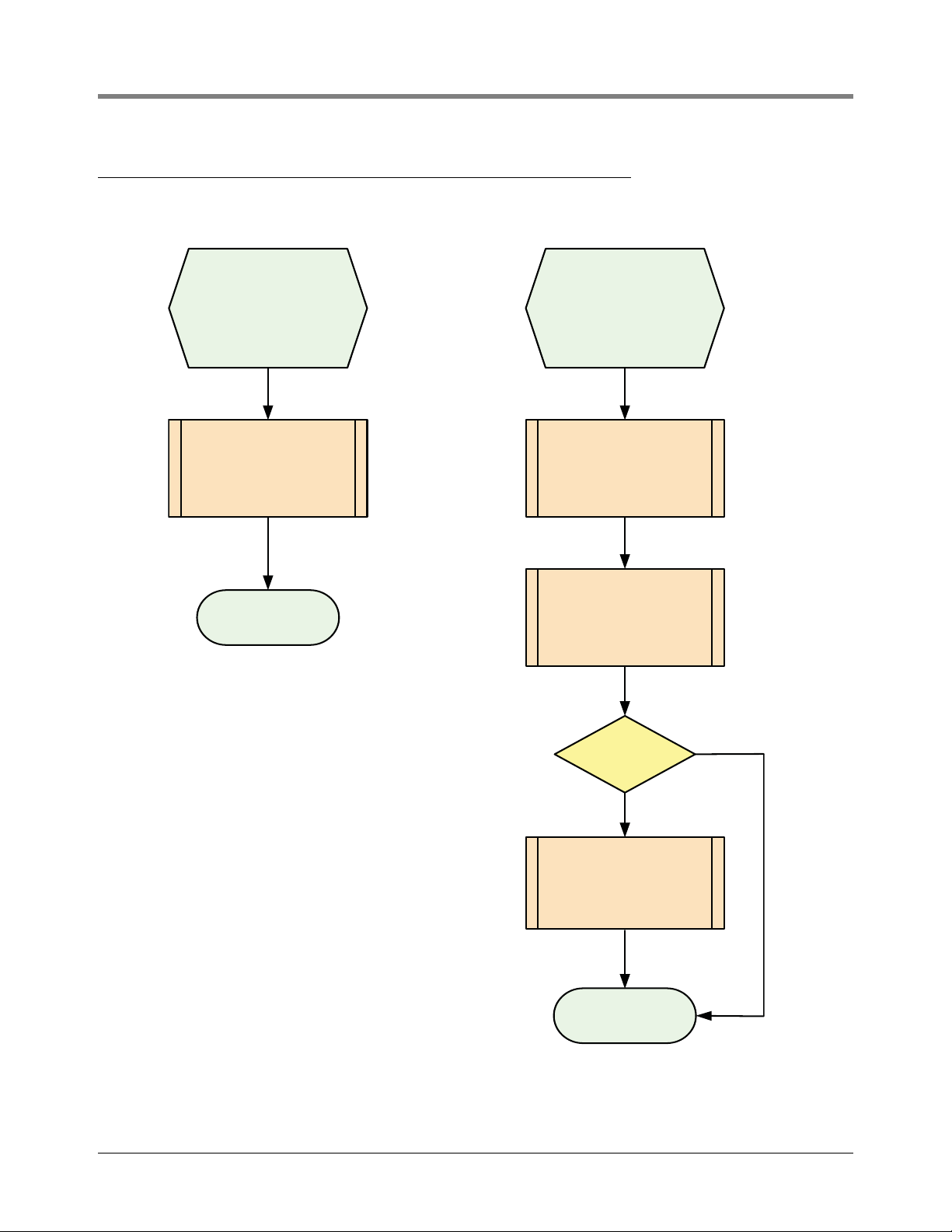

Procedures for Installing Mag Probes

Riser PipeProcess Connection

Procedure for installing Mag

Probes into storage tanks

using a tube gland.

NOTE: Use a tube gland in

locations where it is

mandatory that the Mag Probe

be equipotentially bonded to

the tank structure.

Install the Mag Probe with a

process connection according to

the instructions on Figure 14 of

this manual.

Procedure for installing Mag

Probes into storage tanks

using a riser pipe.

NOTE: Use a riser pipe in

locations that do not require

bonding between the Mag

Probe and the tank structure.

Install either a sleeve or an

adapter as shown on Figure 17,

then install the Mag Probe in a

riser pipe according to the

instructions on Figure 13 of this

manual.

Mag Probe

Installation Complete

Perform a surge risk protection

assessment (SRPA), located on

appendix page A-1 of this manual

to determine the possible use of a

dual channel surge protector for

the Mag Probe.

Is a

surge protector

required ?

Yes

Install a dual channel surge

protector, part number BA-350 or

848100-002, according to Figure

11 of this manual.

Mag Probe

Installation Complete

No

Figure 1. Procedures For Installing Mag Probes Using Wired Connections

5

Page 10

TLS Magnetostrictive Probes International Installation Guide Procedures for Installing Mag Probes

Mag Probe

Installation Complete

Install either a sleeve or an

adapter as shown on Figure 17,

then install the Mag Probe in a

riser pipe according to the

instructions on Figure 13 of this

manual.

Install a single channel surge

protector, part number 848100-

001, according to Figure 25 of

this manual.

Install the Mag Probe with a

process connection according to

the instructions on Figures 14 and

24 of this manual.

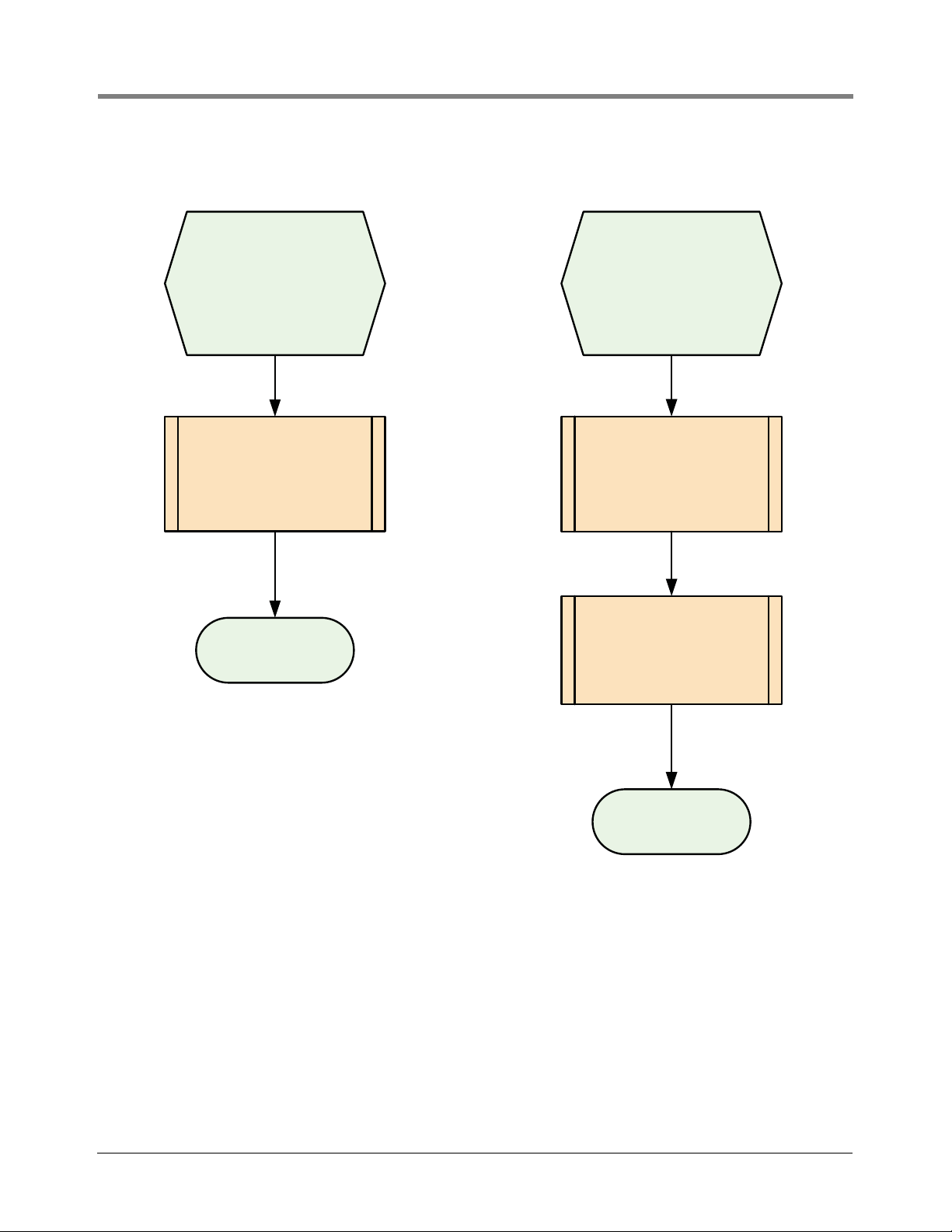

Riser PipeProcess Connection

Mag Probe

Installation Complete

Procedure for installing Mag

Probes into storage tanks

using a riser pipe.

NOTE: Use a riser pipe in

locations that do not require

bonding between the Mag

Probe and the tank structure.

Procedure for installing Mag

Probes into storage tanks

using a tube gland.

NOTE: Use a tube gland in

locations where it is

mandatory that the Mag Probe

be equipotentially bonded to

the tank structure.

Figure 2. Procedures For Installing Mag Probes Using Wireless Connections

6

Page 11

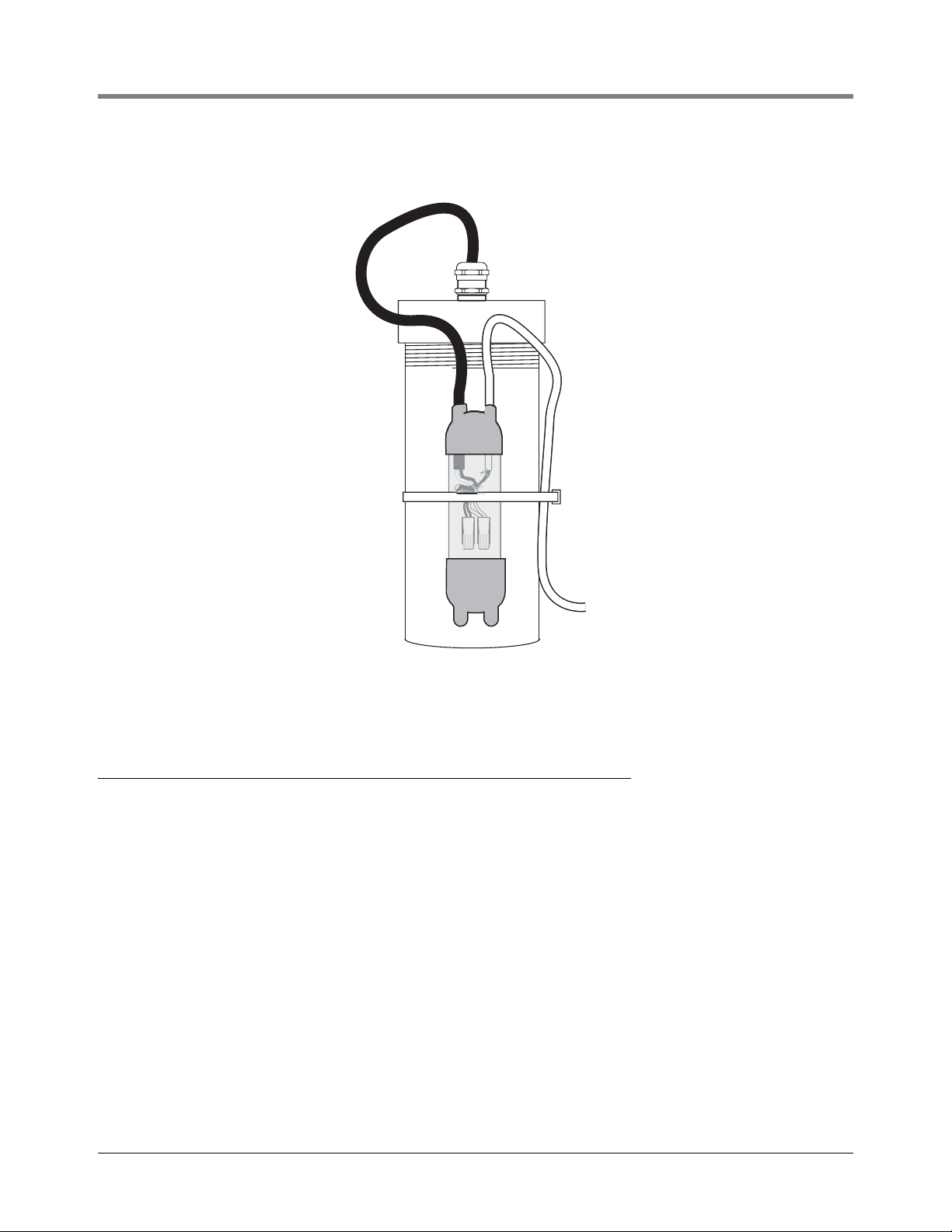

Mag Plus Probe Installation Kits

031-11

Cable

Probe cable connector

(attaches to threaded connector

on the top of probe canister)

These two wires connect in the J-box or splice kit

to the two field wires from the console.

Product float

Product float

Water float (optional)

Sleeves

2-Inch Floats

Water float (optional)

1-Inch Floats

Adapters

Water float (optional)

Product float

3- or 4-Inch Floats

Note: your Mag Probe installation kit will contain

1-inch, 2-inch, 3-inch or 4-inch floats and either

adapters or sleeves as per your order.

Boot

Cable tie

Encapsulant pack

Wire Nuts

Barrel, sleeve & end caps

031-15

The Mag Plus Probe Installation kit.

Cable Seal Kit

Figure 3. Mag Plus Probe Installation Kit 846402

Figure 4. Cable Seal Kit

7

Page 12

TLS Magnetostrictive Probes International Installation Guide Surge Protector Kits

Overvoltage arrestor

Terminal blocks

External connection (PA)

Ground wire

connection clamp

031-12

Surge Protector Kits

When required, a surge arrestor must conform to Clause 12 of IEC/EN 60079-25 and must be installed in

accordance with the requirements for surge protection devices defined in Clause 12.3 of standard IEC/EN

60079-14 as follows:

1. Surge protection is required between each conductor of the cable including the screen and the structure

where the conductor is not already bonded to the structure.

2. The surge protection device shall be capable of diverting a minimum peak discharge current of 10 kA (8/20 us

impulse according to IEC 60060-1 for 10 operations).

3. The connection between the protection device and the local structure shall have a minimum cross-sectional

area equivalent to 4mm

4. The cable between the intrinsically safe apparatus in Zone 0 and the surge protection device shall be installed

in such a way that it is protected from lightning.

5. Any surge protection device introduced into an intrinsically safe circuit shall be suitably explosion protected for

its intended location.

6. The use of surge protection devices which interconnect the circuit and the structure via nonlinear devices

such as gas discharge tubes and semiconductors is not considered to adversely affect the intrinsic safety of a

circuit, provided that in normal operation the current through the device is less than 10 uA.

2

copper.

For example, the two surge arrestors below, supplied by Gilbarco/Veeder-Root, are examples that comply with the

above requirements per the manufacturers declaration of conformity.

Figure 5. Surge Protector Kit For Wired Installations - Dual Channel Surge Protector BA-350 Or Equivalent

8

Page 13

TLS Magnetostrictive Probes International Installation Guide Process Connections

Cable tie

Encapsulant pack

Wire Nuts

Surge Protector

031-26

Probe leader cable gland*

50.8 mm (2”)

galvanised steel

riser cap

031-13

*Hummel probe leader cable gland

P/N: HSK-M-Ex, Size: M16X1,5 (IP68)

Ratings: II 2 G Ex e II

II 1 D Ex tD A20 IP6X

Cert No. KEMA 99ATEX6971X

Figure 6. Surge Protector Kit For Wireless Installations - Single Channel P/N 848100-001

Process Connections

A suitable process connection, IP67 minimum, is required for sealing a tank riser pipe or for forming an appropriate

boundary wall. The two riser caps/glands and process connection gland detailed below can be supplied by

Gilbarco Veeder-Root and are included on the manufactures type approval certificates DEMKO 06 ATEX

0508841X and IECEx UL 06.0001X and provide IP67 zone isolation and have been additionally subjected to a

10 bar pressure test.

51MM CAP AND GLAND

Figure 7. 51mm Threaded Riser Cap Assembly P/N 705-100-2203

9

Page 14

TLS Magnetostrictive Probes International Installation Guide Process Connections

Shield (if required)

Use fitting tool 705-100-3033

to install or remove the cap

3-inch (76mm) BSP riser cap

Probe leader cable gland*

Label

*Hummel probe leader cable gland

P/N: HSK-M-Ex, Size: M16X1,5 (IP68)

Ratings: II 2 G Ex e II

II 1 D Ex tD A20 IP6X

Cert No. KEMA 99ATEX6971X

76MM CAP AND GLAND

Figure 8. 76mm Riser Cap Assembly

MAG PROBE PROCESS CONNECTION (GLAND)

Olive

Locknut

1-inch BSP - 3/4” Coupling

031--23

Figure 9. Mag Probe Process Connection (Gland) P/N 501-000-1206

10

Page 15

Probe Installation

031-22a

Riser Assembly

Magnetostrictive

Probe

Dual Channel

Surge Protector

Field Cables

to Console

Tie Surge Protector (PA)

wire to the tank structure;

e.g., using a customer

supplied terminal lug.

Access Chamber Installation

GENERAL

The installation of the tank access chamber is the responsibility of the customer or their local site contractor and

not that of Gilbarco S.r.l. / Gilbarco UK. However, there are certain requirements which need to be met to allow

the correct installation of Veeder-Root in–tank monitoring probes. Typical installations are shown in

Figure 11.

Riser Assembly

Magnetostrictive

Depending

Probe

on probe type,

canister material

may be aluminum

or black conductive

polymer.

Figure 10 and

Field Cables

to Console

on probe type,

canister material

may be aluminum

or black conductive

polymer.

031-1

Figure 10. Typical Tank Lid Access Chamber Installation w/o Surge Protector

Depending

Figure 11. Typical Tank Lid Access Chamber Installation w/Surge Protector

To allow adequate space for probe installation and servicing, it is recommended that the access chamber is a

minimum 750mm deep and 600mm wide at the base. See Figure 12.

11

Page 16

TLS Magnetostrictive Probes International Installation Guide Access Chamber Installation

031-5a

1

1

1

Dual Channel

Surge

Protector

PROVISION FOR PROBE RISERS

A dedicated probe tapping of either 2-inch BSP (preferred), 3-inch BSP, or 4-inch BSP must be provided.

For maximum height–to–volume accuracy, the probe socket must be as close as possible to the longitudinal axis of

the tank.

The probe entry must not be obstructed by other pipe work. A free area above the probe socket of at least

100mm radius from its center must be provided. See Figure 12.

WARNING! The probe riser probe riser shall comply with IEC/EN 60079-26 and form a suitable process

connection across the boundary between zone 0 and zone 1 subject to the approval of the local authority.

Figure 12. Tank Lid Access Chamber — Critical Dimensions (in mm)

Where mechanical overfill prevention devices are installed, contractors must ensure that no part of these devices

will be obstructed when the probe and riser assembly are installed.

Failure to comply with this warning may result in the overfill prevention device not operating correctly.

12

Page 17

TLS Magnetostrictive Probes International Installation Guide Probe and Riser Installation Criteria

Probe and Riser Installation Criteria

Mag probe installations require a 2-inch or 3-inch (51 or 76mm) riser, regardless of tank entry size. Entry sizes of 1

inch, or entries larger than 3 inches must be with the suitable fittings.

The canister of the probe must be completely contained within the riser. In all cases, the probe must rest on the

bottom of the tank (see

Figure 13). Risers, when fitted, should be a minimum of 100mm above the probe canister.

76mm Entry51mm Entry

51mm Riser

Riser must be

51mm ID and free

of burrs.

76mm Riser

Boot

Note: The riser pipe cap forms a suitable

process connection at the boundary wall.

031-10

View 1 View 2

Installing with a

51mm Riser Pipe

Figure 13. Typical Probe Installations In Riser Pipe

Installing with a

76mm or 102mm Riser Pipe

13

Page 18

TLS Magnetostrictive Probes International Installation Guide Probe and Riser Installation Criteria

Probe leader cable

Probe canister

Encapsulated connection

Field cables to console

Flange

Tank lid

10mm (0.4”)

Minimum gap

1-inch BSPto 2-inch BSP reducer

included with 501-000-1207 kit

031-8

Boot

Zone 1 Installation

with Process Connection (Gland)

Process Connection (gland)

adapter P/N 501-000-1206

inlcluded with 501-000-1207 kit

PROBE INSTALLATION USING PROCESS CONNECTION

Certain installations may require a modified probe mounting arrangement consisting of a process connection

(gland) mounted directly to the tank lid as shown in

tapped G2 inch 11 tpi to DIN 2999 (BS2779) must be provided.

1. Prior to installing or servicing the Magnetostrictive Probe, remove the AC input power going to the TLS

Console and verify that the console power is off. During servicing, disconnect the probe cable and remove the

probe from the tank.

2. Reference Figure 14 to identify the hardware required to complete this installation.

3. Install the flange onto the tank lid then install the gland adapter. For 3-inch and 4-inch float sizes, install the

tube gland and the associated reducer onto the gland adapter prior to performing Step 4.

4. Prior to inserting the Mag Probe, install the tube gland on the probe shaft near the probe canister. Care must

be taken to ensure that the probe shaft is not harmed in any way.

5. Add the fuel float and the water float then install the plastic boot on the very bottom of the probe.

6. Insert the probe assembly into the tank and tighten the tube gland to the gland adapter.

7. Slide the Mag probe downward until the boot makes contact with the tank bottom. Lift the probe at least 10

mm (0.4 inch) from the bottom of the tank to account for thermal expansion of the probe. Tighten the tube

gland once the probe is at the appropriate height.

8. Connect the probe leader cable to the field wiring using the encapsulated splice kit shown in Figure 4.

Figure 14. Either a dedicated tapping or a suitable flange,

9. Restore power to the TLS Console and verify that the system is operating properly.

Figure 14. Installation Of A Mag Probe With A Process Connection (Gland)

14

Page 19

TLS Magnetostrictive Probes International Installation Guide Probe and Riser Installation Criteria

"B"

"E"

"A"

"D"

"C"

A - Tank diameter (internal)

B - Tank bottom to top of tank lid

C - Height of probe entry

D - Probe entry size

E - Vertical clearance for riser assy, above tank lid at probe entry

Dimensions

031-6

DETERMINING THE CORRECT PROBE LENGTH

Refer to Figure 15 and carry out the following procedure.

1. Enter dimensions A, B, C, and E in Tab l e 1.

2. Add dimensions B + C and enter this in column “F”.

3. Select a standard probe length that is equal to or greater than the dimension in column “F”.

Enter the standard probe Length in column “G”.

Figure 15. Dimensions Needed To Calculate Custom Probes And Risers

15

Page 20

TLS Magnetostrictive Probes International Installation Guide Probe and Riser Installation Criteria

DETERMINING THE MINIMUM ACCESS CHAMBER DEPTH

The minimum access chamber depth, is calculated as follows:

1. To the chosen standard probe Length (“G”), add 290mm, this is the overall probe length; enter this in column

“H”.

2. From the overall probe Length subtract dimension “B + C” (bottom of tank to top of probe flange); the result is

the minimum access chamber depth. Enter in column “I”.

3. Calculate the actual access chamber depth, dimension “E” minus dimension “C” and enter in column “J”

4. Calculate the probe clearance (“J” – “I”) and enter in column “K”.

Column “K” must be zero or a positive number. If the result is a negative number there is insufficient clearance

for the probe and riser assembly. In this case please contact Veeder-Root Technical Support or your local

Representative for details on custom length Mag Probes and special skirted risers, having available the

dimensions A - E shown in

Figure 15.

Table 1. Calculation sheet for determining the correct probe length

TANK

No.

1

2

3

4

5

6

7

8

9

10

11

12

A B C E

F

Bottom of

Tank to Top

of Probe

Entry

“B”+“C”

G

Standard

Probe

Length

H

Overall

Probe

Length

“G”+290mm

I

Minimum

Access

Chamber

Depth

“H”-”F”

J

Actual

Access

Chamber

Depth

“E”-”C”

K

Probe

Clearance

“J”-”I”

13

14

15

16

16

Page 21

TLS Magnetostrictive Probes International Installation Guide Probe Riser Pipe Installation

Hummel probe leader

cable gland

Hummel probe leader

cable gland

51mm Threaded Riser Cap Assembly

Shield (if required)

Use fitting tool 705-100-3033

to install or remove the cap

3-inch (76mm) BSP riser cap

76mm BSPT Riser Cap Assembly

50.8mm (2”)

galvanised steel

riser cap

031-3

Probe Riser Pipe Installation

A riser assembly consisting of a riser (either 2- or 3-inch [50.8 or 76mm] nominal bore galvanised steel pipe

threaded 2- or 3-inch BSPT at each end) and a 2- or 3-inch riser cap, designed specifically for the efficient

installation of Veeder-Root magnetostrictive probes, should be used for Mag Probe installation (see

Riser caps are normally fitted at the time of probe installation by Veeder-Root authorised engineers. An optional

cable shield is available for 3-inch (76mm) riser caps, if required.

Non–standard or locally supplied risers may be made from 2- or 3-inch nominal bore galvanised steel pipe

threaded 2- or 3-inch at each end (see

Tabl e 2 for allowable riser dimensions).

Remove the plug from the tank socket. Install a 2-inch (50mm nominal bore) or 3-inch (80mm nominal bore) riser

using an appropriate thread-sealing compound. Reducers are available for 4-inch (102mm nominal bore) sockets.

If the probes are not to be installed immediately, cap the riser.

Where locally supplied, 2-inch risers should be seamless, have a 2-inch ID, and be free of burrs.

Figure 16).

DN Nom Pipe

(mm)

25 1 26.65 1.049 29.34 1.155 29.08 N/A

50 2 52.51 2.067 47.63 1.875 46.86 55

80 3 77.93 3.068 76.58 3.015 75.82 85

100 4 102.26 4.026 95.63 3.765 94.87 110

NPS Nom Pipe

DN = Diameter Nominal, NPS = Nominal pipe size, Pipe type is iron or schedule 40 steel

*Maximum allowable inside diameter for Mag Probe installation.

(inch)

Figure 16. Veeder-Root Riser Cap Assemblies

Table 2. Dimensions for Steel Riser Pipes and Mag Probe Floats

ID Nom Pipe

(mm)

ID Nom Pipe

(inch)

OD Max Float

(mm)

OD Max Float

(inch)

17

OD Min Float

(mm)

ID Max* Pipe

(mm)

Page 22

TLS Magnetostrictive Probes International Installation Guide Probe Riser Pipe Installation

Probe

canister

Up

Probe shaft

Settings for 3" Riser

Settings for 4" Riser

Fit adapters

at each end of

the canister.

Make sure

locking tabs

snap into

grooves in

canister.

Sleeve Assembly - 2” Riser

123

4

Adapter Assembly - 3” & 4” Risers

PROBE SPACER ASSEMBLY

See Figure 17 for example probe sleeve/adapter assembly instructions.

Figure 17. Example Probe Canister Sleeve/Adapter Assembly

18

Page 23

TLS Magnetostrictive Probes International Installation Guide Probe Riser Pipe Installation

ZONE 1 HAZARDOUS LOCATION

Nonhazardous Area

Zone 0

Hazardous

Location

AC

Mains

Equipotential

Bonding Conductor

4 sq.mm

Common

Grounding

System

Probe includes

resistive circuit of

750K to discharge

electrostatic charges.

ATG

Console

Earth

Ground

U

m: 250 V

Intrinsically Safe

Barrier Circuit

Intrinsically Safe

ground

INV.

Tank 1

Tank 2

Tank 3

Shielded Two-Core Cable

for intrinsically safe wiring

Storage Tank

Vapours

Tank Structure

Cable

Bushing

Probe Riser

Pipe with Cap

Magnetostrictive

Probe Enclosure

Sleeves or

adapters

Swimmer

(Liquid product Float)

Swimmer

(Water Float)

Liquid Storage Tank

Storage Tank

Liquid

Probe Boot

(+)

(-)

(+)

(-)

(+)

WHITE

BLACK

Encapsulation Enclosure or

Weatherproof Box

(+)

(-)(-)

(+)

WHITE

Dual Channel Surge Protector

BLACK

To ATG

From

Probe

From

Probe

To ATG

SURGE PROTECTION NOT REQUIRED SURGE PROTECTION REQUIRED

OR

Optional Simple Apparatus

Mount within 1 meter of the

probe riser pipe.

(PA)

(PA)

Note: Each ATG and Magnetostrictive

Probe contains internal surge protection

devices (tranzorbs not shown).

Figure 18. Connection Diagram For A Mag Probe In A Riser Pipe With And Without Optional Surge Protection

19

Page 24

TLS Magnetostrictive Probes International Installation Guide Field Wiring

Splice enclosure cap

TLS cable

Probe cable

51mm

Shield wire

76mm

Black

White

White

Black

031-17

Field Wiring

PROBE TO TLS CONSOLE

Pull appropriate cable from the each probe location to the TLS console.

Explosion could occur if other, non–intrinsically safe wires share TLS intrinsically safe wire conduits or wiring

troughs. Conduits and wiring troughs from probes and sensors to the console must not contain any other wires.

At least 2 metres of free cable must be left for connection at both the TLS console and the probe locations.

Ensure that all cables are correctly identified. All probe field wiring must be legibly and permanently labelled with

the tank number.

Failure to correctly mark probe field wiring may lead to re-work, delays in system installation and additional

charges.

MAXIMUM CABLE LENGTHS

A maximum of 305 metres of cable length per probe must be observed.

SPLICING PROBE FIELD WIRING

1. Insert the probe cable through the top of each riser cap and through the Hummel cable leader bushing.

2. Cut the soft vinyl epoxy enclosure end cap entrance holes to accommodate each cable diameter. Keep the

hole sizes to a minimum. Insert about 127mm of each cable through the openings [

of the outer jacket from each cable. Trim the insulation from the conductors.

Figure 19]. Remove 76mm

Figure 19. Splice Length Dimensions

20

Page 25

TLS Magnetostrictive Probes International Installation Guide Field Wiring

Cable from TLS

Black (–) pair

Aluminum bonding clamp

White (+) pair

Enclosure sleeve

Bare drain wire (cut back to

cable jacket)

Cable from probe

031-16

3. Make the connections using wire nuts [Figure 3]. Cut off the bare shield wire at the cable jacket.

Figure 20. Splice Connections

4. Use the aluminum bonding clamp to hold the cables together (finger tighten, being careful not to damage the

conductor insulation, see

Figure 20). This clamp is not intended to make any electrical connections.

5. Center the splice in the clear plastic sleeve. Assemble the splice closure, making sure the sleeve is fully

inserted into each of the vinyl end caps. Rotate the sleeve cover until both openings line up. Place the splice

on a level surface.

WARNING!

Vapor and liquid may cause sensitization Contains isocyanate. May be

irritating to the eyes. Avoid skin and eye contact. Avoid repeated and

prolonged breathing of vapor. Use only in well ventilated areas.

Inhalation - provide fresh air. In case of eye contact flush eyes with plenty of

water for 10 minutes and get medical attention. If ingested do not induce

vomiting. Get medical attention. Wash with soap and water in case of skin

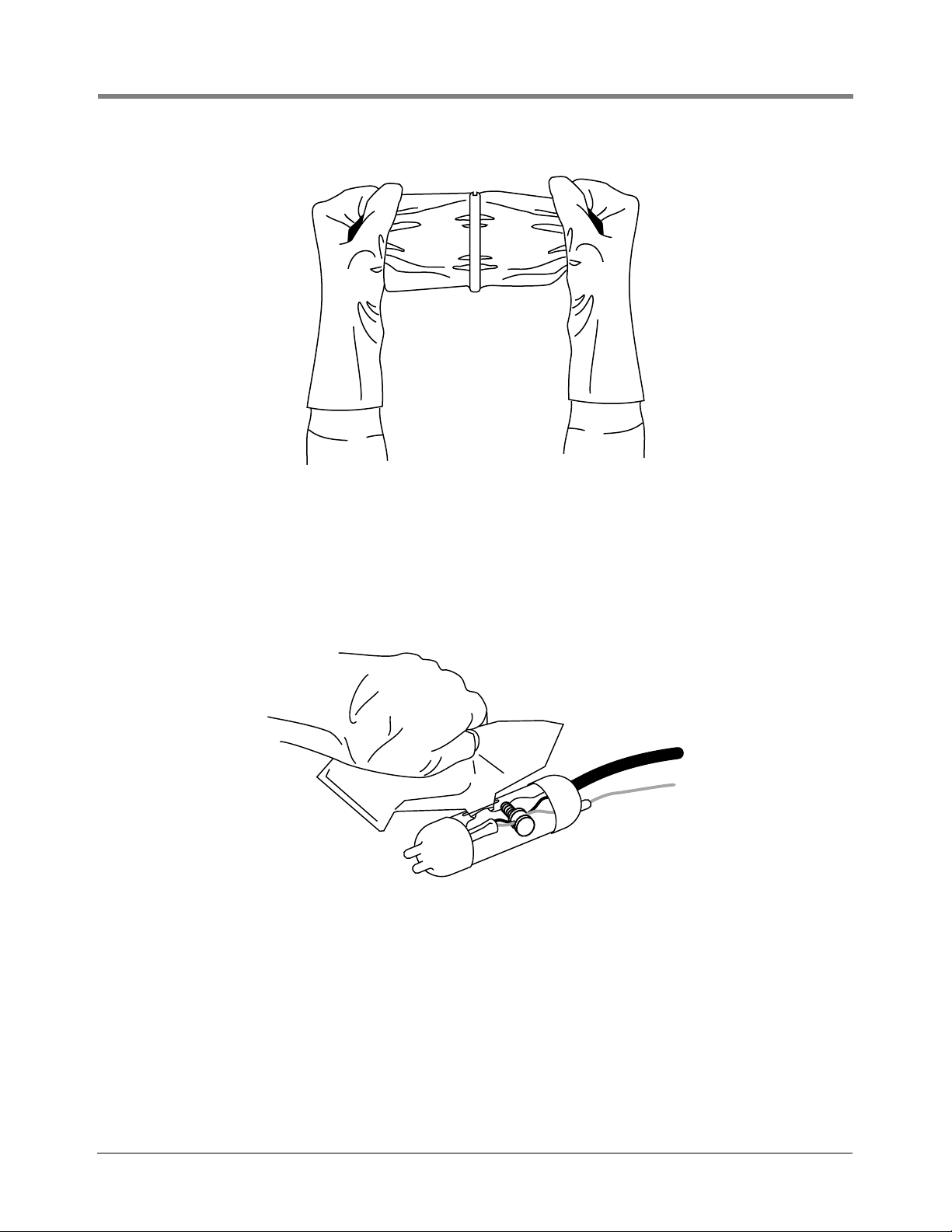

6. Remove bag of “Sealing compound” from foil package. Grasp the ends, one in each hand, then pull sharply to

remove plastic clip [

Figure 21].

contact.

21

Page 26

TLS Magnetostrictive Probes International Installation Guide Field Wiring

Figure 21. Removing Sealing Compound Clip

7. Thoroughly mix compound together. Invert bag several times while squeezing compound from one end to the

other for a minimum of one minute.

8. Once the mixture feels warm, immediately cut one corner and slowly fill the plastic sleeve. Stop just short of

filling the entire sleeve. Do not overfill. [

Figure 22. Pouring Sealing Compound Into Sleeve

Figure 22]

9. With a twisting motion, rotate the outer clear plastic barrel to close the pouring slot.

10. Wait at least five minutes, then use the large cable tie to mount the splice to the riser pipe or probe canister as

applicable (see

Figure 23).

22

Page 27

TLS Magnetostrictive Probes International Installation Guide Surge Protector

031-18

Figure 23. Securing Splice Enclosure With Cable Tie

Surge Protector

INSTALLATION (IF REQUIRED)

When surge protection is required, mount the surge protector as close as possible to the entry point for the probe

leader cable. The surge protector is not polarity sensitive so either cable port may be used for the probe leader

cable. Use the cable port on the opposite side for the wiring coming from the ATG Console. Inside the surge

protector, one side of each spark gap device is wired to the metal enclosure. Use a bonding strap, with a minimum

size of 4 sq. mm, to wire the enclosure to the tank structure using the external potential equalization (PA) terminal.

Connect the wires from each cable as shown in

Figure 24.

23

Page 28

TLS Magnetostrictive Probes International Installation Guide Surge Protector

031-24.eps

Battery

Connection

Battery

Connection

Tie wrap cables

Transmitter

(far side of

bracket)

Battery pack

(this side of

battery support

bracket)

Cable from surge

protector

Red battery labels

two places

Single Channel

Surge Protector

S.P. Connection

Typical Detail

Bond 4 mm2 wire

locally to tank

Pre-installed piping,

e.g., Dip Tube

Probe cable

Process connection (Gland)

Tank flange

W

B

W

B

Y/G

40mm

150mm

Battery

Connection

Battery

Connection

Tie wrap cable

Transmitter

(far side of

bracket)

Battery pack

(this side of

battery support

bracket)

Cable from surge

protector

Red battery labels

two places

Single Channel Surge Protector Install surge arrestor within 1m

of tank entry

S.P. Connection

Typical Detail

Bond 4 mm2 wire

locally to tank

Riser

Tank flange

W

B

W

B

Y/G

Tie wrap cable

40mm

150mm

031-28.eps

Figure 24. Example Wireless Installation With Process Connection And Single Channel Surge Protector

Figure 25. Example Wireless Installation With Riser Pipe And Single Channel Surge Protector

24

Page 29

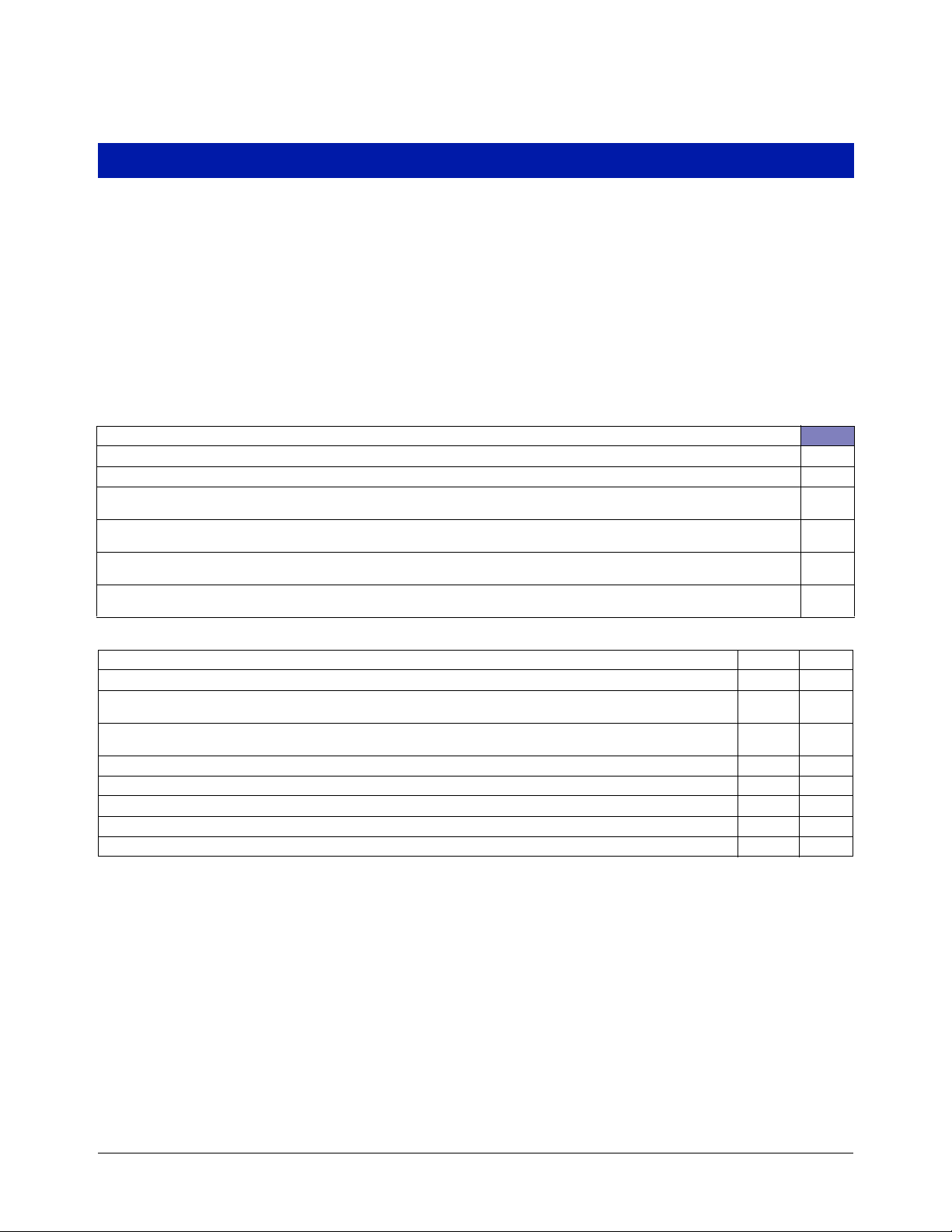

Appendix A - Surge Protection Risk Assessment

Where a tank gauge probe is installed in a ‘riser’ and the entire probe is within the vapour space of the tank, a risk

assessment is required to assess whether additional surge protection is required in close proximity to the probe.

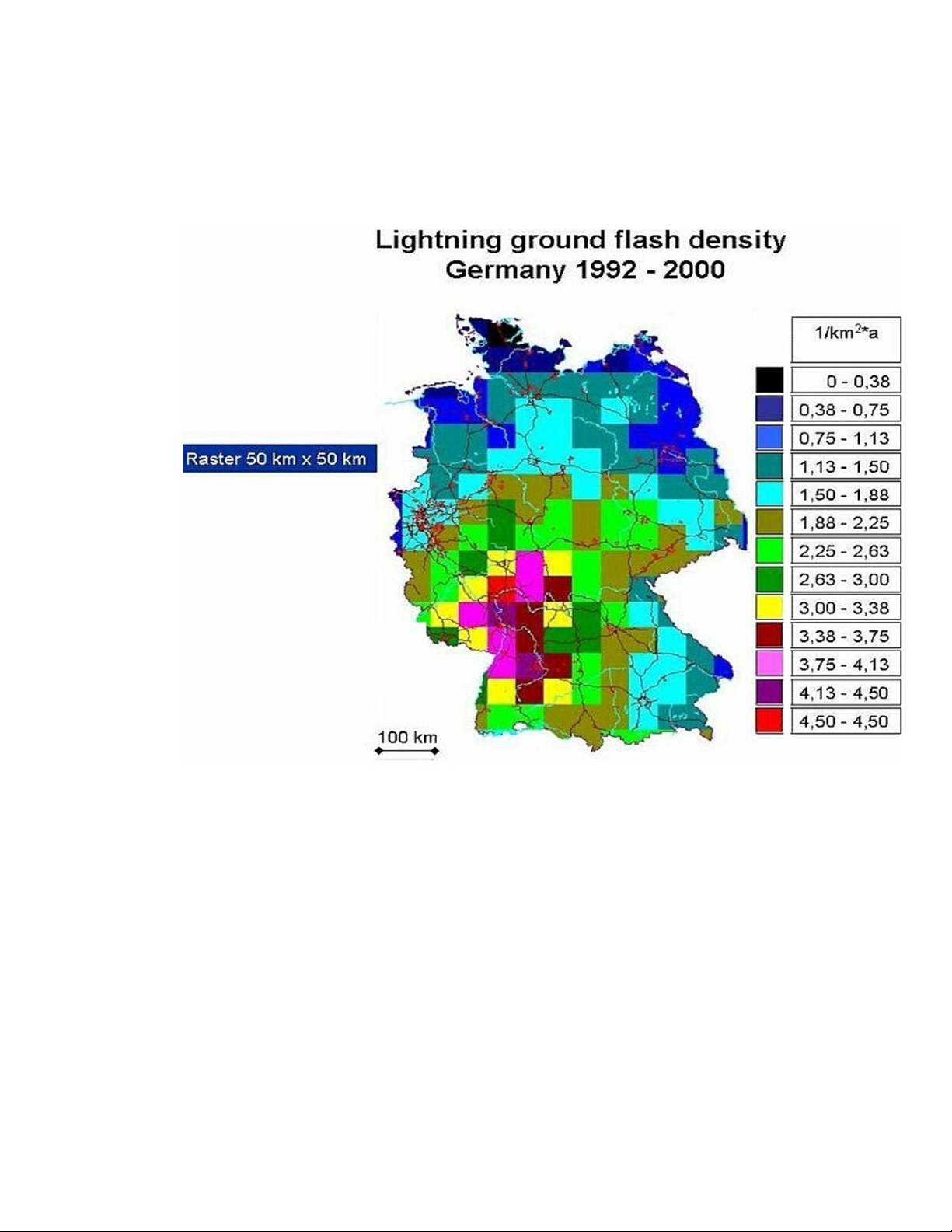

First, complete the Lightning Risk Assessment by identifying whether the site is suitably described by one of the 6

categories listed. Where required, a lightning ground flash density number can be estimated from the lightning

map on the following page. Tick the box next to the description that best describes the site. If none of the

descriptions apply, then do not tick any box. In this instance, additional surge protection is required in close

proximity to the probe.

Second, step through the overall Surge Risk Assessment. For each statement, tick either True or False. Additional

surge protection is required if any of the statements are False.

LIGHTNING RIS K ASSESSM ENT - is the site described by one of the following categories? If yes, tick the relevant box

The site is in a town, village, or built up area

The site is a large motorway site with no probe cable extending more than 5m beyond the area covered by the canopy

The site is a large motorway site with no probe cable extending more than 10m beyond the area covered by the canopy and the

lightning ground flash density is less than 3.38

The site is a large motorway site with no probe cable extending more than 15m beyond the area covered by the canopy and the

lightning ground flash density is less than 2.25

The site is a large motorway site with no probe cable extending more than 20m beyond the area covered by the canopy and the

lightning ground flash density is less than 1.88

The site is in open country with no probe cable extending beyond the area covered by the canopy and the lightning ground flash

density is less than 1.13

SURGE RISK ASSESSMENT Tru e False

A lightning risk assessment has been performed as above and the site falls into one of the categories identified

The installation of the tanks and/or probe is more than 100m away from an electric railway, underground railway, or

tram line

The installation of the tanks and/or probe is more than 100m away from other high voltage sources such as power turbines

The site does not have high voltage power cables supported by pylons passing overhead

The installation does not use above ground tanks

The site is not used for high blend ethanol fuels

The probe cable is buried under the forecourt

The site does NOT use cathodic protection for the tanks

Delete as appropriate

Additional surge protection is not required at this site since all entries in the SURGE RISK ASSESSMENT table

above are marked as TRUE.

Additional surge protection is required at this site since one or more entries in the SURGE RISK ASSESSMENT

table above are marked as FALSE

Site name Date Signatory

Download the Risk Assessment Tool at http://www.mygvr.com/

A-1

Page 30

Example Isokeraunic Map from IEC Lightning Risk Assessment Tool: Germany

Page 31

For technical support, sales or

other assistance, please visit:

www.veeder.com

Loading...

Loading...