Page 1

Introduction

Your V eeder-Root brand C628 Position Indicator is one model in a family of 1/8 DIN units

which offers breakthrough display technology as well as easy-to-program single-line

parameters. Designed to provide instant visual feedback regarding an application’s key

input value, the C628 not only has a 0.71” high LED display (27% larger than other 1/8

DIN units), but also the ability to change display color based on process status

(programmable parameter in Operation Mode). Easy programming is made possible via a

help function and a secondary legend display.

This manual will guide you through the installation and wiring of your C628 unit with

information on proper panel mounting and rear terminal layout and wiring instructions.

In addition, the instrument’s operation and programming modes are thoroughly

explained. The Operation Mode provides day to day operation and allows editing of

preset values. The Program Mode enables the configuration of various parameters prior

to initial operation. These parameters include those for basic configuration as well as

other settable features which will enhance the functionality and usability of the device.

This manual also provides

information on the C628

Position Indicator’s alarms;

transistor, relay and linear

outputs; product

specifications; and ordering

and warranty procedures.

Technical Manual

702138-0002

Features

• AWESOME 0.71” high digit LED display

• Programmable color change display based on

an event

• Programmable help function and secondary

legend display

• High and low alarm outputs

• Optional linear output relative to position

• Accepts encoder inputs

• Filter speed settable for 20, 200, or 10,000 Hz

• Standard outputs: two NPN transistors & one

relay (optional 2nd relay)

• Front panel reset enable and alarm lockout

• Optional RS-485 plug in card

• CE approved

Index

Installation

Panel Mounting page 2

Wiring page 3

Operation

Front Panel page 4

Operation Mode page 5

Programming

Program Mode page 6-9

Appendix A

Specifications page 10

General

Notes page 11

Ordering Information page 12

Warranty page 12

Veeder-Root

brand

Series C628

Position

Indicator

(C628-2XXX)

Page 2

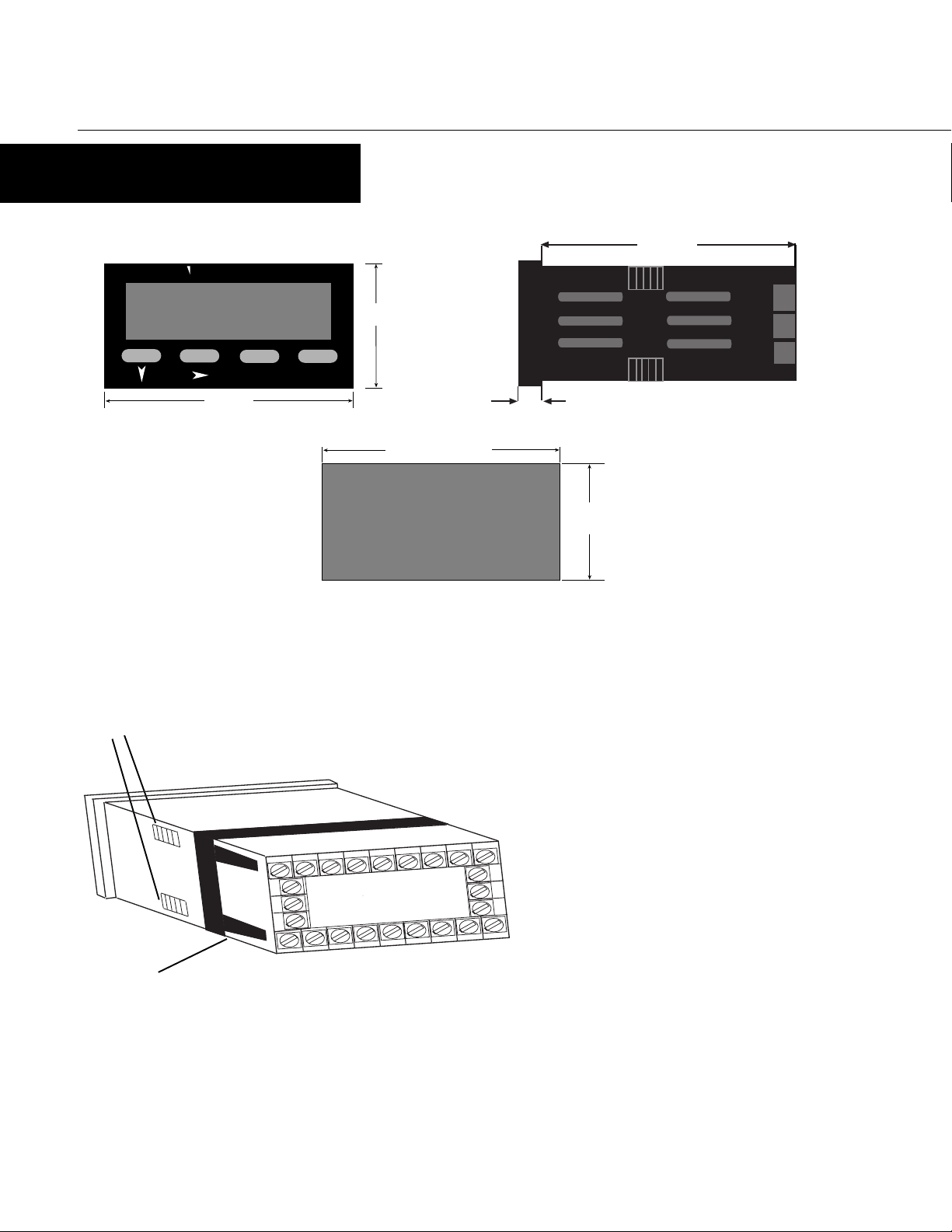

INSTALLATION

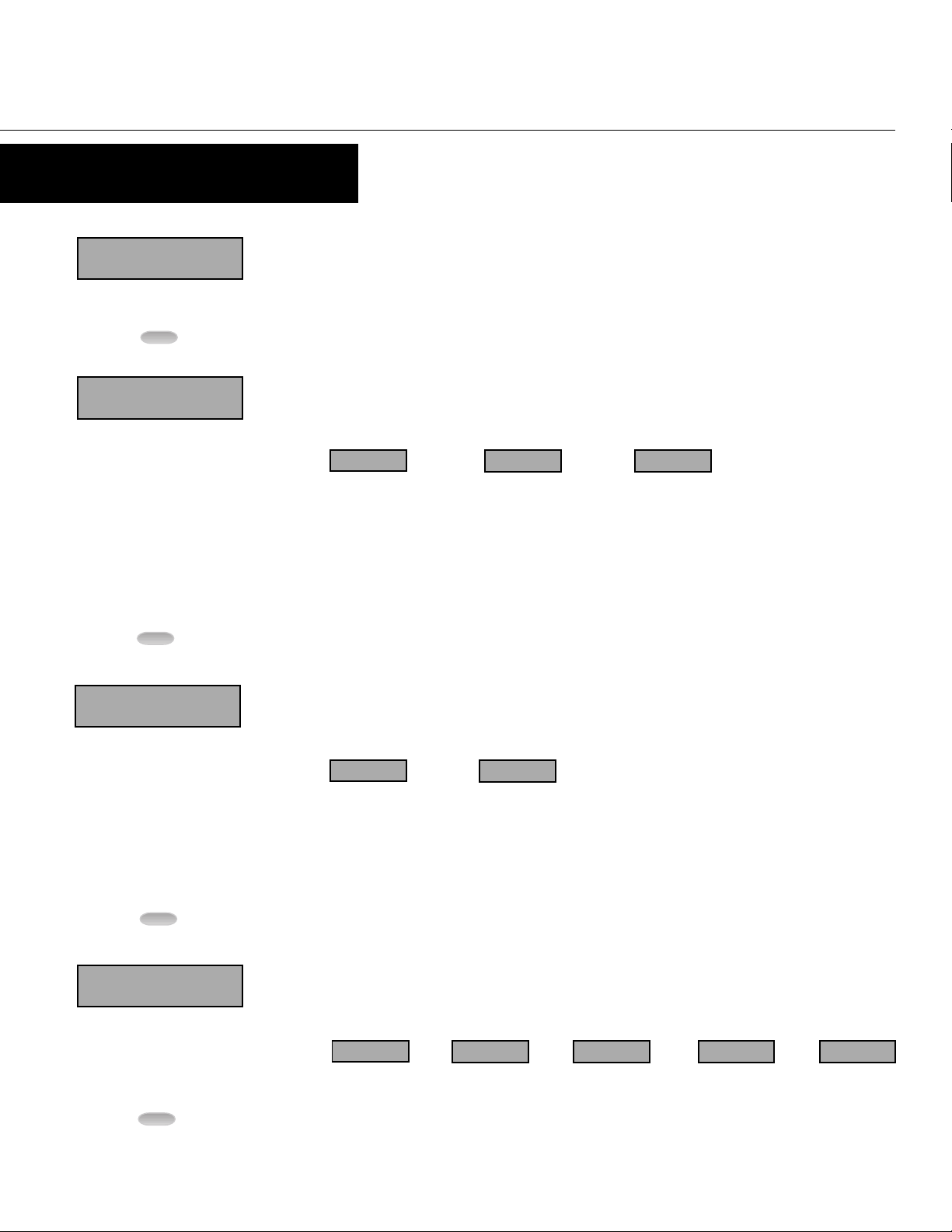

PANEL MOUNTING

100mm

82344

Mounting Grooves

VEEDER-ROOT

PGM

96mm

OP1

OP2

48mm

RST

92mm +0.5 -0.0

CUTOUT

14 15 16 17 18 19 20

10 11 12

10mm

PANEL

45mm

+0.5 -0.0

SIZE

The instrument can be mounted in a panel with a thickness of up to 6mm. The

cutout(s) should be made based on the recommended panel opening illustrated in the

drawing above.

Insert the unit in the panel through the cutout. Ensure that the

panel gasket is not distorted and the instrument is positioned

squarely against the panel. Slide the mounting clamp into place

on the instrument, as shown to the left, and push it forward until

it is firmly in contact with the rear face of the mounting panel and

the tabs on the bracket arm are seated in the mounting grooves

on the side of the unit.

22

23

24

2

345 678

The electronic components of the instrument can be removed from

the housing after installation without disconnecting the wiring.

To remove the components, grip the side edges of the panel and

pull the instrument forward. Take note of orientation of the unit

for subsequent replacement in the housing.

Bracket Arm

2

Page 3

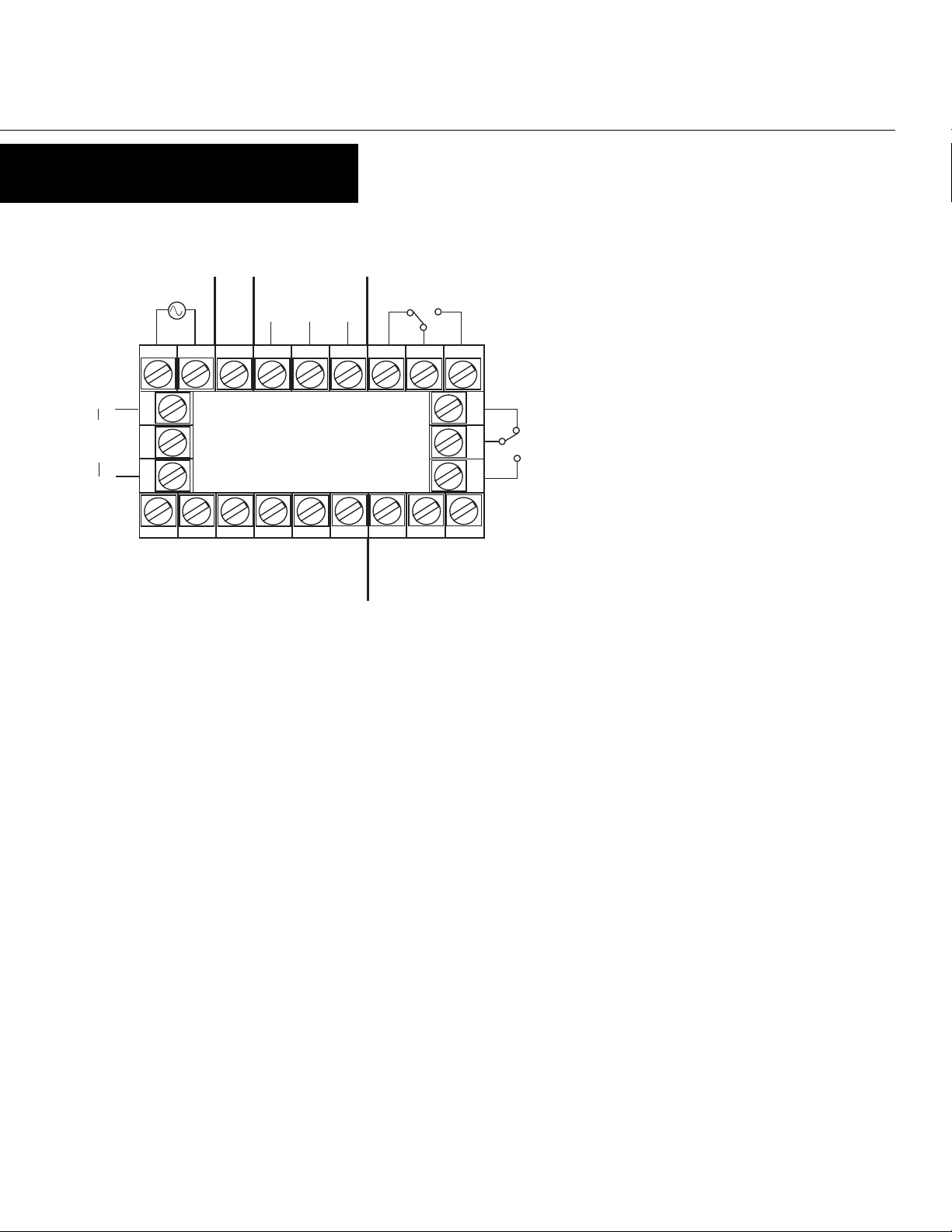

INSTALLATION

WIRING

REAR TERMINAL CONNECTIONS

+

Linear

Output

(opt.)

-

Power Supply

+ VDC -

14 15 16 17 18 19 20

10 11 12

RS-485 Comm.

(opt.)

B A

COM

Relay 1

22

23

23 4 5 6 78

24

Relay 2

(opt.)

Input Power

For an AC powered unit, Terminal #13 serves as the line

or Hot side connection for AC powered units and as the

positive side for DC powered units. The neutral side for

AC powered units and the negative side for DC powered

units are connected to Terminal #14.

NPN Out 2

(LO)

Common

NPN Out 1

(HI)

Digital In 2

(sec. lockout)

Digital In 1

(rem. reset)

Aux. Power

(opt.)

Input A

Input Common

Input B

Count Inputs

Terminal #2 is the connection for Input A, which is used for channel A of

an encoder input. Terminal #1 is the connection for Input B, which is

used for channel B of an encoder input. The common connection for

both Input A and Input B is Terminal #3.

Transistor Outputs

Your unit comes standard with 2 NPN outputs which are activated by

each of the alarms. Transistor Output 1, which is tied to the High Alarm

V alue, is on Terminal #7. Transistor Output 2, which is tied to the Low

Alarm Value, is on Terminal #9. Terminal #8 serves as the common

Control/Digital Inputs

A contact closure or NPN signal can be used to activate preconfigured

functionality. Terminal # 5 is used for a remote reset function, while

Terminal #6 is a security function, that when active, will prohibit entry

into Program Mode. Terminal #8 serves as the common for both of these

inputs.

connection for both transistor outputs.

Relay Outputs

Your unit comes standard with a relay output which is tied to the High

Alarm Value. Terminal #19 is NC, Terminal #20 is common, and

Terminal #21 is NO. A second relay output tied to the Low Alarm V alue

can be added as an option at the time of order or later installed in the

Auxiliary Power Output

field. Terminal #22 is NC, Terminal #23 is common, and Terminal #24 is

NO.

A 9 - 15 VDC for powering external sensors and encoders up to 125 mA

can be accessed by connecting the positive supply side of the sensor to

Terminal #4 and the negative side to Terminal #8.

Serial Communication

An RS-485 communication board, utilizing ASCII protocol, can be

installed as an option. Terminals #16 & #17 serve as the B and A

Linear Output

An option board may be installed that provides a 10 bit linear output

connections respectively, while Terminal #18 is connected as the

common.

signal relative to the Position Value. Terminal #12 is the positive side of

the connection, and Terminal #10 is the negative side. The default range

of the output is 4-20 mA, but can be changed via the front panel to

0-20 mA, 0-10 VDC, 2-10 VDC, 0-5 VDC, or 1-5 VDC.

Terminals 11 & 15 are not used.

3

Page 4

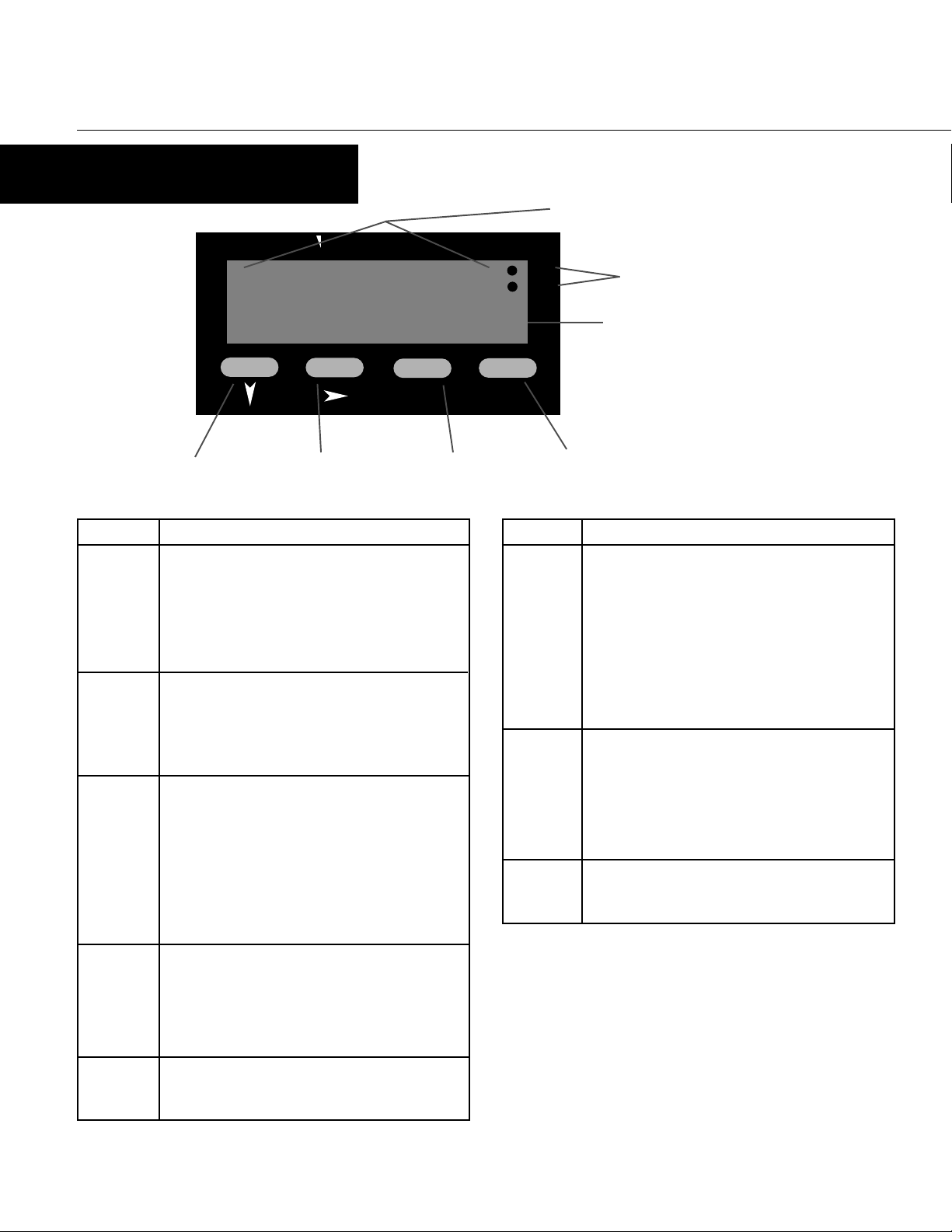

OPERATION

FRONT PANEL

VEEDER-ROOT

Primary Display

OP1

OP2

Output Indicators

82345

PGM

H

RST

Down Key Scroll Key Program Key Reset Key

Key Functions

Key

Down In Operation Mode: Used in edit operation to decrement

the digit highlighted by the Scroll key.

In Program Mode: Used in Edit Operation to decrement

the digit highlighted by the Scroll key, if the setting is

a numerical value, or present the next in the series of

choices for that parameter.

Scroll

Program In Operation Mode: Used to move between the position

In All modes: Moves the unit into Edit Operation,

which is indicated by the left most digit flashing.

Successive presses of the key are used to move to the

digit to be edited. Wrap around will occur from least

significant digit to most significant digit.

display & the alarms and to enter an edited alarm

value. Holding the key down for 3 seconds will cause

the unit to enter Program Mode.

In Program Mode: Used to move from one parameter to

the next and enter the edited parameter values.

Holding the key down for 3 seconds will cause the

unit to return to Operation Mode.

Function

Display

Primary In Operation Mode: Default display is the position.

Secondary In Operation Mode: Indicates alphabetically if one of

Output

Indicators

Secondary Display

Display Functions

Function

Can be scrolled using the program key to display the

alarm values. If the "Help" function is enabled, this

display will first show the parameter description for 3

seconds (see page 5 for example).

In Program Mode: Displays the value or selection for

the current parameter. If the "Help" function is

enabled, this display will first show the parameter

description for 3 seconds (see page 6 for example).

the alarms is being viewed on the primary display.

This display is blank when Position is being shown.

In Program Mode: Provides a 1 digit alpha or numeric

character to indicate which parameter value is being

shown on the primary display.

In All Modes: OP1 illuminates when the High Alarm

Value is reached. OP2 illuminates when the Low Alarm

Value is reached.

Reset In Operation Mode: Resets the position display to zero

(under Reset Value in Program Mode). This button can

be disabled via the "Front Panel Reset Enable"

parameter in Program Mode.

In All modes: No function.

Down &

Scroll

together

4

In All modes: Will abort an Edit Operation and return

the parameter to its previous value.

Page 5

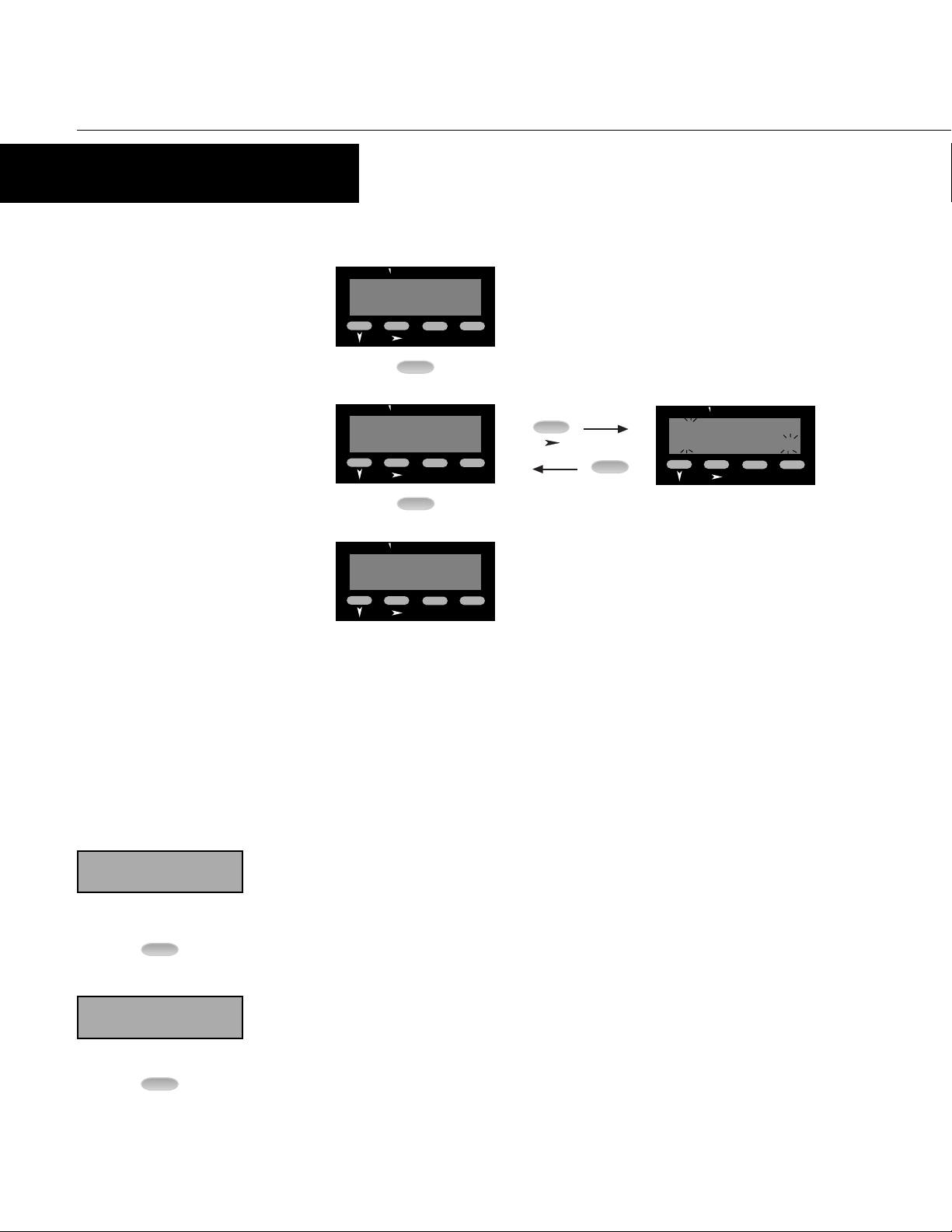

OPERATION

OPERATION MODE

CHANGING A PRESET VALUE

VEEDER-ROOT

Default display is the position value.

OP1

OP2

23456

RST

PGM

PGM

VEEDER-ROOT

PoSn

PGM

RST

Pressing the Program Key will cause the

OP1

OP2

display description to appear on the

main display.* If there is no key activity

for 3 seconds, the primary display will

switch back to the position value.

VEEDER-ROOT

PGM

VEEDER-ROOT

33567

PGM

H34567

RST

H

RST

Use the Scroll Key to move from left to

OP1

OP2

right and highlight the digit that needs

to be changed. Wrap around will occur

from the least significant to the most

significant digit.

Use the Down Key to decrement the

OP1

OP2

digit until the desired value appears.

The display will wrap around from 0 to

9.

PGM

VEEDER-ROOT

Hi AL

PGM

VEEDER-ROOT

34567

PGM

RST

H

RST

Continued pressing of the Program Key

OP1

OP2

will scroll to the Alarms. (See Parameter

Sequence below.) The full parameter

description will appear on the main

display.*

To change a Parameter value, press the

OP1

OP2

Scroll Key. If there was no key activity

for 3 seconds, the Alarm value will

appear (one digit description shown on

secondary display); however, press the

Scroll Key in order to edit. The unit will

now be in Edit Operation as signified by

the most significant digit flashing.**

PARAMETER SEQUENCE

Position

PoSn

Function: Displays position value

Range: -19999 to 99999

PGM

High Alarm Value

Hi

AL

H

Function: Defines the position value at or

above which Alarm 1 will activate

Adjustment Range: -19999 to 99999

Default Value: 1000

PGM

PGM

Hi AL

VEEDER-ROOT

PGM

PGM

RST

After the desired digits have been

OP1

OP2

changed, press the Program Key to enter

the new value. The new value will

appear on the main display without any

flashing digits. Press the Progam Key

again and the parameter description will

appear on the main display.

* Parameter descriptions will not

appear on the primary display if the

"Help" function has been disabled.

** Edit Operation cannot be

accessed if the Preset Lock has

been enabled in Program Mode.

Low Alarm Value

Lo

AL

L

Function: Defines the position value at

or below which Alarm 2 will activate

Adjustment Range: -19999 to 99999

Default V alue: 10

5

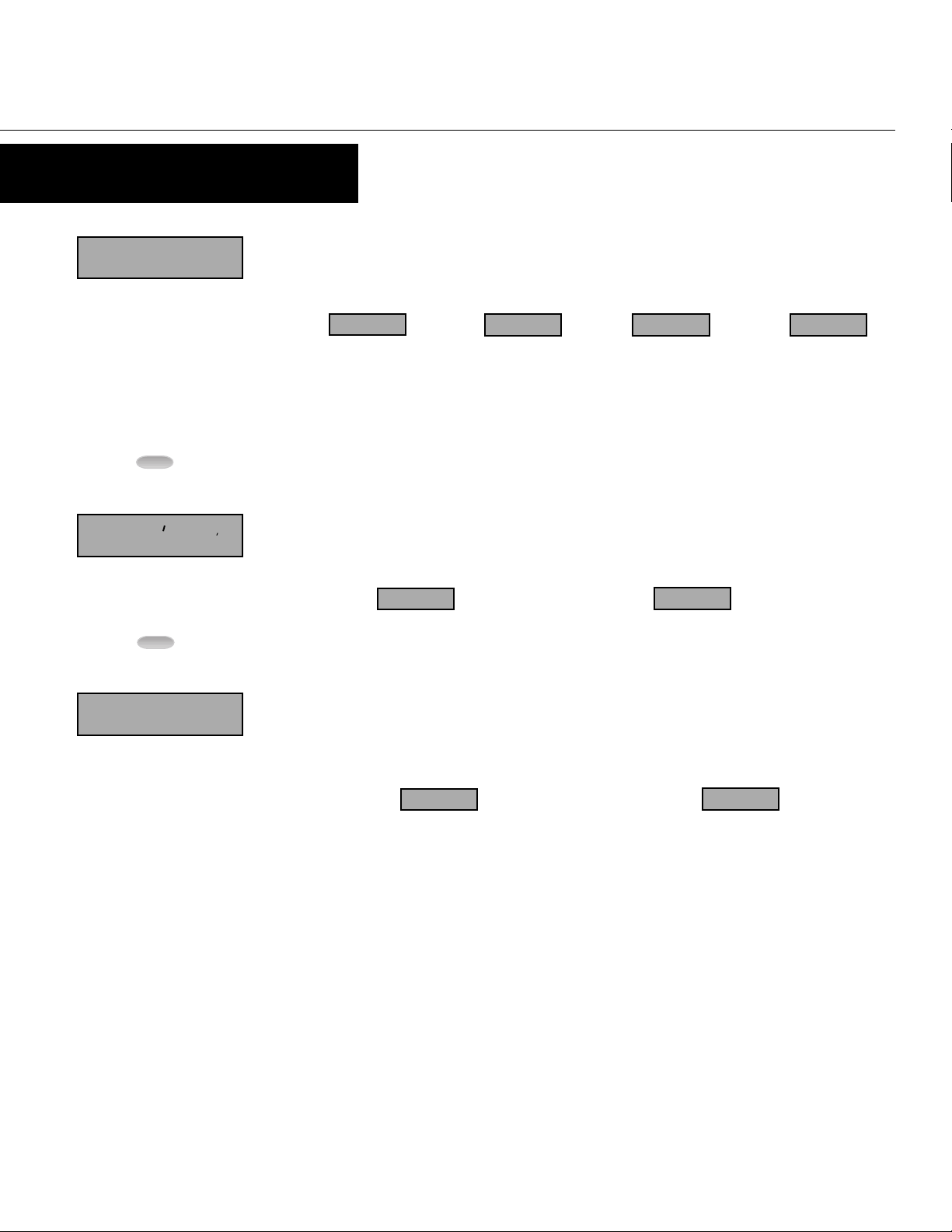

Page 6

PROGRAMMING

PROGRAM MODE

ENTERING PROGRAM MODE AND BASIC OPERATION

The Program Mode can be accessed from the

VEEDER-ROOT

Operation Mode by holding the Program Key

for 3 seconds.

The name of the first parameter will appear

23456

VEEDER-ROOT

on the primary display.*

CAL

Successive presses of the Program Key will

scroll the display through the remaining

parameters in the Program Mode. To exit

Program Mode, hold the Program Key for 3

seconds.

* Parameter names will not appear on the

main display if the "Help" function has been

disabled in Program Mode.

VEEDER-ROOT

dEc P

PGM

for 3 seconds

PGM

PGM

PGM

PGM

RST

RST

RST

OP1

OP2

no key activity

OP1

OP2

for 3 secs. or

PGM

Edit Operation

VEEDER-ROOT

1..0000

PGM

C

RST

OP1

OP2

Pressing the Scroll Key or no key activity for

3 seconds will display the value for that

parameter. The secondary display will

OP1

OP2

indicate the one digit identifier for the

parameter. The digit in the secondary

display will flash to indicate the unit is in

Program Mode. If the Scroll Key was

pressed (instead of waiting 3 seconds), the

unit is in Edit Operation, as indicated by the

MSD flashing. If there had been no key

activity for 3 seconds, press the scroll key to

enter Edit Operation (MSD flashing). Use

the scroll and edit buttons to change the

value as in Operation Mode, described on

page 5. Press the Program Key to enter any

changes.

PARAMETER SEQUENCE

P

C

d

CAL

PGM

dEc

PGM

6

Calibration Factor

Function: Used to scale the input into engineering units by multiplying this value by the number of pulses

received

Adjustment Range: 0.0001 to 9.9999

Default V alue: 1.0000

Decimal Position

Function: Set the decimal point position for the position and alarm displays

Adjustment Range: 0 to 0.0000

Default Value: 0

Page 7

PROGRAMMING

PROGRAM MODE Continued

Reset Value

rESEt

PGM

SPEEd

S

F

Function: Defines a "home position by selecting a value other than zero or another value within the displayed

range of the device to which the counter can reset

Adjustment Range: -19999 to 99999

Default Value: 0

Filter Speed

Function: Enables the debounce filter of the counter to properly match the application

Adjustment Range:

rS

PGM

PGM

En

20 200

20: The unit will accept

up to 20 pulses per

second. Generally used

with contact inputs to

eliminate false counts

caused by contact bounce

Default Value: 10000

Front Panel Reset Enable

r

Function: Determines whether the Front Panel Reset key can be used to reset the position value

Adjustment Range:

En

Enable: The position

value can be reset while

being viewed in Operation

Mode by pressing the

Front Panel Reset Key

Default V alue: Enable

200: The unit will accept

up to 200 pulses per

second. Generally used

for higher speed contact

inputs or to filter noise

on electronic signals in

low speed applications

diS

Disabled: The Front

Panel Reset Key is

disabled and the position

value can only be reset

through the Remote

Reset Input

10000

10,000: The unit will

accept up to 10,000

pulses per second.

Generally used with high

speed electronic inputs

and encoders

rt

PGM

En

Retransmission Enable/Select

t

Function: Determines whether a voltage/current is an output, and if so, which range

Adjustment Range:

nonE

None 0-5 V olts 0-10 Volts 0-20 mA

Default V alue: None

0-5u

0-10u

0-20A

4-20A

4-20 mA

7

Page 8

PROGRAMMING

PROGRAM MODE Continued

rt

rt

Lo

PGM

Hi

PGM

Co<>S

PGM

Retransmission Scale Minimum

L

H

c

Function: Defines the lower end of the linear scale for the retransmission output by defining the value equated

to the minimum output signal - i.e. for a 4-20 mA output, this would be the value corresponding to 4 mA

Adjustment Range: -19999 to 99999

Default Value: 0

Retransmission Scale Maximum

Function: Defines the upper end of the linear scale for the retransmission output by defining the value equated

to the maximum output signal - i.e. for a 4-20 mA output, this would be the value corresponding to 20 mA

Adjustment Range: -19999 to 99999

Default V alue: 100

Serial Communication Enabled

Function: Activates the RS-485 communication option board

Adjustment Range:

nonE

None: No communication

board installed

Default V alue: If ordered from the factory with the RS-485 board, the default will be "fitted". If the board is

installed in the field, this parameter will need to be changed from its default of "none"

Fitted: A communication

board is installed in the

unit

(Appears only if a current/voltage is selected)

(Appears only if a current/voltage is selected)

Fit

Addr

PGM

bAud

PGM

8

Communication Address

A

b

Function: Defines the unique communication address of the unit

Adjustment Range: 1 to 99

Default Value: 1

Baud Rate

Function: Selects the serial communication speed

Adjustment Range:

Default V alue: 4800

(Appears only if communication board is installed and activated)

1200

1200 BPS 2400 BPS 4800 BPS 9600 BPS

(Appears only if communication board is installed and activated)

2400

4800

9600

Page 9

PROGRAMMING

PROGRAM MODE Continued

Display Color Change

Color

o

Function: Defines the color of the display

Adjustment Range:

PGM

Loc/

PGM

HELP

rEd

Red: The display will

always be red

Default V alue: Green to Red

Preset Lock

/

h

Function: Determines whether the Alarm Values can be changed via the front panel

Adjustment Range:

En

Enable: Alarm values are read only

Default Value: Disable

Help Prompt

Function: Determines whether the multi-character parameter name will appear on the main display for 3

seconds prior to the parameter value appearing

Adjustment Range:

GrEEn

Green: The display will

always be green

Gn_rd rd_Gn

Green to Red: The

display will be green prior

to the Alarm value being

reached. It will turn red

after the Alarm has been

reached

diS

Disabled: Alarm values can be viewed and

changed

Red to Green: The

display will be red prior to

the Alarm value being

reached. It will turn green

after the Alarm has been

reached

HLP

Help - Yes: Multi-character parameter descriptions

will appear on the primary display. The value

associated with that parameter will appear by

pressing the scroll key or waiting for 3 seconds

Default V alue: Help - Yes

Y

Help - No: Only the parameter values will appear on

the primary display. The parameter can be identified

by a single digit in the secondary display

HLP

N

9

Page 10

APPENDIX A

SPECIFICATIONS

Count Inputs

Type: Quadrature

Frequency: 5 kHz max.

Logic: Low < 2.0 VDC, High > 3.0, 30V max.

Impedance: 10 KΩ to common - Sourcing

4.7 KΩ to +Voltage - Sinking

Control Inputs

Type: Sinking, Edge Sensitive

Logic: Low < 2.0 VDC, High > 3.0

Impedance: 4.7 KΩ to +Voltage

Response Time: 25 ms

Function: Input 1: Remote Reset

Input 2: Security Lockout

Outputs

Solid State: NPN open collector, 30 VDC max, 100 mA max.

Relay: SPDT, 5A resistive @ 110VAC

Latency: 75 µ seconds, plus 8 ms for relay pull-in

Linear Outputs

Ranges: 0-20mA, 4-20mA, 0-10V, 2-10V, 0-5V, 1-5V

Accuracy: ±0.25% (mA at 250Ω, V at 2kΩ);

degrades linearly to ±0.5%

Resolution: 8 bits in 250ms (10 bits in 1s typ.)

Update: Approximately 4/s

Load Impedence: mA Ranges: 500Ω max.; V Ranges: 500Ω min.

Communication

Type: Serial asynchronous, UAR T to UART

Data For mat: Open ASCII: One start bit, even parity seven

Physical Layer: RS-485

Maximum Zones: 99

Baud Rate: Selectable from 9600, 4800, 2400, or 1200

Electrical

Supply Voltage: 90-264 VAC, 50/60 Hz, or 20-50 VAC/VDC

Power Consumption: 4 Watts

Access. Power Supply:9-15 (unregulated VDC), 125 mA max.

Display

Type: Red/Green, 7 segment LED, 5 digits primary

Height: 0.71" (18mm) primary display,

Annunciators: Output 1 & 2 status

Physical

Dimensions: 48mm x 96mm, 110mm deep

Mounting: Panel mount (mounting bracket supplied),

Ter minals: Screw type - combination head

Front Panel Rating: NEMA 4X/IEC IP65

Case Material: GE Lexan 940

Weight: 0.56 lbs.

data bits, one stop bit

display, single digit secondary display

0.3" (7mm) secondary display

45mm x 92mm cutout

Approvals

General: CE

EMC Susceptibility: Complies with EN50082-1: 1992,

EN50082-2: 1995

EMC Emissions: Complies with EN50081-1: 1992,

EN50081-2: 1994

Safety: Complies with EN61010-1: 1993

10

Environmental

Operating Temp.: 0° to 55° Celsius, 32° to 131° Fahrenheit

Storage Temp.: -20° to 80° Celsius, -4° to 176° Fahrenheit

Relative Humidity: 20% to 95% non-condensing

Page 11

GENERAL

NOTES

11

Page 12

GENERAL

Danaher Controls

ORDERING INFORMATION

C628 - 2

2nd Relay Option

0 None

1 2nd Relay

Linear Output

Option

0 None

3 Linear Output

Serial Communication

Option

0 None

5 RS-485

WARRANTY

Standard products manufactured by the Company are warranted to be

free from defects in workmanship and material for a period of one year

from the date of shipment, and products which are defective in

workmanship or material will be repaired or replaced, at the option of the

Company, at no charge to the Buyer . Final determination as to whether a

product is actually defective rests with the Company. The obligation of

the Company hereunder shall be limited solely to repair and replacement

of products that fall within the foregoing limitations, and shall be

conditioned upon receipt by the Company of written notice of any alleged

defects or deficiency promptly after discovery within the warranty period,

and in the case of components or units purchased by the Company, the

obligation of the Company shall not exceed the settlement that the

Company is able to obtain from the supplier thereof. No products shall

be returned to the Company without its prior consent. Products which

the Company consents to have returned shall be shipped F.O.B. the

Company's factory. The Company cannot assume responsibility or

accept invoices for unauthorized repairs to its components, even though

defective. The life of the products of the Company depends, to a large

extent, upon the type of usage thereof, and THE COMPANY MAKES NO

WARRANTY AS TO FITNESS OF ITS PRODUCTS FOR SPECIFIC

APPLICATIONS BY THE BUYER NOR AS TO PERIOD OF SERVICE

UNLESS THE COMPANY SPECIFICALLY AGREES OTHERWISE IN

WRITING AFTER THE PROPOSED USAGE HAS BEEN MADE KNOWN TO

IT.

THE FOREGOING WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL

OTHER WARRANTIES EXPRESSED OR IMPLIED, INCLUDING, BUT NOT

LIMITED TO ANY WARRANTY OF MERCHANTABILITY OR OF FITNESS

FOR A PARTICULAR PURPOSE.

Power Supply

0 90-264 VAC

2 20-50 VAC/VDC

Additional outputs and options can be

field installed through plug-in boards

which can be ordered separately.

Description Part #

Relay Board T50-001

DC Linear Board T50-003

RS-485 Comm. Board T50-005

Printed in U.S.A.

702138-0002

March 1998

Revision none

12

1675 Delany Road

Gurnee, IL 60031–1282

Phone: 847.662.2666

Fax: 847.662.6633

Loading...

Loading...