Page 1

Introduction

Your Veeder-Root brand Series C342 panel instrument is powered by an external 12 - 24 VDC supply,

features an 6 digit LED display, and is housed in a ultra compact 1/32 DIN package.

This model has been configured at the factory to perform one of the following functions: Count

Totalizer, Position Indicator, Time Totalizer (Hours:Minutes:Seconds), Time Totalizer (Hours, 1/100

resolution), Tachometer or a PLC message display. There are also several programmable features that

let you select a sinking or sourcing input, a count input filtering speed, and whether or not to enable

the front panel reset.

The following pages of the manual will provide information on proper panel mounting of the device,

terminal layout and wiring instructions, directions on how to access and set the field programmable

features, as well as an overview of the basic operating functions of the unit. Also included are the key

product specification, warranty

procedures and ordering information

should you require additional units.

Models Covered in this Manual

C342-0464 Totalizer: Accumulates

and displays counted pulses. Total can

be reset via front panel button (may be

disabled) or remote reset terminals.

Model available with factory

programmed setting of Setpoint,

Prescale Value, and/or Decimal Position.

C342 -8562 Position Indicator: The

instrument will count in a bi-directional

mode based on the quadrature input from an

encoder. Display range is -99999 to 99999.

C342-1464 Time Totalizer: Accumulates

time in the format Hours:Minutes:Seconds.

Can be reset via front panel button (may be

disabled) or remote reset terminals. Model

available with factory programmed preset

output.

Features

•

Available models include count and time

totalization, rate metering, position

indication and a PLC message display

•

Bright 6 digit LED display provides easy to

read process values

•

Compact 1/32 DIN bezel and 60mm

behind the panel depth save panel space

•

Powered by 12 - 24 VDC, with nonvolitale

RAM for retention of process value and

settings

•

Field programmable for NPN or PNP

signals and for hi-speed (7.5 kHz) or low

speed (30 Hz) filtering

•

Factory programmable features: Setpoint,

Scale Value, Decimal Position, Text

Message

•

IEC IP65 rated front panel for use in

washdown environments

C342-2464 Time Totalizer:

Accumulates time in hours with 1/100

resolution. Can be reset via front panel

button (may be disabled) or remote reset

terminals. Model available with factory

programmed preset output.

C342-3464 Tachometer: Pulses are

sampled for a 6 second period then

displayed as a rate value in units per

minute. A Display Hold input can freeze

the current reading. Model available with

factory programmed setting of Setpoint,

and/or Decimal Position.

C342-4562 Message Display: The

instrument will display alpahumeric

messages based on a digital input from a

PLC Please refer to separate insruction

sheet which provides specific information

on how to interface to a PLC. Model

available with factory programmed Text

Message.

Index

Overview

Installation page 2

Terminal Connections page 2

Setup

Front Panel Operation page 3

Programming page 3

General

Specifications page 4

Ordering Information page 4

Warranty page 4

Technical Manual

702085-0001

Veeder-Root

Series C342

DC Powered

LED Display

brand

1

Page 2

OVERVIEW

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

INSTALLATION

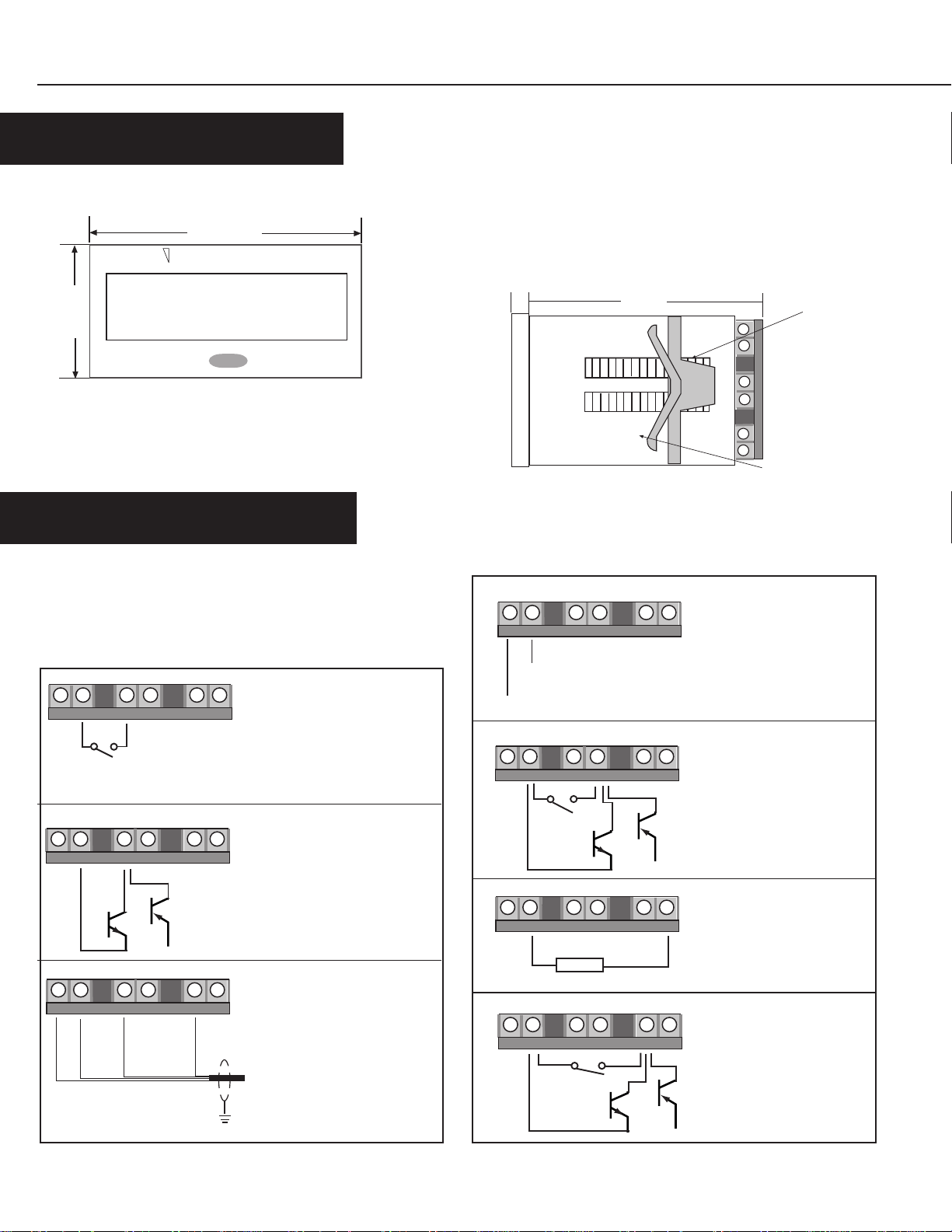

Dimensions

48 mm

VEEDER-ROOT

24

mm

123456

Recommended Panel Cutout: 22mm (±0.3mm) X 45mm (±0.6mm)

Panel Mounting

Make the recommended panel cutout. Place the included gasket

over the rear of the unit and place the unit in the panel cutout.

Slide the panel mount bracket into place over the unit's rear

allowing the bracket tabs to engage the grooves on the case.

Continue to push forward until the bracket arm fits snugly

against the panel.

8

mm

mm

60

Bracket Arm

Mounting

Grooves

REAR TERMINAL CONNECTIONS

Wiring

Insert wire into the appropriate openings as pictured in the drawing

below. Turn the screws, located on the rear of the terminal block to

tighten the clamp and secure the wire.

1 2 3 4 5 6 7 8

Contact

1 2 3 4 5 6 7 8

PNP

NPN

+

1 2 3 4 5 6 7 8

12 VDC

Common

Channel A

Note: Counting reletive to the encoder shaft

rotation can be reversed by swaping Channel A

and Channel B connections

Signal Input (from switch): Contact closure signals are accumulated for count and tachometer

versions. For timer versions the

timer runs when contact is closed.

See "Programming to select low

speed, NPN mode.

Signal Input (transistor): Signal pulses are accumulated for

count and tachometer versions.

For timer versions, timer runs

when signal is present. See

"Programming" for selection of

PNP or NPN signal

Quadrature Input (Encoder):

For bi-directional counting

connect corresponding encoder outputs to channel

A & B input terminals. The

Channel B

eccoder shield wire should be

connected to earth ground at

the counter.

– (Common)

+ (12 to 24 VDC)

Contact

–

10mA DC Maximum

Load

Contact

NPN

Power Wiring: Connect to 12

- 24 VDC (+20%/-10%) voltage source. Power requirement is 5 mA, Maximum

Remote Reset: the displayed

value will be reset. Signal input is ignored when the Reset

PNP

+

is active. For tachometer versions, this input is not used.

Solid State Output: When the

factory programmed preset

value is reached a PNP output

will be triggered. The output

+

will stay active until a reset

signal is received.

Gate Input: all incoming signals will be ingnored and the

present display value will be

held. For Position Indicator

versions, this input is not used.

NPN

PNP

+

2

Page 3

SETUP

OPERATION

VEEDER-ROOT

Front Panel Reset

On Time or Count models, used to

12345678

reset the Process Value Display.

May be disabled through the

keylock input. Also used to perform

Programming mode functions

Your C342 has been configured at the factory to perform one of the following functions:

C342-0562 Totalizer: The instrument will accumulate and display

the pulses received on the count input terminals (2 & 4). Count

capacity is 8 digits:

reset terminals (2 & 5) or the front panel.

C342 -8562 Position Indicator: The instrument will count in a bidirectional mode based on the quadrature input from an encoder

(terminals 2,5 & 7). Display range is -99999 to 99999.

C342-1562 Time Totalizer #1: The instrument will accumulate time

when the input signal (terminals 2 & 4) is active. The time will be

displayed in the format:

reset via the remote reset terminals (2 & 5) or the front panel.

123456

99:59:59

The total can be reset via the remote

Hours:Minutes:Seconds

123456

C342-2562 Time Totalizer #2: The instrument will accumulate time

when the input signal (terminals 2 & 4) are active. The time will be

displayed in hours with 1/100 resolution

reset via the remote input terminals (2 & 5) or the front panel.

C342-3562 Tachometer: Pulses received on the input terminals (2

& 3) are sampled for a 6 second period then displayed as a rate

value in units per minute:

(terminals 2 & 7) will freeze the current reading.

C342-4562 Message Display: The instrument will display

and can be

alpahumeric messages based on a digital input from a PLC Please

refer to separate insruction sheet which provides specific

information on how to interface to a PLC.

Process Value Display

Displays the count, time or rate

value based upon the model

999990

9999.99

A Display Hold function

and can be

PROGRAMMING

L0 NPN

L0 PNP

1

H1

loc

During Power-up

NPNH

PNP

Hold for 2 seconds

To access Input Configuration Parameters:

• Enter the Program Mode by holding the Front Panel Reset (FPR) key during power-up

• Scroll throuugh the 4 input configuration choices by brief press and release of the FPR key

• When the desired choice appears, hold down the the FRP key for seconds to select it

• Scroll between the two Front Panel Enable choices by brief press and release of the FPR key.

Hold the FPR key for 2 sconds to select the desired choice and return to Operating Mode

Note: The NPN/PNP selection applies to the Signal, Reset, and Hold inputs

Low Speed NPN Input: Configures the unit to accept a sinking or dry contact input and sets a filtering

speed of 30 Hz

Low Speed PNP Input: Configures the unit to accept a sourcing input and sets a filtering speed of 30 Hz

High Speed NPN Input: Configures the unit to accept a sinking or dry contact input of up to 7.5 kHz

Note: This choice will not appear for Time Totalizer models

High Speed PNP Input: Configures the unit to accept a sourcing input of up to 7.5 kHz

Front Panel Reset Locked: Pressing the front panel reset key during operation will not reset the

accumualted count/time value

unloc

Hold for 2 seconds to return to Operating Mode

Front Panel Reset Unlocked: Pressing the front panel reset key during operation will cause the

accumualted count/time value to be reset.

3

Page 4

SPECIFICATIONS

GENERAL

Count /Time Input:

Count Input: NPN or PNP Signal field selectable

Count Speed: 30 Hz or 7.5 kHz max

Logic: Low < 0.7 VDC, High > 5 VDC

Minimum Pulse Width: 70 µsecond

Maximum Input: 30 VDC

Quadrature Input (C342-8562 only):

Type: Line driver or square wave pulse (A leading B for up

counting)

Count Speed: 2 kHz

Physical:

Dimensions: 24mm x 48mm, 32mm deep

Mounting: Panel Mount (mounting bracket supplied)

22mm (+ 0.3mm) x 45mm (+ 0.6mm) panel cutout

Maximum Panel Thickness: 26mm

Connections: 6 screw terminals

Weight: Approximately 2.25 ounces

Front Panel Rating: IEC IP65

ORDERING INFORMATION

Part # Description

C342-0562 Count Totalizer

C342-0562-A As above with factory programmed value*

C342-1562 Timer (H:M:S)

C342-1562-A As above with factory programmed value*

C342-3464 Tachometer

WARRANTY

Reset Input:

Type: NPN Signal, Contact Closure

Minimum Pulse Width: 15 ms

Gate Input:

Type: NPN Signal, Contact Closure

Output: (C342-0562, C342-1562, C342-2562):

Type: PNP transistor

Voltage/Curent: Supply less 2 Volt drop, 10 mA max

Operation:

Power Supply: 12 - 24 VDC (+20%/-10%)

Power Consumption: <150 mA

Display Type: 6 digit LED

Display Height: 7.6 mm

Data Retention: Non volatile RAM > 10 years

Factory Programmable Settings: Setpoint, Prescale Value,

Decimal Position, Text Message

Operating Temperature: -10°C to 50°C

Storage Temperature: -20°C to 60°C

Approvals: CE Mark

Part # Description

C342-2562 Timer (Hundreths of Hours)

C342-2562-A As above with factory programmed value*

C342-3562 Tachometer

C342-4562 Message Display

C342-8562 Position Indicator

* Possible Factory Programmable Settings: Setpoint, Prescale

Value, Decimal Position, Text Message. Specifcy the setting

and value when placing an order. (Ex: Setpoint = 4567)

Standard products manufactured by the Company are warranted

to be free from defects in workmanship and material for a period

of one year from the date of shipment, and products which are

defective in workmanship or material will be repaired or replaced,

at the option of the Company, at no charge to the Buyer. Final

determination as to whether a product is actually defective rests

with the Company. The obligation of the Company hereunder

shall be limited solely to repair and replacement of products that

fall within the foregoing limitations, and shall be conditioned

upon receipt by the Company of written notice of any alleged

defects or deficiency promptly after discovery within the warranty

period, and in the case of components or units purchased by the

Company, the obligation of the Company shall not exceed the

settlement that the Company is able to obtain from the supplier

thereof. No products shall be returned to the Company without its

Printed in U.S.A.

#702085-0001

4

February 13, 1997

Revision none

prior consent. Products which the Company consents to have returned

shall be shipped F.O.B. the Company's factory. The Company cannot

assume responsibility or accept invoices for unauthorized repairs to its

components, even though defective. The life of the products of the

Company depends, to a large extent, upon the type of usage thereof,

and THE COMPANY MAKES NO WARRANTY AS TO FITNESS OF ITS

PRODUCTS FOR SPECIFIC APPLICATIONS BY THE BUYER NOR AS

TO PERIOD OF SERVICE UNLESS THE COMPANY SPECIFICALLY

AGREES OTHERWISE IN WRITING AFTER THE PROPOSED USAGE

HAS BEEN MADE KNOWN TO IT.

THE FOREGOING WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL

OTHER WARRANTIES EXPRESSED OR IMPLIED, INCLUDING, BUT

NOT LIMITED TO ANY WARRANTY OF MERCHANTABILITY OR OF

FITNESS FOR A PARTICULAR PURPOSE.

Danaher Controls

1675 N. Delany Road

Gurnee, IL 60031–1282

Phone: 847.662.2666

Fax: 847.662.6633

Loading...

Loading...