Page 1

T^

VEEDER-ROOT

INSTALLATION,

OPERATION

AND

SERVICE

INSTRUCTIONS

SERIES

7886

HIGH-CAPACITY

&

SERIES

7887

METER

REGISTERS

Manual

No.

251325

(REV.

B)

Technical

Manual

8-014

Issued:

12/95

Supersedes

:

5/93

VEEDER-ROOT

Petroleum

Products

Page 2

Installation,

Operation

and

Service

Manual

Series

7886

High-Capacity

&

7887

Meter

Registers

TABLE

OF

CONTENTS

SECTION

1.

INTRODUCTION

A.

General

1

SECTION

2.

SERIES

7887

DESCRIPTION

A.

General

1

B.

Specifications

2

SECTION

3.

SERIES

7886

DESCRIPTION

A.

General

3

B.

Specifications

3

SECTION

4.

PERIODIC

INSPECTION

A.

General

5

B.

Disassembly

Prior

to

Cleaning

5

C.

Cleaning

5

D.

Inspection

5

E.

Lubrication

5

F.

Troubleshooting

7

SECTION

5.

DISASSEMBLY

AND

ASSEMBLY

A.

General

8

B.

Removal

of

Major

Groups

8

C.

Individual

Parts

Replacement

10

D.

Installation

of

Major

Groups

10

E.

Final

Checks

and

Adjustments

15

F.

Operational

Check

16

SECTION

6.

DAMAGE

CLAIMS

AND

WARRANTY

A.

Damage

Claims

16

B.

Return

Shipping

16

C.

Warranty

and

Conditions

16

Page 3

Installation,

Operation

and

Service

Manual

Series

7886

High-Capacity

&

7887

Meter

Registers

SECTION

1.

INTRODUCTION

A.

GENERAL.

These

instructions

are

for

servicing

the

Series

7886

High-Capacity

and

Series

7887

Meter

Registers

designed

and

manufactured

by

the

Veeder-Root

Company,

6th

Avenue

at

Burns

Crossing.

P.O.

Box

1673,

Altoona,

PA

16603.

Phone:

(814)

695-4476.

When a vertical

bar | appears

adjacent

to

text

or

illus

trations,

information

has

been

added

or

changed

at

the

last

issue date.

Note:

Consult

Veeder-Root

on

any

unusual

application,

installation

or

possible

modification

of

this

basic

design.

Every

Meter

Register

is

thoroughly

tested

at

the

Veeder-Root

factory

and

by

the

meter

manufacturer

when

installed

on

the

meter.

However,

like

any

precision

mechanism,

it

requires

periodic

care

to

ensure

maximum

service.

This

manual

is

for

use

in

areas

where

factory

rebuilding

facilities

and

adequate

exchange

stocks

are

not

readily

accessible.

Where

manufacturer's

replacement

stocks

are

available,

it

is

important

that

no

attempt

be

made

to

repair

any

meter

register

defective

within

the

terms

of

the

warranty

as

by

doing

so,

the

warranty

is

void

and

the

user

is

deprived

of

the

protection

provided

by

the

warranty.

It

is

recommended

that,

when

possible,

meter

registers

be

replaced

and

the

defective

unit

returned

to

the

meter

manufacturer.

Note:

See

Section 6 for

complete

Damage

Claims

and

Warranty.

IMPORTANT!

The

instructions,

photographs

and

drawings

in

Sec

tions 4 and 5 are

based

on

the

Series

7887

Meter

Register.

With

the

exception

of

an

additional

count

ing

wheel,

the

Series

7886

High-Capacity

Meter

Register

is

physically

similar

and

the

same

proce

dures

should

be

followed.

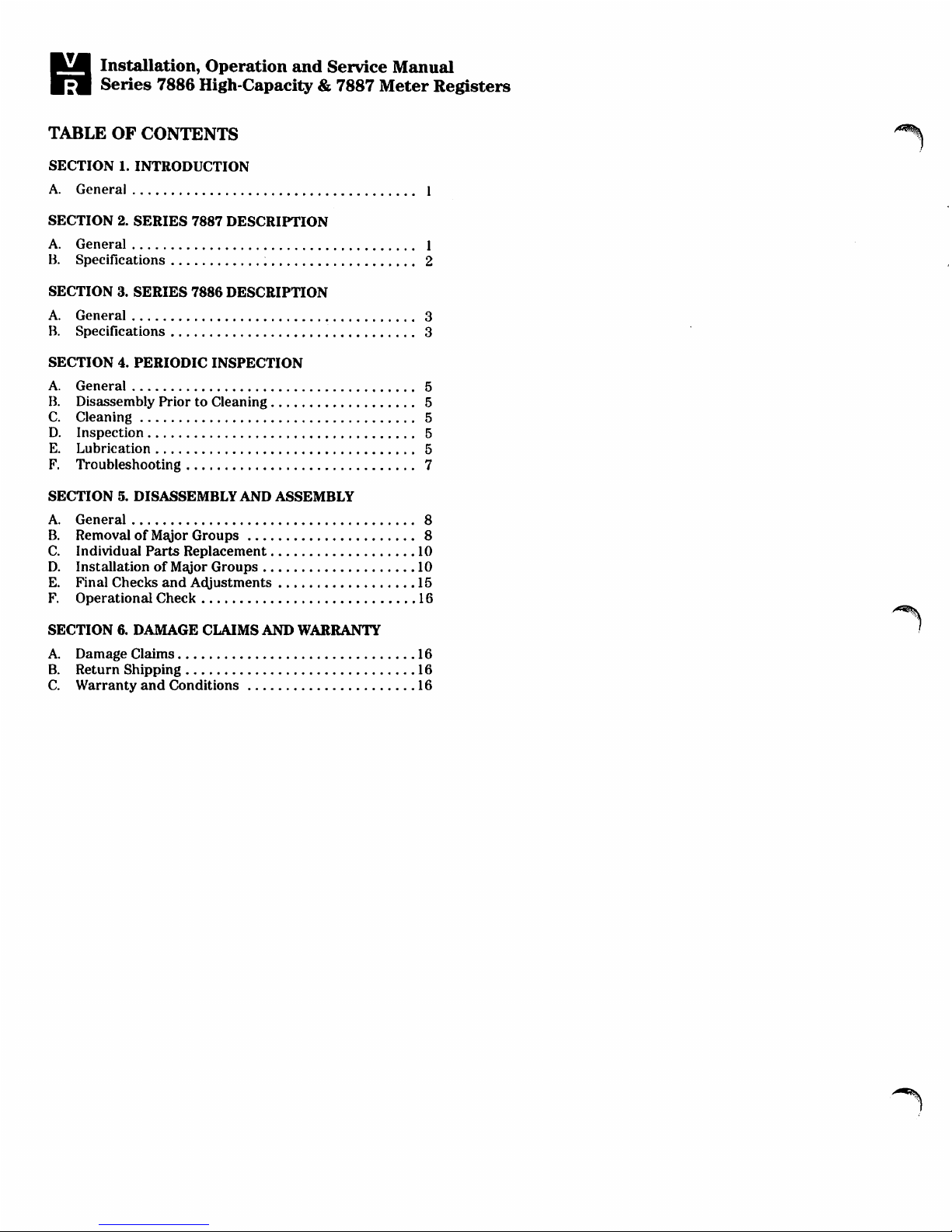

Figure

1.

External

View

of

Series

7887

Meter

Register.

SECTION

2.

SERIES

7887

DESCRIPTION

A.

GENERAL.

1.

Physical.

The

Series

7887

Meter

Register,

Figure

1,

displays

a

running

account,

final

total

and

accumulated

total

of

the

quantity

of

liquid

product

delivery.

Contained

in

a4"x

10"

diecast

enclosure,

individual

delivery

data

is

displayed

on

five

3/4"

high

figures

while

totalizer

information

is

recorded

on

eight 1 /8"

high

figures.

Reset

of

the

Meter

Register

is

accomplished

through a reset

knob

on

the

right-hand

side

of

the

unit.

2.

Operational.

The

Meter

Register

is

operated

by a drive

shaft

connected

to a group

of

gears

on

the

gear

plate

which

converts

the

drive

revolutions

to

the

appropriate

ratio.

The

output

bevel

gear of the

group

drives a bevel

gear,

Figure

5,

which

is

connected

to

the

drive shaft

and

clutch

assembly.

In

rotating,

this

shaft

drives a gear

on

the

clutch

assembly

which

in

turn

drives a gear

on

the

right

(unit)

wheel

assembly.

Revolutions

are

then

accumulated

on

the

wheels.

In

addition,

this

rotating

shaft

drives

the

bracket

group

connected

to

the

accumulative

totalizer

shaft,

thus

both

displays

are

driven

from

the

same

source,

assuring

accurate

recording

of

information.

During

the

reset

operation,

the

clutch

is

disconnected

from

the

drive

shaft, a shutter

moves

into

place

covering

the

display

wheels

and

reset

fingers

engage

heart-shaped

cams

on

the

individual

wheels

to

move

them

back

to a zero

position.

In

addition, a set

of

anti-topping

fingers

engages

the

wheels

to

prevent

jamming.

At

the

completion

of

reset,

the

display

wheels

will

read

all

zeros,

and

the shutter

will

rise

to

the

normal

operating

position.

The

clutch

will

engage

the

drive

shaft

to

transfer

the

information

from

the

next

delivery.

The

totalizer

wheels

will

be

unaffected

by

this

reset

operation,

thus

displaying

an

accurate

measure

of

the

accumulated

totals

of

many

deliveries.

1

Page 4

Installation,

Operation

and

Service

Manual

Series

7886

High-Capacity

&

7887

Meter

Registers

B.

SPECIFICATIONS.

Specifications

listed

are

standard

unless

otherwise

noted.

Optional

features

are

available

at

additional

cost.

Speed:

250

rpm.

Torque:

Average

running

torque

at

room

temperature

with

1:1

input: 4 oz-in.

During

display

wheel

transfer

from

all

9's

to

all

0's,

the

instantaneous

peak

torque

may

reach

40

oz-in.

Operating

Temperature

Range:

40°

to

+71°C

(-40°

to

+

160°F).

Number

of

Figures:

Meter

Register:

5.

Accumulative

Totalizer:

8

Size

of

Figures:

Meter

Register:

0.750"

high x 0.400"

wide

(19.05 x 10.16

mm).

Totalizer:

0.125"

high x 0.078"

wide

(3.175 x 1.98

mm).

Color

of

Figures:

White

on

black,

except

right-hand

totalizer

wheel

which

is

black

on

white

when

recording

tenths

of

units,

and

white

on

black

when

recording

whole

units.

Style

of

Figures:

Veeder-Root/Cornell

for

optimum

read

ability.

Character

Configuration:

0

to 9 (options

available).

Reset:

Single

handle

on

register.

Designed

for

one-handed

operation.

Mounting:

Eight 1 /4 x 28

tapped

holes

with

steel

inserts

on

a

6.625"

(168.28

mm)

diameter.

Special

adaptors

are

available

for

nearly

all

meters.

Construction:

Cover:

cast

aluminum.

Case

and

sub

frame:

cast

Zamak.

Wheels,

pinions,

and

clutch:

acetal

resin.

Gearing:

1:1

is

standard.

1:1

through

42:1

are

available.

Lubrication:

Periodic.

OPTIONS

Nonreset

Pulser:

Meter

Register

with

Series

1871

or

7671

Pulse

Transmitter.

k

\

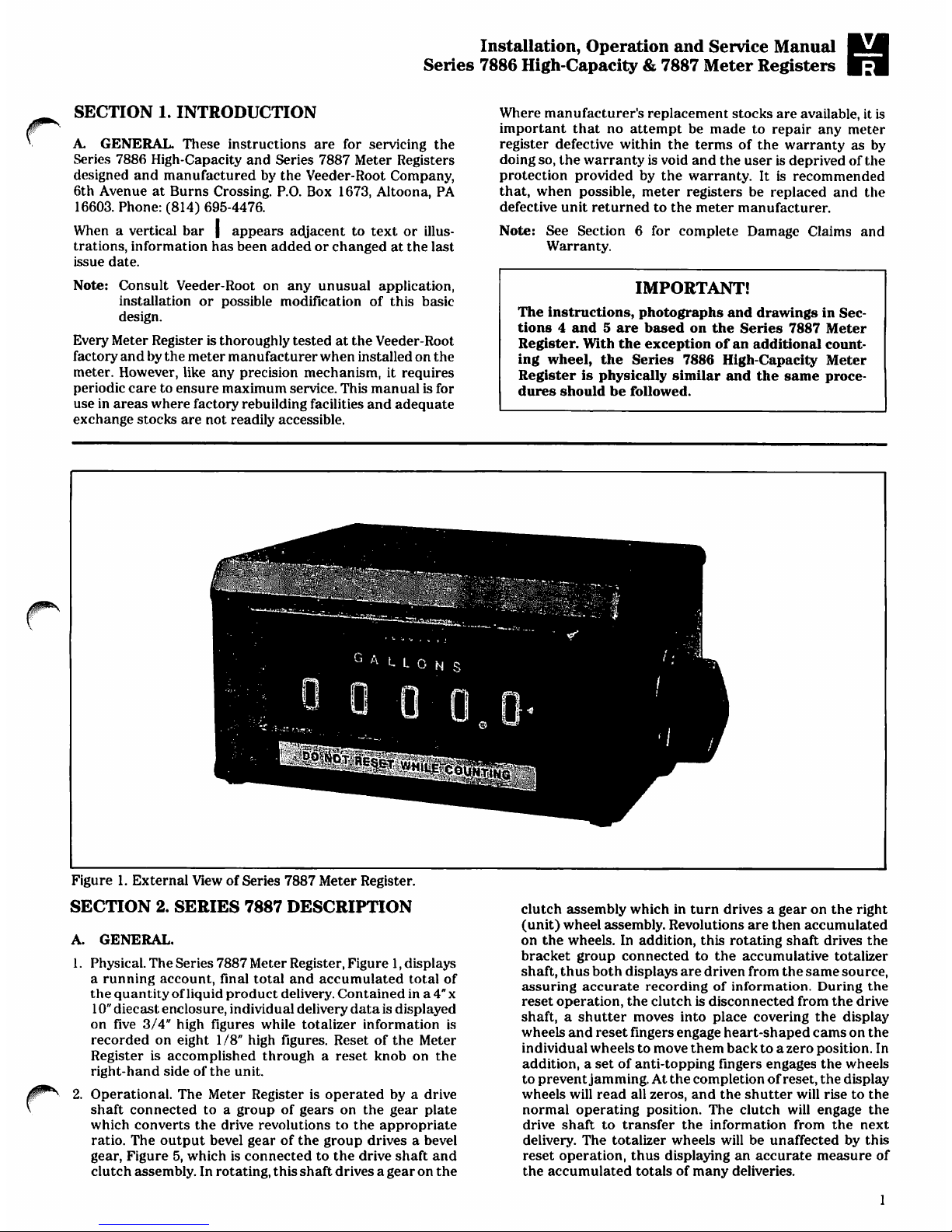

188.925mm

7.438"

Dia.

0.250-28

UNF

2B

8

holes equally

spaced

Studs

must

not

enter

tapped

holes

more

than

7.938mm

(0.312").

168.275mm

6.625"

Dia.

Dimension

Identification

Mounting

Dimensions

214.934mm

-8.462"-

130.429mm

5.

35"

15.88mm + 0.508

0.625"

±0.020

127.863mm

-"

5.034

H

173.126mm

—

6.816

290.525mm

—11.438"

—

56.769mm

2.235"

54.965mm

2.164"

139.7mm

5.5OO"-*

3.175mm

0.125"

Figure

2.

Mounting

Dimensions — Series

7887

Meter

Register.

2

Page 5

Installation,

Operation

and

Service

Manual

Series

7886

High-Capacity

&

7887

Meter

Registers

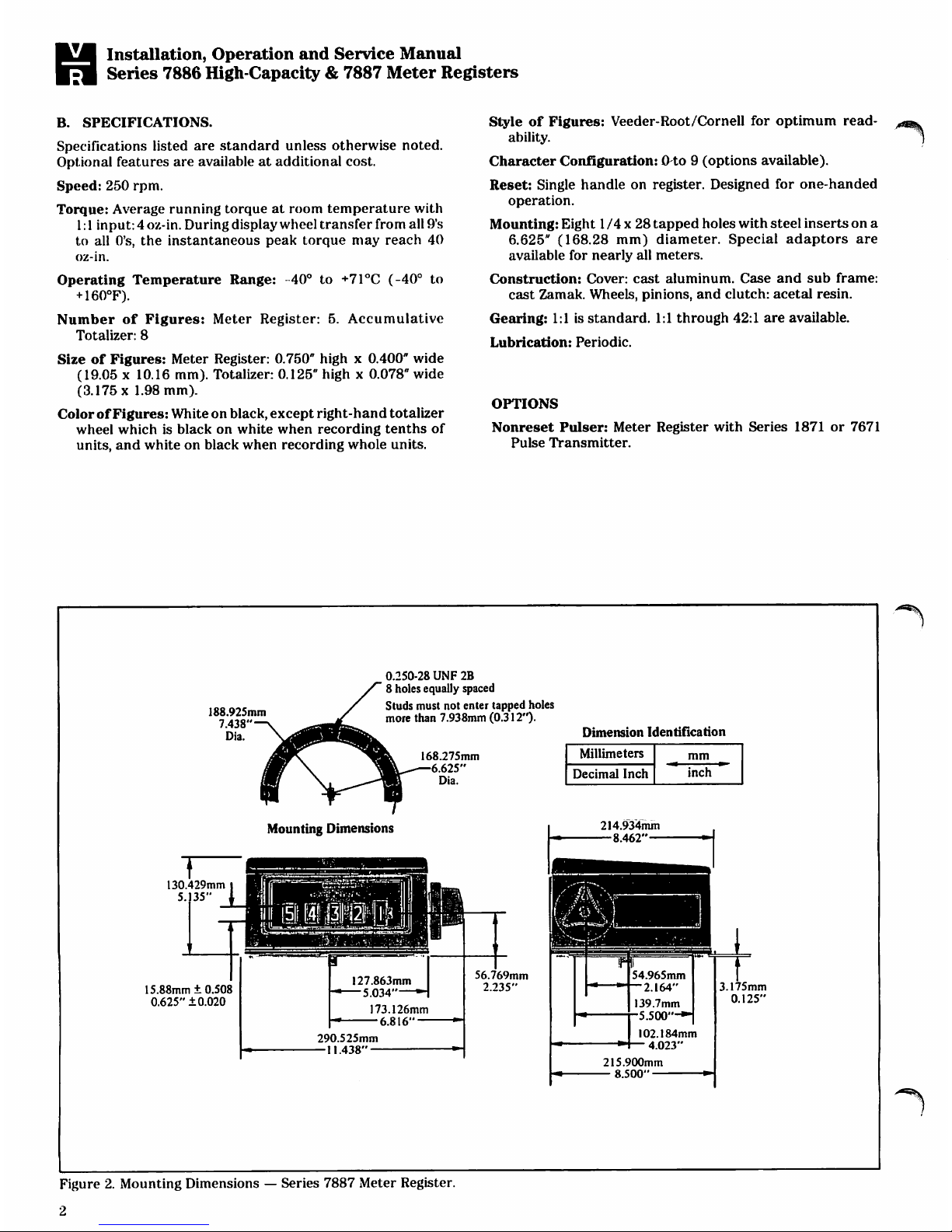

Figure

3.

External

View

of

Series

7886

High-Capacity

Meter

Register.

SECTION

3.

SERIES

7886

DESCRIPTION

A.

GENERAL.

1.

Physical.

The

Series

7886

High-Capacity

Meter

Register,

Figure

3,

displays a running

account,

final

total

and

accumulated

total

of

the

quantity

of

liquid

product

delivery.

Contained

in a 4" x 10"

diecast

enclosure,

individual

delivery

data

is

displayed

on

six

5/8"

high

figures

while

totalizer

information

is

recorded

on

eight

1/8"

high

figures.

Reset

of

the

Meter

Register

is

accom

plished

through a reset

knob

on

the

right-hand

side

of

the

unit.

2.

Operational.

The

Meter

Register

is

operated

by a drive

shaft

connected

to a group

of

gears

on

the

gear

plate

which

converts

the

drive

revolutions

to

the

appropriate

ratio.

The

output

bevel

gear

of

the

group

drives a bevel

gear,

Figure

5,

which

is

connected

to

the

drive shaft

and

clutch

assembly.

In

rotating,

this

shaft

drives

agear

on

the

clutch

assembly

which

in

turn

drives a gear

on

the

right

(unit)

wheel

assembly.

Revolutions

are

then

accumulated

on

the

wheels.

In

addition,

this

rotating

shaft

also

drives

the

bracket

group

connected

to

the

accumulative

totalizer

shaft,

thus both

displays

are driven

from

the

same

source,

assuring

accurate

recording

of

information.

During

the

reset

operation,

the

clutch

is

disconnected

from

the

drive

shaft, a shutter

moves

into

place

covering

the

display

wheels

and

reset

fingers

engage

heart-shaped

cams

on

the

individual

wheels

to

move

them

back

to a zero

position.

In

addition,

a

set

of

anti-topping

fingers

engages

the

wheels

to

prevent

jamming.

At

the

completion

of

reset,

the

display

wheels

will

read

all

zeros,

and

the

shutter

will

rise

to

the

normal

operating

position.

The

clutch

will

engage

the

drive

shaft

to

transfer

the

information

from

the

next

delivery.

The

totalizer

wheels

will

be

unaffected

by

this

reset

operation,

thus

displaying

an

accurate

measure

of

the

accumulated

totals

of

many

deliveries.

B.

SPECIFICATIONS.

Specifications

listed

are

standard

unless

otherwise

noted.

Optional

features

are

available

at

additional

cost.

Speed:

250 rpm.

Torque:

Average

running

torque

at

room

temperature

with

1:1

input: 4 oz-in.

During

display

wheel

transfer

from

all

9's

to

all

0's,

the

instantaneous

peak

torque

may

reach

40

oz-in.

Operating

Temperature

Range:

-40°

to

+71°C

(-40°

to

+

160°F).

Number

of

Figures:

Meter

Register:

6.

Accumulative

Totalizer:

8

Size

of

Figures:

Meter

Register:

0.625"

high x 0.300"

wide

(15.87 x 7.62

mm).

Totalizer:

0.125"

high x 0.078"

wide

(3.175x1.98

mm).

Color

of

Figures:

White

on

black,

except

right-hand

totalizer

wheel

which

is

black

on

white

when

recording tenths

of

units,

and

white

on

black

when

recording

whole

units.

Style

of

Figures:

Veeder-Root/Cornell

for

optimum

read

ability.

Character

Configuration:

0

to 9 (options

available).

Reset:

Single

handle

on

register.

Designed

for

one-handed

operation.

Mounting:

Eight

1/4 x 28

tapped

holes

with

steel

inserts

on

a

6.625"

(168.28

mm)

diameter.

Special

adaptors

are

available

for

nearly

all

meters.

Construction:

Cover:

cast

aluminum.

Case

and

sub

frame:

cast

Zamak.

Wheels,

pinions,

and

clutch:

acetal

resin.

Gearing:

1:1

is

standard.

1:1

through

42:1

are

available.

Lubrication:

Periodic.

OPTIONS

Nonreset

Pulser:

Meter

Register

with

Series

1871

or

7671

Pulse

Transmitter.

Page 6

Installation,

Operation

and

Service

Manual

Series

7886

High-Capacity

&

7887

Meter

Registers

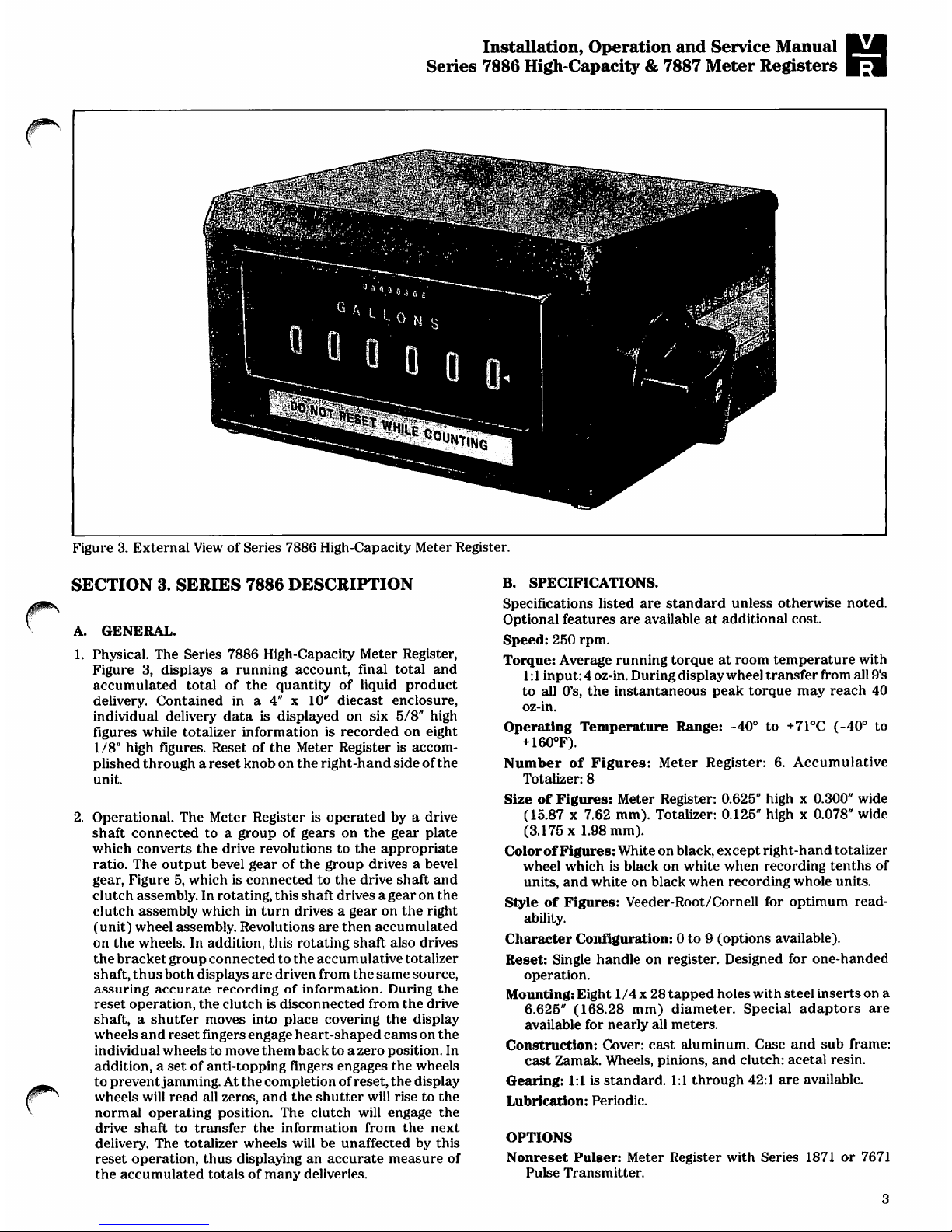

188.925mm

7.438"

Dia.

0.250-28

UNF

2B

8

holes

equally

spaced

Studs

must

not

enter

tapped

holes

more

than

7.938mm

(0.312").

168.275mm

6.625"

Dia.

Mounting

Dimensions

130.429mm

15.88mm

±0.508

0.625"

+0.020

127.863mm

5.034

H

173.126mm

—

6.816

290.525mm

—11.438"

—

56.769mm

2.235"

Dimension

Identification

214.934mm

-8.462"-

54.965mm

2.164"

139.7mm

5.500"-*

3.175mm

0.125"

Figure

4.

Mounting

Dimensions — Series

7886

High-Capacity

Meter

Register.

Bracket-

Croup

Anli-Toppin.

Finger

Unit

Wheel

Shut

tor

Detent

Spring

lutch

Spring

Reset

Spring

Figure

5.

Internal

View

of

Series

7887

Meter

Register

(Series

7886

High-Capacity

Meter

Register

is

similar).

4

Page 7

Installation,

Operation

and

Service

Manual

Series

7886

High-Capacity

&

7887

Meter

Registers

SECTION

4.

PERIODIC

INSPECTION

(For

Series

7886

High-Capacity

and

Series

7887

Meter

Registers)

A.

GENERAL.

The

Meter

Register

is

fully

lubricated

and

properly

adjusted

at

manufacture.

However,

periodic

clean

ing

and

lubrication

are

required.

Judgement

of

the

intervals

at

which

the

meter

register

requires

such

service

must

necessarily

be

left

to

the

individual

user

due

to

varying

conditions

of

service.

Under

normal

conditions,

this

will

be

at

least

once a year,

or

after

each

2-1/2

million

units

of

measure

delivered,

whichever

comes

first.

B.

DISASSEMBLY

PRIOR

TO

CLEANING.

Remove

the

meter

register

from

its

housing

as

follows:

1.

Remove

the

bolts

securing

the

cover

(if

present)

to

the

top

of

the

housing.

These

bolts

are

hex

head

and

are

located

at

the

four

corners

of

the

bottom

of

the

housing.

Remove

the

cover.

2.

Remove

the

three

button-head

bolts

securing

the

meter

register

to

the

housing.

Remove

the

meter

register.

3.

Remove

the

screws

securing

the

gear

plate

to

the

bottom

of

the

housing.

Remove

the

gear

plate.

C.

CLEANING.

CAUTION:

DO

NOT

USE A WIRE

BRUSH.

1.

Wipe

bezel

crystal

with a clean

lint-free

rag.

2.

If

the

wheel

faces

are

dirty,

gently

clean

with a clean

lint-free

rag

dipped

in

mild

soapy

water.

3.

Clean

the

gears

on

the

base

plate

by

flushing

or

with

a

brush

dipped

in

solvent.

Blow

dry

with

compressed

air.

4.

Clean

housing

by

dipping, flushing

or

brushing

with

solvent.

Blow

dry

with

compressed

air.

D.

INSPECTION. A periodic

inspection

of

the

entire

meter

register,

housing

and

gear

plate

is

required

to

make

sure

that

they

function

properly,

parts

are

in

place,

and

no

binding

or

excessive

side-to-side

motion

of

shafts

occurs. A checklist

on

such

procedures

follows:

1.

Check

the

following

shafts

for

perceptible

side-to-side

motion.

Note:

Remove

the

meter

register

from

the

housing

before

checking

shaft

freedom.

a.

Wheel

Shaft

b.

Anti-Topping

Finger

Group

Shaft

c.

Reset

Finger

Group

Shaft

d.

Clutch

Group

Shaft

e.

Pinion

Shaft

2.

Temporarily

install

the

base

plate

and

meter

register

in

the

housing

and

check

for

proper

engagement

and

freedom

of

movement

of:

a.

All

gears

on

gear

plate.

b.

Output

bevel

gear

on

gear

plate

with

the

bevel

drive

gear

on

drive

shaft.

c.

57

tooth

gear

on

clutch

assembly

with

gear

on

right

wheel

assembly.

d.

Gear

drive

shaft

with gear

train

that

operates

the

totalizer,

and

gear

connecting

the

drive

train

to

the

totalizer.

3.

Rotate

drive

shaft

by

hand

to

see

that

unit

operates

freely

and

then

reset,

checking

for

proper

reset

and

shutter

action.

Adjust

pointer

after

reset

as

required.

4.

Check

all

screws,

retaining

rings

and

groove

pins

to

see

that

they

are

tight

and

seated

properly.

E.

LUBRICATION.

I.

Recommended

Lubricants

Note:

Chemlube

and

VTschem

products

are

manufactured

by

Ultrachem

Inc.,

1400

N.

Walnut

St.,

P.O.

Box

2053

Wilmington,

DE

19899

Oil:

Chemlube

201

or

equivalent

with a temperature

range

of

-65°F

to

+275°F

(-54°C

to

+135°C).

Grease:

Vischem

352

or

equivalent

with a temperature

range

of

-65°F

to

+300°F

(-54°C

to

+149°C).

Note:

All

lubricants

used

in

the

register

must

be of a type

which

remains

fluid

over

the

full

temperature

range

to

which

the

register

will

be

subjected.

Also,

they

should

not

oxidize

or

dry

out

leaving a gummy

or

perceptible

residue.

If

the

Chemlube

201

oil

lubricant

is

not

available,

a

substitute

with

equivalent

properties

may

be

used.

To

assist

field

personnel

in

obtaining

suitable

lubricants

for

the

meter

register

and

ticket

printers,

the

following

list

showing

equi

valent

lubricants

has

been

prepared:

OIL

AEROSHELL

FLUID

REGENT

SPINTEX

OIL

GARGOYLE

ARCTIC

OIL

CASTROL

HYSPIN

ANDEROL

AEROSHELL

ESSO

BEACON

ANDEROL

2.

Points

to

Lubricate

GREASE

NO.

3

60

LIGHT

40

401D

14

325

795

Oil:

All

points

indicated

as

"Oil"

on

Figure 6

should

be

lubricated

with

oil

as

described

above.

This

includes

all

shafts,

studs,

and

bosses

on

which a moving

part

bears.

Grease:

Grease

should

be

applied

to

all

points

indicated

as

"Grease"

on

Figure

6.

This

includes

gears

and

the

no-back

ratchet

and

pinion.

Note:

The

oil

and

grease

should

be

applied

with a small

brush

to

make

certain

that

all

areas

will

be

properly

lubricated.

In

this

manner,

the

amount

of

lubricant

being

used

will

be

more

easily

controlled.

Page 8

iM

Installation,

Operation

and

Service

Manual

JJ

Series

7886

High-Capacity

&

7887

Meter

Registers

s/s/s//////////////////

//////. 7 '///

SECTION

Y-Y

WITH

BEZEL

REMOVED

W

Grease

Grease Grease

Gre?se

Y^

/Oil

Oil

Oil

CLUTCH

SHAFT

VIEW

Oil

Oil Oil

ANTI-TOPPING

FINGER

SHAFT

VIEW

Grease

Oil

VIEW

V-V

PARTIAL

VIEW

Z-Z

Grease

Oil

Grease

SECTION

W-W

Oil'

PINION

SHAFT

VIEW

Oil

11

Oil

^Grease

Oil

Oil

RESET

FINGER

SHAFT

VIEW

Oil

"Grease

OH

P

Grease

Grease 5 Places

"

WHEEL

SHAFT

VIEW

Figure

6.

Lubrication

Points.

Page 9

Installation,

Operation

and

Service

Manual

Series

7886

High-Capacity

&

7887

Meter

Registers

F.

TROUBLESHOOTING.

Table 1 is

used

to

assist

in

locating

problems

and making

repairs

and

corrections.

In

some

problems,

similar

defects

can

be

produced

by

several

causes

of

an

entirely

different

nature.

Cause

of

the

trouble

must

be

determined

and

the

correction

made.

Table

1.

Troubleshooting

Page 10

Installation,

Operation

and

Service

Manual

Series

7886

High-Capacity

&

7887

Meter

Registers

SECTION

5.

DISASSEMBLY

AND

ASSEMBLY

(For

Series

7886

High-Capacity

and

Series

7887

Meter

Registers)

A.

GENERAL.

When

disassembling

the

meter

register,

be

extremely

careful

not

to lose

or

intermix

any

of

the

washers

found on

the

shafts.

By

doing

so,

potential

problems

with

end-play

and

backlash

adjustments

will

be

greatly

lessened.

When

removing

retaining

rings

or

other

parts

from

shafts,

do

not

hold

the

shaft

with

any

tool

that

might

gouge

or

create

burrs

on

the

shaft.

B.

REMOVAL

OF

MAJOR

GROUPS.

Instructions

for

removal

of

all

shaft

groups

are

provided.

1.

If

present,

remove

the

retaining

ring

securing

the

reset

idler

gear

to

the

reset

idler

gear

shaft.

2.

Remove

retaining

rings

and

washers

securing

the

pinion,

reset,

anti-topping

and

clutch

shafts

to

the

right-hand

side

plate

(Figure

7).

Remove

screws

and

lockwasher

securing

the

totalizer

group

and

rear

mounting

bar

from

right-hand

side

plate.

3.

Remove

side

plate.

CAUTION:

DO

NOT

LOSE

OR

INTERMIX

WASHERS FROM

EACH

SHAFT.

Note:

Remove

only

those

shaft

groups

necessary

to

gain

access

to

parts

being

replaced.

^\

Accumulative

Totalizer

Group

Retaining

Screw

Pinion

Shaft

Stop

Shaft

Anti-Topping

Finger

Shaft

Clutch

Shaft

Rear

Mounting

Bar

Retaining

Screw

Reset

Shaft

Figure

7.

Right-Hand

Side

Plate.

Figure

8.

Left-Hand

Side

Plate.

8

Page 11

Installation,

Operation

and

Service

Manual

Series

7886

High-Capacity

&

7887

Meter

Registers

|-

4.

Clutch

Shaft

Group

Removal.

a.

Remove

retaining

ring

and

washers

securing

the

clutch

shaft

group

to

the

left-hand

side

plate.

See

Figure

8.

b.

Move

clutch

lever

group

so

clutch

is

free.

See

Figure

9.

Remove

clutch

shaft

group.

See

Paragraph

C, 1 for

parts

replacement.

5.

Reset

Finger

Group

Removal.

a.

Remove

retaining

ring

and

washer

securing

the

reset

group

to

the

left-hand

side

plate.

See

Figure

8.

b.

Disengage

the

reset

fingers

and

no-back

pawl

from

the

wheels.

See

Figure

10.

Remove

the

group.

See

Paragraph

C, 2 for

parts

replacement.

6.

Stop

Shaft

Removal.

a.

Remove

the

springs

from

between

the

anti-topping

fingers

and

the stop

shaft.

b.

Remove

the

spring

from

between

the

detent

lever

group

and

the

stop

shaft.

c.

Remove

the

stop

shaft.

7.

Anti-Topping

Finger

Group

Removal.

a.

Remove

the

retaining

ring

and

washers

securing

the

anti-topping

finger

group

shaft

to

the

left-hand

side

plate.

See

Figure

8.

b.

Disengage

the

anti-topping

fingers

and

the

clutch

lever

group

from

the

wheels.

See

Figure

11.

c.

Remove

the

group

from

the

side

plate.

See

Paragraph

C,

3

for

parts

replacement,

8.

Totalizer

Group

Removal.

a.

Remove

the

screws

securing

the

totalizer

group

to

the

left-hand

and

right-hand

side

plates.

See

Figures 7 and

8.

b.

Remove

the

totalizer

group.

c.

No

additional

disassembly

of

the

totalizer

is

possible.

If

the

totalizer

is

inoperable,

replace

the

group.

j^

Note:

If

the

inoperable

totalizer

has a small

bevel

gear

(approx.

11/32

inch

dia.)

on

the

drive

shaft,

replace

the

bracket

group on

the

leftside

frame

as

well

as

the

totalizer

group

(see

Figure

31

and

Paragraph

D, 7 and

E,

5).

Remove

the

screw

holding

the

pointer

onto

the

old

totalizer

and

save

for

installation

on

new

totalizer.

9.

Pinion

Removal.

a.

Remove

retaining

ring

securing

pinion

shaft

to

the

left-

hand

side

plate.

See

Figure

8.

b.

Rotate

the

detent

lever

group

so

it

will

clear

the

reset

cam.

Remove

shaft.

c.

Remove

pinions,

detent

lever

group

washers

and

re

taining

rings

from

shaft.

10.

Wheel

Group

Removal.

a.

Mark

relationship

of

reset

gear

to

wheel

group

shaft

to

assure

proper

positioning

during

assembly.

b.

Remove

pin

securing

reset

gear

to

the

wheel

group

shaft.

c.

Remove

gear,

retaining

ring

and

washer.

Remove

shaft.

See

Paragraph

C, 4 for

parts

replacement.

Figure

10.

Reset

Finger

Group

Removal.

Figure

9.

Clutch

Group

Removal

Figure

11.

Anti-Topping

Finger

Group

Removal.

Page 12

Installation,

Operation

and

Service

Manual

Series

7886

High-Capacily

&

7887

Meter

Registers

C.

INDIVIDUAL

PARTS

REPLACEMENT

1.

Clutch

Shaft

Parts

Replacement.

See

Figure

12.

a.

Totalizer

and

Drive

Bevel

Gears.

(1)

Drift

out

pin

securing

gear

to

shaft.

(2)

Remove

gear.

(3)

Remove

retaining

rings

and

washers

that

position

drive

gear.

Do

not

change

the

order

of

the

rings

and

washers.

(4)

Drift

out

pin

holding

drive

gear

and

remove

gear.

(5)

Install

new

gear,

pin,

retaining

rings

and

washers.

Use

new

pin

if

required.

(6)

Install

totalizer

bevel

gear

and

secure

with

pin.

CAUTION:

CHECK

SHAFT

FOR

STRAIGHTNESS

AFTER

PINNING. A BENT

SHAFT

WILL

CAUSE

BINDING

DURING

DRIVING

OF

METER

REGISTER.

CLUTCH

MUST NOT

BE

DISASSEMBLED

OR

REPLACED

AS

AN

INDIVIDUAL

GROUP.

IF

CLUTCH

IS

BROKEN

OR

MALFUNCTIONS,

REPLACE

COMPLETE

SHAFT

AND

CLUTCH

AS

AN

ASSEMBLY.

2.

Reset

Finger

Group

Parts

Replacement.

See

Figure

13.

Individual

reset

fingers,

reset

arm,

no-back

pawl

and

pawl

spring

may

be

replaced

as

required.

a

Remove

retaining

rings

and

appropriate

washer

to

reach

particular

part.

b.

Replace

defective

items

with

new

part.

Assemble

remaining

parts

on

shaft.

Install

retaining

rings

and

washers.

Check

end

play

per

Figure

28.

3.

Anti-Topping

Finger

Group

Parts

Replacement.

See

Figure

14.

Individual

anti-topping

fingers,

reset

lever

and

clutch

lever

may

be

replaced

as

required.

a.

Remove

retaining

rings,

washers

and

parts

as

required

to

get

to

part

that

is

to

be

replaced.

b.

Install

parts,

retaining

rings

and

washers

in

the

se

quence

shown

in

Figure

14.

Be

sure

to

install

parts

so

they

are

in

the

proper

direction.

Check

end

play

per

Figure

28.

4.

Wheel

Group

Parts

Replacement.

See

Figures

15,

16,

17

and

18.

The

reset

cam,

individual

wheels,

locking

discs

and

eccentrics

may

be

replaced

as

required.

a.

Remove

retaining

rings,

washers

and

key

as

required

to

remove

reset

cam,

wheels,

locking

discs

and

eccentrics.

b.

Install

parts,

retaining

rings,

washers

and

key

in

the

sequence

shown

in

Figure

17.

When

installing

wheels,

be

sure

the

pin

on

the

locking

disc

engages

the

groove

in

the

wheel

as

shown

in

Figure

18.

Check

end

play

per

Figure

28.

D.

INSTALLATION

OF

MAJOR

GROUPS

Prior to

installing

each

shaft,

lubricate

per

Paragraph E in

Section

4.

During

assembly,

do

not

intermix

washers

from

one

shaft

to

another.

1.

Wheel

Group

Installation.

a.

If

not

present,

install

a

0.030

inch

thick

washer

over

the

end

of

the

wheel

group

shaft

opposite

the

cam.

b.

Install

the

shaft

into

the

proper

hole

in

the

left-hand

side

plate.

See

Figure

8.

2.

Anti-Topping

Finger

Group

Installation.

See

Figure

19.

a.

Hold

wheel

and

side

plate

assembly

upside

down.

b.

Install

anti-topping

finger

group

in

proper

hole

in

left-

hand

side

plate

(see

Figure

8).

Be

sure

all

fingers

and

clutch

lever

are

free

of

wheels

and

the

pin

on

the

reset

lever

engages

the

track

on

the

cam.

•Clutch

Drive

Gear

Retaining

Rings

and

Washers

Pin

Bevel

Gear

Figure

12.

Clutch

Shaft

Group.

\

Figure

13.

Reset

Finger

Group.

Figure

14.

Anti-Topping

Finger

Group.

10

Page 13

Installation,

Operation

and

Service

Manual

Series

7886

High-Capacity

&

7887

Meter

Registers

|?

c.

Seat

the

shaft,

install

washers

and

retaining

ring

to

secure

shaft

to

left-hand

side

plate.

d.

See

that

all

fingers

are

free

to

engage

wheels.

3.

Stop

Shaft

Installation.

a.

Install

retaining

rings

on

ends

of

shaft.

b.

Insert

stop

shaft

into

proper

hole

in

left-hand

side

plate.

See

Figure

8.

4.

Reset

Finger

Shaft

Group

Installation.

a.

Rotate

no-back

pawl

so that

spring

puts

pawl

under

tension.

Slip

an

elastic

band

over

the

reset

fingers

and

pawl

to

hold

pawl

in

position.

See

Figure

20.

b.

Install

shaft

into

left-hand

side

plate

and

secure

with

retaining

ring

and

washers.

See

Figure

8.

c.

Engage

pin

on

reset

lever

group

with

slot

in

reset

arm.

See

Figure

22.

5.

Clutch

Shaft

Group

Installation.

a.

Install

shaft

in

proper

hole

in

left-hand

side

plate.

Add

washers

and

secure

with

retaining

ring.

See

Figure

8.

b.

Make

sure

that

bevel

gears

that

drive

the

totalizer

are

free

to

turn.

Figure

17.

Locking

Disc,

Eccentric

and Washer

Removal

and

Installation.

Figure

15.

Reset

Cam

Removal.

Figure

18.

Unit

Wheel

Installation.

Retaining

Rin

and Washers

Anti-Topping

Finger

Group

Figure

16.

Unit

Wheel

Removal.

Figure

19.

Anti-Topping

Finger

Group

Installation.

11

Page 14

Installation,

Operation

and

Service

Manual

Series

7886

High-Capacity

&

7887

Meter

Registers

6.

Right-Hand

Side

Plate

Installation

a.

Hold

meter

register

assembly

as

shown

in

Figure

22

and

place a rubber

band

around

the

assembly

to

hold

it

together.

Be

sure

the

pin

in

the

reset

lever

group

remains

engaged

in

the

slot

in

the

reset

arm.

b.

Install

side

plate

over

wheel

shaft

first,

then

engage

the

other

shafts.

c.

Temporarily

secure

the

side

plate to

the

rear

mounting

bar

with

screws.

7.

Bracket

Group

(if

required)

and

Totalizer

Installation.

a.

If

required,

install

new

bracket

group

to

inside

of

left

side

frame

and

secure

with

two

screws

and

lock-

washers.

See

Figure

31.

b.

Install

pointer

with

screw

(saved

from

old

totalizer)

onto

new

totalizer

group

but

do

not

tighten

screw

securely.

Pointer

position

must

be

adjusted

after

totalizer

group

is

installed.

See

Paragraph

F,

2.

c.

Install

the

totalizer

group

so

that

the

bevel

gear

is

in

mesh

with

the

top

bevel

gear

on

the

bracket

group

and

secure

with

retaining

screws.

For

adjustment

of

bevel

gear

drive,

see

Paragraph

E,

5.

8.

Spring

Installation.

a.

See

Figure

23

for

identification

of

springs.

\,

b.

Install

the

five

anti-topping

finger

springs

between

the

anti-topping

fingers

and

the

stop

shaft.

See

Figure

24.

c.

Install

the

reset

spring

between

the

reset

lever

and

the

pinion

shaft.

d.

Install

the detent

spring

between

the

detent

lever

group

and

the

stop

shaft.

e.

Install

the

clutch

spring

between

the

clutch

lever

group

and

the

pinion

shaft.

9.

Pinion

Shaft

Assembly

Installation

a.

If

not

previously

accomplished,

remove

all

parts

from

pinion

shaft.

b.

Rotate

wheel

shaft

so

reset

fingers

are

fully

engaged

in

the

heart-shaped

cams

on

each

wheel.

c.

Place

pinions,

with

short

finger

up,

in

between

each

wheel

as

shown

in

Figure

25.

d.

Install

the

end

of

the

shaft

closest

to

the

two

retaining

ring

slots

into

the

left-hand

side

plate

and

through

each

pinion.

Figure

20.

Reset

Finger

Shaft

Group

Preparation

For

Installation.

Figure

22.

Preparation

For

Side

Plate

Installation.

y

_

Figure

21.

Reset

Lever

Group

Pin

Engagement.

12

Figure

23.

Spring

Identification.

Page 15

Installation,

Operation

and

Service

Manual

Series

7886

High-Capacity

&

7887

Meter

Registers

e.

Install

washers

and

detent

lever

group

onto

shaft

and

engage

shutter

with

tab

on

detent

lever.

f.

Push

shaft

through

the

right-hand

side

plate

and

secure

with

washer

and

retaining

ring.

g.

Secure

detent

lever

group

into

position

with

retaining

rings.

h.

After

assembly,

rotate

wheel

shaft

to

make

sure

all

pinions

have been

positioned

properly.

If

binding

occurs,

reposition

pinions

per

step

c.

10.

Reset

Gear

Installation.

a.

Install

reset

gear

on

wheel

shaft,

aligning

orientation

mark

made

at

disassembly.

b.

Secure

gear

to

shaft

with

pin.

11.

Reset

Idler

Gear

Installation.

a.

If

present,

install

reset

idler

gear

on

the

reset

idler

gear

shaft.

See

Figure

8.

b.

Secure

with

retaining

ring.

Note:

This

gear

will

be

timed

when

the

meter

duplicator

and

meter

register

are

assembled

together.

Figure

24.

Anti-Topping

Finger

Spring

Installation.

Figure

26.

Installation

Of

Meter

Register

Onto

Mounting

Fixture.

Figure

25.

Pinion

Positioning.

Figure

27.

Securing

Mounting

Fixture.

13

Page 16

Installation,

Operation

and

Service

Manual

Series

7886

High-Capacity

&

7887

Meter

Registers

Adjust

to give

proper

engagement

with

Drive

Gear on

Gear

Plate

End

Play

O.OO5-O.O12

inch

Maintain

proper

engagement

with

Totalizer

bevel

gear.

CLUTCH

SHAFT

Washer

Clutch

and

Anti-topping

Shafts

end

play

for

proper

actuation

of Clutch

End

Play

0.007

inch

maximum

Adjust

Detent

Lever

for

best

possible

engagement

while

maintaining

0.005-0.010

inch

end

play

to

End

Play

0.005-0.012

inch

PINION

SHAFT

End

play

of

0.002-0.007

inch

between

retaining

rings

Adjust

No-back

Pawl

for

best

possible

engagement

while

maintaining

0.005-0.010

inch

end

play

End

Play

0.005-0.012

inch

0.005-0.010

inch

end

play

between

retaining

rings.

ANTI-TOPPING

FINGER

SHAFT

RESET

FINGER

SHAFT

0.009-0.016

inch

end

play

between

retaining

rings

of

each

wheel.

i

[I

t

Adjust

for

best possible

engagement

of

Reset

Cam

while

maintaining

0.005-0.010

inch

end

play.

End

Play

0.005-0.012

inch

WHEEL

SHAFT

S

Figure

28.

End

Play

Limits.

14

Page 17

Installation,

Operation

and

Service

Manual

Series

7886

High-Capacity

&

7887

Meter

Registers

#

E.

FINAL

CHECKS

AND

ADJUSTMENTS.

1.

End

Play

Check:

Check

end

play

(back

and

forth

motion)

of

shafts

and

parts

as

follows:

a.

For

proper

measurement,

the

meter

register

must

be

installed

in

the

TD-42383

mounting

fixture,

Figure

26,

to

constrain

the

frame

into

the

same

position

that,

it

is

when

installed

in

the

housing.

b.

Secure

the

meter

register

to

the

fixture

with

two 1 ,'4-28

button-head

bolts.

See

Figure

27.

c.

Take

end

play

measurements

of

each

shaft.

Add

or

subtract

washers

as

necessary

to

obtain

correct

end

play.

2.

Input

Drive

Bevel

Gear

Engagement

Adjustment.

a.

Install

the

gear

plate

onto

the

fixture

using

the

appropriate

hardware.

b.

Remove

the

retaining

ring

behind

the

bevel

gear

and

add

or

subtract

washers

as

required

for

proper

mesh

between

the

bevel

gear

on

the

gear

plate

and

the

drive

bevel

gear

on

the

clutch

shaft.

The

shaft

end

play

must

be

maintained

as

specified

in

Figure

28.

c.

Replace

the

retaining

ring

after

adjustment.

3.

Clutch

Lever

Positioning

Adjustment.

a.

Rotate

the

reset

gear

until

the

clutch

is

fully

disengaged.

b.

Measure

the clearances

as

shown

in

Figure

29.

c.

If

the

dimensions

cannot

be

obtained,

add

or

remove

washers

as

required,

or

replace

the

clutch

and

shaft.

d.

The

amount

of

face

engagement

between

the

spur

gear

on

the

input

clutch

and

the

first

wheel

should

be

75%

±

20%.

4.

Wheel

Brake

Adjustment.

a.

Rotate

reset

gear

to

position

cam

as

shown

in

Figure

30.

b.

Measure

clearance

between

brake

and

first

wheel.

If

clearance

is

not

within

the

dimensions

given,

adjust

brake

by

loosening

screw

and

moving

brake

into

position.

c.

Remove

the

meter

register

from

the

fixture

by removing

the

two

button-head

screws.

Remove

the

gear

plate

from

the

fixture.

5.

Gearing

Adjustment

for

Totalizer.

See

Figure

31.

Loosen

set

screw

on

bottom

bevel

gear.

Mesh

the

top

bevel

gear

tightly

with

the

totalizer

bevel

gear.

Press

the

register

clutch

shaft

toward

the

left

side

frame.

Adjust

the

bottom

bevel

gear

such

that

it

has

0.012 -0.015

end

play

when

meshing

with

the

clutch

shaft

bevel

gear.

Tighten

set

screw

and

secure

with a sealant

(Loctite

222

or

equivalent)

to

prevent

loosening.

6.

Apply

Anderol

L-795

or

equivalent

grease

on

teeth

of

bevel

gears.

7.

Backlash

Compensating

Mechanism

Adjustment

for

EEC

UNITS

ONLY.

While

unit

is

running

at

100-200

RPM,

adjust

screw

so

that

pawl

is

approximately

in

the

middle

of

clip

as

shown

in

Figure

32

(on

Page

16).

Oscillation

of

pawl

is

permissible.

To

check

for

proper

operation,

use a 1:1

gear

plate

and

operate

register

at

100-200

RPM.

Stop

counting,

hold

input

shaft

of gear

plate

and

reset

register.

Wheel

should

reset

so

that

some

part

of

graduation

at

zero

always

aligns

with

pointer.

Spur

Gear-

*—0.005

inch

min.

Lever

0.015

inch

min.

Figure

29.

Clutch

Lever

Adjustment.

First

Wheel

Detent

Cam

Small

Dia.

Figure

30.

Brake

Adjustment.

Figure

31.

Inside

Left

Side

Plate

of

Meter

Register.

15

Page 18

Installation,

Operation

and

Service

Manual

Series

7886

High-Capacity

&

7887

Meter

Registers

Figure

32.

Backlash

Compensating

Mechanism

(EEC

UNITS)

F.

OPERATIONAL

CHECK.

Before

returning

the

meter

register

to

normal

service,

check

that

it

operates

properly

as

follows:

1.

Rotate

the

input

bevel

gear

and

see

that

the

totalizer

and

individual

delivery

wheels

are

driven

and

that

they

record

the

same

amount.

There

should be

no

binding

or

drag.

2.

Rotate

the

reset

gear

and

see

that

the

shutter

drops

into

place,

the

wheels

all

reset

and

that

there

is

no

binding

or

drag.

At

the

completion

of

reset,

the

zeros

should

align

with

the

pointer.

3.

See

Troubleshooting,

Table

1.

Page

5,

if

there

are

any

problems.

SECTION

6.

DAMAGE

CLAIMS

AND

WARRANTY

A.

DAMAGE

CLAIMS

1.

Thoroughly

examine

the

enclosure

as

soon

as

it

is

received.

If

damaged,

write

on

the

face

of

the

freight

bill

a

complete

and

detailed

description

of

the

damage.

Have

the

carrier's

agent

sign

the

description.

Note:

Insist

that

the

carrier's

agent

verify

the

inspection

and

sign

the

description.

2.

Immediately

notify

the

delivering

carrier

of

damage

or

loss.

This

notification

may

be

given

either

in

person

or

by

telephone.

Written

confirmation

must

be

mailed

within

48

hours.

Railroads

and

motor

carriers

are

understandably

reluctant

to

make

adjustments

for

damaged

merchandise

unless

inspected

and

reported

promptly.

3.

Risk

of

loss

of,

or

damage

to

merchandise

remains

with

the

Buyer.

It is

the

Buyer's

responsibility

to

file a claim

with

the

carrier

involved.

4.

Immediately

advise

your

Veeder-Root

representative,

distributor,

or

the

factory

so

that

we

may

assist

you.

B.

RETURN

SHIPPING.

All

shipments

of

Veeder-Root

products

must

be

prepaid.

Equipment

must

be

packed

in

a

strong

exterior

container

and

surrounded

by

shock

absorb

ing

material.

Veeder-Root

will

accept

no

liability

for

damage

caused

by

improper

packing.

It

is

suggested

that

the

original

shipping

container

be

used

if

it

is

available.

Address

sh

ipment

to

Veeder-Root

Co.,

6th

Avenue

at

Burns

Crossing,

P.O.

Box

1073,

Altoona.PA

16603.

C.

WARRANTY

AND

CONDITIONS

1.

WARRANTY.

We

warrant

that

our

products

shall

be

free

from

defects

in

material

and

workmanship

for a period

of

one

year

from

the

date

of

shipment

thereof

or

the

product's

total

rated

life,

whichever

first

occurs.

Within

the

warranty

period

we

shall

repair

or

replace

such

products

which

are

returned

to

us

with

shipping

charges prepaid

and

which

are

deter

mined

by

us

to

be

defective.

This

warranty

will

not

apply

to

any

product

which

has

been

subjected

to

misuse,

negligence,

or

accident;

or

misapplied;

or

used

in

violation

of

product

manuals,

instructions,

or

warnings;

or

modified

or

repaired

by

unauthorized

persons;

or

improperly

installed.

2.

INSPECTION.

You

shall

inspect

the

product

promptly

after

receipt

and

shall

notify

us

at

our

Altoona

office,

in

writing,

of

any

claims,

including

claims

of

breach

of

warranty,

within

thirty

days

after

you

discover

or

should

have

dis

covered

the

facts

upon

which

the

claim

is

based.

Your

failure

to

give

written

notice

of a claim

within

the

time

period

shall

be

deemed

to

be a waiver

of

such

claim.

3.

LIMITATION

OF

REMEDY AND

WARRANTY.

The

provisions

of

Paragraph 1 are

our

sole

obligation

and

exclude

all

other

remedies

or

warranties,

express

or

implied,

including

warranties

of

MERCHANTABILITY

and

FITNESS

FOR A PARTICULAR

PURPOSE,

whether

or

not

purposes

or

specifications

are

described

herein.

We

further

disclaim

any

responsibility

whatsoever

to

you

or

to

any

other

person

for injury

to

person

or

damage

to

or

loss

of

property

or

value

caused

by

any

product

which

has

been

subjected

to

misuse,

negligence,

or

accident;

or

mis

applied;

or

used

in

violation

of

product

manuals,

instruc

tions,

or

warnings;

or

modified

or

repaired

by

unauthorized

persons;

or

improperly

installed.

4.

LIMITATION

OF

DAMAGES.

Under

no

circumstances

shall

we

be

liable

for

any

incidental,

consequential

or

special

damages,

losses

or

expenses

arising

from

this

contract

or

its

performance

or

in

connection

with

the

use

of,

or

inability

to

use,

our product

for

any

purpose

whatsoever.

5.

LIMITATION

OF

ACTIONS.

No

action

regardless

of

form

arising

out

of

this

contract

may

be

commenced

more

than

one

year

after

the

cause

of

action

has

accrued,

except

an

action

for

nonpayment.

6.

COLLATERAL

PROMISES.

There

are

no

represen

tations,

warranties,

or

conditions

express

or

implied,

statu

tory

or

otherwise

except

those

herein

contained,

and

no

agreements

or

waivers

collateral

hereto

shall

be

binding

on

either

party

unless

in

writ

ing

and

signed

by

you

and

accepted

by

us

at

our

Altoona

office.

7.

INTERPRETATION.

Rights

and

liabilities

arising

out

of

any

contract

with us

shall

be

determined

under

the

Uniform

Commercial

Code

as

enacted

in

Connecticut.

%

Page 19

1

VEEDER-ROOT

"^

Hm

Petroleum

Products

6th

Avenue

at

Bums

Crossing,

P.O.

Box

1673.

Altoona,

PA

16603-1673

Phone

(800)

873-3313,

Fax

(800)

234-5350.

or

Phone

(814)

695-4476,

Fax

(814)

695-7605

BRAZIL:

Sau

Paulo • CANADA:

Mississauga,

Ontario

•

ENGLAND:

Richmond

Surrey ■ FRANCE:

Rungis

Cedex • GERMANY:

Neuhausen/Filder

•

SINGAPORE:

Singapore

251325

(REV.

B)

13355

Replaces

12569

Loading...

Loading...