Page 1

Manual No: 577014-367 • Revision: D

Startup Guide

QuickServer Industrial Protocol Gateway

Page 2

Notice

Veeder-Root makes no warranty of any kind with regard to this publication, including, but not limited to, the implied warranties of

merchantability and fitness for a particular purpose.

Veeder-Root shall not be liable for errors contained herein or for incidental or consequential damages in

connection with the furnishing, performance, or use of this publication.

Veeder-Root reserves the right to change system options or features, or the information contained in this publication.

This publication contains proprietary information which is protected by copyright. All rights reserved. No part of this publication may be

photocopied, reproduced, or translated to another language without the prior written consent of Veeder-Root.

Contact TLS Systems Technical Support for additional troubleshooting information at 800-323-1799.

DAMAGE CLAIMS / LOST EQUIPMENT

Thoroughly examine all components and units as soon as they are received. If any cartons are damaged or missing, write a complete

and detailed description of the damage or shortage on the face of the freight bill. The carrier's agent must verify the inspection and sign

the description. Refuse only the damaged product, not the entire shipment.

Veeder-Root must be notified of any damages and/or shortages within 30 days of receipt of the shipment, as stated in our Terms and

Conditions.

VEEDER-ROOT’S PREFERRED CARRIER

1. Contact Veeder-Root Customer Service at 800-873-3313 with the specific part numbers and quantities that were missing or

received damaged.

2. Fax signed Bill of Lading (BOL) to Veeder-Root Customer Service at 800-234-5350.

3. Veeder-Root will file the claim with the carrier and replace the damaged/missing product at no charge to the customer. Customer

Service will work with production facility to have the replacement product shipped as soon as possible.

CUSTOMER’S PREFERRED CARRIER

1. It is the customer’s responsibility to file a claim with their carrier.

2. Customer may submit a replacement purchase order. Customer is responsible for all charges and freight associated with

replacement order. Customer Service will work with production facility to have the replacement product shipped as soon as

possible.

3. If “lost” equipment is delivered at a later date and is not needed, Veeder-Root will allow a Return to Stock without a restocking fee.

4. Veeder-Root will NOT be responsible for any compensation when a customer chooses their own carrier.

RETURN SHIPPING

For the parts return procedure, please follow the appropriate instructions in the "General Returned Goods Policy” pages in the

"Policies and Literature" section of the Veeder-Root North American Environmental Products price list. Veeder-Root will not accept

any return product without a Return Goods Authorization (RGA) number clearly printed on the outside of the package.

©Veeder-Root 2019. All rights reserved

.

ii

Page 3

Table of Contents

Introduction

Contractor Certification Requirements ..............................................................................1

Safety Precautions ............................................................................................................1

Safety Warnings ...............................................................................................................2

Related Documents ..........................................................................................................2

Precautions Against Static Electricity ................................................................................2

QuickServer Gateway. ......................................................................................................3

Quick Start Guide ..........................................................................................................4

Setup For QuickServer

Record Identification Data ................................................................................................5

Point Count Capacity And Registers Per Device ..............................................................5

Input COM Settings on the device connected to the QuickServer ....................................6

Selecting The Desired Protocol Configuration ..................................................................6

BMS Network Settings: MAC Address Node-ID And Baud Rate ......................................7

BACnet MS/TP: Setting The MAC Address For BMS Network ................................7

Modbus RTU And Modbus TCP/IP: Setting The Node-ID........................................7

BACnet MS/TP Or Modbus RTU: Setting The Baud Rate For BMS Network ..........8

Interfacing QuickServer To Devices

QuickServer ProtoNode Showing Connection Ports .........................................................9

Device Connections To QuickServer ................................................................................9

QuickServer 6-Pin Phoenix Connector.....................................................................9

Serial Network Wiring Field Port To RS-485 Network ............................................10

Power Up QuickServer ...................................................................................................11

Using QuickServer Web Configurator To Setup The Gateway

Connect The PC To QuickServer Via The Ethernet Port ................................................12

Connecting to QuickServer Web Configurator ................................................................13

Selecting Profiles for Devices Connected to QuickServer ..............................................13

Setting BACnet Parameters ............................................................................................15

Ethernet Network - Setting IP Address For Field Network ..............................................17

How To Start The Installation Over: Clearing Profiles

BACnet EXPLORER NG ................................................................................................19

Appendix A: Troubleshooting

Lost Or Incorrect IP Address ........................................................................................ A-1

Viewing Diagnostic Information ....................................................................................A-2

Check Wiring And Settings ........................................................................................... A-2

LED Diagnostics For Communications Between QuickServer And Devices ................ A-3

Take Diagnostic Capture With The FieldServer Toolbox .............................................. A-4

Update Firmware .......................................................................................................... A-6

Unknown Alarm Category ............................................................................................. A-6

Securing QuickServer With Passwords ........................................................................ A-6

Appendix B: Vendor Information – Veeder-Root

Interface To BACnet & Modbus Tables ........................................................................ B-1

Appendix C: “A” Bank DIP Switch Settings

iii

Page 4

Figures

Table of Contents

Appendix D: Reference

Specifications ................................................................................................................D-1

Compliance With UL Regulations .................................................................................D-1

Certifications - BTL Mark - BACnet® Testing Laboratory ............................................. D-2

Figure 1. QuickServer ProtoNode Connectivity Diagram (TLS450PLUS Shown) .....3

Figure 2. QuickServer S Bank (Profile Selections) DIP Switches ..........................6

Figure 3. QuickServer A Bank DIP Switches .........................................................7

Figure 4. QuickServer B Bank DIP Switches .........................................................8

Figure 5. QuickServer ProtoNode Connections .....................................................9

Figure 6. QuickServer ATG RS-232 and Power Inputs .......................................10

Figure 7. QuickServer Connection To RS-485 Field Network .............................10

Figure 8. QuickServer RS-485 BMS Network EOL Switch Settings .................... 10

Figure 9. Assigning Static IP Address To The PC ...............................................12

Figure 10. Web Configurator Showing No Active Profiles .....................................14

Figure 11. Web Configurator Showing Available Profiles For Selection ................14

Figure 12. Web Configurator Showing Active Profile Additions .............................15

Figure 13. Web Configurator with Protocol Set to BACnet ....................................16

Figure 14. Web Configurator Screen With Active Profiles .....................................17

Figure 15. Changing IP Address Via FS-GUI ........................................................18

Figure 16. BACnet Explorer NG On A BACnet Network ........................................19

Figure A-1. Ethernet Port Location ........................................................................A-1

Figure A-2. Check IP Address ............................................................................... A-1

Figure A-3. Error Messages Screen ......................................................................A-2

Figure A-4. Ethernet Port Location ........................................................................A-3

Figure A-5. FS Toolbox Utility Screen ...................................................................A-4

Figure A-6. Selecting Full Diagnostic For Selected Device ................................... A-4

Figure A-7. Selecting Start Diagnostic For Selected Device ................................. A-5

Figure A-8. Launching Explorer To Located Device’s Diagnostic File ................... A-5

Figure A-9. FS-GUI Passwords Page ....................................................................A-7

Figure A-10. Password Recovery Page .................................................................. A-7

Tables

Table 1. QuickServer Part Number .........................................................................5

Table 2. Registers Per Device .................................................................................5

Table 3. COM Settings ............................................................................................6

Table 4. Profile Settings For QuickServer ...............................................................6

Table 5. BMS Baud Rate .........................................................................................8

Table 6. QuickServer Current Draw .....................................................................11

Table A-1. Diagnostic LED Descriptions ................................................................. A-3

Table B-1. System Veeder-Root Interface To BACnet And Modbus ...................... B-1

Table B-2. Unknown_Type Veeder-Root Interface Mappings To BACnet

And Modbus .......................................................................................... B-1

Table B-3. Tank Veeder-Root Interface To BACnet And Modbus .......................... B-2

Table B-4. Liquid Sensor Veeder-Root Interface Mappings To BACnet

And Modbus .......................................................................................... B-2

Table B-5. Input Veeder-Root Interface To BACnet And Modbus .......................... B-3

Table B-6. Type A Sensor Veeder-Root Interface To BACnet And Modbus .......... B-3

Table B-7. Type B Sensor Veeder-Root Interface To BACnet And Modbus .......... B-3

Table B-8. Vapor Sensor Veeder-Root Interface To BACnet And Modbus ............ B-3

iv

Page 5

Table of Contents

Table B-9. Groundwater Sensor Veeder-Root Interface To BACnet

And Modbus .......................................................................................... B-3

Table B-10. MAG Sensor Veeder-Root Interface To BACnet And Modbus .............. B-4

Table B-11. Smart Sensor Veeder-Root Interface To BACnet And Modbus ............ B-4

Table B-12. PLLD Veeder-Root Interface To BACnet And Modbus ......................... B-4

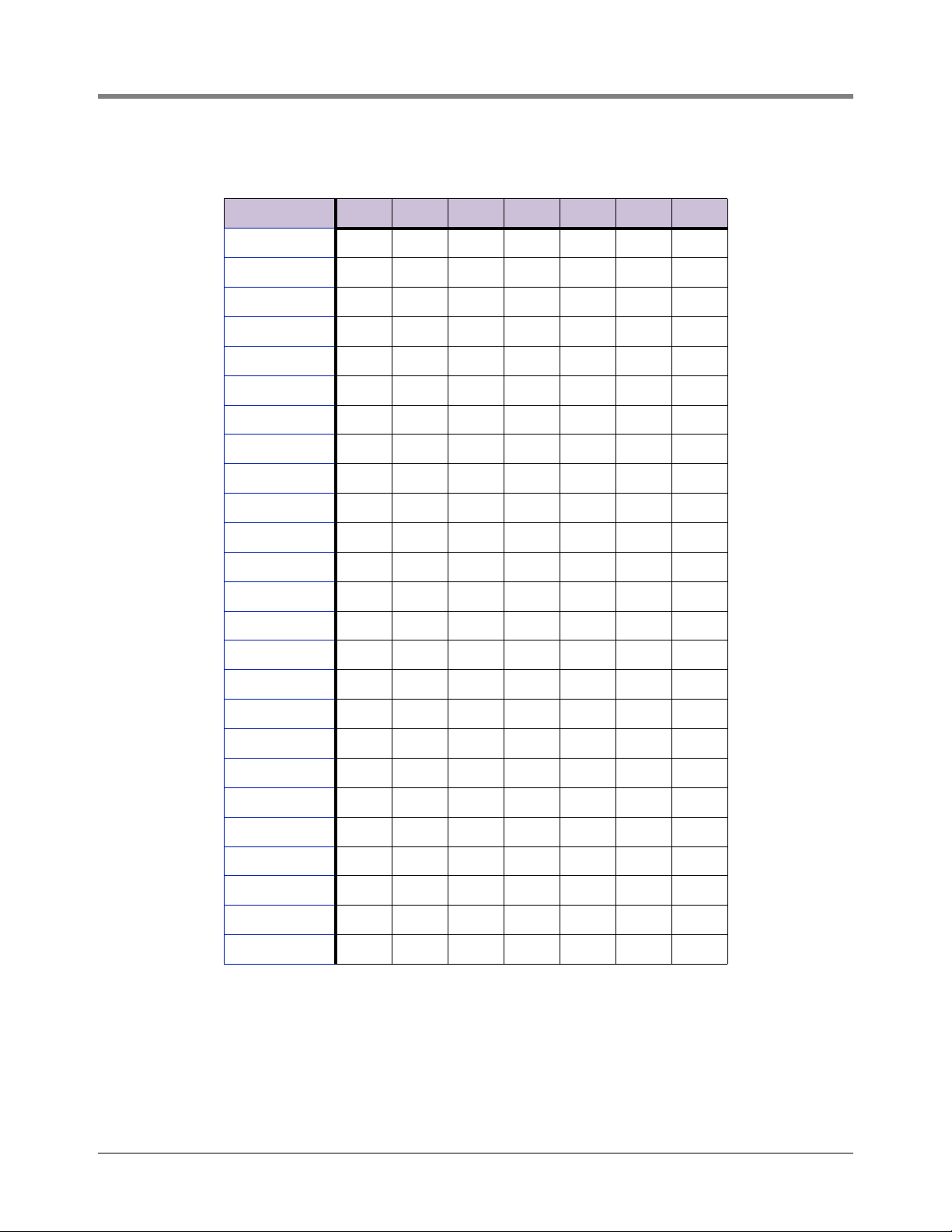

Table C-1. A Bank DIP Switch Settings For Addresses 26-50 ...............................C-1

Table C-2. A Bank DIP Switch Settings For Addresses 51 - 75 .............................C-2

Table C-3. A Bank DIP Switch Settings For Addresses 76 - 100 ...........................C-3

Table C-4. A Bank DIP Switch Settings For Addresses 101-125 ........................... C-4

Table C-5. A Bank DIP Switch Settings For Addresses 126 - 150 .........................C-5

Table C-6. A Bank DIP Switch Settings For Addresses 151 - 175 .........................C-6

Table C-7. A Bank DIP Switch Settings For Addresses 176 - 200 .........................C-7

Table C-8. A Bank DIP Switch Settings For Addresses 201 - 225 .........................C-8

Table C-9. A Bank DIP Switch Settings For Addresses 226-255 ........................... C-9

Table D-1. QuickServer ProtoNode Specifications .................................................D-1

v

Page 6

Introduction

OFF

The QuickServer is an external, high performance building automation multi-protocol gateway that is preconfigured

to automatically communicate between Veeder-Root’s products (hereafter called “device”) connected to the

QuickServer and automatically configures them for BACnet MS/TP, BACnet/IP, Modbus RTU and Modbus TCP/IP.

It is not necessary to download any configuration files to support the required applications. The QuickServer is

pre-loaded with tested profiles/configurations for the supported devices.

The QuickServer ProtoNode is compatible with:

TLS-3XX Consoles hardware/software requirements:

• RS-232/RS-485 Dual Interface Module

TLS-4XX Consoles hardware/software requirements:

• RS-232/RS-485 Dual Interface Module

Contractor Certification Requirements

Veeder-Root requires the following minimum training certifications for contractors who will install and setup the

equipment discussed in this manual:

Installer Certification (Level 1): Contractors holding valid Installer Certification are approved to perform wiring

and conduit routing; equipment mounting; probe, sensor and carbon canister vapor polisher installation; wireless

equipment installation; tank and line preparation; and line leak detector installation.

Technician Certification (Level 2/3): Contractors holding valid Technician Certifications are approved to

perform installation checkout, startup, programming and operations training, system tests, troubleshooting and

servicing for all Veeder-Root Series Tank Monitoring Systems, including Line Leak Detection. In addition,

Contractors with the following sub-certification designations are approved to perform installation checkout, startup,

programming, system tests, troubleshooting, service techniques and operations training on the designated system.

•Wireless 2

• Tall Tank

Warranty Registrations may only be submitted by selected Distributors.

Safety Precautions

The following safety symbols may be used throughout this manual to alert you to important safety hazards and

precautions

EXPLOSIVE

Fuels and their vapors are extremely explosive if ignited.

ELECTRICITY

High voltage exists in, and is supplied to, the device. A

potential shock hazard exists.

FLAMMABLE

Fuels and their vapors are extremely flammable.

TURN POWER OFF

Live power to a device creates a potential shock hazard.

Turn Off power to the device and associated accessories

when servicing the unit.

1

Page 7

Introduction Safety Warnings

OFF

WARNING

Indicates a hazardous situation which, if not avoided,

could result in death or serious injury.

Safety Warnings

READ ALL RELATED MANUALS

Knowledge of all related procedures before you begin

work is important. Read and understand all manuals thoroughly. If you do not understand a procedure, ask someone who does.

WARNING

This console contains high voltages which can be lethal. It is also connected to low

power devices that must be kept intrinsically safe.

FAILURE TO COMPLY WITH THE FOLLOWING WARNINGS AND SAFETY

PRECAUTIONS COULD CAUSE DAMAGE TO PROPERTY, ENVIRONMENT,

RESULTING IN SERIOUS INJURY OR DEATH.

1. Turn off and tag power at the circuit breaker. Do not connect the console AC

power supply wires at the breaker until all devices are connected.

2. Attach conduit from the power panel to the console's Power Area knockouts

only.

3. Comply with all applicable codes including: the National Electrical Code;

federal, state, and local codes; and other applicable safety codes.

Connecting power wires to a live circuit can cause electrical shock that may result in

serious injury or death.

Routing conduit for power wires into the intrinsically safe compartment can result in

fire or explosion resulting in serious injury or death.

Related Documents

576013-879 TLS-3XX Console Site Prep And Installation Manual

577014-073 TLS-450PLUS Console Site Prep And Installation Manual

577013-879 TLS-450 Console Site Prep And Installation Manual

577014-110 TLS-450PLUS/TLS4 Operator’s Manual

Precautions Against Static Electricity

If necessary to install electronic components in the ATG to implement this feature, read the following static

electricity precautions:

1. Before handling any components, discharge your body's static electric charge by touching a grounded surface.

2. Do not remove parts from their anti-static bags until you are ready to install them.

3. Do not lay parts on the anti-static bags! Only the insides are anti-static.

4. When handling parts, hold them by their edges and their metal mounting brackets.

5. Avoid touching comm board components or edge connectors that plug into slots when handling.

6. Never slide parts over any surface.

7. Avoid plastic, vinyl, and Styrofoam in your work area.

2

Page 8

Introduction QuickServer Gateway.

QuickServer Gateway.

Figure 1. QuickServer ProtoNode Connectivity Diagram (TLS450PLUS Shown)

3

Page 9

Quick Start Guide

1

2

5

7

8

10

11

12

1. Record the information about the unit. ( page 5)

2. Set the device’s COM settings for each of the devices that are to connect to the QuickServer. ( page 6)

3. Select the protocol configuration on the S Bank DIP switches. ( page 6)

4. BACnet MS/TP: Set the MAC Address on the A Bank DIP switches. ( page 7)

5. Modbus RTU or Modbus TCP/IP: Set the Node-ID. ( page 7)

6. BACnet MS/TP or Modbus RTU: Set the baud rate of the field protocol on the B Bank DIP switches. (

page 8)

7. Connect the QuickServer 6-pin RS-232 connector to the Veeder-Root ATG. ( page 9)

8. Connect the QuickServer ProtoNode 3 pin RS-485 port to the field protocol cabling. ( page 10)

9. Connect power to the QuickServer 6-pin connector. ( page 11)

10.Use a web browser to access the QuickServer Web Configurator page to select the profiles of the devices

attached to the QuickServer and input the Node-ID from each device. Once the devices are selected, the

QuickServer automatically builds and loads the appropriate configuration. ( page 12)

11.BACnet MS/TP or BACnet/IP: Set the BACnet Device Instance. ( page 15)

12.Ethernet Network: Use a web browser to access the QuickServer Web Configurator page to change the IP

Address. No changes to the configuration are necessary. ( page 17)

9

3

4

6

4

Page 10

Setup For QuickServer

1

Record Identification Data

The QuickServer has a unique part number located on the side or the back of the unit. This number should be

recorded, as it may be required for technical support. The numbers are as follows:

Table 1. QuickServer Part Number

Model Part Number

QuickServer ProtoNode 330020-840 /

QuickServer ProtoNode units have the following 3 ports: RS-232 , Ethernet and RS-485.

330020-841

Point Count Capacity And Registers Per Device

The total number of points presented by the device attached to the QuickServer ProtoNode-1504 cannot exceed

5000.

The total number of points per QuickServer profile is shown in Table 2:

Table 2. Registers Per Device

Profile Points Per Device

System 29

Unknown Type 3

Tank 56

Liquid Sensor 9

Input 6

Type A Sensor 5

Type B Sensor 6

Vapor Sensor 9

Groundwater Sensor 9

MAG Sensor 14

Smart Sensor 17

PLLD 19

5

Page 11

Setup For QuickServer Input COM Settings on the device connected to the QuickServer

2

S0 - S3 DIP Switches Bank DIP Switch Location

When setting DIP switches,

ensure that power to the

board is OFF.

NOTICE

Input COM Settings on the device connected to the QuickServer

• The connected serial device MUST have the same baud rate, data bits, stop bits, and parity settings as the

QuickServer.

• To set the QuickServer’s COM settings, See “Connecting to QuickServer Web Configurator” on page 13.

• Table 3 specifies the device serial port settings required to communicate with the QuickServer.

Table 3. COM Settings

Port Setting TLS-3XX/TLS4XX

Protocol V-R Interface

Baud Rate 9600

Parity Odd

Data Bits 7

Stop Bits 1

Selecting The Desired Protocol Configuration

3

QuickServer ProtoNode units use the ‘S’ bank of DIP switches (S0 - S3) to select the protocol configuration (see

Figure 2).

Off On

S3

S2

S1

S0

Figure 2. QuickServer S Bank (Profile Selections) DIP Switches

See Table 4 for the S Bank DIP switch settings.

Table 4. Profile Settings For QuickServer

QuickServer ProtoNode S Bank DIP Switches

Profile S0 S1 S2 S3

BACnet/IP Off Off Off Off

BACnet MS/TP On Off Off Off

6

Page 12

Setup For QuickServer BMS Network Settings: MAC Address Node-ID And Baud Rate

NOTICE

A0 - A7 DIP Switches Bank DIP Switch Location

A0

A1

A2

A3

A4

A5

A6

A7

Off On

When setting DIP switches,

ensure that power to the

board is OFF.

NOTICE

Table 4. Profile Settings For QuickServer (Continued)

QuickServer ProtoNode S Bank DIP Switches

Profile S0 S1 S2 S3

Modbus TCP/IP and Modbus RTU

Off On Off Off

BMS Network Settings: MAC Address Node-ID And Baud Rate

BACNET MS/TP: SETTING THE MAC ADDRESS FOR BMS NETWORK

4

Only 1 MAC Address is set for QuickServer regardless of how many devices are connected to QuickServer.

•

• Set the BACnet MS/TP MAC Address of the QuickServer to a value between 1 to 127 (Master MAC Address);

this is so that the BMS front end can find QuickServer via BACnet Auto-Discovery.

Never set a BACnet MS/TP MAC Address of the QuickServer to a value from 128 to 255.

Addresses from 128 to 255 are Slave Addresses and can not be discovered by BMS front

ends that support Auto-Discovery of BACnet MS/TP devices.

• Set “A” bank DIP switches A0 – A7 to assign a MAC Address to the QuickServer for BACnet MS/TP (see

Figure 3).

• Refer to Appendix C for the complete range of MAC Addresses and DIP switch settings.

MODBUS RTU AND MODBUS TCP/IP: SETTING THE NODE-ID

5

The Modbus RTU and Modbus TCP/IP Node-IDs are assigned by setting the A-bank dip switches. (see

•

Figure 3).

• Node-ID’s range from 1-255. Refer to Appendix C for the full range of addresses for setting Node-ID.

Figure 3. QuickServer A Bank DIP Switches

7

Page 13

Setup For QuickServer BMS Network Settings: MAC Address Node-ID And Baud Rate

BACNET MS/TP OR MODBUS RTU: SETTING THE BAUD RATE FOR BMS NETWORK

6

DIP switches B0 – B3 can be used to set the field baud rate of the QuickServer to match the baud rate required

by the BMS for BACnet MS/TP (see Figure 4).

Off

B0

B1

B2

B3

On

B0 - B3 DIP Switches Bank DIP Switch Location

Figure 4. QuickServer B Bank DIP Switches

BMS baud rate dip switch selections are shown in Table 5.

.

Table 5. BMS Baud Rate

Baud Rate B0 B1 B2 B3

9600 On On On Off

19200 Off Off Off On

NOTICE

When setting DIP switches,

ensure that power to the

board is OFF.

38400* On On Off On

57600 Off Off On On

76800 On Off On On

*Factory default setting.

8

Page 14

Interfacing QuickServer To Devices

Phoenix

Connector

NOTICE

QuickServer ProtoNode Showing Connection Ports

Figure 5. QuickServer ProtoNode Connections

Device Connections To QuickServer

QUICKSERVER 6-PIN PHOENIX CONNECTOR

7

Pins 1 - 3 are for Veeder-Root ATG input (see Figure 6).

•

• Pins 4 - 6 are for QuickServer power. QuickServer accepts either 9-30V DC or 12-24V AC on pins 4 and 5.

Do not power up QuickServer at this time.

9

Page 15

Interfacing QuickServer To Devices Device Connections To QuickServer

Pin 3 Rx/Pin 2 Tx/+

Pin 5 GND

Pin 3 Rx/-

Pin 2 Tx/+

Pin 7 GND

Power In (+)

Power In (-)

Frame Ground (must be connected)

Pin 1 Pin 6

(If 25 Pin) (If 9 Pin)

Power

Input

Use standard grounding

principles for RS-232 GND.

NOTICE

Console RS-232 Connector

RS-485 (+)

RS-485 (-)

RS-485 GND

BMS

Input

Pin 1

Pin 3

Off (Default)

On

EOL Switch

Figure 6. QuickServer ATG RS-232 and Power Inputs

SERIAL NETWORK WIRING FIELD PORT TO RS-485 NETWORK

8

•

Connect the RS-485 network wires to the 3-pin RS-485 connector on QuickServer ProtoNode as shown in

Figure 7.

• See “Ethernet Network - Setting IP Address For Field Network” on page 17. for information on connecting to

BACnet/IP network.

• If the QuickServer is the last device on the trunk, then the End-Of-Line Termination Switch needs to be set to

the On position (the EOL Termination default setting is Off). If necessary, set the switch to the On position

(see Figure 8).

Figure 7. QuickServer Connection To RS-485 Field Network

Figure 8. QuickServer RS-485 BMS Network EOL Switch Settings

10

Page 16

Interfacing QuickServer To Devices Power Up QuickServer

Power Up QuickServer

9

Verify QuickServer nominal power requirements in Table 6.

Table 6. QuickServer Current Draw

Current Draw

NOTICE

QuickServer ProtoNode

Typical 170 mA 100 mA‘ 80 mA

Maximum 240 mA 140 mA 100 mA

These values are ‘nominal’ and a safety margin should be added to the power supply of the

12V DC/AC 24V DC/AC 30V DC

host system. A safety margin of 25% is recommended.

After verifying power source and with frame ground connected as shown in Figure 6. apply power to QuickServer.

11

Page 17

Using QuickServer Web Configurator To Setup The Gateway

Connect The PC To QuickServer Via The Ethernet Port

10

• Connect a CAT5 Ethernet cable (Straight through or Cross-Over) between the local PC and QuickServer.

• The Default IP Address of QuickServer is 192.168.1.24, subnet mask is 255.255.255.0. If the PC and

QuickServer are on different IP Networks, assign a static IP Address to the PC on the 192.168.1.xxx network:

For Windows 10, Right click on .

click on Local Area Connections. When the Local Area Connections Status box appears click Properties. Click

on Internet Protocol Version 4 (TCP/IPv4) then click Properties. When the Internet Protocol Version 4 (TCP/

IPv4) Properties dialog box appears, click, ‘Use the following IP address’ radio button and enter the ‘IP address’

and ‘Subnet mask’ entries shown in Figure 9, the click the OK button , then the Close buttons to exit.

Then click on Network Connections>Change Adapter Options. Double

Figure 9. Assigning Static IP Address To The PC

12

Page 18

Using QuickServer Web Configurator To Setup The Gateway Connecting to QuickServer Web Configurator

NOTICE

NOTICE

NOTICE

After disconnecting from the QuickServer return to the PC’s Internet Protocol Version 4 (TCP/IPv4) Properties

dialog box and click the Obtain an IP Address Automatically’ radio button to return the PC to its original Local Area

Connection settings.

Connecting to QuickServer Web Configurator

After setting a local PC on the same subnet as the QuickServer (refer to above paragraph), open a web browser

on the PC and enter the IP Address of the QuickServer (the default address is 192.168.1.24).

If the IP Address of the QuickServer was changed, the assigned IP Address can be

discovered using the FS Toolbox utility. See ‘Lost Or Incorrect IP Address’ (Appendix A, page

A-1) for instructions.

Selecting Profiles for Devices Connected to QuickServer

• In the Web Configurator, the Active Profiles are shown below the Configuration Parameters.

• Fill in the parameter values as needed.

- Enter the Veeder-Root PLC Type and COM settings.

See “Input COM Settings on the device connected to the QuickServer” on page 6 for

correct COM settings per PLC Type.

- Once a parameter value is changed as desired click Submit to save it.

• The Active profiles section lists the currently active device profiles, including previous Web Configurator

additions. This list is empty for new installations, or after clearing all configurations (see Figure 10).

• To add an active profile to support a device, click the Add button under the Active Profiles heading. This will

present a drop-down box underneath the Current profile column that lists all the available profiles (see

Figure 11).

• Once the profile for the device has been selected from the drop-down list, enter the value of the Node-ID.

The first entered Node-ID must be set to “1” and be followed by sequential values.

• Then enter the Address Parameter. The Address is used to specify the tank, sensor or input number. This

information can be found in the Veeder-Root ATG Report.

- Tanks are addressed from 1-12.

- Sensors are addressed from 1-64.

- Inputs are addressed from 1-64.

• Then press the “Submit” button to add the Profile to the list of devices to be configured.

• Repeat this process until all the devices have been added.

13

Page 19

Using QuickServer Web Configurator To Setup The Gateway Selecting Profiles for Devices Connected to QuickServer

Figure 10. Web Configurator Showing No Active Profiles

Figure 11. Web Configurator Showing Available Profiles For Selection

14

Page 20

Using QuickServer Web Configurator To Setup The Gateway Setting BACnet Parameters

NOTICE

NOTICE

• Completed additions are listed under “Active Profiles” as shown the Figure 12 example.

Figure 12. Web Configurator Showing Active Profile Additions

Figure 12 shows a console with 3 tanks and 4 liquid sensors. The node IDs are sequential, starting with 1; the

addresses match the console numbering of the tanks (i.e., there is no tank 3 set up in the console). The Node

ID is used for the BACnet Object or Modbus Register (see Appendix B) and its address must match the device

number programmed in the console.

System and Unknown Type points are automatically configured therefore no profile is

required. Refer to Table B-1 and Table B-2 in Appendix B for a list of available points.

Setting BACnet Parameters

11

• Open the Web Configurator with the protocol set to BACnet in “Selecting The Desired Protocol Configuration”

on page 6.

• Fill in the parameter values as needed (see Figure 13).

- Enter the Veeder-Root PLC Type, COM settings and BACnet settings (Bac_device_id)

See See “Input COM Settings on the device connected to the QuickServer” on page 6.

for correct COM settings per PLC Type.

The Bac_device_id field will display the current value (default = 50,000). The BACnet

Device Instance can range from 1 to 4,194,303.

- Once a parameter value is changed as desired click Submit to save it.

15

Page 21

Using QuickServer Web Configurator To Setup The Gateway Setting BACnet Parameters

Figure 13. Web Configurator with Protocol Set to BACnet

16

Page 22

Using QuickServer Web Configurator To Setup The Gateway Ethernet Network - Setting IP Address For Field Network

Ethernet Network - Setting IP Address For Field Network

12

• After setting a local PC to the same subnet as the QuickServer (See “Connect The PC To QuickServer Via The

Ethernet Port” on page 12., open a web browser on the PC and enter the IP Address of the QuickServer; the

default address is 192.168.1.24.

• The Web Configurator is displayed as the landing page (see Figure 14).

• To access the FS-GUI, click on the “Diagnostics & Debugging” button in the bottom right corner of the page.

Figure 14. Web Configurator Screen With Active Profiles

• From the FS-GUI landing page, click on “Setup” to expand the navigation tree and then select “Network

Settings” to access the IP Settings menu (see Figure 15).

17

Page 23

Using QuickServer Web Configurator To Setup The Gateway Ethernet Network - Setting IP Address For Field Network

NOTICE

NOTICE

Figure 15. Changing IP Address Via FS-GUI

• Modify the IP Address (N1 IP Address field) of the QuickServer Ethernet port.

• If necessary, change the Netmask (N1 Netmask field).

• If necessary, change the IP Gateway (Default Gateway field).

If the QuickServer is connected to a managed switch/router, the IP Gateway of the

QuickServer should be set to the IP Address of that managed switch/router.

•Click the “System Restart” button at the bottom of the page to apply changes and restart the QuickServer.

•Unplug Ethernet cable from PC and connect it to the network switch or router.

•Record the IP Address assigned to the QuickServer for future reference.

The FieldPoP™ button (see Figure 15) allows users to connect to FieldPoP, Sierra

Monitor’s device cloud solution for the IIoT. FieldPoP enables secure remote connection to

field devices through a FieldServer and its local applications for configuration, management,

maintenance. For more information about FieldPoP, refer to the FieldPoP™ Device Cloud

Start-up Guide.

18

Page 24

How To Start The Installation Over: Clearing Profiles

1. After setting a local PC to the same subnet as the QuickServer (“Connect The PC To QuickServer Via The

Ethernet Port” on page 12), open a web browser on the PC and enter the IP Address of the QuickServer.

2. If the IP Address of the QuickServer has been changed by previous configuration, the assigned IP Address

must be gathered from the network administrator.

3. The Web Configurator is displayed as the landing page.

4. At the bottom-left of the page, click the “Clear Profiles and Restart” button.

5. Once restart is complete, all past profiles discovered and/or added via Web configurator are deleted. The unit

can now be reinstalled.

BACnet EXPLORER NG

A typical working example of a BACnet Explorer NG on a BACnet Network (see Figure 16).

BACnet Explorer NG

BACnet MS/TP

PC Connected to

BACnet

Explorer’s Web

Browser

Up to 32 BACnet

MS/TP devices

BACnet Router

Multi-Port Swtich

Modbus RTU

BACnet MS/TP

BACnet MS/TP

Modbus RTU

Up to 32 BACnet

MS/TP devices

Figure 16. BACnet Explorer NG On A BACnet Network

• For additional details related to the BACnet Explorer NG, go to the Sierra Monitor website’s Resource Center

and download the BACnet Explorer NG Start-Up Guide

.

• For purchasing information, look up the BACnet Explorer NG page on the Sierra Monitor website and click on

the “BUY NOW” tab.

19

Page 25

Appendix A: Troubleshooting

Lost Or Incorrect IP Address

1. Ensure that FieldServer Toolbox is loaded onto the local PC. Otherwise, download the FieldServer Toolbox.zip

via the Sierra Monitor Resource Center at https://www.sierramonitor.com/content/fieldserver-toolbox-0

2. Extract the executable file and complete the installation.

Ethernet port

Figure A-1. Ethernet Port Location

3. Connect a standard CAT5 Ethernet cable between the user’s PC and QuickServer.

4. Double click on the FS Toolbox Utility and click Discover Now on the splash page.

5. Check for the IP Address of the desired gateway.

Figure A-2. Check IP Address

A-1

Page 26

Appendix A Viewing Diagnostic Information

6. If correcting the IP Address of the gateway: click the settings icon on the same row as the gateway (see

Figure A-2), then click Network Settings, change the IP Address and click Update IP Settings to save.

Viewing Diagnostic Information

1. Type the IP Address of the QuickServer into the web browser or use the FieldServer Toolbox to connect to the

QuickServer.

2. Click on Diagnostics and Debugging Button, then click on view, and then on connections.

3. If there are any errors showing on the Connection page, refer to “Check Wiring And Settings” below for the

relevant wiring and settings.

Figure A-3. Error Messages Screen

Check Wiring And Settings

• No COMS on Veeder-Root Interface side. If the Tx/Rx LEDs are not flashing rapidly then there is a COM issue.

To fix this, check the following:

- Visual observations of LEDs on QuickServer (See “LED Diagnostics For Communications Between

QuickServer And Devices” on page A-3.)

A-2

Page 27

Appendix A LED Diagnostics For Communications Between QuickServer And Devices

NOTICE

SPL

RUN

ERR

RX

TX

PWR

- Check baud rate, parity, data bits, stop bits

- Check device address

- Verify wiring

- Verify device is connected to the same subnet as the QuickServer

- Verify the Modbus device was discovered in Web Configurator (See “Connecting to QuickServer Web

Configurator” on page

• Field COM problems:

13.).

- If Ethernet protocols are used, observe Ethernet LEDs on the QuickServer (See “LED Diagnostics For

Commun

ications Between QuickServer And Devices” below).

- Check DIP switch settings (using correct baud rate and device instance)

- Verify IP Address setting

- Verify wiring

If the problem persists, a Diagnostic Capture needs to be taken and sent to support. (See “Take Diagnostic Capture With The FieldServer Toolbox” on page A-4.).

LED Diagnostics For Communications Between QuickServer And Devices

Reference Figure A-4 and Table A-1 for understanding QuickServer ProtoNode diagnostic LEDs.

Figure A-4. Ethernet Port Location

Table A-1. Diagnostic LED Descriptions

LED Description

SPL The SPL LED will light if the unit is not getting a response from one or more of the configured devices.

RUN The RUN LED will start flashing 20 seconds after power indicating normal operation.

ERR

RX

The SYS ERR LED will go on solid 15 seconds after power up. It will turn off after 5 seconds. A steady red

light will indicate there is a system error on the unit. If this occurs, immediately report the related “system

error” shown in the error screen of the GUI interface to support for evaluation.

The RX LED will flash when a message is received on the serial port on the 6-pin connector. If the serial

port is not used, this LED is non-operational.

TX

PWR This is the power light and should show steady green at all times when unit is powered.

The TX LED will flash when a message is sent on the serial port on the 6-pin connector. If the serial port is

not used, this LED is non-operational.

A-3

Page 28

Appendix A Take Diagnostic Capture With The FieldServer Toolbox

NOTICE

NOTICE

Take Diagnostic Capture With The FieldServer Toolbox

Once the Diagnostic Capture is complete, email it to technical support. The Diagnostic Capture will accelerate diagnosis of the problem.

• Ensure that FieldServer Toolbox is loaded onto the local PC. Otherwise, download the FieldServer Toolbox.zip

via the Sierra Monitor Resource Center Software Downloads. Reference Figure A-1.

• Extract the executable file and complete the installation.

• Connect a standard CAT5 Ethernet cable between the PC and QuickServer.

• Double click on the FS Toolbox Utility.

1. Take a log

a.Click on the diagnose icon of the desired device.

Figure A-5. FS Toolbox Utility Screen

b.Ensure “Full Diagnostic" is selected (this is the default).

Figure A-6. Selecting Full Diagnostic For Selected Device

If desired, the default capture period can be changed.

A-4

Page 29

Appendix A Take Diagnostic Capture With The FieldServer Toolbox

c.Click on ‘Start Diagnostic’.

Figure A-7. Selecting Start Diagnostic For Selected Device

d.When the capture period is finished, the “Diagnostic Test Complete” window will appear

2. Send Log

a.Once the diagnostic test is complete, a zip file is saved on the PC.

Figure A-8. Launching Explorer To Located Device’s Diagnostic File

b.Choose ‘Open’ to launch explorer and have it point directly at the correct folder.

A-5

Page 30

Appendix A Update Firmware

c.Send the Diagnostic zip file to technical support (technicalsupport@veeder.com).

Update Firmware

To load a new version of the firmware, follow these instructions:

1. Extract and save the new file onto the local PC.

2. Open a web browser and type the IP Address of the FieldServer in the address bar.

- Default IP Address is 192.168.1.24

- Use the FS Toolbox utility if the IP Address is unknown (See “Lost Or Incorrect IP Address” on page A-1.).

3. Click on the “Diagnostics & Debugging” button.

4. In the Navigation Tree on the left hand side, do the following:

a.Click on “Setup”

b.Click on “File Transfer”

c.Click on the “General” tab

5. In the General tab, click on “Choose Files” and select the web.img file extracted in Step 1.

6. Click on the orange “Submit” button.

Unknown Alarm Category

If the ProtoNode receives an alarm and or device ID that it does not recognize, it will be stored in the DA_UNKCAT

data array. Only the last device ID, Alarm ID, and address will be stored.

Securing QuickServer With Passwords

Access to the QuickServer can be restricted by enabling a password on the FS-GUI Passwords page – click

Setup and then Passwords in the navigation panel. There are 2 access levels defined by 2 account names: Admin

and User.

• The Admin account has unrestricted access to the QuickServer.

• The User account can view any QuickServer information, but cannot make any changes or restart the

QuickServer.

The password needs to be a minimum of eight characters and is case sensitive.

If the password is lost, click cancel on the password authentication popup window (see Figure A-9), and email the

password recovery token (see Figure A-10) to technical support to receive a temporary password from the support

team. Access the QuickServer to set a new password.

A-6

Page 31

Appendix A Securing QuickServer With Passwords

Figure A-9. FS-GUI Passwords Page

Figure A-10. Password Recovery Page

A-7

Page 32

Appendix B: Vendor Information – Veeder-Root

NOTICE

The ProtoNode provides capability to support any Veeder-Root serial command by defining customized map

descriptors for any command or data type. Refer to Appendix A of the 577014-368 QuickServer Industrial Protocol

Gateway Installation And Setup manual. Appendix A (Security Code) of the same manual also contains instructions

on using a Security Code for the TLS communications port.

Interface To BACnet & Modbus Tables

An X in the BACnet Object ID or Modbus Register represents a one- or two-digit number that equals

the Node ID. In the Liquid Sensor X Fuel Alarm examples below, with a Node ID of 3, the X will be 3;

for a Node ID of 11, the X will be 11.

Point Name Node ID BACnet Object ID (X002) Modbus Register (10X02)

Sensor X Fuel Alarm 3

Sensor X Fuel Alarm 11

Table B-1. System Veeder-Root Interface To BACnet And Modbus

Point Name BACnet Object Type BACnet Object ID Modbus Register

Printer out of Paper BI 1 10001

Printer Error BI 2 10002

EEPROM Configuration Error BI 3 10003

Battery Off BI 4 10004

Too Many Tanks BI 5 10005

System Security Warning BI 6 10006

ROM Revision Warning BI 7 10007

Remote Display Communications Error BI 8 10008

Autodial Error BI 9 10009

Software Module Warning BI 10 10010

Tank Test Shutdown Warning BI 11 10011

Protective Cover Alarm BI 12 10012

BIR Shift Close Pending BI 13 10013

BIR Daily Close Pending BI 14 10014

PC(H8) Revision Warning BI 15 10015

System Self Test Error BI 16 10016

System Clock Incorrect Warning BI 17 10017

System Device Poll Timeout BI 18 10018

Maintenance Tracker NVMem BI 19 10019

Maintenance Tracker Communication Module BI 20 10020

Database Error BI 21 10021

File System Error BI 22 10022

BIR Status Warning BI 23 10023

VR Bus Power Outage Warning BI 24 10024

Software Upgrade Failure Alarm BI 25 10025

iButton Fault Warning BI 26 10026

iButton Fault Alarm BI 27 10027

Version Upgrade Available BI 28 10028

Expansion Box Unsupported BI 29 10029

3002 10302

11002 101102

Table B-2. Unknown_Type Veeder-Root Interface Mappings To BACnet And Modbus

Point Name BACnet Object Type BACnet Object ID Modbus Register

Unknown Device Address AI 1 30001

Unknown Alarm Category AI 2 30002

Unknown Alarm Type AI 3 30003

B-1

Page 33

Appendix B Interface To BACnet & Modbus Tables

Table B-3. Tank Veeder-Root Interface To BACnet And Modbus

Tank X Inventory Volume AI X001 30X01

Tank X Inventory TC Volume AI X002 30X02

Tank X Inventory Ullage AI X003 30X03

Tank X Inventory Height AI X004 30X04

Tank X Inventory Water AI X005 30X05

Tank X Inventory Temperature AI X006 30X06

Tank X Inventory Water Volume AI X007 30X07

Tank X Delivery Product Code AI X008 30X08

Tank X Delivery Number of Deliveries AI X009 30X09

Tank X Delivery Start Time from 01/01/1970 AI X010 30X10

Tank X Delivery Stop Time from 01/01/1970 AI X011 30X11

Tank X Delivery Starting Volume AI X012 30X12

Tank X Delivery Starting TC Volume AI X013 30X13

Tank X Delivery Starting Water AI X014 30X14

Tank X Delivery Starting Temp AI X015 30X15

Tank X Delivery Ending Volume AI X016 30X16

Tank X Delivery Ending TC Volume AI X017 30X17

Tank X Delivery Ending Water AI X018 30X18

Tank X Delivery Ending Temp AI X019 30X19

Tank X Delivery Starting Height AI X020 30X20

Tank X Delivery Ending Height AI X021 30X21

Tank X Tank Setup Warning BI X001 10X01

Tank X Tank Leak Alarm BI X002 10X02

Tank X High Water Alarm BI X003 10X03

Tank X Overfill Alarm BI X004 10X04

Tank X Low Limit Alarm BI X005 10X05

Tank X Theft Alarm BI X006 10X06

Tank X High Limit Alarm BI X007 10X07

Tank X Invalid Height Alarm BI X008 10X08

Tank X Probe Out Alarm BI X009 10X09

Tank X High Water Alarm BI X010 10X10

Tank X Delivery Needed BI X011 10X11

Tank X Maximum Level Alarm BI X012 10X12

Tank X Gross Leak Test Alarm BI X013 10X13

Tank X Monthly Leak Test Alarm BI X014 10X14

Tank X Annual Leak Test Alarm BI X015 10X15

Tank X Monthly Test Warning BI X016 10X16

Tank X Annual Test Warning BI X017 10X17

Tank X Monthly Test Alarm BI X018 10X18

Tank X Annual Test Alarm BI X019 10X19

Tank X Leak Test Active BI X020 10X20

Tank X No CSLD Idle Time Warning BI X021 10X21

Tank X Siphon Break Active Warning BI X022 10X22

Tank X CSLD Rate Increase Warning BI X023 10X23

Tank X AccuChart Calibration Warning BI X024 10X24

Tank X HRM Reconciliation Warning BI X025 10X25

Tank X HRM Reconciliation Alarm BI X026 10X26

Tank X Cold Temperature Warning BI X027 10X27

Tank X Missing Delivery Ticket Warning BI X028 10X28

Tank X Gross Leak Alarm BI X029 10X29

Tank X Delivery Density Warning BI X030 10X30

Tank X Density warning BI X031 10X31

Tank X Fuel Quality Alarm BI X032 10X32

Tank X Tank High Temperature Warning BI x033 10X33

Tank X Tank Low Temperature Warning BI x034 10X34

Tank X Density Offset Warning BI x035 10X35

Point Name BACnet Object Type BACnet Object ID Modbus Register

Table B-4. Liquid Sensor Veeder-Root Interface Mappings To BACnet And Modbus

Sensor X Setup Data Warning BI X001 10X01

Sensor X Fuel Alarm BI X002 10X02

Sensor X Out Alarm BI X003 10X03

Sensor X Short Alarm BI X004 10X04

Sensor X Water Alarm BI X005 10X05

Point Name BACnet Object Type BACnet Object ID Modbus Register

B-2

Page 34

Appendix B Interface To BACnet & Modbus Tables

Sensor X Water Out Alarm BI X006 10X06

Sensor X High Liquid Alarm BI X007 10X07

Sensor X Low Liquid Alarm BI X008 10X08

Sensor X Liquid Warning BI X009 10X09

Table B-5. Input Veeder-Root Interface To BACnet And Modbus

Input X Input Setup Data Warning BI X001 10X01

Input X Input Normal BI X002 10X02

Input X Input Alarm BI X003 10X03

Input X Generator Off BI X004 10X04

Input X Generator On BI X005 10X05

Input X Input Out Alarm BI X006 10X06

Point Name BACnet Object Type BACnet Object ID Modbus Register

Table B-6. Type A Sensor Veeder-Root Interface To BACnet And Modbus

Type-A Sensor X Setup Data Warning BI X001 10X01

Type-A Sensor X Fuel Alarm BI X002 10X02

Type-A Sensor X Out Alarm BI X003 10X03

Type-A Sensor X Short Alarm BI X004 10X04

Type-A Sensor X Water Alarm BI X005 10X05

Point Name BACnet Object Type BACnet Object ID Modbus Register

Table B-7. Type B Sensor Veeder-Root Interface To BACnet And Modbus

Type-B Sensor X Setup Data Warning BI X001 10X01

Type-B Sensor X Fuel Alarm BI X002 10X02

Type-B Sensor X Out Alarm BI X003 10X03

Type-B Sensor X Short Alarm BI X004 10X04

Type-B Sensor X High Liquid Alarm BI X005 10X05

Type-B Sensor X Liquid Warning BI X006 10X06

Point Name BACnet Object Type BACnet Object ID Modbus Register

Table B-8. Vapor Sensor Veeder-Root Interface To BACnet And Modbus

Vapor Sensor X Setup Data Warninq BI X001 10X01

Vapor Sensor X Fuel Alarm BI X002 10X02

Vapor Sensor X Out Alarm BI X003 10X03

Vapor Sensor X Short Alarm BI X004 10X04

Vapor Sensor X Water Alarm BI X005 10X05

Vapor Sensor X Water Out Alarm BI X006 10X06

Vapor Sensor X High Liquid Alarm BI X007 10X07

Vapor Sensor X Low Liquid Alarm BI X008 10X08

Vapor Sensor X Liquid Warning BI X009 10X09

Point Name BACnet Object Type BACnet Object ID Modbus Register

Table B-9. Groundwater Sensor Veeder-Root Interface To BACnet And Modbus

Groundwater Sensor X Setup Data Warninq BI X001 10X01

Groundwater Sensor X Fuel Alarm BI X002 10X02

Groundwater Sensor X Out Alarm BI X003 10X03

Groundwater Sensor X Short Alarm BI X004 10X04

Groundwater Sensor X Water Alarm BI X005 10X05

Groundwater Sensor X Water Out Alarm BI X006 10X06

Groundwater Sensor X High Liquid Alarm BI X007 10X07

Groundwater Sensor X Low Liquid Alarm BI X008 10X08

Groundwater Sensor X Liquid Warning BI X009 10X09

Point Name BACnet Object Type BACnet Object ID Modbus Register

B-3

Page 35

Appendix B Interface To BACnet & Modbus Tables

Table B-10. MAG Sensor Veeder-Root Interface To BACnet And Modbus

MAG Sensor X Setup Data Warninq BI X001 10X01

MAG Sensor X Communication Alarm BI X002 10X02

MAG Sensor X Fault Alarm BI X003 10X03

MAG Sensor X Fuel Warning BI X004 10X04

MAG Sensor X Fuel Alarm BI X005 10X05

MAG Sensor X Water Warning BI X006 10X06

MAG Sensor X Water Alarm BI X007 10X07

MAG Sensor X High Liquid Warning BI X008 10X08

MAG Sensor X High Liquid Alarm BI X009 10X09

MAG Sensor X Low Liquid Warning BI X010 10X10

MAG Sensor X Low Liquid Alarm BI X011 10X11

MAG Sensor X Temperature Warning BI X012 10X12

MAG Sensor X Relay Active BI X013 10X13

MAG Sensor X Install Alarm BI X014 10X14

Point Name BACnet Object Type BACnet Object ID Modbus Register

Table B-11. Smart Sensor Veeder-Root Interface To BACnet And Modbus

Smart Sensor X Setup Data Warninq BI X001 10X01

Smart Sensor X Communication Alarm BI X002 10X02

Smart Sensor X Fault Alarm BI X003 10X03

Smart Sensor X Fuel Warning BI X004 10X04

Smart Sensor X Fuel Alarm BI X005 10X05

Smart Sensor X Water Warning BI X006 10X06

Smart Sensor X Water Alarm BI X007 10X07

Smart Sensor X High Liquid Warning BI X008 10X08

Smart Sensor X High Liquid Alarm BI X009 10X09

Smart Sensor X Low Liquid Warning BI X010 10X10

Smart Sensor X Low Liquid Alarm BI X011 10X11

Smart Sensor X Temperature Warning BI X012 10X12

Smart Sensor X Relay Active X013 10X13

Smart Sensor X Install Alarm X014 10X14

Smart Sensor X Fault Warning X015 10X15

Smart Sensor X Vacuum Warning X016 10X16

Smart Sensor X No Vacuum Warning X017 10X17

Point Name BACnet Object Type BACnet Object ID Modbus Register

Table B-12. PLLD Veeder-Root Interface To BACnet And Modbus

PLLD X Setup Data Warninq BI X001 10X01

PLLD X Gross Test Fail Alarm BI X002 10X02

PLLD X Annual Test Fail Alarm BI X003 10X03

PLLD X Periodic Test Needed Warning BI X004 10X04

PLLD X Periodic Test Needed Alarm BI X005 10X05

PLLD X Sensor Open Alarm BI X006 10X06

PLLD X High Pressure Alarm BI X007 10X07

PLLD X Shutdown Alarm BI X008 10X08

PLLD X High Pressure Warning BI X009 10X09

PLLD X Continuous Handle On Warning BI X010 10X10

PLLD X Periodic Test Fail Alarm BI X011 10X11

PLLD X Annual Test Needed Warning BI X012 10X12

PLLD X Annual Test Needed Alarm BI X013 10X13

PLLD X Low Pressure Alarm BI X014 10X14

PLLD X Sensor Short Alarm BI X015 10X15

PLLD X Continuous Handle On Alarm BI X016 10X16

PLLD X Fuel Out Alarm BI X017 10X17

PLLD X Line Equipment Alarm BI X018 10X18

PLLD X Gross Test Needed Alarm BI X019 10X19

Point Name BACnet Object Type BACnet Object ID Modbus Register

B-4

Page 36

Appendix C: “A” Bank DIP Switch Settings

Table C-1. A Bank DIP Switch Settings For Addresses 26-50

Address A0 A1 A2 A3 A4 A5 A6

26 Off On Off On On Off Off

27 On On Off On On Off Off

28 Off Off On On On Off Off

29 OnOffOnOnOnOffOff

30 OffOnOnOnOnOffOff

31 On On On On On Off Off

32 Off Off Off Off Off On Off

33 On Off Off Off Off On Off

34 Off On Off Off Off On Off

35 On On Off Off Off On Off

36 Off Off On Off Off On Off

37 On Off On Off Off On Off

38 OffOnOnOffOffOnOff

39 On On On Off Off On Off

40 Off Off Off On Off On Off

41 On Off Off On Off On Off

42 Off On Off On Off On Off

43 On On Off On Off On Off

44 Off Off On On Off On Off

45 On Off On On Off On Off

46 OffOnOnOnOffOnOff

47 On On On On Off On Off

48 Off Off Off Off On On Off

49 On Off Off Off On On Off

50 OffOnOffOffOnOnOff

C-1

Page 37

Appendix C

Table C-2. A Bank DIP Switch Settings For Addresses 51 - 75

Address A0 A1 A2 A3 A4 A5 A6

51 On On Off Off On On Off

52 Off Off On Off On On Off

53 On Off On Off On On Off

54 Off On On Off On On Off

55 On On On Off On On Off

56 OffOffOffOnOnOnOff

57 On Off Off On On On Off

58 Off On Off On On On Off

59 On On Off On On On Off

60 Off Off On On On On Off

61 OnOffOnOnOnOnOff

62 OffOnOnOnOnOnOff

63 On On On On On On Off

64 Off Off Off Off Off Off On

65 On Off Off Off Off Off On

66 Off On Off Off Off Off On

67 On On Off Off Off Off On

68 Off Off On Off Off Off On

69 On Off On Off Off Off On

70 Off On On Off Off Off On

71 On On On Off Off Off On

72 Off Off Off On Off Off On

73 On Off Off On Off Off On

74 Off On Off On Off Off On

75 On On Off On Off Off On

C-2

Page 38

Appendix C

Table C-3. A Bank DIP Switch Settings For Addresses 76 - 100

Address A0 A1 A2 A3 A4 A5 A6

76 Off Off On On Off Off On

77 On Off On On Off Off On

78 OffOnOnOnOffOffOn

79 On On On On Off Off On

80 Off Off Off Off On Off On

81 On Off Off Off On Off On

82 Off On Off Off On Off On

83 On On Off Off On Off On

84 Off Off On Off On Off On

85 On Off On Off On Off On

86 Off On On Off On Off On

87 On On On Off On Off On

88 Off Off Off On On Off On

89 On Off Off On On Off On

90 Off On Off On On Off On

91 On On Off On On Off On

92 Off Off On On On Off On

93 OnOffOnOnOnOffOn

94 OffOnOnOnOnOffOn

95 On On On On On Off On

96 Off Off Off Off Off On On

97 On Off Off Off Off On On

98 Off On Off Off Off On On

99 On On Off Off Off On On

100 Off Off On Off Off On On

C-3

Page 39

Appendix C

Table C-4. A Bank DIP Switch Settings For Addresses 101-125

Address A0 A1 A2 A3 A4 A5 A6

101 On Off On Off Off On On

102 OffOnOnOffOffOnOn

103 On On On Off Off On On

104 Off Off Off On Off On On

105 On Off Off On Off On On

106 Off On Off On Off On On

107 On On Off On Off On On

108 Off Off On On Off On On

109 On Off On On Off On On

110 OffOnOnOnOffOnOn

111 On On On On Off On On

112 Off Off Off Off On On On

113 On Off Off Off On On On

114 OffOnOffOffOnOnOn

115 On On Off Off On On On

116 Off Off On Off On On On

117 On Off On Off On On On

118 Off On On Off On On On

119 On On On Off On On On

120 OffOffOffOnOnOnOn

121 On Off Off On On On On

122 Off On Off On On On On

123 On On Off On On On On

124 Off Off On On On On On

125 OnOffOnOnOnOnOn

C-4

Page 40

Appendix C

Table C-5. A Bank DIP Switch Settings For Addresses 126 - 150

Address A0 A1 A2 A3 A4 A5 A6

126 OffOnOnOnOnOnOn

127 On On On On On On On

128 Off Off Off Off Off Off Off

129 On Off Off Off Off Off Off

130 Off On Off Off Off Off Off

131 On On Off Off Off Off Off

132 Off Off On Off Off Off Off

133 On Off On Off Off Off Off

134 Off On On Off Off Off Off

135 On On On Off Off Off Off

136 Off Off Off On Off Off Off

137 On Off Off On Off Off Off

138 Off On Off On Off Off Off

139 On On Off On Off Off Off

140 Off Off On On Off Off Off

141 On Off On On Off Off Off

142 OffOnOnOnOffOffOff

143 On On On On Off Off Off

144 Off Off Off Off On Off Off

145 On Off Off Off On Off Off

146 Off On Off Off On Off Off

147 On On Off Off On Off Off

148 Off Off On Off On Off Off

149 On Off On Off On Off Off

150 Off On On Off On Off Off

C-5

Page 41

Appendix C

Table C-6. A Bank DIP Switch Settings For Addresses 151 - 175

Address A0 A1 A2 A3 A4 A5 A6

151 On On On Off On Off Off

152 Off Off Off On On Off Off

153 On Off Off On On Off Off

154 Off On Off On On Off Off

155 On On Off On On Off Off

156 Off Off On On On Off Off

157 OnOffOnOnOnOffOff

158 OffOnOnOnOnOffOff

159 On On On On On Off Off

160 Off Off Off Off Off On Off

161 On Off Off Off Off On Off

162 Off On Off Off Off On Off

163 On On Off Off Off On Off

164 Off Off On Off Off On Off

165 On Off On Off Off On Off

166 OffOnOnOffOffOnOff

167 On On On Off Off On Off

168 Off Off Off On Off On Off

169 On Off Off On Off On Off

170 Off On Off On Off On Off

171 On On Off On Off On Off

172 Off Off On On Off On Off

173 On Off On On Off On Off

174 OffOnOnOnOffOnOff

175 On On On On Off On Off

C-6

Page 42

Appendix C

Table C-7. A Bank DIP Switch Settings For Addresses 176 - 200

Address A0 A1 A2 A3 A4 A5 A6

176 Off Off Off Off On On Off

177 On Off Off Off On On Off

178 OffOnOffOffOnOnOff

179 On On Off Off On On Off

180 Off Off On Off On On Off

181 On Off On Off On On Off

182 Off On On Off On On Off

183 On On On Off On On Off

184 OffOffOffOnOnOnOff

185 On Off Off On On On Off

186 Off On Off On On On Off

187 On On Off On On On Off

188 Off Off On On On On Off

189 OnOffOnOnOnOnOff

190 OffOnOnOnOnOnOff

191 On On On On On On Off

192 Off Off Off Off Off Off On

193 On Off Off Off Off Off On

194 Off On Off Off Off Off On

195 On On Off Off Off Off On

196 Off Off On Off Off Off On

197 On Off On Off Off Off On

198 Off On On Off Off Off On

199 On On On Off Off Off On

200 Off Off Off On Off Off On

C-7

Page 43

Appendix C

Table C-8. A Bank DIP Switch Settings For Addresses 201 - 225

Address A0 A1 A2 A3 A4 A5 A6

201 On Off Off On Off Off On

202 Off On Off On Off Off On

203 On On Off On Off Off On

204 Off Off On On Off Off On

205 On Off On On Off Off On

206 OffOnOnOnOffOffOn

207 On On On On Off Off On

208 Off Off Off Off On Off On

209 On Off Off Off On Off On

210 Off On Off Off On Off On

211 On On Off Off On Off On

212 Off Off On Off On Off On

213 On Off On Off On Off On

214 Off On On Off On Off On

215 On On On Off On Off On

216 Off Off Off On On Off On

217 On Off Off On On Off On

218 Off On Off On On Off On

219 On On Off On On Off On

220 Off Off On On On Off On

221 OnOffOnOnOnOffOn

222 OffOnOnOnOnOffOn

223 On On On On On Off On

224 Off Off Off Off Off On On

225 On Off Off Off Off On On

C-8

Page 44

Appendix C

Table C-9. A Bank DIP Switch Settings For Addresses 226-255

Address A0 A1 A2 A3 A4 A5 A6

226 Off On Off Off Off On On

227 On On Off Off Off On On

228 Off Off On Off Off On On

229 On Off On Off Off On On

230 OffOnOnOffOffOnOn

231 On On On Off Off On On

232 Off Off Off On Off On On

233 On Off Off On Off On On

234 Off On Off On Off On On

235 On On Off On Off On On

236 Off Off On On Off On On

237 On Off On On Off On On

238 OffOnOnOnOffOnOn

239 On On On On Off On On

240 Off Off Off Off On On On

241 On Off Off Off On On On

242 OffOnOffOffOnOnOn

243 On On Off Off On On On

244 Off Off On Off On On On

245 On Off On Off On On On

246 Off On On Off On On On

247 On On On Off On On On

248 OffOffOffOnOnOnOn

249 On Off Off On On On On

250 Off On Off On On On On

251 On On Off On On On On

252 Off Off On On On On On

253 OnOffOnOnOnOnOn

254 OffOnOnOnOnOnOn

255 On On On On On On On

C-9

Page 45

Appendix D: Reference

NOTICE

Specifications

Specifications subject to change without notice.

Table D-1. QuickServer ProtoNode Specifications

Item Description

Electrical Connections

One 6-pin Phoenix connector with RS-232 port (+/-/gnd) and

Power port (+/-/Frame-gnd)

One 3-pin Phoenix connector with RS-485 port (+/-/gnd)

One Ethernet 10/100 BaseT port

CE Certified; TUV approved to UL 916, EN 60950-1, EN

50491-3 and CSA C22-2 standards; FCC Class A Part 15;

Approvals

Power Requirements Multi-mode power adapter 9-30V DC or 12 - 24V AC

Physical Dimensions 11.5 cm L x 8.3 cm W x 4.1 cm H (4.5 x 3.2 x 1.6 in)

Weight 0.2 kg (0.4 lbs)

Operating Temperature -40°C o 75°C (-40°F to 167°F)

Surge Suppression EN61000-4-2 ESD EN61000-4-3 EMC EN61000-4-4 EFT

Humidity 5 - 90% RH (non-condensing)

DNP 3.0 Conformance Tested; RoHS Compliant; CSA 205

Approved

BTL Marked

Compliance With UL Regulations

For UL compliance, the following instructions must be met when operating QuickServer.

• The units shall be powered by listed LPS or Class 2 power supply suited to the expected operating temperature

range.

• The interconnecting power connector and power cable shall:

- Comply with local electrical code

D-1

Page 46

Appendix D Certifications - BTL Mark - BACnet® Testing Laboratory

NOTICE

- Be suited to the expected operating temperature range

- Meet the current and voltage rating for QuickServer

• Furthermore, the interconnecting power cable shall:

- Be of length not exceeding 3.05m (118.3”)

- Be constructed of materials rated VW-1, FT-1 or better

• If the unit is to be installed in an operating environment with a temperature above 65 °C, it should be installed in

a Restricted Access Area requiring a key or a special tool to gain access.

• This device must not be connected to a LAN segment with outdoor wiring.

Certifications - BTL Mark - BACnet® Testing Laboratory

The BTL Mark on QuickServer is a symbol that indicates that a

product has passed a series of rigorous tests conducted by an

independent laboratory which verifies that the product correctly

implements the BACnet features claimed in the listing. The mark

is a symbol of a high-quality BACnet product.

Go to www.BACnetInternational.net for more information about

the BACnet Testing Laboratory. Click here

Statement.

for the BACnet PIC

BACnet is a registered trademark of ASHRAE

D-2

Page 47

For technical support, sales or

other assistance, please visit:

www.veeder.com

Loading...

Loading...