Installation Manual

Mag-FLEX Probe

Manual No: 577014-042 ● Revision: E

Notice

Veeder-Root makes no warranty of any kind with regard to this publication, including, but not limited to, the implied warranties of

merchantability and fitness for a particular purpose.

Veeder-Root shall not be liable for errors contained herein or for incidental or consequential damages

in connection with the furnishing, performance, or use of this publication.

Veeder-Root reserves the right to change system options or features, or the information contained in this publication.

This publication contains proprietary information which is protected by copyright. All rights reserved. No part of this publication

may be photocopied, reproduced, or translated to another language without the prior written consent of Veeder-Root.

Contact TLS Systems Technical Support for additional troubleshooting information at 800-323-1799.

DAMAGE CLAIMS / LOST EQUIPMENT

Thoroughly examine all components and units as soon as they are received. If any cartons are damaged or missing, write a

complete and detailed description of the damage or shortage on the face of the freight bill. The carrier's agent must verify the

inspection and sign the description. Refuse only the damaged product, not the entire shipment.

Veeder-Root must be notified of any damages and/or shortages within 30 days of receipt of the shipment, as stated in our Terms

and Conditions.

VEEDER-ROOT’S PREFERRED CARRIER

1. Contact Veeder-Root Customer Service at 800-873-3313 with the specific part numbers and quantities that were missing

or received damaged.

2. Fax signed Bill of Lading (BOL) to Veeder-Root Customer Service at 800-234-5350.

3. Veeder-Root will file the claim with the carrier and replace the damaged/missing product at no charge to the customer.

Customer Service will work with production facility to have the replacement product shipped as soon as possible.

CUSTOMER’S PREFERRED CARRIER

1. It is the customer’s responsibility to file a claim with their carrier.

2. Customer may submit a replacement purchase order. Customer is responsible for all charges and freight associated with

replacement order. Customer Service will work with production facility to have the replacement product shipped as soon as

possible.

3. If “lost” equipment is delivered at a later date and is not needed, Veeder-Root will allow a Return to Stock without a restocking

fee.

4. Veeder-Root will NOT be responsible for any compensation when a customer chooses their own carrier.

RETURN SHIPPING

For the parts return procedure, please follow the appropriate instructions in the "General Returned Goods Policy” pages in the

"Policies and Literature" section of the Veeder-Root North American Environmental Products price list. Veeder-Root will not

accept any return product without a Return Goods Authorization (RGA) number clearly printed on the outside of the package.

FCC INFORMATION

This equipment complies with the requirements in Part 15 of the FCC rules for a Class A computing device. Operation of this

equipment in a residential area may cause unacceptable interference to radio and TV reception requiring the operator to take

whatever steps are necessary to correct the interference.

©Veeder-Root 2019. All rights reserved.

Warranty

TLS-350R, TLS-350 PLUS, TLS-350J AND TLS-300I/C MONITORING SYSTEMS

We warrant that this product shall be free from defects in material and workmanship for a period of one (1) year from the date of

installation or twenty-four (24 months) from the date of invoice, whichever occurs first. During the warranty period, we or our

representative will repair or replace the product, if determined by us to be defective, at the location where the product is in use

and at no charge to the purchaser. LAMPS, FUSES, AND LITHIUM BATTERIES ARE NOT COVERED UNDER THIS

WARRANTY.

We shall not be responsible for any expenses incurred by the user.

This warranty applies only when the product is installed in accordance with Veeder-Root’s specifications, and a Warranty

Registration and Checkout Form has been filed with Veeder-Root by an authorized Veeder-Root Distributor. This warranty will not

apply to any product which has been subjected to misuse, negligence, accidents, systems that are misapplied or are not installed

per Veeder-Root specifications, modified or repaired by unauthorized persons, or damage related to acts of God.

If “Warranty” is purchased as part of the Fuel Management Service, Veeder-Root will maintain the equipment for the life of the

contract in accordance with the written warranty provided with the equipment. A Veeder-Root Fuel Management Services

Contractor shall have free site access during Customer’s regular working hours to work on the equipment. Veeder-Root has no

obligation to monitor federal, state or local laws, or modify the equipment based on developments or changes in such laws.

MODULES, KITS, OTHER COMPONENTS (PARTS PURCHASED SEPARATE OF A COMPLETE CONSOLE)

We warrant that this product, exclusive of lithium batteries, shall be free from defects in material and workmanship for

a period of fifteen (15) months from date of invoice. We warrant that the lithium batteries shall be free from defects

in material and workmanship for a period of 90 days from date of invoice. We will repair or replace the product if the

product is returned to us; transportation prepaid, within the warranty period, and is determined by us to be defective.

This warranty will not apply to any product which has been subjected to misuse, negligence, accidents, systems that

are misapplied or are not installed per Veeder-Root specifications, modified or repaired by unauthorized persons, or

damage related to acts of God.

We shall not be responsible for any expenses incurred by the user.

MAG-FLEX PROBE

The same warranty policies for the MAG Plus Rigid Probe apply to the Mag-FLEX Probe. When the Probe is

purchased with a monitoring system (console), the warranty period is one (1) year from the date of installation or

twenty-four (24) months from the invoice date, whichever occurs first. Parts and labor are covered in this warranty.

When the Probe is purchased individually, it has a 15-month parts only warranty from the invoice date. Please refer

to the Policies and Literature section in the Price Book.

Veeder-Root will not warranty the probe if its damage is caused by failing to follow the Veeder-Root MAG-FLEX

Installation & Setup Manual (577014-042). Each Mag-FLEX Probe is made to order, and therefore cannot be

returned for credit.

Introduction

Tank Gauge Requirements ...............................................................................................1

Wireless System Requirements ........................................................................................1

Contractor Certification Requirements ..............................................................................1

Related Documents ..........................................................................................................2

Product Marking Information .............................................................................................2

Related Documents ..................................................................................................2

Safety Symbols .................................................................................................................3

Safety Warnings ...............................................................................................................4

GENERAL PRECAUTIONS ..............................................................................................4

SPECIAL TOOLS REQUIRED For Transmitter Installation .....................................5

General AST Guidelines ...................................................................................................5

AST Construction Safe Work Practices ............................................................................5

Personal Protective Equipment ........................................................................................6

Before you Begin ..............................................................................................................6

Wireless Installations................................................................................................6

Hard-Wired Installations ...........................................................................................6

Mag-FLEX Probe Overview

Product Description ..........................................................................................................7

Mag-FLEX Probe Limitations ............................................................................................7

Mag-FLEX Technical Data ................................................................................................8

Mag-FLEX Probes Part Number Specification ..................................................................8

Mag-FLEX Spare Parts And Accessories.................................................................9

National Electrical Code Compliance ................................................................................9

Mag-FLEX Probe Wire Length .................................................................................9

Veeder-Root Parts ............................................................................................................9

Table of Contents

Example Drawings

Example Mag-FLEX Probe Site Layout Drawing - Wireless Installation .........................10

Example Mag-FLEX Probe Site Layout Drawing - Hard-Wired Installation ....................11

Mag-FLEX Probe Length Calculation .............................................................................12

Probe Handling ...............................................................................................................13

System Safety Layout

Field Cable Ducting / Cable Trays ..................................................................................14

Cable Specifications For Intrinsically Safe Apparatus Cabling .......................................14

Mag-FLEX Installation & Handling Procedures

Probe Installation Requirements .....................................................................................15

Miscellaneous Requirements ..........................................................................................15

Tank Entry ..............................................................................................................15

Probe Assembly .....................................................................................................15

Tools And Materials................................................................................................15

Mag-FLEX Probe Installation ..........................................................................................16

Mag-FLEX Probe Field Wiring Connections ...................................................................21

Optional Junction Box - Wired Installations Only....................................................21

Veeder-Root Encapsulation Kits.............................................................................22

TLS setup .......................................................................................................................25

Float Type...............................................................................................................25

Tank Profile ............................................................................................................25

Tank Diameter........................................................................................................25

iv

Figures

Tables

Table of Contents

Figure 1. Site Drawing - Example TLS RF Wireless 2 System Site Layout –

Two Mag-FLEX Probes ........................................................................10

Figure 2. Site Drawing - Example Hardwired System Site Layout –

Two Mag-FLEX Probes ........................................................................11

Figure 3. Mag-FLEX Probe Parameters ..............................................................12

Figure 4. Junction Box Installation Examples..........................................................20

Figure 5. Veeder-Root Single- And Dual-Channel Encapsulation Kit

Installation Examples ............................................................................20

Figure 6. Splice Length Dimensions ....................................................................22

Figure 7. Splice Connections ...............................................................................23

Figure 8. Removing Sealing Compound Clip .......................................................24

Figure 9. Pouring Sealing Compound Into Sleeve ...............................................24

Table 1. Dimensions For Mag-FLEX Probe Tank Opening .....................................7

Table 2. Part Number Nomenclature .......................................................................9

v

Introduction

This manual contains installation instructions for the Veeder-Root Mag-FLEX probe. Procedures contained within

this manual include:

• Site layout considerations

• Installing the Mag-FLEX

• Cabling between the Mag-FLEX and the TLS Console

• Connecting the Mag-FLEX probe cable and battery pack cable to the transmitter

• TLS Console used with the Mag-FLEX.

Tank Gauge Requirements

The Mag-FLEX is a digital flexible probe able to read temperature, product level and water level in tanks up to 15.0

meters. The Mag-FLEX enables liquid height, water height and temperature to be measured within fuel storage

vessels with maximum liquid levels up to 9.9 metres with TLS2 and 15.0 metres with TLS-3XX and TLS-450. For

storage vessels with maximum liquid levels up to 3.66 metres it is recommended that a Veeder-Root Mag Plus

magnetostrictive probe is used.

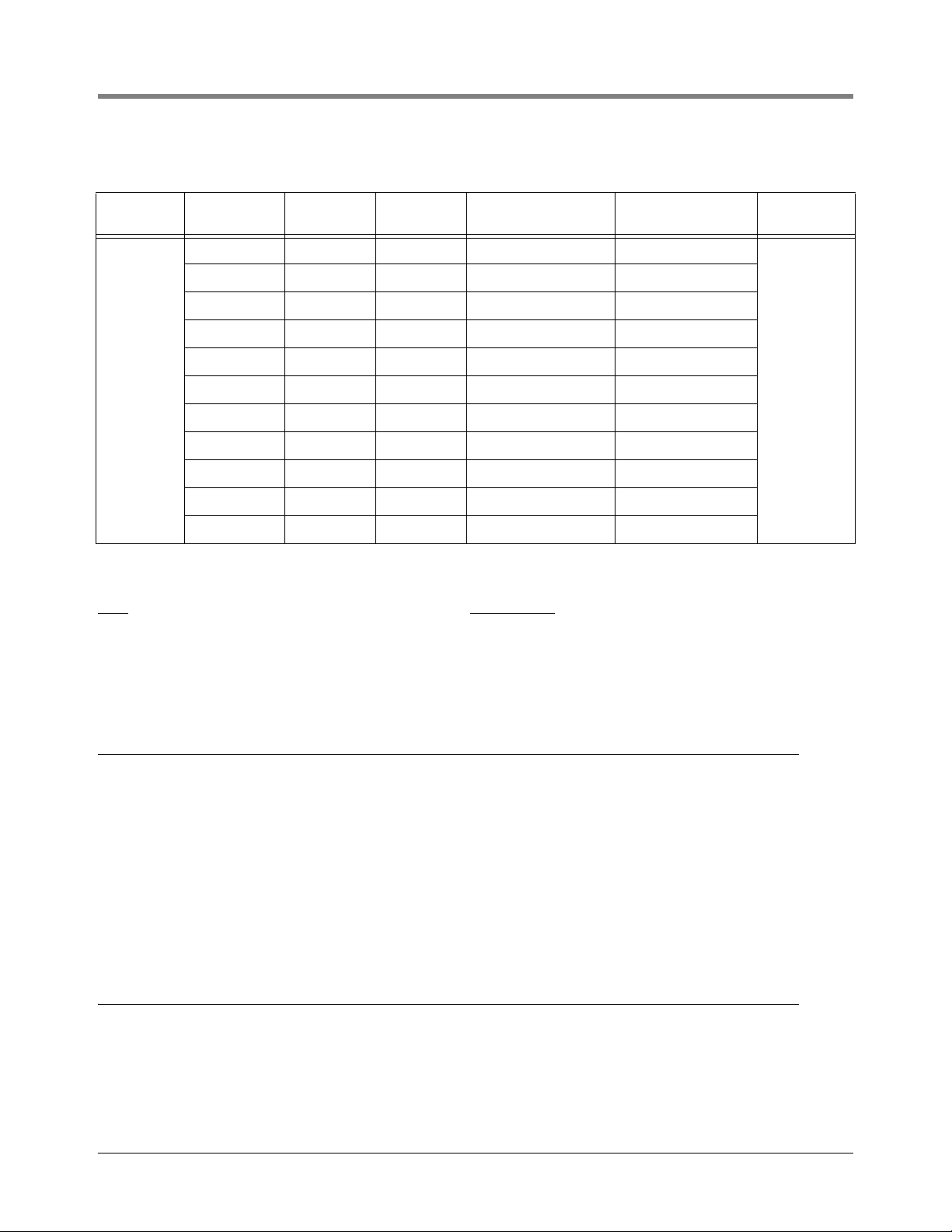

Console with Mag-FLEX

TLS2 32.5 260,000

TLS-300 49.2 999,999

TLS-350 49.2 999,999

TLS-450 49.2 2,641,720

TLS4 49.2 2,641,720

Max Height

(feet)

Max Volume

(gallons)

Wireless System Requirements

The Veeder-Root Wireless 2 (W2) System replacement/spare parts are listed below:

• 330020-668 TLS RF Console for Wireless 2

• 330020-674 Transmitter for Wireless 2 devices

• 330020-669 Receiver for Wireless 2

• 330020-670 Repeater for Wireless 2

Contractor Certification Requirements

Veeder-Root requires the following minimum training certifications for contractors who will install and setup the

equipment discussed in this manual:

Installer (Level 1) Certification: Contractors holding valid Installer Certification are approved to perform wiring

and conduit routing; equipment mounting; probe, sensor and carbon canister vapor polisher installation; wireless

equipment installation; tank and line preparation; and line leak detector installation.

ATG Technician (Level 2/3 or 4) Certification: Contractors holding valid ATG Technician Certifications are

approved to perform installation checkout, startup, programming and operations training, system tests,

1

Introduction Related Documents

troubleshooting and servicing for all Veeder-Root Series Tank Monitoring Systems, including Line Leak Detection.

In addition, Contractors with the following sub-certification designations are approved to perform installation

checkout, startup, programming, system tests, troubleshooting, service techniques and operations training on the

designated system.

•Wireless 2

• Tall Tank

Warranty Registrations may only be submitted by selected Distributors.

Related Documents

It is important that installers have knowledge of all relevant procedures before commencing work. Read and

understand all manuals thoroughly. Do not to undertake work without understanding safety and required

installation practices. For ATG installation and set-up refer to the appropriate TLS manual.

577013-964 TLS RF Wireless 2 System (W2) Installation and Maintenance Guide

577013-756 TLS2 Site Prep Manual

576013-879 TLS-3XX Site prep and Installation Manual

577013-879 TLS-450 Site Prep and Installation Manual

577014-022 8601 Series Console/TLS4 Site Prep Certification Manual

577014-056 Mag-FLEX Probe Low Level Water Float Kit Installation Guide

Product Marking Information

RELATED DOCUMENTS

Documents Required to Install Equipment

This intrinsically safe apparatus is only for use as part of a Veeder-Root Automatic Tank Gauging System (ATG

Console with probes and sensors). To install intrinsically safe apparatus, use the specific control drawing that

appears on the nameplate of the applicable associated apparatus (ATG Console):

Equipment

Associated Apparatus

TLS-450/8600 331940-008

TLS-350, TLS-350R 331940-011

TLS-300 331940-013

TLS-50 or TLS2 or TLS-IB 331940-014

TLS4/8601 331940-018

Intrinsically Safe Apparatus for Wireless Applications

Tank Gauge Accessories 331940-012

UL/cUL Control Drawing Document No.

The control drawings contain information related to the correct installation of the overall intrinsically Safe System.

This includes information such as maximum number of apparatus, specific apparatus allowed in the system,

maximum cable lengths, references to codes, proper grounding and so on. Control drawings can be found on the

2

Introduction Safety Symbols

OFF

NOTICE

WARNING

CAUTION

accompanying Compact Disk (TECH DOCS CD) or on the internet at veeder.com under SUPPORT; VR

TECHNICAL DOCUMENTS; DRAWINGS.

Product Label Contents

I.S. CIRCUIT FOR HAZLOC DEVICE

F/N 889590-XXX

CL I, DIV. 1, GP.D

CL I, ZONE 0

AEx ia IIA

Ex ia IIA

TC=T4

-40°C < Ta < +60°C

MANUAL NO. 577014-042

S/N XXXXXX

SECURITE INTRINSEQUE

Safety Symbols

The following safety symbols may be used throughout this manual to alert you to important safety hazards and

precautions.

EXPLOSIVE

Fuels and their vapors are extremely explosive if ignited.

SLIPPERY

Curved metal tank surfaces can be extremely

slippery. Wear approved boots with slip

resistant soles.

POWER

To prevent ignition of flammable or combustible atmospheres, disconnect battery before

servicing.

WARNING indicates a hazardous situa-

tion which, if not avoided, could result in

death or serious injury.

SAFETY HARNESS

Injury or death resulting from falls while working on tall structures can be prevented by

wearing a 5-point harness that is tethered

securely by a shock absorbing lanyard to the

structure.

READ ALL RELATED MANUALS

Knowledge of all related procedures before

you begin work is important. Read and

understand all manuals thoroughly. If you do

not understand a procedure, ask someone

who does.

FLAMMABLE

Fuels and their vapors are extremely flammable.

FALLING OBJECTS

Being struck by even small objects falling from tall structures can result in severe injury or death. Wear your hard

hat at all times when working alongside tall structures.

NOTICE is used to address practices not related to

physical injury.

CAUTION indicates a hazardous situation which, if

not avoided, could result in minor or moderate

injury.

SAFETY BARRICADES

Unauthorized people or vehicles in the work area are dangerous. Always use safety cones or barricades, safety

tape, and your vehicle to block the work area.

3

Introduction Safety Warnings

OFF

NOTICE

Safety Warnings

To protect yourself and your equipment, observe the following warnings and important information:

WARNING

This product is to be installed in systems operating near locations where highly combustible

fuels or vapors may be present.

FAILURE TO COMPLY WITH THE FOLLOWING WARNINGS AND SAFETY PRECAUTIONS

COULD CAUSE DAMAGE TO PROPERTY, ENVIRONMENT, RESULTING IN SERIOUS INJURY

OR DEATH.

1. Read and follow all instructions in this manual, including all safety warnings to protect

yourself and others from serious injury, explosion, or electrical shock.

2. Comply with all applicable codes including: the National Electrical Code; federal, state,

and local codes; and other applicable safety codes.

3. To protect yourself and others from being struck by vehicles, block off your work area

during installation or service.

4. Do not alter or modify any component or substitute components in this kit.

5. Warning! Substitution of components may impair intrinsic safety.

6. Field wiring to the Probe must be at least 50mm from any non-intrinsically safe device’s

wiring.

7. Warning! To prevent ignition of flammable or combustible atmospheres, disconnect

battery before servicing.

8. Before installing or taking the unit into a hazardous area, earth the unit in a safe area to

remove any static charge. Then immediately transport the unit to the installation site.

Do not rub or clean the unit prior to installation. Cleaning is not required under normal

service conditions. Do not rub or clean the unit after installation. If the unit is not fixed

to a known earth point when installed, ensure that a separate earth connection is made

to prevent the potential of a static discharge. When fitting or removing the unit, use of

anti-static footwear or clothing is required.

Failure to install this product in accordance with its instructions and warnings will result in

voiding of all warranties with this product.

GENERAL PRECAUTIONS

Heed service markings: Opening or removing the console cover may expose you to electric shock. Servicing of

Veeder-Root equipment must be done by Veeder-Root authorized service contractors.

Use product with approved equipment: This product should be used only with Veeder-Root components identified

as suitable for use with the Mag-FLEX Probe.

Use the correct external power sources: This product should be operated only from the type of power sources

indicated on the electrical ratings labels affixed to the components. If you are not sure of the type of power source

required, consult your Veeder-Root authorized service contractor.

Mag-FLEX Probe cable length: The length of the cable from its exit point in the tank riser or tank fitting to the

transmitter cannot exceed 10 feet.

Wet or below grade installations: Installation of this equipment in wet or below grade locations requires that the

installer take steps to ensure that the equipment is mounted above the maximum water level.

4

Introduction General AST Guidelines

NOTICE

The Mag-FLEX Probe insertion length is critical to ordering and installing the correct probe into the correct tank.

An improper probe length could result in the probe weight coming in contact with the tank bottom resulting in

inaccurate fuel height measurement and possible probe damage.

The transmitter will not function properly in water. Also, submersion of the transmitter in

water can cause permanent damage to the internal electronics.

SPECIAL TOOLS REQUIRED FOR TRANSMITTER INSTALLATION

• Wrenches to tighten clamp bolts • Wire strippers • Tape measure

• Small blade screwdriver (max. blade width 3/32”) • T-10/T-15 Torx drivers • Thread sealant or PTFE tape

General AST Guidelines

Above ground storage tanks (AST’s) are an essential element in the distribution of petroleum products. Refer to

the following organizations for applicable standards associated with AST’s:

• American Petroleum Institute (API) – www.api.org

• National Fire Protection Association (NFPA) – www.nfpa.org

• Occupational Safety and Health Administration (OSHA) - www.osha.gov

• Petroleum Equipment Institute (PEI) – www.pei.org

• Steel Tank Institute (STI) – www.steeltank.com

• Underwriters Laboratories (UL) – www.ul.com

The above organizations may not address requirements imposed by individual jurisdictions. Each site owner must

ensure that contractors performing the work be knowledgeable of all applicable regulations. It is fully the

responsibility of the contractor, or employee performing the work, to abide by any and all additional Federal, State,

or local laws, regulations and manufacturer’s requirements that apply to the specific work being done. It is also the

responsibility of each contractor to ensure that subcontractors abide by all applicable safety requirements.

Construction related activities are covered by OSHA regulation 29 CFR 1926.

AST tanks must be properly grounded according to local codes and regulations.

AST Construction Safe Work Practices

Department of Labor rules for construction work practices are governed by OSHA as described in the Code of

Federal Regulations (CFR):

Title 29, Volume 8, Part 1926 - Safety and Health Regulations for Construction. Copies of these regulations are

available from OSHA’s web site located at 29 CFR 1926 (http:\\www.osha.gov). Most maintenance and other

operations are covered by OSHA 29 CFR 1910 (General Industry) regulations. These documents highlight many

of the Federal OSHA requirements that may apply to maintenance and construction work in the retail petroleum/

convenience business, but there is much more in the regulations than can be covered here. Some relevant

subsections are listed:

1910.66: Appendix C - Powered platforms, Man lifts, and Vehicle-Mounted Work Platforms

1910.23: Walking - Working surfaces - Guarding

1910.132: Personal Protective Equipment

Additional important information is available in the API publication: Safe Work Practices for Contractors

Working at Retail Petroleum/Convenience Facilities, API Recommended Practice 1646 First Edition,

August 2006, Product No. A16461. For more Information about API Publications, Programs and Services, go to

www.api.org. The requirements and recommended practices contained in this document are the minimum safety

procedures with which everyone shall comply while working at a retail petroleum/convenience facility.

5

Introduction Personal Protective Equipment

NOTICE

In addition, a task specific Job Safety Analysis shall be completed before any work may begin.

Personal Protective Equipment

The list below contains recommended clothing and protective equipment. Additional items may be advisable

depending on the job’s particular circumstances:

• 5-point safety harness

• 6-foot maximum, shock absorbing lanyard (there must be a support structure on top of the tank to which the safety

lanyard/harness can be attached)

•Hard hat

• Safety glasses

• Safety footwear (ANSI Z41)

•Long pants

• Gloves - leather for materials handling, cut-resistant for sharp materials

• A heavy canvas bag with handles to hold tools and pre-assembled parts

Before you Begin

The instructions in this manual assumes the top of the tank has a 1-1/2” or larger bung to receive the 1-1/2” process

connection.

IMPORTANT! The opening selected for the Mag-FLEX Probe must be as far as possible from

the tank inlet piping.

WIRELESS INSTALLATIONS

• The TLS RF console and receiver are installed.

• The TLS console is installed. Note: the Mag-FLEX Probe is only compatible with TLS Consoles installed with

Wireless 2 (2-Way) components supplied by V-R. The Mag-FLEX Probe is for inventory only applications. Leak

detection is not available.

• Do not mix Wireless 1 and Wireless 2 components on the same site or system. In each Wireless 2 System, there

is only one Receiver and one optional Repeater.

• The combination of the Mag-FLEX Probe, TLS RF Transmitter and Battery Pack form an intrinsically safe system

and as such must be installed according to the instructions listed in this manual.

• Consult the TLS RF system manual 577013-964 for wireless component setup and operation.

HARD-WIRED INSTALLATIONS

• The TLS console is installed.

• Wiring from probe to ATG complies with requirements outlined in the respective console’s site prep manual.

6

Mag-FLEX Probe Overview

Product Description

The Mag-FLEX is digital flexible probe is able to read temperature, product level and water level in the tank.

The Mag-FLEX Probe is a corrugated flexible probe designed to be used with any TLS console wherever there is a

requirement to monitor liquid levels higher than the current maximum height of Veeder-Root Mag probes (3.66m).

The following table details Mag-FLEX maximum measuring heights:

Any combination of Mag probe and Mag-FLEX can be connected to a TLS console, up to the maximum number of

inputs available on the channel.

The Mag-FLEX Probe has a weight and magnet at the base of the probe to give stability, suitable for use in a wide

range of products and available with or without water detection. The Mag-FLEX Probe with standard water float

uses a process connection requiring a 1-½” tank entry point with a BSP thread or 2” NPT when using the

included adapter. Table 1 lists minimum tank opening required for the Veeder-Root Mag-FLEX probe with the

standard water float and with the optional low level water float.

Table 1. Dimensions For Mag-FLEX Probe Tank Opening

V-R Water Float OD

V-R Water Float

Standard 1.7 (43) 2 50

Low Level 3.8 (96.52) 4 100

inch (mm)

Recommended Tank Opening Size

inch mm

Mag-FLEX Probe Limitations

Console Series

Maximum Limits

Probe Length in Feet 54.5 54.5 54.5 54.5 32

Probe Length in Inches 654 654 654 654 384

Probe Length in Centimeters

Tank Volume in Gallons 2,641,720 2,641,720 999,999 999,999 260,000

Tank Volume in Litres 9,999,999 9,999,999 3,785,408 3,785,408 984,207

TLS-450/TLS-XB TLS4/8601 TLS-350 TLS-300 TLS2

1,661 1,661 1,661 1,661 975

Maximum Number of MagFLEX Probes per Console

Console Software Oldest

Compatible Version

32 12 16 2 or 4 6

1C 1 22 22 1

7

Mag-FLEX Probe Overview Mag-FLEX Technical Data

Ø 43mm

Ø 47,2mm

Ø 34mm

M12 coupling (Probe connector)

Earth Connector

Probe canister

M6 x 10mm socket cap screw

(5mm Hex drive)

Screw-in process connection

1-1/2” BSP, 55mm, stainless steel

Probe shaft Ø 12mm, stainless steel

(adjustment range)

Corrugated shaft Ø 12mm,

stainless steel

Probe shaft Ø 12mm, stainless steel

Water float Ø 43mm

Weight, stain

less steel

Magnetic base

Product float Ø 43mm x 43mm high

500 mm

120 mm

500 mm

123 mm

Probe Length

Optional Tank Wall Guide*

Ø 152mm (6”)

*

Part of Low Level Water Float Kit.

Mag-FLEX Technical Data

• Level accuracy:

- Precision: +/- 2mm

- Repeatability: +/- 0.5mm

- Resolution: 0.001 mm

• Digital communication

• Temperature sensing

• Water detection (optional)

• Max liquid height: 15.0m

•Top mounted

• Process connection: for height adjustable

installation R 1½”, stainless steel

• Optional 1-1/2” BSP - 2” NPT adapter included

• Electrical connection: M12 connector

• Housing index of protection: IP68

Mag-FLEX Probes Part Number Specification

• Sensor materials:

- Housing in stainless steel: 303

- Tube: 316Ti

- Corrugated hose: 316L

• Weight: stainless steel: 316L; encapsulation of

retaining magnet: conductive plastic (PTFE

with graphite)

• Operating temperature range: -40°C to +60°C

Important: the instructions below are intended as reference material only, the Gilbarco Veeder-Root training

modules contain comprehensive information and must be completed before any installation work is attempted contact Gilbarco Veeder-Root for details.

8

Mag-FLEX Probe Overview National Electrical Code Compliance

Table 2. Part Number Nomenclature

P/No. Petrol/E10 Diesel No WD

-103 -203 -303 13.16 16.40

-104 -204 -304 16.44 19.69

-105 -205 -305 19.72 22.97

-106 -206 -306 23.00 26.25

-107 -207 -307 26.28 29.53

889590

-108 -208 -308 29.56 32.81

-109 -209 -309 32.84 36.09

-110 -210 -310 36.12 39.37

-111 -211 -311 39.40 42.65

-112 -212 -312 42.68 45.93

-113 -213 -313 45.96 49.21

Probe Minimum

Length (ft)

Probe Maximum

Length (ft) Approvals

UL/cUL

MAG-FLEX SPARE PARTS AND ACCESSORIES

Item Part Number

Leader Cable with M12 Connector 908704 (Spare part only, supplied with all new probes)

Optional 1-1/2” BSP to 2” NPT adapter 579008-708

Optional 2” NPTF to 4” NPTF adapter 333535-001

Optional Low Level Water Float Kit 330020-776 (Gasoline); 330020-777 (Diesel)

National Electrical Code Compliance

The following information is for general reference and is not intended to replace recommended National Electric

Code (NEC) procedures. It is important for the installer to understand that electrical equipment and wiring located

in Class I, Division 1 and 2 installations shall comply with the latest appropriate articles found in the National

Electric Code (NFPA 70) and the Code for Motor Fuel Dispensing Facilities and Repair Garages (NFPA 30A), or

other local codes such as the CEC, Canadian Electrical Code.

AST tanks must be properly grounded according to NFPA 70 and applicable local codes and regulations.

MAG-FLEX PROBE WIRE LENGTH

Improper system operation could result in undetected potential environmental and health hazards if the Mag-FLEX

Probe to TLS RF Transmitter wire runs exceed 10 feet.

Veeder-Root Parts

• Veeder-Root Mag-FLEX Probe, P/N 889590-XXX

• Optional Veeder-Root Mag-FLEX Wireless Installation Kit (includes mounting hardware, transmitter and battery

pack), P/N 330020-770

• Single-Channel Encapsulation Kit, P/N 848100-001

• Dual-Channel Encapsulation Kit, P/N 848100-002

9

Example Drawings

ALARM

WARNING

POWER

9

12

14

042-5

15

16

17

7

10

11

13

2

1

4

5

3

6

8

I.S.

Example Mag-FLEX Probe Site Layout Drawing - Wireless Installation

Figure 1. Site Drawing - Example TLS RF Wireless 2 System Site Layout – Two Mag-FLEX Probes

LEGEND FOR NUMBERED BOXES IN Figure 1

To be installed in accordance with the National Electrical Code, NFPA

70 and the Code for Motor Fuel Dispensing Facilities and Repair Garages (NFPA 30A), or other local codes.

1. Battery Pack

2. Mag-FLEX probe

3. Junction box

4. Transmitter

5. 4mm

2

diameter (10 gauge) ground wire from probe canister to

tank ground.

6. 4mm2 diameter (10 gauge) ground wire from junction box to

tank ground.

7. AST grounding cables and earth electrodes according to

NFPA70, NFPA30A and local codes (ref. example in Figure 3).

8. Receiver

9. RS-485 cable (Belden#3107A or equiv.)

10. TLS RF (Vm=250V)

11. Intrinsically safe wiring

12. TLS console (Vm=250V)

13. Conduit that enters power wiring knockouts

14. 120 or 230 Vac from power panel - separate branch circuits are

required for the TLS RF and TLS console.

15. Non-hazardous area

16. Hazardous area (Class I, Div. 1, Group D)

17. Concrete tank pad.

10

Example Drawings Example Mag-FLEX Probe Site Layout Drawing - Hard-Wired Installation

ALARM

WARNING

POWER

11

042-4

12

13

14

7

1

4

5

2

3

10

I.S. I.S.

9

8

6

Example Mag-FLEX Probe Site Layout Drawing - Hard-Wired Installation

Figure 2. Site Drawing - Example Hardwired System Site Layout – Two Mag-FLEX Probes

LEGEND FOR NUMBERED BOXES IN Figure 2

To be installed in accordance with the National Electrical Code, NFPA

70 and the Code for Motor Fuel Dispensing Facilities and Repair Garages (NFPA 30A), or other local codes.

1. Mag-FLEX probe

2. 4mm2 diameter (10 gauge) ground wire from junction box to tank

ground.

3. Junction box

4. Seal off

5. Conduit

6. 4mm

7. AST grounding cables and earth electrodes according to NFPA70,

8. Intrinsically safe wiring

9. TLS console (Vm=250V)

2

diameter (10 gauge) ground wire from probe canister to

tank ground.

NFPA30A and local codes (ref. example in Figure 3)

10. 120 or 230 Vac from power panel - separate branch circuits are

required for the TLS RF and TLS console.

11. Non-hazardous area

12. Hazardous area (Class I, Div. 1, Group D)

13. Concrete tank pad.

11

Example Drawings Mag-FLEX Probe Length Calculation

042-1.eps

6

1

2

3

1

6

7

5

4

Mag-FLEX Probe Length Calculation

Before ordering the Mag-FLEX Probe, an accurate dimension for “1” must be obtained. Measure internally the

Insertion Length of ‘1’ from the 1½” entry point to the bottom of the tank (see Figure 3). Probe length for ordering

purposes = Length of ‘1’ + 250 mm

LEGEND FOR NUMBERED BOXES IN Figure 3

1. Measured insertion Length (seeTable 2 for probe form number

to order - always order smaller probe if measured insertion

length falls between two probes in the table).

2. Insertion measuring point for 1-1/2” BSP gland (top of entry

bung.

3. Magnet rests on tank bottom.

Figure 3. Mag-FLEX Probe Parameters

4. Tank grounding bracket

5. Grounding cable

6. Concrete tank pad

7. Earth grounded electrode with cable bracket

12

Example Drawings Probe Handling

Probe Handling

It is important to handle the Mag-FLEX probe with care at all times during the installation. Avoid excessive bending

of the probe especially at the points the ridged sections meet with the flexible shaft. Below you can see examples

of mishandling that would cause irreversible damage to the probe and invalidate the terms of warranty.

13

System Safety Layout

NOTICE

WARNING

NOTICE

Conduit/ducting requirements are dependent on local electrical regulations.

WARNING

Substitution of components may impair intrinsic safety. Probe, probe wiring and console wiring are intrinsically safe only when connected via this barrier.

Field Cable Ducting / Cable Trays

Explosion could occur if other wires share ducts with intrinsically safe circuits. Ducting from probes or sensors must not contain any other wiring.

WARNING

Minimum diameters for underground probe ducting are:

• Up to 20 cables -100 mm diameter

• Up to 50 cables -150 mm diameter

Run suitable diameter cable ducting and / or cable trays from the TLS Console to each Mag-FLEX probe location.

For underground tanks, all cable duct entry points must be sealed to prevent the escape of hydrocarbon vapour and

liquid and the ingress of water. Cable duct & cable tray plans must be designed to suit local site requirements and

must conform to local/national regulations and industry standards.

For multiple TLS installations, the Mag Probe and Mag-FLEX cabling for one TLS system must be contained in

separate cable duct or tray to those cables belonging to another TLS system. Combining cables from different TLS

systems will be in violation of the intrinsically safe approval for this system and is not permitted. Combining cables

from different systems may also result in improper system operation.

Unless specified otherwise, any draw pits should be sited at 10 metre intervals or where acute cable duct angles are

unavoidable.

Ensure that all ducting is equipped with cable pull through ropes and that all visible cable ducts are properly fixed

and finished off in a neat and tidy manner.

All above ground cable runs should be properly secured and adequately protected from accidental damage.

FAILURE TO COMPLY WITH THE FOLLOWING WARNINGS AND SAFETY PRECAUTIONS COULD CAUSE DAMAGE TO PROPERTY, ENVIRONMENT, RESULTING IN SERIOUS INJURY OR DEATH.

Cable Specifications For Intrinsically Safe Apparatus Cabling

Cable must be installed to comply with local and national regulations in force at the time of installation. It is the

Installer’s responsibility to ensure that the installation complies with all relevant local and national legislation and

codes of practice.

Do not run the Mag-FLEX probe cable from the tank to the TLS Console in the same cable duct as non-intrinsically

safe wiring.

Gilbarco Veeder-Root requires the use of shielded cable for Mag-FLEX cabling. The cable must have a minimum

conductor CSA of 0.75 mm² and must meet with intrinsically safe system installation requirements. The cable

capacitance, inductance and L/R ratio must conform to the intrinsically safe output characteristics of the TLS

Console and the intrinsically safe input characteristics of the Mag-FLEX probe.

Field Cable, ATG to Probe, direct burial cable, V-R P/N 848100-2XX

The TLS Console to Mag-FLEX probe cable length must not exceed 300 meters.

14

.

Mag-FLEX Installation & Handling Procedures

Probe Installation Requirements

Installation requires a minimum of two people to allow correct handling of the probe. Please note that the flexible

and therefore fragile nature of the Mag-FLEX probe makes it more prone to mechanical shock. The probe must not

be unpacked until it has been brought to its place of installation and where possible unpacked at the Tank top. The

probe corrugated shaft is supplied in a 1 meter diameter coil this coil MUST not be reduced in size. The packaged

curve is the maximum bend possible to prevent damage.

Miscellaneous Requirements

TANK ENTRY

The tank entry point provided must have an internal thread of 1½” BSP. Two optional adapters are available:

• Optional 1-1/2” BSP to 2” NPT adapter (P/N 579008-708)

• Optional 2” NPTF to 4” NPTF adapter (P/N 333535-001)

PROBE ASSEMBLY

The process connection, water float, product float, weight and magnet are shipped pre-assembled on the probe.

TOOLS AND MATERIALS

Before starting the installation you should have the following tools & materials:

• Mag-FLEX probe suitable for the tank height. See Mag-FLEX Probe Length Calculation on page 12.

• 2-Core probe cable run from TLS location to tank top. See Cable Specifications For I.S. Apparatus Cabling on

page 14.

• Optional junction box, part number 848100-004

• Non-sparking 55mm WAF (Width across Flat) spanner to tighten the 1-1/2” BSP process connection

• Non-sparking 65mm WAF spanner to tighten 2” NPT adapter (if used)

• Liquid sealing material for process connection, compatible with the tank material & product to be monitored

• Non-sparking Hexagon key (5mm) for the locking screw

• Non-sparking 30mm Spanner for the gland 30mm WAF (Width across Flat)

• Measuring tape to establish the correct position to lock the probe shaft into place

• For wireless installs - VR Kit 330020-770

• For hardwired installs - necessary conduit and seal offs as required

• Strap wrench (5-inch pipe capacity minimum)

15

Mag-FLEX Installation & Handling Procedures Mag-FLEX Probe Installation

NOTICE

1m

Mag-FLEX Probe Installation

1. Unpacking the Probe

The probe shipping box is 1.1m square

and12cm deep. The probe is coiled to a

diameter of approximately 1m. The probe

should not be unpacked until the tank is

ready to accept it. Where possible, the

probe should be transported to the top of

the tank in its packaging.

2. Removal of the packaging

Two people are required to remove

the probe from its packaging to prevent any kinking or distortion of the

flexible probe shaft. Damage cause by

mishandling will not be covered under

warranty.

• If there is deformation at the transition

points between probe shaft and

corrugated sections extreme care must

be taken to straighten them before

installation in to the tank.

• Always keep the probe coils parallel. Do

not lift one coil separately from the

others. Never twist one coil 90º from the

others.

• Do not twist the probe during

installation. Always keep the coils of the

probe parallel. “Unroll” it progressively

into the tank.

• Do not let the coil become less than 1m

in diameter whilst uncoiling.

16

Mag-FLEX Installation & Handling Procedures Mag-FLEX Probe Installation

1m

M6 x 10 socket

cap screw

3. Probe held ready for installation

The coil should be held as shown maintain-

ing the coiled shape to prevent kinking.

4. Process Connection

With the 5mm hex key, loosen the socket

cap screw and gland. Slide the process

connection towards the probe head and

temporarily secure.

Standard 2” Water Float

If needed, screw the optional 1-1/2” BSP

to 2” NPT adapter into the tank opening

and tighten with a 65mm WAF spanner.

Optional 4” Low Level Water Float

(LLWF)

If the 4” LLWF is being used, screw the

optional 2” NPTF to 4” NPTF adapter into

the 4” tank opening and tighten with the

strap wrench.

5. Lowering the probe through the tank opening

Standard 2” Water Float

Lower the probe’s magnetic base and

floats into the tank opening.

Optional 4” LLWF

With the 4” LLWF removed, slip the

optional 1-1/2” BSP to 2” NPT adapter

over the magnetic base and existing floats.

Snap the 4” LLWF onto the S.S. ball float

as described in the LLWF manual (577014-

056). Lower the probe’s magnetic base

and floats into the tank as shown. As soon

as the probe’s base components are lowered through the 4” NPTF adapter, screw

the 1-1/2” BSP to 2” NPT adapter into the

2” NPTF to 4” NPTF adapter and tighten

with a 65mm WAF spanner.

17

Mag-FLEX Installation & Handling Procedures Mag-FLEX Probe Installation

1m

6. Feeding the probe into the tank

Unroll the corrugated shaft as the probe is

lowered into the tank taking care to avoid

chafing on the tank entry.

7. Corrugated shaft lowered into tank

Steel Tanks

At this point lower the probe slowly until

you feel the magnetic attraction as it contacts the bottom of the tank.

Non-Steel tanks

Lower the probe until you feel the weight

contact the tank bottom.

8. Installation dimension

With the probe in contact with the tank bottom and the probe held taut, measure the clearance from the lower

edge of the probe canister to the top of the tank entry point (installation dimension) record this measurement.

Record

measurement

18

Mag-FLEX Installation & Handling Procedures Mag-FLEX Probe Installation

Tighten process

connection

with 55mm

spanner

NOTICE

M6 x 10mm

socket cap

locking screw

Earth

connector

9. Fitting the process connection

Apply sealant to the thread of the process

connection. Carefully lower the process

connection into the tank entry fitting.

Screw in and tighten using a 55mm WAF

spanner.

10. Securing the probe

Raise the probe canister until the exact

installation dimension that you measured &

recorded in step 8 is achieved.

Do not raise the probe any higher as it

will become detached from the bottom of the tank.

With the probe in this position tighten the

gland nut using a 30mm WAF spanner.

Secure the locking screw with the 5mm

Hexagon key.

19

Mag-FLEX Installation & Handling Procedures Mag-FLEX Probe Installation

Transmitter

(attached to

side of bracket)

Battery pack (in bracket)

Mag-FLEX probe

canister

Riser pipe

4mm

2

0 ground

wire from Surge

Protecter to tank

ground

4mm

2

0 ground

wire from Probe

canister to tank

ground

Mag-FLEX

probe

canister

Seal off

Conduit with Probe

field wiring to ATG

4mm2 0 ground

wire from Surge

Arrester to tank

ground

4mm

2

0 ground wire from Probe

canister to tank ground

Example Wireless Installation Example Hardwired Installation

Single Channel

Encapsulation Kit

(P/N 848100-001)

Dual Channel

Encapsulation Kit

(P/N 848100-002)

11. Example installations

Transmitter

(attached to

side of bracket)

2

0 ground

4mm

wire from Surge

Protecter to tank

ground

Example Wireless Installation Example Hardwired Installation

Battery pack (in bracket)

2

0 ground

4mm

wire from Probe

canister to tank

ground

Mag-FLEX probe

canister

Junction box

Riser pipe

Figure 4. Junction Box Installation Examples

2

4mm

canister to tank ground

4mm2 0 ground

wire from Surge

Arrester to tank

ground

Conduit

Seal off

Conduit with Probe

field wiring to ATG

0 ground wire from Probe

Mag-FLEX

probe

canister

Junction box

Figure 5. Veeder-Root Single- And Dual-Channel Encapsulation Kit Installation Examples

20

Mag-FLEX Installation & Handling Procedures Mag-FLEX Probe Field Wiring Connections

Black wire (-)

White wire (+)

NOTICE

Mag-FLEX Probe Field Wiring Connections

OPTIONAL JUNCTION BOX - WIRED INSTALLATIONS ONLY

12. Connecting the probe leader cable - Connect the leader cable supplied with the probe to the M12 con-

nector located on the top of the probe canister. Attach the connector of the supplied Leader Cable to the M12

connector on the probe head. First tighten the union nut of the M12 connector by hand and then tighten the

nut a further 180° using an open-ended spanner. The tightening torque should be in the range of 100~150 N/

cm.

13. Fitting the screw-in gland assembly - Connect the other end of the probe leader cable to the optional

junction box as shown below.

14. Grounding the probe to the tank

A 10 gauge (4mm²) earth cable must

be connected between the probe canister earth connector and tank ground.

Earth

cable

21

Mag-FLEX Installation & Handling Procedures Mag-FLEX Probe Field Wiring Connections

NOTICE

10 gauge (4mm2) minimum

earth cable to tank ground

Saddle clamp

Probe leader

cable

Field cable to

TLS console or

TLS RF Transmitter

15. Grounding the optional junction box to the tank

A 10 gauge (4mm²) earth cable must

be connected between the junction

box and tank ground connection.

The earth cable should be connected to

the external saddle clamp of the junction

box.

16. Field cable connection - optional junction box

HARDWIRED INSTALLS - Connect the

2 wire field cable from the TLS console

to the junction box as shown. Correct

polarity MUST be maintained. The field

cable length should not exceed 300

metres.

WIRELESS INSTALLS - Connect the 2

wire field cable from the TLS RF transmitter probe to the junction box as

shown.

VEEDER-ROOT ENCAPSULATION KITS

1. Cut the soft vinyl epoxy enclosure end cap entrance holes of the Encapsulation Kit enclosure to accommodate

each cable diameter. Keep the hole sizes to a minimum. Insert about 5 inches (127mm) of each cable through

the openings [Figure 6]. Remove 3 inches (76mm) of the outer jacket from each cable. Trim the insulation from

the conductors.

Probe

cable

TLS

cable

Protective cap

Probe

cable

Transmitter

Cable

2”

(51mm)

Shield wire

3”

(76mm)

Black

White

Black

White

Dual Channel (Wired Installations) Single Channel (Wireless Installations)

2”

(51mm)

Protective cap

Shield wire

(76mm)

Black

White

Black

White

3”

Figure 6. Splice Length Dimensions

22

Mag-FLEX Installation & Handling Procedures Mag-FLEX Probe Field Wiring Connections

Cable from Transmitter

Connect Probe white to

Encapsulation Kit white

Connect Probe black to

Encapsulation Kit black

Connect Transmitter black

to Encapsulation Kit black

Connect Transmitter white

to Encapsulation Kit white

Enclosure

Bare drain wire

(cut back to

cable jacket)

Cable from probe

Cable from TLS

Connect Probe white to

Encapsulation Kit white

Connect Probe black to

Encapsulation Kit black

Connect TLS white to

Encapsulation Kit white

Connect TLS black to

Encapsulation Kit black

Enclosure

Bare drain wire

(cut back to

cable jacket)

Cable from probe

4mm2 mimum

Green/Yellow

ground wire

4mm2 mimum

Green/Yellow

ground wire

Dual Channel - Wired Installations Single Channel - Wireless Installations

2. Make the connections to the four black and white wires in the Encapsulation Kit using wire nuts as shown in

Figure 7. Depending on the installation, cut off the TLS console or Transmitter cable’s bare shield wire at the

cable jacket.

3. Center the splices in the clear plastic sleeve. Assemble the Encapsulation Kit closure, making sure the sleeve

4. Remove bag of “Sealing compound” from foil package. Grasp the ends, one in each hand, then pull sharply to

Figure 7. Splice Connections

is fully inserted into each of the vinyl end caps. Rotate the sleeve cover until both slot openings line up.

Arrange the closure so the slot openings are facing up and the enclosure is as level as possible.

WARNING!

Sealing compound contains isocyanate. Vapor and liquid may cause

sensitization. May be irritating to the eyes.

Avoid skin and eye contact. Avoid repeated and prolonged breathing of vapor.

Use only in well ventilated areas. Wear chemically resistant gloves.

remove plastic clip [Figure 8].

Inhalation - provide fresh air. In case of eye contact flush eyes with plenty of

water for 10 minutes and get medical attention. If ingested do not induce

vomiting. Get medical attention. Wash with soap and water in case of skin

contact.

23

Mag-FLEX Installation & Handling Procedures Mag-FLEX Probe Field Wiring Connections

Chemically resistant

gloves

NOTICE

Figure 8. Removing Sealing Compound Clip

5. Thoroughly mix compound together. Invert bag several times while squeezing compound from one end to the

other for a minimum of one minute.

6. Once the mixture feels warm, immediately cut one corner and slowly fill the enclosure’s plastic sleeve. Stop

just short of filling the entire sleeve. Do not overfill. [Figure 9]

Figure 9. Pouring Sealing Compound Into Sleeve

7. With a twisting motion, rotate the outer clear plastic barrel to close the pouring slot.Wait at least five minutes,

then use the large cable tie to mount the Encapsulation Kit to the riser pipe or probe canister as applicable.

An earth cable must be connected between the Encapsulation Kit and a tank ground

connection. According to the provision of EN/IEC 60079-14, the minimum size of the earth

cable shall be 4 mm².

8. Connect the green/yellow ground wire from the Encapsulation Kit to an appropriate tank ground (see

Figure 5).

24

Mag-FLEX Installation & Handling Procedures TLS setup

TLS setup

The TLS console Mag-FLEX setup is similar to that for a standard Mag Plus Probe setup. Listed below are the

setup exceptions.

FLOAT TYPE

For TLS2, TLS-3XX or TLS-450 consoles, the float type must be set to 3” FLOAT (76.2 mm).

1. This is the default float type.

2. Water detection starts at 5.5” (140mm). Per the console’s programming, water height warnings and alarms

cannot be set above 5” (127mm), therefore when the float reaches 5.5” both the water warning and alarm will

be activated. (Program the console to any amount within the required thresholds of 0.87 to 5.0 inches (22.1 to

127mm).)

If a water reading of 5.5” or below is required, install the Low Level Water Float.

3. See manual 577014-056 for setup instructions when installing a low level water float.

TANK PROFILE

Select ‘Linear’ for TLS2, TLS-3XX or TLS-450 consoles, or ‘Multi-Point’ if an accurate tank chart is available.

TANK DIAMETER

For vertical cylindrical tanks, enter the full tank height here (NOT the diameter of the cylinder). Full height is the

distance from the bottom of the tank to the top of the cylinder excluding the domed lid at the top of the tank. Set

the height in mm.

Exit Setup Mode and check the inventory report, the water reading should now be “0”. Verify all TLS setup

parameters are correct. If necessary, secure all console doors.

25

For technical support, sales or

other assistance, please visit:

www.veeder.com

Loading...

Loading...