Page 1

Technical Installation Guide

EMR4

Manual No: 577014-322 ● Revision: B

Page 2

Notice

Veeder-Root makes no warranty of any kind with regard to this publication, including, but not limited to, the implied warranties of

merchantability and fitness for a particular purpose.

Veeder-Root shall not be liable for errors contained herein or for incidental or consequential damages in

connection with the furnishing, performance, or use of this publication.

Veeder-Root reserves the right to change system options or features, or the information contained in this publication.

This publication contains proprietary information which is protected by copyright. All rights reserved. No part of this publication may be

photocopied, reproduced, or translated to another language without the prior written consent of Veeder-Root.

Contact Technical Support for additional troubleshooting information at 800-323-1799.

DAMAGE CLAIMS / LOST EQUIPMENT

Thoroughly examine all components and units as soon as they are received. If any cartons are damaged or missing, write a complete

and detailed description of the damage or shortage on the face of the freight bill. The carrier's agent must verify the inspection and sign

the description. Refuse only the damaged product, not the entire shipment.

Veeder-Root must be notified of any damages and/or shortages within 30 days of receipt of the shipment, as stated in our Terms and

Conditions.

VEEDER-ROOT’S PREFERRED CARRIER

1. Contact Veeder-Root Customer Service at 800-873-3313 with the specific part numbers and quantities that were missing or

received damaged.

2. Fax signed Bill of Lading (BOL) to Veeder-Root Customer Service at 800-234-5350.

3. Veeder-Root will file the claim with the carrier and replace the damaged/missing product at no charge to the customer. Customer

Service will work with production facility to have the replacement product shipped as soon as possible.

CUSTOMER’S PREFERRED CARRIER

1. It is the customer’s responsibility to file a claim with their carrier.

2. Customer may submit a replacement purchase order. Customer is responsible for all charges and freight associated with

replacement order. Customer Service will work with production facility to have the replacement product shipped as soon as

possible.

3. If “lost” equipment is delivered at a later date and is not needed, Veeder-Root will allow a Return to Stock without a restocking fee.

4. Veeder-Root will NOT be responsible for any compensation when a customer chooses their own carrier.

RETURN SHIPPING

For the parts return procedure, please follow the appropriate instructions in the EMR Products General Returned Goods Policy pages

in the EMR4 Products price list. Veeder-Root will not accept any return product without a Return Goods Authorization (RGA) number

clearly printed on the outside of the package.

©Veeder-Root 2018. All rights reserved

.

Page 3

Safety Information

Safety Warnings ...............................................................................................................2

Special Conditions for Safe Use .......................................................................................2

EMR4 Truck Installation

Installing The Interconnection Box (IB) .............................................................................4

Input Power – Critical Ground Connection ........................................................................4

2-Stage Solenoid Valve Connections .......................................................................8

Valve Operation With The EMR4 .............................................................................8

3-Way Safety Valve for Truck LP Gas Systems ...............................................................9

Installing The 3-way Valve........................................................................................9

Solenoid Valves......................................................................................................12

Wiring The Display Head ................................................................................................14

C&C Mode Switch ...........................................................................................................16

Installing Optional Keypad Kit - Right or Left Side ..........................................................16

IInstalling The Remote Display (Optional) ......................................................................16

Installing The Remote Pulser (Optional) .........................................................................19

Pulse Encoder Specifications.................................................................................19

EMR4 Terminal & Fueling Depot Installation

Wiring The Display Head ................................................................................................21

Installing The Interconnect Box (IB) ................................................................................22

National Electrical Code Compliance .....................................................................22

Grounding...............................................................................................................22

Wire Type for Metallic or PVC Conduit...................................................................23

Wire Length ............................................................................................................23

Mounting and Wiring the IB Unit.............................................................................23

Solenoid Valves......................................................................................................23

Power Conditioning Requirements .................................................................................26

Wire Size And/or Distance Limitations ...................................................................26

Pulse Output Limits ................................................................................................29

EMR4 – Legal Disclaimer Notice ....................................................................................29

Table of Contents

Figures

EMR4 System Specifications

System Power .................................................................................................................30

Component Location .......................................................................................................30

Appendix A: EMR4 Safety Instructions & System Specifications

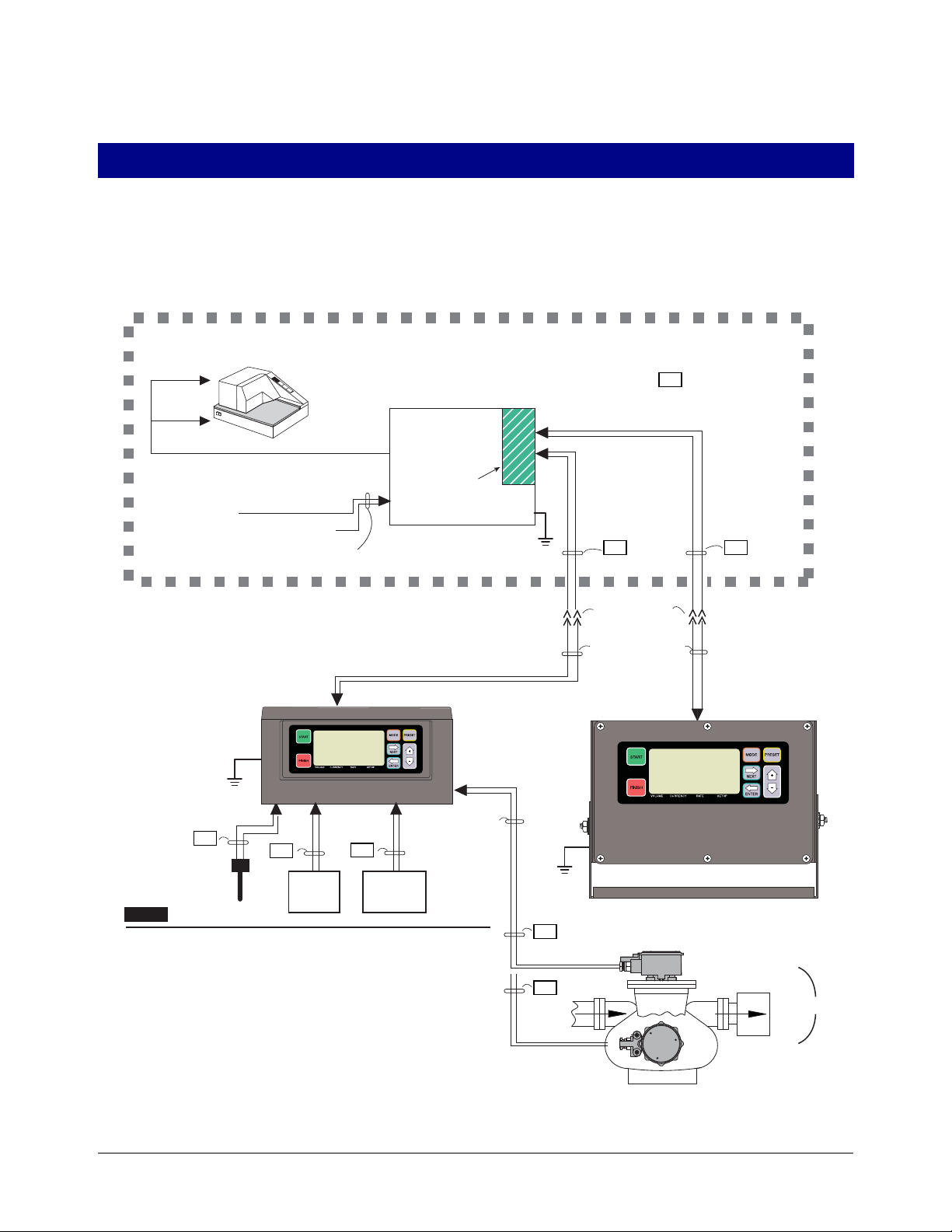

Figure 1. Example EMR4 truck Installation With 2 Display Heads And

Optional Remote Pulser ..........................................................................3

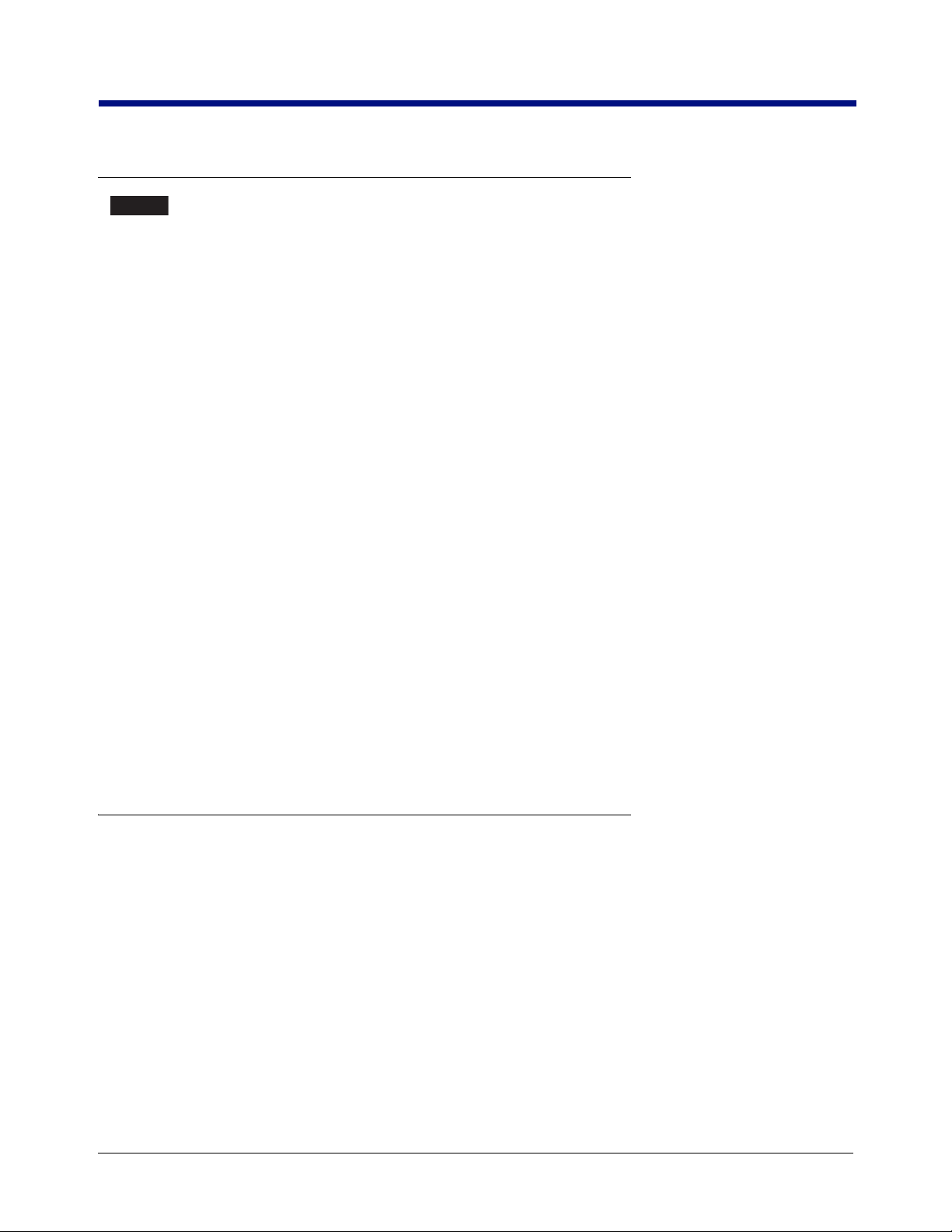

Figure 2. IB Physical Dimensions (Shown With Cover Removed) .........................6

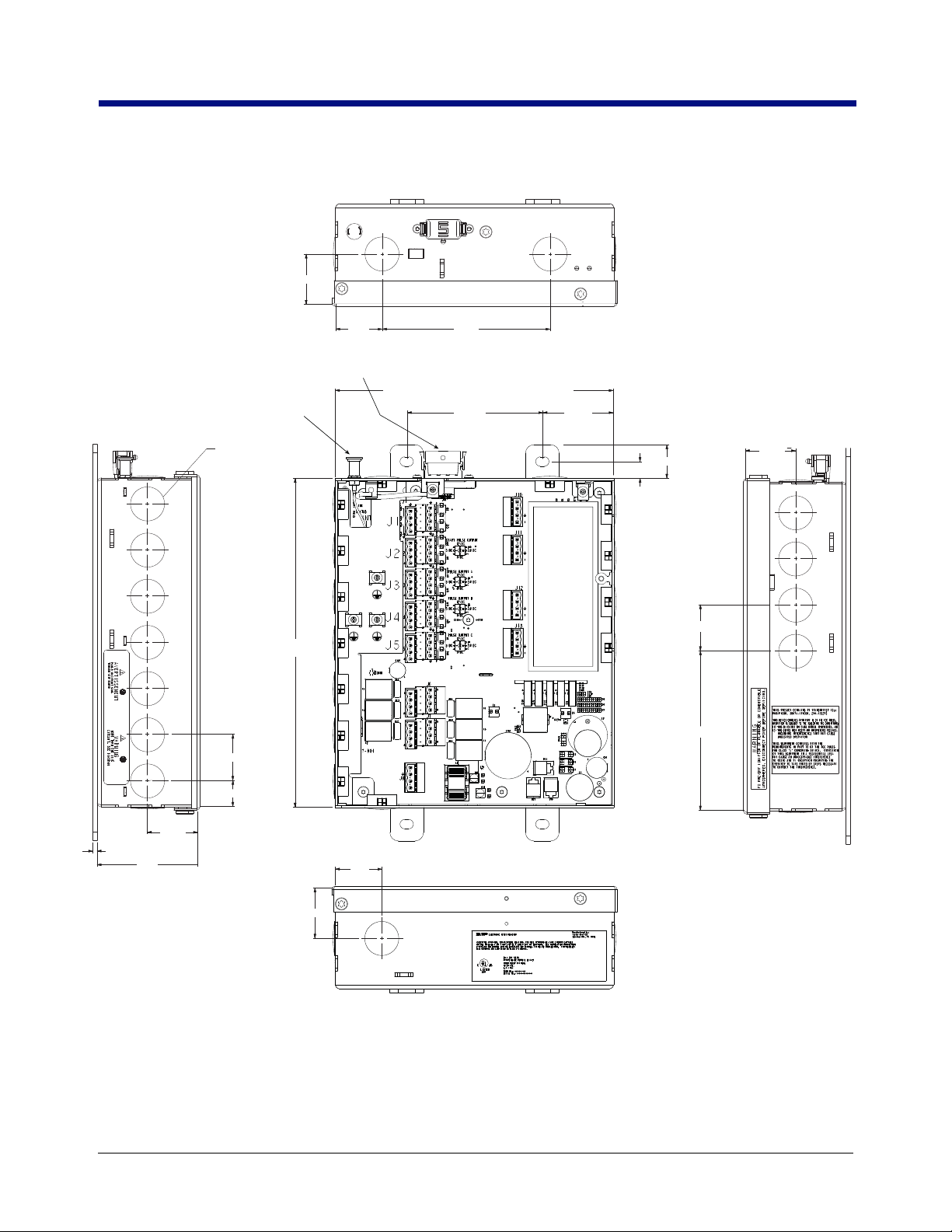

Figure 3. EMR4 IB Box Wiring Connections ..........................................................7

Figure 4. 2-Stage Solenoid Valve ..........................................................................8

Figure 5. Connecting 3-Way Valve To Neptune Meter -

Truck LP Gas Installations ....................................................................10

Figure 6. Connecting 3-Way Valve To L.C./TCS Meter -

Truck LP Gas Installations ....................................................................11

Figure 7. Connecting 3-Way Valve To The Interconnect Box ..............................12

Figure 8. Example Wiring Connections For DC And AC Solenoid Valves ...........13

Figure 9. Display Head Cable Connections .........................................................15

Figure 10. Remote Display Assembly ....................................................................17

iii

Page 4

Tables

Table of Contents

Figure 11. Remote Display Connections (Rear Cover Removed) .........................18

Figure 12. Wiring Connections In Remote Pulser (Top Cover Removed) .............19

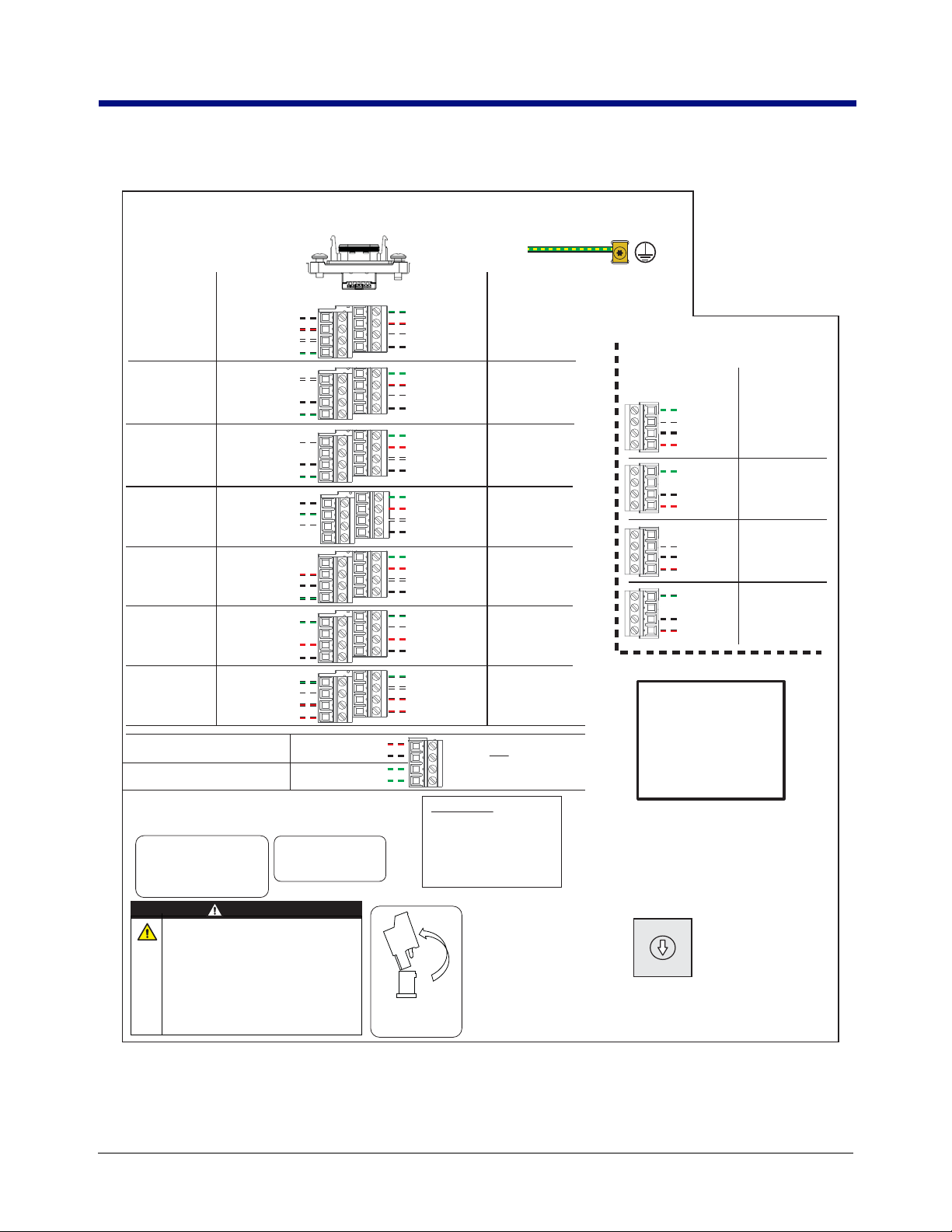

Figure 13. Example Terminal Fueling Depot Installation With 2 Display Heads

And Optional Remote Pulser ................................................................20

Figure 14. Display Head Cable Connections .........................................................22

Figure 15. EMR4 IB Box Wiring Connections ........................................................24

Figure 16. Example Terminal Wiring Connections For DC And

AC Solenoid Valves ..............................................................................25

Figure 17. Digi-Key Power Supply Wiring Diagram ...............................................26

Figure 18. Wiring Pulse Output To A TLS-350 Console ........................................27

Figure 19. Wiring Pulse Output To A TLS-450/TLS4 Console ...............................28

Table 1. 2-Stage Solenoid Wiring ............................................................................8

Table 2. Remote Display (84559X-00X) Components ..........................................16

Table 3. System Component Dimensions ............................................................30

Table 4. Remote Pulser Dimensions ....................................................................31

Table A-1. System Component Information ...........................................................A-3

Table A-2. Remote Pulser Information ................................................................... A-3

iv

Page 5

Safety Information

OFF

WARNING

NOTICE

CAUTION

The following safety symbols may be used throughout this manual to alert you to important safety hazards and

precautions

EXPLOSIVE

Fuels and their vapors are extremely explosive if ignited.

TURN POWER OFF

Live power to a device creates a potential

shock hazard. Turn Off power to the device

and associated accessories when servicing

the unit.

NOTICE

Alerts the user to practices not related to

physical injury.

INJURY

Careless or improper handling of materials

can result in bodily injury.

WEAR EYE PROTECTION

Fuel spray from residual pressure in the lines

can cause serious eye injuries. Epoxy sealant can cause eye injury. Always wear eye

protection when working with pressurized

lines and epoxy mixtures.

READ ALL RELATED MANUALS

Knowledge of all related procedures before

you begin work is important. Read and

understand all manuals thoroughly. If you do

not understand a procedure, ask someone

who does.

FLAMMABLE

Fuels and their vapors are extremely

flammable.

WARNING

Indicates a hazardous situation which,

if not avoided, could result in death or

serious injury.

CAUTION

Indicates a hazardous situation which,

if not avoided, could result in minor or

moderate injury.

GLOVES

Wear gloves to protect hands from irritation or injury.

NO OPEN FLAMES

Open flames from matches, lighters,

welding torches, etc. can ignite fuels

and their vapors.

1

Page 6

Safety Information Safety Warnings

NOTICE

Safety Warnings

Who is allowed to work on this equipment: Only trained or authorized individuals knowledgeable in

the related procedures should install, inspect, maintain, or service this equipment.

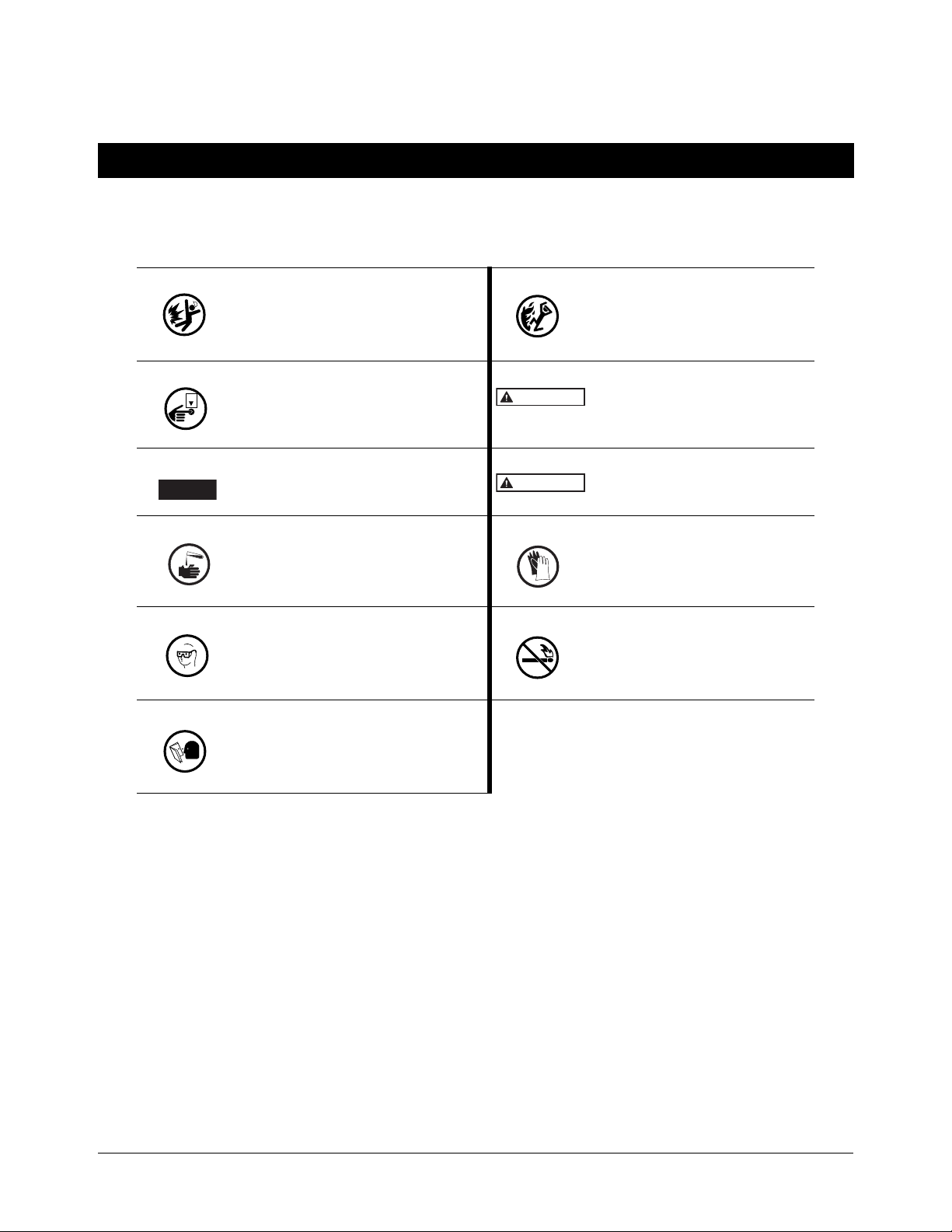

WARNING

This system operates near highly combustible fuel storage tanks.

FAILURE TO COMPLY WITH THE FOLLOWING WARNINGS AND SAFETY

PRECAUTIONS COULD CAUSE DAMAGE TO PROPERTY, ENVIRONMENT,

RESULTING IN SERIOUS INJURY OR DEATH.

VEEDER-ROOT’S EMR4 PRODUCT IS NOT APPROVED FOR USE AS A

COMPONENT THAT PROVIDES LIQUID ADDITIVES TO AN AIRCRAFT FUELING

SYSTEM.

To ensure proper installation, operation, and continued safe use of this product:

1. Read and follow all instructions in this manual, including all safety

warnings.

2. Have equipment installed by a contractor trained in its proper installation

and in compliance with all applicable codes including: the National

Electrical Code; federal, state, and local codes; and other applicable safety

codes.

3. To prevent ignition of flammable or combustible atmospheres, disconnect

power before servicing.

4. Operate this equipment in accordance with the instructions in this manual.

5. Do not modify or use service parts other than those provided by VeederRoot. Substitution of components may impair intrinsic safety.

This system operates on low dc voltage/current inputs. To avoid equipment damage:

•

Dis

connect the EMR power wire prior to using vehicle battery charging equipment.

• Disconnect the EMR po

• Disconnect the EMR po

Always dis

•

If the storage tank to

connect the IB box from truck power before welding on the truck.

be fitted with an EMR4 system either contains or at any time has contained

wer wire prior to jump starting the vehicle.

wer wire prior to replacing the vehicle's battery.

petroleum products then the tank inspection chamber must be considered a hazardous environment

as defined in IEC EN 60079-10 Classification of Hazardous Areas. Suitable working practices for this

environment must be observed.

Special Conditions For Safe Use

All installations must be made in accordance with the accompanying Descriptive System Documentation.

2

Page 7

EMR4 Truck Installation

DC voltage from vehicle's accessory

circuit - at fuse block or ACC position

of ignition switch

Display Head 1

(Meter 1)

Meter 2

Remote Display Head 2

Top mount

Remote Pulser

Front mount

Remote Pulser

TRUCK CAB

OUTSIDE TRUCK CAB

Data (RS-485)

Data (RS-485)

Power

Data

Power 12 Vdc

Power 12 Vdc

5 Vdc

Pulse Input

NON-HAZARDOUS

LOCATION

(RS-232)

Printer

Quick disconnect

fittings (optional)

Temp

Probe

EPSON TM-U295 SLIP

Customer supplied wiring

The following information is for general reference and is not

intended to replace recommended National Electric Code (NEC)

procedures. It is important for the installer to understand that

wiring located in Class I, Group D, Division 1 and 2 installations,

or Class I, Zone 0, Group IIA locations shall comply with the latest

appropriate articles found in the National Electric Code (NFPA

70).

Check continuity between the Display Head chassis and the IB

chassis through the vehicle fra

me. The resistance must be no

more than 1 Ohm.

24 Vdc

Truck ground

Max. cable length

35 ft. (10.6 m)

Max. cable length

1000 ft. (304.8 m)

HAZARDOUS LOCATION

OR

I.S.

I.S.

I.S.

I.S.

I.S.

I.S.

NOTE: Intrinsically safe wiring

(marked ) shall be installed

in accordance with Article 504 of

the NEC, ANSI/NFPA 70.

Intrinsic

Safety Barrier

Interconnection

Box

12 AWG U.S. (4mm2 E.U.)

Barrier Ground

(See Notice 2)

Input Rating: 10-28 Vdc, 5 A

1.

See

Notice 2.

See

Notice 2.

2.

NOTICE

Interlock

Switch

I.S.

ESS

Switch

I.S.

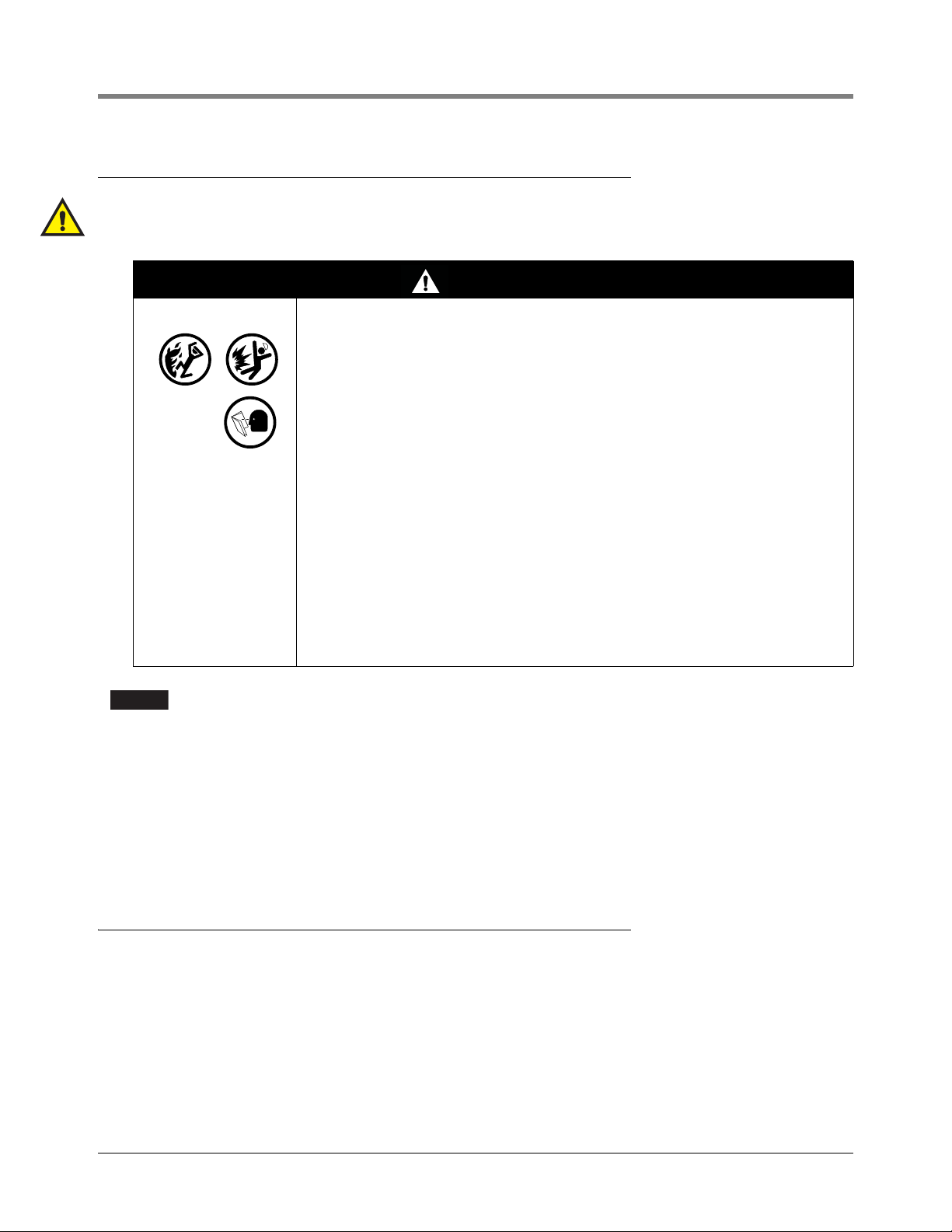

Installation of the EMR4 System involves installing the Display Head(s), the Interconnect Box, and any optional

devices (e.g., Remote Pulser, printer, etc.). This equipment must be installed according to the applicable

installation document. For UL/cUL installations use Control Drawing number 331940-021 and for ATEX

installations use Descriptive System Document number 331940-022. Figure 1 shows an example dual Display

Head installation.

Figure 1. Example EMR4 truck Installation With 2 Display Heads And Optional Remote Pulser

3

Page 8

EMR4 Truck Installation Installing The Interconnection Box (IB)

NOTICE

EMR3 - Truck Installations

Installing The Interconnection Box (IB)

The IB box is not rated for mounting in outdoor locations. The IB box can be mounted only

in a protected enclosure or protected location.

The following information is for general reference and is not intended to replace recommended National Electric

Code (NEC) procedures. It is important for the installer to understand that electrical equipment and wiring located

in Class I, Division 1 and 2 installations shall comply with the latest appropriate articles found in the National

Electric Code (NFPA 70) and other applicable code requirements.

1. The physical dimensions of the Interconnection Box (IB) are shown in Figure 2.The IB is installed in the truck’s

cab either under the seat, mounted on the wall inside the cab, mounted to the passenger si

e” in cab-over trucks, or mounted to a custom-made bracket that can also suppor

hous

ur, 3/16” (4 mm) bolts to mount the IB to the mounting surface. In the event of limited access, the front

Use fo

cover of the IB can be completely removed rather than swung open, by removing four #15 Torx screws. Put

the excess coils of cable under the seat or clamp them to the IB mounting stand.

2. Figure 3 shows IB Power Side terminal wiring connections. Remove hole plugs and use

ables attaching to this terminal block.

c

he power cable from the truck fuse block or ignition switch to the IB. Clamp the power wire at suitable in-

Run t

tervals between the power source

fore connecting the truck power wiring, verify the following:

Be

and the IB.

de of the “dog

t the optional printer.

cord grips for all

ctrical system has a negative ground.

a. Ele

b. Bat

tery terminals and cables are in good condition.

c. Alternato

3. Attach the wire from truck ground to the GND terminal of the Power Side terminal block (J8, Pin 2).

attach the wire from the truck’s Accessory (ACC) circuit to the Input-Pwr terminal of the terminal block (J8-Pin

1).

4.

Refer to Figure 3 for the IB intrinsically safe terminal wiring connections. Remove hole plugs

ps for Display Head cable entries. The drain wire from the Display Head cable must be conne

gri

assis ground clamp in the Interconnect Box.

ch

r current output is sufficient to supply EMR4 System current requirement of 5 amperes.

Also

and use cord

cted to the

Input Power – Critical Ground Connection

On some vehicles, the battery minus terminal, BAT(-), may not be common with the chassis ground or the defined

vehicle ground located in either the accessory panel or in the power distribution box. In this case, directly run the

ground connection for Input Power at J8, Pin 2 (GND) terminal as shown in Figure 3, directly to the BAT(-) terminal

connection point.

Proper operation of the EMR4 hardware depends on the quality of the ground connection from the Interconnect

Box to the source of INPUT-PWR power.

If the INPUT-PWR connection is made at the accessory panel, it must be fused at 5 amps. The installer must

ensure that a minimum of 12.0 volts, between the INPUT-PWR terminal and the GND terminal, is available from

the power source. If an improper ground point is used for input power to the EMR4 there may be insufficient

power for the Display Head to operate properly resulting in various E## error codes or possibly a blank display.

Pay careful attention to the wiring labels on both the EMR4 Display Head and the Interconnect Box.

Each connection must be made according to the wiring tables listed in this manual. Use shielded

cable to connect each device to the Interconnect Box and Display Head and ensure that each cable

jacket is resistant to gas and oil.

4

Page 9

EMR4 Truck Installation Input Power – Critical Ground Connection

NOTICE

NOTICE

EMR3 - Truck Installations

Installations With High Amperage Devices

The input power for an EMR4 must be isolated from devices that use large amounts of electric current such as reel

motors. Connect the EMR4 using dedicated wiring between the voltage source and the Interconnect Box. On

vehicles with multiple voltage sources it may be necessary to use a separate battery or voltage source to power

the EMR4. Also, a battery isolator can be used between the voltage source and the IB to prevent voltage spikes

from entering the Interconnect Box when the high amperage devices are de-energized.

Recharging Vehicle Batteries

In the Interconnect Box, disconnect the wires for both the INPUT-PWR and GND Terminals while charging the

vehicle’s battery. Failure to do so can result in hardware damage to the circuit board inside the Interconnect Box.

5

Page 10

EMR4 Truck Installation Input Power – Critical Ground Connection

2X 1.5” (38mm)

1.39”

(35.3mm)

5.0”

(127mm)

7.8” (198mm) [8.5” (215.9mm) - w/cover in place]

4.04”

(103mm)

USB Port (under cover)

2.13”

(54.1mm)

0.5”

(12.7mm)

9.8”

(249mm)

1.0” (25.4mm)

SMA Connector

(under cover)

4X 1.5”

(38mm)

3X 1.375” (35mm)

4.75” (120.6mm)

REMOVE HOLE PLUG

FOR 1/2” (12.7mm)

CONDUIT OPENING

6X 1.375”

0.775”

7X 1.5”

(38MM)

3.0”

(72mm)

0.125” (3.1mm)

1.39”

(35.3mm)

1.5” (38mm)

EMR3 - Truck Installations

Figure 2. IB Physical Dimensions (Shown With Cover Removed)

6

Page 11

EMR4 Truck Installation Input Power – Critical Ground Connection

J1

J2

J3

J4

J5

J6

J7

J8

FUNCTION

FUNCTION

SIGNAL (COLOR)

SIGNAL (COLOR)

START PULSE OUTPUT 1

START PULSE OUTPUT 2

PULSE OUTPUT 1-A

PULSE OUTPUT 2-A

PULSE OUTPUT 1-B

PULSE OUTPUT 2-B

SERIAL 232 PORT 2

SERIAL 232 PORT 1

PULSE OUTPUT 1-C

PULSE OUTPUT 2-C

PRINTER PORT

(+24V OUT, SERIAL

RS-232 PORT)

RELAY 3 FOR

DISPLAY HEAD 1

RELAY 2 FOR

DISPLAY HEAD 1

RELAY 3 FOR

DISPLAY HEAD 2

RELAY 2 FOR

DISPLAY HEAD 2

RELAY 1 FOR

DISPLAY HEAD 1

RELAY PWR

RELAY 1 FOR

DISPLAY HEAD 2

RELAY PWR

NOTE: INPUT POWER

WIRING MUST USE

DEDICATED WIRES

BETWEEN THE POWER

SOURCE AND THE I.B.

INTERCONNECT BOX WIRING DIAGRAM

INTRINSICALLY SAFE WIRING

FUNCTION

SIGNAL (COLOR)

J10

(FACTORY SETTING)

*VOLTAGE SELECTABLE

RO

TARY SWITCH

*VOLTAGE SELECTABLE

*VOLTAGE SELECTABLE

*VOLTAGE SELECTABLE

*VOLTAGE SELECTABLE

RELAY RATINGS:

5A@120VAC

2.5A@240VAC

24VDC, 5A MAX.

J14

USB

5

6

7

8

5

6

7

8

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

1

2

3

4

1

2

3

4

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

1

2

3

4

GND (BLK)

DH2-RSTOP (RED)

DH2-RSTART (WHT)

GND (GRN)

GND (GRN)

DH1-RSTOP (RED)

DH1-RSTART (WHT)

GND (BLK)

REMOTE STOP INPUT 2

REMOTE START INPUT 2

REMOTE STOP INPUT 1

REMOTE START INPUT 1

GND (WHT)

TX (BLK)

RX (GRN)

GND (GRN)

DH1-SPULSE (RED)

DH2-SPULSE (WHT)

GND (BLK)

GND (WHT)

TX (BLK)

RX (GRN)

GND (GRN)

DH1-POUT-A (RED)

DH2-POUT-A (WHT)

GND (BLK)

HALF-DUPLEX RS-485

GND (BLK)

IBNET-A (GRN)

IBNET-B (WHT)

GND (GRN)

DH1-POUT-B (RED)

DH2-POUT-B (WHT)

GND (BLK)

GND (WHT)

+24V (RED)

PRN-TX (BLK)

PRN-RX (GRN)

GND (GRN)

DH1-POUT-C (RED)

DH2-POUT-C (WHT)

GND (BLK)

DH2-R3-NO (GRN)

DH2-R3-COM (WHT)

DH2-R2-NO (RED)

DH2-R2-COM (BLK)

DH1-R3-NO (GRN)

DH1-R3-COM (WHT)

DH1-R2-NO (RED)

DH1-R2-COM (BLK)

DH1-R1-NO (GRN)

DH1-R1-COM (WHT)

INPUT-PWR (RED)

INPUT-PWR (RED)

DH2-R1-NO (GRN)

DH2-R1-COM (WHT)

INPUT-PWR (RED)

INPUT-PWR (RED)

INPUT-PWR (RED)

GND (BLK)

IB-A (GRN)

IB-B (WHT)

GND (BLK)

PWR 12V (RED)

PWR 5V (GRN)

DATA (WHT)

GND (BLK)

PWR 12V (RED)

DATA (WHT)

GND (BLK)

PWR 12V (RED)

4

3

2

1

IB-A (GRN)

IB-B (WHT)

GND (BLK)

PWR 12V (RED)

4

3

2

1

4

3

2

1

4

3

2

1

DISPLAY HEAD 1

(I.S. PROTECTED)

DISPLAY HEAD 2

(I.S. PROTECTED)

AUX 1

(I.S. PROTECTED)

AUX 2

(I.S. PROTECTED)

5VDC 24VDC

12VDC

0VDC

1

3

2

0

J13

J12

J11

CONNECTORS MAY

BE UNPLUGGED FOR

FIELD WIRING

WARNING

This system operates on low DC voltage/current

inputs.To avoid equipment damage, disconnect

the EMR4 input power plug (J8) prior to

performing ANY of the following truck maintenance issues:

• Using vehic

le battery charging equipment

• Jump starting the vehicle

• Replacing the vehic

le’s battery

• Welding on the truck

12/24V INPUT

FOR USE WITH PERIPHERAL

EQUIPMENT SPECIFIED IN THE

INSTALLATION INSTRUCTIONS.

LED INDICATORS

COMM (D10) : EMR4 STATUS

STATUS (D12) : WIFI STATUS

LINK (D15) : WIFI LINK INDICATION

SEE MANUAL FOR DETAILS

FOR SUPPLY CONNECTION,

USE WIRES RATED FOR A

MINIMUM OF 90°C.

CHASSIS-GND (GRN)

CHASSIS-GND (GRN)

TRUCK BATTERY / TERMINAL UPS:

10-28VDC, 5A MAX.

RELAY GROUND

BARRIER GROUND WIRE

EMR3 - Truck Installations

Figure 3. EMR4 IB Box Wiring Connections

7

Page 12

EMR4 Truck Installation Input Power – Critical Ground Connection

DH 1

Relays

C

N.O.

Single

Flow

C

N.O.

Fast

Flow

DH 2

Relays

C

N.O.

Single

Flow

C

N.O.

Fast

Flow

EMR3 - Truck Installations

2-STAGE SOLENOID VALVE CONNECTIONS

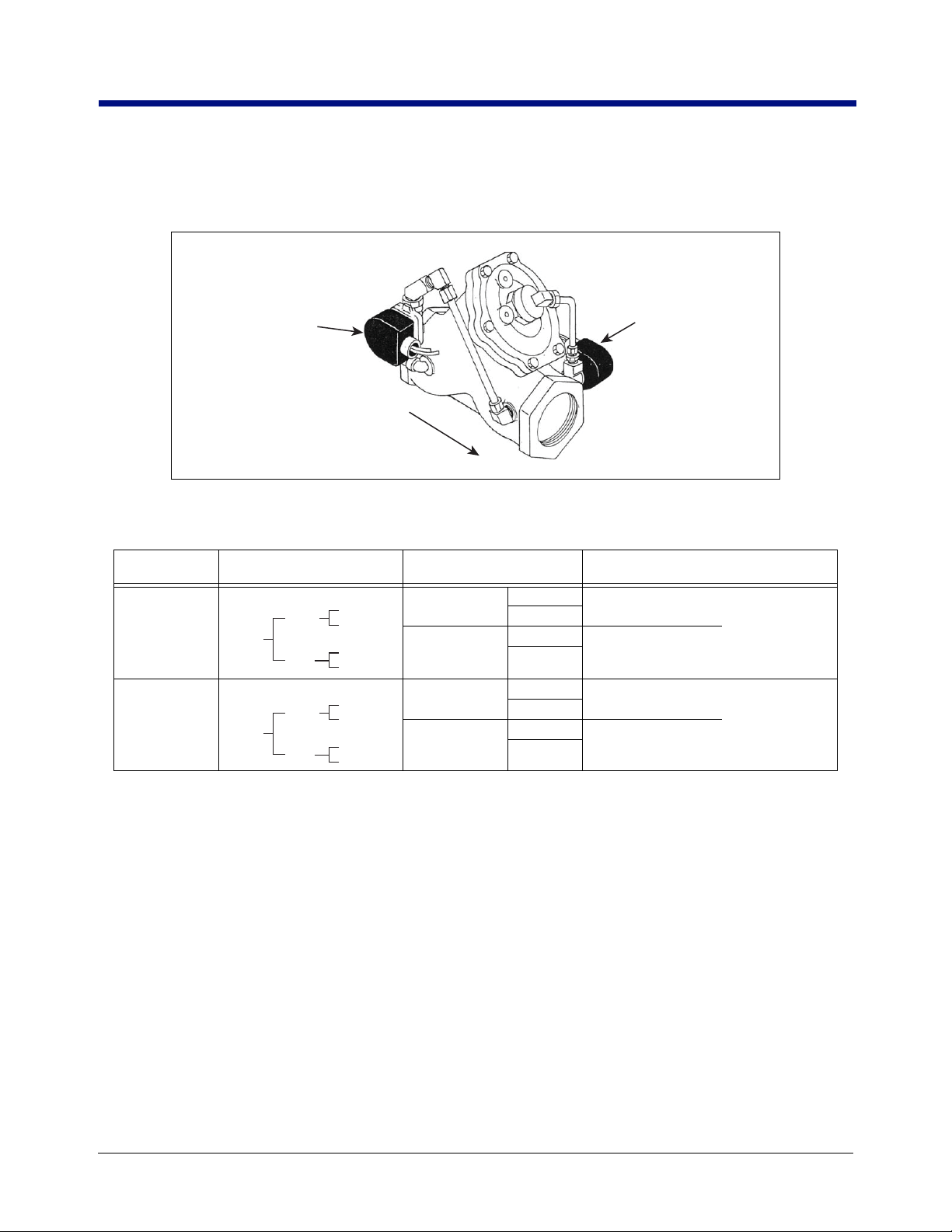

A 2-stage solenoid flow valve is shown in Figure 4 and wiring connections in Table 1.

Single Flow In IB

(Relay 2)

(Solenoid Valve

Number Begins

With 7221)

Display Head Relay Function

Head 1

Head 2

Flow

Figure 4. 2-Stage Solenoid Valve

Table 1. 2-Stage Solenoid Wiring

Diagram In

Installation Manual Setup Manual

DH1-R2

DH1-R1

DH2-R2

DH2-R1

COM

N.O.

COM

N.O.

COM

N.O.

COM

N.O.

Fast Flow In IB

(Relay 1)

(Solenoid Valve

Number Begins

With 7121)

Relay Control

Set Advance Stop

Relay Control

Set Slow Flow

Relay Control

Set Advance Stop

Relay Control

Set Slow Flow

(2nd Stage

Knockoff)

(1st Stage

Knockoff)

(2nd Stage

Knockoff)

(1st Stage

Knockoff)

VALVE OPERATION WITH THE EMR4

Full Flow

The valve is normally closed. When the START button is pushed on the EMR4 display, both relays for that head are

energized, opening the solenoid-operated valves. The Fast Flow solenoid valve allows the main valve diaphragm to

open via the pump pressure pushing on the diaphragm. Full flow is obtained. The Slow Flow solenoid valve allows

flow around the main diaphragm valve. When the FINISH button is pushed on the EMR4 display, both relays are

de-energized, the solenoid valves close stopping flow.

Preset

The valve is normally closed. When the START button is pushed on the EMR4 display, both relays for that head are

energized, opening the solenoid valves and fast/full flow is obtained.

• First Stage Knockoff - When the first stage/slow flow point is reached (1st stage knockoff), the fast flow/relay

de-en

ergizes and the spring assisted main diaphragm of the valve closes as the pressure equalizes. The si

y 2 bypass remains open for slow flow.

8

flow/rela

1

ngle

Page 13

EMR4 Truck Installation 3-Way Safety Valve for Truck LP Gas Systems

NOTICE

EMR3 - Truck Installations

• Second Stage Knockoff - When the advance stop (2nd stage knockoff) point is reached, the single flow/relay 2

ergizes and the single flow/bypass valve closes stopping flow.

de-en

nockoff Control Adjustments - The ‘volume to go’ adjustments are made under RELAY CONTROL in setup

K

mode. The 1st stage defaults to 5 and the 2nd stage defaults to 0.1. Adjustments to these knockoff points,

particularly the 2nd stage/stop point may be required to accommodate the specific systems dynamics.

3-Way Safety Valve For Truck LP Gas Systems

The 3-Way Safety Valve is not intended for flow control or preset control.

WARNING

The Three-Way Safety Valve is installed and operated in the highly

combustible environment of an LPG tank.

FAILURE TO COMPLY WITH THE FOLLOWING WARNINGS AND SAFETY

PRECAUTIONS COULD CAUSE DAMAGE TO PROPERTY, ENVIRONMENT,

RESULTING IN SERIOUS INJURY OR DEATH.

1. It is essential that you carefully read and follow the warnings and

instructions in this manual to protect yourself and others from serious

injury due to fire, explosion, or electrical shock. LPG systems shall be

installed in accordance with the national standards and regulations that

apply.

2. Comply with all federal, state, and local codes, and other applicable

safety codes. All wiring must comply with standard electrical practices,

the local authority, and the latest editions of the National Electrical Code

(NFPA 70) and other applicable code requirements. All work on LPG

systems must comply with NFPA 58, Liquefied Petroleum Gas Code and

other applicable code requirements.

3. LPG tanks must be depressurized (drained) and free of liquid and

combustible vapors before work begins.

4. Flow control valves connected to the EMR4 must be UL Listed. Also, flow

control valves must be suitable for the intended application, i.e.,

gasoline, fuel oil, LPG and must be rated for use in a Class 1, Division 1,

Group C or Group D Hazardous Location. For LPG applications, such as

propane, each valve must have a minimum pressure rating of 350 psi.

INSTALLING THE 3-WAY VALVE

On the male pipe threads, use a pipe sealant when installing fittings or conduit to either

the valve or the junction box.

1. On the valve, install a rigid metal conduit nipple in the threaded opening, provided for the solenoid wiring. Run

the two red wires from the 3-way valve, through the nipple and into a metal junction box. Mechanically attach

the valve/nipple combination to junction box as shown in Figure 5. Even though the 3-way valve will operate

in any position, it will last longer and perform best if mounted vertically upright (port 3 up). Secure the

junction box to the vehicle's frame.

2. Run a 2-wire shielded cable from the Relay Terminals located at J7 in the IB Box, located in the truck cab, to

the 3-way valve junction box. Pass the cable through a cord grip fitting in one of the J-box openings. Cut off 1inch (25.4 mm) of the cable’s shield and jacket, then strip off 1/2-inch (12.7 mm) of each wire’s insulation.

9

Page 14

EMR4 Truck Installation 3-Way Safety Valve for Truck LP Gas Systems

Rigid Metal

Junction Box

Shrink wrapped diode

Shielded 2-Wire Cable

V-R PN 848100-250

Cord Grip

V-R PN 331028-001

Port 1

(N.C.)

Port 3

(N.O.)

Port 2

(COM)

Hose Connections

are 1/4'' NPT

Connect to Line

Pressure

Connect to

Differential

Valve

12 Vdc 10 Watts

3-Way Solenoid Valve

Connect to

Air Eliminator

Connect wires

in IB unit

1/2'' NPT

Nipple or Conduit

758-23.eps

Black

White (+)

To

3-Way

valve

To

IB unit

Red

Red

Wire nuts

Instructions:

NOTE: When temperature is below 50°F (10°C), keep

resin in a warm place prior to mixing (e.g., in an inside

pocket next to body).

1. Attach red wires from 3-way valve to black and white

(+) wire from IB unit with wire nuts as shown in A.

Connect diode white wire to red/white (+) pair.

Connect diode black wire to red/black pair.

2. Open epoxy package, and remove resin pak.

3

. Holding

resin pak as shown in B, bend pak along long

length.

4. As shown in C, firmly squeeze the RED S

IDE of the

resin,

forcing it through the center seal and into

BLACK SIDE.

5.

Mix

thoroughly to a uniform color by squeezing

contents back and forth 25-30 times.

6. Squeeze mixed, warm resin into one end of bag and

cutoff other end.

7. Slowly insert wiring connections into sealing pack until

they fit snugly against the opposite end.

8

. Twist open end of bag and use tie wrap to close it off,

or wrap open end of bag with vinyl electrical tape (not

included) and position the taped end up until the resin

jells.

9. P

lace epoxy pack into junction box and screw on

cover as shown in D.

C

A

D

B

Diode

(+)

EMR3 - Truck Installations

3. Using the wire nuts, connect the stripped wires from the IB box to the 3-way valve wires (see Figure 5). There

s no polarity to the 3-way valve’s wiring. Seal the wire nuts with epoxy sealant using one bag for both wire nu

i

conn

ections and place bag in junction box (see Figure 5).

t

CAUTION

Epoxy sealant is irritating to eyes, respiratory system, and skin. Can cause allergic skin

reaction. Contains: epoxy resin and cycloaliphatic epoxycarboxylate. Precautions: Wear

suitable protective clothing, gloves, eye, and face protection. Use only in well ventilated

areas. Wash thoroughly before eating, drinking, or smoking.

Figure 5. Connecting 3-Way Valve To Neptune Meter - Truck LP Gas Installations

4. Tighten the cable bushing nuts on the cord grip to ensure a watertight seal at the cable’s entry.

5. Remove the protective closures from the 3-way valv

Neptune

Connec

sy

stems, line pressure is available at an opening in the vapor eliminator housing. Connect another hose

he 3-way valve’s port 1 (normally closed port) to the air eliminator. Connect a third hose from the 3-

t

valve’s port 2 (co

L.C./TCS Mete

Connect a hose from the air eliminator to port 3 (normally open port) of the 3-way valve (see Figure 6). Con-

meters:

t a hose from line pressure to port 3 (normally open port) of the 3-way valve (see Figure

mmon port) to the differential valve.

rs:

nect another hose from the 3-way valve’s port 1 (normally closed port) to the strainer cover. Connect a third

hose from the 3-way valve’s port 2 (common port) to the differential valve.

e ports.

10

5). On some

from

way

Page 15

EMR4 Truck Installation 3-Way Safety Valve for Truck LP Gas Systems

EMR3 - Truck Installations

758-24.eps

Hose Connections

are 1/4'' NPT

Port 3

(N.O.)

Connect to Air

Eliminator

A

To

3-Way

valve

Port 2

(COM)

Red

Red

Port 1

(N.C.)

Wire nuts

White (+)

Diode

1/2'' NPT

Nipple or Conduit

12 Vdc 10 Watts

3-Way Solenoid Valve

Black

To

IB unit

Connect to

Strainer

Cover

Rigid Metal

Junction Box

Connect to

Differential

Valve

B

(+)

Shielded 2-Wire Cable

V-R PN 848100-250

Cord Grip

V-R PN 331028-001

Shrink wrapped diode

Connect wires

in IB unit

D

Instructions:

NOTE: When temperature is below 50°F (10°C), keep

resin in a warm place prior to mixing (e.g., in an inside

pocket next to body).

1. Attach red wires from 3-way valve to black and white

(+) wire from IB unit with wire nuts as shown in A.

Connect diode white wire to red/white (+) pair.

Connect diode black wire to red/black pa

Open epoxy package, and remove resin pak.

2.

. Holding

3

4. As shown in C, firmly squeeze the RED S

5.

6. Squeeze mixed, warm resin into one end of bag and

7. Slowly insert wiring connections into sealing pack until

8

. Twist open end of bag and use tie wrap to close it off,

9.

resin pak as shown in B, bend pak along long

length.

resin,

forcing it through the center seal and into

BLACK SIDE.

Mix

thoroughly to a uniform color by squeezing

contents back and forth 25-30 times.

cutoff other end.

they fit snugly against the opposite end.

or wrap open end of bag with vinyl electrical tape (not

included) and position the taped end up until the resin

jells.

Place epoxy pack into junction box and s

cover as shown in D.

ir.

C

IDE of the

crew on

Figure 6. Connecting 3-Way Valve To L.C./TCS Meter - Truck LP Gas Installations

6. At the IB Box, connect the 3-way valve solenoid and a jumper to J7 and J8 as shown in Figure 7.

11

Page 16

EMR4 Truck Installation 3-Way Safety Valve for Truck LP Gas Systems

Wire nut

Red

Red

Black

Black

White

White

Wire nut

3-Way Valve

Solenoid

Cord

Gr

ip

Nipple

J-Box

Suppression Diodes can only be

used with DC powered solenoids.

Suppressor diode

V/R Kit P/N 846000-022

Suppressor Diode Ratings:

Output Current of 1.0 Amp,

Maximum reverse voltage 420 Volts

Interconnect Box

Power-Side Terminals

J7

J8

DH1-R1-NO

DH1-R1-COM

INPUT-PWR

INPUT-PWR

DH2-R1-NO

DH2-R1-COM

INPUT-PWR

INPUT-PWR

INPUT-PWR

GND

CHASSIS-GND

CHASSIS-GND

Note: Use either INPUT-PWR terminal

to provide power to valve

Note: Use either CHASSIS-GND terminal

to provide return for valve

Note: Use DH2-R1-NO and DH2-R1-COM

if using Display Head 2 to control valve

NOTICE

EMR3 - Truck Installations

SOLENOID VALVES

Figure 8 illustrates wiring examples when connecting DC or AC solenoid valves to the IB box.

Figure 7. Connecting 3-Way Valve To The Interconnect Box

12

Page 17

EMR4 Truck Installation 3-Way Safety Valve for Truck LP Gas Systems

DC Solenoid

valve

Rigid conduit

Seal off

J-Box

Rigid

conduit

L

N

Supply

120/240 Vac

1

Interconnect Box

Power Side terminals

AC Solenoid

valve

Rigid conduit

Sealoff

AC Solenoid Wiring

DC Solenoid Wiring

Wire nut

Red

Red

Black

Black

White

White

Wire nut

Suppressor diode

V/R Kit P/N 846000-022

Suppressor Diode Ratings:

Output Current of 1.0 Amp,

Maximum reverse voltage 420 Volts

Suppression Diodes can only be

used with DC powered solenoids.

Interconnect Box

Power-Side Terminals

J7

J8

DH1-R1-NO

DH1-R1-COM

INPUT-PWR

INPUT-PWR

DH2-R1-NO

DH2-R1-COM

INPUT-PWR

INPUT-PWR

INPUT-PWR

GND

CHASSIS-GND

CHASSIS-GND

Note: Use either INPUT-PWR terminal

to provide power to valve

Note: Use either CHASSIS-GND terminal

to provide return for valve

Note: Use DH2-R1-NO and DH2-R1-COM

if using Display Head 2 to control valve

Note: Use DH2-R1-NO and DH2-R1-COM

if using Display Head 2 to control valve

J7

DH1-R1-NO

DH1-R1-COM

INPUT-PWR

INPUT-PWR

DH2-R1-NO

DH2-R1-COM

INPUT-PWR

INPUT-PWR

NOTICE

EMR3 - Truck Installations

Figure 8. Example Wiring Connections For DC And AC Solenoid Valves

13

Page 18

EMR4 Truck Installation Wiring The Display Head

EMR3 - Truck Installations

Wiring The Display Head

1. With the Display Head cover still off, remove the nut and bushing from the top side panel cord grip connector.

: the maximum cable length between the Interconnect Box and the Display Head is 1000 fe

Note

m

eters).

2. Slide the cord grip nut and then the bushing over the IB cable leads. Pull enough cable through so that the

leads reach the terminal block on the display assembly and can be tie wrapped to the pulse encoder mounting

base as shown in Figure 9. Slide the tapered end of the bushing into the cord grip, then screw on t

gri

p nut and tighten securely.

et (304.8

he cord

3. Attach the four-wire IB cable to the terminal block where shown in Figure 9. Attach the drain wire of t

cabl

e to a grounding lug on the Pulse Encoder mounting base.

When

stripping wire for terminal block connections, be careful not to nick the individual strands. Also, be su

o tighten each terminal so the wire can not be pulled out. A failure to follow either of these instructions can re-

t

sult in signal loss and faulty operation.

4. If you have the optional temperature probe and/or ESS switch, remove the lower cord grip nut and slide it

t

hen the tapered bushing, over the temperature probe and/or ESS switch cable. Pull enough cable through

hat the leads reach the terminal block on the display assembly and can be tie wrapped to the pulse e

t

mou

nting base as shown in Figure 9. Slide the bushing into the cord grip and then screw the cord grip nu

onto th

e cord grip and tighten securely. Attach the shield of the temperature probe cable and/or ESS swit

e to a grounding lug on the pulse encoder mounting base.

cabl

5. Attach each wire (no polarity) of the 2-conductor temperature probe and/or ESS switch cable(s) where shown

on the terminal block la

Tie wrap the IB, ESS switch, and temp probe (if installed) cables to the Pulse Encoder mounting base.

6.

7. For transfer Interlock applications, attach the two wires in the switch cable where shown on the terminal bl

l

abel and tie wrap the cable to the pulse encoder’s mounting base.

8. Replace the Display Head cover and screw in the four cover retaining bolts just enough to hold them in (t

c

over will be removed later for system calibration).

9. Using the tie wraps from the installation kit, attach the 4-wire cable from the Display Head to the Interconne

Box along

arp bends and placements where vibration might wear through the cable. Allow ample cable length

sh

compens

rough a split loom or tubing will offer added protection from weather and abrasion. Use a rubber grom

th

cord gri

require detachable plugs, and either a separate tensioning device much like that used to protect air lines

perhaps attach

the inside of the truck frame, to existing piping, or to the reel motor cable back to the cab. Avoi

ate for tilt-cab trucks and to avoid putting additional stress on the assembly. Running the cabl

p to line the hole where cable passes through truck cab wall or floor. Tractor-trailer installations will

the cable to one of the existing air lines with tie wraps.

bel.

he IB

re

,

so

ncoder

t

ch

ock

he

ct

d

to

e

met or

, or

10. Check continuity between the Display Head chassis and IB chassis through the vehicle frame. This resistan

must

be less than 1 ohm.

14

ce

Page 19

EMR4 Truck Installation Wiring The Display Head

ENS1J-489ENS1J-489

-L00100 -L00100

BOURNSBOURNS

VR ENCODERVRENCODER

P/N P/N

331884-001331884-001

331933-001331933-001

I.S.I.S.

Intrinsically-safe inputs from

Interconnect Box, emergency stop switch,

interlock switch, temperature probe,

and optional series 8452 remote pulser

Route cables as shown to

avoid interference with flexible

encoder shaft. Use tie wraps

to attach cables to base.

Pulse encoder

Optional keypad

Encoder shaft

spring

C&C

Jumper

Display head

terminal block

Attach optional remote

pulser, temperature probe,

interlock switch, IB cable and

ESS switch cable shields to

grounding lug on base.

9/64” (3.5mm) max.

Note: Maximum screwdriver

size for attaching wires to

terminal block.

C&C Switch - Removal of corner

bolt releases actuator lever of C&C

switch allowing entry into C&C Mode

#6 Self tapping

screws (3)

Rubber gasket (1)

INTERCONNECT BOX 1000 RPM ENCODER

OPTIONAL KEYPAD

TEMP PRB

INTERLOCK

STOP SWC & C SW

BLK

GND

RED

PWR

YEL+YEL

GND

WHT+BLK

GND

GRN

CHA

WHT

CHB

BLK

GND

RED

+5V

WHT

+

BLK

GND

WHT+BLK

GND

ORA

KP8

BLU

KP7

YEL

KP6

GRN

KP5

WHT

KP4

BLK

KP3

RED

KP2

NOT

USED

GRN

IB-A

WHT

IB-B

EMR3 - Truck Installations

Figure 9. Display Head Cable Connections

15

Page 20

EMR4 Truck Installation C&C Mode Switch

EMR3 - Truck Installations

C&C Mode Switch

The C&C corner switch assembly (P/N 845900-018) that fits into one corner of the Display Head’s housing (see

Figure9). To enter C&C mode, remove the corner bolt from the Display Head’s cover. To exit C&C mode, replace

the bolt. When using the corner switch, remove the C&C jumper.

Installing Optional Keypad Kit - Right Or Left Side

Figure9 shows the installation and wiring of the optional keypad. To attach the keypad housing mounting screws,

you will need to pull/slide up the display assembly away from the Display Head. Insert the keypad wires through

the center hole in the gasket, slide the gasket down against the keypad and align its three holes with the mounting

holes in the keypad. Hold the keypad against the Display Head and screw in the 3 mounting screws, replace the

display assembly and then connect the keypad wiring to the terminal block as shown in Figure9. The screws are

self-tapping. The user may want to pre-tap the holes using the screw to ease installation.

Installing The Remote Display (Optional)

The Remote Display consists of the items listed in Table 2:

Table 2. Remote Display (84559X-00X) Components

Description V-R P/N

Remote Display install kit 330020-430

Opt. Mounting Bracket kit 845900-024

Opt. 4 conductor cable - 6 ft (1.83 m) 846000-107

Opt. 4 conductor cable - 35 ft (10.67 m) 846000-106

Opt. 4 conductor cable - 50 ft (15.24 m) 846000-100

Opt. 4 conductor cable - 100 ft (30.48 m) 846000-101

Opt. 4 conductor cable - 200 ft (60.96 m) 846000-102

Opt. 4 conductor cable - 300 ft (91.44 m) 846000-103

Opt. 4 conductor cable - 400 ft (121.92 m) 846000-104

Opt. 4 conductor cable - 500 ft (152.4 m) 846000-105

Figure 10 shows the Remote Display assembly and Figure 11 shows how to wire the display to the Interconnect

Box. You can mount the display on a wall or dashboard of a truck, a wall in a building, or outside in a hazardous

location. Use appropriate fasteners in any of the pre-drilled holes in the base of the optional bracket when

attaching the bracket to the mounting surface. Adjust the angle of the display by loosening the side bolts and

rotating the unit to the desired position.

Following wiring routing precautions and procedures discussed earlier (page 14) for the meter mounted Display

Head, connect the Remote Display to the Interconnect Box. Wiring connections at the Remote Display are shown

in Figure 11. Install optional cord grip fitting in rear of Remote Display for cable egress. Wiring connections at the

IB are to the identical terminals of the unused Display Head terminal block.

16

Page 21

EMR4 Truck Installation IInstalling The Remote Display (Optional)

Front View Rear View

Mounting bracket kit

(P/N 845900-024)

Plastic caps (remove

for cable entry)

These 2 hex head bolts are drilled

through for sealing the front cover

C&C switch

#30 Torx screws (4)

758-27.eps

#30 Torx screws (4) fasten into back of

Remote Display housing

Adjust mounting strips to desired

indents each side, then tighten nuts

Mounting Strips shown

in low position (2)

1 Nut and 1 lockwasher

each side

Base

Mounting Strips

shown in high

position

Assembly of Remote Display

Head Mounting Bracket

Side view

8.625"

(220 mm)

high position

or

6.625"

(168 mm)

low position

9.5"

(240 mm)

3.25"

(83 mm)

5.625"

(143 mm)

Remote Display Head

(P/N 84559X-002)

EMR3 - Truck Installations

Figure 10. Remote Display Assembly

Figure 11 displays the wiring connections to a remote display.

17

Page 22

EMR4 Truck Installation IInstalling The Remote Display (Optional)

Rear cover of

Remote Display

Front panel

C&C switch

Remote Display

terminal block

Remove a plastic cap from one

of the rear access ports to install

input cable(s)

Cord grip

Nut

To external device

9/64” (3.5 mm) max.

To terminal

block

Bushing

Remote Display (rear cover removed)

Cable entries to Remote Display

Attaching wires to

terminal block

GRN

IB-A

INTERCONNECT BOX

1000 RPM ENCODER OPTIONAL KEYPADTEMP PRBINTERLOCK

STOP SWC & C SW

BLK

GND

WHT

IB-B

RED

PWR

YEL+YEL

GND

WHT+BLK

GND

GRN

CHA

WHT

CHB

BLK

GND

RED

+5V

WHT

+

BLK

GND

WHT+BLK

GND

ORA

KP8

BLU

KP7

YEL

KP6

GRN

KP5

WHT

KP4

BLK

KP3

RED

KP2

NOT

USED

Note: Maximum screwdriver

size for attaching wires to

terminal block.

EMR3 - Truck Installations

Figure 11. Remote Display Connections (Rear Cover Removed)

18

Page 23

EMR4 Truck Installation Installing The Remote Pulser (Optional)

758-30.eps

+V

GND

CHB

CHA

Cable to

Display

Head

EMR3 - Truck Installations

Installing The Remote Pulser (Optional)

The EMR4 remote pulser consists of a 5 Vdc optical encoder assembled into a stand-alone cast housing. The

Remote Pulser can be mounted to either the top or the front of the meter using one of two available kits. The

remote pulser operates under the same specifications as the existing internal pulse encoder. Refer to Veeder-Root

manual number 577014-355 for detailed pulser mounting instructions.

• The top mount kits (P/N 845900-504, 845900-552) contain the remote pulser

hardware.

The front mount kits (P/N 845900-505, 845900-506) contain the remote pulser

•

hardware

. The customer or end user will have to supply the mounting scheme to install the remote pulser to the

front of the meter.

.

Figure 12. Wiring Connections In Remote Pulser (Top Cover Removed)

, mounting plate and mounting

and limited mounting

PULSE ENCODER SPECIFICATIONS

Power: 5 Vdc, 30 mA +10%

Shaft Rotation: 1000 rpm maximum, bidirectional, 20 oz-in

Pulse: 100 ppr, Quadrature type

19

Page 24

EMR4 Terminal & Fueling Depot Installation

Installation of the EMR4 System involves installing the Display Head(s), installing the interconnect box, and

installing any optional devices (e.g., remote pulser, printer, etc.). This equipment must be installed according to the

applicable installation document. For UL/cUL installations use Control Drawing number 331940-021 and for

ATEX installations use Descriptive System Document number 331940-022. Figure 13 shows an example dual

Display Head installation.

The following information is for general reference and is not intended

to replace recommended national electric code (nec) procedures. it is

important for the installer to understand that wiring located in Class I,

Group D Division 1 and 2 installations or Class I, Zone 0, Group IIA

locations shall comply with the latest appropriate articles found in the

National Electric Code (NFPA 70).

NOTICE

This is a control drawing only and does not reflect the actual

locations of conduit entry. In Installation and use of this product,

comply with the national electrical code; Federal, State and Local

Codes.

WARNING

FAILURE TO COMPLY WITH THE FOLLOWING

WARNINGS AND SAFETY PRECAUTIONS COULD CAUSE

DAMAGE TO PROPERTY, ENVIRONMENT, RESULTING IN

SERIOUS INJURY OR DEATH.

The Display Head must never be operated unless the front cover

and wiring shield are closed and properly sealed over the barrier

terminals in the intrinsically safe area of the Interconnect Box.

1. Intrinsically safe wiring (marked ) shall be installed in

accordance with Article 504 of the NEC, ANSI/NFPA 70.

2.

In the non-intrinsically safe compartment of the Interconnect Box,

connect the #12 AWG (4mm

ground lug.

3. To maintain intrinsic safety, display head to interconnect box

wiring must be run in dedicated conduit. Maximum cable length is

1,000 feet (304.8 M).

4. Display Head must be connected to earth ground

through its mounting screws.

I.S.

2

) or larger diameter barrier wire to a

Data

(RS-232)

Power

24 Vdc

120 or 240Vac

line cord

12 Vdc

Power

Supply

UL approved 120W

isolated secondary

Printer

EPSON TM-U220A ROLL

AC Power Protector

UPS

120 or 240Vac line

Input Rating: 10– 28 Vdc, 5 A

Customer supplied

wiring & rigid conduit

Connected to

Earth Ground

TERMINAL

OFFICE

NON-HAZARDOUS

LOCATION

Interconnect

Box

Intrinsic

Safety Barrier

12 AWG U.S. (4mm2 E.U.)

Barrier Ground

I.S.

I.S.

Power

Rigid conduit

Seal-off

Max. cable length

1000 ft. (304.8 m)

Data (RS-485)

Max. Remote

Pulser cable

length 35 ft.

(10.6 m)

Power

Data (RS-485)

Pulse Input

I.S.

I.S.

5 Vdc

Temp

Probe

Switch

Interlock

Switch

ESS

I.S.

I.S.

HAZARDOUS

LOCATION

Display Head 1

(Meter 1)

I.S.

Meter 1

Meter 2

Figure 13. Example Terminal Fueling Depot Installation With 2 Display Heads And Optional Remote Pulser

20

Remote

Display Head 2

Top mount

Remote Pulser

OR

Front mount

Remote Pulser

Page 25

EMR4 Terminal & Fueling Depot Installation Wiring The Display Head

EMR3 - Truck Installations

Wiring The Display Head

1. With the Display Head cover still off, remove the nut and bushing from the right side panel cord grip

connector. Note: the maximum cable length between the Interconnect Box and the Display Head is 1

(304.8

meters).

2. Slide the cord grip nut and then the bushing over the IB cable leads. Pull enough cable through so that the

leads reach the terminal block on the display assembly and can be tie wrapped to the pulse encoder mounting

base as shown in Figure 14. Slide the tapered end of the bushing into the cord grip, then screw on th

gri

p nut and tighten securely.

000 feet

e cord

3. Attach the four-wire IB cable to the terminal block as shown in Figure

stripping wire for terminal block connections, be careful not to nick the individual strands. Also, be su

When

t

o tighten each terminal so the wire can not be pulled out. A failure to follow either of these instructions can re-

sult in signal loss and faulty operation.

4. If you have the optional temperature probe and/or ESS switch, remove the lower cord grip nut and slide it,

hen the tapered bushing, over the temperature probe cable and/or ESS switch cable. Pull enough cable

t

through so that the leads reach the terminal block on the display assembly and can be tie wrapped to t

lse encoder mounting base as shown in Figure 14. Slide the bushing into the cord grip and then

pu

cord gri

groun

5. Attach each wire (no polarity) of the 2-connector temperature probe cable and/or ESS switch where sh

on th

6.

Tie wrap the IB, ESS switch and temp probe (if installed) cables to the pulse encoder mounting base.

7. For transfer Interlock applications, attach the two wires in the switch cable where shown on the terminal bl

abel and tie wrap the cable to the pulse encoder’s mounting base.

l

8. Replace the Display Head cover and screw in the four cover retaining bolts just enough to hold them in (the

c

p nut onto the cord grip and tighten securely. Attach the shield of the temperature probe cable to

ding lug on the Pulse Encoder mounting base.

e terminal block la

over will be removed later for system calibration).

bel.

14.

he

screw the

a

own

re

ock

21

Page 26

EMR4 Terminal & Fueling Depot Installation Installing The Interconnect Box (IB)

ENS1J-489ENS1J-489

-L00100 -L00100

BOURNSBOURNS

VR ENCODERVRENCODER

P/N P/N

331884-001331884-001

331933-001331933-001

I.S.I.S.

Intrinsically-safe inputs from

Interconnect Box, emergency stop switch,

interlock switch, temperature probe,

and optional series 8452 remote pulser

Route cables as shown to

avoid interference with flexible

encoder shaft. Use tie wraps

to attach cables to base.

Pulse encoder

Optional keypad

Encoder shaft

spring

C&C

Jumper

Display head

terminal block

Attach optional remote

pulser, temperature probe,

interlock switch, and

ESS switch cable shields to

grounding lug on base.

9/64” (3.5mm) max.

Note: Maximum screwdriver

size for attaching wires to

terminal block.

C&C Switch - Removal of corner

bolt releases actuator lever of C&C

switch allowing entry into C&C Mode

#6 Self tapping

screws (3)

Rubber gasket (1)

INTERCONNECT BOX 1000 RPM ENCODER

OPTIONAL KEYPAD

TEMP PRB

INTERLOCK

STOP SWC & C SW

BLK

GND

RED

PWR

YEL+YEL

GND

WHT+BLK

GND

GRN

CHA

WHT

CHB

BLK

GND

RED

+5V

WHT

+

BLK

GND

WHT+BLK

GND

ORA

KP8

BLU

KP7

YEL

KP6

GRN

KP5

WHT

KP4

BLK

KP3

RED

KP2

NOT

USED

GRN

IB-A

WHT

IB-B

EMR3 - Truck Installations

Installing The Interconnect Box (IB)

NATIONAL ELECTRICAL CODE COMPLIANCE

The following information is for general reference and is not intended to replace recommended National Electric

Code (NEC) procedures. It is important for the installer to understand that electrical equipment and wiring located

in Class I, Division 1 and 2 installations shall comply with the latest appropriate articles found in the National

Electric Code (NFPA 70) and the Automotive and Marine Service Station Code (NFPA 30A).

GROUNDING

Proper grounding of the EMR equipment is essential for several reasons. First, in a typical installation, grounding

prevents hazardous voltages from being present on the equipment. Secondly, grounding prevents the build-up of

static charge on the equipment. Either of these conditions could be very hazardous when in the proximity of

explosive mixtures found at fuel supply depots and terminals. Proper grounding requires that a very low impedance

connection be made to the earth. At the distribution panel, this is accomplished by means of a dedicated

conductor buried in the earth. It is imperative that all local, regional and national regulations are followed when

connecting to the grounding system.

Figure 14. Display Head Cable Connections

22

Page 27

EMR4 Terminal & Fueling Depot Installation Installing The Interconnect Box (IB)

NOTICE

NOTICE

NOTICE

EMR3 - Truck Installations

WIRE TYPE FOR METALLIC OR PVC CONDUIT

Veeder-Root requires the use of shielded cable when using metallic or PVC conduit in any portion of the wiring

between the Display Head and the IB. In these installations, shielded cable must be rated less than 100 picofarad

per foot and 0.2 microhenry per foot (per 304.8 mm) and be manufactured with a material suitable for the

environment.

Use either the 4-wire cable supplied by V-R, P/N 846000-1XX or any equivalent cable or wiring with rated

capacitance of less than 100 picofarads per foot (per 304.8 mm) and inductance of less than 0.2 microhenry per

foot (per 304.8mm). Note that conductor wire colors vary depending on the cable manufacturer (caution: the

Display Head to IB wiring illustrations in this section show wire colors in the V-R cable. Alternate cables may have

different wire colors).

Field wiring may be both above ground or below grade.

WIRE LENGTH

Improper system operation could result in undetected potential environmental and health hazards if the Display

Head to IB wire runs exceed 1000 feet (304.8 m). Wire runs must be less than 1000 feet to be within the limits of

the UL Certification.

MOUNTING AND WIRING THE IB UNIT

1. The physical dimensions of the Interconnect Box (IB) are shown in Figure 2 on page 6. The IB is installed in

he terminal - fueling depot office. Use four, 3/16” (4 mm) bolts to mount the IB to the mounting surface.

t

2. Figure 15 shows IB wiring connections. For IB Power Side terminal wiring connections, remove hole

and u

se cord grips for all cables attaching to this terminal bl

J10 and J11 terminal I.S. wiring connections, remove hole plugs and use cord grips for all cabl

For IB

att

aching to these terminal blocks. The drain wire from each Display Head cable must be connected to t

assis ground clamp in the IB I.S. area.

ch

ock.

plugs

es

he

3. The printer must be within 6 feet (1.83 m) of the IB box.

All field wiring entering the IB box should be run as straight as possible from the conduit

entry knockout to their designated terminal connectors.

SOLENOID VALVES

Figure 16 illustrates wiring examples when connecting dc or ac solenoid valves to the IB box.

The IB box is not rated for mounting in outdoor locations. The IB box can be mounted

only in a protected enclosure or protected location.

23

Page 28

EMR4 Terminal & Fueling Depot Installation Installing The Interconnect Box (IB)

J1

J2

J3

J4

J5

J6

J7

J8

FUNCTION

FUNCTION

SIGNAL (COLOR)

SIGNAL (COLOR)

START PULSE OUTPUT 1

START PULSE OUTPUT 2

PULSE OUTPUT 1-A

PULSE OUTPUT 2-A

PULSE OUTPUT 1-B

PULSE OUTPUT 2-B

SERIAL 232 PORT 2

SERIAL 232 PORT 1

PULSE OUTPUT 1-C

PULSE OUTPUT 2-C

PRINTER PORT

(+24V OUT, SERIAL

RS-232 PORT)

RELAY 3 FOR

DISPLAY HEAD 1

RELAY 2 FOR

DISPLAY HEAD 1

RELAY 3 FOR

DISPLAY HEAD 2

RELAY 2 FOR

DISPLAY HEAD 2

RELAY 1 FOR

DISPLAY HEAD 1

RELAY PWR

RELAY 1 FOR

DISPLAY HEAD 2

RELAY PWR

NOTE: INPUT POWER

WIRING MUST USE

DEDICATED WIRES

BETWEEN THE POWER

SOURCE AND THE I.B.

INTERCONNECT BOX WIRING DIAGRAM

INTRINSICALLY SAFE WIRING

FUNCTION

SIGNAL (COLOR)

J10

(FACTORY SETTING)

*VOLTAGE SELECTABLE

RO

TARY SWITCH

*VOLTAGE SELECTABLE

*VOLTAGE SELECTABLE

*VOLTAGE SELECTABLE

*VOLTAGE SELECTABLE

RELAY RATINGS:

5A@120VAC

2.5A@240VAC

24VDC, 5A MAX.

J14

USB

5

6

7

8

5

6

7

8

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

1

2

3

4

1

2

3

4

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

1

2

3

4

GND (BLK)

DH2-RSTOP (RED)

DH2-RSTART (WHT)

GND (GRN)

GND (GRN)

DH1-RSTOP (RED)

DH1-RSTART (WHT)

GND (BLK)

REMOTE STOP INPUT 2

REMOTE START INPUT 2

REMOTE STOP INPUT 1

REMOTE START INPUT 1

GND (WHT)

TX (BLK)

RX (GRN)

GND (GRN)

DH1-SPULSE (RED)

DH2-SPULSE (WHT)

GND (BLK)

GND (WHT)

TX (BLK)

RX (GRN)

GND (GRN)

DH1-POUT-A (RED)

DH2-POUT-A (WHT)

GND (BLK)

HALF-DUPLEX RS-485

GND (BLK)

IBNET-A (GRN)

IBNET-B (WHT)

GND (GRN)

DH1-POUT-B (RED)

DH2-POUT-B (WHT)

GND (BLK)

GND (WHT)

+24V (RED)

PRN-TX (BLK)

PRN-RX (GRN)

GND (GRN)

DH1-POUT-C (RED)

DH2-POUT-C (WHT)

GND (BLK)

DH2-R3-NO (GRN)

DH2-R3-COM (WHT)

DH2-R2-NO (RED)

DH2-R2-COM (BLK)

DH1-R3-NO (GRN)

DH1-R3-COM (WHT)

DH1-R2-NO (RED)

DH1-R2-COM (BLK)

DH1-R1-NO (GRN)

DH1-R1-COM (WHT)

INPUT-PWR (RED)

INPUT-PWR (RED)

DH2-R1-NO (GRN)

DH2-R1-COM (WHT)

INPUT-PWR (RED)

INPUT-PWR (RED)

INPUT-PWR (RED)

GND (BLK)

IB-A (GRN)

IB-B (WHT)

GND (BLK)

PWR 12V (RED)

PWR 5V (GRN)

DATA (WHT)

GND (BLK)

PWR 12V (RED)

DATA (WHT)

GND (BLK)

PWR 12V (RED)

4

3

2

1

IB-A (GRN)

IB-B (WHT)

GND (BLK)

PWR 12V (RED)

4

3

2

1

4

3

2

1

4

3

2

1

DISPLAY HEAD 1

(I.S. PROTECTED)

DISPLAY HEAD 2

(I.S. PROTECTED)

AUX 1

(I.S. PROTECTED)

AUX 2

(I.S. PROTECTED)

5VDC 24VDC

12VDC

0VDC

1

3

2

0

J13

J12

J11

CONNECTORS MAY

BE UNPLUGGED FOR

FIELD WIRING

WARNING

This system operates on low DC voltage/current

inputs.To avoid equipment damage, disconnect

the EMR4 input power plug (J8) prior to

performing ANY of the following truck maintenance issues:

• Using vehic

le battery charging equipment

• Jump starting the vehicle

• Replacing the vehic

le’s battery

• Welding on the truck

12/24V INPUT

FOR USE WITH PERIPHERAL

EQUIPMENT SPECIFIED IN THE

INSTALLATION INSTRUCTIONS.

LED INDICATORS

COMM (D10) : EMR4 STATUS

STATUS (D12) : WIFI STATUS

LINK (D15) : WIFI LINK INDICATION

SEE MANUAL FOR DETAILS

FOR SUPPLY CONNECTION,

USE WIRES RATED FOR A

MINIMUM OF 90°C.

CHASSIS-GND (GRN)

CHASSIS-GND (GRN)

TRUCK BATTERY / TERMINAL UPS:

10-28VDC, 5A MAX.

RELAY GROUND

BARRIER GROUND WIRE

EMR3 - Truck Installations

Figure 15. EMR4 IB Box Wiring Connections

24

Page 29

EMR4 Terminal & Fueling Depot Installation Installing The Interconnect Box (IB)

DC Solenoid

valve

Rigid conduit

Seal off

J-Box

Rigid

conduit

L

N

Supply

120/240 Vac

1

Interconnect Box

Power Side terminals

AC Solenoid

valve

Rigid conduit

Sealoff

AC Solenoid Wiring

DC Solenoid Wiring

Wire nut

Red

Red

Black

Black

White

White

Wire nut

Suppressor diode

V/R Kit P/N 846000-022

Suppressor Diode Ratings:

Output Current of 1.0 Amp,

Maximum reverse voltage 420 Volts

Suppression Diodes can only be

used with DC powered solenoids.

Interconnect Box

Power-Side Terminals

J7

J8

DH1-R1-NO

DH1-R1-COM

INPUT-PWR

INPUT-PWR

DH2-R1-NO

DH2-R1-COM

INPUT-PWR

INPUT-PWR

INPUT-PWR

GND

CHASSIS-GND

CHASSIS-GND

Note: Use either INPUT-PWR terminal

to provide power to valve

Note: Use either CHASSIS-GND terminal

to provide return for valve

Note: Use DH2-R1-NO and DH2-R1-COM

if using Display Head 2 to control valve

Note: Use DH2-R1-NO and DH2-R1-COM

if using Display Head 2 to control valve

J7

DH1-R1-NO

DH1-R1-COM

INPUT-PWR

INPUT-PWR

DH2-R1-NO

DH2-R1-COM

INPUT-PWR

INPUT-PWR

NOTICE

EMR3 - Truck Installations

Figure 16. Example Terminal Wiring Connections For DC And AC Solenoid Valves

25

Page 30

EMR4 Terminal & Fueling Depot Installation Power Conditioning Requirements

NOTICE

NOTICE

EMR3 - Truck Installations

Power Conditioning Requirements

Two separate electrical components are installed in EMR4 terminal - fueling depot applications - an uninterruptable

power supply (UPS) (recommended) and a +24 Vdc power supply (required). Veeder-Root recommendations for

this equipment are discussed below.

1. UPS (Uninterrupted Power Supply) - Optional

eder-Root recommends the Tripp Lite UPS model BC PERS450 (or equivalent) for up to 15 minut

Ve

power backup t

o the +24 Vdc power supply. For pricing or additional information, you can phone Tripp Lite

customer support or visit their website at www.tripplite.com/support/bcpers450.

2. Power supply - UL certified, 120 watt minimum, AC to DC - Two Vendors Recommended: Digi-Key or TDKLambda

Digi-Key Model 285-2346-ND 24 Vdc, 6.5 ampere power supply. (See Figure 17 for connection wiring dia-

gram) To order, visit their website at www.digikey.com

TDK-Lambd

a 24 volt power supply - Model No. HWS150A-24/A. To order, visit their website at www.us.tdk-

.

lambda.com/lp/products/hws-series.htm.

The power supply must be rated for at least 120 watts or improper operation of the EMR4

system will occur.

es of

Power supplies are open-type devices and must be mounted in an enclosure suitable for the

application.

Sensing Jumpers

Must be installed

Power Supply

Case Dimensions:

4.21 x 7.7 x 1.75 inches

(107 x 195 x 45 mm)

To IB

Input

Powe r

To IB Chassis

Ground Clamp

V+

Ground

+s +v

WHT

BLK

DRAIN

Figure 17. Digi-Key Power Supply Wiring Diagram

-s

-V

WIRE SIZE AND/OR DISTANCE LIMITATIONS

POUT-1, POUT-2, SP1, and SP2

LN

Terminal strip on rear of

Digi-Key power supply

Wire Color Codes

North

Line

America

WHT

BLK

GRN

Neutral

Ground

Europe

BLU

BRN

GRN/YEL

85 - 265 Vac

Input Power

• Wire size 16 - 24 AWG,

•

5V out length 250 ft. (76.2 m)

• 12V out length 500 ft. (152.4 m)

• 24V out length 1000 ft. (304.8 m)

26

Page 31

EMR4 Terminal & Fueling Depot Installation Power Conditioning Requirements

TLS-350 Console with BIR

Low Voltage DIM Module

Pulse Input

IB Circuit Board

DH1-POUT-A

Ground

<500 feet

12V

1.072 ms

0V

Pulse out waveform

from EMR4 IB

P1

LOW VOLTAGE DISPENSER INTERFACE MODULE

PULSER

P2 P3 P4 SOURCE

INPUT RATING

30 VDC MAX

Source voltage

not required for

application shown

Setup both the EMR4 and the TLS for the same ratio of pulses to volume.

Reference the appropriate setup and operating manuals.

EMR4 IB Pulse Output

Voltage Rotary Switch

(In this example set to 12VDC)

5VDC 24VDC

12VDC

0VDC

5VDC 24VDC

12VDC

0VDC

1

3

2

0

EMR3 - Truck Installations

• Maximum frequency 933 Hz

Figure 18. Wiring Pulse Output To A TLS-350 Console

27

Page 32

EMR4 Terminal & Fueling Depot Installation Power Conditioning Requirements

IB Circuit Board

IB Input Power

Connector (J8)

EMR4 IB Pulse Output

Voltage Rotary Switch

(In this example set to 12VDC)

5VDC 24VDC

12VDC

0VDC

5VDC 24VDC

12VDC

0VDC

1

3

2

0

Ground (-)

12V

0V

To external

pulse counter

Setup both the EMR4 and the TLS for the same ratio of pulses to volume.

Reference the appropriate setup and operating manuals.

LVDIM

LOW VOLTAGE DISPENS ER INTERFACE MODULE

+

-

+

-

+

-

+

-

12

11

10

9

+

-

+

-

+

-

+

-

5

6

7

8

+

-

+

-

+

-

+

-

1

2

3

4

+

-

SOURCE

INPUT RATING

30 VDC MAX

0 1 AMP MAX

<500 feet

INPUT-PWR

GND

When supplying power from

EMR4 IB box, set switch SW1

on LVDIM PC board to the

“EXTERNAL” position.

DH1-POUT-A (+)

NOTICE

EMR3 - Truck Installations

Figure 19. Wiring Pulse Output To A TLS-450/TLS4 Console

28

Page 33

EMR4 Terminal & Fueling Depot Installation EMR4 – Legal Disclaimer Notice

NOTICE

EMR3 - Truck Installations

PULSE OUTPUT LIMITS

EMR4 Setting Maximum Fueling Rate

0.1 pulse/gallon 450,000 gpm

1.0 pulse/gallon 45,000 gpm

10 pulses/gallon 4,500 gpm

100 pulses/gallon 450 gpm

1,000 pulses/gallon 45 gpm

Limits are dependent on the time it takes the EMR4 to send pulses. In this example, a gallon is used to represent a

unit of volume and gpm is gallons-per-minute.

The EMR4 has a maximum pulse rate of 750 pulses per second or 45,000 pulses per minute. At high fueling rates,

the EMR4 will need extra time to send out all of the required pulses. Use the following examples as a guide to

setting the correct pulse-to-unit-volume ratio on the EMR4. Reference the EMR4 Setup And Operation Manual,

577014-350, to enter a value under the SET PULSES/VOL menu.

Example of a correct setting:

Set the PULSES/VOL value to 10 pulses per gallon and deliver 1,600 gallons at a fueling rate of 800 gpm. The

actual delivery takes 2 minutes and the EMR4 can transmit 16,000 pulses within the 2 minute time frame.

Example of an incorrect setting:

Set the PULSES/VOL value to 100 pulses per gallon. Deliver 3,200 gallons at a fueling rate of 800 gpm. The