Page 1

3

EMR

Setup and Operation Manual

Manual No: 577013-766 ● Revision: I

Page 2

Notice

Veeder-Root makes no warranty of any kind with regard to this publication, including, but not limited to, the

implied warranties of merchantability and fitness for a particular purpose.

Veeder-Root shall not be liable for errors contained herein or for incidental or consequential damages in

connection with the furnishing, performance, or use of this publication.

Veeder-Root reserves the right to change system options or features, or the information contained in this

publication.

This publication contains proprietary information which is protected by copyright. All rights reserved. No part

of this publication may be photocopied, reproduced, or translated to another language without the prior written

consent of Veeder-Root.

DAMAGE CLAIMS

1. Thoroughly examine all components and units as soon as they are received. If damaged, write a complete

and detailed description of the damage on the face of the freight bill. The carrier's agent must verify the

inspection and sign the description.

2. Immediately notify the delivering carrier of damage or loss. This notification may be given either in person

or by telephone. Written confirmation must be mailed within 48 hours. Railroads and motor carriers are

reluctant to make adjustments for damaged merchandise unless inspected and reported promptly.

3. Risk of loss, or damage to merchandise remains with the buyer. It is the buyer's responsibility to file a claim

with the carrier involved.

RETURN SHIPPING

For the parts return procedure, please follow the appropriate instructions in the "General Returned Goods

Policy" and "Parts Return" pages in the "Policies and Literature" section of the Veeder-Root North American

Environmental Products price list.

FCC INFORMATION

This equipment complies with the requirements in Part 15 of the FCC rules for a Class A computing device.

Operation of this equipment in a residential area may cause unacceptable interference to radio and TV

reception requiring the operator to take whatever steps are necessary to correct the interference.

©Veeder-Root 2004. All rights reserved

.

Page 3

Table of Contents

Table of Contents

Introduction

System Options ................................................................................................................1

System Setup ...................................................................................................................1

Setup Mode................................................... ...... ..... ...... ...... ................................. ...... ..1

C&C Mode.....................................................................................................................1

Related Manuals ...............................................................................................................2

Safety Symbols .................................................................................................................2

Safety Warnings ...............................................................................................................3

Display Head ............................................... ..... ...... ..... ...... .................................. ..... ........4

Boot-Up Test Sequence ...................................................................................................5

Activating the Display .......................................................................................................6

OEM Message Disabled...............................................................................................6

OEM Message Enabled................................................................................................6

Display Value Fields ................................................................................ ...... ...... ..... ........6

Register Field.............. ...... ...... ................................. ...... ...... ..... ...... ..............................6

Preset Field...................................................................................................................6

Totalizer Field................................................................................................................6

Descriptor Field.............................................................................................................6

Display icons and indicators .............................................................................................6

Display Button Functions - Standard Keypad ...................................................................7

Display Button Functions - Optional Keypad ....................................................................7

Data Entry

Navigation Buttons ............................................................................................................8

Data Entry with Standard Keypad .....................................................................................8

Data Entry with Optional Keypad ......................................................................................9

EMR3 Operating States and Modes

System Operating States ................................................................................................10

Pre-Dispense State.....................................................................................................10

Dispense State............................................................................................................10

Finish State.................................................................... ...... ..... ...... ............................10

System Operating Modes ...............................................................................................10

Volume Mode..............................................................................................................10

Currency Mode........................ ..... ...... ...... ..... .................................. ..... ...... .................10

Rate Mode...................................................................................................................10

Setup Mode................................................... ...... ..... ...... ...... ..... ..................................11

Calibration and Configuration (C&C) Mode.................................................................11

Setup Mode

Initiating the Setup Mode ................................................................................................12

Setup Mode Categories ..................................................................................................12

Enter Security Code....................................................................................................13

Pricing.........................................................................................................................14

Tax/Discount...............................................................................................................14

Defaults.......................................................................................................................15

Relay Control ..............................................................................................................16

Security.......................................................................................................................17

Printer Option..............................................................................................................18

View Records..............................................................................................................20

Restore Records.........................................................................................................21

Shift.............................................................................................................................21

i

Page 4

Table of Contents

Date Format................................................................................................................23

Time/Date....................................................................................................................24

System Address.......... ...... ...... ..... .................................. ...... ..... ...... ..... .......................24

Time Delays................................................................................................................28

Version Number..........................................................................................................28

C&C Mode

Initiating the C&C Mode ..................................................................................................29

C&C Mode Setup Categories .........................................................................................29

Language....................................................................................................................30

Display Syntax............................................................................................................32

Temperature................................................................................................................33

Fuel Source.................................................................................................................34

Meter Calibration.........................................................................................................39

Configure I/O...............................................................................................................42

OEM Message............................................................................................................42

Delivery Options..........................................................................................................43

Report Formats............................................. ...... ..... .................................. ...... ..... ......43

Restart.........................................................................................................................45

Security Code..............................................................................................................46

Exiting C&C Mode ..........................................................................................................46

Operation of the System

Multiple Products ............................................................................................................47

Single Deliveries .............................................................................................................47

Multiple Deliveries ...........................................................................................................47

Transfer Deliveries ..........................................................................................................47

Multiple Products in Multiple Deliveries ..........................................................................47

Driver Selection of Price/with Tax Codes During Operation ...........................................47

Entry of Price Codes & Tax/Discount Assignment in Setup Mode ..................................48

Emergency Stop .............................................................................................................48

Preset Operation and Tank Topping ...............................................................................48

Temperature Compensation Delivery Feature ................................................................49

Changing Modes and Presets During Operation ............................................................49

Typical Dispensing Examples .........................................................................................50

Dispensing Volume without preset..............................................................................50

Dispensing Volume without Price but with Preset before Dispensing.........................50

Dispensing Volume without Price but with Preset after Dispensing............................50

Dispensing Currency with Price Code before Delivery but without Preset..................51

Dispensing Currency with Price Code & Currency Preset before Delivery.................51

Dispensing Currency with Price Code Before & Currency Preset After Dispensing...51

Dispensing Currency with Price Code and Volume Preset Before Dispensing...........52

Dispensing Currency with Price Code & Volume Preset After Dispensing.................52

Dispensing With Tank ID Enabled ..............................................................................52

EMR3 Troubleshooting Guide

Testing an EMR³ System ................................................................................................54

Display Head...............................................................................................................54

Lcd Display.............................. ..... ...... ...... ................................. ...... ..... ...... .................54

Pulse Generator Input Check......................................................................................54

Printer Check ..............................................................................................................54

EMR³ Informational Messages ........................................................................................54

No Records.......................................................................... ..... ...... ..... .......................54

Recalculating...............................................................................................................54

No Price Entry......................... ..... .................................. ...... ..... ...... ..... .......................55

ii

Page 5

Table of Contents

Select Product.............................................................................................................55

Delivery Error Codes ......................................................................................................55

E04 - Encoder Pulse Error..........................................................................................55

E06 - Temp Probe Too Hot.........................................................................................55

E07 - Temp Probe Too Cold.......................................................................................55

E08 - Temperature Probe Failure ...............................................................................55

Startup Error Codes ........................................................................................................55

E05 - Nvram Fail.........................................................................................................55

E15 - Ram Fail............................................................................................................56

E16 - Flash Fail...........................................................................................................56

E17 - Addr Fail............................................................................................................56

E18 - Data Fail............................................................................................................56

E19 - Uart Fail.............................................................................................................56

System Error Codes .......................................................................................................56

E50 - IB Comm Failure................................................................................................56

IB Indicator Lights and IB Self Checks........................................................................57

E66 - Printer Busy.......................................................................................................57

Exc Error ####.............................................. .................................. ..... ...... ...... ...........57

Relay Setup Error Codes ................................................................................................57

E60 - Stop Advance Error...........................................................................................58

Calibration Error Codes ..................................................................................................58

E64 - Fuel Type Undefined.........................................................................................58

E65 - Calibration Error................................................................................................58

Other Problems ...............................................................................................................58

System Boots Up Okay, but Display Keys Don’t Respond .........................................58

Figures

Appendix A: EMR3 Setup - Programming Tips

For Typical Single or Dual-head Installations with One IB ............................................A-1

Appendix B: Epson Printer Characters ........................................................B-1

Figure 1. Display Head Features ..............................................................................4

Figure 2. Display Head with Optional Keypad ..........................................................4

Figure 3. All Segments Activated .............................. ...... ..... .................................. ..5

Figure 4. All Zeros Activated in the Display Fields ...................................................5

Figure 5. Using Front Panel Buttons to Navigate in Setup .......................................8

Figure 6. Logging In Using Default Passcode ........................................................13

Figure 7. Logging In Using Assigned Passcode .....................................................13

Figure 8. Logging Out .............................................................................................13

Figure 9. Pricing Setup ...........................................................................................14

Figure 10. Tax/Discount Setup .................................................................................14

Figure 11. Defaults Setup .........................................................................................15

Figure 12. Start Modes Setup ...................................................................................15

Figure 13. Presets Setup ..........................................................................................16

Figure 14. Relay Control Setup ................................................................................16

Figure 15. Passcode and Setup Access Setup ........................................................17

Figure 16. Printer Option Setup ................................................................................18

Figure 17. Delivery Ticket Format ...........................................................................19

Figure 18. View Records Setup ................................................................................20

Figure 19. Restore Records Procedure ....................................................................21

Figure 20. Shift and Shift Report Setup ....................................................................22

iii

Page 6

Table of Contents

Figure 21. Shift Report Format .................................................................................23

Figure 22. Date Format Setup ........................................................... ...... ...... ..... ......23

Figure 23. Date/Time Setup .....................................................................................24

Figure 24. System Address Setup ............................................................................24

Figure 25. IB Address Setup ....................................................................................25

Figure 26. Port 1 Assign Setup .................................................................................25

Figure 27. Port 2 Assign Setup .................................................................................26

Figure 28. Head Address Setup ...............................................................................26

Figure 29. Printer Address Setup .............................................................................27

Figure 30. Time Delay Setup ....................................................................................28

Figure 31. Version Number Viewer ..........................................................................28

Figure 32. Language Setup ......................................................................................30

Figure 33. Printer Labels Setup ................................................................................31

Figure 34. Display Syntax Setup ..............................................................................32

Figure 35. Temperature Setup .................................................................................33

Figure 36. Temperature Calibration Setup ...............................................................33

Figure 37. Fuel Source Setup ...................................................................................34

Figure 38. Meter ID Setup ........................................................................................34

Figure 39. Input Type Setup .....................................................................................35

Figure 40. Product Description Setup .......................................................................36

Figure 41. Meter Calibration Setup ...........................................................................39

Figure 42. Meter Auto Calibration Setup ..................................................................40

Figure 43. Meter MultiCalibration Setup ...................................................................40

Figure 44. Meter Manual Calibration Setup ..............................................................41

Figure 45. Configure I/O Setup .................................................................................42

Figure 46. OEM Message Setup ..............................................................................42

Figure 47. Delivery Options ......................................................................................43

Figure 48. Delivery and Shift Report Formats ..........................................................44

Figure 49. Delivery and Shift Report Formatting Examples .....................................45

Figure 50. Restart Options .......................................................................................45

Figure 51. Security Code ..........................................................................................46

iv

Page 7

Introduction

This manual describes setup and operating procedures for the EMR3 Electronic Meter Register System. This

manual assumes that the Display Head, Interconnection Box, and printer are installed and connected.

System Options

There are three options available for the EMR3 System:

• Time and Date

• Currency Mode

• Temperature Compensation

References to Time and Date, Currency/Pricing, and Temperature Compensation are found throughout this manual

in setup charts and in operating instructions. The EMR will not display any setup steps connected to an option (in

Setup or C&C Modes) if that option is not installed. When using this manual, please ignore any references to an

option if it is not installed.

System Setup

There are two distinct categories of EMR3 setup; Setup Mode which can be accessed at any time by the

equipment operator, and C&C (Configuration and Calibration) Mode which is only to be entered in accordance

with Weights and Measures (W&M) requirements.

SETUP MODE

The Setup Mode can be accessed by the equipment operator to:

• Establish price, tax, and discount codes,

• Set the shutoff points for preset flow control relays 1 and 2.

• View/print delivery records,

• Select a designated printer type,

• Set system component addresses,

• Set time delays to blank out display,

• Enter shift times, tanker reloads, and odometer readings, and print out end-of-shift activity reports,

• Enter security codes which can be assigned to delivery functions to prevent unauthorized changes.

• Provide Passcode login procedure for access to assigned setup categories.

• Restore up to the last 50 transaction records from IB NVRAM storage to a replacement Display Head,

• Select month, day, year date formats,

• Enter system Time and Date, and

• View component version numbers.

C&C MODE

The C&C Mode setups must be performed before you make selections in the non-metrological controlled Setup

Mode - There is one exception: When initially powering up an EMR

Address Setup (in Setup Mode) must be completed before entering C&C Mode (see page 24 to page 27).

3

System with two Display Heads, System

1

Page 8

EMR3 Setup and Operation Manual Related Manuals

Entering the C&C Mode requires that a seal-protected wire jumper or switch in the Display Head be changed.

Changes in this mode must be accordance with local W&M authority requirements. In the C&C Mode you:

• Enter the meter input type and calibrate the meter,

• Enter product descriptions,

• Enter calibration and temperature compensation parameters,

• Configure system I/O devices,

• Enter the OEM message,

• Select between coefficient of expansion or density as a method of temperature compensation for product

delivery.

• Enable price changing in the delivery state (if allowed),

• Enable system security code to limit unauthorized access to delivery setups,

• Select and modify display formats, operating labels, and print labels, and

• Perform a reboot with or without resetting setup parameters to their factory default positions.

Related Manuals

577013-758 EMR3 Installation Guide

577013-823 EMR

3

Operator Quick Help Card

Safety Symbols

The following safety symbols are used in this manual to alert you to important safety hazards and precautions.

EXPLOSIVE

Fuels and their vapors are extremely

explosive if ignited.

ELECTRICITY

High voltage exists in, and is supplied

to, the device. A potential shock hazard exists.

FLAMMABLE

Fuels and their vapors are extremely

flammable.

READ ALL RELAT ED MANUALS

Knowledge of all related procedures

before you begin work is important.

Read and understand all manuals

thoroughly. If you do not understand

a procedure, ask someone who does.

2

Page 9

EMR3 Setup and Operation Manual Safety Warnings

Safety Warnings

WARNING

This system operates near highly combustible fuel storage tanks.

Fire or explosion resulting in serious injury or death could result if the

equipment is improperly installed or modified or is used in any way other than

its intended use. Serious contamination of the environment may also occur.

T o e nsu re proper installation, o perati on, and continued saf e use of th is product:

1. Read and follow all instructions in this manual, including all safety

warnings.

2. Have equipment installed by a contractor trained in its proper installation

and in compliance with all applicable codes including: the National

Electrical Code; feder al, s tate, and local codes; and oth er appli cable saf ety

codes.

3. Ensure that this equipment is properly programmed.

4. Operate this equipment in accordance with the instructions in this manual.

5. Promptly investigate any alarm conditions.

6. Do not modify or use service parts other than those provided by VeederRoot. Substitution of components may impair intrinsic safety.

3

Page 10

EMR3 Setup and Operation Manual Display Head

D

e

Mode Labels

Display Head

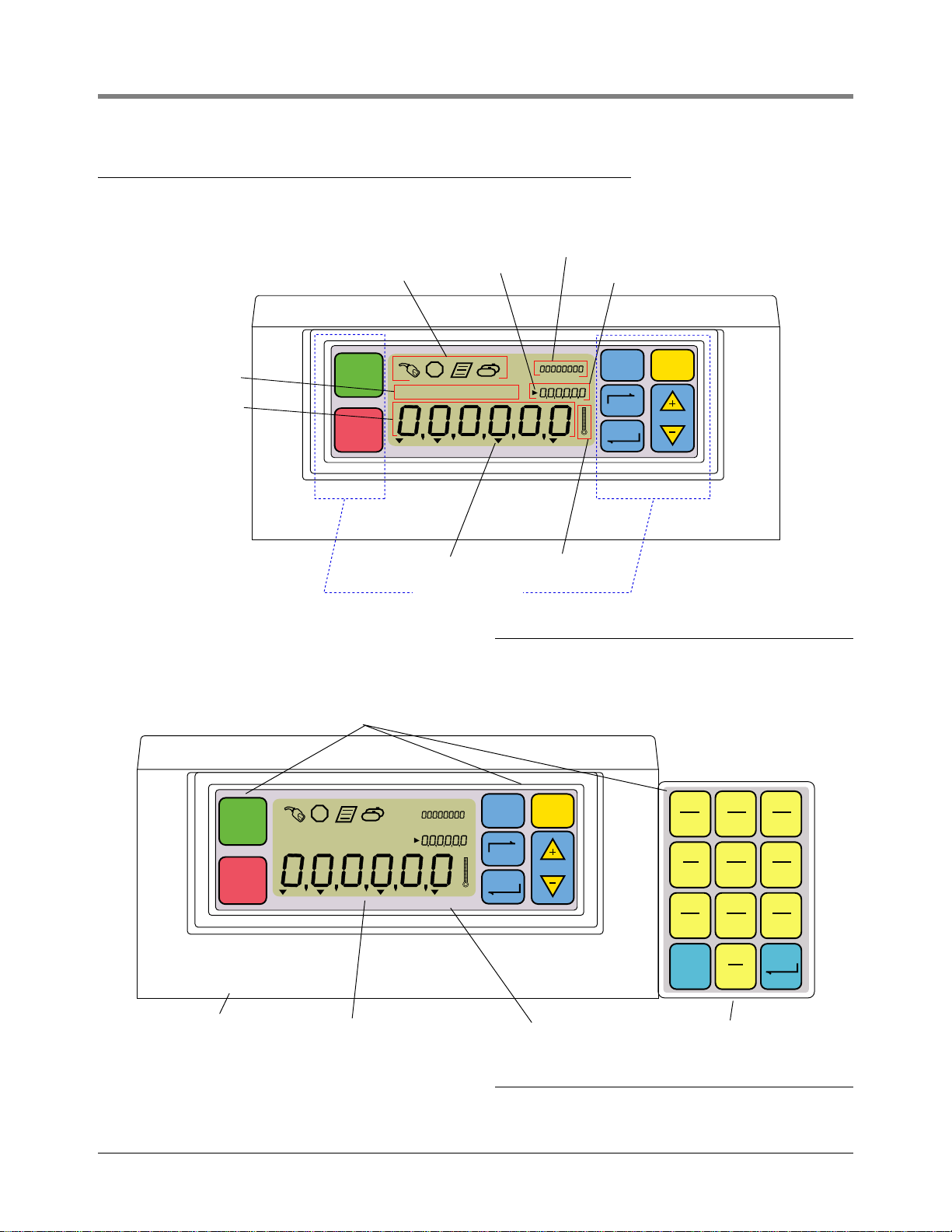

The EMR3 Display Head display features are shown in Figure 1 and Figure 2.

escriptor Field

Register Field

emr/3.1/eps

Operating Icons

START

FINISH

Preset Indicator

VEEDER ROOT CO

VOLUME CURRENCY RATE SETUP

Mode Indicator

Standard Keypad

Temperature Icon

Grand Totalizer Field

Preset Field

MODE PRESET

NEXT

ENTER

Figure 1. Display Head Features

Tactile Feel Buttons

ABC2DEF

START

VEEDER ROOT CO

FINISH

VOLUME CURRENCY RATE SETUP

mr/3.2/eps

Cast Housing

Membrane Front Panel

MODE PRESET

NEXT

ENTER

QZ

1

JKL

GHI

5

4

TUV

PRS

8

7

(EXT)

0

Optional Keypad

3

MNO

6

WXY

9

ENTERCLEAR

Figure 2. Display Head with Optional Keypad

4

Page 11

EMR3 Setup and Operation Manual Boot-Up Test Sequence

Boot-Up Test Sequence

When power is initiated to the Display Head, the screen will power up with a test sequence that satisfies the

requirements of the local Weights and Measures authority. The Display Head test sequence follows below:

• ROM TEST

• DATA BUS TEST (message not displayed)

• ADDRESS BUS TEST (message not displayed)

• RAM TEST

• CS TEST (message not displayed)

• NVRAM TEST

• INIT NVRAM

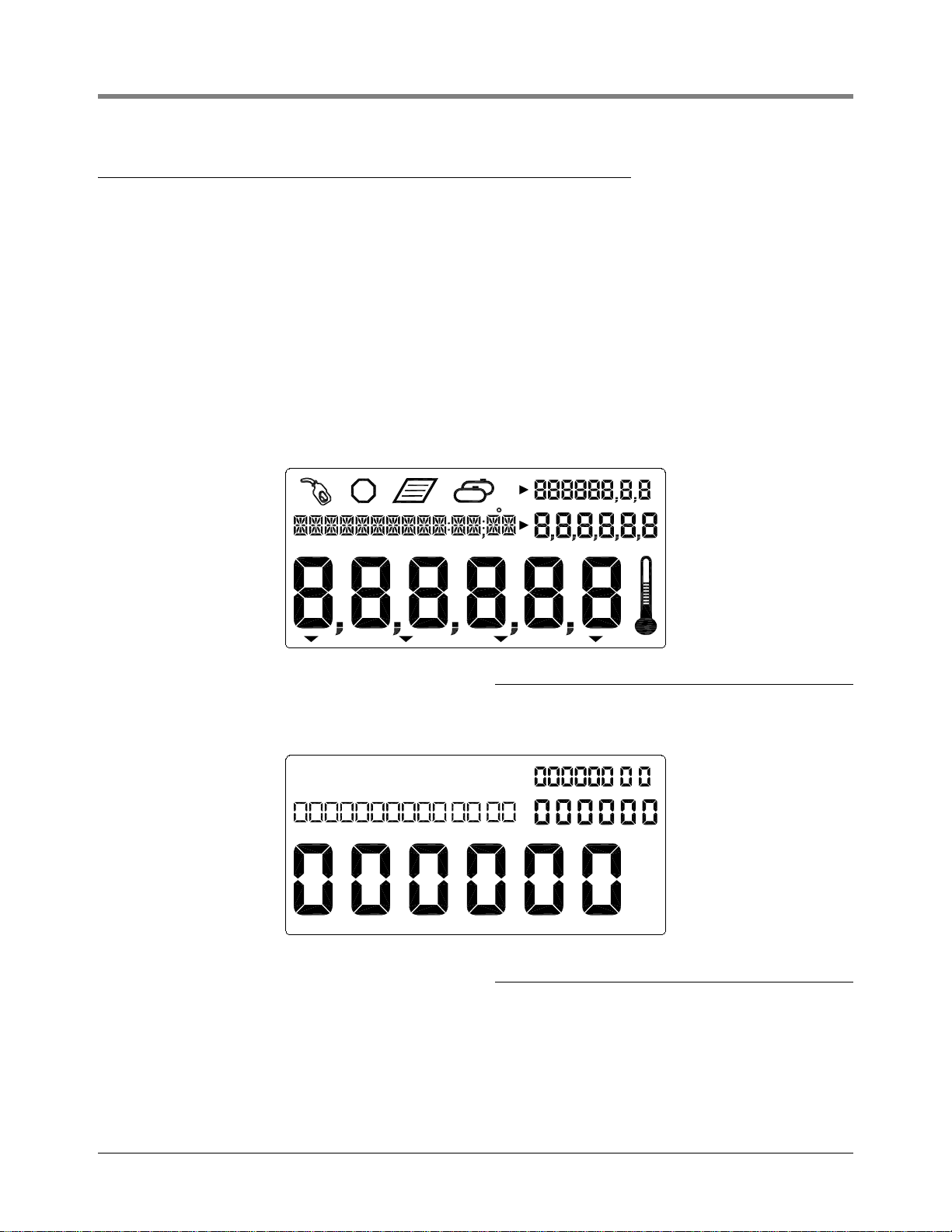

• All segments of the display are activated (see Figure 3):

Figure 3. All Segments Activated

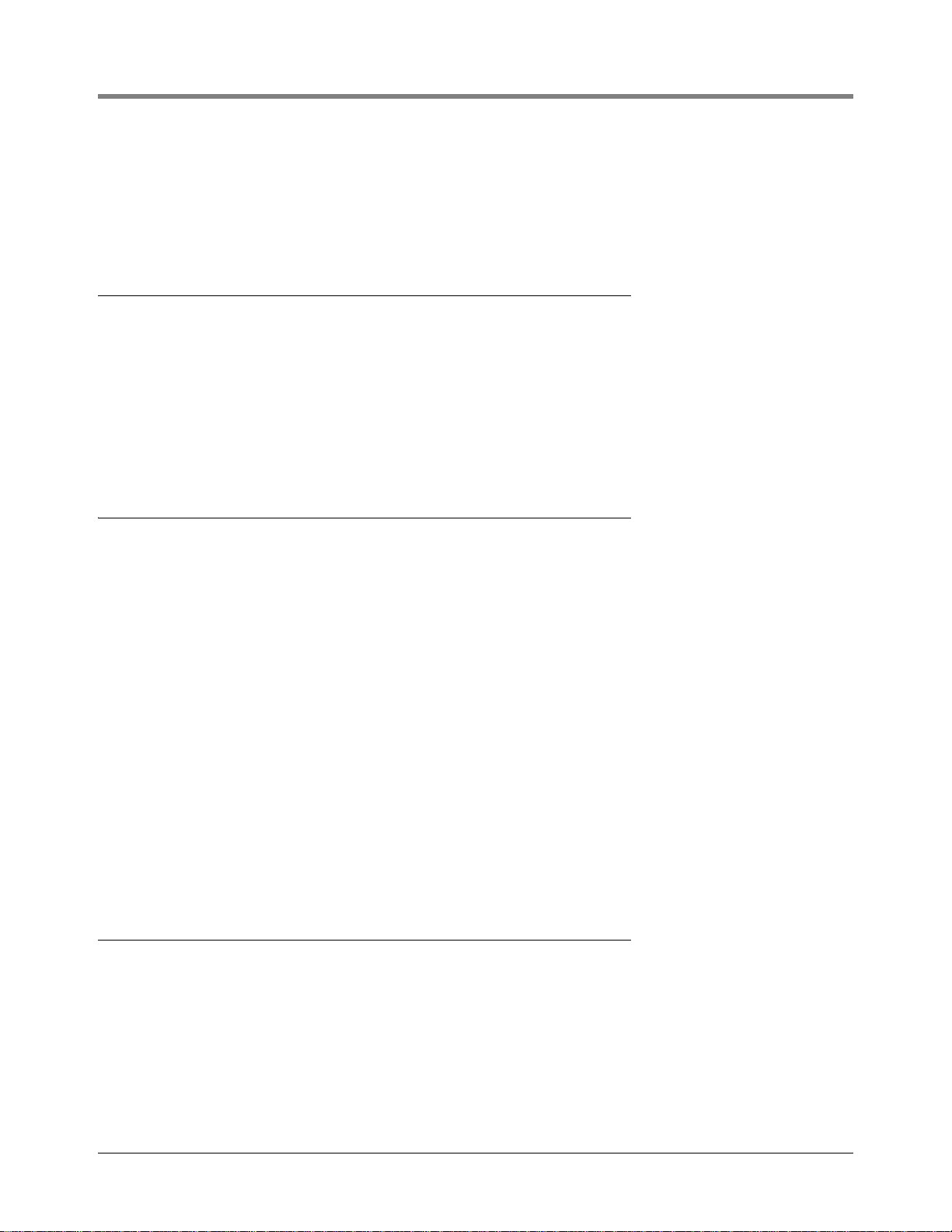

• All zeros appear in the four display value fields (see Figure 4):

Figure 4. All Zeros Activated in the Display F ields

• On initial startup of EMR

(Figure 28 on page 26) and assign an unique Head Address for each Display Head. Because the factory default

Head Address is set to a “1”, one of the two Display Head’s addresses must be changed to a “2”. Caution!

Failure to do so will cause communication problems which will result in erratic operation.

3

Systems with two Display Heads, you must go to the Head Address Setup

5

Page 12

EMR3 Setup and Operation Manual Activating the Display

• Subsequently, if no button press or operation occurs in 30 seconds, the display will go blank and wait for a

button to be pressed to reactivate. Initially, when reactivated, the Display Head enters the Volume mode.

Once the unit has been setup, the default reactivation mode will be the Pre-Dispense mode you choose in

setup. Also, if you enable the OEM message in setup, it will scroll across the Descriptor field until the 30

second timeout.

Activating the Display

OEM MESSAGE DISABLED

Display is blank after the 30 second timeout. Press a button on the display, if the timeout follows setup, the predispense default mode is displayed. Otherwise the display on the screen prior to the timeout will display.

OEM MESSAGE ENABLED

Display is blank after 30 second timeout. Press a button on the display, the OEM message scrolls in the

Descriptor field. Press a button on the display, if the timeout follows setup, the pre-dispense default mode is

displayed. Otherwise the display on the screen prior to the timeout will display.

Display Value Fields

REGISTER FIELD

Six digits display the current volume, currency value, final price, or rate of fuel dispensed. The area is used to

display different selections. Values may display in various resolutions by selecting options in the C&C Mode.

Decimal and comma selection is available in this mode for 5 of the 6 digits.

PRESET FIELD

Six digits display the volume preset, volume preset count down, price, currency preset values, or currency preset

count down. The area is used to enter different selections of price, volume preset, or currency preset. Values may

display in various resolutions by selecting options in the C&C Mode. Decimal and comma selection is available in

this mode for 5 of the 6 digits.

TOTALIZER FIELD

Eight digits display the grand totalizer volume dispensed for the life of the product. Decimal selection is available in

this mode for 2 of the 8 digits.

DESCRIPTOR FIELD

Fourteen Characters at one time, with a rolling text capability for extended messages (up to 24 characters total),

displays description of values, labels, time/date, and instructional messages. labels, descriptions, and messages

are changeable in C&C Mode. Error codes will appear also in this field.

Display icons and indicators

• Emergency Stop - Octagon icon displayed when optional emergency stop switch contacts are closed. This

remote switch will be mounted near the Display Head and is pushed to stop flow and pulled to resume flow.

• Fueling - Fuel nozzle icon displayed constantly when system is ready to dispense. The Icon will flash when

approaching the time-out in delivery mode (30 seconds). See single delivery mode for further explanation.

• Te mp erat ure - The thermometer icon will display only when a temperature compensated product is selected.

6

Page 13

EMR3 Setup and Operation Manual Display Button Functions - Standard Keypad

• Printer - A page icon will display only when a printer is configured for the system. A slow flashing page icon is

displayed when the printer is actively printing. A fast flashing page icon is displayed when the printer requires

operator attention.

• Multiple Delivery - The multi-tank icon will display when the multiple delivery state is initiated.

• Mode Indicators - An indicator icon will point to the current Mode (Volume, Currency, Rate, or Setup) when

appropriate.

• Preset Indicator - An indicator icon will point to the Preset Field to indicate the Status of the Preset when in

that mode, otherwise it will not appear. It will flash when the Preset is set but disabled and will remain solid

when the Preset is enabled.

Display Button Functions - Standard Keypad

• START - Press to begin a fuel dispense transaction. When START is depressed for more than (2) seconds

multiple delivery mode is initiated.

• FINISH - Press to end a fuel dispense transaction. After transaction is complete, pressing FINISH will clear the

display of the last transaction and return you to the Pre-Dispense state. Press FINISH to toggle between

displaying the last transaction and the Pre-Dispense state. If depressed for more than a second after transaction

completed and last dispense is called, pressing FINISH initiates a Duplicate Ticket.

When multiple products are available and you are in the Select Product step prior to dispensing, pressing

FINISH will exit the dispense state, and return you to the pre-dispense state.

• MODE - Prior to pressing START Button, press MODE to cycle between Volume, Currency, and Setup Modes.

After pressing START Button, press MODE to cycle between Volume, Currency, and Rate Modes.

• PRESET - In Volume Mode, press to initiate presetting the amount of volume to dispense. Used in conjunction

with the NEXT, ‘+’, ‘-’, and ENTER Buttons to set a preset value.

In Currency Mode, press to toggle between price screen and currency preset screen. Used in conjunction with

the NEXT, ‘+’, ‘-’, and ENTER Buttons to select and set a Price or a preset value.

• NEXT - Press to enter the value fields - task or function. It is used also to move to the next lesser digit or next

letter in an entry to a value field. At the least significant digit it will wrap to the most significant digit.

• ENTER - Press to accept a selection, price code or data entry.

• Plus button which you press to scroll upward through the menu selections, to increment through numeric

characters 0 to 9, alpha characters Z to A, and special characters for each position in a selected display. Note:

throughout this manual, ‘+’ button will also refer to this button.

• Minus button which you press to scroll downward through the menu selections, to move from alpha

characters A to Z, numeric characters 9 to 0, and special characters for each position in a selected display.

Note: throughout this manual, ‘-’ button will also refer to this button.

Display Button Functions - Optional Keypad

• 0 through 9 - Press to enter alpha, numeric, or special character value into an active field. In alpha or numeric

selections, the cursor advances automatically upon selection of the next number or a different character

represented by the same button (negates the requirement for the NEXT button to be depressed for that

purpose).

• CLEAR - Press to enter a 0 in the active position of the Preset or Register fields. Press to enter blank spaces in

the active position of the descriptor field. Holding the button depressed for 2 seconds clears the entire

descriptor field being edited.

• ENTER - Press to accept a selection, price code, or data entry (functions the same as the ENTER button on the

standard keypad).

7

Page 14

Data Entry

t

P

t

Navigation Buttons

The navigation buttons consist of the MODE, NEXT, ENTER, PRESET, and +/- buttons. They can be used to

either select and set parameters, or select and set alpha and numeric values.

• MODE - Press to navigate through the Modes; Setup, Volume, Currency, and Rate.

• NEXT - Press to move to the next submenu for a selection of a parameter or an alpha (Descriptor Field) or

(Preset Field) numeric selection.

• Press to scroll upward through the menu selections, to cycle through numeric characters 0 to 9, alpha

characters Z to A, and special characters for each position in a selected display.

• Press to scroll downward through the menu selections, to cycle through alpha characters A to Z, numeric

characters 9 to 0, and special characters for each position in a selected display.

• ENTER - Press to accept selection of parameter or alphanumeric values, or to return to prior menu selection.

• PRESET - Press to move to the preset countdown or preset entry.

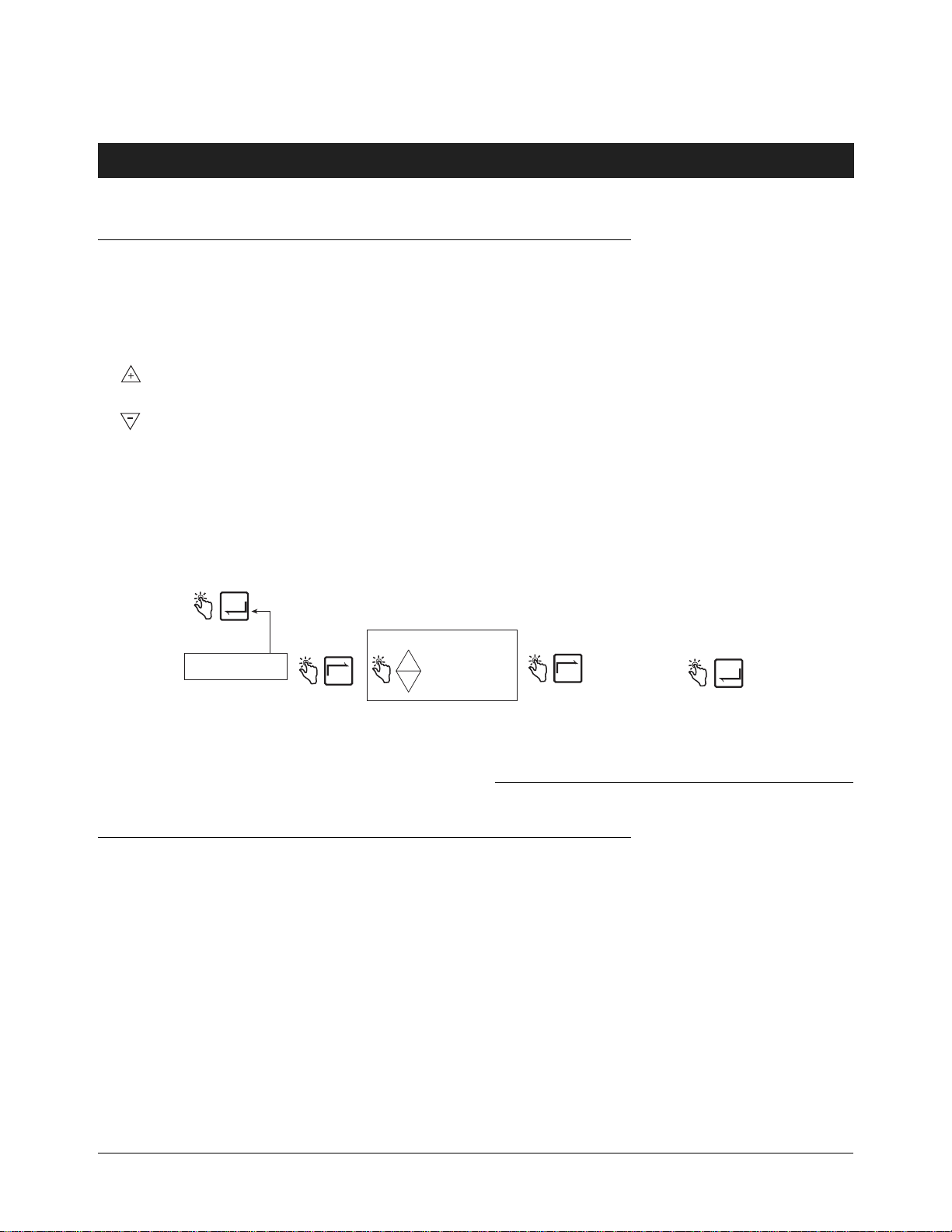

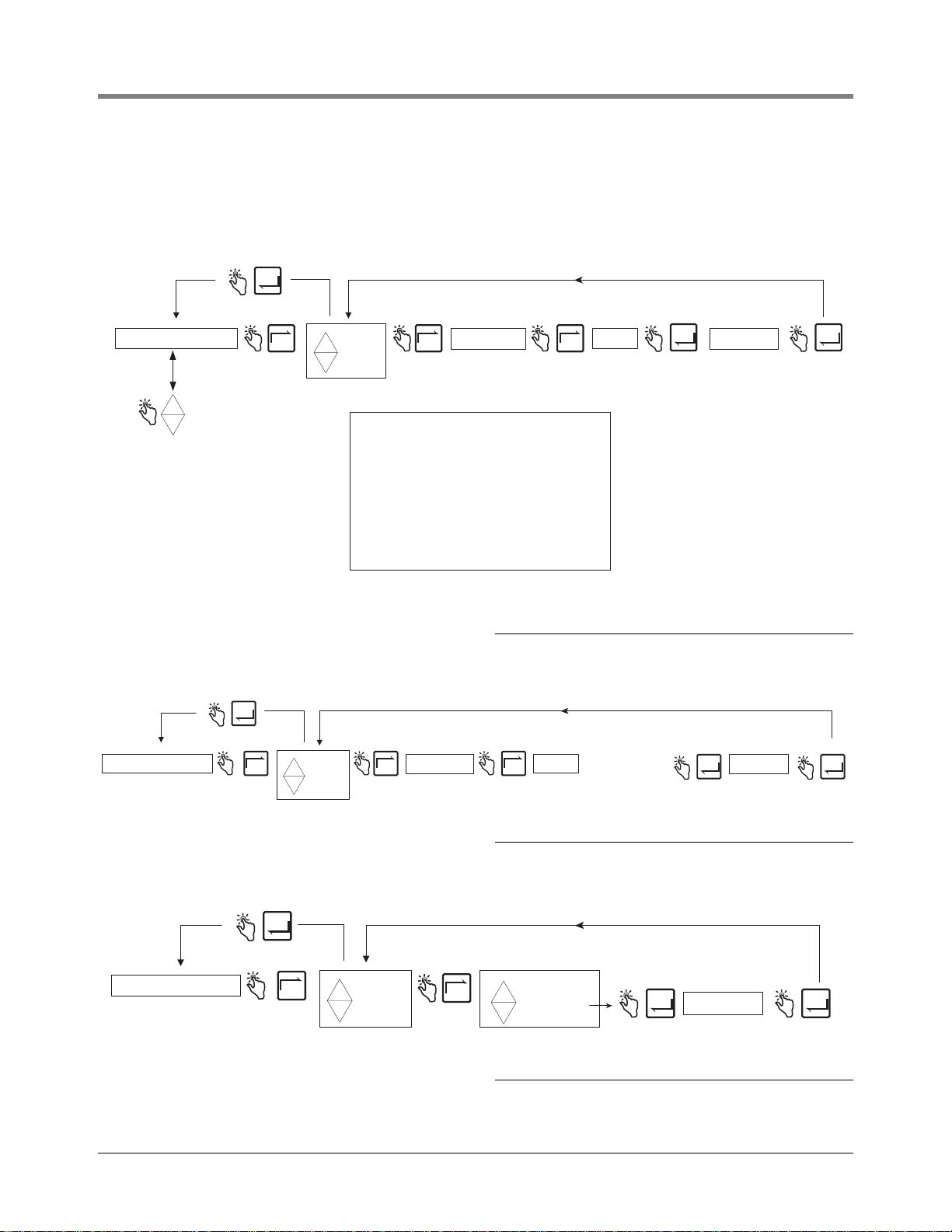

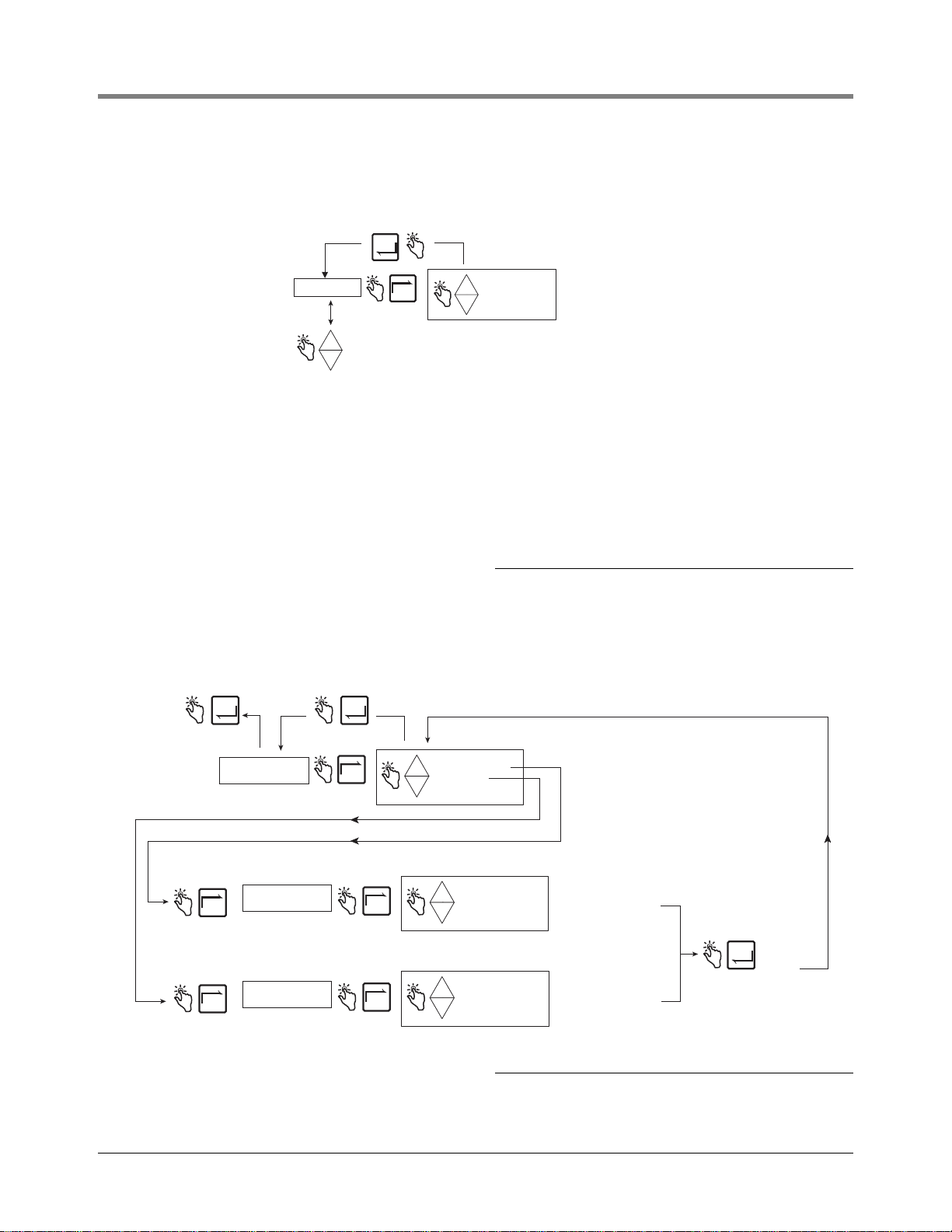

Figure 5 illustrates the use of front panel buttons to make selections and navigate in Setup Mode.

ress ENTER to return

o LABEL CHANGES

ENTER

CURRENCY LABELS

NEXT

PRICE DOLLARS

DOLLAR PRICE

+

PRESET DOLLARS

DOLLAR REMAIN

-

DOLLAR PRESET

Note: 24 characters maximum.

Make your changes

to a label, pressing

up/down arrows to

scroll through the

NEXT

alphabet, and NEXT

to move from one

character of the label

to the next.

Figure 5. Using Front Panel Buttons to Navigate in Setup

Press ENTER to accep

changes and select

another label. Repeat

ENTER

until you enter all

label changes.

Data Entry with Standard Keypad

Upon entering the Descriptor or Preset Field with the use of the navigation buttons, a blinking cursor appears in

the far left of the field if, the field is empty or has a zero value. If the field contains data, a blinking cursor appears

one position to the left of the first non-blank field.

Pressing the +/ - buttons will scroll through alpha or numeric options for entry in the position. Holding down the +/

- buttons will scroll automatically without having to depress the button for each value. Pressing the NEXT button

will move the curser to the right for the next position. During alpha entries numeric, special characters, and blanks

are available. Pressing the NEXT button without scrolling to another selection will leave the current value and move

to the next location.

Subsequent presses of the NEXT button will shift the selected entry point to the right so the next digit/alpha/

space can be selected. When the last or least significant position is reached the subsequent press of the NEXT

button will wrap around to the most significant position. When changes are complete, press ENTER to accept

values.

8

Page 15

EMR3 Setup and Operation Manual Data Entry with Optional Keypad

Data Entry with Optional Keypad

Upon entering the Descriptor or Preset Field with the use of the navigation buttons the optional keypad will permit

alpha and numeric entries.

To enter a numeric in the Preset Field just select the appropriate button on the optional keypad. When a selection

is made, the curser will automatically sequence to the position to the right.

To enter an alpha, numeric, or special character in the Descriptor field, select the number button on the optional

keypad containing that alpha or numeric. Sequential depressions of the button will step through the alpha and

numeric values for that button. To move the curser to the next position, the NEXT button can be depressed.

Alternatively, when another, non-like button is depressed the curser will move to the right and the selection of the

value is obtained as aforementioned. In the case where the same alpha or numeric is desired the NEXT button will

sequence the curser to the next entry position.

When the desired entry is complete, press ENTER to accept.

The display head allows entries using both keypads in conjunction with each other or independently.

9

Page 16

EMR3 Operating States and Modes

System Operating States

The system has three operating states, Pre-Dispense, Dispense, and Finish.

PRE-DISPENSE STATE

Prior to pressing the START button, the system is in the Pre-Dispense state. The setting of system parameters,

pricing, and tax codes for a delivery are made in this state.

DISPENSE STATE

After pressing the START button (and selecting a product if setup for multiple products), the system enters the

Dispense state.

FINISH STATE

After pressing the FINISH button, the system is in the Finish State. The ticket is printed and the last delivery is

displayed.

System Operating Modes

Four operating modes are used in the EMR3 System. They are Volume, Currency, Rate, and Setup. These modes

can be navigated by use of the MODE button. In Setup, the default Mode for Pre-Dispense and Dispense states

can be set. The defaults may be changed through the User Setup menus

VOLUME MODE

The display will default to the Volume mode when the display head is first initialized. In the Pre-Dispense or

Dispense state the display will initiate with volume displayed in the numeric fields. Prior to the START button being

pressed, the mode will remain in Volume unless the MODE button is depressed to change the mode. It may be

changed to Currency, Setup, and back to Volume. If the mode is changed to Currency or Setup prior to delivery,

the mode will change to the default dispense state selected when the START button is depressed to begin that

delivery. At any time, the operator may select the Currency Mode or Rate Mode by depressing the MODE Button.

When in the Volume Mode the indicator will point to the volume label on the front panel.

CURRENCY MODE

The display may be configured in the Setup Mode to default to the currency display. In the Pre-Dispense or

Dispense state the display will initiate with currency displayed in the numeric fields. Prior to the START button

being pressed, the mode will remain in Currency unless the MODE button is depressed to change the mode. It

may be changed to Volume, Setup, and back to Currency. If the mode is changed to Volume or Setup prior to

delivery, the mode will change back to the default Dispense state selected when the START button is depressed to

begin that delivery. At any time, the operator may select the Volume Mode or Rate Mode by depressing the MODE

Button. When in the Currency Mode the indicator will point to the currency label on the front panel.

RATE MODE

The display may show flow rate by depressing the MODE button when the operator is able to deliver product. The

operator cannot access Rate Mode unless the START button initiating a delivery is pressed. The Rate Mode can

be selected as the default dispense state in the Setup Mode. During a delivery, the operator may display the flow

rate by using the MODE button to select Rate. When in the Rate Mode the indicator will point to the rate label on

the front panel.

10

Page 17

EMR3 Setup and Operation Manual System Operating Modes

SETUP MODE

The user can access the Setup Mode before a delivery to change a variety of parameters that are not required to

be under weights & measure seal. Once the delivery state is active, the Setup Mode cannot be accessed. The

Setup Mode is used to enter price codes, default mode setting, single flow and fast flow knock-off values and

other non-metrological settings. The operator can exit the mode by depressing the MODE button at any time.

When in the Setup Mode the indicator will point to the setup label on the front panel. Detailed information on how

to set the parameters is explained the setup sections of this manual.

CALIBRATION AND CONFIGURATION (C&C) MODE

The C&C Mode is entered by a trained technician following instructions in the EMR3 Installation Guide (V-R P/N

577013-758). When the display head is powered up after the C&C Mode is enabled, the C&C related parameters

of the Setup Mode are displayed. C&C Mode is used to set up various calibration and configuration parameters,

which when made, are sealed for metrological conformity. All C&C Mode parameters can be viewed by the user in

the Setup Mode, but no changes are allowed. The operator can not exit the C&C Mode until the C&C switch is

returned to its normal operating state.

11

Page 18

Setup Mode

Initiating the Setup Mode

1. Turn On power to the Display Head and wait until the boot-up sequence completes.

2. Depress the MODE button until the indicator at the bottom of the display points to Setup.

3. On initial power-up of the Display Head, the first Setup Mode category, PRICING, displays in the Descriptor

Field. Press NEXT to enter Pricing Setup, or continue to press the button to step through the remaining

Setup Mode categories. Press NEXT to enter any category once it displays in the Descriptor Field.

Setup Mode Categories

The non-metrologically controlled Setup Mode categories for the EMR3 System are:

• Enter Security Code - enables user log in/out procedure. (Note: This prompt will not display on initial power-up

of the Display Head. If you have enabled Security Code in the C&C Mode, this prompt will be the first category

to display on entering Setup Mode).

• Pricing setup - sets up to 15 different price codes with tax/discount code assignments.

• Tax/ Di scou nt setup - sets up to 15 different tax/discount (T/D) codes with up to 6 different T/D modifiers per

code.

• Defaults setup - lets you set the mode you want the Display Head to enter when beginning pre-dispense and

dispense operations; and lets you enable/disable volume and currency mode presets.

• Relay Control setup - sets the shutoff points for flow control relays 1 and 2 for preset deliveries.

• Security setup - sets the user Passcodes and user access to certain Setup Mode categories. (This setup only

displays after enabling Security Code in the C&C Mode).

• Printer Option setup - sets optional printer type and distance from top of ticket to first printed line.

• View Records setup - lets you select to either view or print any of the last 50 transaction records.

• Restore Records - Allows the user to restore (download from IB to Display Head) up to the last 50

transactions.

• Shift setup - sets up shift start/end times, start/end odometer readings, and tank loadings. Also within Shift

setup, you can print out shift reports.

• Date Format setup - sets the format of year, month, and date for use in display and printouts.

• Time/ Date setup - lets you enter the current time and date.

• System Address setup - sets the addressing and configuration of the individual EMR

inputs from, and outputs to, the system.

3

components and their

• Time Delays setup - sets the delay (in seconds) after which the display will go blank if there is no activity.

• Version Number - lets you view system device version numbers.

• C&C - lets you step through and view, but not change, the C&C Mode setups (see page 29).

Instructions for setting up the Setup Mode categories are shown in the figures that follow. In some cases multiple

figures are used to explain sub-procedures within a Setup Mode category.

Note, once you have entered a Setup Mode category (pressing NEXT), do not press the ‘+’, ‘-’ buttons in that

setup if you do not intend to change a value, because when you press ENTER, the change, even if unintended, will

be accepted. If you want to view setup settings without making changes, press NEXT to move ‘into’ a category’s

setup and ENTER to ‘back out’ of the setup.

12

Page 19

EMR3 Setup and Operation Manual Setup Mode Categories

ENTER SECURITY CODE

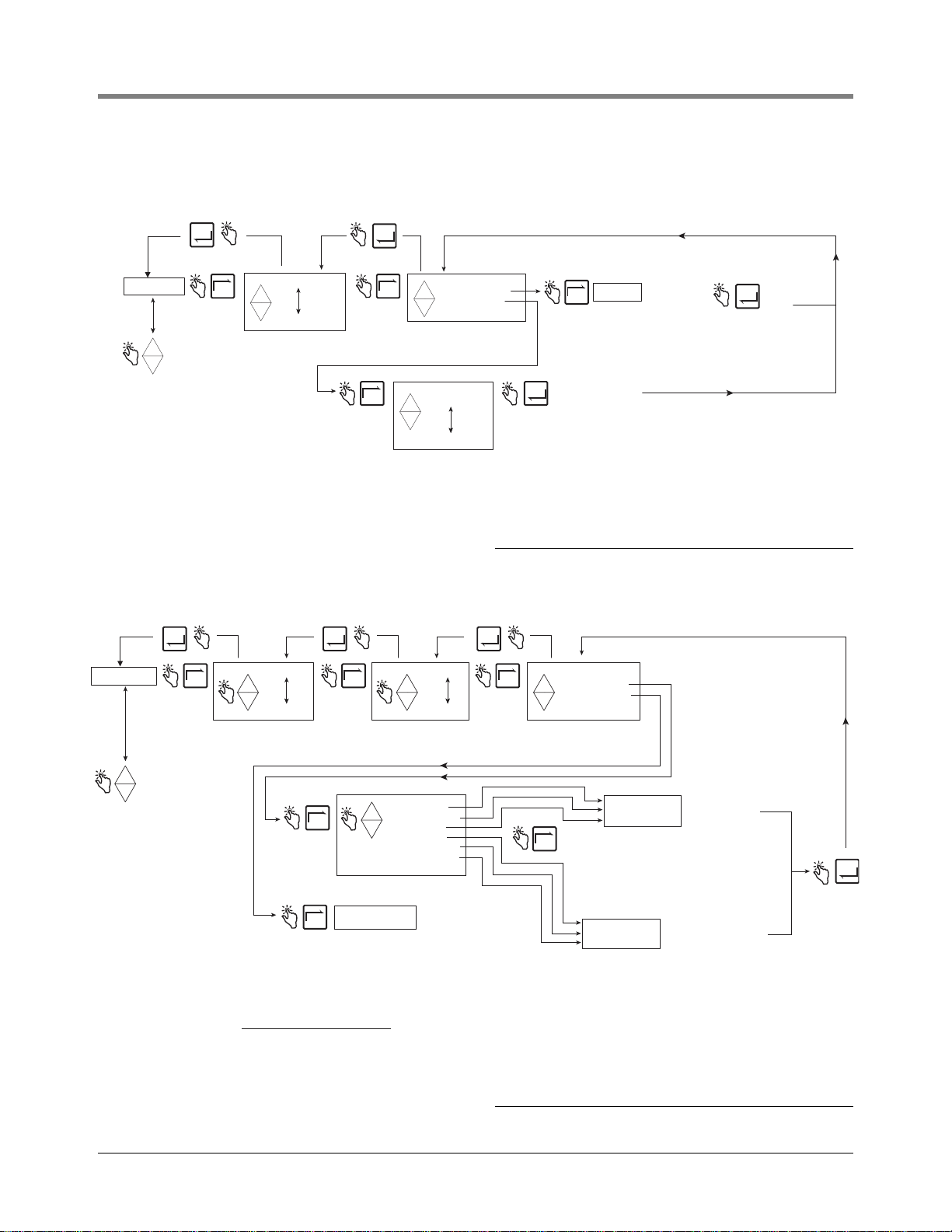

Figure 6 illustrates the initial logging in procedure using the default Passcode after Security Codes are enabled in

C&C Mode (see Figure 51). Figure 7 shows the procedure for logging in using an assigned Passcode, and

Figure 8 shows how to log out.

ENTER

ENTER SECURITY CODE

Press the up/down

buttons to cycle

+

through remaining

-

Setup Mode categories

PRICING

TAX/DISCOUNT

DEFAULTS

RELAY CONTROL

SECURITY

PRINTER OPTION

VIEW RECORDS

RESTORE RECORD

SHIFT

DATE FORMAT

TIME/DATE

SYSTEM ADDRESS

TIME DELAYS

VERSION NUMBER

C AND C

ENTER SECURITY CODE

NEXT NEXT NEXT

USER 1

+

USER 2

+

USER 3

-

LOGGED OUT LOGGED IN000000

Security Code Notes:

1. Upon powering down, the Security Code status

for all users is returned to LOGGED OUT.

2. User 1, Supervisor, must log out or the capability

of changes will remain active if power is not

cycled.

3. Only one user can be logged in at a time. If

another user logs in, other users are automatically

logged out.

IMPORTANT! Security codes do not prevent

dispensing, they only control setup options.

ENTER

NEXT NEXT NEXT

USER 1

+

USER 2

+

USER 3

-

LOGGED OUT LOGGED INXXXXXX

ENTER ENTER

Default code

Figure 6. Logging In Using Default Passcode

ENTER your assigned

pass code.

Press the up/down

arrows to scroll

through the numbers,

and NEXT to move

from one digit of the

code to the next.

ENTER ENTER

ENTER SECURITY CODE

ENTER

NEXT

Figure 7. Logging In Using Assigned Passcode

USER 1

+

USER 2

+

-

USER 3

NEXT

LOGGED IN

+

LOGGED OUT

+

-

ENTER ENTER

LOGGED OUT

Figure 8. Logging Out

13

Page 20

EMR3 Setup and Operation Manual Setup Mode Categories

6 0, 1, 2, 3, 4, and/or 5

PRICING

Figure 9 illustrates Pricing setup in Setup Mode.

ENTER

PRICING

+

-

TAX/DISCOUNT

DEFAULTS

RELAY CONTROL

SECURITY

PRINTER OPTION

VIEW RECORDS

RESTORE RECORD

SHIFT

DATE FORMAT

TIME/DATE

SYSTEM ADDRESS

TIME DELAYS

VERSION NUMBER

C AND C

ENTER SECURITY CODE

NEX

Press the up/down

buttons to cycle

through remaining

Setup Mode categories

T

PRICE CODE 1

+

+

-

PRICE CODE 15

ENTER

NEX

T

CHANGE PRICE X

+

ASSIGN TAX/DIS

+

-

Note: Select ASSIGN TAX/DIS if you

want to also assign a tax/discount to

Price Code X.

NEX

ASSIGN NO T/D

T

ASSIGN T/D 1

+

+

-

ASSIGN T/D 15

Note: ASSIGN NO T/D is the

default selection for all Price

Codes.

TAX/DISCOUNT

Figure 10 illustrates Tax/Discount setup in Setup Mode.

ENTER ENTER ENTER

TAX/DISCOUNT

Press the up/down

+

buttons to cycle

through remaining

-

Setup Mode categories

DEFAULTS

RELAY CONTROL

SECURITY

PRINTER OPTION

VIEW RECORDS

RESTORE RECORD

SHIFT

DATE FORMAT

TIME/DATE

SYSTEM ADDRESS

TIME DELAYS

VERSION NUMBER

C AND C

ENTER SECURITY CODE

PRICING

NEXT

T/D CODE 1

+

+

-

T/D CODE 15

IMPORTANT!

Only TAX PERCENT and DIS PERCENT T/D Values can access the

ASSIGN TO LINE feature. You must select at least one ASSIGN TO

LINE choice for TAX PERCENT and/or DIS PERCENT or they will not

be implemented. Depending on their initial T/D Line Value chosen

above, either one can also be assigned to other T/D Lines as follows:

(Note: Line 0 is the delivery's SUBTOTAL [volume times base price].)

Initial T/D Permissible additional

Line Value T/D Line Assignments

1 0

2 0, and/or 1

3 0,1, and/or 2

4 0,1,2, and/or 3

5 0,1,2,3, and/or 4

NEXT NEXT

Note: The order in which the T/D Value selections

are implemented begins with T/D Line 1 Value

and ends with T/D Line 6 Value.

NEXT

Note: UNUSED is the default T/D Value setting.

NEXT

+

-

ASSIGN TO LINE

T/D LINE 1

+

+

-

T/D LINE 6

TAX PERCENT

TAX PER VOLUME

SURCHARGE

DIS PERCENT

DIS PER VOLUME

DIS SURCHARGE

UNUSED

NEX

Press ENTER to assign

ENTER

a tax/discount selection

to Price X

CHNG T/D VALUE

+

CHNG T/D ASSGN

+

-

NEXT

Press up/down

PRICE X

T

Note: T AX PERCENT

is a percentage.

TAX PER VOLUME

and TAX SURCHARGE

are currency units.

Enter tax % as a percent

(e.g., 6 not 0.06)

ENTER NEW DIS

Note: DIS PERCENT

is a percentage.

DIS PER VOLUME

and DIS SURCHARGE

are currency units.

Enter Dis % as a percent

(e.g., 6 not 0.06)

to change digit

and NEXT to

move to next digit.

ENTER NEW TAX

ENTER

Figure 9. Pricing Se tup

Press up/down to

change digit and

NEXT to move to

next digit.

Press up/down to change

digit and NEXT to move to

next digit.

Press to accept

choice

ENTER

Figure 10. Tax/Discount Setup

14

Page 21

EMR3 Setup and Operation Manual Setup Mode Categories

s.

Press ENTER

D

during Dispensing.

DEFAULTS

Figure 11 illustrates Defaults setup in Setup Mode.

ENTER

DEFAULTS

Press the up/down

+

buttons to cycle

through remaining

-

Setup Mode categories

RELAY CONTROL

SECURITY

PRINTER OPTION

VIEW RECORDS

RESTORE RECORD

SHIFT

DATE FORMAT

TIME/DATE

SYSTEM ADDRESS

TIME DELAYS

VERSION NUMBER

C AND C

ENTER SECURITY CODE

PRICING

TAX/DISCOUNT

NEXT

START MODES

+

PRESETS

+

-

See Start Modes and

Presets figures that

follow for these setup

Figure 11. Defaults Setup

Start Modes

Figure 12 illustrates Start Modes setup in Setup Mode. Start Modes is used to set what screen (mode) will be

displayed before the delivery (pre-dispense) and during the delivery (Dispense). The default Start Mode is Volume.

to return to

EFAULTS

ENTER

ENTER

NEXT

NEXT

START MODES

PRE-DISPENSE

DISPENSE

NEXT

PRE-DISPENSE

+

DISPENSE

+

-

VOLUME MODE

NEXT

NEXT

+

CURRENCY MODE

+

-

SETUP MODE

VOLUME MODE

+

CURRENCY MODE

+

-

RATE MODE

Select the default mode

you want the Display

Head to automatically

enter after finishing a

Delivery.

Select the default mode

you want the Display

Head to automatically

enter once the optional

flow valves open and/or

ENTER

Press ENTER

to accept

selection and

return to

Figure 12. Start Modes Setup

15

Page 22

EMR3 Setup and Operation Manual Setup Mode Categories

Press ENTER

D

3 Currency amounts.

Presets

Figure 13 illustrates Presets setup in Setup Mode.

to return to

EFAULTS

ENTER

PRESETS

NEXT

VOLUME MODE

+

CURRENCY MODE

+

-

NEXT

RELAY CONTROL

Figure 14 illustrates Relay Control setup in Setup Mode.

ENTER

ENTERENTER

NEXT

PRESET 1

+

PRESET 2

+

-

PRESET 3

Note: If enabled, this feature lets

you enter up to 6 different delivery

presets - 3 Volume amounts and/or

PRESET ENABLE

+

PRESET DISABLE

+

-

Make your changes

to the preset, pressing

up/down arrows to

numbers, and NEXT

to move from one

digit of the preset

to the next.

Press ENTER

to accept

ENTER

selection and

return to

Figure 13. Presets Setup

RELAY CONTROL

Press the up/down

buttons to cycle

+

through remaining

-

Setup Mode categories

SECURITY

PRINTER OPTION

VIEW RECORDS

RESTORE RECORD

SHIFT

DATE FORMAT

TIME/DATE

SYSTEM ADDRESS

TIME DELAYS

VERSION NUMBER

C AND C

ENTER SECURITY CODE

PRICING

TAX/DISCOUNT

DEFAULTS

NEX

Note: Flow control relays are located

+

T

+

-

RELAY 1

RELAY 2

in the IB box. Each Display Head (1 or 2)

has two relays assigned to it. Applications

with only one solenoid valve only use the

single-flow relay designated as RELAY 2.

SET SLOW FLOW

NEX

T

Note: This entry sets the number of

volume units prior to the finish of a preset

delivery, at which point, Relay 1

(Fast Flow) will open and close the

fast flow solenoid. Recommended

setting is 5 volume units.

SET ADVANCE STOP

NEX

T

Note: This entry sets the number of

volume units prior to the finish of a preset

delivery, at which point, Relay 2

(Single Flow) will open and close the

single flow solenoid. Recommended

setting is 0.1 volume units.

Press up/down arrows

to select a number and

NEXT to move from

NEX

T

one digit of the number

to the next.

Press up/down arrows

to select a number and

NEXT to move from

NEX

T

one digit of the number

to the next.

ENTER

Press ENTER

to accept

selection and

return to

Figure 14. Relay Control Setup

16

Page 23

EMR3 Setup and Operation Manual Setup Mode Categories

SECURITY

Figure 15 illustrates the procedure for setting user Passcodes and user access to certain setup parameters.

ENTER ENTER

SECURITY

Press the up/down

+

buttons to cycle

through remaining

-

Setup Mode categories

PRINTER OPTION

VIEW RECORDS

RESTORE RECORD

SHIFT

DATE FORMAT

TIME/DATE

SYSTEM ADDRESS

TIME DELAYS

VERSION NUMBER

C AND C

ENTER SECURITY CODE

PRICING

TAX/DISCOUNT

DEFAULTS

RELAY CONTROL

NEXT NEXT

USER 1

+

USER 2

+

USER 3

-

Note: Authorization to change pass codes and assignments is determined by

how you are logged in to the system (see Entering Security - Logging In). The

table below describes a logged in user's ability to make these changes.

If Y ou are

Logged In as:

User 1

User 2

User 3

+

CHANGE CODE

+

CHANGE ASSIGNMENTS

-

You Can Change

Pass codes for:

Users 1, 2, 3

User 2

User 3

NEXT

NEXT NEXT

You Can Change

Assignments for:

Users 2, 3

No one

No one

Enter a six-digit pass code.

XXXXXX

+

+

-

Press the up/down arrows

to scroll through the

numbers, and NEXT to

move from one digit of the

code to the next.

PRICING

TAX/DISCOUNT

DEFAULTS

RELAY CONTROL

PRINTER OPTION

VIEW RECORDS

RESTORE RECORDS

SHIFT

DATE FORMAT

TIME DATE

SYSTEM ADDRESS

TIME DELAYS

DELIVERY PRICE

ENTER

+

+

-

YES

NO

ENTER

Note: All assignments are set to Yes (default) which lets all logged in users access the listed setup

categories. When a selected setup category is set to No, access for the selected user is denied.

Figure 15. Passcode and Setup Access Setup

17

Page 24

EMR3 Setup and Operation Manual Setup Mode Categories

which is the default.

PRINTER OPTION

Figure 16 illustrates Printer Option setup in Setup Mode.

ENTER

PRINTER OPTION

Press the up/down

+

buttons to cycle

through remaining

-

Setup Mode categories

VIEW RECORDS

RESTORE RECORD

SHIFT

DATE FORMAT

TIME/DATE

SYSTEM ADDRESS

TIME DELAYS

VERSION NUMBER

C AND C

ENTER SECURITY CODE

PRICING

TAX/DISCOUNT

DEFAULTS

RELAY CONTROL

SECURITY

ENTER ENTER

+

NEXT NEXTNEXT

ENABLE PRINTER

+

DISABLE PRINTR

-

NEXT

Note: The minimum distance from

the top edge of the ticket down to

the first line of printing is 1 inch

and cannot be changed.

To increase the distance from the

top of the ticket to the first line you

change SET ADVANCE.

The minimum advance is 0 inches

SLIP PRINTER

+

ROLL PRINTER

+

-

1

Printer type assigned to this port must agree

with the printer type selected in Printer Option setup.

+

YES

+

NO

-

NEXT

1

1

SET ADVANCE

Each line advance is = to .167 inch. For example,

to have the first line print 2.5 inches from the top

you would need to add an additional 1.5 inches to

the fixed 1 inch space so you would enter 9 as the

advance (9 x .167 = 1.5 + 1 = 2.5"). Press up/down

arrows to select a number and NEXT to move from

one digit of the number to another.

+

ADVANCE

+

PRINT TEST PAGE

-

ENTER

Press ENTER

to accept

selection and

return to

Figure 16. Printer Option Setup

An example of Printer Format 1 (Delivery Ticket Format), selectable in the Printer Option setup above, is shown in

Figure 17. NOTE: The availability of certain printer labels is dependent on options selected.

18

Page 25

EMR3 Setup and Operation Manual Setup Mode Categories

P

***********************************

Header

(Up to 4 lines)

* Veeder-Root Co. *

* EMR-3 *

* *

* *

***********************************

Optional

Date/time

Delivery

Information

rice/Tax/Discount

Information

Totals

START MMM-DD-YYYY HH:MM:SS

FINISH MMM-DD-YYYY HH:MM:SS

TICKET NUMBER 50399

PROD DSCRPT X PROPANE

METER ID GENERIC 12345

TANK ID TANK DEFAULT

TOTALIZER START 4007.155

TOTALIZER END 4017.155

VOLUME GAL START 0.0000

GROSS VOLUME FINISH 10.000

NET VOLUME FINISH 10.000

AVG FLOW RATE (GPM) 11.111

TEMP THIS DELIVERY 61.00 F

VOLUME CORRECTED TO 60.0 F

COEFFICIENT OF EXPANSION 0.00160

PRICE/GALLON $ 2.0000

SUBTOTAL $ 20.000

%TAX T/D 1 % 10.0000

TAX/UNIT $ 0.2000

AMOUNT $ 2.0000

UNIT TAX T/D 2 $ 10.0000

AMOUNT $ 100.0000

SURCHARGE T/D 3 $ 10.0000

AMOUNT $ 10.0000

%DISCOUNT T/D 4 % 10.0000

DISCOUNT/UNIT $ -1.2200

AMOUNT SUB+T/D 1&2&3 $ -13.2000

UNIT DISCOUNT T/D 5 $ 10.0000

AMOUNT $ -100.0000

DISCOUNT T/D 6 $ 1.0000

AMOUNT $ -1.0000

FINAL PRICE/GALLON $ 0.9800

TOTAL NON-TAX LINES $ -94.00

TAX THIS DELIVERY $ 91.80

GRAND TOTAL $ 17.80

Trailer

You can count on us!

(Up to 3 lines)

19

Figure 17. Delivery Ticket Format

Page 26

EMR3 Setup and Operation Manual Setup Mode Categories

VIEW RECORDS

Figure 18 illustrates View Records setup in Setup Mode.

ENTER

VIEW RECORDS

Press the up/down

+

buttons to cycle

through remaining

-

Setup Mode categories

RESTORE RECORD

SHIFT

DATE FORMAT

TIME/DATE

SYSTEM ADDRESS

TIME DELAYS

VERSION NUMBER

C AND C

ENTER SECURITY CODE

PRICING

TAX/DISCOUNT

DEFAULTS

RELAY CONTROL

SECURITY

PRINTER OPTION

NEXT

Note: Up to the last 50 transaction records

are maintained in the Display Head for viewing

or printing. NO RECORDS displays if no records

are available.

RECORD 1

+

+

-

RECORD 50

NEXT

ENTER

NEXT

+

+

-

Prints out the

selected report

to the printer.

+

VIEW LINES

+

PRINT RECORD

-

Note: View each line or print

the selected report.

TICKET NUMBER

START (Date/Time)

FINISH (Date/Time)

PROD DSCRPT X

TOTALIZER START

TOTALIZER END

GROSS VOLUME FINISH

NET VOLUME FINISH

TEMP THIS DELIVERY

PRICE/GALLON

SUBTOTAL

T AX THIS DELIVERY

TOTAL NON-TAX LINES

GRAND TOTAL

ENTER

ENTER

Displays if

TC enabled

Displays if

pricing

enabled

20

Figure 18. View Records Setup

Page 27

EMR3 Setup and Operation Manual Setup Mode Categories

RESTORE RECORDS

Figure 19 illustrates Restore Records procedure in Setup Mode.

RESTORE RECORDS

Press the up/down

+

buttons to cycle

through remaining

-

Setup Mode categories

SHIFT

DATE FORMAT

TIME/DATE

SYSTEM ADDRESS

TIME DELAYS

VERSION NUMBER

C AND C

ENTER SECURITY CODE

PRICING

TAX/DISCOUNT

DEFAULTS

RELAY CONTROL

SECURITY

PRINTER OPTION

VIEW RECORDS

SHIFT

NEXT

+

+

-

DECLINE

ACCEPT

ENTER

ENTER

RESTORING TRANSCTION

50, 49, ... 1

Note: Last 50 Transactions are being

restored. Counts down from 50 to 1

(number of stored transactions may

be less than 50)

NO TRANSACTIONS IN IB

Note: No transactions in IB memory

Figure 19. Restore Records Procedure

ENTER

Figure 20 illustrates Shift setup and the Shift Report printing procedure in the Setup Mode.

Figure 21 illustrates the format of a shift report. When a shift report is selected, a separate report will be printed

for each product if transactions for that product were recorded in the selected shift.

21

Page 28

EMR3 Setup and Operation Manual Setup Mode Categories

Press ENTER to accept any changes and/or

ENTER

continue pressing to return to SHIFT

SHIFT

Press the up/down

++

buttons to cycle

through remaining

Setup Mode categories

DATE FORMAT

TIME/DATE

SYSTEM ADDRESS

TIME DELAYS

VERSION NUMBER

C AND C

ENTER SECURITY CODE

PRICING

TAX/DISCOUNT

DEFAULTS

RELAY CONTROL

SECURITY

PRINTER OPTION

VIEW RECORDS

RESTORE RECORD

NEXT NEXT

SHIFT TIME

++

ODOMETER

TANK LOAD

PRINT REPORT

NEXT

NEXT

NEXT

++

1

If any transactions are made between shifts, they will be recorded in a new shift

having a start time that is the same as the start of the first of those transactions and an end time

that is the same as the Start time you enter for the next shift.

Also, if a new shift is started by entering a Start Time, the previous shift, if not ended, will be assigned an

end time that is the same as the Start time you enter for the new shift.

++

++

++

Note: Print Report 1 will only

display if you in an active shift.

1

START TIME : HH:MM

END TIME : HH:MM

ODOMETER START

ODOMETER END

PROD DSCRPT 1

PROD DSCRPT 8

PRINT REPORT 1

PRINT REPORT 2

PRINT REPORT 3

PRINT REPORT 4

NEXT

NEXT

NEXT

++

ACCEPT : HH:MM

DECLINE : HH:MM

ENTER ODOMETER

++

ENTER LOAD

REMAINING VOL

NEXT

ENTER

NEXT

ENTER

ENTER

To enter the truck mileage on

the truck odometer at the

start or end of a shift press

the up/down arrows to scroll

through the numbers, and

NEXT to move from one

number to the next.

++

START TIME : HH:MM

END TIME : HH:MM

Prints out shift report 1 (current shift)

++

START TIME : HH:MM

END TIME : HH:MM

Prints out shift report 2 (previous shift)

ENTER

To enter the amount loaded

into the Tank for the selected

product, press the up/down

NEXT

arrows to scroll through the

numbers, and NEXT to move

from one number to the next.

View the volume remaining in

NEXT

the Tank for the selected product.

ENTER

ENTER

ENTER

Returns to Print Report 1 message.

Returns to Print Report 2 message.

++

NEXT

ENTER

NEXT

ENTER

START TIME : HH:MM

END TIME : HH:MM

Prints out shift report 3 (shift prior to 2)

++

START TIME : HH:MM

END TIME : HH:MM

Prints out shift report 4 (shift prior to 3)

Figure 20. Shift and Shift Report Setup

Returns to Print Report 3 message.

ENTER

ENTER

Returns to Print Report 4 message.

22

Page 29

EMR3 Setup and Operation Manual Setup Mode Categories

)

Report Line Item Source

SHIFT BEGIN:

SHIFT END:

ODOMETER START:

ODOMETER END:

MILES DRIVEN:

PROD DSCRPT X:

METER ID:

BEGINNING VOLUME:

LOADED VOLUME:

ENDING VOLUME:

TOTAL GROSS VOLUME:

SINGLE DELIVERIES:

MULTIPLE DELIVERIES:

TRANSFER DELIVERIES:

ITEMIZED DELIVERIES:

TOTAL VOLUME:

TOTAL VOLUME NO PRICE:

TOTAL VOLUME PRICED:

TOTAL SALES W/O TD:

TOTAL TAX/DISCOUNT 1:

TOTAL TAX/DISCOUNT 2:

TOTAL TAX/DISCOUNT 3:

TOTAL TAX/DISCOUNT 4:

TOTAL TAX/DISCOUNT 5:

TOTAL TAX/DISCOUNT 6:

GRAND TOTAL:

Starting time/date of the shift

Ending time/date of the shift (only displayed if shift has ended )

Odometer reading entered at the start of the shift

Odometer reading entered at the end of the shift

Miles driven during the shift (= odometer end - odometer start)

Name assigned to the product (e.g., gasoline)

Meter ID number assigned to the unit

Total volume at the beginning of the shift (= ending volume of last shift)

Compensated or uncompensated load entered in "Tanker Load" shift setup

Volume remaining at the end of the shift (= beginning volume + loaded volume - total volume)

Uncompensated volume

Number of single deliveries during a shift

Number of multiple deliveries during a shift

Number of transfer deliveries during a shift

Total number of itemized deliveries (= single deliveries + multiple deliveries)

Compensated (or uncompensated) volume (differs from total gross vol if the product is compensated)

Total volume that has no price code associated with it

Total volume that has a price code associated with it

Total contribution of sales from the base price (w/o any T/D associated with it)

Total contribution of T/D 1 to the total sales

Total contribution of T/D 2 to the total sales

Total contribution of T/D 3 to the total sales

Total contribution of T/D 4 to the total sales

Total contribution of T/D 5 to the total sales

Total contribution of T/D 6 to the total sales

Total sales during a shift (= total sales w/o T/D + Total T/D 1 + Total T/D 2 + Total T/D 3 + Total T/D 4 + Total T/D 5 + Total T/D 6

DATE FORMAT

Figure 22 illustrates Date Format setup in Setup Mode.

Figure 21. Shift Report Format

DATE FORMAT

Press the up/down

+

buttons to cycle

through remaining

-

Setup Mode categories

TIME/DATE

SYSTEM ADDRESS

TIME DELAYS

VERSION NUMBER

C AND C

ENTER SECURITY CODE

PRICING

TAX/DISCOUNT

DEFAULTS

RELAY CONTROL

SECURITY

PRINTER OPTION

VIEW RECORDS

RESTORE RECORD

SHIFT

ENTER

NEX

T

YEAR FORMAT

+

MONTH FORMAT

+

SEQUENCE

-

SEPARATE CHAR

NEX

NEX

NEX

NEX

T

+

4 DIGIT YEAR

+

2 DIGIT YEAR

-

T

+

3 CHAR MONTH

+

2 DIGIT MONTH

-

T

T

MONTH DAY YEAR

+

YEAR MONTH DAY

+

-

DAY MONTH YEAR

DASH

+

PERIOD

+

-

SLASH

ENTER

ENTER

ENTER

ENTER

Figure 22. Date Format Setup

23

Page 30

EMR3 Setup and Operation Manual Setup Mode Categories

Press up/down arrows to scroll through the

s.

or

TIME/DATE

Figure 23 illustrates Time/Date setup in Setup Mode.

MMM DD HH:MM:SS YYYY

Press the up/down

+

buttons to cycle

through remaining

-

Setup Mode categories

SYSTEM ADDRESS

TIME DELAYS

VERSION NUMBER

C AND C

ENTER SECURITY CODE

PRICING

TAX/DISCOUNT

DEFAULTS

RELAY CONTROL

SECURITY

PRINTER OPTION

VIEW RECORDS

RESTORE RECORD

SHIFT

DATE FORMAT

choices, and NEXT to move from one

group of the date, time, or year to

another. Press ENTER to accept change

Figure 23. Date/Time Setup

SYSTEM ADDRESS

Figure 24 illustrates System Address setup in Setup Mode. The setups shown in Figure 25 through Figure 29

must be followed to set the addresses of each component connected to each IB.

ENTER

SYSTEM ADDRESS

Press the up/down

+

buttons to cycle

through remaining

-

Setup Mode categories

TIME DELAYS

VERSION NUMBER

C AND C

ENTER SECURITY CODE

PRICING

TAX/DISCOUNT

DEFAULTS

RELAY CONTROL

SECURITY

PRINTER OPTION

VIEW RECORDS

RESTORE RECORD

SHIFT

DATE FORMAT

TIME/DATE

NEX

T

IB ADDRESS

+

PORT 1 ASSIGN

PORT 2 ASSIGN

+

-

HEAD ADDRESS

PRINTER ADDRESS

IMPORTANT! When the Head Address is set to

2, the selections for IB Address and the PORT

assignments are no longer valid. Only Head

Address 1 has the capability of setting port

assignment and IB address parameters.

NEX

T

See Address Setup

figures that follow f

each selection's

setup procedure

Figure 24. System Address Setup

24

Page 31

EMR3 Setup and Operation Manual Setup Mode Categories

t

P

t

t

P

t

IB Address Setup

Figure 25 illustrates the IB Address setup selections (the default IB address is 1). This setup is necessary only

when there are more than one IBs connected in a network.

ress ENTER to return