Page 1

Introduction

The Veeder-Root brand C346 family offers a new level of performance in a 1/16 DIN

instrument. Fully programmable to operate as a preset counter, a rate meter (with

outputs) or an elapsed time counter. Enhanced fuctionality provides operating

modes for batching, background totalizing, and operation as dual counters with

master sum. When used as an elapsed time counter, the C346 offers unique

functionality for measurement of pulse widths or time between pulses. The C346 is

available with an LCD display or the industry's only 6 digit LED display for a 48mm

x 48mm product.

A wide variety of features are present that enable use in even the most demanding

applications. Inputs can be accepted from both NPN or PNP sensors, dry contacts or

encoders, and the input scaling function enables rate and count inputs to be

displayed in engineering units. Single and dual preset models are available and

each preset offers both a transistor output, which can interface to an external SSR

or PLC, and a relay output for

directly driving a load. The outputs

can be programmed for latching or

timed operation.

Even with a high level of

functionality, simplicity of operation

is still maintained. Important

parameters such as the preset and

prescale values can be called up

quickly with direct access keys

while an intuitive button per digit

interface enables those values to be changed easily.

The C346 has a NEMA 4 rated faceplate is CE approved, and UL and CUL listed.

Technical Manual

701996-0000

Veeder-Root

C346

brand

Features

• Choice of 6 digit LED or LCD Display

• Button Per-Digit setting and direct access

keys for easy opertation

• Field programmable for operation as a

preset counter, batch counter, rate meter

or elapsed time meter, all with outputs

• Input scale function for display in

engineering units

• Add/Subtract, Add/Add and quadrature

input modes

• Background count value keeps track of

production totals

• 12 - 24 VDC sensor power supply

• Accepts either NPN or PNP inputs

• Relay and transistor outputs for each

preset

• Reset via front panel, remote input or

automatically

• NEMA 4 rated front panel

Index

Overview

Operation

Programming

General

Construction page 2

Terminal Connections page 2

Panel Mounting page 3

Front Panel page 4

Setup/Oper. Overview page 4

Operation Mode page 5

Basic Functionality page 8

Counter Mode page 8

Rate Meter Mode page 11

Elapsed Time Mode page 13

Dual Register Mode page 16

Batch Counter Mode page 17

Specifications page 19

Ordering Information page 20

Warranty page 20

Preset Counter

Rate Meter

Time Counter

Page 2

OVERVIEW

PROGRAMMING

CONSTRUCTION

Compact Design

Standard 1/16 DIN (48mm x 48mm) faceplate

VEEDER-ROOT

346421

P1

E 5 3 1

6

REAR TERMINAL CONNECTIONS

17 16

4 2

6 4 2

R

15

14 13 12 11 10

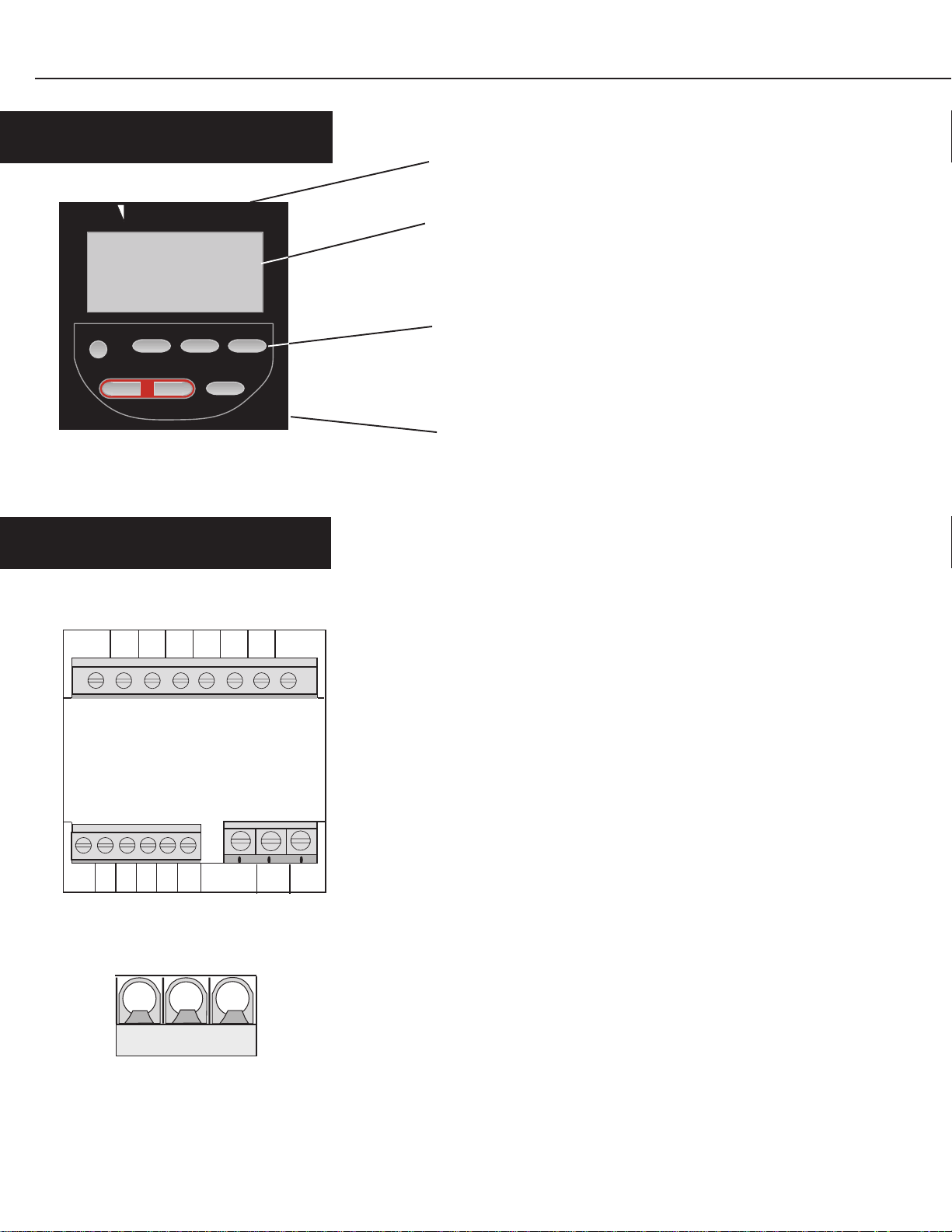

Main Display

Can be toggled quickly between count value, set value and

prescale value. LCD and LED display models available.

Simple Button per Digit Programming

A dedicated button for each of the 6 decades available in the

Preset value enables quick changes. The Edit key allows

quick access to important parameters.

Front Panel Seal

NEMA 4/IEC IP65 front panel for use in washdown environments

1. Sensor Power Supply - Provides 12 -24 VDC for powering of

external sensors up to 50 ma.

Note: For DC powered version, this terminal is used for the positive

input of the DC supply

2. Common - For use with sensor power supply, Inputs A, B, & C, and

transistor outputs 1 and 2

3. Input A- Programmable as the primary count input or channel A for

an encoder input

4. Input B - Programmable to be a directional input, an inhibit input, a

decrementing input, an incrementing input, or channel B of an

encoder input

35612 7 8 94

Top View of Terminals

Insert wire into opening and turn the screw

to tighten the wire clamp.

2

5. Input C - Programmable for use as a reset input or an inhibit input

6. Transistor Output 1 - Provides a PNP open collector output signal

when Preset 1 is activated

7. Relay Output 1 - Normally closed contact

8. Relay Output 1 - Normally open contact

9. Relay Output 1 - Common

10. AC Power Input - Neutral (Not connected for DC powered units)

11. AC Power Input - Line (Not connected for DC powered units)

12. Do Not Connect

13. Transistor Output 2 - Provides a PNP open collector output signal

when Preset 2 is activated

14. Do Not Connect

15. Relay Output 2 - Normally closed contact

16. Relay Output 2 - Normally open contact

17. Relay Output 2 - Common

Page 3

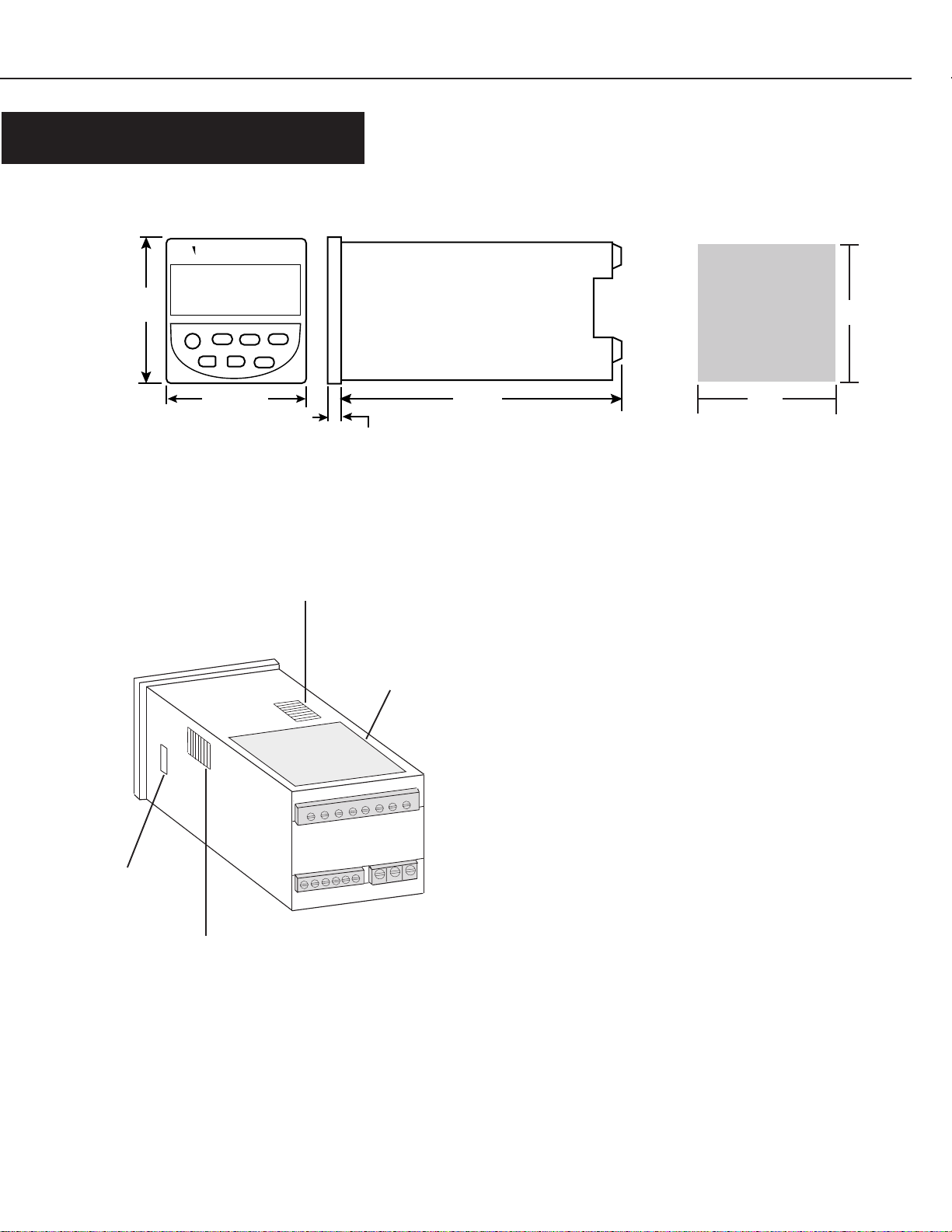

PANEL MOUNTING

123456

48mm

Release Slot

Side Mounting

VEEDER-ROOT

48mm

Grooves

Dimensions

8mm

Top Mounting

Grooves

Wiring Diagram

Panel Cutout

45mm

93mm

45mm

Make cutout(s) based on the recommended panel opening

illustrated in the drawing above.

Place the unit in the panel and slide the included gasket

over the rear of the unit. Make sure the unit is positioned

squarely against the panel and the gasket is not distorted.

Orient the bracket so that the tabs are pointing away from

the panel. Slide the bracket over the unit so that the tabs

catch in the grooves on the housing, and the bracket is as

far forward as possible. Use the panel mount screws to

tighten the bracket until there is a secure seal against the

gasket.

Please note that there are 4 sets of grooves on the housing

so that the bracket can be positioned with the screws on

the top or the side.

The electronic components of the instrument can be

removed from the housing. To do so the bracket must be

loosened and slid back until the release slot on each side is

showing. Place a small screw driver in the release slot and

gently push forward. Repeat the procedure on the release

slot on the other side. The front panel and PCBs should

then be able to be pulled forward out of the housing.

3

Page 4

OPERATION

PROGRAMMING

FRONT PANEL

LCD Version LED Version

VEEDER-ROOT

1. Main Display

346421

P1

E 5 3 1

6 4 2

6 4 2

R

1. Main Display: In Operating mode indicates the present

count, rate or time value. Can also be quickly toggled through

use of the Edit key to indicate the Preset Value or the Prescale

Value. In Program mode, this display indicates the parameter

code on the left side of the display, and the present parameter

value on the right side.

2. Status Displays: Indicates Preset 1 (F1), Preset 2 (F2),

Prescale, (PSC) and Program (PRG). In Operating mode, F1 and

F2 illuminate to indicate the active output(s). In Program

Mode, PRG is illuminated, and either F1, F2 or PSC is lit to

indicate which value is being displayed.

2. Status Displays

3. Edit Key

4. Numeric Keys

3. Edit Key: Can be used with the Numeric Keys 1, 2 and 3 in

Operation Mode to display Preset 1, Preset 2, and Prescale value

respectively. To Enter the Program Mode, depress the Edit key

during power-up and continue to hold for 5 secs. Once in

Program Mode, the Edit key is used to advance from one

parameter to the next.

4. Numeric Keys: Each of the numeric keys is used to

increment the value of the respective digit of the Preset(s) or

Prescale Value . When pressed simultaneously, the "6" and "4"

keys serve as a front panel reset.

VEEDER-ROOT

346421

F1 F2 PSC

E 5 3 1

6 4 2

R

PRG

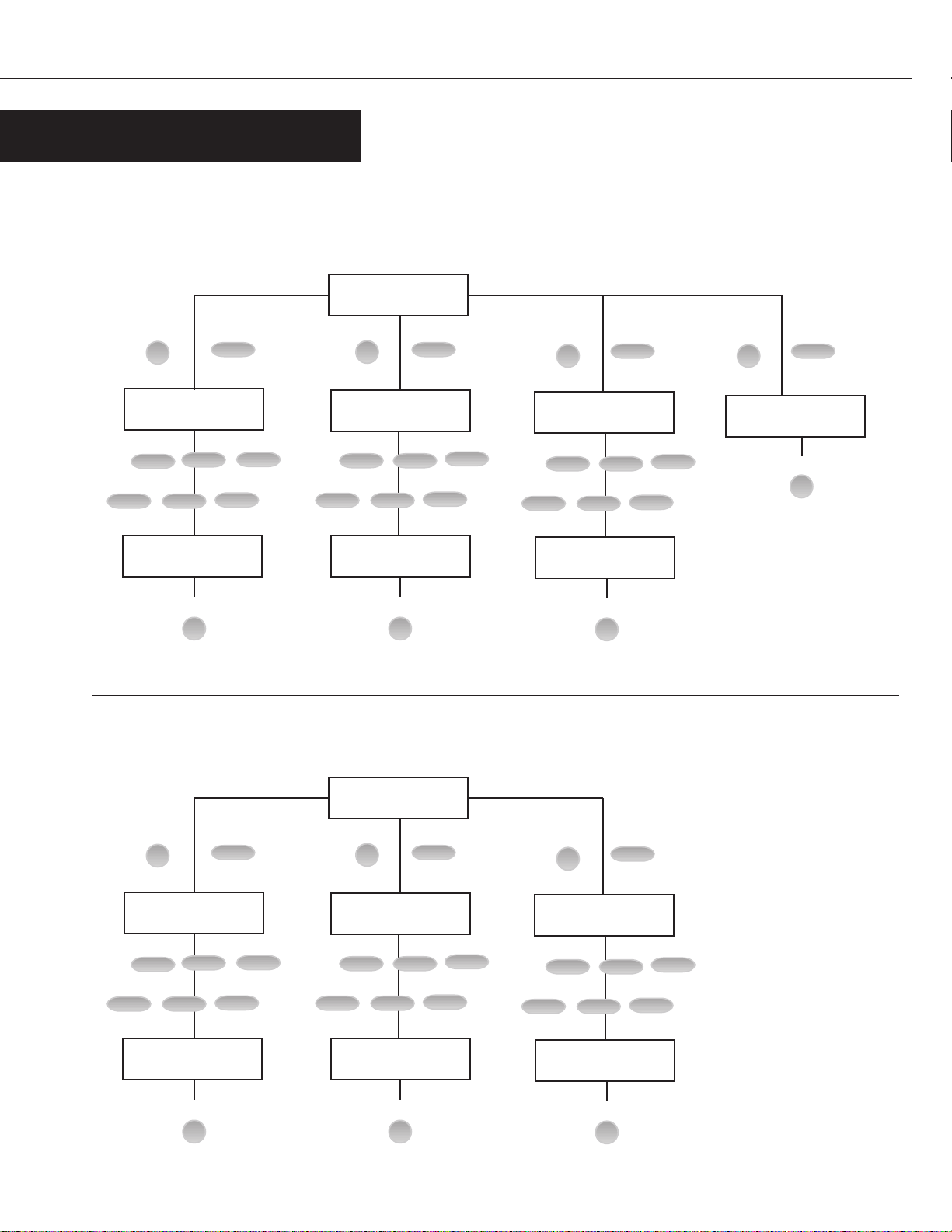

SETUP/OPERATION OVERVIEW

Mode Decision: Your Series C346 is a powerful control

instrument that can be setup to operate in one of 5 modes:

1. Carefully review the following mode descriptions and choose

the Basic Functionality that best suits the application per the

procedure on page 8.

2. Once the mode is selected, it can be customized per the

Setup procedure on the page designated by the table below.

Mode:

Functionality

Follow

procedure on

page 8

Setup Page

Number:

Count Rate Time Dual Register Batch

1 or 2 preset

counter.

Background

Rate indicator

with 2 alarm

limits

totalizer

feature

8

11

3. Since each mode programs and operates in a manner that is specific

to its function, the table below lists the appropriate Operation page

number.

Operation

Page Number:

3

5

1 or 2 preset

timer

13

6

Two seperate

totalizing counters

(A, B) with third

counter providing

sum (A+B)

16

6

Preset counter

with

presettable

batch counter.

Batch total

display

17

7

4

Page 5

OPERATION

COUNT MODE OPERATION

In Operation Mode, the default display is the Count Value. The

Presets and Prescale Value can be accessed by simultaneously

pressing the Edit key and the appropriate Numeric key. The

Numeric keys are then used to alter the value. It is necessary to

then press the Edit key to confirm the change and return to the

Count Value display

123456

E

Edit Preset 1

12

123456

F1 PRG

351

62

4

Change Value

654321

E

Confirm Change

RATE MODE OPERATION

E

Edit Preset 2

123456

F2 PRG

351

642

Change Value

654321

F1 PRGF1 PRG

E

Confirm Change

E

Edit Prescaler

642

Change Value

F1 PRG

Confirm Change

3

000

8.

PSC PRG

351

456

0.

E

E

Background Total

4

123456

F1 F2

E

Return to Count Value

Note: The new value must be

confirmed by pressing the Edit key

within 15 seconds.

E

Edit Preset 1

12

123456

F1 PRG

351

62

4

Change Value

654321

E

Confirm Change

123456

E

Edit Preset 2

123456

F2 PRG

351

642

Change Value

654321

F1 PRGF1 PRG

E

Confirm Change

E

Edit Prescaler

642

Change Value

F1 PRG

Confirm Change

3

000

8.

PSC PRG

351

456

0.

E

Note: The new value must be

confirmed by pressing the Edit key

within 15 seconds.

5

Page 6

OPERATION

PROGRAMMING

TIME MODE OPERATION

123456

E

Edit Preset 1

123456

F1 PRG

62

4

Change Value

654321

Confirm Change

12

123456

351

642

654321

F1 PRGF1 PRG

E

DUAL REGISTER MODE OPERATION

E

Edit Preset 2

F2 PRG

351

Change Value

E

Confirm Change

E

Background or Batch Total

4

123456

F1 F2

E

Return to Count Value

Note: The new value must be

confirmed by pressing the Edit key

within 15 seconds.

E

Sub Total A

12

123456

F1 PRG

123456

E

Sub Total B

123456

F2 PRG

E

Edit Prescaler

642

Change Value

F1 PRG

Confirm Change

3

000

8.

PSC PRG

351

456

0.

E

Note: The new value must be

confirmed by pressing the Edit key

within 15 seconds.

6

Page 7

BATCH MODE OPERATION

123456

E

Edit Preset 1

12

123456

F1 PRG

351

62

4

Change Value

654321

E

Confirm Change

RESET OPERATION

E

Edit Preset 2

123456

F2 PRG

351

642

Change Value

654321

F1 PRGF1 PRG

E

Confirm Change

E

Edit Prescaler

642

Change Value

F1 PRG

Confirm Change

Reset operation (panel reset and remote input) is dependent on

the operating mode setup of the C346. The following table

describes reset operation of the instrument's 5 operating modes.

3

000

8.

PSC PRG

351

456

0.

E

E

Batch Total

123456

F1 F2

Return to Count Value

Note: The new value must be

confirmed by pressing the Edit key

within 15 seconds.

4

E

Mode:

Panel Reset

64

Resets count

value if

displayed

Remote Reset

(Input C)

Resets count

at any time

Count Rate Time Dual Register Batch

No reset

function

Resets time

value if

displayed

Resets

Sub Total A or

Sub Total B if

Resets count

or batch value

if displayed

displayed

No reset

function

Resets time

at any time

Resets

both Sub

Totals and

Resets count

value (not

batch count)

Primary counts

7

Page 8

PROGRAMMING

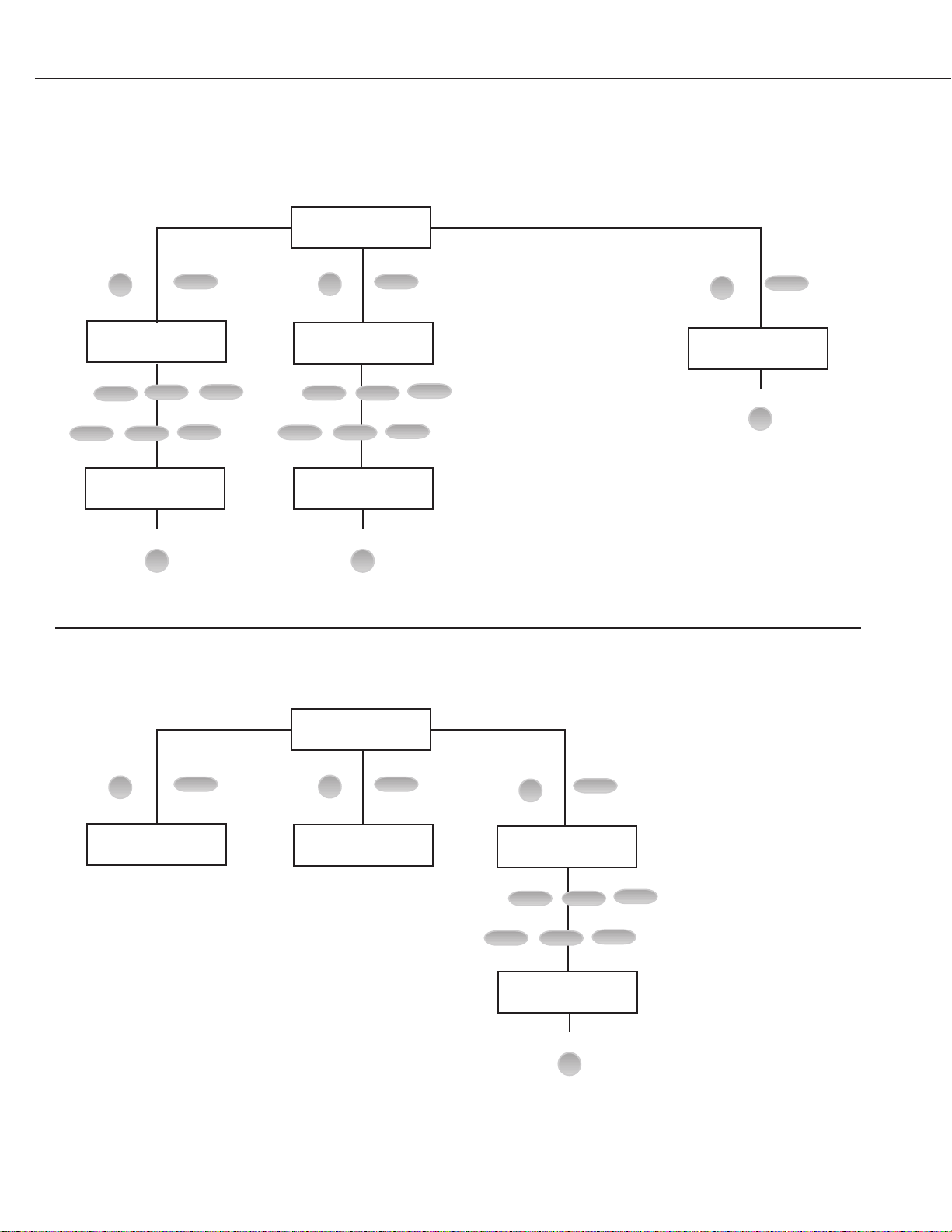

BASIC FUNCTIONALITY

The C346 can be programmed in the field to operate as a Preset Counter, a Rate Meter,

Elapsed Time Counter, Dual Register or Batch Counter. The default is Preset Counter. To

change the function hold down the both the Edit key and the "6" key during power-up. Use

the "1" key to scroll through the 5 choices as shown below.

E

6

FN

During Power-up

Counter Function

1

FN

Dual Register Function

COUNTER PROGRAMMING MODE

E

During Power-up

F0

5

0

PRG

E

PRG

PRG

F0 Default Settings: Changing this value from 0 to 1 will set all parameters back to their default values. A

setting of 0 has no effect on the other parameters.

0

3

1

FN

Rate Meter Function

1

FN

Batch Counter Function

If the functionality has been set to FN0, then the unit will operate as a preset counter. To

enter the Program mode, hold down the Edit key and the "5" key during power-up. Use the

Edit Key to move from one parameter to the next, and the "1" key to scroll though the

parameter choices. Holding down the Edit key for 5 seconds will return the unit to

Operation mode.

1

PRG

4

PRG

1

FN

Time Counter Function

E

2

PRG

F1

E

F3

E

F4

E

F6

8

0

PRG

0

PRG

0

PRG

0.10

PRG

F1 Count Mode: Defines the functionality of the 3 inputs. The choices are:

Code Input A Input B Input C

0 Count Input Inhibit Reset

1 Count Input Direction (U/D) Reset

2 Count Input Direction (U/D) Inhibit

3 Incrementing Decrementing Reset

4 Incrementing Decrementing Inhibit

5 Incrementing Incrementing Reset

6 Channel A Channel B Reset

7 Channel A Channel B Inhibit

F3 Display Decimal Point: Defines the number of digits displayed to the right of the decimal point for the

Count and Preset values. Settable in a range from 0 to 3.

F4 Reset Operation: Defines how the count value will behave when the preset is reached. Choices are:

0 Reset to "0", no Autoreset

1 Reset to "0", Autoreset

2 Reset to Preset, no Autoreset

3 Reset to Preset, Autoreset

F6 Output 1 Time: Sets the amount of time Output 1 will be active once the Preset is reached. Choices are:

Off No output

On Latching output (for dual presets, output 2 will deactivate output 1 )

0.02 20 ms

0.05 50 ms

0.10 100 ms

0.50 500 ms

1.00 1 sec.

Page 9

F7

0

PRG

E

F7 Output 2 Time: Sets the amount of time Output 2 will be active after the Preset is reached. Choices

are the same as Output 1

F9

F10

F11

F12

.10

PRG

E

1

PRG

E

1

PRG

E

0

PRG

E

F9 Output on Reset: When set to ON (1), the primary output (Output 2 on dual preset version) will

activate when the unit is reset.

F10 Input Type: Enables the unit to be programmed to work with either sinking or sourcing inputs.

Choices are NPN (0), and PNP (1)

F11 Count Speed: Enables the unit to be set for full speed of 5 kHz (1) or to 30 Hz (0) to provide debounce

filtering for contact inputs.

F12 Static/Dynamic Reset: When set to static reset (0) counting stops on the leading edge of the reset

input and does not resume until the trailing edge. When set to dynamic reset (1) the Count Value is

immediately reset on the leading edge of the reset signal, and will accumulate while the reset signal is still

active.

F14

F15

F20

0

PRG

E

0

PRG

E

0

PRG

E

F14 Output Signal Memory: Determines if after power interruption the outputs will resume their state

prior to the loss of power (1) or if the output will be reset (0)

F15 Background Totalizer: Setting this parameter to ON (1) will activate the totalizer function.

F20 Front Panel Reset Enable: When active (0), the count value and output(s) can be reset by

simultaneously pressing the "6" and "4" keys. If set to Off (1), reset can only take place through the

remote input, or through the front panel by holding the "6" and "4" keys for 10 seconds (see F29).

9

Page 10

PROGRAMMING

F21

F22

F23

F29

0

PRG

E

0

PRG

E

0

PRG

E

0

PRG

F21 Preset 1 Access Enable: When active (0), the Preset 1 value can be accessed by simultaneously

holding down the Edit key and the "1" key. If set to inactive (1), Preset 1 can not be accessed, or only

accessed by holding down the Edit key and the "1" key for 10 seconds (see F29)

F22 Preset 2 Access Enable: When active (0), the Preset 2 value can be accessed by simultaneously

holding down the Edit key and the "2" key. If set to inactive (1), Preset 2 can not be accessed, or only

accessed by holding down the Edit key and the "2" key for 10 seconds (see F29)

F23 Prescale Access Enable: When active (0), the Prescale value can be accessed by simultaneously

holding down the Edit key and the "3" key. If set to inactive (1), Prescale can not be accessed, or only

accessed by holding down the Edit key and the "3" key for 10 seconds (see F29)

F29 Lockout Mode: If parameters F21, F22 and F23 are set to inactive, Preset 1 & 2 and the Prescale

value can still be accessed by holding down the respective keys for 10 seconds if this parameter is set to

active (0). If set to inactive (1), those values can not be accessed.

10

Page 11

RATE METER PROGRAMMING

E

During Power-up

5

If the functionality has been set to FN1, then the unit will operate as a

programmable rate meter utilizing a time interval (1/Tau) method. To

enter the Program mode, hold down the Edit key and the "5" key during

power-up. Use the Edit key to move from one parameter to the next,

and the "1" key to scroll through the parameter choices. Holding down

the Edit key for 5 seconds will return the unit to Operation mode.

F0

F1

F2

F5

0

PRG

E

0

PRG

E

0

PRG

E

1.0

PRG

F0 Default Settings: Changing this value from 0 to 1 will set all parameters back to their default values. A

setting of 0 has no effect on the other parameters.

F1 Rate Mode: Defines the functionality of the 3 inputs. The choices are:

Code Input A Input B Input C

0 Count Input --- Hold

1 Count Input Direction (U/D) Hold

2 Same as F1 = 1 --- --3 Incrementing Decrementing Hold

4 Same as F1 = 3 --- --5 Incrementing Incrementing Hold

6 Channel A Channel B Hold

7 Same as F1 = 6 --- ---

F3 Display Decimal Point: Defines the number of digits displayed to the right of the decimal point for the

Rate and Preset values. Settable in a range from 0 to 3.

F5 Minimum Input Frequency: Sets the frequency level under which the rate display will read zero.

Choices are 1 Hz or 0.125 Hz (1 pulse in 8 seconds).

F6

F7

E

On

PRG

E

On

PRG

Output 1 Time: Output 1 will be active when the rate value is below Preset 1. Setting this parameter to

"On" enables this function to operate while a setting of "Off" will disable the function.

Output 2 Time: Output 2 will be active when the rate value is above Preset 2. Setting this parameter to

"On" enables this function to operate while a setting of "Off" will disable the function.

Note: It is necessary to have a Dual Preset version to utilize either of the outputs in Rate

Meter mode. Single Preset units will operate as a rate meter with no outputs.

11

Page 12

PROGRAMMING

F10

F11

F13

F21

1

PRG

E

1

PRG

E

0

PRG

E

0

PRG

E

F10 Input Type: Enables the unit to be programmed to work with either sinking or sourcing inputs.

Choices are NPN (0), and PNP (1).

F11 Count Speed: Enables the unit to be set for full speed of 5 kHz (1) or to 30 Hz (0) to provide

debounce filtering for contact inputs.

F13 Start-up Suppression: When active (1), an output can not be On until the Off conditions have been

satisfied. For example, a rate value on start-up below Preset 1 will not trigger output 1; Output 1 will only

be activated after the rate value has risen above Preset 1 and then fallen back below.

F21 Preset 1 Access Enable: When active (0), the Preset 1 value can be accessed by simultaneously

holding down the Edit key and the "1' key. If set to inactive (1), Preset 1 can not be accessed, or only

accessed by holding down the Edit key and the "1" key for 10 seconds (see F29).

F22

F23

F29

0

PRG

E

0

PRG

E

0

PRG

F22 Preset 2 Access Enable: When active (0), the Preset 2 value can be accessed by simultaneously

holding down the Edit key and the "2" key. If set to inactive (1), Preset 2 can not be accessed, or only

accessed by holding down the Edit key and the "2" key for 10 seconds (see F29).

F23 Prescale Enable: When active (0), the Prescale value can be accessed by simultaneously holding

down the Edit key and the "3" key. If set to inactive (1), Prescale can not be accessed, or only accessed

by holding down the Edit key and the "3" key for 10 seconds (see F29).

F29 Lockout Mode: If parameters F21, F22 and F23 are set to inactive, Preset 1 & 2 and the Prescale

value can still be accessed by holding down the respective keys for 10 seconds if this parameter is set to

active (0). If set to inactive (1), those values can not be accessed.

12

Page 13

ELAPSED TIME MODE

E

During Power-up

5

If the functionality has been set to FN2, then the unit will operate as an

elapsed time counter, in one of 3 programmable operation modes. To

enter the Program mode, hold down the Edit key and the "5" key during

power-up. Use the edit key to move from one parameter to the next,

and the "1" key to scroll through the parameter choices. Holding down

the Edit key for 5 seconds will return the unit to Operation mode.

F0

F2

F3

F4

F6

0

PRG

E

0

PRG

E

0

PRG

E

0

PRG

E

.10

PRG

E

F0 Default Settings: Changing this value from 0 to 1 will set all parameters back to their default values. A

setting of 0 has no effect on the other parameters.

F2 Time Format: Sets the units in which will be used for the timing display. Choices are seconds (0),

minutes (1) and hours (2).

F3 Display Decimal Point: Defines the number of digits displayed to the right of the decimal point for the

Time and Preset values. Settable in a range from 0 to 3.

F4 Reset Operation: Defines how the time value will behave when the preset is reached. Choices are:

Code

0 Reset to "0", no Autoreset

1 Reset to "0", Autoreset

2 Reset to Preset, no Autoreset

3 Reset to Preset, Autoreset

F6 Output 1 Time: Sets the amount of time Output 1 will be active once the Preset is reached. Choices

are:

Code

Off No output

On Latching output (for dual presets, output 2 will deactivate output 1 )

0.02 20 ms

0.05 50 ms

0.10 100 ms

0.50 500 ms

1.00 1 sec.

F7

F8

.10

PRG

E

0

PRG

F7 Output 2 Time: Sets the amount of time Output 2 will be active once Preset 1 is reached. Choices are

the same as for Output 1.

F8 Timing Operation: The unit can be programmed to operate in one of 4 modes:

Code

0 Cumulative pulse width measurement

1 Cumulative period measurement

2 Singular Pulse width measurement

3 Singular Period measurement

Note: Timing diagrams for each mode are included at the end of this section

13

Page 14

PROGRAMMING

F9

F10

F11

F12

.10

PRG

E

.10

PRG

E

1

PRG

E

0

PRG

E

F9 Output on Reset: When set to ON (1), the primary output (Output 2 on dual preset version) will

activate when the unit is reset.

F10 Input Type: Enables the unit to be programmed to work with either sinking or sourcing inputs.

Choices are NPN (0), and PNP (1)

F11 Count Speed: Enables the unit to be set for full speed of 5 kHz (1) or to 30 Hz (0) to provide debounce

filtering for contact inputs.

F12 Static/Dynamic Reset: When set to static reset (0) counting stops on the leading edge of the reset

input and can not resume until the trailing edge. When set to dynamic reset (1) the Count Value is

immediately reset on the leading edge of the reset signal, and can accumulate while the reset signal is still

active.

F14

F15

F20

F21

0

PRG

E

0

PRG

E

0

PRG

E

0

PRG

E

F14 Output Signal Memory: Determines if after power interruption the outputs will resume their state

prior to the loss of power (1) or if the output will be reset (0)

F15 Background Totalizer: Setting this parameter to ON (1) will activate the totalizer function.

F20 Front Panel Reset Enable: When active (0), the count value and output(s) can be reset by

simultaneously pressing the "6" and "4" keys. If set to Off (1), reset can only take place through the

remote input, or through the front panel by holding the "6" and "4" keys for 10 seconds (see F29).

F21 Preset 1 Enable: When active (0), the Preset 1 value can be accessed by simultaneously holding

down the Edit key and the "1' key. If set to inactive (1), Preset 1 can not be accessed, or only accessed by

holding down the Edit key and the "1" key for 10 seconds (see F29)

14

Page 15

F22

0

PRG

F22 Preset 2 Enable: When active (0), the Preset 2 value can be accessed by simultaneously holding down

the Edit key and the "2" key. If set to inactive (1), Preset 2 can not be accessed, or only accessed by holding

down the Edit key and the "2" key for 10 seconds (see F29)

E

F29

Note: The function of the 3 inputs are not programmable in this mode. They are preassigned as follows:

0

PRG

Cumulative Pulse Width Measurement, F8 = 0

Preset 2

Preset 1

Input A

Input B

Reset

Output 1

Output 2

F29 Lockout Mode: If parameters F21, F22 and F23 are set to inactive, Preset 1 & 2 and the Prescale

value can still be accessed by holding down the respective keys for 10 seconds if this parameter is set to

active (0). If set to inactive (1), those values can not be accessed.

Input A: Start/Stop Pulse

Input B: Reset

Input C: Latch (When active, timing is not visible on the display, the

new period/pulse width value will be displayed at the end of the start/

stop cycle)

Cumulative Period Measurement F8 = 1

Preset 1

Input A

Dynamic Reset

Input B

Reset

Input C

Latch

Preset 1

Input A

Output 1

Singular Pulse Width Measurement, F8 = 2

Singular Period Measurement, F8 = 3

Preset 1

Input A

Input B

Reset

Input C

Latch

15

Page 16

PROGRAMMING

DUAL REGISTER MODE

E

During Power-up

5

If the functionality has been set to FN3, then the unit will operate as a

totalizer with seperate subtotal registers for input A and input B. To

enter the Program mode, hold down the Edit key and the "5" key during

power-up. Use the Edit key to move from one parameter to the next,

and the "1" key to scroll through the parameter choices. Holding down

the Edit key for 5 seconds will return the unit to Operation mode.

F0

F1

F3

F10

0

PRG

E

F0 Default Settings: Changing this value from 0 to 1 will set all parameters back to their default values.

A setting of 0 has no effect on the other parameters.

F1 Register Mode: Determines the count direction of the dual registers.

0

PRG

E

0

PRG

E

1

PRG

E

F3 Display Decimal Point: Defines the number of digits displayed to the right of the decimal point for

both registers. Settable in a range from 0 to 3.

F10 Input Type: Enables the unit to be programmed to work with either sinking or sourcing inputs.

Choices are NPN (0), and PNP (1)

Code Input A Input B Input C

0 Adding Adding Reset

1 Adding Subtracting Reset

16

F11

F12

F20

1

PRG

E

0

PRG

E

0

PRG

E

F11 Count Speed: Enables the unit to be set for full speed of 5 kHz (1) or to 30 Hz (0) to provide

debounce filtering for contact inputs.

F12 Static/Dynamic Reset: When set to static reset (0) counting stops on the leading edge of the reset

input and does not resume until the trailing edge. When set to dynamic reset (1) the Count Value is

immediately reset on the leading edge of the reset signal, and will accumulate while the reset signal is

still active.

F20 Front Panel Reset Enable: When active (0), the count value and output(s) can be reset by

simultaneously pressing the "6" and "4" keys. If set to Off (1), reset can only take place through the

remote input, or through the front panel by holding the "6" and "4" keys for 10 seconds (see F29).

Page 17

F21

0

PRG

E

F21 Reserved

F22

E

F23

E

F29

E

0

PRG

0

PRG

0

PRG

BATCH COUNTER MODE

E

5

F22 Reserved

F23 Prescale Access Enable: When active (0), the Prescale value can be accessed by simultaneously

holding down the Edit key and the "3" key. If set to inactive (1), Prescale can not be accessed, or only

accessed by holding down the Edit key and the "3" key for 10 seconds (see F29)

F29 Lockout Mode: If parameter F23 is set to inactive, the Prescale value can still be accessed by holding

down the respective keys for 10 seconds if this parameter is set to active (0). If set to inactive (1), those

values can not be accessed.

If the functionality has been set to FN4, the unit will operate as a Batch

Counter with 2 seperate control functions. Preset 2 is for the primary

count value (6 pcs. per box) while preset 1 is for the batch value (24

boxes per pallet). To enter the Program mode, hold down the Edit key

and the "5" key during power-up. Use the Edit key to move from one

parameter to the next, and the "1" key to scroll through the parameter

choices. Holding down the Edit key for 5 seconds will return the unit to

Operation mode.

During Power-up

F0

E

F1

E

F3

E

0

PRG

0

PRG

0

PRG

F0 Default Settings: Changing this value from 0 to 1 will set all parameters back to their default values. A

setting of 0 has no effect on the other parameters.

F1 Count Mode: Defines the functionality of the 3 inputs. The choices are:

Code Input A Input B Input C

0 Count Input Inhibit Reset

1 Count Input Direction (U/D) Reset

2 Count Input Direction (U/D) Inhibit

3 Incrementing Decrementing Reset

4 Incrementing Decrementing Inhibit

5 Incrementing Incrementing Reset

6 Channel A* Channel B* Reset

7 Channel A* Channel B* Inhibit

* Quadrature counting for encoders

F3 Display Decimal Point: Defines the number of digits displayed to the right of the decimal point for

both registers. Settable in a range from 0 to 3.

17

Page 18

PROGRAMMING

F4

F6

F7

F9

E

E

E

E

0

PRG

0.10

PRG

0.10

PRG

0

PRG

F4 Reset Operation: Defines how the count value will behave when the preset is reached. Choices are:

0 Reset to "0", no Autoreset

1 Reset to "0", Autoreset

2 Reset to Preset, no Autoreset

3 Reset to Preset, Autoreset

F6 Output 1 Time: Sets the amount of time Output 1 will be active once the Preset is reached. Choices are:

Off No output

On Latching output (for dual presets, output 2 will deactivate output 1 )

0.02 20 ms

0.05 50 ms

0.10 100 ms

0.50 500 ms

1.00 1 sec.

F7 Output 2 Time: Sets the amount of time Output 2 will be active after the Preset is reached. Choices

are the same as Output 1

F9 Output on Reset: When set to ON (1), the primary output (Output 2 on dual preset version) will

activate when the unit is reset.

F10

F11

F12

F14

1

PRG

E

1

PRG

E

0

PRG

E

0

PRG

E

F10 Input Type: Enables the unit to be programmed to work with either sinking or sourcing inputs.

Choices are NPN (0), and PNP (1)

F11 Count Speed: Enables the unit to be set for full speed of 5 kHz (1) or to 30 Hz (0) to provide

debounce filtering for contact inputs.

F12 Static/Dynamic Reset: When set to static reset (0) counting stops on the leading edge of the reset

input and does not resume until the trailing edge. When set to dynamic reset (1) the Count Value is

immediately reset on the leading edge of the reset signal, and will accumulate while the reset signal is

still active.

F14 Output Signal Memory: Determines if after power interruption the outputs will resume their state

prior to the loss of power (1) or if the output will be reset (0)

18

F20

0

PRG

E

F20 Front Panel Reset Enable: When active (0), the count value and output(s) can be reset by

simultaneously pressing the "6" and "4" keys. If set to Off (1), reset can only take place through the

remote input, or through the front panel by holding the "6" and "4" keys for 10 seconds (see F29).

Page 19

F21

0

PRG

E

F21 Preset 1 Enable: When active (0), the Preset 1 value can be accessed by simultaneously holding

down the Edit key and the "1' key. If set to inactive (1), Preset 1 can not be accessed, or only accessed by

holding down the Edit key and the "1" key for 10 seconds (see F29)

F22

F23

F29

0

PRG

E

0

PRG

E

0

PRG

F22 Preset 2 Access Enable: When active (0), the Preset 2 value can be accessed by simultaneously

holding down the Edit key and the "2" key. If set to inactive (1), Preset 2 can not be accessed, or only

accessed by holding down the Edit key and the "2" key for 10 seconds (see F29).

F23 Prescale Enable: When active (0), the Prescale value can be accessed by simultaneously holding

down the Edit key and the "3" key. If set to inactive (1), Prescale can not be accessed, or only accessed

by holding down the Edit key and the "3" key for 10 seconds (see F29).

F29 Lockout Mode: If parameters F21, F22 and F23 are set to inactive, Preset 1 & 2 and the Prescale

value can still be accessed by holding down the respective keys for 10 seconds if this parameter is set to

active (0). If set to inactive (1), those values can not be accessed.

SPECIFICATIONS

Count Operation:

Count Modes: Add/Subtract Add/Add, Directional input or

Quadrature

Count Speed: 30 Hz (17ms min. pulse width), or 5 kHz (100µs min.

pulse width) field selectable (2 kHz in quadrature)

Presets: 6 digit, Single (C346-0_1), Dual (C346-0_2)

Reset: Front panel (selectable enable), remote input or automatic

Calibrator: 0.001 to 9.999 multiplier common to inputs A and B

Decimal Point: Selectable from XXXX to X.XXX

Rate Meter Operation:

Mode of Operation: Time interval (1/Tau)

Update Time: 500ms for each input if frequency is >2Hz

Alarms: Upper and Lower absolute value

Calibrator: 0.001 to 9.999 multiplier common to inputs A and B

Elapsed Time Operation:

Timing Modes: Pulse Width Measurement (cumulative or singular),

Period Measurement (cumulative or singular)

Time Ranges: Selectable for Seconds, Minutes, Hours

Resolution: Selectable from XXXX to X.XXX

Physical:

Dimensions: 48mm x 48mm, 93.5mm deep

Mounting: Panel mount (mounting bracket supplied), 45mm x 45mm

cutout

Terminals: Screw Type

Display: Single line seven segment LED, 7.6mm high or Single line

LCD, 9mm high

General:

Supply Voltage: 115 VAC, 230 VAC 50/60Hz, 12 - 24 VDC

Current Consumption: DC < 150 mA, AC < 50 mA

Accessory Power: 12 to 24 VDC, 0 - 50mA

Ambient Temperature - Operating: 0 to 50˚ C, 32 to 122˚ F

Ambient Temperature - Storage: -20 to 60˚ C -4 to 140˚ F

Front Panel Rating: NEMA 4/IP65

Approvals: CE, UL, CUL

Inputs:

Count Inputs: Contact Closure, Sourcing, Sinking, low < 2.0 VDC,

high > 8.0 VDC, 40VDC Max.

Control Inputs: Remote Reset and Program Enable; low < 2.0

VDC, high > 8.0 VDC, 40VDC Max.

Input Resistance: approx. 5KΩ

Minimum Pulse Width: 17 ms (30 Hz), 100 µs (5 kHz)

Maximum Voltage: 40 VDC

Outputs:

Number: 1 relay and 1 transistor per preset

Relay(s): SPDT 1A resistive @ 250 VAC

Transistor: PNP open collector, 24 VDC max, 10 mA max

19

Page 20

GENERAL

PROGRAMMING

ORDERING INFORMATION

Description Model #

LCD/Single Preset/AC115 C346-0411

LCD/Single Preset/AC230 C346-0413

LCD/Single Preset/DC 12-24 C346-0412

LCD/Dual Preset/AC115 C346-0421

LCD/Dual Preset/AC230 C346-0423

LCD Dual Preset/DC 12-24 C346-0422

LED/Single Preset/AC115 C346-0511

LED/Single Preset/AC230 C346-0513

LED/Single Preset/DC 12-24 C346-0512

LED/Dual Preset/AC115 C346-0521

LED/Dual Preset/AC230 C346-0523

WARRANTY

LED/Dual Preset/DC 12-24 C346-0522

Standard products manufactured by the

Company are warranted to be free from defects

in workmanship and material for a period of one

year from the date of shipment, and products

which are defective in workmanship or material

will be repaired or replaced, at the option of the

Company, at no charge to the Buyer. Final

determination as to whether a product is

actually defective rests with the Company. The

obligation of the Company hereunder shall be

limited solely to repair and replacement of

products that fall within the foregoing

limitations, and shall be conditioned upon

receipt by the Company of written notice of any

alleged defects or deficiency promptly after

discovery within the warranty period, and in the

case of components or units purchased by the

Company, the obligation of the Company shall

not exceed the settlement that the Company is

able to obtain from the supplier thereof. No

products shall be returned to the Company

without its prior consent. Products which the

Company consents to have returned shall be

shipped F.O.B. the Company's factory. The

Company cannot assume responsibility or accept

invoices for unauthorized repairs to its

components, even though defective. The life of

the products of the Company depends, to a large

extent, upon the type of usage thereof, and THE

COMPANY MAKES NO WARRANTY AS TO

FITNESS OF ITS PRODUCTS FOR SPECIFIC

APPLICATIONS BY THE BUYER NOR AS TO

PERIOD OF SERVICE UNLESS THE COMPANY

SPECIFICALLY AGREES OTHERWISE IN

WRITING AFTER THE PROPOSED USAGE HAS

BEEN MADE KNOWN TO IT.

THE FOREGOING WARRANTY IS EXCLUSIVE

AND IN LIEU OF ALL OTHER WARRANTIES

EXPRESSED OR IMPLIED, INCLUDING, BUT

NOT LIMITED TO ANY WARRANTY OF

MERCHANTABILITY OR OF FITNESS FOR A

PARTICULAR PURPOSE.

20

Printed in U.S.A.

#701996-0000

January 1996

Revision: A

Danaher Controls

1675 Delany Road

Gurnee, IL 60031–1282

Phone: 847.662.2666

Fax: 847.662.6633

Loading...

Loading...