Page 1

Introduction

Veeder-Root

brand

Within the Danaher Controls A103 family you'll find a product to meet nearly every

requirement for panel mounted control and indication. Housed in a DIN standard 36mm x

72mm case, the A103-007 is an ideal choice for event counting operations which require a

preset. An intenal solid state relay provides a logic signal that can be sent to antother

control device or to an external relay.

The 8 digit supertwist LCD display provides easy viewing at a glance. For conditions where

ambient light is poor, the display can be backlit by connecting an external DC (10-28 Volt)

power supply. A single unit can accept NPN & dry contact inputs for low speed (30Hz)

counting and PNP or square wave signals for high speed applications up to 10 kHz.

Powered by either one or two replaceable 3V Lithium batteries, this unique design allows for

a new battery to be installed before removing the old one, thereby retaining count total and

program data. A low battery indicator appears on the screen to provide a warning several

weeks before the end of battery life. If two batteries are used simultaneously, the individual

expected life doubles to 10 years.

Setup is quick and simple as the two

front panel keys are used to scroll

through 4 menu choices. A NEMA 4X

front panel and noise immunity tested

to IEC 801 level 3 makes this unit

suitable for harsh environments.

Several option modules are available,

inclunding a 5 amp relay which would

enalbe the unit to directly drive a

load.

Technical Manual

701954-0008

Features

•

Large, easy to read 8-digit supertwist LCD

with backlighting capability

•

Display can be toggled between count and

preset value

•

Powered by an internal 3 Volt lithium

battery

•

Accepts low speed (30 Hz) NPN & dry

contact inputs, and high speed (10 kHz)

PNP signals or square wave signals

•

0.1 Amp SSR output

•

Option Modules provide added

functionality and convenience

•

Simple menu-driven setup

•

NEMA 4X rated front panel for use in

washdown environments

Index

Overview

Operation page 2

Terminal Connections page 2

Setup

Installation page 3

Programming page 3

General

Specifications page 4

Warranty page 4

A103-007

Preset

Counter

1

Page 2

OVERVIEW

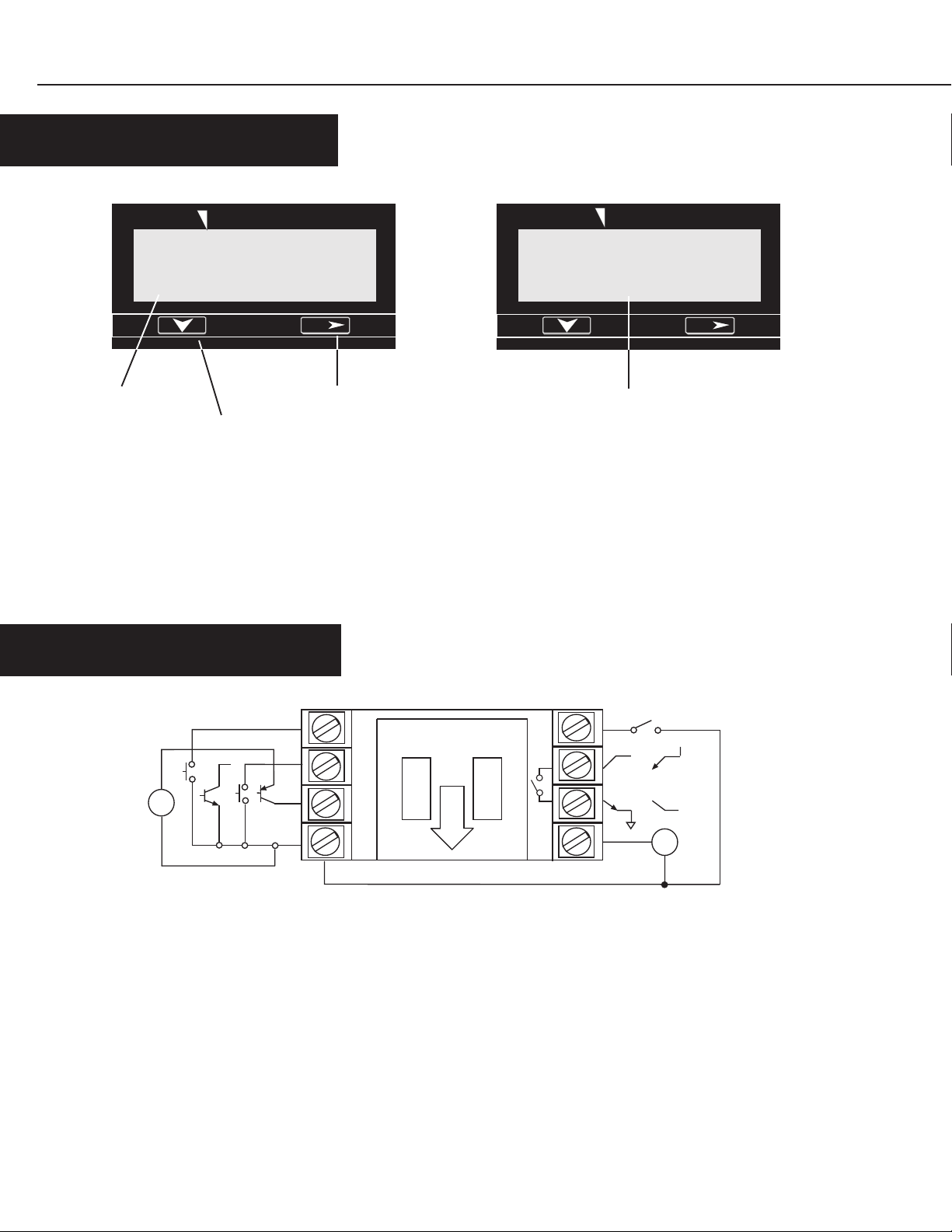

OPERATION

VEEDER-ROOT

C.2345678

R

1. Total Display

2. Down Key

1. Total Display: Indicates the present count value, which is equal to

the number of pulses received since the last reset

2. Down Key: Toggles the unit between the total and preset displays

when in Operation Mode. When the program input is active this key is

used to scroll through the menu items. After a menu item has been

chosen for editing, the down key is used to set the value for the

currently selected (flashing) digit.

REAR TERMINAL CONNECTIONS

3. Next/Reset Key

3. Next/Reset Key: When in Operation Mode, depressing the key will

reset the count value to 0, if Front Panel Reset has been enabled in

Programming Mode. When the program input is active this key is used

to select a menu item for editing (left most digit will begin to flash) and

then move to the desired digit to be changed.

4. Preset Value: Indicates the number at which the output will be

activated (for Up counting) or the reset value (for Down counting)

P.3456789

4. Preset Value

VEEDER-ROOT

R

+

-

1. Common

2. High Speed Input A - PNP or squre

signals up to 10 kHz* for incrementing the

count value

3. Low Speed Input A - NPN or dry contact

inputs up to 30 Hz for incrementing the

count value

4. Remote Reset - Resets count value when

switched to common

2

4

3

2

1

5

+

6

Sink Source

7

8

10 - 28 VDC

5. Front Panel Program Enable - Allows access to

program mode when switched to common

6. & 7. - Form A SSR Output

8. DC Supply Input - For backlighting

* For high speed current sinking devices, provide a pull-up

resistor from terminal 2 to a DC source

+

-

Page 3

SETUP

INSTALLATION

36mm

+ BATT -

BATT +

-

Battery Slots

Battery Installation - The unit is shipped with two battery, which are not

installed. Remove the battery cover by pushing inward and down. Install

the batteries in the two slots. The two batteries are capable of sustaining

the output for 6 months at 50% duty cycle (To extend the battery life to 5

years utilize an external DC supply or the AC option module for powering

the output). Once the battery is in place the unit will go into a self test

mode, and all the segments on the LCD display will be illuminated. The self

test mode is exited by depressing the Next key, which will then display the

model number (7). Depress the Next key again to ready the unit for

operation.

Front Panel Installation - Place the unit in the panel through the

33mm x 68mm cutout. Slide the included gasket over the rear of the

unit, then slide the panel mount bracket into place so that the 4 tabs

catch in the groves on the top and the bottom of the unit (the bracket

should be oriented so that the tabs are on the side nearest the panel).

Use the provided panel mount screws to tighten the bracket until there

is a secure seal against the gasket.

33mm

72mm

68mm

4

3

2

1

8

7

6

5

PROGRAMMING

1. uP

2.

3.

4.

5.

oFF

int

on

on

Programming parameters can be accessed, when the Program Enable input is active, by

pressing the Down key. To edit a parameter use the Down key to scroll until the

desired parameter appears on the screen. Pressing the Next key will cause the leftmost

digit of that value to begin to flash. Use the Next and Down keys in combination to

choose individual digits and change their value.

Count Direction: Determines if the count value will increment from zero and change the state of the

output at the preset (Up), or decrement from the Preset and change the state of the output at zero

(Down).

Preset Lock: When enabled the preset value can not be changed through the front panel.

Output Mode - Determines whether the output will activate prior to reaching the preset (or zero for

down counting) and then release when that value is achieved (Interval), or will be Off prior to reaching

the preset (or zero for down counting) and then activate when that value is achieved (On-Delay).

Front Panel Reset Enable: When active (ON) the count value, when being displayed, can be reset by

pressing the Next/Reset key. If set to OFF, the total value can only be reset through the remote input.

Output Enable: When active (on), the SSR output will activate as described above in Output Mode.

If set to off, the output will not activate. (Use the "off" setting to conserve battery life if not using the output)

3

Page 4

SPECIFICATIONS

GENERAL

High Speed Input (Terminal 2)

Type: PNP Signal or square wave pulse

Count Speed: 10 kHz max (50% duty cycle),

Logic: Low < 1.0 VDC, High > 2.0 VDC

Minimum Pulse Width: 45 µsecond

Maximum Input: 28VDC

Impedence: 15 KΩ to common

Low Speed Input (Terminal 3)

Type: NPN Signal, Contact Closure

Count Speed: 30 Hz max (50% duty cycle)

Logic: Low < 1.0 VDC, High > 2.0 VDC

Minimum Pulse Width: 12 ms

Maximum Input 28VDC

Impedence: 1 MΩ to battery

Front Panel Enable Input (Terminal 5)

Type: NPN Signal, Contact Closure; level sensitive

Maximum Input: 28 VDC

Remote Reset Input (Terminal 4)

Type: NPN Signal, Contact Closure; edge sensitive

Frequency Response: 30 Hz (50% duty cycle)

Maximum input: 28 VDC

WARRANTY

Output (Terminals 6 & 7)

Type: Isolated Photomos Relay

Load Rating: 0.1 Amp @ 30 VAC/VDC

Transistion Time: < 5ms

Power Source:

Type: Single or dual 3V Lithium battery

Expected Life: 5 years typical-single battery if using AC power

supply option module or external DC supply.

6 months if used alone with 50% duty cycle output. No

reduction in battery life if output is programmed to "off"

Low Power Indicator: "Low Bat" flashes on display

approx. 2 weeks prior to end of battery life

Display:

Type: Supertwist LCD for use with or without backlighting

Number: 8 digits

Height: 12mm

Backlighting: Green Illumination over whole

viewable area with a 10 to 28 VDC supply (Terminal 8)

Physical:

Dimensions: 36mm x 72mm, 38mm deep

Mounting: Panel Mount (mounting bracket supplied)

33mm x 68mm (+ 0.3mm) panel cutout

Connections: Up to 8 screw terminals

Weight: Approximately 2.25 ounces

Standard products manufactured by the

Company are warranted to be free from defects

in workmanship and material for a period of one

year from the date of shipment, and products

which are defective in workmanship or material

will be repaired or replaced, at the option of the

Company, at no charge to the Buyer. Final

determination as to whether a product is

actually defective rests with the Company. The

obligation of the Company hereunder shall be

limited solely to repair and replacement of

products that fall within the foregoing

limitations, and shall be conditioned upon

receipt by the Company of written notice of any

alleged defects or deficiency promptly after

discovery within the warranty period, and in the

case of components or units purchased by the

Company, the obligation of the Company shall

not exceed the settlement that the Company is

able to obtain from the supplier thereof. No

products shall be returned to the Company

without its prior consent. Products which the

Company consents to have returned shall be

shipped F.O.B. the Company's factory. The

Company cannot assume responsibility or accept

invoices for unauthorized repairs to its

components, even though defective. The life of

the products of the Company depends, to a large

extent, upon the type of usage thereof, and THE

COMPANY MAKES NO WARRANTY AS TO

FITNESS OF ITS PRODUCTS FOR SPECIFIC

APPLICATIONS BY THE BUYER NOR AS TO

PERIOD OF SERVICE UNLESS THE COMPANY

SPECIFICALLY AGREES OTHERWISE IN

WRITING AFTER THE PROPOSED USAGE HAS

BEEN MADE KNOWN TO IT.

THE FOREGOING WARRANTY IS EXCLUSIVE

AND IN LIEU OF ALL OTHER WARRANTIES

EXPRESSED OR IMPLIED, INCLUDING, BUT

NOT LIMITED TO ANY WARRANTY OF

MERCHANTABILITY OR OF FITNESS FOR A

PARTICULAR PURPOSE.

Danaher Controls

Printed in U.S.A.

#701954-0008

Revision B

4

4/14/04

1675 N. Delany Road

Gurnee, IL 60031–1282

Phone: 847.662.2666

Fax: 847.662.6633

Loading...

Loading...