Veeco MS40 Operation And Maintenance Manual

n

Table Of Contents

Section 1: General Information

1.1 Introduction 1-1

1.2 Unpacking & Inspection 1-3

1.3 Installation 1-7

1.4 Features & Specifications 1-8

1.5 General Description 1-11

Section 2: Operating the MS-40

2.1 Introduction 2-1

2.2 Operator Controls & Indicators 2-3

2.3 Starting the MS-40 Leak Detector 2-19

2.4 Leak Testing 2-20

2.5 Operation With an External Pump 2-22

2.6 Shut Down Procedure 2-25

2.7 Setting Test Parameters 2-25

2.8 Setting Additional Parameters 2-31

2.9 Test Aids & Procedures 2-32

Section 3: Theory of Operation

3.1 Introduction 3-1

3.2 Direct Flow & Reverse Flow Modes. 3-4

3.3 Functional Description of Operation 3-6

3.4 Description of Major Components 3-11

Section 4: Service & Maintenance

4.1 Introduction 4-1

4.2 Service Mode 4-1

4.3

4.4 Periodic Service 4-4

Calibration & Tuning 4-2

VIC Leak Detectio

2099 Ninth Avenue

Ronkonkoma, NY 11779

631.737.0900

1109-186-00 Rev. C toc-i

VIC Leak Detectio

n

n

VIC Leak Detectio

2099 Ninth Avenue

2099 Ninth Avenue

Ronkonkoma, NY 11779

Ronkonkoma, NY 11779

631.737.0900

631.737.0900

4.5 Contamination of the Vacuum System 4-8

4.6 Venting the Vacuum System 4-11

4.7 Cleaning Requirements 4-12

4.8 Calibration Requirements 4-19

4.9 General Service & Repair 4-21

4.10 Troubleshooting Aids 4-32

Section 5: Parts List

5.1 Introduction 5-1

5.2 Recommended Spare Parts for the MS-40 5-2

5.3 Other Components 5-5

Appendix A:

Glossary of Terms Used in Leak Detection

Appendix B:

A.V.S. Standards for Testing of Mass Spectrometer Leak Detectors

Appendix C:

Leakage Conversion Factors

Appendix D:

Remote Port Specifications

Appendix E:

Profile and Revision Switch Positions

Appendix F:

MS-40 Quick Reference

1109-186-00 Rev. A toc-ii

General Information

1.1 Introduction

This Operations & Maintenance Manual describes in detail the

information needed to understand the operation and functions of the

VIC MS-40 Fully Automatic Portable Leak Detector (illustrated in

Figure 1-1), and provides the information needed to service and maintain

the unit in optimal working condition. This manual has been divided into

five chapters:

• Chapter 1 General Information

• Chapter 2 Operating the MS-40

• Chapter 3 Theory of Operation

• Chapter 4 Service & Maintenance

• Chapter 5 Parts Lists

Chapter 1, General Information, describes the features of the MS-40 Leak

Detector, its basic operation, unpacking and inspection of the unit, installation

requirements as well as specifications for the unit.

Chapter 2, Operating the MS-40, details the controls necessary to operate

the MS-40, both during normal operation of the unit as well as when

placed in Service Mode. All external connectors and their

applicability to the unit and its functions are also discussed. This chapter

also includes an explanation of what occurs during the unit’s start-up

procedure, a description of the leak test modes, an explanation of sniff

testing procedures, a step-by-step description of how to perform actual

leak testing, operations involving the optional external pump, an

explanation of what occurs during the unit’s shutdown procedure, the

setting of the unit’s testing parameters, and MS-40 self-testing procedures.

Chapter 3, Theory of Operation, has been included in order to give the

MS-40 user information on how the unit functions. Maintenance

personnel servicing the unit will find this most useful, since a thorough

technical understanding of how the unit operates is critical when

performing the repairs and service discussed in the following chapter.

Vacuum Instrument Corp.

2099 Ninth Avenue

Ronkonkoma, NY 11779

631.737.0900

1109-186-00 Rev. C 1-1

VIC Model MS-40 Portable Automatic Leak Detector

1109-186-00 Rev. C 1-2

Figure 1-1

Vacuum Instrument Corp.

2099 Ninth Avenue

Ronkonkoma, NY 11779

631.737.0900

Chapter 4, Service & Maintenance, describes in further detail the unit’s

Service Mode, the necessary tuning/calibration procedures for the MS-40,

required periodic service procedures and recommended service intervals,

detection and correction of contamination within the vacuum system,

procedures for venting the vacuum system, cleaning requirements and

procedures, calibration of measurement components, valve block service and

repair, repair/replacement of the unit’s electronics and a full listing of front

panel error codes, their probable causes and our recommended corrective

actions.

Chapter 5, MS-40 Parts Lists, contains a full list of recommended spare parts

and a complete listing of the spare parts available from VIC.

This manual provides the specific documentation needed to operate and

service the MS-40 Leak Detector. The MS-40 System is a highly technical

system that incorporates many sophisticated technologies. In view of this,

every effort has been made to automate both the unit’s operation and

maintenance procedures. It is imperative, however, that operations and service

personnel familiarize themselves with the operations and maintenance

procedures in this manual in order to maximize the efficiency of the unit, as

well as minimize downtime caused by improper service and repair.

1.2 Unpacking & Inspection

The MS-40 is shipped in a specially constructed package that minimizes the

possibility of damage during transit. The shipping carton and packing

materials should be saved for future use. Note that a Bill of Material is packed

within the carton indicating all of the items shipped with the unit.

Prior to unpacking the unit, inspect the exterior carton for any signs of

damage. After unpacking the unit, inspect the leak detector itself for any

obvious damage. If damage to the unit is found, a claim should be filed

immediately with the shipping carrier and a copy of that claim must also be

forwarded to Vacuum Instrument. Should the MS-40 fail to function as

required, or fail to meet its specifications, contact the Customer Service

Department at VIC (Vacuum Instrument, 2099 Ninth Avenue Ronkonkoma,

NY 11779, 631-737-0900) or your local representative. Please note that

Vacuum Instrument must be contacted prior to the return of any damaged

equipment.

Once the leak detector has been removed from its package, the MS-40 must

be opened and all shipping material removed from the unit’s internal

roughing and turbo-molecular pumps. To access the internal roughing

pump, the front panel must be opened to access the turbo-molecular pump,

1109-186-00 Rev. C 1-3

the back panel must be opened. Both panels are hinged at the bottom and

held with a single screw at the top of each panel. To open a panel, loosen

the captive screw at the top of the panel (a 1/4 turn is sufficient to unloosen

the screw) and gently lower the door. Make sure that the surface the unit is

placed on a flat surface (VIC Cart, P/N 0137-705-00, recommended).

Remove all shipping materials and tie-down wraps from the internal

pumps.

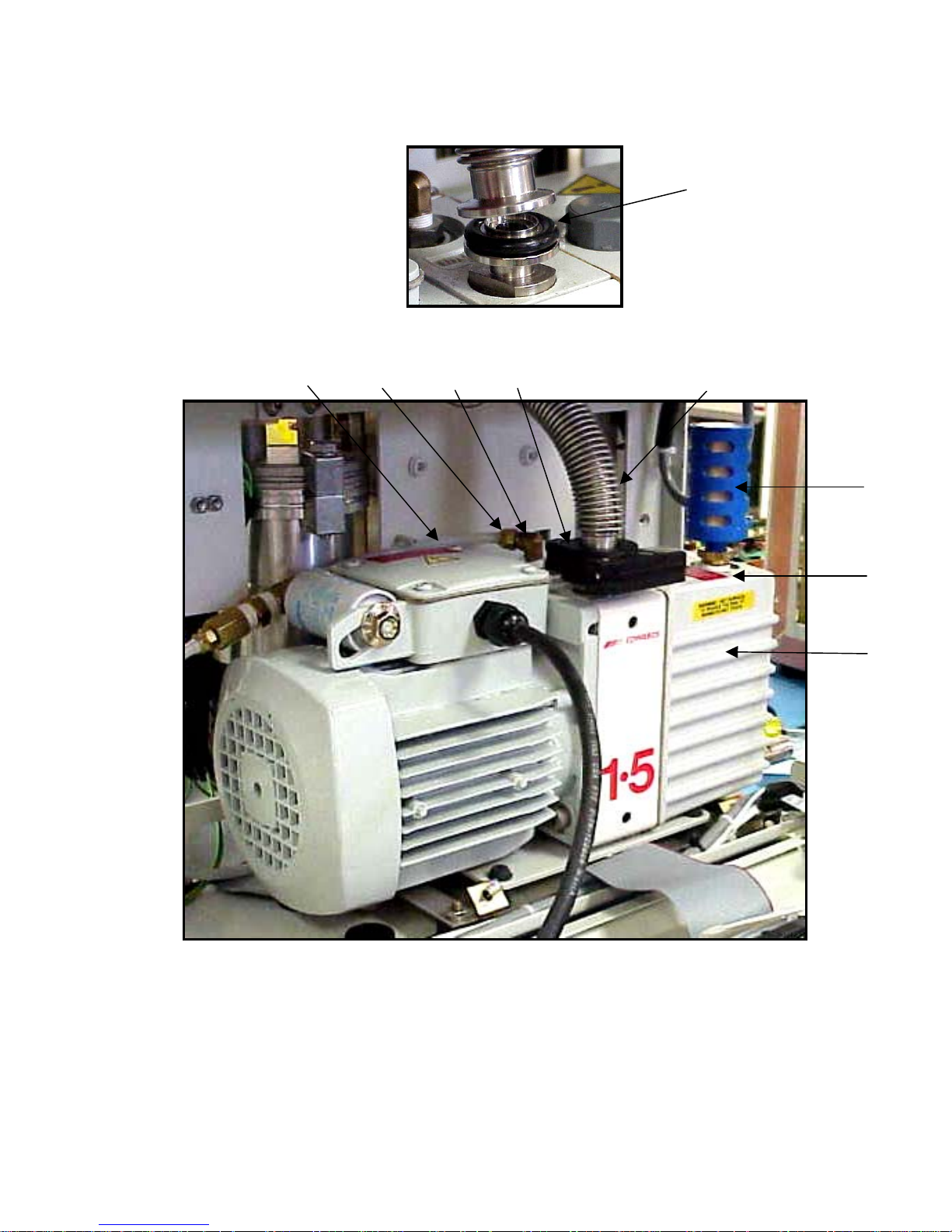

The MS-40 is shipped without oil in the internal roughing pump, which must

be filled prior to use. In addition, to protect the pump during shipment, it is

fitted with two blanks that cover its intake and filter connections. Remove

these blanks and attach the flex hosing and filter (refer to Figure 1-2 for a

diagram illustrating the proper installation for the hose and filter connections)

with the provided centering rings and clamps. Also, the unit’s purge tubing

(refer to Figure 1-2) is fitted with a 1/4” ferrule blank. Unscrew the blank and

reattach the tubing as indicated in Figure 1-2.

Parts List for Figure 1-2:

ILLUSTRATION # PART NUMBER DESCRIPTION

1 1660-362-00 110/120v (60Hz)

1660-362-01 220/240v (50 Hz) Pump

2 1621-183-00 Ferrule Nut

3 1750-046-00 Poly-flo Tubing, Purge Line

4 1620-726-00 Elbow / with ferrule nut

5 1621-231-12 KF16 Centering Ring

6 1621-239-02 KF16 Clamp

7 0137-205-00 Manifold, Roughing Pump

8 1680-055-00 Exhaust Filter

KF16 to 1/4 NPT Adapter

9 1620-743-00 3/8 MPT x ¼ Bushing

Vacuum Instrument Corp.

2099 Ninth Avenue

Ronkonkoma, NY 11779

631.737.0900

1109-186-00 Rev. C 1-4

n

To fill the pump with oil, unscrew the black cap to the right of the exhaust

filter. Using the oil (1990-924-00) and the funnel (1331-191-00) provided

in the installation kit, slowly fill the pump until the level in the sight glass

is approximately 1/4” below the fill line. Replace the black oil fill cap.

When all shipping material has been removed, all pump connections have

been made and the pump has been filled with oil, replace the right side

panel and close the front and rear doors.

NOTE:

The MS-40 Leak Detector is factory tested and calibrated

prior to shipment and once installed, is ready for use.

An Installation Kit (VIC P/N 0137-800-00) is included with the unit when it

is shipped. The kit contains:

Part Number Description

1680-055-00 Exhaust Filter

0103-141-01 Filament Kit (box of 5)

1331-191-00 Funnel

1330-391-00 7/64 Allen Wrench

1990-924-00 VMP-19 Oil (1 liter)

0137-807-00 Kit, Cart Mounting

0137-804-00 N2 Kit

1621-224-02 Adapter, KF16 to 1/4” NPT

1621-227-05 QC Adapter, KF25 to 1 1/8”

0126-284-00 Blank Plug, 1/18

1620-731-00 Elbow, 1/4 NPT to 3/8 Tube

1750-054-00 Tubing, Tygon, 1/4”

VIC Leak Detectio

2099 Ninth Avenue

Ronkonkoma, NY 11779

631.737.0900

1109-186-00 Rev. C 1-5

5

3

2

4

7

8

9

1

INTERNAL ROTARY VANE MECHANICAL PUMP

FIGURE 1 - 2

1109-186-00 Rev. C 1-6

VIC Leak Detectio

n

2099 Ninth Avenue

Ronkonkoma, NY 11779

631.737.0900

1.3 Installation

The MS-40 has been designed as a completely self-contained portable leak

detector and therefore has the capability to work in a wide range of

environments. However, before installation in a work area, certain

requirements must be met.

• A properly grounded electrical supply (115V/60Hz/10A,

230-240V/50Hz/5A, 100V/50Hz/10A, or 100V/60Hz/10A as

labeled on rear of unit) must be available for the unit.

• A user supplied helium supply is usually necessary for the unit

(but not for all testing, e.g., sealed parts should already be pre bombed with helium). The MS-40 can use either a Mass 3 or

Mass 4 helium supply. Virtually any standard purity helium

may be used during leak testing. Depending on the type of leak

testing that will be performed, a spray probe (for vacuum

testing), a sniffer assembly (for sniff testing) or a test cup (for

pressure bombing testing) will be necessary. All of these items

are available directly from Vacuum Instrument.

• The recommended ambient temperature range for the unit is

from 10°C to 40°C. Also, excessively humid environments

should be avoided.

• Depending upon the immediate environment, an external

exhaust facility may be necessary. A bulkhead is installed on

the rear of the MS-40 that is intended for user-provided 3/8”

polyflow tubing. Note that the bulkhead is not connected to the

internal exhaust filter of the unit but must be connected by the

User. The tubing is then attached to a functional exhaust system.

WARNING!

Only qualified service personnel should operate the unit when either

the front or rear panels are open. Potentially lethal high voltages are

continually applied to the circuit boards and other areas within the

unit during its operation. Although these areas are shielded and well

marked, failure to follow this precaution may possibly lead to severe

injury or death.

1109-186-00 Rev. C 1-7

Vacuum Instrument Corp.

2099 Ninth Avenue

Ronkonkoma, NY 11779

631.737.0900

1.4 Features & Specifications

FEATURES

Sensitivity: 4 x 10

-11

std cc/sec air equivalent

Leak Rate Range: 10 to 4 x 10

-11

std cc/sec air equivalent

(with optional external pump)

10 x 10

-4

to 4 x 10

-11

std cc/sec air equivalent

(without external pump)

Start-Up: Fully functional in less than 3 minutes. Consists of:

Turbo-molecular pump acceleration, a complete set

of self-diagnostics, turning on filament, checking

and assuring Hi-Vac status, measuring system

offsets and measuring background helium

Internal Calibrator: Helium 4, 1 x 10

-8

to 3 x 10-8 std cc/sec air

equivalent with integral solenoid valve

Testable Masses: Helium Mass 3 or 4

Tuning: Automatic

Calibration: Automatic for Helium 4 using an internal calibrator

of 1 x 10

-8

to 3 x 10-8 std cc/sec air equivalent

Auto Zero: Automatic zeroing of leak rate while in test mode

initiated by pressing the ZERO pushbutton

Background Continuous automatic compensation for system back

Compensation: ground

Remote Control Molded A.B.S. plastic laminate over tactile

Unit: membrane switch array Controls similar to User

Panel

RS-232C Port: Two standard bi-directional ports. One port

dedicated to the remote control unit. The second

port is dedicated to data transfer to an external

computer or control module.

1109-186-00 Rev. C 1-8

Vacuum Instrument Corp.

Vacuum Instrument Corp.

2099 Ninth Avenue

2099 Ninth Avenue

Ronkonkoma, NY 11779

Ronkonkoma, NY 11779

631.737.0900

631.737.0900

Ranging: Without an external roughing pump, begins at the

[Automatic/Standard least sensitive gross range (10

-4

). The unit ranges

Mode] downward until a leak is detected or until it reaches

its most sensitive range (10

-10

). With the optional

external pump, if a gross leak is detected, the unit

ranges up to the appropriate decade. If a gross leak

is not detected the unit ranges downward until a leak

is detected or until it reaches its most sensitive

range.

Ranging: May operate at any range, selectable by the operator.

[Manual Mode] The 10

0

to 10-3 range is only available when the

optional external pump has been installed.

Measurement Units: Pressure: millitorr or millibar (selectable with a

switch located underneath the Service Panel accessible

when the unit’s front panel has been opened)

Leak Rate: std cc/sec (standard cubic centimeters/

second) or mbar l/sec (millibar liters/second)

PUMPS

Mechanical Pump: Internal 1.5 CFM dual stage rotary vane pump

Turbo Pump: 60 liter/second turbo-molecular pump

External Pump: Optional 7 or 16 CFM dual stage rotary vane

(Mechanical pump)

PERFORMANCE SPECIFICATIONS

Sensitivity: 4 x 10

4 x 10

-11

Std cc/sec air equivalent (direct mode)

-10

Std cc/sec air equivalent (reverse mode)

Resolution: 14 at Mass 4

Response Time: Reverse Mode < 3 seconds

Fine Mode < 2 seconds

Test Time: <2.5 seconds on a blank port to a pre-selected range

in the reverse flow test mode

1109-186-00 Rev. C 1-9

Vacuum Instrument Corp.

2099 Ninth Avenue

Ronkonkoma, NY 11779

631.737.0900

Noise & Drift: <4% on 10

-10

range

Testable Masses: 3 and 4

Maximum 10 x 10

-4

std cc/sec air equivalent (without external

Measurable Leak: pump) 10 std cc/sec air equivalent (with optional

external pump)

Maximum Inlet Gross Mode: Atm (with optional external pump)

Pressure: Reverse Mode: 7.5 Torr

Direct Mode: 100 mTorr

Test Mode Leak Gross: 10 to 1 x 10

Reverse: 10 x 10

Direct: 10 x 10

-3

std cc/sec helium

-4

to 6 x 10

-5

to 6 x 10

-11

-10

ELECTRONICS & USER INTERFACE

System Controller: Microprocessor based; four integrated boards used:

A controls the unit’s computer, logic and sensors

B

controls the unit’s mass spectrometer voltage supplies

C controls the unit’s displays and controls

D controls the unit’s handheld remote

Display: Green LED alphanumeric and bar graph

displays

Data Input: Through dedicated function keys

MISCELLANEOUS

Power Requirements: 115V, 60Hz, 10 Amp

230-240V, 50Hz, 5 Amp

100V, 50Hz, 10 Amp

100V, 60Hz, 10 Amp

Dimensions: 15.5”H x 20.5”W x 14.25”D

Weight: 84.5 lbs.

1109-186-00 Rev. C 1-10

Vacuum Instrument Corp.

2099 Ninth Avenue

Ronkonkoma, NY 11779

631.737.0900

1.5 General Description

The MS-40 is a fully automatic, dual mode, turbo-molecular pumped

portable leak detector. Each of its two modes (Reverse Flow or Direct

Flow) is automatically selected by the leak detector based on the currently

selected leak rate range.

Reverse Flow Mode permits rapid testing for leaks in test objects that are

characterized by a high degree of out-gassing. Testing can start at test port

pressures of Atm for leaks from 10 to 1 x 10

-3

std cc/sec (Gross Mode

testing) when using the optional external pump or pressures of 7.5 Torr

for leaks between 10 x 10

-4

and 6 x 10

-10

std cc/sec (Intermediate Mode

testing) for units not equipped with an external pump.

Direct Flow Mode is most useful for testing objects that demand clean

testing and higher sensitivity. In this mode, the leak detector measures

leaks from 10 x 10

-9

to 6 x 10

-11

std cc/sec, at a test port pressure of 100

millitorr or less. However, this mode is also capable of determining

larger leaks. Once the unit is in this mode and a larger leak has been

detected, the unit will range back to the appropriate decade.

The MS-40 uses two types of automatic testing: an automatic test mode

with automatic ranging and an automatic test mode with manual ranging.

In automatic ranging mode, the leak detector automatically ranges

downward (to more sensitive leak rate ranges) until a leak is found. When

using manual ranging, the operator of the leak detector controls the range

in which a particular test object is tested.

In the Automatic Test Mode, when using Automatic Ranging, all the

functions of the leak detector, including the evacuation (pump down) of

the test object and the functions of all pumps and valves are controlled by

the MS-40 computer. Additionally, all measurements and display

information about the leak rate and system performance are under the

control of the computer.

The Automatic Test Mode, when using Manual Ranging, is identical to

the Automatic Testing/Automatic Ranging mode except that the User

pre-selects the range (e.g., 10

-5

std cc/sec) for testing. If a measured leak is

either above or below the pre-selected decade, the leak detector operator

can manually range the unit either up or down. The remainder of the

testing procedure is handled by the MS-40 computer in exactly the same

manner as with the Automatic Ranging Mode.

1109-186-00 Rev. C 1-11

Vacuum Instrument Corp.

2099 Ninth Avenue

Ronkonkoma, NY 11779

631.737.0900

1.5.1 Standard Operation

This is the normal operating mode for the MS-40. During operation, the User

need only use the right (uncovered) portion of the display panel (the User

Panel is illustrated in Figure 2-1). All functions to be accessed and display

information needed to leak test an object are found on this panel. The panel

displays bar graphs indicating test port pressure and leak rate values.

Additionally, the panel indicates the current leak range mode, an accept/reject

indicator that indicates if the leak being tested is above or below the test set

point, and whether the unit is in test or standby mode. The user panel also has

toggles for automatic or manual ranging (including greater/lesser

pushbuttons), audio volume pushbuttons, an auto- zero pushbutton, a sniff

mode indicator and START and VENT pushbuttons (START is used to

commence the testing cycle as well as to interrupt the testing cycle without the

chance of accidentally venting the system, while VENT is used to interrupt

testing and/or to vent the test port).

1.5.2 Service Mode

WARNING!

The Service Mode of the MS-40 is intended for use by

qualified Vacuum Instrument personnel or Users specifically

trained by Vacuum Instrument. Under no circumstances

should any individual be assigned access to this mode

without a complete knowledge of vacuum systems as well as

the MS-40 System. Use by an unqualified operator may

result in damage to the unit and/or personal injury.

Service Mode is initiated by first opening the rear panel of the unit (loosen the

1/4-turn screw at the top of the panel, then gently lower the door), and then

pressing the black toggle button at the top right hand side of the circuit board

that is attached to the panel. Once the toggle has been pressed, the unit is

placed in Service Mode and the Service Mode indicator is illuminated.

Service Mode disables the automatic valve controls and allows the User to

manually control all of the valves within the vacuum system. The valves are

controlled by a cluster of labeled momentary switches located on the left of

the User Panel. The LED indicator on each switch is lit when the valve is

open. Included within the vacuum system are: the auto-calibrator valve,

external rough valve, fine (direct) valve, fore-line (reverse) valve, gross testing

valve, purge valve, roughing valve, sniffer valve and the vent valve.

1109-186-00 Rev. C 1-12

Grouped to the right of the Service Mode Indicator are a series of LED

indicators. The Service Mode allows the setting of the unit’s Amplifier

Gain, Anode Voltage, Calibration Temperature and Internal Calibration

Value in conjunction with the arrow buttons and LED alphanumeric

display to the right of the indicators. Additionally, the user may view the

unit’s calibration temperature, the emission current of the filament within

the unit’s spectrometer, the error code present (indicating a possible fault

within the unit), the current supplied to the filament in the

mass spectrometer, the calibration standard (e.g., 2 x 10

-8

std cc/sec @

24°C) of the internal calibrator, the leak rate of the test object (a numeric

value - the same leak rate as displayed by the bar graph on the User

Panel), the pressure measured at the test port and the total number of

hours the unit has been in operation.

Below the indicators and to the right of the valve controls are two sets of

momentary switches. In either Standard or Service Modes, they allow the

User to turn on/off the filament within the mass spectrometer, choose

between two different filaments within the spectrometer, and perform an

actual test on the calibrator or optimize the mass spectrometer. When

strictly in Service Mode, the User is also able to choose between either a

helium or air standard for leak rate measurement or choose whether the

MS-40 will measure either with Mass 3 or 4 helium.

Vacuum Instrument Corp.

2099 Ninth Avenue

Ronkonkoma, NY 11779

631.737.0900

1109-186-00 Rev. C 1-13

Operating The MS-40

2.1 Introduction

This chapter contains the information needed by the user to operate the

MS-40 Leak Detector and perform leak checks on a test object. This

chapter is grouped into three general sections:

1 Operator Controls & Indicators

2 Starting & Operating the Leak Detector

3 Testing Aids & Procedures

While this chapter contains sufficient information to operate the MS-40

leak detector, we suggest that you read Chapter 3, Theory of

Operation, prior to any actual testing. An overall understanding of

the various phases of a test cycle will help the operator use the leak

detector more effectively and efficiently.

Vacuum Instrument Corp.

2099 Ninth Avenue

Ronkonkoma, NY 11779

631.737.0900

1109-186-00 Rev. C 2-1

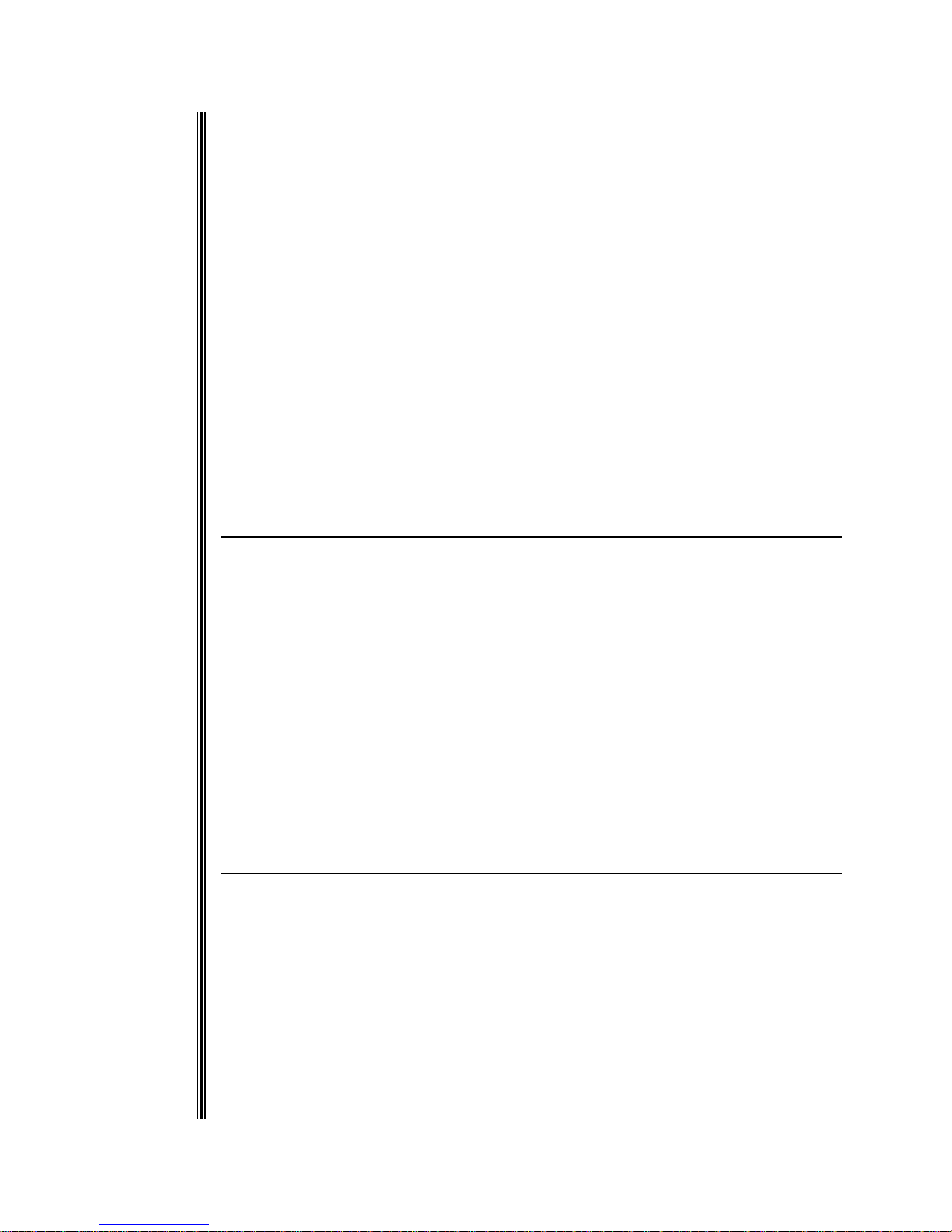

FIGURE 2 – 1

MS-40 USER PANEL

1109-186-00 Rev. C 2-2

n

2.2 Operator Controls & Indicators

The following Controls & Indicators are located on the User Panel at

the top right front of the unit. Items are listed from left to right, top to

bottom (see Figure 2-1 for an illustration of the User Panel).

LEAK RATE BAR GRAPH

An LED bar graph indicating the mantissa of the measured

leak rate of the test object. For a full leak rate reading, this

meter is used in conjunction with the Numeric Display. The

bar graph display is in standard cubic centimeters per second

or in millibar liters per second.

NUMERIC DISPLAY

A two-digit alphanumeric display with two separate functions.

During testing, the display will normally indicate the exponent

of the current leak rate. For example, if the leak rate is 3 x 10

-7

std cc/sec, the Leak Rate Bar Graph will indicate 3 while the

Numeric Display will indicate the number 7. The second

function of the display has been programmed to provide error

codes when a system fault has occurred (see Section 4.10 for a

list of error codes, their description and corrective action).

The display will indicate code EE while at the same time on

the Service Panel the Error Code indicator will be lit and the

Service Panel alphanumeric display will indicate the error

code.

TEST PORT

A bar graph that displays the pressure at the test port. Scaled

for either millitorr or millibar. The test port pressure is also

displayed in digital format on the Service Panel Alphanumeric

Display.

ACCEPT

During leak testing, this indicator will illuminate when the leak

measured is less than the programmed reject rate (or

maximum acceptable leak rate) and the unit is also in or below

the range of the reject value. The reject rate is set by the

user from the Service Panel (see Section 2.7).

VIC Leak Detectio

2099 Ninth Avenue

Ronkonkoma, NY 11779

631.737.0900

1109-186-00 Rev. C 2-3

REJECT

During leak testing, this indicator will illuminate when the leak

measured is greater than or equal to the programmed reject

rate (or maximum acceptable leak rate). The reject rate is

set by the user from the Service Panel (see Section 2.7).

READY

When lit, the unit is in standby mode (all valves except the

Fore-line valve are closed). Pressing the START pushbutton

commences a test cycle.

AUTO/MANUAL

Automatic/Manual Ranging. Prior to and during leak testing,

this momentary switch allows the user to toggle between

Automatic and Manual Ranging modes.

RANGING

While leak testing in Manual Ranging mode, each press of

either the up or down arrow buttons will cause the unit to leak

test in the decade (or range) above or below the current

decade being tested (pressing and holding either arrow button

will cause the unit to sequentially pass through one or more

decades). The numeric display (the exponent of the leak rate)

will indicate the change. Also, when leak testing in the

automatic ranging mode, pressing either arrow button will

force the unit to test in manual ranging mode, at a decade

higher or lower than the decade previously being tested

(corresponding to the arrow key pressed).

AUDIO

During actual testing and while in service mode, the audio

signal of the unit is always turned on. The arrow keys

dedicated to the Audio section of the panel control the

volume. Pressing the down arrow key several times (or

pressing and holding the down arrow key) reduces the volume

to an inaudible level. Note that this function is also available

when using the optional headphones. A connector for a set of

headphones is located under the bottom rear panel of the unit.

Vacuum Instrument Corp.

2099 Ninth Avenue

Ronkonkoma, NY 11779

631.737.0900

1109-186-00 Rev. C 2-4

C Leak Detectio

n

VacuuVIm Instrument Corp.

2099 Ninth Avenue

2099 Ninth Avenue

Ronkonkoma, NY 11779

Ronkonkoma, NY 11779

631.737.0900

631.737.0900

ZERO

In Standard Mode, The ZERO momentary switch is active

only during actual leak testing. When pressed, this unit’s

computer reduces the measured leak rate displayed by the unit.

To zero within the decade being measured (e.g., a 4 x 10

cc/sec leak rate would now be displayed as a 0 x 10

-6

std

-6

std

cc/sec leak rate). This function is usually used when

background helium causes measurement problems during

testing. Note that this function also limits the maximum

sensitivity of testing to two decades (or ranges) below the

zeroed decade.

When the unit is in Service Mode, pressing the ZERO

momentary switch will toggle the turbo-molecular pump on or

off. When the ZERO LED indicator is lit, the turbo-molecular

pump is on.

SNIFF MODE INDICATOR

When lit, the unit has been placed in the Sniff Mode. When

in Standard Mode, the unit is placed in the Sniff Mode by

pressing the SNIFF valve momentary switch located on the

left of the Service Panel. When the unit has been placed in

Service Mode, pressing the SNIFF valve momentary switch

opens the Sniffer Valve.

WARNING

Never operate the MS-40 in Sniff Mode without the optional

Sniffer Assembly or without the standard plug in place on the

Sniffer Quick Connect Fitting (QCF). Running the unit without

covering the Sniffer QCF will cause a dramatic increase in fore-line

pressure within the unit, and will thereby cause the unit’s turbo molecular pump to rapidly shut down.

START

Pressing this pushbutton begins a test cycle. During testing,

pressing the START pushbutton again will halt all testing by

closing all vacuum system valves (except the fore-line valve).

This also places the unit into its standby (wait) mode.

Pressing the START pushbutton instead of the VENT

pushbutton eliminates the chance of the user inadvertently

venting the system (refer to the VENT function, below).

The START pushbutton lights when a test cycle has been initiated.

1109-186-00 Rev. C 2-5

Vacuum Instrument Corp.

Vacuum Instrument Corp.

2099 Ninth Avenue

2099 Ninth Avenue

Ronkonkoma, NY 11779

Ronkonkoma, NY 11779

631.737.0900

631.737.0900

VENT

Dual function pushbutton. When pressed momentarily, the

MS-40 is interrupted from its current testing cycle and placed

in standby (wait) mode. The green READY indicator will

light. When pressed and held for a preprogrammed time (as

programmed by the user; factory default is 0.5 second) the

pushbutton initiates an AUTO-VENT cycle and returns the

test port to atmospheric pressure. The delay may be

programmed for up to 999.9 seconds.

ON/OFF

Turns the MS-40 ON or OFF.

The following Controls & Indicators are accessible from the Service

Panel (the left half of the panel at the top front of the unit). Items are

listed from left to right, top to bottom (see Figure 2-1 for an illustration

of the Service Panel).

SERVICE MODE INDICATOR

When lit, the MS-40 has been placed in Service Mode. The

unit is placed in Service Mode by pressing the Service Mode

Interlock button located on the upper right side of the “A” circuit

board, mounted on the inside of the unit’s rear door.

AMP GAIN

Amplifier Gain. When this function is selected, the

alphanumeric display indicates the setting of the leak rate

amplifier (1.0 to 10.0).

Five different gains are used on the unit. The first, G1,

is used for the unit’s gross flow mode; the second, G2, is

used for the unit’s reverse flow mode and the third G3, is

used for the unit’s direct flow mode. G4 and G5 are used

for sniff mode.

The five different gain settings can be displayed using

the SELECT momentary switches when the AMP GAIN

function has been selected. Gain (calibration) of

the MS-40 is changed by the SET momentary switches.

Normally G2 and G3 are set automatically by the

MS-40 during a Tune and Calibration cycle, however

the G2 and G3 settings can be manually altered in

Service Mode. The actual setting may be viewed in either

1109-186-00 Rev. C 2-6

n

Service or Standard Modes. Note that G1, G4 and G5 are not

controlled by the MS-40 and must be set by the user. G1 may

be set by the user when the MS-40 is leak testing in the Gross

Mode, or when the unit is in the service mode. G4 and G5 can

be set when the unit is in sniff testing mode.

ANODE VOLT

Anode Voltage. When this function is selected, the

alphanumeric display indicates the anode voltage of the unit.

In Service Mode, the anode voltage may be altered

incrementally by pressing either of the SET momentary

switches. Note that the other peak voltages associated with

the mass spectrometer follow the anode voltage setting;

therefore the MS-40 can be manually tuned by changing the

peak voltage.

CAUTION

Only qualified personnel should attempt to alter the anode voltage

setting while the unit is in Service Mode. As stated above, altering

the peak tuning voltages will retune the mass spectrometer. Improper

tuning will greatly effect the accuracy and reliability of the leak

detector.

While the unit is in Standard Mode, pressing either the left or

right SET momentary switches adjusts the unit’s peak tuning

voltages either -30 or +30V. This function, unique to

VIC’s MS series of leak detectors, is referred to as peak scan

and is used to quickly verify if the mass spectrometer is

properly tuned (refer to Section 2.9 for further information on

the Peak Scan function). Releasing either momentary switch

returns the anode voltage of the unit to its original value.

CAL TEMP

Calibrator Temperature. When selected in Standard Mode, the

alphanumeric display will indicate the current temperature of

the calibrator. When selected in Service Mode, the

alphanumeric display will indicate the temperature at which

the internal helium reference standard was originally

calibrated. This parameter may be altered in Service Mode

(using the SET pushbuttons), however, this setting should

not be altered unless a new calibrator is installed in the unit.

VIC Leak Detectio

2099 Ninth Avenue

Ronkonkoma, NY 11779

631.737.0900

1109-186-00 Rev. C 2-7

CROSSOVER 1

The alphanumeric display indicates the programmed test port

pressure needed to crossover from the unit’s gross testing

mode to reverse testing mode (when using the optional

external pump). If an external pump is not connected to the

unit, the crossover set point is the pressure needed to crossover

from the unit’s roughing mode to the reverse testing mode.

This parameter may be altered while the unit is in either

Standard or Service Mode, by using the SET momentary

switches.

CROSSOVER 2

The alphanumeric display indicates the programmed test port

pressure needed to crossover from the unit’s reverse testing

mode to its direct testing mode. This parameter may be

altered while the unit is in either Standard or Service Mode,

by using the SET momentary switches.

DELAY

Seven delay settings are available and may be set while the unit is in

Standard mode:

D1/Fine (Direct) Crossover Delay: The time delay after

Crossover 2 has been reached and the onset of Direct testing.

The MS-40 stays in Reverse Flow during this time. The

factory default is 1.0 second; the parameter may be set between

0.1 to 999.9 seconds. Note that if the MS-40 is set for Manual

ranging in the 10

-10

range, the unit will remain in the

roughing state for the time set in D1 after Crossover 2

has been reached.

D2/Direct Rough Valve Close Delay: When Crossover 2

has been reached, the Rough valve will remain open for

this value and will then close. The factory default is 0.1

second; the parameter may be set between 0.1 to 999.9

seconds. If D2 is set to 999.9 seconds, the Rough valve

will remain open for the entire length of the test cycle.

Vacuum Instrument Corp.

2099 Ninth Avenue

Ronkonkoma, NY 11779

631.737.0900

1109-186-00 Rev. C 2-8

Vacuum Instrument Corp.

Vacuum Instrument Corp.

2099 Ninth Avenue

2099 Ninth Avenue

Ronkonkoma, NY 11779

Ronkonkoma, NY 11779

631.737.0900

631.737.0900

D3/Vent Delay: The amount of time needed to hold the

VENT pushbutton before the venting cycle begins. The

factory default is 1.0 seconds; the parameter may be set

between 0.1 to 999.9 seconds.

D4/Vent Duration: The amount of time the vent valve

will stay open after the unit’s Pirani gauge indicates

atmosphere has been reached. The factory default is 1.0

second; the parameter may be set between 0.1 to 999.9

seconds. If D4 is set to 999.9 seconds, the Vent valve

will remain open until next test cycle is started.

D5/Minimum Gross Testing Time: May be set from 1.0

to 999.9 seconds; the factory default is 1.0 second. Sets

the minimum amount of time that the MS-40 will remain

in the Gross test mode. Prevents unit from auto ranging

and crossing over into Reverse flow mode before a gross

leak is detected. Useful when testing large parts that may

have a long helium response time.

D6/Minimum Rough Time: May be set from 1.0 to 999.9

seconds; the factory default is 1.0 second. Specifies minimum

amount of time that MS-40 will remain in Roughing state before

crossing over into a testing state. Useful for testing parts with high

gas load which require extended pumping.

D7/Reverse Rough Close Delay: May be set from 0.1 to

999.9 seconds; the factory default is 0.1 second. If set to 999.9

seconds, external Rough valve will remain open for entire

duration of reverse flow testing. Keeps external Rough valve open

for specified amount of time after reverse flow valve has opened.

Only active on units equipped with external Rough valve option.

NOTE:

In Service mode, the delay function displays:

D1: the current software version stored in flash memory (e.g.,

FLASH 4.3).

D2: the current software version stored in ROM (e.g.,

EPROM 1.5).

1109-186-00 Rev. C 2-9

n

VIC Leak Detectio

2099 Ninth Avenue

Ronkonkoma, NY 11779

631.737.0900

D3: 10

-7

range electrical offset; expressed as a fraction of a

volt (e.g., 0.00xx).

D4: 10

-10

range electrical offset; expressed as a fraction of a

volt (e.g., 0.00xx).

D5: Same as in Standard mode

D6: Same as in Standard mode

D7: Same as in Standard mode

EMISSION

Emission Current. Indicates the filament emission current.

The alphanumeric display will indicate the current in mA. A

normally operating filament will have an emission current of

5mA, as regulated by the filament control circuit.

ERROR CODE

This function automatically appears after an error has occurred

with the unit. When an error occurs, the alphanumeric display

automatically switches to this function and displays the error code.

The unit will display the code until the problem is resolved. This

Function is also selectable when using the SELECT momentary

switches on the Service Panel. If in Standard Mode, and this

function is selected when a system error has not occurred, the

word “NONE” will appear on the alphanumeric display. In

Service Mode, selecting this function will display the current date.

FIL CURRENT

Filament Current. The alphanumeric display indicates the

filament supply current, in D.C. Amps. The maximum current

is 6.3 amps.

FORE-LINE

Fore-line Pressure. The alphanumeric display indicates fore-line

pressure. May be displayed in millitorr or millibar. The

selection of units to be displayed is made by a blue toggle

switch located underneath the Service Panel. The switch is

accessed by opening the front panel and is mounted on the

circuit board located directly under the Service Panel.

1109-186-00 Rev. C 2-10

HIGH VACUUM

The alphanumeric display indicates pressure in the high vacuum section (the area surrounding the filament within the

spectrometer housing). If the unit’s filament has been turned

off, the display will state OFF, otherwise the display

indicates the high vacuum pressure in either Torr or bar. The

selection of units to be displayed is made by a blue toggle

switch located underneath the Service Panel. The switch is

accessed by opening the front panel and is mounted on the

circuit board located directly under the Service Panel. If the unit is in

Standby mode, the alphanumeric display will occasionally display

“MS-40”. When this occurs, the unit is checking system offsets and

not measuring Hi-Vac pressure.

INT CALIBRATOR

Internal Calibrator. In Service Mode the alphanumeric display

indicates the leak rate value stored in the unit’s computer for

the internal calibrator. This parameter may be altered only in

Service Mode, by using the SET momentary switches. This

parameter should only be changed when the internal calibrator

has been replaced. Note that when the unit is in Standard

Mode, this function will display the current temperature compensated value of the internal calibrator. This parameter

may not be changed, since this value is derived from the leak

rate value of the internal calibrator.

LEAK RATE

The alphanumeric display indicates the actual current leak

rate. Measurement is in either std cc/sec or millibar liter/sec.

REJECT POINT

The alphanumeric display indicates the programmed leak rate

value for the Reject/Accept indicator (the set point that

indicates if the test object is below the maximum acceptable

leak rate). This parameter may be altered only in Standard

Mode, by using the SET pushbuttons. In Service Mode, this

function is used to indicate the speed of the turbo-molecular

pump (the alphanumeric display indicates the percentage of

the pump’s rated speed).

Vacuum Instrument Corp.

2099 Ninth Avenue

Ronkonkoma, NY 11779

631.737.0900

1109-186-00 Rev. C 2-11

p

TEST PORT

Test Port Pressure. The alphanumeric display indicates the

pressure of the test port. May be displayed in millitorr or

millibar. The selection of units to be displayed is made by a

blue toggle switch located underneath the Service Panel. The

switch is accessed by opening the front panel and is mounted

on the circuit board located directly under the Service Panel.

TOTAL HRS

Total Hours. In Standard Mode, the alphanumeric display

indicates the total number of hours the unit has been in

operation. In Service Mode, the display indicates the time of

day. The time (a 24 hour clock) can be altered by using the

SET arrow keys (to select hrs, min. and sec.) and the AUDIO

arrow keys to set the new time for the unit.

SELECT

Up/Down Arrow Keys. Momentary switches that allow the

user to scroll through the sixteen functions located on the

Service Panel. The LED next to each function indicates the

function that has been selected. The selected function’s

readout is displayed on the alphanumeric display.

ALPHANUMERIC DISPLAY

Eight character display. Used to indicate messages as well as

the status of the sixteen selectable functions on the Service

Panel (from AMP GAIN to TOTAL HRS). An LED next to

the function indicates that the function has been selected,

while this display indicates its current status or measurement.

The display also indicates Error Message Codes (see Section

4.x for a list of Error Codes).

SET

Up/Down Arrow Keys. Momentary switches that allow the

user to increase or decrease the value of the settable

functions (AMP GAIN, ANODE VOLTAGE, CAL TEMP,

CROSSOVER 1, CROSSOVER 2, DELAY, INT

CALIBRATOR and REJECT POINT).

Vacuum Instrument Cor

Vacuum Instrument Corp.

2099 Ninth Avenue

2099 Ninth Avenue

Ronkonkoma, NY 11779

Ronkonkoma, NY 11779

631.737.0900

631.737.0900

.

1109-186-00 Rev. C 2-12

n

FIL ON/OFF

Filament ON/OFF. Momentary switch. When the unit is in

Service Mode, pressing this switch will toggle the active

filament on or off.

When the unit is in Standard Mode, this switch also toggles

the active filament on or off. However, whenever the unit is

in Standard Mode, the filament may be turned on only when

the high-vacuum section has been sufficiently evacuated (as

determined by the MS-40’s computer).

CAUTION

As described above, in Service Mode, the spectrometer’s filament

may be turned on or off at any time. In this mode, care should be

taken to make sure that the high-vacuum section has been

pumped down. If the filament is turned on when the highvacuum section is at or near atmosphere, the filament will

quickly burn out.

FIL 1/2

Filament 1 or 2.Momentary Switch. By pressing this switch,

the user can toggle between Filament 1 and 2. A green indicator

next to the 1 or 2 on this switch indicates that the respective

filament is working properly. If a red LED appears next to the

1 or 2 on the switch, the filament is malfunctioning.

HELIUM/AIR

Momentary Switch. Not active in Standard Mode. By

pressing this switch in Service Mode, the user can toggle

between air-equivalent and helium leak rate readings.

The LED next to the HELIUM or AIR labels indicates which

standard is active.

MASS 3/4

Momentary Switch. Not active in Standard Mode. By

pressing this switch in Service Mode, the user can toggle

between Mass 3 or Mass 4 helium tuning voltages. The

LED next to the 3 or 4 indicates whether Mass 3 or Mass 4

is selected.

VIC Leak Detectio

2099 Ninth Avenue

Ronkonkoma, NY 11779

631.737.0900

1109-186-00 Rev. C 2-13

Loading...

Loading...