Veeco MPS-3000 CE Technical Manual

MPS-3000 CE

Power Supply

Technical Manual

425964

MPS-3000 CE

Power Supply

Technical Manual

© 2003 Veeco Instruments Inc. All rights reserved.

Veeco Instruments Inc.

2330 E. Prospect Road, Ft. Collins, CO 80525

970.221.1807

The information contained in this document is believed to be accurate and reliable. However, Veeco Instruments Inc. cannot accept

any financial or other responsibilities that may result from the use of this information. No warranties are granted or extended by this

document.

It is the policy of Veeco Instruments Inc. to improve products as new technology, components and materials become available. Veeco

Instruments, Inc. therefore reserves the right to change specifications without prior notice.

This manual is intended for qualified personnel who are responsible for servicing and or running Veeco Instruments Inc. ion beam

processing systems and equipment. The information contained in this manual is the sole property of Veeco Instruments Inc. and may

not be reproduced, distributed, or transmitted in any form without the written permission of Veeco Instruments Inc.

Manual #425964 Rev.E

Table of Contents

Safety 1

Overview 4

Installation 6

Controls 8

Manual Operation 23

Local Operation 42

Other Modes of Operation 45

Serial Communications 46

Maintenance 65

Troubleshooting/Error Code Definitions 69

Service Support 73

Specifications 74

Tables 83

Environmental Safety 84

Drawings 85

Filament Cathode with Filament Neutralizer or PBN Option 86

Hollow Cathode and HCN - 7 pin or 2 x 4 pin feedthrough 87

Hollow Cathode and Hollow Cathode Neut - 6 pin feedthrough 88

Filament Cathode with Filament Neutralizer or PBN Option 89

3cm Source Filament Cathode and Filament Neutralizer 90

3cm Source Hollow Cathode and Hollow Cathode Neutralizer 91

3cm Source Plasma Bridge Neutralizer 92

Chapter 1: Safety

DANGER

WARNING

CAUTION

Understanding the correct installation, operation, and maintenance procedure is necessary for safe and successful operation. This safety alert symbol

precedes safety messages in this manual, along with one of the three signal

words explained below. Obey the messages that follow these words to

avoid possible injury or death.

This symbol marks an imminent hazard which will kill or injure if ignored.

This symbol marks a potential hazard which may kill or injure if ignored.

This symbol marks a potential hazard which may cause minor injury if

ignored.

CAUTION

This symbol marks a potential hazard which may cause damage if ignored.

Symbols Used on the Unit

Refer to manual

Designates a chassis ground

Designates a protective earth grounding point

1

Dangerous voltage

WARNING

WARNING

WARNING

Unit in standby - power outputs deactivated

Unit on - power outputs active

Unit off - power off

Please read the following before continuing:

To avoid electrical shock, keep clear of “live” circuits. Follow all local lockout/tag-out procedures, before repairing or replacing any electrical

devices.

It is recommended that only trained, qualified persons using established

safety procedures perform any work related to the installation, start-up,

operation or maintenance of this system.

To avoid electrical shock, check that all hardware interlocks are working.

Keep all guards and panels in place during routine system operation.

Complete ion beam systems from Veeco Instruments Inc. are supplied with

hardware interlocks and software safeguards at various points in the system. Whenever components or retrofits are added to existing systems, a

local review of system safety is recommended.

To avoid safety feature impairment and possible injury, the operator must

use this equipment in the manner specified by Veeco Instruments Inc.

The CE I/O Signal Isolation Sub-chassis, attached to the MPS-3000 CE

power supply rear panel, incorporates the isolation circuitry for the user

accessible EIA-232 and system interlock circuits. The integral I/O signal

2

isolation circuit incorporates optical transmitters and photo detectors,

which are coupled together by fiber optic cables. This configuration ensures

that the user accessible EIA-232 and system interlock circuits remain at

Safety Extra Low Voltage (SELV) under normal and single fault conditions.

The customer side supply (+5V DC) is generated from an integral isolating

type DC/DC inverter that inverts the ELV +15V DC supply to the required

SELV +5V DC supply.

3

Chapter 2: Overview

The MPS-3000 CE power supply system is specifically designed and optimized to power and control Veeco ion beam sources.

• The built-in microprocessor provides reliability and flexibility to

the user. The microprocessor automatically checks each of the

power supplies each time the system is turned on.

• When an unsatisfactory condition occurs, an error code

appears on the power supply display. Refer to “Troubleshoot-

ing/Error Code Definitions” on page 69 to determine the

cause and remedy to the problem.

• Programmable limits on the power supplies allow the users to

adjust the system. On the neutralizer power supply, the filament current limit might be adjusted up or down as required,

depending upon the size and type of filament wire used.

• Operate in Manual, Local, Local Restricted, or Remote mode.

Manual Mode

Each of the individual power supplies is controlled from the front panel.

Recall or store complete operating conditions from one of two nonvolatile

memories.

Use these steps to change a parameter:

1. Select a power supply with the MODULE select switch.

2. Select a parameter with the FUNCTION select switch.

3. Turn the Adjust knob to reach the chosen value.

Local Mode

Beam voltage, beam current, and accelerator voltage are adjustable from

the front panel when operating in Local mode. Recall or store two complete

sets of operating conditions from the two nonvolatile memories.

Local Restricted Mode

No adjustments may be made to any parameters from the front panel.

Recall operating conditions from the memory.

4

Operating conditions may not be stored in the memory when operating in

NOTE

Local Restricted mode.

Remote Mode

No adjustments may be made to any parameter from the front panel.

Operating conditions may not be stored from the front panel and conditions may not be recalled from the memory when operating in Remote

mode.

By using an EIA-232

1

interface, a computer may control power supplies

and may recall conditions from memory.

•The MEMORY, MODULE, and FUNCTION select switches are

nonfunctional in Remote mode.

•The SOURCE and BEAM switches may be turned off, but may

not be turned on at the front panel.

•The KEYLOCK switch may “lock” the power supply into any of

the modes.

• When in the Disable position, the mode may not be changed.

1. Formerly known as, and identical to RS-232. The EU equivalent is

CCITT V.24

5

WARNING

CAUTION

WARNING

Chapter 3: Installation

To avoid electrical shock, keep clear of “live” circuits. Follow all local lockout/tag-out procedures before installing any electrical devices.

Single Power Supply System Assembly

The MPS-3000 CE power supply is designed for rack mount. It is shipped

with the rack mount brackets attached.

1. Install the unit in the chosen location.

If cabinet installation is chosen, use the four holes in the rack mount

brackets to attach the unit to a cabinet.

Do not obstruct the cooling ports on the MPS-3000 CE power supply. An

insufficient supply of cooling air will result in the unit overheating, causing

a thermal shutdown and possible damage.

The power supply’s cooling air ports are located in the sides of the

chassis, and the cooling fan port is located in the rear panel of the

chassis.

2. Connect the following:

a. The source/beam cable to the source/beam connector (P33)

located on the unit’s back panel.

b. The neutralizer cable to the neutralizer connector (P32) located on

the unit’s back panel.

c. The interlock cable to the interlock connector (DB9) located on the

unit’s back panel.

d. The source/beam cable to the ion beam source (refer to “Draw-

ings” on page 85).

e. The neutralizer cable to the ion beam source (refer to “Drawings”

on page 85).

The shield in the source cable must be attached to facility ground with a

low impedance connection. If the cable is not attached correctly, the power

supply and facility may float at high voltages.

3. Connect the wires attached to pins 1 and 6 on the interlock cable to

the series-connected external interlock circuitry.

6

The external interlock conditions are met when all series switches are

NOTE

NOTE

closed. The number and type of interlock switches differ from system to system.

Use only dry closure (relay) contacts in the interlock circuit.Interlock wiring should have a minimum insulation rating of 100V DC per lead;

these leads should be shielded, with a drain wire attached to a metallic

connector shell. An insulating sheath covering the leads, shield and

drain wire shall have a minimum insulation rating of 300V DC.

Do not connect the external interlock circuit to a powered circuit.

CAUTION

4. Verify that the POWER ON/OFF switch (on the power supply front) is in

the STANDBY position and that the CB1 circuit breaker (on the power

supply rear panel) is in the OFF position.

5. Connect the unit’s line cord to an appropriate power source. See

“Specifications” on page 74.

• If connecting to a three-wire power service with two hot lines

and facility ground, the power cord is wired as follows:

Service Power Supply

Hot Blue (White)

Hot Brown (Black)

Ground Green/Yellow

• If connecting to a three-wire power service with one hot line, a

neutral line, and earth, the power cord is wired as follows:

Service Power Supply

Hot Brown (Black)

Neutral Blue (White)

It is the user’s responsibility to meet all local and national electrical codes

when installing this equipment.

6. Turn the CB1 circuit breaker on the power supply’s rear panel to the

This completes installation of a single power supply.

Earth Green/ Yellow

ON position.

• If the unit interfaces with an external microprocessor, refer to

“Serial Communications” on page 46, for correct installation.

7

Chapter 4: Controls

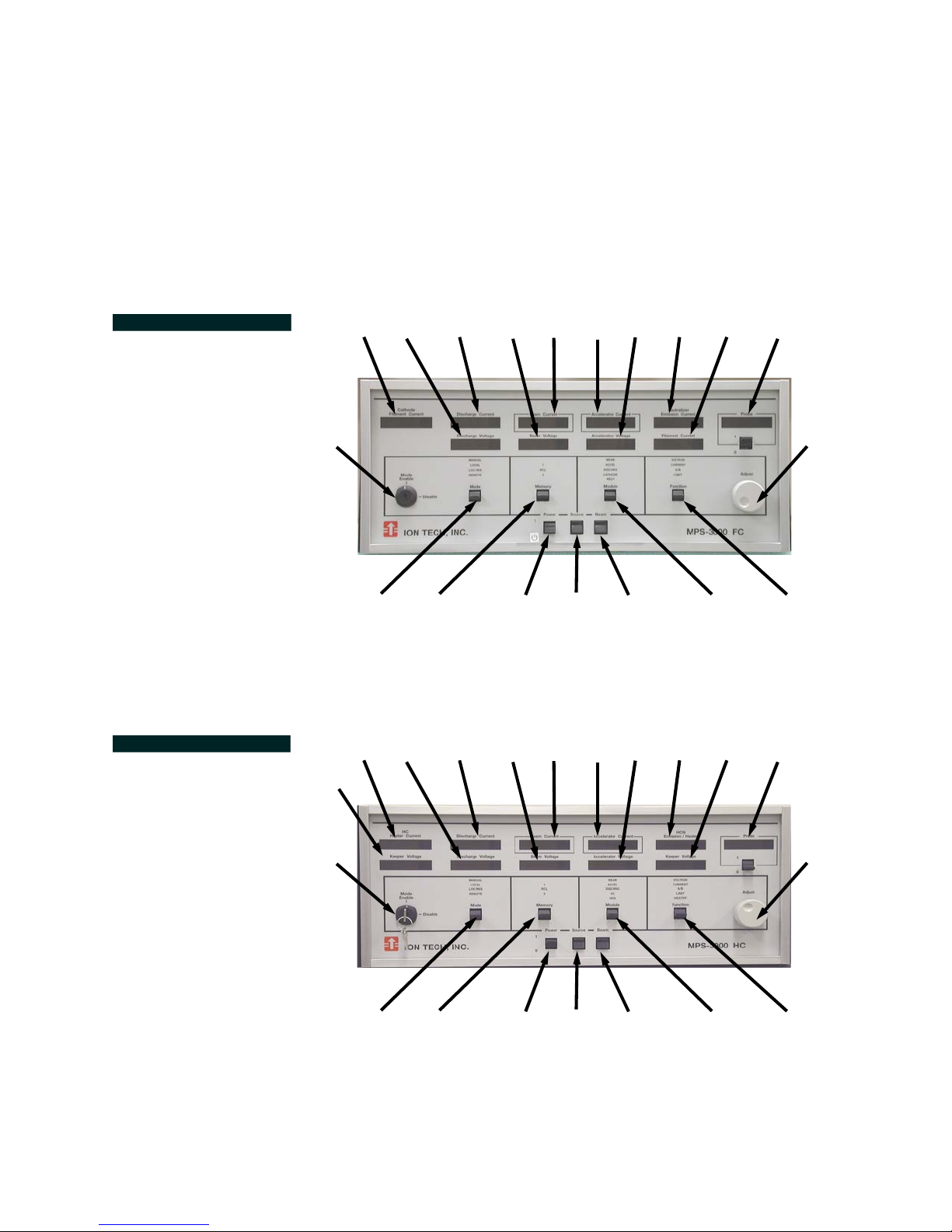

The numbers in FIGURE 4.1 through FIGURE 4.3 will appear throughout to

identify the power supply’s controls as their use and function is referenced.

FIGURE 4.1 Front

Panel: MPS-3000 CE FC

FIGURE 4.2 Front

Panel: MPS-3000 CE HC

4

21

10

20

12

11

14

13 15

16

17

18

19

9

5

12

6

11

14

1

13 15

2

3

16

22

7

23

8

19

4

5

6

1

2

3

7

9

8

8

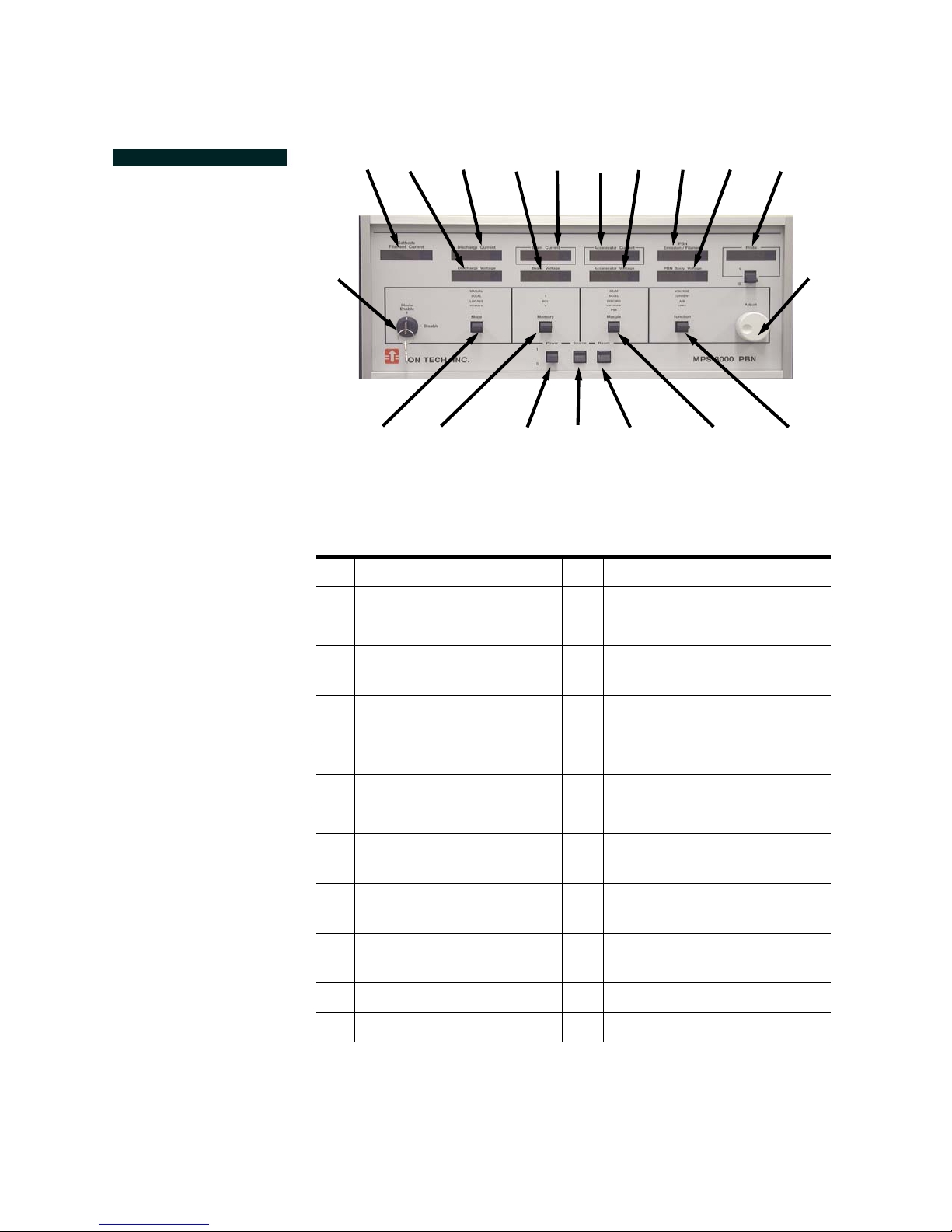

FIGURE 4.3 Front

Panel: MPS-3000 CE

PBN

10

12

11

14

13 15

16

24

25

4

5

6

1

2

3

7

19

9

8

Table 4.1: MPS-3000 CE FC/HC/PBN Front Panel Keys and Switches

1 Power On/Standby 14 Beam Voltage Display

2 Source On/Off 15 Accelerator Current Display

3 Beam On/Off 16 Accelerator Voltage Display

4Keylock 17

5Mode 18

Neutralizer Emission Current

Display

Neutralizer Filament Current

Display

6 Memory 19 Not used

7 Module 20 HC Heater Current Display

8 Function 21 HC Keeper Voltage Display

9Adjust 22

Cathode Filament Current

10

Display

11 Discharge Current Display 24

HCN Emission/Heater Current Display

23 HCN Keeper Voltage Display

PBN Emission/Filament Current Display

12 Discharge Voltage Display 25 PBN Body Voltage Display

13 Beam Current Display

9

Power - On/Standby (1)

The POWER switch controls the AC power to the unit and is controllable in

all modes of operation. When the POWER switch is turned on, the following

occurs:

• Power is applied to the controller board and to all the displays

on the display board. The test program is initiated.

• After about six seconds the main contactor is energized. Each

power supply is checked. The letter “P” will appear on the

upper display of that power supply.

Source - On/Off (2)

The SOURCE switch applies power from the Cathode, Discharge, and

Neutralizer power supplies to the appropriate pins of the neutralizer connectors (P33 and P32), located on the power supply’s rear panel.

• The word SOURCE appears above the switch indicating the

SOURCE switch has been selected.

•The SOURCE switch may be turned off in any mode.

• While in Remote mode, the SOURCE switch may be turned on

through the remote device.

• In any other mode, the SOURCE switch may be controlled

from the front panel.

Beam - On/Off (3)

The BEAM switch applies power from the Beam and Accelerator power supplies to the appropriate pins of the source connector (P33) located on the

power supply’s rear panel.

• The word BEAM appears above the switch indicating the

BEAM switch has been selected.

• While in Manual, Local, and Local Restricted modes, the beam

may be turned on only if the source is already on.

•The BEAM switch may be turned off in any mode.

• While in Remote mode, the BEAM switch may be turned on

through the remote device.

• In any other mode, the BEAM switch may be controlled from

the front panel.

10

Keylock (4)

The KEYLOCK switch enables or disables the MODE switch.

• In the disable position, the MODE switch will not function, and

the active mode will be locked in.

•The KEYLOCK switch must be in the enable position to change

the mode of operation.

Mode (5)

The MODE switch selects the power supply’s operation mode.

•The KEYLOCK switch must be in the Enable position to change

from one mode to another.

Manual

All parameters, except beam current, may be adjusted from the front

panel.

• Operating conditions may be stored or recalled from memory.

• All switches on the front panel are active in this mode.

• The word MANUAL appears indicating that Manual mode has

been selected.

Local

Only the following parameters may be adjusted: beam voltage, beam

current, accelerator voltage, and A/B Ratio when in Local mode. All

remaining parameters may not be changed from the front panel.

• The micro-processor controls the non-adjustable parameters

to obtain the programmed values.

• Operating conditions may be stored in or recalled from memory.

• All the front panel switches are active in this mode.

• The word LOCAL appears above the MODE switch indicating

that Local mode has been selected.

Local Restricted

No parameter may be adjusted in this mode. However, parameters may

be recalled from memory.

• The enunciators above the FUNCTION and MODULE

switches will be dark when in Local Restricted mode.

• The letters LOC RES appear above the MODE switch.

• All switches, except the FUNCTION and MODULE switches,

are active in this mode.

11

Remote

Allows the unit to be controlled by a computer. The computer may

select the Remote mode, recall conditions from either memory, and turn

the SOURCE and BEAM switches on or off.

• All adjustable parameters may be changed through the remote

microprocessor.

• In Remote mode, the SOURCE and BEAM switches may be

turned off but may not be turned on at the front panel.

•The KEYLOCK, MODE, and POWER switches are fully functional, while the MEMORY, MODULE, and FUNCTION

switches are not functional.

• The word REMOTE appears above the MODE switch indicating that Remote mode has been selected.

Memory (6)

Selects one of the two sets of parameters that are stored in memory. The

MEMORY switch is active in all modes, except Remote.

MEM 1

When the number 1 appears above the MEMORY switch, the power

supply will operate from memory location one. When any parameter is

changed, the new value will be stored automatically in MEMORY 1.

MEM 2

When the number 2 appears above the MEMORY switch, the power

supply will operate from memory location two. When any parameter is

changed, the new value will be stored automatically in MEMORY 2.

RCL

When Recall has been selected, the parameters will be displayed from

the memory location not being used. While the parameters are being

recalled from a memory location, the letters RCL appear above the

MEMORY switch. After about four seconds, the displays will return to

their previous readings. The running conditions will not be affected by

selecting Recall.

12

Module (7)

NOTE

Selects the power supply that may have changes made to its parameters.

The MODULE switch is active in Manual or Local mode only. In Local

Restricted or Remote mode, the enunciators above the MODULE switch will

be dark.

Beam

The word BEAM appears above the MODULE switch indicating that

Beam power supply has been selected.

• Beam voltage may be adjusted in Manual, Local or Remote

mode.

• Beam current may be adjusted in Local or remote mode.

Accel

The letters ACCEL appear above the MODULE switch indicating that

Accelerator power supply has been selected.

• The accelerator voltage may be adjusted in Manual, Local or

Remote mode.

• The A/B Ratio may be adjusted in Manual, Local, or Remote

mode.

Discharge

The letters DISCHRG appear above the MODULE switch indicating that

Discharge power supply has been selected.

• MPS-3000 CE FC, PBN, and HC: The discharge current limit

may be selected and adjusted in Manual or Remote mode.

• MPS-3000 CE FC and PBN: The discharge voltage may be

selected and adjusted in Manual mode or may be adjusted

through a remote microprocessor.

• MPS-3000 CE HC: The discharge current may be selected

and adjusted only in Manual mode.

Cathode

The Cathode power supply is part of the MPS-3000 CE FC and PBN.

• The word CATHODE appears above the MODULE switch indicating that Cathode power supply has been selected.

• Cathode filament current and current limit are adjustable in

Manual mode and through a computer.

The filament current may not be adjusted above the programmed current

limit value, and the limit value may not be adjusted below the target filament current.

13

HC

NOTE

The HC power supply is part of the MPS-3000 CE HC.

• The letters HC appear above the MODULE switch indicating

that Hollow Cathode power supply has been selected.

• The hollow cathode keeper voltage limit is the only adjustable

parameter on the Hollow Cathode power supply.

• The keeper voltage limit may be adjusted in Manual mode or

through a remote microprocessor.

NEUT

The Neutralizer power supply is part of the MPS-3000 CE FC.

• The letters NEUT appear above the MODULE switch indicating

that Neutralizer power supply has been selected.

• Neutralizer filament current and current limit are adjustable in

Manual mode and through a computer.

HCN

The HCN power supply is part of the MPS-3000 CE HC.

• The letters HCN appear above the MODULE switch indicating

that Hollow Cathode Neutralizer power supply has been

selected.

• The heater current may be viewed by selecting HEATER with

the FUNCTION switch in Manual or Local mode.

PBN

The PBN power supply is part of the MPS-3000 CE PBN

• The letters PBN appear above the MODULE switch indicating

that PBN power supply has been selected.

• The PBN filament limit may be adjusted either in Manual mode

or through a remote computer.

• The emission current may be adjusted only in Manual mode.

• The PBN filament current may be viewed in Manual or Local

mode by selecting LIMIT with the FUNCTION switch.

Do not adjust the filament current limit below the actual filament current.

14

Function (8)

Selects the parameter to adjust.

•The FUNCTION switch is active only in Manual or Local

mode. The enunciators above the FUNCTION switch will be

blank when in Local Restricted or Remote mode.

Voltage

For an MPS-3000 CE FC power supply, voltage is adjustable for the

Beam, Accelerator, or Discharge power supply. The word VOLTAGE

appear above the FUNCTION switch.

For an MPS-3000 CE HC power supply, voltage is adjustable for the

Beam and Accelerator power supplies only. The word VOLTAGE

appears above the FUNCTION switch.

Current

MPS-3000 CE FC: The current is adjustable only when the Neutralizer

or Cathode power supply has been selected.

MPS-3000 CE HC: The current is adjustable only when the Hollow

Cathode Neutralizer or Discharge power supply has been selected.

MPS-3000 CE PBN: The current is adjustable only when the Cathode

or PBN power supply has been selected.

The beam current may be selected when operating in Local mode. The

word CURRENT appears above the FUNCTION switch indicating that

beam current has been selected.

A/B Ratio

The A/B Ratio may be adjusted only when the Accelerator power supply

has been selected when operating in Manual or Local mode.

• The letters A/B appear above the FUNCTION switch indicating that A/B Ratio has been selected. The A/B Ratio may also

be adjusted through a computer.

Limit

MPS-3000 CE FC, HC, or PBN: The limit is adjustable, when the Cathode, Neutralizer or Discharge power supply has been selected.

• The word LIMIT appears above the FUNCTION switch. Limits

may be adjusted in Manual mode or through a computer.

MPS-3000 CE PBN: The PBN filament current may be viewed when in

Local mode. Select PBN and LIMIT with the MODULE and FUNCTION

switches.

Heater

The letters HCN appear above the module switch indicating that Hollow Cathode Neutralizer has been selected. The word HEATER appears

above the FUNCTION switch.

15

Adjust Knob (9)

The Adjust knob is used to change the value of a selected parameter.

• Turning the knob clockwise increases the parameter value.

• Turning the knob counterclockwise decreases the parameter

value.

If the selected power supply is off, the target parameter will be changed by

turning the Adjust knob, and changes may be viewed on the appropriate

display.

• When the selected power supply is operating and the Adjust

knob is turned, the target parameter will be changed, but the

power supply will react to the new parameter immediately.

• Target parameters are displayed while the knob is being

turned.

• Actual values are displayed when the knob is not being turned.

• Anytime the knob is turned, the new value is stored automatically in the selected memory.

Cathode Filament Current Display (10)

Indicates the amount of current supplied from the Cathode power supply

for heating the cathode filament.

Discharge Current Display (11)

Displays the amount of electron current collected by the ion source anode.

Discharge Voltage Display (12)

Displays the amount of voltage (positive with respect to the cathode)

applied to the ion source anode.

Beam Current Display (13)

Displays the amount of ion current being extracted from the ion source.

Beam Voltage Display (14)

Displays the amount of voltage (positive with respect to facility ground)

applied to the ion source.

Accelerator Current Display (15)

Indicates the amount of current being collected by the accelerator (downstream) extraction grid.

16

Accelerator Voltage Display (16)

Indicates the amount of voltage (negative with respect to facility ground)

applied to the accelerator (downstream) extraction grid.

Neutralizer Emission Current Display (17)

Indicates the amount of electron emission current being supplied by the

neutralizer power supply into the ion beam.

Neutralizer Filament Current Display (18)

Indicates the amount of current being supplied by the neutralizer power

supply for heating of the neutralizer filament.

Probe (19)

This feature is not active at this time.

HC Heater Current Display (20)

Indicates the amount of current provided by the Hollow Cathode power

supply for heating the internal hollow cathode.

HC Keeper Voltage Display (21)

Indicates the amount of keeper voltage necessary for the operation of the

internal hollow cathode or shows the setting of the keeper voltage limit.

• When the letters HC is selected on the MODULE switch and

LIMIT is selected on the FUNCTION switch, the keeper voltage

limit will be displayed.

HCN Emission / Heater Current Display (22)

Indicates the emission current or heater current parameters. The display will

show emission current unless HEATER is selected by the FUNCTION switch.

• The emission current indicates the amount of current being

provided by the Hollow Cathode Neutralizer power supply to

neutralize the ion beam.

• The heater current display indicates the amount of current provided by the Hollow Cathode Neutralizer power supply for

heating the internal hollow cathode neutralizer.

HCN Keeper Voltage Display (23)

17

Indicates the amount of keeper voltage necessary for the operation of the

internal hollow cathode neutralizer or shows the setting of the keeper voltage limit.

• When HCN is selected on the MODULE switch and LIMIT is

selected on the FUNCTION switch, the keeper voltage limit is

displayed.

• When HCN is the module selection and LIMIT has not been

selected with the MODULE switch, the actual keeper voltage

will be displayed.

PBN Emission / Filament Current Display (24)

Indicates one of two parameters: emission current or filament current. The

display will show emission current unless PBN and LIMIT have been

selected by the MODULE and FUNCTION switches.

• The emission current indicates the amount of current being

provided by the Plasma Bridge Neutralizer power supply to

neutralize the ion beam.

• The filament current display shows the amount of current

being provided to heat the PBN filament.

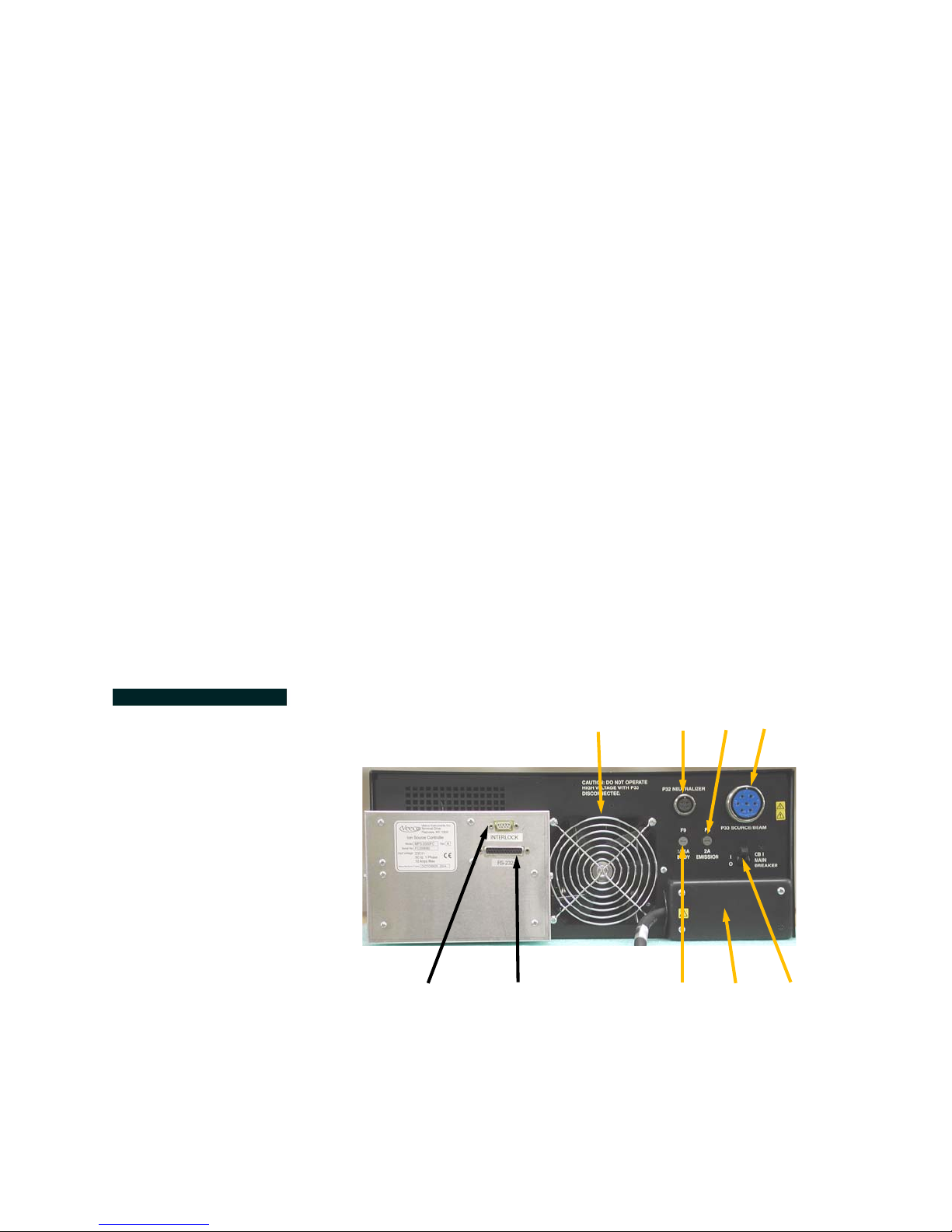

FIGURE 4.4 Rear

Panel: MPS-3000 CE

PBN Body Voltage Display (25)

Indicates the voltage difference between the body and filament on a PBN.

9

6

8

7

5

23

1

4

18

Table 4.2: Power Supply Rear Panel

1Power Line Input

2 Source/Beam Connector (P33)

3 Neutralizer Connector (P32)

4 Circuit Breaker (CB1)

5Body Fuse (F9)

6 Cooling Fan

7 EIA-232 Interface Connector (DB25)

8Interlock Connector (DB9)

9 Emission Fuse (F8)

Power Input (1)

The cable provides power attachment between the power supply and the

facility mains.

Source/Beam Connector (P33) (2)

Output connector for the Cathode, Discharge, Beam, and Accelerator

power supplies and the source cable.

Neutralizer Connector (P32) (3)

Output connector for the Neutralizer power supply and the neutralizer

cable.

Circuit Breaker (CB1) (4)

Primary circuit breaker for the input power.

Body Fuse (F9) (5)

This fuse protects circuitry from positive high-voltage-to-ground shorts.

Cooling Fan (6)

Circulates air through the entire chassis of the power supply.

EIA-232 (RS-232) Interface Connector (DB25) (7)

Connector for interfacing with an external computer.

19

Interlock Connector (DB9) (8)

Output cable connection of the external interlock circuit.

Emission Fuse (F8) (9)

Protects the neutralizer emission circuitry.

Controller Board Switch Definitions

The power supply is designed to allow the user to select several different

operating options. The options are selected and programmed into the

power supply by the appropriate positioning of switches located on the

controller board. To change switch settings refer to “Replacing the

Switches” on page 68.

• The on position indicates that the switch is towards the top of

the board.

• The off position indicates that the switch is towards the bottom

of the board.

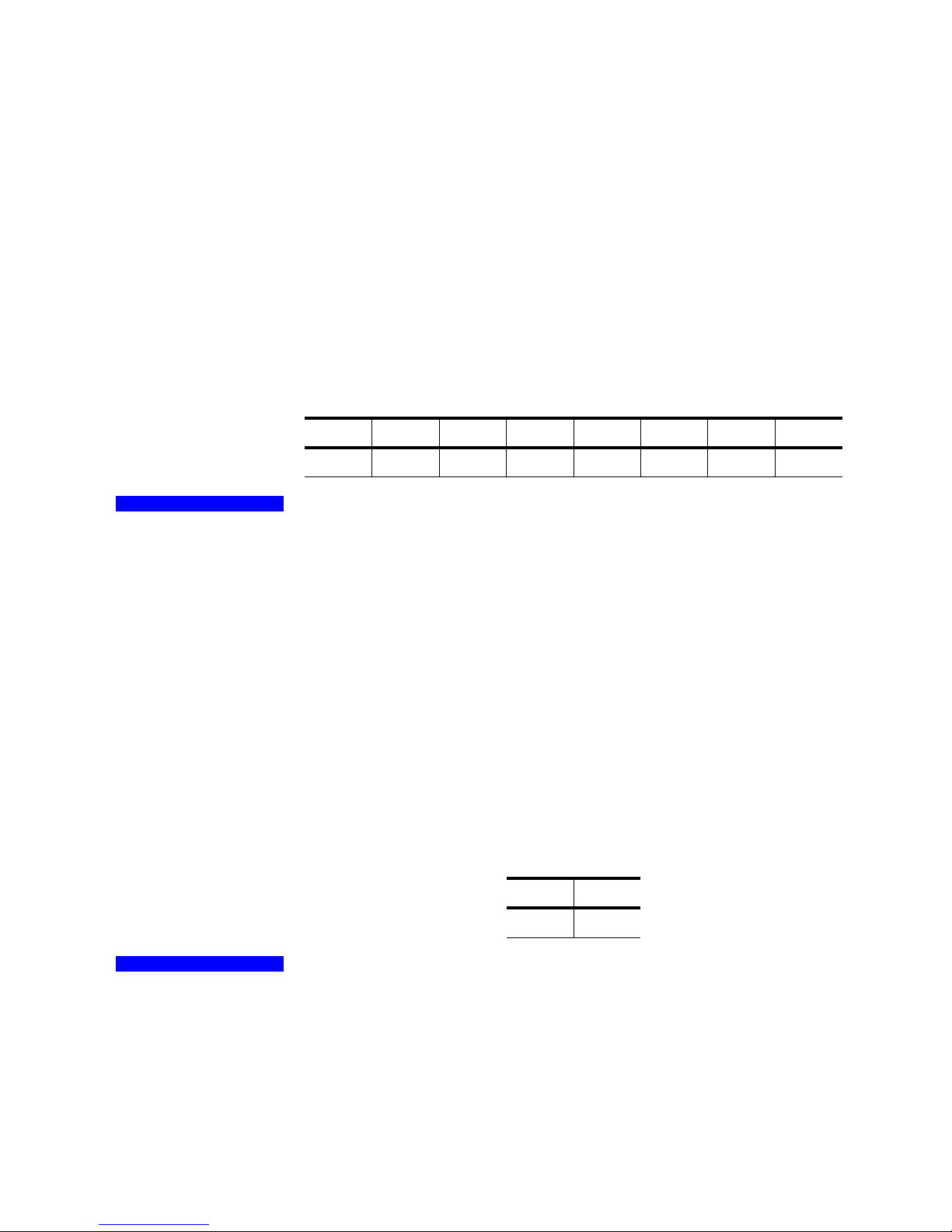

Switch Settings for Switch Bank #1

SW1-1:

For factory use only. Do not change the positions of this switch.

SW1-2, SW1-3:

Power supply identifier. Selects a number for identification of a power

supply through the computer. When more than one power supply is

part of a computer-controlled system, each power supply may be

assigned a different identification number.

ID # SW 1-2 SW 1-3

1OnOn

2OnOff

3OffOn

4OffOff

SW1-4:

Neutralizer Fault Switch

MPS-3000 CE FC

20

On - In the on position, the Discharge power supply will turn on

NOTE

without a neutralizer filament current present. The purpose of this

switch is to allow operation of an ion source without a neutralizer

current. Request zero neutralizer filament current when the Neutralizer Fault Switch is in the on position.

Off - In the off position, the discharge, beam, and accelerator outputs will be held low until the neutralizer filament current is within

0.5A of the target value and the cathode current is greater than

0.75A. Start-up of the ion source will not be possible if the neutral-

izer filament is open; the outputs of all power supplies will be shutdown if the filament fails during ion source operation. When an

open filament is detected, an intermittent audio alarm will sound,

an E23 error message appears on the Neutralizer Filament Current

display, and all other displays will be dark. The SOURCE and

BEAM switches will be inoperative until the neutralizer fault has

been corrected and the power has been cycled.

MPS-3000 CE HC and PBN

On - In the on position, the entire neutralizer supply is kept off.

Off - In the off position, the requested emission current is compared to the beam current. In Local, Local Restricted, or Remote

mode, the emission current will automatically track the beam current, with the emission being 125% or 200% of the beam current. If

the emission current is below 100% of the beam current, an E24

error message appears on the HCN Emission/Heater display, an

audio alarm will sound (if enabled), and the BEAM switch will be

turned off.

SW1-5, SW1-6:

Selects the baud rate. Baud rate represents the speed that the power

supply will communicate to an external computer through an EIA-232

interface.

Baud Rate SW 1- 5 SW 1- 6

9600 On Off

4800 Off On

2400 On On

1200 Off Off

The baud rate is factory preset to 9600 bps.

SW1-7:

Selects the emission-current-to-beam-current ratio in Local or Remote

mode.

21

On - In the on position, the emission current will track the beam cur-

NOTE

NOTE

rent at 200%.

Off - In the off position, the emission current will track the beam current

at 125%.

SW1-8:

On - In the on position, the front panel will remain locked following a

power cycle if it was locked with the serial communication command

NK1.

Off - In the off position. The front panel will be unlocked following a

power cycle.

Table 4.3: Factory Switch Settings For Switch Bank #1

SW1SW2SW3SW4SW5SW6SW7SW8

Off Off Off Off On Off Off Off

All switches will be factory-set. The SW1-1 switch is for factory use only and

should never be changed.

Switch Settings for Switch Bank #2

SW2-1:

Not used.

SW2-2:

Controller Board Alarm Switch

On - In the on position, the controller board alarm will sound when a

Fatal error has been detected and will sound at power-up of the unit.

Off - In the off position, the controller board alarm will not sound when

a Fatal error has been detected or at unit power-up.

Table 4.4: Factory Switch Settings For Switch Bank #2

SW1 SW2

Off On

All switches will be factory-set. The SW1-1 switch is for factory use only

should never be changed.

22

Chapter 5: Manual Operation

NOTE

MPS-3000 CE FC

Before beginning FC power supply operation, check the following:

• The appropriate ion beam source has been properly installed

in the vacuum system.

-2

• The vacuum system pressure is 4 x 10

lower.

• Sufficient gas flow is being introduced into the ion beam

source for appropriate operation.

Refer to the ion source’s technical manual for installation and operation

information.

FC Start-up

Pa (3 x 10-4 Torr) or

1. the facility mains breaker and Turn the unit’s POWER switch (on the

power supply front) to the on position.

a. The fan will start.

b. Random displays will appear, and the audio alarm will sound. This

condition will last about one second.

The controller will self-test each of the power supplies (from right to

left). A power supply has been tested when the letter P appears in

the top display.

c. A click will be heard when the main contactor energizes after about

six seconds.

d. The unit is ready to operate an ion source after each power supply

has been tested.

2. Follow these steps to operate the power supply in Manual Mode:

a. Turn the KEYLOCK switch to the Mode Enable position.

b. Select Manual using the MODE switch. The word MANUAL

appears above the switch indicating that Manual mode has been

selected.

c. To lock the power supply in Manual mode, turn the KEYLOCK

switch to the disable position and remove the key.

3. Use the MEMORY switch to select the memory location the unit will use

to store parameters; the selected memory location will appear.

23

4. Select the discharge voltage. For initial start-up and training purposes,

NOTE

select 55V.

a. Select the Discharge power supply with the MODULE switch. The

letters DISCHARG appear above the switch.

b. Select Voltage with the FUNCTION switch. The word VOLTAGE

appears above the switch.

c. Enter the value by turning the Adjust knob. The programmed value

appears on the Discharge Voltage display.

d. As the Adjust knob is turned, the discharge voltage is entered auto-

matically into the selected memory.

5. Select the discharge current limit. For initial start-up and training purposes, select 1.00A.

a. Select the Discharge power supply with the MODULE switch on the

front panel. The letters DISCHARG appear above the switch.

b. Select Limit with the FUNCTION switch. The word LIMIT appears

above the switch.

c. Enter the chosen value by turning the Adjust knob. The pro-

grammed value appears on the Discharge Current display.

d. As the Adjust knob is turned, the discharge current limit is entered

automatically into the selected memory.

6. Select the cathode filament current limit.

Refer to the “Tables” on page 83 for current limits for various ion

sources.

a. Select the Cathode power supply with the MODULE switch. The

word CATHODE appears above the switch.

b. Select Limit with the FUNCTION switch. The word LIMIT appears

above the switch.

c. Adjust the current limit up or down as needed. The value appears

on the Cathode Filament Current display.

Different sizes and types of filament wire may require adjustments to the

cathode filament current limit. Unless the source size is known, the cathode

current limit will be factory-set at 6.5A.

d. The final selected value is stored automatically in the memory, as

indicated above the MEMORY switch.

24

7. Select the cathode filament current.

NOTE

NOTE

Refer to the “Tables” on page 83 for initial filament currents for various

ion sources.

The current values assume that 0.25mm (0.010 in.) tungsten wire is used

for the cathode filament. If the actual filament is a different size and/or

material, other filament currents could be required.

a. Select the Cathode power supply with the MODULE switch and

Current with the FUNCTION switch. The words CATHODE and

CURRENT appear above the appropriate switches.

b. Select the chosen value by turning the Adjust knob. The new value

appears on the Cathode Filament Current display.

c. As the Adjust knob is turned, the cathode filament current is entered

automatically into the selected memory.

8. Select the neutralizer filament current limit.

Refer to the “Tables” on page 83 for current limits for various ion

sources.

a. Select the neutralizer power supply with the MODULE switch. The

word NEUTRALIZER appears above the switch.

b. Select Limit with the FUNCTION switch. The word LIMIT appears

above the switch.

c. Adjust the current limit upwards or downwards as needed. The

value appears on the Neutralizer Filament Current display.

Different sizes and different types of filament wire may require adjustments

to the neutralizer filament current limit. Neutralizer current limit will be factory-set at 6.5A.

d. The final selected value is stored automatically in the memory, as

indicated above the MEMORY switch.

9. Select the neutralizer filament current.

Refer to the “Tables” on page 83 for initial filament currents for various

ion sources.

a. Select the neutralizer power supply with the MODULE switch and

current with the FUNCTION switch. The words NEUT and CURRENT appear above the appropriate switches.

b. Enter the chosen value by turning the Adjust knob. The value will

appear on the Neutralizer Filament Current display.

c. As the Adjust knob is turned, the neutralizer filament current is

entered automatically into the selected memory location.

25

Loading...

Loading...