VTC2 series

Voltage Controlled Temperature Compensated Crystal Oscillator

The VTC2, VCTXCO

Features

• CMOS Square Wave Output

• Enable Disable Feature

• Output Frequencies to 30 MHz

• Fundamental Crystal Design

• Optional VCXO function available

• Gold over nickel contact pads

• Hermetically Sealed Ceramic SMD package

• Product is compliant to RoHS directive

and fully compatible with lead free assembly

Applications

• FPGA’s

• A/D’s

• DSL Head End

• Wireless Communications

• Base Stations

• Point to point radios

• Broadband Access

• Test Equipment

Description

Vectron’s VTC2 Temperature Compensated

Crystal Oscillator (TCXO) is a quartz stabilized,

CMOS squarewave , temperature compensated

oscillator, operating off either 2.8, 3.0, 3.3 or 5.0

volt supply.

Vectron International 267 Lowell Road, Hudson NH 03051 Tel: 1-88-VECTRON-1 e-mail: vectron@vectron.com

VTC2 Data sheet

Performance Characteristics

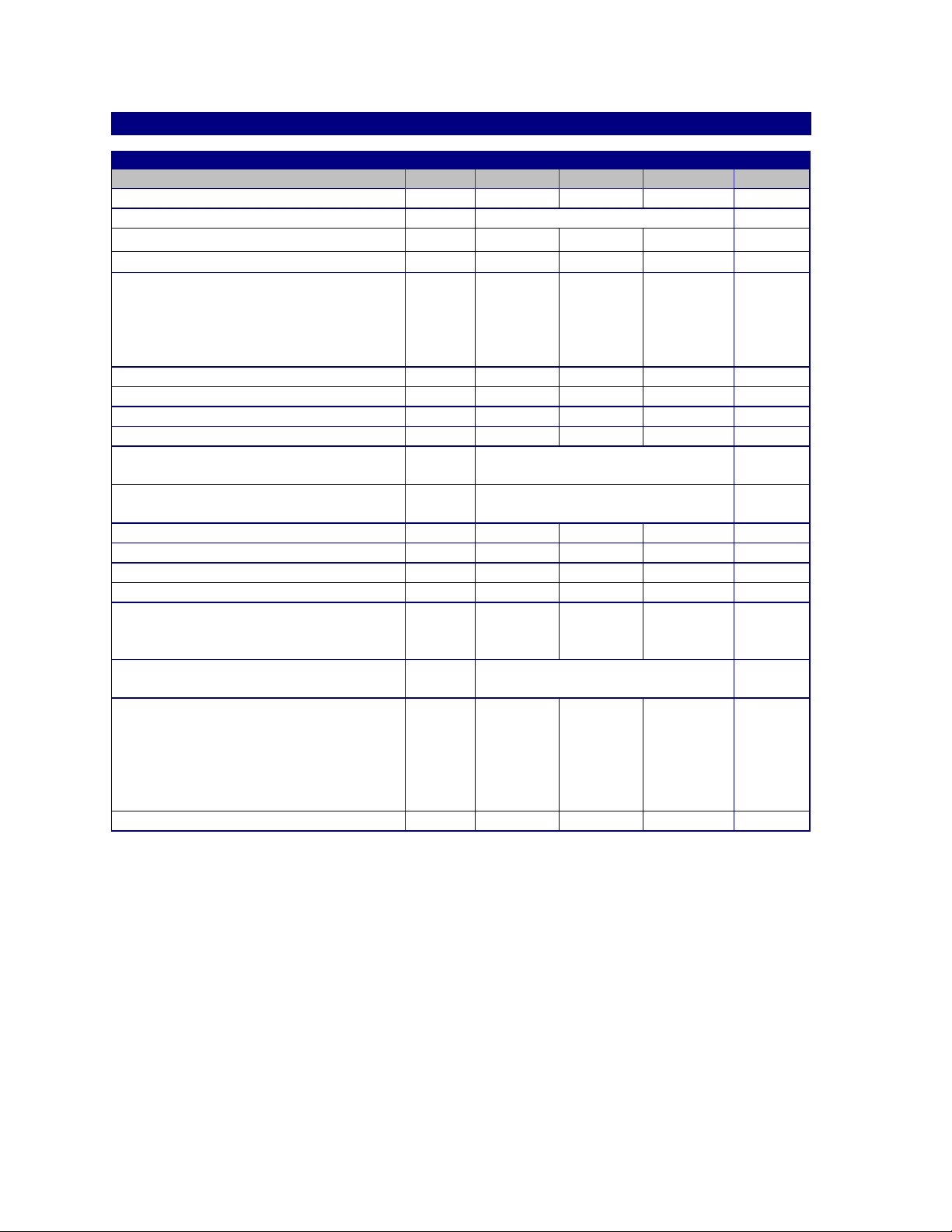

Table 1. Electrical Performance

Parameter Symbol

Min Typical Maximum Units

Frequency fO 10.000 30.000 MHz

Supply Voltage 3.3V ±10% or +5V ±5% VDC

Maximum Supply Voltage 6 VDC

Supply Current , +3.3V IDD 10.0 mA

Output Level

Logic High

Logic Low

Drive High

Drive Low

2

VOH

V

OL

IOH

IOL

0.9*V

4

DD

0.1*V

-4

DD

V

V

mA

mA

Output Load 15pf

Duty Cycle, @ 50% 45/55 %

Control Voltage Impedance ZVc 100 Kohm

Control Voltage to reach pull 0.5 2.5 V

Pull Range

TPR ±5, ±8 ppm

Ordering option, see last page

Temperature Stability

±0.5 to ±5.0 ppm

Ordering option, see last page.

Initial Accuracy, “No Adjust” option ±1.0 ppm

Power Supply Stability ±0.3 ppm

Load Stability ±0.2 ppm

Aging ±1.0 ppm/year

Enable/Disable3

Output Active

Output Disabled

Operating temperature

0.8*VDD

V

0.2*VDD

0/55, -10/60, -20/70, -30/80, -40/85 °C

Ordering option, see last page

Phase Noise, 12.800MHz

10 Hz offset

100 Hz offset

1 kHz offset

10 kHz offset

100 kHz offset

-93

-123

-147

-155

-158

dBc/Hz

Start-up time 2 ms

1. A 0.01uF and a 0.1uF capacitor should be located as close to the supply as possible (to ground) is recommended.

2. Output is DC coupled.

3. Output is active if E/D is open.

Vectron International 267 Lowell Rd, Hudson NH 03051 Tel: 1-88-VECTRON-1 e-mail: vectron@vectron.com

VTC2 Data sheet

VCXO Functional Description

VCXO Feature : The VTC2 can be ordered with a VCXO function for applications were it will be used in a

PLL, or the output frequency needs fine tune adjustments. This is high impedance, 1 Mohm, input and can

be driven with an op-amp or terminated with adjustable resistors etc. Pin 1 should not be left floating on

the VCXO optional devices.

“No Adjust” Feature : In applications were the VTC2 will be not be used in a PLL, or the output frequency

does not fine tune adjustments, the best device to use would be a VTC2-x0xxx. By using the “no adjust”

option, the circuit is simplified as Vc does not need to adjusted or set to a predetermined voltage and pin 1

should be grounded or left open (but not set to a voltage such as the supply).

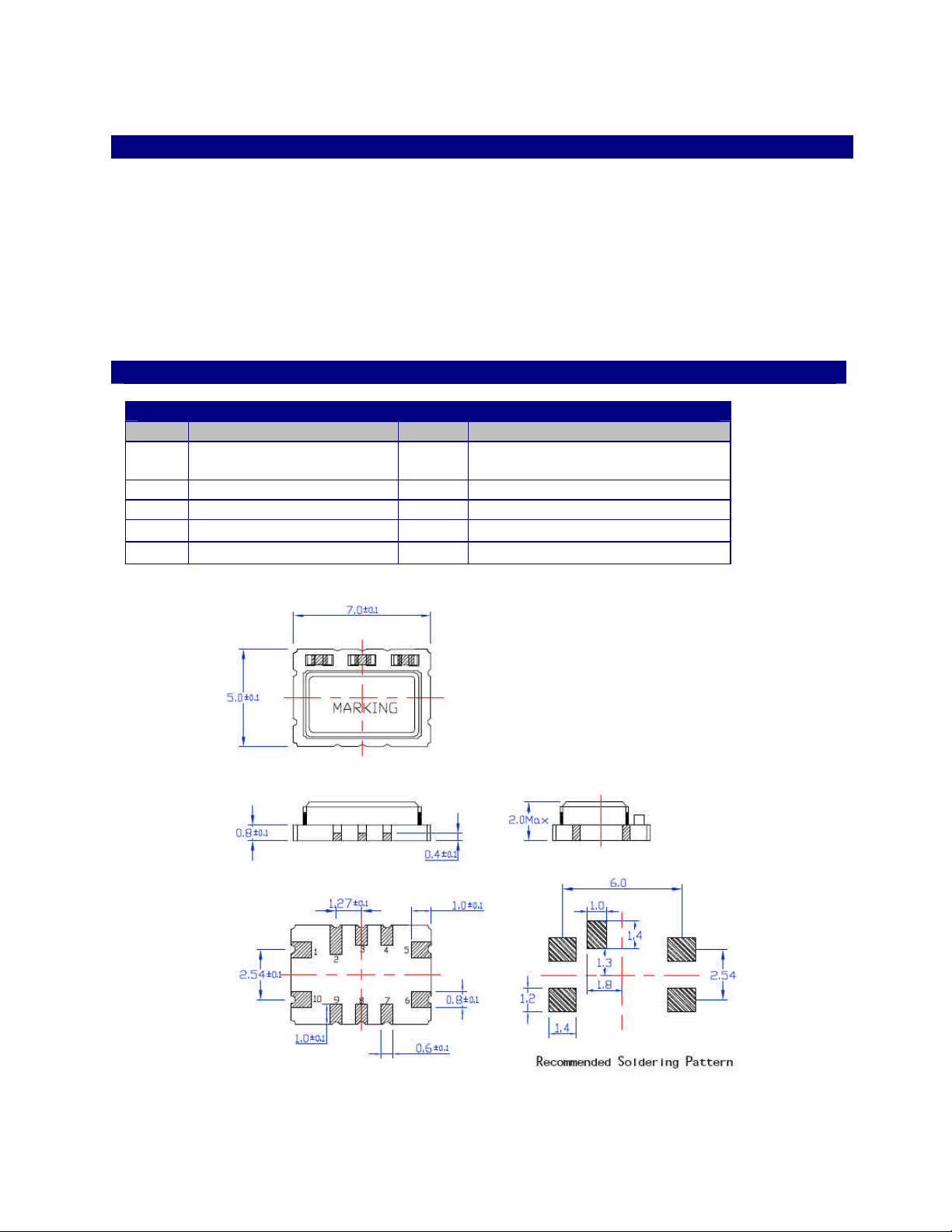

Outline Diagrams, Pad Layout and Pin Out

Table 2. Pinout

Pin # Function Pin # Function

1 No Connect (VTC2-x0xx)

or VCXO Control Voltage

2 Make No Connection 9 Enable/Disable

3 Make No Connection 8 Make No Connection

4 Make No Connection 7 Make No Connection

5 Electrical Ground 6 Output Frequency

NOTE: Additional pads are used to program and adjust the TCXO during manufacturing and should be left

open; do not terminate these to the supply voltage.

10 Supply Voltage

Contact Pads are gold over nickel

Figure 2, Package drawing

Vectron International 267 Lowell Rd, Hudson NH 03051 Tel: 1-88-VECTRON-1 e-mail: vectron@vectron.com

VTC2 Data sheet

Tape and Reel

Table 3. Tape and Reel Dimensions (mm)

Tape Dimensions Reel Dimensions # Per

Product A B C D E F G H I J K L Reel

VTC2

16 7.5 1.5 4 8 1.5 20.2 13 60 2 16.4 180

J

F

CD

A

E

G

B

I

L

KH

1000

Absolute Maximum Ratings

Stresses in excess of the absolute maximum ratings can permanently damage the device. Functional

operation is not implied at these or any other conditions in excess of conditions represented in the

operational sections of this data sheet. Exposure to absolute maximum ratings for extended periods may

adversely affect device reliability.

Table 4. Absolute Maximum Ratings

Parameter Symbol Ratings Unit

Storage Temperature Tstorage -55/125 °C

Reliability

The VTC2 qualification tests have included:

Table 5. Environnemental Compliance

Parameter Conditions

Mechanical Shock MIL-STD-883 Method 2002

Mechanical Vibration MIL-STD-883 Method 2007

Temperature Cycle MIL-STD-883 Method 1010

Solderability MIL-STD-883 Method 2003

Gross and Fine Leak MIL-STD-883 Method 1014

Resistance to Solve nts MIL-STD-883 Method 2015

Moisture Sensitivity Level 1

Contact Pads Gold over Nickel

Vectron International 267 Lowell Rd, Hudson NH 03051 Tel: 1-88-VECTRON-1 e-mail: vectron@vectron.com

VTC2 Data Sheet

Handling Precautions

Although ESD protection circuitry has been designed into the the VTC2, proper precautions should be taken

when handling and mounting. VI employs a Human Body Model and a Charged-Device Model (CDM) for

ESD susceptibility testing and design protection evaluation. ESD thresholds are dependent on the circuit

parameters used to define the model. Although no industry wide standard has been adopted for the CDM, a

standard HBM of resistance = 1.5kohms and capacitance = 100pF is widely used and therefore can be

used for comparison purposes.

Table 6. ESD Ratings

Model Minimum Conditions

Human Body Model 1500 MIL-STD-883 Method 3115

Charged Device Model 1000 JESD 22-C101

Suggested IR profile

Devices are built using lead free epoxy and can also be subjected to standard lead free IR reflow conditions,

Table 7 shows max temperatures and lower temperatures can also be used e.g. peak temperature of 220C.

Table 7. Reflow Profile (IPC/JEDEC J-STD-020B)

Parameter Symbol Value

PreHeat Time

Ramp Up

t S 150 sec Min, 200 sec Max

R

3 oC/sec Max

UP

Time Above 217 oC t L 60 sec Min, 150 sec Max

Time To Peak Temperature

Time At 260 oC (max)

Time At 240 °C (max)

Ramp Down

t

480 sec Max

AMB -P

t P 10 sec Max

tp2 60 sec Max

R

6 oC/sec Max

DN

Vectron International 267 Lowell Rd, Hudson NH 03051 Tel: 1-88-VECTRON-1 e-mail vectron@vectron.com

5

VTC2 Data Sheet

Ordering Information

Table 8. Standard Frequency List

10.000 12.800 16.000 18.000 19.200 20.000 24.000 25.000

26.000 27.000

VTC2 - -

Product Family Output Frequency

TCXO, 5x7 In MHz

Voltage Options Temperature Options

H: +5.0 Vdc ±5%, CMOS Output A: 0 to 55°C

J: +3.3 Vdc ±10%, CMOS Output B: -10 to 60°C

C: -20 to 70°C

Pulling Range D: -30 to 80°C

0: Fixed TCXO, no adjust E: -40 to 85°C

1: ±5ppm

2: ±8ppm Stability Options

A: ±0.5ppm

1: ±1.0ppm

B: ±1.5ppm

2: ±2.0ppm

C: ±2.5ppm

J

0 C

2

10M000

3: ±3.0 ppm

Note: Not all combinations are available: D: ±3.5ppm

±0.5 ppm is available over 0 to 55 °C only 4: ±4.0ppm

±1.0 ppm to ±5.0 ppm is available on all temperature ranges 5: ±5.0ppm

USA: Vectron International • 267 Lowell Road, Hudson, NH 03051

• Tel: 1-88-VECTRON-1 • Fax: 1-888-FAX-VECTRON

EUROPE: Landstrasse, D-74924, Neckarbischofsheim, Germany •

Tel: 49 (0) 7268 8010 • Fax: 49 (0) 7268 801281

www.vectron.com

Vectron International 267 Lowell Rd, Hudson NH 03051 Tel: 1-88-VECTRON-1 e-mail vectron@vectron.com

ASIA: Vectron Asia Pacific Sales 1F~2F. No.8 Workshop No.308 Fenju Rd.,

WaiGaoQiao Free Trade Zone, Pudong New Area Shanghai, China 200131

•Tel: 8621 50480777 • Fax: 8621 50481881

6

For Additional Information, Please Contact:

March 26, 2007

Loading...

Loading...