Page 1

查询RXM-115A供应商

Product Data Sheet

RXM-155

SONET/SDH Fiber-Optic Receiver Module

Features

SONET OC-3 and SDH STM-1 Compatible

PECL Data Outputs

Single +5 Volt Supply

PECL Loss of Signal Flag

Operation at 1300 nm and 1550 nm

-45° to +85°C Operation

-34dBm minimum sensitivity

Wide Dynamic Range

Multi-Sourced 20 Pin DIL Footprint

The RXM-155 SONET/SDH Fiber-Optic Receiver Module

Applications

Telecom Receiver Applications

Medium and Long Haul SONET/SDH @ 155 Mb/s

High Performance Datacom Receiver Applications

ATM @ 155 Mb/s

Description

VI’s RXM-155 is an integrated fiber-optic receiver

module. It is powered by a single +5v power supply and

is housed in a 20 PiN DIL package.It is ideally suited for

SONET OC-3, SDH STM-1 and other 155 Mb/s fiberoptic transmission applications that demand superior

performance. It is available with a multi-mode fiber

pigtail with either FC/PC,ST or SC connector.

Vectron International 166 Glover Avenue Norwalk CT. 06856-5160 Tel: 1-88-VECTRON-1 www.vectron.com

Page 2

RXM-155 SONET/SDH Receiver Module

Product Data Sheet

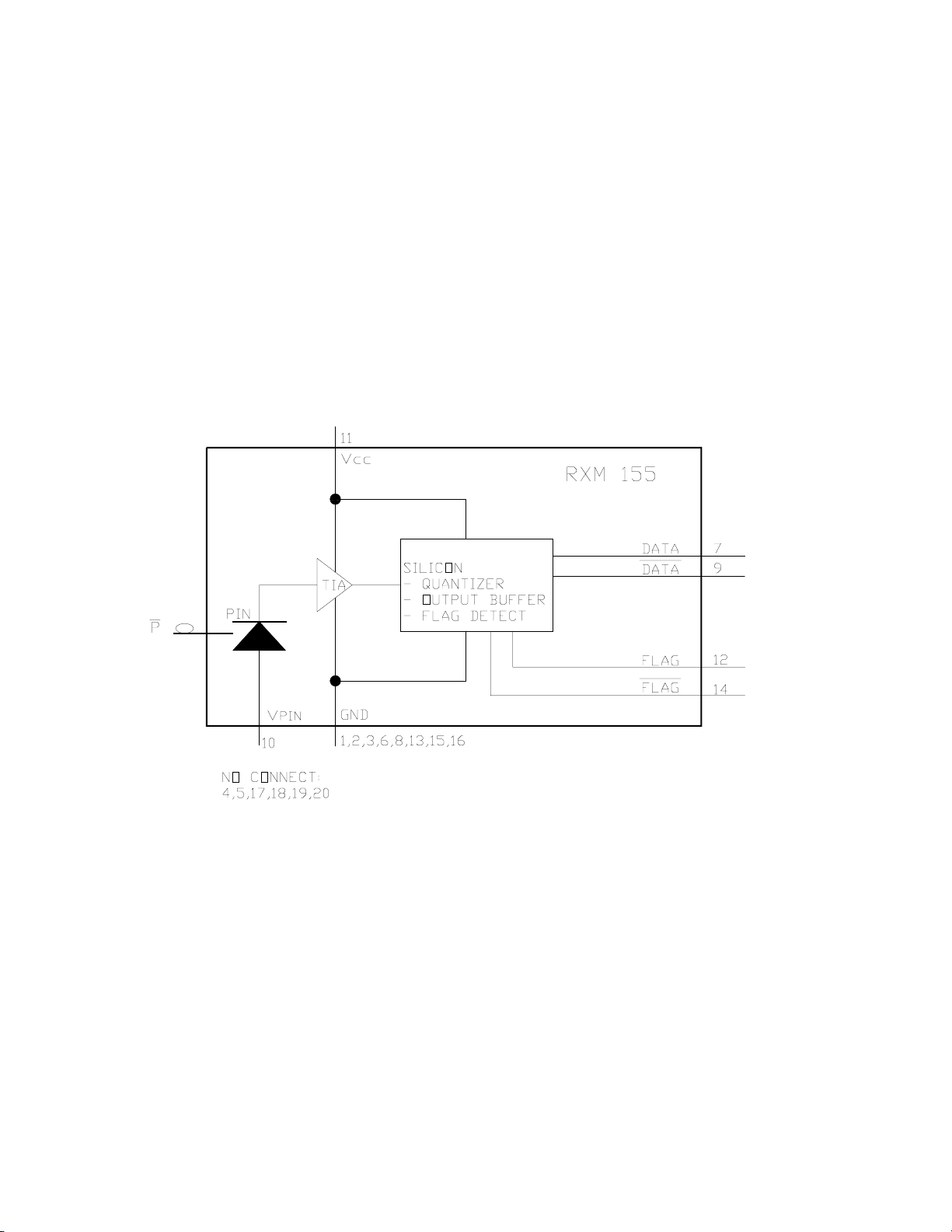

Functional Overview

This highly integrated module converts a 155 Mb/s

fiber-optic NRZ signal to differential PECL data outputs.

A PECL flag alerts the user to a loss of signal condition

when the optical input falls below an acceptable level.

A single +5 Volt supply provides bias for the module’s

preamplifier, and Quantizer. The photodiode may be

biased with -5 Volts or Grounded. All elements are

integrated into fiber-coupled 1.3” X 0.635” 20 pin DIL

package. The RXM-155 footprint and pinout are

industry common for ease of integration.

The optical signal is coupled through a short length of

50.0 µm multimode or single mode optical fiber to a

hermetic module which encases an InGaAs PiNphotodiode and preamplifier. The PiN-photodiode

converts the optical signal to an electrical current. The

signal is then converted to a voltage and amplified by a

low noise transimpedance amplifier.

Further gain is provided by the quantizer, which also

provides a Flag output when the optical signal falls

below an acceptable level.

Figure 1. RXM-155 Functional Block Diagram

Vectron International 166 Glover Avenue Norwalk CT. 06856-5160 Tel: 1-88-VECTRON-1 www.vectron.com

2

Page 3

RXM-155 SONET/SDH Receiver Module

Product Data Sheet

10

Pin 1 Indicator

Top View

11

20

Figure 2. Pin Diagram (Top View)

Table 1. Pin Function

Pin

7 Data PECL Data Output.

9 Data PECL Complementary Data Output.

10 V

11 V

12 Flag Input Signal Level Status. This PECL output switches low when the received

14 Flag Complementary Input Signal Status. PECL complement of Flag.

1,2,3,6,8,13,15,16 GND Ground.

4,5,17,18,19,20 NC No User Connection.

1. By connecting pin 10 to a -5 Volt bias through a series resistor (e.g. 1 kΩ) received optical power can be monitored as a voltage drop across the resistor.

Symbol

D

CC

Function

Detector Anode Bias. Connect to GND or a -5V biased series resistor for

received optical power monitoring.

5 Volt Supply Voltage.

optical power falls below the flag threshold.

1

Absolute Maximum Ratings

Absolute maximum ratings are provided here as

worst case and short duration exposure conditions

only. Exposure to conditions more severe than the

Absolute Maximum Ratings may result in permanent

damage. Exposure to conditions at the Absolute

Table 2. Absolute Maximum Ratings

Parameter Symbol Minimum Maximum Units

Storage Temperature Range T

Supply Voltage V

pin Detector Bias V

Lead Soldering Conditions 250/10 °C/s

Vectron International 166 Glover Avenue Norwalk CT. 06856-5160 Tel: 1-88-VECTRON-1 www.vectron.com

S

CC

D

Maximum Ratings for extended periods may also

adversely affect device performance or reliability.

Functional operation of the device is not implied at

these conditions.

-40 85 °C

0+6V

-15 0 V

3

Page 4

RXM-155 SONET/SDH Receiver Module

Product Data Sheet

Performance Characteristics

Table 3. Electrical Performance

Parameter Symbol Minimum Typical Maximum Units

Input Signal Rate f

Operating Temperature T

Power Supply Voltage V

pin Detector Bias Voltage (pin10) V

Power Supply Current I

Data Output Levels

1

Low

High

Data Output Rise and Fall Times

Received Power Level Flag

2

T

LOS

Decreasing Optical Power

Increasing Optical Power

O

CC

CC

V

OL

V

OH

R, TF

O

D

120 155.52 175 Mb/s

-40 +85 °C

4.5 5.0 5.5 V

-15 0 0 V

200 mA

V

- 1.95

CC

VCC - 1.03

VCC - 1.63

V

- 0.88

CC

275 375 575 ps

-37

-35

V

V

dBm

dBm

Flag Hysteresis Hyst 2 dB

1. Measured with a load of RL = 50Ω to VCC - 2 V. See figures 3 and 4. ECL levels are specified for dc measurement, an additional tolerance of 50 mV should be included for

dynamic measurements.

2. Measured at 20% to 80% levels.

Figure 3. PECL Interface

Vectron International 166 Glover Avenue Norwalk CT. 06856-5160 Tel: 1-88-VECTRON-1 www.vectron.com

4

Page 5

RXM-155 SONET/SDH Receiver Module

Product Data Sheet

Figure 4. ECL (AC Coupled) Interface

Figure 5. Typical Performance @ 155.52MHz

Table 4. Optical Performance

Parameter Symbol Minimum Typical Maximum Units

Minimum Average Sensitivity

Maximum Optical Input

Input Wavelength

1. For a BER less than 1E-10. Measured using a 223 - 1 pseudorandom word and a 50% average optical duty cycle and a 10 dB Extinction Ratio.

Vectron International 166 Glover Avenue Norwalk CT. 06856-5160 Tel: 1-88-VECTRON-1 www.vectron.com

1

Sens. -34.0 dBm

1

P

MAX

λ

1280 1580 nm

0dBm

5

Page 6

RXM-155 SONET/SDH Receiver Module

Product Data Sheet

Qualification

The RXM-155 has been designed to comply with the

requirements of Bellcore specifications GR-468CORE, Reliability Assurance for Optoelectronic

devices and will be subject to a complete qualification

test plan to demonstrate full compliance. All of the

technologies used in the assembly of the module

represent standard microelectronic and optical

technologies that are used in similar products, and

have extensive field reliability data.

All components and technologies used in the optical

receiver are backed by qualification data covering

mechanical and environmental tests along with

accelerated life tests. Typical tests, test conditions

and sample sizes are listed below.

Table 5. Qualification Plan

Test Test Method Sample Size

Physical Dimensions MIL-STD-883, Method 2016 11

Mechanical Shock MIL-STD-883, Method2002, Test B 11

Vibration, variable frequency MIL-STD-883, Method 2007, Test A 11

Lead Solderability MIL-STD-883, Method 2003 22 Leeds

Lead Integrity MIL-STD-883, Method 2004 15 Leeds

Temperature Cycling -40°C/85°C, 300 cycles 11

High Temperature Aging 85°C under bias, 2000 hours 11

Damp Bake 85°C/85% RH/ 1000 hrs 11

Low Temperature Storage -40°C, 168 hours 11

ESD MIL-STD-883,Method 3015 3

Destructive Bond Pull MIL-STD-883,Method 2011 40

Table 6. Optical Fiber Characteristics

Parameter Minimum Typical Maximum Units

Fiber Length 1000 mm

Fiber Core 50 um

Fiber Buffer 900

Vectron International 166 Glover Avenue Norwalk CT. 06856-5160 Tel: 1-88-VECTRON-1 www.vectron.com

µ

m

6

Page 7

RXM-155 SONET/SDH Receiver Module

7

Product Data Sheet

Outline Diagram

Figure 6. Outline Diagram

Ordering Information

Standard modules are built with 50um MM fiber, with an outer jacket diameter of 900um. Alternative fiber type,

connector type and fiber lengths are available upon request. Contact factory for specific details.

Table 7. Part Numbers

Fiber-Optic Connector

FC/PC RXM-155A 330018265

ST RXM-155B 330003674

SC RXM-155C 330018276

1. Other connectors or fiber requirements are available to meet specific application requirements.

Vectron International 166 Glover Avenue Norwalk CT. 06856-5160 Tel: 1-88-VECTRON-1 www.vectron.com

1

Model Number VI Code Number

Page 8

RXM-155 SONET/SDH Receiver Module

8

Product Data Sheet

Notes:

Vectron International • 166 Glover Avenue, Norwalk, CT 06856 • Tel: 1-88-VECTRON-1 • Fax: 1-888-FAX-VECTRON

USA:

In Denmark, Finland, Ireland, Italy, Israel, Norway, Spain, UK: Tel: 44 (0) 1703 766 288 • Fax: 44 (0) 1703 766 822

EUROPE:

In Austria,Belgium,France,Germany,Luxenburg,Netherlands,Sweden,Switzerland:Tel: 49(0)7263 6480 • Fax:49(0)7263 6196

In China, Taiwan, Japan: Tel: 01 603 598 0070 • Fax: 01 603 598 0075

ASIA:

In Korea, Singapore, Australia, India: Tel: 01 203 853 4433 • Fax: 01 203 853 1423

Vectron International, Inc. reserves the right to make changes to the product(s) and/or information contained herein without notice. No liability is

assumed as a result of their use or application. No rights under any patent accompany the sale of any such product(s) or information.

Vectron International 166 Glover Avenue Norwalk CT. 06856-5160 Tel: 1-88-VECTRON-1 www.vectron.com

Loading...

Loading...