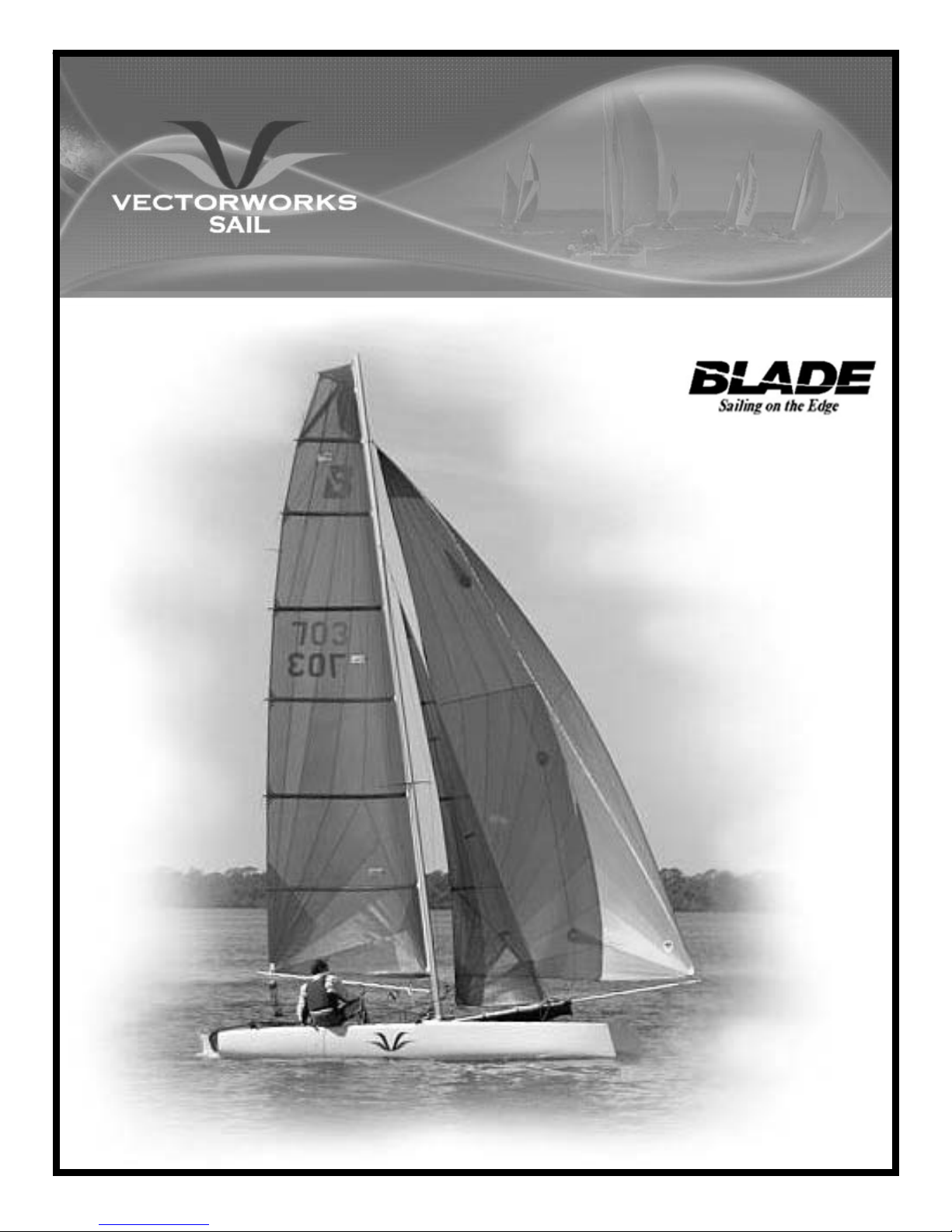

Vectorworks Sail Blade F16 Owner's Manual

Revision Date: 2006-03-17

Owner’s Manual

Copyright © 2006 - Vectorworks Sail - 805 Marina Road - Titusville, FL 32796 USA - 321-269-8444

Page 1

Vectorworks Sail

Statement

This manual covers the basic assembly of the

above listed models. Before starting assembly,

familiarize your self with the contents of the

containers and the steps in this manual. There

are variations between models and may be some

minor variations based on model year and

options, be sure to follow the appropriate

Page 2

Vectorworks Sail

Blade F16

procedures where applicable.

Table of Contents

1.0 Contents

2.0 Hull Assembly

3.0 Trampoline Assembly

4.0 Trap Bungee

5.0 Mast Rotation

6.0 Mast Assembly

6.1 Spreaders

6.2 Diamond Wires

6.3 Main Halyard

6.4 Spin Halyard

6.5 Standing Rigging

6.6 Pelican Striker Assembly

7.0 Stepping the Mast

8.0 Rudders

8.1 Surf System

8.2 Rudder Alignment

9.0 Spin Pole

10.0 Jib Sheet System

10.1 Jib Rotation Limiter

10.2 Jib Sheet

11.0 Boom

12.0 Mast Rotation - Mast connection

13.0 Mainsail

13.1 External Downhaul

14.0 Raising the Mainsail

15.0 Lowering the Mainsail

16.0 Mainsheet

17.0 Downhaul

18.0 Outhaul

19.0 Jib

20.0 Spinnaker

20.1 Halyard Run

20.2 Attaching the Spin

21.0 Spin Sheet

22.0 Sailing and Beaching

23.0 Righting After a Capsize

24.0 Trailering and Storage

25.0 Design Category

26.0 Maintenance

27.0 Warranty

Page 3

1.0 - Contents

***** Need list of contents and picture of them

***** List of required tools

***** List of required Supplies (silicone…)

Picture of all the parts

with descriptions

Some parts may vary slightly from what is pictured.

The exact contents may differ depending on model and options

Fig 1.A

Page 4

2.0 – Hull Assembly

After unpacking the hulls, verifying the contents and verifying they did not receive any

damage in transport, find a flat soft area to begin the assembly of your boat. Place the

hulls on carpet, foam blocks, or other smooth item where they can be moved without

damaging the surface. First check the width spacing while trying to keep them as close

to the same fore and aft setting as possible. The centerline width of the hulls should be

7’. Check at the bow and stern. Once this is set, measure the diagonals of the hulls to

make sure they are not skewed. This should be within 1/8” of each other. Adjust the

fore and aft position of the hulls as required, and recheck the width measurement to

ensure it has not changed. This may take several iterations. It is very important that

this be done very carefully as severe damage could occur to the beams or hulls if they

are tightened with the hulls out of alignment. (Figure 2.A).

Warning

Warning: Diagonal measurements need to be within 1/8” of each other or

Once the hulls are set, remove the bolts from the cross bars and set on the hulls. Dry

fit the bolts to ensure everything will fit smoothly. The hulls were pre-assembled in the

factory, so if they are aligned properly, the bolts should slide smoothly into the hulls.

After you are confident of the fit, lift the beams and place a bead of silicone around the

bolt holes and another small amount around the perimeter of the beam landings. This

will seal the holes to help prevent minor leaking of the boat. Now install the bolts and

tighten to 18 to 20 ft/lbs with a torque wrench, always making sure the hulls have not

shifted. Note these bolts need to be kept tight. Always check them before sailing the

boat. They will need tightening the first few times the boat is sailed. They should settle

in after a few sails.

Picture of silicone

Picture of Hulls on blocks showing

dimensions

Figure 2.A

damage to the beams and/or hulls could occur.

Picture of mounted cross

placement

Fig 2.B

Fig 2.C

bar

Page 5

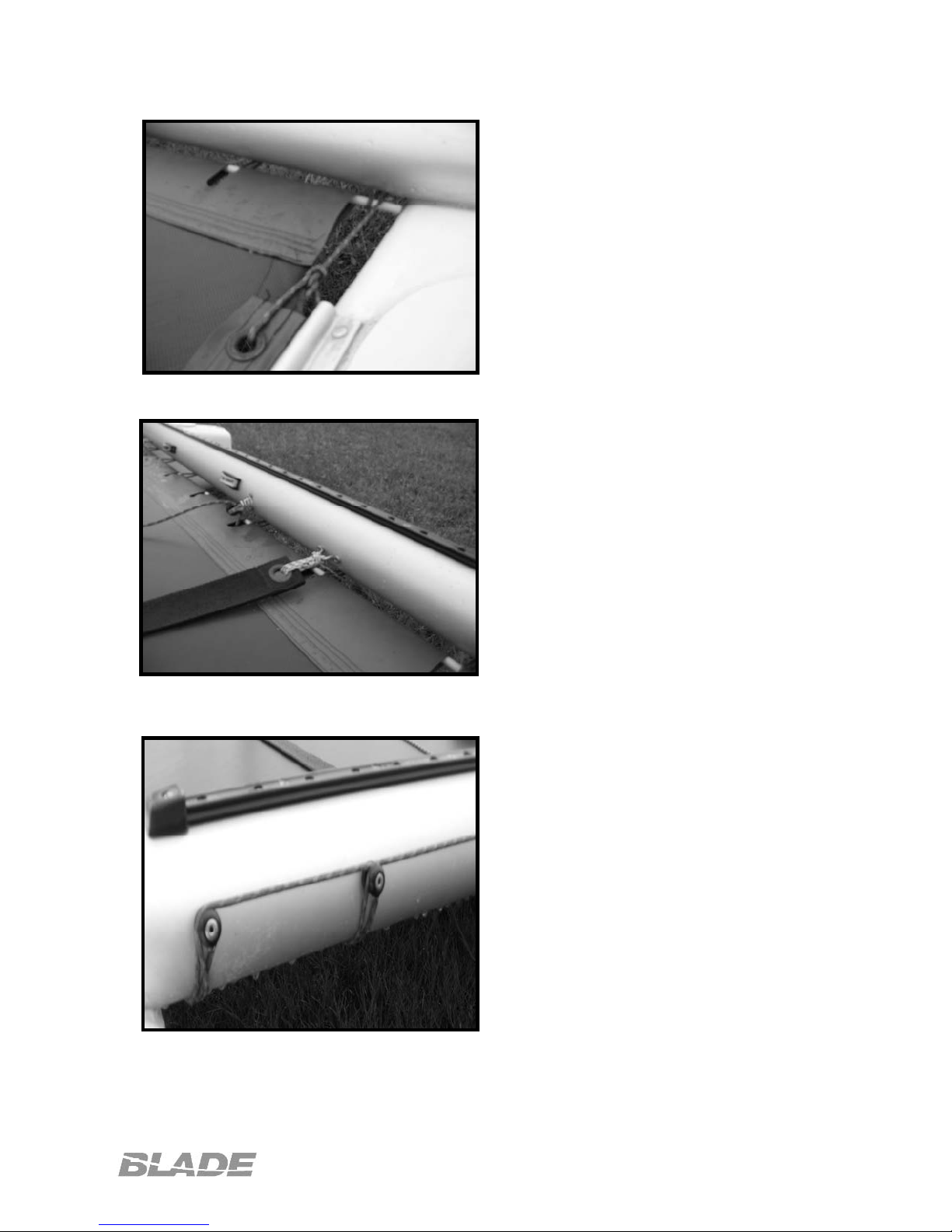

3.0 – Trampoline Assembly

Fig 3.A

Fig 3.B

Fig 3.C

After the cross bars are adequately

tightened, now it is time to string the

trampoline. Find the edge on the tramp with

the larger bolt rope, and slide it into the

groove in the front cross bar with the

zippered pocket facing up. (Figure 3.A)

Now feed the 2 smaller bolt ropes along the

tracks located on the hulls. Note this is a

diagonally cut tramp and you will need to

pull them down the tracks at the same time,

this will either take patience, or an additional

person. Once the tramp bolt ropes are

pulled, slide the 6’ fiberglass rod into the

pocket located on the aft end of the tramp,

and center. (Figure 3.B)

Find the 5/32” x 20’ long line labeled

“Tramp Lacing” and tie one end to either

of the grommets located in the aft

outside corner of the tramp. Pull the line

snug and bring back under the rear cross

bar and wrap over the first of the tramp

lacing buttons located on the aft side of

the cross bar. Bring the line forward and

wrap over the exposed end of the

fiberglass rod, and then back to the first

lacing button again. Pull the line over

the top of the first button and string over

the top of the second. Once over the top

of the second, go back under the cross

bar and wrap around the fiberglass rod at

the first notch, bringing it back to the

second button, over this button then to

the third. (Figure 3.C)

Continue across the entire tramp

finishing the opposite side in a mirror of

the start. Note the tramp will be loose

and will take several tightenings to

become fully taught. Once the back is

laced, remove the 1/8” x 30” lines and tie

the foot straps to the saddles provided

on the rear cross bar.

Page 6

4.0 – Trap Bungee

The forward trap bungee has already

been installed in the forward cross bar.

Remove the bungee from the

packaging and slide the bungee

through the black grommet located on

the hull near the side stay attachment.

Then feed the line through the nearest

tramp grommet, under the tramp and

back up the opposite side. Fix the

ends with the ball stops and hog rings

in identical fashion to the forward set

up. (Figure 4.A)

5.0 – Mast Rotation

Find the 5/32” line labeled “Mast

Rotation”. Feed this line through the

cleat located on the hull just aft of the

front cross bar, and then under the

Fig 4.A

tramp. Bring the line back up through

the tramp at the grommet located in the center of the tramp just aft of the storage

pocket. Run this line through the turning block provided and back through the center

grommet, under the tramp and back up through the cleat on the opposite hull. Note:

the turning block will be attached to the line run through the mast rotation arm on the

mast after the mast is stepped to control rotation.

6.0 – Mast Assembly

6.1 - Spreaders: Attach the

spreader arms to the fittings

located approximately ½ way up

the mast. Use the barrel nut to

adjust the rake of the spreaders

such that they are equally

positioned and a straight edge

placed between them will

provide a gap of at least 1 ½”

measured between it and the

mast. Adjust the extensions

and rake of the spreaders so

that they measure

approximately 27 ½” tip to tip,

and 1 ½” of rake. Note: these

measurements are made from

the location of the wire, and not

the end of the retention clips on

the spreaders. Make sure both are set at the same angle, as failure to do so may put

a permanent twist in the mast.

Fig 6.A

Page 7

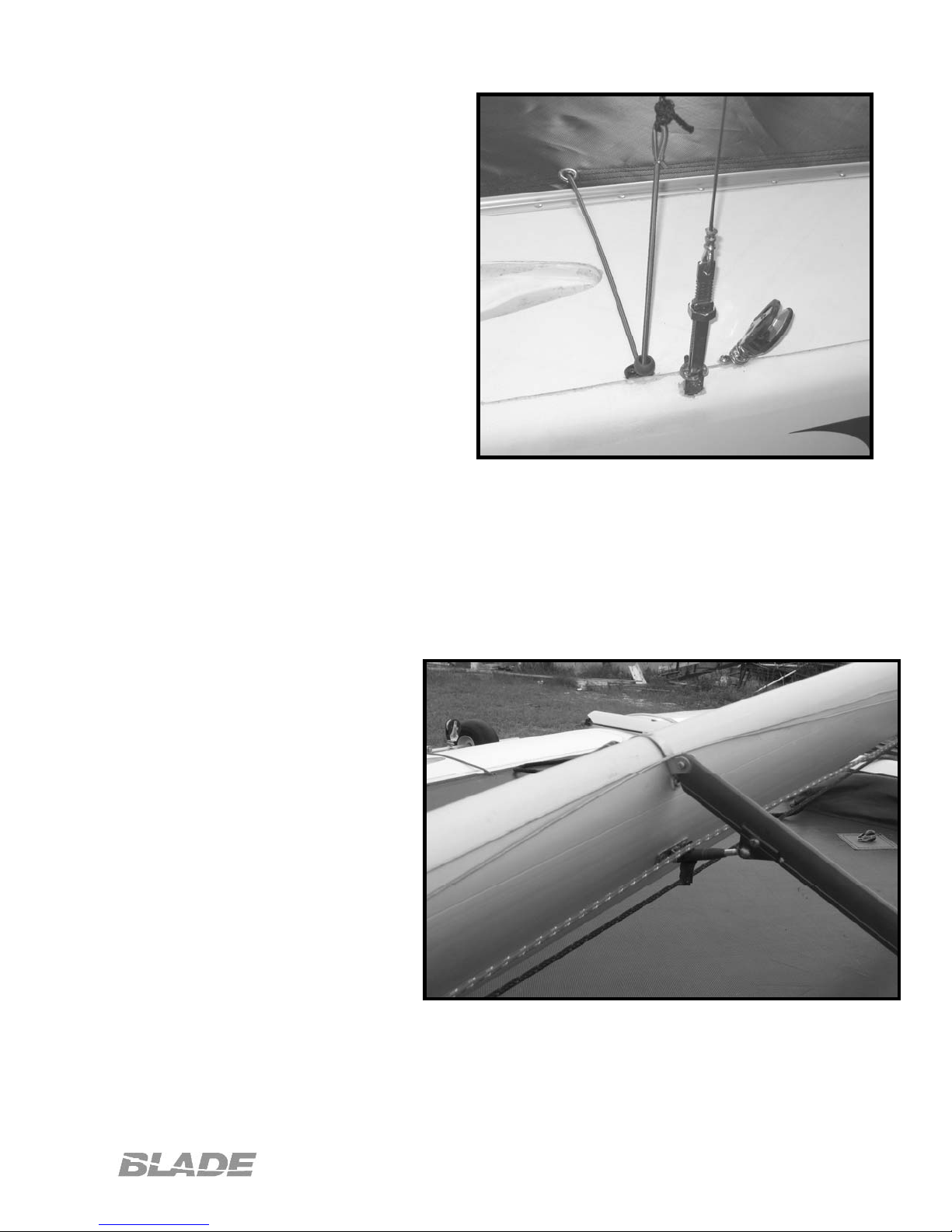

6.2 - Diamond wires: To install the

diamond wires, first place a bead of

silicone in the holes located on the

mast sides above the spreaders.

When wet, place the ball-T end of the

diamond wires in the hole, and bring

the threaded end down to the mast

base. Place the threaded end of the

diamond wire through the holes on the

side of the mast base, putting one of

the jam nuts on each side of the base

plate (2 per wire) It is very important

the adjusting end is completely

lubricated with anti-seize, oil or other

suitable lubricant, as stainless will cold

weld itself if the nuts are tightened

Fig 6.B

under load. Once the threads have

been started, pull the diamond wire onto the spreader bars, as if you were stringing a

crossbow. The wires can then be tightened to the proper setting. A good starting point

will be at least 1 ¼ - 1 ½” of pre-bend as measured with a string line from the mast

base to the sail hook. Note it is best to tighten the wires when they are not under load

to prevent seizing. This may take several iterations to get the proper tension and

ensure that the mast is straight. Once set, tighten the jam nut located on the top of the

mast base, to ensure the wire do not loosen while sailing. These setting are a starting

point, and you will need to adjust them to fit your own sail, weight and sailing

conditions. Always ensure diamond wires have adequate tension. If you notice

you diamond wires loose at any time during sailing, stop and tighten them. Sailing with

loose diamond wires can lead to mast failure or collapse.

Warning

Warning: Always tape spilt rings to prevent them from coming loose during sailing.

Sailing with loose diamond wires can lead to mast failure or collapse.

6.3 - Main Halyard: Attach the main halyard

line to the main sail hook as shown. Run the

opposite end of the line up the exterior of the

mast and through the pulley located on the top

of the mast and then back down the inside of

the sail track. The end will then exit through

the turning pulley located just above the mast

base.

Page 8

Fig 6.C

Loading...

Loading...