Register now

and benefit!

Jetzt Registrieren

und Profitieren!

www.vector-wel ding.com

VECTOR WELDING TECHNOLOGY

GmbH

3

Year s5Year s

transformer

and rectifier

OPERATING INSTRUCTIONS

Welding Machine

VEC TOR DIG ITAL – We op timiz e the qua lit y and pr ices

Loo king to th e future , susta inability, envi ronme nt friendly and h igh on the cu stome r-ori ented

com peten ce - the ke y words t o which w e are res ponsi ble.

For t his rea son, we d evelo p our own p owerf ul bran d VECTO R .

In VE CTO R we ld ing eq ui pm ent co mb ine s ad va nc ed i nv er te r te ch no logy, the hi gh est

qua lity st andar ds of a pre mium br and and l ow pric es to a uni que val ue for mo ney. Inv erte r

te chn olo gy is an e sse nti al c ompon en t of p roces s im pr ove men t an d mi nim ize s en ergy

co nsu mpt ion . In a ll ou r equ ipm ent, we th ere for e tr ust o n th e MOS FET t ech nol ogy f rom

Tos hib a and Inf ine on I GB T techn ol ogy fro m SIE MEN S. T hei r inn ova tive so lut ion s ar e

set ting ne w stand ards in w eldin g techn ology.

VE CTOR w eldi ng eq uip men t can b e use d on ne arl y all w eld a ble m etal s. It is p arti cul arl y

su ita ble w hen qua lit y wel ds a re ex tre mel y im por tan t. Pr iva te ga rdeni ng - m oto rcycl es,

ca rs, truck s, cl ass ic cars, mo del ma kin g, stair an d balc ony r ailings o r in the p rof ess iona l

an d in dus tri al se cto rs such a s Oil p ipe lin e, ch emi cal , autom oti ve, s hipbu ild ing , boile r,

el ect ric p owe r con str uct ion , nuc lea r pow er, ae ros pac e, mi lit ary, i ndu str ial ins tal lat ion ,

br id ge c on st ru ct io n an d ot he r in dus tr ie s, t he h ig he st q uali ty r equ ir em en ts a re m et

suc cessf ully wi th VECT OR wel ding eq uipme nt.

V EC TO R is on e o f t he l ea di ng s up pl ie rs o f we ld in g eq ui pm en t - d is co ve r ou r

po ssi bi lit ies - pro fit f rom our v isi on to off er mo der n, hi gh- pe rfo rma nc e we ldi ng

equ ipmen t at unbe ata ble pr ices .

On the bas is of 4 s tra tegic obj ect ive s, our comp any w ork d ay by

day to opt imi ze th is vision :

◆Number 1 i n Tech nology

◆Number 1 i n the p ric es

◆Number 1 i n Ser vic e

◆Number 1 i n the e nvi ronment al co mpa tibilit y

Mo re th an 30,000 e nthu sia sti c cus tome rs tru st ou r equ ipm ent i n the w elding an d plas ma

te chnol ogy. The y co nfi rm th e suc cess of the se t ren dse tti ng st ra teg y. In a ddi tio n to th e

st ring ent qu ali ty te st and the te st in th e pro duc tion, we subje ct th e equ ipm ent a t horo ugh

ins pection befor e delive ry. We guara ntee delivery of spare pa rts and re pair of al l equip ment.

The c ustom er is ser ved dur ing and a fter th e warra nty per iod fro m us. In ca se of p robl ems,

call us , we are alwa ys availa ble. You are also welc ome to visit us . Highly qua lified employees

are d edic ated t o carr ying o ut the ir various ta sks wi th exp erti se and p assi on. Ou r moti vate d

tea m will al ways fi nd a posi tive so luti on for yo u. Ever yone is w elco me to tes t our equ ipmen t

in de tail un der the g uidan ce of our e xpert s.

Pri vate g arde ning , indu stry o r prof essi onal, in eve ry are a you wi n if you r ely on t echn olog y

of we lding e quipm ent fro m VECTO R.

For q uesti ons or su gge stio ns, pl eas e cont act us .ww w.vec tor -wel ding .co m

WARNINGS

Read and u nde rst and this en tir e Man ual and you r emp loy er’ s safety

practi ces b efo re instal lin g, op erating , or se rvi cing the eq uip men t.

While Th e ope rating in str uctions prov ide a n introducti on to t he safe

use of the p rod uct s.

• Read the o per ati ng instru cti ons f or all syst em co mpo nents!

• Observ e acc ide nt preven tio n reg ulation s!

• Observ e all l oca l regulat ion s!

• Confir m wit h a sig nature wh ere a ppr opriate .

Record the f oll owi ng in for mat ion f or Warranty purpose s:

Whe re Purc hased :

Pur chase D ate:

Ser ial NO. :

Publis hed b y:

VECTOR W ELD ING TE CHN OLOGY GMB H

Hanses tra sse 1 01.

5114 9, Ko ln, G ermany

www.vec tor -we lding.c om

Safety instruction

1. 1 Arc w eldi ng dem age ---- ---- ---- --- ---- --- ---- --- ---- --- ---- ---- ---- --- ---- --- ---- --- 01-0 4

1. 2 Effe cts of low fr equ ency e lec tric a nd mag neti c fie lds---- --- ---- --- ---- --- ---- 0 4-04

1. 3 Symb ol cha rt -- ---- ---- ------- --- ---- ---- ------- --- ------- --- ------- --- ------- --- ---- 0 5-05

V-Ser ie s- --- ------- ---- --- --- ---- ---- --- --- ---- ---- --- --- ---- ---- --- --- ---- ---- --- -- 06 -06

C- Se ries--- ---- ---- ------- --- --- ---- ---- --- ---- --- --- ---- ---- --- ---- --- --- ---- ---- - 50- 50

E- Se ries - --- ---- ---- --- --- ---- ---- --- ------- ---- --- ------- --- --- --- ---- ---- --- --- -- 33-33

1. 1 Brief int rodu cti on-- --- --- ---- ---- --- ---- --- --- ---- ---- --- ---- ---- ------- --- --- ---- -- 07- 08

1. 1 Bri ef in tro duc tio n--- ---- --- --- --- --- --- --- ---- ------ --- --- --- --- ---- ---- ------ --- - 51- 51

1. 1 Bri ef in tro duc tio n-- --- ------- ---- --- --- --- --- --- --- --- --- --- ------- ---- --- --- --- --- 3 4-3 4

1. 2 Spe cif ica tio ns C4 1-- --- ------- ---- --- --- --- --- --- --- ------- ---- --- --- --- --- --- --- - 51- 52

1.2 Work ing pr inc iple ------- ------- ---- --- ---- --- ---- --- ---- ------- ---- ---- ---- ------- --- 09 -09

1. 3 Volt -amp ere c hara cter ist ic- --- --- --- --- --- --- --- --- --- --- --- --- --- --- --- --- --- -- 09 -09

1. 4 Spe cif ica tio ns V1 841/ V241 --- --- --- --- --- --- --- --- --- --- --- --- --- --- --- --- --- -- 10 -10

1. 2 Work ing pr inc ipl e-- ---- ---- --- --- ---- ---- --- --- ------- ---- --- --- ---- ---- --- --- ---- - 34-3 4

1. 3 Spec ific atio ns E16 1/E201 -- --- ---- ---- ------- --- ---- ---- ---- ---- ------- --- ---- ---- 3 5-35

1.11 D uty cy cle- ---- ---- ---- ------- ---- ---- ---- ---- ---- ---- ------- ---- ---- ---- ---- ---- ---- - 39-3 9

1. 7 Pac kag ed it ems --- --- --- --- --- --- --- --- --- --- --- --- ------------- ---- ---- --- --- --- - 37- 37

1.6 P ackaged i tems ---- ---- ----- ------- ---- ---- ---- --- ---- ---- ---- ------- ---- ---- ---- ---- 53 -53

1. 5 Spe cif ica tio ns V3 41- --- --- --- ------- ---- --- --- --- --- --- --- --- --- ------- ---- --- --- - 11-11

1. 6 Dut y cyc le- --- --- --- --- ------- ---- --- --- --- --- --- --- --- ------- ---- --- --- --- --- --- --- 1 2-1 2

1. 5 Dut y cycle --- ---- --- --- ------- --- --- --- ---- ---- --- --- ---- ---- --- --- ---- ---- --- --- --- 3 6-36

1. 4 Duty c ycle --- ---- --- --- ---- --- --- ---- --- --- ---- --- --- ---- --- --- ---- ---- ------- --- ---- 52-5 2

2. 2 Lay out for the pane l E221 --- --- ---- ---- --- --- ---- ---- --- --- ---- ---- --- --- ---- --- 41 -42

1. 9 Spe cificat ions E 301 /E4 01----- ---- --- --- ------- ---- --- --- ---- ---- --- --- ------- -- 38- 38

1. 7 Pac kaged items- --- --- --- ------- --- --- --- ------- ---- --- ------- ---- --- --- ---- ---- --- 1 3-1 3

1. 4 Pac kage d item s-- --- --- ---- ---- --- --- ------- ---- --- ------- ---- --- --- ---- ---- --- --- - 35- 35

1. 3 Pac kaged ite ms-- --- --- ---- ---- --- ------- ---- --- ------- ---- --- ------- --- --- --- ---- - 52-5 2

2. 1 Lay out f or th e pan el E1 61 /E 201 ---- ------ --- --- --- --- ---- ------ --- --- --- --- -- 39 -40

1. 8 Duty cycl e--- --- ------- --- --- ------- --- --- ------- --- --- ------- --- --- ------- ---- --- --- 37-37

2.Opera tion

2.Opera tion

2.Opera tion

1.Summa ry

1.Summa ry

1.Summa ry

2. 1 Lay out f or the pan el V1 841 --- --- --- --- --- --- --- --- ---- --- --- ---- --- --- --- ---- --- 1 3-16

2. 3 Lay out f or th e pan el V2 41l/ V34 1-- --- --- --- --- --- ------- ---- --- --- --- --- --- --- -- 19 -22

1. 6 Spe cif ication s E221 --- --- --- --- --- ------- ---- --- --- --- --- ---- ---- --- --- --- --- ----- 36 -37

1. 5 Specifi cat ion s C71 ---- ---- --- ---- ---- --- ------- --- --- ---- ---- --- ------- --- --- ---- -- 53- 53

1. 10 Packag ed it ems --- ---- ---- --- ---- ---- --- ------- --- --- ------- --- --- ---- ---- --- ----- 38- 38

2. 3 Lay out f or th e pan el E3 01/ E40 1-- --- --- --- -- -- --- --- --- --- ------- ---- --- --- --- - 43- 44

2. 4 Set- up for L IFT TI G (GTAW ) wel din g (on ly for E 221) --- ---- ---- ------- --- --- - 44-4 6

2. 5 Setu p for S TIC K (MMA ) Weld ing- --- ---- ---- ------- --- ---- --- --- ---- --- ------- --- 4 6-47

2. 2 Con trol p anel ---- ---- ---- ---- ---- ---- ---- ---- ---- ---- --- ---- ---- ---- --- ---- ---- --- - 16-19

2. 4 Cont rol pa nel---- --- ---- ---- ---- ---- ---- ---- ------- --- ---- ---- ---- ---- ---- ---- ------- 2 3-2 6

2.5 S etup fo r STIC K(MMA) weld ing- --------- ---- ---- ----- ---- ---- --------- ---- ---- ----- 2 6-27

2. 6 Setu p for LI F TIG weldi ng- ------- --- ---- ---- ------- --- ---- ---- ------- --- ---- ---- - 27- 28

2. 7 Oper ati on en vir onme nt-- --- --- ---- ---- --- --- ---- ---- --- --- ---- ---- --- --- ---- ---- - 29- 29

2. 8 Ope rati on not ices ---- ---- ---- ---- ---- ---- ---- ---- ---- ---- ---- ---- ---- ---- ---- ---- 29-29

3.Troubleshoo ting

3. 1 Trou ble shoo ting --- --- ---- ---- --- --- ---- ---- --- --- ---- ---- --- --- ---- ---- --- --- ---- -- 30- 32

Chapter 1: AC/DC Series Equipment

Chapter 3: Cutting Series Equ ipment

Chapter 2: Stick Series Equip ment

3.Troubleshoo ting

3.1 Troub les hoot ing ---- --- ---- --- ---- --- ---- --- ---- --- ---- --- ---- --- ---- --- ---- ---- ---- - 47- 49

1. 10 Du ty cy cle- ---- --- --- --- ---- ---- --- --- ------- ---- --- --- ------- --- --- --- --- ---- ---- - 55- 55

2.2 L ayout for the pan el C71 ---- ---- ---- --- ---- ---- ---- ---- ------- ---- ---- --- -- ---- --- 57-58

1.8 S pecifica tion s C10 1--- ---- --- ---- ------- ---- --- ---- ---- --- ---- ------- ---- ------- --- 54 -55

2.1 Layo ut for t he pa nel C4 1-- ---- ------- ---- --- ---- ------- ---- --- ---- --- ---- ---- ------ 56- 57

1.7 D uty cycle ---- ---- ---- ---- --- ---- ---- ---- ---- --- ---- ---- ---- ---- ------- ---- - ---- ---- -- 53-54

1.9 P acka ged it ems- ----------- ---- ---- ---- ---- ---- ---- ---- ---- ---- ---- ------- ---- ---- ---- 5 5-55

2.3 Layo ut for t he pa nel C1 01----- ---- --- ---- ------- ---- --- ---- ---- -------- ---- --- ---- - 59-60

2. 4 Stee l cut ting c apab ilit y (thi ckne ss to sc ale) ---- ---- --- ------- --- ---- --- ---- --- - 60- 60

2.5 I nsta llat ion in stru ctio ns-- ---- ---- ---- ---- ---- ---- ---- ---- ---- ---- ---- ---- ---- ---- ---- 6 1-63

3.Troubleshoo ting

04

2.5 S etup f or STI CK (MMA) weld ing O2 41-- ---- ---- ---- ---- ---- ------------- ---- -- 101 -102

2.1 0 Setu p for cu ttin g (CUT ) O251 ---- ---- ---- ---- ---- ---- ---- ---- ---- ---- ---- ---- -- 107 -109

T-Series- ----- ---- ---- ---- --------- ---- ---- --------- ---- ---- ---- ----- ---- ---- ---- ----- - 66-6 6

1.1 Brief in trodu ctio n---- ---- --------- --------- ---- ----- ---- ----- ---- ----- ---- ----- ---- ----- 6 7-68

1.2 Wo rkin g prin ciple---- ---- ---- --------- ---- ---- --------- ---- ---- --------- ---- ---- ----- ---6 8-68

1.2 Wo rkin g princ iple ----- ---- ---- ----- ---- ----- ---- ---- ----- ---- ----- ---- --------- ---- ---- 85 -85

1.3 Vo lt-a mper e char acteristic--- ---- ---- ---- ---- ---- ---- ---- ---- ---- ---- ---- ---- ---- --- 69-69

1.3 Vo lt-a mper e characteristi c--- ---- ---- ---- ---- ---- ---- ---- ---- ---- ---- ---- ----------- 85- 85

1.4 Specif ications T231/T3 31------- --------- ---- ----- ---- ----- ---- ----- ---- ----- ---- ---- 69 -70

1.4 S peci fica tion s O241 /O25 1------------ ---- ---- ---- ---- ---- ---- ---- ---- ---- ---- ---- -- 86-86

1.5 D uty cy cle -- ---- ---- ---- ---- ---- ---- ---- ---- ---- ---- ---- ---- ---- ---- ---- ---- ---- ---- --- 70 -70

1.5 D uty cyc le-- ---- ----- ---- ---- --------- ---- ---- ----- ---- ---- --------- ---- ---- ----- ---- ---- 87-87

1.6 P ackaged ite ms-- ---- ----- ---- ---- ---- --------- ---- ---- --------- ---- ---- ---- ----- ---- -- 71- 71

1.6 P acka ged it ems- ---- ---- ---- ---- ---- ---- ---- ---- ---- ---- ---- ---- ---- ---- ---- ---- ---- -- 88- 88

2.Opera tion

2.Opera tion

2.Opera tion

1.Summa ry

2.1 La yout fo r the pan el T231 /T331 ----- ---- ----- ----- ---- ----- ----- ---- ----- ----- ---- --- 71- 75

2.1 L ayou t for th e pane l O241 ---- ---- ---- ----------- ---- ---- ---- ---- ---- ---- ---- ---- ---- 8 8-92

2.6 S et-u p for LIFT TIG ( GTAW) we ldin g O241 ---- ------- ---- ---- ---- ---- ------- - 102- 103

2.2 Co ntro l panel ----- ---- ----- ----- ---- ----- --------- ----- ---- ----- ----- ---- ----- --------- -- 75-7 6

2.2 Co ntro l panel ----- ---- ----- ----- ---- ----- --------- ----- ---- ----- ----- ---- ----- --------- -- 92-9 3

2.7 S etup f or cut ting ( CUT) O 241- ------- ---- ---- ---- ---- ---- ---- ---- ----------- ---- 1 03-1 05

2.3 Se tup for ST ICK(M MA) wel ding ------- ----- ----- ----- ----- ----- ----- ----- ----- ----- -- 77-77

2.3 L ayout f or the p anel O2 51-- ---- ----- ---- ---- ----- ---- ---- --------- ---- ---- ----- ---- -- 94- 98

2.8 S etup f or STICK (MMA ) weld ing O2 51-- ---- ---- ---- ------------- ---- ---- ---- -- 105 -106

2.4 Se tup for L IF TIG wel ding----- ----- ----- ---- ----- ----- --------- ----- ----- ---- ----- --- 78- 78

2.4 C ontr ol pan el --- ---- ---- ---- ---- ---- ---- ---- ---- ---- ---- ---- ---- ---- ---- ---- ---- ---- - 98-1 01

2.9 S et-u p for LIF T TIG (GTAW ) weld ing O2 51------- ---- ---- ---- ---- ---- ---- ---- 10 6-10 7

2.5 Ope ratio n envir onment--- ----- ----- --------- ----- ----- --------- ----- ----- --------- ---- 79 -79

2.11 Op eration environme nt-- ---- ---- ---- ---- ---- ---- ---- ---- ---- ---- ---- ----------- 109-1 09

2.6 O peration no tice s-------- ---- ---- ----- ---- ---- ---- ----- ---- ---- --------- ---- ---- ------ 79-7 9

2. 12 Op erat ion no tic es- ---- ---- --- ---- ---- --- ---- ---- --- ------- --- --- ------- --- --- - 110-11 0

3.Troubleshoo ting

3.1 Trou blesh ootin g---- ---- ----- ---- ----- ---- --------- --------- ---- ----- ---- ----- ---- ---- 80 -82

3.Troubleshoo ting

Chapter 4: DC Pulse Series Equi pment

Chapter 5: Multifunction Se ries Equipment

3.1 Tr oub lesh ooti ng----- ---- ------- ---- ---- --- ---- ---- ------- ---- ---- --- ---- ---- --- --- 110-112

O-Series-- ---- ---- --- ---- ---- ---- ------- ---- ---- ---- ------- ---- ---- ---- --- ---- ---- --- 83 -83

1.1 B rief in troductio n-------- --------- ----- ---- ----- ---- ----- ---- ----- ---- ----- ---- ----- ---- 84-84

1.Summa ry

3.1 Tr oubl esho otin g--- ---- ---- ---- ---- ---- ---- ---- ---- ---- ---- ---- ---- ---- ---- ---- ---- ---- 6 4-65

R-Series-- ---- ---- ---- --- ---- ---- ---- ---- ------- ---- ---- ---- ------- ---- ---- ---- ---- 11 3-113

1.1 B rief i ntroduc tion ---- ---- ---- --- ---- ---- ---- ---- ------- ---- ---- ---- ---- --- ---- ---- - 114-114

1.Summa ry

Chapter 6: MIG Series Equipme nt

1.2 W orki ng pri ncip le-- ---- ---- ---- ---- ---- ---- ---- ---- ---- ---- ---- ---- ---- ---- ---- ---- 114-114

1.3 S pecific atio ns R22 1--- ------- ---- ---- ---- ------- ---- ---- ---- ------- ---- ---- ---- -- 115- 115

2.1 L ayo ut for t he pan el R22 1--- --- ---- ---- ---- ------- ---- ---- ---- --- ---- ---- ---- -- 121-12 2

1.7 P acka ged it ems -- ------- ---- ---- ---- ---- ---- ---- ---- ---- ---- ------- ---- ---- ---- --- 118-118

1.5 Duty c ycle--- ---- --- ---- --- ---- --- ---- ------- ---- ---- ---- ------- ---- -------- ---- --- 116- 116

2.3 M IG gun polari ty lea d--- ---- ----- ---- ---- ---- ---- ----- ---- ---- ---- ---- --------- --- 12 5-12 5

1.9 S pec ific atio ns R2 51/R 311-- ---- ---- ----- --- ---- ---- ------- ---- ---- ----- --- ---- - 119-119

1. 4 Pac kaged ite ms-- --- --- ------- ---- --- --- ---- ---- --- --- ------- ---- --- --- ---- ---- - 116- 116

2.2 L ayo ut for t he pan el R23 1-- ---- ---- ---- --- ---- ---- ---- --- ---- ---- ---- ----- --- -- 123 -125

1.8 D uty cy cle- ---- ---- ---- ---- ---- ---- ---- ---- ---- ---- ---- ---- ---- ---- ---- ---- ---- ------ 118- 118

1.6 S pecif ications R 231- ------- ---- ------- ---- ------- ---- ------- ---- ------- ---- --- --- 117 -117

1.1 0 Pack age d item s--- ---- ---- ---- ---- ------- ---- ---- ---- ---- ---- ------- ---- ---- ---- - 120- 120

1.11 D uty cyc le-- ---- ---- ---- ---- ---- ---- ---- --------- ---- ---- ---- ---- ---- ---- ---- ---- --- 120-120

2.4 L ayout for the p anel R3 11---- ---- ----- ---- ---- ----- ---- ---- ----- ---- ---- ----- ---- - 126-1 27

2.5 I nsta lling a 5 kg spoo l 200mm d iame ter (for R221 ,R23 1)-- ----- ---- ---- ---- 127-12 8

2.6 Installi ng a 15 kg spool 30 0mm diame ter (sui table for R 251 and R311------1 28-128

2.7 I nser ting w ire in to the fe ed mec hani sm-- ---- ---- ---- ---- ---- ---- --------- ---- - 128- 129

2.1 0 Shie lding gas regul ator o pera ting i nstr ucti ons- ------- ---- ---- ---- ---- ---- - 131- 134

2.8 F eed rol ler pre ssure a djust ment ----- ---- -- --------- ----- ---- ----- ----- ---- ----- - 130-1 30

2.11 Set-up M IG (GM AW) wel ding wi th gas s hielded MIG w ire- ---- ----- ---- --- 13 4-13 5

2.9 C hang ing th e feed r oll- ------------- ---- ---- ---- ---- ---- ---- ---- ---- ---- ---- ---- --- 13 0-13 1

3.Troubleshoo ting

3.1 Tro ubles hooting-- ----- ----- --------- ----- ----- ---- ----- ----- ----- ---- ----- ----- ----- - 139-1 41

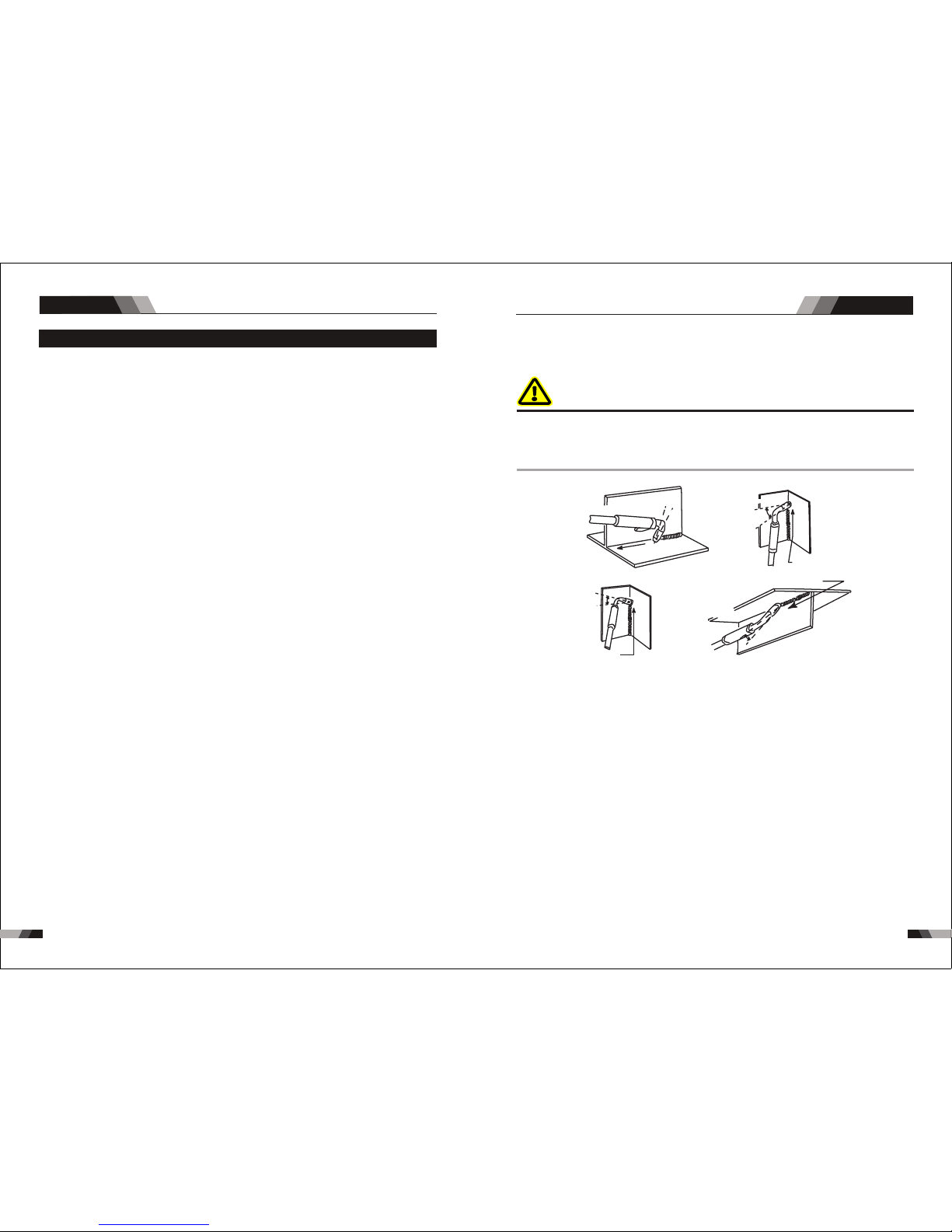

WARNING

PRO TECT YO URSE LF AND OT HERS F ROM PO SSI BLE SE RIOU S INJ URY OR DE ATH.

KEE P CHILDR EN AWAY. PACE MAKE R WEARERS K EEP AWAY UNTI L CONS ULTIN G

YOU R DOCTO R. DO NO T LOSE TH ESE I NSTR UCTI ONS . READ O PERAT ING/ INS TRUCTI ON MANU AL BEFO RE INS TALL ING, OP ERATIN G OR SER VICI NG TH IS EQU IPME NT.

Wel ding p roducts an d weld ing proce sses c an cause se riou s injury or d eath , or damage

to ot her equ ipmen t or prop erty, if t he ope rator d oes not s trict ly ob serv e all sa fety ru les

and t ake pre cauti onary a ction s.

ELE CTRIC S HOCK ca n kill.

Touch ing liv e elect rical p arts ca n cause f atal sh ocks or s evere b urns. T he ele ctrod e and

wor k circu it is ele ctric ally li ve when ever th e outpu t is on. Th e inpu t power circ uit an d

mac hine in terna l circu its are a lso liv e when po wer is on . In semi -auto matic o r autom atic

wir e weldi ng, the w ire, wi re reel , drive r oll hou sing, a nd all me tal parts to uchi ng the weld ing

wir e are ele ctric ally li ve. Inc orrec tly ins talle d or impr operl y groun ded equ ipmen t is a haza rd.

1. D o not to uch l ive el ectr ica l part s.

2. W ear dr y, hole -fre e ins ulat ing gl oves an d body pr otect ion.

3. I nsul ate y ours elf fr om wo rk and g roun d usi ng dry i nsul ating m ats or co vers.

4. D isco nne ct inp ut pow er or s top en gine b efore i nstal ling or s ervic ing thi s equip ment.

Loc k input p ower di sconn ect swi tch ope n, or rem ove lin e fuses s o power c annot b e

tur ned on ac ciden tally.

5. P rope rly i nsta ll and g rou nd thi s equi pment a ccord ing to it s Owner ’s Man ual.

WAR NIN G

1.1 Arc Weld ing Dam age

Saf e pract ices ha ve deve loped f rom pas t exper ience i n the use o f weldi ng and cu tting .

The se pra ctice s must be l earne d throu gh stud y and tra ining b efore u sing th is equi pment .

Som e of thes e pract ices ap ply to eq uipme nt conn ected t o power l ines; o ther pr actic es

app ly to eng ine dri ven equ ipmen t. Anyon e not hav ing extens ive tr aining in w eldi ng and

cut ting pr actic es shou ld not at tempt t o wel d.

Saf e pract ices ar e outli ned in th e Europ ean Sta ndard E N6097 4-1 ent itled : Safet y in

wel ding an d allie d processe s Part 2 : Elec trica l HAVE ALL INS TALLATION , OPERAT ION,

MAI NTENA NCE, AND REPAIR W ORK PE RFORM ED ON LY BY QUAL IFIE D PEO PLE.

SAF ETY INS TRUCT IONS

SAFETY INSTRUCTIONS AND WARNINGS

01

2.12 Se t-up for MIG (FCAW) weld ing with gas less MIG wir e----- ------ ------------ 135-136

2.13 S et-up fo r LIFT TIG (GTAW) welding (only for R2 31)-- ------ ----- ------ ----- - 137-13 7

2.1 3 Set-up f or STICK metal ARC we lding (MMA)---------------------- ----- ----- -- 138- 138

Basic knowledge-- ----- --------- --------- ----- ---- ----- ---- ----- ---- ----- --- 142 -142

1.1 TIG b asic we lding te chniq ue--- ----- ----- ----- ----- ----- ----- ----- ----- ----- -------- 1431 43

1.TIG Weldin g

2.MMA Weldi ng

3.MIG Weldin g

4.Maintenanc e

Chapter 7: Welding Technique And

Maintenance

1.2 Jo int fro ms in TIG- ----- --------- ----- ----- ----- ----- ----- --------- ----- ----- ----- --- 143 -143

1.3 Th e expla natio n of weld ing quality- ----- ----- ----- ----- ---- ----- ----- ----- ----- -- 143- 144

3.1 M IG (GMAW /FCAW ) basic w eldin g techn ique ----- ---- ----- ---- ----- ---- ----- -150-152

1.5 E -ser ies equ ipme nt TIG pa rameters ma tchi ng--- ---- ---- --------- ---- ------- 146 -147

1.4 TI G param eters matchi ng--- ----- ----- ----- ----- ----- ----- ----- --------- ----- ----- - 144-1 46

4.1 M ainte nance---- ----- ---- ----- ---- ----- --------- ----- ---- ----- --------- ----- ---- ----- 1 53-15 3

2.1 MM A basi c welding techn ique-- ----- ----- ----------- ----- ----------- ----- ---------- 14 8-149

WAR NIN G

FLYI NG SPAR KS and H OT META L

can c ause in jur y.

Chi pping a nd grin ding cause f lyin g metal. As we lds co ol, they ca n thro w off sl ag.

1. W ear ap prov ed fa ce shi eld or s afe ty gog gles . Side sh ields r ecomm ended .

2. W ear pr oper b ody p rote ctio n to pr otec t skin .

WAR NIN G

ARC R AYS ca n burn eyes a nd ski n,

NOI SE can da mage he aring .

Arc ra ys from t he weld ing pro cess pr oduce i ntens e heat an d stron g ultra viole t rays th at

can b urn eye s and ski n. Nois e from so me proc esses c an dama ge hear ing.

1. W ear a we ldin g hel met fi tted w ith a pro per sha de of fil ter to pr ote ct you r face a nd ey es

whe n weldi ng or wat ching ;

2. W ear ap prov ed sa fety g lass es. S ide sh ield s recom mende d;

3. U se pro tec tive s cree ns or b arri ers to p rot ect ot hers f rom f lash a nd gla re;

war n other s not to wa tch the a rc;

4. W ear pr otec tiv e clot hing m ade f rom du rabl e, flam e-r esis tant m ateri al(wo ol and le ather )

and f oot pro tecti on;

5. U se app rov ed ear p lugs o r ear m uffs i f nois e leve l is high ;

6. N ever w ear c onta ct len ses w hile w eldi ng.

WAR NIN G

FUM ES AND GA SES ca n be haz ardou s

to yo ur heal th.

Wel ding p roduces fu mes an d gases. Br eath ing these f umes a nd gases ca n be haz ardous

to yo ur heal th.

1. K eep yo ur he ad out o f the fu mes . Do not b reat he th e fume s.

2. I f insi de, v enti late t he ar ea and /or us e exh aust a t the ar c to re move w eldi ng fume s

and g ases.

3. I f vent ila tion i s poor, u se an a ppro ved ai r-sup plied r espir ator.

4. W ork in a c onfi ned s pace o nly if i t is we ll ven tila ted, or w hil e wear ing an a ir-su pplie d

res pirat or. Shie lding g ases us ed for we lding c an disp lace ai r causi ng injury or d eath .

Be su re the br eathi ng air is s afe.

5. D o not we ld in l ocat ions n ear d egre asin g, clea ning, o r spray ing ope ratio ns. The h eat

and r ays of th e arc can r eac t with v apou rs to for m hig hly to xic an d irrit ating g ases.

6. D o not we ld on c oate d meta ls, s uch as g alva niz ed, le ad, or c admiu m plate d steel , unles s

the c oatin g is remo ved fro m the wel d area, t he ar ea is we ll ven tilat ed, and i f neces sary,

whi le wear ing an ai r- supp lied re spira tor. The c oatings a nd any m etals con tain ing these

ele ments c an give o ff toxi c fume s if weld ed.

WAR NIN G

WEL DING ca n cause f ire or ex plo sion .

Spa rks and s patte r fly off f rom th e weldi ng arc. T he fly s parks a nd hot me tal, we ld spat ter,

hot w orkpi ece, an d hot equ ipmen t can cau se fire s and bur ns. Acci denta l conta ct of

ele ctrod e or weld ing wir e to meta l objec ts can ca use spa rks, ov erhea ting, o r fire.

1. P rote ct yo urse lf and o the rs fro m flyi ng sp arks a nd hot m eta l.

2. D o not we ld wh ere fl ying s par ks can s trik e fla mmab le mat erial .

3. R emov e all f lamm able s far a way fr om the w eld ing ar c. If th is is n ot pos sibl e, tigh tly

cov er them w ith app roved c overs .

4. B e aler t tha t weld ing sp ark s and ho t mate ria ls fro m weld ing can e asily g o throu gh smal l

cra cks and o penin gs to adj acent a reas.

5. Wa tch f or fir e, and k eep a f ire ex ting uis her ne arby.

WAR NIN G

CYL INDER S can exp lode if d ama ged.

Shi eldin g gas cyl inder s conta in gas un der high pre ssur e. If damag ed, a cy linder ca n

exp lode. S ince ga s cylin ders ar e norma lly par t of the we lding p rocess, be s ure to t reat

the m caref ully.

1. P rote ct co mpre ssed g as cy lind ers fr om ex cess ive he at, m echa nica l shock s, and ar cs.

2. I nsta ll an d secu re cyl ind ers in a n upri ght p osit ion by c haini ng them t o a stati onary s uppor t

or eq uipme nt cyli nder ra ck to pre vent fa lling o r tippi ng.

3. K eep cy lin ders a way fr om an y weld ing or o ther el ectri cal cir cuits .

4. N ever a llo w a weld ing el ectro de to tou ch an y cyli nder.

5. U se onl y cor rect s hiel din g gas cy lind ers, re gul ator s, hos es, and f itt ings d esig ned for t he

spe cific a pplic ation ; maint ain the m and ass ociat ed part s in good c ondit ion.

6. Tu rn fac e awa y from v alve o utl et whe n open ing c ylin der va lve.

7. K eep pr ote ctiv e cap in p lac e over v alve e xce pt whe n cyli nder is i n use or co nnect ed

for u se.

8. R ead an d fol low in stru cti ons on c ompr essed g as cyli nders , assoc iat ed equ ipme nt.

WAR NIN G

ENG INE FUE L can c ause fi re or exp losio n.

Eng ine fue l is high ly flam mable .

1. S top en gin e befo re che cki ng or ad ding f uel.

2. D o not ad d fue l whil e smok ing o r if uni t is nea r any spa rks or op en fl ames .

3. Al low en gin e to coo l befo re fuel ling. I f pos sibl e,ch eck and a dd fuel t o cold en gine be fore

beg innin g job.

4. D o not ov erf ill ta nk — all ow ro om for f uel to e xpa nd.

5. D o not sp ill f uel. I f fuel lin g is spi lled , cle an up be fore s tarti ng engi ne.

SAF ETY INS TRUCT IONS SAF ETY INS TRUCT IONS

6. B e awar e tha t weld ing on a c eil ing, f loor, b ulkhe ad, or pa rtiti on can ca use fir e on the

hid den sid e.

7. D o not we ld on c lose d cont ain ers su ch as ta nks o r drum s.

8. C onne ct wo rk cab le to th e wor k as clo se to th e wel ding a rea as p racti cal to pr eve nt

wel ding cu rrent f rom tra velli ng long , possi bly unk nown pa ths and c ausin g elect ric

sho ck and fi re haza rds.

9. D o not us e wel der to t haw fr oze n pipe s.

10. Rem ove st ick el ectro de from h older or cut o ff wel ding w ire at cont act ti p when not

in us e.

0302

SAFETY INSTRUCTIONS AND WARNINGSSAFETY INSTRUCTIONS AND WARNINGS

WAR NIN G

SPARKS can cause battery gases to explode;

BATTERY ACID can burn eyes and skin.

Bat terie s conta in acid a nd gene rate ex plosi ve gase s.

1. Al ways w ear a f ace sh ield w hen w orki ng on a ba ttery.

2. S top en gin e befo re dis con nect ing or c onnec ting ba ttery c ables .

3. D o not al low t ools t o caus e spa rks wh en wor kin g on a bat tery.

4. D o not us e wel der to c harg e bat teri es or ju mp st art ve hicl es.

5. O bser ve co rrec t pola rit y (+ and – ) on bat ter ies.

WAR NIN G

STEAM AND PRESSURIZED HOT COOLANT

can burn face, eyes, and skin.

The c oolan t in the ra diato r can be ve ry hot an d under p ressu re.

1. D o not re mov e radi ator c ap wh en eng ine is h ot. Allo w engin e to cool .

2. W ear gl oves a nd pu t a rag ov er cap a rea w hen re movi ng cap.

3. Al low pr ess ure to e scap e bef ore co mple tely re movin g cap.

NO TE

To red uce m agn etic fiel ds in t he workplace , use t he follow ing p roc edures.

1. K eep ca ble s clos e toge the r by twi stin g or ta ping t hem.

2. Ar rang e cab les to o ne sid e and a way fr om the o perat or.

3. D o not co il or d rape c able a rou nd the b ody.

4. K eep we ldi ng Pow er Sou rce a nd cab les as f ar away f rom bod y as prac tical .

5. T he peo ple wi th he art- pace maker s hould b e away fr om the we lding a rea.

1.2 Eff ects Of Low Fr equency El ectric and M agnetic Fi elds

1.3 Symbol Chart

Note tha t onl y som e of these sy mbo ls wi ll appear o n you r model.

SAF ETY INS TRUCT IONS SAF ETY INS TRUCT IONS

Ele ctric c urren t flowi ng thro ugh any c onduc tor cau ses loc alize d Elect ric and M agnet ic

Fie lds (EM F). The d iscu ss on the e ffect o f EMF is o ngo ing al l the wo rld. Up t o now, no

ma ter ial e vid enc es sh ow th at EM F may hav e eff ect s on he alt h. Ho wever, th e res ear ch

on d ama ge of E MF is s till o ngoi ng. B efor e any c onsl usi on, w e shou ld min imi ze ex posu re

to EM F as few as p ossib le.

WAR NIN G

MOVING PARTS can cause injury.

Mov ing par ts, suc h as fans , rotor s, and be lts can c ut fi nger s and ha nds and c atch lo ose

clo thing .

1. K eep al l doo rs, pa nels , cov ers, a nd gua rds clo sed and s ecure ly in pla ce.

2. S top en gin e befo re ins tal ling o r conn ectin g unit.

3. H ave on ly qu alif ied pe ople re move gu ards or c overs f or ma inte nanc e and tro ubles hooti ng

as ne cessa ry.

4. To pr even t acci den tal st arti ng du ring s ervi cing, d iscon nect ne gativ e (-) bat tery ca ble

fro m batte ry.

5. K eep ha nds , hair, l oose c lot hing , and to ols awa y from mo ving pa rts.

6. R eins tal l pane ls or gu ard s and cl ose do ors whe n servi cing is f inish ed and be fore

sta rting e ngine .

0504

SAFETY INSTRUCTIONS AND WARNINGSSAFETY INSTRUCTIONS AND WARNINGS

AC/DC SERIES EQUIPMENT

AC/DC SERIES EQUIPMENT

AC/DC SERIES EQUIPMENT

V-S eries

0706

Sum mary

1.1 Brief Introd uctio n

TI G V1841 V 241 V34 1 AC/ DC we ldi ng ma chi ne ad opt s the lat est pul se wi dth

mo dul ation (P WM) tec hno log y and i nsu lat ed ga te bi pol ar t ran sis tor (IG BT) p owe r

mo dul e, wh ich c an ch ang e wo rk fr equ enc y to medi um fr equ enc y so a s to re pla ce th e

tr adi tional h ulk ing w ork f req uen cy tr ans for mer wit h the cab ine t me diu m fre que ncy

co nsu mption a nd e tc.

The pa rame ters o f TIG V18 41 V241 V341 AC/ DC on the f ront p anel al l can be a djusted

con tinu ousl y and ste ples sly, suc h as star t curr ent, c rater a rc cur rent , weldi ng cur rent , base

cur rent , duty ra tio, u pslo pe time , down slop e time, p re-g as, po st-ga s, pul se fre quenc y, AC

fre quen cy, bala nce, h ot star t, arc f orce et c. Whe n welding, it t akes high fre quen cy and high

vol tage f or arc ig niti ng to ens ure th e succ ess rat io of ig niting arc.

TIG V 1841 V 24 1 V341 AC /DC Ch arac teris tics:

◆MCU c ontro l syste m, resp onds im med iate ly to an y cha nges .

◆Hi gh fr equ enc y and hig h vol tag e fo r ar c ig nit ing t o ens ure t he su cce ss r ati o of

ign itin g arc, t he reve rse po lari ty ign itio n ensures goo d igni tion b ehav ior in TI G-AC

wel ding.

◆Avo id AC arc -brea k with sp eci al mea ns, ev en if arc -br eak oc curs t he HF w ill ke ep

the a rc stab le.

◆Ped al cont rol the w eld ing cu rren t.

◆In D C TIG w ith out H Fope rtat ion , If th e tun gst en electr ode t ouc hes t he wo rkp iece

wh en w eld ing , the cur ren t wil l dro p to sh ort-ci rcu it cu rren t to pr ote ct tu ngs ten .

◆

occ oure d, the a larm la mp on th e fron t panel will be o n and th e outpu t curr ent wi ll

be cu t off. It can sel f-pr otec t and pr olong the usi ng lif e.

◆Do ub le p ur po se s: A C in ve rt er T IG /M MA a nd DC i nver te r TI G/ MM A, E xc el le nt

per forma nce on AL -all oy, car bon st eel , stai nles s ste el, ti tani um.

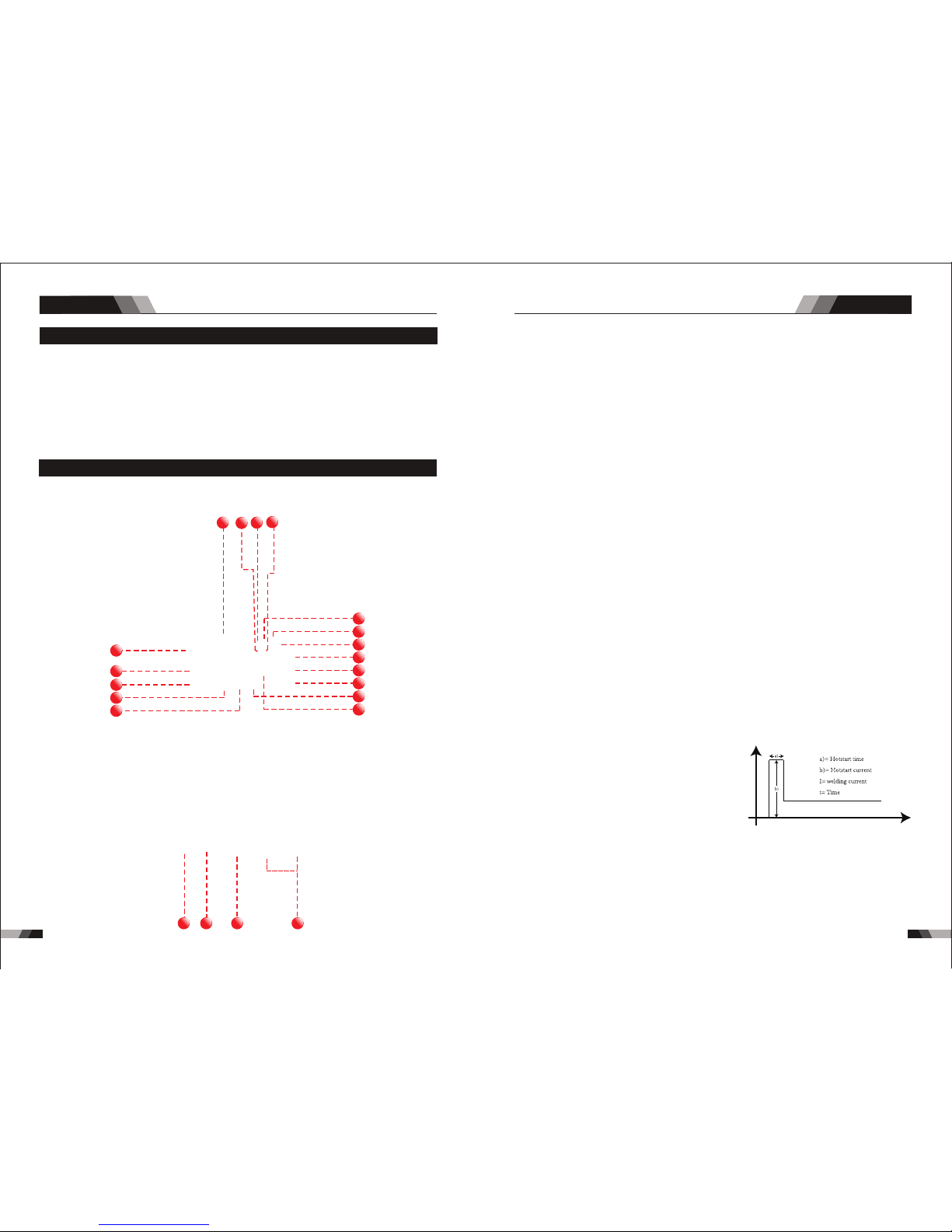

Accord ing t o cho osing the f ron t pan el functi ons , the f ollowin g fiv e wel ding

ways can b e rea liz ed.

DC MMA

DC TI G

DC Pulse T IG

AC TI G

AC Pulse T IG

CHAPTER 1

In tel li gen t pr ote cti on: o ver -cu rr ent , ov er- hea t, wh en t he m ent ion ed pr obl ems

tr ans forme r. Th us, its ch ar acter ized w it h po rt ab le , sm al l si ze, lig ht w ei gh t, l ow

1. Fo r DC MMA, p olari ty conn ectio n can be ch osen ac cordi ng to dif fere nt elec trode s;

2. F or DC T IG, D CEP i s us ed norm ally (w ork pie ce co nne cte d to posi tive po lar ity, whi le

t orch c on necte d to n ega tiv e po la rity) . Th is c on ne cti on h as m any cha racte rs, su ch

a s st able w el di ng ar c, l ow t un gste n po le l os s, mo re w el ding c ur re nt , na rr ow a nd

dee p weld;

3. Fo r AC TIG ( recta ngle wa ve), ar c is more s table t han Sin e AC TIG. At the s ame ti me,

you c an not on ly obta in the ma x penet ratio n and the m in tung sten po le loss , but als o

obt ain bet ter cle aranc e effec t;

4. DC P ulsed T IG has t he foll owing c harac ters:

1) P ulse h eat ing. M eta l in Molten p ool h as sho rt ti me on high te mpe ratu re st atus

an d free zes q uick ly, wh ich ca n red uce th e poss ibil ity t o produce h ot cr ack of t he

mat eri als wi th the rmal se nsiti vity .

2) Th e wor kpie ce get s litt le he at. Arc ener gy is f ocus ed. B e suit able f or thi n she et

and s uper th in shee t weldi ng.

3) Ex actly c ontro l heat in put and t he size o f the mol ten p ool. T he dep th of pe netra tion

is ev en. B e suit able f or weld ing by on e side an d formi ng by two s ides an d all pos ition

wel ding fo r pipe.

4) H igh f req uenc y arc ca n mak e met al fo r mic rolite fa bric , eli min ate blowh ole a nd

imp rove th e mec hani cal pe rform ance of t he join t.

5) Hi gh freq uency a rc is sui table f or high w eldin g speed t o impro ve the pr oduct ivity.

TIG V 1841 V 241 V 341 AC/ DC –se ries we lding m achin es is sui table f or all po sitio ns

we ldi ng fo r variou s pla tes m ade o f sta inl ess s tee l, ca rbon s teel , all oye d ste el, t ita nium ,

ma gne siu m, cu prum, e tc, W hich is als o ap pli ed to p ipe i nstal lme nt, m oul d mend,

petr och em ica l, arch ite ct ure , dec ora tio n, c ar re pai r, bi cyc le, h and icr af t an d co mmo n

ma nuf ac tur e.

MMA ----- --Man ual Met al Arc Wel ding

PWM ----- --Pul se-Wi dth Mod ula tion

IGB T----- ---In sulat ion G ate Bi pola r Tra nsis tor

TIG ---- ----- -Tung sten I nser t Gas Wel ding

AC/DC SERIES EQUIPMENT

AC/DC SERIES EQUIPMENT

Sum mary Sum mary

0908

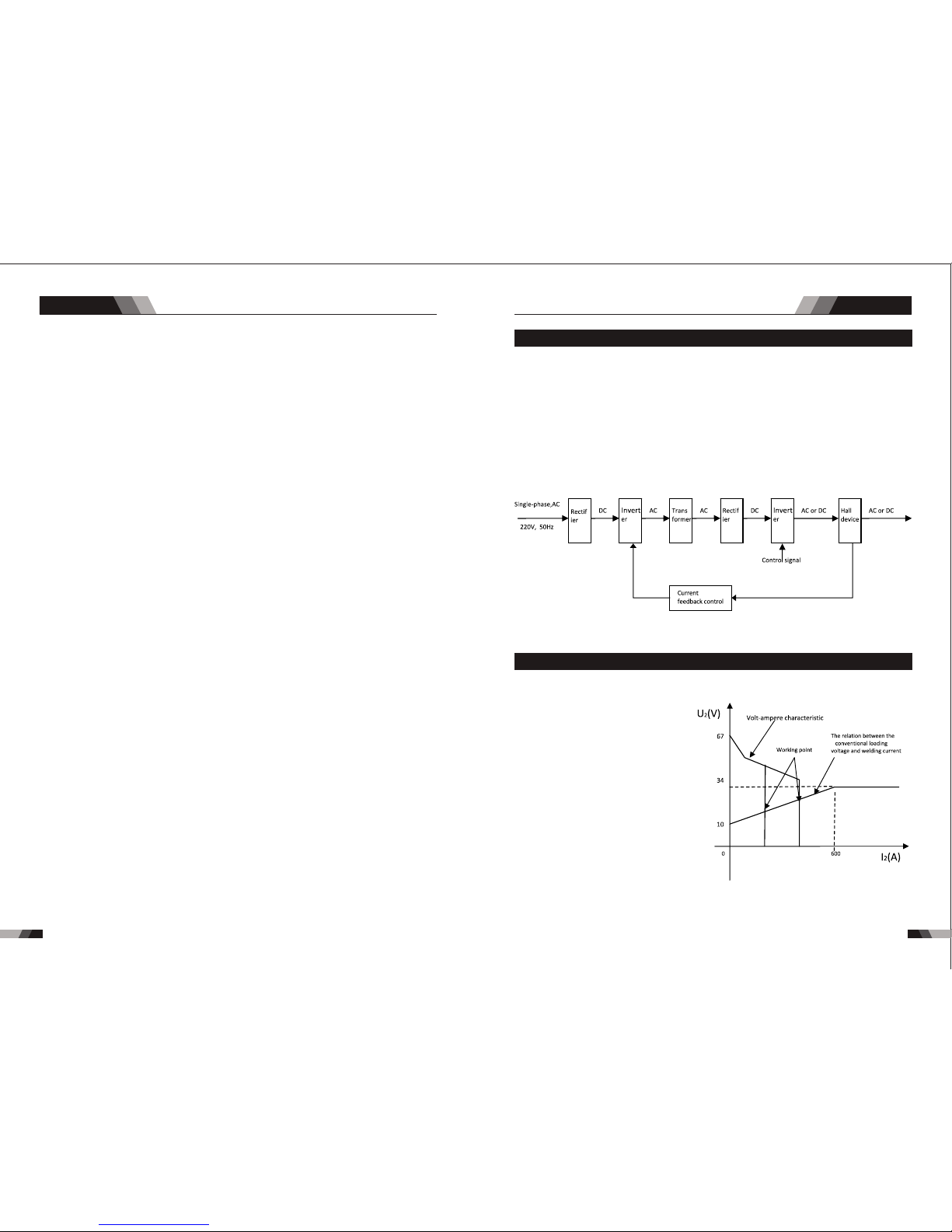

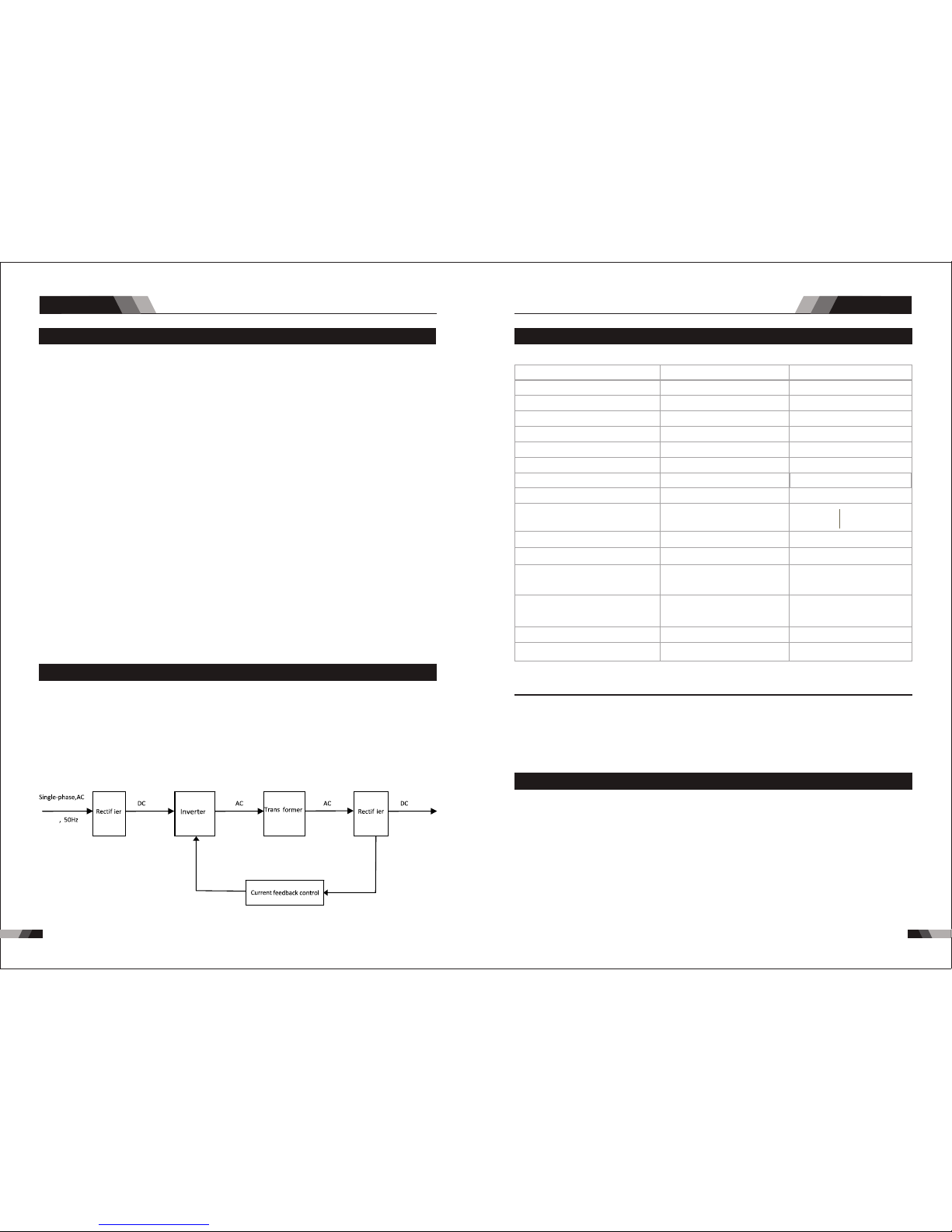

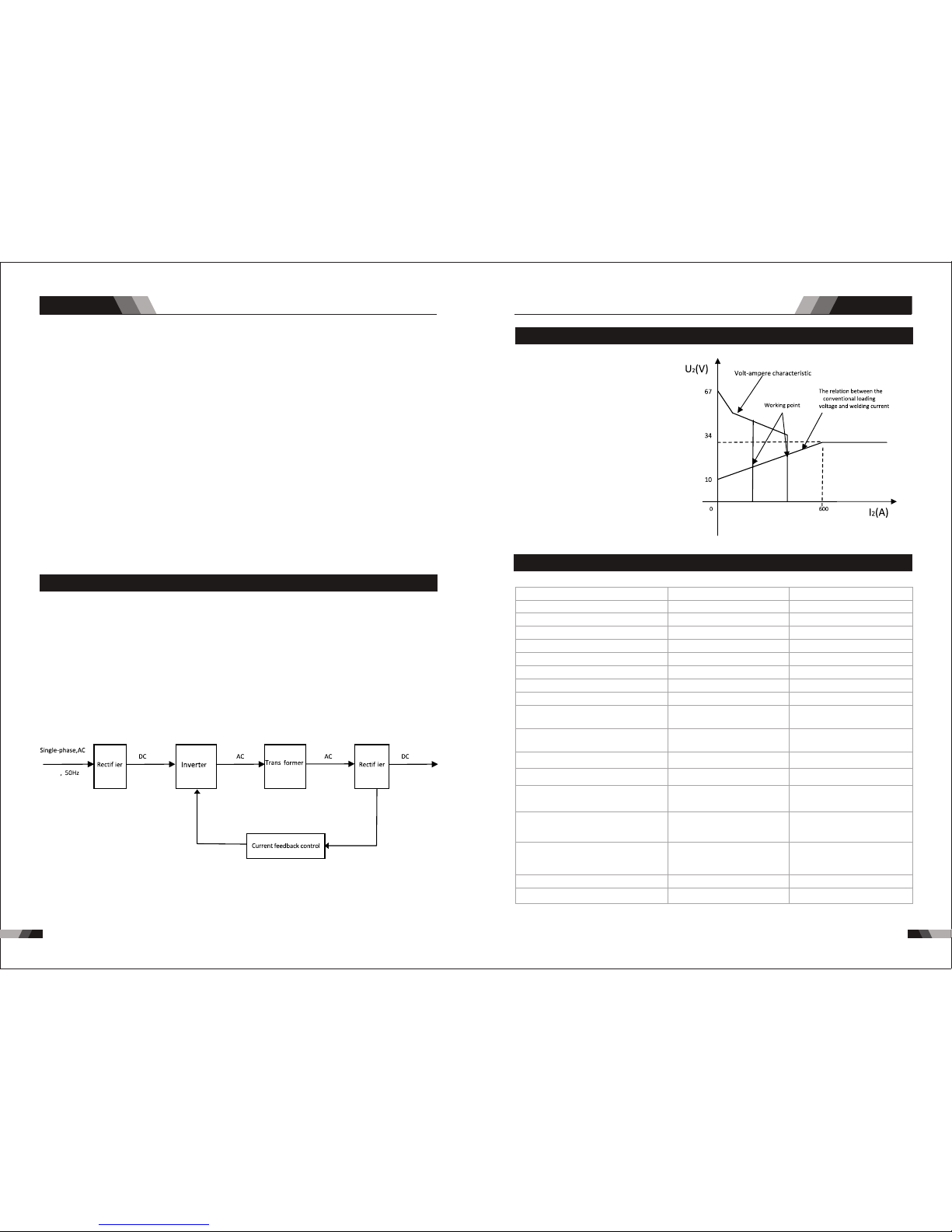

1.3 Volt - Ampere Cha racte ristic

Whe n I ≤600A , U =10 +0.04 I (V) ;

2 2 2

Whe n I >60 0A,U =34 (V).

2 2

1.2 Wor king Pr inciple

The w orki ng prin ciple o f TIG V 1841 V2 41 V341 AC /DC weldin g mach ines is sho wn as

the f ollow ing fig ure. Si ngle- phase 2 30V wor k frequ ency AC is r ectif ied int o DC (abo ut

312 V), the n is conv erted t o med ium fr eque ncy AC (ab out 20- 40KHz ) by inve rter de vice

(IG BT modu le), a fter re ducin g volta ge by med ium tra nsfor mer (th e main tr ansfo rmer) a nd

rec tifyi ng by med ium fre quenc y recti fier (f ast rec ove ry dio des) , then is o utput ted DC or AC

con tinuo usly an d stepl essly t o meet wi th the re quire ments o f weldi ng craf t.

wel ding ma chine h as an exc ellent

vol t-amp ere cha racte risti c, whos e

gra ph is sho wn as the f ollow ing

fig ure. Th e rela tion be tween t he

con venti onal ra ted loa ding vo ltage

U an d the con venti onal we lding

2

cur rent I i s as foll ows:

2

cu rrent o utp ut stab ly. M ean whi le, the w eld ing cur ren t par ame ter can b e adj usted

by se lect ing IG BT mod ule. Th e circ uit ad opts c urre nt fee dbac k cont rol te chno logy t o insu re

TI G V1 841/ V2 41/ V 341 AC/ DC

AC/DC SERIES EQUIPMENT

AC/DC SERIES EQUIPMENT

Sum mary Sum mary

111 0

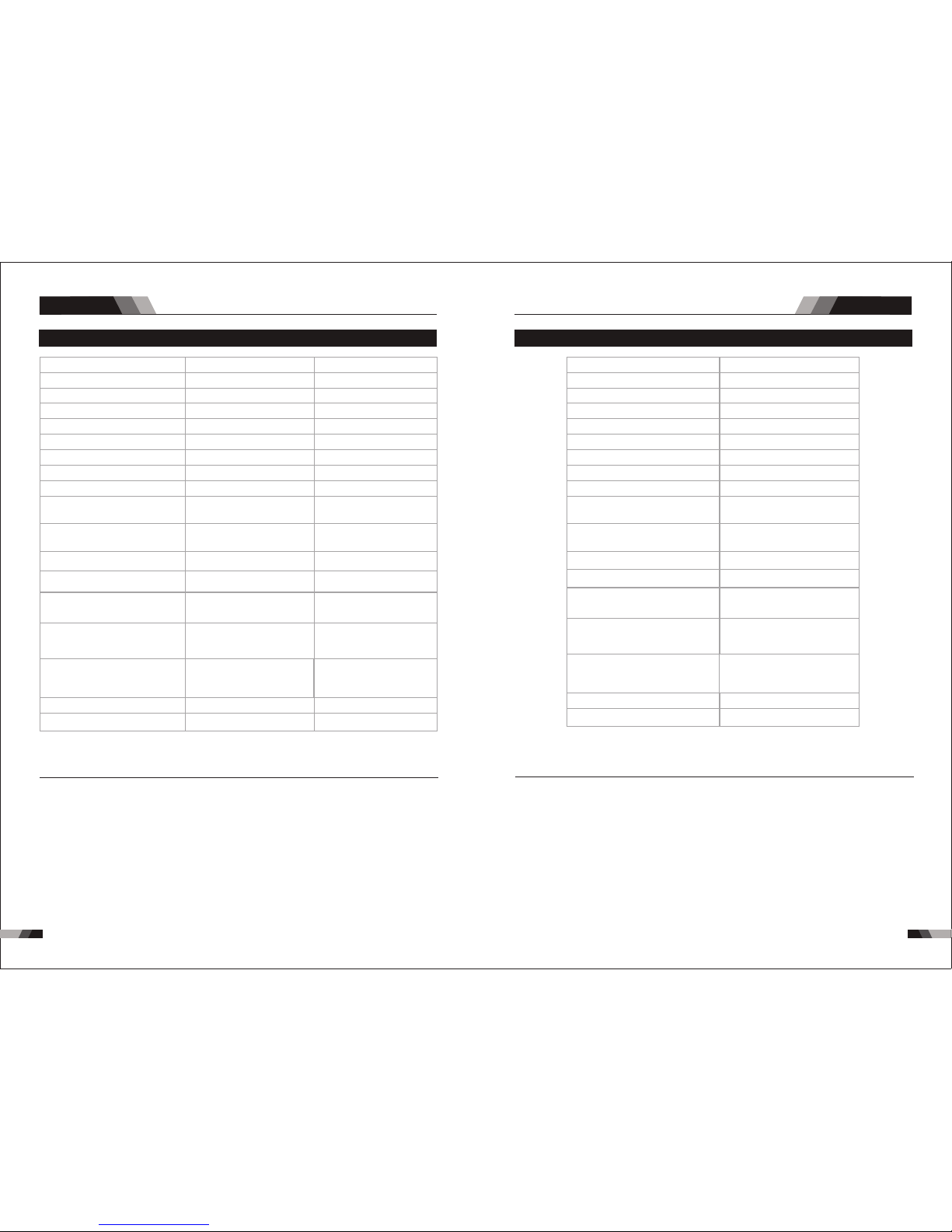

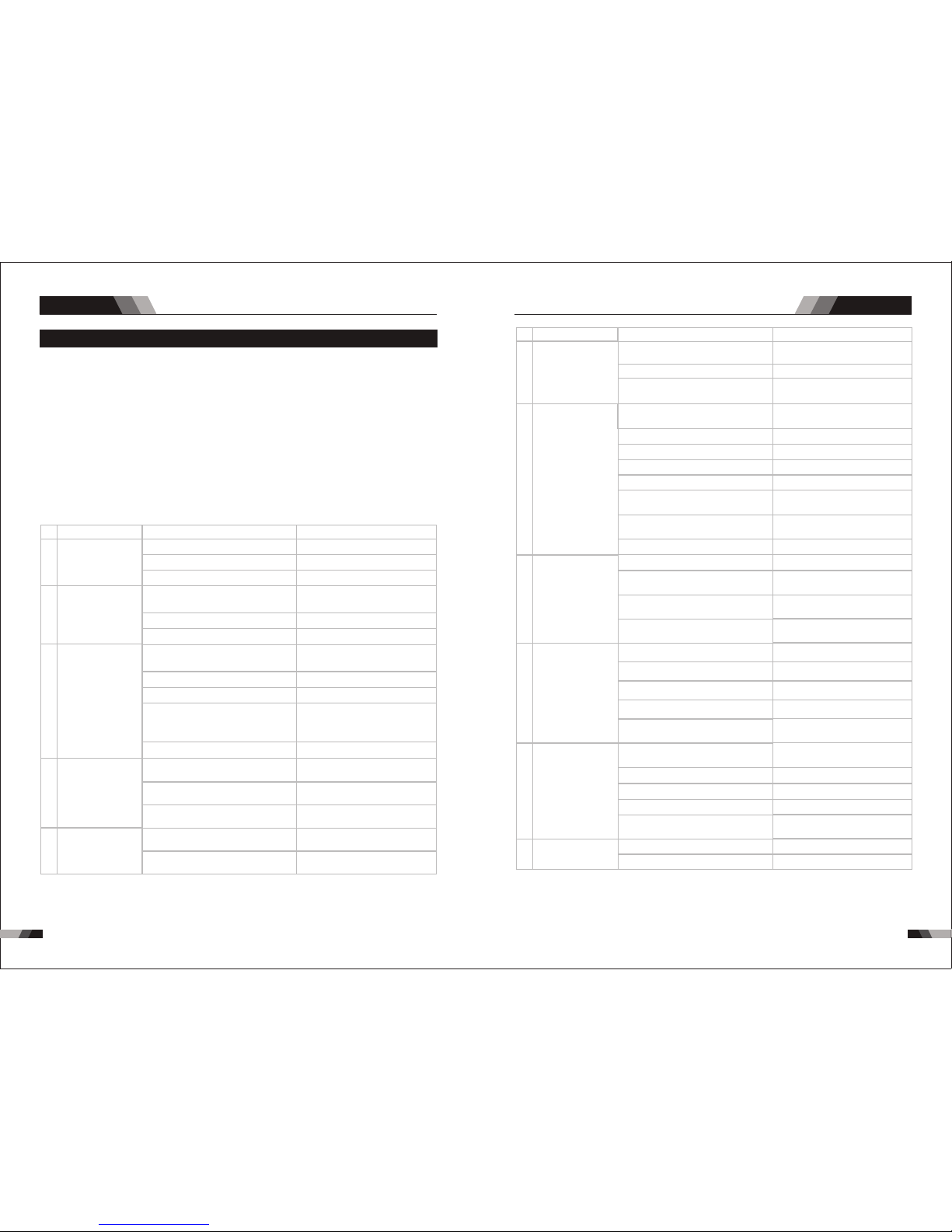

1.5 Specificat ions V3 411.4 Specificat ions V1 841/V241

NO TE

Not e 1: The Ef fect ive In put Cur rent sh ould be u sed for t he dete rmina tion of c able si ze &

Not e 1: The Ef fect ive In put Cur rent sh ould be u sed for t he dete rmina tion of c able si ze &

sup ply r equi reme nts .

sup ply r equi reme nts .

Not e 2: Gene rator R equir ement s at the Ma ximum O utput D uty Cyc le.

Not e 2: Gene rator R equir ement s at the Ma ximum O utput D uty C ycle .

Not e 3: Moto r start f use s or the rmal c ircui t break ers are r ecomm ended f or this a ppl icat ion.

Not e 3: Moto r start f use s or the rmal c ircui t break ers are r eco mmen ded fo r this ap plica tion.

Che ck lo cal re quir ement s for you r sit uati on in th is rega rd.

Che ck lo cal re quir ement s for you r sit uati on in th is re gard .

Due t o varia tions t hat can o ccur in m anufa cture d produ cts, cl aimed p erfor mance , volta ges,

Due t o varia tions t hat can o ccur in m anufa cture d produ cts, cl aimed p erfor mance , volta ges,

rat ings, a ll capa citie s, meas ureme nts, di mensi ons and w eight s quote d are app roxim ate

rat ings, a ll capa citie s, meas ureme nts, di mensi ons and w eight s quote d are app roxim ate

onl y. Achieva ble ca pacitie s and ra tings in us e and op eration w ill de pend upon c orre ct

onl y. Achieva ble ca pacitie s and ra tings in us e and op eration w ill de pend upon c orre ct

ins talla tion, u se, app licat ions, m ainte nance a nd serv ice.

ins talla tion, u se, app licat ions, m ainte nance a nd serv ice.

IP2 3

IP2 3

Des cript ionDes cript ion

Wei ghtWei ght

Pow er Sour ce Dime nsion sPow er Sour ce Dime nsion s

Coo lingCoo ling

Wel der Typ eWel der Typ e

Eur opean S tanda rdsEur opean S tanda rds

Num ber of Ph asesNum ber of Ph ases

Nom inal Su pply Vol tageNom inal Su pply Vol tage

Nom inal Su pply Fr equen cyNom inal Su pply Fr equen cy

Wel ding C urrent Ran ge

(DC S TICK Mo de)

Wel ding C urren t Range

(DC S TICK Mo de)

Wel ding C urrent Ran ge

(DC T IG Mod e)

Wel ding C urren t Range

(DC T IG Mod e)

Sin gle Pha se Gene rator

Req uirem ent

Sin gle Pha se Gene rator

Req uirem ent

STI CK (MMA )

Wel ding O utput , 40ºC, 1 0 min.

STI CK (MMA )

Wel ding O utput , 40ºC, 1 0 min.

TIG ( GTAW)

Wel ding O utput , 40ºC, 1 0 min.

TIG ( GTAW)

Wel ding O utput , 40ºC, 1 0 min.

Ope n circu it volt age

Ope n circu it volt age

Pro tecti on Clas s

Pro tecti on Clas s

Max imum In put Cur rent

Max imum In put Cur rent

Effective Input Current

Effective Input Current

VEC TOR DIG ITAL V24 1 AC/ DC

21. 9 kg

H52 5mmxW 260mm xD445 mm

Fan C ooled

Inv erter P ower So urce

EN 60 974-1 / I EC 6097 4-1

1

230 V +/- 15%

50/ 60Hz

10 - 20 0A

10 - 20 0A

29. 5A

41. 7A

14. 4kVA

200 A @ 50% , 28V

141 A @ 100 %, 25. 6V

200 A @ 50% , 18V

141 A @ 100 %, 15. 6V

66V D C

IP2 3

VEC TOR DIG ITAL V34 1 AC/ DCVEC TOR DIG ITAL V18 41 AC/DC

26. 4 kg

10. 9 kg

Fan C ooledFan C ooled

Inv erter P ower So urceInv erter P ower So urce

EN 60 974-1 / I EC 6097 4-1EN 60 974-1 / I EC 6097 4-1

31

400 V +/- 15%230 V +/- 15%

50/ 60Hz50/ 60Hz

30 - 30 0A10 - 17 0A

10 - 30 0A10 - 18 0A

12. 4A

20A

17. 5A

33. 9A

18. 2KVA

11.7 KVA

300 A @ 50% , 32.0 V

212 A @ 100 %, 28. 5V

170 A @ 35% , 26. 8V

100 A @ 100 %, 24V

300 A @ 50% , 22.0 V

212 A @ 100 %, 18. 5V

180 A @ 35% , 17. 2V

107 A @ 100 %, 14. 3V

66V D C

66V D C

H52 5mmxW 260mm xD445 mmH39 5mmxW 180mm xD375 mm

AC/DC SERIES EQUIPMENT

AC/DC SERIES EQUIPMENT

Sum mary

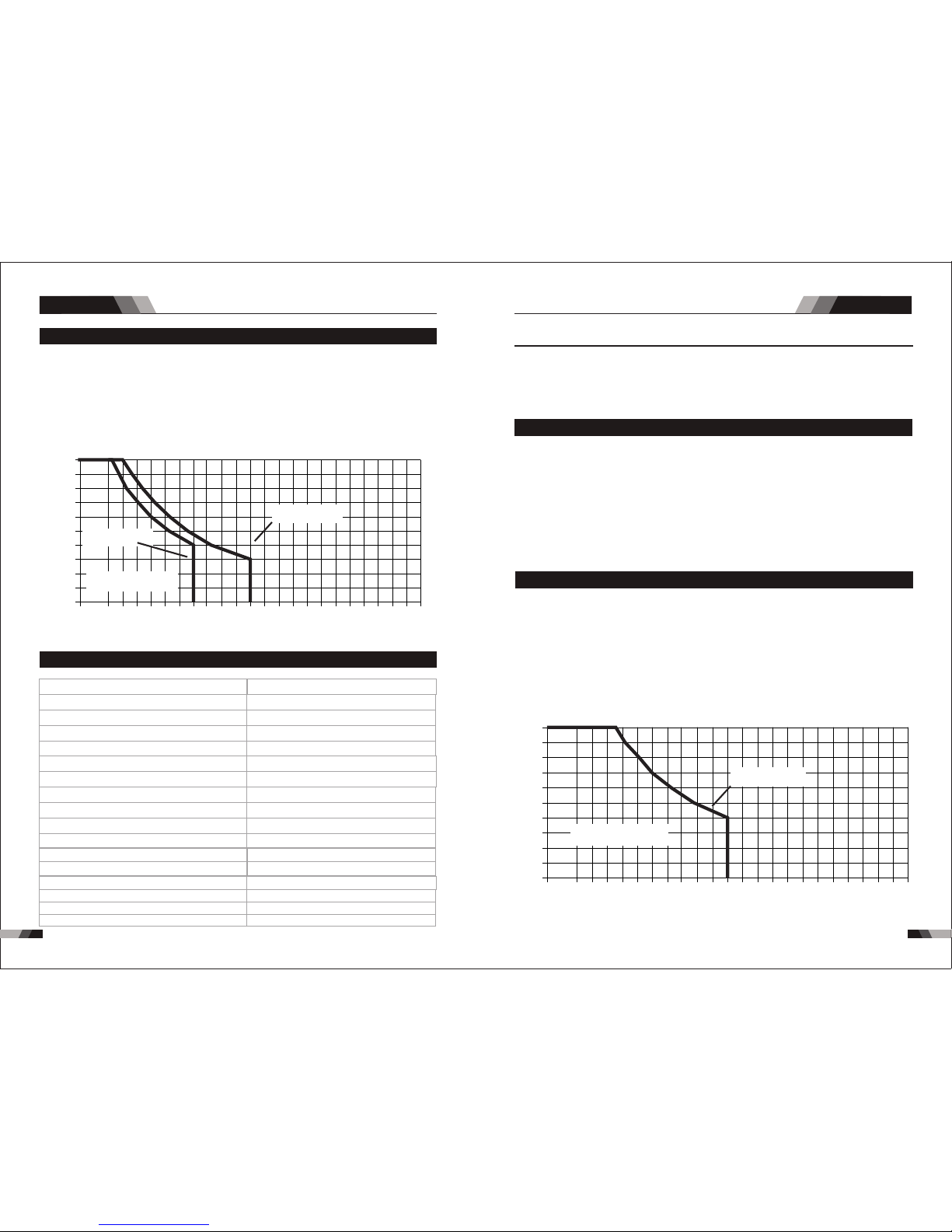

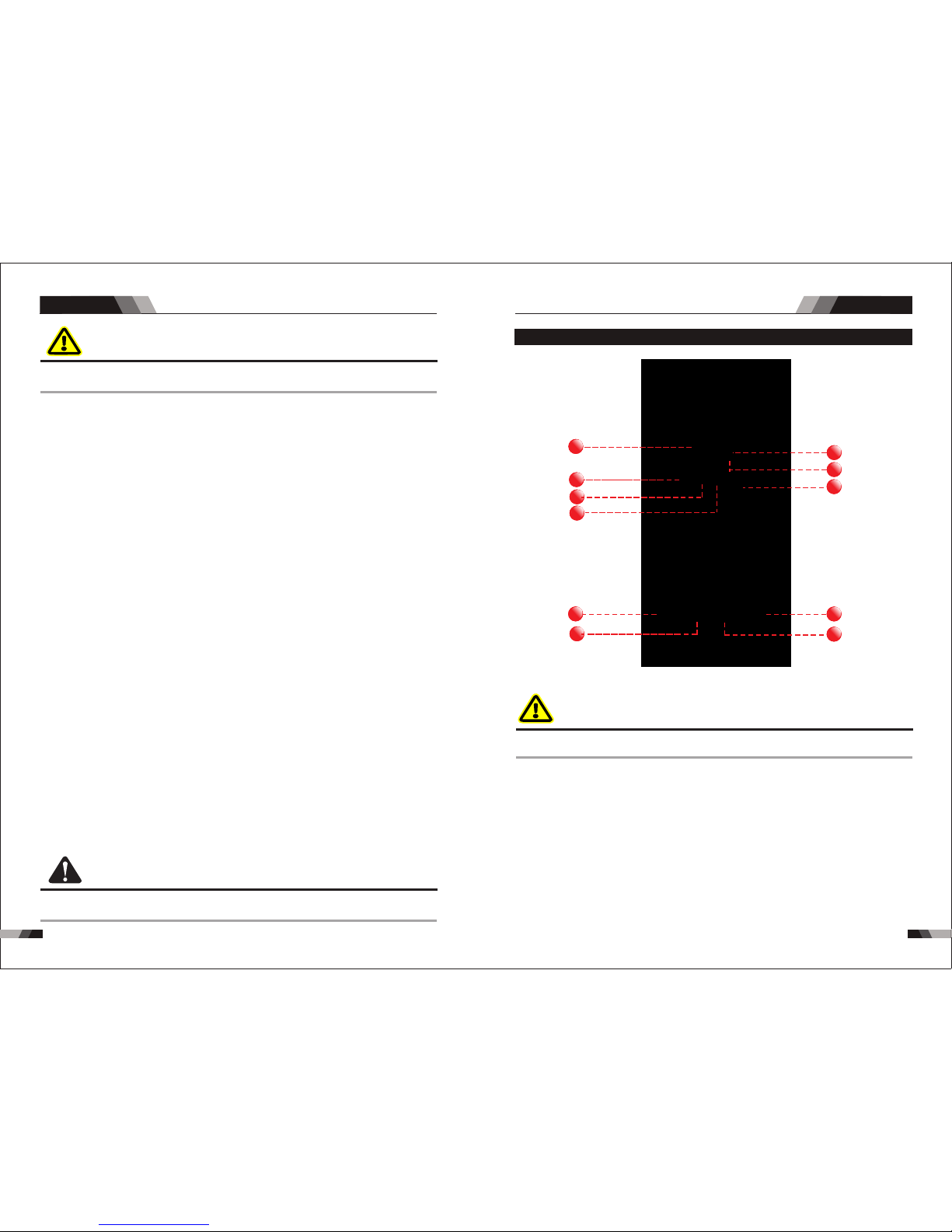

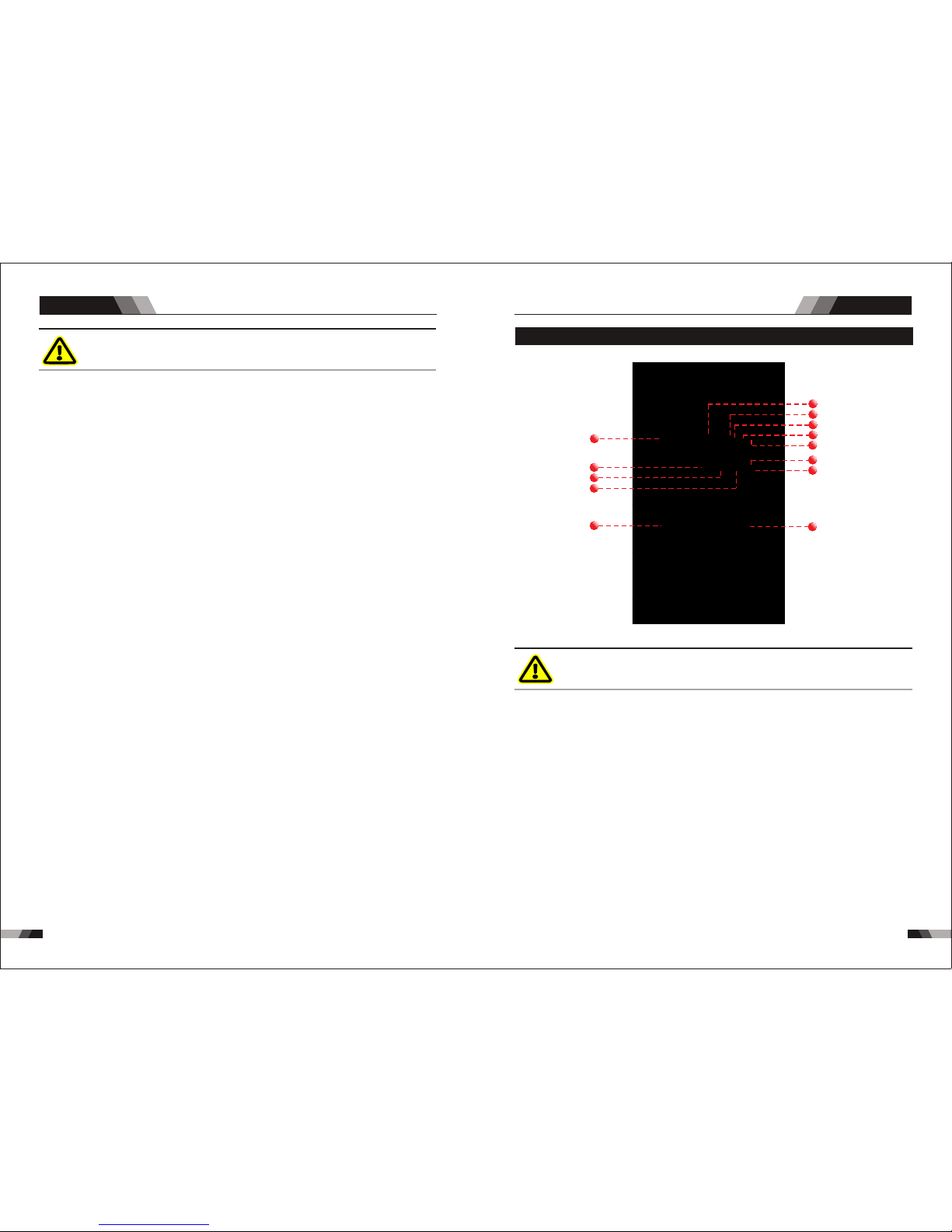

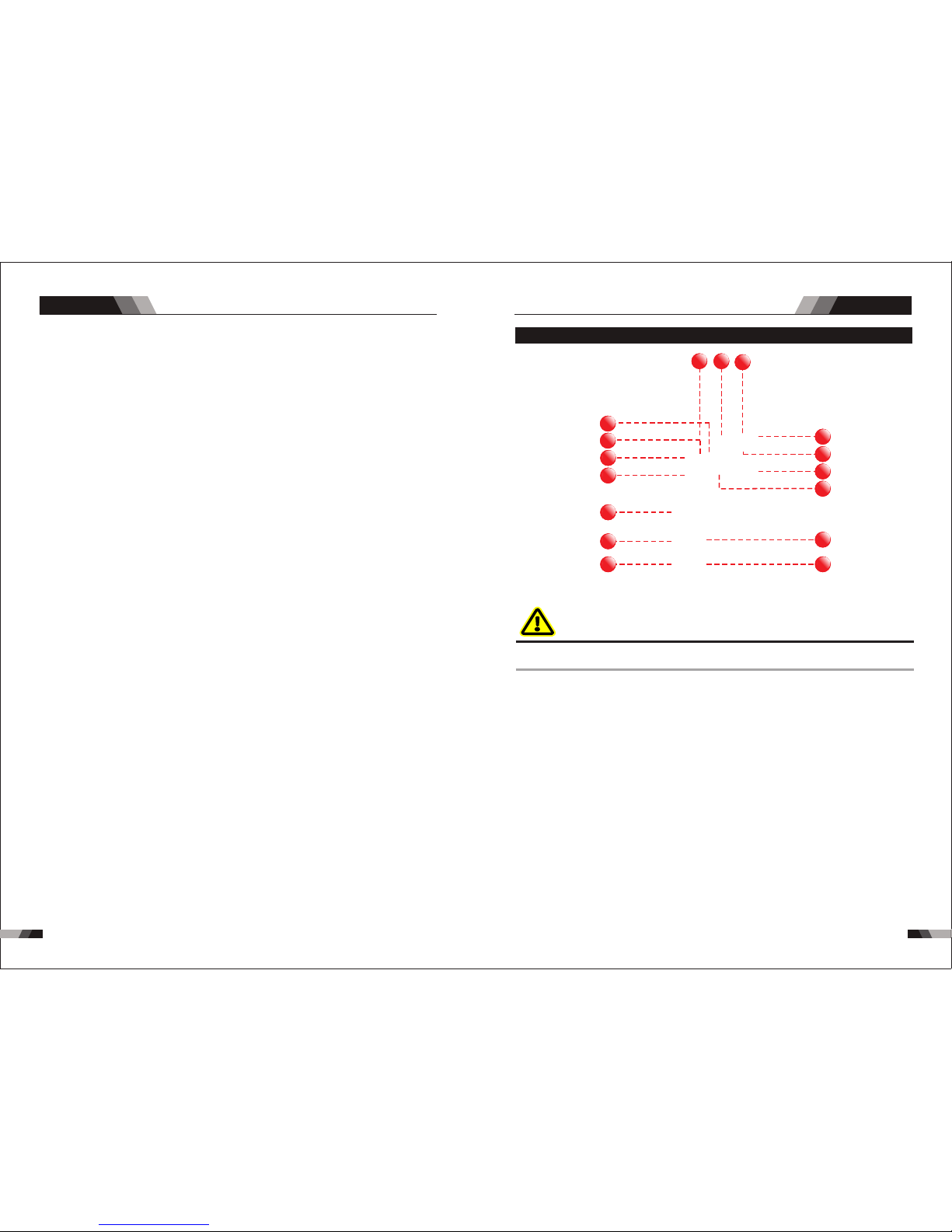

2.1 Layout For The P anel V1 841

1312

Ope ratio n

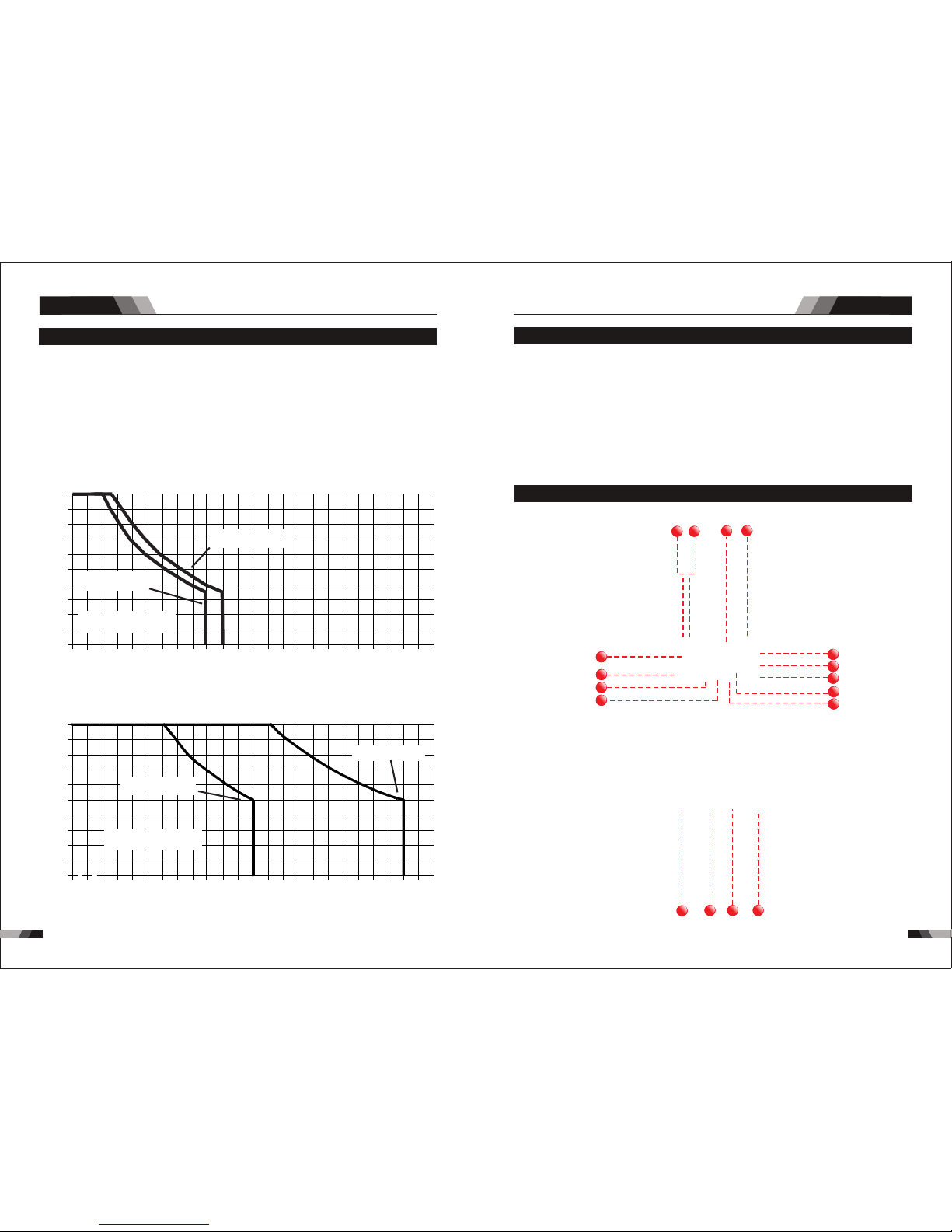

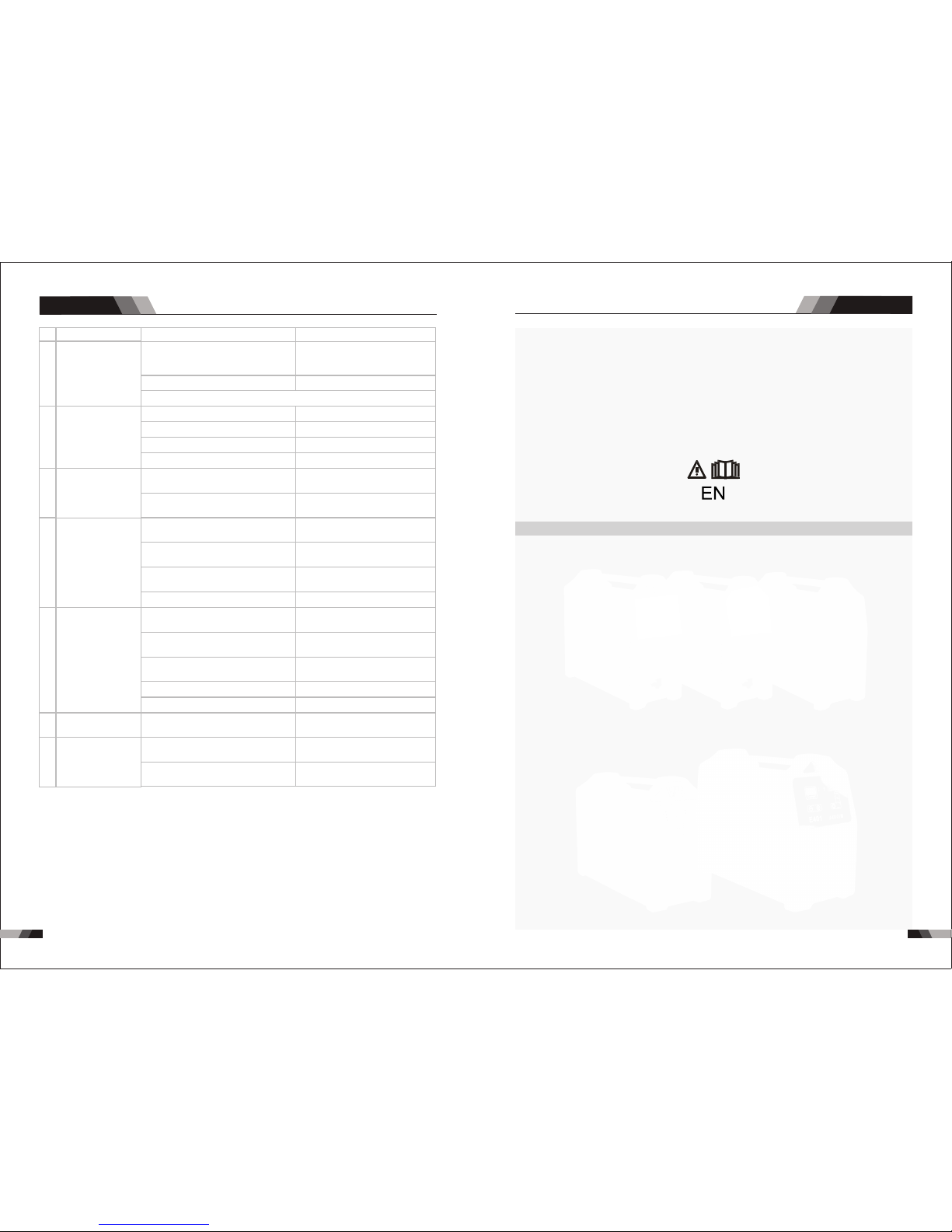

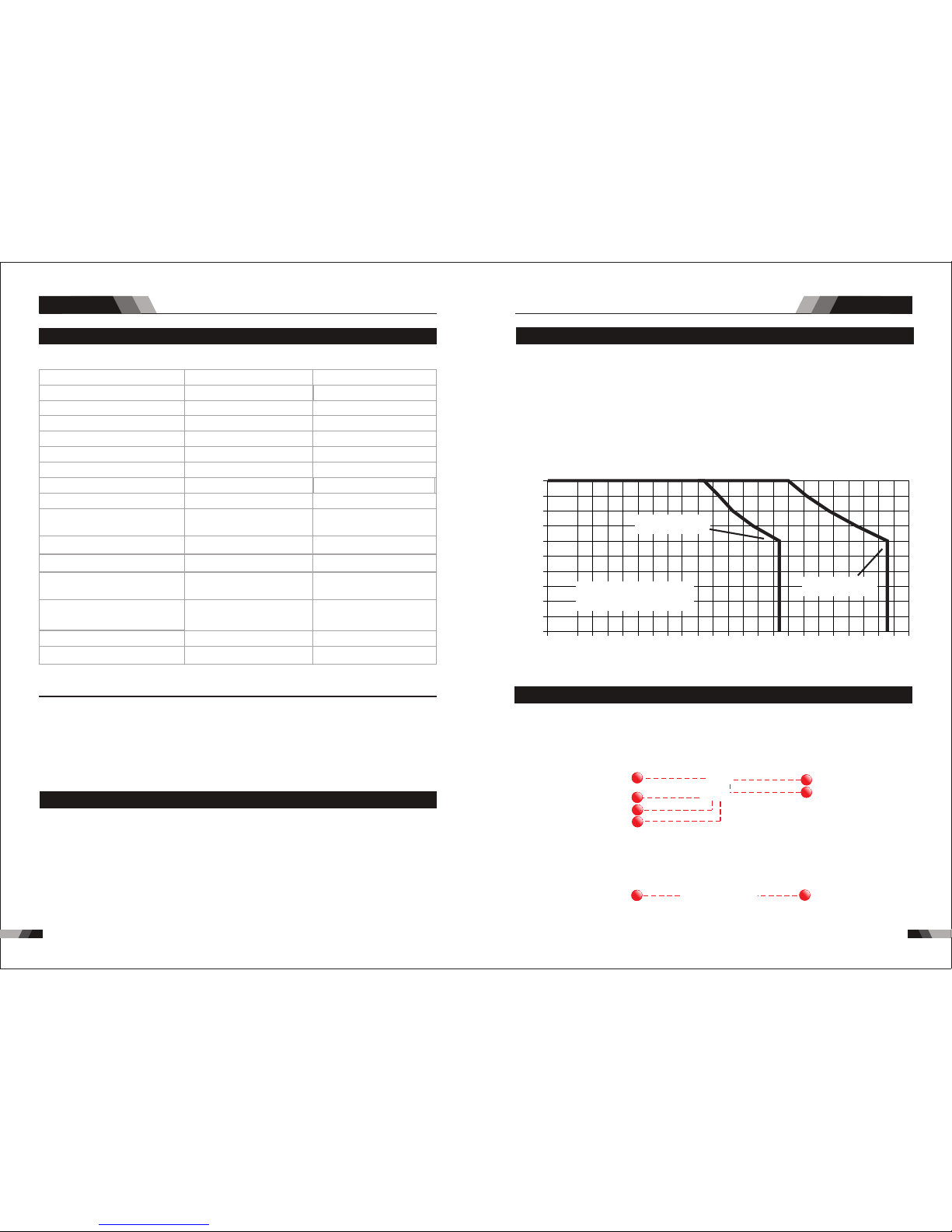

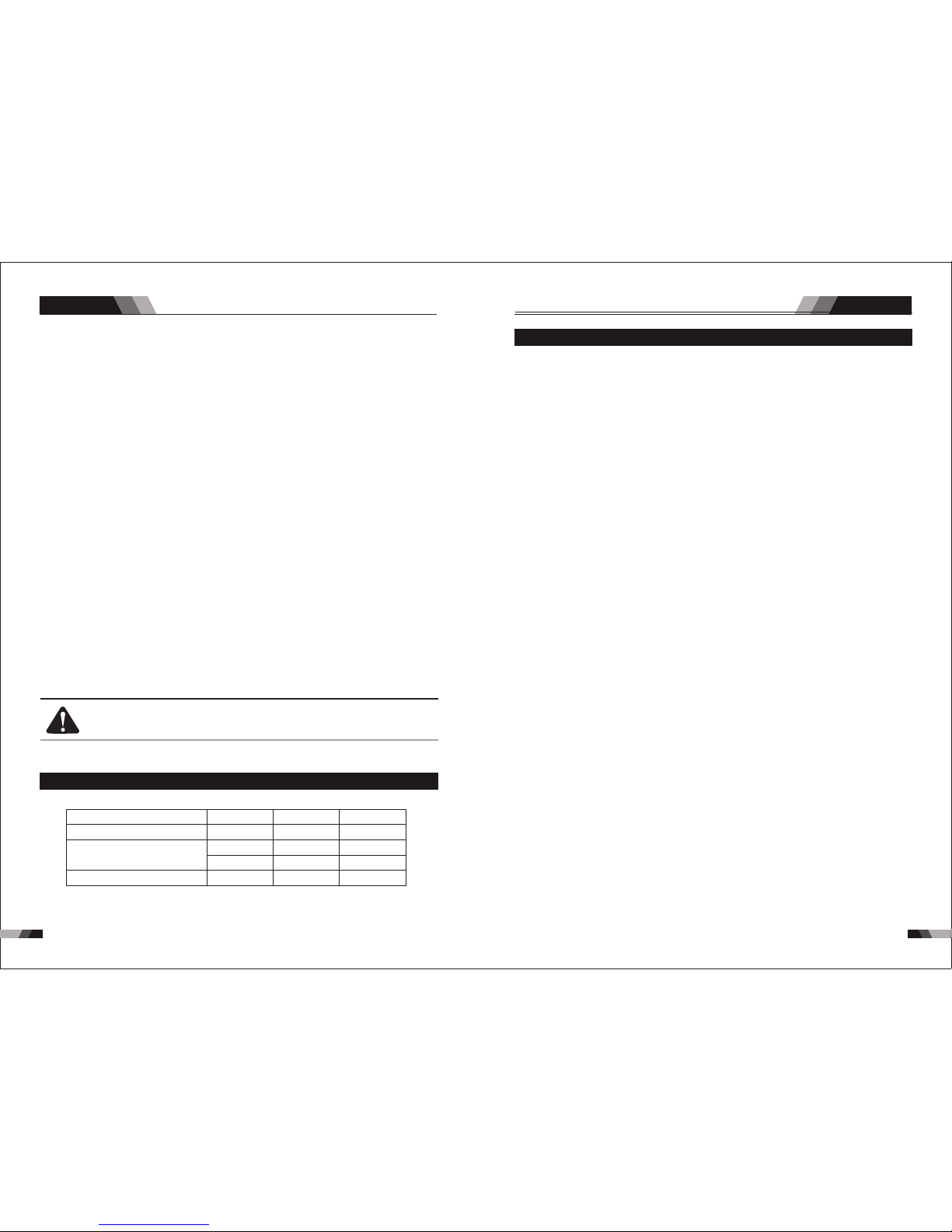

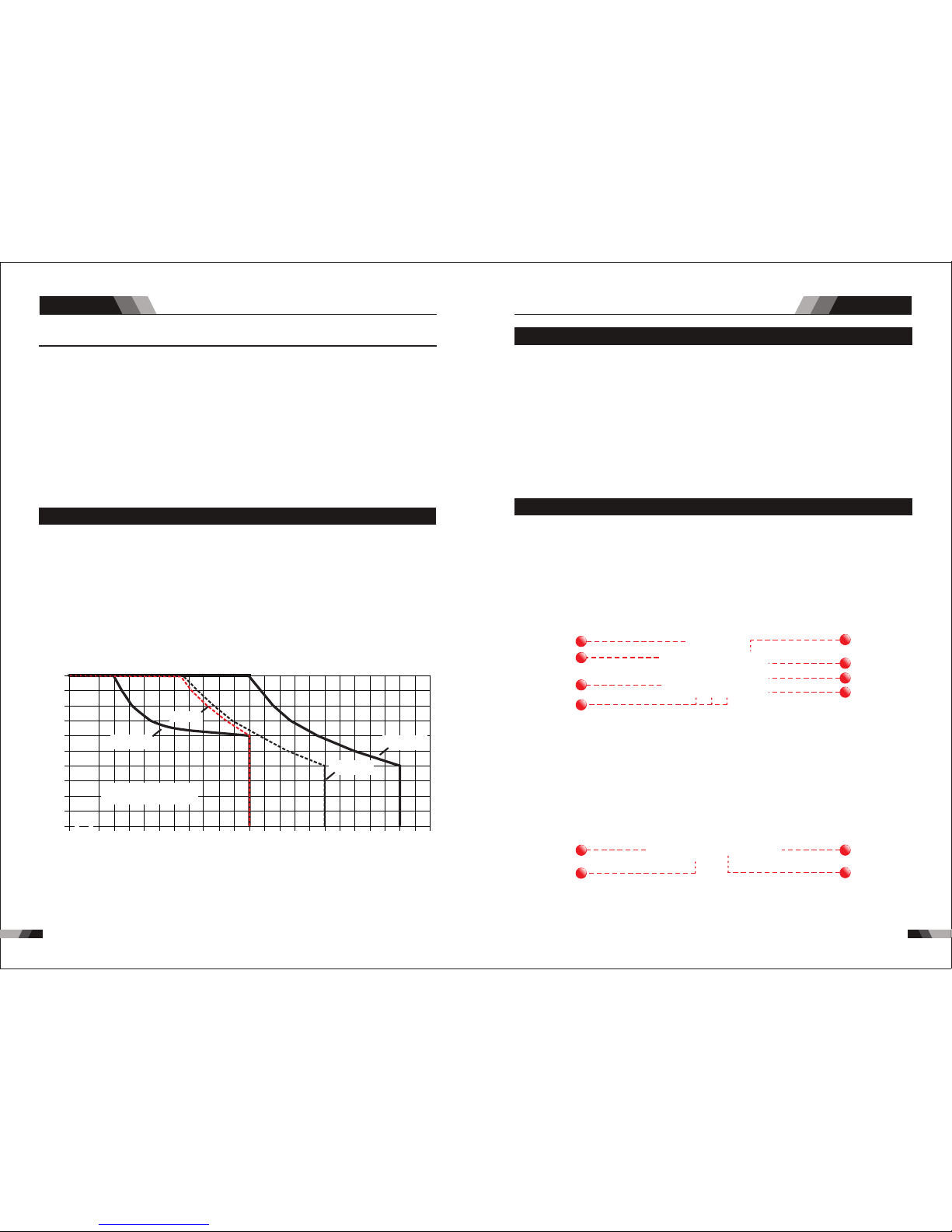

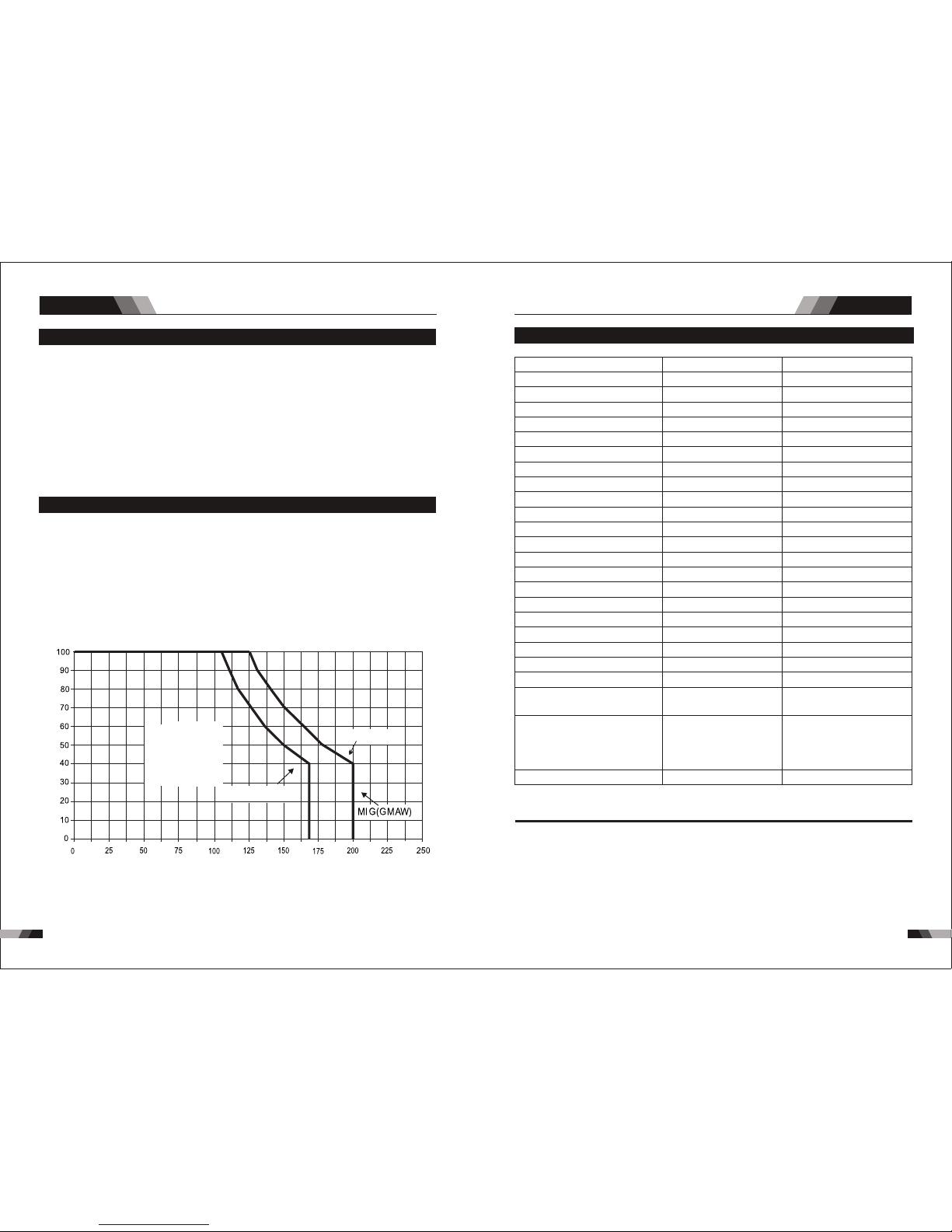

1.6 Duty Cy cle

The r ated d uty cyc le of a Wel ding P ower So urce, i s a state ment of t he ti me it ma y be

ope rated a t its rat ed weld ing cur rent ou tput wi thout e xceed ing the t emper ature l imits o f

th e in sulat ion of t he c omp one nt p ar ts. To ex pla in t he 1 0 mi nut e du ty c ycl e perio d th e

fo llo win g exa mpl e is u sed . Sup pos e a Wel din g Pow er S our ce i s des ign ed to ope rat e at

a 50 % dut y cyc le, 300 a mpe res a t 32 vo lts . Thi s mea ns th at it has b een des ign ed an d

buil t to p rov ide the rat ed am per age ( 300 A) fo r 5 mi nut es, i.e . arc wel din g tim e, out of

ev ery 10 mi nut e per iod ( 50% o f 10 m inu tes i s 5 mi nut es) . Dur ing t he o the r 5 mi nut es of

th e 10 m inu te peri od th e Wel din g Pow er So urc e mus t id le a nd b e al low ed to cool. T he

the rmal cu t out wil l opera te if the d uty cyc le is exc eeded .

◆3M Po wer cor d

◆200 Am p elect rode ho lder wi th 3M cab le

◆200 Am p earth c lamp wi th 3M cab le

◆4M TI G Torch WP2 6

◆3M Ga s Hose

◆Ope ratin g Manua l

1.7 Packa ged Ite ms

V1841/V 241

◆3M Po wer cor d

◆300 Am p elect rode ho lder wi th 3M cab le

◆300 Am p earth c lamp wi th 3M cab le

◆4M TI G Torch WP1 8

◆3M Ga s Hose

◆Ope ratin g Manua l

V341

Duty Cyc le( PERCENTA GE)

Weldi ng Curr ent(A MPS)

10 0 12 0 14 0 16 0 18 0 2 00 2 20

0

10

20

30

40

50

60

70

80

90

10 0

24 0 26 0 28 0 30 0 32 00

Saf e Opera ting Re gion

(TI G&STI CK)

V18 41 TIG

V18 41 STIC K

Duty Cyc le( PERCENTA GE)

Weldi ng Curr ent(A MPS)

10 0 12 0 14 0 16 0 18 0 2 00 2 20

0

10

20

30

40

50

60

70

80

90

10 0

24 0 26 0 28 0 30 0 32 00

V24 1 STICK /TIG

V34 1 STICK /TIG

3

2

1

4

8

7

5

14

15

16

17

6

12

13

9

10

11

3

2

1

4

8

7

5

14

15

16

17

6

12

13

9

10

11

Saf e Opera ting Re gion

(TI G&STI CK)

1. Digit al Ammete r / Par ameter me ter

The digita l Ammeter i s used t o displ ay the a ctua l outpu t curr ent of the powe r sour ce. It is

als o used to d ispla y Param eters i n Progr ammin g Mode.

De pend ing o n the Progr amm ing Pa ram eter sele cte d, the s tatu s indi cto r adjacen t to th e

Amme ter wil l illum inate t o show th e units o f the pro gramm ing par amete r.

Whe n weldi ng, the Am meter w ill dis play ac tual we lding c urren t.

2. Power O N Ind ica tor

4. Ar cforce/Hot S tar t/Hotst art c urr ent

The PO WER ON i ndicator il lumi nates when th e ON/OF F swit ch is in th e ON pos ition a nd

Cha nge the select ed weld f uncti ons mode from we ldin g curre nt to hot start t o start t ime to

arc fo rce from the digital d ispla y.

the c orrec t mains v olt age is p rese nt.

3. Therm al Ov erl oad Indic ato r Lig ht

Thi s weld ing pow er sour ce is pro tecte d by a self r esett ing the rmost at. The i ndic ator wi ll

illumi nat e if the d uty c ycle o f the p ower s ourc e has be en ex ceed ed. S houl d the th erma l

ov erl oad indic ator i llu min ate t he output o f the po wer s our ce wi ll be d isa ble d. Once the

po wer s our ce cools down th is lig ht wi ll go O FF an d the o ver t emp era tur e con diti on wil l

au tomatic all y res et. N ote th at the m ain s pow er sw itch s houl d rem ain i n the o n posi tion

su ch that the f an con tin ues t o oper ate th us al low ing th e unit t o coo l suff icie ntl y. Do not

swi tch the u nit off s houl d a therm al over load co nditi on be pre sent.

AC/DC SERIES EQUIPMENT

AC/DC SERIES EQUIPMENT

Ope ratio n

Ope ratio n

1514

5. JOB and S AVE

You ca n pre ss JO B to se lect t he me mor y rec ord s tha t you h ave s ave d bef ore f rom 1 -9.

For t he ne w sett ing of p resen t curre nt Amp s ,jus t pres s SAVE.

6. Mode Bu tto n

Pre ss th e MODE b utto n to to ggle AC a nd DC ou tput in L IFT TIG , HF TIG .

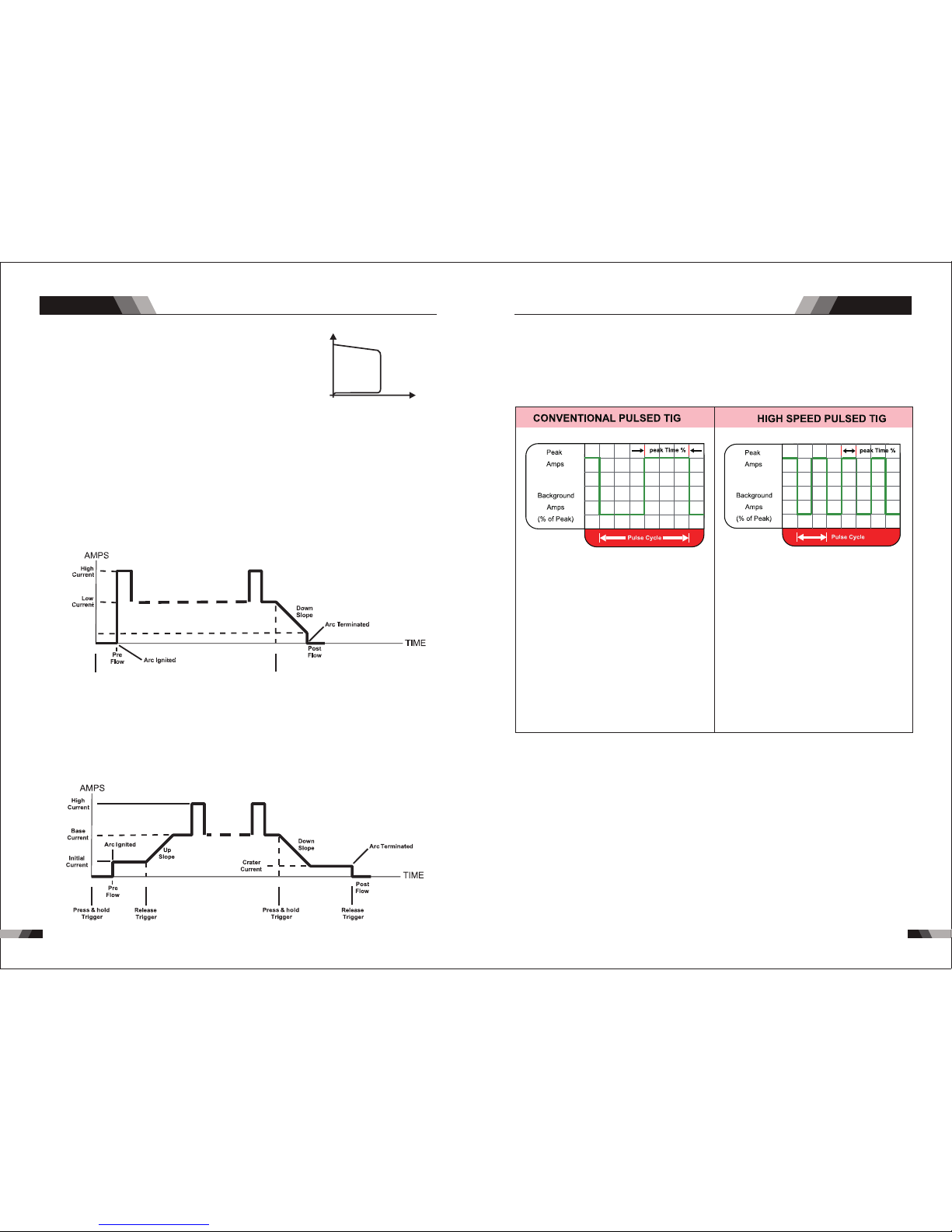

7. Trigge r Mod e Con trol Butt on (H F TIG a nd LIFT TIG M ode o nly)

The t rig ger mo de con trol is u sed to sw itch th e funct ion alit y of the t orc h trig ger be tween

2T an d 4T.

Min imum

Cur rent

Pre ss & hold

Trig ger

Rel ease

Trig ger

No te: th at w hen op erati ng i n GT AW (HF a nd L IFT T IG m od es ), t he p ow er s ou rc e wi ll

rem ain act ivate d until t he sele cted do wn slop e time ha s elaps ed

8. Proce ss Se lec tion Butt on

Th e pro ces s sel ect ion c ont rol i s use d to se lec t the d esi red w eld ing m ode . Two mo des

are a vaila ble, GTAW ( TIG ), and M MA (Sti ck) m odes .

9. Pulse B utt on

Pre ss the PU LSE b utto n to tog gle P ulse O n and OF F.

10. Prog ram min g Paramet er In dic ators

The se ind icato r light s will il lumin ate whe n progr ammin g.

Set ting ra nges

Arcfor ce: 1-1 00AMP Hot S tart:0.1-0 .5S H otstart curr ent :1-100 AMP

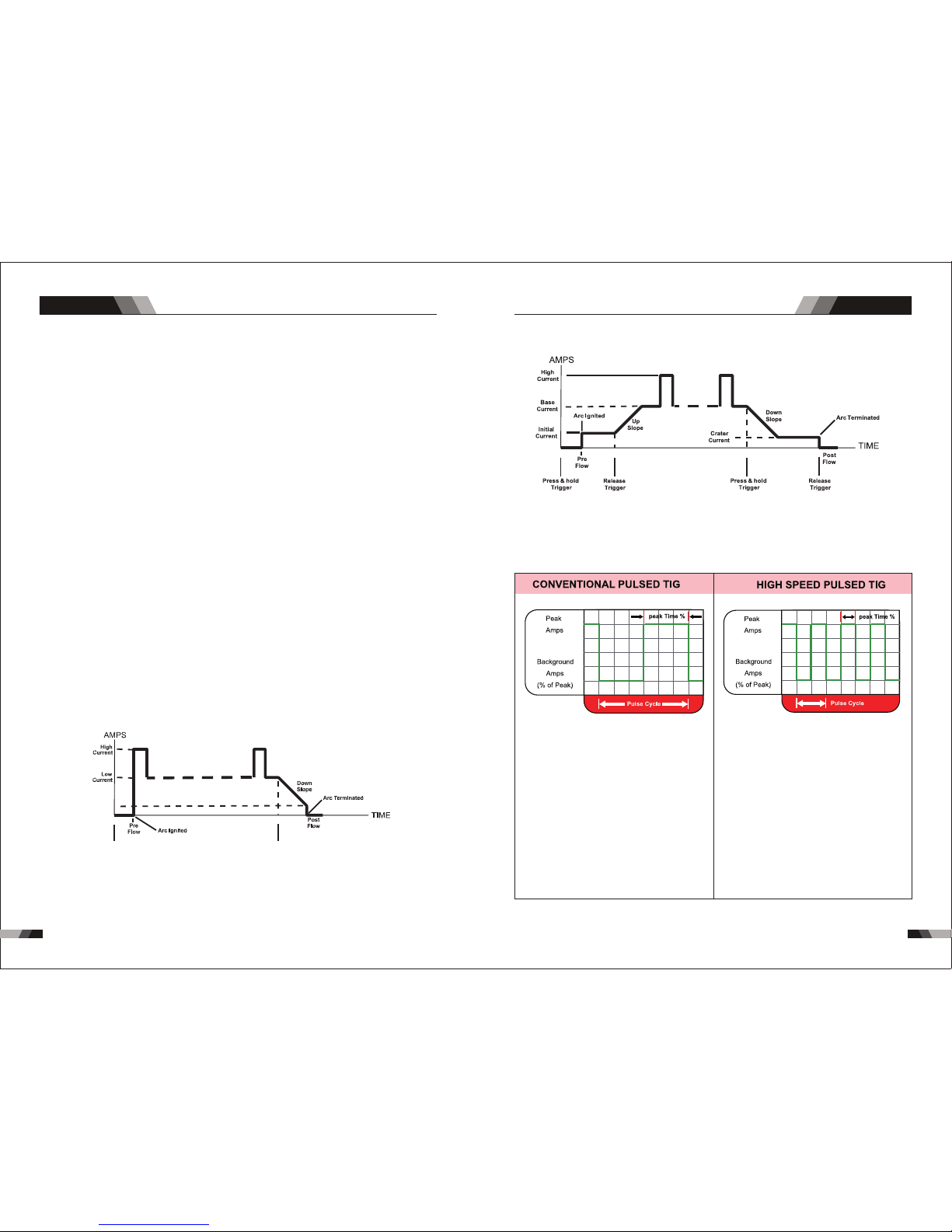

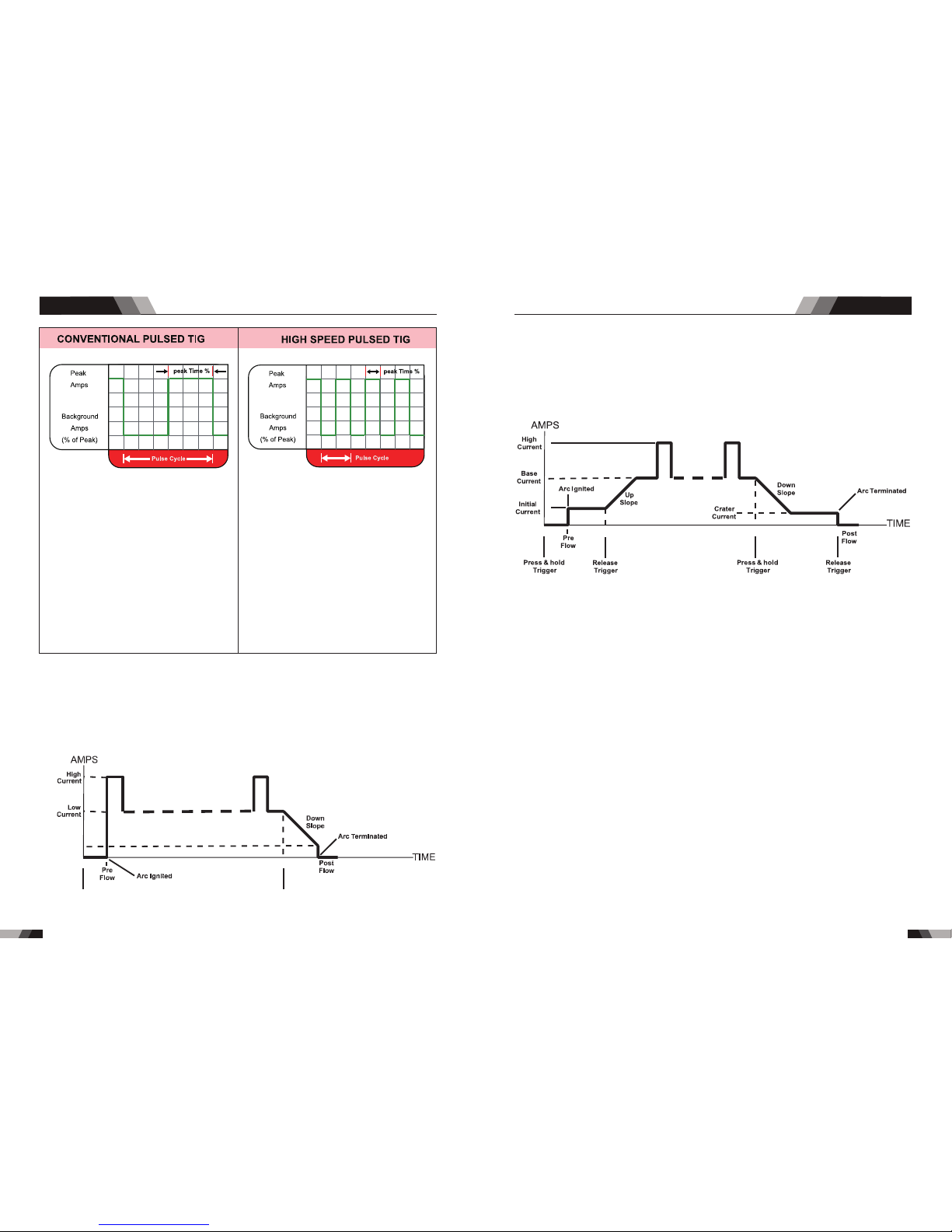

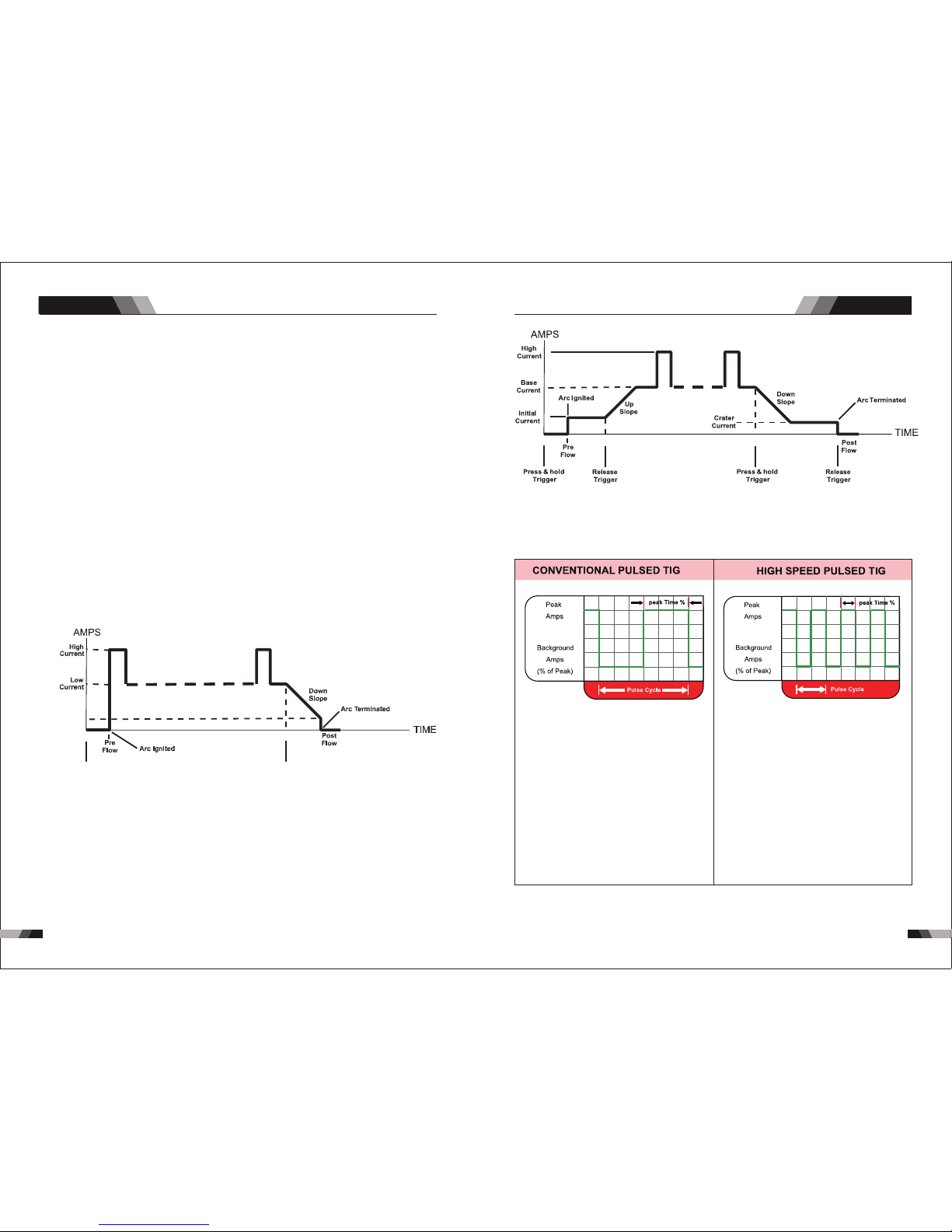

Typi cally f rom 1 to 10 P PS. Pro vides a h eatin g

and c oolin g effec t on the w eld pud dle an d can

red uce dis torti on by low ering t he aver age

amp erage . Th is heat ing and c oolin g effec t also

pro duces a d istin ct ripp le patt ern in th e weld

bea d. The re lati onshi p betwe en pul se freq uency

and t ravel s peed de termi nes the d istan ce

bet ween th e rippl es. Slo w pulsi ng can al so be

coo rdina ted wit h fille r metal a dditi on and

inc rease o veral l contr ol of the w eld pud dle

In ex cess of 4 0 PPS, Pu lsed TI G beco mes mor e

aud ible th an visi ble-c ausin g incre ased pu ddle

agi tatio n for a bet ter as- welde d micro struc ture.

Pul sing th e weld cu rrent a t high sp eeds- betwe en

a hig h Peak an d a low Bac kgrou nd ampe ragecan a lso con stric t and foc us the ar c.Thi s resul ts

in ma ximum a rc stab ility, i ncre ased pe netra tion

and i ncrea sed tra vel spe eds(C ommon R ange:

100 -500 PP S).

The Ar c-Sha rpeni ng effe cts of h igh spe ed

pul sing ar e expan ded to ne w dimen sions . The

abi lity to p ulse at 5 ,000P PS furt her enh ances

arc s tabil ity and c oncen trati on pote ntial -whic h

is ex tre mel y benef icial t o autom ation w here

max imum tr avel ts peeds a re requ ired.

ou tput t o be ac tive .

Press an d hol d the to rch t rigg er to a ctiv ate th e powe r sou rce (w eld) . Rele ase t he tor ch

trigge r swi tch to c eas e weld ing .

2T N orm al M ode In th is mo de, t he to rch t rig ger mus t rem ain p res sed for the wel din g

op era tor f atigu e. I n thi s mod e th e ope rat or ca n pre ss an d re lea se t he to rch t rig ger a nd

to rch tri gger.

4T La tc h mod e th is m ode of we ld in g is ma inly u sed fo r lo ng w el din g ru ns t o re duce

th e out put wil l rem ain act ive . To d eac tiv ate t he p owe r sourc e, th e tr igg er sw itc h must

ag ain be p re ssed a nd r el eased , th us e li minat ing th e ne ed f or t he o per ato r to h old the

AC/DC SERIES EQUIPMENT

AC/DC SERIES EQUIPMENT

Ope ratio n

Ope ratio n

Lo ose wel ding te rmi nal c onn ect ion s can cau se o ver heati ng a nd re sul t in t he ma le pl ug

be ing fus ed i n the ter min al.

2.2 Control Pane l

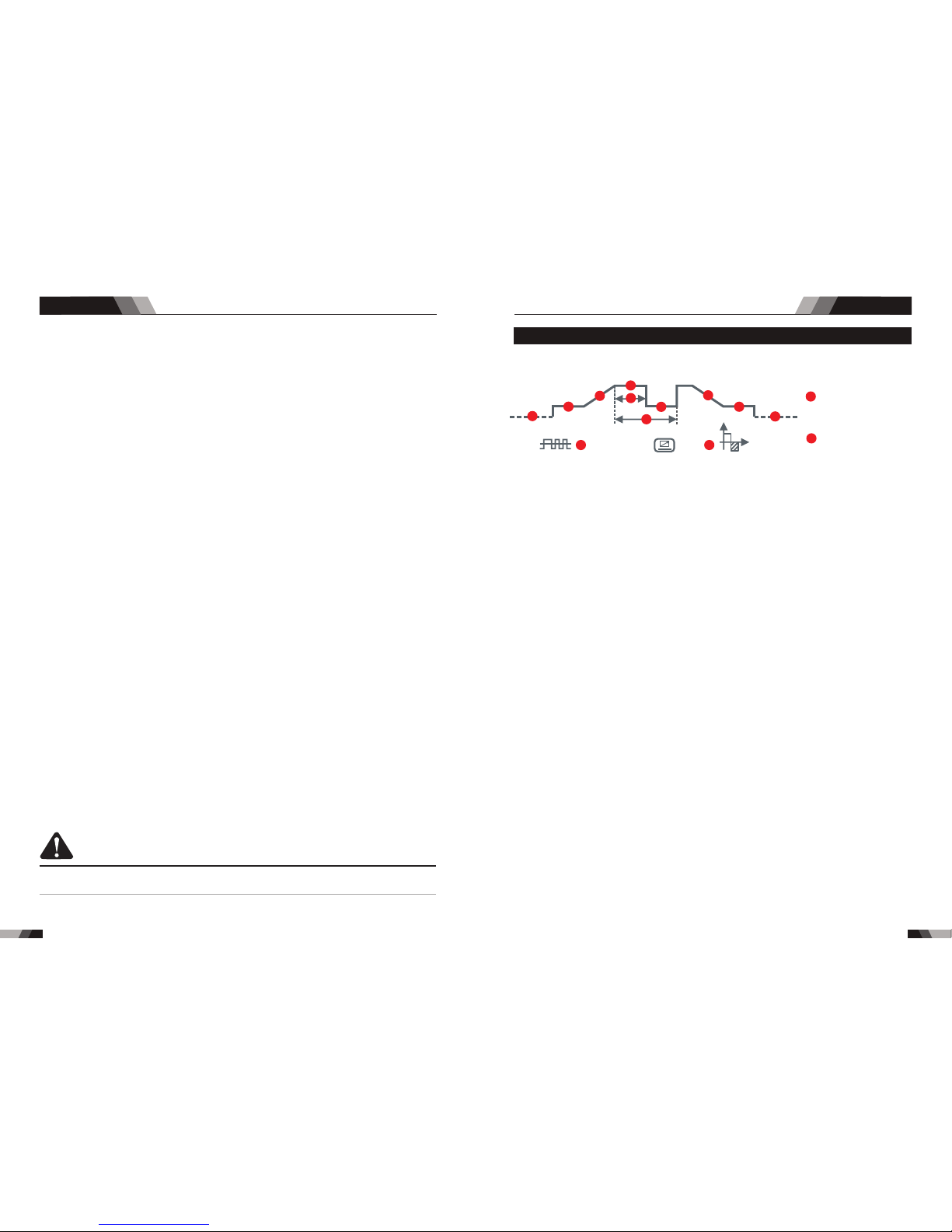

.Gas Pre-Fl ow 1

Abs olut e sett ing r ange 0 .1s to 5 s (0. 1S inc reme nts )

Thi s param eter op erate s in TIG mo des on ly and is u sed to pr ovide g as to the w eld zon e

use d to dram atica lly red uce wel d poros ity at th e start o f a weld.

2.Init ial C urr ent

The m ain cur ren t Sett ing ra nge 1 0AMP t o 100A MP

Thi s parameter ope rates i n (4T) TIG m odes onl y and is used to set the start cu rrent f or TIG.

Th e Sta rt Cu rre nt rema ins o n un til t he torc h tri gge r swi tch i s rel eas ed af ter i t has bee n

dep resse d.

No te: T he ma xim um in iti al cu rre nt avai lab le wi ll b e lim ite d to t he se t val ue o f the bas e

cur ren t.

3.Up Slo pe

Set ting ra nges :0 .1S -10S ( 0.1S i ncr emen ts)

Thi s para mete r oper ates in (2T an d 4T) TIG modes only and is use d to set t he tim e for th e

we ld cu rre nt to ram p up, aft er th e tor ch tr igger sw itc h has b een pre sse d then re lea sed ,

fro m Initi al Curr ent to Hi gh or bas e curre nt.

4.Peak C urr ent

Set ting ra nges

V18 41: 10- 18 0A( DC TIG a nd AC HF T IG) ,10 -170A( Sti ck mod e)

Th is p ara met er sets t he TI G WE LD cu rre nt. T his p ara met er a lso set s th e ST ICK w eld

cur rent.

5.Base C urr ent

Set ting ra nges

V18 41:10 AMP to 18 0AMP ( DC TIG m ode), 10A MP to 18 0AMP ( AC HF TI G mode )

Sec ondar y curre nt (TIG )/pul se paus e curre nt.

6.Puls e Wid th

Set ting ra nges 10 %-90%

Th is pa ram ete r set s the p erc ent age o n tim e of th e PUL SE FR EQU ENC Y for H igh weld

cur rent wh en the PU LSE is ON .

7.Puls e Fre que ncy

Set ting ra nge s 1HZ -2 00HZ

Thi s param eter se ts the PU LSE F REQU ENCY w hen th e PULSE i s ON.

8.Down S lop e

Set ting ra nges 0. 1-1 0s

Thi s parameter o pera tes in TIG modes o nly and i s used to s et the time for t he weld c urre nt

to r amp d own, afte r the to rch t rig ger switc h has b een p res sed t o end c urre nt. Th is co ntro l

is us ed to eli minat e the cra ter tha t can for m at the co mpl etio n of a wel d.

9.End Cu rre nt

Set ting ra nges 10 A-180 A

This pa ramete r operate s in (4T) TIG mod es only and is us ed to set the fin ish curre nt for TIG.

The e nd current re main s ON unti l the to rch tri gger s witch is rele ased after it h as been

dep resse d.

No te: T he ma xim um crat er cu rre nt av ail abl e wil l be l imi ted t o the set v alu e of th e base

cur ren t.

10. Post F low

Set ting ra nges 1. 0-1 0S

Th is p arame te r ope rat es i n TI G modes o nly a nd is use d to ad jus t th e po st g as flow

ti me o nc e th e ar c ha s ex ti ng ui she d. T hi s co nt ro l is us ed t o dr am atic al ly r ed uc e

ox ida tio n of t he tu ngs ten e lec tro de.

171 6

17. Posi tiv e Welding Te rminal

Po sit ive W eld ing Ter min al. Wel din g cu rre nt f low s fr om th e Pow er S our ce v ia he avy

du ty ba yon et ty pe te rmi nal s. It i s ess ent ial , how eve r, th at th e mal e plu g is i nsert ed

and t urn ed sec urel y to achi eve a sou nd elec trica l conne ction .

and t urn ed sec urel y to achi eve a sou nd elec trica l conne ction .

15. Shie ldi ng Ga s Outlet

Th e Shi eld ing G as Ou tle t loc ate d on th e fro nt pa nel i s a fas t conn ecti on of a s uita ble

TIG Tor ch.

14. Nega tiv e Welding Te rminal

Ne gat ive W eld ing Te rmi nal . Wel din g cur ren t flo ws fr om th e Pow er So urce via h eav y

du ty ba yon et t ype t erm ina ls. I t is es sen tia l, ho wev er, t hat the mal e pl ug is ins ert ed

16. 5 Pin Co ntr ol So cket

The 5 pin rece ptac le is us ed to co nnec t a trig ger switch or r emot e cont rol to t he wel ding

Pow er Sour ce circ uit ry:

To make connectio ns, align ke yway, insert plug, and rota te thread ed collar fu lly clock wise.

12. Nega tiv e Con trol

13. Sele cti ng Fu nction Bu tto n

The N egat ive but ton is us ed to min us sele cted in P rogra mming s equen ce.

Thi s butt on can se lect di ffere nt pro gramm ing par amete r from No . 10

11. Posit ive C ont rol

The P osit ive but ton is us ed to plu s selec ted in Pr ogr ammi ng seq uence .

CAUTION

pr ior to s trik ing th e arc, o nce t he tor ch tr igg er swi tch h as be en pre ssed . This c ont rol is

AC/DC SERIES EQUIPMENT

AC/DC SERIES EQUIPMENT

Ope ratio n

Ope ratio n

1918

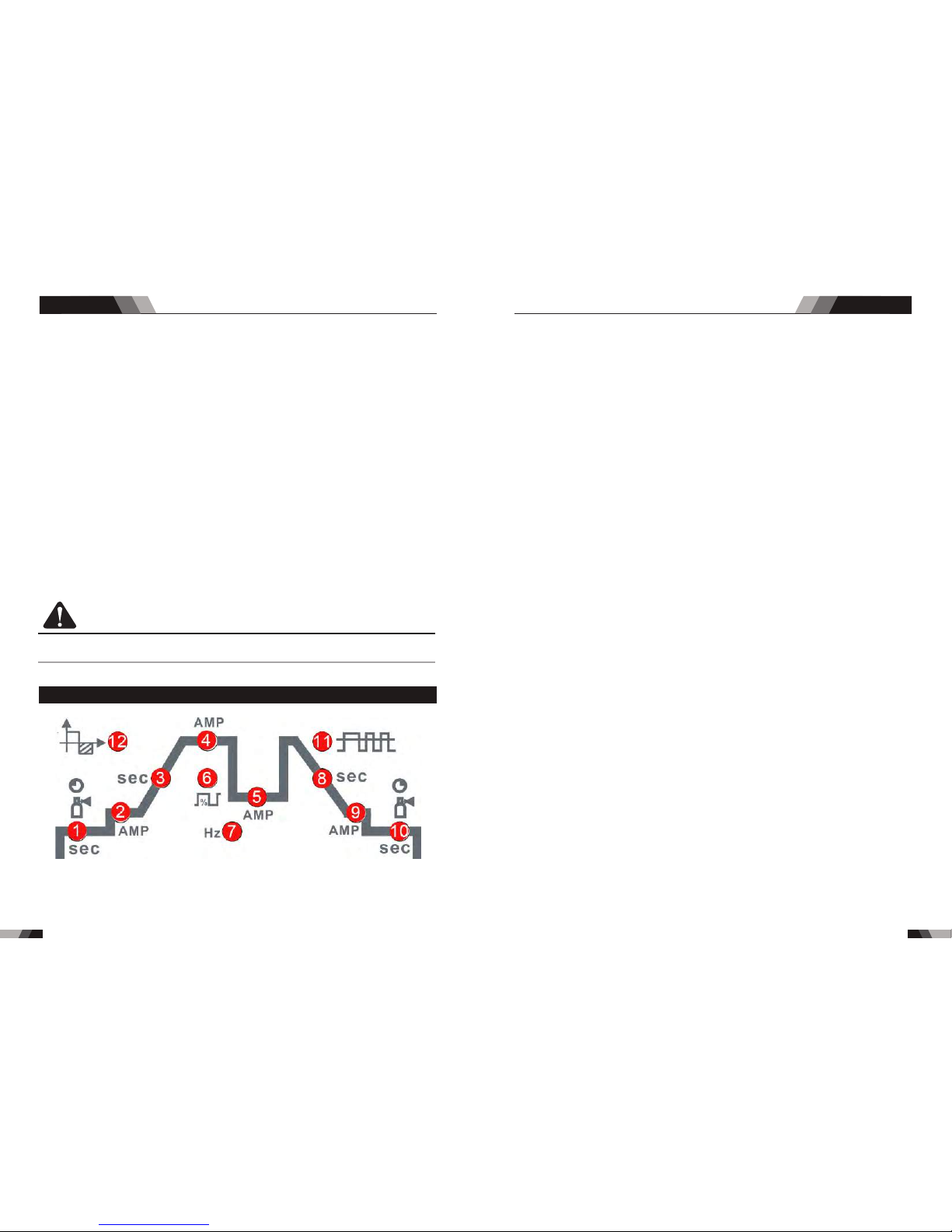

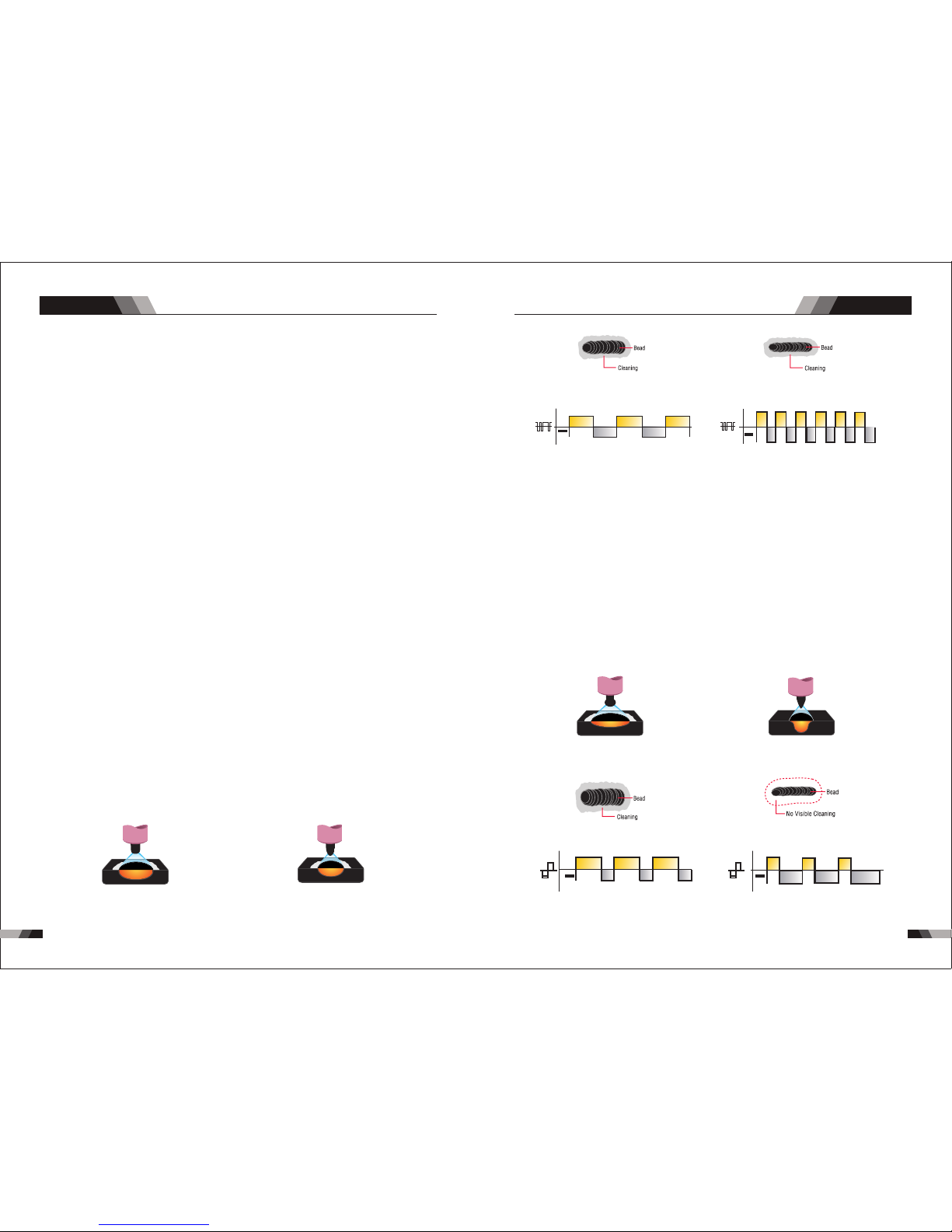

12.Wave Balance

Set ting ar range s 10%-5 0%

T hi s pa ra me te r o pe ra te s in AC T IG mo de an d i s u se d to se t t he pe ne tr at io n t o

cl ean ing act ion ra tio fo r th e AC w el d cu rr ent. G enera lly WAVE BALAN CE i s se t to

5 0% fo r AC ST IC K we ld in g. T he WAV E B AL AN CE co nt ro l c ha ng es th e ra ti o o f

pe net rat ion t o cle ani ng ac tio n of th e AC TI G wel din g arc . Max imu m wel d penet rat ion

i s ac hie ved when t he WAV E BA LANCE con tro l is s et t o 10 %. Ma xim um c lea nin g of

h ea vi ly ox id is ed a lu mi ni um o r m ag ne si um a ll oy s is ac hi ev ed wh en t he WAV E

B AL AN CE co nt ro l is se t t o 5 0%

Wid er bead , good pe netra tion

ide al for bu ildup w ork

Nar rower b ead for f illet w elds an d

aut omate d appli catio ns

Wid er bead a nd clea ning ac ting Nar rower b ead and c leani ng acti ng

AC Ba lance C ontro l

Co ntr ols a rc cl ean ing a ction. Ad jus ting the % E N of th e AC wav e cont rol s the w idth o f the

etc hing zo ne surr oundi ng the we ld.

No te : Se t the A C Ba lan ce co ntr ol f or a deq uat e ar c cl ean ing a cti on a t th e si des and in

fr ont of t he w el d pu dd le . AC B al an ce s hou ld b e fi ne t uned a cc or ding t o ho w he av y or

thi ck the ox ides ar e.

Wid er bead , good pe netra tion

ide al for bu ildup w ork

Nar rower B ead, Go od Pene trati on

Ide al For Bu ildup W ork

Wid er bead a nd clea ning ac tion Nar rower b ead, wi th no vis ible cl eanin g

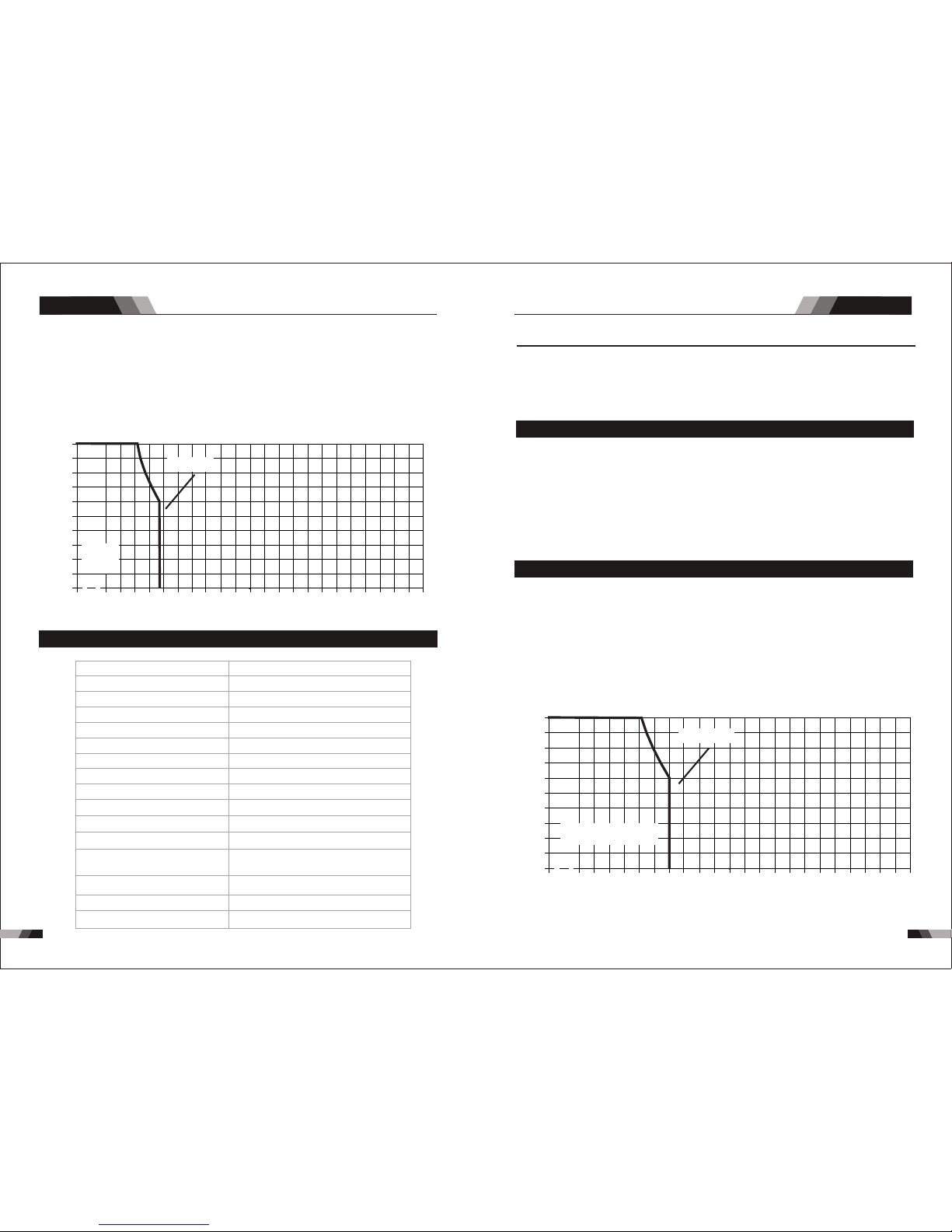

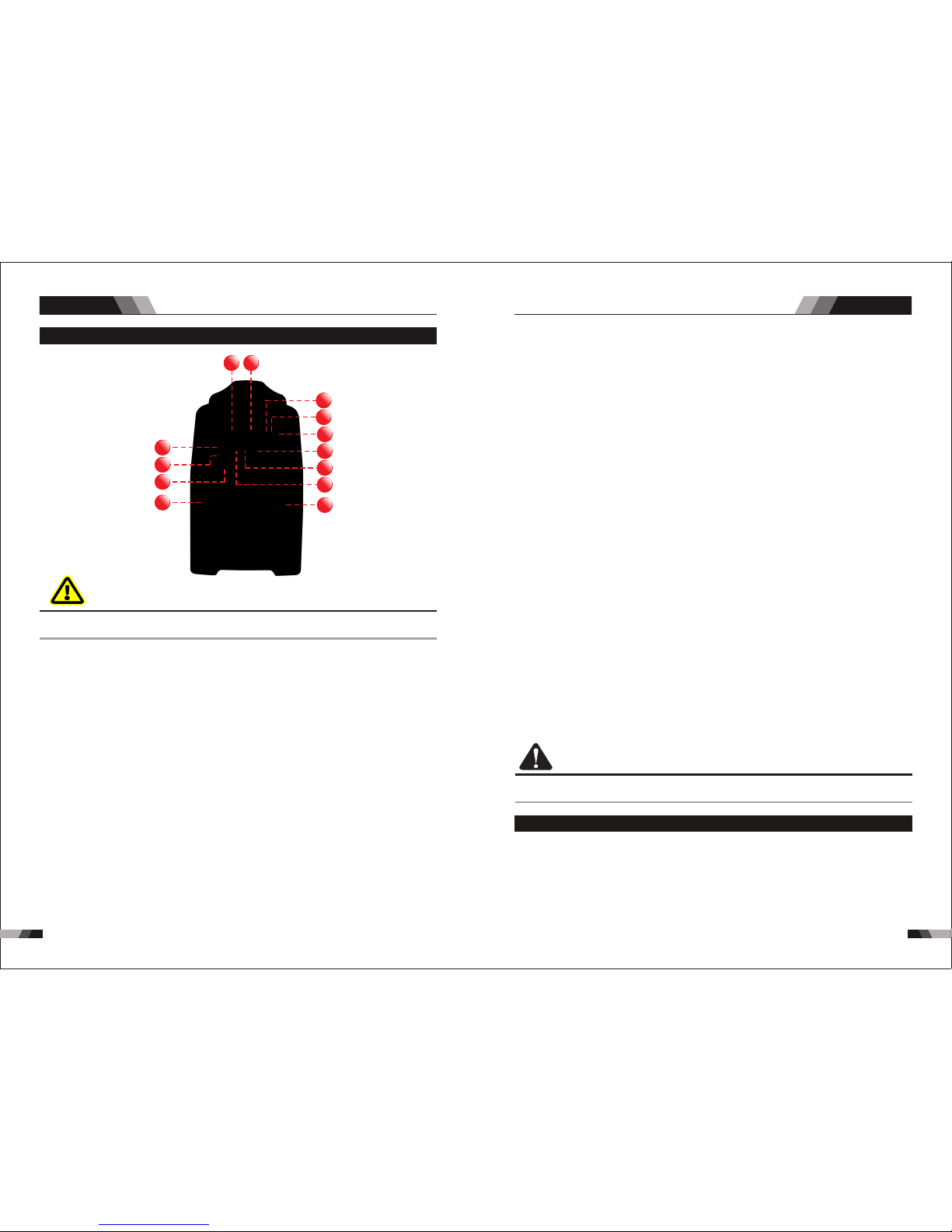

2.3 Layout For The P anel V2 41/V341

10

11

12

13

14

15

9

6 78

5

4

3

2

1

16

17

18

19

20

1. RE SET B utton

Whe n softw are h as pro blem p lease t rigge r RESET b utto n.

2. Pu lse B utton

Pre ss the PU LSE b utto n to tog gle P ulse O n and OF F.

AC Fr equen cy cont rol

Con trols t he widt h of the ar c cone. I ncrea sing th e AC fr eque ncy pr ovides a mor e focu sed

arc w ith inc rease d direc tiona l contr ol.

No te : De creasi ng t he AC Fr eq ue nc y so ft en s th e ar c and b ro ade ns t he w el d pu dd le

f or a wi de r we ld b ead .

11. AC F requency

Set ting ra nges 50 HZ-20 0HZ

Th is pa rame ter op era tes i n AC TIG m ode o nly a nd is u sed t o set t he fr equency f or the

AC we ld curr ent.

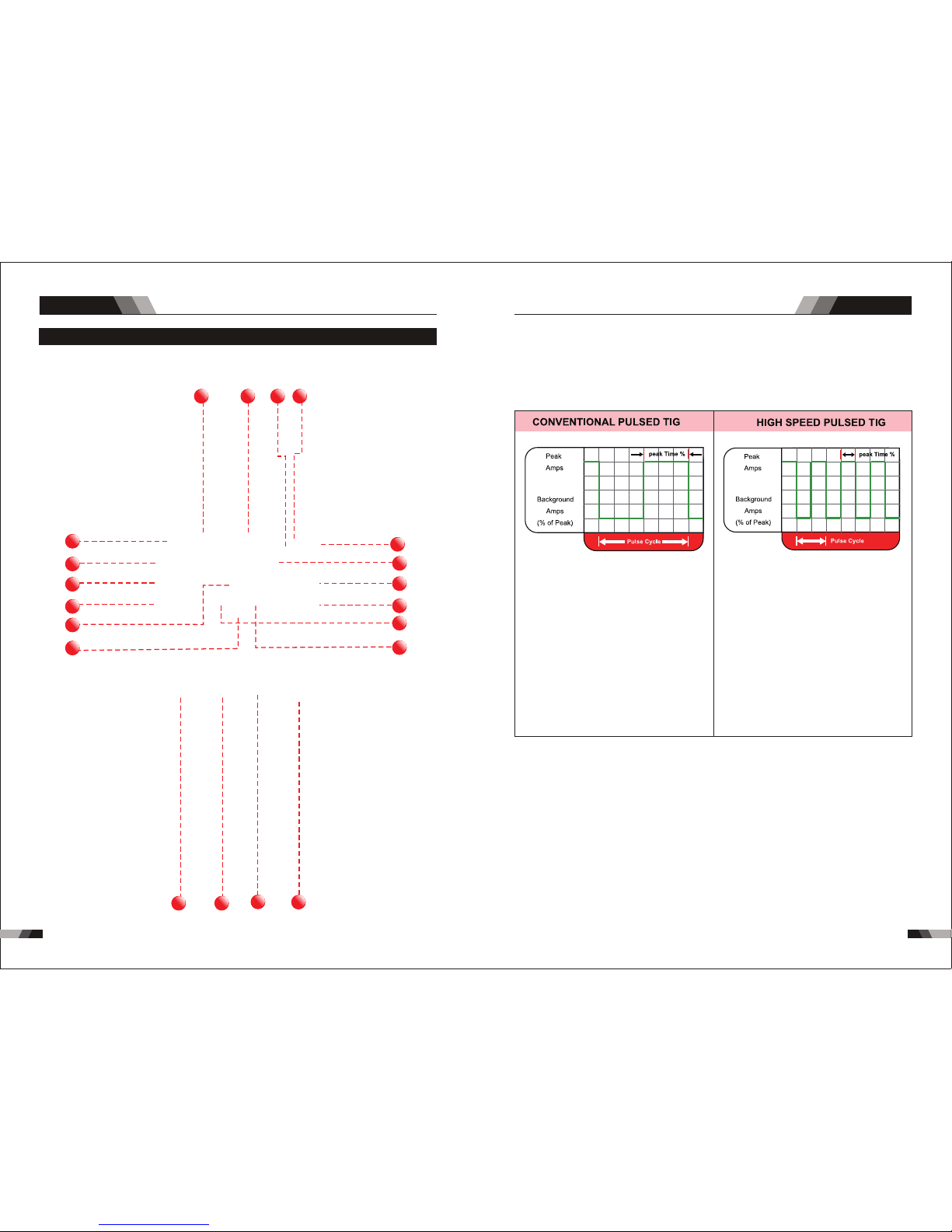

3. Trigge r Mod e Con trol Butt on (H F TIG a nd LIFT TIG M ode o nly)

The t rig ger mo de con trol is u sed to sw itch th e funct ion alit y of the t orch tr igg er bet ween

2T an d 4T.

ou tput t o be ac tive .

Press an d hol d the to rch t rigg er to a ctiv ate th e powe r sou rce (w eld) . Rele ase t he tor ch

trigge r swi tch to c eas e weld ing .

2T N orm al M ode In th is mo de, t he to rch t rig ger mus t rem ain p res sed for the wel din g

AC/DC SERIES EQUIPMENT

AC/DC SERIES EQUIPMENT

Ope ratio n

Ope ratio n

No te : th at w he n op er at in g in G TAW ( HF a nd L IF T TI G mo des ), t he p ow er s ou rc e wi ll

rem ain act ivate d until t he sele cted do wn slop e time ha s elaps ed

Min imum

Cur rent

Pre ss & hold

Tri gger

Rel ease

Tri gger

4. Proce ss Se lec tion Butt on

Th e pro ces s sel ect ion c ont rol i s use d to se lec t the d esi red w eld ing m ode . Two mo des

are a vaila ble, GTAW ( TIG ), and M MA (Sti ck) m odes .

cur rent of t he po wer so urce .

At ti mes of n on-w eldi ng, t he amp erag e mete r wil l display a p re- set (p revi ew) am per age

val ue. Thi s valu e can be ad juste d by vary ing the m ultif uncti on cont rol whe n the

Pro gramm ing Par amete r Indic ator li ght sho ws BASE C URR ENT.

5. Digit al Ammete r

The digital ampe rage m eter i s used to d ispl ay bot h the pr e-set curre nt and a ctua l outp ut

6. Digit al Vol tmeter / Pa ram eter Meter

The di gita l volt me ter is us ed to dis play th e actual outp ut volt age of th e power sourc e. It is

als o used to d ispla y Param eters i n Progr ammin g Mode.

De pend ing o n the Progr amm ing Pa ram eter sele cte d, the s tatu s indi cto r adjacen t to th e

vol t meter w ill ill umina te to sho w the uni ts of the p rogra mming p arame ter.

Whe n weldi ng, the v olt met er will d ispla y actua l weldi ng volt age.

7. Power O N Ind ica tor

The PO WER ON i ndicator il lumi nates when th e ON/OF F swit ch is in th e ON position a nd

the c orrec t mains v oltag e is pres ent.

2120

Typi cally f rom 1 to 10 P PS. Pro vides a h eatin g

and c oolin g effec t on the w eld pud dle an d can

red uce dis torti on by low ering t he aver age

amp erage . Th is heat ing and c oolin g effec t also

pro duces a d istin ct ripp le patt ern in th e weld

bea d. The re lati onshi p betwe en pul se freq uency

and t ravel s peed de termi nes the d istan ce

bet ween th e rippl es. Slo w pulsi ng can al so be

coo rdina ted wit h fille r metal a dditi on and

inc rease o veral l contr ol of the w eld pud dle

In ex cess of 4 0 PPS, Pu lsed TI G beco mes mor e

aud ible th an visi ble-c ausin g incre ased pu ddle

agi tatio n for a bet ter as- welde d micro struc ture.

Pul sing th e weld cu rrent a t high sp eeds- betwe en

a hig h Peak an d a low Bac kgrou nd ampe ragecan a lso con stric t and foc us the ar c.Thi s resul ts

in ma ximum a rc stab ility, i ncre ased pe netra tion

and i ncrea sed tra vel spe eds(C ommon R ange:

100 -500 PP S).

The Ar c-Sha rpeni ng effe cts of h igh spe ed

pul sing ar e expan ded to ne w dimen sions . The

abi lity to p ulse at 5 ,000P PS furt her enh ances

arc s tabil ity and c oncen trati on pote ntial -whic h

is ex tre mel y benef icial t o autom ation w here

max imum tr avel ts peeds a re requ ired.

8. Therm al Ov erl oad Indic ato r Lig ht

Thi s weld ing pow er sour ce is pro tecte d by a self r esett ing the rmost at. The i ndic ator wi ll

illumi nat e if the d uty c ycle o f the p ower s ourc e has be en ex ceed ed. S houl d the th erma l

ov erl oad indic ator i llu min ate t he output o f the po wer s our ce wi ll be d isa ble d. Once the

po wer s our ce cools down th is lig ht wi ll go O FF an d the o ver t emp era tur e con diti on wil l

au tomatic all y res et. N ote th at the m ain s pow er sw itch s houl d rem ain i n the o n posi tion

su ch that the f an con tin ues t o oper ate th us al low ing th e unit t o coo l suff icie ntl y. Do not

swi tch the u nit off s houl d a therm al over load co nditi on be pre sent.

op era tor f atigu e. I n thi s mod e th e ope rat or ca n pre ss an d re lea se t he to rch t rig ger a nd

to rch tri gger.

4T La tc h mod e th is m ode of we ld in g is ma inly u sed fo r lo ng w el din g ru ns t o re duce

th e out put wil l rem ain act ive . To d eac tiv ate t he p owe r sourc e, th e tr igg er sw itc h must

ag ain be p re ssed a nd r el eased , th us e li minat ing th e ne ed f or t he o per ato r to h old the

AC/DC SERIES EQUIPMENT

AC/DC SERIES EQUIPMENT

Ope ratio n

Ope ratio n

Lo ose wel ding te rmi nal c onn ect ion s can cau se o ver heati ng a nd re sul t in t he ma le pl ug

be ing fus ed i n the ter min al.

1.Gas Pr e-F low

V24 1: Abso lute s etti ng ra nge 0. 1s to 20 s (0. 1S inc reme nts )

V34 1: Abso lute s etti ng ra nge 0. 1s to 20 s (0. 1S inc reme nts )

Thi s param eter op erate s in TIG mo des on ly and is u sed to pr ovide g as to the w eld zon e

use d to dram atica lly red uce wel d poros ity at th e start o f a weld.

2.4 Control Pane l

17. Posi tiv e Welding Te rminal

Po sit ive W eld ing Ter min al. Wel din g cu rre nt f low s fr om th e Pow er S our ce v ia he avy

du ty ba yon et ty pe te rmi nal s. It i s ess ent ial , how eve r, th at th e mal e plu g is i nsert ed

and t urn ed sec urel y to achi eve a sou nd elec trica l conne ction .

18. 5 Pin Co ntr ol So cket

The 5 pin rece ptac le is us ed to co nnec t a trig ger switch or r emot e cont rol to t he wel ding

Pow er Sour ce circ uit ry:

To make connectio ns, align ke yway, insert plug, and rota te thread ed collar fu lly clock wise.

20. Shie ldi ng Ga s Outlet

Th e Shi eld ing G as Ou tle t loc ate d on th e fro nt pa nel i s a fas t conn ecti on of a s uita ble

TIG Tor ch.

19. Nega tiv e Welding Te rminal

Ne gat ive W eld ing Te rmi nal . Wel din g cur ren t flo ws fr om th e Pow er So urce via h eav y

du ty ba yon et t ype t erm ina ls. I t is es sen tia l, ho wev er, t hat the mal e pl ug is ins ert ed

and t urn ed sec urel y to achi eve a sou nd elec trica l conne ction .

AC Fr equen z

Wav e Bala nce

Rem ote

ARC H otsta rt

ARC S tart Tim e

Arc force C orrec tion

AMP %

sec

AMP

%

HZ

sec

AMP %

sec

AMP %

sec

%

1

2

3

4

6

5

7

11

12

8

9

10

13

14

2.Init ial C urr ent

V241:T he ma in cur rent S ett ing ra nge 10 AMP to 2 00A MP

This parame ter oper ates in (4 T) TIG mod es only and is used to set the start curren t for TIG.

Th e Sta rt Curr ent r ema ins o n unt il th e tor ch trigg er sw itc h is rele ase d aft er it has b een

dep resse d.

No te: T he ma xim um initi al cu rre nt av ail able wil l be li mit ed to the s et va lue of the b ase

cur ren t.

3.Up Slo pe

Set ting ra nge s :0.1 S-10 S (0. 1S inc reme nts)

Thi s param eter op erate s in (2T and 4 T) TIG mod es only a nd is used t o set the ti me for th e

we ld cur rent t o ram p up, a fter t he tor ch tr igg er swi tch ha s bee n pre ssed t hen re lea sed,

fro m Initi al Curr ent to Hi gh or bas e curre nt.

4.Peak C urr ent

Set ting ra nge s

V24 1:10- 20 0A( DC TIG a nd AC HF T IG) ,10 -20 0A(S tic k mode )

V34 1:10- 30 0A( DC TIG a nd AC HF T IG) ,30 -30 0A(S tic k mode )

Th is pa ramete r set s the TIG W ELD c urrent . Thi s par ameter a lso s ets t he ST ICK wel d

cur rent.

5.Base C urr ent

Set ting ra nge s

V24 1:10A MP to 200 AMP (D C TIG mo de), 1 0AMP to 2 00AMP (AC HF TIG mode)

V34 1:10A MP to 300 AMP (D C TIG mo de), 1 0AMP to 3 00AMP (AC HF TIG mode)

Sec ondar y curre nt (TIG )/pul se paus e curre nt.

232 2

9. JOB and S AVE

You ca n pre ss JO B to se lect t he me mor y rec ord s tha t you h ave s ave d bef ore f rom 1 -9.

For t he ne w sett ing of p resen t base cu rrent Am ps ,jus t press S AVE.

10. Prog ram min g Paramet er In dic ators

The se ind icato r light s will il lumin ate whe n progr ammin g.

11. HF Butt on

Pres s and hold the HF butt on to purge the gas li ne in LIF T TIG an d HF TIG modes. To HF

the shie ldi ng gas l ine i n LIFT T IG and H F TI G mode s pre ss the H F but ton an d rele ase.

12. Mode B utt on

Pre ss th e MODE b utto n to to ggle AC a nd DC ou tput in L IFT TIG , HF TIG a nd STI CK.

13. Forw ard P rog ramming B utt on

Pre ssi ng thi s butt on will a dvanc e to the ne xt step i n the pro gramm ing seq uence .

14. Back P rog ram ming Butt on

Pre ssi ng thi s butt on will g o back to t he prev ious st ep in the p rogra mming s equen ce.

15. Posi tiv e Con trol

The P osit ive but ton is us ed to plu s selec ted in Pr ogr ammi ng seq uence ..

16. Nega tiv e Con trol

The N egat ive but ton is us ed to min us sele cted in P rogra mming s equen ce..

CAUTION

V341:T he ma in cur rent S ett ing ra nge 10 AMP to 3 00A MP

pr ior to s trik ing the arc , onc e the t orch t rigg er sw itch h as be en pr esse d. Th is con trol i s

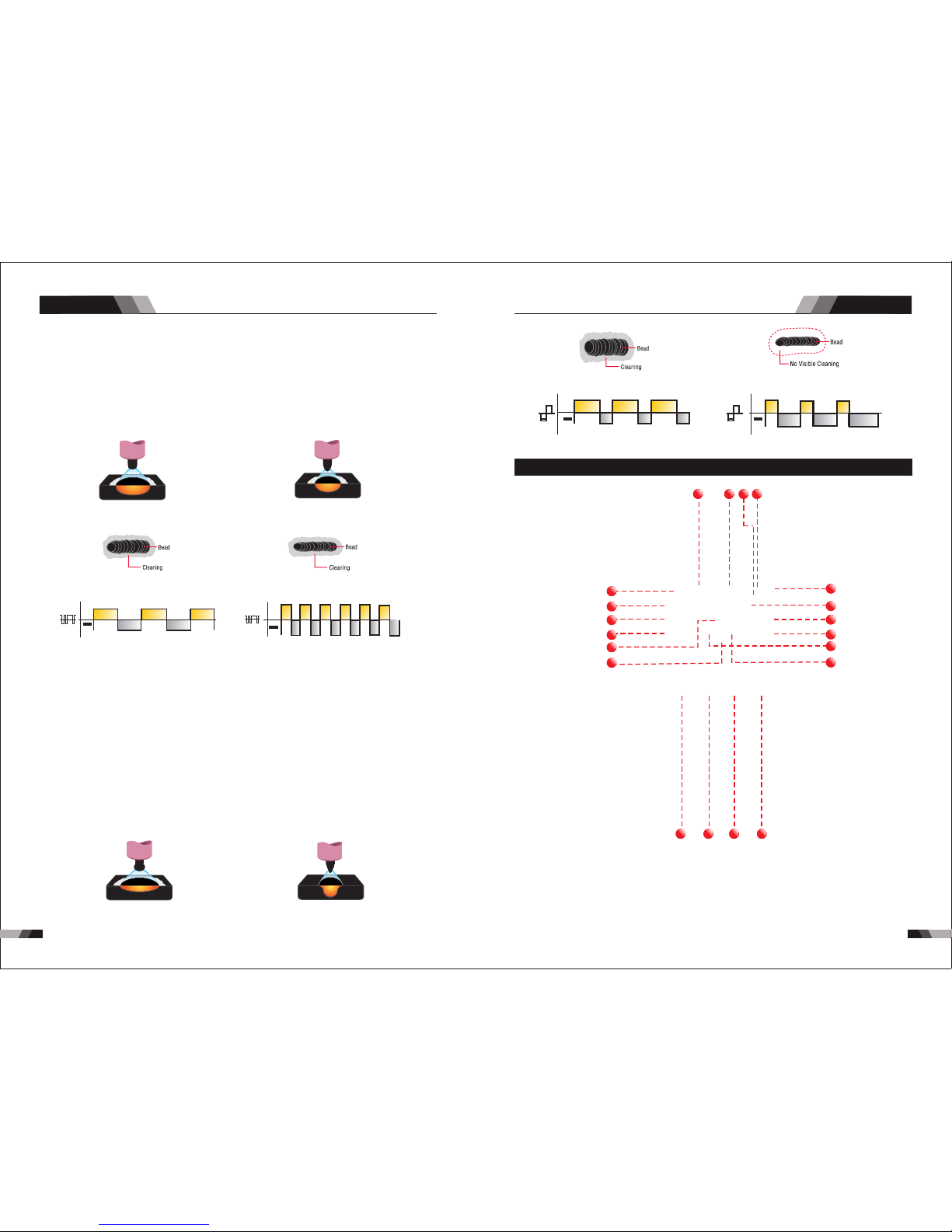

AC Ba lance C ontro l

Co ntr ols a rc cl ean ing a ction. Ad jus ting the % E N of th e AC wav e cont rol s the w idth o f the

etc hing zo ne surr oundi ng the we ld.

No te : Se t the A C Ba lan ce co ntr ol f or a deq uat e ar c cl ean ing a cti on a t th e si des and in

fr ont of t he w el d pu dd le . AC B al an ce s hou ld b e fi ne t uned a cc or ding t o ho w he av y or

thi ck the ox ides ar e.

Wid er bead , good pe netra tion

ide al for bu ildup w ork

Nar rower B ead, Go od Pene trati on

Ide al For Bu ildup W ork

Wid er bead a nd clea ning ac tion Nar rower b ead, wi th no vis ible cl eanin g

AC/DC SERIES EQUIPMENT

AC/DC SERIES EQUIPMENT

Ope ratio n Ope ratio n

AC Fr equen cy cont rol

Con trols t he widt h of the ar c cone. I ncrea sing th e AC fr eque ncy pr ovides a mor e focu sed

arc w ith inc rease d direc tiona l contr ol.

No te: D ecr eas ing t he AC F req uen cy so fte ns the a rc a nd b roade ns th e we ld p uddle

f or a w id er w eld be ad.

Wid er bead , good pe netra tion

ide al for bu ildup w ork

Nar rower b ead for f illet w elds an d

aut omate d appli catio ns

Wid er bead a nd clea ning ac ting Nar rower b ead and c leani ng acti ng

12.Wave Balance

Set ting ar range s 10%-5 0%

11. AC F requency

Set ting ra nges 50 HZ-20 0HZ

Th is pa rame ter op era tes i n AC TIG m ode o nly a nd is u sed t o set t he fr equency f or the

AC we ld curr ent.

2524

6.Puls e Wid th

Set ting ra nges 10 %-90%

Th is para met er s ets t he pe rce nta ge on t ime of th e PUL SE FR EQU ENC Y for Hig h wel d

cur rent wh en the PU LSE is ON .

7.Puls e Fre que ncy

Set ting ra nge s 1HZ -2 00HZ

Thi s param eter se ts the PU LSE F REQU ENCY w hen th e PULSE i s ON.

8.Down S lop e

Set ting ra nges 0. 1-10s

Thi s para mete r operates in T IG modes only a nd is us ed to set t he tim e for th e weld cu rren t

to ra mp down , after t he to rch tr igge r switc h has bee n press ed to end c urren t. This c ontr ol

is us ed to eli minat e the cra ter tha t can for m at the co mpl etio n of a wel d.

10. Post F low

V24 1: Sett ing ran ges 1-2 0S

V34 1: Sett ing ran ges 1-2 0S

Th is p ara met er op era tes i n TIG mod es o nly a nd is u sed to ad jus t the pos t ga s flo w

tim e once th e arc has e xting uishe d. This c ontr ol is use d to dram atica lly red uce

oxi datio n of the tu ngste n elect rode.

Thi s para mete r oper ates i n AC TIG mo de and i s used t o set the penetrat ion to clean ing

act ion ra tio fo r the AC we ld cur rent . Gene rall y WAVE BAL ANCE i s set to 5 0% for AC

STI CK wel ding . The WAVE B ALAN CE con trol c hang es the r atio o f pene trat ion to

the WAVE BALA NCE co ntro l is set t o 10%. M axim um cle anin g of hea vily o xidi sed

alu mini um or ma gnes ium al loys i s achi eved w hen th e WAVE BAL ANCE c ontr ol is se t to

50%

9.End cu rre nt

V24 1:Set ting ra nges 10 A-200 A

Thi s parame ter ope rates in ( 4T) TIG mod es only and is used to s et the fin ish current for TI G.

The e nd curr ent rem ains ON until t he torc h trigg er swit ch is release d after i t has bee n

dep resse d.

No te: T he m axi mum c rat er cu rre nt av ail abl e wil l be li mit ed to t he se t val ue of t he ba se

cur ren t.

V34 1:Set ting ra nges 10 A-300 A

cle anin g acti on of the AC TIG weld ing ar c. Max imum we ld pen etra tion is achie ved wh en

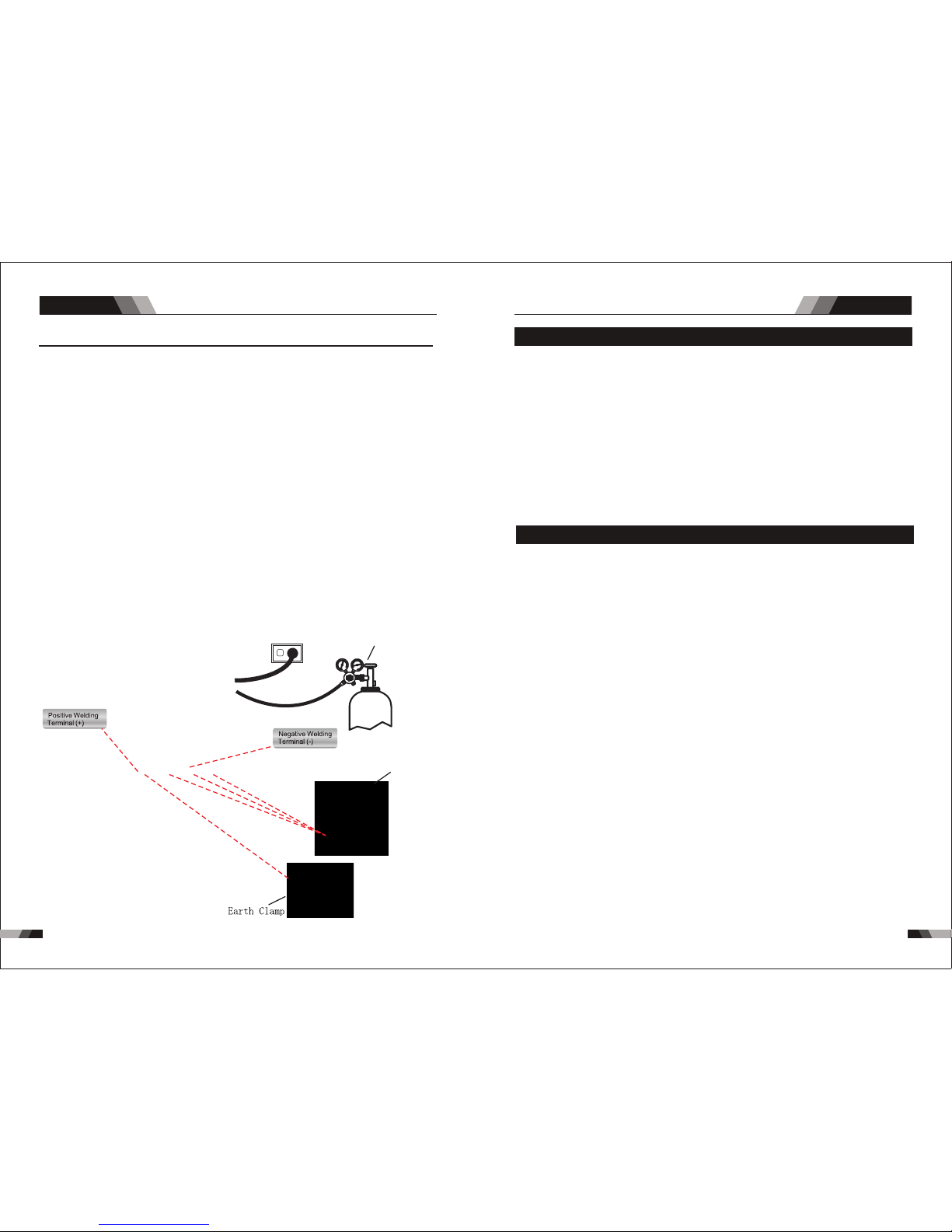

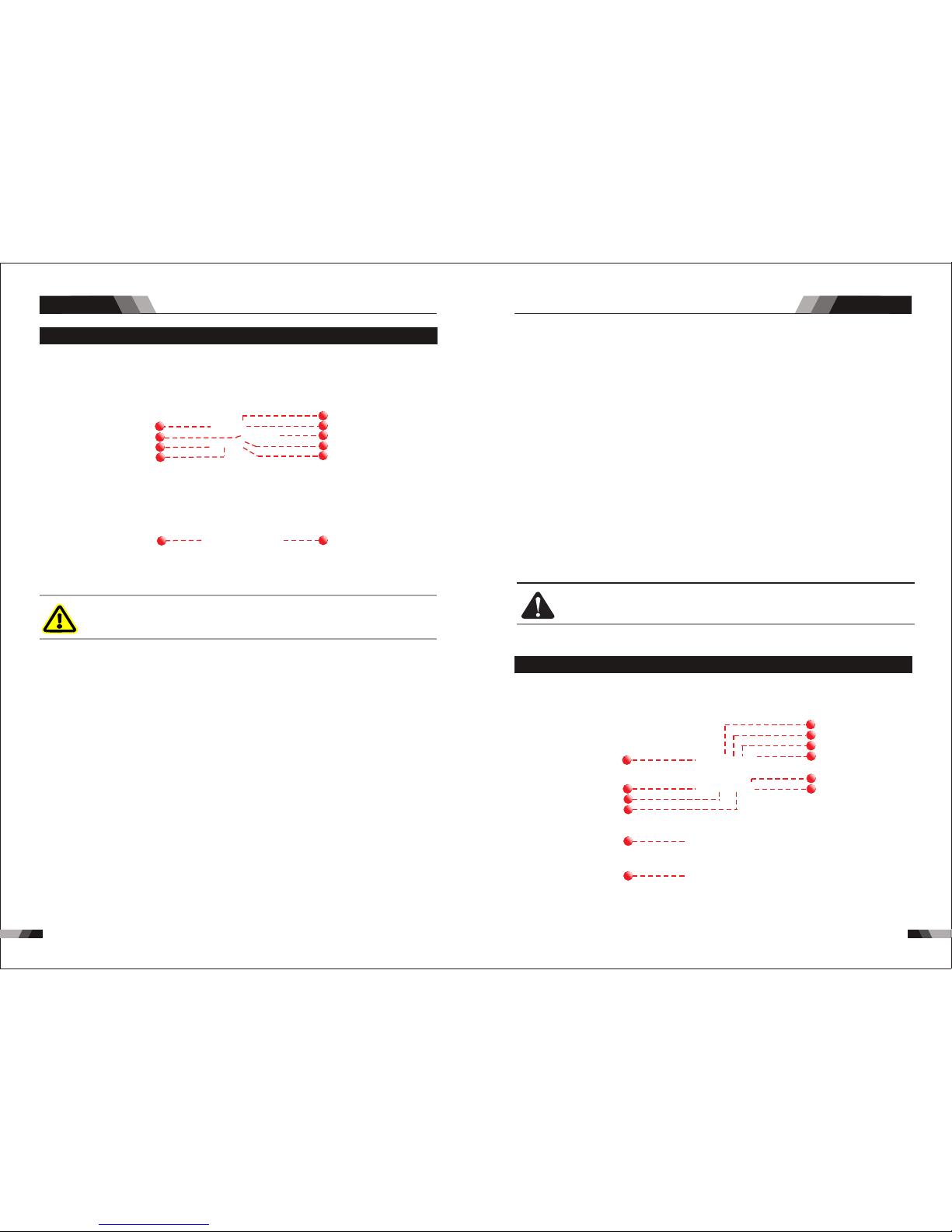

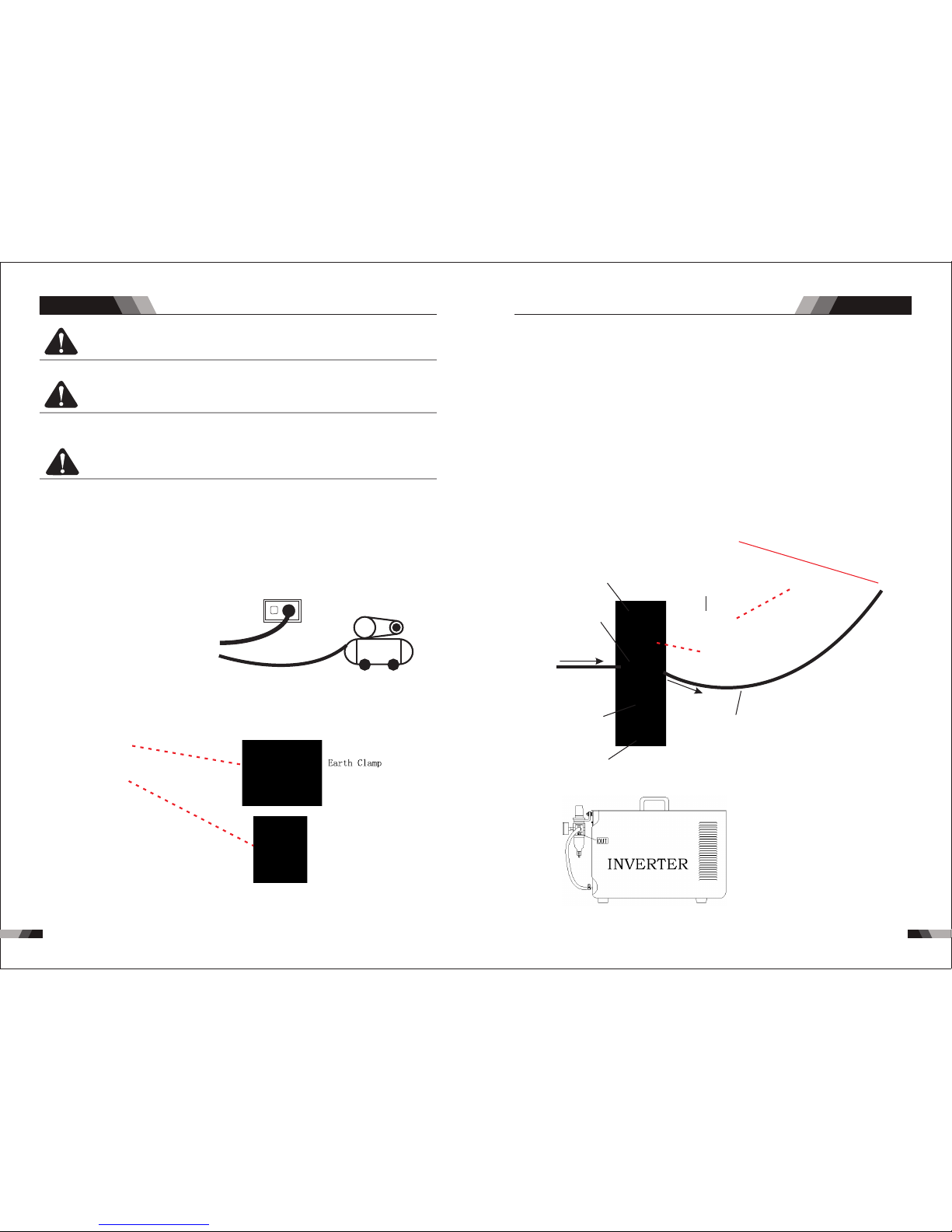

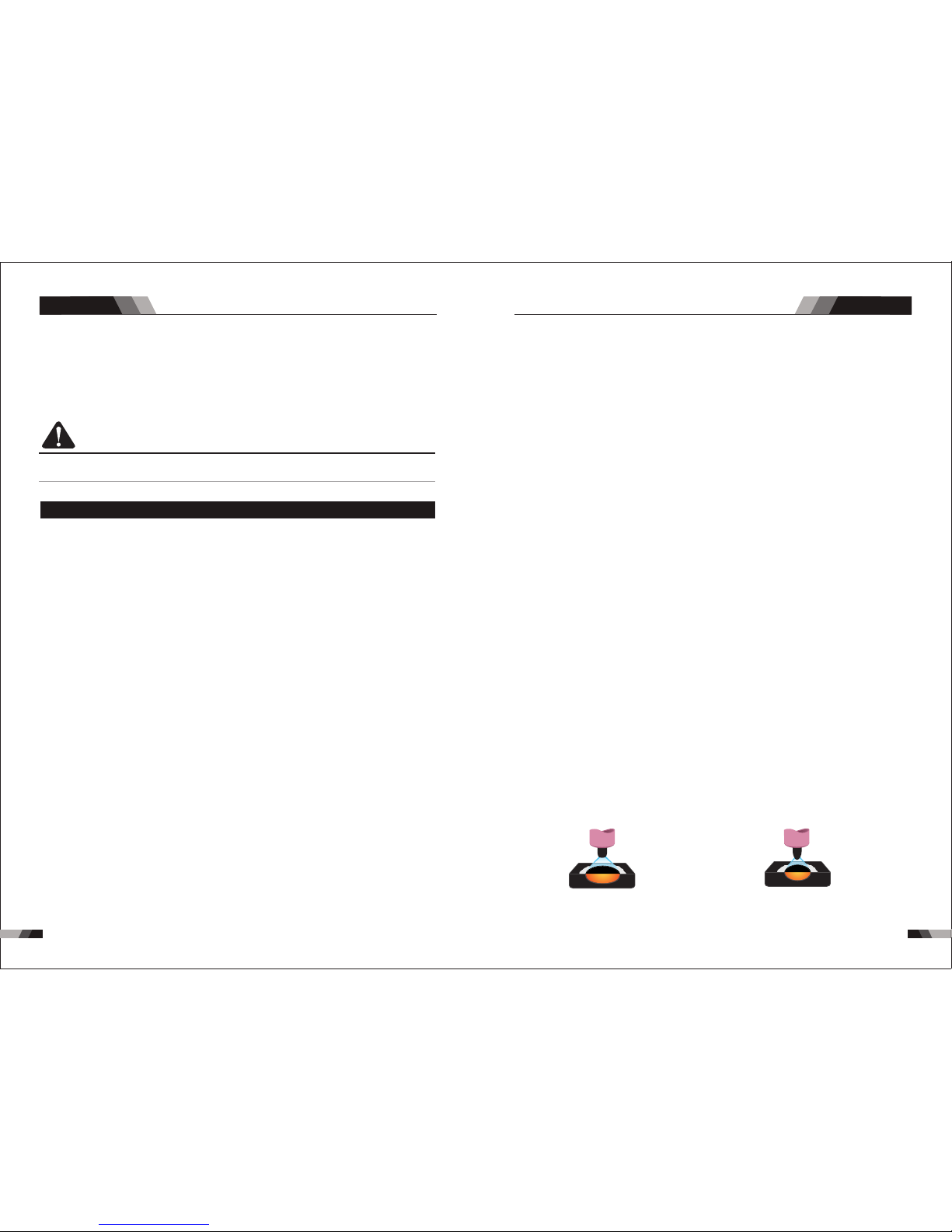

2.5 Setup For STIC K (MMA) Welding

WAR NIN G

CA UTI ON

CA UTI ON

Be fo re c onn ectin g th e wo rk c lam p to th e wo rk a nd

in ser tin g the ele ctr ode i n the ele ctr ode h old er ma ke

sur e the mai ns powe r sup ply is s witc hed o ff.

Re mov e any p ack agi ng m ate ria l pri or to use . Do n ot

bl ock the a ir ve nts a t the f ron t or rear o f th e Wel din g

Pow er Sour ce.

Lo os e we ldi ng t erm in al c on ne ct io ns c an c aus e

ov erh eat ing a nd resu lt i n th e ma le p lug bei ng fu sed

in th e bayon et te rmin al.

AC/DC SERIES EQUIPMENT

AC/DC SERIES EQUIPMENT

Ope ratio n

Ope ratio n

27

26

pow er supp ly

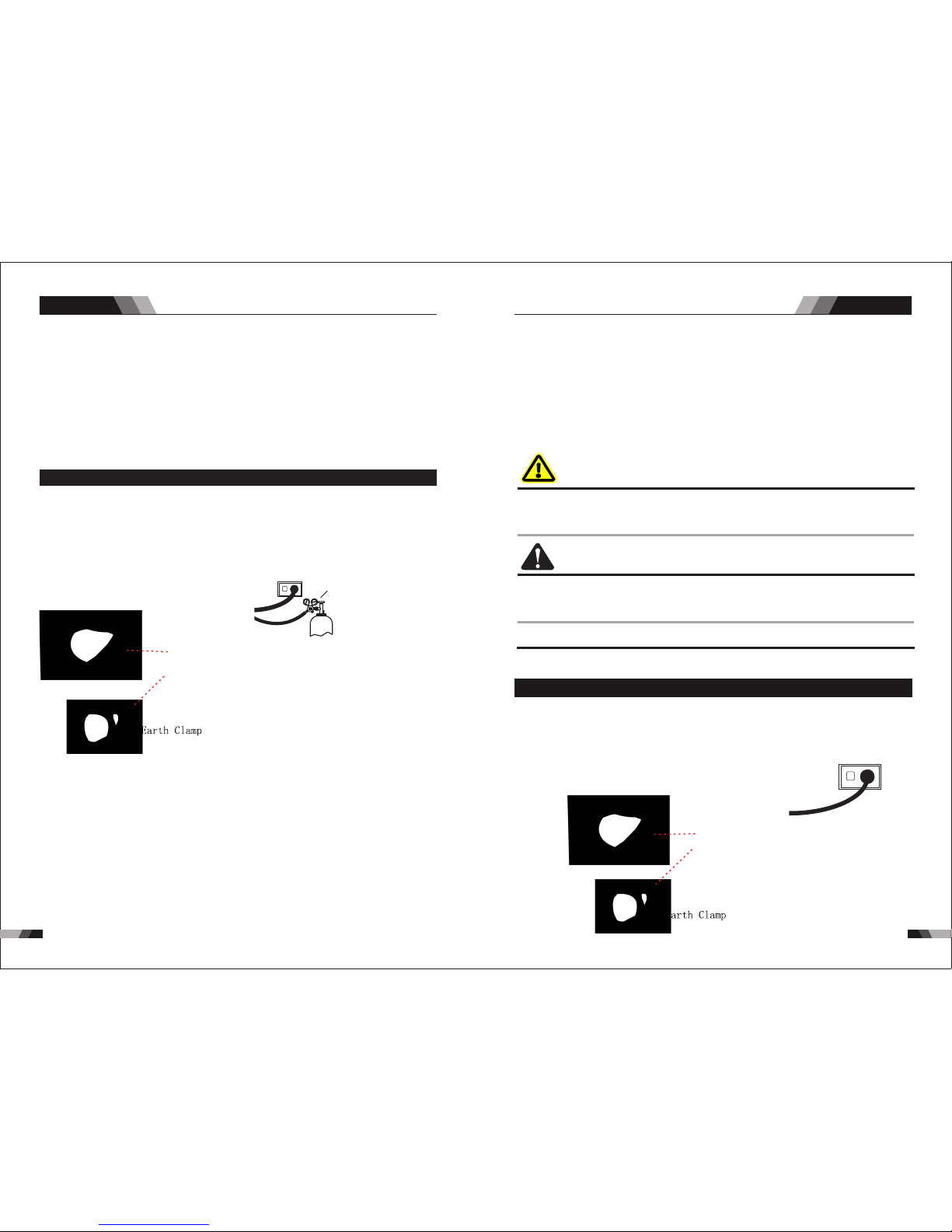

2.6 Set-up For LIF T TIG (GTAW) Wel ding

WAR NIN G

Bef ore any w eldin g is to b egin , be sur e to we ar all

app ropri ate and r eco mmen ded sa fety eq uip ment .

Ant istic k

Ant istic k

U

I

13. Hot St art

14. Ar cforce Co rre cti on

Hot S tart Fu nctio n relia bly ign ites th e elect rode

and m elts pe rfect ly to ens ure the b est qua lity

eve n at the st art of th e sea m. thi s solu tion ma kes

lac k of fusi on and co ld weld s a thing o f the pas t

and s ignif icant ly redu ces wel d reinf orcem ent.

Adj ust the h ot star t curre nt here a nd the ti me here .

Dur ing the w eldin g proce ss, arc force p reven ts

t he el ec tr od e s ti ck in g in th e w el d p oo l w it h

inc rease s in curr ent. th is make s it easi er to wel d

lar ge-dr op mel ting el ectro de typ es at low curren t

str ength s with a sh ort arc i n parti cular.

Ant i-sti ck prev ents th e elect rode fr om an neal ing.

If t he el ect rod e sti cks i n sp ite of th e arc ror ce d evi ce , the

mac hi ne au to ma ti ca ll y sw it ch es o ve r t o th e mi ni mum

cu rrent wi th in a bou t 1 se co nd t o pr event th e el ect ro de

e le ct ro de a nd el ec tr od e h ol de r t o pr ot ec t th e wel de r.

Fo r Alk alin e Elec tro de, con nec t the e lec trod e hold er to t he po sit ive w eld ing termi mal

El ectr ode, please c onne ct th e ele ctrode ho lder t o the n egat ive w elding termi mal a nd

ma nufa ctur er. We ldin g curr ent f low s from the Po wer So urc e via h eavy duty b ayon et ty pe

te rmin als. I t is es sen tial, how eve r, tha t the m ale p lug i s inserte d and t urn ed se curely to

ac hiev e a soun d ele ctr ical conn ecti on. S elect STI CK mo de wi th th e pro cess sele cti on

co ntro l.

a nd c on ne ct th e wo rk le ad to th e neg at iv e w el di ng te rm in al , wh il e f or th e A ci d

con nect the wor k lead to the po sitve wel ding t ermi nal. If in d oubt c onsu lt the e lect rode

f ro m o v er h e at i ng . I n or d er to e as i ly se p ar a t e t h e

2.8 Operation No tices

◆Height a bove sea le vel is belo w 100 0m.

◆Operat ion tempe rature ra nge:-10 ˚C~ +40˚ C.

◆Relati ve humidi ty is below 9 0%( 20˚C ).

◆Prefer ably site t he machin e som e angl es ab ove th e flo or lev el, the ma xim um

angle do es not exce ed 15˚.

◆The cont ent of dust ,acid,c orrosiv e gas i n the su rro undi ng ai r or sub sta nce

can not ex ceed norm al standa rd.

◆Take care th at there is s uffi cie nt ven til atio n dur ing we ldi ng.Ther e is at least

30cm fre e disstan ce betwee n the machi ne an d wall .

2.7 Operation En viron ment

◆Read saf ty instru ction and C hap ter 1 ca ref ully b efo re att emp ting t o use t his

equipm ent.

◆Connec t the groun d wire the ma chi ne dir ect ly

◆In case cl osing the p ower swit ch, no-lo ad vo ltag e may b e expo rte d.Do n ot to uch

the outp ut electr ode with an y part of you r bod y.

◆Before o peratio n,no conc ern ed peo ple s houl d be le ft,D o not w atch t he ar c in

unprot ected eye s.

◆Ensure g ood venti lation of t he ma chin e to im prov e dut y rati o.

◆Tur n off th e engine wh en the oper ati on fin ish ed to ec ono mize e ner gy sou rce .

◆When pow er switch s huts off pr otec tiv ely be cau se of fa ilu re.Don’ t restart i t until

until pr oblem is re solved.

Otherw ise,the r ange of pro blem will b e ext ende d.

AC/DC SERIES EQUIPMENT

AC/DC SERIES EQUIPMENT

Ope ratio n Ope ratio n

2928

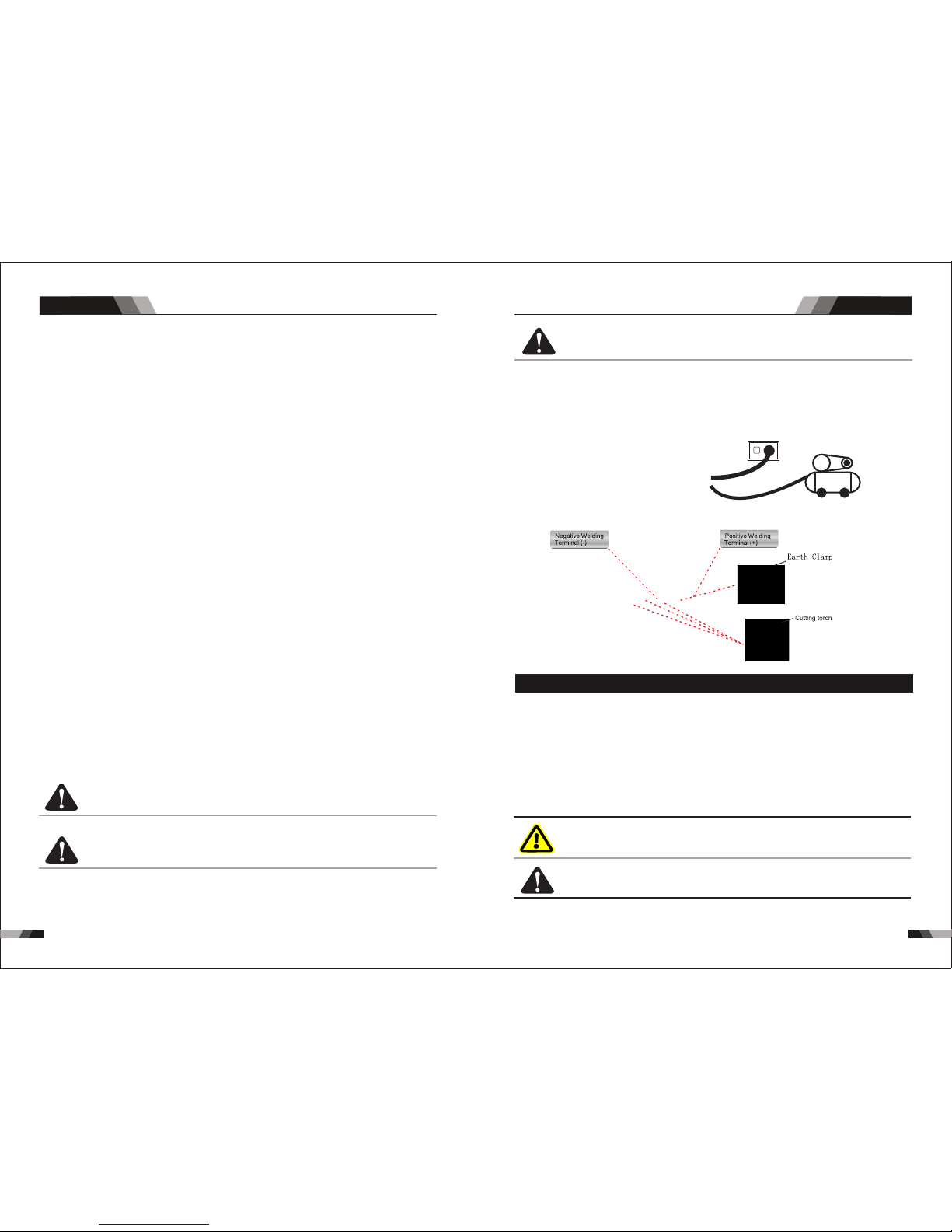

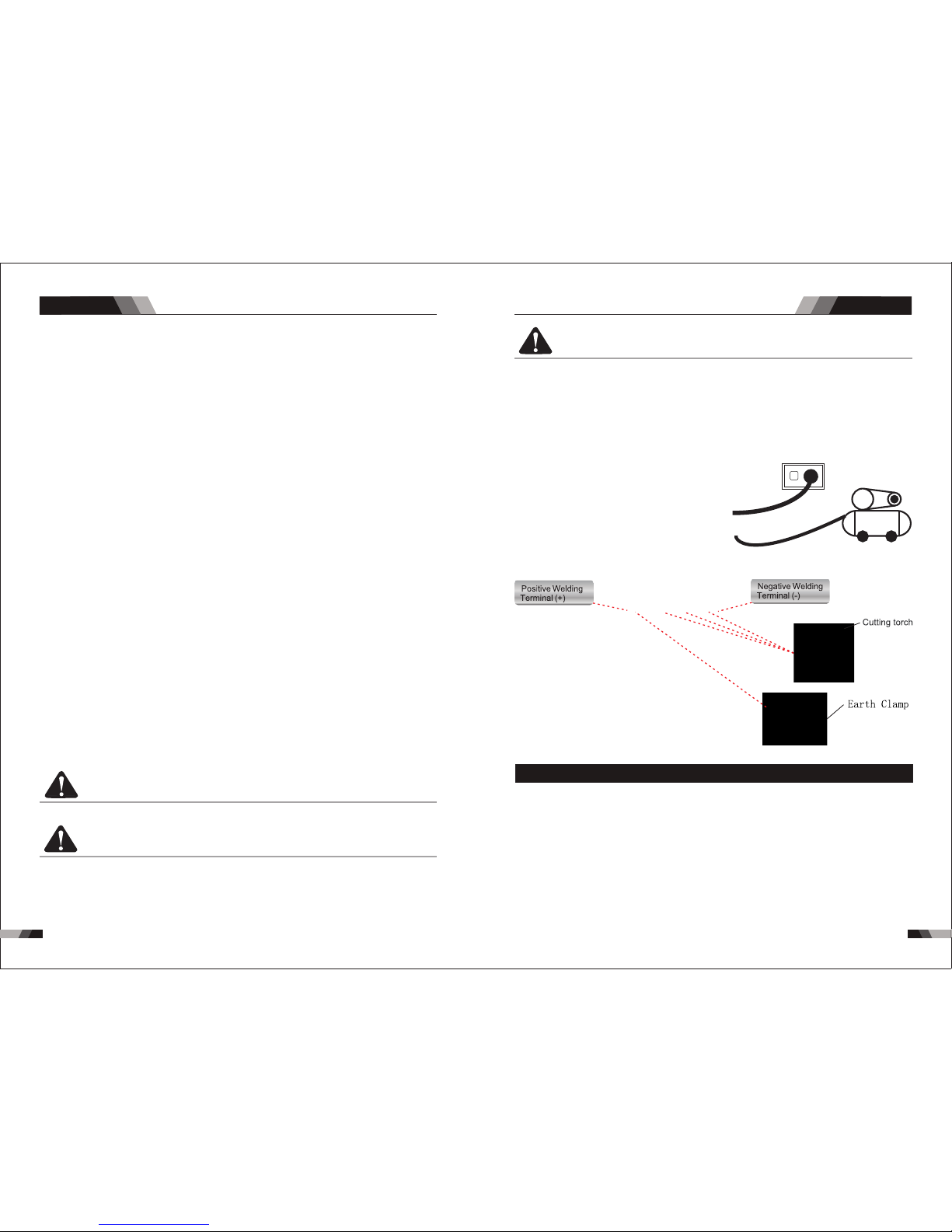

The f ollow ing set u p is know n as Stra igh t Pola rity o r DC elec trode p ositi ve. Thi s is

com monly u sed for D C LIFT TI G weld ing on m ost mat erial s such as s teel an d stain less

ste el.

1. Sw itch th e ON/OF F Swi tch (l ocat ed on t he rea r pane l) to OFF.

2. Co nnect t he work l ead cab le to the p ositi ve outp ut term inal, a nd the LI FT TIG Torch

cab le to the n egati ve outp ut term inal.

3. Co nnect t he gas li ne/ho se to the p roper s hield ing gas s ource .

4. Sl owly op en the Arg on Cyli nder Val ve to th e fully o pen positi on.

5. Co nnect t he work l ead cla mp to you r work pi ece.

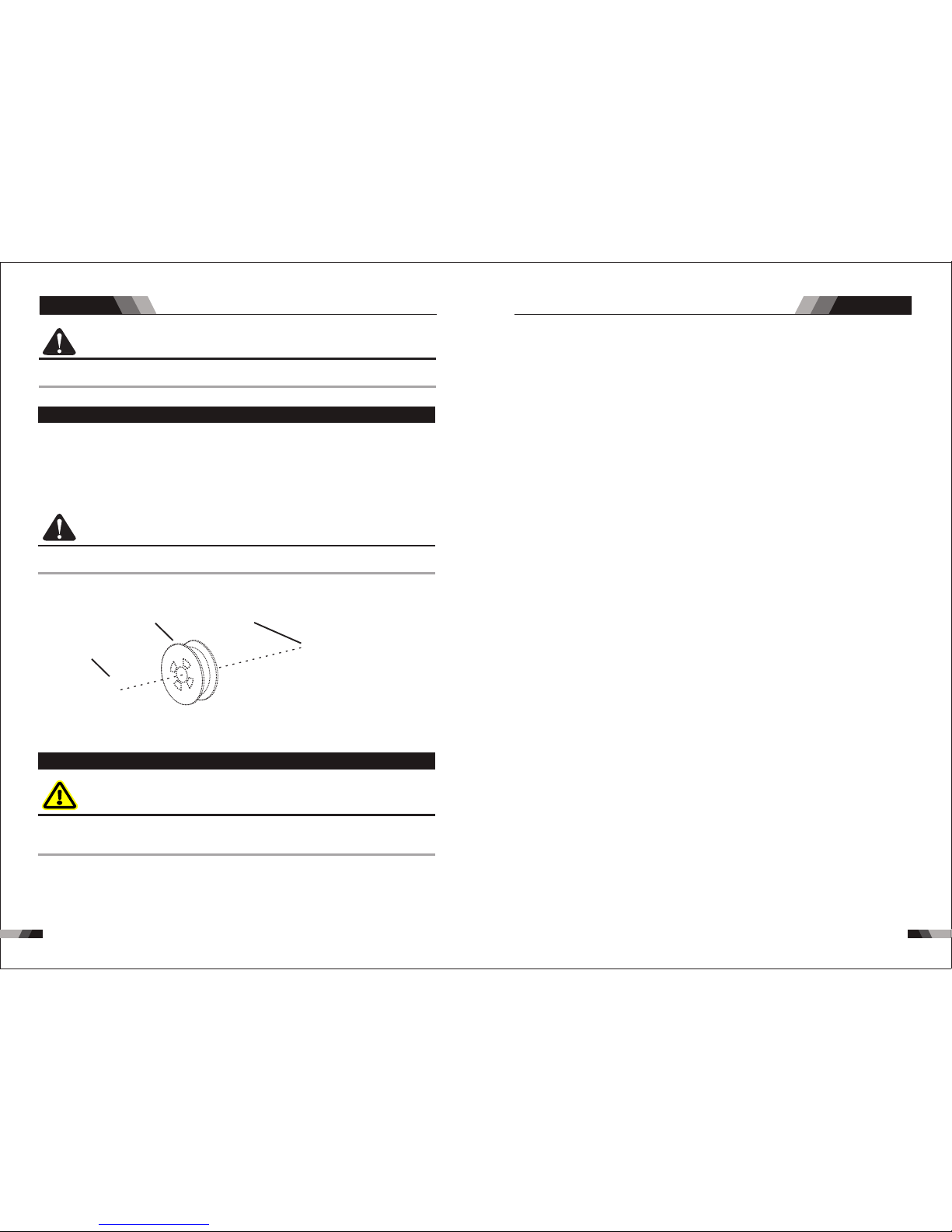

6. Th e tung sten mu st be gro und to a bl unt poi nt (sim ilar to a p encil ) in orde r to achi eve

opt imum we lding r esult s. See il lustr ation . It is cri tic al to gr ind th e tun gste n elec trode

in th e direc tion th e grind ing whe el is tur ning. G rind at a 3 0 degre e angle a nd neve r

to a sh arp poi nt.

7. In stall t he tung sten wi th appr oxima tely 1. 6mm to 3. 2mm s tick ing ou t from th e

gas c up, ens uring y ou have c orrec t sized c ollet .

8. Tig hten th e back ca p.

9. Tur n the swi tch to th e “ON” po sitio n. The po wer L. E.D. li ght sho uld ill umina te.

10. S et the we lding p roces s to LIFT T IG.

11. Se t the We ld Cur rent Co ntrol K nob to th e desir ed ampe rage.

12. You are no w read y to begin LI FT TIG We lding.

pow er supp ly

Ar./ GAS(T IG/WI G)

TIG torc h

NO TE

3130

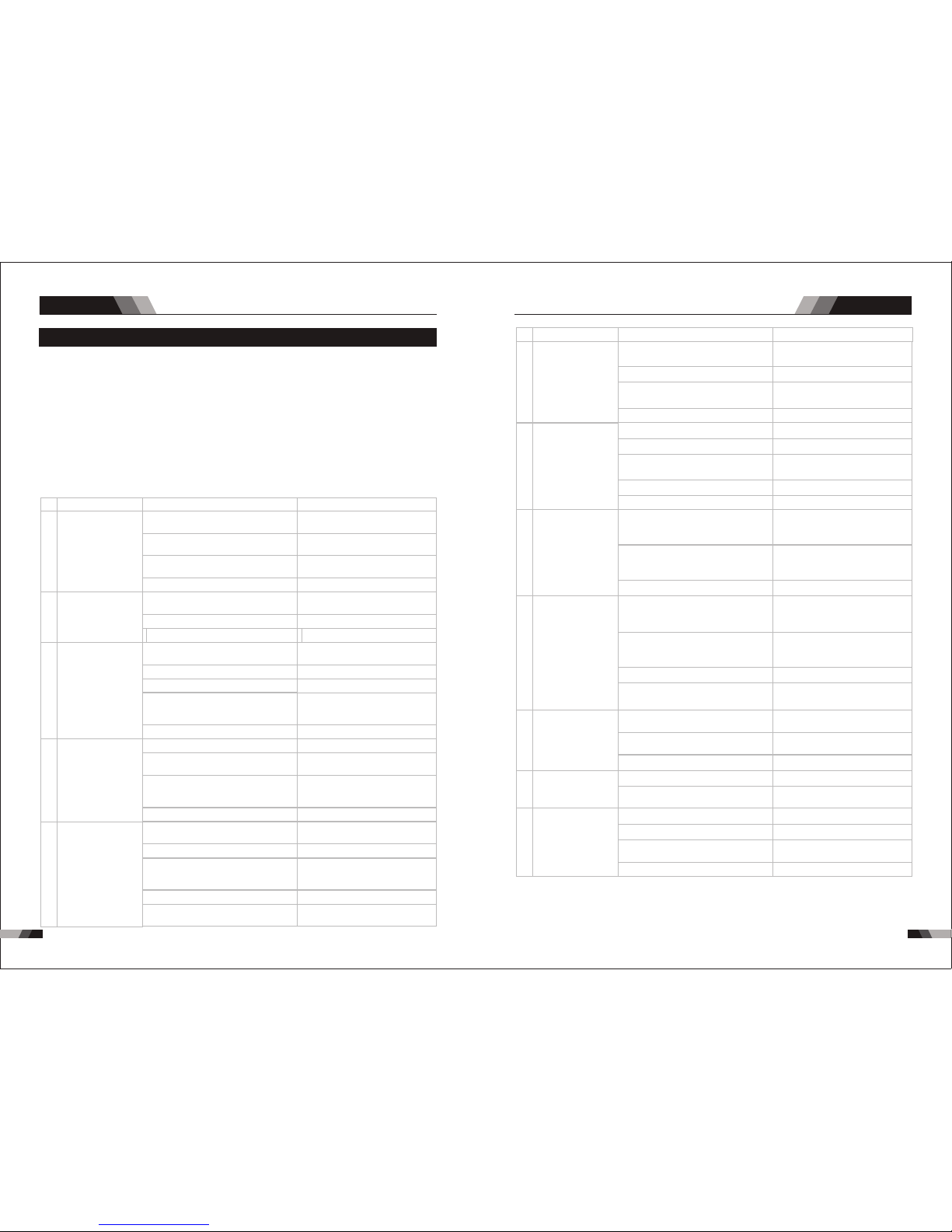

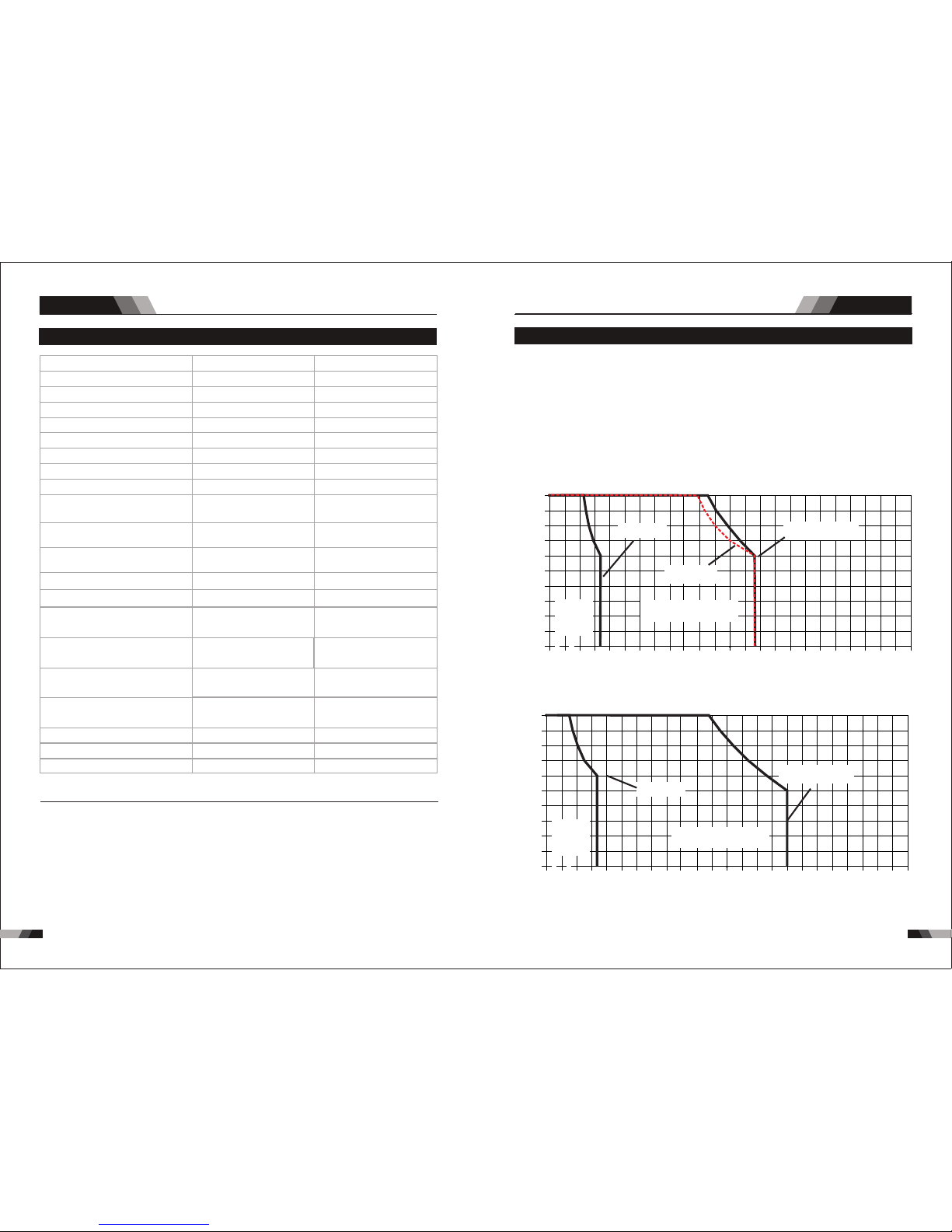

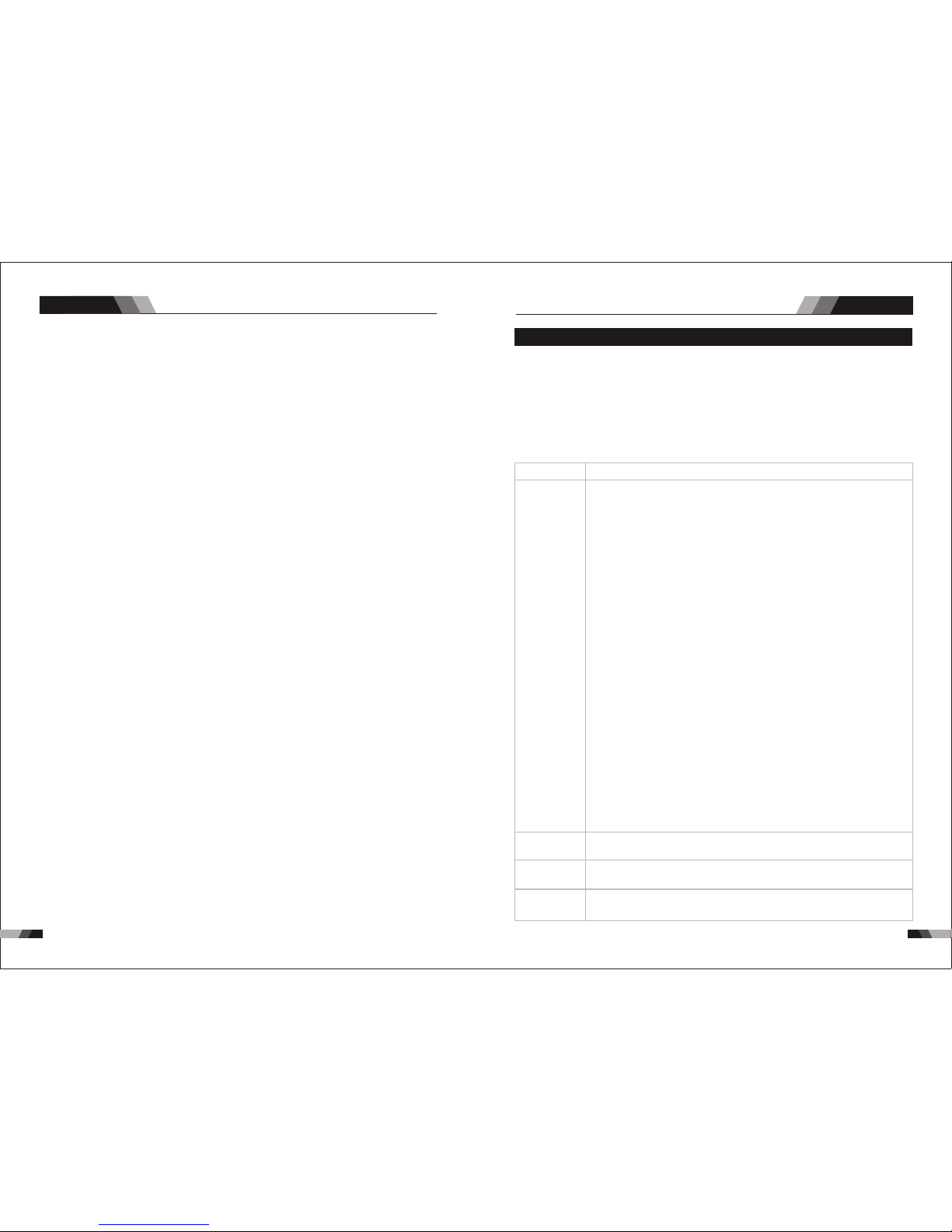

3.1 Troubleshoo ting

◆Bef ore arc w eldin g machi nes are d ispat ched fr om the fa ctory, t hey ha ve alre ady bee n

deb ugged a ccura tely. So f orbi d anyon e who is no t autho rized b y us to do an y chang e to

the e quipm ent!

◆Mai ntena nce cou rse mus t be oper ated ca reful ly. If any w ire be comes f lexib le or is

mis place d, it may be pote ntial d anger t o user!

◆Onl y profe ssion al main tenan ce pers onal wh o is auth orize d by us cou ld overhau l the

mac hine!

◆Gua rante e to shut o ff the ar c weld ing mac hine’ s power bef ore tu rn on the out line o f

the e quipm ent!

◆If th ere is an y probl em and ha s no the au thori zed pro fessi onal ma inten ance pe rsona l,

ple ase con tact lo cal age nt or the b ranch c ompan y!

If th ere a re som e simp le tr oubl es of V-s eries w eldin g machi ne, you c an cons ult the

fol lowin g overh aulin g chart :

Nr.

Nr.

1

7

8

9

10

11

2

3

4

5

6

Troubles

Troubles

AC/DC SERIES EQUIPMENT

AC/DC SERIES EQUIPMENT

Tro ubles hooti ng Tro ubles hooti ng

Solution

Solution

Fan is broken

The welding cable is not connected

with the two output if the welder

Connect the welding cable to

the welder's output

The power board is broken

The power cable is broken

There is something in the fan

The welding cable is damaged

The earth cable connected unstably

The welding cable is too long

Input voltage not stable

There is oil or dust on the workpiece

Gas cylinder is close or gas

pressure is low

The HF igniting board does not work

Something is in the valve

Check if the function selected MMA

Change the function to TIG

Check the HF funtion is selected Select the HF funtion

HF board is broken

Earth clamp connect not stable

Repair or change it

Check the earth clamp

Open or change the gas cylinder

Remove it

Remove it

Change it

Change it

Change it

The distance between discharge r is

too short or too long

The malfunctio n of the welding gun

switch

No argon gas flow or the air tube

connect not good

No argon gas flow or the air tube

connect not good

Pressure too high or air regulator is

broken

There is no Argon flow or the

connectio n is poor

The distance between tungsten

electrode and workpiece is too long

Repair or change it

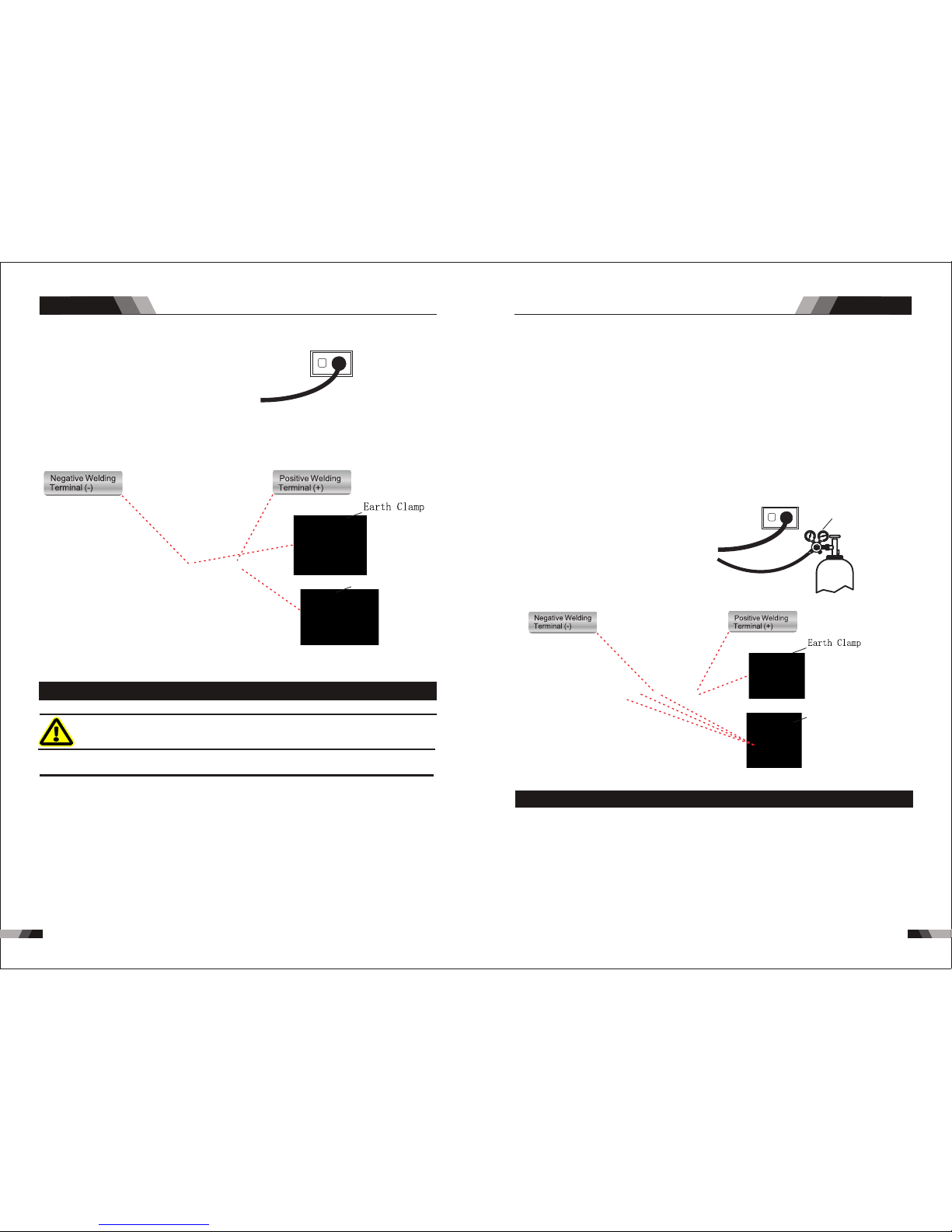

Check the earth cable