Vector Welding London2400, Tokyo 2300 Operating Instructions Manual

OPERATING INSTRUCTIONSOPERATING INSTRUCTIONS

London2400 Welding Machine

Register now

and benefit!

Jetzt Registrieren

und Profitieren!

www.smart-iwm.com

VEC TOR DIG ITA L – We op ti mi ze t he q ua li ty a nd prices

Loo kin g to the f utu re, sust ain abi lit y, envi ron men t fri end ly an d hig h on the cust ome r-o rie nte d

com peten ce - the ke y words t o which w e are res ponsi ble.

For t his rea son, we d evelo p our own p owerf ul bran d VECTO R .

In VEC TOR we ld in g eq u ipm ent c om bine s ad v an ce d i n ve rter tec hno logy,t he h i gh es t

qua lity st andar ds of a pre mium br and and l ow pric es to a uni que val ue for mo ney. Inv er te r

te chn olo gy is an es sen tia l com pon ent of pr oce ss im pro vem ent an d min imi zes en erg y

co nsu mp tio n. In a ll ou r e qu i pm e nt , w e t he r ef o re t rus t on th e M OS FET t ec hno lo gy fr om

Tos hi ba and In fin eon IG BT te chn olo gy fr om SI EME N S. T hei r i n no vat i ve so lut i on s are

set ting ne w stand ards in w eldin g techn ology.

VE CT OR w el di ng equ ipm en t ca n b e us ed o n near ly al l we ld a ble me ta ls. It i s part ic ular ly

su ita b le w hen q u al i ty w eld s a re e xtr em ely i mpo r ta n t. P riv at e gar den ing - mo t or cyc le s ,

ca rs , tr uc ks , clas si c ca rs, mo de l mak in g, s ta ir an d ba lc on y rai li ng s or i n the pr of essi on al

an d i nd ust ri al se cto rs su c h as Oi l pip e li ne, c hem i ca l, au tom o ti v e, sh i pb uil di ng, b oil e r,

el ect ric p owe r co nst ru c ti o n, n ucl ea r pow er , ae ros pa ce, m il ita ry, i ndu st rial in sta ll a ti o n,

br id g e c ons tr u c tio n an d ot her i n d ust ri e s , t h e h ig h es t qu al i ty r e q u ire me n t s a r e m et

suc cessf ully wi th VECT OR w el di ng e qu ip me nt .

V E C TOR i s on e of th e l ea d i n g su pp l i e r s of w el d i n g e qu ip m e n t - d is c o v e r o ur

po ssi b il iti e s - p r of it fro m our vi sio n t o off er mo der n , h ig h-p erf o rm anc e w eld i ng

equ ipmen t at unbe at ab le p ri ce s.

On the b as is o f 4 st rateg ic o bj ec tives , ou r co mp any w or k da y by

day to o pt im iz e this vi si on :

◆Numb er 1 i n Tec hn ol og y

◆Numb er 1 i n th e pr ices

◆Numb er 1 i n Se rv ice

◆Numb er 1 i n th e en viron me nt al c ompat ib il it y

Mo re t ha n 30, 00 0 en thu si as ti c cust om ers t ru st o ur equ ip men t in t he we ld in g an d plas ma

te c hn olo gy. Th e y c on fir m t he s ucc e ss o f the se tr end se tti ng st rat eg y. In a dd iti on to th e

st ri ng en t qua li ty t es t and t he t es t i n th e pr od uct io n, w e su bjec t th e equ ip me nt a t horo ug h

ins pec tio n before de livery. We guarant ee del ivery of s par e par ts and r epa ir of all equ ipm ent.

The c ustom er is ser ved dur ing and a fter th e warra nty per iod fro m us. In ca se o f pr ob le ms ,

call us , we are alway s availabl e. You are also wel come to visit us . High ly qual ified empl oyee s

are d ed ic ate d to c ar ryi ng o ut t heir va ri ou s tas ks w it h exp er ti se and pa ss io n. Ou r mo ti vat ed

tea m wil l alw ay s fin d a pos itive s olu ti on fo r you . Eve ry one i s wel co me to t est o ur eq ui pme nt

in de tail un der the g uidan ce of our e xpert s.

Pri va te g ar den in g, i nd ustry o r pr of essio na l, i n every a re a yo u win if yo u re ly o n tec hn ol og y

of we lding e quipm ent fro m VECTO R.

For q uesti ons or su gg es ti on s, p le as e co nt ac t us .w ww. sm ar t- iw m. co m

WARNINGS

Read a nd u nd er stand t hi s en ti re Ma nu al a nd y our emp lo ye r ’s s af et y

prac ti ce s be fore in st al li ng, ope ra ti ng ,or se rv ic in g the equ ip me nt.

Whil e The op er at in g instr uc ti ons pro vi de a n in trodu ct io n to t he safe

use of t he p ro du cts.

• Read t he o pe ra ting in st ru ct ion s fo r al l sy stem co mp on en ts!

• Obse rv e ac ci dent pr ev en ti on regu la ti ons!

• Obse rv e al l lo cal reg ul at io ns!

• Conf ir m wi th a s ignat ur e wh er e app ro pr ia te.

Reco rd the fo llo wi ng in fo rma tion fo r Warr anty pu rpo se s:

Whe re Purc hased :

Pur chase D ate:

Ser ial NO. :

Publ is he d by :

VECTOR WEL DI NG T EC HN OL OGY GM BH

Hans es tr as se 101.

5114 9, Koln , Ge rm an y

www.s ma rt -i wm.co m

1. 1 Ar c w el di ng da ma ge- -- ---- ----- -- ---- --- -- -- ----- -- ---- ----- -- ---- ----- -- ---- ----0 1- 04

1. 2 Eff ec ts o f low f re qu ency el ec tric a nd magn et ic fi el ds-- ---- ---- - -- -- ---- --- - 04 -04

1. 3 Sy mb ol ch ar t- -- -- ---- -- -- -- ---- -- -- -- ---- -- -- ---- -- -- -- ---- -- -- -- ---- -- -- --- -- -- -- -- 0 5-05

1. Saf ety ins tru ct ion s

5. Trou blesh oot in g

5.1 Tro ub le sh oo ti ng -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- ---- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- 25 -2 7

6. Mai ntena nce

6.1 Ma in te na nc e- -- -- -- -- -- -- -- -- ---- -- -- -- -- -- -- -- -- -- -- -- -- -- -- ---- -- -- -- -- -- -- -- -- -- -- 2 8- 28

2. Sum mary

2.2 W or ki ng p ri nc iple- -- -- -- -- -- -- -- -- -- ----- -- -- -- -- -- -- -- -- -- ----- -- -- -- -- -- -- -- -- -- --- 07- 07

2.1 Brief Introduction--- --------------------------- --------------------------- ----------- 06-07

2.4 Spec if ic at io ns -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- 0 8- 09

2.5 Duty cyc le -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- - 09 -0 9

2.6 Packaged I te ms -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- 0 9- 09

2. 3 -- -- -- -- -- -- -- ---- -- -- -- -- ---- -- -- -- -- ---- -- -- -- -- ---- -- 08 -0 8Vol t- a mp er e cha ra ct er is ti c

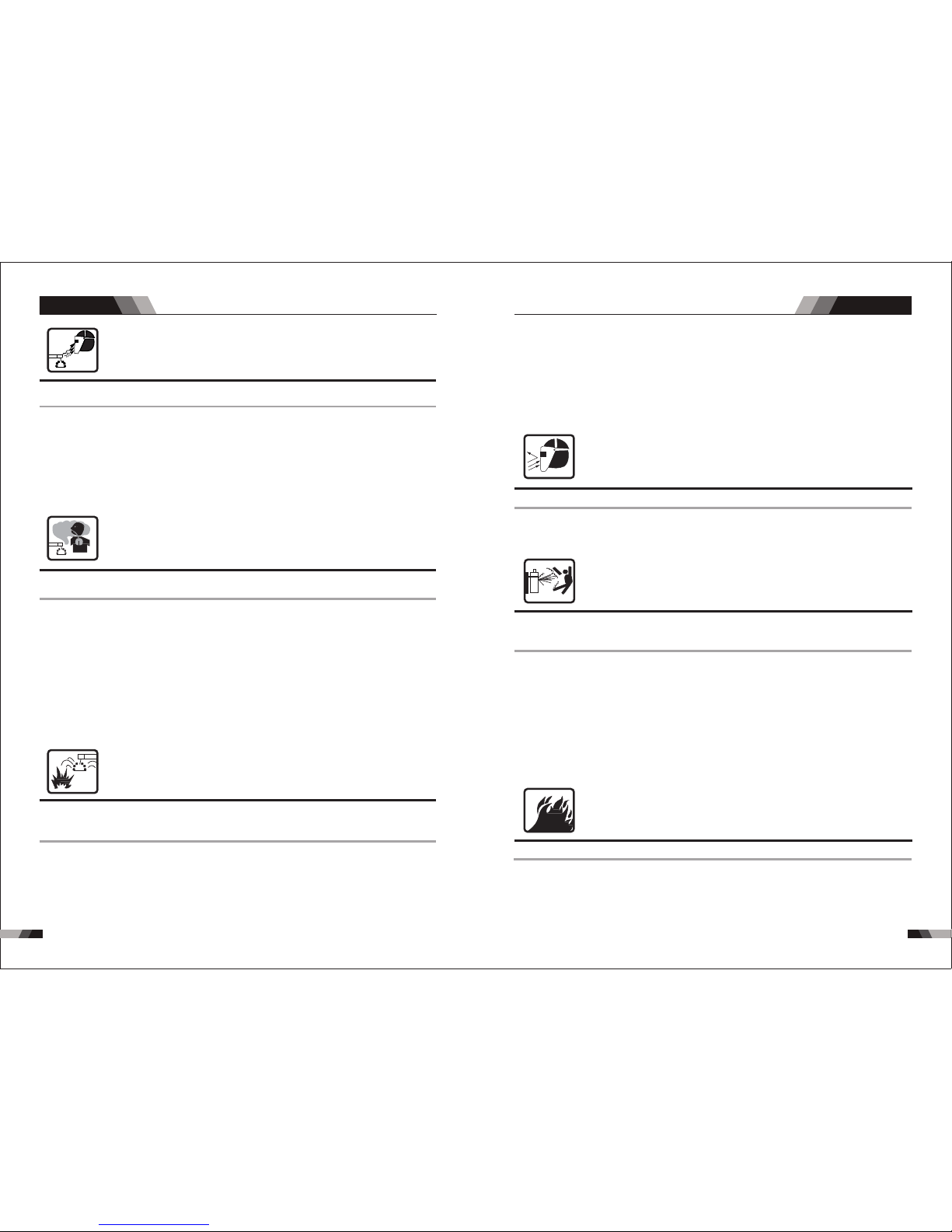

WARNI NG

PRO TECT YO UR SE LF AN D OT HE RS F RO M PO SS IB LE S ER IO US I NJ URY O R DEATH.

KEE P CHI LDREN AWAY. PACE MA KE R WE AR ERS KEEP AWAY UNTIL CO NS ULT IN G

YOU R DOCTO R. D O NO T LO SE T HE SE I NS TR UC TI ONS. RE AD OPER ATIN G/INS TRUCTI ON MANU AL BEFO RE I NS TAL LING, OPE RATING O R SE RV IC IN G THIS EQ UIPME NT.

Wel di ng p ro du ct s an d we ld in g pr oc esses can c ause se rious i njury o r death , or dama ge

to ot her equ ipmen t or prop erty, if t he o pe ra to r do es n ot s tr ic tl y observe a ll safe ty rule s

and t ake pre cauti onary a ction s.

ELE CTRIC S HOCK ca n kill.

Touch ing liv e elect rical p arts ca n cause f atal sh ocks or s evere b urns. T he e le ct ro de a nd

wor k circu it is ele ctric ally li ve when ever th e outpu t is on. Th e in pu t po we r ci rc ui t an d

mac hine in terna l circu its are a lso liv e when po wer is on . In semi -auto matic o r autom atic

wir e weldi ng, the w ire, wi re reel , drive r oll hou sing, a nd all me tal parts t ou ch in g th e we ld in g

wir e are ele ctric ally li ve. Inc orrec tly ins talle d or impr operl y groun ded equ ipmen t is a haza rd.

1. D o no t to uc h li ve e le ct ri ca l parts.

2. W ea r dr y, hol e- fr ee i ns ul at in g gl ov es a nd b od y pr otectio n.

3. I ns ul at e yo ur se lf f ro m wo rk and grou nd usin g dry ins ulati ng mats o r cover s.

4. D is co nn ec t in pu t po we r or s top engine be fo re i ns ta ll in g or s er vi ci ng t hi s eq ui pm en t.

Loc k input p ower di sconn ect swi tch ope n, or rem ove lin e fuses s o power c annot b e

tur ned on ac ciden tally.

5. P ro pe rl y in st al l an d gr ou nd this equip ment ac co rd in g to i ts O wn er ’s Manu al .

WAR NI N G

1.1 Arc We ldin g Damage

Saf e pract ices ha ve deve loped f rom pas t exper ience i n the use o f weldi ng and cu tting .

The se p ra ct ic es m us t be l ea rn ed t hrough st udy and t raini ng befo re usin g this eq uipment .

Som e of thes e pract ices ap ply to eq uipme nt conn ected t o power l ines; o ther pr actic es

app ly to eng ine dri ven equ ipmen t. Anyon e not hav ing exten si ve t ra in in g in w el di ng a nd

cut ting pr actic es shou ld not at tempt t o we ld .

Saf e pract ices ar e outli ned in th e Europ ean Sta ndard E N6097 4-1 ent itled : Safet y in

wel ding an d allie d process es P ar t 2: E le ct ri ca l HAV E ALL IN STALLATIO N, O PE RAT ION,

MAI NTENA NCE, AND REPAIR W OR K PE RF OR ME D ON LY BY QU AL IF IED PEOPLE.

Saf ety in struc tions

01

3. Ope ratio n

3.2 C ont ro l pan el --- -- --- -- --- -- --- -- --- -- --- -- --- -- --- -- --- -- ----- ----- ----- ----- ----- -- --- 1 5-1 8

3.1 Layout for the panel--- ------------------- ----------------- ----------------- --------- 10-15

3.3 S et up f or s ti ck (M MA ) we ld in g- ----- -- -- -- -- -- ----- -- -- -- -- -- -- --- -- -- -- -- -- -- --- -- 1 8- 18

3.4 S et -u p for l if t tig (GTAW ) weldi ng -- ----- -- -- --- -- -- -- --- -- -- -- --- -- -- ----- -- -- ----- 1 9- 19

3.5 O pe ratio n en viron me nt --- -- -- ----- -- -- --- -- -- --- -- -- ----- -- -- --- -- -- ----- -- -- --- -- -- 2 0-2 0

3.6 O pe ratio n no tices -- ----- -- -- --- -- -- ----- -- -- --- -- -- --- -- -- ----- -- -- --- -- -- --- -- -- ----- 2 0- 20

4. Weldi ng tech niq ue

4.1 T IG b as ic w el di ng t ec hnique- ----- -- -- -- -- -- -- -- -- -- -- -- -- ------- -- -- -- -- -- -- -- -- -- 2 0- 20

4. 2 Jo in t f ro ms i n tig -- -- -- ---- -- -- ---- -- -- ---- -- --- -- -- -- ---- -- -- ---- -- -- ---- -- --- -- -- -- 2 1-21

4.3 The e xp la nati on o f we ld in g qu al it y- -- -- -- -- -- -- -- -- -- -- -- -- -- ---- -- -- -- -- -- -- -- -- 2 1- 21

4.4 T IG p ar am et er s ma tc hi ng -- -- -- -- --------- ----- ------- ----- ------- ----- ------- ----- 2 1-23

4. 5 MM A bas ic w el ding t ec hn iq ue -- ---- -- -- -- -- -- ---- -- -- -- -- -- -- ---- -- -- -- -- -- ---- -- 2 3- 24

AC/DC WIG SERIES EQUIPMENT

WAR NI N G

FLYI NG S PARK S an d HO T ME TAL

can c ause in ju ry.

Chi pping a nd grin ding caus e fl yi ng m et al . As we ld s co ol , th ey c an t hr ow o ff sl ag .

1. W ea r ap pr oved face s hield o r safet y goggl es. Sid e shiel ds reco mmend ed.

2. W ea r pr op er body pro tecti on to pro tect sk in .

WAR NI N G

ARC R AYS ca n bu rn e ye s an d sk in ,

NOI SE can da mage he aring .

Arc ra ys f ro m th e weldi ng p ro ce ss p ro duce in te ns e he at a nd st ro ng u lt ra vi olet ra ys t ha t

can b urn eye s and ski n. Nois e from so me proc esses c an dama ge hear ing.

1. W ea r a we ld ing helme t fitte d with a pr oper sh ade of fi lter to p rotec t your fa ce a nd e ye s

whe n weldi ng or wat ching ;

2. W ea r ap pr oved safe ty glas ses. Si de shie lds rec ommen ded;

3. U se p ro te ct iv e sc re en s or b arriers t o prote ct othe rs from f lash an d glare ;

war n other s not to wa tch the a rc ;

4. W ea r pr otective cl othin g made fr om dura ble, fl ame-r esist an t ma te ri al (w oo l an d le at he r)

and f oot pro tecti on;

5. U se a pp ro ve d ea r pl ug s or e ar m uff s if n oi se l ev el i s hi gh ;

6. N ev er w ea r co nt ac t le ns es w hile weldin g.

WAR NI N G

FUM ES AND GA SE S ca n be h azardou s

to yo ur heal th.

Wel di ng p ro du ce s fu me s an d ga se s. Breathin g th es e fu me s an d ga se s ca n be h az ar do us

to yo ur heal th.

1. K ee p yo ur h ea d ou t of t he f um es . Do not brea the the f umes.

2. I f in si de , ve nt il at e th e ar ea and/or u se exha ust at th e arc to re move we lding f umes

and g ases.

3. I f ve nt il at io n is p oo r, us e an a pproved a ir-supp li ed r es pi ra to r.

4. W or k in a c on fined spa ce only i f it is wel l venti lated , or whil e weari ng an air -supp lied

res pirat or. Shie lding g ases us ed for we lding c an disp lace ai r causi ng injury o r de at h.

Be su re the br eathi ng air is s afe.

5. D o no t we ld i n lo ca ti on s ne ar d egreasing , clean ing, or s prayi ng oper ation s. The he at

and r ays of th e arc can r ea ct w it h va po ur s to f or m hi gh ly t ox ic a nd i rr it ating gas es.

6. D o no t we ld o n co at ed m et al s, s uch as galv anized, l ea d, o r ca dm iu m pl at ed s te el , un le ss

the c oatin g is remo ved fro m the wel d area, t he area i s well ve ntila ted, an d if nece ssary,

whi le wear ing an ai r- supp lied re spira tor. The c oa ti ng s an d an y me ta ls c on ta in ing these

ele ments c an give o ff toxi c fu me s if w el de d.

WAR NI N G

WEL DING ca n cause f ire or ex pl os io n.

Spa rks and s patte r fly off f ro m th e we ld in g ar c. Th e fl y sp ar ks a nd h ot m et al , we ld s pa tt er,

hot w orkpi ece, an d hot equ ipmen t can cau se fire s and bur ns. Acci denta l conta ct of

ele ctrod e or weld ing wir e to meta l objec ts can ca use spa rks, ov erhea ting, o r fire.

1. P ro te ct y ou rs el f an d ot he rs from fly ing spa rks and h ot meta l.

2. D o no t we ld w he re f ly in g sp ar ks can stri ke flam mable m ateri al.

3. R em ov e al l fl am ma bl es f ar a way from th e welding a rc . If t hi s is n ot p os si bl e, t ig ht ly

cov er them w ith app roved c overs .

4. B e al er t th at w el di ng s pa rk s and hot mat erial s from we lding c an easi ly go thr ough smal l

cra cks and o penin gs to adj acent a reas.

5. Wa tc h fo r fi re , an d ke ep a f ir e ex ti ng ui sh er n ea rby.

WAR NI N G

CYL INDER S can exp lode if d am ag ed .

Shi eldin g gas cyl inder s conta in gas un der high pr es su re . If d am ag ed , a cy li nd er c an

exp lode. S ince ga s cylin ders ar e norma lly par t of the we lding p rocess, b e su re t o tr ea t

the m caref ully.

1. P ro te ct c om pr es se d ga s cy linders f rom exc essiv e heat, m echan ical sh ocks, a nd arcs .

2. I ns ta ll a nd s ec ur e cy li nd ers in an uprig ht p os it io n by c ha in in g th em t o a st at io na ry s up port

or eq uipme nt cyli nder ra ck to pre vent fa lling o r tippi ng.

3. K ee p cy li nd er s aw ay f ro m an y welding or ot he r el ec tr ic al c ir cu it s.

4. N ev er a ll ow a w el di ng e le ct rode to touch a ny c yl in de r.

5. U se o nl y co rr ec t sh ie ld in g gas cylin ders, reg ul at or s, h os es , an d fi tt in gs d es ig ne d fo r th e

spe cific a pplic ation ; maint ain the m and ass ociat ed part s in good c ondit ion.

6. Tu rn f ac e aw ay f ro m va lv e ou tl et when ope ning cyli nd er v al ve .

7. K ee p pr ot ec ti ve c ap i n pl ac e over valv e excep t when cy linder is i n us e or c on ne ct ed

for u se.

8. R ea d an d fo ll ow i ns tr uc ti ons on compre ss ed g as c yl in de rs , as so ci at ed e qu ip me nt .

WAR NI N G

ENG INE FUE L can c ause fi re o r ex pl os io n.

Eng ine fue l is high ly flam mable .

1. S to p en gi ne b ef or e ch ec ki ng or adding fu el .

2. D o no t ad d fu el w hi le s mo ki ng o r if unit is near a ny s pa rk s or o pe n fl am es .

3. Al lo w en gi ne t o co ol b ef or e fu elling. If po ss ib le ,c he ck a nd a dd f ue l to c ol d en gi ne b ef or e

beg innin g job.

4. D o no t ov er fi ll t an k — al lo w ro om for fuel t o expan d.

5. D o no t sp il l fu el . If f ue ll in g is spille d, clea n up befo re star ting en gine.

6. B e aw ar e th at w el di ng o n a ce il ing, floor, bu lkhea d, or par titio n can cau se fire o n the

hid den sid e.

7. D o no t we ld o n cl os ed c on ta in ers such as tan ks o r dr um s.

8. C on ne ct w or k ca bl e to t he w or k as close to t he weld ing are a as prac tical t o preve nt

wel ding cu rrent f rom tra velli ng long , possi bly unk nown pa ths and c ausin g elect ric

sho ck and fi re haza rds.

9. D o no t us e we ld er t o th aw f ro ze n pipes.

10. Rem ov e st ic k electro de from h older or cu t of f we ld in g wi re a t co nt ac t tip when not

in us e.

0302

Saf ety in struc tions Saf ety in struc tions

AC/DC WIG SERIES EQUIPMENTAC/DC WIG SERIES EQUIPMENT

WAR NI N G

SPARKS can cause battery gases to explode;

BATTERY ACID can burn eyes and skin.

Bat terie s conta in acid a nd gene rate ex plosi ve gase s.

1. Al wa ys w ea r a fa ce s hi el d wh en w orking on a bat tery.

2. S to p en gi ne b ef or e di sc on necting or co nn ec ti ng b at te ry c ab le s.

3. D o no t al lo w to ol s to c au se s pa rks when wo rking on a ba tt er y.

4. D o no t us e we ld er t o ch ar ge b at teries or j ump sta rt vehi cles.

5. O bs er ve c or re ct p ol ar it y (+ and –) on ba tteri es.

WAR NI N G

STEAM AND PRESSURIZED HOT COOLANT

can burn face, eyes, and skin.

The c oolan t in the ra diato r can be ve ry hot an d under p ressu re.

1. D o no t re mo ve r ad ia to r ca p wh en engine is ho t. Al lo w en gi ne to cool.

2. W ea r gl ov es and put a ra g over ca p area wh en remo ving ca p.

3. Al lo w pr es su re t o es ca pe b ef ore complet el y re mo vi ng c ap .

NO TE

To red uce mag ne ti c fi elds in t he w or kp lace, u se t he f ol low in g pr oc edure s.

1. K ee p ca bl es c lo se t og et he r by twisti ng or tap ing the m.

2. Ar ra ng e ca bl es t o on e si de a nd a way from the op er at or.

3. D o no t co il o r dr ap e ca bl e ar ou nd the body.

4. K ee p we ld in g Po we r So ur ce a nd cables as fa r aw ay f ro m bo dy a s pr ac ti ca l.

5. T he p eo pl e with hear t-pac emake r shoul d be away f rom the w eldin g area.

1.2 Effects Of Low Frequency Electric and M agn eti c Fie lds

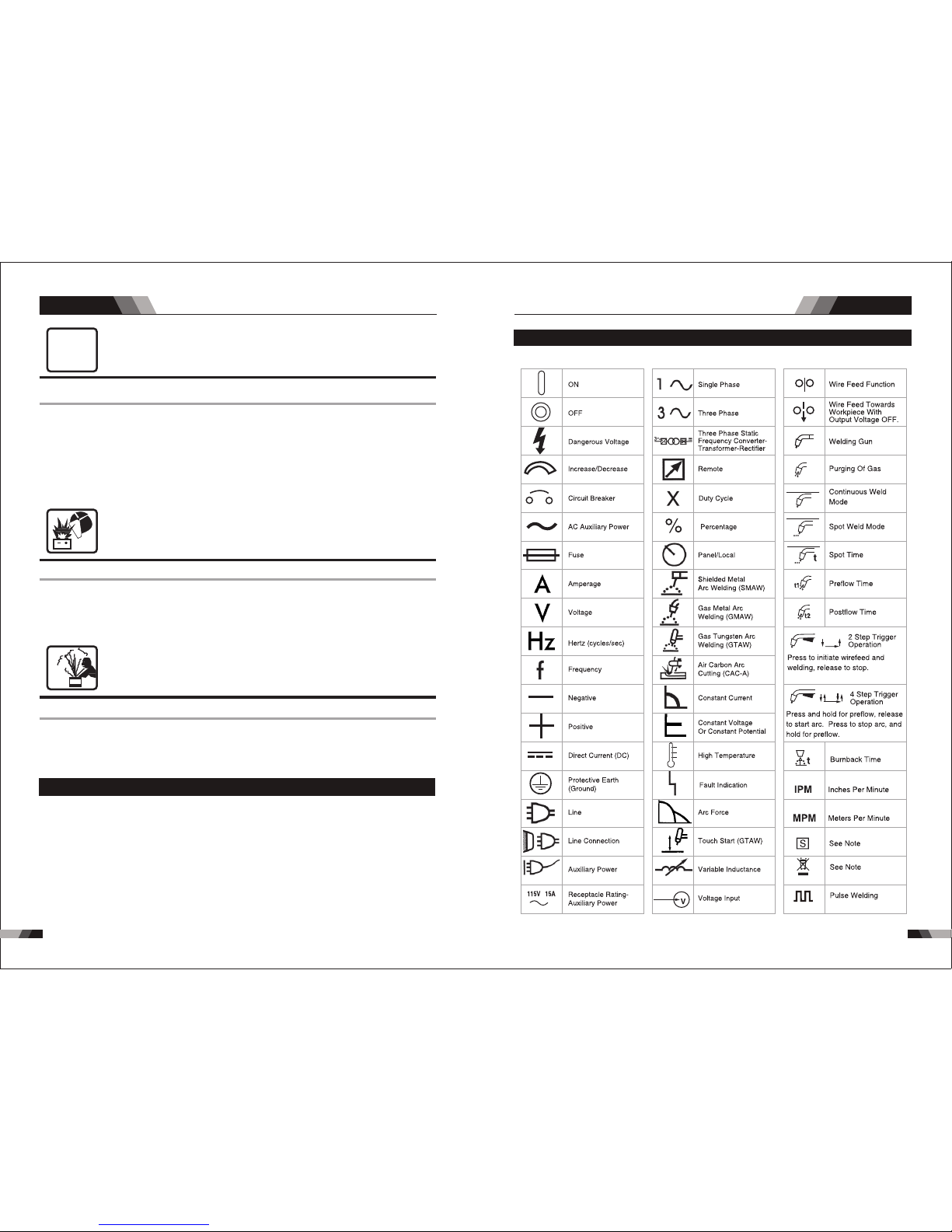

1.3 Sym bol Ch art

Note t ha t on ly s ome of th es e sy mb ols wil l ap pe ar o n you r mo de l.

Ele ctric c urren t flowi ng thro ugh any c onduc tor cau ses loc alize d Elect ric and M agnet ic

Fie lds (EM F). The d is cu ss o n th e effect of E MF i s on go in g al l th e wo rl d. U p to n ow, n o

ma te ria l evi de nce s sh ow th at EM F may h ave e ffec ts on h eal th. H oweve r, t he re searc h

on d am age o f EM F is stil l on goin g. Be fo re an y co nslu si on, we sh ou ld mi ni miz e ex pos ur e

to EM F as few as p ossib le.

WAR NI N G

MOVING PARTS can cause injury.

Mov ing par ts, suc h as fans , rotor s, and be lts can c ut f in ge rs a nd h an ds a nd c at ch l oo se

clo thing .

1. K ee p al l do or s, p an el s, c ov ers, and gu ards cl osed and se cu re ly i n pl ac e.

2. S to p en gi ne b ef or e in st al ling or conne cting u nit.

3. H av e on ly q ua li fi ed p eo pl e re move guar ds or cov ers for m ai nt en an ce a nd t ro ub le sh oo ti ng

as ne cessa ry.

4. To pr ev en t ac cidenta l start ing dur ing ser vicin g, disc onnec t negat ive (-) b atter y cable

fro m batte ry.

5. K ee p ha nd s, h ai r, lo os e cl ot hing, and too ls a wa y fr om m ov in g pa rt s.

6. R ei ns ta ll p an el s or g ua rd s and close doo rs when s ervic ing is fi nishe d and bef ore

sta rting e ngine .

0504

Saf ety in struc tions Sa fety in struc tions

AC/DC WIG SERIES EQUIPMENTAC/DC WIG SERIES EQUIPMENT

0706

2.1 Bri ef Int roducti on

Sum marySum mary

TI G Lond on 24 00 AC/D C weld in g mach in e adop ts the late st p ul se wid th mod ul at io n

(P WM ) te ch no lo gy an d in su la ted ga te b ip olar t ra ns is tor (I GB T) p ower m od ul e, wh ic h ca n

ch an ge w or k fr eq ue ncy to m ed iu m fr eq uenc y so a s to r ep la ce the t ra di ti on al hul ki ng w or k

fr eq ue nc y t ra ns fo rm er wi th th e cab in et me di um f requ en cy tr an sf or me r. T hu s, it s ch arac te ri ze d wi th p or ta ble, s ma ll s iz e, l ight w ei gh t, l ow c onsu mp ti on a nd e tc .

T he p arame ter s of TIG Lo ndo n24 00 AC/D C on the fr ont panel all can be adj usted con tin uou sly a nd st epl es sly, su ch as star t cur ren t, cr ate r arc c urr ent, weldi ng cu rre nt, b ase c urren t, du ty r ati o, upsl ope t ime , do wns lop e time, p re- gas , po st- gas , pulse f req uen cy, AC freque ncy, balanc e, hot s tart, arc for ce et c. When wel ding, it ta ke s hig h fre que nc y and high

vol tag e for a rc ig nit ing t o ens ure t he su cce ss ra tio of ign iti ng ar c.

TIG L ondon 24 00 A C/ DC Charac teris tics:

◆MCU c ontro l syste m, resp onds im me di at el y to a ny c ha ng es .

◆Hi gh fr equ en cy an d hig h vol tag e for ar c ign iti ng to en sur e t h e s uc ces s r a ti o of

ign it ing a rc , th e rev er se pola ri ty igni ti on ensu re s good ig ni tio n be ha vio r in T IG -AC

wel ding.

◆Avo id AC a rc -b re ak w it h sp ec ia l me ans, even i f ar c- br ea k oc cu rs t he H F wi ll k ee p

the a rc stab le.

◆Ped al cont rol the w el di ng c ur re nt .

◆In D C TI G wit ho ut H Fo pert at ion , If t he tu ng st en e lect ro de to uc he s t he w or kp iece

wh e n we ldin g, th e cu rre nt w i ll d rop t o sh ort- cir cu it cu rre nt to p rote ct tu ng sten .

◆

occ ou red , th e al arm l am p on th e fr on t pan el w ill b e on a nd th e ou tput cu rr ent wil l

be cu t off. It c an self -p ro tec t an d pro lo ng t he us in g life.

◆Do ub l e p ur pos es : A C i nv e r t er T I G / M M A a n d D C in v e r t e r T IG/ MM A , E xc ell en t

per forma nce on AL -a ll oy, ca rb on s te el , st ai nl es s st ee l, t it an ium.

Acco rd in g to c hoosi ng t he f ro nt pane l fu nc tions , th e fo ll owing f iv e we lding w ay s

can be r ea li ze d.

DC MMA

DC TI G

DC Pul se TIG

AC TI G

AC Pul se TIG

In tel l ig ent pr ote cti o n: o ve r-c urr e nt , ov er -he at, w hen th e ment ion e d p rob lem s

1. Fo r DC MMA, p olari ty conn ectio n can be ch osen ac cordi ng to dif fe re nt e le ct ro de s;

2. F or DC T IG, D CEP i s u se d nor mal ly (w ork p ie ce co n ne cte d t o p os iti ve po lar it y, whi le

t orc h co n ne cte d to n ega tiv e po l ar ity) . Th is c on nec tion has man y ch a ra cte rs, s uch

a s st able w eldin g arc , low tung st en p ole l os s, m ore w elding c urre nt , na rrow a nd

dee p weld;

3. Fo r AC TIG ( recta ng le w av e) , ar c is m or e st ab le t ha n Si ne AC TI G. At the sa me time ,

you c an not on ly obta in the ma x penet ratio n and the m in tung sten po le loss , but als o

obt ain bet ter cle aranc e effec t;

4. DC P ulsed T IG h as t he f ol lo wi ng c ha ra ct ers:

1) P ul se h ea ti ng . Me ta l in M ol ten po ol h as s ho rt t im e on h ig h temp er at ur e st at us

an d fr ee ze s qu ic kl y, wh ic h ca n re du ce t he pos si bi li ty t o pr od uc e ho t crac k of t he

mat er ia ls w it h th er ma l se ns it iv it y .

2) Th e wo rkpi ec e ge ts l it tl e he at . Arc e nerg y is f oc us ed . Be s ui ta bl e for th in s he et

and s uper th in s he et w el di ng .

3) Ex actly c ontro l heat in put and t he size o f the mol te n po ol . Th e de pt h of p en et ra tion

is ev en . Be s ui ta bl e fo r we ld in g by o ne s id e an d fo rm in g by two sides an d all pos ition

wel ding fo r pipe.

4) H ig h fr eque nc y arc c an m ak e meta l fo r micr ol it e fabr ic , elim in at e blow ho le and

imp rove th e me ch an ic al p er fo rm an ce o f th e jo in t.

5) Hi gh freq uency a rc is sui table f or high w eldin g speed t o impro ve the pr oduct ivity.

TI G Lo nd on2 40 0 AC/ DC – ser ie s we lding mac hi nes is s ui tab le f or all pos it ion s w eld in g

for v ari ou s pla tes mad e of st ain le ss st ee l, ca rbo n st eel , alloy ed st ee l, ti taniu m, ma gn esi um ,

cup rum, etc , W hi ch is also app li ed to pip e ins tallm ent, mou ld me nd, petro che mi cal , arc hitec ture, d eco ra tio n, car re pai r, bic yc le, h an dic ra ft an d com mo n man ufact ure.

MMA ----- --Man ual Met al Arc Wel di ng

PWM ----- --Pul se-Wi dth Mod ulati on

IGB T----- ---In sulat ion Gat e Bi po la r Tra ns is to r

TIG -- -- -- -- -- Tun gs te n In se rt G as Weld ing

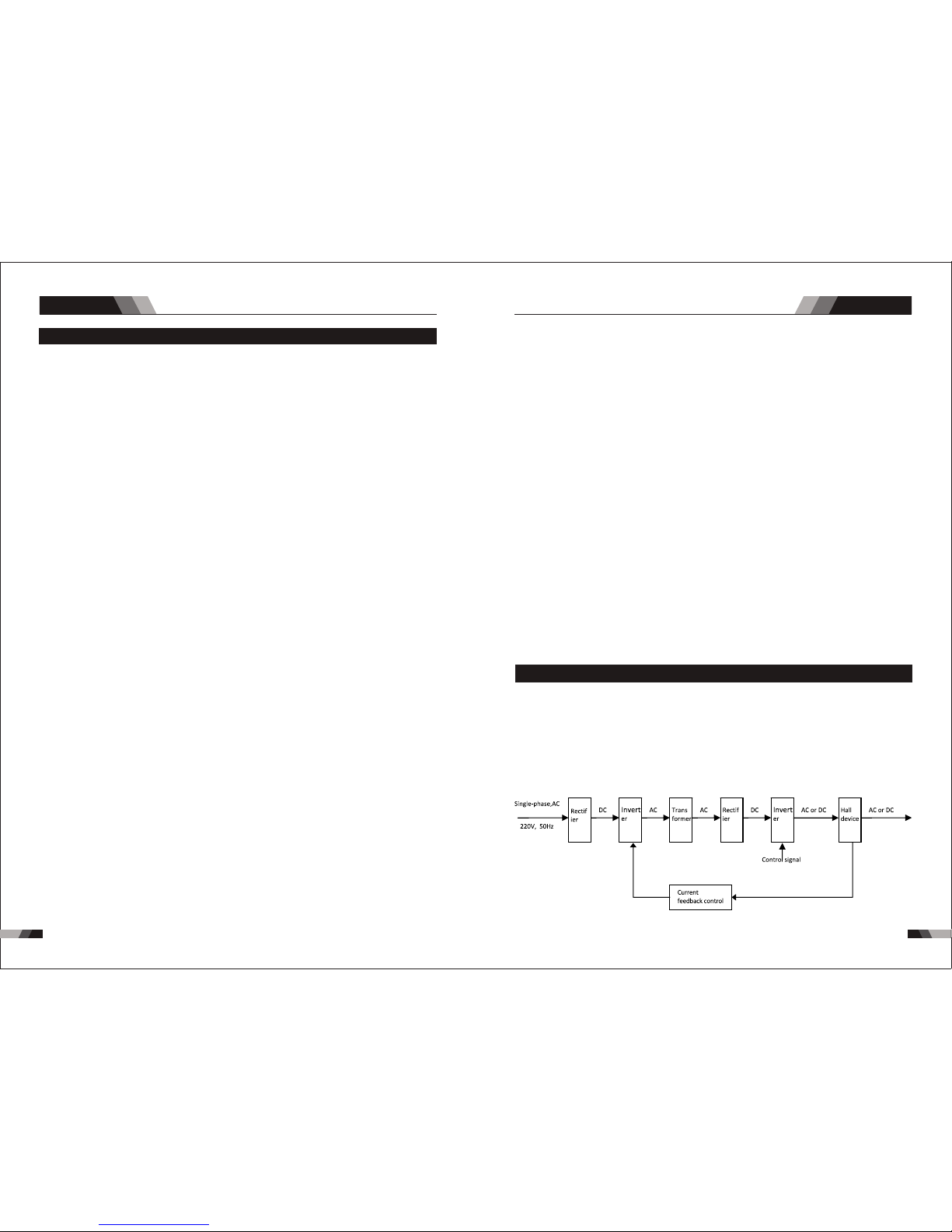

2.2 Wo rkin g Principle

The wo rkin g princi ple o f London 240 0 wel ding mac hine s is s how n as th e follow ing f igu re.

Sing le- phas e 2 30V work frequ enc y AC is rec tif ied int o D C ( abo ut 312 V), th en is con ver ted

to med ium f requ enc y AC (abo ut 20 -40 KHz ) by inv ert er de vice ( IGB T modu le) , afte r red ucing

volt age by med ium transfo rmer ( the main trans for mer) and re cti fyi ng by med ium frequen cy

rect ifi er (fa st recove ry diodes) , then is ou tpu tte d DC or AC by selecti ng IGB T modu le. The

circ uit ad opt s curr ent fe edba ck con tro l tech nology to in sure current output stabl y. Meanw hile,

the weld ing cur rent parame ter can be a dju sted contin uou sly and steples sly to m eet wit h th e

requ ire ment s of wel ding c raft .

AC/DC WIG SERIES EQUIPMENTAC/DC WIG SERIES EQUIPMENT

Loading...

Loading...