Page 1

VN-100 User Manual

Embedded Navigation Solutions

Firmware v2.1.0.0

Document Revision 2.22

UM001 1

Page 2

Document Information

Title

VN-100 User Manual

Subtitle

Inertial Navigation Modules

Document Type

User Manual

Document Number

UM001 v2.22

Document Status

Released

The information symbol points to important information within the manual.

The warning symbol points to crucial information or actions that should be followed to avoid

reduced performance or damage to the navigation module.

Email: support@vectornav.com

Phone: +1.512.772.3615

VectorNav Technical Documentation

In addition to our product-specific technical data sheets, the following manuals are available to assist

VectorNav customers in product design and development.

VN-100 User Manual: The user manual provides a high-level overview of product specific

information for each of our inertial sensors. Further detailed information regarding hardware

integration and application specific use can be found in the separate documentation listed

below.

Hardware Integration Manual: This manual provides hardware design instructions and

recommendations on how to integrate our inertial sensors into your product.

Application Notes: This set of documents provides a more detailed overview of how to utilize

many different features and capabilities offered by our products, designed to enhance

performance and usability in a wide range of application-specific scenarios.

Document Symbols

The following symbols are used to highlight important information within the manual:

Technical Support

Our website provides a large repository of technical information regarding our navigation sensors. A list

of the available documents can be found at the following address:

http://www.vectornav.com/support

If you have technical problems or cannot find the information that you need in the provided documents,

please contact our support team by email or phone. Our engineering team is committed to providing the

required support necessary to ensure that you are successful with the design, integration, and operation

of our embedded navigation sensors.

Technical Support Contact Info

2 UM001

Page 3

Table of Contents

1 Introduction 5

1.1 PRODUCT DESCRIPTION 5

1.2 FACTORY CALIBRATION 5

1.3 OPERATION OVERVIEW 5

1.4 PACKAGING OPTIONS 6

1.5 VN-100 PRODUCT CODES 8

2 Specifications 9

2.1 VN-100 SURFACE-MOUNT SENSOR (SMD) ELECTRICAL 9

2.2 VN-100 RUGGED ELECTRICAL 12

2.3 VN-100 SURFACE-MOUNT SENSOR (SMD) DIMENSIONS 14

2.4 VN-100 RUGGED DIMENSIONS 14

2.5 ABSOLUTE MAXIMUM RATINGS 15

2.6 SENSOR COORDINATE SYSTEM 15

3 VN-100 Software Architecture 17

3.1 IMU SUBSYSTEM 17

3.2 NAVSTATE SUBSYSTEM 20

3.3 NAVFILTER SUBSYSTEM 20

3.4 VECTOR PROCESSING ENGINE 22

3.5 COMMUNICATION INTERFACE 26

3.6 COMMUNICATION PROTOCOL 27

3.7 SYSTEM ERROR CODES 27

3.8 CHECKSUM / CRC 29

4 User Configurable Binary Output Messages 31

4.1 AVAILABLE OUTPUT TYPES 31

4.2 CONFIGURING THE OUTPUT TYPES 31

4.3 SERIAL OUTPUT MESSAGE FORMAT 36

4.4 BINARY GROUP 1 – COMMON OUTPUTS 41

4.5 BINARY GROUP 2 – TIME OUTPUTS 45

4.6 BINARY GROUP 3 – IMU OUTPUTS 46

4.7 BINARY GROUP 5 – ATTITUDE OUTPUTS 49

5 System Module 53

5.1 COMMANDS 53

UM001 3

Page 4

5.2 CONFIGURATION REGISTERS 57

5.3 STATUS REGISTERS 75

5.4 FACTORY DEFAULTS 76

5.5 COMMAND PROMPT 77

6 IMU Subsystem 79

6.1 IMU MEASUREMENT REGISTERS 79

6.2 IMU CONFIGURATION REGISTERS 81

6.3 FACTORY DEFAULTS 88

6.4 COMMAND PROMPT 89

7 Attitude Subsystem 91

7.1 COMMANDS 91

7.2 MEASUREMENT REGISTERS 92

8 Hard/Soft Iron Estimator Subsystem 100

8.1 CONFIGURATION REGISTERS 100

8.2 STATUS REGISTERS 101

8.3 FACTORY DEFAULTS 102

8.4 COMMAND PROMPT 103

9 Velocity Aiding 106

9.1 OVERVIEW 106

9.2 CONFIGURATION REGISTERS 110

9.3 STATUS REGISTERS 111

9.4 INPUT MEASUREMENTS 112

9.5 FACTORY DEFAULTS 113

Index Error! Bookmark not defined.

4 UM001

Page 5

1 Introduction

1.1 Product Description

The VN-100 is a miniature surface mount high-performance Inertial Measurement Unit (IMU) and Attitude

Heading Reference System (AHRS). Incorporating the latest solid-state MEMS sensor technology, the VN100 combines a set of 3-axis accelerometers, 3-axis gyroscopes, 3-axis magnetometers, a barometric

pressure sensor and a 32-bit processor. The VN-100 is considered both an IMU in that it can output

acceleration, angular rate, and magnetic measurements along the X, Y, & Z axes of the sensor as well as

an AHRS in that it can output filtered attitude estimates of the sensor with respect to a local coordinate

frame.

1.2 Factory Calibration

MEMS inertial sensors are subject to several common sources of error: bias, scale factor, misalignments,

temperature dependencies, and gyro g-sensitivity. All VN-100 sensors undergo a rigorous calibration

process at the VectorNav factory to minimize these error sources. Compensation parameters calculated

during these calibrations are stored on each individual sensor and digitally applied to the real-time

measurements.

Thermal Calibration – this option extends the calibration process over multiple temperatures to

ensure performance specifications are met over the full operating temperature range of -40 C to

+85 C.

1.3 Operation Overview

The VN-100 has a built-in microcontroller that runs a quaternion based Extended Kalman Filter (EKF),

which provides estimates of both the attitude of the sensor as well as the real-time gyro biases. VectorNav

uses a quaternion based attitude filter because it is continuous over a full 360 degree range of motion

such that there are no limitations on the angles it can compute. However, the VN-100 also has a built-in

capability to output yaw, pitch, and roll angles from the VN-100, in which the sensor automatically

converts from quaternions to the desired attitude parameter. Outputs from the VN-100 include:

Attitude:

o Yaw, Pitch, & Roll

o Quaternions

o Direction Cosine Matrix

Angular Rates:

o Bias-Compensated

o Calibrated X, Y, & Z Gyro Measurements

Acceleration:

o Calibrated X, Y, & Z Measurements

Magnetic:

o Calibrated X, Y, & Z Measurements

Barometric Pressure

The VN-100 EKF relies on comparing measurements from the onboard inertial sensors to two reference

vectors in calculating the attitude estimates: gravity down and magnetic North. Measurements from the

UM001 5

Page 6

three-axis accelerometer are compared to the expected magnitude and direction of gravity in determining

The VN-100 Kalman Filter is based on the assumption that the accelerometer measurements should only

be measuring gravity down. If the sensor is subject to dynamic motion that induces accelerations, the

pitch and roll estimates will be subject to increased errors. These measurements can be accounted and

compensated for by using the VN-100 Velocity Aiding Feature (See Section 10 for more information).

The VN-100 filter relies on comparing the onboard magnetic measurements to Earth’s background

magnetic field in determining its heading angle. Common objects such as batteries, electronics, cars,

rebar in concrete, and other ferrous materials can bias and distort the background magnetic field leading

to increased errors. These measurements can be accounted and compensated for by using the VN-100

Hard/Soft Iron Algorithms (See Section 9 for more information).

VectorNav has developed a suite of tools called the Vector Processing Engine (VPE™), which are builtinto the VN-100 and minimize the effects of these disturbances; however, it is not possible to obtain

absolute heading accuracies better than 2 degrees over any extended period of time when relying on

magnetometer measurements.

the pitch and roll angles while measurements from the three-axis magnetometer are compared to the

expected magnitude and direction of Earth’s background magnetic field in determining the heading angle

(i.e. yaw angle with respect to Magnetic North).

The VN-100 EKF also integrates measurements from the three-axis gyroscopes to provide faster and

smoother attitude estimates as well as angular rate measurements. Gyroscopes of all kinds are subject

to bias instabilities, in which the zero readings of the gyro will drift over time to due to inherent noise

properties of the gyro itself. The VN-100 EKF uses the accelerometer and magnetometer measurements

to continuously estimate the gyro bias, such that the report angular rates are compensated for this drift.

1.4 Packaging Options

The VN-100 is available in two different configurations; a 30-pin surface mount package (VN-100 SMD)

and an aluminum encased module (VN-100 Rugged). The VN-100 surface mount package is well suited

for customers looking to integrate the VN-100 sensor at the electronics level while the VN-100 Rugged

provides a precision enclosure with mounting tabs and alignment holes for a more off-the-shelf solution.

6 UM001

Page 7

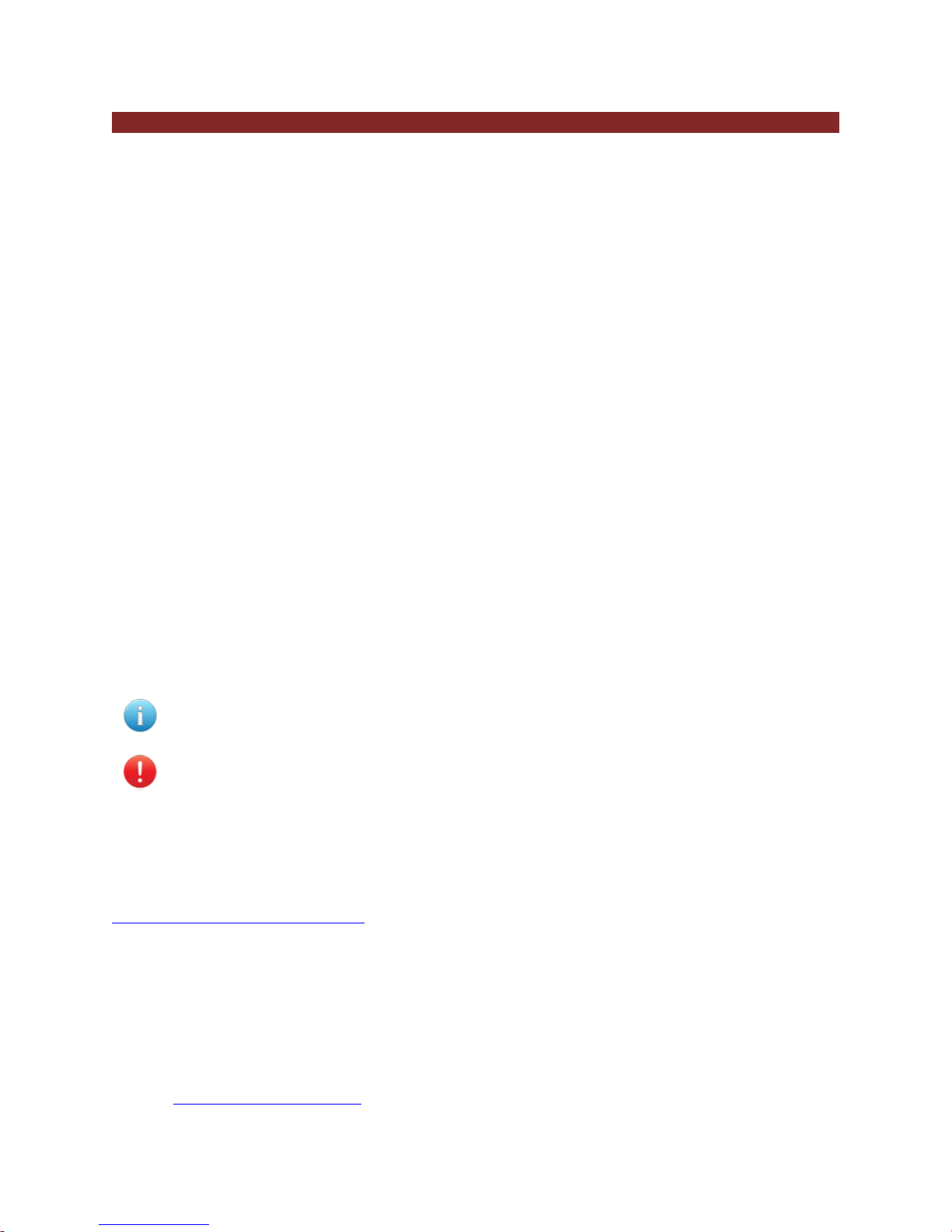

1.4.1 Surface-Mount Package

For embedded applications, the VN-100 is available in a

miniature surface-mount package.

Features

Small Size: 22 x 24 x 3 mm

Single Power Supply: 3.2 to 5.5 V

Communication Interface: Serial TTL & SPI

Low Power Requirement: < 105 mW @ 3.3V

The VN-100 Rugged consists of the VN-100 sensor installed

and calibrated in a robust precision aluminum enclosure.

Features

Precision aluminum enclosure

Locking 10-pin connector

Mounting tabs with alignment holes

Compact Size: 36 x 33 x 9 mm

Single Power Supply: 4.5 to 5.5 V

Communication Interface: Serial RS-232 & TTL

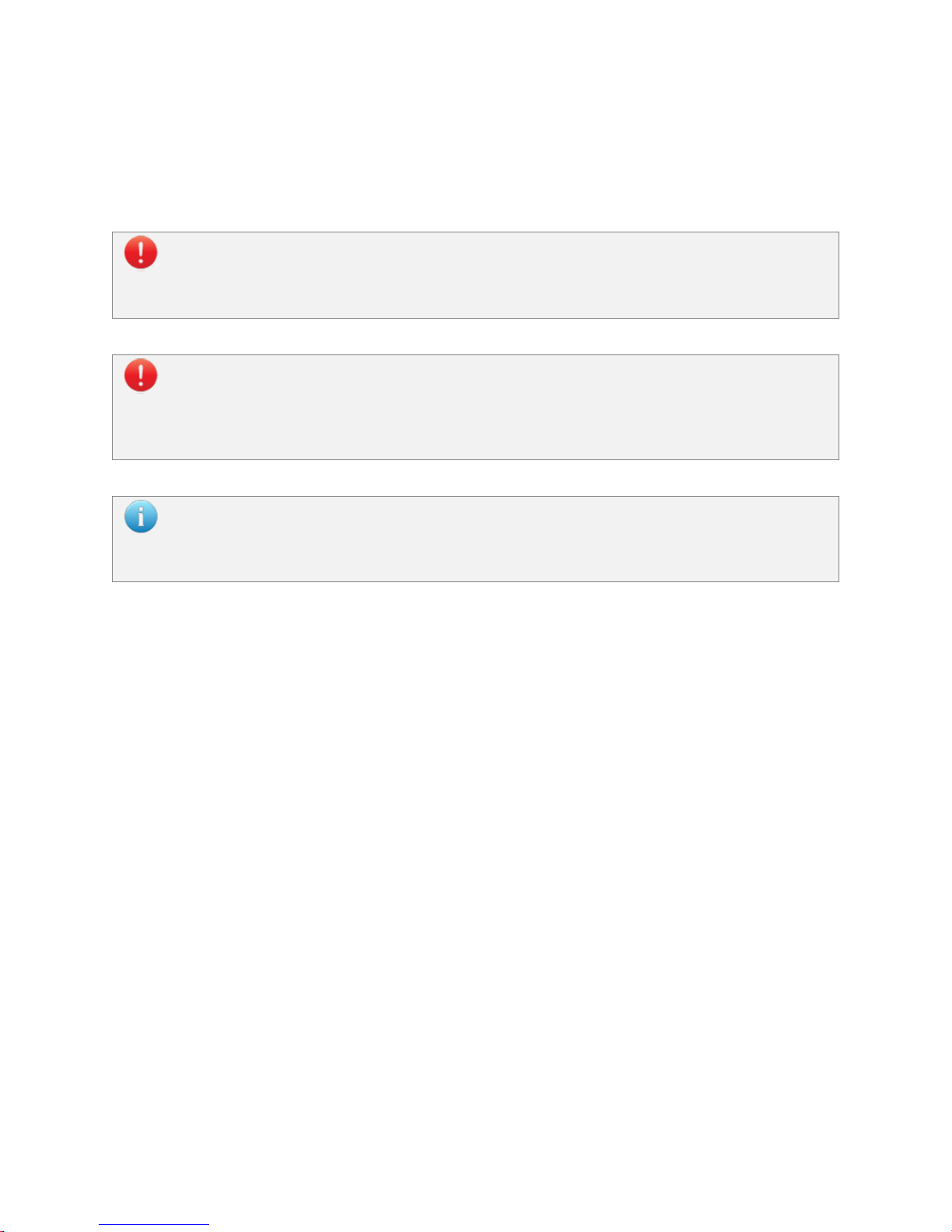

The VN-100 Development Kit provides the VN-100

surface-mount sensor installed onto a small PCB,

providing easy access to all of the features and pins on

the VN-100. Communication with the VN-100 is

provided by USB and RS-232 serial communication

ports. A 30-pin header provides easy access to each of

the critical pins. The VN-100 Development Kit also

includes all of the necessary cabling, documentation,

and support software.

Features

Pre-installed VN-100 Sensor

Onboard USB->Serial converter

Onboard TTL->RS-232 converter

30-pin 0.1” header for access to VN-100 pins

Power supply jack – 5V (Can be powered from

USB)

1.4.2 Rugged Package

1.4.3 Surface Mount Development Kit

UM001 7

Page 8

Board Size: 76 x 76 x 14 mm

1.4.4 VN-100 Rugged Development Kit

The VN-100 Rugged Development Kit includes the

VN-100 Rugged sensor along with all of the

necessary cabling required for operation. Two

cables are provided in each Development Kit: one

custom cable for RS-232 communication and a

second custom cable with a built in USB converter.

The Development Kit also includes all of the relevant

documentation and support software.

Features

VN-100 Rugged Sensor

10 ft RS-232 cable

10 ft USB connector cable

Cable Connection Tool

CD w/Software Development Kit

User Manual, Quick Start Guide &

Documentation

Carrying Case

VN-100 Options

Item Code

Sensor Packaging

Calibration Option

Product Type

VN-100S

Surface Mount Device

Standard at 25C

IMU/AHRS

VN-100T

Surface Mount Device

Thermal -40C to +85C

IMU/AHRS

VN-100S-DEV

Surface Mount Development Kit

Standard at 25C

IMU/AHRS

VN-100T-DEV

Surface Mount Development Kit

Thermal -40C to +85C

IMU/AHRS

VN-100S-CR

Rugged Module

Standard at 25C

IMU/AHRS

VN-100T-CR

Rugged Module

Thermal -40C to +85C

IMU/AHRS

VN-100S-CR-DEV

Rugged Development Kit

Standard at 25C

IMU/AHRS

VN-100T-CR-DEV

Rugged Development Kit

Thermal -40C to +85C

IMU/AHRS

VN-C100-0310

VN-100 Rugged USB Adapter Cable

N/A

Cable

VN-C100-0410

VN-100 Rugged Serial Adapter Cable

N/A

Cable

1.5 VN-100 Product Codes

8 UM001

Page 9

2 Specifications

2.1 VN-100 Surface-Mount Sensor (SMD) Electrical

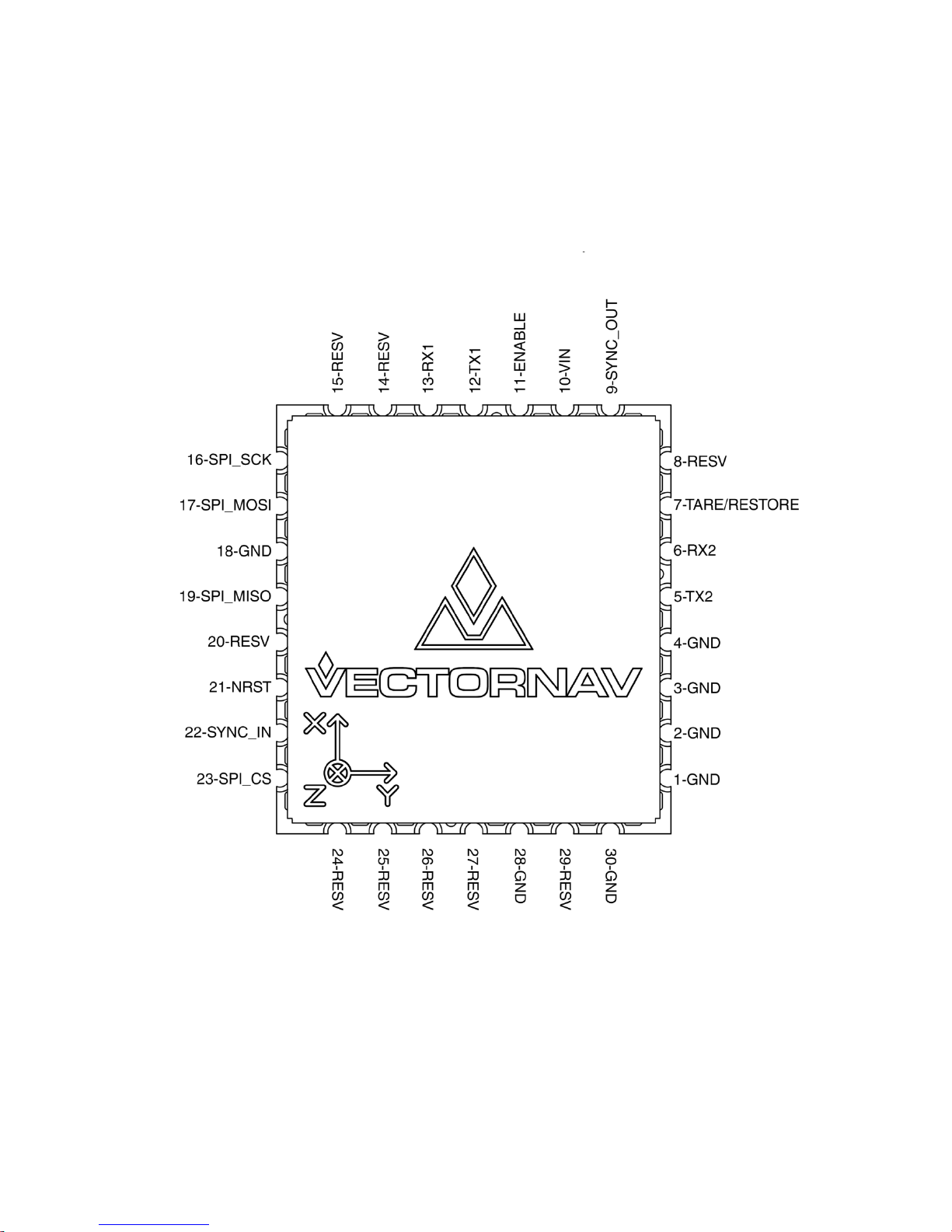

Pin assignments (top down view)

UM001 9

Page 10

VN-100 SMD Pin Assignments

Pin

Pin Name

Type

Description

1

GND

Supply

Ground.

2

GND

Supply

Ground.

3

GND

Supply

Ground.

4

GND

Supply

Ground.

5

TX2

Output

Serial UART #2 data output. (sensor)

6

RX2

Input

Serial UART #2 data input. (sensor)

7

RESTORE

Input

Normally used to zero (tare) the attitude. To tare, pulse high for at least 1 μs.

During power on or device reset, holding this pin high will cause the module to

restore the default factory settings.

As a result, the pin cannot be used for tare until at least 5 ms after a

power on or reset.

Internally held low with 10k resistor.

8

RESV

N/A

Reserved for internal use. Do not connect.

9

SYNC_OUT

Output

Time synchronization output signal.

10

VIN

Supply

3.2 - 5.5 V input.

11

ENABLE

Input

Leave high for normal operation. Pull low to enter sleep mode. Internally pulled

high with pull-up resistor.

12

TX1

Output

Serial UART #1 data output. (sensor)

13

RX1

Input

Serial UART #1 data input. (sensor)

14

RESV

N/A

Reserved for internal use. Do not connect.

15

RESV

N/A

Reserved for internal use. Do not connect.

16

SPI_SCK

Input

SPI clock.

17

SPI_MOSI

Input

SPI input.

18

GND

Supply

Ground.

19

SPI_MISO

Output

SPI output.

20

RESV

N/A

Reserved for internal use. Do not connect.

21

NRST

Input

Microcontroller reset line. Pull low for > 20 μs to reset MCU. Internally pulled

high with 10k.

22

SYNC_IN

Input

Time synchronization input signal.

23

SPI_CS

Input

SPI slave select.

24

RESV

N/A

Reserved for internal use. Do not connect.

25

RESV

N/A

Reserved for internal use. Do not connect.

26

RESV

N/A

Reserved for internal use. Do not connect.

26

RESV

N/A

Reserved for internal use. Do not connect.

28

GND

Supply

Ground.

29

RESV

N/A

Reserved for internal use. Do not connect.

30

GND

Supply

Ground.

10 UM001

Page 11

2.1.1 VN-100 SMD Power Supply

Specification

Min

Typical

Max

Input low level voltage

-0.5 V

0.8 V

Input high level voltage

2 V 5.5 V

Output low voltage

0 V 0.4 V

Output high voltage

2.4 V

3.0 V

Specification

Min

Typical

Max

Input low level voltage

-0.5 V

0.8 V

Input high level voltage

2 V 5.5 V

Output low voltage

0 V 0.4 V

Output high voltage

2.4 V

3.0 V

Clock Frequency

8 MHz

16 MHz

Close Rise/Fall Time

8 ns

Specification

Min

Typical

Max

Input low level voltage

-0.5 V

0.8 V

Input high level voltage

2 V 5.5 V

Weak pull-up equivalent resistor

30 kΩ

40 kΩ

50 kΩ

NRST pulse width

20 μs

Specification

Min

Typical

Max

Input low level voltage

-0.5 V

0.8 V

Input high level voltage

2 V 5.5 V

Pulse Width

100 ns

Specification

Min

Typical

Max

Output low voltage

0 V 0.4 V

Output high voltage

2.4 V

3.0 V

Output high to low fall time

125 ns

Output low to high rise time

125 ns

Output Frequency

1 Hz

1 kHz

The minimum operating supply voltage is 3.2V and the absolute maximum is 5.5V.

2.1.2 VN-100 SMD Serial (UART) Interface

The serial interface on the VN-100 operates with 3V TTL logic.

Serial I/O Specifications

2.1.3 VN-100 SMD Serial Peripheral Interface (SPI)

Serial I/O Specifications

2.1.4 VN-100 SMD Reset, SyncIn/Out, and Other General I/O Pins

NRST Specifications

SyncIn Specifications

SyncOut Specifications

UM001 11

Page 12

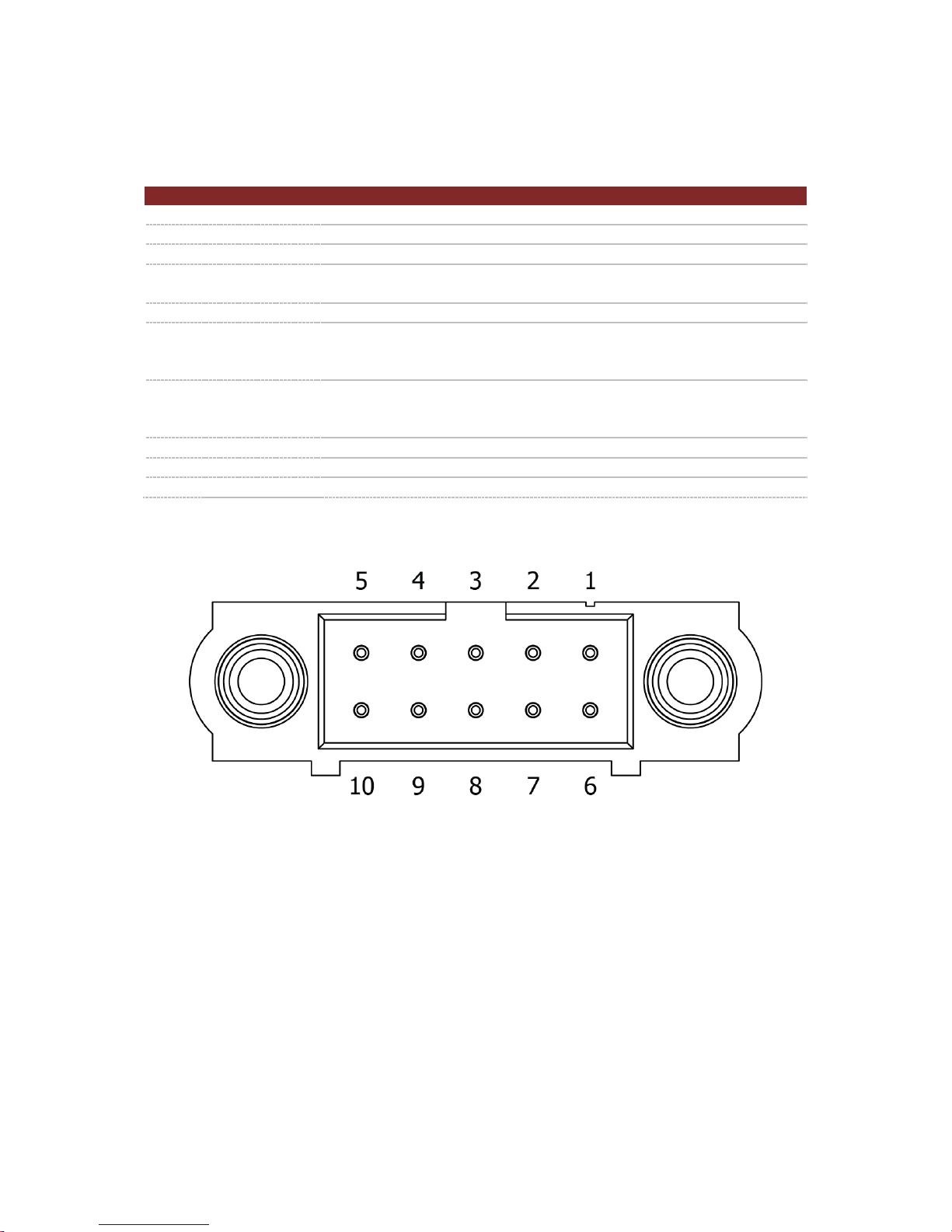

2.2 VN-100 Rugged Electrical

Pin

Pin Name

Description

1

VCC

+4.5V to +5.5V

2

TX1

RS-232 voltage levels data output from the sensor. (Serial UART #1)

3

RX1

RS-232 voltage levels data input to the sensor. (Serial UART #1)

4

SYNC_OUT

Output signal used for synchronization purposes. Software configurable

to pulse when ADC, IMU, or attitude measurements are available.

5

GND

Ground

6

TARE/RESTORE

Input signal used to zero the attitude of the sensor. If high at reset, the

device will restore to factory default state. Internally held low with 10k

resistor.

7

SYNC_IN

Input signal for synchronization purposes. Software configurable to

either synchronize the measurements or the output with an external

device.

8

TX2_TTL

Serial UART #2 data output from the device at TTL voltage level (3V).

9

RX2_TTL

Serial UART #2 data into the device at TTL voltage level (3V).

10

RESV

This pin should be left unconnected.

VN-100 Rugged Pin Assignments

VN-100 Rugged External Connector

12 UM001

Page 13

2.2.1 VN-100 Rugged Power Supply

Specification

Min

Typical

Max

Input low level voltage

-25 V

Input high level voltage

25 V

Output low voltage

-5.0 V

-5.4 V

Output high voltage

5.0 V

5.5 V

Output resistance

300 Ω

10 MΩ

Data rate

1 Mbps

Pulse slew

300 ns

Specification

Min

Typical

Max

Input low level voltage

-0.5 V

0.8 V

Input high level voltage

2 V 5.5 V

Weak pull-up equivalent resistor

30 kΩ

40 kΩ

50 kΩ

NRST pulse width

20 μs

Specification

Min

Typical

Max

Input low level voltage

-0.5V

0.8V

Input high level voltage

2V 5.5V

Pulse Width

100 ns

Specification

Min

Typical

Max

Output low voltage

0 V 0.4 V

Output high voltage

2.4 V

3.0 V

Output high to low fall time

125 ns

Output low to high rise time

125 ns

Output Frequency

1 Hz

1 kHz

The power supply input for the VN-100 Rugged is 4.5 to 5.5 V DC.

2.2.2 VN-100 Rugged Serial UART Interface

Serial I/O Specifications

2.2.3 VN-100 Rugged Reset, SyncIn/Out, and Other General I/O Pins

NRST Specifications

SyncIn Specifications

SyncOut Specifications

UM001 13

Page 14

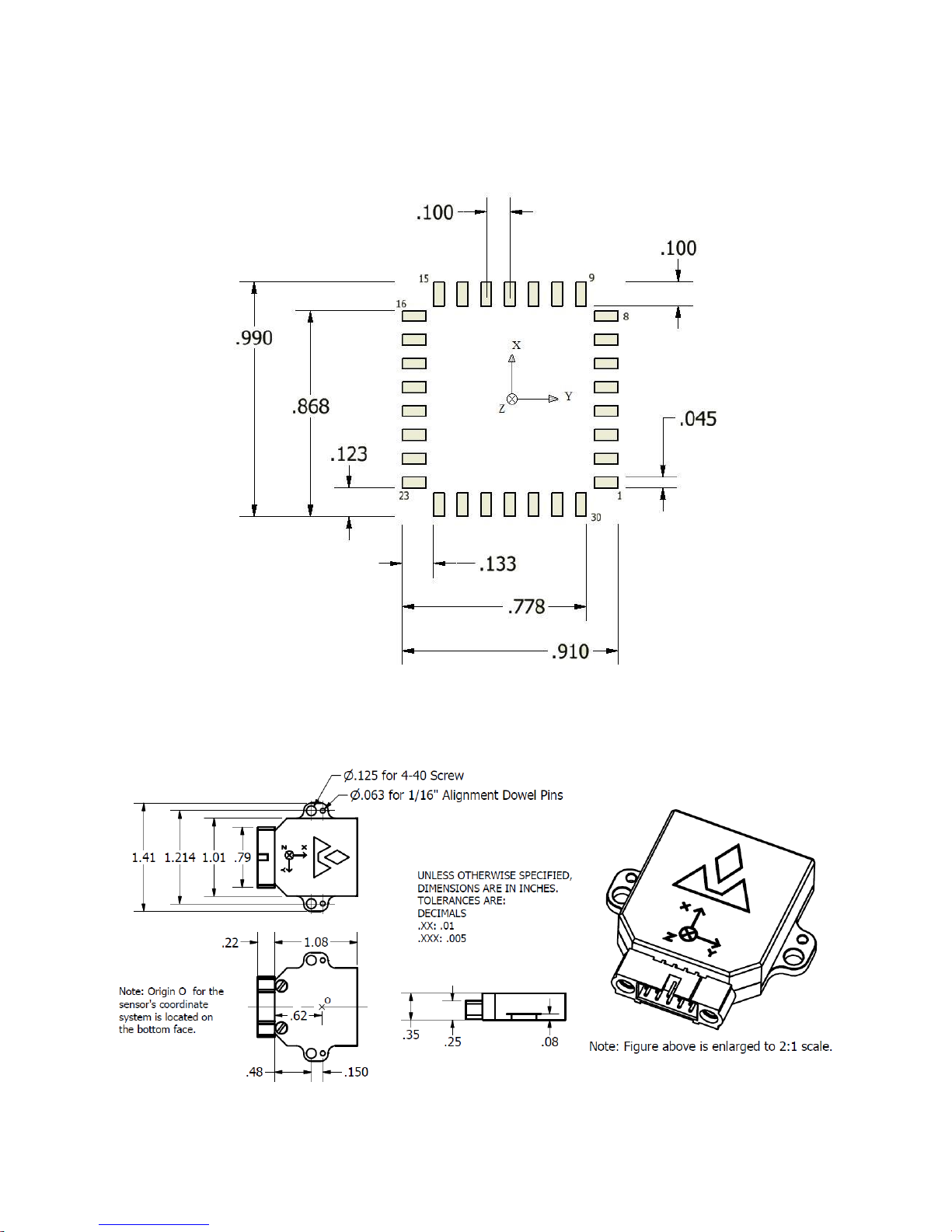

2.3 VN-100 Surface-Mount Sensor (SMD) Dimensions

* Measurements are in inches

2.4 VN-100 Rugged Dimensions

14 UM001

Page 15

2.4.1 Rugged Connector Type

Specification

Min

Max

Input Voltage

-0.3 V

5.5 V

Operating Temperature

-40 C

85 C

Storage Temperature

-40 C

85 C

Specification

Min

Max

Input Voltage

-0.3 V

5.5 V

Operating Temperature

-40 C

85 C

Storage Temperature

-40 C

85 C

The main connector used on the VN-100 Rugged is a 10-pin Harwin M80-5001042. The mating connector

used on the cable assemblies provided by VectorNav for use with the VN-100 Rugged is a Harwin M80-

4861005.

2.5 Absolute Maximum Ratings

SMD Absolute Maximum Ratings

Rugged Absolute Maximum Ratings

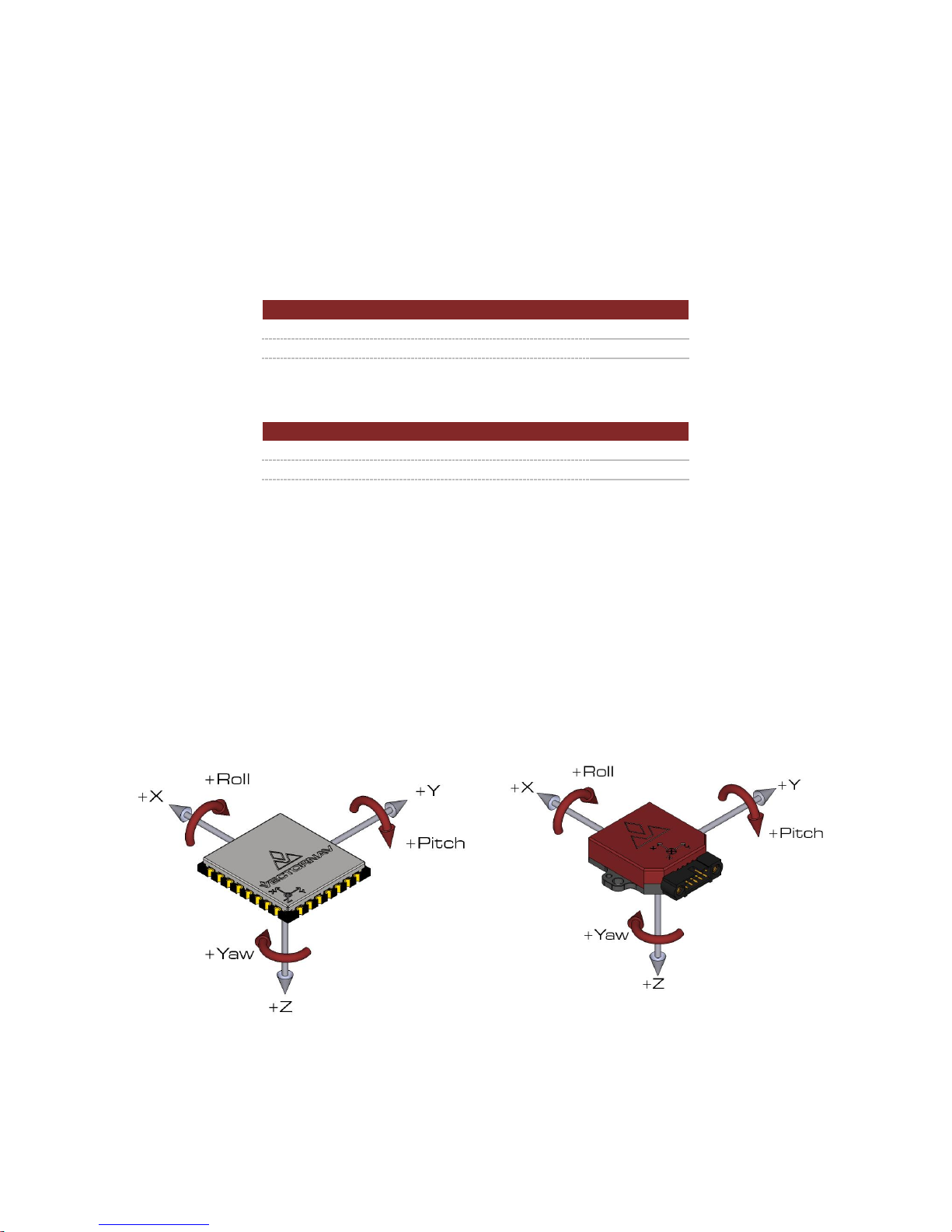

2.6 Sensor Coordinate System

2.6.1 Sensor Coordinate Frame

The VN-100 uses a right-handed coordinate system. A positive yaw angle is defined as a positive righthanded rotation around the Z-axis. A positive pitch angle is defined as a positive right-handed rotation

around the Y-axis. A positive roll angle is defined as a positive right-handed rotation around the X-axis.

The axes direction with respect to the VN-100 module is shown in the figure below.

VN-100 Coordinate System

UM001 15

Page 16

2.6.2 North-East-Down Frame

The VN-100 velocity estimates can be output in the North-East-Down (NED) coordinate frame defined as

follows (NX, NY, NZ):

Right-handed, Cartesian, non-inertial, geodetic frame with origin located at the surface of Earth

(WGS84 ellipsoid);

Positive X-axis points towards North, tangent to WGS84 ellipsoid;

Positive Y-axis points towards East, tangent to WGS84 ellipsoid;

Positive Z-axis points down into the ground completing the right-handed system.

16 UM001

Page 17

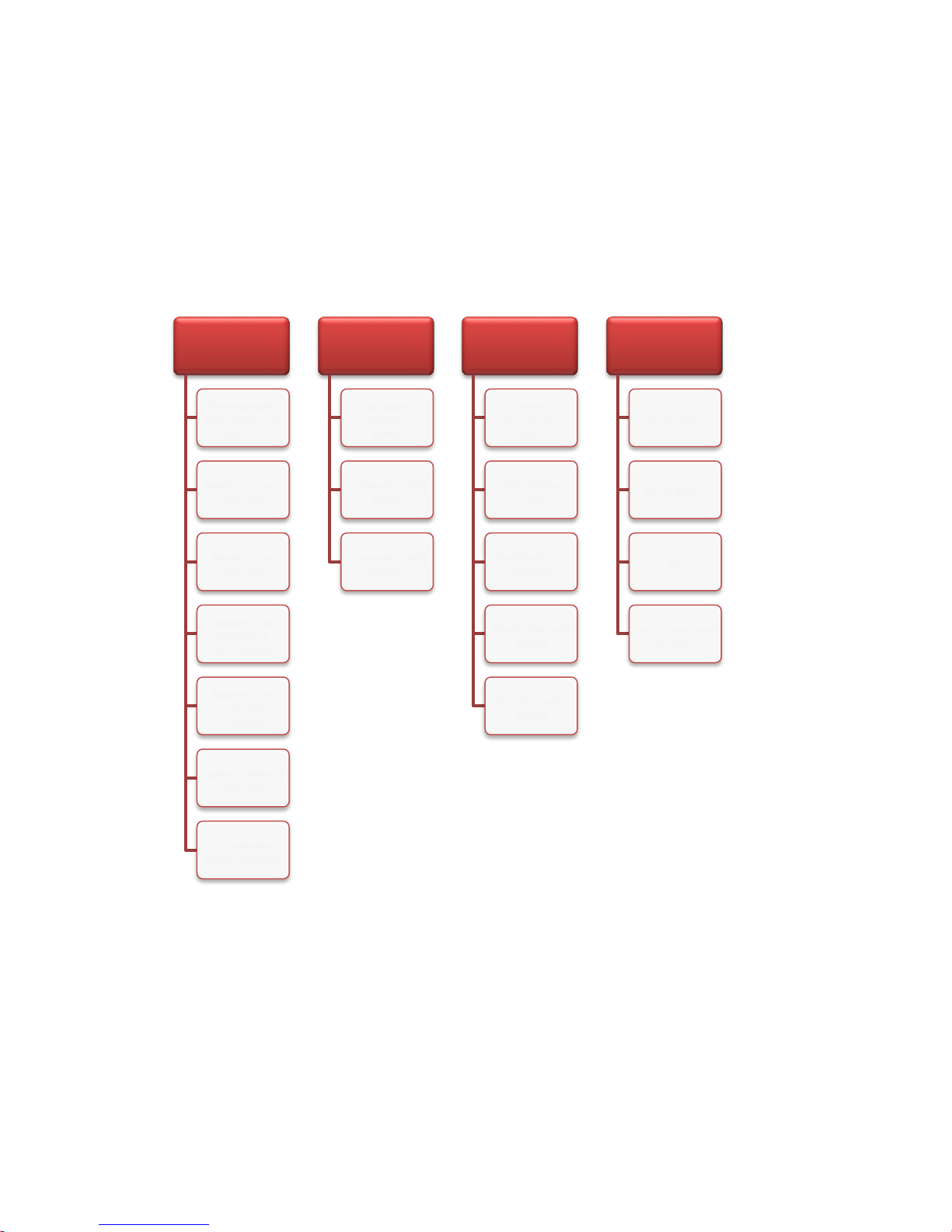

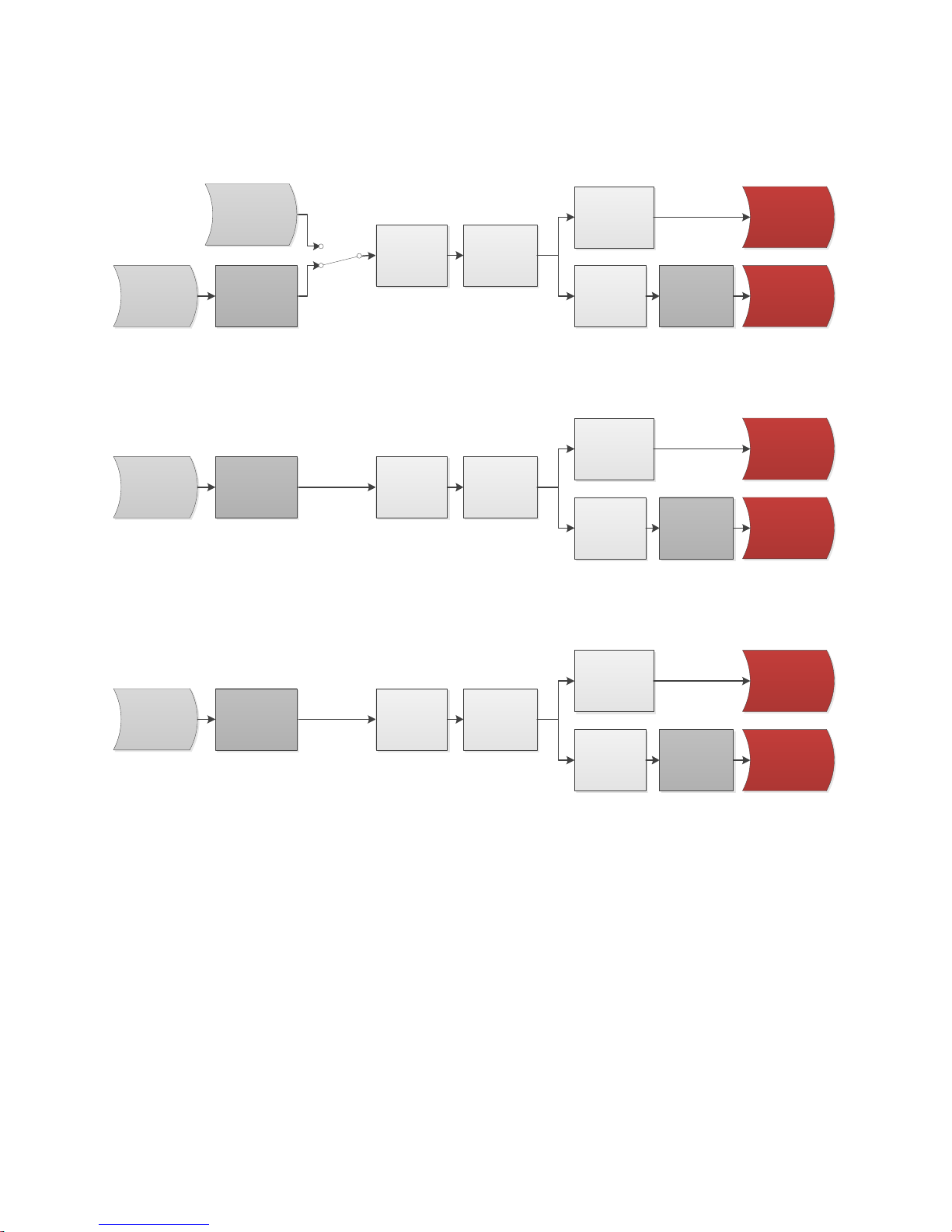

3 VN-100 Software Architecture

IMU

Downsamples

IMU sensors to

800 Hz

Applies Factory

Calibration

Applies User

Calibration

Applies User

Reference

Frame Rotation

Applies User

Low-Pass

Filtering

Applies Onboard

Calibration

Timestamps

Measurements

NavState

Calculates

orientation at

400Hz

Computes delta

angles

Computes delta

velocity

NavFilter

Vector

Processing

Engine

AHRS Kalman

Filter

Hard/Soft Iron

Estimator

World Magnetic

Model

World Gravity

Model

Comm

Interface

Serial ASCII

Serial Binary

SPI

Serial Command

Prompt

The software architecture internal to the VN-100 includes four separate subsystems. These subsystems

are the IMU, the NavState, the NavFilter, and the Communication Interface. The high-level functions

performed by these subsystems are outlined below. This chapter describes these functions performed by

these subsystems in more detail and describes which of the various measurement outputs originate from

each of these corresponding subsystems.

VN-100 Software Architecture

3.1 IMU Subsystem

The IMU subsystem runs at the highest system rate, described from this point forward as the IMU Rate

(defaults to 800 Hz). It is responsible for collecting the raw IMU measurements, applying a factory, user,

and dynamic calibration to these measurements, and optionally filtering the individual sensor

measurements for output. The coning and sculling integrals also are calculated by the IMU subsystem at

the full IMU Rate. The IMU subsystem is also responsible for time stamping the IMU measurements to

internal system time, and relative to the SyncIn signal.

UM001 17

Page 18

3.1.1 Magnetometer

Raw

Magnetometer

Data

Factory

Calibration

External

Magnetometer

Data

User

Magnetometer

Compensation

(Register 23)

User Reference

Frame Rotation

(Register 26)

User Low-Pass

Filtering

(Uncompensated)

(Register 85)

Onboard Hard/

Soft Iron

Compensation

(Register 44+47)

Uncompensated

Magnetometer

(uncompMag)

Compensated

Magnetometer

(magBody)

User Low-Pass

Filtering

(Compensated)

(Register 85)

Raw

Accelerometer

Data

Factory

Calibration

User

Accelerometer

Compensation

(Register 25)

User Reference

Frame Rotation

(Register 26)

User Low-Pass

Filtering

(Uncompensated)

(Register 85)

Uncompensated

Accelerometer

(uncompAccel)

Compensated

Accelerometer

(accelBody)

User Low-Pass

Filtering

(Compensated)

(Register 85)

Accelerometer

Filter Bias

Compensation

Raw Gyro Data

Factory

Calibration

User Gyro

Compensation

(Register 84)

User Reference

Frame Rotation

(Register 26)

User Low-Pass

Filtering

(Uncompensated)

(Register 85)

Gyro Filter Bias

Compensation

Uncompensated

Angular Rate

(uncompGyro)

Compensated

Angular Rate

(angularRate)

User Low-Pass

Filtering

(Compensated)

(Register 85)

3.1.2 Accelerometer

Magnetometer IMU Measurements

Accelerometer IMU Measurements

3.1.3 Gyro

3.1.4 Raw IMU Measurements

The raw IMU measurements are collected from the internal MEMS at the highest rate available for each

individual sensor. For the gyro and accelerometer, the measurements are down-sampled to the IMU Rate.

3.1.5 Factory Calibration

Each VN-100 sensor is tested at the factory at multiple known angular rates, accelerations, and magnetic

field strengths to determine each sensor’s unique bias, scale factor, axis alignment, and temperature

dependence. The calibration coefficients required to remove these unwanted errors are permanently

stored in flash memory on each sensor. At the IMU Rate, these calibration coefficients are applied to the

raw IMU measurements, to correct for and remove these known measurement errors. For thermally

calibrated units the onboard temperature sensor is used to remove the measurement temperature

dependence. The output of the factory calibration stage is referred to as the calibrated (but uncompensated) IMU measurements.

18 UM001

Gyro IMU Measurements

Page 19

3.1.6 User Calibration

A write settings and reset command must be issued after setting the Reference Frame Rotation Register

before coordinate transformation will be applied.

The VN-100 provides the user with the ability to apply a separate user calibration to remove additional

bias, scale factor, and axis misalignments. The user calibration is applied after the factory calibration, and

can be used to optionally fine tune the calibration for each of the individual sensors. The user calibration

is optional and in most cases not required for normal operation.

3.1.7 User Reference Frame Rotation

The user reference frame rotation provides the user with the ability to apply a rigid body rotation to each

of the sensor outputs. This can be used to transform the coordinate system of the onboard sensors into

any other coordinate frame of the user’s choice. Since this transformation is applied to the IMU

measurements prior to their use in the onboard attitude estimation algorithms, applying a user reference

frame rotation will not only change the output coordinates for the IMU measurements, it will also change

the IMU body frame for all subsequent attitude estimation calculations.

3.1.8 User Low-Pass Filtering

The VN-100 also provides a means (see Register 85) to apply low-pass filtering to the output compensated

IMU measurements. It is important to note that the user low-pass filtering only applies to the output

compensated IMU measurements. All onboard Kalman filters in the NavFilter subsystem always use the

unfiltered IMU measurements after the User Reference Frame Rotation (Register 26) has been applied.

As such the onboard Kalman filtering will not be affected by the user low-pass filter settings. The user

low-pass filtering can be used to down-sample the output IMU measurements to ensure that information

is not lost when the IMU measurements are sampled by the user at a lower rate than the internal IMU

Rate.

3.1.9 Timestamp Measurements

All onboard measurements captured by the IMU subsystem are time stamped relative to several internal

timing events. These events include the monotonically increasing system time (time since startup), the

time since the last SyncIn event, and the time since the last GPS PPS pulse. These timestamps are recorded

with microsecond resolution and ~10 microsecond accuracy relative to the onboard temperature

compensated crystal oscillator. The onboard oscillator has a timing accuracy of ~20ppm over the

temperature range of -40C to 80C.

3.1.10 Coning & Sculling

The IMU subsystem is also responsible for computing and accumulating the coning and sculling integrals.

These integrals track the delta angle and delta velocity accumulated from one time step to another. The

coning and sculling integrals are reset each time the delta angle and/or delta velocity are outputted

(asynchronously) or polled from the delta theta and velocity register (Register 80). Between output and

polling events, the coning and sculling integration are performed by the IMU subsystem at the IMU Rate.

UM001 19

Page 20

3.2 NavState Subsystem

NavState Outputs

Attitude

(Yaw, Pitch, Roll, Quaternion, DCM)

Position

(LLA, ECEF)

Velocity

(NED, ECEF, Body)

Delta Angle (Available at full IMU rate)

Delta Velocity (Available at full IMU rate)

NavFilter Outputs

Attitude Uncertainty

Position & Velocity Uncertainty

Gyro & Accel Filter Biases

Mag & Accel Disturbance Estimation

Onboard Magnetic Hard & Soft Iron Estimation

World Magnetic & Gravity Model

The NavState subsystem generates a continuous reliable stream of low-latency, low-jitter state outputs

at a rate fixed to the IMU sample rate. The state outputs include any output such as attitude, position,

and velocity, which are not directly measureable by the IMU and hence must be estimated by the onboard

Kalman filters. The NavState runs immediately after, and in sync with the IMU subsystem, at a rate

divisible into the IMU Rate. This rate is referred to as the NavState Rate (default 800 Hz). The NavState

decouples the rate at which the state outputs are made available to the user from the rate at which they

are being estimated by the onboard Kalman filters. This is very important for many applications which

depend on low-latency, low-jitter attitude, position, and velocity measurements as inputs to their control

loops. The NavState guarantees the output of new updated state information at a rate fixed to the IMU

Rate with very low latency and output jitter. The NavState also provides the ability for the VN-100 to

output estimated states at rates faster than the rate of the onboard Kalman filters, which may be affected

by system load and input measurements availability.

3.2.1 NavState Measurements

The measurements shown below are calculated by the NavState subsystem and are made available at the

NavState Rate (default 800 Hz).

3.3 NavFilter Subsystem

The NavFilter subsystem consists of the INS Kalman filter, the Vector Processing Engine (VPE), and its

collection of other Kalman filters and calculations that run at a lower rate than the NavState. Most high

level states such as the estimated attitude, position, and velocity are passed from the NavFilter to the

NavState, and as such are made available to the user at the NavState rate. There are a handful of outputs

however that will only update at the rate of the NavFilter, some of which are listed below.

3.3.1 INS Kalman Filter

The INS Kalman filter consists of an Extended Kalman filter which nominally runs at the NavFilter rate

(default 200 Hz). The INS Kalman filter uses the accelerometer, gyro, GPS, and (at startup) the

magnetometer to simultaneously estimate the full quaternion based attitude solution, the position and

20 UM001

Page 21

velocity, as well as the time varying gyro, accelerometer, and barometric pressure sensor biases. The

output of the INS Kalman filter is passed to the NavState, allowing for the attitude, position, and velocity

to be made available at the higher fixed rate of the NavState.

3.3.2 Vector Processing Engine

The Vector Processing Engine (VPE) is a collection of sophisticated algorithms which provide real-time

monitoring and simultaneous estimation of the attitude as well as the uncertainty of the input

measurements used by the attitude estimation algorithm. By estimating its own input measurement

uncertainty the VPE is capable of providing significantly improved performance when compared to

traditional statically tuned Kalman Filters. The estimated measurement uncertainty is used to in real-time

adaptively tune the onboard Kalman filters. This adaptive tuning eliminates the need in most cases for

the user to perform any custom filter tuning for different applications.

3.3.3 AHRS Kalman Filter

The AHRS Kalman filter consists of an EKF which nominally runs at the NavFilter Rate (default 200 Hz). The

AHRS Kalman filter simultaneously estimates the full quaternion based attitude as well as the time varying

gyro bias. The quaternion based attitude estimation eliminates any potential gimbal lock issues incurred

at high pitch angles, which can be problematic for Euler-angle based AHRS algorithms. The real-time

estimation of the gyro bias allows for the removal of small perturbations in the gyro bias which occur over

time due to random walk.

3.3.4 Hard/Soft Iron Estimator

The NavFilter subsystem also includes a separate EKF which provides real-time estimation of the local

magnetic hard and soft iron distortions. Hard and soft iron distortions are local magnetic field distortions

created by nearby ferrous material which moves with the sensor (attached to the same vehicle or rigidbody as the sensor). These ferrous materials distort the direction and magnitude of the local measured

magnetic field, thus negatively impacting the ability of an AHRS to reliably and accurately estimate

heading based on the magnetometer measurements. To remove the unwanted effect of these materials,

a hard & soft iron calibration needs to be performed which requires rotating the sensor around in multiple

circles while collecting magnetic data for off-line calculation of the magnetic hard & soft iron calibration

coefficients. This calibration can be very time consuming, and might not be possible for some applications.

The onboard hard/soft iron estimator runs in the background without requiring any user intervention. For

many applications this simplifies the process for the end user, and allows for operation in environments

where the hard/soft iron may change slowly over time. While the onboard hard/soft iron estimator runs

in the background by default, it can be turned off by the user if desired in the Magnetic Calibration Control

Register.

3.3.5 World Magnetic Model

The world magnetic model (WMM) is a large spatial-scale representation of the Earth’s magnetic field.

The internal model used on the VN-100 is consistent with the current WMM2016 model which consist of

a spherical-harmonic expansion of the magnetic potential of the geomagnetic field generated in the

Earth’s core. By default the world magnetic model on the VN-100 is turned off, allowing the user to

directly set the reference magnetic field strength. Alternatively the world magnetic model can be

manually used to calculate the magnetic field strength for a given latitude, longitude, altitude, and date

which is then subsequently used as the fixed magnetic field reference strength. Control of the world

magnetic model is performed using the Reference Vector Configuration Register.

UM001 21

Page 22

3.3.6 World Gravity Model

The world gravity model (WGM) is a large spatial-scale representation of the Earth’s gravity potential as a

function of position on the globe. The internal model used on the VN-100 is consistent with the Earth

Gravity Model (EGM96), which consist of a spherical-harmonic expansion of the Earth’s geopotential. By

default the world gravity model on the VN-100 is turned off, allowing the user to directly set the reference

gravity vector. Control of the world gravity model is performed using the Reference Vector Configuration

Register.

3.4 Vector Processing Engine

The Vector Processing Engine (VPE) is a collection of sophisticated algorithms which provide real-time

monitoring and simultaneous estimation of the attitude as well as the uncertainty of the input

measurements used by the attitude estimation algorithm. By estimating its own input measurement

uncertainty the VPE is capable of providing significantly improved performance when compared to a

traditional statically tuned EKF AHRS attitude estimation algorithm. The estimated measurement

uncertainty is used too in real-time at the NavFilter rate (default 200 Hz) adaptively tune the attitude

estimation Kalman filter. This adaptive tuning eliminates the need in most cases for the user to perform

any custom filter tuning for different applications. It also provides extremely good disturbance rejection

capabilities, enabling the VN-100 in most cases to reliably estimate attitude even in the presence of

vibration, short-term accelerations, and some forms of magnetic disturbances.

3.4.1 Adaptive Filtering

The VPE employs adaptive filtering techniques to significantly reduce the effect of high frequency

disturbances in both magnetic and acceleration. Prior to entering the attitude filter, the magnetic and

acceleration measurements are digitally filtered to reduce high frequency components typically caused

by electromagnetic interference and vibration. The level of filtering applied to the inputs is dynamically

altered by the VPE in real-time. The VPE calculates the minimal amount of digital filtering required in order

to achieve specified orientation accuracy and stability requirements. By applying only the minimal amount

of filtering necessary, the VPE reduces the amount of delay added to the input signals. For applications

that have very strict latency requirements, the VPE provides the ability to limit the amount of adaptive

filtering performed on each of the input signals.

3.4.2 Adaptive Tuning

Kalman filters employ coefficients that specify the uncertainty in the input measurements which are

typically used as “tuning parameters” to adjust the behavior of the filter. Normally these tuning

parameters have to be adjusted by the engineer to provide adequate performance for a given application.

This tuning process can be ad-hoc, time consuming, and application dependent. The VPE employs adaptive

tuning logic which provides on-line estimation of the uncertainty of each of the input signals during

operation. This uncertainty is then applied directly to the onboard attitude estimation Kalman filter to

correctly account for the uncertainty of the inputs. The adaptive tuning reduces the need for manual filter

tuning.

3.4.3 VPE Heading Modes

The VectorNav VPU provides three separate heading modes. Each mode controls how the VPE interprets

the magnetic measurements to estimate the heading angle. The three modes are described in detail in

the following sections.

22 UM001

Page 23

Absolute Heading Mode

If a magnetic disturbance occurs due to an event controlled by the user, such as the switching on/off of

an electric motor, an absolute heading can still be maintained if the device is notified of the presence

of the disturbance.

To correctly track an absolute heading you will need to ensure that the hard/soft iron distortions remains

well characterized.

In Absolute Heading Mode the VPE will assume that the principal long-term DC component of the

measured magnetic field is directly related to the earth’s magnetic field. As such only short term magnetic

disturbances will be tuned out. This mode is ideal for applications that are free from low frequency (less

than ~ 1Hz) magnetic disturbances and/or require tracking of an absolute heading. Since this mode

assumes that the Earth's magnetic field is the only long-term magnetic field present, it cannot handle

constant long-term magnetic disturbances which are of the same order of magnitude as the Earth's

magnetic field and cannot be compensated for by performing a hard/soft iron calibration. From the

sensor's perspective a constant long-term magnetic disturbance will be indistinguishable from the

contribution due to the Earth's magnetic field, and as such if present it will inevitably result in a loss of

heading accuracy.

Absolute Heading Mode Advantages

Provides short-term magnetic disturbance rejection while maintaining absolute tracking of the

heading relative to the fixed Earth.

Absolute Heading Mode Disadvantages

If the magnetic field changes direction relative to the fixed Earth, then its direction will need to

be updated using the reference vector register in order to maintain an accurate heading

reference.

Hard/Soft iron distortions that are not properly accounted for will induce heading errors

proportional to the magnitude of the hard/soft iron distortion. In some cases this could be as high

as 30-40 degrees.

Relative Heading Mode

In Relative Heading mode the VPE makes no assumptions as to the long term stability of the magnetic

field present. In this mode the VPE will attempt to extract what information it reasonably can from the

magnetic measurements in order to maintain an accurate estimate of the gyro bias. The VPE will

constantly monitor the stability of the magnetic field and when it sees that its direction is reasonably

stable, the VPE will maintain a stable heading estimate. Over long periods of time under conditions where

the magnetic field direction changes frequently, in Relative Heading mode it is possible for the VN-100 to

accumulate some error in its reported heading relative to true North. In this mode the VPE will not attempt

to correct for this accumulated heading error.

Relative Heading mode does not assume that the Earth's magnetic field is the only long-term magnetic

field present. As such this mode is capable of handling a much wider range of magnetic field disturbances

while still maintaining a stable attitude solution. Relative Heading mode should be used in situations

where the most important requirement is for the attitude sensor is to maintain a stable attitude solution

UM001 23

Page 24

which minimizes the effect of gyro drift while maintaining a stable and accurate pitch and roll solution.

Use the Relative Heading mode for applications where the stability of the estimated heading is more

important than the long-term accuracy relative to true magnetic North. In general, the Relative Heading

mode provides better magnetic disturbance rejection that the Absolute Heading mode.

Since the Relative Heading mode assumes that other magnetic disturbances can be present which are

indistinguishable from the Earth's field, Relative Heading mode cannot always ensure that the calculated

heading is always referenced to Earth's magnetic north.

Relative Heading Mode Advantages

Capable of handling short-term and long-term magnetic interference.

Can handle significant errors in the hard/soft iron while still maintaining a stable heading and gyro

bias estimate.

Relative Heading Mode Disadvantages

Unable to maintain heading estimate relative to true North in environments with frequent long-

term magnetic field disturbances.

Indoor Heading Mode

The Indoor Heading mode was designed to meet the needs of applications that require the enhanced

magnetic disturbance rejection capability of the Relative Heading mode, yet desire to maintain an

absolute heading reference over long periods of time. The Indoor Heading mode extends upon the

capabilities of the Relative Heading mode by making certain assumptions as to the origin of the measured

magnetic fields consistent with typical indoor environments.

In any environment the measured magnetic field in 3D space is actually the combination of the Earth’s

magnetic field plus the contribution of other local magnetic fields created by nearby objects containing

ferromagnetic materials. For indoor environments this becomes problematic due to the potential close

proximity to objects such as metal desk and chairs, speakers, rebar in the concrete floor, and other items

which either distort or produce their own magnetic field. The strength of these local magnetic fields are

position dependent, and if the strength is on the same order of magnitude as that of the Earth’s magnetic

field, directly trusting the magnetic measurements to determine heading can lead to inaccurate heading

estimates.

While in Indoor Heading mode the VPE inspects the magnetic measurements over long periods of time,

performing several different tests on each measurement to quantify the likelihood that the measured

field is free of the influence of any position dependent local magnetic fields which would distort the

magnetic field direction. Using this probability the VPE then estimates the most likely direction of the

Earth’s magnetic field and uses this information to correct for the heading error while the device is in

motion.

Indoor Heading Mode Advantages

Capable of handling short-term and long-term magnetic interference

Can handle significant errors in the hard/soft iron while still maintaining a stable heading and

gyro bias estimate.

Capable of maintaining an accurate absolute heading over extended periods of time.

24 UM001

Page 25

Indoor Heading Mode Disadvantages

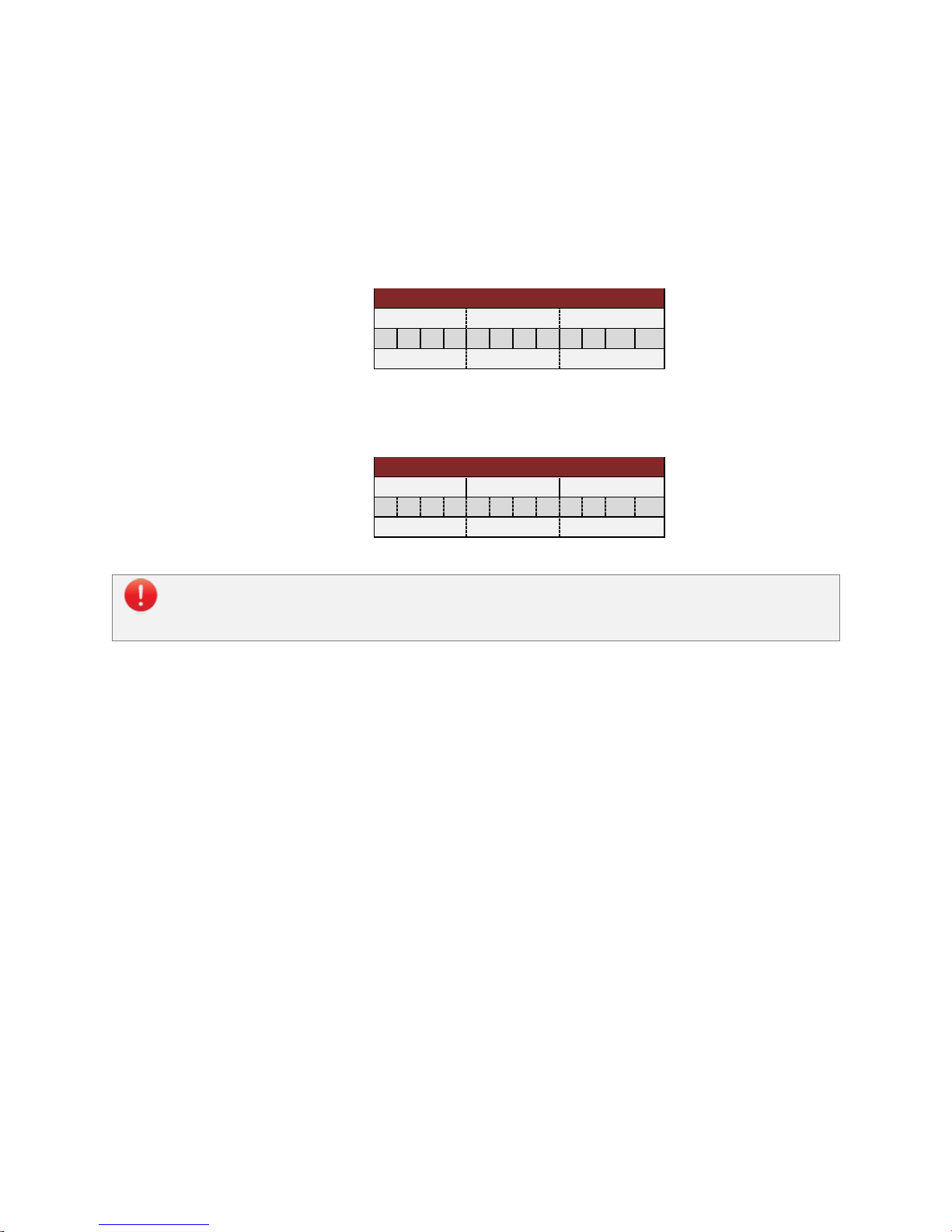

Capabilities

Absolute

Heading

Relative

Heading

Indoor

Mode

Capabilities

Handle high frequency magnetic

disturbances greater than 1Hz?

Yes

Yes

Yes

Handle high frequency magnetic

disturbances greater than 1Hz?

Handle constant disturbances lasting

less than a few seconds?

Yes

Yes

Yes

Handle constant disturbances

lasting less than a few seconds?

Handle constant disturbances lasting

longer than a few seconds?

No

Yes

Yes

Handle constant disturbances

lasting longer than a few seconds?

Measurement repeatability may be worse than Relative Mode during periods when the VPE

corrects for known errors in absolute heading.

Overview of Heading Modes

A summary of the different types of disturbances handled by each magnetic mode is summarized in the

table below.

3.4.4 VPE Adaptive Filtering and Tuning Settings

The VPE actively employs both adaptive filtering and adaptive tuning techniques to enhance performance

in conditions of dynamic motion and magnetic and acceleration disturbances. The VPE provides the ability

to modify the amount of adaptive filtering and tuning applied on both the magnetometer and the

accelerometer. In many cases the VPE can be used as is without any need to adjust these settings. For

some applications higher performance can be obtained by adjusting the amount of adaptive filtering and

tuning performed on the inputs. For both the magnetometer and the accelerometer the following settings

are provided.

Static Measurement Uncertainty

The static gain adjusts the level of uncertainty associated with either the magnetic or acceleration

measurement when no disturbances are present. The level of uncertainty associated with the

measurement will directly influence the accuracy of the estimated attitude solution. The level of

uncertainty in the measurement will also determine how quickly the attitude filter will correct for errors

in the attitude when they are observed. The lower the uncertainty, the quicker it will correct for observed

errors.

This parameter can be adjusted from 0 to 10.

Zero places no confidence (or infinite uncertainty) in the sensor, thus eliminating its effect on

the attitude solution.

Ten places full confidence (minimal uncertainty) in the sensor and assume that its measurements

are always 100% correct.

Adaptive Tuning Gain

The adaptive tuning stage of the VPE monitors both the magnetic and acceleration measurements over

an extended period of time to estimate the time-varying level of uncertainty in the measurement. The

adaptive tuning gain directly scales either up or down this calculated uncertainty.

This parameter can be adjusted from 0 to 10.

UM001 25

Page 26

The minimum value of zero turns off all adaptive tuning.

It is important to note that the ability to update the firmware using the onboard bootloader is only

supported on the serial port 1 interface. It is highly recommended that if serial port 1 is not used for

normal operation, a means of accessing it is designed into the product to support future firmware

updates.

The maximum value of 10 applies several times the estimated level of uncertainty.

Adaptive Filtering Gain

The adaptive filtering stage of the VPE monitors both the magnetic and acceleration measurements to

determine if large amplitude high frequency disturbances are present. If so then a variable level of filtering

is applied to the inputs in order to reduce the amplitude of the disturbance down to acceptable levels

prior to inputting the measurement into the attitude filter. The advantage of the adaptive filtering is that

it can improve accuracy and eliminate jitter in the output attitude when large amplitude AC disturbances

are present. The disadvantage to filtering is that it will inherently add some delay to the input

measurement. The adaptive filtering gain adjusts the maximum allowed AC disturbance amplitude for the

measurement prior to entering the attitude filter. The larger the allowed disturbance, the less filtering

that will be applied. The smaller the allowed disturbance, the more filtering will be applied.

This parameter can be adjusted from 0 to 10.

The minimum value of zero turns off all adaptive filtering.

The maximum value of 10 will apply maximum filtering.

Keep in mind that regardless of this setting, the adaptive filtering stage will apply only the minimal amount

of filtering necessary to get the job done. As such this parameter provides you with the ability to set the

maximum amount of delay that you are willing to accept in the input measurement.

3.5 Communication Interface

The VN-100 provides two separate communication interfaces on two separate serial ports.

3.5.1 Serial Interface

The serial interface consists of two physically separate bi-directional UARTs. Each UART supports baud

rates from 9600 bps up to a maximum of 921600 bps.

The rugged version includes an onboard TTL to RS-232 level shifter, thus at the 10-pin connector one serial

port is offered with RS-232 voltages levels (Serial 1), while the other serial port (Serial 2) remains at 3V

TTL logic levels.

3.5.2 SPI Interface

The SPI interface consists of a standard 4-wire synchronous serial data link which is capable of high data

rates up to 16 Mbps. The VN-100 operates as slave on the bus enabled by the master using the slave

select (SPI_CS) line. See the Basic Communication chapter for more information on the operation of the

SPI interface.

26 UM001

Page 27

3.6 Communication Protocol

$VNRRG,8*4B

$VNRRG,08,-114.314,+000.058,-001.773*5F

The VN-100 utilizes a simple command based communication protocol for the serial interface. An ASCII

protocol is used for command and register polling, and an optional binary interface is provided for

streaming high speed real-time sensor measurements.

3.6.1 Serial ASCII

On the serial interface a full ASCII protocol provides support for all commands, and register polling. The

ASCII protocol is very similar to the widely used NMEA 0183 protocol supported by most GPS receivers,

and consists of comma delimited parameters printed in human readable text. Below is an example

command request and response on the VN-100 used to poll the attitude (Yaw Pitch Roll Register in the

Attitude subsystem) using the ASCII protocol.

Example Serial Request

Example Serial Response

At the end of this user manual each software subsystem is documented providing a list of all the

commands and registers suported by the subsystem on the VN-100. For each command and register an

example ASCII response is given to demonstrating the ASCII formatting.

3.6.2 Serial Binary

The serial interface offers support for streaming sensor measurements from the sensor at fixed rates using

user configurable binary output packets. These binary output packets provide a low-overhead means of

streaming high-speed sensor measurements from the device minimizing both the required bandwidth and

the necessary overhead required to parse the incoming measurements for the host system.

3.6.3 Serial Command Prompt

A simple command prompt is also provided on the serial interface, which provides support for advanced

device configuration and diagnostics. The serial command prompt is an optional feature that is designed

to provide more detailed diagnostic view of overall system performance than is possible using normal

command & register structure. It is strictly intended to be used by a human operator, who can type

commands to the device using a simple serial terminal, and is not designed to be used programmatically.

Each software subsystem described in the software module chapters provides information on the

diagnostic commands supported by the serial command prompt at the end of each subsystem section.

3.7 System Error Codes

In the event of an error, the VN-100 will output $VNERR, followed by an error code. The possible error

codes are listed in the table below with a description of the error.

UM001 27

Page 28

Error Codes

Error Name

Code

Description

Hard Fault

1

If this error occurs, then the firmware on the VN-100 has experienced a

hard fault exception. To recover from this error the processor will force

a restart, and a discontinuity will occur in the serial output. The

processor will restart within 50 ms of a hard fault error.

Serial Buffer Overflow

2

The processor’s serial input buffer has experienced an overflow. The

processor has a 256 character input buffer.

Invalid Checksum

3

The checksum for the received command was invalid.

Invalid Command

4

The user has requested an invalid command.

Not Enough Parameters

5

The user did not supply the minimum number of required parameters

for the requested command.

Too Many Parameters

6

The user supplied too many parameters for the requested command.

Invalid Parameter

7

The user supplied a parameter for the requested command which was

invalid.

Invalid Register

8

An invalid register was specified.

Unauthorized Access

9

The user does not have permission to write to this register.

Watchdog Reset

10

A watchdog reset has occurred. In the event of a non-recoverable error

the internal watchdog will reset the processor within 50 ms of the error.

Output Buffer Overflow

11

The output buffer has experienced an overflow. The processor has a

2048 character output buffer.

Insufficient Baud Rate

12

The baud rate is not high enough to support the requested

asynchronous data output at the requested data rate.

Error Buffer Overflow

255

An overflow event has occurred on the system error buffer.

28 UM001

Page 29

3.8 Checksum / CRC

// Calculates the 8-bit checksum for the given byte sequence.

unsigned char calculateChecksum(unsigned char data[], unsigned int length)

{

unsigned int i;

unsigned char cksum = 0;

for(i=0; i<length; i++){

cksum ^= data[i];

}

return cksum;

}

The serial interface provides the option for either an 8-bit checksum or a 16-bit CRC. In the event neither

the checksum nor the CRC is needed, both can be turned off by the user. Refer to the Communication

Protocol Control Register for details on disabling the checksum/CRC.

3.8.1 Checksum Bypass

When communicating with the sensor using a serial terminal, the checksum calculation can be bypassed

by replacing the hexadecimal digits in the checksum with uppercase X characters. This works for both the

8-bit and 16-bit checksum. An example command to read register 1 is shown below using the checksum

bypass feature.

$VNRRG,1*XX

3.8.2 8-bit Checksum

The 8-bit checksum is an XOR of all bytes between, but not including, the dollar sign ($) and asterisk (*).

All comma delimiters are included in the checksum calculation. The resultant checksum is an 8-bit number

and is represented in the command as two hexadecimal characters. The C function snippet below

calculates the correct checksum.

Example C Code

UM001 29

Page 30

3.8.3 16-bit CRC

// Calculates the 16-bit CRC for the given ASCII or binary message.

unsigned short calculateCRC(unsigned char data[], unsigned int length)

{

unsigned int i;

unsigned short crc = 0;

for(i=0; i<length; i++){

crc = (unsigned char)(crc >> 8) | (crc << 8);

crc ^= data[i];

crc ^= (unsigned char)(crc & 0xff) >> 4;

crc ^= crc << 12;

crc ^= (crc & 0x00ff) << 5;

}

return crc;

}

For cases where the 8-bit checksum doesn't provide enough error detection, a full 16-bit CRC is available.

The VN-100 uses the CRC16-CCITT algorithm. The resultant CRC is a 16-bit number and is represented in

the command as four hexadecimal characters. The C function snippet below calculates the correct CRC.

Example C Code

30 UM001

Page 31

4 User Configurable Binary Output Messages

Time

•TimeStartup

•TimeGps

•GpsTow

•GpsWeek

•TimeSyncIn

•TimeGpsPps

•TimeUTC

•SyncInCnt

•SyncOutCnt

•TimeStatus

IMU

•Status

•UncompMag

•UncompAccel

•UncompAngularRate

•Temp

•Pres

•DeltaTheta

•DeltaVel

•Mag

•Accel

•AngularRate

•SatFlags

Attitude

•Status

•YawPitchRoll

•Quaternion

•DCM

•MagNed

•AccelNed

•LinearAccelBody

•LinearAccelNed

•YprU

The VN-100 supports 3 separate user configurable binary output messages available on the serial

interface. Each message can be configured by the user to contain any of the available output

measurement types from the IMU, NavState, or NavFilter subsystems. The device can be configured to

asynchronously output each message at a fixed rate based upon a divisor of the IMU internal sampling

rate (IMU Rate).

4.1 Available Output Types

All real-time measurements either measured or estimated by the VN-100 are available using the user

output messages. The different output types are organized into 6 separate output groups. The first group

is a combination of the most common outputs from the remaining groups. The other groups are shown

below.

Binary Outputs

4.2 Configuring the Output Types

Configuration of the 3 output messages is performed using the User Output Configuration Registers

(Register 75-77). There are 3 separate configuration registers, one for each available output message.

The Binary Output Register 1-3 in the System subsystem section describes in more detail the format for

these registers. In each of these configuration registers the user can select which output types they want

the message to include by specifying the OutputGroup and the OutputFields parameters.

4.2.1 OutputGroup

The OutputGroup and OutputFields parameters consist of variable length arguments to allow conciseness

where possible and expandability where necessary.

The OutputGroup parameter consists of one or more bytes which are used to identify the Binary Output

Groups from which data will be selected for output (see OutputField parameter). Each 8-bit byte consists

of seven group selection bits (Bit 0 through Bit 6) and an extension bit (Bit 7). The extension bit in each

byte is used to indicate the presence of a following continuation byte to select additional (highernumbered) groups. The first byte selects Groups 1-7 (with bit offsets 0-6, respectively), the second byte

UM001 31

Page 32

(if present) selects Groups 8-14, and so on. The sequence of group selection bytes will always end with a

Name

Bit Offset

Description

Output Group 1

0

Common Group

Output Group 2

1

Time Group

Output Group 3

2

IMU Group

Output Group 5

4

Attitude Group

Output group 4, 6, & 7 are not used on the VN-100. The bits for these unused output groups must be

set to zero.

Groups 8-14 are not used, however they are reserved for use in future firmware versions.

Bit

Offset

Group 1

Common

Group 2

Time

Group 3

IMU

Group 5

Attitude

0

TimeStartup

TimeStartup

ImuStatus

VpeStatus

1

Reserved

UncompMag

YawPitchRoll

2

TimeSyncIn

UncompAccel

Quaternion

3

YawPitchRoll

UncompGyro

DCM

4

Quaternion

TimeSyncIn

Temp

MagNed

5

AngularRate

Pres

AccelNed

6

Reserved

DeltaTheta

LinearAccelBody

7

Reserved

SyncInCnt

DeltaVel

LinearAccelNed

8

Accel

SyncOutCnt

Mag

YprU

9

Imu

TimeStatus

Accel

10

MagPres

Gyro

11

DeltaTheta

12

VpeStatus

13

SyncInCnt

14

15

byte whose extension bit is not set.

4.2.2 OutputFields

The OutputField parameter consists of a series of one or more 16-bit words per selected output group

(see OutputGroup parameter) which are used to identify the selected output fields for that group. The

first series of one or more words corresponds to the fields for the first selected group, followed by a series

of word(s) for the next selected group, and so on. Each 16-bit word consists of 15 group selection bits (Bit

0 through Bit 14) and an extension bit (Bit 15). The extension bit in each word is used to indicate the

presence of a following continuation word to select additional (higher-numbered) output fields for the

current group. The first word corresponding to a specific group selects fields 1-15 (with bit offsets 0-14,

respectively), the second word (if present) selects fields 16-30, and so on. Each sequence of field selection

words corresponding to a selected output group ends with a word whose extension bit is not set, and is

then followed by a sequence of words for the next selected group (if any).

Below is a list of the available output fields for each output group.

32 UM001

Page 33

4.2.3 Setup the Configuration Register

Binary Output Register 1-3

Register ID :

75-77

Access :

Read / Write

Comment :

These registers allow the user to construct a custom output message that contains a

collection of desired estimated states and sensor measurements.

Size (Bytes):

6-22

Example Response:

$VNWRG,75,2,4,1,8*XX

Offset

Name

Format

Unit

Description

0

AsyncMode

uint16

-

Selects whether the output message should be sent out on

the serial port(s) at a fixed rate.

0 = None. User message is not automatically sent out

either serial port.

1 = Message is sent out serial port 1 at a fixed rate.

2 = Message is sent out serial port 2 at a fixed rate.

3 = Message is sent out both serial ports at a fixed rate.

2

RateDivisor

uint16

-

Sets the fixed rate at which the message is sent out the

selected serial port(s). The number given is a divisor of the

ImuRate which is nominally 800Hz. For example to have

the sensor output at 50Hz you would set the Divisor equal

to 16.

4+N

OutputGroup(N)

uint8

-

Selects which output groups are active in the message.

The number of OutputFields in this message should equal

the number of active bits in the OutputGroup.

4+N+2*M

OutputField(1)

uint16

-

Selects which output data fields are active within the

selected output groups.

In the offset column above the variable N is the number of output group bytes. If data is requested

from only groups 1-7, there will be only one output group present (N=1). If data is requested from an

output group of 9-14, then two output groups bytes will be present.

The number of OutputFields present must be equal to the number of output groups selected in the

OutputGroup byte(s). For example if groups 1 and 3 are selected (OutputGroup = 0x05 or 0b00000101),

then there must be two OutputField parameters present (M = 2).

If the number of OutputFields is inconsistent with the number of OutputGroups selected, then the unit

will respond with an invalid parameter error when attempting to write to this register.

If the user attempts to turn on more data than it is possible to send out at the current baud rate, the

unit will resond with a insufficient baud rate error.

To turn off the binary output it is recommended to set the AsyncMode = 0.

Once you have determined the desired outputs for your output messages, you will need to configure the

User Output Message Configuration Registers (Register 75 – 77). These registers are described in detail

under the Binary Output Register 1-3 in the System subsystem section, however for reference the format

of the register is shown below.

UM001 33

Page 34

4.2.4 Example Case 1 – Selecting outputs from only the Common Group

Bit

Offset

Group 1

Common

0

TimeStartup

3

YawPitchRoll

5

AngularRate

Field

Value

Description

Header

$VN

ASCII message header

Command

WRG

Write register command

Register ID

75

Register 75 (Config register for first output message)

AsyncMode

2

Message set to output on serial port 2.

RateDivisor

16

Divisor = 16. If the ImuRate = 800Hz then, the message output rate

will be (800 / 16 = 50 Hz).

OutputGroup

01

Groups = 0x01. (Binary group 1 enabled)

GroupField 1

0029

Group 1 Field = 0x0029. In binary 0x0029 = 0b00101001.

The active bits correspond to the following active output fields:

Bit 0 – TimeStartup

Bit 3 – YawPitchRoll

Bit 5 - AngularRate

Checksum

XX

Payload terminator and checksum. XX instructs the VN-100 to

bypass the checksum evaluation. This allows us to manually type

messages in a serial terminal without needing to calculate a valid

checksum.

End Line

\r\n

Carriage return and line feed. Terminates the ASCII message.

Bit

Offset

Group 1

Common

Group 3

IMU

Group 5

Attitude

0

TimeStartup

1

2 UncompAccel

Quaternion

3 UncompAngularRate

For many applications you might be able to get by with only the output types available in the common

group. For these situations the configuration of the output message is simple. Suppose only the following

information shown below is desired.

For this example we will assume that the data will be polled using serial port 2 at 50 Hz.

To configure this output message you would send the following command to the VN-100.

$VNWRG,75,2,16,01,0029*XX

Now let’s dissect this command to see what is actually being set:

4.2.5 Example Case 2 – Outputs from multiple Output Groups without

extention bits

This example case demonstrates how to select multiple output fields from more than one output group.

Assume that the following bold output types are desired:

34 UM001

Page 35

4

MagNed

Also assume that you want the message to stream at 50 Hz over serial port 1.

Field

Value

Description

Header

$VN

ASCII message header

Command

WRG

Write register command

Register ID

75

Register 75 (Config register for first output message)

AsyncMode

1

Message sent on serial port 1.

RateDivisor

16

Divisor = 16. If the ImuRate = 800Hz then, the message output rate

will be (800 / 16 = 50 Hz).

OutputGroup

15

Groups = 0x15. In binary 0x15 = 0x00010101.

The active bits correspond to the following active output groups:

Bit 0 – Common

Bit 2 – Imu

Bit 4 - Attitude

GroupField 1

0001

Group 1 Field = 0x0001. In binary 0x0001 = 0b00000001.

The active bits correspond to the following active output fields:

Bit 0 – TimeStartup

GroupField 2

000C

Group 2 Field = 0x000C. In binary 0x000C = 0b00001100.

The active bits correspond to the following active output fields:

Bit 2 – UncompAccel

Bit 3 – UncompGyro

GroupField 3

0014

Group 3 Field = 0x0014. In binary 0x0014 = 0b00010100.

The active bits correspond to the following active output fields:

Bit 2 – Qtn

Bit 4 – MagNed

Checksum

XX

Payload terminator and checksum. XX instructs the VN-200 to

bypass the checksum evaluation. This allows us to manually type

messages in a serial terminal without needing to calculate a valid

checksum.

End Line

\r\n

Carriage return and line feed. Terminates the ASCII message.

To configure this output message you would send the following command to the VN-100.

$VNWRG,75,1,16,15,0001,000C,0014*XX

Now let’s dissect this command to see what is actually being set:

UM001 35

Page 36

4.3 Serial Output Message Format

Header

Payload

CRC

Field

Sync

Groups

Group Field 1

Group Field 2

Payload

CRC

Byte Offset

0 1 2 3 4 5 6 7 … N N+1

N+2

Type

u8

u8

u16

u16

Variable

u16

Name

Bit Offset

Description

Binary Group 1

0

General Purpose Group.

Binary Group 2

1

Time and Event Count Group.

Binary Group 3

2

Inertial Measurement Unit Group.

Binary Group 4

3

Not used. Must be set to zero.

Binary Group 5

4

AHRS Group.

Binary Group 6

5

Not used. Must be set to zero.

Binary Group 7

6

Not used. Must be set to zero.

Binary Group 8

7

Not used. Must be set to zero.

Groups 8-14 are not used, however they are reserved for use in future firmware versions.

The binary output message packets on the serial interface consist of a simple message header, payload,

and a 16-bit CRC. An example packet is shown below for reference. The header is variable length

depending upon the number of groups active in the message.

4.3.1 Sync Byte

The sync byte is the first byte in the header. Its value will always be equal to 0xFA.

4.3.2 Groups

The Group and Group Field parameters consist of variable length arguments to allow conciseness where

possible and expandability where necessary.

The Group parameter consists of one or more bytes which are used to identify the Binary Output Groups

from which data will be selected for output (see OutputField parameter). Each 8-bit byte consists of seven

group selection bits (Bit 0 through Bit 6) and an extension bit (Bit 7). The extension bit in each byte is used

to indicate the presence of a following continuation byte to select additional (higher-numbered) groups.

The first byte selects Groups 1-7 (with bit offsets 0-6, respectively), the second byte (if present) selects

Groups 8-14, and so on. The sequence of group selection bytes will always end with a byte whose

extension bit is not set. The various groups are shown below.

36 UM001

Page 37

4.3.3 Group Fields

The Group Field parameter consists of a series of one or more 16-bit words per selected output group

which are used to identify the selected output fields for that group. The first series of one or more words

corresponds to the fields for the first selected group, followed by a series of word(s) for the next selected

group, and so on. Each 16-bit word consists of 15 group selection bits (Bit 0 through Bit 14) and an

extension bit (Bit 15). The extension bit in each word is used to indicate the presence of a following

continuation word to select additional (higher-numbered) output fields for the current group. The first

word corresponding to a specific group selects fields 1-15 (with bit offsets 0-14, respectively), the second

word (if present) selects fields 16-30, and so on. Each sequence of field selection words corresponding to

a selected output group ends with a word whose extension bit is not set, and is then followed by a

sequence of words for the next selected group (if any).

The group fields represent which output types have been selected in the active binary groups. The

number of group fields in the header will depend upon how many groups are active in the message. The

number of group fields present in the header will always be equal to the number of active bits in the group

byte. When parsing the binary packet you can count the number of active bits present in the group byte,

and then you can assume that this number of group fields will be present in the header. For example if

only binary group 1 is selected (Group Byte = 0x01), then only one Group field will be present in the

header, thus the header will be 4 bytes in length. If both binary group 1 and 3 are active (Group Byte =

0x05), then two Group field elements will be present in the header (4 bytes), thus the header in this case

will be 6 bytes in length.

4.3.4 Payload

The payload will consist of the output data selected based upon the bits selected in the group byte and

the group field bytes. All output data in the payload section consist of the active outputs selected for

binary group 1, followed by the active outputs selected for binary group 2, and so forth. No padding bytes

are used between output fields.

4.3.5 CRC

The CRC consists of a 16-bit CRC of the packet. The CRC is calculated over the packet starting just after

the sync byte in the header (not including the sync byte) and ending at the end of the payload. More

information about the CRC algorithm and example code for how to perform the calculation is shown in

the Checksum/CRC section of the Software Architecture chapter. The CRC is selected such that if you

compute the 16-bit CRC starting with the group byte and include the CRC itself, a valid packet will result

in 0x0000 computed by the running CRC calculation over the entire packet. This provides a simple way of

detecting packet corruption by simply checking to see if the CRC calculation of the entire packet (not

including the sync byte) results in zero.

UM001 37

Page 38

4.3.6 Payload Length

Group

1

Group

2

Group

3

Group 4

Group

5

Group

6

Group 7

Field 1

8 8 2 8 2 2 8

Field 2

8 8 12 8 12

24

8

Field 3

8 8 12 2 16

24

2

Field 4

12 2 12 1 36

12

1

Field 5