Page 1

User Manual

GL2000/GL2010

Version

English

– Data Logger

2.4

Page 2

Imprint

Vector Informatik GmbH

Ingersheimer Straße 24

D

Vector reserves the right to modify any information and/or data in this user documentation without notice. This documentation nor any of

its parts may be reproduced in any form or by any means without the prior written consent of Vector. To the

under law, all technical data, texts, graphics, images and their design are protected by copyright law, various international

other applicable law. Any unauthorized use may violate copyright and other applicable laws o

© Copyright 201

All rights reserved.

-70499 Stuttgart

maximum extent permitted

7, Vector Informatik GmbH. Printed in Germany.

r regulations.

treaties and

Page 3

User Manual GL2000/GL2010 – Data Logger Table of Contents

Table of Contents

1 Introduction 3

1.1 About this User Manual 4

1.1.1 Certification 5

1.1.2 Warranty 5

1.1.3 Support 5

1.1.4 Trademarks 5

2 GL2000 – Data Logger 7

2.1 General Information 8

2.2 Features 9

2.2.1 Connectors 9

2.2.2 SD/SDHC Memory Card 12

2.2.3 Serial Number 14

2.2.4 LED Display 15

2.2.5 Digital Input/Output 16

2.2.6 Analog Inputs 17

2.2.7 Serial Interface 17

2.2.8 Real Time Clock with Battery 17

2.2.9 Beep 19

2.2.10 Wake-up / Sleep 19

2.2.11 CCP/XCP 20

2.2.12 Diagnostics 21

2.3 Operating Modes 21

2.4 CAN and LIN 22

2.4.1 CAN 22

2.4.2 CAN Piggybacks 22

2.4.3 LIN 24

2.5 GPS Mouse 25

2.6 Ethernet 25

2.7 3G (UMTS) 26

2.8 Technical Data 27

2.9 Included with Delivery 28

2.10 Accessories 28

3 Installation Configuration Programs 29

3.1 Overview 30

3.2 Installation Vector Logger Configurator 30

3.2.1 Requirements 30

3.2.2 Setup 31

3.2.3 Overview 31

3.2.4 Quick Start 32

3.3 Installation G.i.N. Configuration Program 33

3.3.1 Requirements 33

3.3.2 Setup 33

3.3.3 Overview 33

3.3.4 Quick Start 34

4 Index 37

© Vector Informatik GmbH Version 2.4 - I -

Page 4

User Manual GL2000/GL2010 – Data Logger Table of Contents

© Vector Informatik GmbH Version 2.4 - II -

Page 5

User Manual GL2000/GL2010 – Data Logger Introduction

1 Introduction

In this chapter you find the following information:

1.1 About this User Manual page 4

Certification

Warranty

Support

Trademarks

© Vector Informatik GmbH Version 2.4 - 3 -

Page 6

User Manual GL2000/GL2010 – Data Logger Introduction

The user manual provides you the following access helps:

> At the end of the user manual you will find an index.

regarding utilized spellings and symbols.

Source code

Here you can find additional information.

Step-by-step instructions provide assistance at these points.

Instructions on editing files are found at these points.

1.1 About this User Manual

To find information

quickly

> At the beginning of each chapter you will find a summary of the contents,

> In the header you can see the current chapter and section,

> In the footer you can see to which version the user manual replies,

Conventions

In the two following charts you will find the conventions used in the user manual

Style Utilization

bold

Windows Legally protected proper names and side notes.

Hyperlink Hyperlinks and references.

<STRG>+<S> Notation for shortcuts.

Symbol Utilization

Blocks, surface elements, window- and dialog names of the

software. Accentuation of warnings and advices.

[OK] Push buttons in brackets

File | Save Notation for menus and menu entries

File name and source code.

Here you can find additional information and hints that eases the

work with the loggers.

This symbol calls your attention to warnings.

Here is an example that has been prepared for you.

This symbol warns you not to edit the specified file.

© Vector Informatik GmbH Version 2.4 - 4 -

Page 7

User Manual GL2000/GL2010 – Data Logger Introduction

Management System

The ISO standard is a globally recognized standard.

the contents and for damages which may result from the use of this documentation.

or you write an email to support@vector.com.

trademarks

trademarks of their respective owners.

1.1.1 Certification

Certified Quality

Vector Informatik GmbH has ISO 9001:2008 certification.

1.1.2 Warranty

Restriction of

warranty

We reserve the right to modify the contents of the documentation or the software

without notice. Vector disclaims all liabilities for the completeness or correctness of

1.1.3 Support

You need support? You can get through to our hotline at the phone number

+49 711 80670-200

1.1.4 Trademarks

Protected

All brand names in this documentation are either registered or non registered

© Vector Informatik GmbH Version 2.4 - 5 -

Page 8

Page 9

User Manual GL2000/GL2010 – Data Logger GL2000 – Data Logger

2 GL2000 – Data Logger

In this chapter you find the following information:

2.1 General Information page 8

2.2 Features page 9

Connectors

SD/SDHC Memory Card

Serial Number

LED Display

Digital Input/Output

Analog Inputs

Serial Interface

Real Time Clock with Battery

Beep

Wake-up / Sleep

CCP/XCP

Diagnostics

2.3 Operating Modes page 21

2.4 CAN and LIN page 22

CAN

CAN Piggybacks

LIN

2.5 GPS Mouse page 25

2.6 Ethernet page 25

2.7 3G (UMTS) page 26

2.8 Technical Data page 27

2.9 Included with Delivery page 28

2.10 Accessories page 28

© Vector Informatik GmbH Version 2.4 - 7 -

Page 10

User Manual GL2000/GL2010 – Data Logger GL2000 – Data Logger

configuration program. The installation is described in chapter 3.

eliminated.

Support.

2.1 General Information

GL2000 The GL2000 is a data logger with USB interface which processes CAN messages

with either 11-bit or 29-bit identifiers and LIN messages. Furthermore, received

messages and analog values can be logged on an inserted SD/SDHC card. The

configuration of the logger is done with the Vector Logger Configurator or the G.i.N.

GL2010

The GL2010 is equivalent to the GL2000 and differs only in the design of the housing

and the connections (watertight according to IP65). The SD card is located in the

housing and is no longer accessible from the outside. The opening for the speaker is

Note: Please note that the housing of the GL2010 must not be opened under any

circumstances, since otherwise the IP65 protection class of the data logger is no

longer guaranteed. The SD/SDHC card, the piggybacks, and the battery may only be

replaced by Vector Informatik GmbH. For more information, please contact the Vector

Figure 1 – GL2000 (left), GL2010 (right)

Info: Due to the openings in the housing for the LED, leak tightness may not be

guaranteed if the label is damaged.

© Vector Informatik GmbH Version 2.4 - 8 -

Page 11

User Manual GL2000/GL2010 – Data Logger GL2000 – Data Logger

> Event connector for switch box E2T2L (GL2000 V2.0 only)

pin assignment

included connection cable Vehicle.

the power supply ground.

2.2 Features

2.2.1 Connectors

General information The loggers have the following connectors:

> USB connector: data transfer between PC and logger

> DSUB25 connector Vehicle containing:

4 CAN channels

2 LIN channels

2 digital inputs/outputs

4 analog inputs

Battery and ground

Ignition

> DSUB15 connector Extension containing:

2 digital inputs/outputs

GPS module

Switch box

External supply for galvanically isolated piggybacks

> SD/SDHC card slot (externally accessible)

> AUX connection for logger accessories

DSUB25

The pins of the Vehicle connector have the following meaning. The colors refer to the

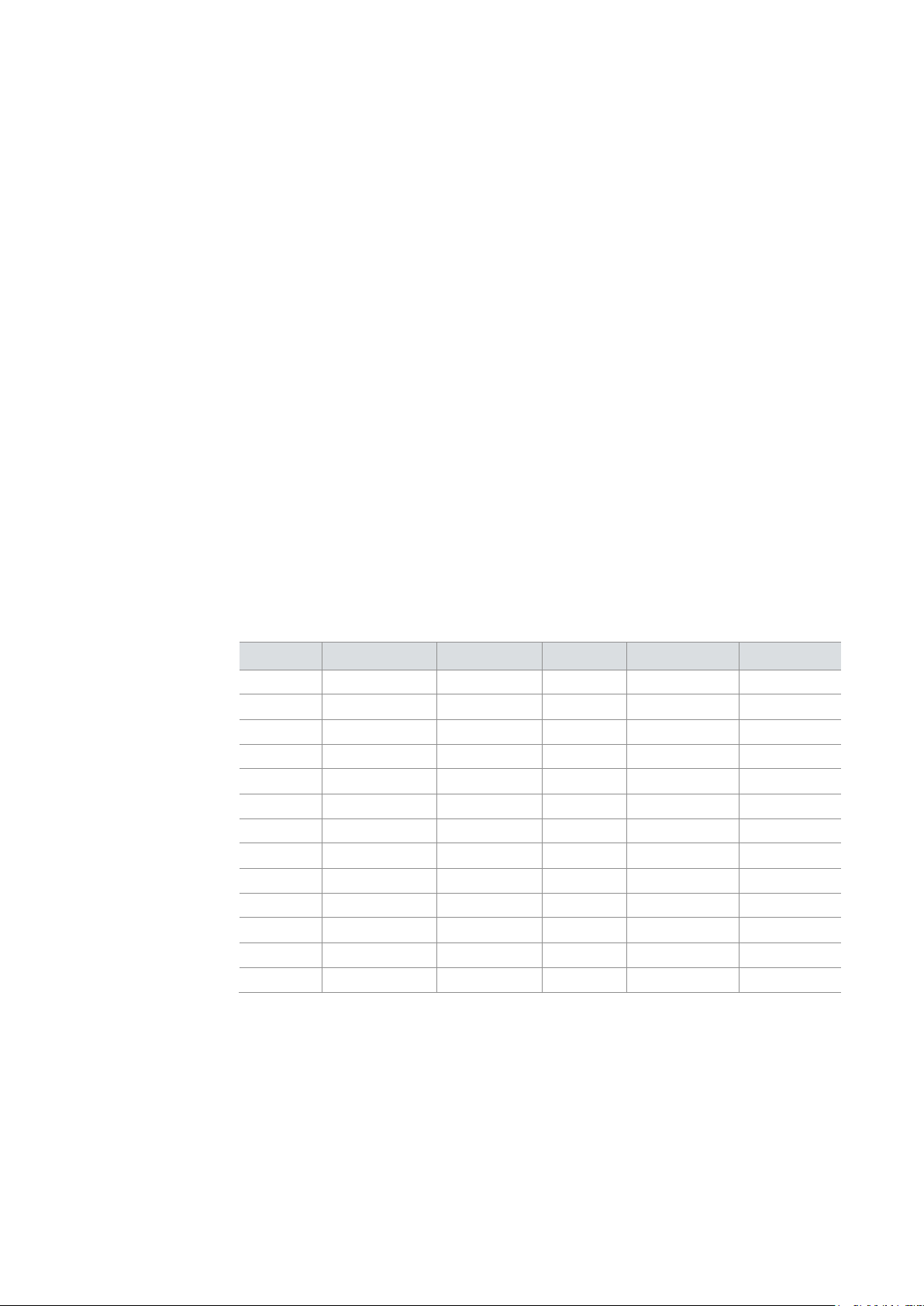

Pin Assignment Color Pin Assignment Color

1 Battery (VCC) white 14 CAN3 Low white/blue

2 RS232 Rx white/green 15 CAN1 High yellow

3 RS232 Tx brown/pink 16 CAN1 Low green

4 GND brown 17 CAN4 High white/gray

5 Battery (VCC) white/black 18 CAN4 Low white/pink

6 I/O 1 white/yellow 19 CAN2 High grey

7 GND brown/red 20 Wake/KL15 black

8 I/O 2 brown/yellow 21 CAN2 Low pink

9 Analog In 1 grey/pink 22 GND brown/blue

10 Analog In 2 red/blue 23 LIN 1 lilac

11 Analog In 3 blue 24 LIN 2 red

12 Analog In 4 brown/green 25 K-Line brown /gray

13 CAN3 High white/red

© Vector Informatik GmbH Version 2.4 - 9 -

The three GND pins are connected together internally and have the same potential as

Page 12

User Manual GL2000/GL2010 – Data Logger GL2000 – Data Logger

ground (GND) pins of the two voltage supplies must be connected.

Vehicle

following connections.

time the EMC properties are improved.

pin assignment

internally and have the same potential as the power supply ground.

You can find further information about the GPS mouse in chapter 2.5.

Caution: It is recommended to connect the logger to the same voltage supply (e.g.

battery of the vehicle) as the vehicle or test equipment, respectively.

If two different voltage supplies are used for the logger and the test equipment, the

Connection cable

DSUB15

In the delivery a connection cable for the Vehicle connector is included with the

CAN1

CAN2

LIN1

V

/KL30

batt

GND

Wake/KL15

DSUB9 with black cap

DSUB9 with red cap

DSUB9 with yellow cap

red pin plug

black pin plug

red pin plug

All other wires have open wire ends. If these wires are not used, it is recommended to

terminate them. This prevents short circuits between the open wires. At the same

Note: The connecting cable does not conform to IP65.

The pins of the Extension connector have the following meaning.

Pin Assignment Pin Assignment

Connection cable

Extension

(not for GL2000

V2.0)

1 CAN3_Vbatt 9 CAN3_GND

2 CAN4_Vbatt 10 CAN4_GND

3 LIN1_Vbatt (24V) 11 I/O 4

4 LIN2_Vbatt (24V) 12 V+ (switch box)

5 I/O 3 13 T1 (switch box)

6 V+ (GPS) 14 T2 (switch box)

7 Rx (GPS) 15 GND

8 Tx (GPS)

The four GND pins on the connectors Vehicle and Extension are connected together

In the delivery a connection cable for the Extension connector is included.

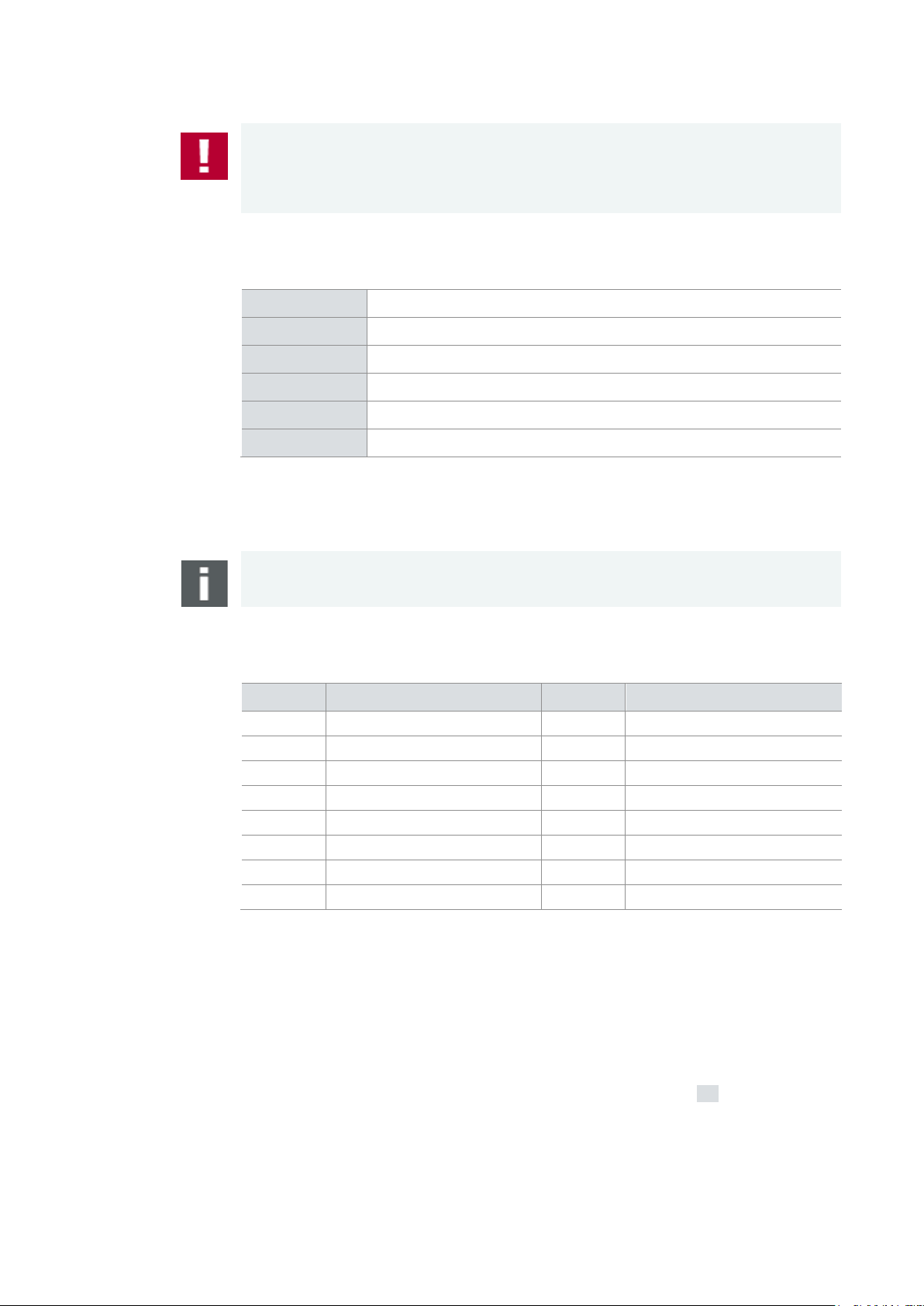

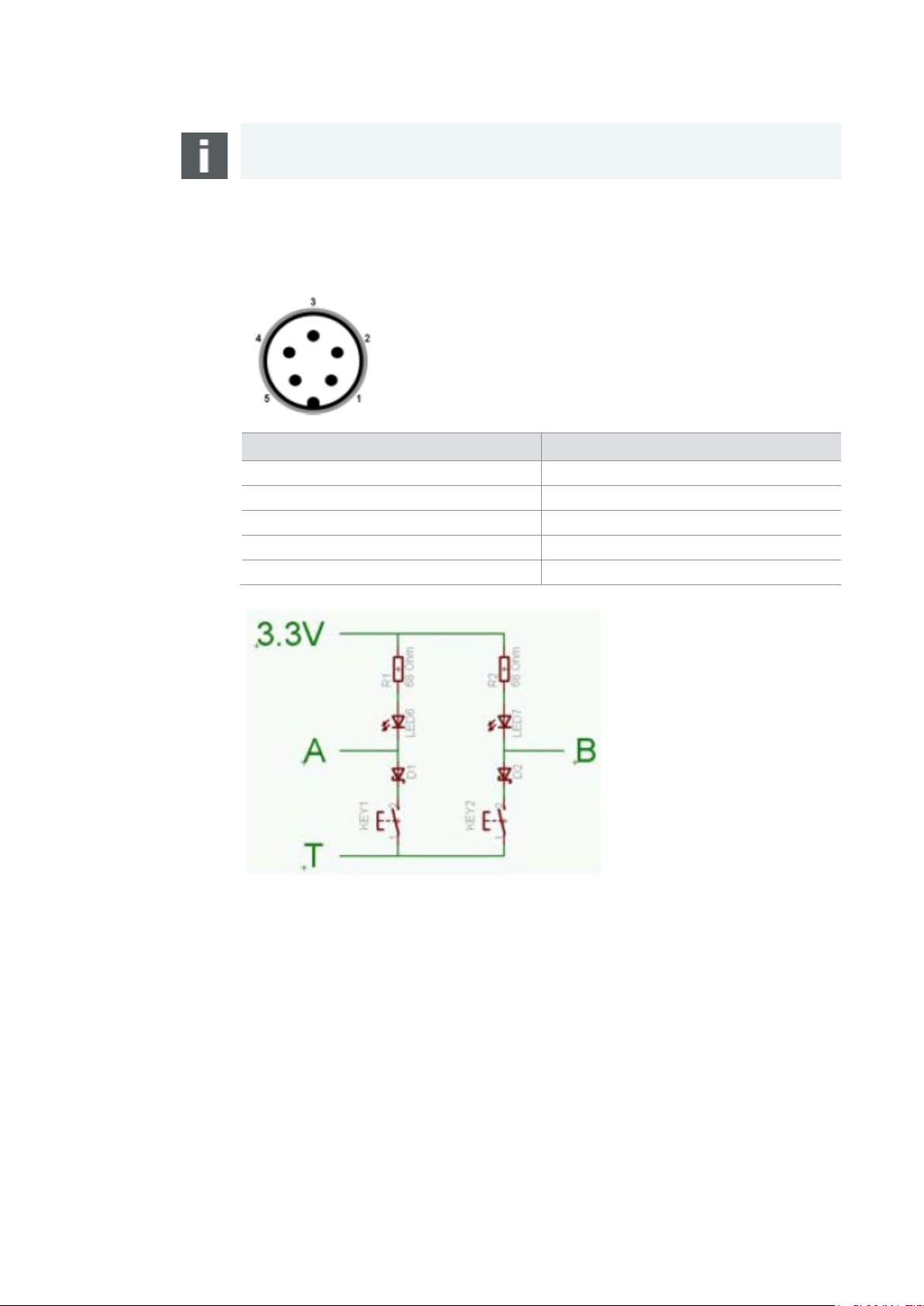

The delivered switch box E2T2L is connected to the 5-pin Binder connector. The PS2

connector is provided for an optional serial GPS mouse. The contacts for further pins

are loosely added.

© Vector Informatik GmbH Version 2.4 - 10 -

Page 13

User Manual GL2000/GL2010 – Data Logger GL2000 – Data Logger

programmable.

The plug pin assignment is as follows (view of the contacts of the logger plug):

2

3.3 V

5

T

connection of the following logger accessories:

not supported)

Note: The connecting cable does not conform to IP65.

Event connection

(GL2000 V2.0 only)

Switch Box wiring

This plug is used for the connection of the switch box E2T2L with two buttons and two

LEDs, which is included in the scope of delivery. The buttons and the LEDs are freely

Pin Assignment

1 NC

3 A

4 B

AUX connection

© Vector Informatik GmbH Version 2.4 - 11 -

The additional 5-pin plug connection (connector series 711) AUX is intended for the

> LOGview (external display)

> Switch Box CAS1T3L (with one button, three LEDs and one sound)

> Switch Box CASM2T3L (with two buttons, three LEDs, one sound, and

microphone for voice recording)

> VoCAN (with one button, four LEDs. microphone for voice recording, voice output

Page 14

User Manual GL2000/GL2010 – Data Logger GL2000 – Data Logger

The plug pin assignment is as follows (view of the contacts of the logger socket):

longer be used freely if an AUX connection is used.

These cards are listed below.

> Cactus Industrial Grade 2 GB (KS 2GRI-800), some higher start-up time

> SanDisk Industrial XT 32 GB (SDSDAF-032G-XI SD)

mechanical damage!

Pin Assignment

1 +5V

2 Ground

3 CAN high

4 CAN low

5 Vbatt

The AUX connection is wired to CAN5 internally. For this reason, this channel is

always equipped with a high-speed transceiver without wake-up capability and can no

2.2.2 SD/SDHC Memory Card

SD and SDHC cards The logger supports industrial grade SD cards up to 2 GB and industrial grade SDHC

cards.

For the proper use only the industrial grade cards released by Vector may be used.

Note for formatting: The memory cards have to be FAT32 formatted. For optimum

speed we recommend FAT32 formatting with the possible maximum cluster size.

Recommended

SD cards

Recommended

SDHC cards

The following SD cards with industrial grade are recommended, see also section 2.8:

> Xmore industrial 2 GB (SD-2G0-XIWE21, SD-2G0-XIE82)

The following SDHC cards with industrial grade are recommended, see also section

2.8:

> Xmore industrial 8 GB (SD-8G0-XIE23, SD-8G0-XIE82)

> Xmore industrial 16 GB (SD-16G-XIE23, SD-16G-XIE82)

> Cactus Industrial Grade 4 GB (KS 4GRI-800)

> Cactus Industrial Grade 8 GB (KS 8GRI-800)

GL2000:

Inserting and

removing SD card

© Vector Informatik GmbH Version 2.4 - 12 -

The GL2000 has a push-and-pull card holder for inserting and removing the SD card.

To insert the memory card, push it in until the locking mechanism engages securely.

To remove the memory card, push it slightly into the card holder until it unlocks. Now,

release the memory card. The card moves from its original position and can now be

removed.

Do not pull the SD card from the card holder forcefully, since this could cause

Page 15

User Manual GL2000/GL2010 – Data Logger GL2000 – Data Logger

SP4).

and the SD LED is lit.

can be removed.

mechanics!

such as bus activity occurs, the logger wakes up again and continues logging.

made to establish the connection.

GL2000 V2.0:

Remove SD card

with shutdown button

The GL2000 V2.0 has a shutdown button on the top cover. It interrupts an active

logging in order to remove or exchange the SD card. Therefore the logger must

contain the firmware V1.38 or higher (available from Vector Logger Configurator 2.5

Make the following steps to deactivate the SD card:

1. Press the shutdown button for one second until the signal tone is heard.

2. Release the shutdown button for one second until the signal tone is heard.

3. Press the shutdown button for at least 2-3 seconds until the signal tone is heard

When the correct sequence is detected a longer signal tone sounds (step 3 above)

and the GL2000 V2.0 is shut down. The USB LED and the SD LED light up for 15

seconds. During this time the SD/SDHC card is disconnected from the system and

Do not pull the SD card forcefully from the card holder, because this may damage the

After 15 seconds elapse, the logger changes to sleep mode. When a wake event

GL2000 V2.0:

Remove SD card

with ML Server

connection

Observe the following when deactivating the SD card via the shutdown button in

conjunction with a data transmission to the ML Server:

> The establishment of a connection to the ML Server using the Stop logging

during transmission setting (LTL: ConnectionRequest) is executed to

completion beforehand.

If a new configuration is transferred from the ML Server, the SD card is

deactivated for 15 seconds after the end of the transmission. The logger then

changes to sleep mode and is only re-configured at a restart.

If the establishment of the connection fails or the connection is terminated, the SD

card is deactivated only after the end of the connection timeout.

The shutdown button is deactivated during an active connection because the

logger has already introduced a shutdown.

> The establishment of a connection to the ML Server Continue logging during

transmission (LTL: TransferRequest) is terminated. After a restart an attempt is

© Vector Informatik GmbH Version 2.4 - 13 -

Page 16

User Manual GL2000/GL2010 – Data Logger GL2000 – Data Logger

Logger Configurator 2.6 SP3).

system and can be removed.

mechanics!

such as bus activity occurs, the logger wakes up again and continues logging.

removed or replaced.

GmbH. For more information, please contact the Vector Support.

converted.

program.

GL2000 V1.0:

Remove SD card

with event buttons

Make the following step to deactivate the SD card:

Do not pull the SD card forcefully from the card holder, because this may damage the

After 15 seconds elapse, the logger changes to sleep mode. When a wake event

GL2010: SD card

The GL2000 V1.0 has no shutdown button on the top cover. Instead you can use the

two buttons on the delivered switch box E2T2L to interrupt an active logging in order

to remove or exchange the SD card.

Therefore the logger must contain the firmware V1.40 or higher (available from Vector

> Press the two buttons on the switch box E2T2L simultaneously for five seconds.

After each second a signal tone is heard.

Afterwards the GL2000 V1.0 is shut down and LED1 to LED4 are off. The USB LED

lights up for 15 seconds. During this time the SD/SDHC card is disconnected from the

The SD card is already contained in the housing of the GL2010 and cannot be

Note: Please note that the housing of the GL2010 must not be opened under any

circumstances, since otherwise the IP65 protection class of the data logger is no

longer guaranteed. The SD/SDHC card may only be replaced by Vector Informatik

Data transfer

The logged data can be downloaded with a configuration program from the SD/SDHC

card in the GL2000

copied to the PC via the Windows Explorer. On the PC the logging files can be

/GL2010 or in a card reader. Alternatively logging files can be

2.2.3 Serial Number

Serial number The serial number is stored in the logger and is copied to the SD card after download

of the configuration and start in logging mode.

The configuration program reads out the serial number of the logger in the

configuration mode. The serial number is displayed correctly, if an SD card is inserted

and the logger was at least one time in the logging mode with this SD card. If this SD

card is inserted in another logger and the logger is not started in logging mode

afterwards, the serial number of the first logger will be displayed in the configuration

© Vector Informatik GmbH Version 2.4 - 14 -

Page 17

User Manual GL2000/GL2010 – Data Logger GL2000 – Data Logger

and the LED Power indicates the operating status of the logger.

the USB after the boot process.

2.2.4 LED Display

LED display The logger has six LEDs. LED 1 to LED 4 are freely programmable. They can be

used to display different states. LED USB indicates the USB connection to the PC

Operating Status

Card reader On

Card reader logged

off

No SD card inserted Blinking Blinking Blinking Blinking

No configuration

available (in flash and

card)

Information are

flashed (set clock

time or new

configuration)

Device error (defect

SD card, invalid

device information)

Configuration is

running

ML Sever connection

establishment before

shutdown.

Configuration is

stopped.

SD card is logged off On for 15 s

LED 1

(green)

Blinking

Blinking

On

Blinking

LED 2

(yellow)

Configurable

Running light LED 1 to LED 4

LED 3

(red)

LED 4

(red)

USB-LED

(green)

SDLED

© Vector Informatik GmbH Version 2.4 - 15 -

If the logger is already connected via USB with a booting PC, then it is in the status

Card reader logged off. To access the SD/SDHC card, disconnect and reconnect

Page 18

User Manual GL2000/GL2010 – Data Logger GL2000 – Data Logger

outputs.

input with GND the status is set to Low (FALSE).

Technical data

connect it between the pin of the digital output and the battery.

Technical data

* Output current depends on external circuit

2.2.5 Digital Input/Output

Digital IO The logger supports four pins which can be used either as digital inputs or as digital

Using as input A digital input can be used e.g. as external trigger.

In unconnected state the digital inputs are set to High (TRUE). After connecting the

Operating voltage range

-0.3 V…36 V

Using as output

Pull-up resistor

Threshold Low → High

Threshold High → Low

Sampling rate

State unconnected input

10 kΩ to 3.3 V

1.9 V

0.55 V

1 kHz

High (TRUE)

When used as a digital output, the pin is connected to GND when the output is

switched on (so called “low side switch”). To switch a consumer it is necessary to

Operating voltage range

Current when switched on

Nominal output current

-0.3 V…36 V

Max. 500 mA per output

Max. 250 mA* per output

(all channels on)

Amount of all digital outputs

Internal resistance

Max. 1000 mA*

1 Ω

(on resistance)

Circuit time

Typ. 1 ms

© Vector Informatik GmbH Version 2.4 - 16 -

Page 19

User Manual GL2000/GL2010 – Data Logger GL2000 – Data Logger

separately.

Technical data

channel.

CAN messages.

logged data.

It is recommended to set the real time clock before first logging.

T = -40°C to +40°C in the rest of the time

2.2.6 Analog Inputs

Analog inputs The logger has four independent analog channels which can be configured

Voltage range

0 V … 18 V

Resolution

Precision

Sampling rate

Type

Input resistance

Reverse-polarity protection

10 bit

1 %

Max. 1 kHz

Single-ended to ground, unipolar

155.6 kΩ

-50 V … +50 V

-150 V … +150 V (for max. 3 seconds)

Averaging

It is possible to average the measured analog inputs over a defined sampling period

between 1 kHz and 1 Hz. E.g. for a 1 Hz sampling frequency, the measured values

are averaged over the last second. The internal sampling rate is 1 kHz for each

2.2.7 Serial Interface

RS232 The serial interface with the Rx and Tx lines is logging interfaces only. The baudrate

of the interfaces can be configured. Received data can be stored on the SD card as

Info: The serial interface cannot be used to download a configuration or upload

logging data.

2.2.8 Real Time Clock with Battery

Real time clock

The configuration of the clock is done with the configuration program (SD card must

Battery The internal battery supplies the real time clock only. The battery has a typical

The GL2000/GL2010 has an internal real time clock, which is battery supplied, and

thus continues running even if the logger is disconnected from power supply. The real

time clock inside the logger is required to store the date and time together with the

be inserted). After setting the real time clock the logger is switched off.

durability of approximately 5-10 years under the following conditions:

T = +40°C to +80°C for at most 40 hours per week

© Vector Informatik GmbH Version 2.4 - 17 -

Page 20

User Manual GL2000/GL2010 – Data Logger GL2000 – Data Logger

more information, please contact the Vector Support.

> This must be done very cautiously and carefully.

The battery is exchanged as follows:

cover completely from the housing.

cable.

9. Please also attach the black decorative caps.

in Germany).

GL2010: Battery Please note that the housing of the GL2010 must not be opened under any

circumstances, since otherwise the IP65 protection class of the data logger is no

longer guaranteed. The battery may only be replaced by Vector Informatik GmbH. For

GL2000:

Replacing battery

The battery of the GL2000 can be is exchanged after life cycle end.

Notes:

> First read the installation instruction completely.

> The case has to be opened to exchange the piggybacks.

1. First remove the two black decorative caps and the screws from the bottom cover

of the GL2000. The bottom cover contains the two DSUB connectors.

2. Then, remove the two black decorative caps and the screws from the top cover.

Among other things, the top cover contains the USB connector.

3. Carefully remove the bottom cover together with the main board and the top

Note: The circuit board is connected to the AUX connection of the top cover via a

cable. Therefore the top cover must be inserted together with the circuit board

from the top to the bottom of the housing. Please make sure not to damage the

4. You will find mounting location almost at the center of the main circuit board (see

green circle in Figure 3).

5. Remove the battery carefully from the mounting location.

6. Insert the replacement battery. Look out for the correct polarity, + must be on top.

Please handle the contact spring with care. Do not bend it too much and make

sure the spring has contact to the new battery after replacement.

7. Reassemble the unit in reverse order. First insert the top cover into the housing

via the opening at the bottom. Insert the circuit board into the housing afterwards

and make sure that the circuit board has been inserted into the correct guide rail

(groove 1). Please be sure that the frame around the LEDs do not snag on the

housing.

8. It should be possible to slide the main board in the housing up to a few

millimeters from the end without forcing it in. Close the housing by applying light

pressure, and then secure the covers with the appropriate screw fasteners. The

screws should be secure but not excessively tight.

Dispose of the removed battery according to the applicable laws (e.g. the Battery Law

© Vector Informatik GmbH Version 2.4 - 18 -

Page 21

User Manual GL2000/GL2010 – Data Logger GL2000 – Data Logger

trigger. Triggers and beep can be defined using the configuration program.

> wake-up timer via real time clock

Layout GL2000

Figure 2 – Layout GL2000

2.2.9 Beep

Beep

The GL2000/GL2010 has a speaker that acoustically alerts the user e.g. in case of a

2.2.10 Wake-up / Sleep

Wake-up

The GL2000

> after reception of a CAN message

> after reception of a LIN message

> positive edge on the wake-up line (clamp 15)

Info: The logger has to be equipped with CAN transceivers with wake-up capability to

support the wake-up functionality on CAN (see section 2.4 CAN and LIN).

/GL2010 starts after power on. A sleeping logger wakes up

© Vector Informatik GmbH Version 2.4 - 19 -

Page 22

User Manual GL2000/GL2010 – Data Logger GL2000 – Data Logger

The sleep mode needs a very low current consumption of typ. 1 mA.

mA the standby mode has a higher current consumption than the sleep mode.

license also includes the Seed & Key support.

FAQ

Sleep The logger can be configured to go to sleep mode if no CAN and LIN messages are

received for a defined time. This time can be configured (max. 18.000 s = 5 hours).

Fast wake-up from

standby mode

2.2.11 CCP/XCP

Overview

The loggers can be configured in the configuration program such that they go to

standby mode instead of sleep mode. The fast wake-up from standby mode allows

the recoding of the very first message waking up the logger. The logger is waken up

from standby mode by the same events as from sleep mode. However, with typ. 50

The GL2000

/GL2010 supports the recording of CCP/XCP data in DAQ and polling

mode. The A2L file is inserted directly in the Vector Logger Configurator and the

signals to be measured are selected.

For ECUs which are protected via Seed & Key procedure CANape is also required to

program the Seed & Key algorithm and create an SKB file containing this algorithm.

This SKB file is added to the logger configuration.

CCP/XCP is available as option. The license must be installed in the logger. The

Measurement mode DAQ (data aquisition) mode, polling mode

Supported CCP version

Supported XCP version

CCP 2.1

XCP 1.0 and higher

Vector Logger Configurator V2.5 or higher

CANape for Seed & Key only

Configuration

Alternative:

CANape V8.0 or higher for DAQ mode, Seed & Key

CANape V13.0 or higher for polling mode

A2L file

Number of ECUs

Direct import in Vector Logger Configurator

Import in CANape

still available

Multiple ECUs possible

© Vector Informatik GmbH Version 2.4 - 20 -

Page 23

User Manual GL2000/GL2010 – Data Logger GL2000 – Data Logger

Overview

The loggers support the logging of diagnostic data via CAN bus.

analysis is supported in CANoe/CANalyzer.

FAQ

USB connection and power supply respectively.

SD card can be uploaded to the PC.

DSUB25 connector.

2.2.12 Diagnostics

The diagnostic descriptions (CDD, ODX, PDX, MDX) are read into the Vector Logger

Configurator. These files are necessary to set the communication parameters and to

select diagnostic service requests that would be sent on different events. The

CDD (CANdela diagnostic descriptions) up to V7.1

Diagnostic descriptions

ODX/PDX V2.0.1 and V2.2.0

MDX V3.0

Supported transport

protocol

Supported addressing

modes

Supported diagnostic

protocols

Seed & Key

Number of ECUs

2.3 Operating Modes

Overview

The GL2000/GL2010 supports two operating modes, which are switched by using the

USB connection Voltage supply Mode

ISO-TP

Normal

Normal fixed

Extended

KWP2000, UDS

Not supported

Several ECUs on different CAN buses possible

yes optional Configuration mode

no yes Logging mode

Configuration mode

In the Configuration mode the logger can be configured with the configuration

program. The configuration can be downloaded to the logger. Logging data from the

Logging mode

The Logging mode enables the PC independent usage of the logger and allows the

logging of CAN, LIN and analog values. For this case the logger must be unplugged

from the USB connector of the PC. The voltage supply is done externally by the

© Vector Informatik GmbH Version 2.4 - 21 -

Page 24

User Manual GL2000/GL2010 – Data Logger GL2000 – Data Logger

CAN channels

The loggers support four CAN channels.

be executed via these channels.

Available piggybacks for the GL2000 series:

Piggyback 1055/1055mag as successor of Piggyback 1054/1054mag

30 V can be applied.

2.4 CAN and LIN

2.4.1 CAN

Channel 1 - 2

Permanently occupied by high-speed CAN transceiver TJA1043

Channel 3 - 4

Wake-up capability

The logger can be woken up on the four CAN channels. Channel 3 and 4 must be

occupied with piggybacks with wake-up capable CAN transceivers if the wake-up will

2.4.2 CAN Piggybacks

Piggybacks

A piggyback is a plug-in PC-board which implements the interconnection of the logger

to a specific CAN bus by the use of various transceivers. The piggybacks are also

used in other loggers.

CAN Piggyback Transceiver Description Wake-up

Piggyback 10431 TJA1043 CAN high-speed Yes No

Piggyback 1043mag1 TJA1043 CAN high-speed Yes Yes

Piggyback 10422 TJA1042 CAN high-speed No No

Piggyback 1050 TJA1050 CAN high-speed No No

Piggyback 10553 TJA1055 CAN low-speed Yes No

Piggyback 1055mag3 TJA1055 CAN low-speed Yes Yes

Piggyback Single

Wire

Piggyback Truck

Trailer

1

Piggyback 1043/1043mag as successor of Piggyback 1041/1041mag

2

Piggyback 1042 as successor of Piggyback 251

3

Freely configurable via piggyback PCBs

TLE6255G CAN Single Wire Yes No

WABCO CAN

Yes No

Truck&Trailer

Galvanically

decoupled

Note: Transceivers with wake-up capability are supplied directly from the supply

voltage of the logger. During logger start, for the TJA1041 and TJA1054 transceivers

the supply voltage must not exceed 27 V in order to not damage the transceivers.

After start and during operation for these transceivers a supply voltage of maximum

© Vector Informatik GmbH Version 2.4 - 22 -

Page 25

User Manual GL2000/GL2010 – Data Logger GL2000 – Data Logger

than the logger.

GmbH. For more information, please contact the Vector Support.

piggybacks

> This must be done very cautiously and carefully.

Now proceed as follows:

of its length.

more than maximum to the STOP marker.

8. Please also attach the two black decorative caps.

Galvanically

decoupled

piggybacks

GL2010: Piggybacks

GL2000:

Replacing

Piggybacks 1041mag, 1043mag, 1054mag and 1055mag are magnetically decoupled

and available for CAN channels 3 and 4. Due to the decoupling, the power supply and

ground for these piggybacks must be connected at the DSUB15 plug Extension. For

proper galvanic isolation, the piggybacks must be powered from a different source

Info: For the galvanically decoupled transceiver, power supply (CAN3/4_Vbatt) and

ground (CAN3/4_GND) must be connected separately.

Please note that the housing of the GL2010 must not be opened under any

circumstances, since otherwise the IP65 protection class of the data logger is no

longer guaranteed. The piggybacks may only be replaced by Vector Informatik

The piggybacks can be exchanged. The installed piggybacks are automatically

detected (“plug & play”).

Info:

> First read the installation instruction completely.

> The case has to be opened to exchange the piggybacks.

1. First remove the two black decorative caps and the screws from the bottom cover

of the GL2000. The bottom cover contains the both DSUB connectors.

2. Carefully pull out the cover with the main circuit board from the housing until you

can reach the piggybacks. For this you only have to pull out the circuit board 1/3

Caution: The other side of the circuit board is connected to the AUX connection

of the top cover via a cable. Therefore you have to pull out the circuit board not

3. You will find the mounting location for channel 3 close to the edge of the main

circuit board and the mounting location for channel 4 close to the center of the

main circuit board. The locations are marked red in Figure 3.

4. Remove the piggyback carefully from the mounting location.

5. Insert the replacement piggyback. When doing this please make sure that the

single and dual-row connectors are not laterally shifted.

6. Push the GL2000 main circuit board back in the housing. Please be sure that the

frame around the LEDs do not snag on the housing.

7. It should be possible to slide the main circuit board in the housing up to a few

millimeters from the end without forcing it in. Close the housing by applying light

pressure, and then secure it with the appropriate screw fasteners. The screws

should be secure but not excessively tight.

© Vector Informatik GmbH Version 2.4 - 23 -

Page 26

User Manual GL2000/GL2010 – Data Logger GL2000 – Data Logger

for this purpose and is available as a logger accessory.

Therefore LIN piggybacks are not needed.

It is recommended to connect also GND as ground supply beside the LIN pins.

Wake-up capability

The logger can be woken up over either LIN channel.

Caution: When performing this operation be sure not to touch the top or bottom of

the boards (logger main circuit board or piggybacks).

Figure 3 – Open GL2000 for replacing piggybacks

2.4.3 LIN

LIN channels LIN frames can be recorded with both internal LIN channels. The sending of LIN

frames is not supported on these channels. A LINprobe X or LINprobe G are required

LIN transceiver The LIN transceivers TJA1021 are already mounted on the main board of the loggers.

LIN level The LIN transceivers are supplied from the supply voltage. On this way reference

voltage for the LIN levels and supply voltage have the same value. For example if the

logger is supplied with 24 V, the reference value for LIN is also 24 V.

© Vector Informatik GmbH Version 2.4 - 24 -

Page 27

User Manual GL2000/GL2010 – Data Logger GL2000 – Data Logger

the logger.

The plug pin assignment is as follows (view of the contacts of the logger plug):

Ethernet connector

An Ethernet connection with the following function is located on the top cover:

described in Tutorial: Usage as interface.

Find more information to 3G/UMTS in chapter 2.7 3G (UMTS).

via LAN

For data transmission the TransferRequest license must be installed on the logger.

2.5 GPS Mouse

Overview For recording the vehicle position via GPS the serial GPS mouse can be connected to

Connection The GPS mouse is connected to the PS2 connector of the GL2000 connection cable

Extension (DSUB15) respectively of the GL2000 GPS connection cable (GL2000

V2.0).

Pin Assignment

1 GND

2 VCC

3, 6 NC

4 Rx (GPS)

5 Tx (GPS)

2.6 Ethernet

Logger as bus

interface

Connection of

3G router

Connection to a PC

Note: Please ensure that the used GPS mouse supports the NMEA messages GGA,

RMC, GSA and GSV and sends with 4800 baud.

The logger supports a monitoring interface that allows the use of the logger as bus

interface for monitoring in CANoe/CANalyzer (since version 8.2).

The logger is connected via Ethernet to the CANoe/CANalyzer PC and sends after

measurement start the bus data to CANoe/CANalyzer, where the data can be

analyzed in the measurement setup. Sending messages with CANoe/CANalyzer is

not possible. The relevant CANoe/CANalyzer licenses must be provided by a

connected hardware interface on the PC or by a license dongle.

You can find further information in the Vector Logger Configurator manual, chapter

Monitoring Interface. There the configuration of the logger and CANoe/CANalyzer is

The connection of the GL2000/GL2010 3G router enables wireless data transmission

via 3G/UMTS.

The logger supports the data transmission to a PC directly via LAN.

© Vector Informatik GmbH Version 2.4 - 25 -

Page 28

User Manual GL2000/GL2010 – Data Logger GL2000 – Data Logger

basic version is included in the scope of delivery.

of the transmission.

> North America

entered into with a provider.

GLA600

Technical data of adapter:

You can set the events that cause a connection and the transfer of logged data from

the logger to the destination system in the Vector Logger Configurator.

The data transmission is carried out using the Multi-Logger ML Server software. The

2.7 3G (UMTS)

Overview The logger optionally supports wireless data transmission via 3G/UMTS.

The GL2000/GL2010 3G router is connected to the Ethernet connection of the logger

for this. The router is either permanently supplied externally or via the GLA600

adapter. In the latter case, the router is switched on by the logger only for the duration

The router is certified for the following regions:

> EU member states

Please see the technical data in the device manual of the manufacturer.

For data transmission the TransferRequest license must be installed on the logger.

The events that cause a 3G connection and the transfer of logged data from the

logger to the destination system can be set in the Vector Logger Configurator.

The data transmission is carried out using the Multi-Logger ML Server software. The

basic version is included in the scope of delivery.

A SIM card is not included in the scope of delivery. A contract must be separately

Temperature range

Power supply

Dimensions (LxWxH)

-40°C…+85°C

8 V…28 V

ca. 80 mm x 40 mm x 20 mm

© Vector Informatik GmbH Version 2.4 - 26 -

Page 29

User Manual GL2000/GL2010 – Data Logger GL2000 – Data Logger

up time.

2.8 Technical Data

PC interface

Channels

Analog inputs

Digital inputs/outputs

Start-up time

Ethernet

Current consumption

Temperature range

USB 2.0

4 CAN channels (2 of these channels via piggybacks)

2 LIN channels

4 inputs:

- Resolution 10 bit (1% precision)

- Sampling rate 1 kHz

- Voltage range 0 V…18 V

4 inputs/outputs, 0 V…36 V

GL2000: approx.170 ms with delivered 2 GB Xmore

SD card

GL2010: approx. 170 ms with delivered 8 GB Xmore

SD card

Time varies with capacity and type of the SD/SDHC

card

10/100 Mbit/s

Operation: typ. 170 mA at 12 V DC

Sleep mode: typ. <1 mA

Standby mode: typ. 60 mA

GL2000: -40°C…+80°C

GL2010: -20°C…+80°C

USB interface: 0°C…+70°C

Start-up time

Power supply

Dimensions (LxWxH)

Housing

Battery

Data is recorded after the given start-up time if the logger already contains a

configuration. Updating the configuration or using a new SD card increases this start-

Cross reference: The recommended SD/SDHC cards are listed in section 2.2.2

SD/SDHC Memory Card.

6 V…30 V, typ. 12 V

GL2000: approx. 194 mm x 137 mm x 35 mm

GL2000 V2.0:

GL2010

Aluminium housing: Alubos 1300

Lithium primary cell, BR2032 type

: approx. 175 mm x 137 mm x 35 mm

approx. 175 mm x 137 mm x 35 mm

© Vector Informatik GmbH Version 2.4 - 27 -

Page 30

User Manual GL2000/GL2010 – Data Logger GL2000 – Data Logger

> Mounting brackets (GL2000 only)

> GL2010 Ethernet cable IP65/IP20

> LOGview for displaying signal and status information

2.9 Included with Delivery

Standard scope of

delivery

Optional

> GL2000

> Vector Logger Configurator on CD

> Vector Logging Exporter on CD

> G.i.N. configuration program on CD

> Basic version of Multi-Logger ML Server software

> Manuals on CD

> 2 GB SD memory card

> Switch box E2T2L

> USB cable

> Connection cable Vehicle for DSUB25

> Connection cable Extension DSUB15 with Binder 5-pol (connection for switch

> CCP/XCP license for CAN

> TransferRequest license for data transfer to ML Server

2.10 Accessories

/GL2010 Logger

box E2T2L) (not for GL2000 V2.0)

Optional

> 3G modem (incl. antennas) for wireless data transfer

> GPS receiver for recording the vehicle position via GPS

> LINprobe as extension for the LIN channels

> VoCAN for voice recording (1 button, 4 LEDs and signal tone)

> CASM2T3L for voice recording (2 buttons, 3 LEDs and signal tone)

> CAS1T3L (1 button, 3 LEDs and signal tone)

© Vector Informatik GmbH Version 2.4 - 28 -

Page 31

User Manual GL2000/GL2010 – Data Logger Installation Configuration Programs

3 Installation Configuration Programs

In this chapter you find the following information:

3.1 Overview page 30

3.2 Installation Vector Logger Configurator page 30

Requirements

Setup

Overview

Quick Start

3.3 Installation G.i.N. Configuration Program page 33

Requirements

Setup

Overview

Quick Start

© Vector Informatik GmbH Version 2.4 - 29 -

Page 32

User Manual GL2000/GL2010 – Data Logger Installation Configuration Programs

The programs are included with delivery.

used in the G.i.N. configuration program.

write own configurations in LTL.

> This user manual

Restriction Windows 8.1: AUTOSAR databases are not supported.

3.1 Overview

Overview This instruction describes the installation of the software package for the

GL2000

> Vector Logger Configurator

> G.i.N configuration program

/GL2010 containing:

Graphic user interface for easy configuration

User interface to create complex configurations with LTL (Log Task Language)

Vector Logger

Configurator

G.i.N. configuration

program

The Vector Logger Configurator offers a wide range of features to easily create

configurations for the logger. The Vector Logger Configurator also supports the

download of the configuration and the upload of logging data including the export to

different file formats. Additionally the configuration can be saved as LTL code to be

The G.i.N. configuration program can be used as configuration program for high end

configurations. It offers full support of all features available with LTL (Log Task

Language). This program can be used to import LTL code from the Vector Logger

Configurator or from existing configurations written in LTL (e.g. from GL1000) or to

3.2 Installation Vector Logger Configurator

Overview This instruction describes the installation of the Vector Logger Configurator for the

GL2000

> Vector Logger Configurator

> Online help for the Logger Configurator

> User manual for the Logger Configurator

/GL2010 containing:

3.2.1 Requirements

Operating system The following software requirements must be fulfilled to run the Vector Logger

Configurator:

> Windows 7 / Windows 8.1 (32/64 Bit)

> Windows 10 (64 Bit)

© Vector Informatik GmbH Version 2.4 - 30 -

Page 33

User Manual GL2000/GL2010 – Data Logger Installation Configuration Programs

found on the installation CD under .\GLtools\setup.exe

> CCP/XCP (optional)

3.2.2 Setup

The Vector Logger Configurator is installed as follows.

1. Execute the setup, which is found on the installation CD: .\VLConfig\Setup.exe

2. Please, follow the instructions in the setup program to complete the installation.

3. After successful installation, the Vector Logger Configurator can be found in the

start menu (if selected during installation).

4. Also install the basic software e.g. for wireless transmission. The software can be

3.2.3 Overview

About Vector Logger

Configurator

Vector Logger Configurator enables the configuration of the loggers and offers a wide

range of settings. You may set baud rates for CAN and LIN, define triggers and filters,

set LEDs and manage logging files on the SD card. Furthermore for the CAN bus

diagnostics and CCP/XCP can be configured. For CCP/XCP the logger needs an

installed license. For Seed & Key CANape is required. Vector Logger Configurator

also supports trigger and filter access by symbolic names defined in CAN and LIN

databases.

Main features are:

> Customizable filters for CAN and LIN messages

> Customizable triggers

> Support of CAN and LIN databases

> Support of diagnostics

> File management

© Vector Informatik GmbH Version 2.4 - 31 -

Page 34

User Manual GL2000/GL2010 – Data Logger Installation Configuration Programs

side.

be opened via the program group in the start menu.

logging data.

before first logging).

subdirectory>.

Device Information The Vector Logger Configurator can read out hardware information from the logger.

Connect the GL2000

File Manager|Logger Device|Device Information in the list view on the left hand

Cross reference: The Vector Logger Configurator is described in detail in the user

manual of this configuration program. The user manual is available as PDF and can

/GL2010 with inserted memory card via USB and select the item

3.2.4 Quick Start

Quick start Follow the instructions below to configure the logger, start logging and read out

1. Start the program.

2. Open a new configuration via the menu File|New Project…. Select in the

displayed dialog the logger type GL2000.

3. Select suitable baud rates for CAN and/or LIN (Hardware|CAN Channels and/or

Hardware|LIN Channels), respectively.

4. Select the timeout to sleep mode (Hardware|Settings).

5. Configure the logger for a permanent logging of all data from switching on to

switching off of the logger by activating the Use permanent logging option in

Logging|Triggers.

6. Insert an empty, FAT32 formatted SD card into the GL2000.

The SD card is contained in the GL2010.

7. Connect the logger to PC via USB cable. If the logger is not automatically

detected, press <F5> to refresh the display of connected logger devices.

8. Download the configuration via menu Configuration|Write to Device….

9. Set the real time clock via menu Device|Set Real-Time Clock… (recommended

10. Disconnect the logger from the PC.

11. Connect the logger e.g. to your test system (CAN bus). Switch power on via

connecting cable on DSUB25.

12. Start logging. LED1 flashes permanently (standard setting for new configurations,

can be configured).

13. Stop logging by switching off CAN. Wait until the logger goes to sleep mode (CAN

transceiver with wake-up capability necessary) i.e. LED1 must be off.

14. Connect the logger to PC via USB cable.

15. Open the File Manager node in the tree view.

16. Click on Logger Device|Classic View. Now the logging files are displayed.

17. Select in the General Settings the destination folder and the format for the

converted files.

18. Select in the Advanced Settings the options for conversion.

19. Click on the [Convert] button to start the readout and conversion of all data. The

files will be located in <Destination folder>/< Destination

© Vector Informatik GmbH Version 2.4 - 32 -

Page 35

User Manual GL2000/GL2010 – Data Logger Installation Configuration Programs

> G.i.N. user manuals for the configuration program and the hardware

Windows 7, Windows 8.1 and Windows 10

found on the installation CD under .\GLtools\setup.exe

> CCP/XCP (optional)

3.3 Installation G.i.N. Configuration Program

Overview This instruction describes the installation of the G.i.N. Configuration Program for the

GL2000

> G.i.N. configuration program

3.3.1 Requirements

Operating system The following software requirements must be fulfilled to run the G.i.N. configuration

program:

3.3.2 Setup

Follow the instructions below to install the G.i.N. configuration program:

/GL2010 containing:

3.3.3 Overview

About G.i.N.

configuration

program

1. Execute the setup, which is found on the installation CD:

.\GiNconf\setup.exe

2. Please, follow the instructions found there to complete the installation.

3. After successfully installation, the G.i.N. configuration program can be found in

the start menu.

4. If you want to use 3G, you also have to install the basic software that can be

The G.i.N. configuration program enables the configuration of the loggers and offers a

wide range of settings via LTL (Log Task Language). You may set baud rates for

CAN and LIN, define triggers and filters, set LEDs and manage logging files on the

SD card. CCP/XCP can also be configured with the means of CANape, if the license

is installed. G.i.N. configuration program also supports trigger and filter access by

symbolic names defined in CANdb databases.

Main features are:

> Customizable filters for CAN and LIN messages

> Customizable complex triggers

> Support of databases

> File management

© Vector Informatik GmbH Version 2.4 - 33 -

Page 36

User Manual GL2000/GL2010 – Data Logger Installation Configuration Programs

after installation of the program and can be called by the Help menu.

logging data.

The SD card is contained in the GL2010.

Cross reference: The G.i.N. configuration program is described in detail in the LTL

user manual of the configuration program. The LTL user manual is available as PDF

3.3.4 Quick Start

Quick start Follow the instructions below to configure the logger, start logging and readout

1. Start the program.

2. Create a new project (File|New Project). Select the project path and the device

GL2000.

3. Create a new source file (File|New File) and set the baud rate for CAN and the

timeout for sleep mode, e.g.

SYSTEM

Can1Timing = Timing500K

Can2Timing = Timing500K

SleepSeconds = 5

END

4. Save the file (File|Save File as) as LTL file in your project directory.

5. Compile this file via Project|Compile or press [F9]. A COD file is created.

6. Insert an empty, FAT32 formatted SD card in the logger.

© Vector Informatik GmbH Version 2.4 - 34 -

Page 37

User Manual GL2000/GL2010 – Data Logger Installation Configuration Programs

selected file format.

7. Connect the logger to PC via USB cable.

8. Download the COD file with [F10] or via Project|Compile and Download.

9. Disconnect the logger from PC.

10. Connect the logger e.g. to your test system (CAN bus). Switch power on via

connecting cable on DSUB25.

11. Start logging.

12. Stop logging by switching off CAN. Wait until the logger goes to sleep mode (CAN

transceiver with wake-up capability necessary).

13. Connect logger to PC via USB cable.

14. Start the control program with [F11] or via Project|Run Control Program. Select

Read out and Export after readout for the CAN logfile and click on [OK].

15. Select the destination directory for the logging files. The upload is started

afterwards.

16. The log files are uploaded in a raw format and displayed in the tree view under

Logfiles GiN Logger.

17. After readout the Export dialog is automatically displayed. Select the file format

and export parameters and click on [OK]. The raw log file is now converted to the

© Vector Informatik GmbH Version 2.4 - 35 -

Page 38

Page 39

User Manual GL2000/GL2010 – Data Logger Index

4 Index

3

3G (UMTS) ......................................................... 26

A

Analog inputs ...................................................... 17

B

Battery................................................................. 17

Beep.................................................................... 19

C

CAN .................................................................... 22

CCP/XCP ............................................................ 20

Configuration mode ............................................ 21

Connection cable ................................................ 10

Connectors ........................................................... 9

D

Delivery ............................................................... 28

LED .................................................................... 15

LIN...................................................................... 24

Logging mode .................................................... 21

M

Memory cards .................................................... 12

O

Operating modes ............................................... 21

P

Piggybacks ......................................................... 22

Pin assignment .............................................. 9, 10

Q

Quick start .................................................... 32, 34

R

Real time clock ................................................... 17

Requirements ............................................... 30, 33

Device information .............................................. 32

Diagnostics ......................................................... 21

Digital input/output .............................................. 16

DSUB15 .............................................................. 10

DSUB25 ................................................................ 9

E

Ethernet .............................................................. 25

F

FAT32 ................................................................. 12

Features ................................................................ 9

G

G.i.N configuration program................................ 33

GPS mouse ........................................................ 25

L

Layout GL2000 ............................................. 19, 24

S

SD/SDHC ........................................................... 12

Serial interface ................................................... 17

Serial number ..................................................... 14

Sleep .................................................................. 19

Start-up time ...................................................... 27

Support ................................................................ 5

T

Technical data .................................................... 27

Transceiver ........................................................ 22

U

UMTS ................................................................. 26

V

Vector Logger Configurator ............................... 30

© Vector Informatik GmbH Version 2.4 - 37 -

Page 40

User Manual GL2000/GL2010 – Data Logger Index

W

Wake-up ............................................................. 19

© Vector Informatik GmbH Version 2.4 - 38 -

Page 41

Page 42

More Information

> News

> Products

> Demo Software

> Support

> Training Classes

> Addresses

www.vector.com

Loading...

Loading...