Page 1

E-Vehicle and Charging Station – It’s Better If They Get Along Right Away

Smart Testing of Conformance and Interoperability

The availability of a dense network of fast charging stations is a decisive factor for the acceptance of e-mobility. Ensuring interoperability between e-vehicles and charging stations still tends to be underestimated today, so comprehensive

tests in this area are indispensable to vehicle manufacturers. Until today, common practice has been to test vehicles

manually using as many real charging stations as possible. Considering the increasing number of different e-vehicles and

charging stations, this way of doing things is now reaching its limits. Manufacturers and suppliers can only reach their

goals more quickly and cost-effectively and with considerably greater test coverage if they use a suitable test system

that enables automated conformance tests based on international standards.

The use of DC-charging with high power is planned for the

fast charging of e-vehicles (EV) along highways and expressways. Public charging like this is incomparably more complex than charging an EV at home in your garage using a

typical wallbox where power flows through your own electricity meter. Primarily in Europe and the US, the CCS

(Combined Charging System) serves as the general standard for DC fast charging. A variety of different companies

and organizations have together brought the CharIN

(Charging Interface Initiative e.V.) to life, whose task is to

further develop the CCS and establish it as a global standard for the charging of battery-powered EVs. The different

areas of responsibility are divided among five focus groups,

to which members bring their expertise and workforce. The

Focus Group Conformance Test & Interoperability is, among

other things, responsible for creating specifications for test

hardware and software that can be used by e-vehicle and

charging station manufacturers for automated testing of

their products for CCS conformance.

From Charge Park to Global Testing Events

Using test systems that correspond to these specifications,

e-vehicle and charging station manufacturers are now able

to test their products without laborious manual testing.

Manual testing, which has been common until now, will no

longer be feasible in the future due to the increasing number of EVs and variety of different charging stations. For

100% test coverage, every EV would have to be tested with

01

Page 2

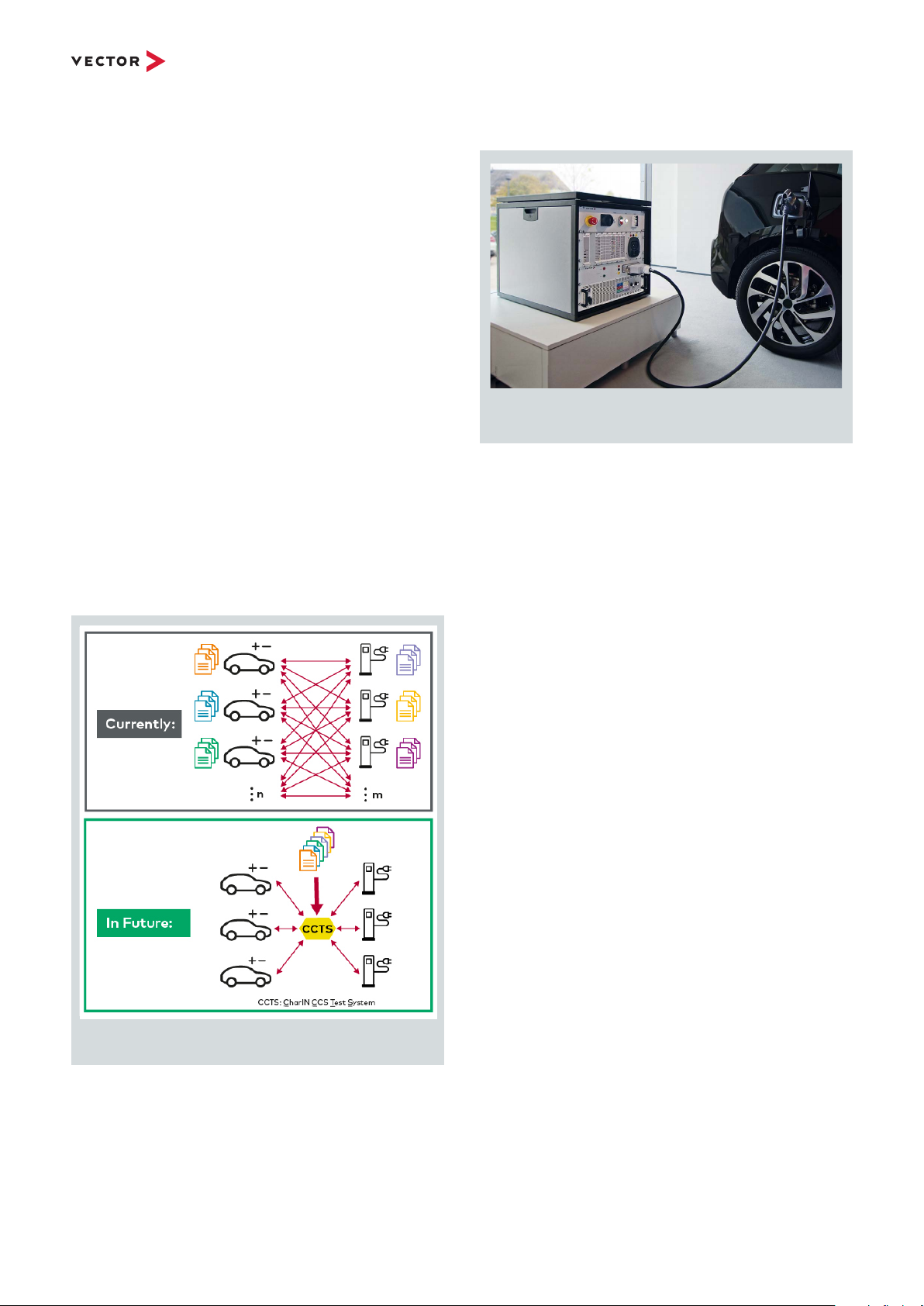

every conceivable charging station (Figure 1). Large OEMs

maintain “charge parks” with a selection of representative

charging stations for this purpose. Testing events where

respective manufacturers of e-vehicles and charging stations

converge to test their product against as many other products as possible are also held across the globe on a regular

basis. In more basic cases, events like this only concern the

ECU electronics level, but they can also involve entire vehicles

and charging stations. This takes lots of effort, incurs high

costs, and exceeds the abilities of smaller manufacturers

and suppliers in particular.

This is why the future belongs to conformance tests that

companies can easily execute at their own laboratories.

Developers test their actual product against a test system

corresponding precisely to the specifications of the CharIN

Focus Group Conformance Test & Interoperability on the

hardware and software side (Figure 2). This is the only way

the complexity of CCS can actually be handled. The CCS is

a powerful system that deals with a variety of different

charging modes for DC and AC charging and must take assorted standards into account at the same time, such as

DIN70121, ISO 15118 and IEC61851-1.

Technical Article / September 2020

Figure 2: Performing a conformance test on a real e-vehicle with a

CCS test system, in this case from Vector.

with incorrect content and the like. Errors cannot be inserted

intentionally through manual tests with real counterparts,

as only good cases are tested in general here. Message

sequences and content, charging parameters and other

marginal conditions can only be flexibly modified through

simulation using test systems.

As a longer-term goal, the CCS is striving toward convenient charging following the plug-and-charge principle.

Here, the vehicle need only be connected to the charging

station with a plug, after which all the necessary actions –

such as identification, billing, negotiating electricity rates

etc. – are carried out automatically. In the future, there will

also be product certification that documents that a vehicle

can be charged at any certified charging station. This certification is being promoted by CharIN. During the certification process, test companies and test partners will be involved and will subject the test object to all tests prescribed

by CharIN.

Figure 1: Ensuring interoperability of e-vehicles and charging

stations – now and in the future.

Stress for Charging Electronics: Inserting Errors

Using automated conformance tests, fault cases can also

be covered systematically. In this context, for example, you

have to check whether the charging electronics also exhibit

behavior specified by the standard if the counterpart does

not comply with the required timing or sends messages

Instructions for Standard-Compliant Test Systems

Testing a variety of different functions begins at development departments long before the official test date. The

documents provided by CharIN contain detailed instructions on how the hardware and software of a suitable test

system can be implemented, which functions are required

and which out of hundreds of possible tests are necessary.

Anyone who has the corresponding expertise and wants to

make the effort can develop a CharIN CCS Test System

(CCTS) (Figure 2). This being the case, there isn’t just “one

CCTS” – individual implementations can differ from one

another in many details, be it the user interface on the software side or the hardware equipment depending on the

System Under Test (SUT). The power unit permits a large

number of possible variations, for example. Using a power

unit with comparatively low charging power is sufficient for

testing communication. In practice, however, customer

requirements in this area differ significantly from one

02

Page 3

Technical Article / September 2020

Figure 3: Identical test cases can be applied on a

variety of different integration levels

another. This is why the CCTS specification intentionally

covers only the minimum requirements for a test system.

Ideally, test software and CCTS of this type are designed in

such a way that they permit tests on every integration level

of the development process (Figure 3). When developing

software on the first, lowest level, hardware is not yet involved, but the test cases can already be used to check the

embedded code for errors independently of any hardware.

At the next level it is the turn of the A or B sample of the

ECU. The communication hardware is connected, and communication via Powerline Communication (PLC), PulseWidth Modulation (PWM), etc. can be tested, but this still

occurs without the flow of energy. On the third level, the

pre-series or series is tested. The entire CCTS test setup,

including the power unit with a high voltage source, is required. When the vehicle requests power, the test system

can actually supply power, thus representing a complete

charging process. In any case, early testing pays off, as

troubleshooting becomes more expensive the later an error

is discovered.

Available Test Solution With a Large Number of Test

Cases in the Source Code

Vector is a contributor in the Focus Group Conformance

Test & Interoperability and is offering test cases for testing

conformance and ensuring interoperability with the CANoe

Test Package EV product. These test cases are fully oriented

toward the existing test specifications of the individual

protocols of the CCS standard and their amendments by

CharIN and fit seamlessly into the existing Vector test tool

chain. The new test package is based on the CANoe .SmartCharging option and the vTESTstudio test editor and includes a large number of individual tests available in the

source code.

As a modular system for HIL tests, the VT System test

hardware with the VT7870 insert card is available. The latter

is responsible for charging communication via PLC and

PWM. The test cases can be run immediately on the

VT System. Upon request, Vector can upgrade the VT System

to a full-featured CCTS with an additional power unit. The

power electronics are always designed individually for each

customer, as the requirements can differ not only in the

case of the final power level here. In one case, for example,

charging voltages up to 600 V are sufficient, whereas 1,000 V

are required in another. This puts Vector in a position to

supply all the required components from a single source.

The Vector E-Mobility Testing Solution also supports the

CharIN interface. This is an interface which makes it possible

to combine CCTS hardware and software from different

manufacturers. In this way, the Vector E-Mobility Testing

Solution can be used in conjunction with third-party hardware if this also supports the CharIN interface and provides corresponding drivers. The user is not only able to

continue using the available or preferred hardware but also

doesn’t have to buy expensive new hardware.

Easy Operation and Transparent Tool Flow

Operation and tool flow of the CANoe Test Package EV follow the Vector product philosophy and are simple and

clearly structured. The user generates a test unit with the

push of a button using the vTESTstudio test editor. This is

then loaded into CANoe, which functions as the executing

instance and controls the test hardware. At the end of each

test run, the system automatically generates a test report

(Figure 4). As the test scripts are available in the source

code, the user is not only able to comprehend exactly what

happens in each individual case but can also adapt the

tests to the existing test environment if necessary, for

example – once again with vTESTstudio. The tests to be

executed can easily be selected with a click of the mouse.

During the test run, the tester can already see in CANoe

which tests were successful, which were not passed, and

which are still to be executed.

This simple workflow is identical on all development levels

with the same tools, whether it’s for software testing, testing the ECU with the VT System or testing the finished

03

Page 4

Technical Article / September 2020

Figure 4: The workflow of CANoe Test

Package EV with the tools vTESTstudio

and CANoe from Vector.

pre-series/series in conjunction with the entire CCTS. In addition to CANoe, the vVIRTUALtarget software tool is used

to test the embedded code. Even when general vehicle

tests not related to e-mobility are carried out, the same

tools are always used and the processes are analogous,

which has a positive effect on investment costs.

Support for International Standards CCS, GB/T and

CHAdeMO

The CANoe Test Package EV will always be continuously

developed and supports all global charging standards. In

addition to the CCS, this primarily includes the Chinese

GB/T standard and the CHAdeMO standard, which originated in Japan. A corresponding test package is also in the

works for charging station manufacturers.

The modular nature of the Vector solution makes it possible

for users to assemble their desired test system customtailored to their needs and to only use those options and

charging standards they actually need. In addition to

CANoe with the smart charging option and vTESTstudio,

the CCS also requires the CANoe Ethernet option, as CCS

communication uses Ethernet protocol-based Powerline.

GB/T, on the other hand, uses the J1939 protocol for communication, for which the CANoe J1939 option is to be used.

CHAdeMO works solely with CAN and does not require any

additional options.

flexible in its adaptation to customer requirements and

also works with test hardware from other manufacturers

over the CharIN interface. Support for current standards is

continually being expanded, and existing test cases are always being updated based on availability and the publication of corresponding test specifications. While the CCS

and GB/T charging standards are already supported,

CHAdeMO will follow in a later version of the CANoe Test

Package EV.

A test package for the testing of charging stations will also

be released by Vector beginning in 2021. The procedure for

charging station tests will be largely identical to the one

described here for e-vehicles, and the same tools will be

used.

Jan Großmann

has been with Vector since 2011 and is responsible for the Vector

E-Mobility Testing Solution in the field of networks and distributed

systems.

Translation of German publication in Hanser automotive,

issue 7/2020

Conclusion and Outlook

The test solution presented here frees vehicle manufacturers

and suppliers from the time-consuming and laborious testing

of their products with real charging stations and also provides significantly more detailed test results. It’s extremely

Image rights: Vector Informatik GmbH

04

Loading...

Loading...